Page 1

Page 2

Page 3

Quick Start Guide

Combustion Gas Analyzer

This quick guide provides basic setup, operating and maintenance

information for the Fyrite® INSIGHT. If required, more detailed

information concerning the analyzer’s technical specifications,

operation, set-up, calibration, and parts list can be downloaded from

MyBacharach.com/insight (P/N 24-9460) .

MyBachar ach.com • Fyrite® InSIght • Instruction 24-9460

2

Page 4

Setting Up the Analyzer

Front Panel Push Buttons

Note that a push button may perform several functions, depending on the analyzer’s model number

and what screen is being displayed at the time.

• Turns the analyzer ON and OFF.

• Turns the backlight ON and OFF while the analyzer is turned ON.

• Scrolls up, down, left, and right through the display screen options.

• Causes the displayed value to increase or decrease correspondingly.

• Acts as an ENTER button. Performs the action selected.

• While in the HOLD screen, turns the sample pump on, displays the RUN screen,

and begins a combustion test.

• While in the RUN screen, turns the sample pump off, displays the HOLD screen

and the last set of combustion data.

• Displays the HOLD screen while pressing it from most menus.

• Return the display to the HOLD screen while pressing it during the

5 second power down sequence.

• Cancels most operations and displays the previous screen.

• Pressing function keys accepts the corresponding function defined at the bottom

of the display including PRINT, SAVE, MENU, differential pressure ZERO,

differential temperature ZERO, PAGE UP, PAGE DOWN, and CLEAR data.

Instruction 24-9460 • Fyrite® InSIght • MyBacharach.com

3

Page 5

Operating Tips

1. When an analyzer is brought in from a cold vehicle, let it warm up slowly to minimize

condensation. Temperatures below freezing will not damage the analyzer; however, bringing

a cold analyzer into a warm, humid environment may cause condensate to form inside the

case.

CAUTION: Although the analyzer itself is not damaged by an extremely cold environment,

the electrochemical sensors may be damaged. The O

at approximately -20 °F and the CO sensors at approximately -94 °F. If the analyzer is

exposed to an extremely cold condition, it is strongly suggested that the sensor housings

be examined for hairline cracks. Be aware that a leaking sensor can cause chemical

burns to the skin and possibly damage the PCB assemblies.

2. Ensure that the analyzer is sampling fresh air when turned ON. Pulling a stack-gas sample

through the analyzer during its warm-up period will not damage the analyzer, but it will result

in incorrect sensor readings, and may result in sensor error messages appearing after the

warm-up cycle completes.

Note that flue-gas condensate is acidic and very corrosive. It is important not to allow the

analyzer ’s internal components to come in contact with condensate for long periods of time.

3. Before each use, inspect the filter element of the water-trap / filter assembly. Replace the filter

if it looks dirty.

4. When sampling flue-gas, keep the analyzer above the water-trap, and keep the trap in a vertical

position. This will maximize the effectiveness of the trap and keep liquid from being drawn

directly into the analyzer.

5. When liquid condensate is seen inside the water trap, empty the trap before it becomes full.

6. When storing the analyzer, it’s a good idea to empty the water trap and leave it open to further

dry it out.

7. Calibrate the analyzer every 6 months - 1 year to assure its accuracy

sensor’s electrolyte will freeze

2

MyBachar ach.com • Fyrite® InSIght • Instruction 24-9460

4

Page 6

Performing Tests

Make sure that the sample point is before any draft diverter/hood or barometric damper so that the

flue gasses are not diluted and the stack temperature has not been decreased by surrounding air

used to balance the draft.

The sample point should also be as close to the breach area as possible, again, to obtain an accurate

stack temperature. This will also provide a more accurate O

gas stream through joints in sheet metal vent connectors.

When testing atmospheric, forced air heating equipment with a clamshell or sectional heat exchanger

design, test each of the exhaust ports at the top of the heat exchanger. The probe should be inserted

back into each of the exhaust ports to obtain a flue gas sample, before any dilution air is mixed in.

Draf t tests should be taken from a hole drilled in the stack downstream from the draft hood.

