Page 1

Flow Sensor

Series 4000

SEN-UM-01714-EN-01 (April 2018)

User Manual

Page 2

Flow Sensor, Series 4000

CONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Mechanical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation for PVC Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation of PVDF Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Wiring for a Digital Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Wiring for an Analog Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Impeller Assembly and Shaft Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electronic Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Detecting Coil Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Calibration Pipe Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Wetted Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Digital Meter Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Analog Meter Specications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Technical Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pressure, Temperature Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Check Using a Digital Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Checking the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Checking the Electronic Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Checking the Impeller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Check Using an Analog Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Connecting Via DIC COM Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Page 2 April 2018SEN-UM-01714-EN-01

Page 3

Flow Sensor Conguration Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Analog Loop Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Flow Rate Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Replacement Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Part Number Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Electronics Repair Kit Part Number Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Page 3 April 2018 SEN-UM-01714-EN-01

Page 4

Introduction

INTRODUCTION

The Series 4000 Flow Sensor has an in line, flow-through design using a tangential six bladed impeller. The Sensor is

available in 1/2 in. (12.70 mm), 3/4 in. (19.05 mm) and 1 in. (25.40 mm) pipe sizes, and a wide range of pressure and

temperature specifications.

The sensors have a molded housing, rotating impeller and externally mounted electronics housing using a proprietary,

nonmagnetic sensing technology. The closed, six-bladed impeller design provides higher and more constant torque than

four-bladed designs, and is less prone to fouling by water borne debris. The shape of the impeller and the absence of

magnetic drag provides improved operation and repeatability even at low flow rates. The housing design allows the impeller,

bearings, shaft or O-rings to be cleaned or replaced without removing the sensor from the piping system.

Two signal output options are available. One option is a square wave frequency proportional to flow rate. Power for the circuit

is provided by an external source through a three-wire shielded cable. An internal preamplifier allows the signal to travel a

maximum of 2000 ft (609 m) without amplification, and 20 ft (6 m) of three-conductor cable is included. The second output

option is a 4…20 mA current analog signal. Power is provided by the two-wire loop so the distance from the receiver is a

function of power supply voltage and wire resistance. A maximum 30 in. (762 mm) connector cable is included.

Sensors of similar type are interchangeable, so there is no need for recalibration after servicing or replacement.

Theory of Operation

The Sensor operates by converting kinetic energy (in the flow stream) into rotation (of an impeller). Almost all flow

sensors work on the principle of converting flow energy to output signals. The only arguable exceptions are ultrasonic and

electromagnetic sensors. The interaction of the flow stream and the impeller depend, to a currently unquantified extent, on

fluid properties (density, viscosity, and pressure) and on physical properties of the impeller. The Badger Meter impeller design

features the following:

• A low mass polar moment of inertia

• No magnetic drag

• Very low eddy current drag

• Low bearing friction

The impeller housing forms the periphery of a rotating fluid stream, the only source of drag tending to retard the impeller.

The efficiency of this design is the key to the repeatability of sensor output at very low flow rates, and is the reason that the

pressure drop across the installed sensor is so low.

MECHANICAL INSTALLATION

Vibration

There is a direct relationship between sensor housing vibration levels and impeller wear. Sensors mounted in a low vibration

region (close to pipe supports) consistently give longer bearing life than those mounted in a high vibration region. The

difference in bearing life persists, independent of impeller and shaft materials, or methods of construction. The wear is most

obvious at high flow rates, when high levels of pipe vibration are most pronounced.

When mounting a Sensor, minimize housing vibration using either of the following methods:

• Mount the sensor as close as possible to a stable, low vibration, anchored inlet or outlet pipe. Provide 10 diameters

upstream and 5 diameters downstream of straight pipe.

• Provide pipe supports, on both sides of the sensor, that are firmly anchored to a stable platform. This is particularly

important if the sensor is mounted in the approximate center of a pipe section two feet long between supports.

You must minimize sensor vibration, or sensor accuracy will be affected and impeller life reduced.

Page 4 April 2018SEN-UM-01714-EN-01

Page 5

Mechanical Installation

Accuracy

The accuracy of flow measurement depends on proper location of the sensor in the piping system. Irregular flow velocity

profiles caused by valves, fittings and pipe bends can produce inaccurate overall flow rate indications even though local

velocity measurement might be accurate. A sensor located in the pipe where it can be affected by air bubbles, floating debris,

or sediment might not achieve full accuracy, and could be damaged. Follow these directions for maximum system accuracy:

• Install the sensor in a pipe with 10 pipe diameters of straight pipe upstream and 5 pipe diameters of straight pipe

downstream of the sensor for no flow disturbance. Allow no pipe bends, valves, other fittings, pipe enlargements and

reductions in this length of pipe.

• For horizontal flow applications, install the sensor with the curved portion of the housing down. Sensors installed with

the curved portion in the up position trap air, causing inaccurate flow measurement, especially at low flows. Sensors

installed with the curved portion pointing sideways not only trap air, but increase impeller friction, which might also affect

measurements at low flow rates. Install the sensor to facilitate servicing.

• The preferred vertical location is with liquids flowing up. If vertical flow downward is the only option, the pipe must be

completely filled with fluid. Any circumferential orientation is correct, but the sensor location should facilitate servicing. A

vertical location might result in reduction of accuracy.

• Mount sensors with a minimum of 3 in. (75 mm) clearance in all directions around the gray electronics assembly to prevent

electro-mechanical interference. This space requirement applies to multiple sensor sensors installed in close proximity as

well as to other EMI generators, such as electric motors or controls for motors, heaters or lighting.

