Page 1

4050 Manual

MULTI-INPUT

LINEAR FLOW COMPUTER

INSTALLATION AND MAINTENANCE MANUAL

MODEL NO. 4050

15555 North 79th Place

Scottsdale, AZ 85260

tel: (480) 922-7446 • fax: (480) 948-3610

Email: sales@cox-instruments.com

Page 2

4050 Multi-Input Linear Flow Computer

Table of Contents

Description Page

1. Introduction To The Multiflow Computer………………………………….. 1

2. Specifications………………………………………………………………… 2

3. Programming The Multiflow Computer…………………………………….

4. Programming The Units And Idents (Gpm,Lpm,Pph, Etc)………………. 4

5. Frequency Input Card( Programming K Factor & F/V)…………………... 4

6. Analogue Input Card (Fluid Data)………………………………………….. 8

7. Front Panel Test ,Functions & Test………………………………………...

8. RS232 / RS485 Command Structure…………………………………….. 10

9. Special Options………………………………………………………………. 12

10. Programming Help Chart…………………………………………………….

11. Wiring And Terminal Diagram (How To Wire)…………………………….. 14

12. Manifold Example Installation………………………………………………. 15

3

9

13

i

Page 3

4050 Multi-Input Linear Flow Computer

1.INTRODUCTION TO THE LINEAR MULTI-FLOW COMPUTER

4050

Designed to meet the ever-changing requirements of flow metering, the Multi-flow computer can be tailored to

virtually any flow applicati on. It is desi gned to accept up to 3 meters and correct for temperatur e changes and

produce a usable output in whatever flow units you require. The 4050 is designed to work with manifold

systems and switches relays that are adjustable at which point they trigger. This output (dry) can be used to

change valve states and switch which meter measures the flow.

Each 4050 is programmed to your own individual requirements, software is written for each unit as and when

required. Each 4050 comes standard with a frequency input card, an analogue input card , a relay card and a

communication card. Other cards are optional, please call for additional options.

(COX) MODEL

Frequency Input Card

32 point Linearization curve for the derivation of flow and a programmable factor for unit conversion.

Programmable cut-off points enable displays of both frequency and flow to be inhibited below pre-set values.

The update is programmable from 0.02 seconds up to virtual infinity. (Standard)

Up to three freq uenc y inp uts ca n be ac ce pted fr om fl ow sen so rs; eac h inpu t wit h a

Analogue Input Card 16 bit Resolution Up to six analogue process inputs 0-10V or 4 to 20mA, are

available for use with sensors of temperat ure; flow; dens ity; vis cosity; pressures - absolute, bar ometric, ga uge

or differenti al, and other fact ors requiring compens ation. Each input has a five point Linearization curve. For

conversion to alternative mass units a programmable mass factor can be used.

Analogue Output Card 16 bit Resolution Up to three analogue outputs 0-10V or 4 to 20mA,

proportional to any desired parameter, are available for connection to remote facilities such as alarms,

indicators, chart recorders, PLCs and the like. The analogue output reference parameter may be configured by

the user.

Pulse Outputs Three TTL o r op en c olle ct or o utpu ts are av ai labl e fo r ret rans mi ss ion of rat e, or f or out put of

pulses per unit volume of total. These outputs, too, may be connected to remote indicators, totalizers or PLCs.

Relay Card

purposes. If the process includes a batching unit or controller, the relays can be used to control valves

solenoids or pump starters

The Multi-flow can accommodate up to three volt-free relays which can be deployed for alarm

Communications To monitor paramet ers or pro gram c al ibrat ion dat a RS23 2, RS 485 and in terf ac es c an be

incorporated. For connection to panel or desk mounted printers either a serial or parallel port can be

incorporated, with the option of time and date indication.

The Main Display The standard display is alphanumeric with red dot matrix characters, 152mm wide and

18mm high, which give an exceptionally wide viewing angle. The display itself comprises three fields: on the

left, a maximum of five characters may be used to give the parameter i dentity; i n the centre is the read-out of

the quantity being measured; and to the right are the characters defining the units of measurement. These can

be changed by the end user. User test routines, and buzzer.

Data Entry All calibration data are entered by means of a hand-held infra-red keypad following a successful

pass-code entry.

To prevent incorrect data entry, when two Multiflow units are positioned in close proximity, the reception of the

unit that is not being addressed can be inhibited by a sequence of keystrokes on the front panel keyboard of

that unit.

1

Page 4

4050 Multi-Input Linear Flow Computer

2.SPECIFICATIONS

Frequency

(gallons, litres; etc) by interpolation between points and, by extrapolation, from the first and last two points of

the curve. An engineering factor is included for the conversion of units.

Frequency range:

The default range is 0.5hertz to 65kHz with accuracy +/- 0.002Hz +/- least significant digit. A low cut off can be

programmed by the end user, which will allow the computer to measure frequency down to 0.01 of a Hz.

Signal conditioning:

By Special request the COX 4050 can take signals from contact closure (reed switch): sine wave; low level

input to base of PNP transistor and two wire modulated curren t frequency inputs. The default is a st andard TTL

type signal input or voltage pulse.

Sensor Excitation Voltage

An adjustable 1.5 to 24-volt dc output. Default is 12volts. Can be adjusted by the end user, it does involve

adjusting a pot entiometer.

Please call the factory for details. (215) 639-0900 ext. 316

32 point Linearization curve of frequency/viscosity versus counts per units measured

:

Analogue Inputs

Resolution: 16 bit

Accuracy: +/- 0.001% of full scale

5 point Linearization, can be either 4 - 20mA or 0 - 10V dc.

:

Analogue Outputs: Either 4 - 20mA or 0 - 10V dc.

Resolution: 16 bit

Accuracy:

+/- 0.001% of full scale +/- least significant digit.

Pulse Outputs:

TTL or Open Collector outputs with a range of 1 hertz to 1 kHz

Relays: Rating: 0.25A at 240Vac 9( Dry relay) .

