Page 1

Series 380 BTU System

380DS Meter

IND-UM-02074-EN-01 (July 2016)

User Manual

Page 2

Series 380 BTU System , 380DS Meter

Introduction

CONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Series 380 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Ordering System Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Mechanical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing the Sensor Tee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

RS-485 Network Congurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INTRODUCTION

The Series 380 BTU System from Badger Meter® provides

a low cost solution for metering cold or hot systems. The

380DS can accurately measure flow and temperature

differential to compute energy. Using BACnet™ or Modbus®

RS-485 communications protocols or a scaled pulse

output, the BTU System can interface with many existing

control systems.

The rugged design incorporates an impeller flow sensor

and two temperature probes. One temperature probe is

conveniently mounted directly in the flow sensor tee. The

second temperature probe is placed on either the supply or

the return line depending on installation requirements. These

minimal connections help simplify installation and save time.

The main advantage of the Series 380 BTU System is the cost

savings over other systems offered on the market today.

The integration of flow and temperature sensors, along with

metering components provide a single solution for metering.

With this system, it will be possible to meter energy where

metering had not cost effective.

Ordering System Matrix

Commissioning of this meter can be completed in the

field via a computer connection. Setup includes energy

measurement units, measurement method, communications

protocol, pulse output option, fluid density and specific

heat parameters.

Series 380

The 380 combines an electronics package with a PEEK sensor

probe inserted in a 3/4", 1", 1-1/4", 1-1/2" and 2" proprietary

cast bronze pipe tee with threaded NPT connections.

