Page 1

M-Series®

7500P

MAG-UM-00365-EN-05 (October 2014)

User Manual

Page 2

M-Series®, 7500P

CONTENTS

Scope of Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Product Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Meter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Piping Conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Partially Full Pipe Situations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting to 110V AC from Batch Control Panel Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Wiring to PC100 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Wiring to ER-8 Totalizer/Rate Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Recalibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pre-Selection Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Jumper Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Page 2 October 2014

Page 3

Scope of Manual

SCOPE OF MANUAL

This manual contains information concerning the installation, operation and maintenance of the M-Series 7500P flow meters.

To ensure proper performance of the meters covered, the instructions given in this manual should be thoroughly understood.

Retain the manual in a readily accessible location for future reference.

OPERATION

The 7500P Mag meter is intended for use in fluid metering applications for process batching in industrial plants or

concrete operations.

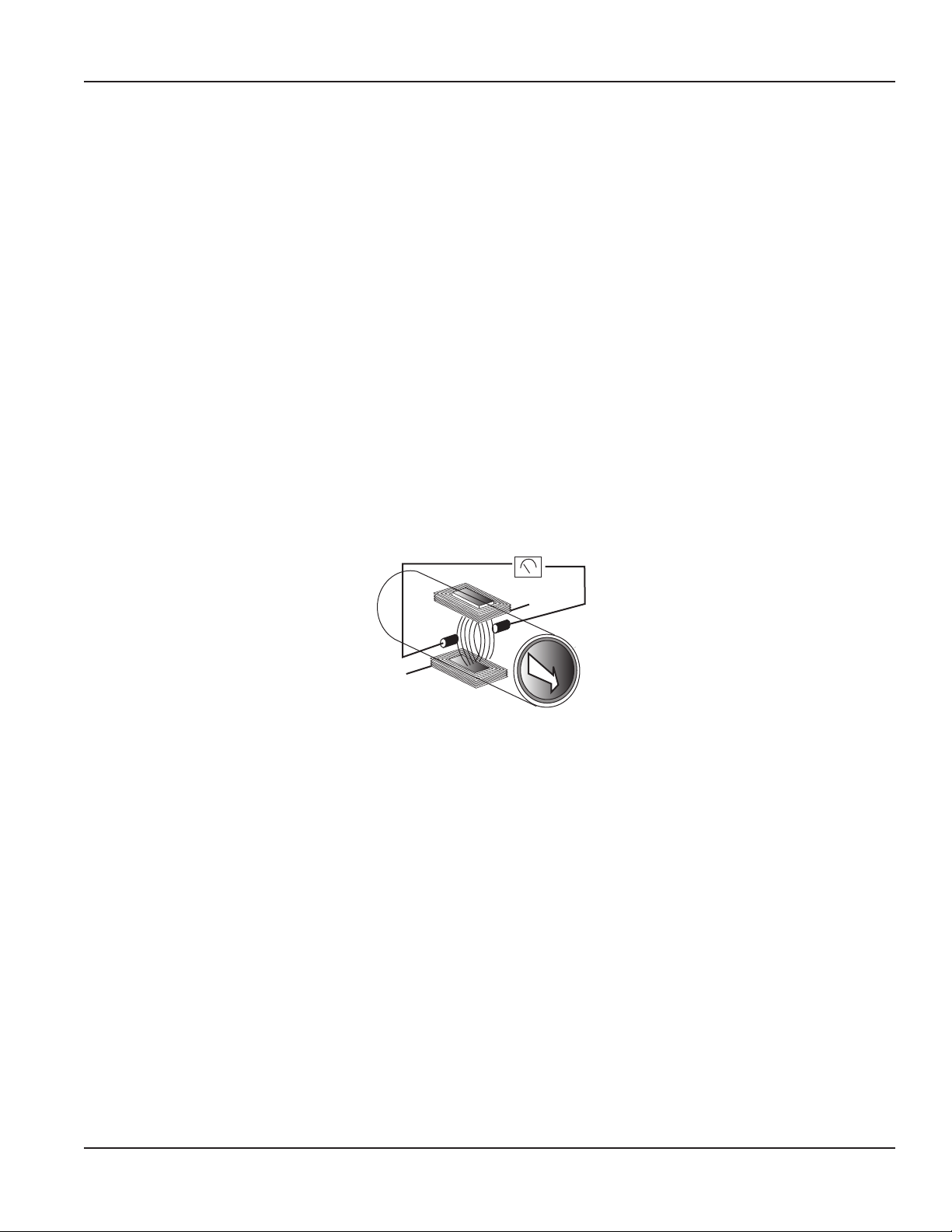

The 7500P Mag meter is a stainless steel flow tube with an internal isolating lining. Two electromagnetic coils are located

outside the flow tube, diametrically opposed to each other and protected by a stainless steel housing. Two electrodes,

inserted into the flow tube, are positioned "flush" with the internal diameter of the tube and perpendicular to the coils. The

coils are energized by a pulsed DC voltage provided by the electronic converter, and a magnetic field is generated across

the flow tube section. According to Faraday's law, when conductive liquid flows through this magnetic field of the meter,

