Page 1

Turbine Flow Meter

1100 Series Turbine Meter

TUR-UM-00014-EN-03 (July 2014)

User Manual

Page 2

Turbine Flow Meters, 1100 Series

CONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operating Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Materials of Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pressure Drop Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operational Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Turbine Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Part Number Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Page ii July 2014

Page 3

Introduction

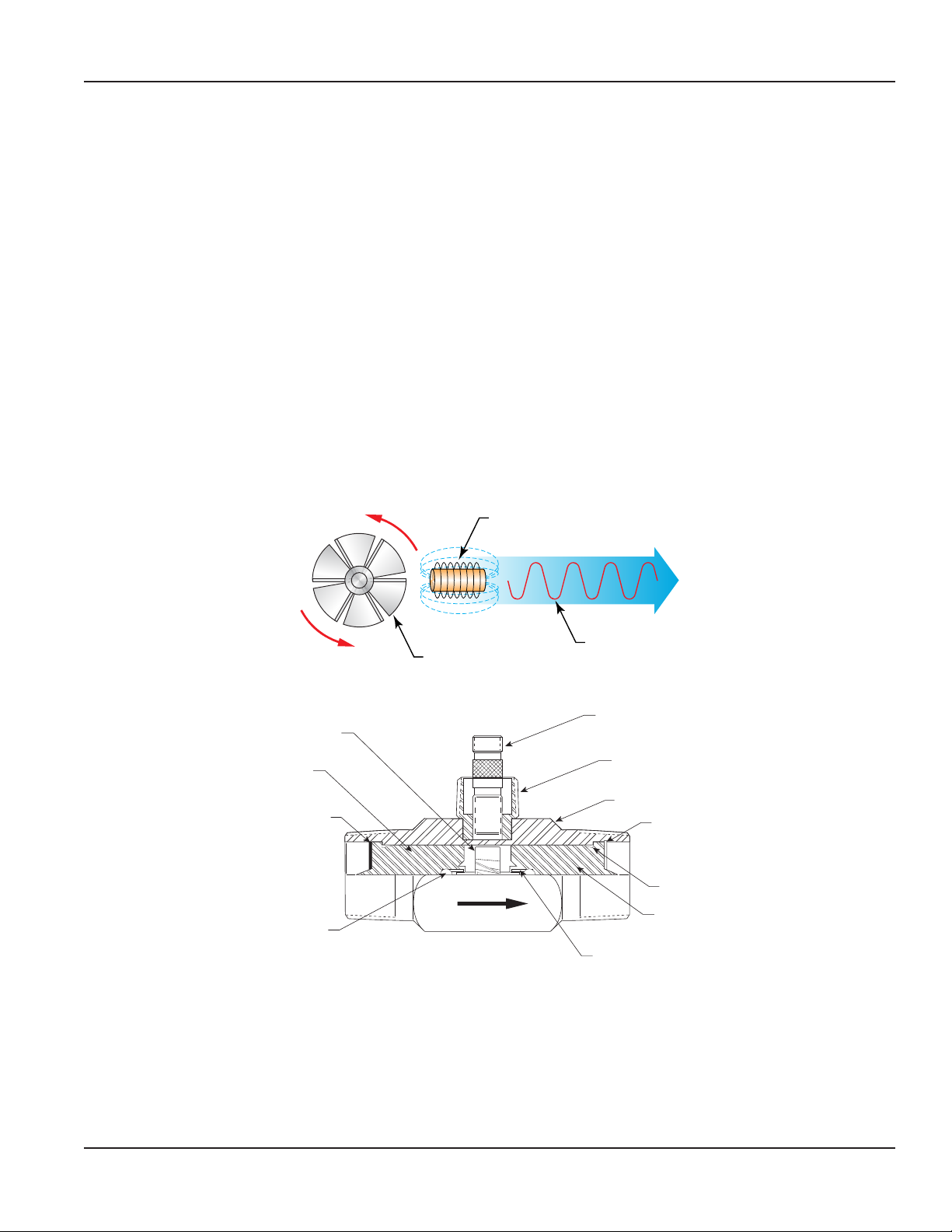

Turbine Rotor

Signal

INTRODUCTION

Designed to withstand the demands of the most rigorous flow measurement applications the Model 1100 turbine flow meter

is reliable, rugged and cost effective. Originally developed for the secondary oil recovery market, the Model 1100 is an ideal

meter for liquid flow measurement on or off the oil field.

