© 2015 Baileigh Industrial, Inc.

OPERATOR’S MANUAL

ROTARY DRAW BENDER

MODEL: RDB-050 (B8000)

Rev. 03/2015

Table of Contents

INTRODUCTION ............................................................................................................. 1

GENERAL NOTES .......................................................................................................... 1

SAFETY INSTRUCTIONS .............................................................................................. 2

SAFETY PRECAUTIONS ............................................................................................... 4

TECHNICAL SPECIFICATIONS ..................................................................................... 6

TECHNICAL SUPPORT ................................................................................................. 6

UNPACKING AND CHECKING CONTENTS .................................................................. 7

TRANSPORTING AND LIFTING .................................................................................... 8

INSTALLATION ............................................................................................................... 8

ASSEMBLY AND SET UP ............................................................................................ 10

GETTING TO KNOW YOUR MACHINE ....................................................................... 11

GENERAL DESIGN DESCRIPTION ............................................................................. 12

OPERATION ................................................................................................................. 13

Bending ..................................................................................................................... 13

Die Selection ............................................................................................................. 14

Die Installation ........................................................................................................... 15

Material Insertion ....................................................................................................... 16

Material Insertion Limitations ..................................................................................... 16

UNDERSTANDING SPRINGBACK .............................................................................. 17

MATERIAL SELECTION ............................................................................................... 17

MATERIAL LAYOUT ..................................................................................................... 18

PIPE AND TUBE BENDING DIAGRAMS ..................................................................... 19

BENDING GLOSSARY ................................................................................................. 20

BENDING SUGGESTIONS .......................................................................................... 21

Aluminum Bending .................................................................................................... 21

Heavy Wall DOM tubing ............................................................................................ 21

LUBRICATION AND MAINTENANCE .......................................................................... 22

TABLES, CHARTS, & DIAGRAMS ............................................................................... 23

Table 1 Standard Pipe Sizes and Schedules ............................................................ 23

Table 2 ARC LENGTH TABLE .................................................................................. 24

Diagram 1 .................................................................................................................. 25

Diagram2 ................................................................................................................... 26

STAND ASSEMBLY PARTS DIAGRAM ....................................................................... 27

Stand Assembly Parts List ......................................................................................... 27

TOP FRAME ASSEMBLY PARTS DIAGRAM .............................................................. 28

Top Frame Assembly Parts List ................................................................................. 29

RATCHET WHEEL ASSEMBLY PARTS DIAGRAM ..................................................... 30

Ratchet Wheel Assembly Parts List ........................................................................... 31

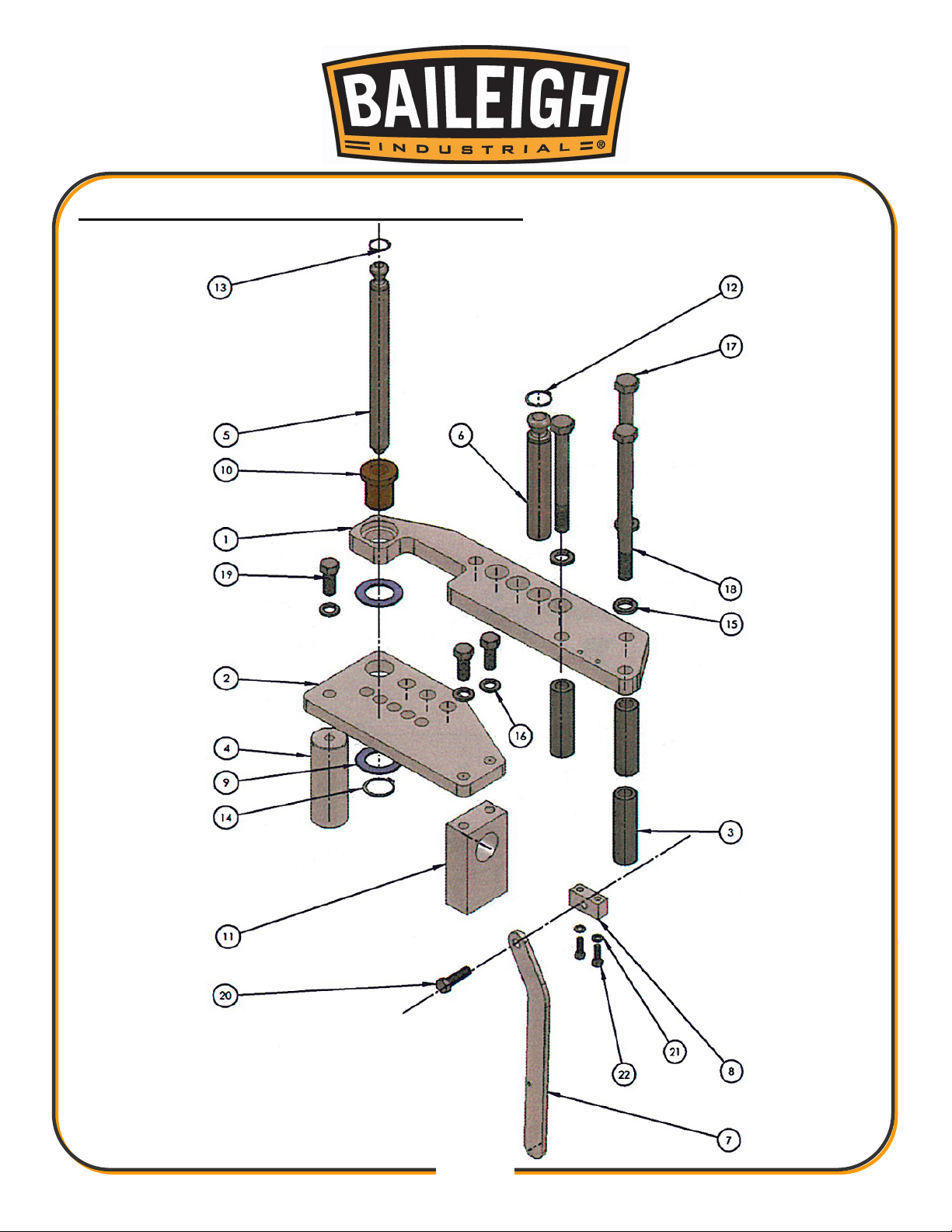

DRIVE LEVER ASSEMBLY PARTS DIAGRAM............................................................ 32

Drive Lever Assembly Parts List ................................................................................ 33

1

1

INTRODUCTION

The quality and reliability of the components assembled on a Baileigh Industrial machine

guarantee near perfect functioning, free from problems, even under the most demanding working

conditions. However if a situation arises, refer to the manual first. If a solution cannot be found,

contact the distributor where you purchased our product. Make sure you have the serial number

and production year of the machine (stamped on the nameplate). For replacement parts refer to

the assembly numbers on the parts list drawings.

