Bacharach Fyrite Pro, Fyrite Pro 100, Fyrite Pro 105, Fyrite Pro 110, Fyrite Pro 120 Operation & Maintenance Manual

...Page 1

Fyrite® Pro

Combustion Gas Analyzer

Instruction 0024-9395

Operation & Maintenance

Rev. 12 – October 2010

&

CO

O

25

2

52

PPM

%

.

Product Leadership • Training • Service • Reliability

ENTER

HOLD

LIGHT

I/O

Page 2

WARRANTY

Bacharach, Inc. warrants to Buyer that at the time of delivery this Product will be free from defects in mater ial

and manufac ture and will conform substan tially to Bach arach Inc.’s ap plicable spec i fi ca tions. Bacharach’s

li a bil i ty and Buyer’s remedy under this warranty are lim it ed to the repair or replacement, at Ba charach’s option,

of this Product or parts thereof returned to Seller at the factory of manufac ture and shown to Bacharach Inc.’s

reasonable satisfaction to have been defective; provided that written notice of the defect shall have been given

by Buyer to Bacharach Inc. within two (2) years after the date of delivery of this Product by Bacharach, Inc.

Bacharach, Inc. warrants to Buyer that it will convey good title to this Product. Bacharach’s liability and Buyer’s

remedy under this warranty of title are limited to the removal of any title defects or, at the election of Bacha rach,

to the replacement of this Product or parts thereof that are defective in title.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN AND ACCEPTED IN LIEU OF (I) ANY

AND ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, IN CLUD ING WITH OUT LIMITATION THE IMPLIED WARRANTIES OF MERCHAN TABILITY AND FITNESS FOR A PARTICULAR PURPOSE: AND (II) ANY

OBLIGA TION, LIABILITY, RIGHT, CLAIM OR REM E DY IN CON TRACT OR TORT, WHETHER OR NOT ARISING FROM BACH A RACH’S NEGLIGENCE, ACTUAL OR IM PLIED. The remedies of the Buyer shall be limited

to those provided herein to the exclusion of any and all other remedies includ ing, without limita tion incidental or

consequen tial dam ag es. No agree ment varying or ex tend ing the foregoing warranties, remedies or this limitation will be binding upon Bacharach, Inc. unless in writing, signed by a duly au tho rized officer of Bacharach.

Register Your Warranty by Visiting

www.MyBacharach.com

Notice:

Product improvements and enhancements are continuous, therefore the spec i fi ca tions and in for ma tion

contained in this document may change without notice.

Bacharach, Inc. shall not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

No part of this document may be photocopied, reproduced, or translated to another language without the prior

written consent of Bacharach, Inc.

Copyright © 2002–2010, Bacharach, Inc., all rights reserved.

BACHARACH and Fyrite are registered trademarks of Bacharach, Inc. All other trademarks,

trade names, service marks and logos referenced herein belong to their respective companies.

A

Instruction 0024-9428

Page 3

Fyrite Pro

Contents

Ordering Information .......................................................... iii

1.0 INTRODUCTION .............................................................. 1

1.1 The Fyrite Pro..................................................................................1

1.2 Operational Overview .....................................................................2

2.0 TECHNICAL CHARACTERISTICS .............................. 3

3.0 SETTING UP THE ANALYZER ..................................... 5

3.1 Preliminary Steps ............................................................................5

3.2 Checking & Replacing the Batteries .............................................. 5

3.3 Connecting the Probe Hose and Thermocouple ............................. 6

3.4 Front Panel Push Buttons ............................................................11

3.5 Setup Mode ....................................................................................12

3.5.1 Entering Setup ................................................................12

3.5.2 Selecting Temperature Units ..........................................12

3.5.3 CO Channel Setup ...........................................................13

3.5.4 Draft Channel Setup .......................................................13

3.5.5 Time Setup .......................................................................14

3.5.6 Date Setup ....................................................................... 14

3.5.7 Year Setup ....................................................................... 15

3.5.8 Selecting Printer Protocol ...............................................15

3.5.9 Exiting the Setup Screen ................................................ 15

4.0 OPERATION .................................................................... 17

4.1 Performing CO and Draft Testing ................................................ 17

4.1.1 Analyzer Turn On and Warm Up ...................................17

4.1.2 Measuring CO ..................................................................18

4.1.3 Measuring Draft .............................................................. 18

4.2 Performing a Combustion Test using the Model 110/120/125 ....19

4.2.1 Analyzer Turn On and Warm Up ...................................19

4.2.2 Selecting a Fuel ............................................................... 19

4.2.3 Sampling Point ................................................................20

4.2.4 Performing a Combustion Effi ciency Test ...................... 22

4.2.5 Ending a Combustion Test .............................................. 22

4.3 Operating Tips ............................................................................... 23

4.4 Using the Backlight .......................................................................24

4.5 Using the Probe .............................................................................24

4.6 Saving Test Data in Memory ........................................................ 24

Instruction 0024-9395

i

Page 4

Fyrite Pro

4.7 Opening and Viewing Saved Test Data .......................................25

4.8 Printing Test Data.........................................................................26

4.9 Clearing Saved Test Data .............................................................28

4.10 Turning OFF the Analyzer & CO Purge .....................................28

4.11 Resetting the Microprocessor ...................................................... 29

4.12 Run Mode Screens ........................................................................29

4.13 Screen Descriptions ..................................................................... 33

4.13.1 Warm-Up Screens .........................................................33

4.13.2 CO Screen .....................................................................33

4.13.3 CO & Draft Screen ........................................................ 34

4.13.4 Draft Zero Screen ......................................................... 34

4.13.5 Fuel Screen ................................................................... 35

4.13.6 O

4.13.7 CO & O

4.13.8 CO

Screen .......................................................................35

2

Screen ............................................................36

2

& Excess Air Screen ............................................. 36

2

4.13.9 Temperature Differential Screen .................................37

4.13.10 Stack Temperature & Effi ciency Screen ...................37

4.13.11 Ambient Air Temperature Screen ............................38

4.13.12 CO Air Free Screen ...................................................38

4.13.13 Sensor Error Screen ..................................................39

5.0 CALIBRATION & MAINTENANCE ............................ 41

5.1 Entering the Calibration Mode and Testing

the Display Segments ....................................................................41

5.2 Ambient Temperature Calibration ..............................................42

5.3 Combustion Air Thermocouple Calibration ................................42

5.4 Stack Thermocouple Calibration .................................................. 43

5.5 Oxygen Sensor Zero ...................................................................... 44

5.6 CO Sensor Zero & Calibration ...................................................... 45

5.7 Draft Calibration .......................................................................... 47

5.8 Water Trap / Filter Maintenance .................................................48

5.9 O

Sensor Replacement ................................................................. 49

2

5.10 CO Sensor Replacement ..............................................................50

5.11 Pump Assembly Replacement ..................................................... 51

6.0 PARTS & SERVICE ........................................................ 55

6.1 Replacement Parts ........................................................................ 55

6.2 Accessories .....................................................................................55

6.2.1 Standard Accessories ......................................................55

6.2.2 Optional Accessories ........................................................56

6.3 Service Centers .............................................................................. 57

ii

Instruction 0024-9395

Page 5

Fyrite Pro

Confi gurations

Fyrite Pro

Ordering Information

Model 100 100

Printer

Kit

24-

Part Number

Measurements:

Oxygen

Stack

Temperature

Ambient

Temperature

Second

Thermocouple

Channel

(Combustion Air

Temperature)

8200

24-

8201

105 1 10 120 125 125

Printer

Kit

24-

8202

24-

8103

24-

8104

24-

8105

24-

8205

125

Printer/

Oil Kit

24-

8206

Differential

Temperature

Carbon Monoxide

(CO)

Draft

Differential

Presssure*

Instruction 0024-9395

iii

Page 6

Fyrite Pro

Notes:

iv

Instruction 0024-9395

Page 7

Fyrite Pro

1.0 INTRODUCTION

1.1 The Fyrite Pro

The Fyrite Pro series of instruments are hand-held an a lyz ers that are

designed for on-demand sampling of residential furnaces and appliances.

The more advanced models can also to used to check combustion efficiency

by measuring the stack temperature and the percent oxygen level in the

flue-gas stream.

The Fyrite Pro is completely upgradable from the very simple Model 100

that measures only carbon monoxide, to the Model 125 that measures

carbon monoxide (CO), oxygen (O

air temperature, stack temperature, and combustion air temperature, as

well as calculating combustion efficiency, excess air, carbon dioxide (CO

differential temperature, and CO air free.

), draft, differential pressure, ambient

2

),

2

This manual contains information on all models of the Fyrite Pro. Please

disregard any information that does not pertain to your model.

WARNING S!

This analyzer should not be used on a continuous basis.

This analyzer does not have an audible alarm, and should

not be used as a safety device.

Except for battery replacement, this analyzer should only be

opened and ser viced by au tho rized personnel.

When testing an appliance, a full visual in spec tion of the

appliance should be carried out to ensure its safe op er a tion.

CAUTION!

When the instrument is used in an ineffi cient furnace or

boiler application where there is a high emission of soot,

probe sample fi lter may become clogged. Check fi lter before

every use to confi rm that it is clean for use or replace with

a new fi lter. To prevent this from occurring, a smoke test

should be performed before operating under such conditions

to ensure that the furnace is burning at a level appropriate

for the use of this instrument.

Instruction 0024-9395

1

Page 8

Fyrite Pro

1.2 Operational Overview

Pressing the I/O button turns the analyzer ON. Note that there is a warm-

up period of either 10 or 60 seconds, dependent on the analyzer’s model and

setup, that must elapse before the analyzer can be used.

When using the analyzer to just measure CO or draft, insert the analyzer’s probe into the flue-gas stream of the appliance under test and begin

testing. The measured values of draft and/or CO will appear on the analyzer’s LCD.

For models that calculate combustion efficiency, choose a fuel code that corresponds to the fuel being burned by the appliance being tested, and then

press the ENTER button to place the analyzer into its Run Mode. Begin

testing by inserting the analyzer’s probe tube into the flue-gas stream

of the appliance under test. The analyzer will monitor the flue gas and

display measured and calculated values that are relative to the combustion

process. These values are dis played on the analyzer’s LCD, and are chosen

for display by pressing the In cre ment (▲) and Dec re ment (▼) but tons.

Pressing the HOLD button during a test will freeze all measured and calculated values at their current levels. Pressing the ENTER button resumes testing.

For analyzers with memory, pressing the HOLD button twice during a

test will display the Print/Memory Menu Screen. Using the ▲▼ and

ENTER buttons the operator can choose to print the current readings,

save the current readings in memory, recall and view saved readings from

memory, clear all the memory, or print all saved readings.

A backlight enables an operator to read the display in dimly-lit areas.

Pressing the LIGHT button turns the backlight ON and OFF. The backlight

will automatically turn OFF after 10 minutes of keyboard inactivity.