The meter features a rugged 316 stainless steel housing and rotor support assemblies, CD4MCU stainless steel rotor, and

abrasive-resistant tungsten carbide rotor, shaft, and journal bearings. The Model 1100 maintains measurement accuracy

and mechanical integrity in the corrosive and abrasive fluids commonly found in oil field water flood project and many

industrial applications.

OPERATING PRINCIPLE

Fluid entering the meter passes through the inlet flow straightener which reduces its turbulent flow pattern and improves

the fluid’s velocity profile. Fluid then passes through the turbine, causing it to rotate at a speed proportional to the fluid

velocity. As each turbine blade passes through the magnetic field, the blade generates an AC voltage pulse in the pickup coil

at the base of the magnetic pickup (see Figure 1). These pulses produce an output frequency proportional to the volumetric

flow through the meter. The output frequency represents flow rate and/or totalization of fluid passing through the turbine

flow meter.

Magnetic Pickup

or

Other Frequency

Output Device

Figure 1: Schematic illustration of electric signal generated by rotor movement

*Rotor and

Rotor Shaft

*Upstream

Rotor Support

*Retaining Ring

*Thrust Ball

NOTE: *Indicates parts supplied in repair kits.

Figure 2: Typical cross-section of B110-375…B111-121 turbine flow meter

Output

Magnetic Pick-up

Conduit Adaptor

Meter Body

Retaining Ring

Groove

Retaining Pins

*Downstream

Rotor Support

*Bearing

Page 3 July 2014 TUR-UM-00014-EN-03

Page 4

Turbine Flow Meter, 1100 Series

SPECIFICATIONS

Materials of Construction

Body 316 Stainless Steel

Rotor CD4MCU Stainless Steel

Rotor Support 316 Stainless Steel

Rotor Shaft and

Bearing

Operating Parameters

Temperature

Pressure

Accuracy

Repeatability ±0.1%.

Calibration Water (NIST traceable calibration).

Approvals

End Connections NPT, BSP, Victaulic, Flange, and Hose Barbed.

*Contact the factory for ordering options.

OTE:N Consult factory for pressure ratings for flanged meters.

Tungsten Carbide

–150…350° F (–101…177° C).

The meter should not be subjected to temperatures above 350° F (177° C), or below –150° F (–101° C) or the

freezing point of the metered liquid.

Maximum pressure ratings as follows:

5000 psi for all NPT meters up to 2 in.

3000 psi for 3 in. and 4 in. Grayloc meters.

800 psi for 3…10 in. grooved end meters.

±1% of reading for 7/8 in. and larger meters.

±1% of reading over the upper 70% of the measuring range for 3/8 in., 1/2 in., and 3/4 in. meters.

“Single Seal”: ANSI/ISA 12.27.01-2003; MWP 5,000 PSI (34.5 MPa), 350° F.

I.S. Entity Parameters with Badger Meter B111109 standard magnetic pickup installed:

Vmax = 10V, Imax = 7mA, Ci = 0µF, Li = 0.9H

INSTALLATION

PRESSURE IN EXCESS OF ALLOWABLE RATING MAY CAUSE THE HOUSING TO BURST AND CAUSE SERIOUS

PERSONAL INJURY.

AVERTISSEMENT

LA PRESSION AU-DESSUS DE L’ESTIMATION PERMISE PEUT FAIRE ÉCLATER ET CAUSER LE LOGEMENT LE DOMMAGE

CORPOREL SÉRIEUX.

1. Check the internals of the ow meter for any foreign material. Make sure the turbine rotor spins freely prior to installation.

Also, check uid lines and remove any debris found.

2. Install the ow meter with the ow arrow, etched on the exterior of the meter body, pointing in the direction of uid ow.

Though the meter is designed to function in any position, where possible, install it horizontally with the conduit adapter

facing upward.

3. Thread a magnetic pickup (Badger Meter model B111109 or equivalent) into the conduit adapter completely nger tight

without forcing. Secure with a lock nut if supplied.

4. Install conduit or other ttings suitable for the installation area onto the conduit adapter hub on the ow meter.

Page 4 July 2014

Page 5

Installation

All Badger Meter Model 1100 turbine meters use stainless steel and tungsten carbide construction materials. Make sure the

operating fluid is compatible with these materials. Incompatible fluids can cause deterioration of internal components and

cause a reduction in meter accuracy.

