© 2012 Baileigh Industrial, Inc.

REPRODUCTION OF THIS MANUAL IN ANY FORM WITHOUT WRITTEN APPROVAL OF BAILEIGH INDUSTRIAL, INC.

IS PROHIBITED. Baileigh Industrial, Inc. does not assume and hereby disclaims any liability for any damage or loss

caused by an omission or error in this Operator’s Manual, resulting from accident, negligence, or other occurence.

Rev. 8/2012

Baileigh Industrial, Inc.

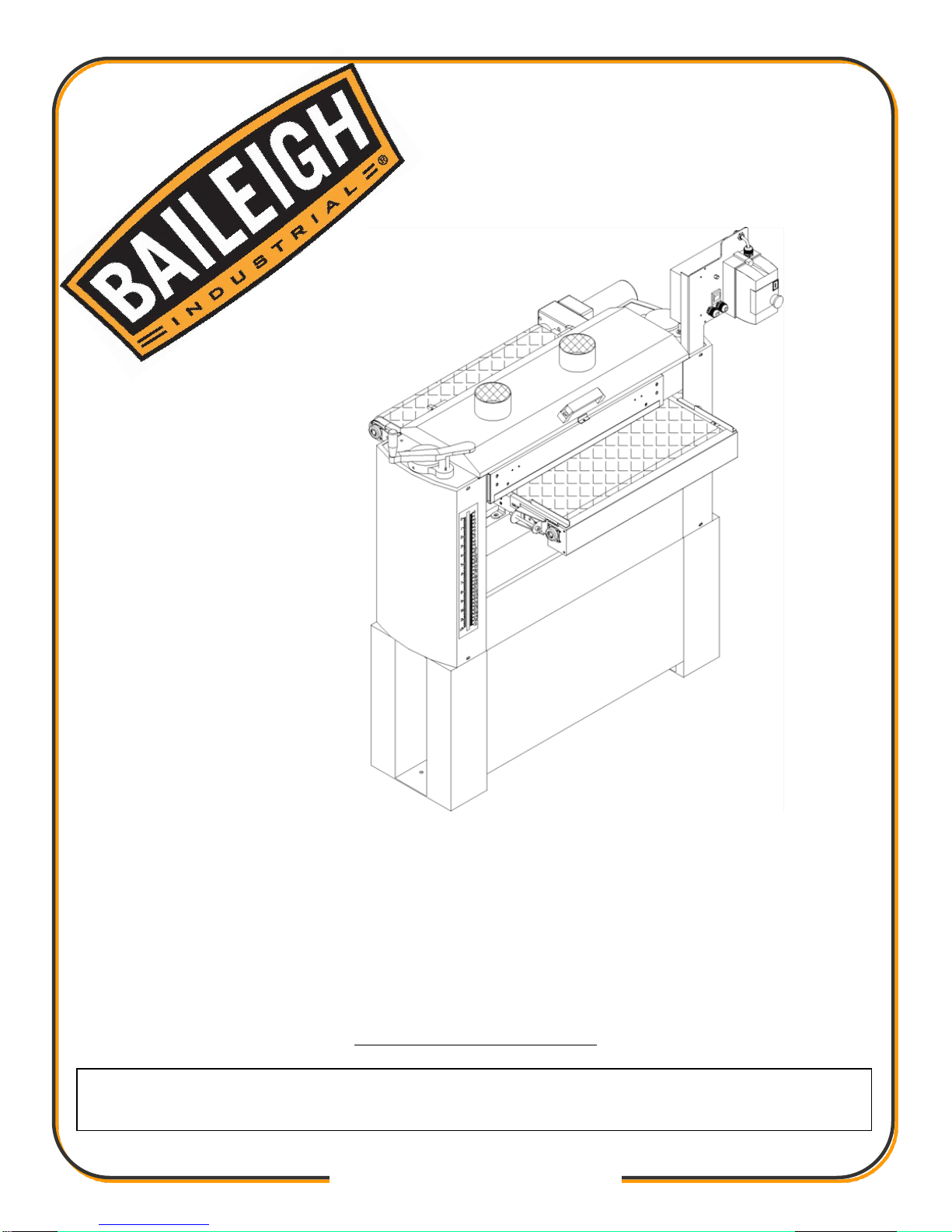

OPERATOR’S

MANUAL

DRUM SANDER

MODEL: SD-255

Manitowoc, WI 54221-0531

sales@baileighindustrial.com

P.O. Box 531

Phone: 920.684.4990

Fax: 920.684.3944

Table of Contents

THANK YOU & WARRANTY .......................................................................................... 1

INTRODUCTION ............................................................................................................ 3

GENERAL NOTES.......................................................................................................... 3

