Page 1

Flow Sensors

Series 220PVCS Insertion Style Flow Sensors

DESCRIPTION

The Data Industrial® Series 200 flow sensors from Badger Meter®

feature a six-bladed impeller design with a proprietary nonmagnetic sensing mechanism. The forward swept impeller shape

provides higher, more consistent torque and is less prone to be

fouled by waterborne debris. The forward curved shape coupled

with the absence of magnetic drag provides improved operation

and repeatability at lower flow rates. This is especially true where

the impeller is exposed to metallic or rust particles found in steel or

iron pipes. As the liquid flow turns the impeller, a low impedance

square wave signal is transmitted with a frequency proportional to

the flow rate. The signal can travel up to 2000 ft between the flow

sensor and the display unit without the need for amplification. All

sensors except irrigation versions are supplied with 20 ft of Belden

type 9320 two-conductor shielded cable.

MODEL 220PVCS

The 220PVCS flow sensor is an insertion style flow sensor

constructed of non-metallic materials for all wetted parts. These

sensors are designed for service in corrosive liquids. The metallic

trim, in non-wetted areas, is 316 stainless steel. The sensor mounts

in a 2 in. NPT thread and may be attached to the pipe with a saddle

or other types of mounting hardware.

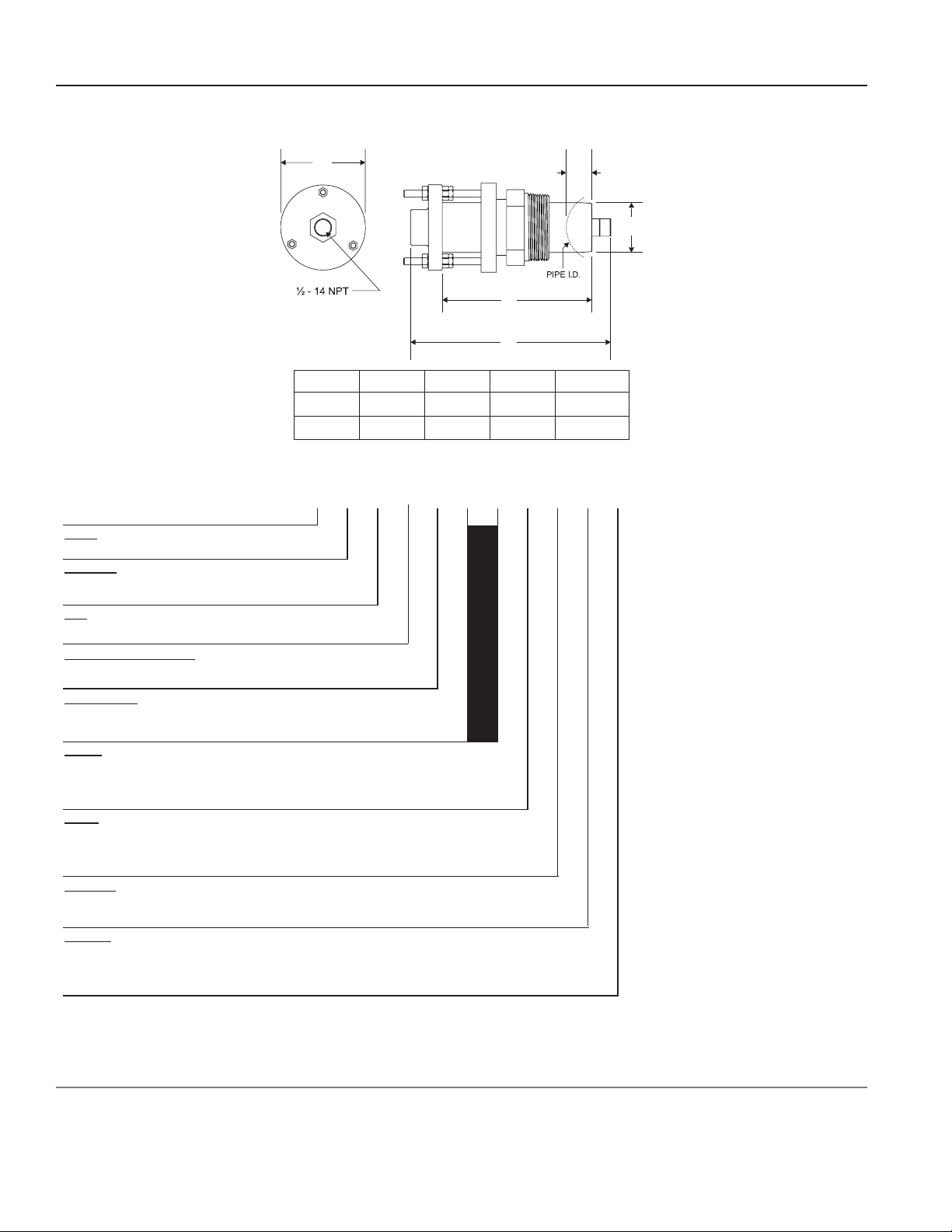

DIMENSIONS

A

B

C

D

E

A B C D E

3-1/4 in. 1-1/2 in. 1-9/10 in. 8 in. 9-11/16 in.

83 mm 38 mm 48 mm 203 mm 249 mm

Figure 1: Dimensions for 220PVCS

SPECIFICATIONS

Impeller & Bearing: Tefzel®

Wetted

Materials

Trim 316 stainless steel

Maximum

Pressure

Recommended

Design Flow

Range

Accuracy ± 1.0% of full scale over recommended design flow range

Repeatability ± 0.3% of full scale over recommended design flow range

Linearity ± 0.2% of full scale over recommended design flow range

Transducer

Excitation

Output

Frequency

Output Pulse

Width

Electrical

Cable

for Standard

Sensor

Electronics

Electrical

Cable

for IR Sensor

Electronics

Certifications CE certified

Shaft: Zirconia ceramic

Housing: Glass reinforced polyphenylene sulfide (PPS)

O-Ring: Ethylene propylene (EPDM)

Sleeve & Mounting Adapter: Polyvinyl chloride (PVC)