A power saver function will shut the analyzer OFF after 20 min utes of keyboard inactivity. For models with an O

saver function is dis abled if the detected O

and CO sensor, however, the power

2

value is less than 17.9% or the

2

CO value is more than 50 ppm.

Press the I/O button to turn the analyzer OFF. Note that there is a 5 sec-

ond delay before the analyzer actually turns OFF, during which time the

unit can be kept ON by pressing the ENTER button. For analyzers that

contain a CO sensor, there is a CO purge feature that keeps the analyzer’s

pump running until the measured CO level drops below 50 ppm.

2

Instruction 0024-9395

Page 9

Fyrite Pro

2.0 TECHNICAL CHARACTERISTICS

The Analyzer Directly Measures and Displays:

• Ambient Temperature ............................32 to 212 °F (0 to 100 °C)

• Flue Gas O

• Flue Gas Temperature ...........................0 to 999 °F (–18 to 537 °C)

• Flue Gas CO content ..............................0 to 2,000 ppm CO

• Draft ........................................................–9.99 to 27 inWC

The Analyzer Computes and Displays:

(when the measured oxygen level is below 17.9%)

• Combustion Efficiency ............................0.1 to 99.9%

• Flue Gas CO

• Flue Gas CO Air-Free content ...............0 to 9,999 ppm

• Excess Air ...............................................0 to 400%

content ................................ 0.0 to 20.9% O

2

2

(–9.99 to 67 mb/HPa)

content .............................0.1 to a fuel dependent

2

maximum value in %

Fuel Selection:

(F1 thru F4 denotes the fuel selected as displayed on the LCD)

• Natural Gas (F1)

• Oil #2 (F2)

• LPG (F3)

• Kerosene (F4)

Normal Operating Conditions:

Temperature:

• Analyzer .................................................32 to 104 °F (0 to 40 °C)

• Probe .......................................................1,000 °F max (538 °C) at

5" insertion

Humidity .......................................................15 to 90% RH,

Non-Condensing

Power Requirements ....................................Four disposable ‘AA’ Alkaline

batteries (an optional AC adapter is available that eliminates

the need for batteries)

Operating Time ................................. Up to 18 hours con tin u ous (pump

run ning and backlight off)

Warm Up Time ................................... 10 or 60 seconds, dependent on

Instruction 0024-9395

analyzer’s model and setup (Refer

to Section 4.13.1)

3

Page 10

Fyrite Pro

Memory

(Model 105/110/120/125) ..................... Up to 10 sets of readings can be

saved in memory. When memory

is full, the next reading saved will

overwrite the oldest reading.

Display ................................................ 4 Digit, 2 Line, 7-segment Liquid

Crystal Dis play

Front Panel Controls ....................... Six push button switches

(Refer to Section 3.4)

Accuracy:

• Oxygen............................................. ±0.3% O

concentration of CO

with a typical flue gas

2

2

• Carbon Monoxide ............................ ±5% of reading or ±10 ppm, which-

ever is greater*

• Flue Gas Temperature .................... ±4 °F between 32 & 255 °F

(±2 °C between 0 & 124 °C)

±6 °F between 256 & 480 °F

(±3 °C between 125 & 249 °C) ±8 °F

between 481 & 752 °F

(±4 °C between 250 & 400 °C)

• Second Thermocouple Channel ...... ±4 °F between 32 & 212 °F

(±2 °C between 0 & 100 °C)

• Ambient Temperature ..................... ±4 °F between 32 & 104 °F

(±2 °C between 0 & 40 °C)

• Draft ................................................ ±1% of reading or ±0.02 inWC

(±0.05 mB), whichever is greater

* Tighter CO accuracy in the lower ranges, up to ±2 ppm, may be

attained if a lower range calibration gas (e.g. 100 ppm CO) is used.

4

Instruction 0024-9395

Page 11

Fyrite Pro

3.0 SETTING UP THE ANALYZER

3.1 Preliminary Steps

Before using the analyzer . . .

• Check batteries (Section 3.2)

• Connect probe to analyzer (Section 3.3)

• Check setup (Section 3.5)

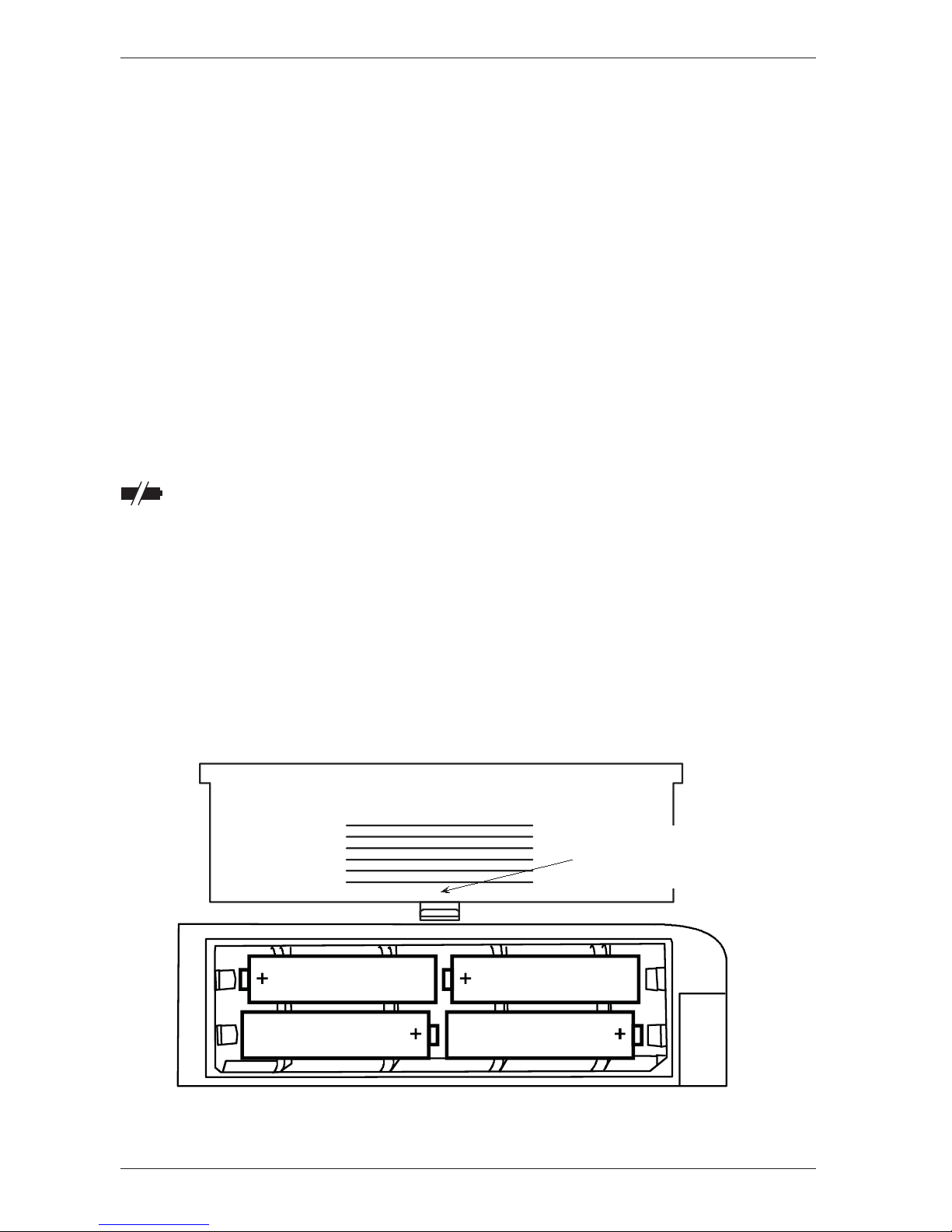

3.2 Checking & Replacing the Bat ter ies

Install fresh batteries as described below. Check the analyzer for sufficient

charge prior to each use. Replace the batteries if the low-battery symbol

appears in the lower right corner of the screen. To re place the bat-

ter ies:

1. Remove battery cover from back of analyzer.

2. If old batteries are installed, remove them and properly discard.

3. Observing the polarity markings inside the battery com part ment,

install four ‘A A’ Al ka line bat ter ies as shown in Fig ure 3-1.

