Page 1

Industrial Flow Monitors

Series 3050

DSY-UM-01668-EN-02 (June 2018)

User Manual

Page 2

Industrial Flow Monitors, Series 3050

Page ii June 2018DSY-UM-01668-EN-02

Page 3

User Manual

CONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Panel Mount Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Wall Mount Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power Supply Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flow Sensor Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Analog Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Temperature Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Solid-State Switch and Form C Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

RS-485 Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Modbus Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Addr Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

USB Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Display and Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Selection Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Option List Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Data Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Programming Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Flow Inputs Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Flow Inputs Flowchart (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

BTU and Temperature Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

BTU and Temperature Inputs (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Relays and Pulse Outputs Flowchart (Manual, Setpoint Rate and Pulse/Volume) . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Analog Output Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

RS485 Communication Port Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

USB Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Page iii June 2018 DSY-UM-01668-EN-02

Page 4

Industrial Flow Monitors, Series 3050

Command Lists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

USB Command List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Display Conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Flow Input Channel Conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

BTU Conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Relay Output Conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Analog Output Conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

RS485 Comm Port Conguration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Modbus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Flow Sensor Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Specications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Part Number Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Page iv June 2018DSY-UM-01668-EN-02

Page 5

Introduction

INTRODUCTION

The Badger Meter® Data Industrial® Series 3050 BTU flow monitor is an economical, full featured, compact unit designed for

sub-metering applications.

The two line × 16-character alphanumeric display shows any combination of Energy Rate, Energy Total, Flow Rate or Flow Total.

You can configure both preprogrammed and user-defined units of measure.

The Series 3050 BTU flow monitor accepts pulse or linear analog input signals. Like all Badger Meter flow monitors, the

Series 3050 BTU flow monitor may be field-calibrated. For Badger Meter sensors, K and offset numbers are entered, while other

pulse or frequency output sensors may use a K-factor only. Analog inputs are fully programmable for slope and intercept.

The flow monitor requires two temperature units and can accept 10 kΩ thermistors, 100 Ω three-wire RTDs or user-defined

custom thermistors or RTDs.

The panel-mounted model has a NEMA 4X rated front panel and conforms to DIN Standard dimensions, 96 mm × 96 mm, for

meter sizes and panel cutouts. An optional NEMA 4 wall-mount model is also available.

Programming

You can program the flow sensor from the front panel by entering a K and offset or only a K-factor, depending on the flow

sensor used.

Programming is menu driven. All data is entered using the LCD/keypad interface. A password gate is included to prevent

unauthorized access to programming parameters. Programming flexibility is extended to units of measure. In addition to

several factory units of measure, the Series 3050 BTU flow monitor software lets you create custom units for rate and total.

The Series 3050 BTU flow monitor provides one Form C solid-state relay, and one solid-state switch output. Both are fully

programmable as Pulse or Volume, or Setpoint control-based Flow Rate, Flow Total, Energy Rate, Energy Total, Temperature 1,

Temperature 2 or Delta T. For pulse output, you can program both the resolution and the pulse width. The Setpoint control is

extremely versatile with fully independent set and release points, each with its own time delay.

LEDs on the front panel indicate status of both the relay and pulse outputs.

All calibration information, units of measure and flow totals are stored in a non-volatile memory that does not require battery

backup for data retention.

Options

• Analog output

• USB

• RS485

• BACnet

• Modbus®

• Wall mounting

SAFETY INFORMATION

The installation of the flow monitor must comply with all applicable federal, state, and local rules, regulations, and codes.

Failure to read and follow these instructions can lead to misapplication or misuse of the flow monitor, resulting in personal

injury and damage to equipment.

UNPACKING AND INSPECTION

Upon opening the shipping container, visually inspect the product and applicable accessories for any physical damage such

as scratches, loose or broken parts, or any other sign of damage that may have occurred during shipment.

OTE:N If damage is found, request an inspection by the carrier’s agent within 48 hours of delivery and file a claim with the

carrier. A claim for equipment damage in transit is the sole responsibility of the purchaser.

Page 5 June 2018 DSY-UM-01668-EN-02

Page 6

Installation

INSTALLATION

Mechanical Installation

The Series 3050 BTU flow monitor can be either panel-mounted or wall-mounted.

Location

In any mounting arrangement, the primary concern is easy viewing and convenient operation of the keypad. The unit

generates very little heat, so no consideration need be given to cooling or ventilation. However, prolonged direct sunlight can

damage the front panel so some level of shading is recommended, especially if installed in a tropical climate.

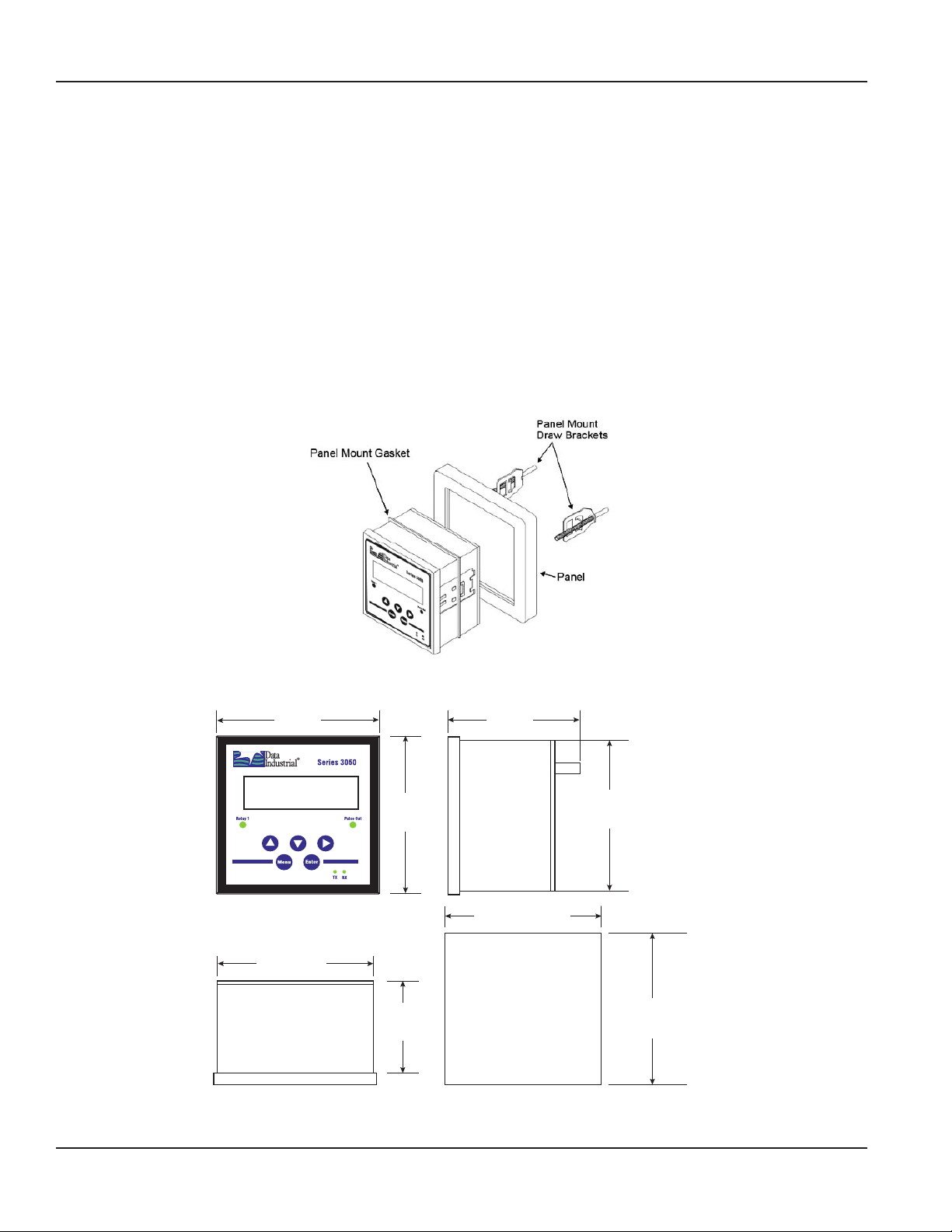

Panel Mount Installation

The Series 3050 BTU flow monitor panel-mount model is designed for through-panel mounting, which allows access to the

back of the unit. The monitor is secured to the panel by two draw brackets shown in Figure 1 below. Also refer to Figure 2 for

monitor and panel cutout dimensions.