SAFETY INSTRUCTIONS .............................................................................................. 4

SAFETY PRECAUTIONS ............................................................................................... 6

EMERGENCY STOP AND SAFETY DEVICE ................................................................ 9

SPECIFICATIONS ........................................................................................................ 10

MACHINE LEGEND ...................................................................................................... 11

OVERALL DIMENSIONS .............................................................................................. 12

TRANSPORTING AND LIFTING .................................................................................. 13

INSTALLATION ............................................................................................................ 13

UNPACKING AND ASSEMBLY .................................................................................... 14

Cleaning .................................................................................................................... 15

Electrical .................................................................................................................... 15

ELECTRICAL CONNECTIONS .................................................................................... 16

ATTACHING A DUST COLLECTOR ............................................................................ 16

MOUNTING AND REPLACING SANDING BELT ......................................................... 17

Removing the Sanding Belt ....................................................................................... 17

Mounting a New Sanding Belt ................................................................................... 17

ADJUSTING THE CONVEYOR BELT TRACKING AND TENSION ............................. 18

ADJUSTING THE SANDING DRUM BELT DRIVE ....................................................... 18

REPLACING THE CONVEYOR BELT .......................................................................... 19

SANDING OPERATIONS ............................................................................................. 19

LUBRICATION AND MAINTENANCE .......................................................................... 20

TROUBLESHOOTING .................................................................................................. 21

ELECTRICAL DRAWING .............................................................................................. 22

PARTS DIAGRAM 1 ..................................................................................................... 23

PARTS DIAGRAM 2 ..................................................................................................... 24

PARTS DIAGRAM 3 ..................................................................................................... 25

PARTS DIAGRAM 4 ..................................................................................................... 26

PARTS DIAGRAM 5 ..................................................................................................... 27

1

1

THANK YOU & WARRANTY

Thank you for your purchase of a machine from Baileigh Industrial. We hope that you find it

productive and useful to you for a long time to come.

Inspection & Acceptance. Buyer shall inspect all Goods within ten (10) days after receipt thereof. Buyer’s

payment shall constitute final acceptance of the Goods and shall act as a waiver of the Buyer’s rights to inspect or

reject the goods unless otherwise agreed. If Buyer rejects any merchandise, Buyer must first obtain a Returned

Goods Authorization (“RGA”) number before returning any goods to Seller. Goods returned without a RGA will be

refused. Seller will not be responsible for any freight costs, damages to goods, or any other costs or liabilities

pertaining to goods returned without a RGA. Seller shall have the right to substitute a conforming tender. Buyer will

be responsible for all freight costs to and from Buyer and repackaging costs, if any, if Buyer refuses to accept

shipment. If Goods are returned in unsalable condition, Buyer shall be responsible for full value of the Goods.

Buyer may not return any special order Goods. Any Goods returned hereunder shall be subject to a restocking fee

equal to 30% of the invoice price.

Specifications. Seller may, at its option, make changes in the designs, specifications or components of the Goods

to improve the safety of such Goods, or if in Seller’s judgment, such changes will be beneficial to their operation or

use. Buyer may not make any changes in the specifications for the Goods unless Seller approves of such changes

in writing, in which event Seller may impose additional charges to implement such changes.

Limited Warranty. Seller warrants to the original end-user that the Goods manufactured or provided by Seller

under this Agreement shall be free of defects in material or workmanship for a period of twelve (12) months from

the date of purchase, provided that the Goods are installed, used, and maintained in accordance with any

instruction manual or technical guidelines provided by the Seller or supplied with the Goods, if applicable. The

original end-user must give written notice to Seller of any suspected defect in the Goods prior to the expiration of

the warranty period. The original end-user must also obtain a RGA from Seller prior to returning any Goods to

Seller for warranty service under this paragraph. Seller will not accept any responsibility for Goods returned without

a RGA. The original end-user shall be responsible for all costs and expenses associated with returning the Goods

to Seller for warranty service. In the event of a defect, Seller, at its sole option, shall repair or replace the defective

Goods or refund to the original end-user the purchase price for such defective Goods. Goods are not eligible for

replacement or return after a period of 30 days from date of receipt. The foregoing warranty is Seller’s sole

obligation, and the original end-user’s exclusive remedy, with regard to any defective Goods. This limited warranty

does not apply to: (a) die sets, tooling, and saw blades; (b) periodic or routine maintenance and setup, (c) repair or

replacement of the Goods due to normal wear and tear, (d) defects or damage to the Goods resulting from misuse,

abuse, neglect, or accidents, (f) defects or damage to the Goods resulting from improper or unauthorized

alterations, modifications, or changes; and (f) any Goods that has not been installed and/or maintained in

accordance with the instruction manual or technical guidelines provided by Seller.

