Page 1

Badger® Meter Accuracy

Models 340, 340LW, and

340N2,

Series 1550 and 2300

Btu Meter System Accuracy

Technical

Brief

The purpose of this technical brief is to explain the basis of the

statement of accuracy for the Badger Meter Series 2300, 1550 and

340 Btu meters. On the basis of tests and theoretical analysis, these

meters are stated to be accurate within ± 0.48%. The balance of

this note justifi es the claim, and provides information on the effects

of the accuracy of the sensors used for input to the meters.

A method of specifi cation of Btu meter accuracy has not as yet

been determined by any recognized body, and such specifi cation

is currently reported by the various manufacturers of this type of

instrument as their best estimate of the performance of the various

proprietary designs they offer. The fi nal accuracy of the meter is af-

fected by the installation of the individual input sensor components

and by the parameters under which they operate, and indeed may

be dependent on the confi guration of ancillary systems to which they

are connected. Any instrument accuracy claim by any supplier of Btu

measuring systems should be carefully studied by the potential user,

to reach a clear understanding of the basis of the such claims.

The energy content in any fl uid system is a function of the pressure

and temperature of the fl uid being monitored. The rate of energy

pumped into a heated volume or out of a refrigerated volume, is a

function of the difference in pressure and temperature between the

inlet conditions and the outlet conditions, and of the fl uid velocity.

The function of a Btu meter is to transform these measurable phenomena, into a rate of energy transfer, e.g. Btu/minute.

Most commercially available Btu meters function by combining either

volumetric or mass fl ow rate transducer output with outputs from two

temperature transducers, one located at the entrance to the metered

volume and one at the exit. The effect of pressure on variation in

isothermal energy content is under ± ¼% in the temperature region

from 50°F to 150°F at pressures below saturation pressure at the

given temperature. Thus for operation in this range, the energy content with variations in pressure is usually neglected. Errors caused

by not compensating for the effect of pressure on specifi c enthalpy

increase rapidly as operating temperature approaches 32°F.

to raise the temperature of one pound (mass) of water exactly 1°F,

without regard to the variation in mass density of water with temperature. Thus, a 1°F temperature rise for 1 gallon of water is, in

these terms, 8.337 Btu. This assumption can result in large errors

over relatively low temperature differentials when the water is at high

input temperatures. For example, in a 50 psia (35.3 psig) system

operating at 220 °F inlet and 210°F outlet, this assumption has a

built-in error of 3.3%, before any consideration is given to calculation

errors in the meter software, in A to D conversion of the temperature

sensor signal, and in basic sensor calibration errors.

ERROR SOURCES

Errors in any non-pressure compensated Btu meter installation are

the result of:

1. Built in systematic errors in the basic meter. These include:

a. Method of compensation for changes in density of

the metered fl uid that are temperature and pressure

dependent.

b. Conversion errors in relating temperature sensor

output to Temperature. (The effect of this error in the

Btu calculation in a condition of low temperature difference (∆T) between the inlet and outlet temperature

sensors can be an error source, but such errors are

normally far smaller than errors resulting from the

basic errors in sensor calibration.)

c. Conversion errors in relating fl ow signal input to a

calculated fl ow rate.

2. Basic errors in transducer calibration and installation. These

include:

a. Flow meter calibration error

b. Temperature sensor calibration error

c. Installation wiring for temperature sensors

Error analysis has been performed on each of the above sources

with the following results.

This basic data input, from the fl ow rate and temperature transducers,

is manipulated mathematically to provide a rate of energy transfer

within the monitored volume. While the effect of pressure on energy

content is not monitored, an average value of Btu per pound mass

is used in the calculations as a means of compensation of the pressure effect. This simplifi cation results in some loss in accuracy in the

instrument reading as discussed above. The actual error will vary

depending on the method used by the instrument manufacturer to

compensate for this unavoidable simplifi cation required by using

temperature transducers only.

Many Btu meters using volumetric fl ow rate sensors take an even

more simplistic approach, assuming that 1 Btu is the heat required

BadgerMeter, Inc.

1. Systematic errors in the Btu meter:

a. Compensation for density changes:

The Series 340, 1550 and 2300 Series Badger Meter

Btu meters convert the volumetric fl ow rate entering

the metered area to an enthalpy fl ow rate by converting

the volumetric rate at operating temperature, to a mass

fl ow rate based on the specifi c density of the fl uid at the

incoming temperature. The resulting mass fl ow rate is

then converted to an incoming Btu (enthalpic) rate by

using an adjusted average specifi c enthalpy of water

over the temperature range from 32°F to 250°F and the

pressure range of 15 to 50 psia. The fi tting constants are

derived from ASME Steam Tables, Ed IV, published by

the American Society of Mechanical Engineers (1983).

