© 2012 Baileigh Industrial, Inc.

REPRODUCTION OF THIS MANUAL IN ANY FORM WITHOUT WRITTEN APPROVAL OF BAILEIGH INDUSTRIAL, INC.

IS PROHIBITED. Baileigh Industrial, Inc. does not assume and hereby disclaims any liability for any damage or loss

caused by an omission or error in this Operator’s Manual, resulting from accident, negligence, or other occurence.

Rev. 11/2012

Baileigh Industrial, Inc.

P.O. Box 531

Manitowoc, WI 54221-0531

Phone: 920.684.4990

Fax: 920.684.3944

sales@baileighindustrial.com

OPERATOR’S

MANUAL

TABLE SAW

MODEL: TS-1044H

Table of Contents

THANK YOU & WARRANTY .......................................................................................... 1

INTRODUCTION ............................................................................................................ 3

GENERAL NOTES.......................................................................................................... 3

SAFETY INSTRUCTIONS .............................................................................................. 4

SAFETY PRECAUTIONS ............................................................................................... 6

SPECIFICATIONS ........................................................................................................ 10

INTENDED USE ........................................................................................................... 11

Tools: ......................................................................................................................... 11

TECHNICAL SUPPORT ............................................................................................... 11

UNPACKING ................................................................................................................. 12

Cleaning .................................................................................................................... 12

GETING TO KNOW YOUR MACHINE ......................................................................... 13

TRANSPORTING AND LIFTING .................................................................................. 15

INSTALLATION ............................................................................................................ 16

ASSEMBLY ................................................................................................................... 18

INSTALL TABLE EXTENSION WINGS ..................................................................... 18

MOUNT FENCE STORAGE BRACKETS ................................................................. 18

FRONT RAIL INSTALLATION ................................................................................... 19

REAR RAIL INSTALLED ........................................................................................... 20

INSTALL BLADE GUARD ............................................................................................. 21

LOOSEN LOCK KNOB .............................................................................................. 21

ANTI-KICK BACK PAWL ........................................................................................... 22

RIVING KNIFE ........................................................................................................... 23

TABLE INSERT ......................................................................................................... 24

SAW BLADE ................................................................ ................................................. 25

FENCE ASSEMBLY...................................................................................................... 26

Align the Fence Parallel to the Blade ......................................................................... 26

Align the Rip Fence Perpendicular (90°) to the Table ................................................ 26

LEVEL THE FENCE .................................................................................................. 27

ADJUST & ALIGN RIP FENCE POINTER ................................................................ 27

DUST COLLECTOR ..................................................................................................... 28

PUSH STICK ................................................................................................................ 29

MITER GAUGE ............................................................................................................. 29

ELECTRICAL ................................................................................................................ 30

Extension Cord Safety ................................ ................................ ............................... 31

ADJUSTMENT .............................................................................................................. 32

ADJUSTING THE 45° & 90° BEVEL STOPS ............................................................ 32

ADJUSTING THE BEVEL ANGLE POINTER ............................................................ 33

BLADE TILT /BEVEL ADJUSTMENT ................................................................ ........ 33

BLADE HEIGHT ADJUSTMENT ............................................................................... 34

OPERATION ................................ ................................ ................................................. 35

Safety Precautions Before Operations ...................................................................... 35

Electrical Operation ................................................................................................... 35

Operation ................................................................................................................... 35

Non-Through & Through Cuts ................................................................................... 36

Workpiece Inspection ................................................................................................ 36

BLADE REQUIREMENTS ............................................................................................ 37

BLADE SELECTION ..................................................................................................... 37

DADO BLADES ............................................................................................................ 38

Ripping ...................................................................................................................... 39

Miter Ripping ............................................................................................................. 41

Ripping Small Work Pieces ....................................................................................... 41

Crosscutting............................................................................................................... 41

MAINTENANCE ............................................................................................................ 50

Cleaning .................................................................................................................... 51

Lubrication ................................................................................................................. 51

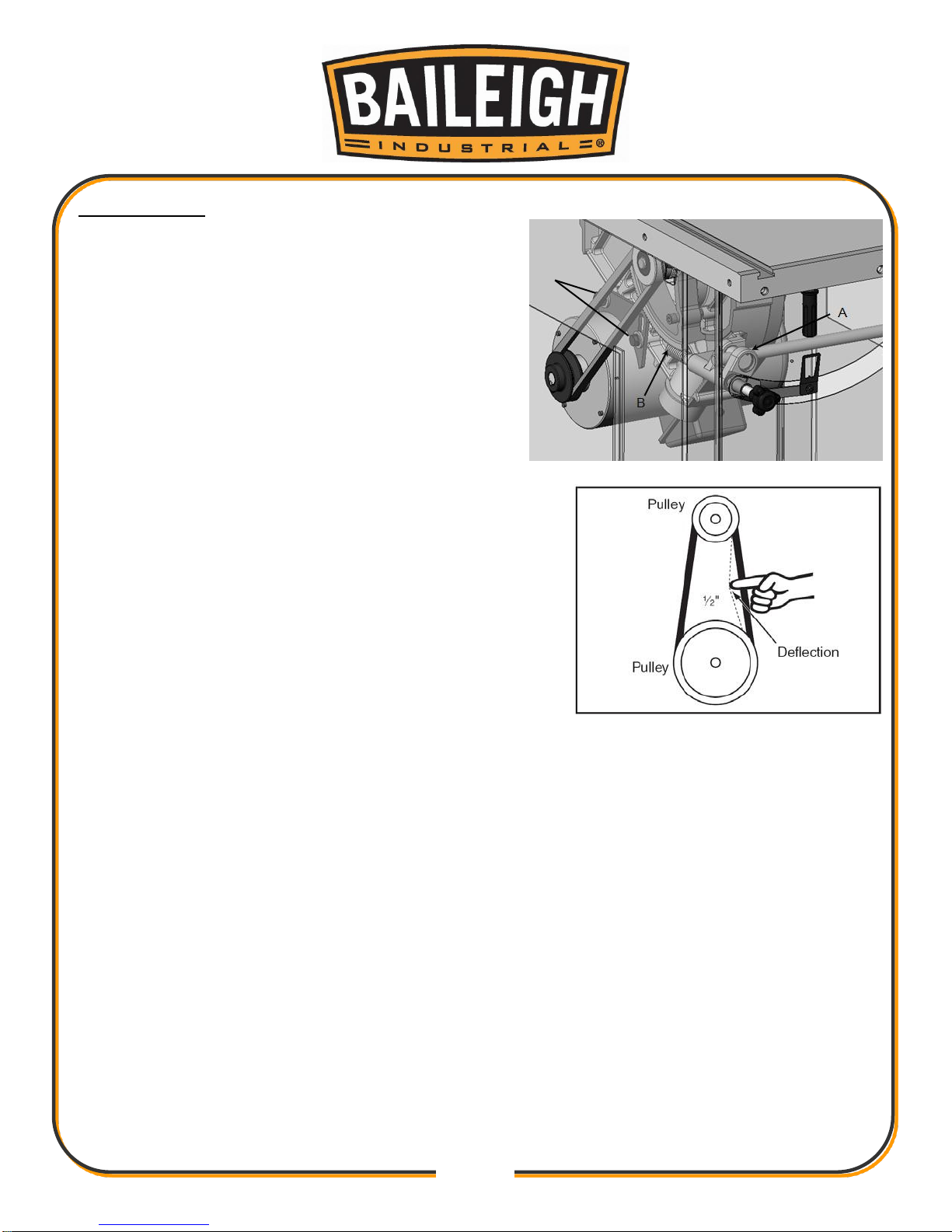

Changing Belt ............................................................................................................ 52

TROUBLESHOOTING .................................................................................................. 53

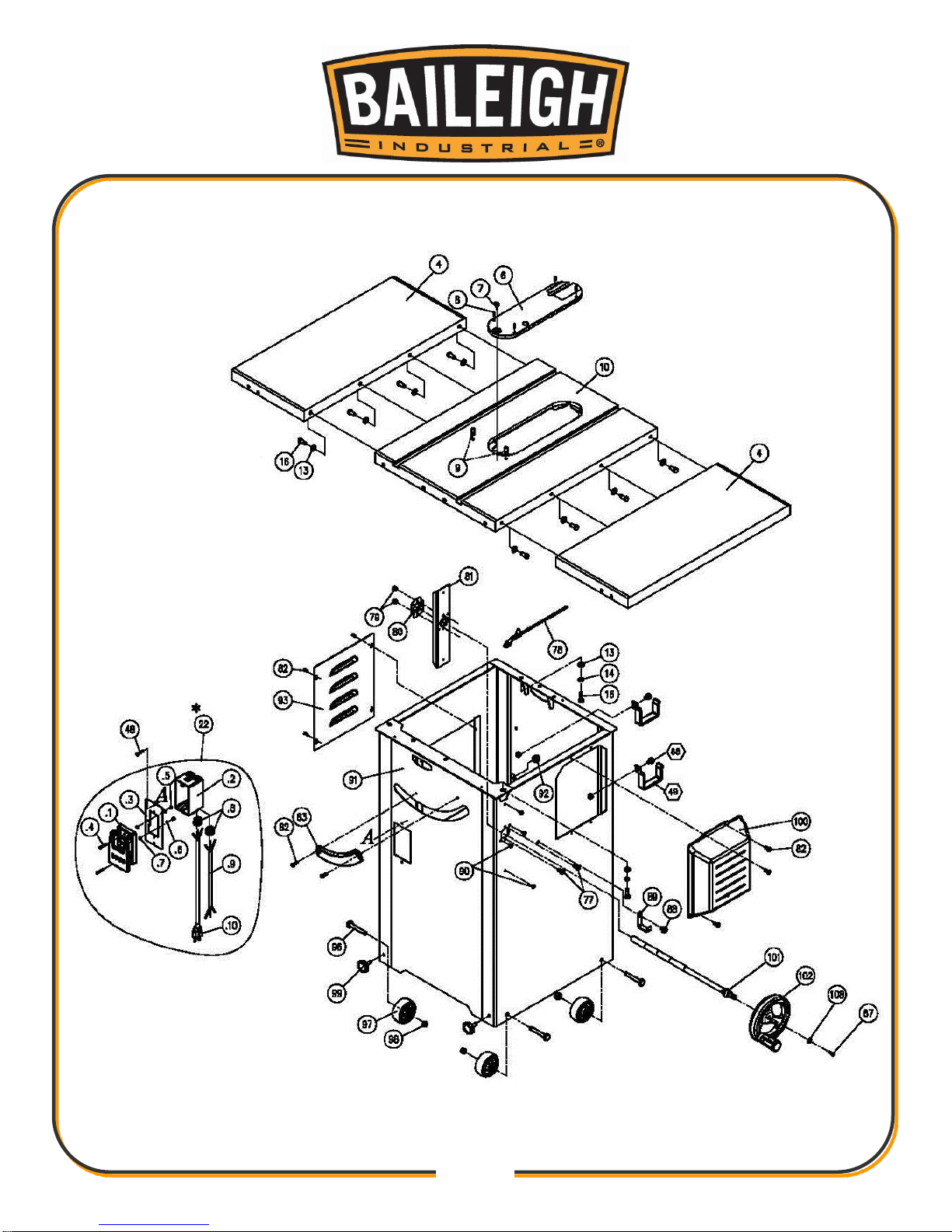

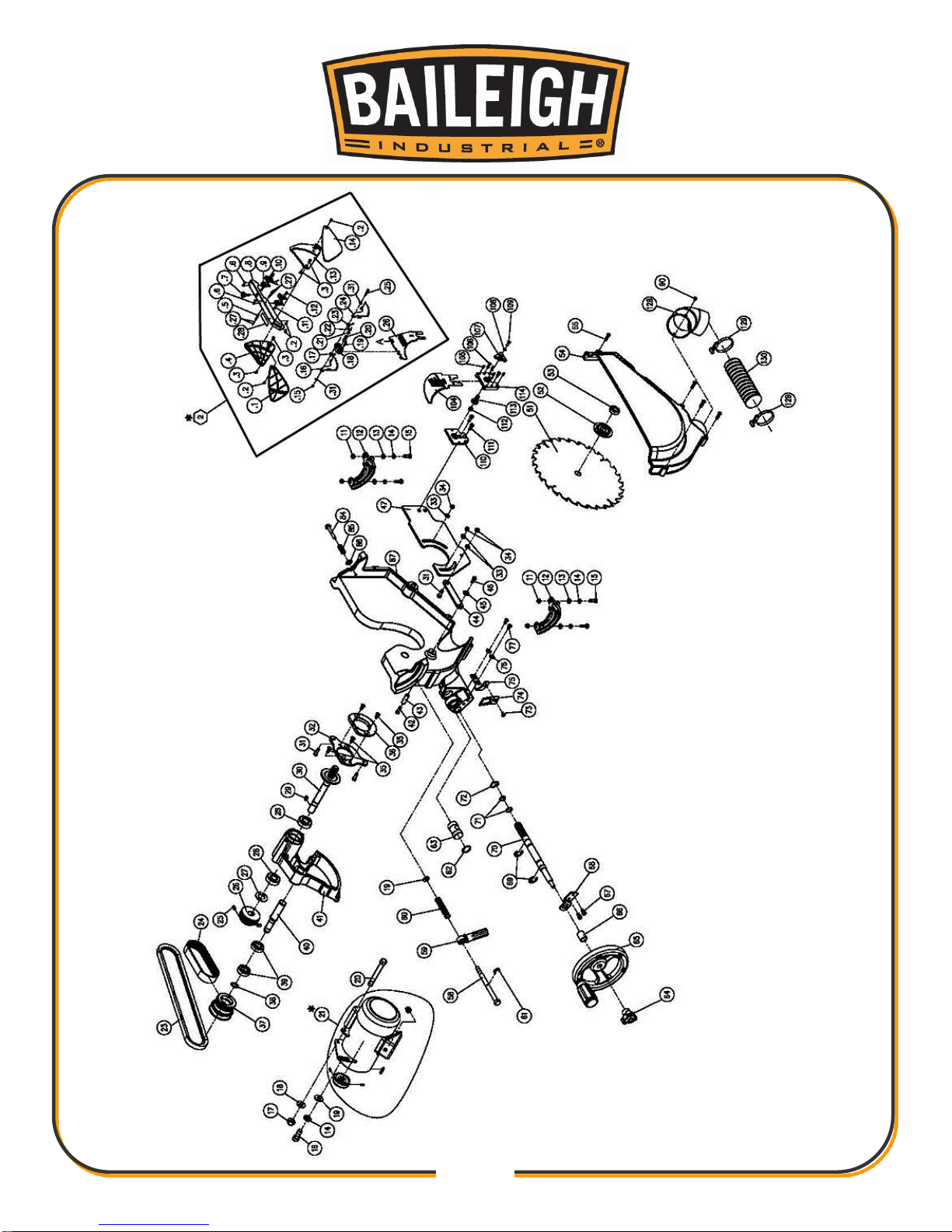

TABLE SAW PARTS DIAGRAMS................................................................................. 55

Table Saw Parts List .................................................................................................. 59

1

1

THANK YOU & WARRANTY

Thank you for your purchase of a machine from Baileigh Industrial. We hope that you find it

productive and useful to you for a long time to come.