EXCLUSION OF OTHER WARRANTIES. THE FOREGOING LIMITED WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED. ANY AND ALL OTHER EXPRESS, STATUTORY OR IMPLIED

WARRANTIES, INCLUDING BUT NOT LIMITED TO, ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE ARE EXPRESSLY DISCLAIMED. NO WARRANTY IS MADE WHICH

EXTENDS BEYOND THAT WHICH IS EXPRESSLY CONTAINED HEREIN.

Limitation of Liability. IN NO EVENT SHALL SELLER BE LIABLE TO BUYER OR ANY OTHER PARTY FOR

ANY INCIDENTIAL, CONSEQUENTIAL OR SPECIAL DAMAGES (INCLUDING, WITHOUT LIMITATION, LOST

PROFITS OR DOWN TIME) ARISING FROM OR IN MANNER CONNECTED WITH THE GOODS, ANY BREACH

BY SELLER OR ITS AGENTS OF THIS AGREEMENT, OR ANY OTHER CAUSE WHATSOEVER, WHETHER

BASED ON CONTRACT, TORT OR ANY OTHER THEORY OF LIABILITY. BUYER’S REMEDY WITH RESPECT

TO ANY CLAIM ARISING UNDER THIS AGREEMENT IS STRICTLY LIMITED TO NO MORE THAN THE

AMOUNT PAID BY THE BUYER FOR THE GOODS.

2

2

Force Majuere. Seller shall not be responsible for any delay in the delivery of, or failure to deliver, Goods due to

causes beyond Seller’s reasonable control including, without limitation, acts of God, acts of war or

terrorism, enemy actions, hostilities, strikes, labor difficulties, embargoes, non-delivery or late delivery of materials,

parts and equipment or transportation delays not caused by the fault of Seller, delays caused by civil authorities,

governmental regulations or orders, fire, lightening, natural disasters or any other cause beyond Seller's reasonable

control. In the event of any such delay, performance will be postponed by such length of time as may be reasonably

necessary to compensate for the delay.

Installation. If Buyer purchases any Goods that require installation, Buyer shall, at its expense, make all

arrangements and connections necessary to install and operate the Goods. Buyer shall install the Goods in

accordance with any Seller instructions and shall indemnify Seller against any and all damages, demands, suits,

causes of action, claims and expenses (including actual attorneys’ fees and costs) arising directly or indirectly out

of Buyer’s failure to properly install the Goods.

Work By Others; Safety Devices. Unless agreed to in writing by Seller, Seller has no responsibility for labor or

work performed by Buyer or others, of any nature, relating to design, manufacture, fabrication, use, installation or

provision of Goods. Buyer is solely responsible for furnishing, and requiring its employees and customers to use all

safety devices, guards and safe operating procedures required by law and/or as set forth in manuals and instruction

sheets furnished by Seller. Buyer is responsible for consulting all operator’s manuals, ANSI or comparable safety

standards, OSHA regulations and other sources of safety standards and regulations applicable to the use and

operation of the Goods.

Remedies. Each of the rights and remedies of Seller under this Agreement is cumulative and in addition to any

other or further remedies provided under this Agreement or at law or equity.

Attorney’s Fees. In the event legal action is necessary to recover monies due from Buyer or to enforce any

provision of this Agreement, Buyer shall be liable to Seller for all costs and expenses associated therewith,

including Seller’s actual attorneys' fees and costs.

Governing Law/Venue. This Agreement shall be construed and governed under the laws of the State of

Wisconsin, without application of conflict of law principles. Each party agrees that all actions or proceedings arising

out of or in connection with this Agreement shall be commenced, tried, and litigated only in the state courts sitting in

Manitowoc County, Wisconsin or the u.s. Federal Court for the Eastern District of Wisconsin. Each party waives

any right it may have to assert the doctrine of “forum non conveniens” or to object to venue to the extent that any

proceeding is brought in accordance with this section. Each party consents to and waives any objection to the

exercise of personal jurisdiction over it by courts described in this section. Each party waives to the fullest extent

permitted by applicable law the right to a trial by jury.

Summary of Return Policy.

10 Day acceptance period from date of delivery. Damage claims and order discrepancies will not be accepted

after this time.

You must obtain a Baileigh issued RGA number PRIOR to returning any materials.

Returned materials must be received at Baileigh in new condition and in original packaging.

Altered items are not eligible for return.

Buyer is responsible for all shipping charges.

A 30% re-stocking fee applies to all returns.

Baileigh Industrial makes every effort to ensure that our posted specifications, images, pricing and product

availability are as correct and timely as possible. We apologize for any discrepancies that may occur. Baileigh

Industrial reserves the right to make any and all changes deemed necessary in the course of business including but

not limited to pricing, product specifications, quantities, and product availability.