4. Replace battery cover.

Remove battery cover by

pushing down on cover

and sliding it outward

Figure 3-1. Battery Installation

Instruction 0024-9395

5

Page 12

Fyrite Pro

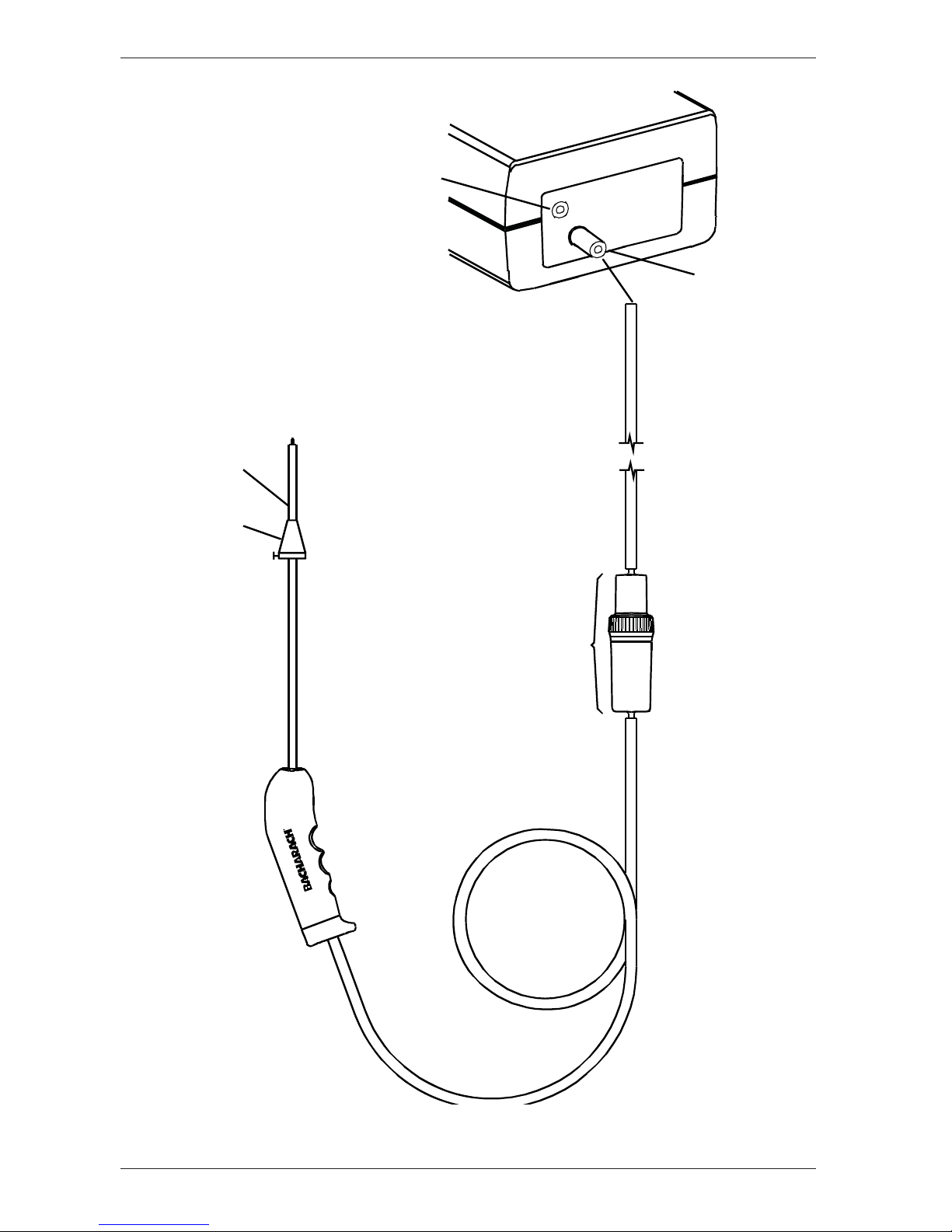

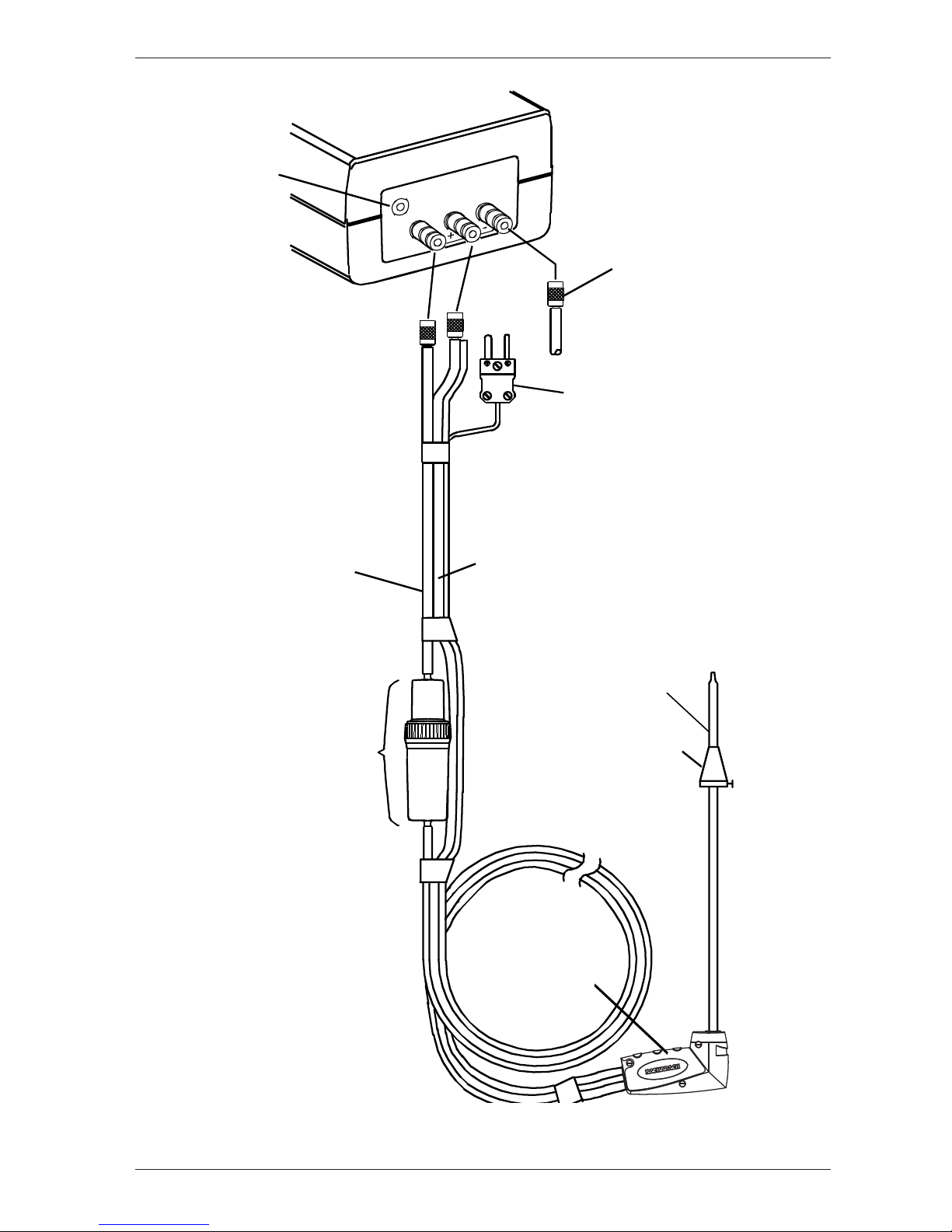

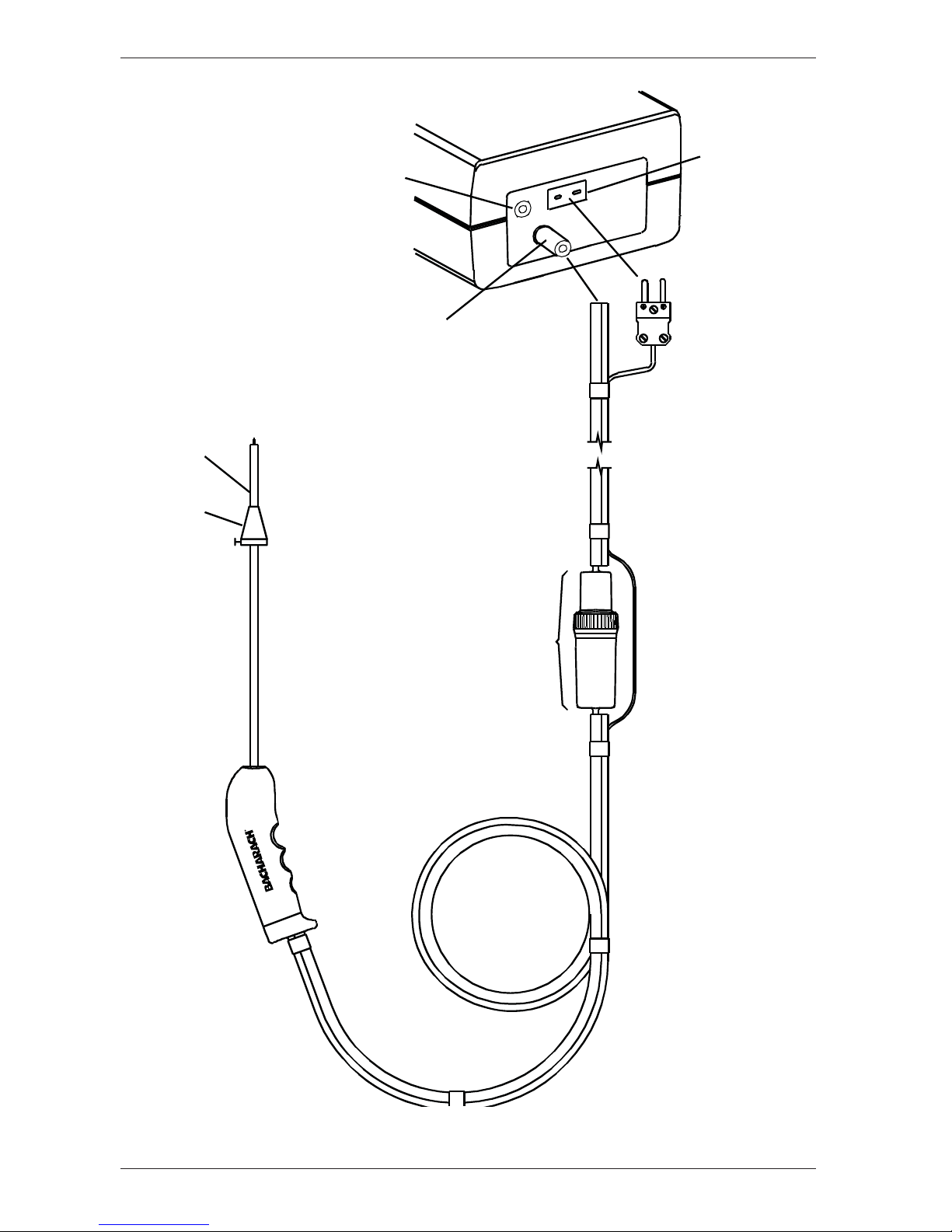

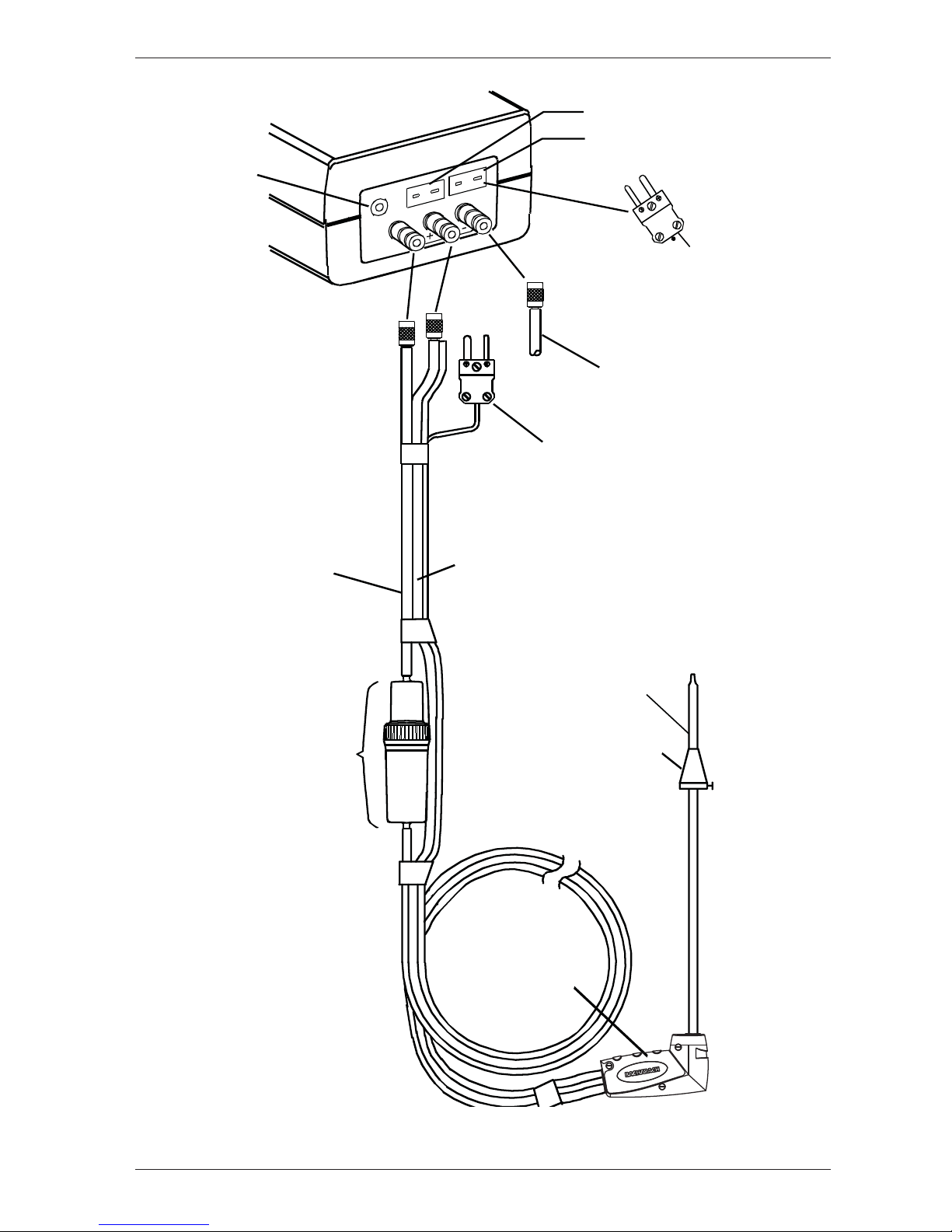

3.3 Connecting the Probe Hose and

Thermocouple

The analyzer’s model number determines which hose and thermocouple

connections are made at the bottom of the unit. Perform the following steps

as required by your particular analyzer model (see Figures 3-2A thru D):