3.78 in.

(96 mm)

3.49 in.

(88.7 mm)

TOP

Figure 1: Panel mounting

3.23 in.

(82 mm)

5

3.78 in.

(96 mm)

2.21 in.

(56 mm)

Figure 2: Panel-mount dimensions and panel cutout

SIDE

3.57…3.60 in.

(90.6…91.4 mm)

PANEL

CUTOUT

3.49 in.

(88.7 mm)

3.57…3.60 in.

(90.6…91.4 mm)

Page 6 June 2018DSY-UM-01668-EN-02

Page 7

Installation

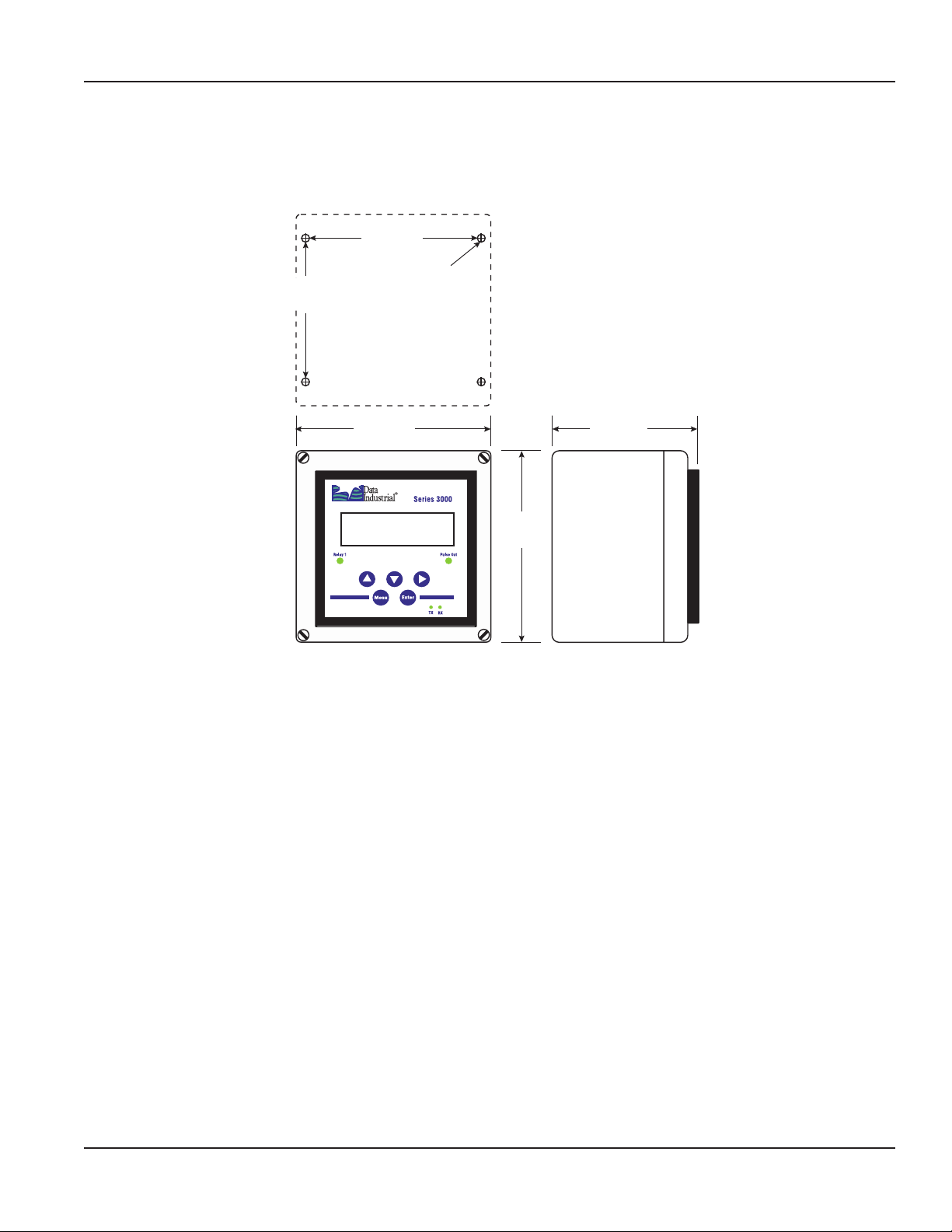

Wall Mount Installation

The Series 3050 BTU flow monitor wall-mount model is designed to mount onto a wall with four bolts or screws. The

mounting hole pattern and box dimensions for the Series 3050 BTU flow monitor NEMA4 waII-mount model are shown in

Figure 3.

4.33 in.

(110 mm)

1/8 in.

3.54 in.

(90 mm)

MOUNTING TEMPLATE

(3.2 mm)

WALL

4.80 in.

(122 mm)

4.72 in.

(120 mm)

Figure 3: Wall-mount dimensions and cutout

3.62 in.

(92 mm)

SIDE

Page 7 June 2018 DSY-UM-01668-EN-02

Page 8

Installation

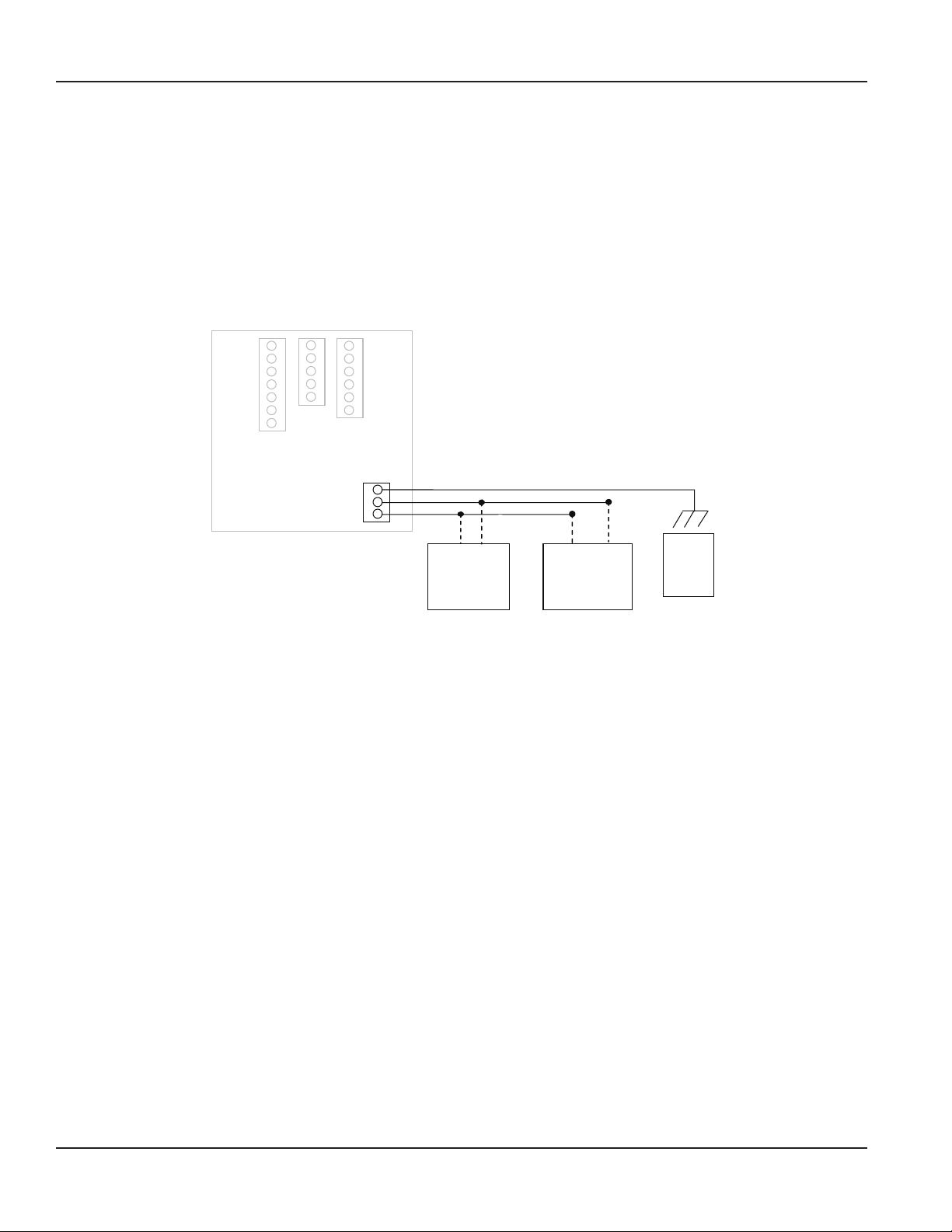

Electrical Installation

Power Supply Wiring

The Series 3050 BTU flow monitor requires 12…24 V DC/AC to operate. Check the "Specifications" on page 30 for DC current

draw and AC Volt-Amp requirements.