For Customer Service & Technical Support:

Please contact one of our knowledgeable Sales and Service team members at:

(920) 684-4990 or e-mail us at sales@baileighindustrial.com

3

3

INTRODUCTION

The quality and reliability of the components assembled on a Baileigh Industrial machine

guarantee near perfect functioning, free from problems, even under the most demanding

working conditions. However if a situation arises, refer to the manual first. If a solution cannot be

found, contact the distributor where you purchased our product. Make sure you have the serial

number and production year of the machine (stamped on the nameplate). For replacement parts

refer to the assembly numbers on the parts list drawings.

Our technical staff will do their best to help you get your machine back in working order.

In this manual you will find: (when applicable)

Safety procedures

Correct installation guidelines

Description of the functional parts of the machine

Capacity charts

Set-up and start-up instructions

Machine operation

Scheduled maintenance

Parts lists

GENERAL NOTES

After receiving your equipment remove the protective container. Do a complete visual

inspection, and if damage is noted, photograph it for insurance claims and contact your

carrier at once, requesting inspection. Also contact Baileigh Industrial and inform them of the

unexpected occurrence. Temporarily suspend installation.

Take necessary precautions while loading / unloading or moving the machine to avoid any

injuries.

Your machine is designed and manufactured to work smoothly and efficiently. Following proper

maintenance instructions will help ensure this. Try and use original spare parts, whenever

possible, and most importantly; DO NOT overload the machine or make any unauthorized

modifications.

Note: This symbol refers to useful information throughout the manual.

4

4

IMPORTANT

PLEASE READ THIS OPERATORS MANUAL CAREFULLY

It contains important safety information, instructions, and necessary operating procedures.

The continual observance of these procedures will help increase your production and

extend the life of the equipment.

SAFETY INSTRUCTIONS

LEARN TO RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol

on your machine or in this manual, BE ALERT TO THE

POTENTIAL FOR PERSONAL INJURY!

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A signal word – DANGER, WARNING, or CAUTION is

used with the safety alert symbol. DANGER identifies a

hazard or unsafe practice that will result in severe Injury

or Death.

Safety signs with signal word DANGER or WARNING are

typically near specific hazards.

General precautions are listed on CAUTION safety signs.

CAUTION also calls attention to safety messages in this

manual.