Our technical staff will do their best to help you get your machine back in working order.

In this manual you will find: (when applicable)

• Safety procedures

• Correct installation guidelines

• Description of the functional parts of the machine

• Capacity charts

• Set-up and start-up instructions

• Machine operation

• Scheduled maintenance

• Parts lists

GENERAL NOTES

After receiving your equipment remove the protective container. Do a complete visual

inspection, and if damage is noted, photograph it for insurance claims and contact your

carrier at once, requesting inspection. Also contact your distributer and inform them of the

unexpected occurrence. Temporarily suspend installation.

Take necessary precautions while loading / unloading or moving the machine to avoid any

injuries.

Your machine is designed and manufactured to work smoothly and efficiently. Following proper

maintenance instructions will help ensure this. Try and use original spare parts, whenever

possible, and most importantly; DO NOT overload the machine or make any unauthorized

modifications.

2

2

SAFETY INSTRUCTIONS

Note: This symbol refers to useful information throughout the manual.

IMPORTANT

PLEASE READ THIS OPERATORS MANUAL CAREFULLY

It contains important safety information, instructions, and necessary operating

procedures. The continual observance of these procedures will help increase your

production and extend the life of the equipment.

LEARN TO RECOGNIZE SAFETY INFORMATION

This is the safety alert symbol. When you see this symbol on

your machine or in this manual, BE ALERT TO THE

POTENTIAL FOR PERSONAL INJURY!

Follow recommended precautions and safe operating

practices.

UNDERSTAND SIGNAL WORDS

A signal word – DANGER, WARNING, or CAUTION

is used with the safety alert symbol. DANGER

identifies a hazard or unsafe practice that will result in

severe Injury or Death.

Safety signs with signal word DANGER or WARNING are

typically near specific hazards.

General precautions are listed on CAUTION safety signs.

CAUTION also calls attention to safety messages in this

manual.

3

3

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

PROTECT EYES

Wear safety glasses or suitable eye protection

when working on or around machinery.

PROTECT AGAINST NOISE

Prolonged exposure to loud noise can cause impairment or loss of

hearing. Wear suitable hearing protective devices such as ear muffs or

earplugs to protect against objectionable or uncomfortable loud noises.

BEWARE OF CRUSH HAZARD

NEVER place your hands, fingers, or any

part of your body in the die area of this

machine. Be aware of the area on either side

of the dies for crush points created by

material movement.

4

4

BEWARE OF PINCH POINTS

Keep hands and fingers away from the drive

mechanisms, cylinders, ratchets, and other

moving linkage while the machine is in

operation.

KEEP CLEAR OF MOVING OBJECTS

Always be aware of the position of the material and the swing area in

which the material will travel. The material will swing with significant

force. This swing area will create pinch points and the force of the

material movement may cause serious bodily injuries.

SAFETY PRECAUTIONS

Metal working can be dangerous if safe and proper operating procedures are not followed. As

with all machinery, there are certain hazards involved with the operation of the product. Using

the machine with respect and caution will considerably lessen the possibility of personal injury.

However, if normal safety precautions are overlooked or ignored, personal injury to the operator

may result.

Safety equipment such as guards, hold-downs, safety glasses, dust masks and hearing

protection can reduce your potential for injury. But even the best guard won’t make up for poor

judgment, carelessness or inattention. Always use common sense and exercise caution in

the workshop. If a procedure feels dangerous, don’t try it.

REMEMBER: Your personal safety is your responsibility.

WARNING: FAILURE TO FOLLOW THESE RULES MAY RESULT IN

SERIOUS PERSONAL INJURY

1. Only trained and qualified personnel can operate this machine.

2. Make sure guards are in place and in proper working order before operating

machinery.

3. Remove any adjusting tools. Before operating the machine, make sure any adjusting tools

have been removed.

5

5

4. Keep work area clean. Cluttered areas invite injuries.

5. Overloading machine. By overloading the machine you may cause injury from flying parts.

DO NOT exceed the specified machine capacities.

6. Dressing material edges. Always chamfer and deburr all sharp edges.

7. Do not force tool. Your machine will do a better and safer job if used as intended. DO NOT

use inappropriate attachments in an attempt to exceed the machines rated capacity.

8. Use the right tool for the job. DO NOT attempt to force a small tool or attachment to do the

work of a large industrial tool. DO NOT use a tool for a purpose for which it was not

intended.

9. Dress appropriate. DO NOT wear loose fitting clothing or jewelry as they can be caught in

moving machine parts. Protective clothing and steel toe shoes are recommended when

using machinery. Wear a restrictive hair covering to contain long hair.

10. Use eye and ear protection. Always wear ISO approved impact safety goggles. Wear a full-

face shield if you are producing metal filings.

11. Do not overreach. Maintain proper footing and balance at all times. DO NOT reach over or

across a running machine.

12. Stay alert. Watch what you are doing and use common sense. DO NOT operate any tool or

machine when you are tired.

13. Check for damaged parts. Before using any tool or machine, carefully check any part that

appears damaged. Check for alignment and binding of moving parts that may affect proper

machine operation.

14. Observe work area conditions. DO NOT use machines or power tools in damp or wet

locations. Do not expose to rain. Keep work area well lighted. DO NOT use electrically

powered tools in the presence of flammable gases or liquids.

15. Keep children away. Children must never be allowed in the work area. DO NOT let them

handle machines, tools, or extension cords.

16. Store idle equipment. When not in use, tools must be stored in a dry location to inhibit rust.

Always lock up tools and keep them out of reach of children.

17. DO NOT operate machine if under the influence of alcohol or drugs. Read warning

labels on prescriptions. If there is any doubt, DO NOT operate the machine.

