Page 1

Installation and Instruction

Manual

MODEL COIN

Flow Meters

Page 2

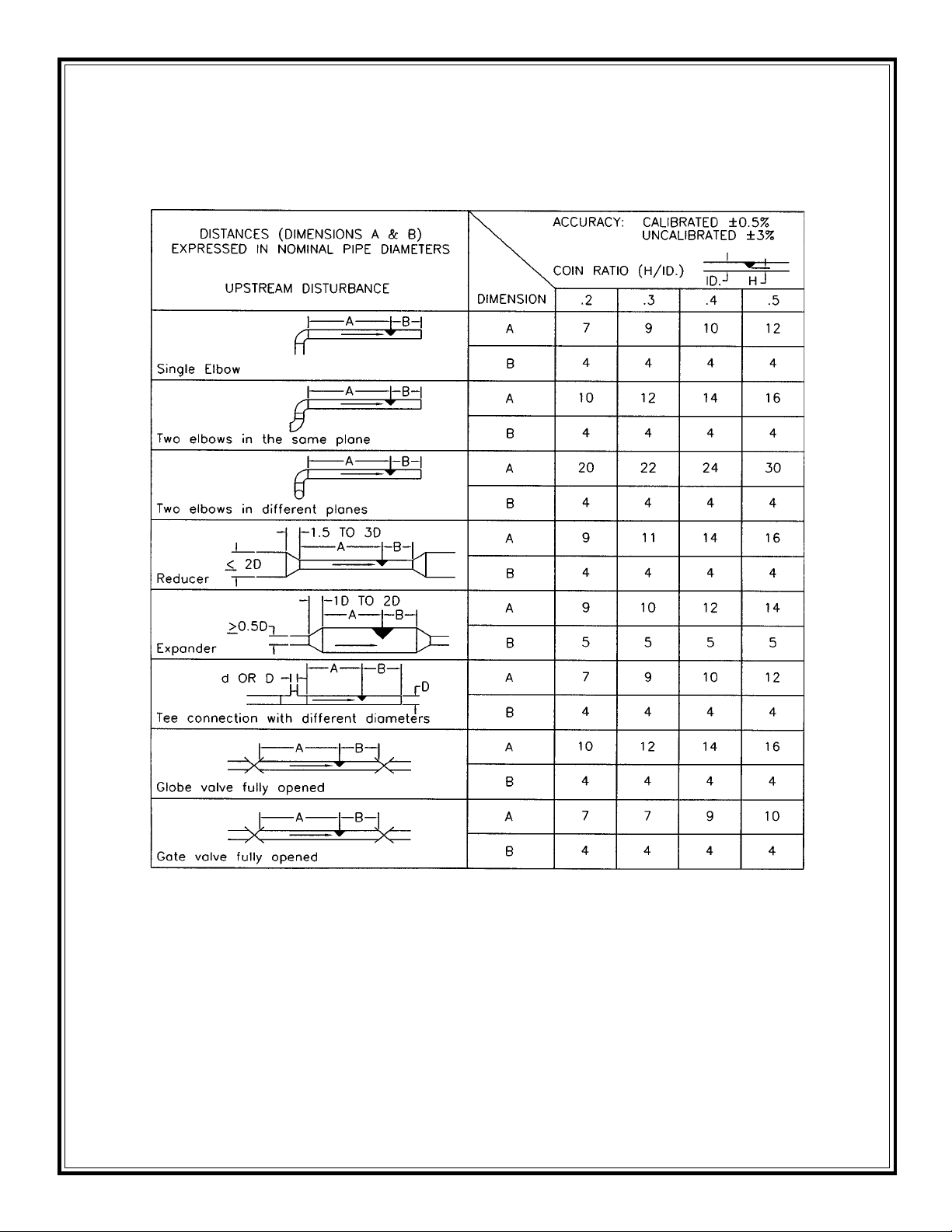

PRESO COIN LOCATION INSTRUCTIONS

Straight pipe requirements: Accuracy is affected by the piping configurations due to

the disturbances of the flow profile. A fully developed symmetrical flow profile is

achieved with the minimum upstream and downstream recommended lengths.

NOTES:

1 - For upstream and downstream lengths equal to one half the values shown

add 1 percent to the accuracy value.

2 - Any flow conditioner shall be installed in the straight length between the

primary element and the upstream distance, or the fitting closest to the

element. The straight lengths between fitting and conditioner shall be at

least 10D and the length between conditioner and Coin Meter shall be at

least 15D.

3 - For other fittings, configurations, contact PRESO.

