Page 1

Tune-Rite™ Software

Operation Manual

P/N: 0024-9504

Revision 0

July 2014

Product Leadership • Training • Service • Reliability

Page 2

Tune-Rite

Table of Contents

SECTION 1. INTRODUCTION ........................................................................... 3

SECTION 2. SAFETY ........................................................................................ 4

2.1. Conventions ................................................................................................. 4

2.2. Safety Precautions ....................................................................................... 5

2.3. Data Ranges ................................................................................................. 6

SECTION 3. TUNE-RITE BASICS .................................................................... 7

3.1. Supported Appliances and Fuel Types ......................................................... 7

3.2. Typical Combustion Process Review ............................................................ 8

3.3. The Tune-Rite Integration ......................................................................... 9

SECTION 4. USING TUNE-RITE ................................................................... 12

4.1. Introduction ............................................................................................... 12

4.2. Selecting Fuel Type and Accessing Tune-Rite ......................................... 12

4.3. Furnace/Boiler Light-Off ............................................................................ 14

4.4. Sample Smoke Test (Oil-Fired Appliances Only) ........................................ 14

4.5. Tune-Rite Draft Analysis .......................................................................... 17

4.6. Tune-Rite Combustion Analysis .............................................................. 20

4.7. Custom Reporting ...................................................................................... 28

SECTION 5.

REFERENCE, SERVICE, AND SUPPORT ........................................ 31

List of Figures

Figure 1-1. Fyrite INSIGHT Plus Reporting Package Kit ................................... 3

Figure 3-1. Typical Combustion Analysis Flowchart ............................................ 8

Figure 3-2. Accessing Tune-Rite™ from the Main Menu ..................................... 9

Figure 3-3. Tune-Rite Process Map Integration ................................................ 10

Figure 4-1. Fuel Selection Screens for Supported Fuel ..................................... 13

Figure 4-2. Fuel Selection Screens for Unsupported Fuel ................................. 13

Figure 4-3. Cycling Through Tracking Options .................................................. 16

Figure 4-4. Sample Printout Showing Service Checklist .................................... 30

List of Tables

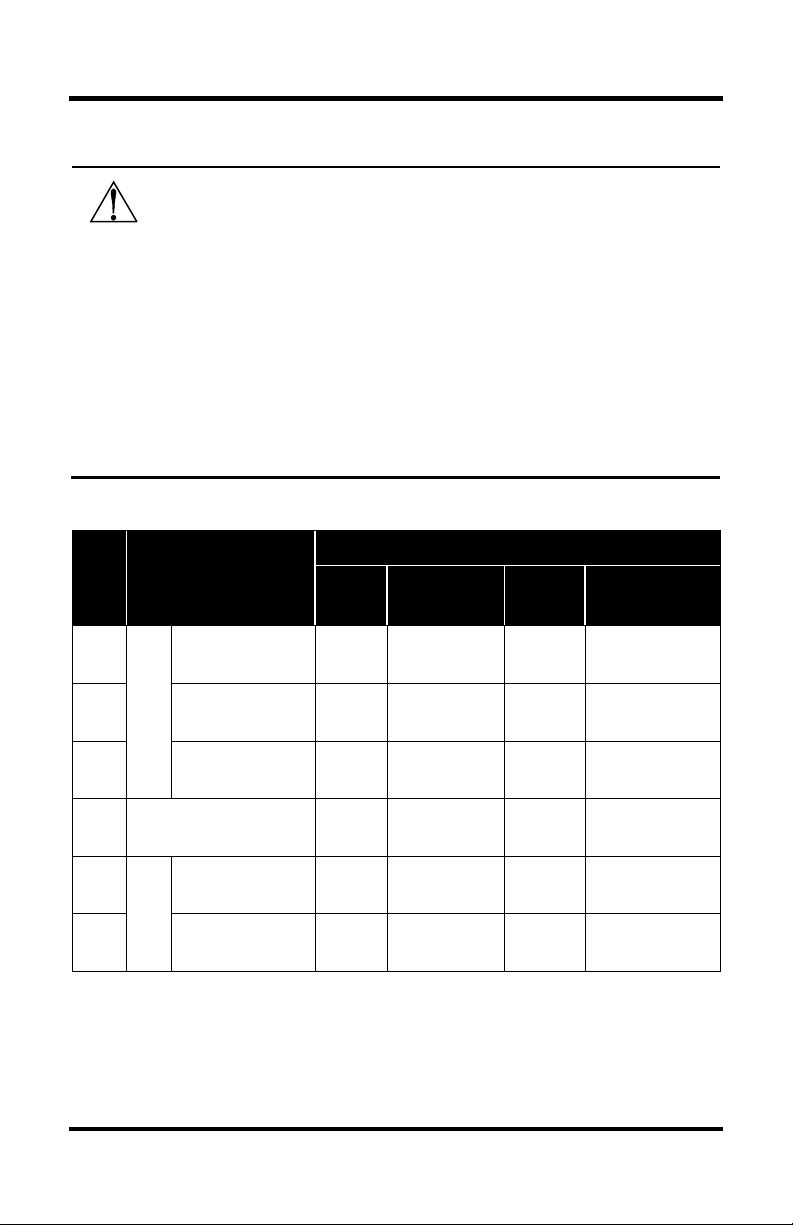

Table 2-1. Default “In Range” Data Ranges Used During Analysis ...................... 6

Table 4-1. Tune-Rite™ Menu Navigation Keys .................................................. 12

Table 5-1. Reference Material Part Numbers ................................................... 31

2 0024-9504 Rev 0

© Bacharach, Inc. 2014. All rights reserved.