Power supply: A mains input or dc inpu t can be used to supply the COX. The 110/240Vac is selec table

on a switch inside the Flow computer..

220 to 240Vac 50-60Hz will draw approx mA (this depends on options fitted)

110 to 120Vac 50 -60Hz will draw approx mA (this depends on options fitted)

12V dc will draw approx mA (this depends on options fitted)

24V dc will draw approx mA (this depends on options fitted)

CAUTION

Users are advised that although the equipment has protection and conforms to CE approvals, for trouble free

operation the Multiflow system should be connected to a clean power supply; i.e. free of noise and not in the same

phase as heavy machinery.

Any machinery using heavy contacts in the immediate proximity of Multiflow should be suitably suppressed.

Inductive loads switched by the volt-free relay contacts should be fitted with suitable snubber networks.

2

Page 5

4050 Multi-Input Linear Flow Computer

Working Displays (when COX 4050 is powered on)

Refer to programming helper for additional assistance.

When the unit is powered up the serial number is displayed for approximately 5 seconds then t he first display

line is shown. The left direction key (Å)

Primary Disp lays (see table below) and the Seconda ry Displays (see t able below). A mess age is momentaril y

displayed indicating which section is selected. Use the ÇÈ direction keys to select a display. The same keys

on the hand held remote control would perform the same function.

Press right or left arrow keys to display primary or secondary displays.

Use the up (Ç)

The same keys on the hand held remote control would perform the same function.

key or the down (È) key to scroll t hrough th e resultan t displ ays see t able below.

or the right (Æ) can be used to toggle between the

Default Primary-

Temperature.

Tables used to input data.

Primary Display

Shows basic values: Visc. Sg, RT (rate), Mas (mass), Tv(total Volume), Tm( total mass),

Description of resultant displays

ident result units

Default Secondary Displays

Manifold (on/off), Volume (on/off), Raw data: (F) requency1, 2,3, Ros, STr, K factor, A1 temp, Date.

Refer to special settings section for changing settings.

Tables used to input data.

Secondary Display

Description of resultant displays

ident result units

To Change idents and units see section titled DISPLAY IDENTS AND UNITS

3

Page 6

4050 Multi-Input Linear Flow Computer

3. PROGRAMMING THE COX 4050

Entering The Programming Mode

Press the right arrow key until Secondary is displayed. Press the alter key and.’CODE ****’ will be displayed. A

four-digit code can now be entered (serial number). On each press of a key the

sequence from left to right. When all four

shows ‘WRONG CODE’ then try again making sure that you are entering the correct code, as each instrument

has a different code setting. If a mistake is made during setting, then use the CLEAR key and try again.

If you are sure that the code is correct and the instrument still shows WRONG CODE then it is probable that

the batteries need changing in the hand held remote control.

If you press t he A LTE R key b y mi stak e th e dis play wil l reve rt to normal after approx. 20 seco nds. Pres sing the

Å Æ keys will have the same effect. Pressing any other key will reset the timer allowing sufficient time to enter

each digit of code.

Exit program mode by pressing clear.

will change to

‘*’

have been set the code is automatically checked. If the display

‘*’

‘+’

in

The Code Number

The code number for each instrument is taken from the last 4 digits of the serial number. The serial number can

be found on the front page of this manual, on the rear of the instrument, and is also displayed when the

instrument is first powered up, and finally by entering the Front panel Test routine.

For complete security it is recommended that the remote controller should be kept in a safe and secure place.

Unable To Enter A Code?

1) Enabling and disabling the Infrared hand held keypad.

The infra-red keypad will work with any COX unit and therefore it may be necessary to disable this function on

one unit where they are in close proximity. To LOCK OUT the infrared keyboard you must enter the Front Panel

Test Routine and select N for the ENABLE IR control. Once locked out, the infrared keypad is totally inactive on

that particular unit and the lock LED will be lit in the lower square panel. With the REMOTE OFF the displays

may still be viewed by means of the front panel keys. To restore operation of the infra-red keyboard use the

Front Panel Test Routine and select Y to the ENABLE IR menu.

2) Automatic LOCK OUT

In some cases the instrument itself will inhibit the ALTER key as it may be performing a sequence of events

that can not be interrupted, i.e. BATCHING. Please see the special instructions if applicable.

Unable To Use The Keys Or Key Bounce

If you are exper ienc ing key bounce or you are un abl e to us e the keys then there is probably interference with

the infra-red remote control. Problems may occur when trying to operate the unit in

sodium lights etc. If there are problems then please contact your supplier.

direct sunlight;

or using

4

Page 7

4050 Multi-Input Linear Flow Computer

4. PROGRAMMING THE IDENTS AND UNIT LABELS (L/M, PPH, ETC)

1) When in any mode , select th e display to be a ltered using the ÇÈ keys. Note if yo u are a curve menu you

change the units only, this will change all points in that curve.

2) Press the

side of the display.

3) Use the ÇÈ keys to select the required character for that position and the ÅÆ keys to alter the po sition of

the cursor. Using these key, the unit s on the right hand side may be altered.

4) To move the cursor to the left hand side of the display press the

across.

5) Use the ÇÈ keys to select the required character for that position and the ÅÆ keys to alter the position of

the cursor. Using these keys the display designation may be altered.

6) Once the de sired character s have been programmed then pressing t he

display.

7) Use the ÇÈ keys to select another display to be altered and repeat the above sta ges.

IMPORTANT NOTE:

that the display designation is limited to four or fewer charact ers, otherw ise the displ ays will overlap

causing apparent corruption. If this should occur then the number of characters for the display

designation should be reduced, after which the display will return to normal.