Applied to a metered area operating within the range

of 32 - 250°F, with a 5 psia DP and a 10°F ∆T between

the inlet and outlet, the algorithm as implemented has

an inherent error of ± 0.43% maximum over the entire

DTB-051-01

4-09

Page 2

range. Standard error of the algorithm results based on

actual steam table values is 0.237%.

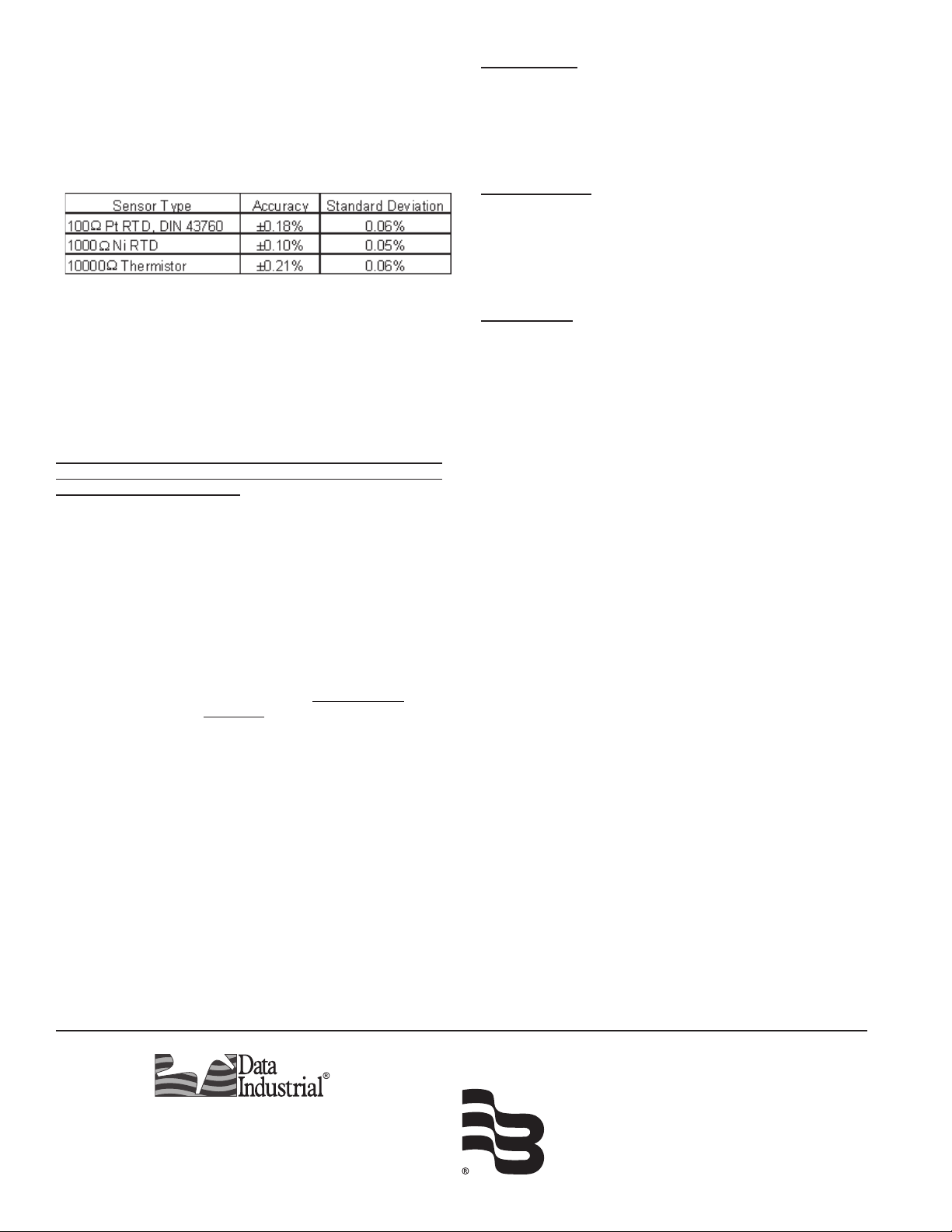

b. A/D Conversion errors, temperature sensors:

By actual test in the Badger Meter laboratories, using a

precision resistor decade box to simulate temperature

sensor resistance, the following % error data over the

input range of 32°F to 250°F data was developed:

THERMISTORS: (used in Badger® Series 2300, 1550, and 340)

10,000Ω @ 25°C (77°F) thermistor temperature transducers

are commercially available as ±0.8°F interchangeable devices.