Page 3

Section 1. Introduction

Thank you for purchasing a Bacharach Fyrite INSIGHT Plus. Your new

combustion analyzer provides a suite of features and functionality to simplify

Tune-Rite

the combustion analysis process. These features and functions are detailed in

the Fyrite

INSIGHT Plus manual that is included with your instrument.

Figure 1-1. Fyrite INSIGHT Plus Reporting Package Kit

Fyrite INSIGHT Plus is a next-generation combustion analyzer that integrates

Bacharach’s new Tune-Rite combustion analysis assistant into the featurerich, state-of-the-art programming of the traditional Fyrite

Bacharach’s Fyrite

Tune-Rite help system provides:

• A “when-you-need-it” solution that is integrated with the Fyrite®

INSIGHT® Plus

• Guidance based on live data and typical characteristics of the

combustion appliance

• An additional layer of diagnostic thoroughness to the traditional

combustion analysis process

• Additional comfort and confidence for the service technician

• A detailed, customizable, and value-added service report for the

customer

Tune-Rite is a non-intrusive combustion analysis assistant offering as much

0024-9504 Rev 0 3

INSIGHT Plus.

Page 4

Tune-Rite

warning statement denotes a potential hazard

injury. Caution statements may also be used to alert against

important feature, operation, etc. Failure to follow this

, result in improper

help as the technician chooses. It is integrated into the Fyrite INSIGHT Plus

interface and provides feedback and diagnoses throughout the entire

combustion analysis process if requested.

• It tells you when the combustion appliance is ready for analysis.

• It reviews combustion test results based on the appliance type,

fuel type, and various live readings.

• It identifies possible causes and recommends ways to correct

problems and improve overall combustion efficiency.

• It provides tools allowing you to track your progress through the

analysis and troubleshooting process.

• It includes a reporting feature enabling you to build then print a

customized summary report of your analysis, including “as found”,

“as left”, and service checklist data.

It is a help and training tool that’s as useful to the seasoned HVAC veteran as it

is to the novice technician.

Section 2. Safety

2.1. Conventions

WARNING: A

associated with the use of this equipment. Failure to follow this

information could result in serious personal injury or death.

CAUTION: A caution statement indicates a potentially hazardous

situation which, if not avoided, may result in minor or moderate

unsafe practices.

IMPORTANT: An important statement provides emphasis of an

information could void your warranty

operation, or cause equipment damage.

NOTE: A note statement provides emphasis of a feature,

operation, practice, etc.

4 0024-9504 Rev 0

Page 5

Only trained technicians should use a combustion

Failure to adjust the appliance to specifications

injury, death, or property

damage.

facturer’s instructions before servicing the

combustion analysis using the analyzer to confirm that the

2.2. Safety Precautions

For important information on proper operation and operator safety, read and

follow the contents of this manual. Failure to do so can result in serious injury,

death, or property damage.

WARNING:

analyzer.

recommended by the appliance manufacturer can cause it to

malfunction and result in serious

WARNING: Failure to prevent combustion by-products such as CO

gas from leaking into the living space can create hazardous

conditions that could result in serious injury, death, or property

damage.

WARNING: Tune-Rite screens help to optimize the combustion

efficiency of a heating appliance while reducing flue gas emissions

such as soot and CO. Before using the analyzer, read and follow

the INSIGHT® Plus instruction manual. ALWAYS refer to the

appliance manu

appliance. Where the appliance manufacturer’s recommendations

are in conflict with the analyzer’s screens, operating values, or

instructions, the appliance manufacturer’s recommendations take

Tune-Rite

precedence and should always be followed.

WARNING: After making appliance adjustments, always rerun the

appliance is operating within the appliance manufacturer’s

recommendations.

0024-9504 Rev 0 5

Page 6

Tune-Rite

type and typical operating values. The operating

values programmed in the analyzer are typical but not

2.3. Data Ranges

WARNING: The probable causes in the help screens are based on

the appliance

comprehensive.

CO recommendations are based on 100 ppm CO. Local rules and

regulations always take precedence. Where applicable, smoke

tests (in fuel oil applications) and draft tests (for all fuels) should

be performed prior to combustion tests.

The operator should compare the appliance manufacturer’s

operating values to the analyzer’s default values to ensure that

analyzer results are applicable to the appliance under test. Review

Table 2-1 for a list of default values used during the analysis.

Table 2-1. Default “In Range” Data Ranges Used During Analysis

Default “In Range” Data Ranges

NG

NG

NG

Appliance Type

Fuel

Furnace

Atmospheric

Draft (70%)

Fan Induced

Draft (80%)

Condensing

(90%)

O2

(%)

6 to 9 375 to 550 < 100 -0.01 to -0.05

6 to 9 325 to 425 < 100 -0.01 to -0.05

5 to 9 < 125 < 100 n/a

T-Stack

(°F)

CO

(ppm)

Draft-Stack

(inwc)

NG Water Heater 5 to 9 380 to 580 < 100 -0.01 to -0.05

Oil 1

Oil 1

Flame

Retention

Non-Flame

Boiler

Retention

3 to 6 350 to 500 < 100 -0.02 to -0.05

5 to 9 400 to 600 < 100 -0.02 to -0.05

1 – Fuel type “Oil” includes Oil #2, Oil #4, Oil # 6, and B5.