The measured liquid should be free of any large particles that may inhibit rotation of the turbine blades. If particles are

present, install a mesh strainer upstream before operating the flow meter. See Table 1 for strainer recommendations.

Part Number Strainer Mesh Clearance Filter Size

B110-375 60 x 60 0.0092 in. 260 μm

B110-500 60 x 60 0.0092 in. 260 μm

B110-750 60 x 60 0.0092 in. 260 μm

B110-875 60 x 60 0.0092 in. 260 μm

B111-110 60 x 60 0.0092 in. 260 μm

B111-115 20 x 20 0.0340 in. 0.86 mm

B111-120 10 x 10 0.0650 in. 1.6 mm

B111-121 20 x 20 0.0340 in. 0.86 mm

B111-130, B117-130 8 x 8 0.0900 in. 2.3 mm

B111-140, B117-140 10 x 10 0.0650 in. 1.6 mm

B111-160 4 x 4 0.1875 in. 4.8 mm

B111-180 8 x 8 0.0900 in. 2.3 mm

B111-200 4 x 4 0.1875 in. 4.8 mm

Table 1: Strainer mesh installation details

The preferred plumbing setup is one containing a bypass line (see Figure 3) that allows meter inspection and repair without

interrupting flow. If a bypass line is not used, it is important that all control valves be located downstream of

the flow meter (see Figure 4).

STRIKING AN EMPTY METER WITH HIGH VELOCITY FLOW STREAM CAN CAUSES DAMAGE.

ATTENTION

DES DOMMAGES PEUVENT ÊTRE PROVOQUÉS EN FRAPPANT UN MÈTRE VIDE AVEC UN JET D’ÉCOULEMENT DE VITESSE

ÉLEVÉE.

This is true with any restriction in the flow line that may cause the liquid to flash. If necessary, install air eliminators to ensure

that the meter is not incorrectly measuring entrained air or gas.

Badger Meter recommends installation of a minimum length, equal to ten (10) pipe diameters of straight pipe on the

upstream side and five (5) diameters on the downstream side of the flow meter. Otherwise, meter accuracy may be affected.

Piping should be the same size as the meter bore or threaded port size.

Severe pulsation and mechanical vibration affect accuracy and shorten the life of the meter. If this condition is present,

consider using a flow meter possessing superior resistance to pulsation and vibration like the Badger Meter QuicSert. Do not

locate the flow meter or connection cable close to electric motors, transformers, sparking devices, high voltage lines, or place

connecting cable in conduit with wires furnishing power for such devices. These devices can induce false signals in the flow

meter coil or cable, causing the meter to read inaccurately.

If problems arise with the flow meter, consult the Troubleshooting Guide on page 11. If further problems arise, consult

the factory.

If damaged replace the internal components of the turbine flow meter with a turbine meter repair kit available from

Badger Meter. For information pertaining to the repair kits, see Turbine Replacement on page 8.

Page 5 July 2014 TUR-UM-00014-EN-03

Page 6

Turbine Flow Meter, 1100 Series

Isolation Valve

21

Electronic

Flow Monitor

Isolation and

Flow Rate

Control Valve

10 Pipe

Diameters

Electronic

Flow Monitor

Turbine

Flow Meter

Bypass Valve

Figure 3: Meter installation with a bypass line

21

5 Pipe

Diameters

Control Valve

10 Pipe

Diameters

Turbine

Flow Meter

Figure 4: Meter installation without a bypass line

5 Pipe

Diameters

Page 6 July 2014

Page 7

PRESSURE DROP CHARTS

Pressure drop charts

30

Pressure Drop vs Flow Rate

2

Pressure Drop vs Flow Rate

1

10

3/4”

3/8”

3”

1/2”

3/4”

7/8”

1”

1

3/8”

1-1/2”

2”

6”

4”

10”

8”

0.1

Pressure Drop Bar

1/2”

1”

7/8”

1-1/2”

2”

4”

3”

8”

6”

10”

Pressure Drop PSID

0.01

0.1

0.5

(17)

(34)

1

10

(343)

100

(3429)

1000

(34,286)

8000

(274,236)

Flow Rate GPM (BPD)

0.005

1

(1.44)

10

(14.4)

Flow Rate LPM (m³/Day)

100

(144)

1000

(1440)

10,000

(14,400)

30,000

(57,600)

Figure 5: English units pressure drops Figure 6: Metric units pressure drops

OPERATIONAL STARTUP

Follow these steps when installing and starting the meter.