Inspection & Acceptance. Buyer shall inspect all Goods within ten (10) days after receipt thereof. Buyer’s

payment shall constitute final acceptance of the Goods and shall act as a waiver of the Buyer’s rights to inspect or

reject the goods unless otherwise agreed. If Buyer rejects any merchandise, Buyer must first obtain a Returned

Goods Authorization (“RGA”) number before returning any goods to Seller. Goods returned without a RGA will be

refused. Seller will not be responsible for any freight costs, damages to goods, or any other costs or liabilities

pertaining to goods returned without a RGA. Seller shall have the right to substitute a conforming tender. Buyer will

be responsible for all freight costs to and from Buyer and repackaging costs, if any, if Buyer refuses to accept

shipment. If Goods are returned in unsalable condition, Buyer shall be responsible for full value of the Goods.

Buyer may not return any special order Goods. Any Goods returned hereunder shall be subject to a restocking fee

equal to 30% of the invoice price.

Specifications. Seller may, at its option, make changes in the designs, specifications or components of the Goods

to improve the safety of such Goods, or if in Seller’s judgment, such changes will be beneficial to their operation or

use. Buyer may not make any changes in the specifications for the Goods unless Seller approves of such changes

in writing, in which event Seller may impose additional charges to implement such changes.

Limited Warranty. Seller warrants to the original end-user that the Goods manufactured or provided by Seller

under this Agreement shall be free of defects in material or workmanship for a period of twelve (12) months from

the date of purchase, provided that the Goods are installed, used, and maintained in accordance with any

instruction manual or technical guidelines provided by the Seller or supplied with the Goods, if applicable. The

original end-user must give written notice to Seller of any suspected defect in the Goods prior to the expiration of

the warranty period. The original end-user must also obtain a RGA from Seller prior to returning any Goods to

Seller for warranty service under this paragraph. Seller will not accept any responsibility for Goods returned without

a RGA. The original end-user shall be responsible for all costs and expenses associated with returning the Goods

to Seller for warranty service. In the event of a defect, Seller, at its sole option, shall repair or replace the defective

Goods or refund to the original end-user the purchase price for such defective Goods. Goods are not eligible for

replacement or return after a period of 30 days from date of receipt. The foregoing warranty is Seller’s sole

obligation, and the original end-user’s exclusive remedy, with regard to any defective Goods. This limited warranty

does not apply to: (a) die sets, tooling, and saw blades; (b) periodic or routine maintenance and setup, (c) repair or

replacement of the Goods due to normal wear and tear, (d) defects or damage to the Goods resulting from misuse,

abuse, neglect, or accidents, (f) defects or damage to the Goods resulting from improper or unauthorized

alterations, modifications, or changes; and (f) any Goods that has not been installed and/or maintained in

accordance with the instruction manual or technical guidelines provided by Seller.

EXCLUSION OF OTHER WARRANTIES. THE FOREGOING LIMITED WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED. ANY AND ALL OTHER EXPRESS, STATUTORY OR IMPLIED

WARRANTIES, INCLUDING BUT NOT LIMITED TO, ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE ARE EXPRESSLY DISCLAIMED. NO WARRANTY IS MADE WHICH

EXTENDS BEYOND THAT WHICH IS EXPRESSLY CONTAINED HEREIN.

Limitation of Liability. IN NO EVENT SHALL SELLER BE LIABLE TO BUYER OR ANY OTHER PARTY FOR

ANY INCIDENTIAL, CONSEQUENTIAL OR SPECIAL DAMAGES (INCLUDING, WITHOUT LIMITATION, LOST

PROFITS OR DOWN TIME) ARISING FROM OR IN MANNER CONNECTED WITH THE GOODS, ANY BREACH

BY SELLER OR ITS AGENTS OF THIS AGREEMENT, OR ANY OTHER CAUSE WHATSOEVER, WHETHER

BASED ON CONTRACT, TORT OR ANY OTHER THEORY OF LIABILITY. BUYER’S REMEDY WITH RESPECT

TO ANY CLAIM ARISING UNDER THIS AGREEMENT IS STRICTLY LIMITED TO NO MORE THAN THE

AMOUNT PAID BY THE BUYER FOR THE GOODS.

2

2

Force Majuere. Seller shall not be responsible for any delay in the delivery of, or failure to deliver, Goods due to

causes beyond Seller’s reasonable control including, without limitation, acts of God, acts of war or

terrorism, enemy actions, hostilities, strikes, labor difficulties, embargoes, non-delivery or late delivery of materials,

parts and equipment or transportation delays not caused by the fault of Seller, delays caused by civil authorities,

governmental regulations or orders, fire, lightening, natural disasters or any other cause beyond Seller's reasonable

control. In the event of any such delay, performance will be postponed by such length of time as may be reasonably

necessary to compensate for the delay.

Installation. If Buyer purchases any Goods that require installation, Buyer shall, at its expense, make all

arrangements and connections necessary to install and operate the Goods. Buyer shall install the Goods in

accordance with any Seller instructions and shall indemnify Seller against any and all damages, demands, suits,

causes of action, claims and expenses (including actual attorneys’ fees and costs) arising directly or indirectly out

of Buyer’s failure to properly install the Goods.

Work By Others; Safety Devices. Unless agreed to in writing by Seller, Seller has no responsibility for labor or

work performed by Buyer or others, of any nature, relating to design, manufacture, fabrication, use, installation or

provision of Goods. Buyer is solely responsible for furnishing, and requiring its employees and customers to use all

safety devices, guards and safe operating procedures required by law and/or as set forth in manuals and instruction

sheets furnished by Seller. Buyer is responsible for consulting all operator’s manuals, ANSI or comparable safety

standards, OSHA regulations and other sources of safety standards and regulations applicable to the use and

operation of the Goods.

Remedies. Each of the rights and remedies of Seller under this Agreement is cumulative and in addition to any

other or further remedies provided under this Agreement or at law or equity.

Attorney’s Fees. In the event legal action is necessary to recover monies due from Buyer or to enforce any

provision of this Agreement, Buyer shall be liable to Seller for all costs and expenses associated therewith,

including Seller’s actual attorneys' fees and costs.

Governing Law/Venue. This Agreement shall be construed and governed under the laws of the State of

Wisconsin, without application of conflict of law principles. Each party agrees that all actions or proceedings arising

out of or in connection with this Agreement shall be commenced, tried, and litigated only in the state courts sitting in

Manitowoc County, Wisconsin or the u.s. Federal Court for the Eastern District of Wisconsin. Each party waives

any right it may have to assert the doctrine of “forum non conveniens” or to object to venue to the extent that any

proceeding is brought in accordance with this section. Each party consents to and waives any objection to the

exercise of personal jurisdiction over it by courts described in this section. Each party waives to the fullest extent

permitted by applicable law the right to a trial by jury.

Summary of Return Policy.

10 Day acceptance period from date of delivery. Damage claims and order discrepancies will not be accepted

after this time.

You must obtain a Baileigh issued RGA number PRIOR to returning any materials.

Returned materials must be received at Baileigh in new condition and in original packaging.

Altered items are not eligible for return.

Buyer is responsible for all shipping charges.

A 30% re-stocking fee applies to all returns.

Baileigh Industrial makes every effort to ensure that our posted specifications, images, pricing and product

availability are as correct and timely as possible. We apologize for any discrepancies that may occur. Baileigh

Industrial reserves the right to make any and all changes deemed necessary in the course of business including but

not limited to pricing, product specifications, quantities, and product availability.

For Customer Service & Technical Support:

Please contact one of our knowledgeable Sales and Service team members at:

(920) 684-4990 or e-mail us at sales@baileighindustrial.com

3

3

INTRODUCTION

The quality and reliability of the components assembled on a Baileigh Industrial machine

guarantee near perfect functioning, free from problems, even under the most demanding

working conditions. However if a situation arises, refer to the manual first. If a solution cannot be

found, contact the distributor where you purchased our product. Make sure you have the serial

number and production year of the machine (stamped on the nameplate). For replacement parts

refer to the assembly numbers on the parts list drawings.

Our technical staff will do their best to help you get your machine back in working order.

In this manual you will find: (when applicable)

Safety procedures

Correct installation guidelines

Description of the functional parts of the machine

Capacity charts

Set-up and start-up instructions

Machine operation

Scheduled maintenance

Parts lists

GENERAL NOTES

After receiving your equipment remove the protective container. Do a complete visual

inspection, and if damage is noted, photograph it for insurance claims and contact your

carrier at once, requesting inspection. Also contact Baileigh Industrial and inform them of the

unexpected occurrence. Temporarily suspend installation.

Take necessary precautions while loading / unloading or moving the machine to avoid any

injuries.

Your machine is designed and manufactured to work smoothly and efficiently. Following proper

maintenance instructions will help ensure this. Try and use original spare parts, whenever

possible, and most importantly; DO NOT overload the machine or make any unauthorized

modifications.

Note: This symbol refers to useful information throughout the manual.

4

4

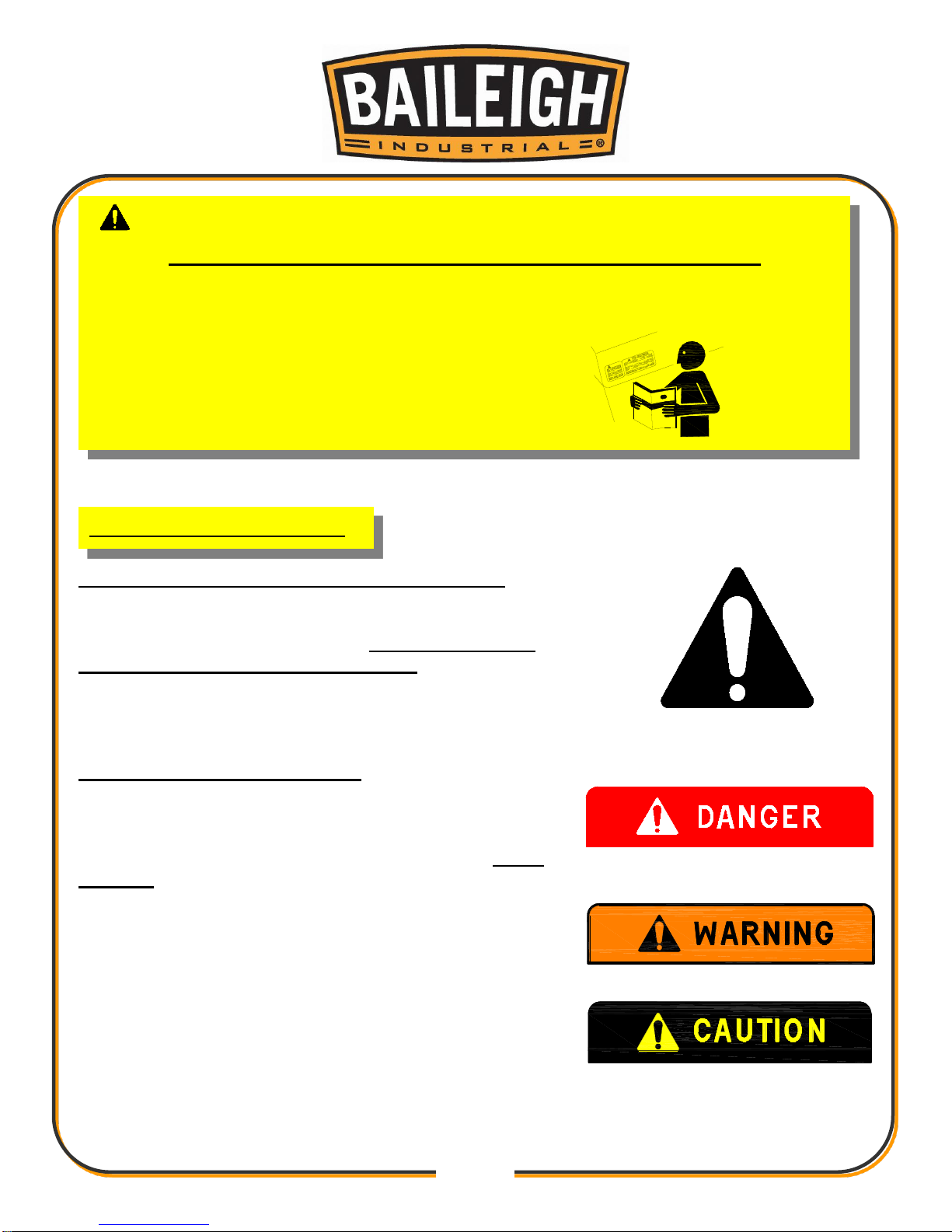

IMPORTANT

PLEASE READ THIS OPERATORS MANUAL CAREFULLY

It contains important safety information, instructions, and necessary operating procedures.