6 0024-9504 Rev 0

Page 7

Section 3. Tune-Rite Basics

3.1. Supported Appliances and Fuel Types

The Fyrite INSIGHT Plus instrument is useful in analyzing the combustion

Tune-Rite

process in a wide variety of applications. (For a complete list of features and

applications, refer to your Fyrite

Tune-Rite focuses exclusively on the gas-fired furnaces, gas-fired water

heaters, and oil-fired boilers listed below.

Supported Appliance Types are shown below.

• Natural gas (NG) 70% efficient atmospheric furnaces

• Natural gas (NG) 80% efficient induced furnaces

• Natural gas (NG) 90% high-efficiency/condensing furnaces

• Natural gas (NG) water heaters (standard and FVIR)

• Flame retention oil boilers (>80% efficient)

• Non-flame retention oil boilers (<75% efficient)

Supported Tune-Rite Fuel Types are shown below.

• Natural gas

• Oil #2

• Oil #4

• Oil #6

• B5

Refer to your Fyrite

INSIGHT Plus manual for the locations of sampling points

on your combustion appliance.

INSIGHT Plus combustion analyzer manual.)

IMPORTANT: Review the appliance manufacturer’s

recommendations for the combustion device being tested, and be

aware of accepted practices of the local jurisdiction before

introducing sampling holes into exhaust pipes or ducts.

WARNING: To prevent dangerous exhaust gases from leaking into

the space, be sure to completely and securely seal any sampling

holes made in the exhaust pipes or ducts.

0024-9504 Rev 0 7

Page 8

Tune-Rite

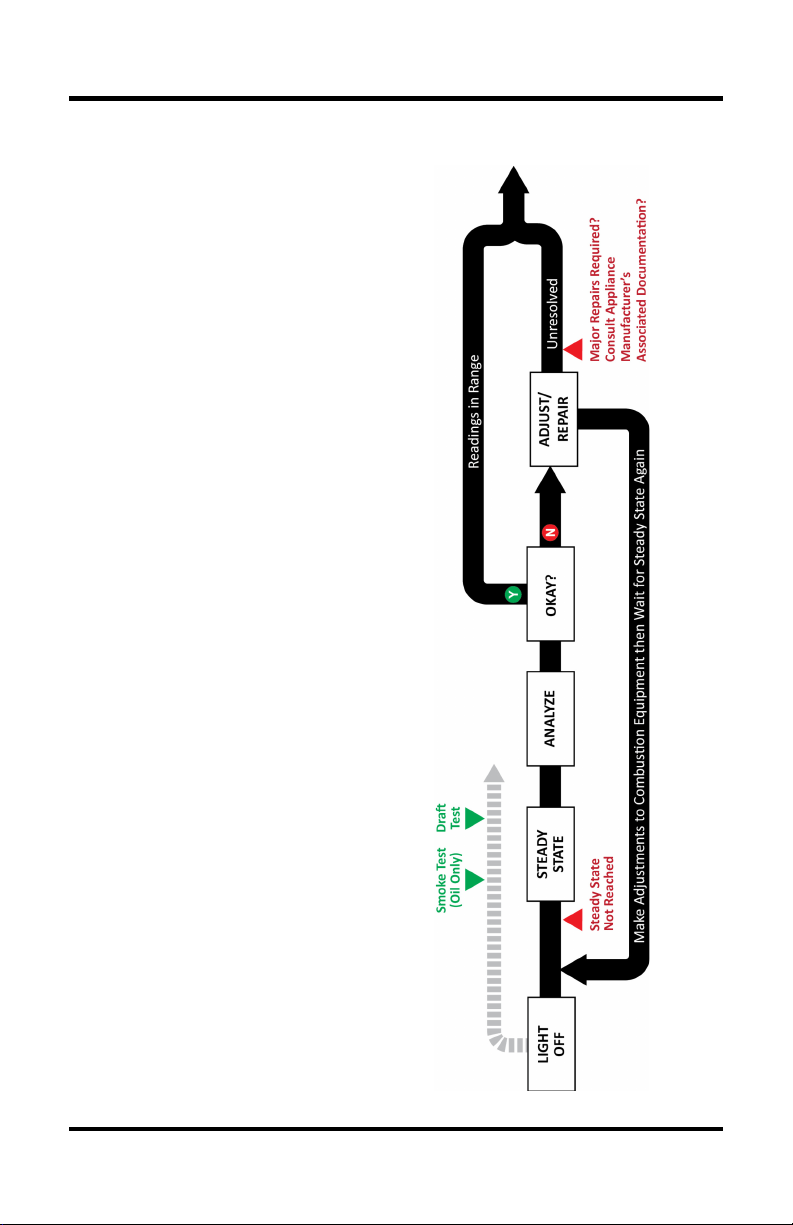

In a typical combustion process (see

), the following steps usually

may indicate hardware problems and

Additional adjustments may be made

3.2. Typical Combustion Process Review

Figure 3-1

take place:

• Initial light-off of the combustion

appliance

• The system warms up to the point

when a steady-state condition is

reached. If steady-state is not

reached, the combustion appliance

may require major tuning, major

repairs, or replacement.

• For oil-fired appliance, a smoke test

is performed.

• A draft test is performed to verify

proper draft in the system.

• Combustion variables (O

, CO, CO2,

2

ambient temperature, stack

temperature, etc.) are analyzed to

determine efficiency and proper

operation.