MAKE SURE TO SHUT OFF FLUID FLOW AND RELEASE PRESSURE IN THE LINE BEFORE ATTEMPTING TO INSTALL THE

METER IN AN EXISTING SYSTEM.

AVERTISSEMENT

ASSUREZ-VOUS QUE LE FLUX DE FLUIDE A ÉTÉ COUPÉ ET DE LA PRESSION DANS LA LIGNE A ÉTÉ LIBÉRÉE AVANT

D’ESSAYER D’INSTALLER LE MÈTRE DANS UN SYSTÈME ACTUEL.

After meter installation, close the isolation valves and open the bypass valve. Allow liquid to flow through the bypass valve for

sufficient time to eliminate any air or gas in the flow line.

HIGH VELOCITY AIR OR GAS MAY DAMAGE THE INTERNAL COMPONENTS OF THE METER.

ATTENTION

DES DOMMAGES PEUVENT ÊTRE PROVOQUÉS EN FRAPPANT UN MÈTRE VIDE AVEC UN JET D’ÉCOULEMENT DE VITESSE

ÉLEVÉE.

5. Open the upstream isolating valve slowly to eliminate hydraulic shock while charging the meter with the liquid. Open the

valve to full open.

6. Open downstream isolating valve to permit meter to operate.

7. Close the bypass valve to a full closed position.

8. Adjust the downstream valve to provide the required ow rate through the meter.

OTE:N If necessary, use the downstream valve as a control valve.

Page 7 July 2014 TUR-UM-00014-EN-03

Page 8

Turbine Flow Meter, 1100 Series

TURBINE REPLACEMENT

The Model 1100 turbine flow meter uses wear resistant moving parts to provide trouble-free operation and long service life.

The Designed for easy field service of a damaged flow meter Model 1100 repair kits replace only the internal parts, rather than

replacing the entire flow meter. Repair parts use stainless steel alloys and tungsten carbide construction materials.

Each repair kit is factory calibrated to ensure accuracy throughout the entire flow range. Each kit is complete and includes

a new K factor, which is the calibrated number of pulses generated by each gallon of liquid. Recalibration of the monitor or

other electronics uses the K factor to provide accurate output data.

OTE:N If the meter repair kit part number ends in NCC (no calibration), it was not factory calibrated. For these repair kits, use

the nominal K factor.

Turbine Replacement Kit Part Number

Flow Meter Size

3/8 in. B110-375, B110-375-1/2 B251-102

1/2 in. B110-500, B110-500-1/2 B251-105

3/4 in. B110-750, B110-750-1/2 B251-108

7/8 in. B110-875 B251-109

1 in. B111-110 B251-112

1-1/2 in. B111-115 B251-116

2 in. Low B111-121 B251-116

2 in. B111-120 B251-120

3 in. B111-130 B251-131

4 in. B111-140 B251-141

6 in. B111-160 B251-161

8 in. B111-180 B251-181

10 in. B111-200 B251-200

Standard Magnetic Pick-up All Meter Sizes B111109

Replacement Kit Fits

Meter Part Number

Repair Kit Part Number

Table 2: Repair kit part numbers

Turbine Assembly Removal

HIGH-PRESSURE LEAKS ARE DANGEROUS AND MAY CAUSE PERSONAL INJURY. MAKE SURE TO SHUT OFF FLUID FLOW

AND RELEASE RESIDUAL PRESSURE IN THE LINE BEFORE ATTEMPTING TO REMOVE THE METER.

AVERTISSEMENT

LES FUITES À HAUTE PRESSION SONT DANGEREUSES ET PEUVENT CAUSER LE DOMMAGE CORPOREL. ASSUREZ-VOUS

QUE LE FLUX DE FLUIDE A ÉTÉ COUPÉ ET DE LA PRESSION DANS LA LIGNE A ÉTÉ LIBÉRÉE AVANT D’ESSAYER D’ENLEVER

LE MÈTRE.

