Page 1

Badger® Series 330

®

Industrial

Power Out

(+)

(-)

Shield

AC Load/DC +

AC Common/DC -

DIC Comm.

Port

Output

Input

®

Model: 330

SN# 0000000

N.O.

ComA

N.C.

ComB

Hi

Com

Low

Programmable - Set-Point

Relay Control

Installation &

Operation Manual

BadgerMeter, Inc.

872039

Rev. 6

4-09

Page 2

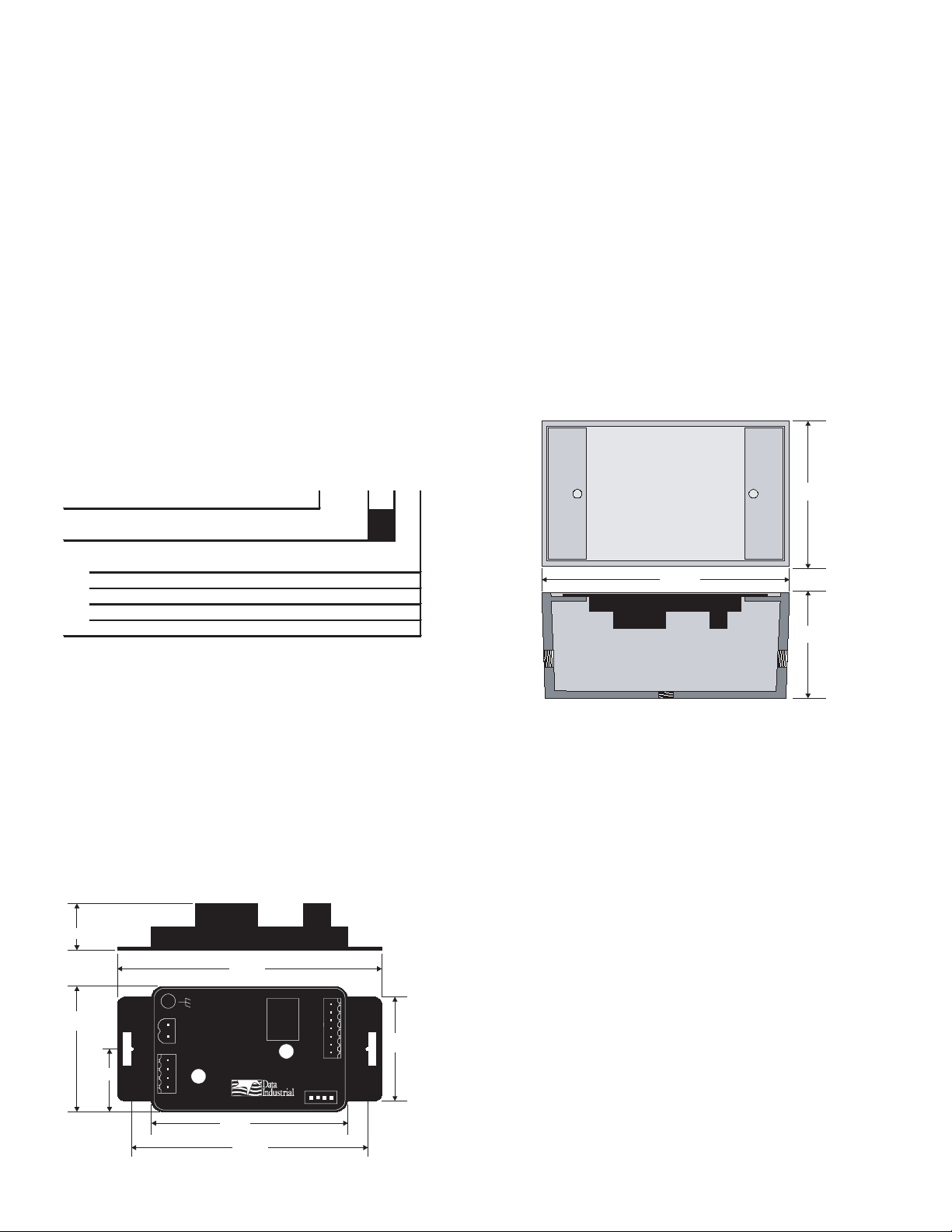

1.50”

3.65”

3.25”

.875”

1.75”

Side

1.50”

2.75”

®

Industrial

Power

(+)

(-)

Shield

AC Load/DC +

AC Common/DC -

DIC Comm.