Analysis of resistance/temperature data indicates that the

error band actually achieved is a smooth non-linear function

decreasing from ± 1.01% @ 32°F to ±0.57% @ 212°F and then

increasing to ±1.17% @ 250°F.

PLATINUM RTDs: (optional in Series 2300)

0.00385Ω/Ω/°C, 100Ω @ 0°C, RTD transducers are commer-

cially available as conforming to IEC 751. Analysis of resistance/

temperature data indicates that the error band actually achieved

is a smooth non-linear function monotonically increasing from

± 0.45°F (1.41 %) @ 32°F to ±0.70°F (0.58%) @ 120°F and

then increasing to ± 1.0°F (0.40%) @ 250°F.

c. A/D Conversion errors, fl ow rate calculation:

Flow rate is measured by the internal system clock which

is accurate within ±3 microseconds. The usual frequency

range for DI sensors is from 3 Hz to 200 Hz, with concomitant periods of 250 milliseconds to 5 milliseconds.

The greatest % error thus occurs at the 200 Hz level or

±0.06%. Calculations are carried out to 7 decimal digits

for a maximum error of 10

-5

% (0.00001%).

The total basic error of the instrument is found by adding, in

quadrature, the individual errors listed above, or ±0.48% for the

model described in 1.a above

2. Basic errors in transducer calibration and installation:

a. Flowmeter calibration error:

For the purpose of this note, fl owmeter calibration er-

ror is the variation from true fl ow rate and that resulting

from the use of the calibration constants supplied by the

manufacturer. This error affects the reported values of

Btu/minute directly, and is independent of the instrument

itself. All other things being equal, the % error in fl owmeter

calibration produces the same % error in Btu output.

b. Temperature sensor calibration errors:

Temperature sensor calibration error affects the accuracy

of the reported energy fl ow, with increasing error as the

operating ∆T decreases. For example, in a system operating at a 5°F ∆T using two sensors each with an error

of ± 1°F will produce an error of ± 40%. The practice of

trimming the paired temperature sensors so that their

temperature output is identical at one measurement

point can reduce the effect of calibration error, provided

that this is done at the mean operating temperature.

This zeroing practice could actually increase the error

in the readout if performed at temperatures outside the

operating range.

NICKEL RTDs: (optional in Series 2300)

A multitude of Nickel RTDs are available, frequently to proprietary

designs, although DIN 43760 may govern the basic specifi ca-

tions. There is little available information on the temperature/

resistance tolerances achieved with this sensor, and thus little

can be said here. The rule of thumb should be to use as precise

a sensor as is economical for the installation. (Of course, the

same recommendation applies for thermistors and platinum

RTDs, as well.) Note that use of nickel RTDs should be referred

to the instrument manufacturer, with temperature/resistance

data, so that the proper conversion algorithm can be supplied

with the delivered instrument.

c. Installation wiring for temperature sensors:

Wiring of the temperature sensors and the fl ow rate

transducer should follow the instrument suppliers wiring

specifi cations. Generally, for the fl ow rate transducer,

shielded twisted pairs of appropriate size should be

used with careful attention to any special grounding

instructions.

The temperature sensor wiring deserves special attention. Wire sizes appropriate to the basic sensor resistance

should be used. Splices in either or both leads from each

sensor must be avoided, and termination connections

should be carefully used. 100Ω RTDs should be wired

to apply at least a 3-wire bridge connection. Thermistors

and 1000Ω or higher nickel RTDs are less sensitive to

lead resistance. Thermistors are usually wired using a

two wire twisted shielded pair. 1000Ω and higher RTDs

are usually used to avoid the 3 or 4-wire bridge type of

wiring confi guration.

Badger® and Data Industrail® is a registered trademark of Badger Meter, Inc.

Due to continuous research, product improvements and enhancements, Badger

Meter reserves the right to change product or system specifications without notice,

except to the extent an outstanding contractual obligation exists.

Please see our website at www.badgermeter.com

for specific contacts.

Copyright © Badger Meter, Inc. 2009. All rights reserved.

BadgerMeter, Inc.

P.O. Box 581390, Tulsa, Oklahoma 74158

(918) 836-8411 / Fax: (918) 832-9962

www.badgermeter.com

Loading...

Loading...