Installation for PVC Sensors

Any compatible size and type of fitting or adapter can be connected to the pipe nipples by thermal or solvent welding. Make

sure the fittings and method you choose to install the PVC unit comply with American Society for Testing and Materials

(ASTM) standards. Install the sensor so the arrow in the stainless steel cover is pointing the same direction as the flow of the

fluid. Do not connect directly to reducing or enlarging fittings. Install an additional 10 diameter upstream and five diameter

downstream allowance if this is unavoidable.

Installation of PVDF Sensors

PVDF sensors are supplied with combination end connections. A Heat Weld Female Slip connection can accept most metric

sized PVDF pipes. The external thread is used with George Fisher type Unions. Badger Meter® offers PVDF, 316SS FNPT, and

CPVC Slip Socket Union Ends.

In PVDF sensors with the enhanced flow feature, the flow enhancement jet must be inserted before installing the sensor into

the system. With the stainless steel cover facing you, insert the jet into the left socket (upstream end) and then perform the

method chosen for installation. Install the sensor with the arrow on the stainless steel cover pointing in the same direction

as the flow of the liquid. Follow the same ten and five diameter upstream and downstream allowance and orientation

recommendations, as described in "Installation for PVC Sensors".

Page 5 April 2018 SEN-UM-01714-EN-01

Page 6

Electrical Installation

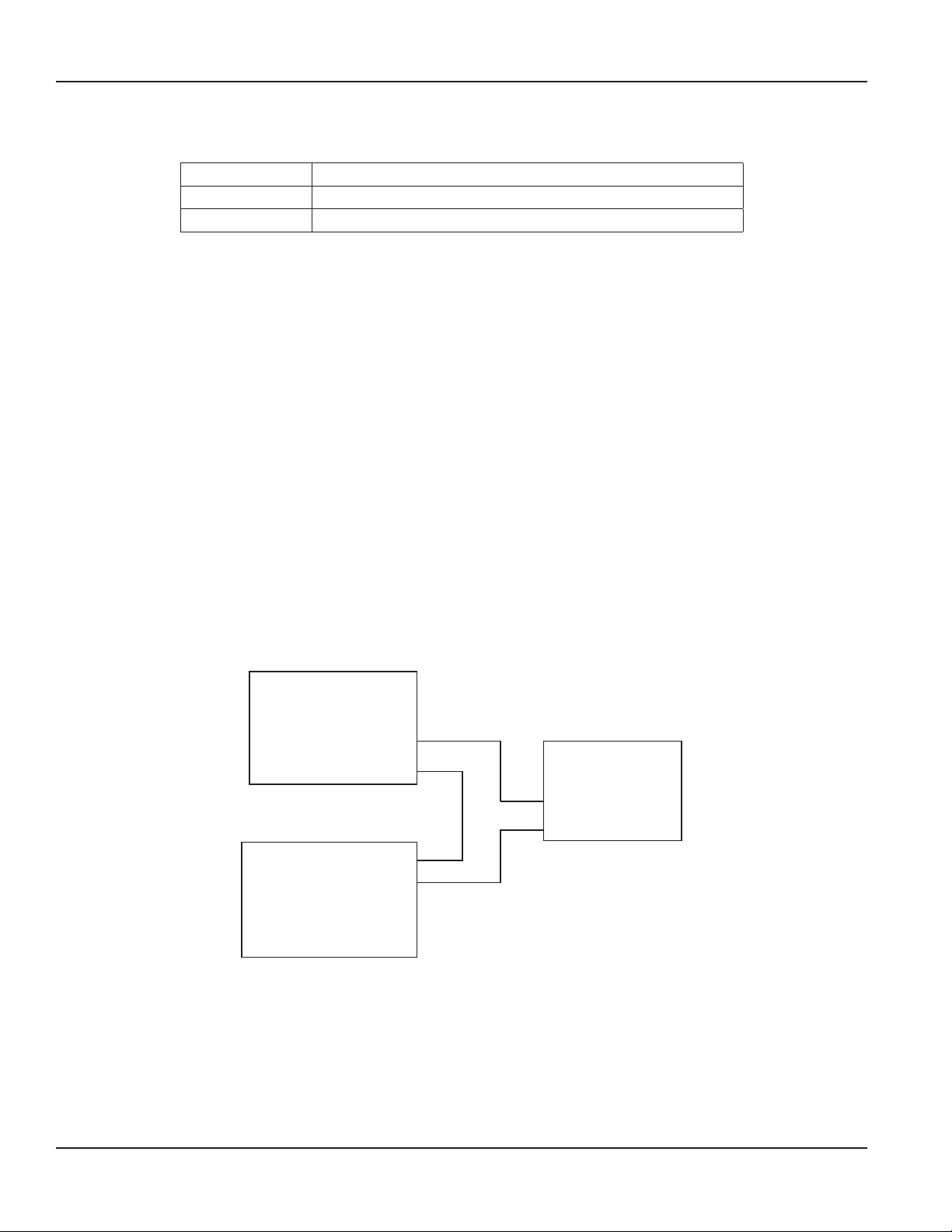

ELECTRICAL INSTALLATION

Sensor part Cable supplied

Digital Transmitter 20 ft (6 m) of 20 AWG three-conductor cable with drain wire and shield

Analog Unit 30 in. (762 mm) of AWG two-conductor cable with drain wire and shield

Make electrical wiring connections according to accepted trade practices.