• Out-of-range values are indicative of

less-than-optimal combustion, and

even safety issues.

• Further investigation may occur and

adjustments may be made to the

combustion equipment.

• Combustion variables are re-

evaluated.

•

until the combustion appliance is

operating within the appliance

manufacturer’s recommended

guidelines. If this state is never

reached, major repairs may be

required, the appliance

manufacturer’s associated

documentation may need to be

referenced, or a full system

replacement may be warranted.

8 0024-9504 Rev 0

Figure 3-1. Typical Combustion Analysis Flowchart

Page 9

and fuel you are using (as well as combustion data).

Technology can be used to simplify this process. The Fyrite INSIGHT Plus

combustion analyzer provides precise live readings of critical combustion data

during this process. To determine if the combustion appliance is operating

properly and within the appliance manufacturer’s recommended specifications,

the HVAC technician must still refer to the following.

• Industry experience to evaluate the combustion data

• Familiarity with the combustion appliance

• Familiarity and understanding of the operation of the analyzer

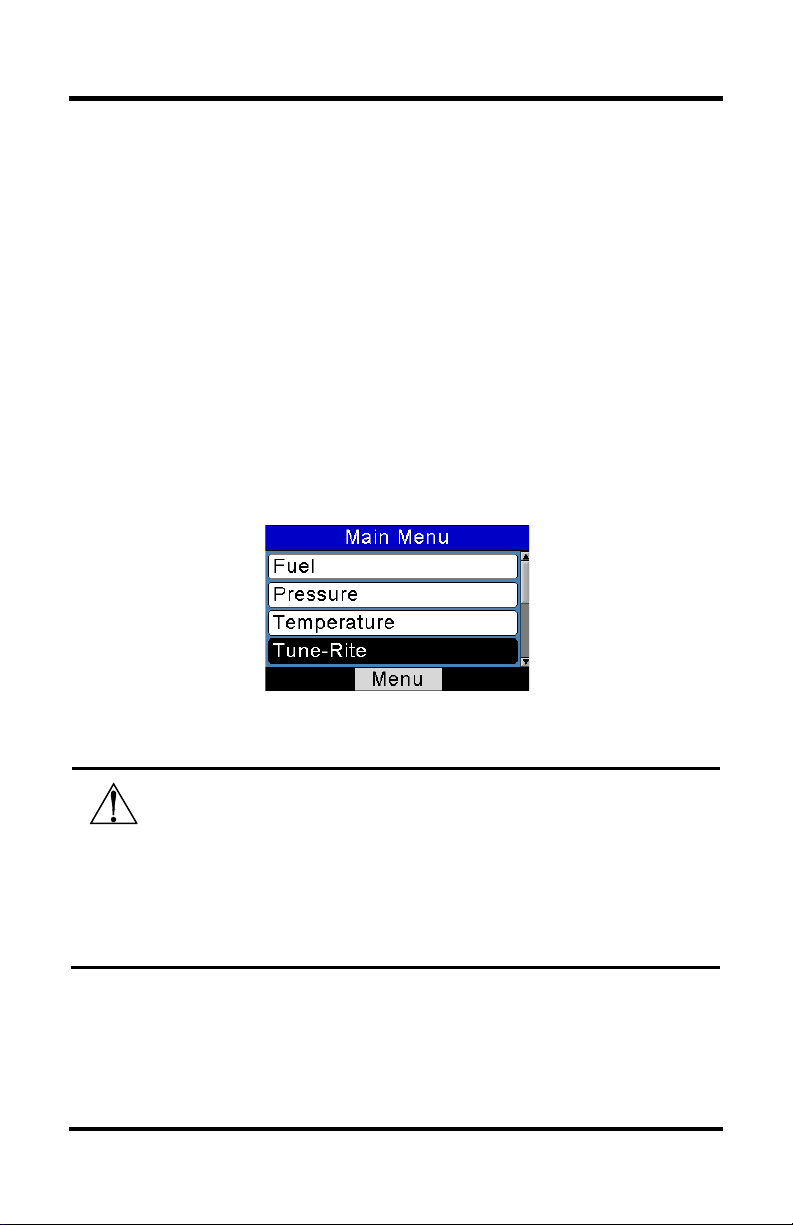

3.3. The Tune-Rite Integration

Tune-Rite provides an integrated “when-you-need-it” solution that offers

guidance based on live data and typical characteristics of the combustion

appliance. It gives an additional layer of diagnostic thoroughness to the

traditional combustion analysis process, while offering additional confidence to

the service technician.

Tune-Rite

Figure 3-2. Accessing Tune-Rite™ from the Main Menu

WARNING: Be aware of operating limits associated with the

combustion appliance you are analyzing. Tune-Rite provides

general tuning and efficiency recommendations based on the type

of appliance

However, always follow the operating instructions and guidelines

from the appliance manufacturer for details on precise operating

limits.