In some cases the unit may prevent changes to the display. This is because the instrument needs to

have these displays fixed to run correctly. See any special instructions supplied.

key followed by the

SHIFT

Where a maximum number of digits are to be displayed e.g. on total, it is advised

EXP/UNIT

key and the cursor will begin to flash at the far right hand

ALTER

key and the cursor will move

ENTER

key will store t hem in that

5. FREQUENCY INPUT CARD (EDIT CURVES) K FACTORS VS. F/V

This secti on describes how to program the F low Curve, which t he machine uses to compute the f low rate, by

using The K factor (count s per unit measured) and frequency /viscosity.

1) Display shows ‘EDIT CURVE 1’ or 2 or 3.

2) Press ALTER to display the first point of calibration. Then use the ÇÈ keys to select the required calibration

point to be entered or altered. The left hand display will always show the curve and point number i.e. C

right hand display will show the units, i.e. Hz, Hzv, L/M etc. This label can be changed by pressing the SHIFT

then UNIT key.

3) To enter/alt e r dat a ei t her pres s t he CL E A R k ey or ent er a num er ic v alue . T he mac h ine read s f ro m t he lowes t

to highest K factor and frequency/viscosity, so they should be programmed lowest (first) to highest (last). The

display will show SET on the left indicating that data is being entered. To obtain +/- values press the SHIFT key

followed by the +/- key. To obtain EXP values enter the numeric value followed by the EXP key and the

exponential value. Press the CLEAR key to delete incorrect data entry.

4) Having ent ered the correct va lue, press the ENT ER key and the entered dat a with the channel and point

number will be displaye d

5) Use the ÇÈ key to select the next point of calibration or press the ENTER key to exit this mode and return to the list of

program options.

101

, the

5

Page 8

4050 Multi-Input Linear Flow Computer

CHn Setup

To set up a frequency channel the following will apply, however some items are optional and may not appear in

your specific application.

Display shows CHn SETUP, pressing alte r and using the ÇÈ will show options . Use ALTER to change the

values.

FRQ CUT OFF When below this value of Frequency then FRQ = 0.0

VOL CUT OFF When below this value of volume flow then Vol Flow = 0.0

MASS CUT OFF When below this value of mass flow then Mass Flow = 0.0

TIME BASE Used to calculate flow rate in Kfactors or Total in flow 1, 60 or 3600 based on time

UP DATE TIME 0.02 sec to 9999 secs for update control

FRQ CONSTANT Default 2.0

VOL FACTOR Multiplier Volume flow rate by this factor (for special applications)

MASS FACTOR Multiplier Mass flow rate by this factor (for changing to pounds 8.32778)

ALPHA Alpha factor used for Stro and Ros calculation.

CAL_TEMP Calibration temperature of sensor used for Stro and Ros.

-7

used to adjust the internal crystal frequency.

Sort Curve

Through out the system each curve can be sorted or left as entered. Each curve works from lowest entry to

highest entry

the highest then use the sort curve function.

, if entered this way then the sort routine does not need to be used. If you add a point that is not

Reset Totals

This option allows the user to clear totals, please note that there maybe more than one total, i.e. Volume and

Mass totals, each needs to be cleared! Use the ALTER key when on a RESET VOL 0=Y option to scan for the

next total.