a voltage is generated in the liquid. This voltage is directly proportional to the liquid flow velocity, and therefore to the

actual volumetric flow rate of the liquid. The electronic converter measures this voltage, processes the signal and provides

two digital pulse outputs, scalable to the desired volumetric value. These digital pulse outputs can be connected to a batch

controller, a totalizer display unit for monitoring purposes, or to both devices simultaneously. The 7500P operation is not

affected by suspended solids in the liquid. Variations of liquid temperature, viscosity or density have no influence in its

principle of operation. A set of convenient, field proven pulse scaler rotary switches are provided for easy and straight-forward

batch accuracy compensation.

Coil

DC supply

Electrode

Figure 1: Meter operation

Liner

Flow

PRODUCT UNPACKING AND INSPECTION

Upon receipt of the product, perform the following unpacking and inspection process:

If the product package is damaged, request the carrier to be present when unpacking the product. If the product is damaged

and the carrier is not present, request an inspection by the carrier’s agent within 48 hours of delivery and file a claim with the

carrier. A claim for equipment damage in transit is the sole responsibility of the purchaser.

Carefully open the shipping package and follow any instructions marked on the exterior. Remove all packing material and

carefully remove the product from the package.

Retain an undamaged package and all packing material for possible use in reshipment or storage.

Visually inspect the product and applicable accessories for any physical damage such as scratches, loose or broken parts, or

any other sign of damage that may have occurred during shipment.

Storage

If the meter is not to be installed right away, store it in the original container in a dry, sheltered location. Storage temperature:

-4…158° F (-20…70° C).

