Page 1

Badger

Series 200

The Badger Meter Series 200 fl ow sensors feature a six bladed

impeller design with a proprietary non-magnetic sensing

mechanism. The forward swept impeller shape provides higher,

more consistent torque and is less prone to be fouled by water

borne debris. The forward curved shape coupled with the

absence of magnetic drag provides improved operation and

repeatability even at lower fl ow rates. This is especially true

where the impeller is exposed to metallic or rust particles found

in steel or iron pipes. As the liquid fl ow turns the impeller, a low

impedance square wave signal is transmitted with a frequency

proportional to the fl ow rate. The signal can travel up to 2000

feet between the fl ow sensor and the display unit without the

need for amplifi cation. All sensors except irrigation versions are

supplied with 20 feet of 2-conductor 20 A WG shielded U.L. type

PTLC 105°C cable.

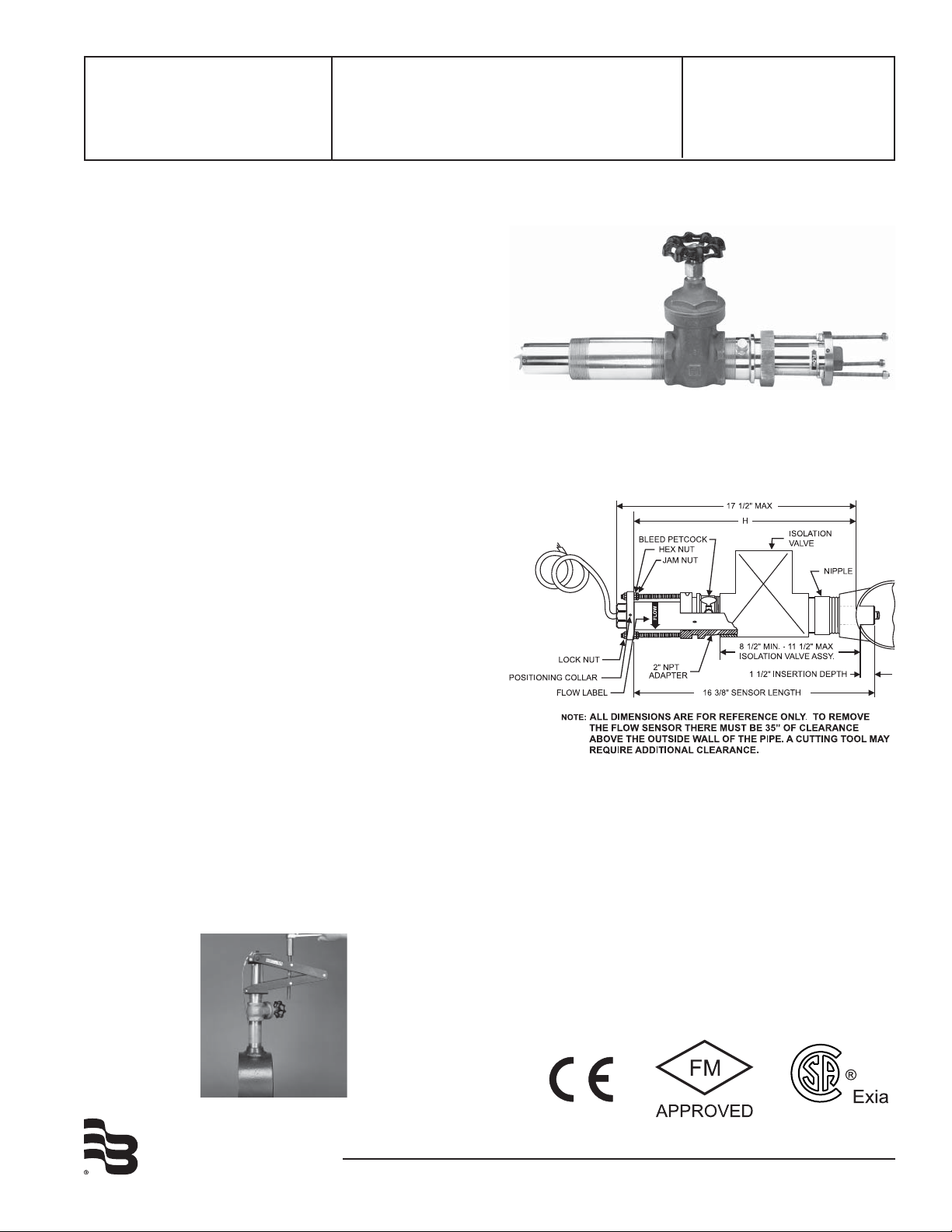

MODEL 225BR AND 226BR/226SS SENSORS

The Model 225BR and 226BR/226SS sensors are used for fl ow

measuring applications in most metallic or non-metallic pipes

where it would be diffi cult to shut down or drain the line for

installation or service. The Model 225 features a gate valve for

isolation. The Model 226 uses a ball valve. If the pipe is to be

hot tapped, the ball valve is recommended. The sensor mounts

in a 2” NPT pipe saddle or Threadolet® for installation in pipe

sizes from 3” to over 40”. Positioning nuts on the three threaded

retaining rods allow the sensor to be accurately positioned to

a standard insertion depth of 1½” into the pipe. When this

insertion depth is maintained, and there are at least 10 upstream

and 5 downstream diameters of straight uninterrupted fl ow, an

accuracy of +/-1% of full scale can be obtained between fl ow

velocities of 0.5 to 30 feet/second. Each sensor is equipped

with an isolation valve and pipe nipple to allow the sensor to

be installed in a pressurized pipe. This is accomplished by fi rst

attaching a saddle or Threadolet® to the pipe and screwing the

nipple and isolation valve into the saddle or Threadolet fi tting. A

hole is then drilled through the pipe using a commercial tapping

machine. When completed, the tapping apparatus is removed,

the isolation valve is closed, and the sensor is installed using a

Model HTT Hot Tap Tool.

®

Models 225/226

Hot Tap Flow Sensor

Technical

Brief

Dimensions Models 225/226

NOTE: that the overall length of the sensor tube is 18 inches

(457mm), however, a clearance height of 35 inches (127mm)

should be allowed for the fully extended length of the sensor

tube outside the isolation valve.

Model HTT - Hot Tap Tool

BadgerMeter, Inc.