1. Push the probe’s sample-gas hose onto the GAS inlet fitting.

2. Push the probe’s draft hose onto the “+” pressure fitting.

3. Push the probe’s thermocouple into the T-STACK jack

Important: DO NOT force the thermocouple connector into

its jack. The con nec tion tabs are dif fer ent sizes, allowing the

connector to fit in only one way.

4. Push the optional room-air/primary-air thermocouple into the

T-AIR jack.

Inspect the flue-gas hose for cracks. If a hose is defective, replace the entire probe assembly.

Before using the analyzer, check that the Water Trap / Filter is dry and

not dirty. If necessary, dry out the trap and replace the filter el e ment per

Section 5.8.

6

Instruction 0024-9395

Page 13

PROBE TUBE

Fyrite Pro

AC ADAPTER

JACK

GAS INLET

SAMPLE-GAS

HOSE

PROBE STOP

(Optional)

WATER TRAP /

FILTER ASSEMBLY

Figure 3-2A. Connecting the 0019-7110 Probe (Model 100)

Instruction 0024-9395

7

Page 14

AC ADAPTER

JACK

Fyrite Pro

GAS DRAFT

DIFFERENTIAL

PRESSURE HOSE

(Optional)

THERMOCOUPLE

CONNECTOR

(Not used on the

Model 105)

SAMPLE-GAS

HOSE

WATER

TRAP / FILTER

ASSEMBLY

DRAFT HOSE

PROBE TUBE

PROBE STOP

PROBE

HANDLE

Figure 3-2B. Connecting the 0024-3004 Probe (Model 105)

8

Instruction 0024-9395

Page 15

Fyrite Pro

PROBE TUBE

PROBE STOP

(Optional)

AC ADAPTER

JACK

GAS

INLET

SAMPLE-GAS

HOSE

T-STACK

THERMOCOUPLE

CONNECTOR

(T-STACK)

WATER TRAP /

FILTER ASSEMBLY

Figure 3-2C. Connecting the 0019-7111 Probe (Model 110/120)

Instruction 0024-9395

9

Page 16

AC ADAPTER

JACK

Fyrite Pro

GAS DRAFT

T-STACK

T-AIR

ROOM AIR /

PRIMARY AIR

THERMOCOUPLE

CONNECTOR

(T-AIR)

DIFFERENTIAL

PRESSURE HOSE

(Optional)

SAMPLE GAS

THERMOCOUPLE

CONNECTOR

(T-STACK)

SAMPLE-GAS

HOSE

WATER

TRAP / FILTER

ASSEMBLY

DRAFT HOSE

PROBE TUBE

PROBE STOP

PROBE

HANDLE

Figure 3-2D. Connecting the 0024-3004 Probe (Model 125)

10

Instruction 0024-9395

Page 17

Fyrite Pro

3.4 Front Panel Push Buttons

Note that a push button may perform several functions, depending on the

analyzer’s model number and what screen is being displayed at the time.

I/O • Toggles the analyzer ON and OFF.

• Places the analyzer into either its Setup or Calibration Mode

when used in conjunction with the ENTER or HOLD button.

▲ • Scrolls up through the display screens during a test.

• Causes the displayed value to increase or change while in the

Calibration, Setup, or Print/Memory Menu Screen.

▼ • Scrolls down through the display screens during a test.

• Causes the displayed value to decrease or change while in the

Calibration, Setup, or Print/Memory Menu Screen.

ENTER • Enters the Run Mode (starts a combustion test) from the Fuel

Select Screen.

• Unfreezes the display after pressing the HOLD button.

• Displays the Fuel Select Screen when held down for 2 seconds

while in the Run Mode.

• Performs the action selected in the Print/Memory Menu Screen.

• Stores the displayed value and automatically steps to the next

screen when pressed during calibration or setup.

• Places the unit into its Run Mode when held down for 2 seconds

while in the Calibration Mode.

• Aborts turn-off and keeps the analyzer turned ON when

pressed during the 5 second turn-off-delay period.

• Aborts the CO purge function at turn-off when the measured

CO level is above 50 ppm.

• Sets up the analyzer to be placed into its Calibration Mode

when held down with the analyzer OFF. (Used in conjunction

with the I/O button.)

HOLD • Places the analyzer on hold and freezes the values in all Run

Mode Screens during a test, allowing the op er a tor to scroll

through the displays and view all test values at that point in

time. Pressing ENTER resumes testing.

• Model 100: Starts a printout when pressed twice from the Run Mode.

• Model 105/110/120/125: Displays the Print/Memory Menu

Screen when pressed twice from the Run Mode.

• Sets up the analyzer to be placed into its Setup Mode when held down

with the analyzer OFF. (Used in conjunction with the I/O button.)

LIGHT

Instruction 0024-9395

Toggles the back light ON and OFF.

11

Page 18

Fyrite Pro

3.5 Setup Mode

The analyzer is preset at the factory for the parameters shown below, but

can be changed as described in their associated sec tions.

Function Parameter To Change

Fuel Natural Gas (F1) Section 4.13.5

Temperature Unit °F Section 3.5.2

CO Channel Auto Zero (A2) Section 3.5.3

Draft (Pressure) WC Section 3.5.4

Clock Not Initialized Section 3.5.5 thru 3.5.7

Printer Protocol IrDA Section 3.5.8

3.5.1 Entering Setup

1. With the analyzer turned OFF, press and hold down the HOLD

button.

2. Press the I/O button.

3. Release both buttons.

4. The analyzer is now in its Setup Mode. Refer to Sec tions 3.5.2 thru

3.5.8 for information on how to set up each analyzer parameter.

3.5.2 Selecting Temperature Units

The Temperature Setup Screen is labeled “Unit.”

1. Enter the Setup Mode per Section 3.5.1. If necessary, repeatedly

press the EN TER button until “Unit” is dis played.

2. Press the ▲ or ▼ button until the desired temperature unit (°F or

°C) is displayed.

3. Press ENTER to move to the next Setup Screen, or I/O to exit setup.

12

Instruction 0024-9395

Page 19

Fyrite Pro

3.5.3 CO Channel Setup

The CO Channel Setup Screen is labeled “CO.”

1. Enter the Setup Mode per Section 3.5.1. If necessary, repeatedly

press the ENTER button until “CO” is displayed.

2. Press the ▲ or ▼ button until the desired parameter is dis played.

- no Sensor disabled. Use this function to turn off the CO channel if the sensor is missing or known to be bad to avoid inaccurate CO readings from appearing.

- 2Ero Manual Zero. When the CO channel is set to man u al zero,

the analyzer does not zero the CO sensor to ambient conditions during start up.

- A2 Auto Zero. With the CO channel set to auto zero, the CO

sensor is zeroed to the ambient CO level during start up.

Important: When using this mode the analyzer must

be turned ON in fresh air; otherwise, in cor rect CO

readings will occur.

3. Press ENTER to move to the next Setup Screen, or I/O to exit setup.

3.5.4 Draft Channel Setup

The Draft Setup Screen is labeled “PrES Unit”.

1. Enter the Setup Mode per Section 3.5.1. If necessary, repeatedly

press the ENTER button until “PrES” is displayed.

2. Press the ▲ or ▼ button until the desired parameter is dis played.

- no Pressure sensor disabled or not installed.

- WC inches of Water Column

- mB Millibars

- HPa Hecto Pascals

3. Press ENTER to move to the next Setup Screen, or I/O to exit setup.

Instruction 0024-9395

13

Page 20

Fyrite Pro

3.5.5 Time Setup

There are two Time Setup Screens, one for hours and the other for minutes. Two bars appear above the segments being changed. The clock is in

a 24 hour format, but will appear as AM/PM on the printout.

1. Enter the Setup Mode per Section 3.5.1. If necessary, repeatedly

press ENTER until the first Time Setup Screen is displayed—the

one with two bars over the hour digits.

2. Press the ▲ or ▼ button until the correct hour value is displayed.

3. Press ENTER to move the selection bars over the minute digits.

4. Press the ▲ or ▼ button until the correct minute value is displayed.

5. Press ENTER to move to the next Setup Screen, or I/O to exit setup.

3.5.6 Date Setup

There are two Date Setup Screens, each labeled “DAtE”. The first screen

sets the month while the second sets the day.

1. Enter the Setup Mode per Section 3.5.1. If necessary, repeatedly

press ENTER until the first Date Setup Screen is displayed.

2. Press the ▲ or ▼ button until the correct month is displayed.

3. Press ENTER to change the ‘Day’ value.

4. Press the ▲ or ▼ key until the correct day is displayed.

5. Press ENTER to move to the next Setup Screen, or I/O to exit setup.

14

Instruction 0024-9395

Page 21

Fyrite Pro

3.5.7 Year Setup

The Year Setup Screen is labeled “YEAr”.

1. Enter the Setup Mode per Section 3.5.1. If necessary, repeatedly

press ENTER until the Year Setup Screen is displayed.

2. Press the ▲ or ▼ button until the correct year is displayed.

3. Press ENTER to move to the next Setup Screen, or I/O to exit setup.

3.5.8 Selecting Printer Protocol

The analyzer can be set up for either an HP or IrDA type printer.

1. Enter the Setup Mode per Section 3.5.1. If necessary, repeatedly

press ENTER until one of the following screens is displayed.

2. Press the ▲ or ▼ button to select the desired printer protocol.

3. Press ENTER to move to the next Setup Screen, or I/O to exit setup.

3.5.9 Exiting the Setup Screen

Press the I/O button at any time to exit the Setup Mode and turn OFF the

analyzer. Note that the last displayed parameter is automatically saved in

memory.

