Page 1

Badger® Series

340N2

METASYS® Compatible

Energy Transmitter

Installation &

Operation Manual

BadgerMeter, Inc.

872033

Rev. 6

4-09

Page 2

IntroductIon

The Badger Meter Series 340N2 Btu transmitter is an

economical, compact device for sub-metering applications

using Johnson Controls Metasys® Network Companion™ and

Facilitator™ Supervisory Systems.

The Badger® Series 340N2 works in conjunction with a

ow sensor and two temperature sensors to calculate

thermal energy by measuring liquid ow and inlet and outlet

temperatures in a closed pipe system. The Series 340N2

requires two 10 kW thermistors for temperature input. The ow

input may be provided by any Badger Meter sensor and many

other pulse or sine wave signal ow sensors.

The onboard microcontroller and digital circuitry make precise

measurements and produce accurate, drift-free outputs. The

Series 340N2 is congured using Badger Meter Windows

®

based programming software. Calibration information for the

ow sensor, units of measurement and output scaling may be

preselected or entered in the eld. Btu transmitter information

is available when connected to a PC or laptop computer. This

information includes real-time ow rate, ow total, both T1 and

T2 temperature probe information, energy rate, and energy

total.

The Series 340N2 transmitter features two LED’s to verify input

and output signals.

The primary output for the Series 340N2 is an isolated solid

state switch closure that is user programmed for units of energy

or ow. The output pulse width is adjustable from 50 mS to 5

sec.

Surface Mount Installation

The Series 340N2 may be mounted to the surface of any panel

using double-sided adhesive tape or by attaching fasteners

through the holes in the mounting anges of the unit.

din rail Mounting

Optional clips snap onto the mounting anges allowing the

Series 340N2 to be attached to DIN 15, 32, 35 mm DIN rail

systems.

Wall Mounting

Optional metal and plastic enclosures are available for the

Series 340N2. The enclosure is rst attached to the wall using

fasteners through its mounting holes.

After wiring, the transmitter may be attached to the enclosure

with the terminal headers facing in using the slots in the Series

mounting anges. As an alternate mounting arrangement, the

340N2 may be fastened to the box cover using double-sided

adhesive tape.

temperature Sensor Installation

The location of the temperature sensors with regard to the ow

sensor is important to the accuracy of the energy calculation.

temperature sensor t1 must be located closest to the

ow sensor. A distance of 5 pipe diameters will give the

greatest accuracy. Always install the temperature sensor

downstream of the ow sensor.

The secondary output is the Johnson Controls N2

communications protocol that allows the Series 340N2 to be

assigned an address and allow all measurement parameters:

inlet and outlet temperature, ow rate, ow total, energy rate

and energy total to be transmitted from as many as 255 units on

a single 3-wire RS-485 bus.

The Series 340N2 Btu transmitter operates on AC or DC power

supplies ranging from 12 to 24 volts.