Page 3 October 2014 MAG-UM-00365-EN-05

Page 4

Meter Installation

METER INSTALLATION

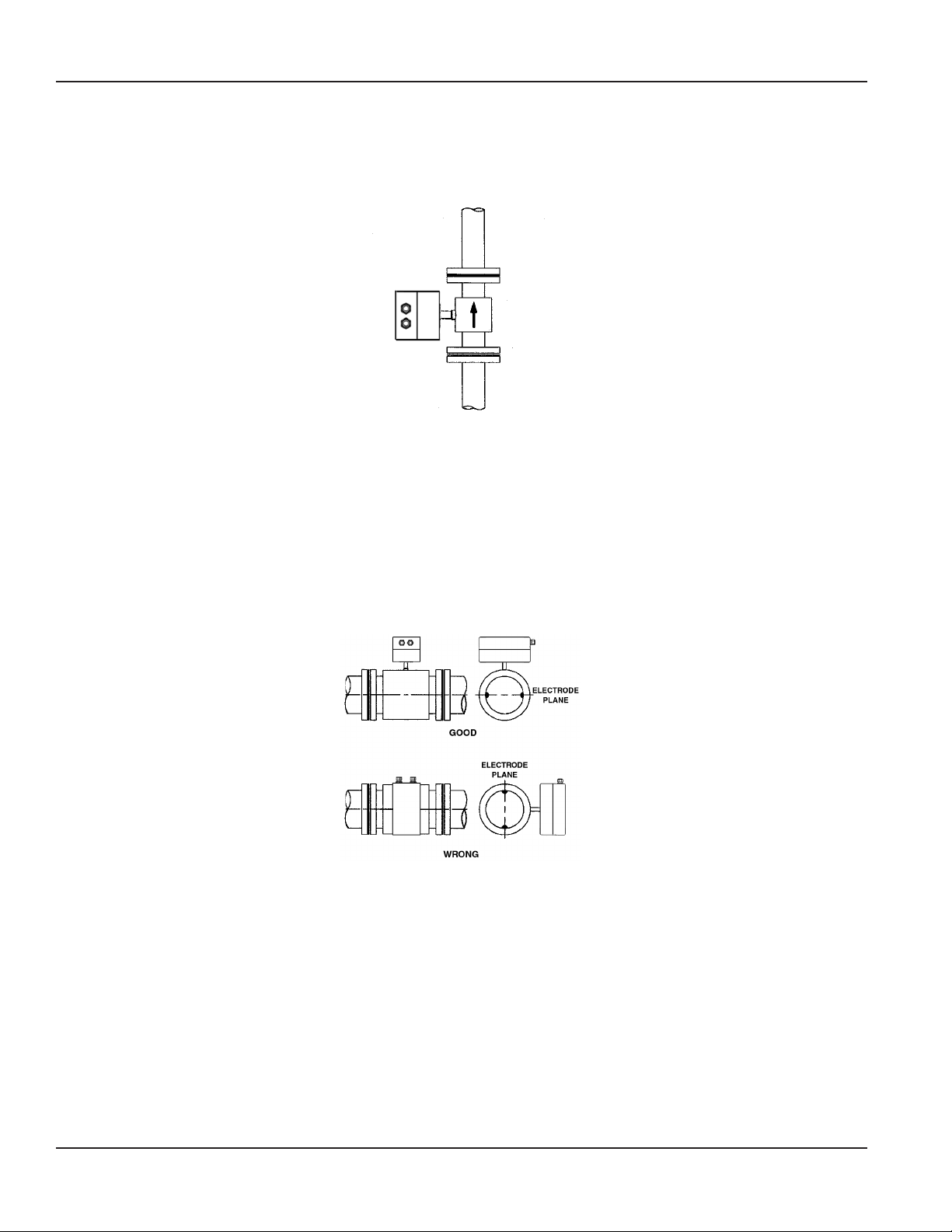

Mag meters can operate accurately in any pipe line orientation. However, the most recommended installation position is

vertical piping, with the liquid flowing upward.

Figure 2: Vertical pipe mounting

This installation practice ensures two objectives:

• The pipe remains completely full of liquid, even at low flow, low pressure applications with a discharge to the atmosphere.

• Solid build-up or sediments that could be part of the process fluid will not deposit or accumulate on the liner

and/or electrodes.

The model 7500P meter is designed to measure flow in one direction only. Carefully observe the "forward flow" label attached

to the meter body and install the meter accordingly.

If horizontal piping orientation is required, the detector should be mounted in a position at which the electrodes axis will

remain in an horizontal plane. See Figure 3.

Figure 3: Horizontal installation

Page 4 October 2014MAG-UM-00365-EN-05

Page 5

Meter Installation

Piping Conguration

Appropriate piping arrangements should be made to ensure the meter is not exposed to extreme pipe vibrations. The piping

arrangements should include appropriate pipe supports.