6

Page 9

4050 Multi-Input Linear Flow Computer

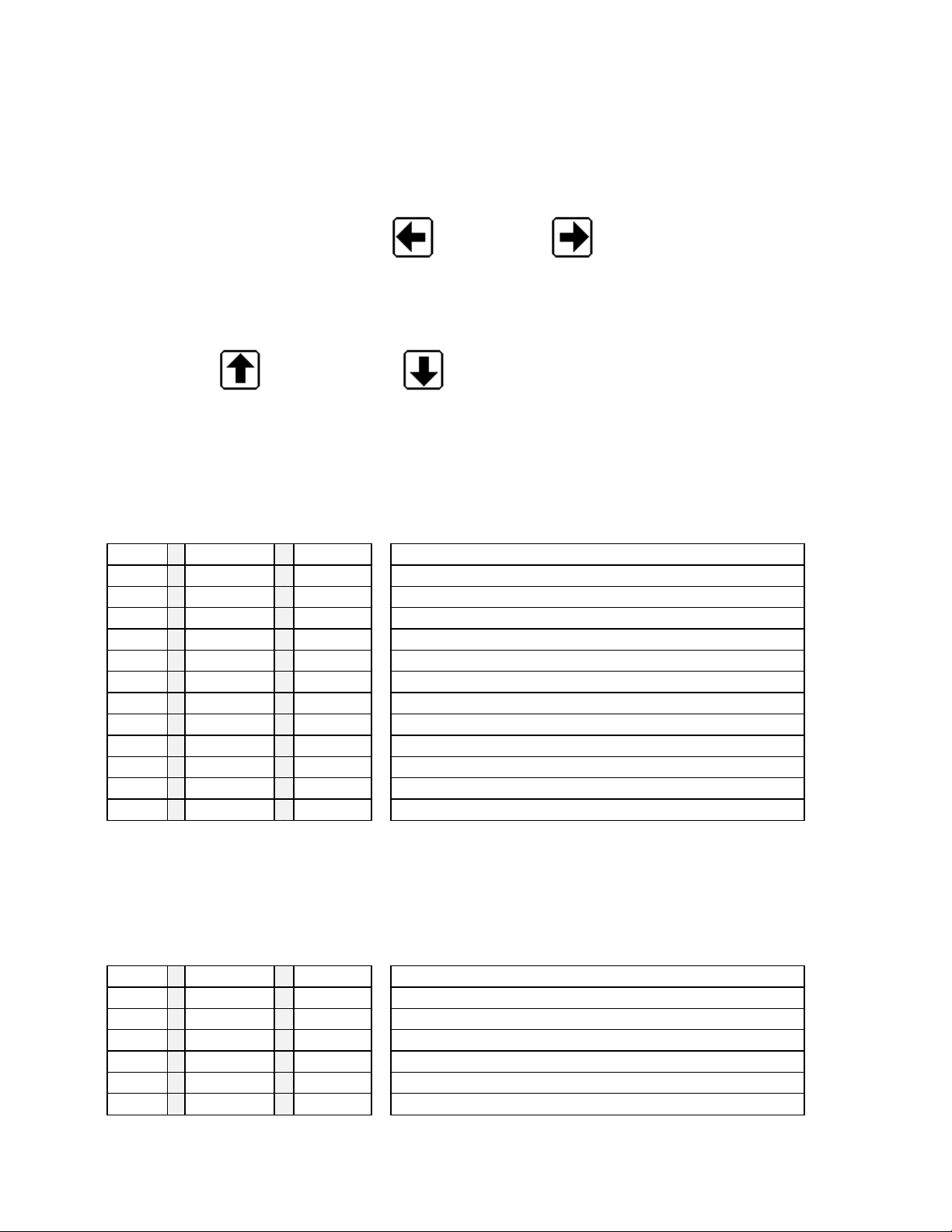

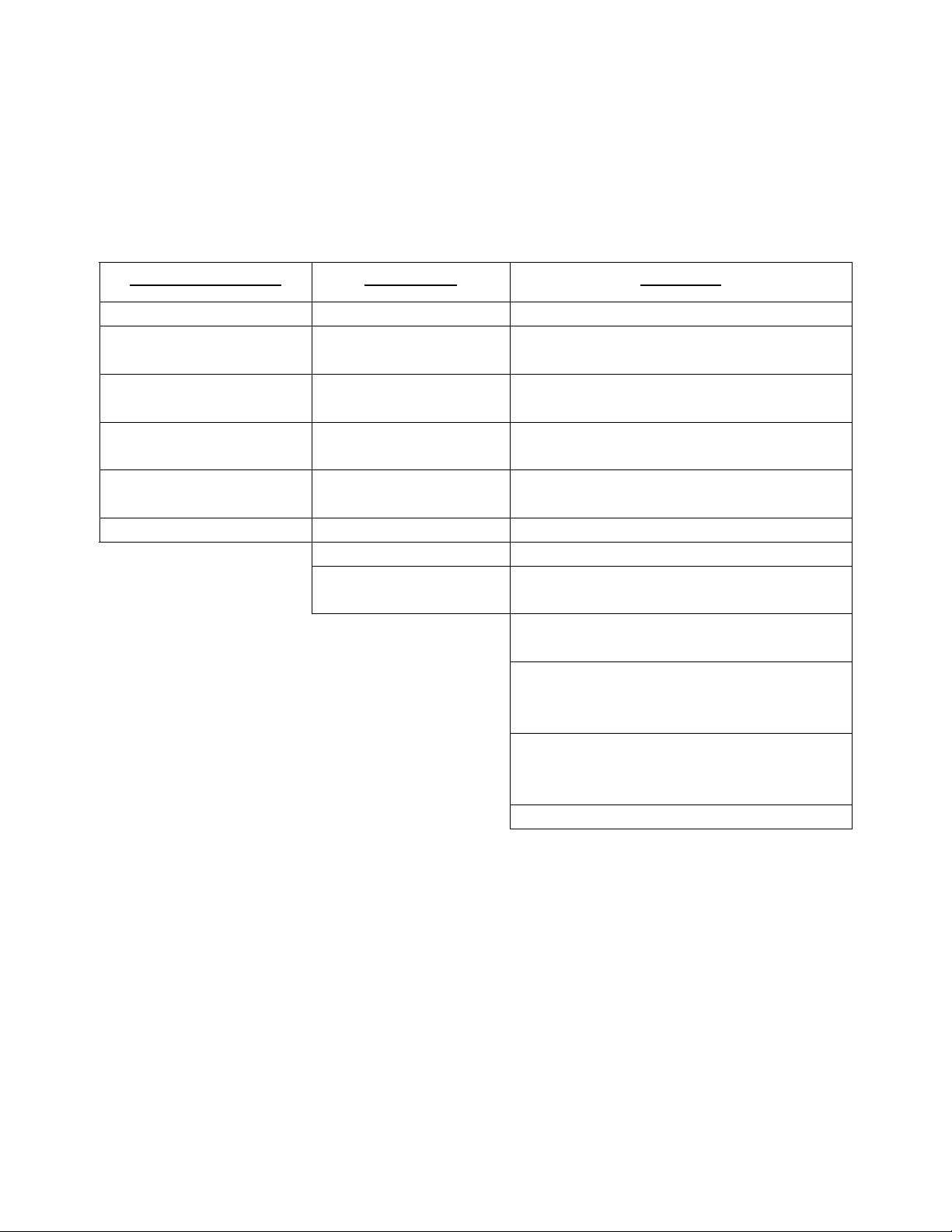

BLANK TABLE INTO WHICH DATA MY BE WRITTEN FOR REFERENCE.

K Factor and F/V Data Edit Curve

Meter #1 (Typically Low Flow) Meter #2 (Mid Flow)

K Factors exp F/V K Factors exp F/V

01 01

02

03

04 04

05

06 06

07

08 08

09

10

11 11

12

13 13

14

15 15

16

17

18 18

19

20 20

21

22 22

23

24

25 25

26

27 27

28

29 29

30

31

32 32

02

03

05

07

09

10

12

14

16

17

19

21

23

24

26

28

30

31

7

Page 10

4050 Multi-Input Linear Flow Computer

BLANK TABLE INTO WHICH DATA MY BE WRITTEN FOR REF.

K factor and F/V Data Edit Curve

Meter (High Flow) #3

K Factors exp F/V K Factors exp F/V

01 17

02

03 19

04

05 21

06

07

08 24

09

10 26

11

12 28

13

14

15 31

16

18

20

22

23

25

27

29

30

32

6. ANALOGUE INPUT CARD EDIT CURVES

Set Viscosity/ Set S.G.

This section describes how to program Specific Gravity and Viscosity for an individual chemical and its

characteristics.