SAVE THESE INSTRUCTIONS

5

5

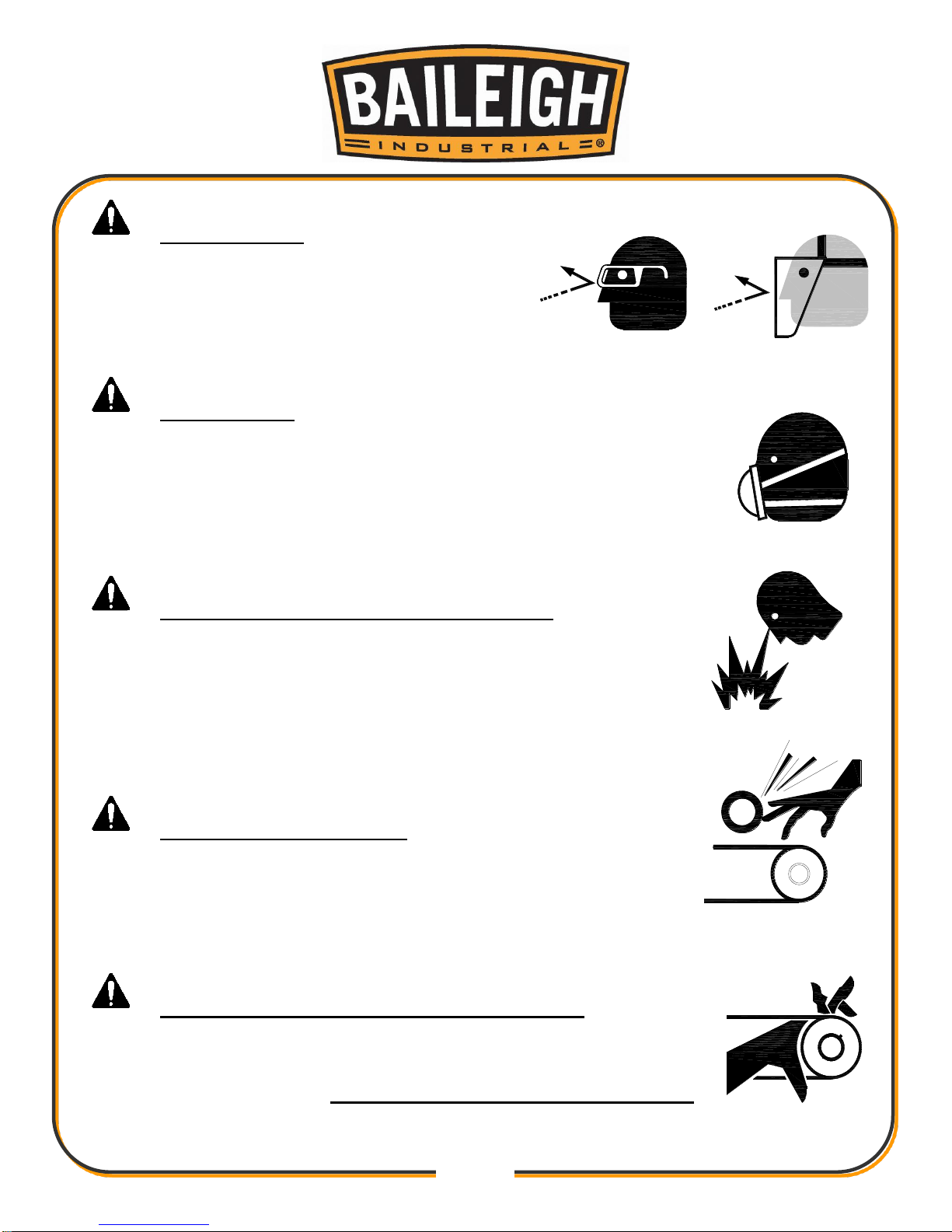

PROTECT EYES

Wear safety glasses or suitable eye

protection when working on or around

machinery.

DUST HAZARD

Wear appropriate dust mask. Dust created while using machinery can

cause cancer, birth defects, and long term respiratory damage. Be

aware of the dust hazards associated with all types of materials.

DUST PARTICLES AND IGNITION SOURCES

DO NOT operate the drum sander in areas where explosion risks

are high. Such areas include locations near pilot lights, open

flames, or other ignition sources.

MOVING BELT ABRASIONS

DO NOT place hands or fingers near, or in contact with sanding

drum or conveyor during operation.

MOVING BELTS CAN CRUSH AND DISMEMBER

DO NOT allow fingers to get pinched between conveyor belt and belt

roller. This may pull the operator’s hand into the machine causing

serious personal injury. DO NOT operate without guards in place.

6

6

WARNING:

SERIOUS PERSONAL INJURY

PROTECT AGAINST NOISE

Prolonged exposure to loud noise can cause impairment or loss of

hearing. Wear suitable hearing protective devices such as ear muffs

or earplugs to protect against objectionable or uncomfortable loud

noises.

HIGH VOLTAGE

USE CAUTION IN HIGH VOLTAGE AREAS. DO NOT assume the

power to be off.

(FOLLOW PROPER LOCKOUT PROCEDURES)

SAFETY PRECAUTIONS

Wood working can be dangerous if safe and proper operating procedures are not followed. As

with all machinery, there are certain hazards involved with the operation of the product. Using

the machine with respect and caution will considerably lessen the possibility of personal injury.

However, if normal safety precautions are overlooked or ignored, personal injury to the operator

may result.

Safety equipment such as guards, push sticks, hold-downs, feather boards, goggles, dust

masks and hearing protection can reduce your potential for injury. But even the best guard won’t

make up for poor judgment, carelessness or inattention. Always use common sense and

exercise caution in the workshop. If a procedure feels dangerous, don’t try it. REMEMBER: Your

personal safety is your responsibility.

FAILURE TO FOLLOW THESE RULES MAY RESULT IN

1. FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFORE OPERATING THE

MACHINE. Learn the machine’s application and limitations as well as the specific hazards.

2. Only trained and qualified personnel should operate this machine.

3. Make sure guards are in place and in proper working order before operating machinery.

4. Remove any adjusting tools. Before operating the machine, make sure any adjusting tools

have been removed.

7

7

SAFETY PRECAUTIONS (cont.)

5. Feeding Stock. DO NOT stand in the direct path of a piece part at the in-feed end when

feeding the stock. NEVER sand more than one piece part at a time or jam the piece part

into the sander. Firmly grasp the piece part in both hands and using light pressure, ease the

piece part into the machine.

6. Keep work area clean. Cluttered areas invite injuries.

7. Overloading machine. By overloading the machine you may cause injury from flying parts.

DO NOT exceed the specified machine capacities.

8. Stock Dimensions. DO NOT sand stock thinner than 1/8” (3mm), narrower than 2” (51mm),

or shorter than 8” (203mm).