18. Keep visitors a safe distance from the work area.

6

6

Maximum Center Line Radius (CLR)*

7" (178mm)

Minimum Center Line Radius (CLR)*

3" (76mm)

Minimum OD

.75" (19mm)

Mild Steel Pipe (Schedule 40)

Call for Details

Stainless Steel Pipe (Schedule 40)

Call for Details

Mild Steel Round Tube (Wall)

2.5" (.120) (63.5mm [3mm])

Aluminum Round Tube (Wall)

2.5" (.120) (63.5mm [3mm])

Stainless Steel Round Tube (Wall)

2" (.120) (50.8mm [3mm])

Chromolly Round Tube (Wall)

2" (.120) (50.8mm [3mm])

Mild Steel Solid Rod

1" (25.4mm)

Mild Steel Square Tube (Wall)

1" (.125) (25.4mm [3.175mm])

Shipping Weight (Lbs.)

300lbs. (136kg)

Shipping Dimensions (L x W x H)

35.5” x 35.5” x 17” (900 x 900 x 430mm)

TECHNICAL SPECIFICATIONS

*CLR will vary based upon actual material and wall thickness.

TECHNICAL SUPPORT

Our technical support department can be reached at sales@machineryhouse.com.au listing

support and the model number in the subject line. Tech Support handles questions on machine

setup, schematics, warranty issues, and individual parts needs: (other than die sets and blades).

List the model number, serial number and contact name and phone number as well as a brief

description of the nature of the contact in the body of the message.

For specific application needs or future machine purchases contact the Sales Department at:

sales@machineryhouse.com.au

Note: The photos and illustrations used in this manual are representative only and

may not depict the actual color, labeling or accessories and may be intended to illustrate

technique only.

Note: The specifications and dimensions presented here are subject to change

without prior notice due to improvements of our products.

7

7

SUFFOCATION HAZARD! Immediately discard any plastic

the machine. They have low flash points and can explode or cause fire.

GAS

UNPACKING AND CHECKING CONTENTS

Your Baileigh machine is shipped complete in one crate. Separate all parts from the packing

material and check each item carefully. Make certain all items are accounted for before

discarding any packing material.

WARNING:

bags and packing materials to eliminate choking and suffocation hazards to children

and animals.

If any parts are missing, do not plug in the power cable, or turn the power switch on

until the missing parts are obtained and installed correctly.

Cleaning

Your machine may be shipped with a rustproof waxy oil coating and grease on the exposed

unpainted metal surfaces. To remove this protective coating, use a degreaser or solvent

cleaner. For a more thorough cleaning, some parts will occasionally have to be removed. DO

NOT USE acetone or brake cleaner as they may damage painted surfaces.

Follow manufacturer’s label instructions when using any type of cleaning product. After cleaning,

wipe unpainted metal surfaces with a light coating of quality oil or grease for protection.

WARNING: DO NOT USE gasoline or other petroleum products to clean

CAUTION: When using cleaning solvents work in a well-ventilated area.

Many cleaning solvents are toxic if inhaled.

8

8

TRANSPORTING AND LIFTING

CAUTION: Lifting and carrying operations should be carried out by skilled

workers, such as a truck operator. Make sure the machine is well balanced. Choose a

location that will keep the machine free from vibration and dust from other machinery.

Keep in mind that having a large clearance area around the machine is important for

safe and efficient working conditions.

Follow these guidelines when lifting:

• The lift truck must be able to lift at least 1.5 – 2 times the machines gross weight.

• Make sure the machine is balanced. While transporting, avoid rough or jerky motion, and

maintain a safe clearance zone around the transport area.

• Use a fork lift with sufficient lifting capacity and forks that are long enough to reach the

complete width of the machine.

• Remove the securing bolts that attach the machine to the pallet.

• Approaching the machine from the side, lift the machine on the frame taking care that there

are no cables or pipes in the area of the forks.

• Move the machine to the required position and lower gently to the floor.

• Level the machine so that all the supporting feet are taking the weight of the machine and no

rocking is taking place.

INSTALLATION

IMPORTANT:

Consider the following when looking for a suitable location to place the machine:

• Overall weight of the machine.

• Weight of material being processed.

• Sizes of material to be processed through the machine.

• Space needed for auxiliary stands, work tables, or other machinery.

• Clearance from walls and other obstacles.

• Maintain an adequate working area around the machine for safety.

• Have the work area well illuminated with proper lighting.

9

9

.31"

(7.87mm)

.50"

(12.7mm)

• Keep the floor free of oil and make sure it is not slippery.

• Remove scrap and waste materials regularly, and make sure the work area is free from

obstructing objects.

• If long lengths of material are to be fed into the machine, make sure that they will not extend

into any aisles.

• LEVELING: The machine should be sited on a level, concrete floor. For stationary machines,

provisions for securing it should be in position prior to placing the machine. The accuracy of

any machine depends on the precise placement of it to the mounting surface.

• FLOOR: This tool distributes a large amount of weight over a small area. Make certain that

the floor is capable of supporting the weight of the machine, work stock, and the operator.

The floor should also be a level surface. If the unit wobbles or rocks once in place, be sure to

eliminate by using shims.

• WORKING CLEARANCES: Take into consideration the size of the material to be

processed. Make sure that you allow enough space for you to operate the machine freely.

• POWER SUPPLY PLACEMENT: The power supply should be located close enough to the

machine so that the power cord is not in an area where it would cause a tripping hazard. Be

sure to observe all electrical codes if installing new circuits and/or outlets.

Anchoring the Machine

• Once positioned, anchor the machine to the floor, as shown in

the diagram, using bolts and expansion plugs that connect

through holes in the base of the stand.

IMPORTANT: If the machine is not anchored to the

floor, it will twist and rotate during bending. It will also be tippy

when loaded with long material.

10

10

ASSEMBLY AND SET UP

WARNING: For your own safety, DO NOT connect the machine to the

power source until the machine is completely assembled and you read and

understand the entire instruction manual.

1. Unpack and remove the machine from the

crate it was shipped in.

2. Install the bender assembly (1, bottom

plate) (full ratchet plate assembly not shown

for clarity), onto the stand using the

fasteners (4 and 5) shown.