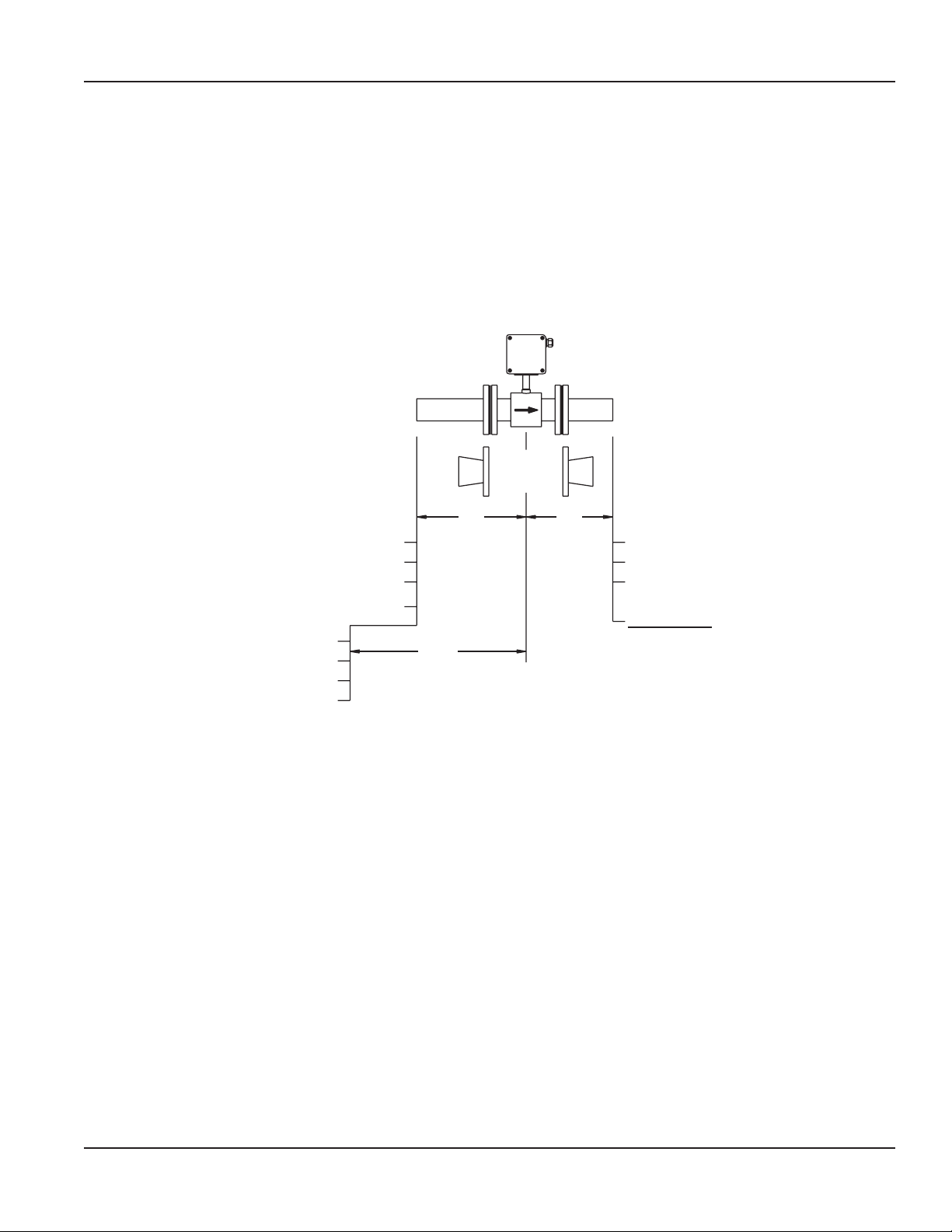

For optimum accuracy performance, sufficient inlet and outlet straight pipe runs are required. Three diameters of straight

pipe are required on the inlet side of the meter, and two diameters are required on the outlet side, measured from the center

of the meter body. See Figure 4 for additional requirements.

