Page 1

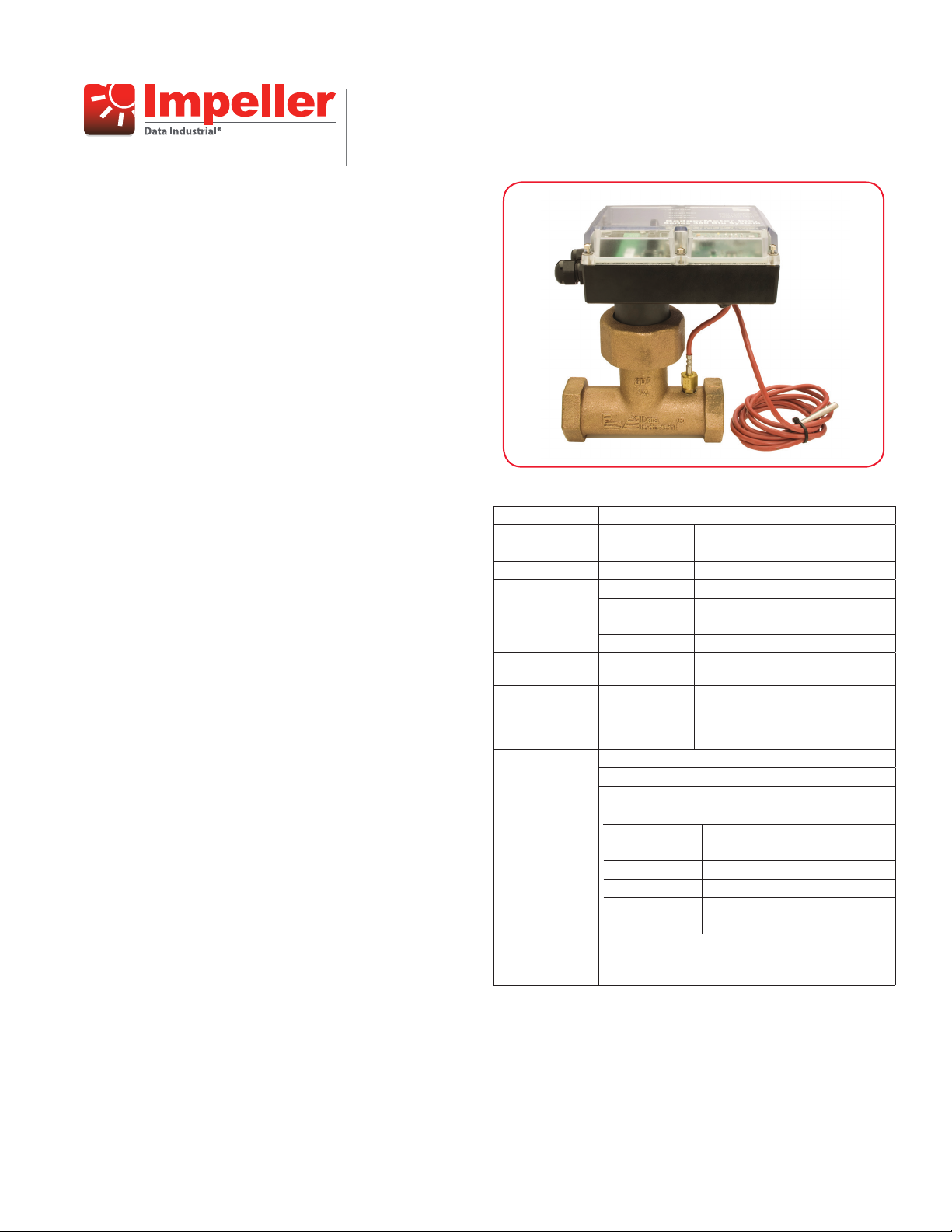

Series 380 BTU System

380CS/HS Meter

DESCRIPTION

The Series 380 BTU Systems provide a low cost system for metering

cold or hot systems. The 380CS/HS can accurately measure flow and

temperature differential to compute energy. Using either BACnet or

Modbus RS-485 communications protocols or a scaled pulse output,

the BTU Meter can interface with many existing control systems.

The rugged design incorporates an impeller flow sensor and two

temperature probes. One temperature probe is conveniently

mounted directly in the flow sensor tee. The second temperature

probe is placed on either the supply or the return line, depending on

ease of installation for the application. These minimal connections

help simplify installation and save time.

The main advantage of the Series 380 BTU meters is the cost savings

over other systems offered on the market today. The integration of

flow and temperature sensors provide a single solution for metering.

With this system it will be possible to meter energy where it has not

been cost effective before.

Commissioning of this meter can be completed in the field via a

computer connection. Setup includes energy measurement units,

measurement method, communication protocol, pulse output

control, fluid density, and specific heat parameters.