3. Remove the pivot bolt and install the anti-springback lever

into the latch plate and re-install and tighten the pivot bolt.

4. Connect the latch spring.

5. Read through the remainder of the manual and become

familiar with the die installation and settings as well as

normal operation.

6. Position the machine as desired following the installation

guidelines.

11

11

I B C E G

D

F

H

A

GETTING TO KNOW YOUR MACHINE

12

12

Item

Description

Function

A graduated scale used to indicates the bend angle

that the spindle is currently positioned at.

Used to grip and hold the material during the

bending process.

Forming Die (shown with a 180°

forming die installed)

The Material is formed to the radius and contour of

this die.

Presses the material into the forming die during

bending. Must match the forming die.

Changes the leverage and the speed of the bending

equals slower speed with greater leverage.

F

Pull Handle Assembly

Supply the bending force to rotate the bending plate.

G

Anti-springback Lever

Disengages the lock pin from the locking teeth.

Pointer indicated the bending degrees on the bend

angle scale.

Supports the bend tooling and frame. Rotates during

the bending process.

A Bend Angle Scale

B Sleeve Holder with Sleeve

C

D Counter Die

E Speed/Leverage Pin

rotation for the ratchet plate. Closer to the plate

H Bend Angle Pointer

I Ratchet Plate

GENERAL DESIGN DESCRIPTION

You have made a practical choice in purchasing the RDB-050 Manual Bending Machine. It has

been carefully built of high quality materials and designed to give many years of efficient

service. The simplicity of design and minimum effort required to operate the machine contributes

towards meeting schedules and producing greater profits.

The RDB-050 is a manually powered “Rotary Draw” bending machine. To bend material, a

bending die and hook sleeve are required. The material is hooked by the hook sleeve and is

powerfully rotated in the clockwise direction. As the bending die rotates, the counter die forces

the material to conform to the radius and shape of the bending die. This machine is capable of

producing 180 degree bends (200 deg. max.) by continuing to pull release and pull the ratchet

handle. Each pull of the ratchet handle produces approximately 4 degrees of movement.

The RDB-050 Bending Machine you have purchased is built of solid steel ensuring maximum

rigidity. Grade 8 bolts throughout provides very high rigidity and stability.

Throughout this manual are listed various safety-related descriptions for attention. These

matters for attention contain the essential information to the operators while operating, and

maintaining. Failure to follow these instructions may result in great damage to the machine or

injury to the operator.

13

13

footwear, and leather gloves to protect from burrs and sharp edges.

A B 1 2 3

OPERATION

CAUTION: Always wear proper eye protection with side shields, safety

Bending

1. Before actually bending, several "dry runs" should be performed to familiarize yourself with

all of the machine functions.

2. Keep hands away from the bending zone.

3. With the drive lever and the ratchet wheel in the home (0°) position, bending or dry running

can take place.

4. Depending on the material size, you will

need to choose bending speed 1, 2, or 3.

Until you are familiar with the machine

always start bending using speed 1. You

can change speeds at any time during a

bend. If it is easy for the user to pull on the

bending handle, then the speed can be

increased if desired.

5. Each pull of the handle equals the degrees

listed below.

a. 4 degrees per pull in speed 1

b. 8 degrees per pull in speed 2

c. 12 degrees per pull in speed 3

d. Increasing speed increases pulling

effort of the bending handle.

When the machine is in the home position, engage the anti-springback lever (A).

Next engage the ratchet release lever (B).

Without material in the machine. Pull on the ratchet wheel clockwise. You will hear a "click"

every time the lever is cycled through one stroke in speed 1. Return the lever counter

clockwise and you will hear another "click". You just engaged another tooth on the ratchet

wheel. Continue though these cycles and you can "bend" or "ratchet” all the way to 200 deg.

If you select speed two, you will hear 2 clicks with each full stroke of the handle, and 3 clicks on

speed three.

14

14

whip around possibly causing injury.

CAUTION: It is important to release pressure gently. If the anti-springback

lever is released without caution, the handle assembly and ratchet wheel can violently

When the desired degree position is reached, the anti-springback lever (A) needs to be

deactivated to release the material. If the machine has a heavy bending load on it, you may

have to pull the bending lever forward to relieve the pressure allowing you to release the

anti-springback lever.

Now that the pressure is released, you can disengage the ratchet release lever (B).

The ratchet wheel is now free to rotate back to the home (0°) position.

To bend with material, go to the next section for instruction on how to choose and install the

bending dies.

After the dies are installed, insert material through the hook sleeve aligning the start of bend

with the "0" mark on the die.

Select a speed and follow the above steps and begin ratcheting the machine until you feel

tension on the pull lever. As your tubing just begins to bend, position your pointer to the "0"

on the decree dial. This will compensate for most of your "springback".

Die Selection

IMPORTANT: Damaged or worn tooling should be replaced before attempting to bend

material. This will ensure that bends are correct and provide a longer life to machine

components.

1. Before any bending can take place, the proper die set must be chosen to match the material

being bent. Example; 1-1/2" diameter tubing requires a die set marked 1-1/2" tube.

2. Two different types of dies are available. 90 degree and 180 degree dies. The 180 degree

dies allow you to bend to a full 180 degrees, and the 90 degree dies will allow you to bend to

90 degrees.

3. "Pipe" and "Tube" are not the same. All of the dies will be marked in actual outside diameter

(OD) of the material. This will relate directly to "Tube" dimensions. For “Pipe” dimensions,

refer to Table #1 near the back of the manual for the “Pipe Size Table” to find the standard

pipe OD dimensions.

Caution: When installing large dies use another person to help load into the machine.

15

15

Die Installation

1. To install the die. Remove all of the pivot pins and install them in their storage area to the left

of the ratchet wheel.

2. Choose either a 90 or 180 degree die set. Locate the dies center hole with the center of the

machine.

3. Install the 1" diameter main die pin through the center and all the way until the snap ring

bottoms out.

4. Next install the 7/8" die drive pin into the holes that line up with the respective machine hole.

5. Locate the proper hook sleeve holder and position it so the center of the assembly lines up

with the centerline radius of the die and install the 3/4" hook pin. There are two different hook

sleeve holders. One for whole number nominal CLR dies (ie: 4.0 clr) and one for fractional

(0.5) increment dies (ie: 4.5 clr).