Always use a fused circuit.

Connect the positive of the power supply to the flow monitor terminal marked (ACL/DC+), and connect the negative of the

power supply to the flow monitor terminal marked (ACC/DC-).

If a Badger Meter plugin power supply (Model A-1028) is being used, connect the black-white wire to the terminal marked

(ACL/DC+) and the black wire to the terminal marked (ACC/DC-).

POWER

Earth

LV AC/DC (-)

LV AC/DC (+)

3

2

1

Ground wire should be heavy gauge and as short as possible.

(+) (-)

12 . . . 24V DC

Power

Supply

Figure 4: Power supply wiring

or

(Line) (Com)

12 . . . 24V AC

Power

Supply

Earth

or

Panel

Ground

Page 8 June 2018DSY-UM-01668-EN-02

Page 9

Installation

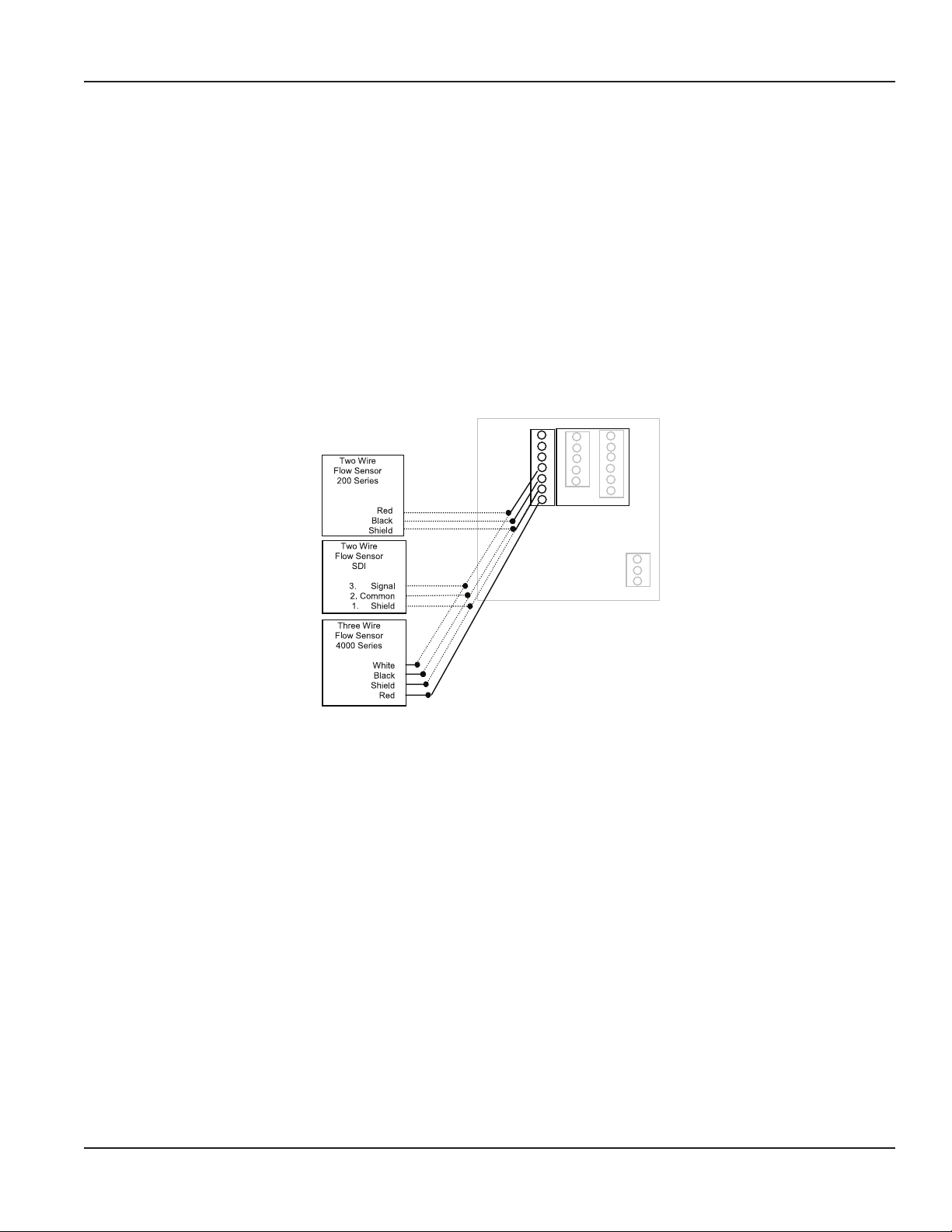

Flow Sensor Wiring

The Series 3050 flow sensor inputs are extremely versatile, designed to accept either two-wire or three-wire pulse inputs

(Badger Meter 200 Series, SDI or 4000 Series) or Analog inputs. Although different rear panel terminals are used, all

parameters are set with the LCD/keypad interface. There are no internal or external jumpers, switches or potentiometers to

move or adjust.

The following pulse input types are accommodated:

• Pulse-DI: Used for all Badger Meter Data Industrial Flow Sensors. Provides an internal pullup resistor and uses K and

“Offset” values for calibration.

• Pulse–K Factor: Accepts non zero-crossing inputs but provides no internal pullup, classical K ( pulses/gallon) values for

calibration.

• Pullup-K Factor: Provides an internal pullup resistor and uses classical K (pulses/gallon) values for calibration.

OTE:N All the above pulse input types wire the same as shown in Figure 5 on page 9. See the "Programming Flowcharts"

on page 18 through page 25 for required input configuration.

1 ANALOG IN+

2 ANALOG IN3 SHIELD

4 SENSOR IN

5 GND

6 SHIELD

7 SENSOR PWR

Figure 5: Badger Meter flow sensor wiring examples (two- and three-wire pulse types)

