Page 1

Badger® T-Series

Series 340, 1550 &

2300

2-Wire 10K Thermistors Btu Monitor

Temperature Sensors

Technical

Brief

Badger Meter's Series 340 Btu T ransmitter , 1550 Energy Monitor,

and 2300 Btu Energy Monitor each require two temperature

sensors, as well as a flow sensor , to operate. The proper selection

and placement of the temperature sensors is extremely important

to the operation of these Btu monitors. There are a number of

options available to help maximiz e the efficiency of Btu monitoring.

The following are a f e w hints to help fully take advantage of the

Badger Meter monitoring capabilities.

The temperature sensor is based on a 10kΩ thermistor. A

thermistor is actually a resistor made of specific semiconductor

material whose resistance decreases as the temperature around

it increases. Thermistors should NO T be confused with thermocouples, which are fabricated from two dissimilar conductors

joined at the ends, as where the junction is heated, the voltage

across it becomes proportional to the rise in temperature.

The actual resistance values for Badger Meter thermistors are

based on all temperature sensors being 10kΩ resistance at

25° C. 25° C is the industrial standard used as the main point

of reference for most thermistor calibration. The following chart

references the change in resistance values relative to changes

in temperature. Note that at 25° C (77° F) the resistance value

is 10,000 ohms.