6. Choose a counter die that matches your bend die and install the 1-1/4" counter die pin so the

gap between the die and the counter die is approximately 1/8". For dies under 3.5 clr, the

3/4" die counterdie pin supplied with the machine will be used.

Correct counter die position is approximately 1/8' away from the forming die.

IMPORTANT: It is critical that ail of the pins are fully seated down to the snap ring. If

you attempt to bend without making sure the pins are fully down machine damage will occur and

this will not be covered under warranty.

16

16

Material Insertion

1. Once the die set is properly installed, the material that matches the die can be inserted (I.E.

1-1/4”tube would go into a die mark DS-**-1250T-R***).

2. With the ratchet wheel in the home (0°) position insert the material through the counter die

and forming die and into the hook sleeve so that the material extends at least 1/4" past the

sleeve or until the until the material is at the position of the desired bend. The start of bend

mark is engraved with an “O” on the top of the die. Once the material is placed properly, the

counter die slide block assembly can be tightened.

Important: Liberally apply lubricant along the counterdie and the 1/2 of the

material that contacts the counter die with a WD-40 style lubricant or equivalent. Do not

lubricate the bending die or the hook sleeve. Lubricating the bending die and hook sleeve will

encourage slipping of material during the bend.

Follow the bending steps to bend the material to the desired degrees.

Material Insertion Limitations

• Using the Material Layout formula, calculate the amount of material that will be pulled

through the die.

• Verify that the material is long enough to provide at least 80% coverage in the counter die at

the end of the bend. This will provide enough material remaining in the counter die to be fully

supported in plastic slide.

• Extreme care must be taken when bending material with an existing bend. There must be

enough straight material to complete the bend. If there is not enough material the bent part

of the material will crash into the counter die and damage the machine and tooling.

IMPORTANT: Orienting your material in this fashion will cause damage to your tooling

and machine!! DO NOT pull bent material into the counter die! Make sure you have enough

straight material on the draw side of the material to create your bend.

17

17

potentially hazardous to operator or

personnel working nearby.

UNDERSTANDING SPRINGBACK

Springback can be difficult to understand. As material is bent, the materials yield strength resists

being formed. As a final degree is reached, the machine will have enough power to hold the

bend at a set degree, but as the pressure of the machine is released, the material has a

resistance built in, so it “springs back”

Springback will vary with every size, type and wall thickness, so it will never be consistent from

size to size.

The best way to determine a materials springback is to do sample bends to 90 degrees until a

perfect 90 is obtained.

• At that point document the actual machine degrees.

• Full manual mode is the best place to do these tests.

• Use the overbend amount and enter that value into the springback field.

MATERIAL SELECTION

CAUTION: It must be determined by the customer that materials being

processed through the machine are NOT

When selecting materials keep these instructions in mind:

• Material must be clean and dry. (without oil)

• Material should have a smooth surface so it processes easily.

• Dimensional properties of material must be consistent and not exceed the machine capacity

values.

• Chemical structure of material must be consistent.

• Buy certificated steel from the same vendor when possible.

18

18

MATERIAL LAYOUT

In order to create accurate parts, you will have to layout the material in flat form. First you will

need to determine how much material is used per degree of bend. Use the multiplier table on

Table #3 to determine the arc lengths for the die in use. Or use the following formula:

Alternate arc length formula:

Example: 6.0 clr x2=12 12x3.14=37.699 37.699/360=0.1047” per degree

0.1047x 90 degrees =9.425” of material used for a 90 degree bend.

Once the arc lengths are determined you can begin layout of the material using Diagram #1 as a

reference.

• Diagram #1 shows a simple part bent on the same plane in the same direction.

• Diagram #2 shows bending based off of a centerline in two directions.

• For symmetrical bends, centerline bending is easiest.

• For non-symmetrical bends, continuous one direction bending is best.

• Another way to layout material is to draw them in a 2D computer software program like Auto

Cad. There are many free programs on the internet. In a 2D program you will draw the parts

centerline only with corresponding clr’s. Then you will be able to list individual segments of

the bent part. This data can be directly entered into the control.

• Another program available is BEND-TECH which is a program specifically designed for tube

bending and will give you all of the required data to make a part. This software is available

from Baileigh Industrial.

• Bending with a rotary draw bender requires determining the start of bend point which will line

up with the “0” mark on the die. The portion of the tube toward the hook arm will be locked to

the die, the portion toward the counter die is the draw side and will slide along the counter

die and conform to the dies shape/radius.

19

19

PIPE AND TUBE BENDING DIAGRAMS

L = Arc length (outside)

R = Rise (inside)

D = Tube outside diameter

t = Tube wall thickness

a = First bend arc angle H = Height of offset

b = Second bend arc angle L = Length of offset

A = First tangent R1 = First radius

B = Straight between bends R2 = Second radius

C = Second tangent t = Tube Wall Thickness

D = Tube outside diameter

20

20

Arc Length

The length of material along the centerline of the tubing

Distance in inches from the center of curvature to the centerline

CLR. See Tube Bending and Pipe Bending Diagram

Angle in degrees to which the tube/pipe bends are formed (i.e. 45

degrees, 90 degrees, 180 degrees, etc.)

Bending of a rectangular tube with its short side in the plane of the

tube or pipe bend

Bending of a rectangular tube with its long side in the plane of the

tube or pipe bend

I.D.

Inside diameter of the tube or pipe bends

The minimum straight on the end of pipe bends required by the

bending machine to form the bend

That portion of the pipe or tube that is neither in compression or

tension.

O.D.

Outside diameter in inches of the tube or pipe

The deviation of the horizontal plane of a single pipe bend

the pipe bend

The distortion or flattening of pipe or tube from its normal, round

shape caused by the pipe bending process

Amount of degrees material will return after bending pressure is

released

The straight portion of material on either side of arc of bending

bends. See Tube Bending and Pipe Bending Diagrams.

The point at which the bend starts or ends. See Tube Bending

and Pipe Bending Diagrams.

Wall

The thickness in inches of tubular pipe bending material.

Wrinkles

Waving or corrugation of pipe bending bends in the inner radius.