Page 9 June 2018 DSY-UM-01668-EN-02

Page 10

Installation

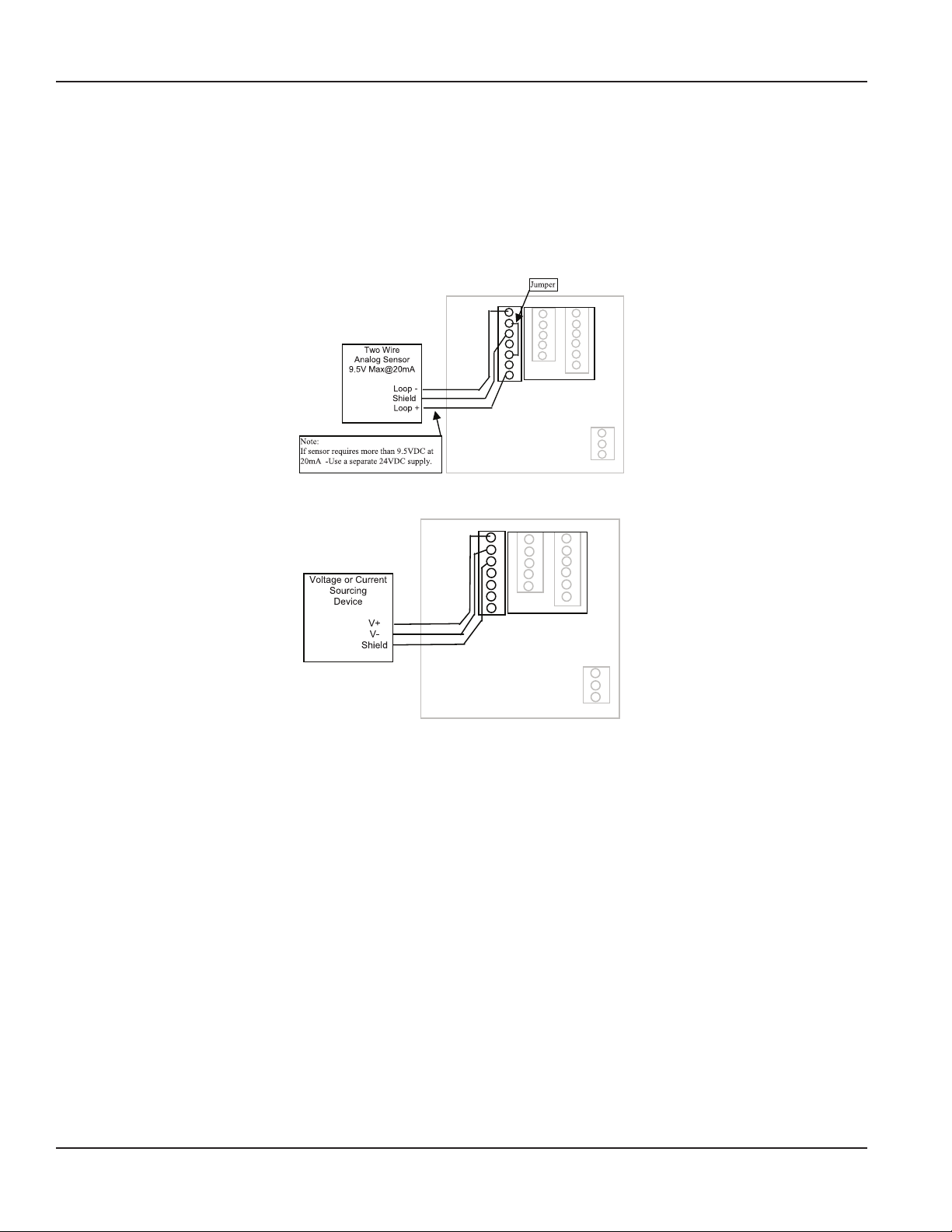

Analog Input

As an alternative to the pulse inputs, the Series 3050 BTU flow monitor can accept an Analog input. The input is non-isolated,

but can accept 0…1V DC, 0…5V DC, 0…10V DC, 0…20 mA and 4…20 mA with both factory-defined and custom units

of measure.

Low impedance 100 Ω input for current inputs optimizes performance and flexibility or loop power supplies. Both the

low-end and high-end scaling are independent and can be field-configured.

OTE:N See the "Programming Flowcharts" on page 18 through page 25 for required input configuration.

1 ANALOG IN+

2 ANALOG IN3 SHIELD

4 SENSOR IN

5 GND

6 SHIELD

7 SENSOR PWR

Figure 6: 4…20 mA analog loop powered wiring

1 ANALOG IN+

2 ANALOG IN3 SHIELD

4 SENSOR IN

5 GND

6 SHIELD

7 SENSOR PWR

Figure 7: Voltage or current sourcing analog inputs

Page 10 June 2018DSY-UM-01668-EN-02

Page 11

Flow Sensor

Installation

Temperature Input

The Series 3050 BTU flow monitor can accept inputs from either a pair of thermistors or RTDs. The inputs are labeled T1 and

T2. Since the T1 sensor is used to convert the volumetric flow (Example: GPM) to the mass flow (Example: Lbs/Hr) used in the

BTU calculations, the sensor connected to T1 should be in the same supply or return line as the flow sensor.

The temperature inputs of the flow monitor are extremely versatile. In addition to the factory default two-wire 10k @ 77° F

Type II Thermistors and three-wire 100 Ω platinum RTDs, the unit can be programmed in the field for a wide variety of custom

RTDs and thermistors. See the "Programming Flowcharts" on page 18 through page 25. Contact the factory for assistance

with any custom inputs.

1 TEMP 1 IN +

2 TEMP 1 IN 3 TEMP 1 GND

Jumpers

4 SHIELD

5 TEMP 2 GND

6 TEMP 2 IN 7 TEMP 2 IN +

2 W ire

Th ermistor

Located

in same

Supply

or

Return line

Flow Sensor

3 W ire

RTD

T1

Located

in same

Supply

or

Return line

as

2 W ire

Th ermistor

Figure 8: Wiring two-wire thermistors and RTDs

Dierent Color Wire

Same Colored 2 Wires

3 W ire

RTD

Figure 9: Wiring three-wire RTDs

1 TEMP 1 IN +

2 TEMP 1 IN 3 TEMP 1 GND

4 SHIELD

5 TEMP 2 GND

6 TEMP 2 IN 7 TEMP 2 IN +

Page 11 June 2018 DSY-UM-01668-EN-02

Page 12

Installation

Solid-State Switch and Form C Output Wiring

The Series 3050 BTU flow monitor has one Normally Open (N.O.) solid-state switch, and one solid-state Form C relay.

See the "Specifications" on page 30 for maximum voltage and current ratings for each type output. These outputs are

completely independent, electrically isolated, and can be programmed as either Pulse or Setpoint outputs.

When the Totalizer function is selected, the unit of measure and resolution are independent from the displayed units and can

be programmed where one pulse occurs once every 0000000.1…999999999.0 of units selected, with any pulse width from

0001…9999 mS.

When the Alarm is selected as the unit of measure and the resolution is independent from the displayed units, it allows the

unit to be programmed as either a high or low rate Setpoint. Since the Setpoint, Release Point and their associated time delays

are fully independent, this output can be either a classical high rate or low rate alarm, depending on the settings selected.

When design planning, keep in mind that although both of these outputs can be programmed as alarm points only, the relay

provides both N.O. and N.C. contacts. The switch is a simple N.O. contact.

Example of High Flow Setpoint Control

The Setpoint must be a value greater than the Release Point.

The relay output will have continuity between its N.C. terminal and COM until the flow has exceeded the Setpoint (SETPT) for

a continuous period of time exceeding the Setpoint Delay (SDLY), at which time the N.C. connection will open and the N.O.

contact will have continuity to the COM terminal. When the flow has dropped below the Release Point (RELP) for a continuous

period of time exceeding the Release Point Delay (RDLY), the relay states will return to their original states. If the latch has been

set to ON, the relay will not release until manually reset once the Setpoint and Setpoint Delay have been satisfied. Sources for

the Setpoint control can be Flow Rate, Energy Rate, T1, T2 or Delta T.

Example of Low Flow Setpoint Control

The Setpoint must be a value less than the Release Point.

The relay output will have continuity between its N.C. terminal and COM until the flow drops below the Setpoint (SETPT)

for a continuous period of time exceeding the Setpoint Delay (SDLY), at which time the N.C. connection will open and the

N.O. contact will have continuity to the COM terminal. When the flow has again risen above the Release Point (RELP) for a

continuous period of time exceeding the Release Point Delay (RDLY), the relay states will return to their original states. If

the latch has been set to ON, the relay will not release until manually reset once the Setpoint and Setpoint Delay have been

satisfied. Sources for the Setpoint control can be Flow Rate, Energy Rate, T1, T2 or Delta T.

1 RELAY 1 NO

2 RELAY 1 NC

3 RELAY 1 COM

4 PULSE 1 OUT

5 PULSE 2 OUT

Figure 10: Relay and switch wiring examples

Page 12 June 2018DSY-UM-01668-EN-02

Page 13

Figure 11: Relay and switch wiring examples (continued)

Chiller control based on high energy usage with indication.

1 RELAY 1 NO

2 RELAY 1 NC

3 RELAY 1 COM

4 PULSE 1 OUT

5 PULSE 2 OUT

1 RELAY 1 NO

2 RELAY 1 NC

3 RELAY 1 COM

4 PULSE 1 OUT

5 PULSE 2 OUT

Installation

Figure 12: Relay and switch wiring examples (continued)

Chiller control based on low temperature warning with indication.

Page 13 June 2018 DSY-UM-01668-EN-02

Page 14

Installation

OUTPUT OPTION CARD

If the Series 3050 BTU flow monitor was ordered with the Output Option card, it will have these additional outputs:

• Analog Output ( 0…20 mA or 4…20 mA ) that can be converted externally to 0…5V DC, 1…5V DC with a 250 Ω resistor;

or 0…10V DC or 2…10V DC with a 500 Ω resistor. A 15V DC power supply is provided to permit current sinking or sourcing.