1) Display shows ‘Temperature’/ ‘Viscosity’ or ‘S.G. ‘set’ or another option

2) Press ALTER to display the first point of calibration. Then use the ÇÈ keys to select the required calibration

point to be entered or altered. The left hand display will always show the curve and point number i.e. C

right hand display will show the units, i.e.

then UNIT key.

3) To enter/al ter data ei ther press the CLEA R key or ent er a numeric v alue. The dis play will show SE T on the

left indicating that data is being entered. To obtain +/- values press the S HIFT key followed by the +/- key. To

obtain EXP values enter the numeric value followed by the EXP key and the exponential value. Press the

CLEAR key to delete incorrect data entry.

4) Having ent ered the correct va lue, press the ENT ER key and the entered dat a with the channel and point

number will be displaye d

5) Use the ÇÈ key to select the next point of calibration or press the ENTER key to exit this mode and return to

the list of program options.

O

C, CTS, S.G. etc. This label can be changed by pressing the SHIFT

101

, the

Sort Curve And Vis Temp Etc.

Through out the system each curve can be sorted or left as entered. Each curve works from lowest entry to

highest entry, if entered this way then the sort routine does not need to be used. If you add a point that is not

the highest then use the sort curve function.

8

Page 11

4050 Multi-Input Linear Flow Computer

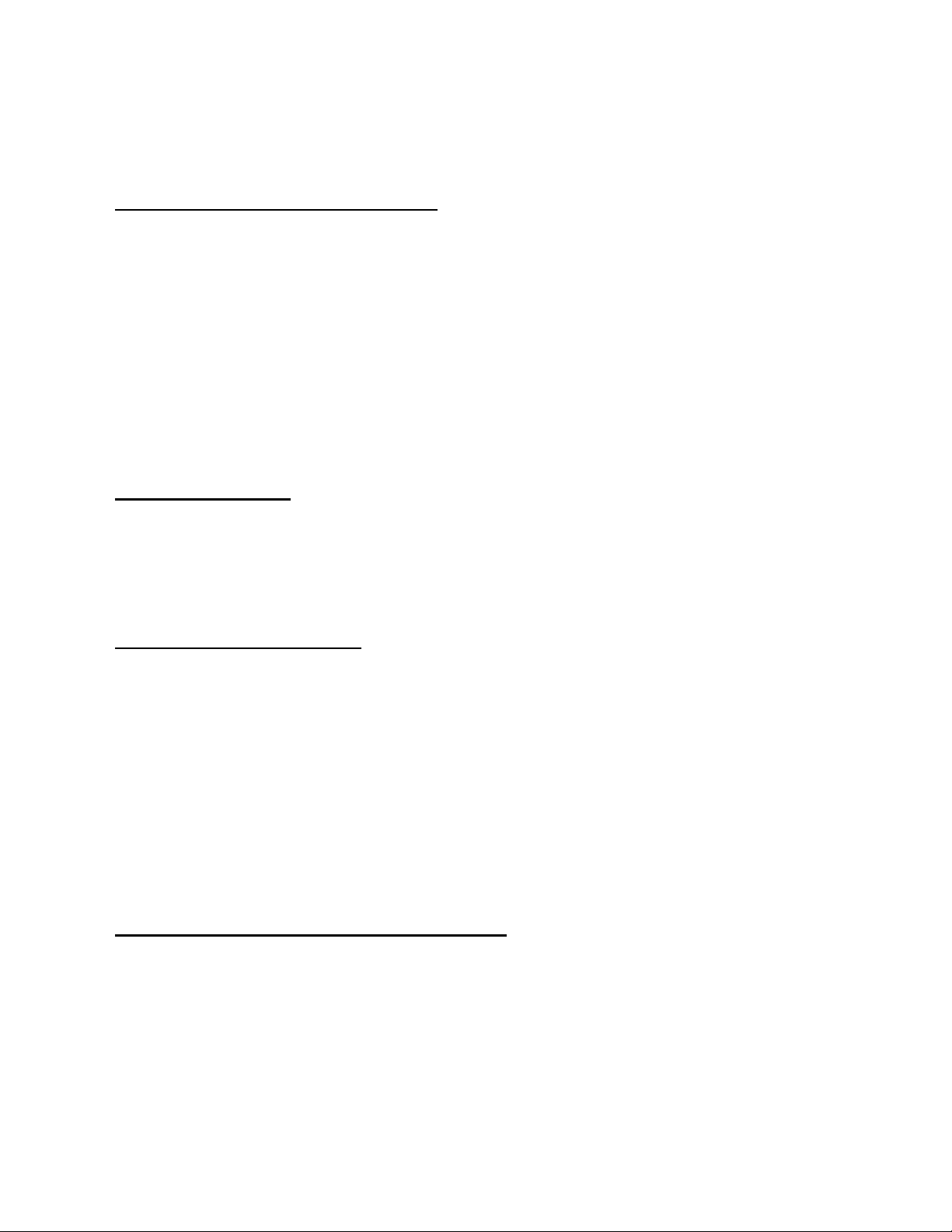

BLANK TABLE INTO WHICH DATA MY BE WRITTEN FOR REFERENCE.

Set Viscosity Set Specific Gravity

Temperature

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Viscosity Temperature S.G.

7. FRONT PANEL TEST MODE

By pressing the ÅÆ at the same time the front panel set up and test mode are entered.

The display will show the following options by pressing the ÇÈ.

ENABLE IR Y User alter to enable Y and disable N the IR keyboard

KEY CLICK N User alter to select Y and disable N the audible key click

TEST REMOTE Ç Test the IR keyboard

MAN 1234 Serial number of unit

ALTER TO EXIT

Press ALTER to exit this mode

9

Page 12

8. RS232 / RS485

4050 Multi-Input Linear Flow Computer

Command Structure.

Viewing data from th e Mul tiflow;

All data is sent and received as ASCII HEX pairs, the maths used in PIC Hex format, 2 exam ple routines are

included to convert this data into PC or ASCII strings. The PIC Hex format is always 4 bytes and represents a

32-bit floating-point number system. To read data use the following format.