BENDING GLOSSARY

Centerline Radius (CLR)

Degree

Easy Way (EW)

Hard Way (HW)

Minimum Tangent

Neutral Axis

Out of Plane

Ovality

Springback

axis of the tube bending or pipe bending bends. Abbreviated as

between its tangent points, based on the theoretical center-line of

Tangent

Tangent Point

21

21

BENDING SUGGESTIONS

Aluminum Bending

If bending aluminum, lubrication is very important, if the results are less than desirable with WD40 other lubricants can be used such as:

• Johnson Paste Wax (seems to work the best)

• High Pressure grease

• Highly rich dish soap

• The bronze counter die must be polished and have no aluminum deposits or it will continue

to pick up metal.

• Both steel rollers as well as plastic rollers are available. Plastic rollers are used primarily for

polished aluminum. Steel rollers would be used for non-polished materials.

• Some aluminum will crack as it is being bent, 6061-T6 is very hard and may need to be

annealed or ordered in the “T-0” condition. Aluminum will age harden so if possible try to get

freshly run material.

Heavy Wall DOM tubing

If heavy wall materials are bent to a tight radius, they can tend to slip in the hook arm causing a

poor bend result, below are some suggestions

• Use a vise clamp on the outside of the hook arm to “lock” the material in place.

• Use a piece of two sided coarse emery cloth in between the hook arm and the material, this

works very well.

• In only this application, high pressure grease applied to the DIE GROOVE also helps.

22

22

LUBRICATION AND MAINTENANCE

WARNING: Make sure the electrical disconnect is OFF before working on

the machine.

Maintenance should be performed on a regular basis by qualified personnel.

Always follow proper safety precautions when working on or around any machinery.

• Check daily for any unsafe conditions and fix immediately.

• Check that all nuts and bolts are properly tightened.

• On a weekly basis clean the machine and the area around it.

• Lubricate threaded components and sliding devices.

• Apply rust inhibitive lubricant to all non-painted surfaces.

Note: Proper maintenance can increase the life expectancy of your machine.

• There are two grease zerks on the machine, at the main spindle pivots. Grease these zerks

every month with only two pumps from a standard grease gun.

• Check for any loose or worn parts

23

23

PIPE

SIZES

O.D.

Pipe Schedules and Wall Thickness

5

10

40

80

160

XX STRONG

1/8

0.405

0.400

0.050

0.068

0.095

1/4

0.540

0.500

0.070

0.088

0.119

3/8

0.675

0.500

0.070

0.091

0.126

1/2

0.840

0.700

0.080

0.109

0.147

0.188

0.294

3/4

1.050

0.700

0.080

0.113

0.154

0.219

0.308

1

1.315

0.700

0.110

0.133

0.179

0.250

0.358

1-1/4

1.660

0.700

0.110

0.140

0.191

0.250

0.382

1-1/2

1.900

0.700

0.110

0.145

0.200

0.281

0.400

2

2.375

0.700

0.110

0.154

0.218

0.344

0.436

2-1/2

2.875

0.800

0.120

0.203

0.276

0.375

0.552

TABLES, CHARTS, & DIAGRAMS

Table 1 Standard Pipe Sizes and Schedules

24

24

Degrees

Constant

Degrees

Constant

Degrees

Constant

1

0.0175

31

0.5410

61

1.0645

2

0.0349

32

0.5584

62

1.0819

3

0.0524

33

0.5759

63

1.0994

4

0.0698

34

0.5933

64

1.1168

5

0.0873

35

0.6108

65

1.1343

6

0.1047

36

0.6282

66

1.1517

7

0.1222

37

0.6457

67

1.1692

8

0.1396

38

0.6631

68

1.1866

9

0.1571

39

0.6806

69

1.2041

10

0.1745

40

0.6980

70

1.2215

11

0.1920

41

0.7155

71

1.2390

12

0.2094

42

0.7329

72

1.2564

13

0.2269

43

0.7504

73

1.2739

14

0.2443

44

0.7678

74

1.2913

15

0.2618

45

0.7853

75

1.3088

16

0.2792

46

0.8027

76

1.3262

17

0.2967

47

0.8202

77

1.3437

18

0.3141

48

0.8376

78

1.3611

19

0.3316

49

0.8551

79

1.3786

20

0.3490

50

0.8725

80

1.3960

21

0.3665

51

0.8900

81

1.4135

22

0.3839

52

0.9074

82

1.4309

23

0.4014

53

0.9249

83

1.4484

24

0.4188

54

0.9423

84

1.4658

25

0.4363

55

0.9598

85

1.4833

26

0.4537

56

0.9772

86

1.5007

27

0.4712

57

0.9947

87

1.5182

28

0.4886

58

1.0121

88

1.5356

29

0.5061

59

1.0296

89

1.5531

30

0.5235

60

1.0470

90

1.5705

Table 2 ARC LENGTH TABLE

EXAMPLE: Arc Length = Constant x Bend Radius. Example: 90deg bend with 6” clr

EXAMPLE: 1.575 (from table) x 6” (clr) = 9.45” (Arc Length)

For bends more than 90deg, Constants can be added together.

25

25

Diagram 1

26

26

Diagram2

27

27

Item

Part No.

Description

Qty.

1

M050-6A002

Bottom Plate

1 2 AA-838-16

Sleeve Bushing

1 3 M050-5A005

Stand Weldment

1 4 LW 0.375

3/8” Lockwasher

4 5 0.375-16 x 1.00 HHCS

3/8”-16 x1” Hex Head Cap Screw

4 6 0.250”-20 x 1.00 SHCS

1/4"-20 x 1” Socket Head Cap Screw

1

7

0.250-20 Hex Nut

18/4”-20 Hex Nut

1

STAND ASSEMBLY PARTS DIAGRAM

Stand Assembly Parts List

28

28

TOP FRAME ASSEMBLY PARTS DIAGRAM

29

29

Item

Part No.

Description

Qty.