Instruction 0024-9395

15

Page 22

Fyrite Pro

Notes:

16

Instruction 0024-9395

Page 23

Fyrite Pro

4.0 OPERATION

4.1 Performing CO and Draft Testing

4.1.1 Analyzer Turn On and Warm Up

1. Connect the probe and make sure that the analyzer is properly set

up per Sec tion 3.0.

2. Turn ON the analyzer in fresh air by pressing is I/O button and

observe that the following Warm-Up Screens are displayed.

These screens show the analyzer’s model number, the unit’s soft-

ware revision, and finally the remaining warm-up time. If an O

sensor is installed, then its current output level is also displayed.

2

Note: The warm-up time is 10 seconds for analyzers that do

not contain an oxygen sensor, and have their CO channel

set up for manual zero. The warm-up time is 60 seconds for

analyzers that contain an oxygen sensor, and/or have their

CO channel set up for auto zero.

Tip: An O

drops to between 80 and 90. Consider replacing the oxygen

sensor when its output level drops below 100.

3. Wait for the analyzer to count down its warm-up period; after

which, either the CO Screen (Model 100), the CO & Draft Screen

(Model 105), or the Fuel Screen (Model 110/120/125) is displayed.

Model 100 Model 105 Model 110/120/125

If, however, any errors were detected during warm-up, the Sensor

Status Screen is displayed. If this occurs, refer to Section 4.13.13 for

information on how to correct the error.

error will occur when the oxygen sensor’s output

2

Instruction 0024-9395

17

Page 24

Fyrite Pro

4.1.2 Measuring CO (Model 100/105/120/125)

1. Turn ON the analyzer and allow it to warm-up per Section 4.1.1.

Important: If the CO channel is set up for auto zero, then

the analyzer must be turned ON in fresh air; otherwise,

incorrect CO readings will occur. Refer to Section 3.5.3.

When the CO channel is set up for manual zero, and if the

CO reading is higher than zero when sampling fresh air, then

manually zero the CO channel per Section 5.6, Steps 1 thru 4.

2. For the Model 100/105, the CO Screen should already be displayed. For

the Model 120/125, push ENTER until the CO & O

Model 100 Model 105 Model 120/125

Screen appears.

2

3. Insert the analyzer’s probe into the area to be tested and observe

the detected CO level on the LCD.

4.1.3 Measuring Draft (Model 105/125)

1. Turn ON the analyzer and allow it to warm-up per Section 4.1.1.

2. For the Model 105, the CO & Draft Screen should already be dis-

played. For the Model 125, press ENTER and then press the ▲ or▼

button as necessary to display this screen.

3. The draft reading should be zero when sampling room air. If not,

press the ▼ button once to display the Draft Zero Screen, and then

press the ENTER button to zero the draft channel to ambient atmo-

spheric conditions.

4. Insert the analyzer’s probe into the area to be tested and observe

the draft reading on the LCD.

18

Instruction 0024-9395

Page 25

Fyrite Pro

4.2 Performing a Combustion Test using

the Model 110/120/125

4.2.1 Analyzer Turn On and Warm Up

Important: The probe must be at room temperature before

performing the following steps.

1. Connect the probe and make sure that the analyzer is properly set

up per Sec tion 3.0.

2. Perform one of the following:

• Model 110/120 – Before turning ON the analyzer, its probe must

be located in the area containing the burner’s combustion-air supply. If the burner is using room air, simply place the probe within

the room. In the case of a high-efficiency furnace where combustion air is drawn in from an outside source, insert the probe into

the combustion-air stream so it can measure its temperature with

the burner op er at ing.

• Model 125 – This analyzer has a second thermocouple channel

that can be used to independently monitor the temperature of the

burner’s combustion-air supply. When using this second thermocouple channel, insert the thermocouple into the burner’s combustion-air stream, and position the probe to measure the ambient

room temperature. If the second thermocouple channel is not

used, then use the probe’s thermocouple to measure the combustion-air temperature as described above for the Model 110/120.

3. Turn ON the analyzer and allow it to warm-up per Section 4.1.1.

4.2.2 Selecting a Fuel

1. With Fuel Screen displayed, use the ▲ or ▼ button to step through

the fuels codes until the proper fuel is selected. The analyzer defaults to the most re cent ly se lect ed fuel.

F1 = Natural Gas

F2 = Oil #2

F3 = LPG

F4 = Kerosene

2. Press the ENTER button to select the displayed fuel code and enter

the Run Mode.

Instruction 0024-9395

19

Page 26

Fyrite Pro

4.2.3 Sampling Point

Forced Air Furnace – When testing atmospheric burner or gravity

vented, forced air heating equip ment with a clamshell or sectional heat

exchanger design, test each of the exhaust ports at the top of the heat exchanger. The probe should be inserted back into each of the exhaust ports

to obtain a flue gas sample, before any dilution air is mixed in.

Hot Water Tank – Domestic hot water tanks with the ‘bell’ shaped draft

diverter on top can be accurately tested by inserting the probe tip directly

into the top of the fire tube be low the diverter.

80% Efficiency Fan Assist or Power Vented – Combustion testing of

fan assist or power vented, furnaces/boilers should be done through a hole

drilled in the vent immediately above the inducer fan.

90% Efficiency Condensing – Condensing furnaces/boilers can be tested

through a hole drilled in the plastic vent pipe (when allowed by the manufacturer or local authority of jurisdiction) or taken from the exhaust termination.

Atmospheric or Gravity Vented Boiler – Boilers, which have a ‘bell’

shaped draft diverter directly on top, should be tested directly below the

diverter through a hole drilled in the vent connector.

Atmospheric Burner or

Gravity Vented Forced Air Hot Water Tank

20

Instruction 0024-9395

Page 27

Fyrite Pro

80% Eff. Fan Assist

or Power Vented

Furnace/Boiler

90% Eff. Condensing

Furnace/Boiler

Atmospheric or

Gravity Vented Boiler

Instruction 0024-9395

21

Page 28

Fyrite Pro

4.2.4 Performing a Com bus tion Efficiency Test

1. After turning ON the analyzer and selecting the appropriate fuel,

press the ▲ or ▼ button to display the Stack Temperature & Efficiency Screen (refer to Section 4.13.10).

2. Position the probe in the flue-gas stream to obtain the hottest

“Stack” reading. Lo cat ing the highest stack temperature is very im-

por tant for ac cu rate ef fi cien cy calculations.

3. Burner-service pro ce dures can now begin. Use the ▲ and ▼ buttons

to scroll through the analyzer’s other display screens (refer to Section 4.12). The analyzer read ings will update con tin u ous ly showing

changes in burner performance.

Note: When a calculation cannot be made because of im-

proper data (i.e., oxygen level above 17.9%), four dashes “- - -

-” appear in place of the calculated value on both the screen

and printout.

Tip: Pressing the HOLD button will freeze all readings and

stop the pump, allowing the operator to scroll through the

Run Mode Screens and examine the readings at any single

point in time. Press ENTER to restart the pump and resume

testing.

4.2.5 Ending a Combustion Test

WARNING! Burn Hazard. Do not touch the probe after

removing it from the stack. Allow the probe to cool before

handling (about 5 minutes).

1. Remove probe from the flue-gas stream.

2. Allow the pump to run until all combustion gases are flushed from

the analyzer as indicated by the O

reading returning to 20.9%.

2

3. Turn OFF the analyzer per Section 4.10.

22

Instruction 0024-9395

Page 29

Fyrite Pro

4.3 Operating Tips

• When an analyzer is brought in from a cold vehicle, let it warm up

slowly to minimize condensation. Temperatures below freezing will not

damage the analyzer; however, bringing a cold analyzer into a warm,

humid environment may cause condensate to form inside the case.

• If the CO channel (Model 100/105/120/125) is set up for Auto Zero

(refer to Section 3.5.3), ensure that the analyzer is sampling fresh air

when turned ON. Pulling a flue-gas sample through the analyzer during its warm-up period will not damage the analyzer, but it will result

in incorrect CO readings. Also note that a CO sensor error will occur if

the detected CO level is above 50 ppm during warm-up.

• For analyzers that are used to measure flue-gas, note that flue-gas

condensate is acidic and very corrosive. It is important not to allow

the analyzer’s internal components to become soaked in condensate for

long periods of time.

• Before each use, inspect the filter element of the water-trap / filter assembly. Replace the filter if it looks dirty.

• When sampling flue-gas, keep the analyzer above the water-trap, and

keep the trap in a vertical position. This will maximize the effectiveness of the trap and keep liquid condensate from being drawn directly

into the analyzer.

• When liquid condensate is seen inside the water trap, empty the trap

before it becomes full. Refer to Section 5.8.

• It is recommended that the analyzer be purged after taking a flue-gas

measurement before turning it OFF. Once the probe is removed from

the stack, disconnect the hose assembly from the bottom of the analyzer and let the pump run for 10 minutes or so to completely remove any

remaining flue gases and dry any condensate from inside the sensor

chamber.

• When storing the analyzer, it’s a good idea to empty the water trap and

leave it open to further dry it out.

• Calibrate the analyzer every 6 months to ensure its accuracy.

Instruction 0024-9395

23

Page 30

Fyrite Pro

4.4 Using the Backlight

The LCD can be read in dimly-lit areas by pressing the LIGHT button.

The backlight automatically turns OFF after 10 minutes of keyboard inactiv-

ity, but can be turned OFF at any time by again pressing the LIGHT button.

4.5 Using the Probe

A rigid stainless steel probe with handle, connected to a flexible hose with

integral water-trap / filter can be used to draw a gas sample into the analyzer from the room, grilles, diffusers, and furnace flues.

The hose and probe assembly can be detached from the analyzer when the

operator desires to sample without the probe.

4.6 Saving Test Data in Memory

(Model 105/110/120/125)

Up to 10 individual sets of test data can be saved in memory as follows:

Note: When memory is full, the next reading saved will over-

write the oldest reading.

Note: The analyzer's setup information as entered in Sec-

tion 3.5 is stored along with the test data. For example,

temperatures stored in °C are recalled and printed in °C even

if the analyzer is currently set up for °F.

1. If the analyzer is in its Run Mode, press the HOLD button twice to

enter the Print/Memory Menu Screens. If the analyzer is already in

its Hold Mode, press the HOLD button only once. The first menu item

displayed is the Print Screen.

24

Instruction 0024-9395

Page 31

Fyrite Pro

2. Press the ▼ button once to display the Save Screen. The number

shown in this screen represents the memory location (1 thru 10) to

which the current test data will be saved.

3. Press ENTER to save the test data and return to the Hold Mode, or

press HOLD to return to the Hold Mode without saving.

4.7 Opening and Viewing Saved Test Data

(Model 105/110/120/125)

Perform the following to open and view saved test data:

Note: If no test data has been saved, the option to open the

memory for viewing will not be available.