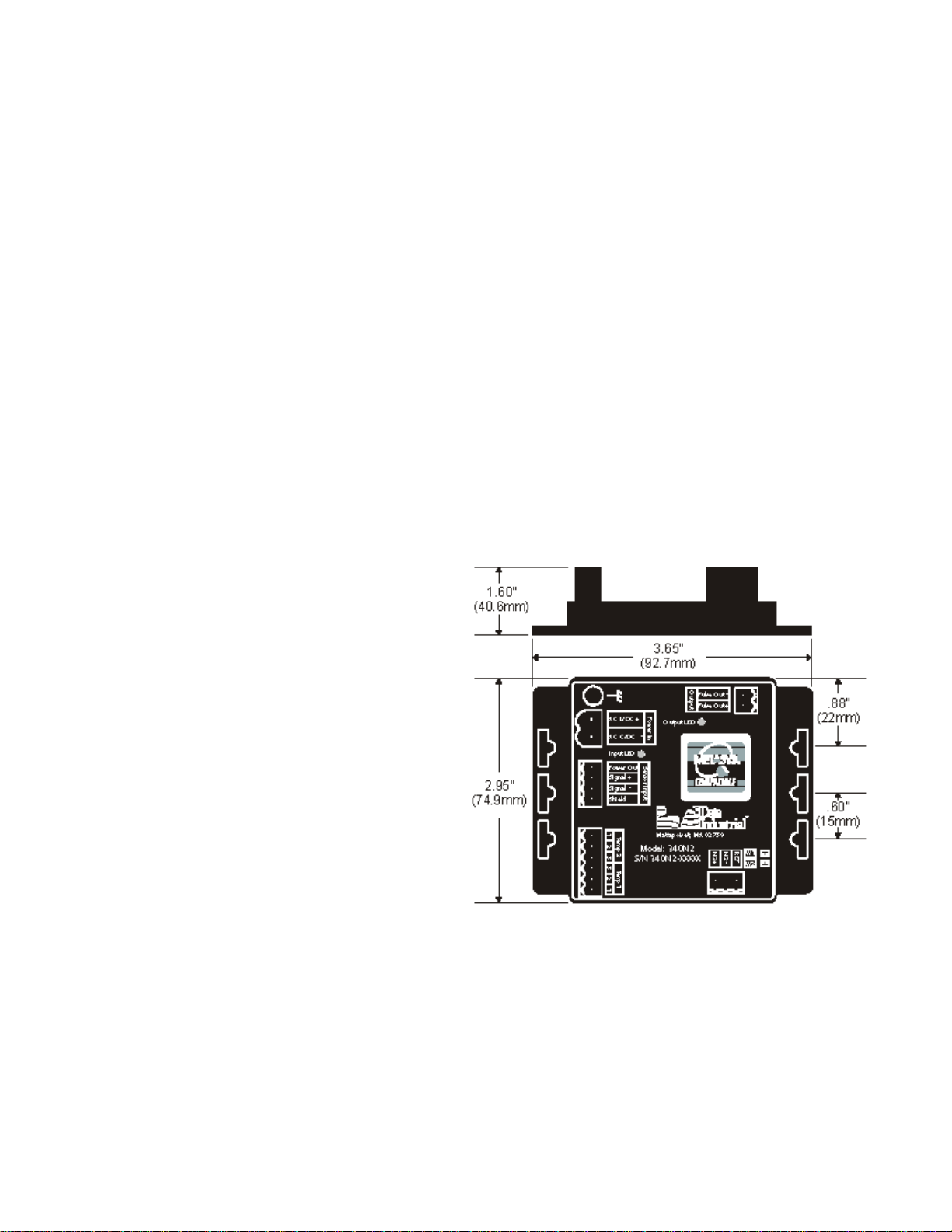

The compact cast epoxy body measures 3.65”(93mm) x

2.95”(75mm) and can be easily mounted in panels, enclosures

or on DIN rails.

InStallatIon

Mechanical Installation

The series 340N2 transmitter may be surface mounted onto a

panel, attached to DIN rails using adapter clips or wall mounted

using optional enclosures.

location

Although the Series 340N2 device is encapsulated, all wiring

connections are made to exposed terminals. The unit should

be protected from weather and moisture in accordance with

electrical codes and standard trade practices.

In any mounting arrangement, the primary concerns are ease of

wiring and attachment of the programming cable.

The unit generates very little heat so no consideration need be

given to cooling or ventilation.

Series 340n2 dimensions

2

Page 3

340n2 Metal Box dimensions

Sensor Wiring

All ow sensor types connect to the four terminal header

labeled “Sensor Input”.

Series 200

Connect the red wire to Series 340N2 Sensor signal (+),

connect the ow sensor black wire to Series 340N2 Sensor

signal (-) and the bare wire to shield.

SdI Series (standard pulse output option)

Connect SDI number 3 sensor signal to the Series 340N2

transmitter sensor signal (+) and the SDI number 2 sensor

common terminal to Series 340N2 transmitter sensor signal

(-). Connect the shield terminal of the SDI sensor to the shield

terminal of the Series 340N2 transmitter.

other Sensors

The Sensor Input power out terminal supplies nominal 12VDC

excitation voltage for 3 wire sensors. Connect sensor signal +

and sensor signal - wires to transmitter terminals.

Note:

The green input LED toggles on and off as sensor pulses

are received. With no ow input the LED will remain in its

last state (either on or off).

340n2 Plastic Box dimensions

Electrical Installation

All connections to the Series 340N2 are made to screw terminals on removable headers.