Page 8 July 2014

Page 9

Turbine replacement

Disassembly

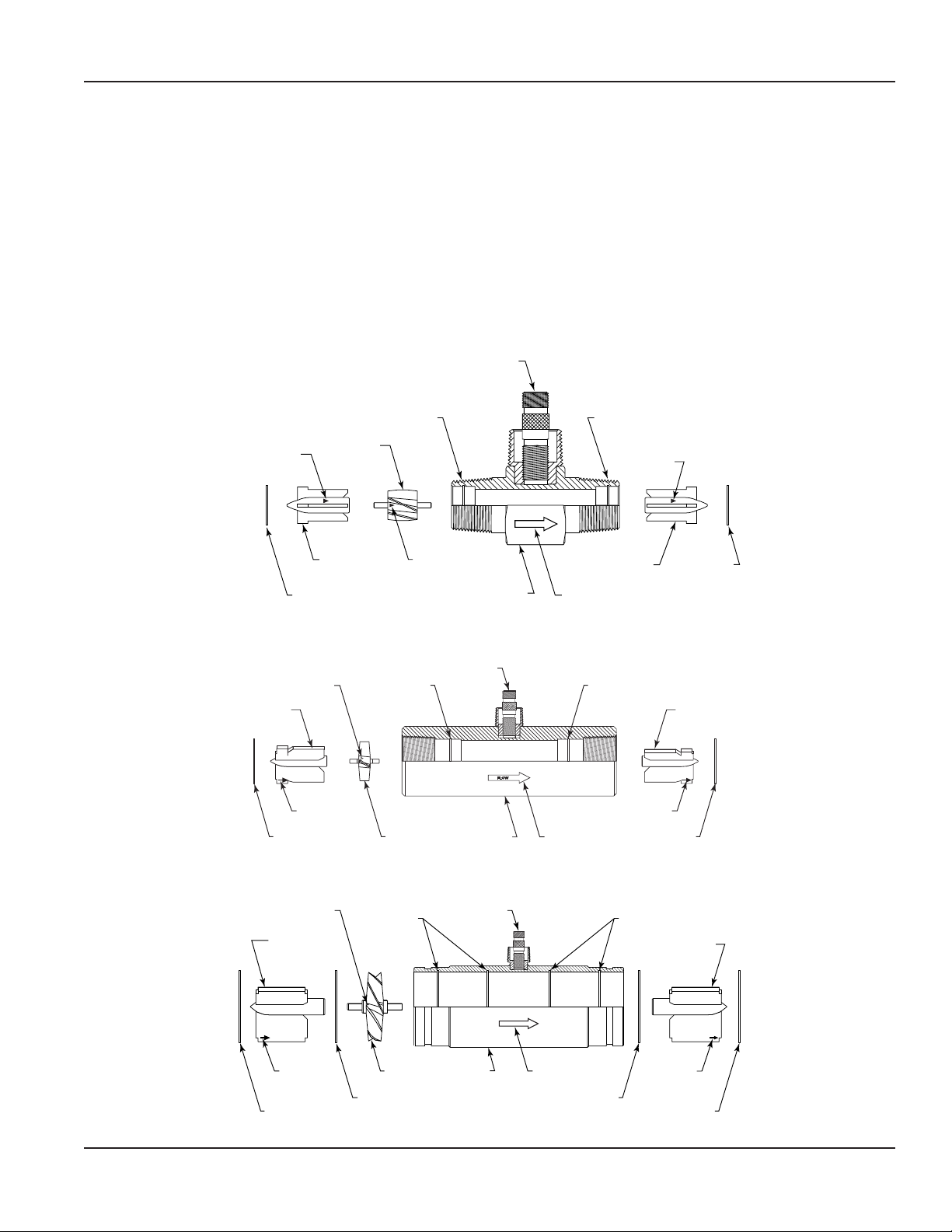

1. Refer to Figure 7, Figure 8 and Figure 9 for relative positions of repair kit components.

2. Remove the magnetic pickup from the meter body to avoid damage during repair.

3. Remove the retaining ring from one end of the meter.

4. Remove the rotor support from the body. If the rotor support is jammed in the body, use a pair of pliers or vise-grips to

break the rotor support free.

5. The rotor may also be removed at this time.

OTE:N 4 in. and larger meters have two retaining rings (one on either side of the rotor) that require removal before the rotor

can be removed (see Figure 9).