1. If the analyzer is in its Run Mode, press the HOLD button twice to

enter the Print/Memory Menu Screens. If the analyzer is already in

its Hold Mode, press the HOLD button only once. The first menu item

displayed is the Print Screen.

2. Press the ▲ or ▼ button until the Open Screen is displayed, and

then press ENTER to open the memory locations for viewing. The

number shown in the second screen represents the most recent

memory location where data was stored.

3. Press the ▲ or ▼ button to scroll to the desired memory location,

and then press ENTER to recall the stored data and return to the

Hold Mode. While in the Hold Mode, the recalled data can be viewed

using the ▲ and ▼ buttons, or printed per Section 4.9.

Instruction 0024-9395

25

Page 32

Fyrite Pro

4.8 Printing Test Data

Tip: To avoid printing errors, it is important to select the

correct protocol per Section 3.5.8 before saving data.

Turn ON the printer. Refer to the printer’s instruction manual for detailed

operation and maintenance information.

If not already done, set the printer parameters as follows:

• Data: 8 bits • Parity: None

• Baud: 9600 • Handshaking: X-on/X-off

Align the printer with the top of the analyzer as shown in Figure 4-1.

The next step in the printing procedure depends on the model of the analyzer, and whether the operator desires to print only the current test data,

or all stored test data starting with the most recent. Perform the appropriate procedure below:

Model 100 – Print Current Test Data

With the analyzer in its Run Mode, begin printing by pressing the HOLD

button twice.

Model 105/110/120/125 – Print Current Test Data

1. With the analyzer in its Run Mode, press the HOLD button twice to

display the Print Screen.

2. Press ENTER to start printing.

Model 105/110/120/125 – Print All Test Data

1. With the analyzer in its Run Mode, press the HOLD button twice

to display the Print Screen. Then press the ▲ button to display the

Print All Screen.

2. Press ENTER to start printing.

26

Instruction 0024-9395

Page 33

60°

max.

45 cm

(18 in.)

max.

Fyrite Pro

BACHARACH, INC.

FYRITE PRO ANALYZER

=======================

DATE: 8/20/2003

TIME: 2:45 PM

FUEL: (F1)Natural Gas

EFFICIENCY 82.6 %

EXCESS AIR 21.3 %

STACK TEMP 374 °F

PRIMARY TEMP 68.0 °F

DELTA TEMP 306 °F

O2 4.0 %

CO2 9.5 %

CO 12 ppm

CO AIR FREE 15 ppm

Draft -0.25 WC

ENTER

HOLD

LIGHT

I/O

COMMENTS:

Notes: When a calculation cannot be

made because of improper data (i.e.,

oxygen level above 17.9%), four dashes

“- - - -” appear in place of the calculated

value on both the screen and printout.

When one or more of the following

sensors are not installed, their

associated values do not print:

Oxygen Sensor:

Fuel, Efficiency, Excess Air, Stack

Temp, Primary Temp, O2, CO2, and

CO Air Free

CO Sensor:

CO, and CO Air Free

Draft Sensor:

Draft

Figure 4-1. Printer Alignment & Sample Printout

Instruction 0024-9395

Either Thermocouple:

Delta Temp

27

Page 34

Fyrite Pro

4.9 Clearing Saved Test Data (Model 105/110/120/125)

Clear all saved test data as follows:

Note: If no test data has been saved, the option to clear

memory will not be available.

1. With the analyzer in its Run Mode, press the HOLD button twice to

display the Print Screen.

2. Press the ▲ or ▼ button to scroll to the Clear Screen, and then press

ENTER to display the Clear All Screen.

3. Press ENTER again to clear memory and return to the Hold Mode, or

press HOLD to return to the Hold Mode without clearing memory.

4.10 Turning OFF the Analyzer & CO Purge

Press the I/O button to turn OFF the analyzer. The unit will count down

from 5 before turning OFF, thus allowing time for the operator to abort the

turn OFF process by press ing the ENTER button.

If a high CO level is detected at turn OFF, the unit will remain ON with

its pump running and display “PUrG CO”. The countdown from 5 will not

begin until the detected CO level drops below 50 ppm. Although not recom-

mended, the purging process can be bypassed by pressing the I/O button a

second time.

28

Instruction 0024-9395

Page 35

Fyrite Pro

4.11 Resetting the Microprocessor

If the analyzer ‘locks up’ and cannot be turned OFF, reset the microprocessor by removing one of the batteries for 5 seconds.

4.12 Run Mode Screens

Figures 4-2A thru 4-2E show the order in which the screens are displayed

by pressing the ENTER and ▲▼ buttons after the analyzer warms-up and

enters its Run Mode.

The top screen in each figure is the one that appears immediately after the

analyzer completes its warm-up cycle.

Refer to Section 4.13 for a detailed description of each screen.

CO

CO

9

PPM

Figure 4-2A. Model 100 Run Mode Screen

CO &

Draft

Draft Zero

ppmCO

WC

WC

Figure 4-2B. Model 105 Run Mode Screens

Instruction 0024-9395

29

Page 36

Fuel Select:

F1 = Natural Gas

F2 = Oil #2

F3 = LPG

F4 = Kerosene

Fyrite Pro

ENTER

U

F

E

F1

F1

L

O

2

Ambient /

Combustion Air

Temperature

Stack

Temperature &

Efficiency

&

CO

2

Excess Air

O

2

AMBIENT F1

EFF

7

5

46

5

STACK F1

0

787

CO

2

9

251

EXCESS AIR

.

.

2

0

.

F1

.

2

.

%

°F

°F

%

%

Figure 4-2C. Model 110 Run Mode Screens

30

Instruction 0024-9395

Page 37

Fuel Select:

F1 = Natural Gas

F2 = Oil #2

F3 = LPG

F4 = Kerosene

CO &

O

2

Fyrite Pro

ENTER

U

F

E

F1

F1

CO

O

2

46

L

9

.

PPM

%

CO Air Free

Ambient /

Combustion Air

Temperature

Stack

Temperature &

Efficiency

&

CO

2

Excess Air

CO

12

FREE

AIR

AMBIENT F1

7

5

STACK F1

5

EFF

00

787

CO

2

9

251

EXCESS AIR

F1

.

2

.

F1

.

2

.

PPM

°F

°F

%

%

Figure 4-2D. Model 120 Run Mode Screens

Instruction 0024-9395

31

Page 38

Fuel Select:

F1 = Natural Gas

F2 = Oil #2

F3 = LPG

F4 = Kerosene

CO & O

CO Air Free

2

Fyrite Pro

ENTER

U

F

E

F1

F1

CO

O

2

CO

AIR

46

12

FREE

L

9

.

F1

PPM

%

PPM

Ambient /

Combustion Air

Temperature

Temperature

Differential

Stack

Temperature &

Efficiency

&

CO

2

Excess Air

CO &

Draft

AMBIENT F1

7

5

STACK F1

5

EFF

0

787

CO

2

92

251

EXCESS AIR

F1

CO

.

004

.

2

0

.

F1

.

.

9

°F

F1

°F

°F

%

%

PPM

7#

Draft Zero

Figure 4-2E. Model 125 Run Mode Screens

32

2

7#

E

Instruction 0024-9395

Page 39

Fyrite Pro

4.13 Screen Descriptions

4.13.1 Warm-Up Screens

As soon as the analyzer is turned ON, a series of Warm-Up Screens

are dis played. These screens show the analyzer’s model number (Pro

100/105/110/120/125), the unit’s software revision, and finally the remaining warm-up time counted down from either 10 or 60 seconds. If an O

sensor is installed, then its current output level is also displayed. The 60

second countdown only occurs when the analyzer contains an O

sensor,

2

or if the analyzer contains a CO sensor that has been set up for auto zero

(refer to Section 3.5.3). At the end of warm-up, the analyzer’s first display

screen appears (refer to Section 4.12).

2

Note: If any errors were de tect ed during warm-up, the

Sensor Error Screen (Section 4.13.13) is displayed.

Tip: An O

error will occur when the oxygen sensor’s output

2

drops to between 80 and 90. Consider replacing the oxygen

sensor when its output level drops below 100.

4.13.2 CO Screen (Model 100)

The CO Screen is displayed after warm-up and shows the current CO level

in ppm. If the probe is being used, insert the probe tip into the area to be

sampled.

Front Panel Button Functions:

▲ – No effect

▼ – No effect

HOLD – Freezes display (press ENTER to unfreeze)

ENTER – Restarts testing after the HOLD button was pressed

LIGHT – Toggles backlight ON/OFF

I/O – Turns analyzer OFF (5 second delay)

Instruction 0024-9395

33

Page 40

Fyrite Pro

4.13.3 CO & Draft Screen (Model 105/125)

The CO reading is a measurement of how much carbon monoxide in ppm

is present in the flue-gas stream. Note, however, that the amount of CO

dis played may be diluted by secondary air (refer to Section 4.13.12 CO Air

Free Screen).

The draft display is the difference between the pressure at the analyzer’s

“+” port and the pressure at the “–” port when using probe model 24-7266.

Front Panel Button Functions:

▲ – Displays next screen (refer to Section 4.12)

▼ – Displays previous screen (refer to Section 4.12)

HOLD – Freezes display (press ENTER to unfreeze)

ENTER – Hold for 2 seconds to display Fuel Screen (Model 125)

LIGHT – Toggles backlight ON/OFF

I/O – Turns analyzer OFF (5 second delay)

4.13.4 Draft Zero Screen (Model 105/125)

The Draft Zero Screen allows the user to manually zero the draft channel

when the pressure reading is anything other than zero when measuring

ambient room pressure. To zero the draft channel, remove all tubing from

the analyzer’s “+” and “–” ports and press the ENTER button.

Front Panel Button Functions:

▲ – Displays next screen (refer to Section 4.12)

▼ – Displays previous screen (refer to Section 4.12)

HOLD – Freezes display (press ENTER to unfreeze)

ENTER – Zeros the draft channel, and returns to the screen containing

the draft reading.

LIGHT – Toggles backlight ON/OFF

I/O – Turns analyzer OFF (5 second delay)

34

Instruction 0024-9395

Page 41

Fyrite Pro

4.13.5 Fuel Screen (Model 110/120/125)

The Fuel Screen is displayed after warm-up, and is where an operator

chooses which fuel is to be used by the analyzer to calculate com bus tion

efficiency. Press ing the ▲ or ▼ button scrolls the dis play through the fuel

codes. Pressing ENTER selects the dis played fuel and places the analyzer

into its Run Mode. Note that the fuel code will be dis played in the top right

corner of all screens while in the Run Mode.

Fuel Codes:

F1 = Natural Gas F3 = LPG

F2 = Oil #2 F4 = Kerosene

Front Panel Button Functions:

▲ – Displays next fuel code

▼ – Displays previous fuel code

ENTER – Go to Run Mode (refer to Section 4.12)

HOLD – No effect

LIGHT – Toggles backlight ON/OFF

I/O – Turns analyzer OFF (5 second delay)

4.13.6 O2 Screen (Model 110)

.