Power Supply Wiring

The Badger® Series 340N2 requires 12-24 Volts AC or DC to

operate. The power connections are made to the

header. The connections are labeled beside the header.

Observe the polarity shown on the label.

If a Badger Meter plug in type power supply (Model A-1026

or A-503) is used, connect the black/white striped wire to the

terminal marked positive (+) and the black wire to the terminal

marked negative (-).

Note:

Included with every Series 340N2 is a Model 340N2IK kit

containing a screw, lockwasher and ground lead to connect

the Series 340N2 to earth ground. Connect the earth

ground lug of the Series 340N2 to a solid earth ground with

as short a wire as possible. This will help prevent electrical

interference from affecting the Series 340N2’s normal

operation.

oranGE

Side View - Typical Series 300 Removable

connector Wiring

Sample Power Supply Wiring Diagram

3

Page 4

N2+

N2-

REF

2 pmeT

1 pmeT

Model: 340N2

S/N 340N2- XXXX X

W1

W2

FER

2N

-2N+

Mattapoisett, MA 0 273 9

11 22 33

Metasys

®

CPN, FAC,

or NCM

T emp 2

T emp 1

Ma

t

10KΩ Thermistors

Sample Sensor Wiring diagram

temperature Element Wiring

The Badger Meter thermistors are not polarity sensitive.

Connect the thermistor closest to the ow sensor to the Series

340N2 terminal block marked Temp 1 number 3 and number

2. The other thermistor wires to Series 340N2 terminal marked

Temp 2 number 3 and number 2.

Pulse output Wiring

The Badger® Series 340N2 has solid state switch output rated

for a maximum sinking current of 100 mA @ 36 VDC. In

most cases the Series 340N2 pulse out (+) will connect to the

unput pulse (+) and the Series 340N2 pulse out (-) terminal to

the input pulse (-) of the receiving device. The separate two

terminal removable header on the Series 340N2 is labeled

Output. Observe the electrical polarity of the output.

Note:

When the solid state switch is closed the red output LED

will turn on.

connecting the n2 Bus

Observe polarity when connecting the Series 340N2. Connect

the N2+, N2- and Ref to the appropriate connections in the N2

network.

Note:

The Series 340N2 default address must be changed before

it is introduced into an existing network to avoid any pos-

sible address conicts. See programming instructions on

the following page.

Thermistor Wiring Diagram

Sample Pulse Output wiring Diagram

If the Series 340N2 is connected at the beginning or the end of the N2 network, jumpers W1 and W2 can be shorted for

biasing and terminating of the network. The Series 340N2 biasing circuitry is shown in the diagram on the right.

4

Sample wiring to N2 Network

Page 5

Programming the Badger® Series 340n2

Step #1

Select a new N2 address by pressing the

new polling address drop down arrow

Step #2

Press Set Address to select the new

polling address

Step #3

Press Exit to return

to the main screen

Press the Auto Find Address to

search for the Series 340N2

Polling address

Step 1

Press the search button to begin the

search for the Series 340N2 polling

address once an address has been found

press the stop button.

Step 2

Select the detected Series 340N2 address

Step 3

Press the Select button to return to

the N2 polling address window with

the auto find address

Step #1

Press Set Address to select

the new polling address

Step #2

Press Exit to return to the main

screen

To go to the calibration

settings screen select

“parameters” from either

place shown.

Prior to introducing the Badger Series 340N2 onto a N2

network, it needs to be congured for the pipe’s size, desired

units of measure, and its the default network address should

be changed to an unused address to avoid any conicts with

other instruments on the N2 network. Programming the Series

340N2 is accomplished using the Badger Meter PC software.

1. Load the interface software into the computer that was

shipped with the Model A-302 programming cable or download from our website.

2. The Series 340N2 buss connector should be connected to

a Com port using Badger Meter Model A-302 programming

cable. (If not available a B&B Electronics Model 485SD9TB

may be used) The RS232 side should be connected to a

PC Com port and the RS485 side to the Series 340N2.

3. Connect the Series 340N2 transmitter to a power supply.

4. Open the interface software and select the appropriate

Com port as shown in the dialog box below.

5 Select the N2 Protocol as shown below

8. If the Series 340N2 polling address is not known then press

the Auto Find Address button as shown below.