Port

Output

Input

®

Model: 330

SN# 0000000

NO1

NO2

NC1

NC2

Hi

Com

Lo

The Badger® Series 330 is a compact, programmable relay

EXAMPLE:

330 - xx

Series

Programmable Local Relay Control

330

Options

Transmitter Only

00

W / NEMA 4X Enclosure

01

W / Metal Enclosure 02

W / Plastic Enclosure 03

W / DIN Rail Mounting Clips 04

Series 330 Ordering Matrix

Side

4.5”

2.8”

2.0”

TOP

SIDE

control capable of converting the signal from a Badger Meter

flow sensor into a flow switch.

any panel using double sided adhesive tape or by attaching

fasteners through the holes in the mounting flanges of the

unit.

With an onboard microcontroller and digital circuitry, the

Badger Series 330 is programmed from a Windows® based

computer program. This eliminates the need to set dip

switches or potentiometers and produces precise, accurate

and drift free control of the relay outputs. In addition to

accepting the Badger Meter square wave signal, the Badger

Series 330 can accept other pulse and sine wave inputs.

The compact cast epoxy body measures 1.75” (44mm) x

2.75” (70mm) x 1.5” (38mm) and can easily be mounted to

panels, DIN rails or enclosures. With multiple inputs, ease of

use and a variety of enclosures, the Badger Series 330 is a

powerful, competitive priced relay control.

INStallatION

Mechanical installation

The Badger Series 330 transmitter may be surface mounted

onto a panel, attached to DIN rails using adapter clips or wall

mounted using two optional enclosures.

Series 330 Ordering Matrix

DIN Rail Mounting

Optional clips snap onto the mounting flanges allowing the

Series 330 to be attached to DIN 15, 32, 35 mm DIN rail

systems.

Wall Mounting

Optional metal and plastic enclosures are available to mount

the Badger Series 330 to a wall when no other enclosure is

used. The enclosure is first attached to the wall using fasteners through its mounting holes.

After wiring, the transmitter may be attached to the enclosure with the terminal headers facing in using the slots in

the mounting flanges. As an alternate mounting arrangement, the Series 330 may be fastened to the box cover using

double-sided adhesive tape.

location

Although the Badger Series 330 device is encapsulated,

all wiring connections are made to exposed terminals.

The unit should be protected from weather and moisture

in accordance with electrical codes and standard trade

practices.

In any mounting arrangement, the primary concerns are

ease of wiring and attachment of the programming cable.

The unit generates very little heat so no consideration need

be given to cooling or ventilation.