The Series 3050 BTU flow monitor has special software that permits the Analog output.

• USB for direct access to a computer using a standard mini-USB cable.

• RS-485 for fully addressable Modbus or BACnet communication.

Analog Output

+

1 RS485 B

2 RS485 A

3 RS485 GND

4 LOOP +

5 LOOP 6 GND

-

RS-485 Output

Figure 13: Current sourcing analog output

1 RS485 B

2 RS485 A

3 RS485 GND

4 LOOP +

5 LOOP 6 GND

Figure 14: Current sinking analog output

1 RS485 B

2 RS485 A

3 RS485 GN D

4 LOOP +

5 LOOP 6 GND

Model 3700

Model 345WT

or other

MODBUS

Master

Device

Shield

RS485 -

RS485 +

Figure 15: RS-485 output wiring

Page 14 June 2018DSY-UM-01668-EN-02

Page 15

Installation

Modbus Registers

All of the following are available as Input Registers. Data is formatted as a float (CD AB) and each data point isstored in two

Modbus registers.

Addr Function

1 Flow 1 Rate (GPM)

3 Flow 2 Rate (GPM)

5 Flow 1 Total (gallons)

7 Flow 2 Total (gallons)

9 Energy Rate (BTU/min)

11 Energy Total (BTU)

13 Batch 1 Count

15 Batch 2 Count

17 Temp 1 (deg F)

19 Temp 2 (deg F)

21 Temp Delta (T2-T1)

USB Port

Use

Figure 16: USB analog output

Standard Cable

USB Type A Male

to

Type Mini B 5 Pin Male

Connect to

Computer USB

Com Port

OTE:N Communication via the USB port requires a terminal emulator. This port is part of the Analog Output Option card. See

"USB Communication" on page 26 for instructions on how to use this port.

Page 15 June 2018 DSY-UM-01668-EN-02

Page 16

Display and Keypad

DISPLAY AND KEYPAD

The Series 3050 BTU flow monitor has a two line by 16-character display with two modes of operation and 5 keys on the front

panel for programming.

Menu

Enter

When the Series 3050 BTU flow monitor is first powered up, it runs through internal self checks while displaying

“Badger Meter DIC Initializing." At the end of this cycle its normal mode display will appear.

In the normal mode, if still using the factory defaults, flow rate will be displayed on the top line, and flow total displayed on

the bottom. Both lines can be custom-defined in the field as desired. In the normal mode the Enter key has no function.

1-Switch to main menu

2-Backward/Previous menu

1-Save value

2-Forward/Next menu

Up Arrow

Down

Arrow

Right

Arrow

1-Select Menu option

2-Increase numerical value

1-Select Menu option

2-Decrease numerical value

1-Select Menu option

2-Move cursor to the right

0.0 GPM

0.0 gal

Menu Enter

Figure 17: Normal mode display

The other mode is the program mode, used to configure the unit. Press Menu to enter and exit this mode. See "Programming"

on page 17.

RESET SETUP DIAG

Menu Enter

Figure 18: Program mode display

Page 16 June 2018DSY-UM-01668-EN-02

Page 17

Flow 1 units

Programming

PROGRAMMING

With the normal mode display showing, press Menu to enter the programming mode. In this mode, you use the three arrow

keys () on the selection screens to select the option displayed above the key, and on the option list screens to scroll up

or down a list of choices, like a pull-down menu. Most screens presenting choices show three choices, one for each arrow key.

When the number of choices exceeds three, a small arrow () appears on the upper right of the display, indicating there are

more choices on that level. Press Enter to toggle to the next set of choices. Once the selection has been made, press Enter to

complete the selection. Press Menu again to return to the normal mode display.

Selection Screens

Most selection screens show three choices, one for each arrow () key. When the number of choices exceeds three, a

small arrow ( ) appears on the upper right side of the display, indicating there are more choices on that level. Press Enter to

view the next set of choices.

For example, pressing Menu from the normal mode screen shows the RESET SETUP DIAG screen. Pressing the Up Arrow key

brings up the RESET screens. Pressing the Down Arrow key brings up the SETUP screens and pressing the Right-Arrow key

brings up the DIAG (diagnostic) screens. In this example, if you press the Down Arrow key, this screen appears:

SETUP

PWORD DSPY FLOW1

Menu Enter

Figure 19: Selection screen

Option List Screens

Units of measure is an example of an options list screen.

Press the Up Arrow key to scroll up the list or press the Down Arrow key to scroll down the list. In this case, the list starts with

GPM; gal/s; gal/hr;…LPM;…. and ends with Custom Units.

With a selection highlighted, press Enter to complete the selection or press Menu to leave the selection unchanged. The

Right-Arrow key has no function on this type of screen.

GPM

Menu Enter

Figure 20: Option list screen

Data Screens

Some screens are data entry screens. For example, the Setpoint or Custom Unit screens.

When a data entry screen is active, the current value displays. The left-most digit flashes. Press the Up Arrow key to increase

the value. Press the Down Arrow key to reduce the value. If the decimal point is flashing, press the Up Arrow key to move the

decimal point to the right or press the Down Arrow key to move the decimal point to the left.

Setpoint

1.00000000

Menu Enter

Figure 21: Data screen

Page 17 June 2018 DSY-UM-01668-EN-02

Page 18

Programming

Programming Flowcharts

RESET SETUP DIAG

Reset ow 1?

OK CANCEL

Reset ow 1?

Reset

Require setup PW

YES [NO]

RESET

FLOW1 BTU

Password setup

ENAB SETUP RESET

Setup password

0000

Reset BTU total?

OK CANCEL

Reset BTU total?

Reset

Reset password

0000

Enter password

0000

SETUP

PWORD DSPY FLOW1

Go to

Flow

Inputs

DISPLAY

LINE1 LINE2 RATE

DIAG

MODL# SER# REV#

Model #:

3050xx

Serial #:

######

SETUP

BTU RLY1 PULSE

Go to BTU &

Temperature

Inputs

DIAG ERROR

Firmware rev:

v1.2.xx

Error codes

000 000 000 000

SETUP

AOUT1 COMM

Go to

Analog

Out

Go to Relays &

Pulse Outputs

Go to RS485

Communications

Port

LINE1

Flow 1 Rate

Flow 1 Total

BTU Rate

BTU Total

Temp 1 and 2

T2 - T1

Page 18 June 2018DSY-UM-01668-EN-02

LINE2

Flow 1 Rate

Flow 1 Total

BTU Rate

BTU Total

Temp 1 and 2

T2 - T1

Update rate

+0.50000000 sec

Page 19

Flow Inputs Flowchart

Flow 1 setup

RATE TOTAL SENSR

Programming

Flow 1 rate

UNITS #.DIG CUST

Flow 1 # digits

0

1

2

Flow X units

GPM

gal/s

gal/hr

Mgal/day

L/s

LPM

L/hr

ft3/s

ft3/min

ft3/hr

m3/s

m3/min

m3/hr

acre-ft/s

acre-ft/min

acre-ft/hr

bbl/s

bbl/min

bbl/hr

Custom units

Custom units

LABEL CONV

1 unit =

+0.00000001 gpm

.

.

.

999999999.

Flow 1 total

UNITS #.DIG CUST

Total X units

gal

Mgal

L

ft3

m3

acre-ft

bbl

Custom units

Total 1 # digits

Custom units

LABEL CONV

0

1

2

Enable password?

YES [NO]

Enable password?

[YES] NO

1 UNIT =

+0.00000001 gal

.

.

.

999999999.

Flow 1 total

RESET

Reset ow total

PASSWD RESET

Reset total NOW?

OK CANCEL

Unit label

?

>

=

<

;

:

9999999999

8888888888

.

.

.

1

0000000000

/

.

,

+

*

)

(

'

&

%

$

"

!

Continued

at A on

next page.

{

z

y

x

.

.

.

c

b

a

`

_

^

]

¥

[

ZZZZZZZZZZ

Y

X

.

.

.

J

BBBBBBBBBB

AAAAAAAAA

Page 19 June 2018 DSY-UM-01668-EN-02

Page 20

Programming

Flow Inputs Flowchart (continued)

Continued

A

from previous

page.

Sensor 1 type

Flow 1 sensor

TYPE xxxxxxxx

Flow 1 sensor

Pulse DI

TYPE AVG DICAL

DI Sensor Cal.