Description ID View Hub/Slot Reg/Mem Slot Address No.Bytes CR

String a V H R 00A0 04 CR

Hex 61 56 48 52 00A0 04 0D

ASCII Hex 36 31 35 36 34 38 35 32 30 30 41 30 30 34 0D

Notes: Reg/Memory all ows the user to view live data within the Processors own working registers or the Flash

memory address space that is used to store constant and curve data. The Hub is the main process or (the card

connected to the serial link), whilst the SLOTs need to be addressed as follows.

Description ID View Hub/Slot Reg/Mem Slot Address No.Bytes CR

String a V S M 04 0600 04 CR

Hex 61 56 49 4D 04 0600 04 0D

ASCII Hex 36 31 35 36 34 39 34 44 30

30 36 30 30 30 34 0D

34

SLOT ID Hex Ascii Hex Position

4 04 30 34 1A

5 05 30 35 1B

6 06 30 36 1C

7 08 30 38 2A

8 09 30 39 2B

9 0A 30 41 2C

10 0C 30 43 3A

11 0D 30 44 3B

12 0E 30 45 3C

13 10 31 30 4A

14 11 31 31 4B

15 12 31 32 4C

16 14 31 34 5A

17 15 31 35 5B

18 16 31 36 5C

General Address.

To obtain the list address for your instrument please send email to ed-s@s-k.com

also included are the conversion routines of the PicHex to st andard PC/Ascii data.

Char output FAST M EDIUM or SLOW

to request a complete list,

Computer interface information

Port Settings.

The display shows menu ‘SETUP COMMS’, press ALTER to select the possible sub menus

BAUD 19200 Baud rate change using ALTER to 9600, 1200 or 19200

READ ONLY At present the system is set to read only

ID a Use ALTER to scan Ids a to z lower case only

RS485 FAST Delay for bus transceiver FAST MEDIUM or SLOW

COMMS FAST Delay between Char output FAST MEDIUM or SLOW

10

Page 13

4050 Multi-Input Linear Flow Computer

PIN SETTINGS.

RS232 RS485

9 way D, Pin 2 RX B

Pin 3 TX A

Pin5 0v 0v

Label27.Caption = b

Sub cal_dec(dec, result, dp_pos, result_str)

dec = 0

eb = Left$(result, 2)

If eb = "00" Then GoTo the_res_is_zero

sethex = Right$(result, 6)

e = Val("&h" + eb) - 127

bin_data = ""

For p = 1 To 6

Select Case UCase(Mid$(sethex, p, 1))

Case "0" nibble = "0000"

Case "1" nibble = "0001"

Case "2" nibble = "0010"

Case "3" nibble = "0011"

Case "4" nibble = "0100"

Case "5" nibble = "0101"

Case "6" nibble = "0110"

Case "7" nibble = "0111"

Case "8" nibble = "1000"

Case "9" nibble = "1001"

Case "A" nibble = "1010"

Case "B" nibble = "1011"

Case "C" nibble = "1100"

Case "D" nibble = "1101"

Case "E" nibble = "1110"

Case "F" nibble = "1111"

End Select

bin_data = bin_data + nibble

Next p

If Left$(bin_data, 1) = "1" Then

sign = "-"

Else

sign = ""

End If

dec = 1

For p = 2 To Len(bin_data)

Bit = Mid$(bin_data, p, 1)

If Bit = "1" Then dec = dec + 2 ^ -(p - 1)

Next

dec = (2 ^ e) * dec

wiv_sign = sign + Str(dec)

dec = Val(wiv_sign)

the_res_is_zero:

Select Case Val(dp_pos)

Case 1

result_str = Format(dec, "0.0")

Case 2

result_str = Format(dec, "0.00")

Case 3

result_str = Format(dec, "0.000")

Case 4

result_str = Format(dec, "0.0000")

Case 5

result_str = Format(dec, "0.00000")

Case 6

result_str = Format(dec, "0.000000")

Case 7

result_str = Format(dec, "0.0000000")

Case 8

result_str = Format(dec, "0.00000000")

Case 9

result_str = Format(dec, "0.000000000")

Case Else

result_str = Format(dec, "0")

End Select

Code Examples:

Cal_dec(returned decimal value, asciihex string from input buffer 8 bytes, number of decimal places, returned ascii

string)

cal_dec(a, Left$(rx_buff, 8), 3, b)

End Sub

11

Page 14

4050 Multi-Input Linear Flow Computer

9. SPECIAL OPTIONS

(Under Secondary)

Setting RTC

Setting the real time clock. When either the time or the date is viewed pressing ALTER will enable the user to

set the time/date.

Manifold ON/OFF

When this display is showing, pressing ALTER on the IR keyboard will toggle this selection, ON or OFF. When

off a manual option is enabled. This option allows the user to set the machine up for multiple meters and a relay

state change at a particular set points.

Manifold Autoranging Trip Points (Section 12)

Used for switching valves etc. These values are set for at what point relays open or close (usually used to

control valves).

Under the menu system the display will show SETUP AUTO pressing alter will display the following. Access by

using the ↑↓.

1

2

3

2

These values should not be set above or below the next meters calibration figures, leave some space for the

meter to switch over. An example is if meter 1 is set & calibrated for 20(1gpm) to 1100 hz(100gpm) and meter 2

at 100(85gpm) to 1000hz(500gpm) set trip point 1 to 2 at about 1000hz(saying 1000Hz= 92gpm) and set 2 to

1trip point at about 110 hz (sayi ng 110Hz = 90gpm) .This allows room for som e varian ce and avoids 4050 being

in a switching loop.

The user should take care to enter a reasonable hysterisis. Refer to section 12 for the relay truth table.