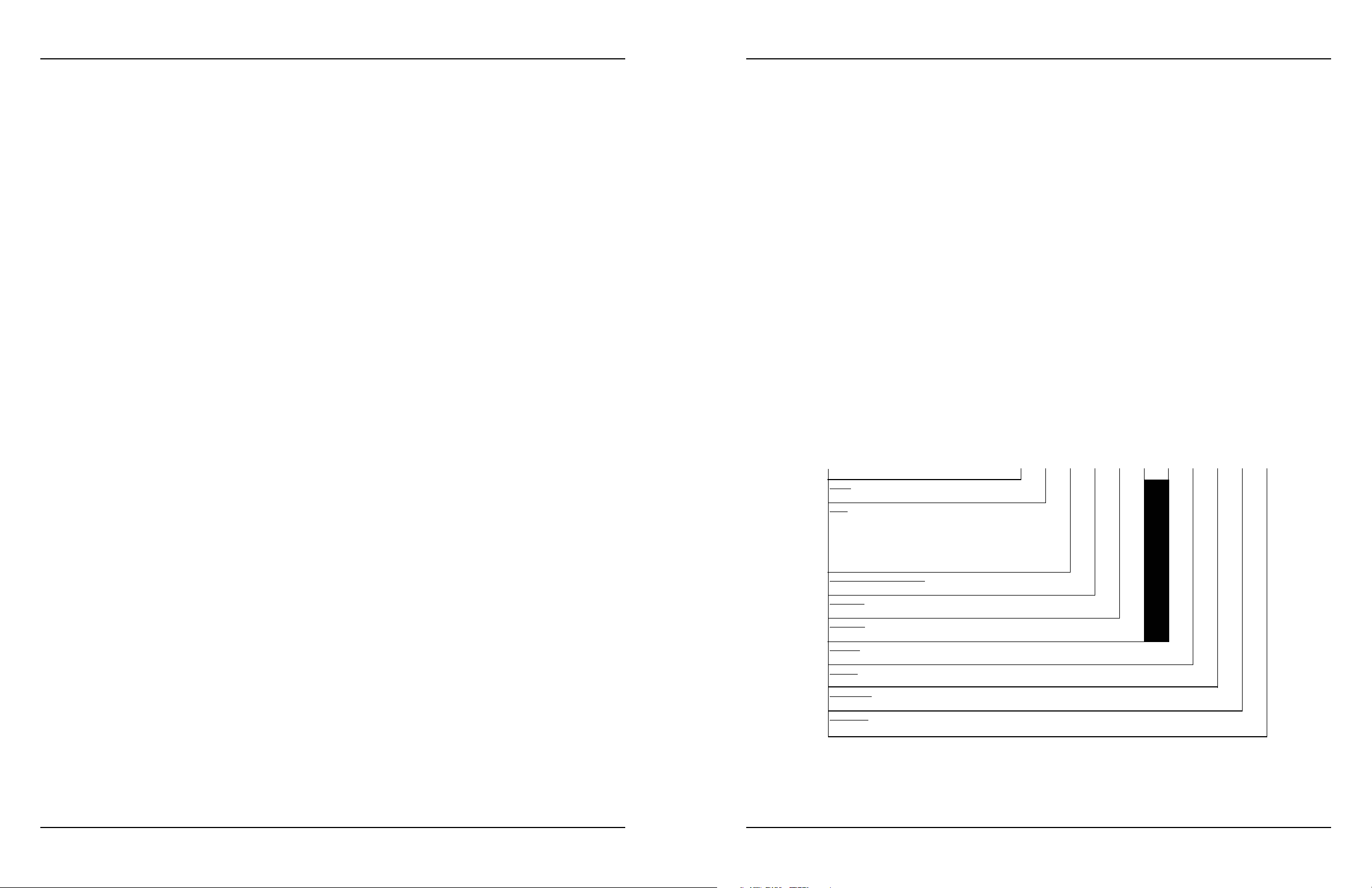

Series 380 Btu System Ordering Matrix

380 DS Meter

TYPE

DS - Dual Service 2

SIZE

0.75" 07

1" 10

1.25" 12

1.5" 15

2" 20

ELECTRONIC HOUSING

Polycarbonate 0

OUTPUT

Scaled Pulse and RS-485 (Modbus and BACnet) 0

DISPLAY

N/A 0

O-RING

EPDM 1

SHAFT

Tungsten Carbide (STANDARD) 2

IMPELLER

Stainless Steel 0

BEARING

Ketron® 2

Example: 380 2 07 0 0 0 - 1 2 0 2

Figure 1: Ordering system matrix

Page 3 July 2016 IND-UM-02074-EN-01Page ii July 2016IND-UM-02074-EN-01

Page 3

Mechanical Installation

Commissioning

MECHANICAL INSTALLATION

General

The accuracy of flow measurement for all flow measuring

devices is highly dependent on proper location of the

sensor in the piping system. Irregular flow velocity profiles

caused by valves, fittings, pipe bends, etc. can lead to

inaccurate overall flow rate indications, even though local

flow velocity measurement may be accurate. A sensor

located in the pipe can be affected by air bubbles, floating

debris, or sediment may not achieve full accuracy and could

be damaged. Badger Meter flow sensors are designed to

operate reliably under adverse conditions, but the following

recommendations should be followed to ensure maximum

system accuracy.

1. Choose a location along the pipe where 10 pipe

diameters upstream and 5 pipe diameters downstream

of the sensor provide no ow disturbances. Pipe bends,

valves, other ttings, pipe enlargements and reductions

should not be present in this length of pipe.

2. The recommended location for the sensor around the

circumference of a horizontal pipe is on top of the pipe.

The sensor should never be located at the bottom of the

pipe, as sediment may collect there. Locations away from

the top-center on a pipe cause the impeller friction to

increase, which may aect performance at low ow rates.

Any circumferential location is correct for installation in

vertical pipes. Rising ow is preferred to reduce eects of

any trapped air.

Installing the Sensor Tee

1. Position the tee for unrestricted pipe ow for at least

10 pipe diameters upstream and 5 pipe diameters

downstream of the tee.

2. Apply pipe compound over the rst 3 or 4 threads of the

mating pipe.

3. Thread the pipe into the sensor tee until hand tight.

4. Tighten the pipe an additional 1-1/2 turns, using a

wrench.

ELECTRICAL INSTALLATION

1. The Series 380 requires an isolated 12…24 V AC/DC

power supply. To avoid ground fault conditions, the 380

power should not be shared with other devices. This is

especially true when the RS-485 network connections are

being utilized, where damage to the product or system

could result.

The power connections are labeled 1 and 2 and are not

polarity sensitive.