You can attach an electrical junction box directly to the sensor electronic module, or mount it in the vicinity of the sensor.

Locate it conveniently to facilitate replacement of the electronic module assembly. Do not subject the wiring connections to

water or conductive liquids, as these might impair operations or damage the sensor circuitry.

When connecting to the electronic device, observe the wire colors and polarity to allow proper performance and to prevent

damage to the sensor or electronic device.

Electrical Wiring for a Digital Unit

Below are the general wiring instructions for the digital output unit. If you are connecting to a Badger Meter flow monitor,

consult the user manual.

1. Connect the red sensor wire to the positive (+) wire or terminal.

2. Connect the black sensor wire to the negative (–) wire or terminal.

3. Connect the white sensor wire to the signal (S) wire or terminal.

4. Connect the bare sensor wire to sensor shield.

Electrical Wiring for an Analog Unit

Turn off the 4…20 mA power and finish all wiring before turning on the loop power.

1. Wire the red wire (+ analog loop) of the ow sensor to the positive (+) output of a DC power supply.

2. Wire the black wire (– analog loop) of the ow sensor to the positive (+) input of your analog device.

3. Wire the negative (–) input of your analog device to the negative (–) of the DC power supply.

Power Supply

10...35V DC

(– output) DC

(+ output) DC

(+ analog loop) Red

(- analog loop) Black

4xxx10-xxxx

Flow Sensor

Figure 1: Wiring for analog 4000

Analog Input

Device

(–) Input

(+) Input

OTE:N Some legacy units may have additional orange and brown wires. Do not connect these wires. Connecting to these

wires will damage the unit and void the warranty. They are for factory calibration only.

Calibration

If you are replacing an existing sensor and have already calibrated your flow monitor, no calibration changes are necessary.

For installation of a new flow monitor, please refer to the calibration instructions in the flow monitor manual.

Page 6 April 2018SEN-UM-01714-EN-01

Page 7

Maintenance

MAINTENANCE

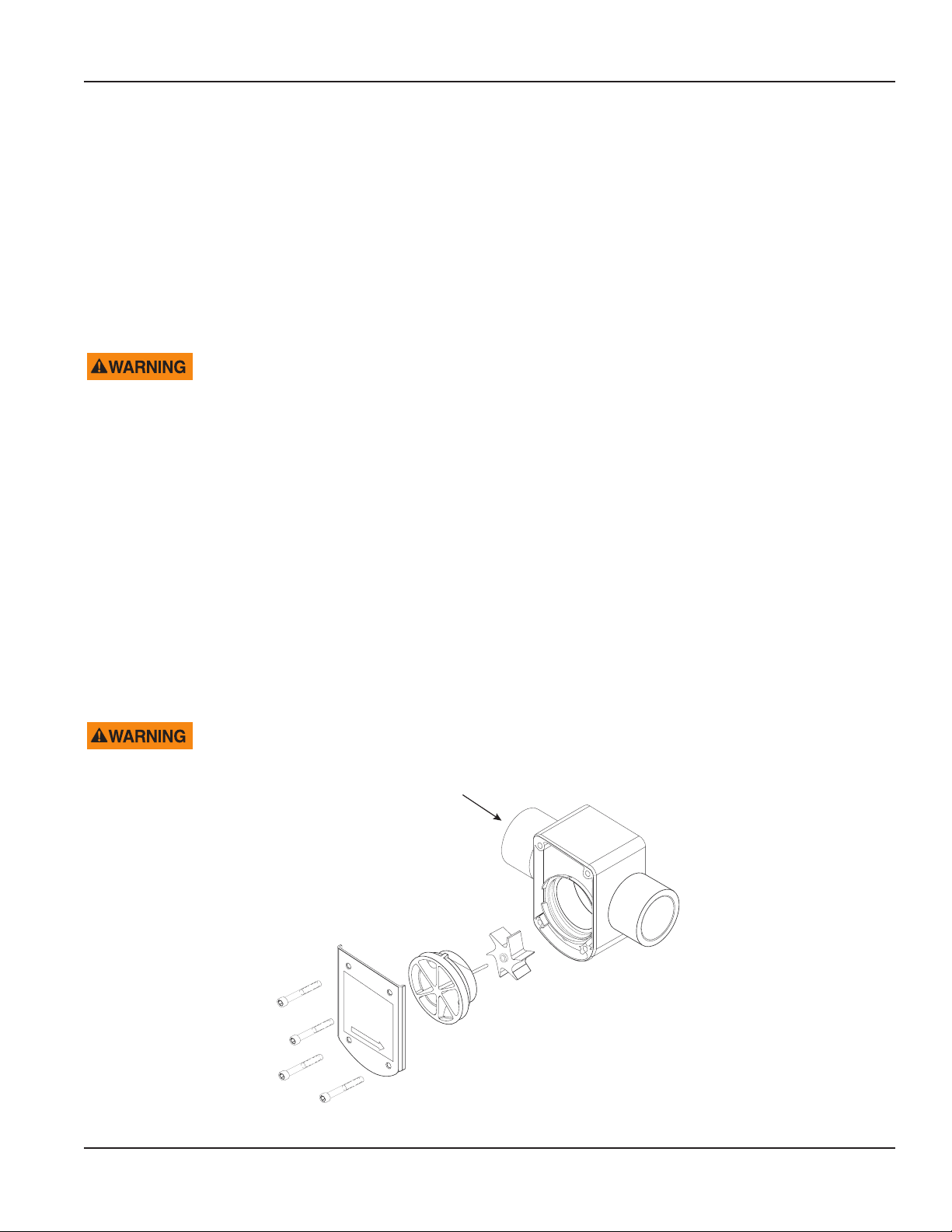

Impeller Assembly and Shaft Replacement

The following tools are required for the replacement of the impeller and shaft:

• 5/32 in. Allen wrench

• Flat blade screwdriver

• Torque driver in in-lb with 5/32 in. male hex adapter

OTE:N Units are factory calibrated at 12 in-lb.