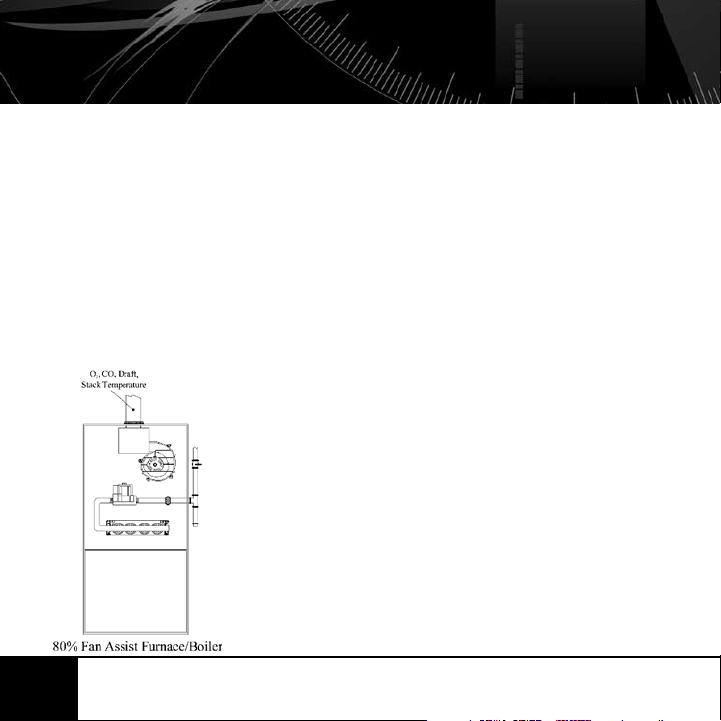

Combustion and draft testing fan assist, furnaces/boilers should be

done through a hole drilled in the vent immediately above the inducer

fan. While fan assist equipment operates under a negative draft, it

is good practice to seal the sample hole, high temperature silicone is

generally recommended.

reading should air be entering the flue

2

Instruction 24-9460 • Fyrite® InSIght • MyBacharach.com

5

Page 7

Performing Tests

Boilers, which have a ‘bell’ shaped draft diver ter directly on top,

should be tested directly below the diverter through a hole-drilled

in the vent connector.

Should draft tests below the diverter measure insufficient draft

levels, an additional test should be performed above the diverter to

determine if the reason for insufficient draft is related to a chimney

problem or a draft hood problem.

It is also a good idea to test any areas with openings that provide a

path for combustion air to be introduced to the flame. These areas

provide a path where flue gases can potentially be exhausted.

With forced air systems this area is generally limited to

immediately in front of the burners while many styles of

boilers allow secondary combustion air to also be drawn

in from all around the base of the cabinet.

Gas and oil fired power burners should be tested up

stream from the barometric, as close to the breech area

as possible.

While stack draft may be an impor tant measurement,

fuel oil and gas fired power burners require draft control

over the fire to maintain a proper and controlled intake

of combustion air.

MyBachar ach.com • Fyrite® InSIght • Instruction 24-9460

6

Page 8

Performing Tests

Diagnostics Menu

1. In the MAIN MENU highlight the DIAGNOSTICS MENU and select ENTER. This screen

allows you to look at the total run times for the instrument, check O2 and CO sensor status

and thermocouple output.

Turning Off the Analyzer

1. Before turning off the instrument, disconnect the hose and probe assembly and check the

water trap for moisture, empty if necessary. Allow the instrument to continue to pump

fresh air for a few minutes to make sure all water and flue gases are purged from the internal

components.

2. Press and hold down the POWER button for approximately 2 seconds at which time the display

will read PURGING SENSORS, then count down for 5 seconds and power off.

3. You can also opt to set the instrument up to do a longer post purge period by going to the

MAIN MENU, SETUP and scrolling down to the POST-PURGE PERIOD and pressing the

ENTER button. The default time from the factory is 5 seconds; you can also select NONE

(We recommend against no purge), 1 minute, 5 minutes or 10 minutes.

Calibration and Maintenance: IMPORTANT

1. Before performing any calibration procedure, ensure that fresh batteries are installed or use

the optional AC power adapter. Also, ensure that the analyzer is at room temperature and

will be sampling fresh air when turned ON.