9. Search for the Series 340N2 polling address by following

the steps as shown below.

6. If the Series 340N2 is new from the factory the default

Series 340N2 address is 248. If the selected Series 340N2

address is wrong the unit will not communicate with the

software. To select the correct polling address press the

select button as shown below.

7. If the Series 340N2 has a known address then select it with

the New Polling Address drop down menu as shown below

and press the Set Address button then the exit button.

Proceed to step 11.

10. Then follow the steps as shown below.

11. Open the Parameters Screen as shown below.

12. Program using diagram below as a reference.

13. Set the Series 340N2 address by pressing the Advanced

button in the Parameters window opening the Advanced

Parameters window. Press the Change Device’s Address

button and set as shown below.

5

Page 6

Step 1

see note #1

Select the flow sensor type

(sine or pulse) and enter the

K and Offset -

Step 4

Select the desired flow

rate and total units here

Step 7

Press send to transmit

calibration data to the

Series 340N2

Step 5

Select the desired energy

rate and total units here

Step 2

Select the desired temperature

sensor units.

Step 3

See Note #2

Typically:

Select the method of computing the

temperature differential

T1>T2 for Heating

T1<T2 for Cooling

Step 6

Select the output units per

pulse, and the pulse width

Press to restore the factory default

settings to the screen

must press “send” before values

take effect

Note:

Step 8

Press to exit parameters screen

and to go back to main screen

Press to refresh the parameters screen with

current Series 340N2 settings

Will overwrite any changes not sent to Series 340N2.

See Note #3

Step 1

Select a new device address using the

New Device Address pull down box.

Step 2

Press the Set New Device Address

button to send a new N2 address to

the Series 340N2.

Step 3

Press the Exit button to return

to the Parameters screen

Note #1:

Badger Meter sensors are pulse type sensors. The K and

Offset information is printed in the owners manual shipped with

the product. This information is also available on our website.

Calibration constants for other sensors must be supplied by the

manufacturer.

Note #2

Typically the temperature measured by T1 will be greater

than T2 in a heating application and less than T2 in a cooling

application. The selection of one of these choices will determine

if energy calculations are made for heating only (T1>T2),

cooling only (T1<T2), or both (absolute).

Note #3

The lter coefcient screen allows adjustment of the ow and

energy lters. A scale of 0-10 is used with 10 providing the

greatest degree of smoothing. Settings greater then “10” are

permitted by selecting other. However, settings greater then

“10” should be used with extreme caution as it will cause the

Series 340N2 to respond very slowly to actual changes in ow

and energy. This could cause misreporting of fast changing ow

and energy consumption data. See the dialog box below.

6

Page 7

®

340N2 Point Map

NPT

1

NPA

2

UNITS POINT DESCRIPTION RANGE / VALUENOTES

binary output (2:4)

BO 01 n/aReset Total 1 = reset totals Note 1

float data (1:5, 2:5)

ADF01gpm * (flow rate

conv coeff)

Flow Rate 0-max float

ADF 02 gallons * (flow

total conv coeff)

Flow Total 0-((2^32)-1)

ADF03kBtu/hr *

(energy rate

conv coeff)

Energy Rate 0-max float

ADF04Btu * (energy

total conv coeff)

Energy Total 0-((2^32)-1)

ADF05°F or °C Temp1

ADF06°F or °C Temp2

ADF07n/a Flow Rate Conversion Coefficient 0-max float

ADF08n/a Flow Total Conversion Coefficient 0-max float

ADF09n/a Energy Rate Conversion Coefficient 0-max float

ADF0An/a Energy Total Conversion Coefficient 0-max float

integer data (1:6, 2:6)

ADI01n/a Temperature Units (0-1)Note 2

Note 1: This point resets flow and energy totals when sent an override of value 1. It will

recognize this command, but keep a value of 0 always.

Note 2: 0 = Fahrenheit, 1 = Centigrade

1

Network Point Type

2

Network Point Address

Metasys

To incorporate point data into the Metasys Network and the Metasys Companion Network the following Point Map is provided

Network Setup

Series 340n2 Point Map

Badger Meter, Inc. has decided not to implement the change

of state feature in our Badger® Series 340N2 Btu transmitter.