0024-9504 Rev 0 9

Page 10

Tune-Rite

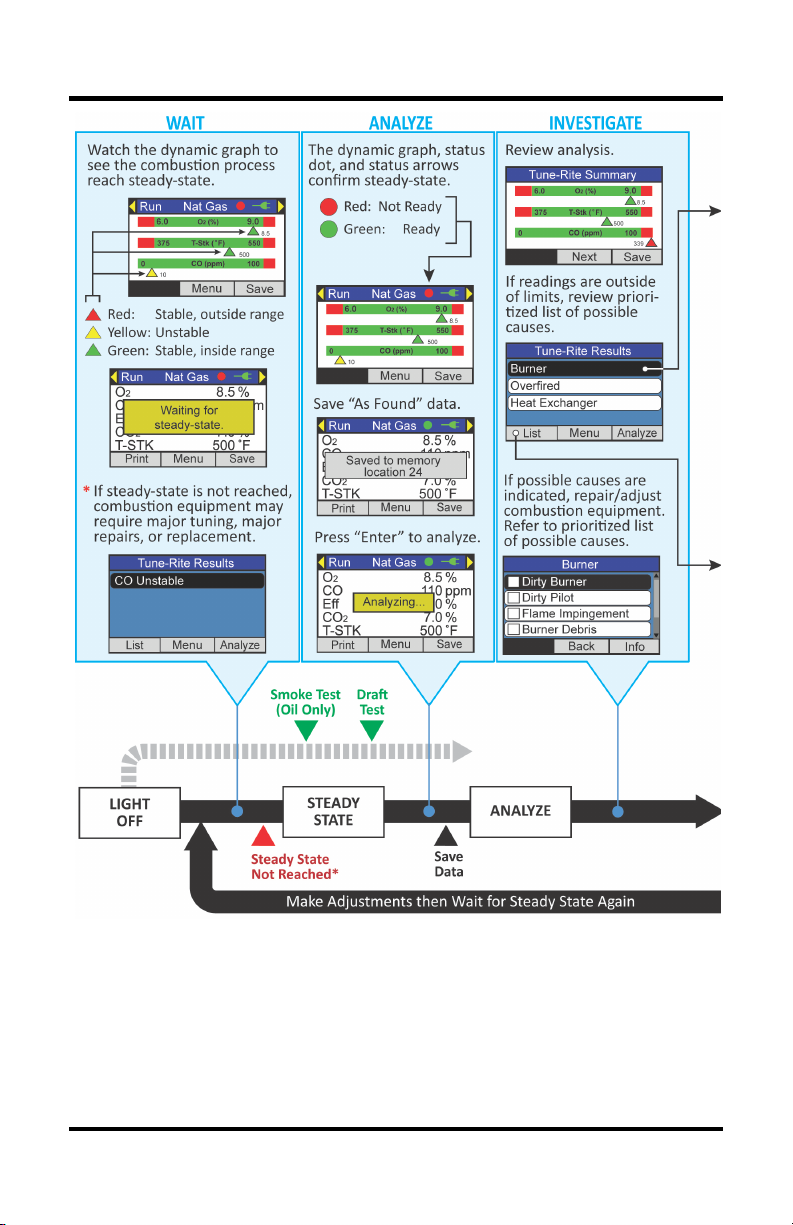

Figure 3-3. Tune-Rite Process Map Integration

10 0024-9504 Rev 0

Page 11

Tune-Rite

Figure 3-3. Tune-Rite Process Map Integration (Continued)

0024-9504 Rev 0 11

Page 12

Tune-Rite

Section 4. Using Tune-Rite

4.1. Introduction

Using the Tune-Rite combustion analysis assistant is similar to using the

Fyrite

IINSIGHT Plus combustion analyzer. If you are already familiar with

the INSIGHT

screens and menu structure are very similar. Below is a review of the basic

menu navigation keys, which also apply to navigation within the Tune-Rite

screens.

Table 4-1. Tune-Rite™ Menu Navigation Keys

Key Name Symbol General Navigation Function

Plus, using the Tune-Rite feature will be very intuitive as the

Arrow Keys , , ,

Enter Key

Up, down, left, and right movement within

a screen or between screens

Proceed; perform the selected action

Escape Key ESC Go back

If you are new to using the Fyrite INSIGHT Plus, please refer to the INSIGHT

Plus manual for details on combustion analyzer operating instructions, menus,

complete navigation instructions, and important warnings.

Multiple fuel types, appliance types, and combustion readings could produce

many Tune-Rite recommendations. This section shows only a small sampling

of those options in order to familiarize the operator with Tune-Rite behavior

and intuitive operation.

4.2. Selecting Fuel Type and Accessing Tune-Rite

Step Description

1

Turn on the Fyrite

combustion analyzer and wait for it to

complete its initialization and warm-up

procedure. Refer to the INSIGHT® Plus

Instruction Manual P/N: 0024-9487 for

details.

INSIGHT Plus

12 0024-9504 Rev 0

Page 13

you are testing

Step Description

2

From the Main Menu of the Fyrite

INSIGHT

Plus, select the Fuel option

and press the Enter key ( ). This

displays the Select Fuel menu.

3 From the list of fuel types in the Select

Fuel menu, select the fuel type for the

combustion appliance

(see Figure 4-1 below and Supported

Tune-Rite Fuel Types on page 7).

4 From the Main Menu, use the up and

down arrow keys (,) to select the

Tune-Rite option, then press the Enter

key ( ).

5 Read and accept the disclaimer that is

displayed. If you selected a fuel that is

unsupported by Tune-Rite, an error is

displayed when you attempt to access

Tune-Rite. Refer to Figure 4-2

below.

Tune-Rite

Figure 4-1. Fuel Selection Screens for Supported Fuel

Figure 4-2. Fuel Selection Screens for Unsupported Fuel

0024-9504 Rev 0 13

Page 14

Tune-Rite

Select Smoke Number from the

4.3. Furnace/Boiler Light-Off

If the combustion appliance you are testing is new or is shut off (i.e., “cold”), be

sure to start the appliance according to the appliance manufacturer’s

instructions so that it can warm-up and the process can begin to reach steadystate conditions (which usually takes about 5-10 minutes).