Surface Mount Installation

The Badger Series 330 may be mounted to the surface of

2

Series 330 Dimensions

Series 330 Optional Enclosure Dimensions

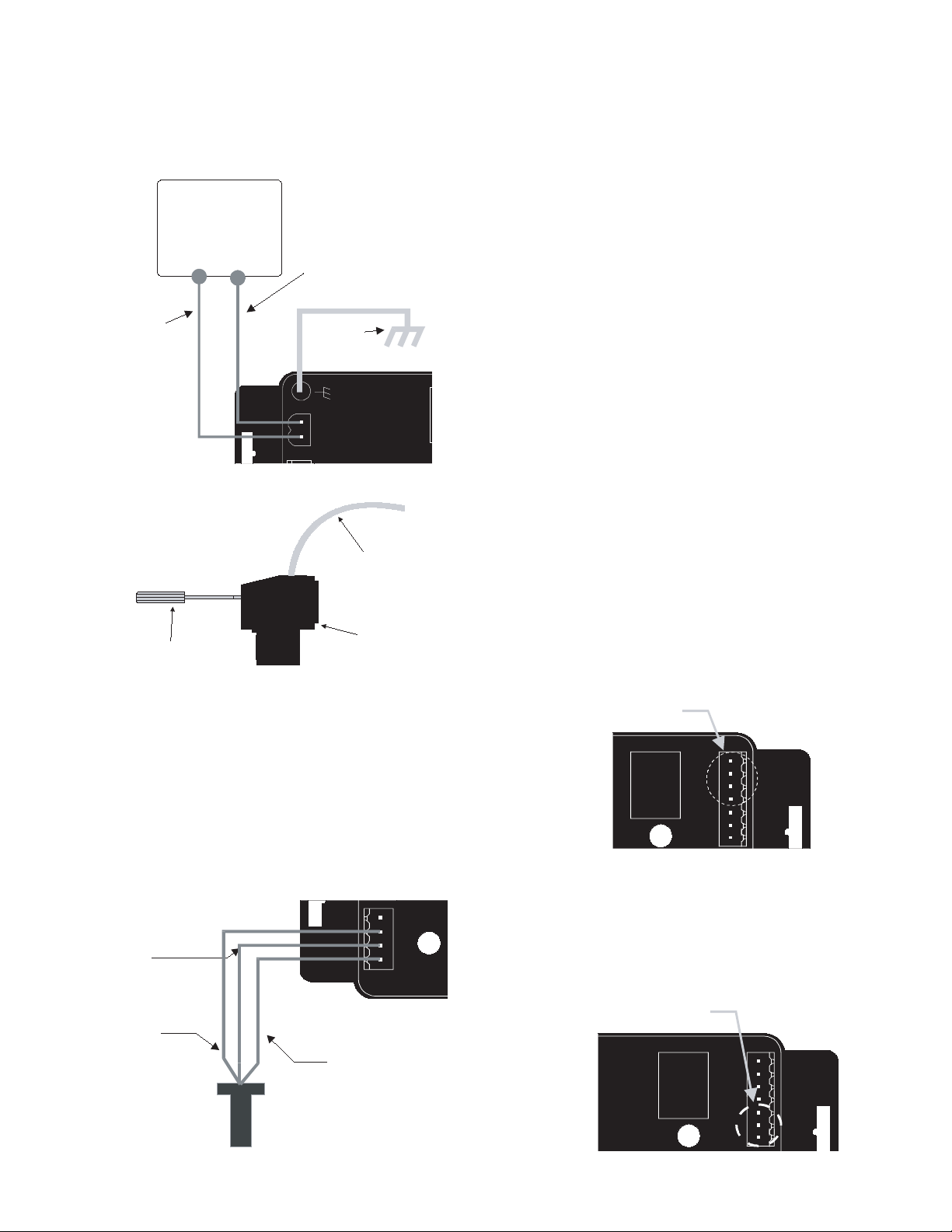

Electrical Installation

All connections to the Badger Series 330 are made to screw

terminals on removable headers.

Power Supply Wiring

The Badger Series 330 requires 12-24 Volts AC or DC to

operate. The power connections are made to the ORANGE

header. The connections are labeled beside the header.

Observe the polarity shown on the label.

If a Badger Meter plug in type power supply

(Model A-1026 or A-503) is used to connect the black/white

striped wire to the terminal marked positive (+) and the black

wire to the terminal marked negative (-).

Page 3

®

Industrial

AC Load/DC +

AC Common/DC -

N.O.

ComA

N.C.

ComB

Hi

GND

Low

DC +

or

AC Load

DC -

or

AC Common

Earth

Ground

AC or DC

Power Supply

3/32” Flathead

Screwdriver

Series 300

Connector

Wire

Note:

®

Industrial

Power

(+)

(-)

Shield

AC Load/DC +

AC Common/DC -

DIC Comm.

Port

Output

Input

®

Model: 330

SN# 0000000

N.O.

ComA

N.C.

ComB

Hi

GND

Low

Red

Black

Shield

(if applicable)

Series 200

or

SDI

NO1

NO2

NC1

NC2

Hi

Com

Lo

Remote Reset

NO1

NO2

NC1

NC2

Hi

Com

Lo

Relay

Included with every Series 330 is a Series 330IK kit

containing a screw, lock washer and ground lead to

connect the Series 330 to earth ground. This will help

prevent electrical interference from affecting the Series

330’s normal operation.