The O

flue-gas stream.

Front Panel Button Functions:

Screen shows the measured percentage of oxygen present in the

2

▲ – Displays next screen (refer to Section 4.12)

▼ – Displays previous screen (refer to Section 4.12)

HOLD – Freezes display (press ENTER to unfreeze)

ENTER – Hold for 2 seconds to display Fuel Screen

LIGHT – Toggles backlight ON/OFF

I/O – Turns analyzer OFF (5 second delay)

4.13.7 CO & O2 Screen (Model 120/125)

Instruction 0024-9395

35

Page 42

Fyrite Pro

The CO reading is a measurement of how much carbon monoxide in ppm

is present in the flue-gas stream. Note, however, that the amount of CO

dis played may be diluted by secondary air (refer to Section 4.13.12 CO Air

Free Screen).

The O2 reading is the measured percentage of oxygen present in the fluegas stream.

Front Panel Button Functions:

▲ – Displays next screen (refer to Section 4.12)

▼ – Displays previous screen (refer to Section 4.12)

HOLD – Freezes display (press ENTER to unfreeze)

ENTER – Hold for 2 seconds to display Fuel Screen

LIGHT – Toggles backlight ON/OFF

I/O – Turns analyzer OFF (5 second delay)

4.13.8 CO2 & Excess Air Screen (Model 110/120/125)

The CO2 reading is a calculation of the percentage of carbon dioxide that is

being produced by the combustion process.

Excess Air is a calculation of the percentage of extra air that was avail able

in the combustion chamber above the theoretical amount needed for perfect

combustion.

Front Panel Button Functions:

▲ – Displays next screen (refer to Section 4.12)

▼ – Displays previous screen (refer to Section 4.12)

HOLD – Freezes display (press ENTER to unfreeze)

ENTER – Hold for 2 seconds to display Fuel Screen

LIGHT – Toggles backlight ON/OFF

I/O – Turns analyzer OFF (5 second delay)

36

Instruction 0024-9395

Page 43

Fyrite Pro

4.13.9 Temperature Differential Screen (Model 125)

The Temperature Differential reading is the measured difference between

the temperatures being measured by the T-STACK and T-AIR thermocouples.

Front Panel Button Functions:

▲ – Displays next screen (refer to Section 4.12)

▼ – Displays previous screen (refer to Section 4.12)

HOLD – Freezes display (press ENTER to unfreeze)

ENTER – Hold for 2 seconds to display Fuel Screen

LIGHT – Toggles backlight ON/OFF

I/O – Turns analyzer OFF (5 second delay)

4.13.10 Stack Temperature & Efficiency Screen

(Model 110/120/125)

The STACK reading is the temperature mea sured at the tip of the probe.

The EFF (Efficiency) reading is a cal cu la tion of what percentage of energy

present in the fuel was con vert ed into usable heat.

Front Panel Button Functions:

▲ – Displays next screen (refer to Section 4.12)

▼ – Displays previous screen (refer to Section 4.12)

HOLD – Freezes display (press ENTER to unfreeze)

ENTER – Hold for 2 seconds to display Fuel Screen

LIGHT – Toggles backlight ON/OFF

I/O – Turns analyzer OFF (5 second delay)

Instruction 0024-9395

37

Page 44

Fyrite Pro

4.13.11 Ambient Air Temperature Screen

(Model 110/120/125)

The AMBIENT reading is the combustion-air temperature in either °F or

°C that is used for efficiency calculations. This temperature is measured

by either the T-AIR thermocouple on a continuous basis ( Model 125), or by

the T-STACK thermocouple during start-up (Model 110/120/125). If neither

thermocouple is installed when the analyzer is turned ON, then this

temperature reading comes from a temperature sensor located inside the

analyzer. Refer to Section 4.2.1.

Front Panel Button Functions:

▲ – Displays next screen (refer to Section 4.12)

▼ – Displays previous screen (refer to Section 4.12)

HOLD – Freezes display (press ENTER to unfreeze)

ENTER – Hold for 2 seconds to display Fuel Screen

LIGHT – Toggles backlight ON/OFF

I/O – Turns analyzer OFF (5 second delay)

4.13.12 CO Air Free Screen (Model 120/125)

The CO AIR FREE reading is a calculation of the exact ppm con cen tra tion

of car bon mon ox ide at the flame if oxygen were 0.0% in accordance with

ANSI standard Z21.1.

CO

Air Free

CO x 20.9

=

20.9 – O

2

Front Panel Button Functions:

▲ – Displays next screen (refer to Section 4.12)

▼ – Displays previous screen (refer to Section 4.12)

HOLD – Freezes display (press ENTER to unfreeze)

ENTER – Hold for 2 seconds to display Fuel Screen

LIGHT – Toggles backlight ON/OFF

I/O – Turns analyzer OFF (5 second delay)

38

Instruction 0024-9395

Page 45

Fyrite Pro

4.13.13 Sensor Error Screen (Model 100/105/110/120/125)

An O

warm-up cycle that the oxygen sensor’s output is too low for it to be usable.

However, in the extreme condition when the O

sor error will not occur. Instead, the O

the O

sensor error is displayed if the analyzer determines during the

2

sensor has no output, a sen-

2

reading will be 0.0 as displayed in

2

Screen or the CO & O2 Screen.

2

Tip: To avoid O

ing the O

sensor when its output level drop below 100 as

2

errors from occurring, consider replac-

2

displayed during warm-up (refer to Section 4.13.1).

When the CO channel is set up for Auto Zero (refer to Sec tion 3.5.3), a

CO sensor error will occur if the detected carbon mon ox ide level is above

50 ppm during the warm-up cycle. Note that if the CO chan nel is set up for

manual calibration, the analyzer does not auto-zero the CO sensor during

warm-up, and thus does not generate a CO sensor error when the analyzer

is turned ON in an atmosphere containing a high back ground level of CO.

Do the following before replacing a suspected spent or defective sensor:

1. Turn OFF the analyzer and turn it back ON in an area of fresh air

(con tain ing 20.9% O2 and no CO).

2. Perform the Oxygen Sensor Zero procedure (Section 5.5) and, if applicable, the CO Sensor Zero & Calibration procedure (Sec tion 5.6).

3. If Steps 1 & 2 do not eliminate the error condition, re place sensor(s)

(refer to Sections 5.9 or 5.10).

Instruction 0024-9395

39

Page 46

Fyrite Pro

Notes:

40

Instruction 0024-9395

Page 47

Fyrite Pro

5.0 CALIBRATION & MAINTENANCE

Important: Fresh batteries should be installed, and the unit

allowed to sta bi lize at room temperature for at least two

hours before proceeding with calibration. To main tain ac cu ra cy as listed in the Technical Characteristics Sec tion of

this manual, the standards used must be at least four times

as accurate as the stated accuracy of the Fyrite Pro.

5.1 Entering the Calibration Mode and

Testing the Display Segments

1. With the analyzer turned OFF, place the unit in fresh, ambient air;

then press and hold down the ENTER button.

2. Press the I/O button and release it. Observe that all LCD seg ments

are turned ON.

3. Release the ENTER button. Observe the unit’s model number and

soft ware version are displayed. The word “CAL” is then displayed

while the unit warms up counts down from 60 seconds.

At the end of 60 seconds, the first calibration screen is displayed.

Note: The order in which the calibration screens are displayed

depends on whether the CO channel is set up for automatic or

manual zero (Section 3.5.3).

Calibration Screen Display Order

CO Auto Zero: Ambient, TA, Stack, O

CO Manual Zero: CO, Pressure, Ambient, TA, Stack, O

, CO, Pressure

2

2

Instruction 0024-9395

41

Page 48

Fyrite Pro

5.2 Ambient Temperature Calibration

(Model 110/120/125)

Material Required: Calibrated Thermometer

Procedure:

1. Enter the Calibration Mode as described in Section 5.1. Observe

that “AMBIENT” will appear at the top of the display; if not, re-

peatedly press ENTER until “AMBIENT” is dis played.

2. Use the ▲ and ▼ buttons to set the displayed value to match the

reading of a calibrated thermometer at room temperature.

3. Press ENTER to store the displayed value and move to the next

cal i bra tion screen, or hold down ENTER for 2 seconds to store the

displayed value and enter the Run Mode, or press the I/O button to

exit the Cal i bra tion Mode and turn OFF the an a lyz er with out saving the changes.

5.3 Combustion Air Thermocouple

Calibration (Model 125)

Material Required: Thermocouple Simulator

Procedure:

1. Attach the thermocouple simulator to the Combustion Air Ther mo cou ple connector on the analyzer (T-AIR, see Figure 3-2).

2. Enter the Calibration Mode as described in Section 5.1. Then re-

peatedly press the ENTER button until “TA” appears at the top of

the display.

42

Instruction 0024-9395

Page 49

Fyrite Pro

3. Set the simulator to 32.0 °F (0 °C); then use the ▲ and ▼ buttons to

set the dis played value to match the simulator’s value.

4. Set the simulator to 212.0 °F (100 °C); then use the ▲ and ▼ but-

tons to adjust the dis played value to match simulator’s value.

5. Repeat Steps 3 and 4 as necessary until the unit is reading cor rect ly at both temperatures.

6. Press ENTER to store these calibration values and move to the next

cal i bra tion screen, or hold down ENTER for 2 seconds to store these

calibration values and enter the Run Mode, or press the I/O button

to exit the Cal i bra tion Mode and turn OFF the an a lyz er with out

saving the changes.

7. Remove thermocouple simulator from analyzer.

5.4 Stack Thermocouple Calibration

(Model 110/120/125)

Material Required: Thermocouple Simulator

Procedure:

1. Attach the thermocouple simulator to the Stack Ther mo cou ple connector on the analyzer (T-STACK, see Figure 3-2).

2. Enter the Calibration Mode as described in Section 5.1. Then re-

peatedly press the ENTER button until “STACK” appears at the top

of the display.

3. Set the simulator to 32 °F (0 °C); then use the ▲ and ▼ buttons to

set the dis played value to match the simulator’s value.

4. Set the simulator to 572 °F (300 °C); then use the ▲ and ▼ buttons

to adjust the dis played value to match simulator’s value.

5. Repeat Steps 3 and 4 as necessary until the unit is reading cor rect ly at both temperatures.

Instruction 0024-9395

43

Page 50

Fyrite Pro

6. Press ENTER to store these calibration values and move to the next

cal i bra tion screen, or hold down ENTER for 2 seconds to store these

calibration values and enter the Run Mode, or press the I/O button

to exit the Cal i bra tion Mode and turn OFF the an a lyz er with out

saving the changes.

7. Remove thermocouple simulator from analyzer.

5.5 Oxygen Sensor Zero (Model 110/120/125)

Material Required: • Cylinder of 100% Nitrogen, P/N 9550-0049

• Calibration Kit, P/N 0024-7059

Procedure:

1. With the analyzer sampling fresh air, enter the Calibration Mode as

described in Section 5.1. Then repeatedly press the ENTER button

until “O

” appears in the lower-left side of the display.

