Badger Meter 735PV0506-1201, 735PV0706-1201, 735PV1006-1201, 735PV0606-1201, 735PV0806-1201 User Manual

...Page 1

Sensor

Series 735 Plastic Tee Type Flow Sensor

SEN-UM-01665-EN-04 (October 2015)

User Manual

Page 2

Sensor, Series 735 Plastic Tee Type Flow Sensor

CONTENTS

Scope of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Terminology and Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Electronic Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

IR Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Series 735 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Flow Sensor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Calibration Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Ordering Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Page ii October 2015SEN-UM-01665-EN-04

Page 3

Scope of This Manual

SCOPE OF THIS MANUAL

This manual is intended to help you get the Series 735 flow sensor up and running quickly.

MPORTANTI

Read this manual carefully before attempting any installation or operation. Keep the manual accessible for future reference.

UNPACKING AND INSPECTION

Upon opening the shipping container, visually inspect the product and applicable accessories for any physical damage such

as scratches, loose or broken parts, or any other sign of damage that may have occurred during shipment.

OTE:N If damage is found, request an inspection by the carrier’s agent within 48 hours of delivery and file a claim with the

carrier. A claim for equipment damage in transit is the sole responsibility of the purchaser.

SAFETY

Terminology and Symbols

Indicates a hazardous situation, which, if not avoided, is estimated to be capable of causing death or

serious personal injury.

Indicates a hazardous situation, which, if not avoided, could result in severe personal injury or death.

Indicates a hazardous situation, which, if not avoided, is estimated to be capable of causing minor or

moderate personal injury or damage to property.

Considerations

THE IMPELLER STYLE FLOW SENSOR DESCRIBED IN THIS MANUAL IS NOT INTENDED FOR USE IN SAFETY CRITICAL

APPLICATIONS. USE OF THE DEVICE IN THIS MANNER IS DONE AT THE SOLE DISCRETION OF THE CUSTOMER AND/OR

END USER OF THE DEVICE

THE IMPELLER STYLE FLOW SENSOR DESCRIBED IN THIS MANUAL IS NOT INTENDED FOR USE IN SYSTEMS WITH

FLAMMABLE LIQUIDS OR GASES. ADDITIONALLY, THE DEVICE IS NOT INTENDED FOR SYSTEMS CONTAINING

HAZARDOUS FLUIDS, OR FLUIDS OTHER THAN WATER.

THE IMPELLER STYLE FLOW SENSOR DESCRIBED IN THIS MANUAL MUST BE INSTALLED IN ACCORDANCE WITH ALL

LOCAL AND FEDERAL CODES OR END USE STANDARDS AS APPLICABLE.

IF THE DEVICES DESCRIBED IN THIS MANUAL ARE USED IN A MANNER NOT SPECIFIED BY THE MANUFACTURER, THE

PROTECTION PROVIDED BY THE EQUIPMENT MAY BE IMPAIRED.

MPORTANTI

Not following instructions properly may impair safety of equipment and/or personnel.

Page 3 October 2015 SEN-UM-01665-EN-04

Page 4

Introduction

INTRODUCTION

Used in conjunction with any Badger Meter® flow monitor or endpoint, Badger Meter non-magnetic Impeller flow sensors

provide an accurate reading of the rate of liquid flow as well as total accumulated flow. A number of sensor models are

offered, which cover applications for a wide range of pipe sizes and pressure/temperature specifications.

The flow sensors generate a frequency which is proportional to flow rate. An internal preamplifier allows the pulse signal to

travel up to 2000 feet without further amplification. The impeller bearing assembly, shaft and O-rings are replaceable in

the field.

The Series 735 Impeller flow sensors feature a four-blade impeller design, using a proprietary, non-magnetic sensing technology.

As the liquid flow turns the impeller, a low impedance signal is transmitted with a frequency proportional to the flow rate.

Sensors of similar type are interchangeable, so there is no need for recalibration after servicing or replacement.

ELECTRONIC TYPES

Sensors are supplied with two single-conductor 18 AWG solid copper wire leads with UL Style 116666 direct burial insulation.

These IR models are used in below grade applications such as irrigation, municipal and groundwater monitoring. All

Badger Meter Series 735 sensor electrical components are self-contained. See "Specifications" on page 10 for pressure and

temperature ratings.