9. Dress appropriate. DO NOT wear loose fitting clothing or jewelry as they can be caught in

moving machine parts. Protective clothing and steel toe shoes are recommended when

using machinery. Wear a restrictive hair covering to contain long hair.

10. Hand Protection. DO NOT place hands near or in contact with the sanding drum during

machine operation.

11. Use eye and ear protection. Always wear ISO approved impact safety goggles

12. Do not overreach. Maintain proper footing and balance at all times. DO NOT reach over or

across a running machine.

13. Stay alert. Watch what you are doing and use common sense. DO NOT operate any tool or

machine when you are tired.

14. Check for damaged parts. Before using any tool or machine, carefully check any part that

appears damaged. Check for binding of moving parts that may affect proper machine

operation.

15. Observe work area conditions. DO NOT use machines or power tools in damp or wet

locations. Do not expose to rain. Keep work area well lighted. DO NOT use electrically

powered tools in the presence of flammable gases or liquids.

16. DO NOT bypass or defeat any safety interlock systems.

17. Know the location of the ON - OFF switch and the “E”- STOP button.

18. Keep visitors a safe distance from the work area.

19. Keep children away. Children must never be allowed in the work area. DO NOT let them

handle machines, tools, or extension cords.

20. DO NOT operate machine if under the influence of alcohol or drugs. Read warning

labels on prescriptions. If there is any doubt, DO NOT operate the machine.

8

8

SAFETY PRECAUTIONS (cont.)

21. Belt Adjustment. NEVER attempt a belt tracking adjustment while the drum sander is

running.

22. DO NOT touch live electrical components or parts.

23. Be Sure all equipment is properly installed and grounded according to national, state, and

local codes. If machine is equipped with a three-prong plug, it should be plugged into a

three-hole electrical receptacle. If an adapter is used to accommodate a two-prong

receptacle, the adapter plug must be attached to a known ground. Never remove the third

prong.

24. Inspect power and control cables periodically. Replace if damaged or bare wires are

exposed. Bare wiring can kill!

25. Maintain machine in top condition. Keep clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

26. Reduce the risk of unintentional starting. Make sure switch is in “OFF” position before

plugging in power cord.

27. Never leave machine running unattended. TURN POWER OFF. Don’t leave machine

until it comes to a complete stop.

28. Make sure machine is disconnected from power supply while motor is being mounted,

connected or reconnected.

29. Sanding Paper on Drum. DO NOT operate the Drum sander if the sand paper is damaged

or badly worn. Replace at once.

30. Inspect Piece Part. Always inspect piece part for staples, nails, knots, or other

imperfections that could become projectiles causing personal injury.

31. Sand Appropriate Material. Only use this sander for natural wood stock. It is NOT

recommended to sand particle board, plastics, laminates, medium-density fibre board

(MDF), metal, glass, ceramics, or products containing asbestos or lead paint. Some of these

materials contain hazardous dust and will shorten the life span of the belt.

32. Warning: The dust generated by certain woods and wood products can be injurious to your

health. Always operate machinery in well ventilated areas and provide for proper dust

removal. Use a wood dust collection system whenever possible.

9

9

Series Enclosed Compact Switch

Stopper

Series Safety Limit Switch

EMERGENCY STOP AND SAFETY DEVICE

10

10

MODEL

SD-255

Max. sanding width

25" (635mm)

Max. thickness of piece part

5" (127mm)

Min. thickness of piece part

1/4" (6.35mm)

Sanding drum speed

1600RPM

Conveyor belt speed

6 ~ 24 FPM

Sanding drum motor

3 HP (2.23kw)

Feed drive motor

1/6 HP (DC) (0.124kw)

Sanding drum diameter

5" (127mm)

Net weight

394 lbs (180 kgs)

Gross weight

460 lbs (210 kgs)

Machine dimensions

45" x 28" x 52" (1143 x 711 x 1321mm)

Voltage

220V, 1Ph, 60hz

Number of sanding drums

2

Noise level

76dB

SPECIFICATIONS

Note: The specifications and dimensions presented here are subject to change

without prior notice due to improvements of our products.

11

11

MACHINE LEGEND

12

12

Model A B

C

SD-255

45” (1143mm)

28” (711mm)

52” (1320mm)

OVERALL DIMENSIONS

13

13

CAUTION: Lifting and carrying operations should be carried out by skilled

workers, such as a truck operator, crane operator, etc. If a crane is used to lift the

machine, attach the lifting chain carefully, making sure the machine is well balanced.

Choose a location that will keep the machine free from vibration and dust from other

machinery. Keep in mind that having a large clearance area around the machine is

important for safe and efficient working conditions.

71”

(1800mm)

78”

(2000mm)

TRANSPORTING AND LIFTING

INSTALLATION

IMPORTANT:

Maintain an adequate working area around the machine for safety.