1. Depressurize the pipe on which the sensor is being serviced.

DO NOT REMOVE SOCKET HEAD CAP SCREWS WHILE SYSTEM IS UNDER PRESSURE.

2. Using the Allen wrench, loosen and remove the four #10 socket head cap screws along with the stainless steel cover. It is

not necessary to remove the electronics to service the impeller and shaft.

3. Use the at-blade screwdriver to pry the impeller cover/shaft assembly from the sensor housing by using the provided

slots alternately.

4. Inspect the impeller and impeller cover/shaft assembly for signs of wear.

5. Replace the O-rings before reassembly. Do not use lubricants on the O-rings.

6. Insert the impeller into the cavity of the sensor housing, making sure the six blades are pointing into the ow direction.

The unit does not operate if the impeller is positioned incorrectly. For example, if ow direction is to the right, position the

impeller with blades pointing to the left. See Figure 2.

7. Orient the keyway of the impeller cover/shaft assembly to the small slot between the two large slots and align the shaft to

the shaft hold of the impeller.

8. Hand press the impeller cover/shaft assembly into the sensor housing cavity.

9. Fasten the stainless steel cover to the sensor housing using the #10 socket head cap screws.

10. Torque the #10 hardware to 12 in-lb.

11. Pressurize the system.

ALL FOUR SCREWS MUST BE IN PLACE AND TORQUED CORRECTLY BEFORE PRESSURIZING SYSTEM!

Flow

Direction

PVC Version

Impeller

Impeller Cover/Shaft Assembly

Stainless Steel

Cover

#10 Hardware

Figure 2: Assembly and shaft replacement

Page 7 April 2018 SEN-UM-01714-EN-01

Page 8

Maintenance

Electronic Assembly Replacement

A #1 Phillips screwdriver is required for servicing electronics. It is not necessary to depressurize or drain the system to service

the electronics.

1. Disconnect the sensor wiring from the display or transmitter.

2. Using a Phillips screwdriver, remove the two #4 Phillips head screws and accompanying hardware.

LETTING THE ELECTRONIC ASSEMBLY DROP FROM THE SENSOR COULD DAMAGE THE DETECTING COIL.

3. Unplug the coil from the electronics

OTE:N On analog units, the coil is permanently attached to electronics.

4. Plug the coil into the replacement electronics.

5. Reattach the electronics to the sensor with the two #4 Phillips screws. See "Replacement Part Numbers" on page 20 for

replacement part numbers.

MPORTANTI

Make sure the wires from the coil are tucked in before tightening the screws.