6. Remove the retaining ring from the opposite side of the meter.

7. Remove the second rotor support.

Magnetic

Pick-up

Flow Direction

Arrow

Flow Direction

Upstream

Rotor Support

Retaining Ring

Upstream

Rotor Support

Retaining Ring

Rotor

Assembly

Retaining Ring

Groove

Flow Direction

Arrow

Flow Meter

Body

FLOW

Retaining Ring

Downstream

Rotor Support

Flow Direction

Arrow

Figure 7: Component positions for B110-375…B111-115 and B111-121

Magnetic

Pick-up

Body

Retaining Ring

FLOW

Flow Direction

Arrow

Arrow

Flow Direction

Arrow

Retaining Ring

Groove

Rotor

Assembly

Groove

Flow Direction

Arrow

Groove

Flow Direction

Arrow

Retaining RingFlow Meter

Retaining Ring

Downstream

Rotor Support

Flow Direction

Arrow

Upstream

Rotor Support

Flow Direction

Arrow

Retaining Ring

Figure 8: Component positions for B111-120 and B111-130

Retaining Ring

Grooves

Rotor

Assembly

Retaining Ring Retaining Ring

Magnetic

Pick-up

Flow Meter

Body

FLOW

Flow Direction

Arrow

Retaining Ring

Figure 9: Component positions for B111-140 and B111-200

Grooves

Downstream

Rotor Support

Flow Direction

Arrow

Retaining Ring

Page 9 July 2014 TUR-UM-00014-EN-03

Page 10

Turbine Flow Meter, 1100 Series

New Turbine Kit Installation

MPORTANTI

Before reassembly, note that an arrow is cast or engraved on each component. The arrow indicates the primary flow direction. When

reassembled, the arrowheads must point in the direction of the fluid flow. The arrows must also be oriented in the up position on

both rotor supports. The magnetic pickup side of the body signifies the up position. Performance of repair kit calibration is in the up

position. Reinstallation of the repair kit in the up position ensures continuation of accurate measurements. Figure 7, Figure 8, and

Figure 9 show the proper alignment and orientation of the repair kits.

OTE:N Fractional size (3/8 in., 1/2 in. and 3/4 in.) rotors do not contain a cast or engraved arrow. However, a colored cap

on the downstream side of the rotor shaft indicates flow direction. Remove this cap before assembly, noting

flow direction.

1. Install one of the rotor supports into the body bore, noting the orientation of the arrow.

2. Secure a retaining ring in the groove provided. Check for complete installation of retaining rings in each groove.

OTE:N 4 in. and larger meters have a retaining ring at both ends of the rotor (see Figure 9).

3. Insert the rotor and second rotor support in the opposite side of the body, noting the orientation of the arrow.

4. Secure the second retaining ring in the opposite groove, using the same procedure as in step 2 above.

EXCESS AIR PRESSURE MAY DAMAGE THE ROTOR AND BEARINGS BY OVER SPINNING.

ATTENTION

LA PRESSION ATMOSPHÉRIQUE EXCESSIVE PEUT ENDOMMAGER LE ROTOR ET LES ROULEMENTS PRÈS AU-DESSUS DE

LA ROTATION.

5. Check the meter by lightly pung air through the assembly. If the rotor does not turn freely, disassemble the meter and

remove anything that might obstruct movement of the rotor.

OTE:N At this time, electronics require recalibration. Refer to the display's user manual. If there are any questions on

recalibration, contact Badger Meter, Inc. or the manufacturer of the associated electronics.