Have the work area well illuminated with proper lighting.

Remove scrap and waste materials regularly, and make sure the work area is free from

obstructing objects.

Keep the floor free of oil and make sure it is not slippery.

If long lengths of material are to be fed into the machine, make sure that they will not extend

into any aisles.

14

14

UNPACKING AND ASSEMBLY

1. Remove the sander and all parts from the container, and check to ensure that all parts are

present as indicated. If any parts are damaged or missing, contact your distributor

immediately.

2. Move the sander to the worksite with a forklift or lifting hook. Make sure that the equipment

used for transportation of the sander is of adequate capacity.

3. Mount the table elevation crank handle as shown in figure. Align the slots on the shaft and

crank handle, and use the pin supplied to fasten the crank handle to the shaft.

CRANK

HANDLE

15

15

WARNING: DO NOT USE gasoline or other petroleum products to clean

the machine. They have low flash points and can explode or cause fire.

CAUTION: When using cleaning solvents work in a well ventilated area.

Many cleaning solvents are toxic if inhaled.

WARNING: Baileigh Industrial is not responsible for any damage caused

by wiring up to an alternative 3-phase power source other than direct 3-phase. If you

are using an alternate power source, consult a certified electrician or contact

Baileigh Industrial prior to energizing the machine.

CAUTION: HAVE ELECTRICAL UTILITIES CONNECTED TO MACHINE BY

Check if the available power supply is the same as listed on the machine nameplate.

WARNING: Make sure the grounding wire (green) is properly connected

to avoid electric shock. DO NOT switch the position of the green grounding wire if

any electrical plug wires are switched during hookup.

GAS

Cleaning

Your machine may be shipped with a rustproof waxy oil coating and grease on the exposed

unpainted metal surfaces. To remove this protective coating, use a degreaser or solvent

cleaner. For a more thorough cleaning, some parts will occasionally have to be removed. DO

NOT USE acetone or brake cleaner as they may damage painted surfaces.

Follow manufacturer’s label instructions when using any type of cleaning product. After cleaning,

wipe unpainted metal surfaces with a light coating of quality oil or grease for protection.

Electrical

A CERTIFIED ELECTRICIAN!

16

16

WARNING: DO NOT operate this machine without a dust collector

attached and running.

ELECTRICAL CONNECTIONS

This Sander is rated for voltage and amperage appropriate to the area where it is sold. Confirm

that the electrical specifications match your setup before use. Proper grounding is essential.

Failure to properly ground the machine may result in electrical shock and injury to the operator

or other personnel. If the machine is to be used with other electrical configurations, all

connections must be made by qualified service personnel, and the setup must comply with local

codes and ordinances. Use of an extension cord is not recommended. If an extension cord must

be used, it must be of adequate size and capacity to support the amperage and distance

between the machine and the power source.

ATTACHING A DUST COLLECTOR

The machine is provided with two 4-inch (102mm) dust chutes. Use ring clamps to attach dust

collection hoses to the chutes.

DUST

CHUTES

17

17

WARNING: Make sure the

machine is disconnected from the

power source before mounting the

sanding belt

MOUNTING AND REPLACING SANDING BELT

Removing the Sanding Belt

Lift the upper guard and tilt it to the rear, in order to access the sanding drum.

The sanding belt is fixed at either end of the drum by spring loaded clamps. To remove the

sanding belt, push the right clamp forward and pull the tab of the sanding belt out of the right

drum slot. Unwind the sanding belt from the drum, and push the clamp forward at the left side of

the drum to remove the sanding belt tab from the left drum slot.

Mounting a New Sanding Belt

Insert the tab of the belt on the left end of the drum, and push the left clamp forward so that the

tab will slide under the clamp. Releasing the clamp will lock belt tab into place. Roll the sanding

belt onto the drum, keeping the edges snug. Tuck the tab at the right end of the sanding belt into

the slot at the other end of the drum, pushing the clamp forward so that the tab will slide in. The

clamps are spring loaded, and will hold the belt increasingly tightly as the drum revolves.

Replace and mount sanding belt on both sanding drums by this method.

18

18

ADJUSTING THE SANDING DRUM BELT DRIVE

turning the M12 nuts on the height adjustment bolts

CONVEYOR

ADJUSTMENT BOLTS

HEIGHT

5/16” NUT

ADJUSTING THE CONVEYOR BELT TRACKING AND TENSION

If the conveyor belt runs to the right or left during operation, or the conveyor belt tension is too

loose or too tight, adjust it by turning the adjustment nuts on either side of the conveyor table.

The conveyor belt should run at the center of the conveyor table, and should be tensioned so

that there is good traction during stock feeding.