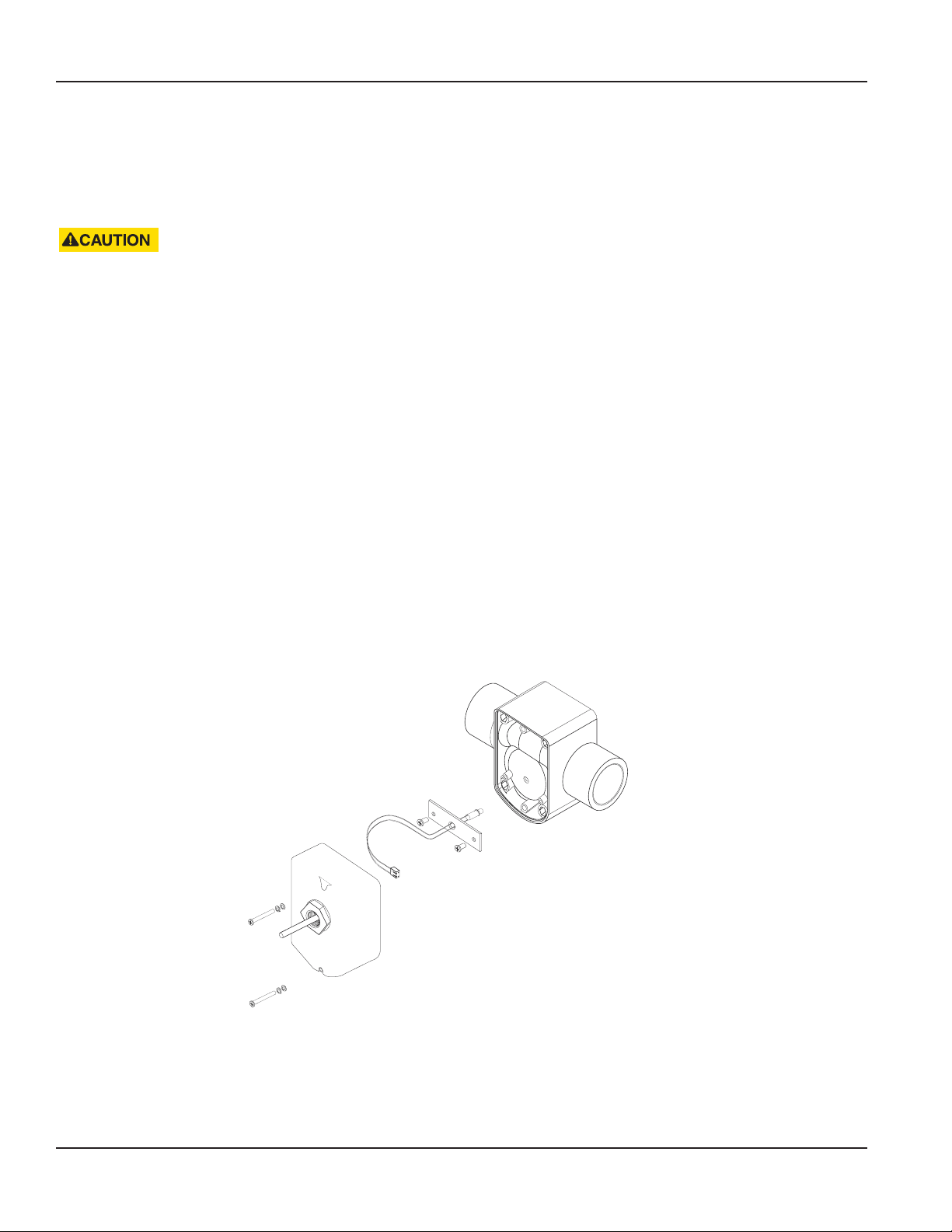

Detecting Coil Replacement

A #1 Phillips screwdriver is required for replacing the detecting coil. Depressurizing or draining the system is not necessary for

detecting coil replacement.

1. Remove the electronic assembly like in step 1 in "Electronic Assembly Replacement".

2. Unplug the coil from the electronics.

3. Using a Phillips screwdriver, remove the two #6 Phillips head screws, and the coil retaining plate.

4. Secure new coil to sensor housing with the #6 hardware.

5. Plug the replacement coil into the electronic assembly.

6. Fasten the electronics to the sensor with the #4 hardware. The coil wire orientation is not critical to operation. See

"Replacement Part Numbers" on page 20 for replacement part numbers.

Coil

Coil Retaining Plate

#6 Hardware

Electronic

Assembly

#4 Hardware

Figure 3: Coil and electronic assembly replacement

Page 8 April 2018SEN-UM-01714-EN-01

Impeller Body

Page 9

SPECIFICATIONS

Wetted Materials

• Sensor Housing and Enhancing Jet (If Applicable)

• PVC - Virgin polyvinyl chloride, type 1, grade 1

• PVDF - Virgin polyvinylidene fluoride

Digital Meter Specications

Specications

Sensor

Model #

400200 PVC 1/2 #80 0.08 (2.13) 0.55 (13.97) 0.413 0.3496 0.75 15.00 1.46 35.97

401200 PVC 3/4 #80 1.05 (26.67) 0.82 (20.83) 0.5735 0.2638 1.75 35.00 2.78 60.76

402000 PVC 1 #80 1.32 (33.40) 0.96 (24.38) 0.6134 0.1826 2.25 45.00 3.48 73.17

410200 PVC

411200 PVC

400300

400400

400500

401300

401400

401500

402300

402400

402500

410300

410400

410500

411300

411400

411500

Housing

Material

PVDF 1/2 0.79 (20.00) 0.64 (16.26) 0.5987 0.0008 1.00 20.00 1.66 33.40

PVDF 3/4 0.98 (24.99) 0.84 (21.34) 0.613 0.02664 1.75 35.00 2.82 57.06

PVDF 1 1.26 (32.00) 1.07 (27.18) 0.6266 0.0314 3.00 50.00 4.75 79.76

PVDF

PVDF

Nominal Pipe

Size (in.)

1/2 #80 Enhanced

Low Flow

3/4 #80 Enhanced

Low Flow

1/2 Enhanced

Low Flow

3/4 Enhanced

Low Flow

Pipe OD

in. (mm)

0.08 (2.13) 0.55 (13.97) 0.1421 0.8474 0.18 6.00 0.48 41.37

1.05 (26.67) 0.82 (20.83) 0.3287 0.2159 0.40 13.00 1.00 39.33

0.79 (20.00) 0.64 (16.26) 0.1445 0.4841 0.25 8.00 1.24 54.87

0.984 (25) 0.84 (21.34) 0.3195 0.4679 0.40 14.00 0.78 44.28

Pipe ID

in. (mm)

Slope

K

Offset

Min Flow

Rate

(GPM)

Max Flow

Rate

(GPM)

Min

Pulse

Rate

(Hz)

The calibration constants in columns Slope K and Offset relate frequency (Hz) to flow rate (GPM) in the equations:

Max

Pulse

Rate

(Hz)

FREQ =

GPM = K (FREQ + Offset)

GPM

K

–Offset

Page 9 April 2018 SEN-UM-01714-EN-01

Page 10

Specications

Analog Meter Specications

Analog versions of the sensor are precalibrated at the factory using the flow ranges below.