Avoid installing the detector close to flow disturbance generating valves and fittings.

Do not install the detector in the outlet side of piston or diaphragm type pumps. Avoid all pipe locations where the flow is

pulsating. Avoid installing the detector in the suction side of any pumps; possible creation of a vacuum can affect the meter

performance or cause damage to the PTFE liner.

DOWN STREAM

2 D3 D

ELBOW

TEE

ANY VALVE

ELBOW

TEE

GATE VALVE

(FULLY OPENED)

BALL VALVE

UPSTREAM

PIPE REDUCERS

NO REQUIREMENT

NO PUMPS

GLOBE VALVE

NEEDLE VALVE

CHECK VALVE

PUMP

5-7 D

STRAIGHT PIPE RUN

(ANY POSITION)

Figure 4: Pipe diameters

Temperature

OTE:N Environmental temperature of installation is not to exceed maximum specification of 122° F (50° C) for the meter. See

"Specifications" on page 13 for full temperature specifications.

Page 5 October 2014 MAG-UM-00365-EN-05

Page 6

Meter Installation

Partially Full Pipe Situations

M-series meters are designed to operate in closed, full pipes.

It is relatively common to encounter situations where the process pipe will remain momentarily partially filled due to certain

hydraulic conditions. Examples of this include discharge to the atmosphere (lack of back pressure), insufficient line pressure

and gravity flow applications.

To eliminate the negative performance effects, a few guidelines should be observed (see Figure 5):

• Avoid installing the detector in the highest point of the pipe line.

• Do not install the detector in vertical, downward flow sections of the pipe.

• On-Off valves should always be located on the downstream side of the detector.

• Select the recommended vertical orientation when ever possible.

• Make sure the selected detector size complies with the application flow rate. Do not oversize pipe line and detector size.

WRONG

FLOW

WRONG

FLOW

Figure 5: Proper installation locations

RIGHT

FLOW

RIGHT

FLOW

Page 6 October 2014MAG-UM-00365-EN-05

Page 7

Grounding

GROUNDING

Proper grounding is vital to ensure a good mag meter operation. To ensure proper grounding, the 7500P mag meter is

provided with a set of protective grounding rings. The rings also serve as protection for the liner. The main purpose of the

ground connection is to provide electrical continuity between the liquid media, the amplifier’s input ground or zero voltage

reference, and a good, solid earth ground. Connect a grounding strap to a solid, local earth ground (tower structure or pipe

support) (see illustration). It is recommended to use copper wire, at least 12 AWG. When installing the meter, also use standard

gaskets to avoid leaks.

Good Local

Earth Ground

Protective Grounding Ring

Protective Grounding Rings

Figure 6: Protective grounding rings

Page 7 October 2014 MAG-UM-00365-EN-05

Page 8

Electrical Connections

ELECTRICAL CONNECTIONS

Ground

Neutral 115V AC

Hot 115V AC

Ground

Neutral 115V AC

Hot 115V AC

Figure 7: Power supply connection

Connecting to 110V AC from Batch Control Panel Power Supply

This connection is for batch panels that require a 115V AC hot pulse for meter signals.

BATCH PANEL

Ground

Neutral 115V AC

Hot 115V AC

Meter Pulse Input

Solid State

Relay Output

Ground

Neutral 115V AC

Hot 115V AC

Common

DC-Switched

T2

T1

Open Collector

Transistor Output

Figure 8: Connection for batch panels

It is recommended that the batch panel manufacturer be consulted to confirm the required pulse signal. For a 115V AC

neutral pulse signal to the batch panel, simply connect the T2 jumper to the 115 neutral power supply.