The continual observance of these procedures will help increase your production and

extend the life of the equipment.

SAFETY INSTRUCTIONS

LEARN TO RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol

on your machine or in this manual, BE ALERT TO THE

POTENTIAL FOR PERSONAL INJURY!

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A signal word – DANGER, WARNING, or CAUTION is

used with the safety alert symbol. DANGER identifies a

hazard or unsafe practice that will result in severe Injury

or Death.

Safety signs with signal word DANGER or WARNING are

typically near specific hazards.

General precautions are listed on CAUTION safety signs.

CAUTION also calls attention to safety messages in this

manual.

5

5

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

PROTECT EYES

Wear safety glasses or suitable eye

protection when working on or around

machinery.

DUST HAZARD

Wear appropriate dust mask. Dust created while using machinery can

cause cancer, birth defects, and long term respiratory damage. Be aware

of the dust hazards associated with all types of materials.

DUST PARTICLES AND IGNITION SOURCES

DO NOT operate the table saw in areas where explosion risks are

high. Such areas include locations near pilot lights, open flames, or

other ignition sources.

ROTATING BLADE HAZARD

Moving saw blade may result in loss of fingers or limb. DO NOT

operate with guard removed. Follow lockout/tagout procedures

before servicing.

6

6

WARNING: FAILURE TO FOLLOW THESE RULES MAY RESULT IN

SERIOUS PERSONAL INJURY

PROTECT AGAINST NOISE

Prolonged exposure to loud noise can cause impairment or loss of

hearing. Wear suitable hearing protective devices such as ear muffs or

earplugs to protect against objectionable or uncomfortable loud noises.

HIGH VOLTAGE

USE CAUTION IN HIGH VOLTAGE AREAS. DO NOT assume the

power to be off.

(FOLLOW PROPER LOCKOUT PROCEDURES)

SAFETY PRECAUTIONS

Wood working can be dangerous if safe and proper operating procedures are not followed. As

with all machinery, there are certain hazards involved with the operation of the product. Using

the machine with respect and caution will considerably lessen the possibility of personal injury.

However, if normal safety precautions are overlooked or ignored, personal injury to the operator

may result.

Safety equipment such as guards, push sticks, hold-downs, feather boards, goggles, dust

masks and hearing protection can reduce your potential for injury. But even the best guard won’t

make up for poor judgment, carelessness or inattention. Always use common sense and

exercise caution in the workshop. If a procedure feels dangerous, don’t try it.

REMEMBER: Your personal safety is your responsibility.

1. FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFORE OPERATING THE

MACHINE. Learn the machine’s application and limitations as well as the specific hazards.

2. Only trained and qualified personnel should operate this machine.

3. Make sure guards are in place and in proper working order before operating

machinery.

7

7

SAFETY PRECAUTIONS (cont.)

4. Kickback. Kickback happens when the piece part is thrown back toward the operator at a

high rate of speed. Before operating this saw, understand how kickback occurs, and how to

prevent it.

5. Reaching Over Saw Blade. NEVER reach behind or over the blade with either hand while

the saw is operating. If kickback of a piece part were to occur, you could amputate your

hands, arms, or fingers.

6. Blade Height. Adjust the blade to the correct height above the piece part so it does not

kickback toward the operator causing injury.

7. Remove any adjusting tools. Before operating the machine, make sure any adjusting tools

have been removed.

8. Blade Guard / Riving Knife. To reduce the risk of kickback, always use the riving knife and

blade guard. Make sure they are properly installed during cutting operations.

9. Dado and Rabbet Operations. Dado and Rabbeting operations require that the blade guard

be removed. Be aware of your personal safety while the guard is off, and replace the blade

guard after these operations are completed.

10. Keep work area clean. Cluttered areas invite injuries.

11. Push Sticks and Push Blocks. When ripping narrow stock, there is a risk of your hands

and fingers contacting the rotating blade, resulting in serious personal injury.

12. Overloading machine. By overloading the machine you may cause injury from flying parts.

DO NOT exceed the specified machine capacities.

13. Crosscutting Operations. Remove the rip fence whenever using the miter gauge to

crosscut a piece part.

14. Operator Position. If kickback occurs, the blade will eject the piece part into the path of the

operator. NEVER stand in- line with the cutting path of the blade during operation.

15. Dress appropriate. DO NOT wear loose fitting clothing or jewelry as they can be caught in

moving machine parts. Protective clothing and steel toe shoes are recommended when

using machinery. Wear a restrictive hair covering to contain long hair.

16. Awkward Positions. Avoid awkward hand and body positions where a sudden slip could

cause your hands or body to contact the spinning blade.

17. Use eye and ear protection. Always wear ISO approved impact safety goggles

18. Do not overreach. Maintain proper footing and balance at all times. DO NOT reach over or

across a running machine.

19. Damaged Saw Blades. A damaged saw blade can cause kickback. If in doubt as to the

condition of the blade, DO NOT use it.

8

8

SAFETY PRECAUTIONS (cont.)

20. Stay alert. Watch what you are doing and use common sense. DO NOT operate any tool or

machine when you are tired.

21. Check for damaged parts. Before using any tool or machine, carefully check any part that

appears damaged. Check for binding of moving parts that may affect proper machine

operation.

22. Observe work area conditions. DO NOT use machines or power tools in damp or wet

locations. Do not expose to rain. Keep work area well lighted. DO NOT use electrically

powered tools in the presence of flammable gases or liquids.

23. DO NOT bypass or defeat any safety interlock systems.

24. Know the location of the ON - OFF switch and the “E”- STOP button.

25. Removing Piece Parts. Before removing cut-offs, always turn the saw OFF, and wait for the

blade to stop turning, to avoid contact with a moving blade.

26. Control of the Piece Part. If the piece part should unexpectedly move or bind the blade,

kickback could occur. Make sure the piece part is supported by either the rip fence or the

crosscut fence. NEVER back a piece part out of a cut.

27. Supporting Piece Part. Provide adequate support to the sides and rear of the saw table for

material that is extra wide and long.

28. Keep visitors a safe distance from the work area.

29. Keep children away. Children must never be allowed in the work area. DO NOT let them

handle machines, tools, or extension cords.

30. DO NOT operate machine if under the influence of alcohol or drugs. Read warning

labels on prescriptions. If there is any doubt, DO NOT operate the machine.

31. DO NOT touch live electrical components or parts.

32. Be Sure all equipment is properly installed and grounded according to national, state, and

local codes. If machine is equipped with a three-prong plug, it should be plugged into a

three-hole electrical receptacle. If an adapter is used to accommodate a two-prong

receptacle, the adapter plug must be attached to a known ground. Never remove the third

prong.

33. Inspect power and control cables periodically. Replace if damaged or bare wires are

exposed. Bare wiring can kill!

34. Maintain machine in top condition. Keep clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

35. Reduce the risk of unintentional starting. Make sure switch is in “OFF” position before

plugging in power cord.

9

9

SAFETY PRECAUTIONS (cont.)

36. Never leave machine running unattended. TURN POWER OFF. Don’t leave machine until

it comes to a complete stop.

37. Make sure machine is disconnected from power supply while motor is being mounted,

connected or reconnected.

38. Saw Appropriate Material. Only use this saw for natural wood stock and wood stock

products such as particle board, plastics, laminates, and medium-density fibre board (MDF).

DO NOT try and cut metal, glass, ceramics, or products containing asbestos or lead paint.

Some of these materials contain hazardous dust and can cause severe respiratory

problems.

39. Warning: The dust generated by certain woods and wood products can be injurious to your

health. Always operate machinery in well ventilated areas and provide for proper dust

removal. Use a wood dust collection system whenever possible.

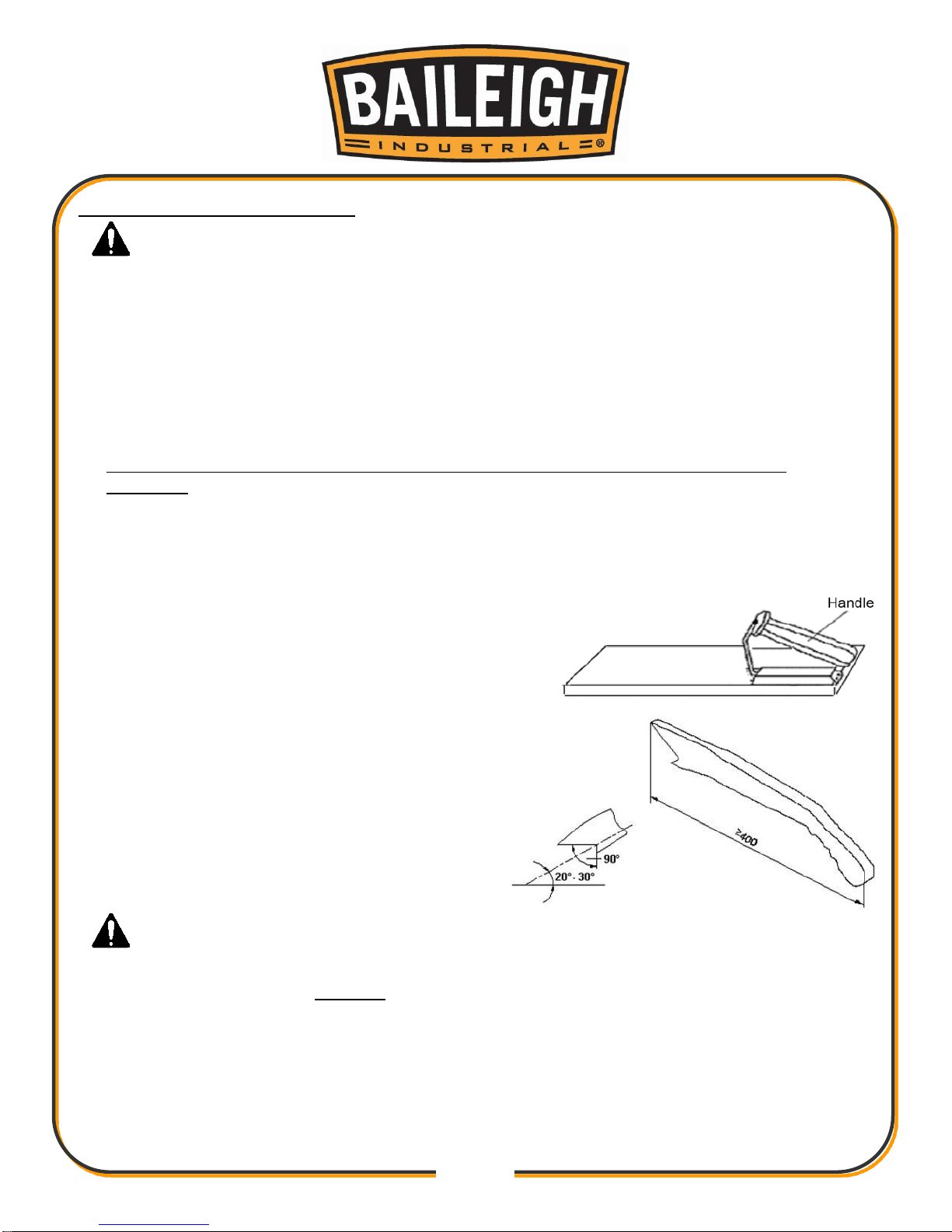

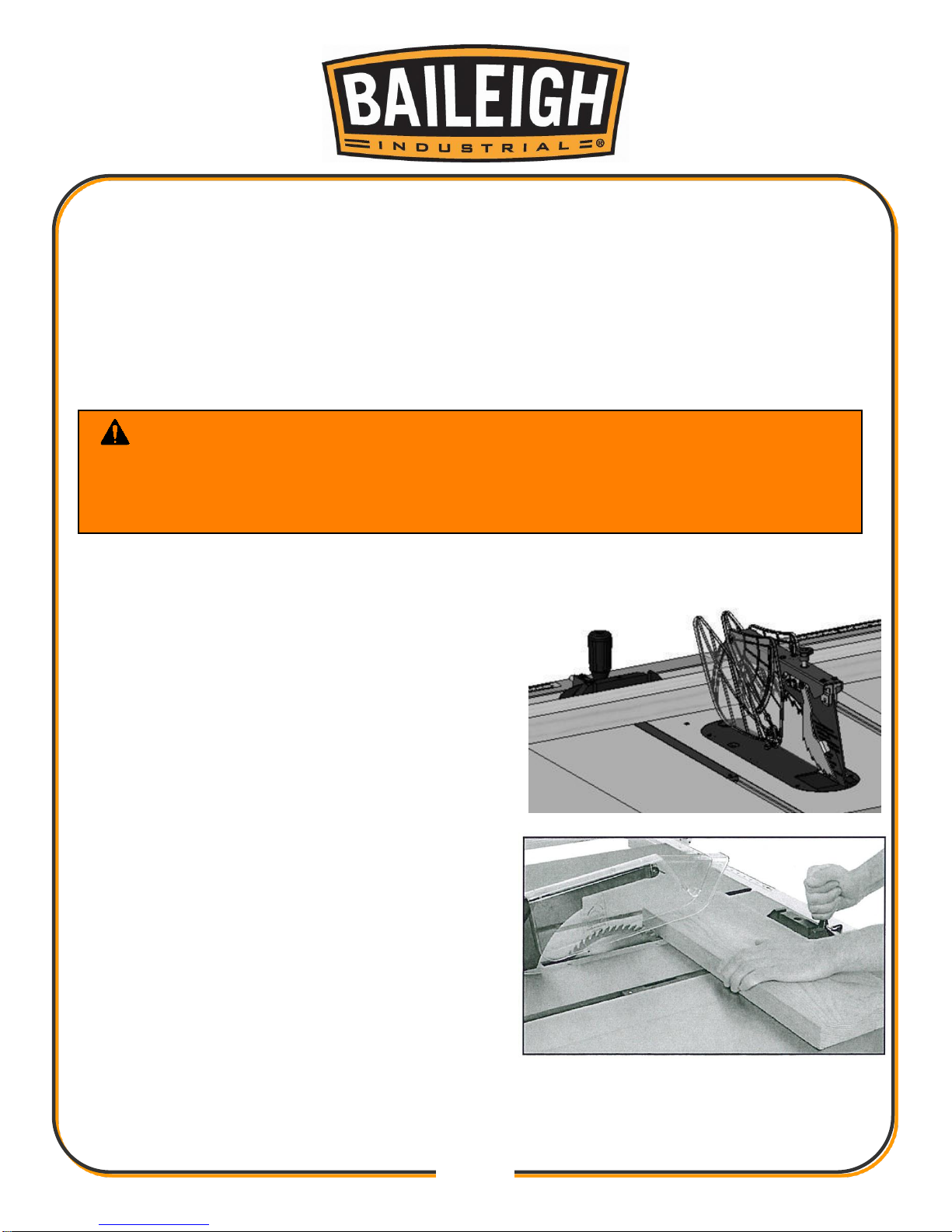

40. A push block and/or a push stick must be used if

the workpieces is less than 5” (127mm) to prevent

your hands from getting too close to the saw blade.