2. The RS-485 requires three connections: RS-485+, RS-485and REF.

The connections are labeled 1 (+), 2 (-) and 3 (GND). RS485 is a high-speed connection and should be wired to

meet TIA-EIA-485-A standards.

This is especially true if a long cable run is involved or

multiple devices are to be networked.

3. The pulse output is a simple solid state switch.

The connections are labeled "PULSE OUTPUT 1" and

"PULSE OUTPUT 2". The switch is not polarity sensitive,

however, be careful that the maximum voltage and

current ratings are not exceeded. See "Specifications" on

page 7 for details.

OTE:N The pulse and RS-485 may be used simultaneously.

COMMISSIONING

All setup and commissioning of the Series 380 is done using

a USB to Mini USB cable and the Badger Meter Series 380

commissioning software.

Figure 2 shows the main setup screen. Flow and Energy rates

and totals can be selected or a custom unit can be put in with

the correct conversion factor.

For the temperature sensors the user can select the units

along with the calculation mode, i.e., T1>T2, Absolute, or

T1<T2. The Diff Zero parameter is the difference between T1

and T2 that will still read 0 energy rate.

If the Scaled Pulse Output is going to be used, the user can

select what the pulse is representing (Energy or Flow), along

with Units/Pulse and the pulse width. If the Scaled Pulse

Output is not going to be used, this output can be set to OFF.

Figure 3 shows the communication parameters tab. The

user can select BACnet or Modbus along with the network

address. If using BACnet, the Device Name, Device ID

BACnet BitRate and the Max Master number should be

entered for the appropriate network for which the 380 is

being connected.

Figure 2: Main setup screen

RS-485 Network Congurations

The RS-485 Section can be configured in two ways:

• Modbus

• BACnet

The following sections explain each in detail.

RS-485 Network Configurations—Modbus

Figure 4: Comm parameters—modbus

Select Modbus, to access the Modbus pull-down menus.

Select the Address, Bit Rate (Baud Rate) and Mode (RTU

or ASCII).

The Series 380 uses IEEE 754 Float Data Located in “Read

Holding Registers.”

The Series 380 Data Format is “Float 32” where the Data is

stored across two “Read Holding Registers”.

In the case of sensor mounted in the 380 body, the upper

byte is stored in register 40001 and the lower byte is stored in

the register 40002.

For example, a temperature of 53.36° F when converted to

IEEE 754 is “425570A4.” In the case of the Series 380, Register

# 40001 = 70A4 Hex and Register # 40002 = 4255 Hex. See

Table 1 on page 6 for additional information.

Page 4 July 2016 Page 5 July 2016 IND-UM-02074-EN-01IND-UM-02074-EN-01

Figure 3: Communication parameters

Page 4

Commissioning

Specications

Modbus Register Map

Series 380 Register Map

Register

Name

Sensor

Temperature

Remote

Sensor

Flow Rate 40005 + 40006 IEEE 754 Float Read Only

Flow Total 40009 + 40010 IEEE 754 Float Read Only

Energy Rate 40007 + 40008 IEEE 754 Float Read Only

Energy Total 40011 + 40012 IEEE 754 Float Read Only

Energy Calc

Mode

Flow Filter 40015 + 40016 IEEE 754 Float Read Only

Temp Coef 40017 + 40018 IEEE 754 Float Read Only

Specific Heat 40019 + 40020 IEEE 754 Float Read Only

Fluid Density 40021 + 40022 IEEE 754 Float Read Only

Address Data Type Read/Write

40001 + 40002 IEEE 754 Float Read Only

40003 + 40004 IEEE 754 Float Read Only

40013 + 40014 IEEE 754 Float Read Only

Table 1: 380 register map

RS-485 Network Configuration—BACnet

Figure 5: Comm parameters—BACnet

Select BACnet to access the BACnet pull-down menus.

Select the Bit Rate (BAUD rate) to match other devices on

the network.

BACnet Device Name can be set to help identify this device

and location.

BACnet Device ID (Incidence #) is a unique number that

identifies this device on the network. Typically, the first part

of the number is the same as the network #, and the last two

characters are the same as the address.