Sample Power Supply Wiring Diagram

(-) on the Badger Series 330.

3) Connect the Bare wire (if applicable) of the sensor to

the Shield terminal on the Series 330.

If sensor is a Badger Series 4000 then:

1) Connect the red wire of the Series 4000 to Power on

the Series 330.

2) Connect the black wire of the Series 4000 to the

Sensor (-) on the Series 330.

3) Connect the clear wire of the Series 4000 to the

Sensor (+) on the Series 330.

4) Connect the bare wire of the Series 4000 to the Shield

on the Series 330.

If sensor is a SDI Series with standard frequency (pulse)

output then:

1) Connect terminal 3 (sensor signal) of the SDI to

Sensor (+) on the Badger Series 330.

2) Connect terminal 2 (sensor common) of the SDI to

Sensor (-) on the Series 330.

3) Connect the terminal 1 (shield) of the SDI to the Shield

on the Series 330.

If sensor is a Non Badger Meter Flow Sensor:

The sensor input power terminal supplies nominal 9.1VDC

excitation voltage for 3 wire sensors. Connect sensor signal

+ and sensor signal - wires to transmitter terminals.

Side View - typical Series 300

Removable Connector Wiring

Sensor Wiring

All flow sensor types connect to the four terminal header

shown in the “sample sensor wiring diagram.”

If sensor is a Badger

®

Series 200 then:

1) Connect the Red Wire of the sensor to Sensor signal

(+) on the Badger Series 330.

2) Connect the Black wire of the sensor to Sensor signal

Relay Output Wiring

The Badger Series 330 is supplied with a removable DPST

relay with normally open and normally closed contacts. To

wire to the normally closed contacts connect to the terminals

“NC1” and “NC2”. To wire to the normally open contacts

connect to the terminals “NO1” and “NO2”. Note: this relay

may be used as a Form C relay. Use a jumper to connect

one terminal from each set together as the common

terminal.

Relay Location

Remote Reset Switch Wiring (if applicable)

The “Hi”, “Com”, and “Lo” terminals on the Badger Series

330 are used for a remote reset. If the remote reset device

provides a momentary dry contact closure - then connect

to the “Lo” and “Com” terminals. If the remote reset device

provides a momentary voltage (up to the supply voltage to

the Series 330) - then connect to the “Hi” terminal.

Sample Sensor Wiring Diagram

Remote Reset Location

3

Page 4

Communications Cable Wiring

DIC Com port

®

Industrial

DIC Comm.

Port

®

N.O.

ComA

N.C.

ComB

Hi

GND

Low

Field calibration requires a Badger Meter Series A330

Programming kit (consisting of a custom cable and software)

and a PC running Windows® XP or Vista. In order to

program, the Badger® Series 330 must be connected to

power, and the Series A301 cable must be connected to the

Series 330 Com port connector and an available 9-pin Com

port on a computer.

Note:

The Badger Meter Series A301 Cable will work with all

Series 300 products. However the older version of the

cable (A300) does not have sufficient bandwidth to work

with the Series 340 transmitters.

Badger Meter provides free programming software updates

via the Internet for all Badger Series 300 devices. Go to

www.badgermeter.com for these updates.

DEFINItIONS:

High alarm – A condition where if the flow rate exceeds

the set point the relay is energized.

low alarm - A condition where if the flow rate drops below

the set point the relay is energized.

Set Point – The flow rate that will trigger the event. (i.e.

energize the relay).

Release Point – The flow rate that will de-energize the relay.

Set Point Delay – A time interval in seconds between the

point when the flow rate crosses the set point and the relay

energizes.

Release Point Delay - A time interval in seconds between

the point when the flow rate crosses the release point and

the relay de-energizes.

latch – A function that will hold the relay in the energized

state until reset even if the flow rate crosses the release

point.

Remote Reset - Reset is the ability to interrupt all timing

functions and return them to the initial programmed settings

and/or de-energize the relay coil that has been latched as a

result of an alarm function.