Push block must be used to cut narrow workpieces

and, when necessary, to push the workpiece

against the fence, a push block can be easily made

by the operator.

EMERGENCY STOP

In the event of incorrect operation or dangerous conditions, the machine can be stopped

immediately by pressing the ON/OFF switch.

10

10

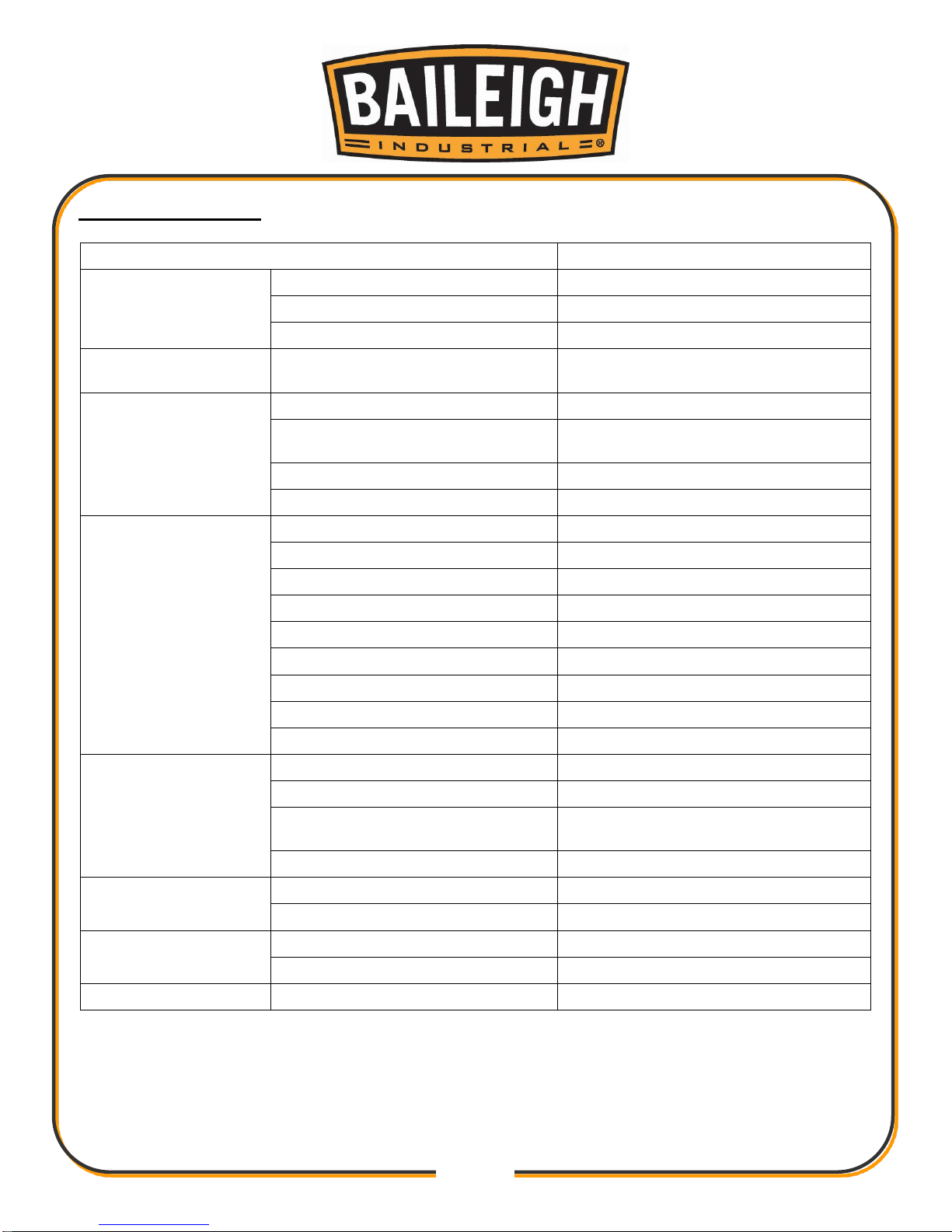

Item

TS-1044H

Product Dimensions

Weight

347Ibs

L x W x H

66.4" x 40" x 41"

Foot Print (L x W)

19.1" x 19.5"

Electrical

Switch

Magnetic with Thermal Overload

Protection

Motor

Type

TEFC Capacitor Start Induction

Horsepower, Voltage, Cycle,

Phase, Amps

1.75HP, 110V/220V, 60Hz, 1PH,

14A/7A (pre-wired 110V)

Speed

3450 RPM

Power Transfer

V-Belt Drive

Blade Information

Maximum Blade Diameter

10"

Riving Knife/Spreader Thickness

0.09" (2.3mm)

Required Blade Body Thickness

0.078" (2mm)

Required Blade Kerf Thickness

0.118" (3mm)

Maximum Width of Dado

13/16"

Blade Tilt

Left 0-45°

Arbor Size

5/8“

Arbor Speed

4000 RPM

Arbor Bearings

Sealed and Permanently Lubricated

Cutting Capacities

Maximum Depth of Cut At 90°

3-1/8"

Maximum Depth of Cut At 45°

2-3/16"

Maximum Rip To Right of BladeStandard

36"

Maximum Rip To Left Of Blade

12"

Table

Floor To Table Height

34.5"

Main Table (L x W x T)

44" x 27" x 1-1/2"

Miter Gauge

Miter Gauge Slot Type

T-Slot

Miter Gauge Slot Type (W x H)

3/4" x 3/8"

Other

Dust Port Size

4"

SPECIFICATIONS

11

11

INTENDED USE

Table saw and the workpiece guide equipment supplied with it are intended to be used

exclusively for the following purposes:

Laminated and unlaminated board materials (e.g. chipboard, coreboard, MDF board, ...)

Solid wood

Gypsum plasterboard, Cardboard, Veneer with a suitable clamping device.

Dimensionally stable plastics (thermoset plastics, thermoplastics). Sawing these materials

does not normally involve any risks in respect of dust, chips, and thermal degradation

products.

Tools:

The chosen saw blade must be suitable both for the specific work cycle and for the specific

material.

Only circular blades which are solid chrome vanadium (CV) or tungsten carbide tipped (TCT)

and have a diameter of 10” (255mm), arbor size 5/8” (16mm), as well as a maximum width of

13/16” (20mm) are allowed for the main saw.

Saw blades made of high-alloy high-speed steel (HSS) are not allowed to be used.

Saw blades and their fixing devices shall conform to EN 847-1:2005.

Note:The photos illustrations in this manual are representative only and may not

depict the actual color, labeling or accessories and may be intended to illustrate technique only.

Note: The specifications and dimensions presented here are subject to change

without prior notice due to improvements of our products.

TECHNICAL SUPPORT

Our technical support department can be reached at 920.684.4990, and asking for the support

desk for purchased machines. Tech Support handles questions on machine setup, schematics,

warranty issues, and individual parts needs: (other than die sets and blades).

For specific application needs or future machine purchases contact the Sales Department at:

sales@baileighindustrial.com, Phone: 920.684.4990, or Fax: 920.684.3944.

12

12

WARNING: DO NOT USE gasoline or other petroleum products to clean

the machine. They have low flash points and can explode or cause fire.

CAUTION: When using cleaning solvents work in a well ventilated area.

Many cleaning solvents are toxic if inhaled.

GAS

UNPACKING

Remove saw from the shipping cartons. Check for damage and ensure all parts are intact. Any

damage should be reported immediately to your distributor and shipping agent. Before

assembling, read the manual thoroughly, familiarizing yourself with correct assembly and

maintenance procedures and proper safety precautions.

If you can't find an item on this list, check the mounting location on the machine or examine the

packaging materials carefully. Occasionally we pre-install certain components for shipping

purposes.

Cleaning

Your machine may be shipped with a rustproof waxy oil coating and grease on the exposed

unpainted metal surfaces. To remove this protective coating, use a degreaser or solvent

cleaner. For a more thorough cleaning, some parts will occasionally have to be removed. DO

NOT USE acetone or brake cleaner as they may damage painted surfaces.

Follow manufacturer’s label instructions when using any type of cleaning product. After cleaning,

wipe unpainted metal surfaces with a light coating of quality oil or grease for protection.

With a screw driver, push a solvent-saturated rag into the T-slots to remove the grease.

13

13

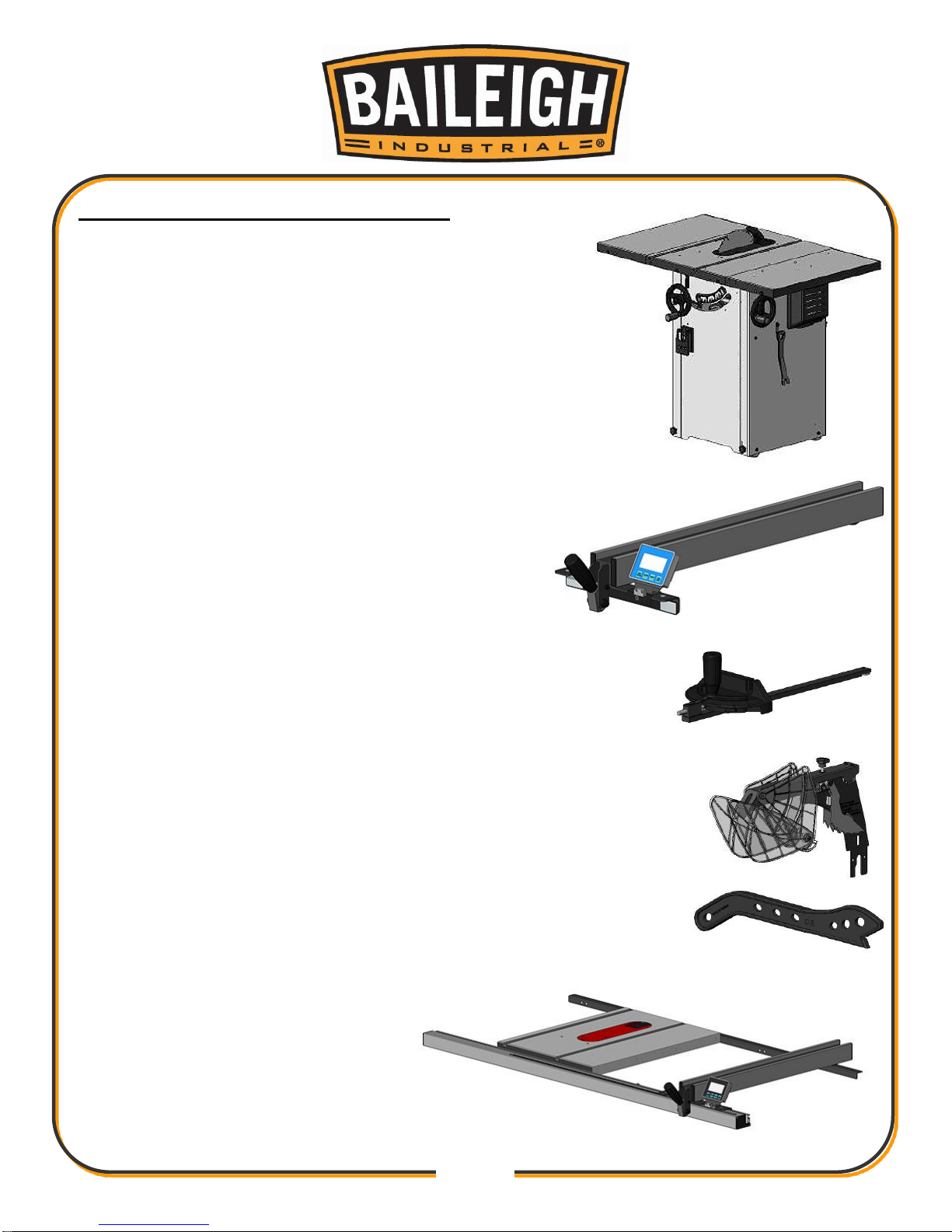

GETING TO KNOW YOUR MACHINE

Thank you for choosing this table saw. This unit is carefully

tested and inspected before shipment and if properly used

and maintained, will provide you with years of reliable

service. To ensure optimum performance and trouble free

operation a reasonable amount of care and attention is

required.

To get the most from your new table saw, please take the

time to read this manual before assembling, installing and

operating the unit.

The table saw features a circular blade underneath that

can be raised and lowered to control the depth of cut.