IR Sensor

Designed for below grade applications such as irrigation, municipal, and groundwater monitoring where the flow rates are

between 2…20 ft/sec. and temperatures are below 110° F. IR sensors are supplied with two single conductor, 18 AWG solid

copper wire with UL Style 116666 direct burial insulation.

Series 735

These models feature a modified PVC tee with solvent weld socket end connections, and a removable PPS sensor insert. Available

sizes are 1/2 in. (12.7 mm), 3/4 in. (19.05 mm) and 1 in. (25.4 mm). BSP threaded adapters are available.

MECHANICAL INSTALLATION

DEPRESSURIZE AND VENT PIPING SYSTEM PRIOR TO ANY INSTALLATION OR MAINTENANCE OF THE FLOW SENSOR.

The accuracy of flow measurement for all flow measuring devices is highly dependent on proper location of the sensor in the

piping system. Irregular flow velocity profiles caused by valves, fittings, and pipe bends can lead to inaccurate overall flow

rate indications, even though local flow velocity measurement may be accurate. A sensor located in the pipe where it can be

affected by air bubbles, floating debris or sediment may not achieve full accuracy and could be damaged. Badger Meter flow

sensors are designed to operate reliably under adverse conditions, but the following recommendations should be followed to

ensure maximum system accuracy:

• Choose a location along the pipe with ten pipe diameters upstream and five pipe diameters downstream of the sensor

provide no flow disturbance. Pipe bends, valves, other fittings, pipe enlargements and reductions should not be present in

this length of pipe.

• The preferred location for the sensor around the circumference of a horizontal pipe is on top. If trapped air or debris will

interfere, then the sensor should be located further around the pipe from the top but not more than 45 degrees from

top dead center. The sensor should never be located at the bottom of the pipe, as sediment may collect there. Locations

off top dead center cause the impeller friction to increase, which may affect performance at low flow rates and increase

wear. Any circumferential location is correct for installation in vertical pipes. Rising flow preferred to reduce effects of any

trapped air.

Page 4 October 2015SEN-UM-01665-EN-04

Page 5

Electrical Installation Guidelines

ELECTRICAL INSTALLATION GUIDELINES

DISCONNECT POWER FROM FLOW SENSOR SOURCE AND/OR RECEIVING DEVICE PRIOR TO ANY INSTALLATION OR

MAINTENANCE OF THE SYSTEM.

FLOW SENSOR SOURCE AND/OR RECEIVING DEVICE MUST PROVIDE BASIC ISOLATION FROM MAINS FOR SAFE

OPERATION OF THE SYSTEM.

The sensor leads are supplied with watertight caps over the ends.

• Do not remove the plastic caps from the sensor leads until you are ready to splice.

• Use a twisted pair cable suitable for direct burial to connect the sensor to the endpoint, monitor, or controller. Multi-pair

telecommunication cable or direct burial cables may be used.

• Make a watertight splice using a two-part epoxy type waterproof kit. Be sure the epoxy seals the ends of the cable jacket.

• Make sure the epoxy is hardened before inverting the splice or dropping it in standing water.

• Do not make an underground splice unless absolutely necessary.

• Route the cable from the sensor to a Badger Meter flow monitor or endpoint. The cable may be extended up to 2000 ft,

using two-conductor shielded 20 AWG or larger stranded copper wire with appropriate ratings. Leave enough flexibility in

the cable or conduit to allow for future service.

• When connecting to a Badger Meter flow monitor or endpoint, locate the section of terminal strip on the monitor labeled

SENSOR INPUT or SENSOR. Connect the red wire to IN, SIGNAL(+) or SIGNAL terminal and the black wire to GND, SIGNAL(–)

or COM terminal and the shield drain wire (if applicable) to SLD.

• When interfacing with other equipment, the signal wave forms and power requirements are as shown in "Specifications" on

page 10.

Page 5 October 2015 SEN-UM-01665-EN-04

Page 6

Flow Sensor Installation

FLOW SENSOR INSTALLATION

DEPRESSURIZE AND VENT PIPING SYSTEM PRIOR TO ANY INSTALLATION OR MAINTENANCE OF THE FLOW SENSOR.

DISCONNECT POWER FROM FLOW SENSOR SOURCE AND/OR RECEIVING DEVICE PRIOR TO ANY INSTALLATION OR

MAINTENANCE OF THE SYSTEM.