DTB-011-01

4-09

Page 2

SPECIFICATIONS

SIZE

ELECTRONICS HOUSING

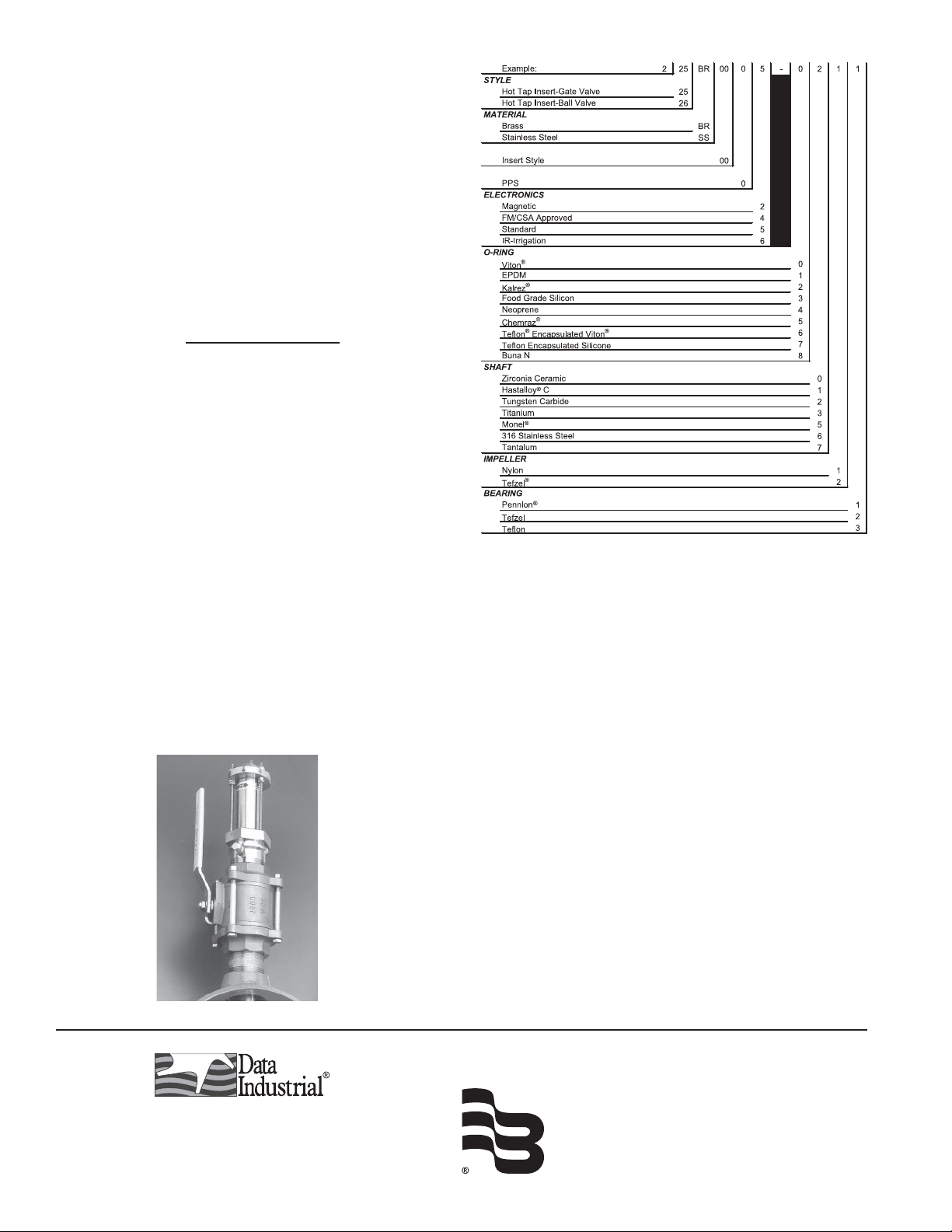

Series 200 Hot Tap Matrix (sizes 3” and up)

Wetted Materials for all sensors

–(see ordering matrix)

Sensor Sleeve and Hex Adapter for 225BR and 226BR

– Sleeve: Admiralty Brass, UNS C44300

– Hex Adapter: Valve Bronze, UNS C83600

Sensor Sleeve and Hex Adapter for 226SS

– 316 Series Stainless Steel

Temperature Ratings

– Standard Version:

221°F (105°C) continuous service

– Irrigation Electronics

150°F (66°C)

Pressure Ratings

At 100°F

225BR 300 psi

226BR 400 psi

226SS 400 psi

Recommended Design Flow Range

– 0.5 to 30 ft/sec

– Initial detection below 0.3 ft/sec

Accuracy

– ± 1.0% of full scale over recommended design fl ow range

– ± 4.0% of reading within calibration range

Repeatability

– ± 0.3% of full scale over recommended design fl ow range

Linearity

– ± 0.2% of full scale over recommended design fl ow range

Transducer Excitation

– Quiescent current 600uA@8VDC to 35VDC max.

– Quiescent voltage (V

Supply Voltage -(600uA*Supply impedance)

– ON State (V

Max. 1.2VDC@40mA current limit (15W+0.7VDC)

Low

Output Frequency

– 3.2 Hz to 200 Hz

Output Pulse Width

)

high

)

– 5 msec ±25%

Electrical Cable for Standard Sensor Electronics

– 20 feet of 2-conductor 20 AWG shielded U.L. type PTLC wire