Page 3

STRAIGHT PIPE RUN REQUIREMENTS

As with most flow elements, proper operation and performance is dependent on

the required lengths of unrestricted upstream and downstream piping. The recommended minimum length of the upstream side of the COIN Flow Element depends on the type of fitting at the start of the straight run, and the pipe configuration. Minimum upstream and downstream lengths are shown in the location instructions on back page. The minimum lengths will cause a slight coefficient shift.

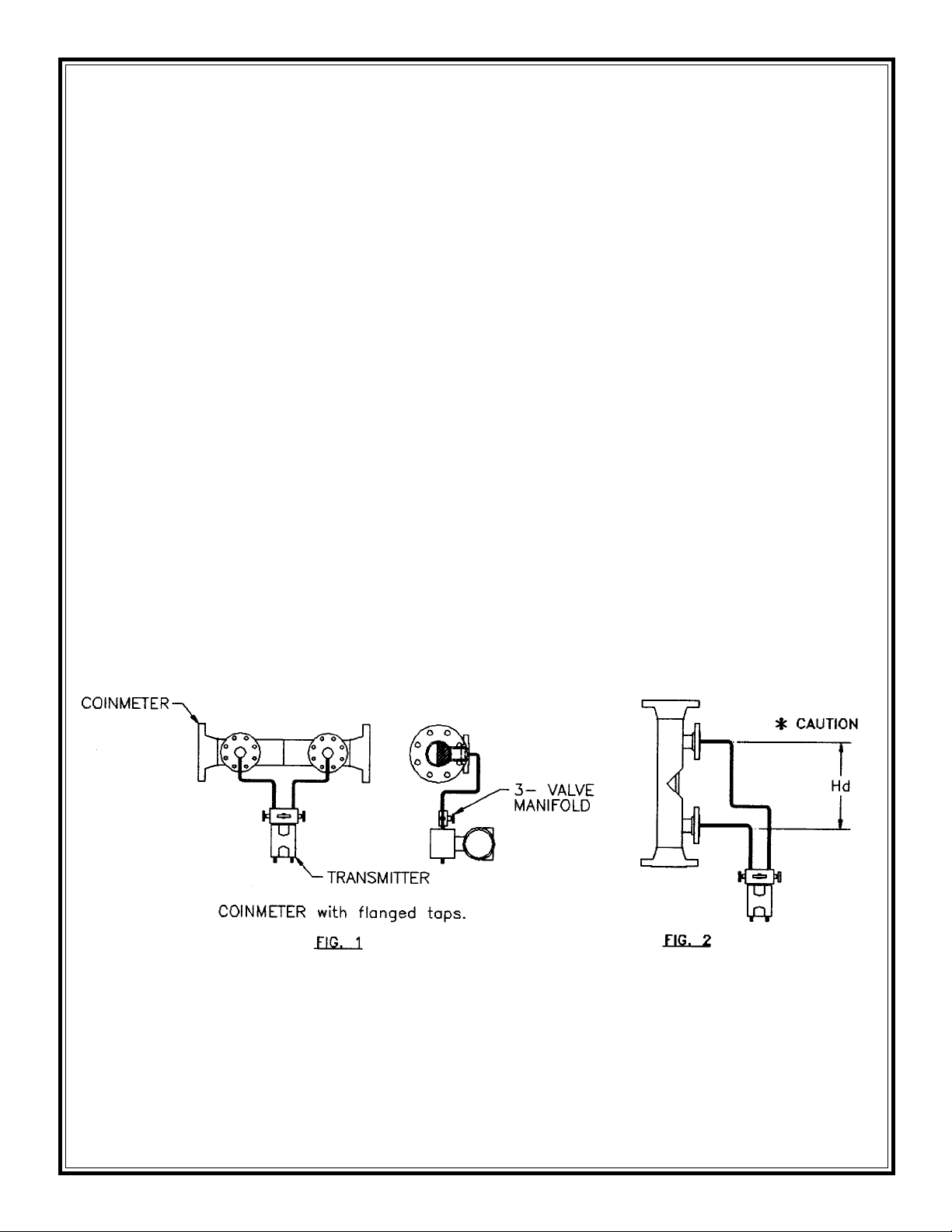

SELECTING A MOUNTING LOCATION

A horizontal installation is recommended for all COIN elements rotated 90° along

the pipe center line (Figure 1).

This method of mounting allows for free passage of solids and eliminates air entrapment at the transmitter connection. Other positions are acceptable provided

proper venting of the transmitter is accomplished and differences in lead line elevations are considered. Vertical installations as shown in Figure 2 may introduce

a slight hydrostatic head effect, which must be considered when zeroing the

transmitter. Connections between the COIN Meter and the transmitter should be

3/8” tubing minimum. The use of a 3-valve manifold is recommended for zeroing

the transmitter.