Wiring to PC100 Controller

For connection of the open collector scaled pulse output from the Model 7500P to the PC 100 Controller, follow the

diagram below:

Open Collector

Transistor Output

Common

DC-Switched

T2

T1

PC100 Controller

Figure 9: PC100 wiring

Page 8 October 2014MAG-UM-00365-EN-05

Page 9

Wiring to ER-8 Totalizer/Rate Indicator

Electrical Connections

Open Collector

Transistor Output

Common

DC-Switched

T2

T1

Wiring Terminals (ER-8)

4 5

3

2

1

6

7

8

1 DC common

2 Count input - NPN signal 280 Hz or dry contact 95 Hz

3 Not used

4 Remote reset - resets count value when switched to common

5 Front panel program enable - allows access to program mode

when connected to common

6 Not used

7 Not used

8 DC supply input - 10…28V DC for backlighting

Page 9 October 2014 MAG-UM-00365-EN-05

Page 10

Calibration

CALIBRATION

The Model 7500P is tested and calibrated with a test configuration included with each meter when shipped. If recalibration of

your system accuracy may be required, the Model 7500P provides a feature, using four rotary switches, that permits a simple

recalibration procedure.

Figure 10: Rotary switch location

Page 10 October 2014MAG-UM-00365-EN-05

Page 11

Calibration

Recalibration Procedure

If it is necessary to recalibrate the meter, this can be done by changing the scale factor which is set on the four rotary switches

located in the upper left hand corner. See Figure 10 on page 10. To make this change, follow the following step.

1. Determine the exact quantity of uid that actually passed through the meter by using a calibrated volumetric container or

by weighing the container.

2. Note the volume of uid indicated by meter.

3. Note the current scale factor on the four rotary switches.

4. Use the following formula to calculate the new scale factor for recalibration:

Qty delivered

Qty on meter

X

Old scale

factor

New scale

factor

5. Enter new scale factor on the rotary switches.

6. Rerun test to verify that the recalibration is correct.

Example:

You have a 3" size meter in your installation. You run a test batch quantity of 238 gallons. The totalizer on the meter indicates

203 gallons. Your present scale factor on the four rotary switches is .2533. See Table 1 for preset scale factors.

Using the formula:

238

203

.

.

8

0.2533 0.2969

X

x 0.1 x 0.01 x 0.001 x 0.0001

0

1

9

2

3

7

4

6

5

2 9 6

0

1

9

2

8

3

7

4

6

5

0

1

9

8

7

6

5

9

2

8

3

7

4

0

1

2

3

4

6

5

9

1/2" Meter (1…30 gpm) Scaling factor

1 pulse per gallon 0.0500

10 pulse per gallon 0.5000

100 pulse per gallon 0.5000

500 pulse per gallon 0.5000

1 pulse per liter 0.5000

1" Meter (3…80 gpm)

1 pulse per gallon 0.5000

10 pulse per gallon 0.5000

100 pulse per gallon 0.5000

500 pulse per gallon 0.5000

1 pulse per liter 0.5000

2" Meter (10…315 gpm)

1 pulse per gallon 0.2500

10 pulse per gallon 0.2500

1 pulse per liter 0.0946

3" Meter (24…690 gpm)

1 pulse per gallon 0.2533

10 pulse per gallon 0.2533

1 pulse per liter 0.1892

4" Meter (40…1200 gpm)

1 pulse per gallon 0.5000

10 pulse per gallon 0.5000

1 pulse per liter 0.1892

Table 1: Scale factors

Page 11 October 2014 MAG-UM-00365-EN-05

Page 12

Calibration

Pre-Selection Switches

In Figure 10 on page 10, note the location of the four Pre-Selection Rotary Switches. These switches are set at the factory per

meter size and general magnitude of pulse output desired. If a change of resolution (pulse output value) is required, change

the Pre-Selection Switches to the values in Table 2.

Example:

0

1

9

2

8

3

1000

7

If you have a 3" meter with 1

pulse per gallon the switches

are set at 0380.