1

M050-6A004

Top Plate

1 2 M050-6A005

Pin Plate

1 3 M050-7A002

Spacer Tube

3 4 M050-7A016

Plate Spacer

1

5

M050-7A003

Main Die Pin

1 6 M050-7A005

Counter Die Pin (Large)

1 7 M050-6A010

Spring Back Lever

1 8 M050-6A009

Lever Pivot Block

1 9 M050-7A007

Thrust Washer 1/8”

2

10

M050-7A008

Top Bushing

1

11

M050-6A025

Rectangular Spacer

1

12

1250 Snap Ring

1-1/4” Snap Ring (External)

1

13

1000 Snap Ring

1” Snap Ring (External)

1

14

1500 Snap Ring

1-1/2” Snap Ring (External)

1

15

LW 0.75

3/4" Split Ring Lockwasher

3

16

LW 0.625

5/8" Split Ring Lockwasher

3

17

0.75-10 x 6.50 HHCS

3/4"-10 x 6-1/2” Hex Head Cap Screw

2

18

0.75-10 x 9.00 HHCS

3/4"-10 x 9” Hex Head Cap Screw

1

19

0.625-11 x 1.50 HHCS

5/8"-11 x 1-1/2” Hex Head Cap Screw

3

20

0.500-13 x 1.75 HHCS

1/2"-13 x 1-3/4” Hex Head Cap Screw

1

21

LW 0.3125

5/16" Split Ring Lockwasher

2

22

0.313-18 x 1.00 HHCS

5/16"-18 x 1” Hex Head Cap Screw

2

Top Frame Assembly Parts List

30

30

RATCHET WHEEL ASSEMBLY PARTS DIAGRAM

31

31

Item

Part No.

Description

Qty.

1

M050-6A001

Ratchet Wheel

1 2 M050-6A003

Middle Plate

1 3 M050-6A002

Bottom Plate

1 4 M050-7A016

Plate Spacer

1

5

M050-7A017

Short Tube Spacer

1 6 M050-7A003

Main Die Pin

1 7 M050-7A011

Bumper Pin (Long)

1 8 M050-7A012

Bumper Pin (Short)

1 9 M050-6A013

Latch Drive Bar (Thin)

1

10

M050-7A020

Bumper Pin (Thin)

2

11

M050-6A017

Latch Drive Bar (Lower)

1

12

M050-7A007

Thrust Washer 1/8”

4

13

M050-7A025

Lower Pivot Sleeve

1

14

M050-7A026

Special Hex Nut

1

15

M050-6A025

Rectangular Spacer

1

16

M100-6A019

Degree Sticker

1

17

M050-7A024

Lower Bushing

1

18

1000 Snap Ring

1” Snap Ring (External)

1

19

0750 Snap Ring

3/4” Snap Ring (External)

4

20

LW 0.75

3/4” Split Ring Lockwasher

1

21

M050-6A011

Latch Plate

1

22

0.750-10 x 9.00 HHCS

3/4"-10 x 9” Hex Head Cap Screw

1

23

0.250-20 x 0.75 SHCS

1/4"-20 x 3/4” Socket Head Cap Screw

2

24

0.625-11 x 1.50 HHCS

5/8"-11 x 1-1/2” Hex Head Cap Screw

3

25

LW 0.625

5/8” Split Ring Lockwasher

3

26

M050-6A026

Pointer Block

1

27

DK-1216

Hand Knob

1

28

FF-838-1

Flanged Sleeve Bushing

2

29

0.250-20 x 1.00 SHCS

1/4"-20 x 1” Socket Head Cap Screw

3

30

0.25-20 Hex Nut

1/4"-20 Hex Nut

3

31

PP-1073

3” Spring

3

32

M050-6A027

Pointer

1

Ratchet Wheel Assembly Parts List

32

32

DRIVE LEVER ASSEMBLY PARTS DIAGRAM

33

33

Drive Lever Assembly Parts List

Item

Part No.

Description

Qty.

1

M050-6A013

Latch Drive Bar (Upper)

1 2 M050-6A014

Drive Link

2 3 M050-6A015

Connecting Block

1 4 M050-6A012

Shaft Block

1

5

M050-7A021

Drive Pin

1 6 M050-7A018

Spacer

1 7 M050-6A016

Lock Tab

2 8 M050-7A019

Release Spacer

1 9 M050-7A020

Bumper Pin (Thin)

2

10

M050-6A017

Latch Drive Bar (Lower)

1

11

M050-7A022

Pivot Pin

1

12

M050-7A023

Pivot Pin (Short)

1

13

M050-7A030

Die Drive Pin

1

14

FL-75-4

Flanged Sleeve Bushing

8

15

M050-7A024

Lower Bushing

1

16

M050-7A007

Thrust Washer 1/8”

4

17

AA-838-16

Sleeve Bushing

2

18

M050-7A026

Special Hex Nut

1

20

FF-838-1

Flanged Sleeve Bushing

1

21

AA-838-25

Sleeve Bushing

1

22

M050-7A025

Lower Pivot Sleeve

1

23

0750 Snap Ring

3/4” Snap Ring (External)

6

24

0625 Snap Ring

5/8” Snap Ring (External)

2

25

0.313-18 x 1.00 HHCS

5/16"-18 x 1” Hex Head Cap Screw

8

26

0.313-18 x 0.50 HHCS

5/16"-18 x 1/2” Hex Head Cap Screw

2

27

0.375-16 x 1.75 FHCS

3/8"-16 x 1-3/4” Flat Head Cap Screw

1

28

PP-1073

3” Spring

2

29

0.250-20 x 1.00 SHCS

1/4"-20 x 1” Socket Head Cap Screw

4

30

0.25-20 Hex Nut

1/4"-20 Hex Nut

4

34

34

Distributed By

SYDNEY

(02) 9860 9111

MELBO URNE

(03) 9212 4422

BRIS BANE

(07) 3715 2200

PERT H

(08) 9373 9999

General Machinery Safety Instructions

Machinery House

requires you to read this entire Manual before using this machine.

1. Read the entire Manual before starting

machinery.

not correctly used.

Machinery may cause serious injury if

2. Always use correct hearing protection when

operating machinery.

permanent hearing damage.

Machinery noise may cause

3. Machinery must never be used when tired, or

under the influence of drugs or alcohol.

running machinery you must be alert at all times.

When

4. Wear correct Clothing. At all times remove all loose

clothing, necklaces, rings, jewelry, etc. Long hair

must be contained in a hair net. Non-slip protective

footwear must be worn.

5. Always wear correct respirators around fumes

or dust when operating machinery.

fumes & dust can cause serious respiratory illness.