OTE:N The numbering sequence is not a requirement, but

can help in system planning.

BACnet Protocol Implementation Conformance

Statement

BACnet Standardized Device Profile

BACnet Smart Actuator (B-SA)

Supported BIBBs

Supported BIBBs BIBB Name Tested

DS-RP-B ReadProperty - B

DS-WP-B WriteProperty - B

DM-DDB-B

Standard Object Types Supported

Analog Input No No

Analog Value No No

Device No No

Data Link Layer Options

MS/TP Slave

Segmentation Capability

Able to transmit segmented messages No N/A

Device Address Binding

Static Binding Supported Tested

No N/A

Character Sets

Character Sets supported Tested

ANSI X3.4

Dynamic Device Binding - B (Who-Is, I-Am)

Object Type Creatable Deletable Tested

Data Link Options Tested

Segmentation Type Supported

Device Profile Tested

baud rates: 9600, 19200,

38400, 76800 bps

Window Size

(MS/TP product limited to 1)

�

Figure 6: BACnet Device Profile

�

�

�

�

�

�

�

�

Tested

SPECIFICATIONS

Electrical Input

Electrical Output Scaled Pulse Open drain, 0.01…100 Hz max.

Materials

Sensor Body

Sizes

Environmental

Accuracy

Flow Range

Power 12…35V DC, 12…28V AC

Communication Modbus RTU, BACnet MSTP

Housing Polycarbonate

Flow Sensor PEEK

Potting Material Polyurethane

Tee Material Brass

Tee Sizes

Fluid Temperature 20…260° F (–6.7…126.7° C)

Ambient

Temperature

± 2% of flow rate within flow range

± 0.5% repeatability

RTD meets IEC751 Class B

1…15 ft/sec

Diameter

0.75 in.

(19 mm)

1 in.

(25 mm)

1.25 in.

(32 mm)

1.5 in.

(38 mm)

2 in.

(50 mm)

This chart is based on ASME/ANSI B336.10 Welded and

Seamless Wrought Steel Pipe and ASME/ANSI B3619

Stainless Steel Pipe.

3/4 in., 1 in., 1-1/4 in., 1-1/2 and

2 in.

–4…149° F (–20…65° C)

380 BTU Meter

Flow Range

1.65…24.69 gpm

(6…93 lpm)

2.70…40.48 gpm

(10…153 lpm)

4.66…69.93 gpm

(17…265 lpm)

6.35…95.18 gpm

(24…360 lpm)

10.49…157.34 gpm

(40…595 lpm)

Weight

6.5 lbs

(2.9 kg)

7.5 lbs

(3.4 kg)

9.5 lbs

(4.3 kg)

11 lbs

(4.9 kg)

13 lbs

(5.9 kg)

Series 380 BACnet Object Map

Description ID Name Units

Analog Input AN1 TempIn ºC, ºF

Analog Input AN2 TempOut ºC, ºF

Analog Value AV1 VolFlow gpm, gph, lpm, lps, lph, ft3/s, ft3/m, ft3/h, m3/s, m3/min, m3/h, custom

Analog Value AV2 EnergyFlow kBtu/min, kBtu/h, kW, MW, HP, Tons, custom

Analog Value AV3 TotalVol gallons, galx100, galx1000, liters, ft3, m3, custom

Analog Value AV4 TotEnergy Btu, kBtu, MBtu, kWh, MWh, kJ, MJ, custom

Analog Value AV5 TempMode dimensionless

Analog Value AV6 FFilterCoef dimensionless

Analog Value AV7 TFiltCoef dimensionless

Analog Value AV8 SpHtCapac Btu/lb-F

Analog Value AV9 Density lb/gallon

Analog Value AV10 SerialNum dimensionless

Table 2: 380 BACnet object map

Page 6 July 2016 Page 7 July 2016 IND-UM-02074-EN-01IND-UM-02074-EN-01

Page 5

Series 380 BTU System , 380DS Meter

Control. Manage. Optimize.

Data Industrial is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous

research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an

outstanding contractual obligation exists. © 2016 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11 Legacy Document Number: 880102-0001

Loading...

Loading...