Channel “ # ”

This display shows the current channel number running, however if the MANIFOLD OFF option is running then

pressing the ALTER key will change the channel number, (relay and analogue output)

VOL ON / MASS ON

Pressing ALTER (IR Keyboard) will select the VOLume or The MASS to be running. The effect is:

↑

2 0.0 Hz This shows the trip point in Hertz from meter 1 (Chan 1 low flow) to 2

↑

3 0.0 Hz This shows the trip point in Hertz from meter 2 (Chan 2. medium flow) to 3

↓

2 0.0 Hz This shows the trip point in Hertz from meter 3 (Chan 3. high flow) to 2

↓

1 0.0 Hz This shows the trip point in Hertz from meter 2 (Chan 2. medium flow) to 1

1. Each time t he AUTO MANIFOLD changes the display will change to the new channel and display

either the VOLume or the MASS flow rate.

2. If fitted the analogue output will represent Volume or Mass flow rate.

12

Page 15

4050 Multi-Input Linear Flow Computer

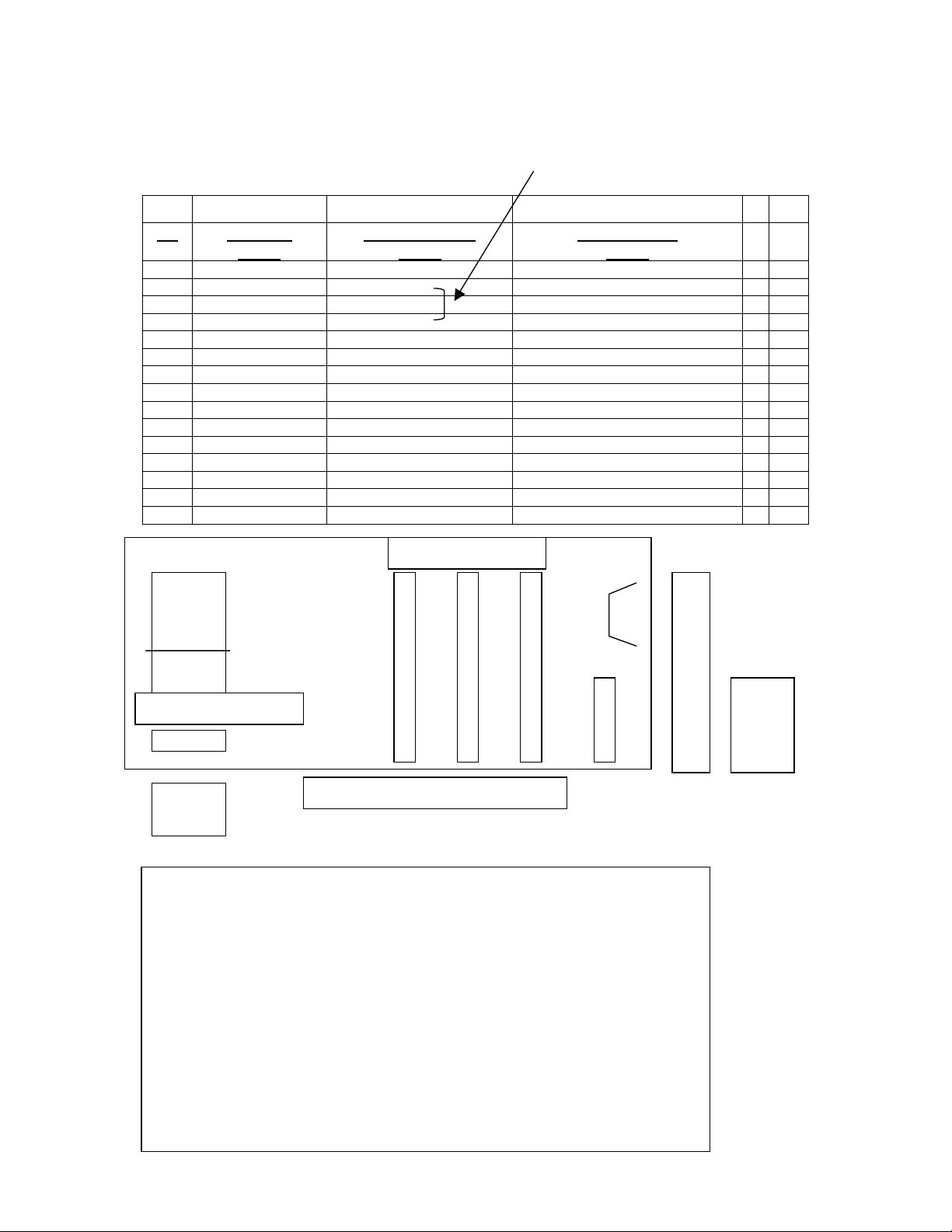

10. PROGRAMMING HELPER

Primary

(Basic settings)

Computed Data

Viscosity Frequency 1, 2 &3 Set-up Auto (Hz Trip points)

Specific Gravity Roshkoe Cards Fitted

Volume Rate 1, 2 & 3 Strouhal Set-up Comms

Mass 1, 2 & 3 K factor 1, 2 & 3 Edit Curve

Total Volume A1 Temperature =

Temperature Date Clear Totals

Manifold(on/off) Sort Curve

Volume(on/ off) Set Viscosity

Raw Data Settings

ma

Secondary

Program Mode

Enter by pressing ALT &

Serial #

(what cards are installed)

(Port settings)

(K Factor Programming)

Channel set-up 1, 2, 3

(programming fluid data)

Set specific Gravity

(programming fluid data)

Set Temperature

(setting C or F by ranging ma

output)

Set-up Inputs

(system changes not

recommended)

Sort Vis/Sg/Temp

13

Page 16

4050 Multi-Input Linear Flow Computer

11. WIRING DIAGRAM TERMINALS

COMPENSATION

JUMPER FOR TEMP.