°C °F Resistance

0 32 32,654 Ω

10 50 19,903 Ω

20 68 12,493 Ω

25 77 10,000 Ω

30 86 8,056 Ω

40 104 5,325 Ω

50 122 3,602 Ω

60 140 2,488 Ω

70 158 1,753 Ω

80 176 1,257 Ω

90 194 917 Ω

100 212 679 Ω

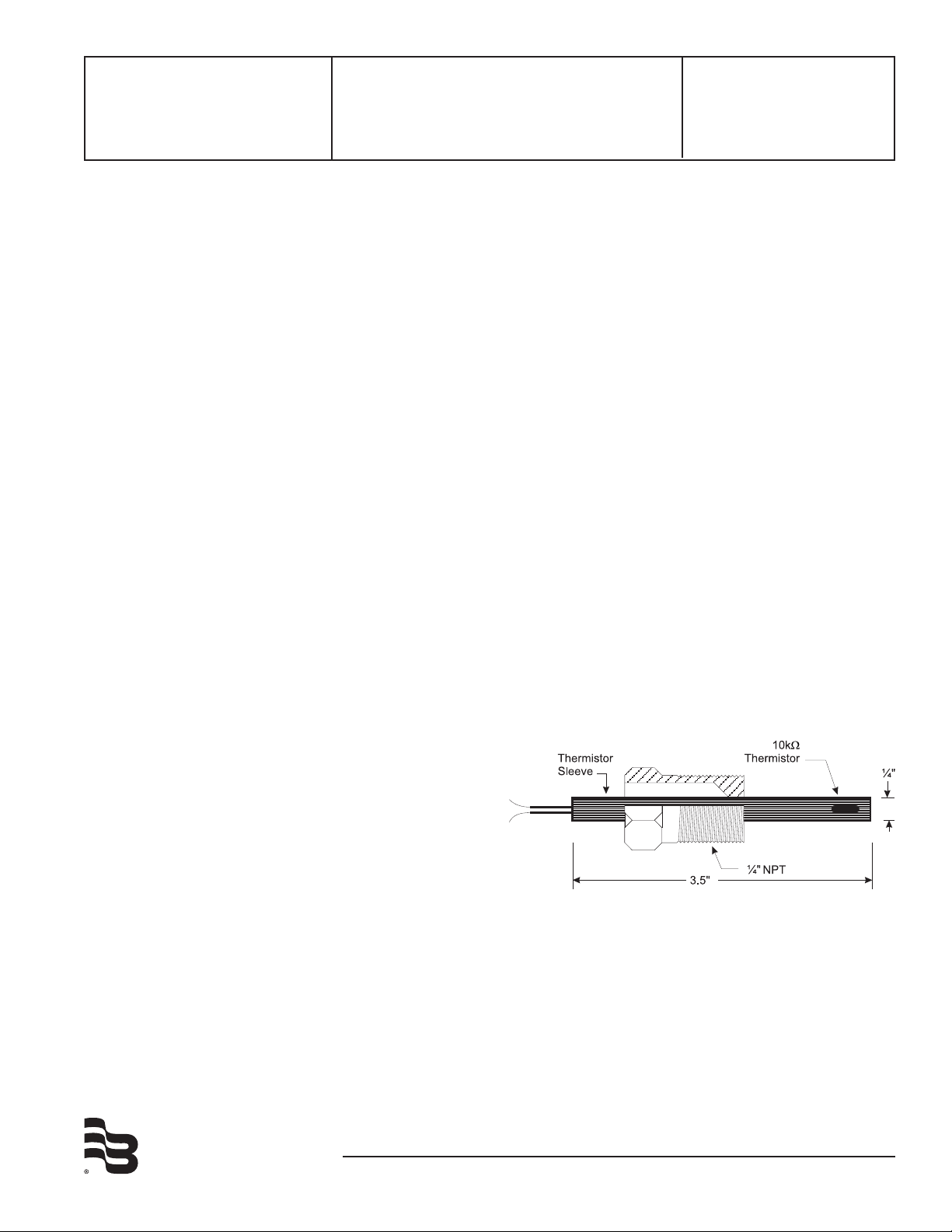

The simplest temperature sensor option is a 1/4 inch tube, 3 ½

inch long with ½ inch NPT pipe connections. The thermistor is

potted solid inside the tube fixture. The potting is used to eliminate

any air pockets from forming around the temperature sensitive

areas of the 10kΩ thermistor. If air is present, it will act as an

insulation barrier to the thermistor, adversely affecting the heat

transfer coefficients of the tubing wall, the potting material, and

the semiconductor material itself. The quality built into the Badger

Meter temperature sensors allows minimum variation from sensor

to sensor. Each temperature sensor can be replaced without

affecting either the other temperature sensor or the accuracy

of the Btu calculations. Individual circuit adjustments are NOT

required when changing temperature sensors.

PROTECTING TUBE CONFIGURATION

Badger Meter temperature sensors are available as a thermistor potted in protecting tube for direct insertion or for use with a

thermowell. The T106 has an adjustable length and a ¼” process

connection so it can be used in line sizes from ½” and up. The

sensing portion of the probe is at the tip and must be mounted

so that the tip is completely immersed in the direct fl ow stream.

All sensors measure not only the fl uid they are in, but also the

mass and effect of their own body to the fl uid stream.

For higher velocity or pressure systems or for industrial applications in larger pipe sizes, we suggest that thermowells be used.

A thermowell is a sleeve assembly that protects the temperature

sensing device from direct damage by higher velocities, and also

allows ease in service or replacement of the thermistor elements

without draining or shutting down of the fl uid system.

Badger Meter thermistors' accuracy is ±0.2° C. They can

operate accurately from 0° C (32° F) to 70° C (158° F) with

maximum temperature of 110° C (230° F), and are designed

for use with liquid heating and cooling media. The maximum

distance between a temperature sensor and any Badger Meter

Btu monitor is 500 feet.

BadgerMeter, Inc.