RS-485 Conguration

All Series 380 BTU meters are equipped with BACnet and Modbus

protocols as standard features. The protocol of choice can be

selected and set up in the field at the user’s discretion. These

common protocols allow for quick and easy commissioning while

gaining valuable application data beyond energy total. Information

such as Flow Rate, Flow Total, Energy Rate, Energy Total, Temp 1,

Temp 2, and Delta T can all be transmitted on the RS-485 connection.

Scaled Pulse Output

If the RS-485 is not required for the application, a simple scaled pulse

output is available. The pulse output would represent energy total

and can be set in various units of measure. The pulse output is an

open drain scaled pulse output that is compatible with a variety of

PLCs, counters and the Badger Meter® 350 wireless system, so the

unit is easily compatible with most inputs.

SPECIFICATIONS

Mass Less than 13 lb

Electrical Input

Electrical Output Scaled Pulse Open drain, 0.01…100 Hz max.

Materials

Sensor Body

Sizes

Environmental

Accuracy

Flow Range

Power 12…35V DC, 12…28V AC

Communication Modbus RTU, BACnet MSTP

Housing Polycarbonate

Flow Sensor PEEK

Potting Material Polyurethane

Tee Material Brass

Tee Sizes 3/4 in., 1 in., 1-1/4 in., 1-1/2 and 2 in.

Fluid

Temperature

Ambient

Temperature

± 2% of flow rate within flow range

± 0.5% repeatability

RTD meets IEC751 Class B

1…15 ft/sec

Diameter 380 BTU Meter Flow Range

0.75 in. (19 mm) 1.65…24.69 gpm (6…93 lpm)

1 in. (25 mm) 2.70…40.48 gpm (10…153 lpm)

1.25 in. (32 mm) 4.66…69.93 gpm (17…265 lpm)

1.5 in. (38 mm) 6.35…95.18 gpm (24…360 lpm)

2 in. (50 mm) 10.49…157.34 gpm (40…595 lpm)

This chart is based on ASME/ANSI B336.10 Welded and

Seamless Wrought Steel Pipe and

ASME/ANSI B3619 Stainless Steel Pipe.

Chilled: –4…140° F (–20…60° C)

Hot: 40…260° F (4…125° C)

–4…149° F (–20…65° C)

IND-DS-01131-EN-04 (October 2015)

Product Data Sheet

Page 2

Series 380 BTU System, 380CS/HS Meter

380 07000 -1200

Badger Meter®Series 380 BTU System Ordering Matrix

Type

CS - Cold Service 0

HS - Hot Service 1

Size

0.75" 07

1" 10

1.25" 12

1.5" 15

2" 20

Electronic Housing

Polycarbonate 0

Output

Scaled Pulse and RS-485 (Modbus and BACnet) 0

Display

N/A 0

O-Ring

EPDM (CS - Cold Service) 1

Aflas® (HS - Hot Service) 2

Shaft

Tungsten Carbide [Standard] 2

Impeller

Stainless Steel 0

Bearing

Torlon® (CS - Cold Service) 0

Ketron® (HS - Hot Service) 2

DIMENSIONS

450

400

350

PSIG

300

250

200

0 50 100 150 200 250 300

Temp F

*Max. Temp. 250º F 230 PSIG

Unit can be used to –20º F @ 400 PSIG

Top view

Ø8”

360°

Pivot area

case from

center of tee

B

Overall height

C

Tee length

A

Overall length

T2

Custom

RTD tting

1/8 in.

NPT

Hex

PG7 PG9

E

D

Tee/NPT

Size

3/4"

T1

Length 2 meters

Ø6 mm

1"

1.25"

1.5"

2"

Width

A B C D E

6-43/64 in.

(169.5 mm)

6-43/64 in.

(169.5 mm)

7-3/32 in.

(180 mm)

7-21/64 in.

(186 mm)

7-7/8 in.

(200 mm)

7-55/64 in.

(199 mm)

7-55/64 in.

(199 mm)

8-3/64 in.

(204 mm)

8-15/64 in.

(209 mm)

8-1/2 in.

(216 mm)

5-3/8 in.

(137 mm)

5-3/8 in.

(137 mm)

6-15/64 in.

(158 mm)

6-45/64 in.

(170 mm)

7-49/64 in.

(197 mm)

2 in.

(50 mm)

2 in.

(50 mm)

2-3/8 in.

(60 mm)

2-3/4 in.

(70 mm)

3-5/16 in.

(84 mm)

3-31/64 in.

(88 mm)

3-31/64 in.

(88 mm)

3-31/64 in.

(88 mm)

3-31/64 in.

(88 mm)

3-31/64 in.

(88 mm)

Control. Manage. Optimize.

Data Industrial is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous

research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an

outstanding contractual obligation exists. © 2015 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412 Legacy Document Numbers: DTB-083-01

Loading...

Loading...