4.4. Sample Smoke Test (Oil-Fired Appliances Only)

If the combustion appliance you are testing uses oil as a fuel, it is important to

perform a smoke test. Excessive smoke from oil combustion is indicative of a

serious combustion process problem, and can also be harmful to people and

bad for sensitive combustion analysis equipment like the INSIGHT

smoke test is used to ensure that the oil-fired system is at least adequately

“coarsely” tuned to warrant finer detailed tuning using the combustion

analyzer.

A smoke test is a mechanical test that samples the combustion gas by drawing

it through a white paper filter. Visual comparison of the combustion gas

residue against standard smoke level samples shows the operator if the

combustion system is significantly out of tune and in need of coarse tuning

before the combustion analyzer should be used.

Step Description

Plus. A

1 After setting the fuel type (oil) and

accepting the disclaimer, select the oil

boiler type and press Enter ( ).

• Boiler with flame retention burner

head (>80% efficient)

• Boiler with non-flame retention

burner head (<75% efficient)

2

Analyze menu and press Enter ( ).

The Smoke Number screen is displayed

and a Smoke Number is requested.

14 0024-9504 Rev 0

Page 15

sample the oil burners’ combustion

Inspect, adjust, and/or repair the

Refer to INSIGHT® Plus Instruction

, track your

progress by cycling through options

Step Description

3

Use a True Spot Smoke Tester to

gas. Compare the sample with the

smoke chart to determine the smoke

number.

4 Enter the oil burner’s smoke number.

Based on the smoke number value that

you enter, you may be asked if oil is

seen on the paper, to which you will

enter either Yes or No.

5

Tune-Rite results are displayed. In

this case a “Smoke High” result is

displayed. Press Enter ( ) to see the

checklist of possible items to check for

a high smoke condition.

6 Review the checklist using the up and

down arrow keys (,) to navigate

through the list.

Tune-Rite

7

appliance based on safety guidelines,

local regulations, the appliance

manufacturer’s recommendations, and

system guidance from Tune-Rite™.

Manual for further safety details.

8 As you inspect, repair, and adjust the

combustion appliance

using the Enter key ( ). Refer to

Figure 4-3 below.

0024-9504 Rev 0 15

Page 16

Tune-Rite

the results screen. Then press the

the Analyze menu. The Smoke

Number screen is displayed and a

sample the oil burners’ combustion

Enter the oil burner’s new smoke

Figure 4-3. Cycling Through Tracking Options

Step Description

9 Press the Back key (F2) to go back to

Analyze key (F3) to re-analyze.

10 Select the Smoke Number option from

Smoke Number is requested.

11

Use a True Spot Smoke Tester to

gas. Compare the sample with the

smoke chart to determine the smoke

number.

12

number after repairs and adjustments

have been made.

13 Check the smoke test paper for signs of

oil residue and enter the appropriate

response.

16 0024-9504 Rev 0

Page 17

The adjustments have reduced the

what you investigated and the

and accepting the

Step Description

14

high smoke condition to an acceptable

range.

Select the Analyze option (F3) to return

to the Analyze menu.

15 Select the List option (F1) to review

adjustments you made.

16 Select the Save option (F3) to save this

service checklist for printing later.

Tune-Rite

4.5. Tune-Rite Draft Analysis

Ensuring the appliance under test has proper draft is vital in the combustion

analysis process. You can directly measure the draft/venting data using the

INSIGHT

yourself, or you can have Tune-Rite automatically evaluate the draft data of

the combustion appliance.

Plus (refer to the INSIGHT Plus manual) and evaluate the data

Step Description

1 After setting the fuel type (natural gas

in this example)

disclaimer, select the appliance type:

• NG 70+ (atmospheric)

• NG 80+ (induced)

• NG 90+ (high-efficiency/

condensing)

• NG Water Heater.

Appliance type will vary based on fuel

selection.

0024-9504 Rev 0 17

Page 18

Tune-Rite

based on the selected fuel type and

condition is reached before taking

from the

to analyze

data (to be used as your “as found”

Step Description

2 Select the draft option from the Analyze

menu. Note that the number of options

in this screen and their names will vary

appliance type.

3 A steady-state reminder message is

displayed. Be sure that a steady-state

venting or draft measurements.

4 The draft measurement

INSIGHT Plus is displayed.

5 Press the Enter key ( )

using Tune-Rite.

6

Tune-Rite results are displayed. Press

Next (F2) to see the Tune-Rite Results

screen.

7 Press the Save key (F3) to save draft

draft data when you build your service

checklist and report).

8 In this case, a “Draft Low” message is

displayed. Press Enter ( ) to see the

list of possible causes for this condition.

18 0024-9504 Rev 0

Page 19

Inspect, adjust, and/or repair the

appliance based on safety guidelines,

recommendations, and

Refer to INSIGHT® Plus Instruction

progress by cycling through options

data when you build your service

Step Description

9 Review the list of possible causes. Note

that the list may scroll off the screen, so

you may need to use the arrow keys

(,) to navigate through the list.

10

Tune-Rite

local regulations, the appliance

manufacturer’s

system guidance from Tune-Rite™.

Manual for further safety details.

11 As you inspect, repair, and adjust the

combustion appliance, track your

using the Enter key ( ). Refer to

Figure 4-3 on page 16.