Before installation of any COIN element inspect for damage; particularly at sealing surfaces. Any damage should be reported to Preso Meters as soon as possible. Each flow element has an arrow indicating the required direction of flow.

Failure to properly orient the COIN element may cause improper results when

using data supplied for an element that has been calibrated.

Page 4

TYPICAL HORIZONTAL INSTALLATION FOR LIQUID

TYPICAL HORIZONTAL INSTALLATION FOR GAS

TYPICAL HORIZONTAL INSTALLATION FOR STEAM

Page 5

TYPICAL VERTICAL INSTALLATION FOR LIQUID

TYPICAL VERTICAL INSTALLATION FOR GAS

TYPICAL VERTICAL INSTALLATION FOR STEAM

Page 6

WARNING:

Never exceed the maximum pressure or temperature recommended for the

measured process. Exceeding proper pressure or temperature ratings can

lead to personal injury or equipment damage. The process piping flanges

should be identical to those on the COIN meter. The process temperature

and pressure should never exceed that for which the element was designed.

LINE INSTALLATION

All flanged COIN flow elements require a gasket between the process line connection and the mating flange. Ensure the gaskets selected match the the size

and rating of the COIN meter and the line flanges. Gasket material must be selected to resist corrosive attack of the process.

Before completing the bolting process, be sure that the gaskets are properly

centered so that protrusion into the pipe opening is minimized. Misalignment

may cause added flow turbulence, however performance affects are typically

minimal depending upon the application. Bolt the element in line with suitable

hardware using recommended bolt torques for the type and class rating of the

flanges.

Torque all models per ANSI flange ratings.

Tighten the flange bolts in a progressive “star” pattern to avoid localized stresses

on the gaskets.

DO NOT EXCEED SPECIFIED TORQUE!

DIFFERENTIAL PRESSURE CONNECTIONS

The high pressure connection is always on the upstream side of the flow direction arrow and the Iow pressure connection on the downstream side. Fittings

used must be able to withstand the process temperature and pressure conditions as well as provide proper corrosion resistance. Preso offers three types of

fittings (See next page). Refer to the appropriate transmitter manual for connections to the transmitter high and Iow ports.

Page 7

When installing chemical tee seals tighten cap screws uniformly in a “star” pattern

to avoid localized stresses on the gaskets.

The ANSI flanged taps seals require a backup flange rated for the same type

and class as that on the COIN element. Backup flanges with bolts and nuts are

generally offered as an option to the transmitter and are not supplied with the

COIN element. Again, observe recommended torque specifications for the type

and class being used.

TYPICAL PRESSURE PORT CONFIGURATIONS

NPT TAPS

FLANGE TAPS

CHEM TEE TAPS

Page 8

PRESO

Flow Metering Equipment

A Division of Racine Federated Inc.

Limited Warranty and Disclaimer

PRESO Flow Metering Equipment, a division of Racine Federated Inc. warrants to

the end purchaser, for a period of one year from the date of shipment from our

factory, that all flow meters manufactured by it are free from defects in materials

and workmanship. This warranty does not cover products that have been damaged due to abnormal use, misapplication, abuse, lack of maintenance, modified

or improper installation. PRESO’s obligation under this warranty is limited to the

repair or replacement of a defective product, at no charge to the end purchaser, if

the product is inspected by PRESO and found to be defective. Repair or replacement is at PRESO’s discretion. A return goods authorization (RGA) number must

be obtained from PRESO before any product may be returned for warranty repair

or replacement. The product must be thoroughly cleaned and any process chemicals removed before it will be accepted for return.

The purchaser must determine the applicability of the product for its desired use

and assumes all risks in connection therewith. PRESO assumes no responsibility

or liability for any omissions or errors in connection with the use of its products.

PRESO will under no circumstances be liable for any incidental, consequential,

contingent or special damages or loss to any person or property arising out of the

failure of any product, component or accessory.

All expressed or implied warranties, including the implied warranty of merchant-

ability and the implied warranty of fitness for a particular purpose or application are expressly disclaimed and shall not apply to any products sold or

services rendered by PRESO.

The above warranty supersedes and is in lieu of all other warranties, either expressed or implied and all other obligations or liabilities. No agent or representative has any authority to alter the terms of this warranty in any way.

8635 Washington Ave., • Racine, WI 53406

Tel.: (262) 639-6770 • Fax: (262) 639-2267

Toll Free: (800) 632-7337

www.preso.com • info@preso.com

COIN INSTRUCTIONS 05-16-2003

Loading...

Loading...