The rail-mounted fence, which slides freely toward or

away from the blade, is used as the main cutting guide

for the workpiece.

The miter gauge is used to guide and support the

workpiece during the cut when the workpiece cannot slide against the

fence in a stable manner that miter gauge body can be rotated to

allow a wide range of cutting angles.

The blade guard assembly is equipped with a spreader, anti-kickback

pawls and riving knife, which work to prevent kickback and stop or slow

kickback if it happens. The riving knife is used when the guard is

removed for certain non through cuts.

The push stick is used to support the workpiece during the cut and

reduces the risk of injury by keeping hands away from the blade while

cutting.

36” Rail and Extension Table (optional)

14

14

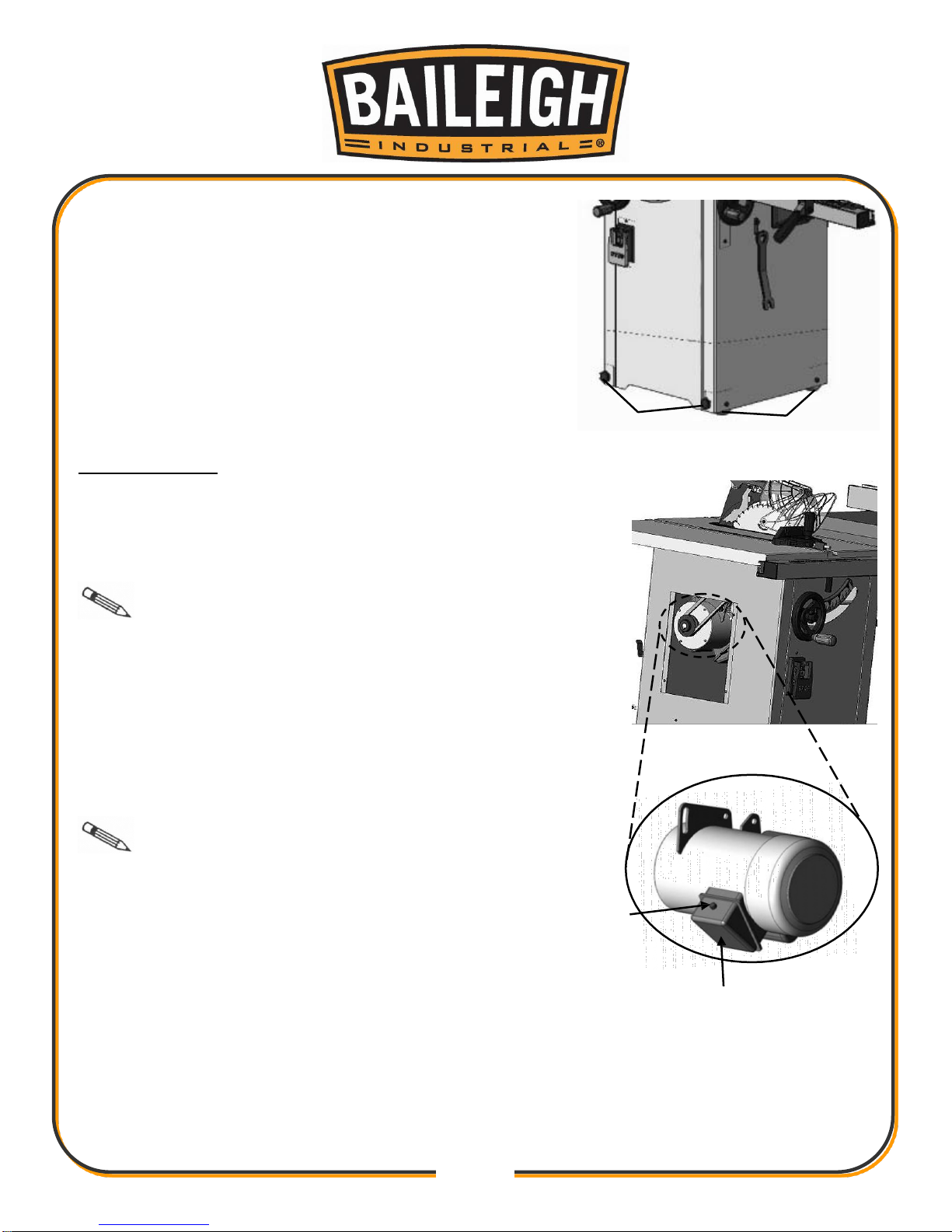

Reset

Switch

Junction

Box

Leveling

Caster

The moveable caster on this saw with (2) casters (2)

leveling screws front caster and front pedal that will

easier to move this saw and to place this saw as you

want.

Before performing machine leveling adjustment, shift the

foot pedal upward to allow the leveling screws to rest on

the floor. Turn the (2) leveling screws located at the

front bottom of the stand using a open wrench.

Reset Protector

Your saw comes equipped with a manual-reset thermaloverload protector designed to open the power line

circuit when the motor temperature exceeds a safe

level, when motor is overloaded, or when a low voltage

condition exists.

Note: This motor should be blown out or

vacuumed frequently to prevent sawdust buildup which

can interfere with normal motor ventilation.

Once the motor is cooled to a safe operating

temperature, reset the thermal overload protector by

pushing the red button on the front of the junction box.

An audible click will indicate the thermal overload

protector is reset. Once the switch button is reset, the

saw may be started and operated as normal.

Note: If the reset button won't click into

place immediately, the motor is still too hot and must be

allowed to cool.

Frequent “blowing” of fuses or tripping of circuit

breakers may result if:

Motor is overloaded. Overloading can occur if a

workpiece is fed too rapidly or if the saw is

misaligned.

Motor circuit is fused differently from recommendations. Always follow instructions for the

proper fuse/breaker. Do not use a fuse/breaker of greater capacity without consulting a

qualified electrician.

15

15

CAUTION: Lifting and carrying operations should be carried out by skilled

workers, such as a truck operator, crane operator, etc. If a crane is used to lift the

machine, attach the lifting chain carefully, making sure the machine is well balanced.

Choose a location that will keep the machine free from vibration and dust from other

machinery. Keep in mind that having a large clearance area around the machine is

important for safe and efficient working conditions.

Low voltage. Although the motor is designed for operation on the voltage and frequency

specified on the motor, normal loads will be handled safely on voltage no more than ten

percent above or below that figure. Heavy loads, however, require that voltage at motor

terminals equal the voltage specified on the motor.

motor fails to perform satisfactorily.

The table saw is equipped with a push-button switch

that will accept a safety padlock (not included). To

safeguard your machine from unauthorized operation

and accidental starting by young children, the use of a

padlock is required.

Note: Always check the connections, the load and the supply circuit whenever the

TRANSPORTING AND LIFTING

While transporting or handling the machine, be careful and let the

activity be done by qualified personnel especially trained for this

kind of activity!

While the machine is being loaded or unloaded, make sure that no

person or object gets crushed by the machine!

Select proper transportation device according to the weight of the machine.

Make sure the lifting capacity of transportation device is competent for the weight of the

machine.

16

16

INSTALLATION

IMPORTANT:

Consider the following when looking for a suitable location to place the machine:

Overall weight of the machine.

Weight of material being processed.

Sizes of material to be processed through the machine.

Space needed for auxiliary stands, work tables, or other machinery.

Clearance from walls and other obstacles.

Maintain an adequate working area around the machine for safety.

Have the work area well illuminated with proper lighting.

Keep the floor free of oil and make sure it is not slippery.

Remove scrap and waste materials regularly, and make sure the work area is free from

obstructing objects.

This machine should be installed and operated only on a solid, flat and stable floor that is able to

support the weight of the saw (312 lbs-142 kgs) and the operator.

Using the dimensions shown as a guideline, plan for placement within your shop that will allow

the operator to work unencumbered and unobstructed by foot traffic or other tools or machinery.

It is important to maintain free area of 36” (914mm) around the machine, which is required for

the working place. If any long material is machined, it is necessary to have a sufficient room in

front of the machine as well behind it in the places of material input and output.

Before beginning assembly, take note of the following precautions and suggestions

The machine is bolted to the pallet. Before attempting any of the assembly procedures

remove all of the loose parts and hardware from the inside of the machine and unbolt the

machine from the pallet.

FLOOR: This tool distributes a large amount of weight over a small area. Make certain that

the floor is capable of supporting both the weight of the machine and the operator. The floor

should also be a level surface. If the unit wobbles or rocks once in place, be sure to eliminate

by using shims.

WORKING CLEARANCES: Take into consideration the size of the material to be processed.

Make sure that you allow enough space for you to operate the machine freely.

OUTLET PLACEMENT: Outlets should be located close enough to the machine so that the

power cord or extension cord is not in an area where it would cause a tripping hazard. Be

sure to observe all electrical codes if installing new circuits and/or outlets.

17

17

WARNING: Before operating; make sure it is positioned firmly on a solid

work surface. If it tips over on you, it could cause severe injury or death.

18

18

WARNING: For your own safety, DO NOT connect the machine to the

power source until the machine is completely assembled and you read and

understand the entire instruction manual.

ASSEMBLY

INSTALL TABLE EXTENSION WINGS

1. Attach the table extension wings to the main table

using 8 x 12mm hex head bolts (4 per wing), and

8 lock washers.

2. Align the table extensions with the table and

loosely attach the bolts.

3. Place a straightedge on the table and extension

to align the extension table and then tighten the

bolts.

MOUNT FENCE STORAGE BRACKETS

The miter gauge and arbor wrench storage brackets are already

installed on the saw.

Install the fence storage brackets on the right side of the saw as

shown in using two Phillips head screws and flat washers.

Note: Be sure that the table extension wings are flush with front edge.

19

19

FRONT RAIL INSTALLATION

The 36” front rail consists of 2 pieces of tubes and

joining pins.

1. Loosely thread the six square head bolts to

the front of the table.

2. Do not tighten down the nuts; leave the square heads of the bolt protruding

from the table

3. From the left side of the saw, slide the upper slot of the left

(shorter) front rail onto the square head bolts

4. Set the left end of the rail flush to the outside edge of the

extension wing.

20

20

5. From the right side of the saw, slide the upper slot of

the right front rail onto the square head bolts.

6. Fit the 2 rails together.

7. Tighten down the nuts to firmly secure the front rails to

the table.

REAR RAIL INSTALLED

36” rear rail with 2 pieces of rail.

1. Use 6 cap screws with lock washers and nuts to

assemble the rear rails to the rear of the saw as

shown.

2. Make sure that the intersection between the two rear

rails is leveled (for 36” rail only).

21

21

CAUTION: After changing a saw blade, always check that the Riving

knife or Blade Guard is correctly set!

INSTALL BLADE GUARD

The blade guard assembly that consists of the clear shield, the spreader and the anti-kickback

pawls on each side. Each has important safety functions during the operation of the saw.

1. Disconnect and lockout power to the saw!

2. Remover the table blade insert.

3. Insert the spreader into the bracket slot and

tighten the lock knob shown to secure the

spreader.

4. Tug the spreader up to verify it is locked.

5. Lift the blade guard cover just enough to slide the

table insert into the table slot over the blade, and

then secure the insert with the knob on the front

of the insert. It should swing up high enough to

accommodate the workpiece.

6. Lifting up the right spreader pawl.

7. Place a straightedge against the blade and the

spreader. When properly aligned the

spreader/riving knife will be in the "alignment

zone," shown and will be parallel with the blade.

LOOSEN LOCK KNOB

If you could not loosen the knob by hand, used the

arbor wrench on the knob inside then turn the arbor

wrench counter-clockwise to loosen the knob.

22

22

ANTI-KICK BACK PAWL

The anti-kickback pawls allow the workpiece to travel in only one direction. If the workpiece

moves backwards, the pawls will dig into the workpiece to slow or stop it.

The pawls must return to their bottom-most position

after pivoting.

Note: The right pawl is designed to tilt

slightly away from the blade guard assembly to

prevent the pawl from catching in the table insert.

If the pawls fail to return to the bottom position, the

pivot spring may have been dislodged or broken and

will need to be fixed/replaced.

23

23

RIVING KNIFE

Use the riving knife for all non-through cuts made with

a standard table saw blade or dado blade. Use the

riving knife for those special operations where the

blade guard or its components get in the way of safe

operation, such as with very narrow cuts.

The key difference between the spreader and the

riving knife is that the riving knife mounts below the

blade's highest point of rotation

The riving knife must be kept within the range shown.

A 10" blade is required for operations that use a riving

knife. Do not use the riving knife with a dado blade

that has a diameter smaller than 10". If a smaller

diameter blade is used, the riving knife height will

exceed the blade height and the workpiece will hit the

riving knife during use. This will create a dangerous

situation of trying to turn the saw off with the

workpiece stuck halfway through the cut.

e Riving Knife Thickness

b Saw Blade Thickness

B Blade Kerf (width of saw blade cut)

Note: In order to work properly, the riving knife cannot be bent or misaligned with

the blade. If the riving knife gets accidentally bent, take the time to straighten it or just replace it.

Using a bent or misaligned riving knife will increase the risk of kickback!

24

24

TABLE INSERT

To install the zero clearance insert:

1. Disconnect and lockout power to the saw!

2. Lower the blade to the lowest position below the

table surface.

3. Verify that the blade is properly installed and

secure.

4. Install the table insert.

5. Adjust the table insert set screws with a 2.5mm

hex wrench to make sure the insert is flush with

the table then turn the lock knob to secure the

insert.

6. Connect power to the saw and turn the saw ON.

7. Set the blade angle at 90° then slowly raise the

blade to the maximum height that will be used

during normal operations.

8. Stop the saw and disconnect and lockout power

to the saw.

9. Use a straightedge to determine whether the insert is level with the table top.

10. Turn each of the 5 adjusting screws with the allen wrench until level at all positions.

25

25

WARNING: Blades are dangerously sharp. Use extreme caution when

working with or around the blade. Wear proper safety protection such as heavy

gloves.