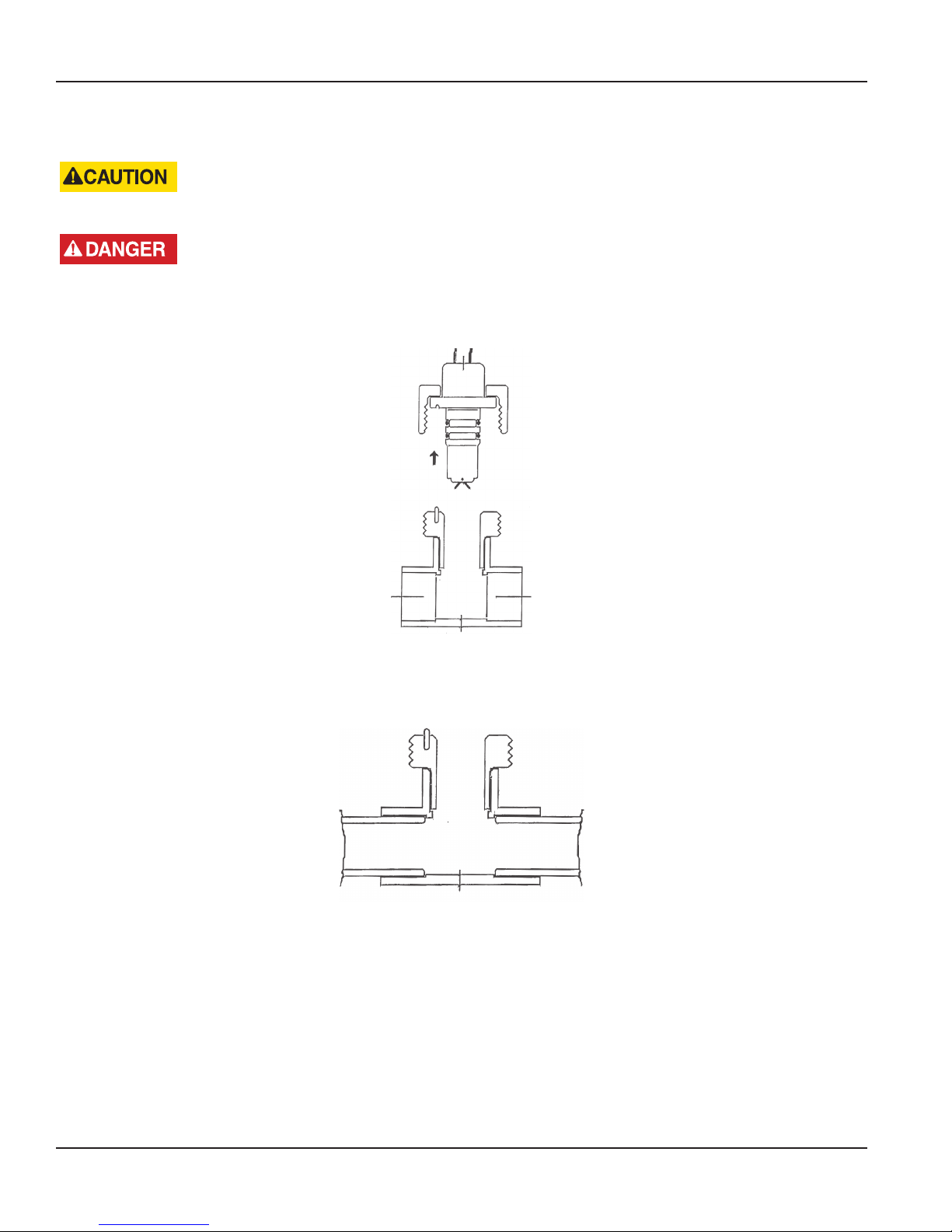

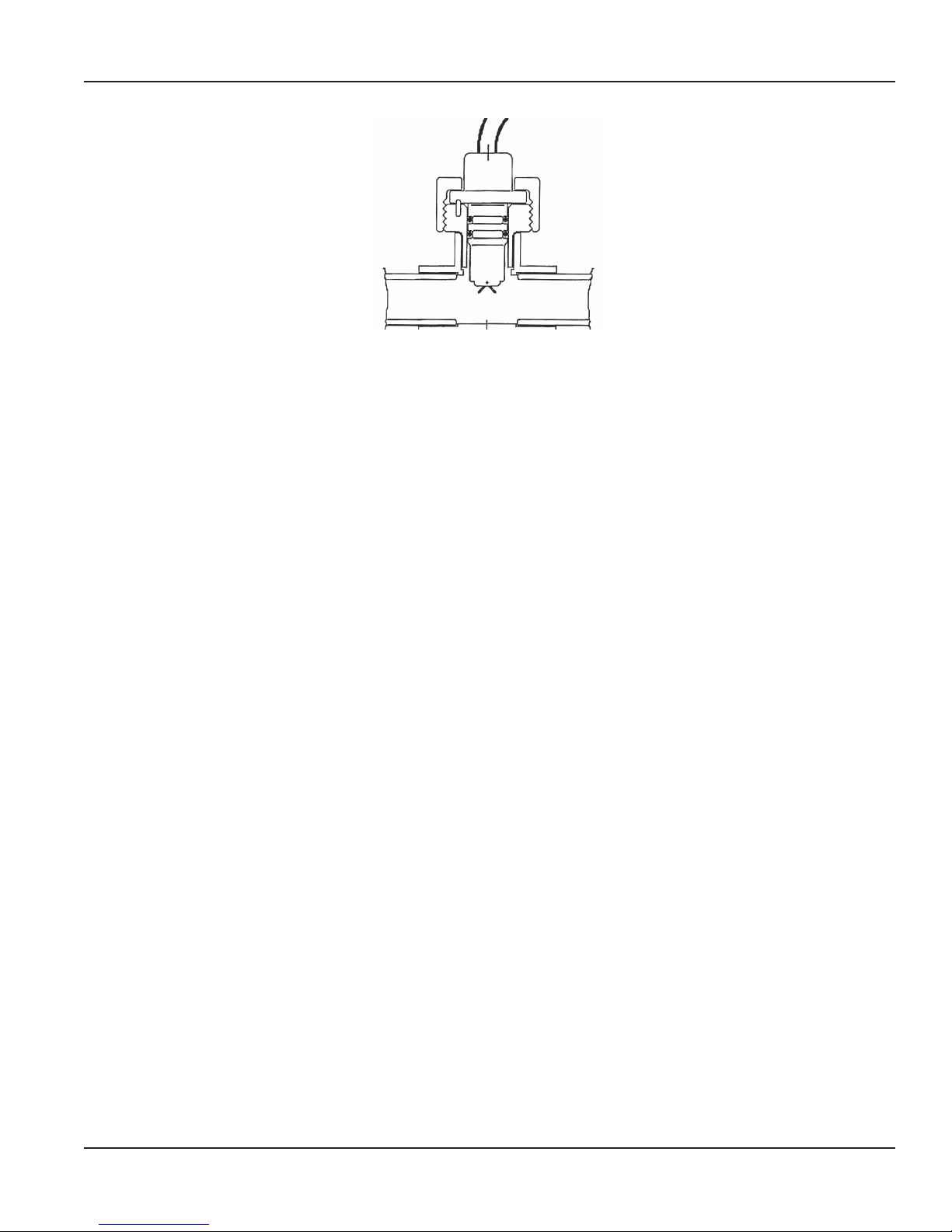

1. Remove the sensor assembly and the nut from the tee.

2. Remove burrs from the pipe ends and remove dirt and loose debris from pipe and tee sockets.

3. Glue the line pipe into the tee using an appropriate primer and cement according to the manufacturer's instructions. Do

not use or leave excess glue. Glue build-up in the tee can aect the measurement performance of the unit and/or prevent

the impeller from turning. Do not let the glue or primer contact the bore where the O-rings seal.

4. Insert the sensor into the tee, carefully lining up the locating hole in the sensor with the locating pin in the tee.

5. Install and hand-tighten the retaining nut.

6. Complete the wiring connections. See "Electrical Installation Guidelines" on page 5 for details.

7. Complete the wiring connections.

Page 6 October 2015SEN-UM-01665-EN-04

Page 7

Flow Sensor Installation

Additional Information

• The unit functions best with schedule 40 or a pipe wall thinner than schedule 40.