12 Go back and re-analyze. Select the

Draft option from the Analyze menu

and press the Enter key ( ).

13 The updated draft measurement from

the INSIGHT

14 Press the Save key (F3) to save this draft

data (to be used as your “as left” draft

Plus is displayed.

checklist and report).

15 Press the Enter key ( ) to re-analyze

using Tune-Rite.

0024-9504 Rev 0 19

Page 20

Tune-Rite

what you investigated and the

Step Description

16 The adjustments have corrected the low

draft condition. The draft reading is

now within an acceptable range.

17 Select the List option (F1) to review

adjustments you made.

18 Select the Save option (F3) to save this

service checklist for printing later.

4.6. Tune-Rite Combustion Analysis

You can directly measure combustion data using the INSIGHT Plus (refer to

the INSIGHT

Plus manual) and evaluate the results yourself, or you can have

Tune-Rite automatically analyze the combustion data and make

recommendations for repairs and any appropriate optimization.

IMPORTANT: Possible cause recommendations and range-ofoperation values provided during combustion analysis testing

assume the combustion appliance is running in high-fire mode.

20 0024-9504 Rev 0

Page 21

and accepting the

. Note that the

their names will vary based on the

Step Description

1 After setting the fuel type (Natural gas

in this example)

disclaimer (F3), select the NG appliance

type from the list and press Enter ( ).

• NG 70+ Furnace (atmospheric)

• NG 80+ Furnace (induced)

• NG 90+ Furnace

(high-efficiency/condensing)

• NG Water Heater.

Note that the appliance types displayed

will vary based on the selected fuel.

2 Select the Combustion option from the

Analyze menu and press Enter ( ) to

initiate the analysis

number of options in this screen and

Tune-Rite

selected fuel type and appliance type.

0024-9504 Rev 0 21

Page 22

Tune-Rite

the upper right portion of the screen

ssing the

this popup indicates that the analyzer

the analyzer’s probe may not be

So, your analyzer will not perform a

of other

Step Description

3 The steady-state reminder message

Waiting for steady-state. is displayed

briefly. In addition, the red dot () in

indicates that combustion readings have

not yet reached a steady-state

condition.

If you attempt to initiate a Tune-Rite™

combustion analysis (by pre

Enter key ) before steady state is

reached, an Insufficient Wait Time

message is displayed briefly. (Note that

has insufficient data to make a steadystate determination – unlike the similar

terminology in the Results screen which

relates to the appliance wait time.)

Similarly, if you attempt to initiate a

Tune-Rite™ combustion analysis with a

combustion oxygen level above 16%, a

message is displayed to warn you that

connected?.

connected: O

above 16%. Is probe

2

NOTE: Remember that ambient “air”

contains approximately 21% O

gas usually contains less than 16% O

. Flue

2

.

2

combustion analysis (or an efficiency

calculation, or a number

calculations) until the O2 reading is 16%

or lower.

22 0024-9504 Rev 0

Page 23

the left and right arrow keys

reach steady state condition, you may

on the

be within the acceptable

Rite confirms the

) has

Step Description

4 Press

(,) to scroll through different display

types. As combustion readings begin to

Tune-Rite

notice that those readings will begin to

settle into stable values.

Though individual values may be stable

(that is, they are no longer displayed

with a yellow pointer [ ]

dynamic graph display), they may or

may not

operating range for the selected fuel

and appliance type (green pointer [ ]

for within range, red pointer [ ] for

outside the acceptable range).

5 After a sufficient wait time has elapsed

and after Tunestability of all combustion parameters,

the round steady-state dot changes

from red (

) to green ().

Notice that the previously unstable CO

reading (yellow pointer

changed to a red pointer ( ),

indicating stability, but an operating

range that is not acceptable (similar to

the T-Stack value, which is also out of

range in this example).

6 Press the Enter key ( ) to analyze the

combustion data using Tune-Rite.

7 An Analyzing… message is displayed

temporarily showing that Tune-Rite™ is

analyzing the combustion data to

determine possible causes for the outof-range conditions.

0024-9504 Rev 0 23

Page 24

Tune-Rite

may span several

Step Description

8 When the analysis is complete, the

Analyzing… message disappears, and

the bar graph summary screen is

displayed.

Press the Save key (F3) to save this

steady-state snapshot (“as found” data)

for use later in the custom report to

show the conditions before any

corrective actions were performed.

9 From the Tune-Rite Summary screen,

press the Next key (F2) to show the

Tune-Rite Results screen. It provides a

prioritized list of possible causes for the

out-of-range conditions.

Possible causes

screens (as indicated by the scroll bar

on right side of the display).

10 Use the up and down arrow keys (,)

to highlight the possible cause that you

want to investigate. Press the Enter key

( ) to get a prioritized checklist of

items to inspect and evaluate.

24 0024-9504 Rev 0

Page 25

Checklist items may span several

Step Description

11

screens (as indicated by the scroll bar

on right side of the display).

Use the up and down arrow keys (,)

to highlight the current checklist item

under investigation.

12 Press the

Info key (F3)

to get a

brief

description

of the

highlighted

checklist

item. Press

Back (F1) to

return.

Tune-Rite

0024-9504 Rev 0 25

Page 26

Tune-Rite

Inspect, adjust, and/or repair the

appliance based on safety guidelines,

recommendations, and

repeatedly to cycle through

After making adjustments and/or

the combustion process to see the

state after your adjustments and/or

Step Description

13

local regulations, the appliance

manufacturer’s

system guidance from Tune-Rite™.