1/2" Meter (1…30 gpm) Pre-Selection Factor Jumper Position

1 pulse per gallon 1500 D

10 pulse per gallon 1500 D

100 pulse per gallon 0150 D

500 pulse per gallon 0030 D

1 pulse per liter 3965 D

1" Meter (3…80 gpm)

1 pulse per gallon 6000 D

10 pulse per gallon 0600 D

100 pulse per gallon 0060 D

500 pulse per gallon 0012 D

1 pulse per liter 1585 D

2" Meter (10…315 gpm)

1 pulse per gallon 0750 C

10 pulse per gallon 0075 C

1 pulse per liter 0075 C

3" Meter (24…690 gpm)

1 pulse per gallon 0380 B

10 pulse per gallon 0038 B

1 pulse per liter 0038 B

4" Meter (40…1200 gpm)

1 pulse per gallon 0250 A

10 pulse per gallon 0025 A

1 pulse per liter 0025 A

4

6

5

0

1

9

2

8

3

7

4

6

5

0

1

9

2

8

3

7

4

6

5

0

1

9

2

8

3

7

4

6

5

0

100

3

10

8

1

0

Table 2: Pre-selection factor and jumper position

Jumper Location

There are four jumper positions designated by A, B, C, and D. See Figure 10 on page 10 for jumper positions for meter size.

OTE:N The jumper must be located in the correct position for the respective meter size.

Page 12 October 2014MAG-UM-00365-EN-05

Page 13

SPECIFICATIONS

Detector

Working Pressure 150 psi (10 bar)

End Connections ANSI 150# carbon steel flanges

Flow Tube Material AISI 316 stainless steel

Housing and Flange Material Carbon steel, enamel paint finishing

Liner Material PTFE

Electrode Material Alloy C

Maximum Liquid Temperature 212° F (100° C)

Amplifier

Power Supply 110V AC ±10%, 5 VA

Coil Excitation Pulsed DC, 7.5 Hz

Minimum Liquid Conductivity 5 micromhos/cm

Maximum Output Frequency 10 khz

System Accuracy ±0.5% of rate

Repeatability ±0.2%

Enclosure Powder coated cast aluminum, NEMA 4

Mounting Meter mounted only

Environmental –4…122° F (–20…50° C)

Output 1 Solid state relay up to 230V, 500 mA

Output 2 Opto-isolated open collector, 50 mA @ 24V DC

Flow Direction Unidirectional

Pulse Width 50% duty cycle

Cable Connections Two 1/2 in. NPT cord grip

Specications

Page 13 October 2014 MAG-UM-00365-EN-05

Page 14

INCLUDING PROTECTIVE/GROUNDING RING

Dimensions

DIMENSIONS

"B"

.12"

4.7"

(120mm)

"A"

8.66"

(220mm)

3.54"

(90mm)

"C"

Meter

Size

A

in. (mm)

B

in. (mm)C in. (mm)

Flow Ranges

gpm (lpm)

min. max.

1/2 in. 6.9 (175) 8.1 (207) 3.5 (89) 1 (3.8) 20 (76)

1 in. 9.1 (231) 8.1 (207) 4.3 (108) 3 (11.4) 80 (303)

2 in. 10 (254) 9.1 (232) 6 (152) 10 (37.9) 320 (1211)

3 in. 12 (305) 9.8 (250) 7.5 (191) 22 (83.3) 690 (2612)

4 in. 14 (356) 10.1 (257) 9 (229) 40 (151.4) 1300 (4921)

Page 14 October 2014MAG-UM-00365-EN-05

Page 15

INTENTIONAL BLANK PAGE

Dimensions

Page 15 October 2014 MAG-UM-00365-EN-05

Page 16

Control. Manage. Optimize.

M-SERIES is registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous research,

product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an outstanding

contractual obligation exists. © 2014 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, O ce #C209 | Dubai / UAE | +971-4-371 2503

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Raciansk a 109/B | 831 02 Bratislava, Slovak ia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412 Legacy Document: IOM-075-04 53400-075

Loading...

Loading...