6. Install the magnetic pickup.

PART NUMBER INFORMATION

Part Number Meter Size

B110-375-1/2 3/8 in. 3 76.2 1/2 in. Male NPT 0.6…3.0 20…100 3.3…16

B110-500-1/2 1/2 in. 3 76.2 1/2 in. Male NPT 0.75…7.5 25…250 4.1…41

B110-750-1/2 3/4 in. 3 76.2 1/2 in. Male NPT 2…15 68…515 10.9…81.75

B110-375 3/8 in. 4 101.6 1 in. Male NPT 0.6…3.0 20…100 3.3…16

B110-500 1/2 in. 4 101.6 1 in. Male NPT 0.75…7.5 25…250 4.1…41

B110-750 3/4 in. 4 101.6 1 in. Male NPT 2…15 68…515 10.9…81.75

B110-875 7/8 in. 4 101.6 1 in. Male NPT 3…30 100…1000 16…160

B111-110 1 in. 4 101.6 1 in. Male NPT 5…50 170…1700 27.25…272.5

B111-115 1-1/2 in. 6 152.4 1-1/2 in. Male NPT 15…180 515…6000 82…981

B111-121 2 in. Low 6 152.4 2 in. Male NPT 15…180 515…6000 82…981

B111-120 2 in. 10 254 2 in. Female NPT 40…400 1300…13,000 218…2180

B111-130

B111-140 4 in. 12 304.8 4 in. Grooved End 100…1200 3400…41,000 545…6540

B111-160 6 in. 12 304.8 6 in. Grooved End 200…2500 6800…86,000 1090…13,626

B111-180 8 in. 12 304.8 8 in. Grooved End 350…3500

B111-200 10 in. 12 304.8 10 in. Grooved End 500…5000

3 in. 12-1/2 317.5 3 in. Grooved End 60…600 2100…21,000 327…3270

End to End Length

inches mm gpm bpd m³/d

End Connection

Flow Ranges

12,000…120,000

17,000…171,000

1363…19,076

2725…27,252

Page 10 July 2014

Page 11

TROUBLESHOOTING GUIDE

Trouble Possible Cause Remedy

Part number information

Cavitation.

Meter indicates higher than actual flow rate

Meter indicates lower than actual flow rate.

Erratic system indication, meter alone works

well (remote monitor application only).

Indicator shows flow when shut off.

No flow indication.

Full or partial open position.

Erratic indication at low flow, good

indication at high flow.

No flow indication. Faulty pickup. Replace pickup.

System works perfect, except indicates

lower flow over entire range.

Debris on rotor support.

Build up of foreign material on meter bore.

Gas in liquid.

Debris on rotor.

Worn bearing.

Viscosity higher than calibrated.

Ground loop in shielding.

Mechanical vibration causes rotor to

oscillate without turning.

Fluid shock, full flow into dry meter or

impact caused bearing separation or

broken rotor shaft.

Rotor has foreign material wrapped around

it.

By-pass flow, leak.

Increase back pressure.

Clean meter.

Clean meter.

Install gas eliminator ahead of meter.

Clean meter and add filter.

Clean meter and add filter.

Recalibrate monitor.

Ground shield one place only. Look for

internal electronic instrument ground.

Reroute cables away from electrical noise.

Isolate meter.

Rebuild meter with repair kit and recalibrate

monitor. Move to location where meter

is full on startup or add downstream flow

control valve.

Clean meter and add filter.

Repair or replace bypass valves, or faulty

solenoid valves.

Meter indicating high flow, upstream piping

at meter smaller than meter bore.

Meter indicating low flow, upstream piping

at meter smaller than meter bore.

Fluid jet impingement on rotor. Change piping.

Viscosity lower than calibrated.

Change temperature, change fluid or

recalibrate meter.

Page 11 July 2014 TUR-UM-00014-EN-03

Page 12

Control. Manage. Optimize.

Blancett is a registered trademarks of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous research,

product improvements and enhancements, Badger Meter reserves the right to change product or system specications without notice, except to the extent an outstanding

contractual obligation exists. © 2014 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

The Americas | Badger Meter | 4545 West Brown Deer Rd | PO Box 245036 | Milwaukee, WI 53224-9536 | 800-876-3837 | 414-355-0400

México | Badger Meter de las Americas, S.A. de C.V. | Pedro Luis Ogazón N°32 | Esq. Angelina N°24 | Colonia Guadalupe Inn | CP 01050 | México, DF | México | +52-55-5662-0882

Europe, Middle East and Africa | Badger Meter Europa GmbH | Nurtinger Str 76 | 72639 Neuen | Germany | +49-7025-9208-0

Europe, Middle East Branch Oce | Badger Meter Europe | PO Box 341442 | Dubai Silicon Oasis, Head Quarter Building, Wing C, Oce #C209 | Dubai / UAE | +971-4-371 2503

Czech Republic | Badger Meter Czech Republic s.r.o. | Maříkova 2082/26 | 621 00 Brno, Czech Republic | +420-5-41420411

Slovakia | Badger Meter Slovakia s.r.o. | Racianska 109/B | 831 02 Bratislava, Slovakia | +421-2-44 63 83 01

Asia Pacic | Badger Meter | 80 Marine Parade Rd | 21-06 Parkway Parade | Singapore 449269 | +65-63464836

China | Badger Meter | 7-1202 | 99 Hangzhong Road | Minhang District | Shanghai | China 201101 | +86-21-5763 5412 Legacy Document Number: 02-TUR-UM-00103-EN

Loading...

Loading...