DTB-030-01

4-09

Page 2

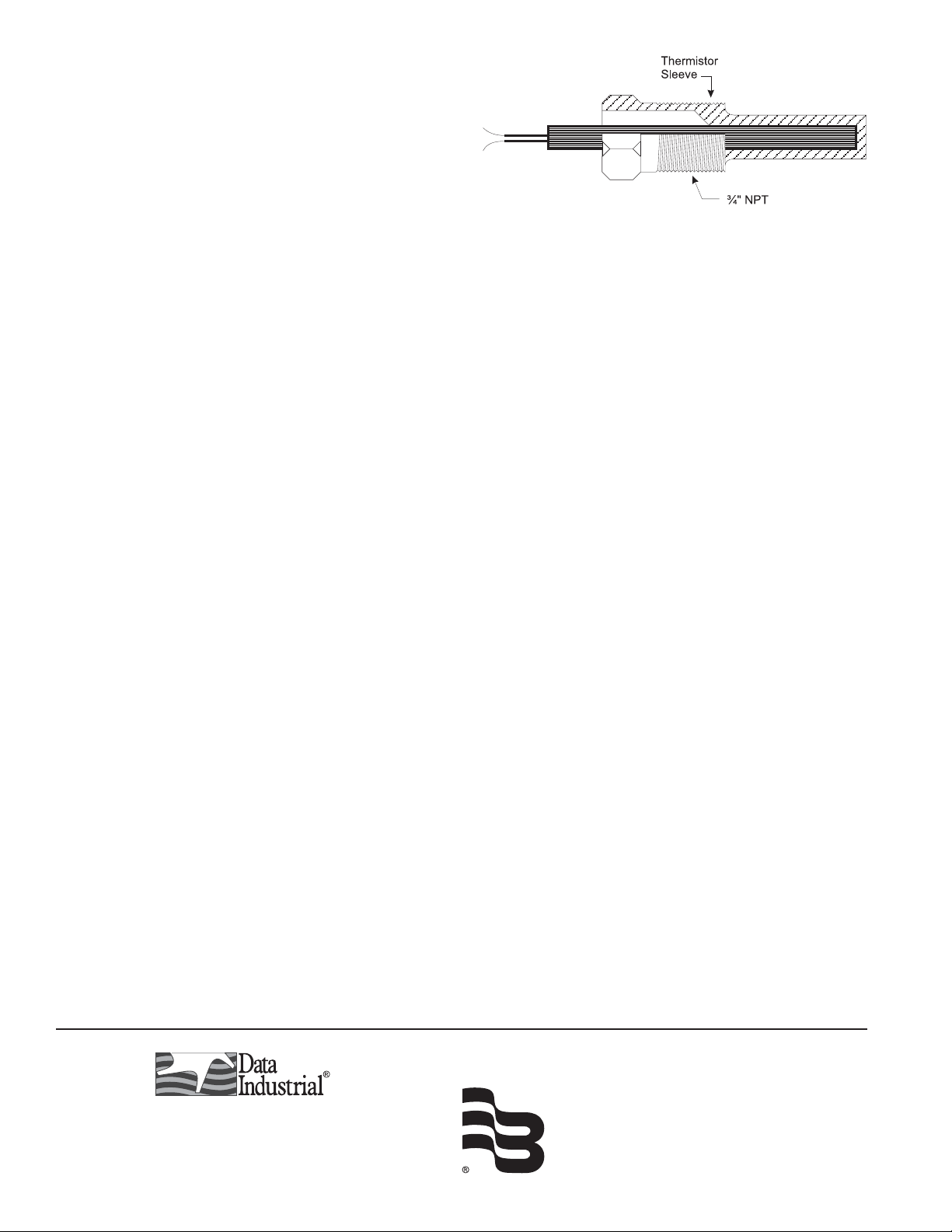

THERMOWELL STYLE

Thermowells also allow deeper sensor penetration into larger

piping systems. A general rule is to allow the sensing area of the

thermowell to be as close to the actual center of the pipe I.D. as

practical. This helps make the response time of the thermistor

faster and more representative of the actual fluid temperature.

Badger Meter offers a number of optional thermowells. When

the actual thermistor sleeve is mounted at the bottom of the thermowell, make sure some type of heat transf er material (silicone

grease) is used to fill the area between the I.D . of the thermowell

and the O.D. of the thermistor tubes. This mater ial serves the

same purpose as potting the actual thermistor element in the

tube assembly previously discussed. The thermistor sleeve is

held in the thermowell by a threaded retainer.

Badger® and Data Industrial® is a registered trademark of Badger Meter, Inc.

Due to continuous research, product improvements and enhancements, Badger

Meter reserves the right to change product or system specifications without notice,

except to the extent an outstanding contractual obligation exists.

Please see our website at www.badgermeter.com

for specific contacts.

Copyright © Badger Meter, Inc. 2009. All rights reserved.

BadgerMeter, Inc.

P.O. Box 581390, Tulsa, Oklahoma 74158

(918) 836-8411 / Fax: (918) 832-9962

www.badgermeter.com

Loading...

Loading...