WARNING: Turn the power switch “OFF” and unplug the power cord

from its power source when changing the saw blade.

When replacing blades, check the thickness stamped onto the riving knife. You must

select a blade with a kerf width larger than the thickness of the riving knife. Thinner

blades may cause the workpiece to bind during cutting.

USE ONLY 10″diameter blades with 5⁄8″arbor holes, rated at or higher than 3800 rpm.

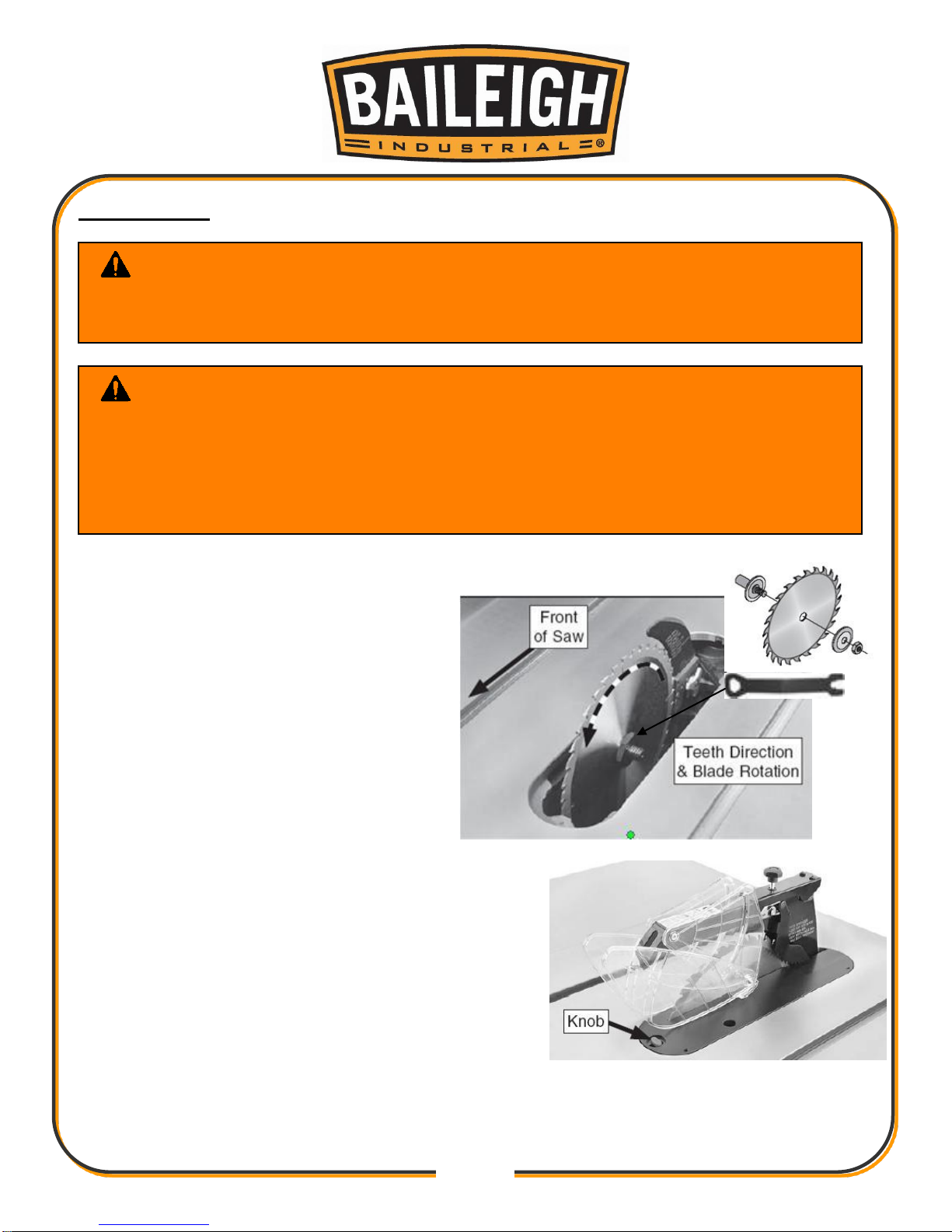

SAW BLADE

1. Disconnect and lockout power to the

saw!

2. Set the blade to 90º and raise it to its

highest position.

3. Loosen the knob on the table insert and

remove the table insert and blade

guard/riving knife, depending on what is

installed.

4. Use the arbor wrenches to loosen and

remove the arbor nut, flange, and blade.

Note: Loosen the arbor nut by turning

counterclockwise.

5. Reinstall the arbor flange and arbor nut then tighten

them against the blade. Do not over tighten.

6. Slide the blade over the arbor with the teeth facing

the front of the saw.

7. Install the arbor flange and arbor nut, and tighten

them against the blade. Do not overtighten.

8. Install the blade guard/riving knife and table insert.

26

26

WARNING: The rip fence must be parallel to the blade during operation.

Failure to set the rip fence parallel to the blade can result in kickback and possible

serious injury.

FENCE ASSEMBLY

Align the Fence Parallel to the Blade

1. Disconnect and lockout power to the saw!

2. Slide the fence over to the right T-slot on the saw table

top.

3. Lock down the fence handle and make a visual check

that the fence is parallel with the T-slot along the entire

length. Also, you can place a small 3/4” thick block of

wood, upright into the T-slot and slide it from the front to

the back checking its distance from the left edge of the

fence.

4. If the fence is not parallel, it can be adjusted by using an

Allen wrench to turn one or both of the screws (C) or (D).

Do this slowly, just an eighth to a quarter turn at a time, or

you will quickly overshoot the desired adjustment.

recheck the alignment of your fence to the blade.

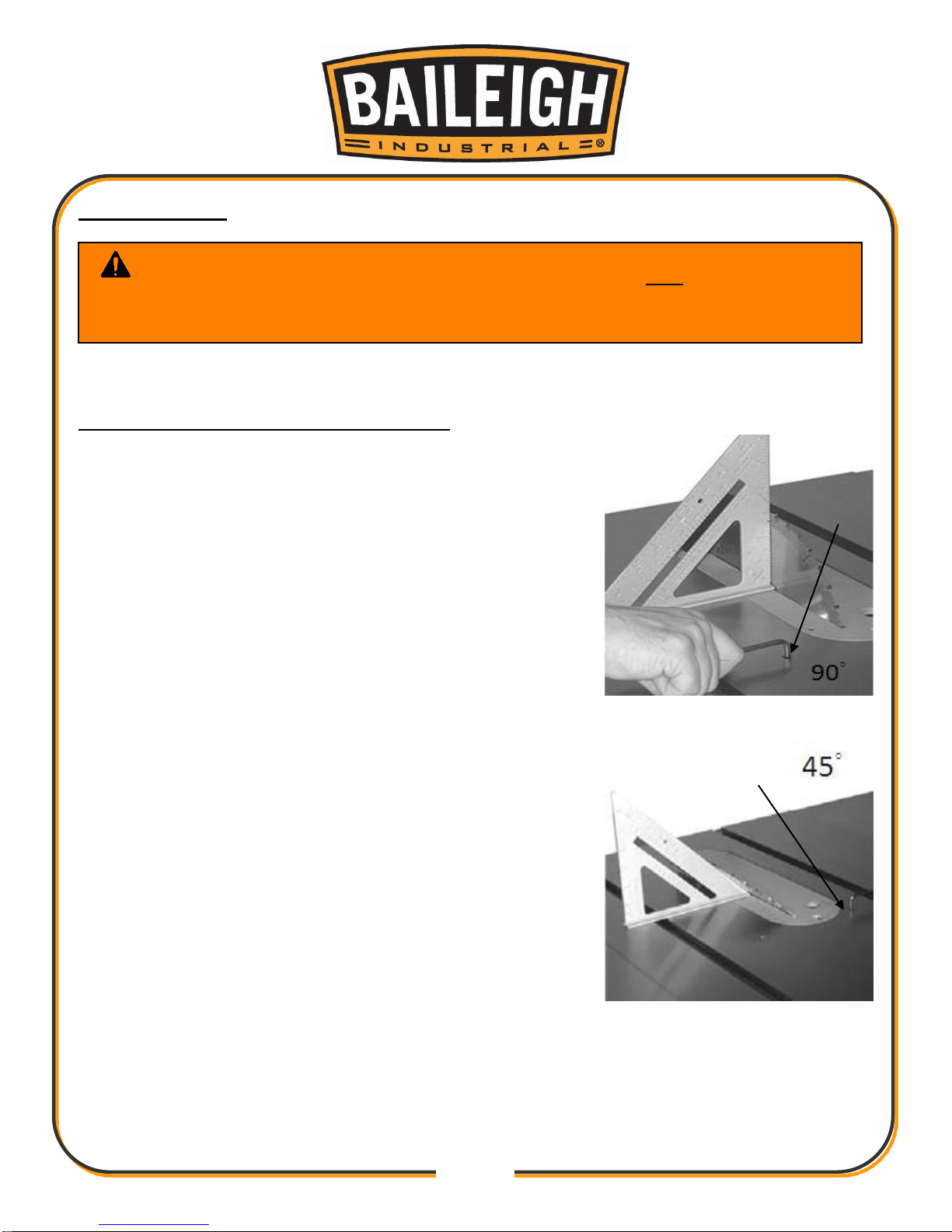

Align the Rip Fence Perpendicular (90°) to the Table

1. Disconnect and lockout power to the saw!

2. Place a machinist square on the table against the

fence and look for a gap between the square and the

fence (bottom and top) or the table.

3. If needed, adjust either of the two plastic set screws to

tilt the fence slightly and square it to the table.

Note: It is always good practice to periodically

27

27

E

LEVEL THE FENCE

The fence should be parallel to the table and sit

approximately 2mm above the table’s surface (so the

fence will not scratch the table and a thin work piece

will not get stuck or jammed under the fence).

1. Disconnect and lockout power to the saw!

2. Loosen the hex nut (F) on the leveling foot (G)

located under the rear end of the fence.

3. Raise or lower the leveling foot until there is a

spacing of approximately 5/64” (2mm) between

the bottom of the fence and the table.

4. Hold the leveling foot in position and tighten the

hex nut to lock the setting of the leveling foot.

5. If needed, to level the fence, adjust the plastic set

screws (E) equally, thereby raising or lowering the

front of the fence an equal amount on either side

so as not to undo the previous perpendicular

adjustment.

ADJUST & ALIGN RIP FENCE POINTER

1. Disconnect and lockout power to the saw!

2. Set blade to 90° and raise it to the maximum

height.

3. Move the fence until it lightly touches the right

side of the blade and push down the locking lever

to lock the fence in place.

4. With the fence locked in place against the blade,

loosen the pointer screws (B).

5. Line up the reference line on the pointer with the zero point on the tape and tighten the

pointer screws.

Note: When changing blades, re-align the pointer with the zero points on the tapes

to account for thinner or thicker blades.

28

28

DUST COLLECTOR

It is recommended that you use a dust collector (not included) when using this saw. The saw

comes with a 4” dust port located on the lower left side of the machine.

The minimum air flow requirement for this machine are listed below.

Air current speed is 20m/s for vacuum suction dust emission index.

When air current speed of dust collector device (in accordance with EN12779:2004) is not lower

than 20m/s, ensure machine can be normal exhausted. User must wear dustproof mask.

1. Required air flow: 1500 m3/h.

2. Ensure pressure drop of each dust collector outlet carrying air current speed: 1100Pa.

3. Wind speed of dust collector tube m/s:

Dry Chips: 20m/s,

Wet chips: 28m/s (water content is equal to18%)

1. Fit the 4" dust hose over the dust port (not

included), and secure in place with a hose clamp.

2. Make sure the hose does not come off. A tight fit is

necessary for proper performance.

Important: Always turn on the dust

collector before starting the saw and stop the saw

before turning off the dust collector.

29

29

PUSH STICK

The proper use of a push stick will reduce the risk

of injury by keeping your hands away from the

blade while cutting.

Whenever your hands will get within 12" of the

blade a push stick should be used.

To maintain control when cutting large workpieces,

start the cut by feeding with your hands then use

push sticks to finish the cut, so your hands are not

on the end of the workpiece as it passes through

the blade.

Plan and Practice.

With the power to the saw OFF, place the push stick(s) in a position where they will be easy to

reach without reaching over the saw blade or losing control of the workpiece.

MITER GAUGE

The miter gauge is equipped with stop screws that

allow you to easily adjust the miter gauge from 45° to

the left, 90° (centered) and 45° to the right.

The stop screws contact the stop shaft to stop the

gauge at the three most common positions.

The stop shaft moves in to contact the stop screws or

out to allow the gauge to swing past the stop.

For adjustments slide the miter gauge into the T-slot on

the table, and then push the sliding shaft all the way

into the miter gauge.

To use a setting other than 90°, loosen the lock knob (A) by turning it

counter-clockwise, pull the stop-lock pin (B) and rotate the miter head

to 45°, or any angle shown on the numerical guide.

Turn the lock knob (A) clockwise to tighten and secure the miter head.

To check the accuracy of the miter gauge’s settings, set it at 90° and

check it with an L-square or T-square. To verify the setting, make a

test cut in scrap stock and then use a square to check the cut piece.

Repeat adjustment if necessary.

If the miter gauge needs adjusting, manually turn the head so the

pointer is where you think it ought to be, tighten the lock knob and

loosen the nut.

30

30

CAUTION: HAVE ELECTRICAL UTILITIES CONNECTED TO MACHINE BY

A CERTIFIED ELECTRICIAN!

Check if the available power supply is the same as listed on the machine nameplate.

WARNING: Make sure the grounding wire (green) is properly connected

to avoid electric shock. DO NOT switch the position of the green grounding wire if

any electrical plug wires are switched during hookup.