The drum is driven by one belt and powered by the main motor. If the belt become too loose,

remove the right end guard, front guard, and then adjust the position of the motor (height) by

ADJUSTMENT BOLT

If the motor becomes damaged and needs to be replaced, remove the bolts on the bottom of the

motor base plate, and remove the entire motor assembly.

19

19

SCREWS

NUTS

REPLACING THE CONVEYOR BELT

If the conveyor belt becomes too worn, the workpiece will not be fed effectively. To replace the

conveyor belt, remove the guards at both ends of the sander, and remove the four fix screws at

the bottom of the feed table assembly. The feed table can then be removed so that the feed belt

can be replaced. (see figure below)

SANDING OPERATIONS

Start the dust collector before turning on the sander.

To start the machine, press the green 'ON' button on the control box. Turn the key switch to start

the conveyor belt running. Turn the conveyor speed adjustment knob to the desired stock

feeding speed. To stop the machine, press the red 'OFF' button on the control box.

Use the crank handle to set the sanding height to the desired thickness. If the thickness is not

known, place the piece part on the table under the sanding drums, and then raise the conveyor

table until the sanding drums reach the piece part. The thickness can be read on the depth

gauge located on the front left of the machine. When feeding the piece part, place it at the

center of the conveyor belt. There is a centering gauge on the infeed side of the machine frame

that indicates the center of the conveyor belt.

The maximum workpiece thickness acceptable for this machine is 5" (127mm). The minimum

workpiece thickness is 1/4" 6.35mm). Do not attempt to sand piece parts outside of these

specifications.

20

20

A. Control box

E. Conveyor belt adjustment knob

H. Depth gauge

WARNING: Make sure the machine is disconnected from the power

LUBRICATION AND MAINTENANCE

B. ON button

C. Off button

D. Conveyor belt key switch

source before performing any Maintenance, Lubrication, or Troubleshooting.

1. The table height adjustment screw shafts located at either end of the machine must be well

lubricated with grease.

2. Make sure all nuts and screws are tight before sanding. Check that the sanding belt is

mounted properly, and has not become loose or torn.

3. Do not allow excessive dust to accumulate on or in the machine.

21

21

FAULT

REMEDY

Sanding belt clogs too quickly

1. Sanding belt grit too fine.

2. Too much material being removed in one

pass.

3. Dirty piece part suction.

4. Insufficient dust suction.

5. Piece part contains too much moisture.

Rounding occurs at edges or workpiece.

1. Too much material being removed in one

pass.

Uneven thickness of right and left sides of

piece part after sanding.

1. Sanding drum is not parallel to the table.

2. Uneven wear on sanding belt

Stock slips on conveyor belt.

1. Too much material being removed in one

pass.

2. Sanding belt grit too fine.

Shiny spots on sanded piece part.

1. Conveyor belt is too smooth.

2. Conveyor belt tension is insufficient

3. Excessive dust accumulated on

conveyor belt surface.

Marks on sanded surface of piece part.

1. Sanding belt is too worn.

2. Sanding height set incorrectly

3. Sanding belt damaged.

Conveyor belt does not run smoothly, or

stops.

1. Insufficient conveyor belt tension.

TROUBLESHOOTING

22

22

POWER SUPPLY

220V, 1Ph, 60Hz

Fuse 20A

ELECTRICAL DRAWING

23

23

PARTS DIAGRAM 1

24

24

PARTS DIAGRAM 2

25

25

PARTS DIAGRAM 3

26

26

PARTS DIAGRAM 4

27

27

PARTS DIAGRAM 5

28

28

NOTES

29

29

NOTES

30

30

BAILEIGH INDUSTRIAL, INC. 1625 DUFEK DRIVE MANITOWOC, WI 54220

PHONE: 920. 684. 4990 FAX: 920. 684. 3944

WWW.BAILEIGHINDUSTRIAL.COM

BAILEIGH INDUSTRIAL, INC. 1455 S. CAMPUS AVENUE ONTARIO, CA 91761

PHONE: 920. 684. 4990 FAX: 920. 684. 3944

BAILEIGH INDUSTRIAL LTD. UNIT 1 FULLWOOD CLOSE

ALDERMANS GREEN INDUSTRIAL ESTATE

COVENTRY, CV2 2SS UNITED KINGDOM

PHONE: +44 (0)24 7661 9267 FAX: +44 (0)24 7661 9276

WWW.BIFABUK.CO.UK

BAILEIGH INDUSTRIAL GMBH HOFENER STRAßE 64

70736 FELLBACH

DEUTCHSLAND

WWW.BAILEIGHINDUSTRIAL.DE

Loading...

Loading...