KNUM OFFSET

Pulse K-Factor

Pullup K-Factor

Sine K-Factor

Analog

Flow x units

GPM

gal/s

gal/hr

Mgal/day

L/s

LPM

L/hr

ft3/s

ft3/min

ft3/hr

m3/s

m3/min

m3/hr

acre-ft/s

acre-ft/min

acre-ft/hr

bbl/s

bbl/min

bbl/hr

Custom units

Flow 1 sensor

TYPE AVG KFACT

Flow 1 sensor

TYPE ANALOG

Analog ow 1

UNITS RANGE HIGH

Analog x range

0 to 1V

0 to 5V

0 to 10V

0 to 20 mA

4 to 20 mA

Max reading = ?

0.00000001

999999999.

Flow 1 timeconst

+0.00000001 sec

.

.

.

100.000000

Flow 1 timeconst

+0.00000001 sec

.

.

.

100.000000

Analog ow 1

LOW CAL

Min reading = ?

0.00000001

.

.

.

999999999.

Sampling

XXXXXXXXXXXX

DI sensor K num

1.00000000

.

.

.

999999999.

K-Factor

1.00000000

.

.

.

999999999.

0V = xxxx

Read Factory

1V = xxxx

Read Factory

5V = xxxx

Read Factory

10V = xxxx

Read Factory

.

.

4 mA = xxxx

.

Read Factory

20 mA = xxxx

Read Factory

DI Sensor Ost

-999999999.

.

.

.

-0.00000001

+0.00000001

.

.

+999999999.

Page 20 June 2018DSY-UM-01668-EN-02

Page 21

BTU and Temperature Inputs

SETUP

BTU RLY1 PULSE

BTU Monitor

RATE TOTAL SENSR

Programming

BTU rate display

UNITS #.DIG CUST

Displayed digits

0

1

2

BTU rate units

BTU/min

kBTU/hr

Custom units

J/sec

Tons

kW

Custom units

LABEL CONV

1 unit = ? kBTU/hr

+0.00000001 gpm

.

.

.

999999999.

BTU 1 total

UNITS #.DIG CUST

Totalizer units

BTU

kBTU

MBTU

kWh

MWh

kJ

Custom units

Displayed digits

0

1

2

Enable password?

YES [NO]

Enable password?

[YES] NO

Custom units

LABEL CONV

1 UNIT = ? BTU

+0.00000001 gal

.

.

.

999999999.

Totalizer

RESET

Reset BTU total

PASSWD RESET

Reset total NOW?

OK CANCEL

Unit label

?

>

=

<

;

:

9999999999

8888888888

.

.

.

1

0000000000

/

.

,

+

*

)

(

'

&

%

$

"

!

Continued

at A on

next page.

{

z

y

x

.

.

.

c

b

a

`

_

^

]

¥

[

ZZZZZZZZZZ

Y

X

.

.

.

J

BBBBBBBBBB

AAAAAAAAA

Page 21 June 2018 DSY-UM-01668-EN-02

Page 22

Programming

BTU and Temperature Inputs (continued)

Continued

A

from previous

page.

BTU Monitor

RATE TOTAL SENSR

Temp Sensor

TYPE TUNIT TMODE

Temp units

Sensor type

DI Thermistor

DI RTD

Cust. Thermistor

Custom RTD

No Sensor

Totalizing

T1 < T2

T1 > T2

Absolute

°F

°C

Thermistor calib

A0 A1 A3

A0*10^4

+0.000000000

A01*10^4

+0.000000000

RTD calib

A0 A1 A2

A0

+0.000000000

A1

+0.000000000

Temp Sensor

T2ADJ CUST SHC

Temp 2 Adj

-10.00000000 °F

.

.

.

+10.00000000 °C

A03*10^4

+0.000000000

A2*10^5

+0.000000000

Current Source

1 mA

Specic Heat

+0.0000000 °F

.

.

.

+99999999 °C

Temp Sensor

CSRC SLOPE OFFSET

Slope XX µA

EDIT NEXT FACTORY

Slope XX µA

+0.0000000

.

.

.

+99999999

Slope

1 mA

8 µA

40 µA

200 µA

Oset

T1 T1COMP T2 T2COMP

Oset

EDIT NEXT FACTORY

X Oset

+0.0000000

.

.

.

+99999999

X Oset

1 mA

8 µA

40 µA

200 µA

Factory reset?

YES [NO]

Factory reset?

YES [NO]

Temp Sensor

CAL

Calibrate

YES FACTORY

Factory reset?

CONFIRM

Jumper T1 and T2

PROCEED

Page 22 June 2018DSY-UM-01668-EN-02

Page 23

Relays and Pulse Outputs Flowchart (Manual, Setpoint Rate and Pulse/Volume)

SETUP

RLY1 Pulse

Relay 1 (or Pulse)

FUNC xxxxx xxxxx

Manual Control

Programming

Relay 1 (or Pulse)

FUNC MANUAL

Totalizer

Alarm

Relay 1 (or Pulse)

FUNC INPUT UNITS

Relay 1 input

(or Pulse)

Flow 1 Rate

BTU Rate

Temperature 1

Temperature 2

T2 - T1

}

Relay 1 (or Pulse)

FUNC INPUT UNITS

Totalizer input

Flow 1 Total

BTU Total

Relay 1 (or Pulse)

FUNC INPUT UNITS

Set point units

°F

°C

Pulse rate units

BTU

kBTU

MBTU

kWh

MWh

kJ

Custom units

Relay 1 (or Pulse)

FUNC INPUT UNITS

Set point units

kBTU/hr

BTU/min

kW

Tons

J/sec

Custom units

Flow total units

gal

Mgal

L

ft3

m3

acre-ft

bbl

Custom units

Relay 1 (or Pulse)

FUNC INPUT UNITS

Relay 1 Latch?

ON [OFF]

Flow x units

GPM

gal/s

gal/hr

Mgal/day

L/s

LPM

L/hr

ft3/s

ft3/min

ft3/hr

m3/s

m3/min

m3/hr

acre-ft/s

acre-ft/min

acre-ft/hr

bbl/s

bbl/min

bbl/hr

Custom units

Relay 1 (or Pulse)

RATE CTIME

1 pulse = ?

0.00000001

.

.

.

999999999.

Relay 1 (or Pulse)

LATCH SETPT RELP

Set point

-0.00000001

.

.

.

+999999999.

Release point

Time closed

0001 mS

9999 mS

-0.00000001

+999999999.

Relay 1 (or Pulse)

ON [OFF]

Relay 1 (or Pulse)

[ON] OFF

.

.

.

Relay 1 (or Pulse)

SDLY RDLY

Trigger delay

0000000 mS

.

.

.

10000000 mS

Release delay

0000000 mS

.

.

.

10000000 mS

.

.

.

Page 23 June 2018 DSY-UM-01668-EN-02

Page 24

Programming

Analog Output Flowchart

SETUP

AOUT1 COMM

Analog output 1

FUNC RANGE SCR

Flow Rate

BTU Rate

Temperature

Analog output 1

FUNC RANGE SCR

Analog

output

range

0-20 mA

4-20 mA

Analog output 1

FUNC RANGE UNIT

Analog output range

0-20 mA

4-20 mA

Analog output 1

FUNC RANGE SCR

Analog

output

range

0-20 mA

4-20 mA

Drive source

Temp 1

Temp 2

T2 - T1

Drive source

Flow 1 Rate

Analog 1 units

kBTU/hr

BTU/min

kW

Tons

J/sec

Custom units

Analog output 1

UNITS LOW HIGH

0 mA = ?

0.0000000

Analog 1 units

°F

°C

0 mA = ?

0.0000000

Analog output 1

CAL

20 mA = ?

0.0000000

Analog output 1

LOW HIGH CAL

20 mA = ?

0.0000000

Adjust 4 mA

12107 FACTRY

Adjust 20 mA

60748 FACTRY

Analog output 1

UNITS LOW HIGH

Analog 1 units

GPM

gal/s

gal/hr

Mgal/day

L/s

LPM

L/hr

ft3/s

ft3/min

ft3/hr

m3/s

m3/min

m3/hr

acre-ft/s

acre-ft/min

acre-ft/hr

bbl/s

bbl/min

bbl/hr

Custom units

0 mA = ?