Sensor

Model #

400210 PVC 1/2 #80 0.08 (2.13) 0.55 (13.97) 0 20

401210 PVC 3/4 #80 1.05 (26.67) 0.82 (20.83) 0 30

402010 PVC 1 #80 1.32 (33.40) 0.82 (20.83) 0 30

410210 PVC 1/2 #80 0.08 (2.13) 0.55 (13.97) 0 8

411210 PVC 3/4 #80 1.05 (26.67) 0.82 (20.83) 0 12

400310

400410

400510

401310

401410

401510

402310

402410

402510

410310

410410

410510

411310

411410

411510

Housing

Material

PVDF 1/2 in. 0.79 (20.00) 0.64 (16.26) 0 20

PVDF 3/4 in. 0.98 (24.99) 0.84 (21.34) 0 30

PVDF 1 in. 1.26 (32.00) 1.07 (27.18) 0 40

PVDF 1/2 in. 0.79 (20.00) 0.64 (16.26) 0 8

PVDF 3/4 in. 0.98 (24.99) 0.84 (21.34) 0 12

Nominal Pipe

Size (in.)

Pipe OD

in. (mm)

Pipe ID

in. (mm)

Min Flow

Rate 4 mA

Max Flow

Rate 20 mA

Page 10 April 2018SEN-UM-01714-EN-01

Page 11

Technical Specications

Viton® Neoprene®

O-Rings

Impeller Shafts

Process Connections

Impeller and Bearing Tefzel®

Nominal Pipe Size 1/2 in. (12.70 mm), 3/4 in. (19.05 mm), 1 in. (25.40 mm)

End Connections

Max Temp Rating

Max Pressure Rating

Pressure, Temperature

Ratings

Cable

Digital Output Unit

Analog Output Unit

Operating Flow Range

Recommended Design

Flow Range

Accuracy

Repeatability ±0.5% of full scale over recommended design flow range

Linearity

EPDM Chemraz®

Kalrez® Teflon® Encapsulated Viton

Silicon, food grade —

Zirconia Ceramic Monel,® Grade K500

Hastelloy,® C-276 316 stainless steel

Tungsten Carbide, GE carboloy 883 colbalt

binder

Titanium alloy 86Ti-6AL-6V-25A —

PVC (virgin polyvinyl chloride, type 1, grade

1) schedule 80 tail pieces

PVDF (virgin polyvinylidene fluoride) sockets PVDF flanges

PVDF union thread (for joining existing

piping systems with GF unions)

PVDF union nuts with socket union ends —

PVC

PVDF

PVC

PVDF

PVC

PVDF

Depends on hardware configurations. See Figure 4 on page 12.

Digital output 3-wire

Analog output 2-wire

Pulse Square wave (approximately) output at 1 pulse/revolution

Voltage

Sink current 2 mA maximum

Output signal is 5V CMOS and LSTTL compatible. The output can be forced to any logic level up to 20V by an

external pullup resistor

Signal

Sink current 2 mA maximum

Output signal is 5V CMOS and LSTTL compatible. The output can be forced to any logic level up to 20V by an

external pull-up resistor.

0…20 ft/sec for standard range units

0…10 ft/sec for enhanced flow range units

1…20 ft/sec for standard range units to maintain calibration accuracy

0.25…8 ft/sec for enhanced flow range units to maintain calibration accuracy

Better than ±1.0% of full scale over recommended design flow range with water at 50…80° F (10…26.67° C)

and 20…40 psig

±0.7% of full scale over recommended design flow range

±1.0% frequency to current conversion

Plain end pipe

Socket weld/union

140° F (60° C)

220° F (104° C)

350 psi @ 73° F (23° C)

275 psi @ 65° F (18° C)

0.4V maximum (output low)

45V minimum (output high) into high impedance load

Loop powered 4…20 mA current analog output with offset compensation for

ripple less then 0.25% of full scale

Tantalum, commercial grade

PVDF union nuts with 316 stainless steel FNPT

union ends

PVDF union nuts with CPVC socket union ends

Specications

Page 11 April 2018 SEN-UM-01714-EN-01

Page 12

Specications

Digital Output Unit

Transducer Power

Analog Output Unit

Accessories

Model A301-20 programming kit with 20 ft cable

USB to COM adapter

Pressure, Temperature Diagram

400

350

300

275

250

Normally provided by flow monitor or transmitter. Any alternate supply must be

of a resistance-limited type meeting the following constraints:

Supply voltage: 9…20V DC

Supply current: 2 mA maximum

10…35V DC maximum. The combination of loop supply voltage and total loop

series resistance must make sure that the device voltage remains within these

limits over the 4…20 mA output span

Pressure

(psi)

200

150

100

50

PVC PVDF

0

50 100 150 200 250

Figure 4: Sensor pressure temperature diagram

140 220

Page 12 April 2018SEN-UM-01714-EN-01

Page 13

DIMENSIONS

Dimensions

PVC PVDF

PVC PVDF

Model A B Model A B C

1/2 in. 8.77 in. ± 0.25 in. (222 mm ± 6.35 mm) 4.33 in. (104 mm) 1/2 in. 5.03 in. (128 mm) 3.54 in. (90 mm) 1.85 in. (47 mm)

3/4 in. 10.57 in. ± 0.25 in. (268 mm ± 6.35 mm) 4.69 in. (119 mm) 3/4 in. 5.55 in. (141 mm) 3.92 in. (100 mm) 2.24 in. (57 mm)

1 in. 13.03 in. ± 0.25 in. (331 mm ± 6.35 mm) 5.40 in. (137 mm) 1 in. 6.10 in. (155 mm) 4.32 in. (110 mm) 2.52 in. (64 mm)

Page 13 April 2018 SEN-UM-01714-EN-01

Page 14

Troubleshooting

TROUBLESHOOTING

General

When troubleshooting a sensor, first establish that the problem lies with the sensor and not with the electronic device

connected to it. A simple way to determine this is to substitute a known working sensor for the suspect unit. If the electronics

react as they should, the problem is sensor related. Another option is to provide a similar, square wave pulse simulation by

hooking up a frequency generator to the interface electronics and simulating, as close as possible, the actual sensor signal.