Refer to the INSIGHT® Plus Instruction

Manual for further safety details.

As you inspect, evaluate, and repair the

appliance, track your progress through

the checklist.

For each item selected, press the Enter

key ( )

three evaluation options:

Not Investigated

Checked/Okay

Adjusted/Repaired

14

repairs, press the Back key (F2) to

return to the Tune-Rite Results screen.

15 Press the Analyze key (F3) to re-analyze

effects of the repairs and adjustments.

Use the arrow keys (,) to highlight

Combustion, and then press Enter ( )

to start the combustion analysis again.

16 As before, the analyzer will ensure that

combustion values have reached steady

repairs. The Waiting for steady- state.

message is displayed

26 0024-9504 Rev 0

Page 27

In this example, note that the

adjustments were

Rite™ results from the

Rite™ confirms that combustion

to view the

Step Description

17 As the combustion appliance reaches

steady state, the status dot will change

from red (

) to green ().

Tune-Rite

combustion values all appear to be

within recommended ranges, therefore

the pointers are all shown in green

( ), i.e., within range, after steady

state is reached.

18 With repairs completed and combustion

values within acceptable ranges, press

the Save key (F3) to save this steadystate snapshot (“as left” data) for use

later in the service checklist to show the

conditions after

performed.

19 Press the Next key (F2) to show the new

Tuneadjustments that were made. Tune-

readings are within range.

20 Press the List key (F1)

combustion checklist. Use the up and

down arrows (,) to view the entire

list.

0024-9504 Rev 0 27

Page 28

Tune-Rite

investigations were made and what

Print Report option, and then press

Use the date/time stamp and the

record to add (L=checklist data,

, T=temperature

Step Description

21 Press the Save key (F3) to save the

checklist for use later to show what

corrective actions were performed.

Then press the Back key (F2) to return

to the Menu.

NOTE: Checklist tracking marks remain

active until you exit Tune-Rite™.

Tracking marks are only cancelled when

you exit Tune-Rite™.

4.7. Custom Reporting

Prepare for your final report: You should record data throughout the

troubleshooting process for use later in the reporting phase.

Step Description

1 Select the Memory option from the

Main Menu and press Enter ( ).

2 Use the arrow keys (,) to select the

Enter ( ).

3 Using the up and down arrow keys

(,), select the desired “As Found”

combustion item then press Enter ( )

to view that record’s data to confirm.

record’s suffix to identify the desired

C=combustion record

data, and P=pressure data).

28 0024-9504 Rev 0

Page 29

Review the combustion data as the

to add that “As Found”

, select the desired “As Left”

Review the combustion data as the

to add that “As Left”

, select the desired Checklist

checklist to the print report, or press

Step Description

4

correct “As Found” data, then press the

Add key (F3)

record to the print report, or press Back

(F1) to select a different combustion

record for the report.

5 Using the up and down arrow keys

(,)

combustion item then press Enter ( )

to view that record’s data to confirm.

6

correct “As Left” data, then press the

Add key (F3)

record to the print report, or press Back

(F1) to select a different combustion

record for the report.

Tune-Rite

7 Using the up and down arrow keys

(,)

record then press Enter ( ) to view

that checklist to confirm. Press the Skip

key (F2) to create a report without the

checklist.

8 Review the checklist to confirm it is the

correct one (you may have saved other

checklists in the analyzer’s memory),

then press the Add key (F3) to add that

Back (F1) to select a different checklist

for the report.

0024-9504 Rev 0 29

Page 30

Tune-Rite

, then

to print the final

Note that the sample

sample screens shown in this section.

Step Description

9 Turn on and align your printer

press Enter ( )

report. A sample printout is shown in

Figure 4-4.

printout does not reflect all of the

Your printout will reflect the data you

save and the records you choose for

your printout.

Figure 4-4. Sample Printout Showing Service Checklist

30 0024-9504 Rev 0

Page 31

Section 5. Reference, Service, and Support

Refer to the following documents for additional reference material about the

INSIGHT Plus, Tune-Rite, and combustion process terminology. On

Fyrite

the web, visit www.Tune-Rite.com.

Table 5-1. Reference Material Part Numbers

Reference Material Title Part Number

Tune-Rite

Tune-Rite Quick Start Guide

Tune-Rite Reference Guide and Glossary

True-Spot Smoke Tester Instructions and Parts List

Fyrite INSIGHT Plus Instruction Manual

0024-9505

0024-9507

0021-9012

0024-9487

Service and technical support can be obtained by contacting one of the

following Bacharach Service Centers.

United States

Bacharach, Inc.

621 Hunt Valley Circle

New Kensington, PA 15068

Phone: 724-334-5051

Fax: 724-334-5723

Email: help@MyBacharach.com

Canada

Bacharach of Canada, Inc.

20 Amber Street Unit #7

Markham, Ontario L3R 5P4

Phone: 905-470-8985

Fax: 905-470-8963

Email: support@BachCan.ca

∇ ∇ ∇

0024-9504 Rev 0 31

Page 32

Tune-Rite

World Headquarters

621 Hunt Valley Circle, New Kensington, Pennsylvania 15068

Phone: 724-334-5000 • Toll Free: 1-800-736-4666 • Fax: 724-334-5001

Website: www.MyBacharach.com • E-mail: help@MyBacharach.com

-*-

32 0024-9504 Rev 0

Loading...

Loading...