100 psi (6.9 bar) @ 68° F (20° C)

0.5…30 ft/sec (0.15…9.1 m/sec) Initial detection below

0.3 ft/sec (0.09 m/sec)

Supply voltage = 8V DC min. 35V DC max.

Quiescent current = 600 uA (typical)

OFF State (V

Supply impedance)

ON State (V

3.2…200 Hz

5 msec ±25%

20 ft (6 m) of 2-conductor 20 AWG shielded UL type

PTLC wire provided for connection to display or analog

transmitter unit. Rated to 221° F (105° C). May be

extended to a maximum of 2000 ft (610 m) with similar

cable and insulation appropriate for application.

48 in. (122 cm) of UL style 116666 copper solid AWG 18

wire with direct burial insulation.

Rated to 221° F (105° C).

) = Supply voltage – (600 uA

High

) = 1.2V DC @ 40 mA (15 Ω + 0.7V DC)

Low

*

SEN-DS-01554-EN-08 (January 2019)

Product Data Sheet

Page 2

Flow Sensors, Series 220PVCS Insertion Style Flow Sensors

A

B

C

D

E

Viton

0

Tefzel

Tefzel

®

Teflon

DIMENSIONS

A B C D E

3-1/4 in. 1-1/2 in. 1-9/10 in. 8 in. 9-11/16 in.

83 mm 38 mm 48 mm 203 mm 249 mm

Figure 2: Dimensions for 220PVCS

PART NUMBERING CONSTRUCTION

Example: 2 20 PVS 00 0 5 - 1 0 2 2

STYLE

Standard Flow 20

MATERIAL

PVC Sleeve w/Stainless Steel Trim PVS

SIZE

Insert Style for pipe sizes 3" and up 00

ELECTRONICS HOUSING

PPS 0

ELECTRONICS

Standard Flow (STANDARD) 5

IR-Irrigation 6

O-RING

®

EPDM (STANDARD) 1

Buna N 8

SHAFT

Zirconia Ceramic 0

Tungsten Carbide (STANDARD) 2

316 Stainless Steel 6

IMPELLER

Nylon (STANDARD) 1

®

BEARING

UHMWPE (STANDARD) 1

®

2

2

3

Control. Manage. Optimize.

Impeller and Data Industrial are registered trademarks of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to

continuous research, product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent

an outstanding contractual obligation exists. © 2019 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Eastern Europe Branch Oce (for Poland, Latvia, Lithuania, Estonia, Ukraine, Belarus) | Badger Meter Europe | ul. Korfantego 6 | 44-193 Knurów | Poland | +48-32-236-8787

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

Switzerland | Badger Meter Swiss AG | Mittelholzerstrasse 8 | 3006 Bern | Switzerland | +41-31-932 01 11 Legacy Document Number: DTB-004

Loading...

Loading...