If you suspect a sensor problem, address these mechanical considerations:

• Make sure there is flow in the pipe line appropriate to the operations range (0.25…20 feet/second) of the sensor.

• Make sure that the wiring between the sensor and the electronics is correct. If a junction box has been added, make sure

that all wiring connections are correct.

• Check the impeller assembly to make sure it is not mounted in the reverse direction of flow.

• Make sure that the impeller can spin freely on the shaft and that no foreign matter or debris has lodged in the

sensor housing.

Check Using a Digital Circuit

A sensor is a powered device, required voltage at 8… 20V DC, applied between the red (+) and black (–) sensor leads. The

sensor normally draws about 1mA for this supply.

DO NOT EXCEED 20V DC; SENSOR DAMAGE MIGHT RESULT.

Checking the Sensor

1. Make sure that the black, red and shield wires remain connected to the proper terminals. Disconnect the white

sensor wire.

2. Install a voltmeter, positive (+) to the white sensor wire and negative (–) to the black sensor wire. If ow exists, a square

wave signal switches between 0.0V DC (low) and 4.0V DC (high).

OTE:N The pulse might be too fast for the voltmeter to recognize as a square wave, but it might appear as an unstable

reading somewhere between 2.0…4.9V DC. If flow is stopped, the output holds in either a high (4.0V DC) state or low

(0.0V DC) state, depending on the position of the impeller reflector or other factors. To simulate impeller rotation,

pass a metal object (like a large screwdriver or pliers) past the back of the sensor. The output signal should then

switch states.

3. If the sensor produces pulses in the above tests, reconnect the white sensor wire to the signal input terminal of

the transmitter.

4. With the voltmeter still connected, note the actual voltage levels between the output switching (such as 0.0V DC low or

4.0V DC high). If reconnecting the sensor to the transmitter either stops or signicantly alters the voltage levels of the

pulses, or if the transmitter does not respond to the pulses, consult the factory or your local representative.

5. If the sensor switches states when a metal object is passed near the back of the sensor, but no pulse occurs when ow

exists, verify that the ow meets our minimum ow requirements for the sensor. Check the condition of the impeller and

the shaft for mechanical wear or damage. If replacement is necessary, order a repair kit.

Checking the Electronic Module

A nonworking sensor could be the result of a sensing coil failure or a component failure in the electronic module (gray cover).

1. Use an Ohmmeter to determine the coil resistance

a. Remove the gray electronics cover containing the encapsulated circuitry.

b. Unplug the coil from the electronics in the cover.

c. Connect the probes of the Ohmmeter to the wire terminals of the coil plug-in connector. The coil resistance should

measure 5…10 Ohms. A very low or very high resistance reading might indicate a failed coil. In this case, replace

the coil.

Page 14 April 2018SEN-UM-01714-EN-01

Page 15

Troubleshooting

2. If the coil appears to be within specication, check the electronic assembly.

a. Replace the gray cover assembly with one from another working device.

b. If the sensor begins working, the electronic assembly is not functioning. Replace it.

Checking the Impeller

If the sensor was working and a rebuild kit was installed due to a failure of the impeller or shaft and the sensor did not return

to working order, check to verify that the impeller was installed in the proper direction. If the impeller was installed backwards

to the flow direction, no signal pulse is generated, even if the impeller spins freely.

If you experience any other difficulties with the sensor, please consult the factory or your local representative. Please have a

description of the problem, model, serial number and application information available when you call.

Check Using an Analog Circuit

1. Connect power supply and ammeter in a series loop.

2. With no ow in the pipe, check to see if the output is reading 4 mA. If the output is greater or less than 4 mA, the analog

electronics assembly must be recalibrated at the factory.

3. With ow in the pipe, the output should be something higher than 4 mA but not greater than 20 mA. If you cannot get

ow through the system, you can simulate ow in two ways. Either method excites the analog output to change and read

greater then 4 mA.

◊ Blow into one side of the unit to make the impeller spin

◊ Pass a metal object (nut driver or wrench) across the back of the electronics housing

4. If the analog output does not change, replace the electronics assembly.

5. If the analog changes when you pass a metal object across the rear of the electronics assembly but does not at any other

time, inspect the impeller assembly, according to the directions in "Checking the Impeller" on page 15.

Page 15 April 2018 SEN-UM-01714-EN-01

Page 16

Programming

PROGRAMMING

Connecting Via DIC COM Port

To program the transmitter, follow these steps:

1. Load the interface software into the computer.

2. Power the ow meter.

3. Connect the computer to the ow meter with the Data Industrial Series A-301 communications cable to the socket

labeled “D.I.C. COM port”, taking care to properly align the tab on the plug and socket to maintain polarity. Connect the

DB9 connector of the Data Industrial Series A301 communications cable to a PC COM port that has the 340

software installed. If a DB9 COM port is not available, a USB to COM Port Adapter may be purchased locally or from

Badger Meter.

4. Open the program and from the Device tab and select 4000 as shown in Figure 5.

5. Under the Conguration tab, select Set Comm Port.

Figure 6: Select Set Comm Port

Figure 5: Select 340

Page 16 April 2018SEN-UM-01714-EN-01

Page 17

Programming

6. Select the Comm Port from the drop-down menu.

Figure 7: Select the Comm Port

If the COM and Device type have been properly selected, the dashes (“---”) are replaced with values.