WARNING: In all cases, make certain the receptacle in question is

properly grounded. if you are not sure, have a qualified electrician check the

receptacle.

ELECTRICAL

Connections

A separate electrical circuit should be used for your tools. If an extension cord is used, use

only 3-wire extension cords, which have grounding type plugs and receptacles, which accept

the tool’s plug. Before connecting the motor to the power line, make sure the switch is in the

“OFF” position and be sure that the electric current is of the same characteristics as

indicated on the tool.

All line connections shall make good contact. Running on low voltage will damage the motor.

In the event of a malfunction or breakdown, grounding provides a path of least resistance for

electric current to reduce the risk of electric shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and a grounding plug. The plug must be plugged

into a matching outlet that is properly installed and grounded in accordance with all local

codes and ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by

a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric

shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment-grounding conductor to a live

terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have grounding type plugs and receptacles that accept

the tool’s plug.

31

31

LENGTH

AMP RATING

25ft

50ft

100ft

0-6

16

16

16

7-10

16

16

14

11-12

16

16

14

13-16

14

12

12

17-20

12

12

10

21-30

10

10

No

WIRE GAUGE

Repair or replace damaged or worn cord immediately.

Extension Cord Safety

Extension cord should be in good condition and meet the minimum wire gauge requirements

listed below:

An undersized cord decreases line voltage, causing loss of power and overheating. All cords

should use a ground wire and plug pin. Replace any damaged cords immediately.

32

32

WARNING: Make sure the electrical disconnect is OFF before working on

the machine.

Always follow proper safety precautions when working on or around any machinery.

ADJUSTMENT

Before operation, the machine should be carefully adjusted for best performance.

ADJUSTING THE 45° & 90° BEVEL STOPS

1. Disconnect and lockout power to the saw!

2. Raise the blade to its highest position and lift the blade

guard.

3. Loosen the bevel lock knob and turn the blade tilting

handwheel clockwise until it stops.

4. Verify the angle of the blade with a combination square

from the left side of the blade; keep the square flat against

the table and against the flat part of the blade. Do not

touch the teeth or the table insert.

5. If the blade angle is incorrect, turn the 90° A stop screw

located on the table top to the left of the blade one full

counter-clockwise turn using the supplied 6 mm allen key.

6. Turn the hand wheel until the blade is at 90° to the table

surface. Then re-tighten the 90° stop screw clockwise until

slight resistance is felt. Do not over tighten stop screw.

7. Verify the 45° setting by tilting the blade as far as possible

to the left and using the square, check the angle and if

needed adjust as for the 90° stop, this time using the right

stop screw B.

33

33

ADJUSTING THE BEVEL ANGLE POINTER

The bevel pointer should read “0” when the blade is

at 90° to the table. If not, with the blade set 90°

vertical to the table, proceed as follows:

1. Disconnect and lockout power to the saw!

2. Remove the handwheel by loosening the

handwheel lock knob.

3. Once the hand wheel has been removed, loosen

the cap screw on the pointer mounting bracket

with screw driver, and manually align the pointer

with the zero on the bevel scale, then re-tighten the

screw and re-attach the hand wheel.

BLADE TILT /BEVEL ADJUSTMENT

The blade tilt (bevel) adjustment handwheel (C) is located on the side of the saw. The bevel

locking lever (D) is located under the table at the front of the saw and allows the user to lock the

tilting mechanism and secure the blade at the desired angle.

To change the angle of the blade:

1. Loosen the bevel locking handle (D) by turning it

counter-clockwise.

2. Turn the handwheel (C) left or right as required to

set the blade to the desired angle. The blade can

be tilted to the left anywhere from 0° (90° to the

table) to 45°.

3. With the blade tilted to the desired angle, tighten

the bevel locking handle by turning it clockwise to

lock the tilting mechanism and secure the blade.

34

34

CAUTION: To limit your exposure to the blade and maximise the

effectiveness of the anti-kickback pawls (when using the riving style splitter & blade

guard), never take more blade height than is required to complete the cut. When

setting the blade height for through-cuts (cuts all the way through the thickness of a

board) set the height of the blade to roughly 1/4" higher than the thickness of the

board.

BLADE HEIGHT ADJUSTMENT

The blade height adjustment handwheel is located on

the front of the saw and there is a lock knob on the

handwheel that allows you to lock the wheel and

secure the blade at the desired height.

To raise or lower the blade:

1. Loosen the blade height lock knob by turning

counter clockwise.

2. To raise the blade: Turn the handwheel clockwise.

To lower the blade: Turn the handwheel counter

clockwise.

3. With the blade set to the desired height, tighten the lock knob by turning clockwise to lock

the blade.

35

35

WARNING: Never operate the saw with any gaurds or covers removed

missing or damaged. It could cause severe injury or death.

CAUTION: Always wear proper eye protection with side shields or a face

shield, safety footwear, dust mask, and possibly heavy gloves to protect from, chips,

dust, burrs, and slivers.

WARNING: Check that saw blade clamping system is tight before

operating the machine.

B

A

OPERATION

Safety Precautions Before Operations

The operation of power tools involves a certain amount of hazard for the operator. Before

attempting regular work we recommend you get the feel of operations using scrap lumber to

check settings. Read entire instructions before you start to cut workpiece.

Always pay attention to safety precautions to avoid personal injury.

Electrical Operation

Become familiar with the location and operation of the Start and

Stop buttons. Practice reaching for the buttons, espesially the Stop

button, with power disconnected from the saw.

A Start button

B Stop button

DO NOT stand directly inline with the saw blade when starting.

Operation

Plain sawing includes ripping and crosscutting, plus a few other standard operations of a

fundamental nature. The following methods feature safety. As with all power tools there is a

certain amount of hazard involved with the operation and use of the tool. Using the tool with the

respect and caution demanded as far as safety precautions are concerned will considerably

lessen the possibility of personal injury. However, if normal safety precautions are overlooked or

completely ignored, personal injury to the operator can develop. It is good practice to make trial

cuts using scrap material when setting up you saw for operation.

36

36

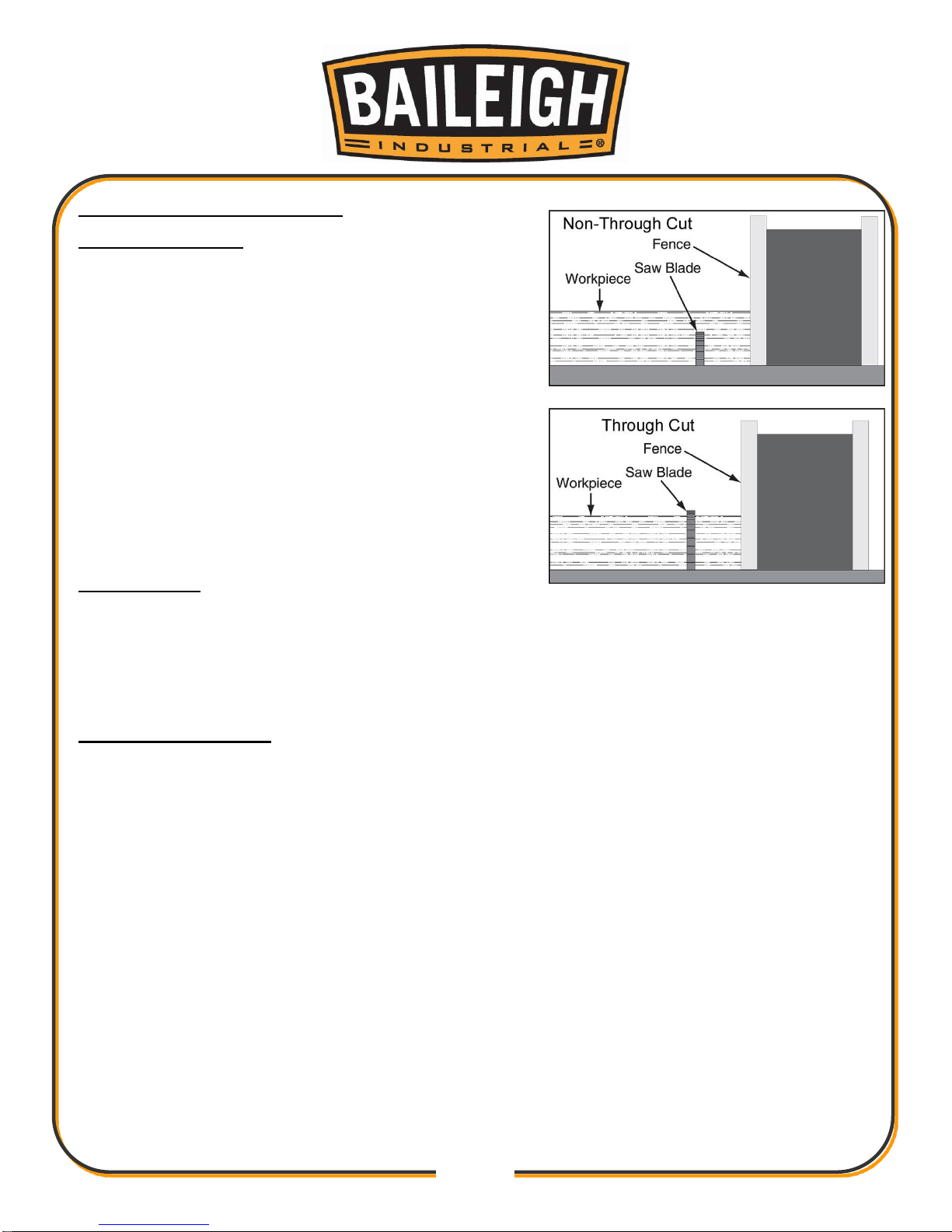

Non-Through & Through Cuts

Non-Through Cuts

A non-through cut is a sawing operation where the

blade does not extend above the top face of the wood

stock.

Examples of non-through cuts include dadoes and

rabbets. Non-through cuts have a higher risk of injury

from kickback because the blade guard must be

removed. However, the riving knife MUST be installed

because it still provides some protection. When making

non-through cuts with a dado blade, do not attempt to

cut the full depth in one pass. Instead, take multiple

light passes to reduce the load on the blade. A dado

blade smaller than 10" will require removal of the riving

knife, because the riving knife will be higher than the

blade.

Through Cuts

A through cut is a sawing operation in which the blade does extend through the workpiece and

the result is a workpiece which is completely sawn through. Examples of through cuts are rip

cuts, cross cuts, miter cuts, and beveled cuts. The blade guard assembly MUST be used when

performing through cuts.

Workpiece Inspection

Some workpieces are not safe to cut on this machine or may need to be modified before they

can be safely cut. Before cutting, inspect all workpieces for the following:

Material Type: This machine is intended for cutting natural and man-made wood products,

laminate covered wood products, and some plastics. Cutting drywall or cement based backer

board creates extremely fine dust and may reduce the life of the motor bearings. This

machine is NOT designed to cut metal, glass, stone, tile, etc.; cutting these materials with a

table saw greatly increases the risk of injury and damage to the saw or blade.

Foreign Objects: Nails, staples, dirt, rocks and other foreign objects are often embedded in

wood. While cutting, these objects can become dislodged and hit the operator, cause

kickback, or break the blade, which might then fly apart. Always visually inspect your

workpiece for these items. If they can't be removed, DO NOT cut the workpiece.

Large/Loose Knots: Loose knots can become dislodged during the cutting operation. Large

knots can cause kickback and machine damage. Choose workpieces that do not have

large/loose knots or plan ahead to avoid cutting through them.

Wet or "Green" Stock: Cutting wood with a moisture content over 20% causes

unnecessary wear on the blades, increases the risk of kickback, and yields poor results.

Excessive Warping: Workpieces with excessive cupping, bowing, or twisting are dangerous

to cut because they are unstable and may move unpredictably when being cut.

37

37

Minor Warping: Slightly cupped workpieces can be safely supported with cupped side

facing the table or fence; however, work-pieces supported on the bowed side will rock during

the cut, which could cause kickback.

BLADE REQUIREMENTS

To ensure that the spreader or riving knife works safely, the following requirements MUST be

met when installing new blades.

Blade Diameter: 10"

Required Blade Body Thickness (excluding teeth): 0.078" (2mm)

Required Blade Kerf Thickness: 0.118"- (3mm)

The spreader or riving knife MUST be aligned/adjusted to blade.

These requirements DO NOT apply to dado blades.

BLADE SELECTION

This section on blade selection is by no means comprehensive. Always follow the saw blade

manufacturer's recommendations to ensure safe and efficient operation of your table saw.