Location of the

DIC Com port

PROgRaMMINg

Programming the Badger Series 330 is accomplished by

installing the Badger Meter programming software on a

computer and entering data on templates of the Windows®

based program.

1. Load the interface software into the computer.

2. Connect the computer to the Series 330 transmitter with

the Badger Meter Model A-301 communications cable

to the socket labeled “D.I.C Com port”, taking care to

properly align the tab on the plug and socket to maintain polarity. Connect the DB9 connector of the Badger

Meter Model A301 communications cable to a PC Com

port that has the Series 330 software installed.

3. Connect the Series 330 transmitter to a power supply.

4. Open the interface software and select the appropriate

Com port as shown in the dialog box below.

This reset may be accomplished by momentarily

disconnecting the power supply or connecting an external

device to the reset terminals.

Filter Coefficient - An averaging routine that smooths out

unstable flow. The non-linear reference scale from 0-9

defaults to a value of 2. Do not change unless flow changes

interfere with the control functions.

6. Program using the diagram below as a reference.

5. Open the Parameters Screen as shown below.

4

Page 5

SPECIFICATIONS

Power

Power Supply Options

12-36 VDC (+/- 10%)

12-26 VAC (+/- 10%)

Current Draw

60 mA @ 12 VDC

FLOw SENSOR INPuT

All Sensors

Excitation voltage 3 wire sensors:

9.1 VDC 500Ω source

impedance

Pulse Type Sensors

Signal Amplitude

2.5 VDC threshold

Signal Limits

Vin < 35V (DC or AC peak)

Frequency

0-10kHz

Pull-up

2 kΩ

Sine wave Sensors

Signal Amplitude

10 mV p-p threshold

Signal Limits

Vin < 35V (DC or AC peak)

Frequency:

0-10kHz

SENSOR CALIBRATION

Badger Meter

Use K and Offset provided in sensor owner’s manual

Other Sensors

Check with factory

uNITS OF MEASuRE

Flow Measurement Rate

gpm, gph, l/sec, l/min, l/hr, ft3/sec, ft3/min, ft3/hr, m3/sec,

m3/min, m3/hr

PROgRAMMINg

Requires PC or laptop running Windows XP or Vista

Operating Temperature

-25° C to +70° C

-20° F to +158° F

Storage Temperature

-40° C to +85° C

-40° F to +185° F

weight

4.8 oz. with headers installed

Accessories

Model A-330 programming kit containing software and 3

feet Model A301 cable

RELAy RATINg

DPST Contact Ratings

5A@30VDC

5A@125VAC

5A@250VAC

Time Delay

1-9999 second delay between ow point and relay actuation

Transient Suppression

Designed to withstand a 5000 volt 1/2 microsecond, 100KHz

ring wave

Model A-330-20 programming kit containing software

and 20 feet Model A301-20 cable (longer cable may be

required for eld programming)

5

Page 6

FaCtORY DEFaUltS

Default Values Customer Values

Serial Number n/a

Version n/a

Sensor Type Pulse

K= 1

Offset= 0

Flow Rate Units gpm

Alarm Type off

High Alarm Latched off

High Alarm Set Point 120

High Alarm Set Point Delay 5

High Alarm Release Point 110

High Alarm Release Point Delay 10

Low Alarm Latched off

Low Alarm Set Point 10

Low Alarm Set Point Delay 5

Low Alarm Release Point 15

Low Alarm Release Point Delay 10

Filter Coeff 2

6

Page 7

(This page intentionally left blank.)

7

Page 8

(This page intentionally left blank)

Badger® and Data Industrial® are registered trademarks of Badger Meter Inc.

Windows® is a registered trademark of Microsoft Corporation.

Please see our website at www.badgermeter.com

for specific contacts.

Copyright © Badger Meter, Inc. 2009. All rights reserved.

Due to continuous research, product improvements and enhancements, Badger

Meter reserves the right to change product or system specifications without notice,

except to the extent an outstanding contractual obligation exists.

BadgerMeter, Inc.

6116 E. 15th Street

Tulsa, Oklahoma 74112

(918) 836-8411 / Fax: (918) 832-9962

www.badgermeter.com

Loading...

Loading...