0.0000000

20 mA = ?

0.0000000

Analog output 1

CAL

Adjust 4 mA

12107 FACTRY

Adjust 20 mA

60748 FACTRY

PID

Analog output 1

FUNC RANGE SCR

Analog output range

0 to 20 mA

4 to 20 mA

Drive source

Flow 1 Rate

Flow 2 Rate

Analog output 1

UNITS SETPT P

Flow x units

GPM

gal/s

gal/hr

Mgal/day

L/s

LPM

L/hr

ft3/s

ft3/min

ft3/hr

m3/s

m3/min

m3/hr

acre-ft/s

acre-ft/min

acre-ft/hr

bbl/s

bbl/min

bbl/hr

Custom units

PID P const

+000.000

+999.000

PID Set point

-0.00000000

+999.99999

Analog output 1

I D LOW

PID I const

+000.0000

.

.

.

+999.9999

.

.

.

4 mA = ?

+000.0000

.

.

.

+999.9999

PID D const

+000.000

+999.000

.

.

.

.

.

.

Analog output 1

HIGH

20 mA = ?

+000.0000

.

.

.

+999.9999

Adjust 4 mA

12107 FACTRY

Analog output 1

CAL

Adjust 20 mA

60748 FACTRY

Page 24 June 2018DSY-UM-01668-EN-02

Page 25

RS485 Communication Port Flowchart

Comm

NET BAUD ADDR

Programming

Network

Disable

MODBUS

BACnet/MSTP

Comm

NET

Comm

NET BAUD ADDR

Network

MODBUS

Baud Rate

300

1200

2400

9600

19200

38400

76800

Comm

NET BAUD ADDR MAX DEVID

MODBUS Address

001

.

.

.

255

Network

BACnet/MSTP

Baud Rate

Auto

9600

19200

38400

76800

MSTP Address

001

127

MSTP Max master

.

.

.

001

127

Device Instance

.

.

.

00000000

.

.

.

99999999

Page 25 June 2018 DSY-UM-01668-EN-02

Page 26

Programming

USB Communication

If you order the Series 3050 BTU flow monitor with an Analog Output Option card, a five-pin USB connector is also included.

As much as possible, the commands mimic the use of the front panel controls.

To use this feature, you need:

• A PC with USB ports and any terminal emulator software

• Windows 7, 8 or Windows XP operating system

• FTDI Virtual COM port drivers from http://www.ftdichip.com/FTDrivers.htm

• A USB 2.0 A to Mini-B 5-pin cable

To communicate using terminal:

1. Make sure that the Series 3050 BTU flow monitor has a Mini-B ve-pin connector on the back panel. The Series 3050 BTU

flow monitor must have an Analog Output Option card installed and the monitor marked Series # 3050-1x.

2. Check that the appropriate FTDI Virtual COM port drivers are installed on your computer.

3. Plug the USB 2.0 A end of the cable into a USB port on your computer. Plug the Mini-B five-pin end into the back of the

Series 3050 BTU flow monitor.

4. Run any terminal emulator and create a new connection with the proper COM port selected. Use the Windows Device

Manager to locate the COM port. The 3050 device will show up under Ports and will be called USB Serial Port.

5. Congure this port as:

◊ Bits per second: 38400

◊ Data bits: 8

◊ Parity: None

◊ Stop bits: 1

◊ Flow control: None

6. When connected, a greater-than (>) symbol appears in the upper left corner of the main HyperTerminal display screen.

Press Enter. Both the Rx and Tx LEDs on the front of the flow monitor ash once, and the “Badger Meter DIC … Software

Version…” text message appears.

The Series 3050 BTU flow monitor is now communicating, ready to take commands from the lists on the following pages.

Page 26 June 2018DSY-UM-01668-EN-02

Page 27

Command Lists

COMMAND LISTS

USB Command List

In the list below, brackets indicate an argument, specifying its type

and value range. For instance [0-18] stands for any number between

0 and 18 (inclusive).

Example: “display line1 = 1” sets Line 1 of the display to display #1,

which happens to be the totalizer for flow channel 1.

Diagnostics:

id – show model number & software version

echo [on/o] – turn on/o interactive command line:

with echo o, this interface is more

amenable to scripting; it still accepts the same

commands.

Any command entered without an “ = “ sign and

variable will display the current setting.

Example: Typing “display line1” returns “0” which is the variable for Flow rate.

read ow [1-2] – read the current ow on channel 1 or 2 in

GPM.

read ow [1-2] total – read the current total ow on channel

1 or 2 in gallons.

Display Configuration

display line1 = [0-18] – set line 1 of the display

display line2 = [0-18] – set line 2 of the display

valid options are:

0: ow 1 rate

1: ow 1 total

2: ow 2 rate

3: ow 2 total

4: ow 1+2 rate

5: ow 1+2 total

6: ow 1-2 rate

7: ow 1-2 total

8: ow 2-1 rate

9: ow 2-1 total

14: BTU rate

15: BTU total

16: temperature 1&2

17: temperature 1-2

display urate = [0.1-10] – set the update rate of the display, in

seconds

Flow Input Channel Configuration

ow [1-2] sensor type = [0-4] – ow sensor type:

0: PulseDI,

1: PulseKFactor,

2: PullupKFactor

3: Analog

ow [1-2] sensor dical k = [x] – DI-type ow sensor k

ow [1-2] sensor dical o = [x] – DI-type ow sensor oset

ow [1-2] sensor kfact = [x] – K factor for non-DI sensors

ow [1-2] sensor analog units = [0-19] – ow units for analog input

ow [1-2] sensor analog range = [0-4] – current range for

analog input

ow [1-2] sensor analog high = [x] – ow rate @max current

ow [1-2] sensor analog low = [x] – ow rate @min current

ow [1-2] sensor avg = [0-100] – averaging "time constant," in

seconds:

ow [1-2] rate units = [0-19] – ow (channel) rate units to display.

0: GPM

1: gal/s

2: gal/hr

3: Mgal/day

4: L/s

5: LPM

6: L/hr

7: ft3/s

8: ft3/min

9: ft3/hr

10: m3/s

11: m3/min

12: m3/hr

13: acreft/s

14: acreft/min

15: acreft/hr

16: bbl/s

17: bbl/min

18: bbl/hr

19: Custom

ow [1-2] rate ndigits = [2-10] – number of decimal places to show

for ow rate

ow [1-2] rate custom label = [string] – set the label for custom units

ow [1-2] rate custom conv = [0-100] – conversion factor for

custom units

ow [1-2] total units = [0-7] – set the totalizer units to display

0: gal

1: Mgal

2: L

3: ft3

4: m3

5: acreft

6: bbl

7: Custom

Page 27 June 2018 DSY-UM-01668-EN-02

Page 28

Command Lists

BTU Configuration

BTU rate units = [0-5] – set the BTU rate units:

0: kBTU/hr

1: BTU/min

2: kW

3: TR

4: J/s

5: Custom

BTU rate ndigits = [2-10] – number of decimal digits to display

BTU rate custom label = [string] – BTU rate custom unit label

BTU rate custom conv = [0-100] – custom unit conversion factor

BTU total units = [0-6] – BTU totalizer units:

0: BTU

1: kBTU

2: MBTU

3: kWh

4: MWh

5: kJ

6: Custom

BTU total ndigits = [2-10] – number of decimal digits to display

BTU total custom label = [string] – BTU totalizer custom unit

label

BTU total custom conv = [0-100] – custom unit conversion

factor

BTU total mode = [0-2] – totalizer mode:

0: Heating

1: Cooling

2: Heating & Cooling

BTU sensor type = [0-4] – temperature sensor type:

0: DI Thermistor

1: DI RTD

2: Custom Thermistor

3: Custom RTD

4: No sensor

BTU sensor correct_k = [0-10] – correction factor

BTU sensor temp_unit = [0-1] – temperature units to display

0: deg F

1: deg C

BTU sensor t2adj = [-10-10] – t2a

Relay Output Configuration

relay [1-5] func = [0-9] – relay function; relay 5 is the pulse output

0: Totalizer

1: Alarm

2: Manual Control

relay [1-5] input = [0-8] – relay input; depends on source

for totalizer:

0: Flow 1 Total

for alarms:

0: Flow 1 Rate

relay [1-5] units = [0-19] – units on setpoints/rates; depends on src/

input

ow units: same as 'ow [1-2] rate units' above

volume units: same as 'ow [1-2] total units'

relay [1-5] manual = [on/o] – manually set relay on or o, if in

manual mode

relay [1-5] rate = [x] – totalizer rate

relay [1-5] ctime = [0-10000] – pulse width in milliseconds

relay [1-4] latch = [on/o] – turn on/o relay latching

relay [1-4] setpoint = [x]

relay [1-4] releasepoint = [x]

Analog Output Configuration

analogout [1-2] func = [0-3]

0: Flow rate

1: BTU rate

2: Temperature

3: PID control

analogout [1-2] src = [0-4]

for ow rate:

0: Flow 1 rate

1: Flow 2 rate

2: Flow sum

3: Flow 1-2

4: Flow 2-1

for BTU rate: not used

for temperature:

0: Flow rate

1: Temp 2

2: Temp Delta

for PID control:

0: Flow 1 rate

1: Flow 2 rate

analogout [1-2] range – [0-1]

0: 0-20mA

1: 4-20mA

analogout [1-2] low = [x] – value corresponding to 0 (or 4) mA

analogout [1-2] high = [x] – value corresponding to 20mA

analogout [1-2] setpoint = [x] – PID setpoint

analogout [1-2] P = [x] – PID constants

analogout [1-2] I = [x] – PID constants

analogout [1-2] D = [x] – PID constants

Page 28 June 2018DSY-UM-01668-EN-02

Page 29

Command Lists

RS485 Comm Port Configuration

comm baudrate = [0-7]

0: Auto

1: 300

2: 1200

3: 2400

4: 9600

5: 19200

6: 38400

7: 76800

comm mstpaddr = [0-127] – BACnet/MSTP address

comm maxmaster = [0-127] – BACnet/MSTP max master address

comm devinst = [x] – BACnet device instance ID

comm mbslaveaddr = [0-255] – Modbus slave address

Modbus

Addr Function

1 Flow 1 rate (GPM)

3 Flow 2 rate (GPM)

5 Flow 1 Total (gallons)

7 Flow 2 Total (gallons)

9 Energy Rate (BTU/min)

11 Energy Total (BTU)

13 Batch 1 Count

15 Batch 2 Count

17 Temp 1 (deg F)

19 Temp 2 (deg F

21 Temp Delta (T2-T1)

Troubleshooting

Trouble Codes

1 Relay 1 totalizer rate exceeded

2 Relay 2 rate exceeded

3 Relay 3 rate exceeded

4 Relay 4 rate exceeded

5 Pulse out rate exceeded

20 Error reading EEPROM on faceplate

21 Error writing EEPROM

22 Analog Input card missing

24 Temperature Input card missing

25 Invalid ow units congured

26 Invalid volume units congured

27 Bad input frequency

29 Internal error calculating ow rate

31 Error reading from analog input AD converter channel 1

32 Error reading from analog input AD converter channel 2

36 Error writing to analog input AD converter channel 1

37 Error writing to analog input AD converter channel 2

50 Error reading I2C address 0 (relays, buttons, and LEDs)

51 Error writing to I2C address 0

52 Error reading I2C address 1 (analog input card control lines)

53 Error writing I2C address 1

54 Error reading I2C address 2 (temperature input card control lines)

55 Error writing I2C address 2

71 Watchdog timer reset occurred

82 Fatal error initializing EEPROM

Page 29 June 2018 DSY-UM-01668-EN-02

Page 30

Flow Sensor Inputs

FLOW SENSOR INPUTS

Type Threshold Signal Input Frequency Pull-up Impedance Aux. Power Calibration

Pulse-DI 2.5V DC 30V DC 0.4 Hz…10 kHz 1K…12V DC — 12V DC @30mA K + Offset

Pulse K-factor 2.5V DC 30V DC 0.4 Hz…10 kHz — — 12V DC @30mA Pulse/Gal

Pull-up K-factor 2.5V DC 30V DC 0.4 Hz…10 kHz 1K…12V DC — 12V DC @30mA Pulse/Gal

Analog 4…20mA 10mVPP 50 mA Fused — — 100 Ω 12V DC @30mA Linear

Analog 0…20mA — 50 mA Fused — — 100 Ω 12V DC @30mA Linear

Analog 0…1V DC — 30V DC — — 100 Ω 12V DC @30mA Linear

Analog 0…5V DC — 30V DC — — 100 Ω 12V DC @30mA Linear

Analog 0…10V DC — 30V DC — — 100 Ω 12V DC @30mA Linear

SPECIFICATIONS

Voltage 12…24V DC/AC (limit: 8…35V DC); (limit: 8…28V AC)

Operating

Temperature

Storage Temperature –22…176° F (–30…80° C)

Weight Panel Mount: 12 oz

Pulse and Relays Both pulse and relay are fully functional as either totalizing or setpoint outputs

Pulse Electrical 1 Amp at 35V DC/30V AC Closed: 0.5 Ω at 1 Amp; Open: >108 Ω

Relay Electrical

Pulse/Unit Volume

(Totalizer)

Setpoint (Alarm)

Optional Analog

Output

USB Communication Provides complete access to all programming and operation features

RS-485

Communication

Accessories Programming kit; wall-mount kit

Temperature Inputs

Units of Measure

–4…158° F (–20…70° C)

Resistive Load:

5A @ 120V AC/30V DC

Driving Source: flow total,

BTU total

Driving Source: flow rate,

BTU rate, temperature 1,

temperature 2, delta T

Delay to Set: 1…9999 sec Release Point: 1.0000000…999999999 Delay to Release: 1…9999 sec

Driving Source: flow rate,

BTU rate, temperature 1,

temperature 2, delta T, PID

control

Supports Modbus and BACnet/MSTP

Two of 2-wire 10k type II thermistor; 25…170° F (–3.9…76.7° C) or custom field-defined

3-wire platinum 100Ω RTD; 25…250° F (–3.9…121.1° C) or custom field-defined

Unis of Measure: °F and °C

Zeroing: Compensate

for variances between

temperature elements by

adjusting T2 reading to match

T1 reading.

Rate

Total

Inductive Load:

1A @ 120V AC/30V DC

Rate: 1 pulse per 1.0000000…99999999

units

Units: Any predefined or custom unit Setpoint: 1.0000000…999999999

Range: 4…20 mA; 0…20 mA (isolated

current sinking or sourcing)

Energy Rate Units: kBTU/hr; BTU/min;

kW; Tons; J/Sec; and field programmed

custom units

Constant: Single point correction for

variances in specific heat of transfer

liquid.

US gpm; US gal/sec; gal/hr; US mgal/day; lps; lpm; lph; ft3/Sec; ft3/min; ft3/hr; m3/

sec; m3/min; m3/hr; acre-ft/sec; acre-ft/min; acre-ft/hr; bbl/sec; bbl/min; bbl/hr;

and field programmed custom units 0.00…999999999

US mgal; liters; ft3; m3; acre-ft; bbl; and field programmed custom units

0.00…999999999

DC current draw (~ 280 mA)

AC Power rating (~5 VA)

Contact Time: 1…9999 mS

Sinking: 30V DC @ 0 mA max.;

3V @ 20 mA min.

Sourcing: 600 W max load

Requirements: USB 2.0 A to Mini-B,

five-pin cable

Operating Mode: T1<T2; T1>T2;

absolute; Defines how reverse

energy flows are handled (T1 should

be installed in the same pipe as the

flow sensor)

Energy Total units: kBTU;

Mbtu; kWh; MWh; kJ; and field

programmed custom units

Page 30 June 2018DSY-UM-01668-EN-02

Page 31

PART NUMBER MATRIX

3050

3050

SERIES

Btu Monitor

OPTIONS

No Option 0

Analog Output, RS485 with BACnet and Modbus, and USB 1

MOUNTING

Panel Mount 0

Wall Mount 1

Part Number Matrix

Example: - x x

Figure 7: Series 3050 BTU flow monitor part number matrix

Page 31 June 2018 DSY-UM-01668-EN-02

Page 32

Industrial Flow Monitors, Series 3050

Control. Manage. Optimize.

Data Industrial is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous

research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an

outstanding contractual obligation exists. © 2018 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11 Legacy Document Number: 941700-0030

Loading...

Loading...