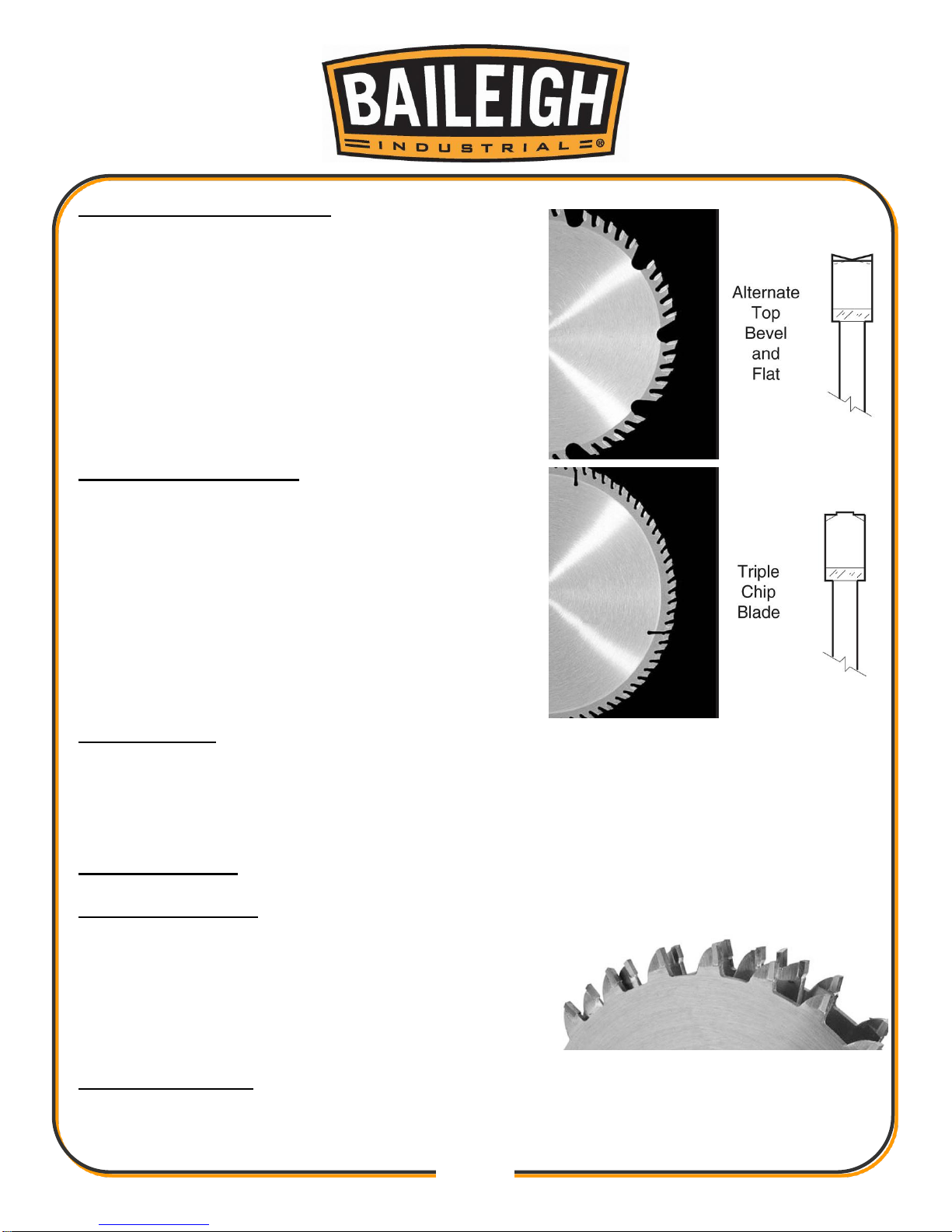

Ripping Blade Features

Best for cutting with the grain

20-40 teeth

Flat-top ground tooth profile

Large gullets for large chip removal

Crosscut Blade Features

Best for cutting across the grain

60-80 teeth

Alternate top bevel tooth profile

Small hook angle and a shallow gullet

38

38

Combination Blade Features

Designed to cut both with and across grain

40-50 teeth

Alternate top bevel and flat, or alternate top bevel

and raker tooth profile

Teeth are arranged in groups

Gullets are small and shallow (similar to a cross-cut

blade), then large and deep (similar to a ripping

blade

Laminate Blade Features

Best for cutting plywood or veneer

40-80 teeth

Triple chip tooth profile

Very shallow gullet

Thin Kerf Blade

A blade with thinner kerf than a standard blade. Since the spreader/riving knife included with this

table saw is sized for standard blades, thin kerf blades cannot be used on this saw unless they

meet the Blade Requirements specified in this manual; otherwise, they will increase the risk of

kickback.

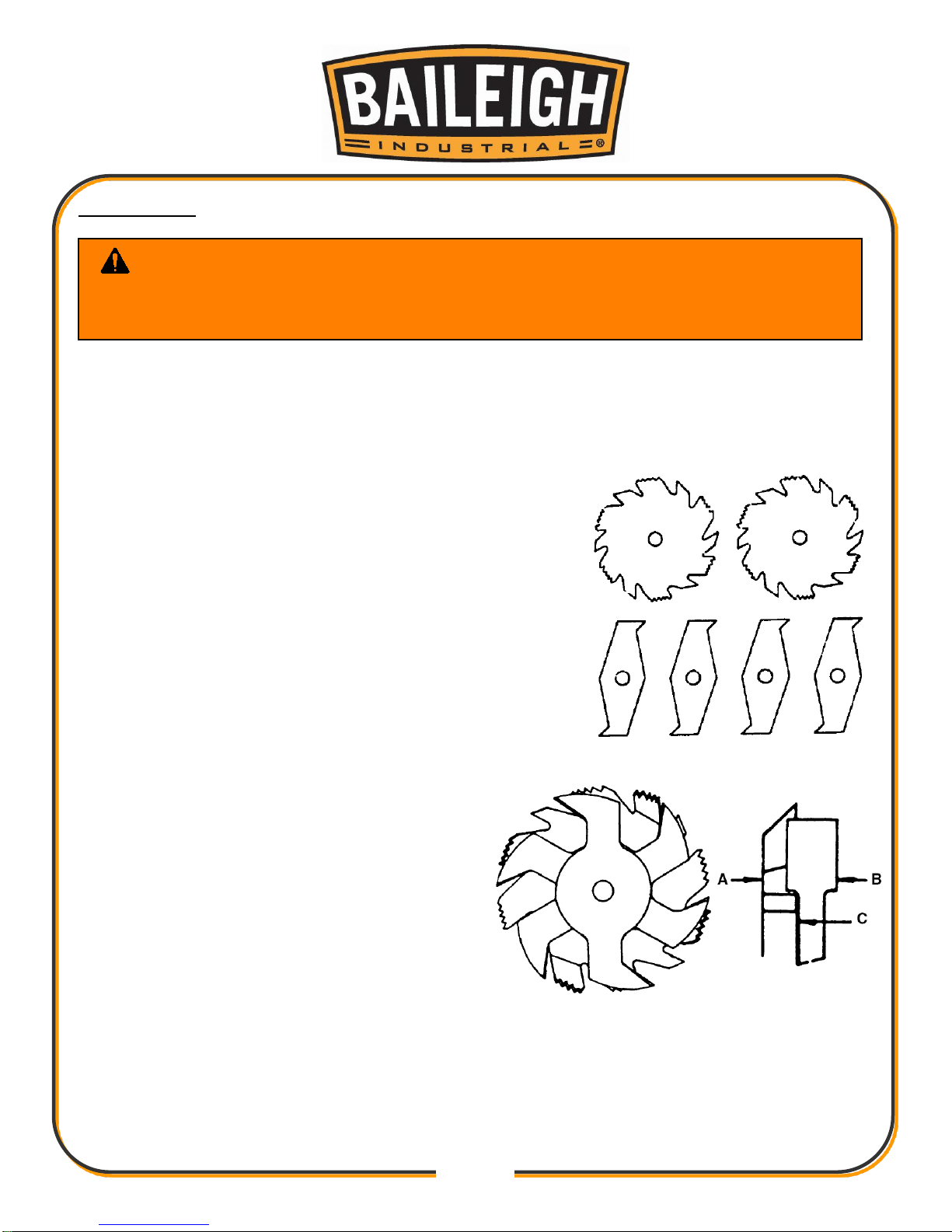

DADO BLADES

Stacked Dado Blade

Multiple blades are stacked together to control the

cutting width. Stacked dado blades are more expensive

than wobble blades, but typically produce higher quality

results.

Wobble Dado Blade

A single blade mounted at a slight angle on an arbor hub. The blade angle is adjustable on the

hub, and the width of the dado cut is controlled by the angle setting of the blade.

39

39

WARNING: Keep the blade guard installed and in the down position.

Failure to do this could result in serious personal injury or death.

Never reach in towards the blade while the blade is still spinning!

Whenever a rip cut is completed, turn off the saw and wait for the blade to come to a

complete stop before reaching in to remove the workpiece or the waste material.

Failure to follow this warning could result in accidental contact with rotating blade,

causing lacerations or amputation.

Ripping

Ripping is the operation of making a lengthwise cut through a board. The rip fence is used to

position and guide the workstock. One edge of the workstock rides against the rip fence while

the flat side of the board rest on the table.

Since the workstock is pushed along the fence, it must have a straight edge and make solid

contact with the table.

The saw guard must be used. The guard has antikickback fingers and a splitter to prevent the saw kerf

from closing.

• Never rip or cut wood without using the fence or

miter gauge to guide it because the stock could

kickback.

• Always use the blade guard and splitter assembly

when cutting wood. It has anti-kickback fingers

and a splitter to prevent the saw “kerf” (the slit cut

by the blade) from closing and binding the blade, which can overload and/or stall the motor

or cause the blade to lift and eject the workpiece towards the front of the saw at very high

speeds. The blade guard keeps your fingers away from the blade and also reduces the

amount of sawdust flying free.

• While certain operations require the removal of the blade guard and splitter assembly, it

should always be replaced for regular cutting.

• If the work to be ripped is narrow, it is safer to use

a push stick, rather than the hands, to feed it into

the blade. Push sticks with non-slip grippers can

be purchased, but shop-made push sticks works

just as well. When ripping extremely narrow stock

that may not clear the width of the blade guard, or

very thin material such as paneling, which may

slip between the underside of the fence and the

table surface, a strip of wood as an auxiliary guide

can be attached to the fence.

40

40

WARNING: Serious injury can be caused by kickback. Kickback is a

high-speed ejection of stock from the table saw toward an operator. The operator or

bystanders may be struck by flying stock, or the operator's hands can be pulled into

the blade during the kickback.

1. Take the necessary precautions to reduce the likelihood of kickback.

2. If using natural wood, joint one long edge of the workpiece on a jointer. This provides a flat,

consistent surface that can slide along the fence, which minimizes chances of the workpiece

moving during the cut, and reduces the risk of kickback.

3. Disconnect and lockout power to the saw!

4. Verify that the blade guard and spreader are

installed.

5. Set the fence to the desired width of cut on the

scale.

6. Adjust the blade height so the highest saw tooth

extends no more than 1/4" above the

workpiece.

7. Set up safety devices such as featherboards or

other anti-kickback devices.

8. Rotate the blade to make sure it does not come

into contact with any of the safety devices.

9. Connect the saw to the power source, turn it ON, and allow it to reach full speed.

Note: The jointed edge of the workpiece must slide against the fence during the

cutting operation.

10. Advance the workstock using push sticks as needed, through the saw blade holding it down

and against the fence until the workpiece is completely beyond the saw blade. Never, stand

in the line of the saw cut when ripping.

11. When the cut is complete, the workstock will either stay on the table, tilt up slightly and be

caught by the rear end of the guard or slide off the table to the floor. Alternately, the feed can

continue to the end of the table, after which the workstock is lifted and brought back along

the outside edge of the fence. The waste stock remains on the table and is not touched with

the hands until the saw is stopped and the blade comes to a complete stop. This will allow

for safe removal.

41

41

WARNING: Keep the blade guard installed and in the down position.

Failure to do this could result in serious personal injury or death.

Never reach in towards the blade while the blade is still spinning!

Whenever a cut is completed, turn off the saw and wait for the blade to come to a

complete stop before reaching in to remove the workpiece or the waste material.

Failure to follow this warning could result in accidental contact with rotating blade,

causing lacerations or amputation.

Miter Ripping

Miter ripping is performed the same as ripping but with the saw blade set to an angle not

perpendicular with the table surface. To tilt the blade to the left, anywhere between 0° and 45°.

This is used most often when cutting bevels, compound miters or chamfers.

After changing the bevel angle verify the alignment of the guard and splitter; make sure there is

clearance with the saw blade.

Ripping Small Work Pieces

Do not attempt rip cuts if the work piece is too small, as this will oblige you to place your hands

too close to the blade and put you at serious risk of injury. When ripping narrower widths; use a

push block or a push stick in order to avoid placing hands near the blade.

Crosscutting

Cutting against the grain, to shorten the length of a

board is crosscutting. With some smaller sized and

rectangular pieces, you often have the choice of

ripping or crosscutting. Always use the miter gauge,

when crosscutting; never cut a piece unsupported. The

miter gauge may be used in either slot, but most

operators prefer the left groove for typical work. When

the blade is tilted for bevel cutting, use the table slot

that does not cause interference with your hand or the

saw blade guard.

Place the workstock against the miter gauge and

advance both the miter gauge and workstock toward the saw blade.

Start the cut slowly and hold the workstock firmly against the miter gauge and the table.

42

42

WARNING: Serious injury can be caused by kickback. Kickback is a

high-speed ejection of stock from the table saw toward an operator. The operator or

bystanders may be struck by flying stock, or the operator's hands can be pulled into

the blade during the kickback.

• One of the rules in running a saw is that you never hang onto or touch a free piece of

workstock. Hold the supported piece, not the free piece that is cut off. The feed in

crosscutting continues until the workstock is cut in two, The workstock is then slid sideways

slightly away from the blade and then the miter gauge and workstock are pulled back to the

starting point.

• Never pick up any short length of free workstock from the table while the saw is running. A

smart operator never touches a cut-off piece unless it is at least a foot long.

• Never use the fence as a cut-off gauge when crosscutting.

• Never use the miter gauge in combination with the rip fence.

To make a crosscut using the miter gauge:

1. Disconnect and lockout power to the saw!

2. Verify that blade guard and spreader is installed.

3. Move or remove the rip fence so that it will not

interfere with the cut.

4. Position the miter gauge in either the left or right

miter slot, and adjust it to 90°

5. Adjust the saw blade to not more than 1/4" higher

than the workpiece to be cut.

6. Slide the miter gauge near the blade, and adjust

the workpiece so the blade will cut on the waste

side of the line.

7. Place the work on the miter gauge and slide it

up close to the blade to align the outer edges of

the teeth with your cut mark.

8. Keep a firm grip as you pull the miter gauge and

the workstock back away from the blade.

9. Lower the blade guard.

10. Start the saw and make the cut. When the work

is cut through, move one or both cut pieces. If

long enough to handle without danger immediately off to the side, away from the turning

blade.

11. Turn off the motor.

43

43