• Keep all parts as clean as possible. Do not let the glue or primer contact the surfaces where the O-rings make their seal.

• Although the meter can measure at velocities up to 20 ft/sec, do not exceed velocities above 7.5 ft/sec.

Page 7 October 2015 SEN-UM-01665-EN-04

Page 8

Calibration

CALIBRATION

Badger Meter Impeller sensors use unique K and offset numbers for calibration. These numbers are derived from calibration

runs using NIST traceable instruments. Using both a K and an offset number provides higher accuracy than using a K-factor

alone. The K and offset numbers for each tee configuration are listed in the table below.

Calibration Table

Size/Schedule K Offset

1/2" S40 0.078000 0.9

1/2" SDR 13.5 0.120119 0.1

3/4" S40 0.156300 0.9

3/4" SDR 21 0.197000 –0.6

1" S40 0.261119 1.2

1" SDR 21 0.321739 0.6

Input the information in the table above into the following equation to determine the frequency of the Series 735 Impeller

flow sensors:

Freq =

This information is required when calibrating an output board when using the raw sensor data as direct output to interface

with a device that is not a Badger Meter product.

gpm

K

– oset

Page 8 October 2015SEN-UM-01665-EN-04

Page 9

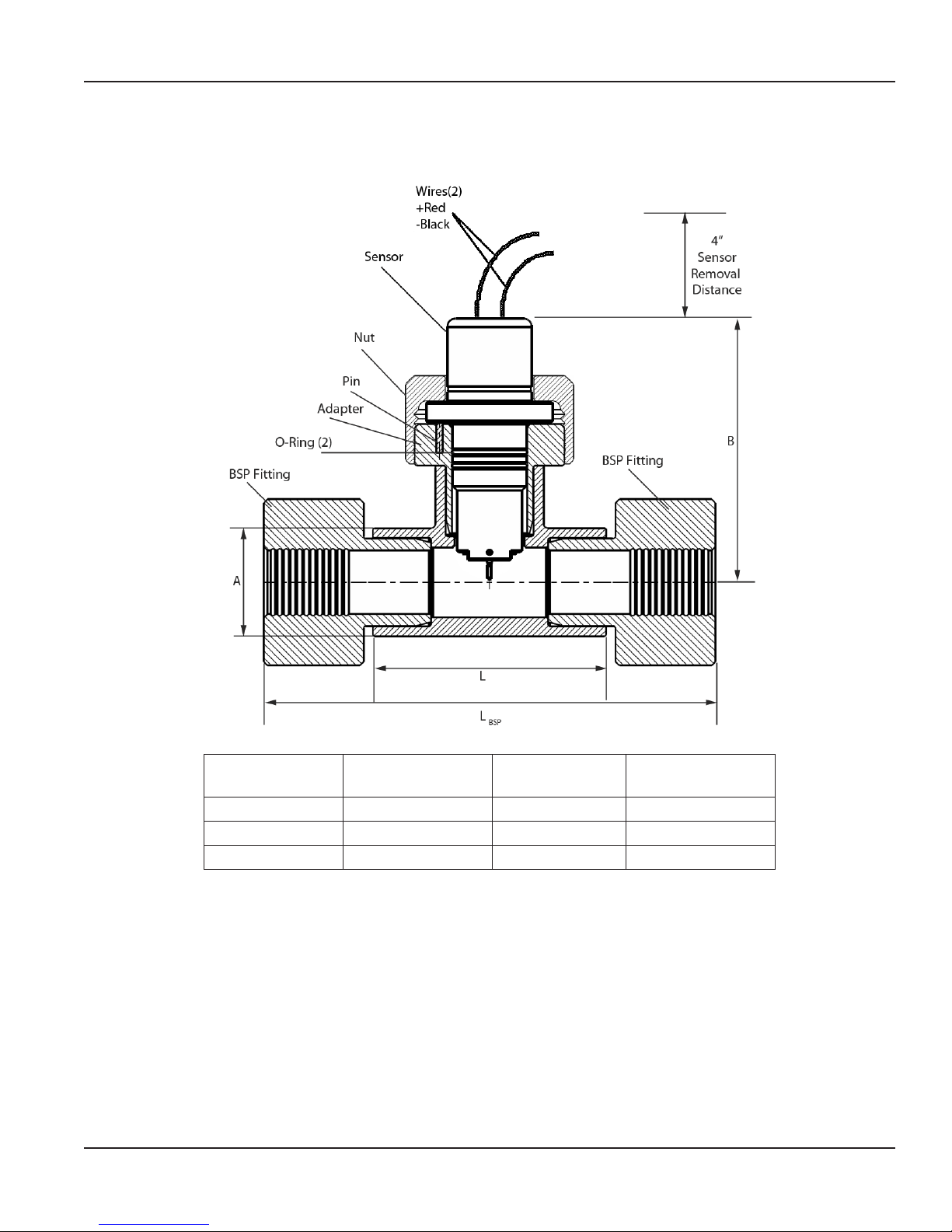

DIMENSIONS

Dimensions

A

Soc Size, NPS

1/2 in. [Ø 0.840"] 3.85 in. (97.8 mm) 3.06 in. (77.7 mm) 6.086 in. (154.6 mm)

3/4 in. [Ø 1.050"] 3.85 in. (97.8 mm) 3.31 in. (84.1 mm) 6.775 in. (172.1 mm)

1 in. [Ø 1.315"] 3.94 in. (100.1 mm) 3.50 in. (88.9 mm) 6.775 in. (172.1 mm)

B

Centerline to Top

L L

Optional

BSP

Page 9 October 2015 SEN-UM-01665-EN-04

Page 10

Specications

SPECIFICATIONS

Wetted Materials (except tees) See "Ordering Matrix" on page 11 for material specifications

Materials

Tee PVC Type 1, white

Adapter PVC Type 1, gray

BSP Fitting PVC Type 1

Sensor Housing PPS

Retaining Nut Acetal copolymer, black

Locating Pin 300SST

Impeller 300SST

Shaft Tungsten Carbide

Bearing UHMWPE

O-Rings EPDM

Wires 18 AWG Irrigation Wire (solid copper)

Pressure/Temperature Ratings