TB RELAYS

1 NO RELAY 1 +SIG 1 V OR I SPECIAL IP 1

2 COMMON 0v SPECIAL IP 2

3 NO RELAY 2 +SIG 2 V OR I EX. VOLTAGE Meter input Vdc 3

4 COMMON 0v + SIGNAL 1 4

5 NO RELAY 3 +RTD PROBE - SIGNAL 1 or 0v 5

6 COMMON 0v 0v 6

7 +RTD PROBE EX. VOLTAGE Meter input Vdc 7

8 0v + SIGNAL 2 8

9 -RTD - SIGNAL 2 or 0v 9

10 0v 0v 10

11 -RTD EX. VOLTAGE Meter input Vdc 11

12 0v + SIGNAL 3 12

13 +12v Output - SIGNAL 3 or 0v 13

14 0v 0v 14

3 2 1

SLOT

ANALOGUE IN

SLOT

FREQUENCY

SLOT

3 2 1

1 2 3 4 5 6 7 8 9 10 11 12 13 14

Fuse on/off switch

Mcon1

123456

Mcon1 1 +24vDC input from 100mA to 200mA (depends on cards fitted)

2 0v

3 0v

4 +24vDC output repeated from input 1 or when on Main supply

5 Optional relay C

6 Optional relay NO

Mains input 80 to 265 ac auto. Fuse 1.0 amp.

HubCon

1 Fused 5vDC

2 Open Collector Output

3 SW1 input

4 SW2 input

5 SW3 input

6 0v

Slot # 3 2 1

1 2 3 4 5 6

Hub con

14

Page 17

4050 Multi-Input Linear Flow Computer

,12,

,

,

,7,9,

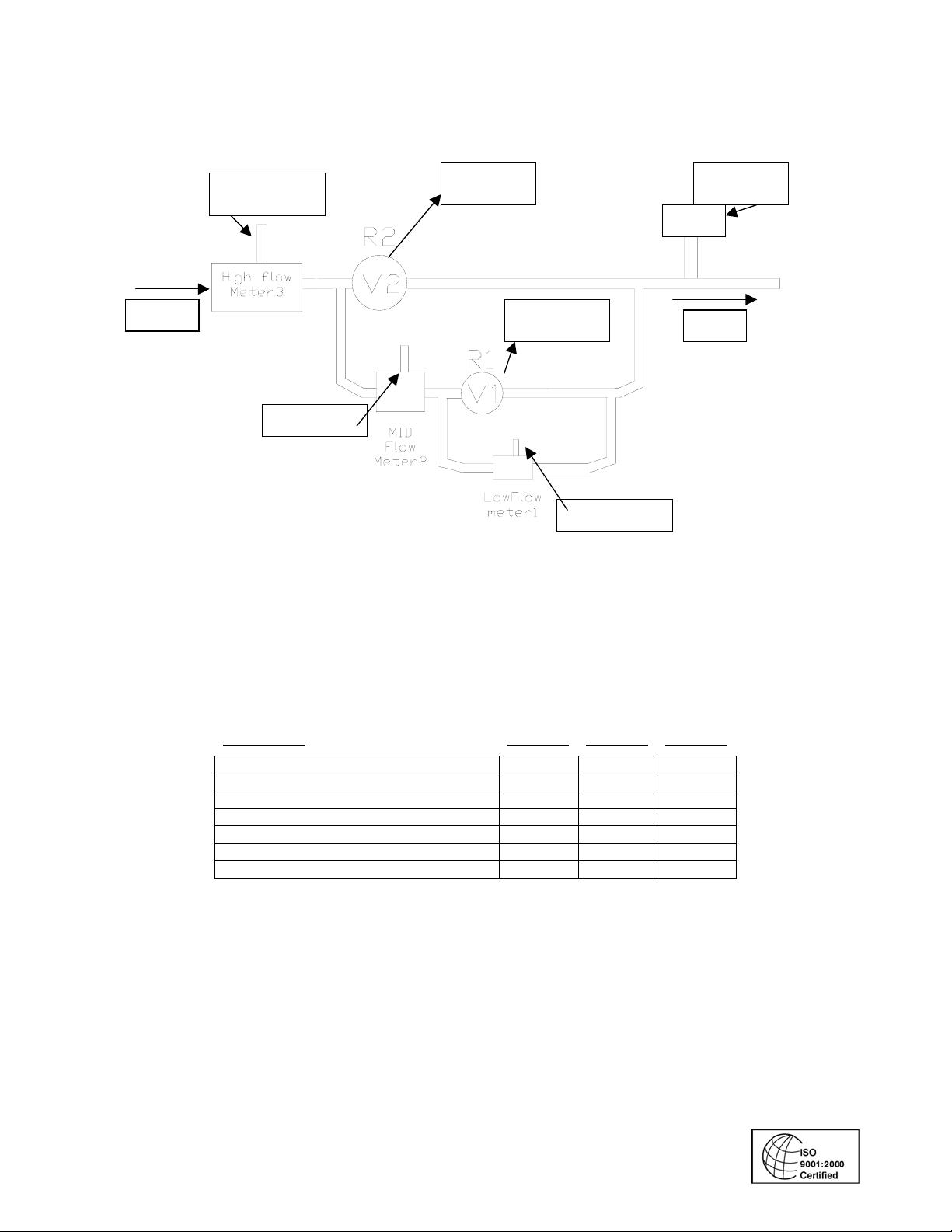

12. MANIFOLD SYSTEM INSTALLATION EXAMPLE

Flow

S1/P 11

13

S 1/ P7,8,9

(S) Slot –(V) Valve (R ) Relay (P) Pins

Relay2

S3/ P 3

4

Relay 1

S3/ Pins 1

RTD

2

S 1/P 3,4,5

S 2

P 5

Flow

11

Truth Table for Relays

Relays are dry outputs with open (o) or closed (c) states, which can be used to switch valves etc.

CONDITION

No power to unit O O O

Power On No Flow C C O

Low Flow C C O

1 to 2 trip point (Flow at 2) O C O

2 to 3 trip point (Flow at 3) O O O

3 to 2 trip point O C O

2 to 1 trip point C C O

RELAY 1 RELAY 2 RELAY 3

090804

15

Loading...

Loading...