provided for connection to display or analog transmitter unit.

Rated to 105°C. May be extended to a maximum of 2000 feet

with similar cable and insulation appropriate for application.

Electrical Cable for IR Sensor Electronics

– 48 inches of U.L. Style 116666 copper solid AWG 18 wire with

direct burial insulation. Rated to 105°C.

Badger® and Data Industrial® is a registered trademark of Badger

Meter, Inc.

Pennlon® is a registered trademark of the Dixon Corporation.

Hastalloy ® is a registered trademark of The Haynes Stellite Company.

Monel® is a registered trademark of Inco Alloys International, Inc.

Tefl on®, Tefzel® and Viton® are registered trademarks of DePont Dow

Elastomers.

Chemraz® is a registered trademark of Green Tweed.

226SS

Threadolet® is a registered trademark of Bonney Forge & Tool Works

Coorporation.

Due to continuous research, product improvements and enhancements, Badger

Meter reserves the right to change product or system specifications without notice,

except to the extent an outstanding contractual obligation exists.

Please see our website at www.badgermeter.com

for specific contacts.

Copyright © Badger Meter, Inc. 2009. All rights reserved.

BadgerMeter, Inc.

P.O. Box 581390, Tulsa, Oklahoma 74158

(918) 836-8411 / Fax: (918) 832-9962

www.badgermeter.com

Loading...

Loading...