Dust extractors must be used where applicable.

Machinery

6. Always wear correct safety glasses. When

machining you must use the correct eye protection

to prevent injuring your eyes.

7. Keep work clean and make sure you have good

lighting.

accidents.

Cluttered and dark shadows may cause

8. Personnel must be properly trained or well

supervised when operating machinery.

sure you have clear and safe understanding of the

machine you are operating.

Make

9. Keep children and visitors away. Make sure

children and visitors are at a safe distance for you

work area.

10. Keep your workshop childproof. Use padlocks,

Turn off master power switches and remove start

switch keys.

14. Use correct amperage extension cords.

Undersized extension cords overheat and lose

power. Replace extension cords if they become

damaged.

15. Keep machine well maintained. Keep blades

sharp and clean for best and safest performance.

Follow instructions when lubricating and changing

accessories.

16. Keep machine well guarded. Make sure guards

on machine are in place and are all working

correctly.

17. Do not overreach. Keep proper footing and

balance at all times.

18. Secure workpiece. Use clamps or a vice to

hold the workpiece where practical. Keeping the

workpiece secure will free up your hand to operate

the machine and will protect hand from injury.

19. Check machine over before operating. Check

machine for damaged parts, loose bolts, Keys and

wrenches left on machine and any other conditions

that may effect the machines operation. Repair and

replace damaged parts.

20. Use recommended accessories. Refer to

instruction manual or ask correct service officer

when using accessories. The use of improper

accessories may cause the risk of injury.

21. Do not force machinery. Work at the speed and

capacity at which the machine or accessory was

designed.

22. Use correct lifting practice. Always use the

correct lifting methods when using machinery.

Incorrect lifting methods can cause serious injury.

23. Lock mobile bases. Make sure any mobile bases

are locked before using machine.

11. Never leave machine unattended. Turn power off

and wait till machine has come to a complete stop

before leaving the machine unattended.

12. Make a safe working environment. Do not use

machine in a damp, wet area, or where flammable

or noxious fumes may exist.

13. Disconnect main power before service

machine.

position before re-connecting.

Make sure power switch is in the off

24. Allergic reactions. Certain metal shavings and

cutting fluids may cause an ellergic reaction in

people and animals, especially when cutting as the

fumes can be inhaled. Make sure you know what

type of metal and cutting fluid you will be exposed

to and how to avoid contamination.

25. Call for help. If at any time you experience

difficulties, stop the machine and call you nearest

branch service department for help.

Manual Pipe/Tube Bender Safety Instructions

Machinery House

requires you to read this entire Manual before using this machine.

1. Maintenance. Make sure all moving parts have come

to a complete stop before any inspection, adjustment

or maintenance is carried out.

2. Pipe/Tube Bender Condition. The Pipe/Tube Bender

must be maintained for a proper working condition.

Never operate a Pipe/Tube Bender that has damaged

or worn parts. Scheduled routine maintenance should

performed on a scheduled basis. Check frame, rollers,

springs & formers for cracks or damage. Replace if

necessary.

3. Former Condition. Never operate a Pipe/Tube Bender

with damaged or badly worn Formers. Replace if

required.

4. Hand Hazard. Keep hands away from the Pipe/Tube

Bender under any circumstances while the machine is

in operation mode. Serious injury can occur.

5. Gloves & Glasses. Always wear protective gloves and

approved safety glasses when using this machine.

6. Work area hazards. Keep the area around the

Pipe/Tube Bender clean from oil, tools, objects &

chips. Pay attention to other persons in the area and

know what is going on around the area to ensure

unintended accidents.

7. Guards. Do not operate the Pipe/Tube Bender

without the guards if supplied. The only other area

which needs to be carefully monitored during use is

the rotational area of the formers.

10. Avoiding Entanglement. Pipe/Tube Bender guards

must be used at all times. Tie up long hair and use

the correct hair nets to avoid any entanglement with

the Pipe/Tube Benders moving parts.

11. Trained Operator. This machine must be operated

by authorized and trained personnel.

12. Warning Labels. Take note of any warning labels on

the machine and do not remove them.

13. Material Hazard. Do not bend plastics or other

objects that could shatter. Serious injury can occur.

Make sure your hardness is same throughout the

material. We recommend that you use certified

material.

14. Stopping the Former. Do not stop or slow the

former with your hand or workpiece. Allow the

machine to stop on its own.

15. Secure Pipe/Tube Bender. Make sure you bolt the

machine down so it is secure when in operation.

16. Pinching. Prevent pinching by releasing pressure on

the workpiece when not in use.

17. Call for help. If at any time you experience

difficulties, stop the machine and call you nearest

branch service department for help.

8. Understand the machines controls. Make sure you

understand the use and operation of all controls.

9. Overloading Pipe/Tube Bender. Do not over load

the machine by using material which exceeds the

rated capacity.

Revised Date:

www.machineryhouse.com.au

www.machineryhouse.co.nz

29th January 2019

Plant Safety Program to be read in conjunction with manufactures instructions

O

Use equipment in the correct manner as to avoid parts being ejected out under pressure.

Ensure correct formers are used for the correct job.

HIGH

Always support material properly.

LOW

Wear safety glasses as required.

Check equipment for damage prior to use.

Risk Control Strategies

(Recommended for Purchase / Buyer / User)

Never put any part of your body between moving formers and material.

Do not exceed maximum capacity.

Keep hand away from moving parts.

Wear safety boots.

MEDIUM

OR PUNCTURING

OTHER HAZARDS, EYES.

BCE

CRUSHING

Item

Hazard

Assessment

STRIKING

PLANT SAFETY PROGRAM

No.

Hazard

Identification

Safety officer:

Authorised and signed by:

This program is based upon the Safe Work Australia, Code of Practice - Managing Risks of Plant in the Workplace ( WHSA 2011 No10 )

NEW MACHINERY HAZARD IDENTIFICATION, ASSESSMENT & CONTROL

CUTTING, STABBING

MEDIUM

Use equipment in the correct manner as to avoid parts being ejected out under pressure.

Developed in Co-operation Between A.W.I.S.A and Australia Chamber of Manufactures

Manual Pipe/Tube Benders

Manager:

Loading...

Loading...