By our decision not to use this feature, normal Metasys COS

(alarm limits for analog values and normal condition for binary)

notication will be defeated. If COS notication is required, it is

necessary for the operator to perform the following:

1) Map the specic object(s) requiring COS to a CS

object.

2) Dene an AD or BD object with the CS object of

the required COS point, as the associated in.

3) Assign alarm limits to the AD.

4) The AD or BD point will only be scanned at a

5) The normal state of the BO must be updated

Analog/binary input points that are mapped in directly that do

not support COS will never report a change of state condition.

They will report the current value when read, but no alarm

notication will occur. A read will only occur if a focus window is

open or a feature requires the current value.

minimum of 30 seconds.

(written to) by GPL.

7

Page 8

SPEcIFIcatIonS

Power

Power supply options:

12-35 VDC +/- 5%

12-24 VAC +/- 10%

Current Draw:

60 mA @ 12 VDC

n2 output

RS-485 output compliant with

EIA / TIA - 485 standards

operating temperature

-29° C to +70° C

-20° F to +158° F

Flow Sensor Input

All sensors:

Excitation voltage 3 wire sensors:

7.9 – 11.4 VDC 270W source impedance

Pulse type sensors:

Signal amplitude:

2.5 VDC threshold

Signal limits:

Vin < 35V (DC or AC peak)

Frequency:

0-10kHz

Pull-up:

2 kW

Sine wave sensors:

Signal amplitude:

10 mV p-p threshold

Signal limits:

Vin < 35V (DC or AC peak)

Frequency:

0-10kHz

temperature Sensor Input

2 required:

10 kW thermistor, 2 wire, type II, 10 kW @ 25°C

Pulse output

Opto-isolated solid state switch

Operating Voltage range:

0 - ±60V (DC or AC peak)

Closed (on) state:

Load Current - 700mA max. over operating temperature

range

On-resistance - 700mW max. over operating temperature

range

Open (off) state – leakage @ 70°C

<1µA @ 60V (DC or AC peak)

Storage temperature

-40° C to +85° C

-40° F to +185° F

Weight

4.8 oz. with headers installed

SEnSor calIBratIon

Badger Meter

Use K and Offset provided in sensor owner’s manual

other Sensors

Check with factory

unItS oF MEaSurE

Flow measurement

Rate:

gpm, gph, l/sec, l/min, l/hr, ft3/sec, ft3/min, ft3/hr, m3/sec,

m3/min, m3/hr

Total:

gallons, liters, cubic feet, cubic meters

Energy measurement

Rate

kBtu/min, kBtu/hr, kW, MW, hp, tons

Total

Btu, kBtu, MBtu, kWh, MWh, kJ, MJ

temperature units

Fahrenheit, Centigrade

ProGraMMInG

Requires PC or laptop running Windows

®

XP or Vista

Badger Meter Model A-302-20 programming kit containing

software and Model A302-20 programming cable

8

Page 9

FACTORY DEFAULTS

Default Values Customer Values

Serial Number n/a

Version n/a

Temperature Units °F

Sensor Type Pulse

K= 1

Offset= 0

Flow Rate Units gpm

Flow Total Units gallons

Energy Rate Units kBtu/hr

Energy Total Units Btu

Energy Calculation absolute

Flow Filter 0

Energy Filter 0

Scaled Pulse Output Units energy

Scaled Pulse Output Units Per Pulse 1

Scaled Pulse Output Pulse Width 100

9

Page 10

10

Page 11

(This page intentionally left blank.)

11

Page 12

(This page intentionally left blank.)

Badger® and Data Industrial® are registered trademarks of Badger Meter, Inc.

Metasys® is a registered trademark of Johnson Controls.

Windows® is a registered trademark of Microsoft Corporation.

Please see our website at www.badgermeter.com

for specific contacts.

Copyright © Badger Meter, Inc. 2009. All rights reserved.

Due to continuous research, product improvements and enhancements, Badger

Meter reserves the right to change product or system specifications without notice,

except to the extent an outstanding contractual obligation exists.

BadgerMeter, Inc.

6116 E. 15th Street, Tulsa, Oklahoma 74112

(918) 836-8411 / Fax: (918) 832-9962

www.badgermeter.com

Loading...

Loading...