OTE:N If this does not happen, communication has not been established and you cannot continue to the next step. If it does

not connect automatically, click on Poll Now.

a. If communication still does not occur and you are using a DB9-to-COM 1 or COM2, try using a USB-to-COM adapter.

This usually creates a new COM port that was not previously listed. Use the Windows Device Manager to determine the

actual COM ports that are available.

Figure 8: Device manager

b. Select this new port created by the adapter and the screen should change to display the information. The dashes ( “---“)

are replaced with values, confirming normal communications.

Page 17 April 2018 SEN-UM-01714-EN-01

Page 18

Programming

7. When communication has been conrmed, click Parameters. The Parameters screen displays.

Figure 9: Parameters screen

8. From this screen, set up the following:

◊ Flow sensor piping material, scaling and units

◊ Analog loop low to high settings

◊ Flow rate filter number

9. Press Send before leaving this page to save any changes.

Refresh rereads the unit and refreshes the screen. Defaults restores all factory settings. Exit returns to the

main screen.

Figure 10: Parameter screen buttons

Page 18 April 2018SEN-UM-01714-EN-01

Page 19

Programming

Flow Sensor Configuration Section

Figure 11: Pulse or sine

1. Select the material that the ow sensor is installed in.

2. Find the k and oset values in the chart for either "Digital Meter Specications" on page 9 or "Analog Meter Specications"

on page 10.

3. Select the ow rate units of measure from the drop-down box.

Analog Loop Settings

Figure 12: Analog loop settings box

Enter flow rates for the low and high outputs.

Flow Rate Filter

Choose the flow rate filter from the drop-down box.

Figure 13: Flow rate filter box

Page 19 April 2018 SEN-UM-01714-EN-01

Page 20

Replacement Part Numbers

REPLACEMENT PART NUMBERS

Name Included Parts Part No.

Impeller Impeller 08010

(1) coil

Coil Kit

(For Digital Output Unit Only)

O-ring Kit

(PVDF Units Only for Use With Unions)

Union Kit 1/2 in. (20 mm) PVDF

Union Kit 3/4 in. (25 mm) PVDF

Union Kit 1 in. (32 mm) PVDF

(1) retaining plate

(2) #6 screws

O-Ring Kit, EPDM O-Rings, 1/2 in. for 20 mm Union 4003OKE

O-Ring Kit, EPDM O-Rings, 3/4 in. for 25 mm Union 4013OKE

O-Ring Kit, EPDM O-Rings, 1 in. for 32 mm Union 4023OKE

O-Ring Kit, Viton O-Rings, 1/2 in. for 20 mm Union 4003OKV

O-Ring Kit, Viton O-Rings, 3/4 in. for 25 mm Union 4013OKV

O-Ring Kit, Viton O-Rings, 1 in. for 32 mm Union 4023OKV

(2) PVDF Union Ends, 20 mm

(2) PVDF Union Nuts, 20 mm

(2) Viton O-Rings

(2) PVDF Union Ends, 25 mm

(2) PVDF Union Nuts, 25 mm

(2) Viton O-Rings

(2) PVDF Union Ends, 32 mm

(2) Viton O-Rings

711333

711380

711381

711382(2) PVDF Union Nuts, 32 mm

Page 20 April 2018SEN-UM-01714-EN-01

Page 21

Part Number Matrix

Replacement Part Numbers

Series

4000

Style

Standard Flow

Enhanced Flow (available with 1/2 in. and 3/4 in. only)

Size

1/2 in.

3/4 in.

1 in.

Material

PVC furnished with schedule 80 tail pieces

PVDF socket

PVDF union threaded

PVDF with unions and socket ends

PVDF with 316 stainless steel FNPT union end

PVDF with CPVC socket union end

Electronics

Pulse output

Pulse output with EFI foil shield

Pulse output with CE housing

4…20 mA analog output

4…20 mA analog output with EFI foil shield

4…20 mA with CE housing

O-Ring (set of 3 rings)

Viton®

EPDM

Shaft

Zirconia Ceramic

Hastelloy® C

Tungsten Carbide

316 Stainless Steel

Tantalum

Impeller

Tefzel®

Bearing

UHMWPE

Tefzel

Teon®

Example

4

0 0

4

0

1

7 10

0

1

2

2

3

4

5

7

9

00

01

05

10

11

15

-

0 0 2 2

0

1

0

1

2

6

7

2

1

2

3

Figure 14: Part number matrix

Page 21 April 2018 SEN-UM-01714-EN-01

Page 22

Replacement Part Numbers

Electronics Repair Kit Part Number Matrix

Electronics

Pulse Output

Pulse output with EFI foil shild

CE Pulse output

4-20 mA analog output

4-20 mA analog output with foil shild

CE 4-20 mA analog output

Figure 15: Electronics repair kit matrix

Example: 4000EK

- 10

00

01

05

10

11

15

Page 22 April 2018SEN-UM-01714-EN-01

Page 23

INTENTIONAL BLANK PAGE

User Manual

Page 23 April 2018 SEN-UM-01714-EN-01

Page 24

Flow Sensor, Series 4000

Control. Manage. Optimize.

Data Industrial is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous

research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an

outstanding contractual obligation exists. © 2018 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11 Legacy Document Number: 872121

Loading...

Loading...