2

2. Allow pump to run and sample fresh air for at least 1 minute.

3. Use the ▲ and ▼ buttons to set the display to 20.9%.

4. Set up the Calibration Kit with 100% N

as de scribed in the in struc -

2

tions supplied with the kit.

5. Connect the tubing of the Calibration Kit to the GAS inlet of the

an a lyz er; then adjust the regulator for ap prox i mate ly 2 SCFH of

excess flow (see Figure 5-1).

6. After the analyzer has stabilized (2 to 3 minutes,) use the ▲ and ▼

buttons to set the displayed value to 0.0%.

7. Disconnect tubing from analyzer and turn off gas flow.

8. Allow the analyzer’s pump to run until the O

20.9. If necessary, use the ▲ and ▼ buttons to readjust the reading

to 20.9. Repeat Steps 3 thru 7 to verify the zero adjustment.

44

reading returns to

2

Instruction 0024-9395

Page 51

Fyrite Pro

9. Press ENTER to store the new calibration values and move to the

next cal i bra tion screen, or hold down ENTER for 2 seconds to store

the new calibration values and enter the Run Mode, or press the

I/O button to exit the Cal i bra tion Mode and turn OFF the an a lyz er

with out saving the changes.

5.6 CO Sensor Zero & Calibration

(Model 100/105/120/125)

Material Required: • Cylinder of 100 ppm (P/N 0051-1994) or

500 ppm (P/N 0024-0492) CO calibration gas

• Calibration Kit, P/N 0024-7059

To improve the accuracy of the CO reading, we suggest that if the analyzer

will be primarily used for flue gas testing, then calibrate using 500 ppm

CO. If the analyzer, however, will be pri ma ri ly used for ambient testing,

then calibrate using 100 ppm CO.

Procedure:

1. With the analyzer sampling fresh air, enter the Calibration Mode as

described in Section 5.1. Then repeatedly press the ENTER button

until “CO” appears in the upper-left side of the display.

2. Allow the pump to run and sample fresh air for at least 1 minute.

3. Use the ▲ and ▼ buttons to set the displayed value to 0 ppm.

4. Do one of the following:

a. End this procedure and save the new zero value by holding down

the ENTER button for 2 seconds; after which, the analyzer enters

its Run Mode.

b. Continue with Step 5 to span the CO sensor on a known concen-

tration of carbon monoxide.

5. Set up the Calibration Kit with 100 or 500 ppm CO as de scribed in

the in struc tions supplied with the kit.

Instruction 0024-9395

45

Page 52

Fyrite Pro

6. Connect the tubing of the Calibration Kit to the GAS inlet of the an a lyz er. Note that the gas fitting (Item 6) is only required on Fyrite

Pro Models 105 and 125.

7. Adjust the regulator for ap prox i mate ly 2 SCFH of excess flow (see

Figure 5.1).

8. After the analyzer has stabilized (2 to 3 min utes), use the ▲ and

▼ buttons to set the displayed value to match the CO con cen tra tion

stamped on the gas cylinder.

9. Press ENTER to store the new calibration values and move to the

next calibration screen, or hold down ENTER for 2 seconds to store

the new calibration values and enter the Run Mode, or press the

I/O button to exit the Calibration Mode and turn OFF the analyzer

without saving the changes.

10. Disconnect tubing from analyzer and turn off gas flow.

46

LEAVE TOP

PORT OPEN

23 4 5

1

Parts Shown:

1. Gas Cylinder

2. Regulator*

3. Tubing*

4. Tee*

5. Flowmeter*

6. Fitting, Gas*

* Contained in Calibration Kit

3

Figure 5-1. Calibration Kit Hookup

Instruction 0024-9395

6

Page 53

Fyrite Pro

5.7 Draft Calibration (Model 105/125)

Material Required: • Bellows

• Micromanometer

Range: ±8 in. H

Accuracy: ±0.01 in. H

Procedure:

1. Set the draft units to “WC” per Section 3.5.4.

2. Enter the Calibrate Mode per Section 5.1, and then

press the ENTER button until “WC” is displayed.

O column (±20 mb)

2

O column (±20 mb)

2

3. If necessary, zero the draft channel by using the ▲

.

and ▼ buttons to adjust the reading to 0.00 ±0.02.

4. Set up the analyzer and its test equipment per Figure 5-2.

5. Use the bellows to apply a positive pressure of 4.00 in. H

O, and then use

2

the ▲ and ▼ buttons to adjust the displayed value to match the

reading on the manometer.

6. Remove pressure and repeat Steps 3 thru 5 until the desired readings are obtained.

7. Press ENTER to store the new calibration values and move to the

next calibration screen, or hold down ENTER for 2 seconds to store

the new calibration values and enter the Run Mode, or press the

I/O button to exit the Calibration Mode and turn OFF the analyzer

without saving the changes.

Parts Shown:

Figure 5-2. Draft Calibration Equipment

Instruction 0024-9395

1. Tubing*

2. Tee*

3. Fitting, “+” Pressure Port

* Contained in Calibration Kit

2

1

1

Bellows

47

Page 54

Fyrite Pro

5.8 Water Trap / Filter Maintenance

The Water Trap / Filter Assembly removes water con den sate from the gas

sam ple, and also prevents soot from con tam i nat ing the internal com po nents of the analyzer.

Drain the water condensate after every test.

Procedure:

1. Disassemble the trap (see Figure 5-3).

2. Pour out all water condensate; then reassemble the trap.

Replace the Filter Element when dirty.

Material Required: • Filter Element, P/N 0007-1644

• Small Flat Blade Screwdriver

Procedure:

1. Disassemble the trap (see Figure 5-3).

2. Remove and discard old filter.

3. Install new filter and reassemble trap.

Pull apart using a slight

twisting motion

Pry apart filter chamber using

a small flat-blade screwdriver

inserted into notch

WATER TRAP

CHAMBER

FILTER

CHAMBER

FILTER ELEMENT

Figure 5-3. Water Trap / Filter Assembly

48

“A” “B”

When reassembling

the trap, make sure

that surfaces “A” and

“B” are in contact.

Instruction 0024-9395

Page 55

Fyrite Pro

5.9 O2 Sensor Replacement (Model 110/120/125)

Be sure to perform all of the checks listed in Sec tion 4.13.13 to ensure that

the O

Material Required: • Oxygen Sensor, P/N 0024-8106

• #1 Phillips Screwdriver

Procedure:

sensor needs to be replaced.

2

1. Disassemble the analyzer as follows:

a. Remove the battery cover and the batteries, uncovering one of

the cover hold-down screws.

b. Remove and set aside all four cover hold-down screws.

c. With the analyzer on its back, remove the front cover, laying it

face down to the left of the body.

d. Carefully remove the circuit board, slipping off the battery con-

nec tor on top, and then laying the circuit board face down in the

top cover.

2. Slip off the oxygen sensor’s electrical con nec tor from the circuit

board. Then push down; twist counterclockwise; then pull the oxygen sensor out of its socket (see Figure 5-4).

Tip: To obtain a better grip on the oxygen sensor, it may be necessary

to remove the screw that secures the sensor socket to the case.

3. Using the old sensor as a guide, remove the paper backing from the

new sensor gasket contained in the re place ment kit, and adhere it to

the new sensor.

4. Dispose of the old oxygen sensor in a proper manner (see the in struc tion sheet that comes with the new sensor).

5. Mount the new oxygen sensor in its socket. If the sensor socket was

removed in Step 2, re-attach it to the case.

6. Plug the oxygen sensor’s electrical connector into the printed circuit

board (observe polarity, see Figure 5-5), and then reassemble the

analyzer.

Note: The sensor may take several hours to sta bi lize after

being connected to the printed circuit board.

Instruction 0024-9395

49

Page 56

Fyrite Pro

5.10 CO Sensor Replacement

(Model 100/105/120/125)

Be sure to perform all of the checks listed in Sec tion 4.13.13 to ensure that

the CO sensor needs to be replaced.

Material Required: • CO Sensor, P/N 0024-7265

• CO Sensor Gasket, P/N 0024-1112

• #1 Phillips Screwdriver

Procedure:

1. Disassemble the analyzer as follows:

a. Remove the battery cover and the batteries, uncovering one of

the cover hold-down screws.

b. Remove and set aside all four cover hold-down screws.

c. With the analyzer on its back, remove the front cover, laying it

face down to the left of the body.

d. Carefully remove the circuit board, slipping off the battery con-

nec tor on top, and then laying the circuit board face down in the

top cover.

2. Gently pull CO sensor out of its socket (see Figure 5-5).

3. Properly dispose of the old CO sensor (see the in struc tion sheet that

comes with the new sensor).

4. It is recommended that the CO sensor gasket be re placed at the

same time as the sensor. Remove the old gasket and discard. Remove the paper backing from the new gasket and adhere it to the

case in the same position as the old one.

Important: Ensure that the new gasket does not restrict the

inlet and exhaust holes in the case.

5. Plug the new CO sensor into its socket.

6. Reassemble the analyzer.

50

Instruction 0024-9395

Page 57

Fyrite Pro

5.11 Pump Assembly Replacement

Material Required: • Pump, P/N 0024-3048

• #1 Phillips Screwdriver

Procedure:

1. Disassemble the analyzer as follows:

a. Remove the battery cover and the batteries, uncovering one of

the cover hold-down screws.

b. Remove and set aside all four cover hold-down screws.

c. With the analyzer on its back, remove the front cover, laying it

face down to the left of the body.

d. Carefully remove the circuit board, slipping off the battery con-

nec tor on top, and then laying the circuit board face down in the

top cover.

2. Slip off the pump motor’s electrical connector from the circuit board.

3. Unscrew the pump’s hold down clamp and remove it from the pump

(see Figure 5-4). Make note of how the pump wiring is routed.

4. Make note of how the tubing connects to the pump; then care ful ly

remove tubing from pump.

5. Remove the old pump and discard.

6. Install the new pump and reinstall the tubing, taking care not to

pinch or crimp the tubing. Also be sure pump wiring is routed as

was noted in Step 3.

7. Reassemble the analyzer.

Instruction 0024-9395

51

Page 58

Fyrite Pro

CO SENSOR

GASKET

(Model 125E only)

PUMP

HOLD

DOWN

CLAMP

OXYGEN SENSOR

& SOCKET

PRESSURE

SENSOR

ON PCB

Figure 5-4. Case Components & Plumbing Schematic

52

Instruction 0024-9395

Page 59

Fyrite Pro

To

BATTERY

PRESSURE

SENSOR

(RED

WIRE)

(RED

WIRE)

CO

SENSOR

(Model 125E only)

To

OXYGEN

SENSOR

Figure 5-5. PCB Components

Instruction 0024-9395

To

PUMP

(RED