Rated Temperature

Recommended Design Flow

Range

Accuracy ± 3.0% of full scale over recommended design flow range

Repeatability ± 1.5% of full scale over recommended design flow range

Linearity ± 1.5% of full scale over recommended design flow range

Transducer Excitation

Output Frequency 3.2…200 Hz

Output Pulse Width 5 msec ±25%

Environmental

Electrical Cable for IR Sensor

Electronics

150 psig @ 73° F (22.8° C)

75 psig @ 110° F (43.3° C)

Operating: 35…110° F (1.67…43.3° C)

Storage 14…110° F (–10…43.3° C)

2…20 ft/sec (0.6…6.1 m/sec)

8…35V DC max. input, source limited to 100 mA

Quiescent current 600 uA @ 8…35V DC max.

Quiescent voltage (Vhigh=Supply Voltage–(600 uA*Supply impedance))

ON State (Vlow) Max. 1.2V DC @ 40 mA current limit (15 + 0.7V DC)

IP 68 / NEMA 4X

Suitable for pollution degree 4 environments

Suitable for outdoor use above or below grade

Suitable for use in 100% humidity

UL Style 116666 copper solid AWG 18 wire w/direct burial insulation rated to 105° C

Page 10 October 2015SEN-UM-01665-EN-04

Page 11

ORDERING MATRIX

Example: 7 35 PV 05 0 6 - 1 2 0 1

STYLE

Tee Mounted Insert Sensor 35

MATERIAL

PVC (.5", .75", 1" Sch 40 only) PV

SIZE

0.5" 05

0.75" 07

1" 10

0.5" with BSP Adapters 06

0.75" with BSP Adapters 08

1" with BSP Adapters 11

ELECTRONICS HOUSING

PPS 0

ELECTRONICS

IR-Irrigation 6

O-RING

EPDM 1

SHAFT

Tungs ten Carbide 2

IMPELLER

300 SST 0

BEARING

UHMWPE 1

Ordering Matrix

Page 11 October 2015 SEN-UM-01665-EN-04

Page 12

Sensor, Series 735 Plastic Tee Type Flow Sensor

Control. Manage. Optimize.

DATA INDUSTRIAL is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous

research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an

outstanding contractual obligation exists. © 2015 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, O ce #C209 | Dubai / UAE | +971-4-371 2503

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Raciansk a 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412 Legacy Document Number: 880096-0001-EN

Loading...

Loading...