IMPORTANT: To maintain accuracy, the standards used must be at least four times as

ac cu ra te as t he st ated ac cu rac y o f the Fy ri te® INSIGHT. (See INSIGHT instruction manual

P/N 24-9460)

Instruction 24-9460 • Fyrite® InSIght • MyBacharach.com

7

Page 9

B-Smart™ Sensors

The Fyrite® INSIGHT utilizes Bacharach’s new Smart Sensor technology for its CO sensors.

B-Smar t™ sensors are market with a 10-Digit Calibration Code that can be entered in the

B-Smart™ calibration screen. Once the B-Smar t™ code is entered and the sensor is installed

the CO channel is calibrated.

Benefits of Smart Sensors:

a. New sensors can be installed without needing to be calibrated.

b. Sensors can be pre-calibrated and installed when needed.

c. Sensors can be moved from one analyzer to another.

d. Sensors can be sent in for calibration without sending in the entire instrument.

The smart sensors should be calibrated every

6 months to 1 year to assure that the analyzer

con tinues to meet its published accuracy

specifications. For details surrounding the

B- Smar t™ re-calibr atio n progr a m, go to

MyBacharach.com\bsmart. For additional

in formation re g a r d i n g Ca lib ration, see

specification model located at MyBacharach.

com\insight.

MyBachar ach.com • Fyrite® InSIght • Instruction 24-9460

8

Page 10

Setting Up the Analyzer

Preliminary Steps

Before using the analyzer . . .

• Check batteries

• Connect probe to analyzer

• Check setup

Analyzer Turn On and Warm up

1. Remove the back cover and install the 4 AA batteries.

2. Connect the probe and hose assembly. Note the combustion hose fitting is slightly larger

in diameter than the pressure hose fitting. The stack thermocouple plugs into the yellow

connector on the left hand side with the wider prong on the right.

3. Turn ON the analyzer by pressing the PWR button for a second until the pump starts up and

the display comes on. For several seconds you will see the Version, Model Number and Serial

Number of the instrument displayed, the instrument will then start a 60 second countdown to

allow the sensors to calibrate. NOTE: make sure the probe is sampling fresh air during these

60 seconds. To set the time/date and other settings go to the SETUP section.

4. The first screen that comes up is in the HOLD position. To start sampling press the RUN/

HOLD button. The backlight will be illuminated at start-up.

Fuel Type

1. The FUEL TYPE will be displayed at the top of the screen. To change to another fuel, press the

MENU (F2) button, the MAIN MENU will be displayed with the FUEL selection highlighted.

Press t he ro und , g re en, ENTER bu tt on in t he ce nt er o f t he k ey pa d to se le ct FUEL, scroll the up/

down keypad until the cursor is highlighting the desired fuel and press the ENTER button. That

will return you to the HOLD screen; press the RUN/HOLD button to continue operation.

Instruction 24-9460 • Fyrite® InSIght • MyBacharach.com

9

Page 11

Setting Up the Analyzer

Setup

1. The analyzer is preset at the factor y for the parameters shown below, but can be changed as

described in their associated sections. The functions include:

Fuel (8 options)

Temperature Unit (Fahrenheit/Celsius)

Pressure Units (Inches of water column, Pascals, etc.)

Clock

O2 REFERENCE (calculates the CO reference to O2 reading)

Print Pressure (measurement on combustion printout)

Zoom (2-4 lines of text in the screen)

Username (company name, address, phone #)

Run/Hold Format*

Language Selection (English, French, Spanish)

Button Sound

Calibration Reminder Period (6, 8, 10, 12 or 15 month reminders)

Inact ivi ty Timeout (30 or 60 minutes – set to None)

Post-Purge Period (5 seconds, 1,5 or 10 minute s)

Date Format

2. To enter Setup; in the MAIN MENU screen, highlight SETUP and press ENTER.

3. Highlight the function you want to change by scrolling up and down. Make selections by

hitting the ENTER button. From there, additional scrolling either up and down or side to side

is required.

4. *RUN/HOLD FORMAT determines what order the combustion readings are displayed. Press

the ENTER button and select ED IT FO RM AT. To change the order in which the data is displayed,

scroll up or down to select the position you want to change and press the ENTER button.

The cursor should start flashing. Press the up or down keys to scroll through and select the

desired data to appear in that location and press ENTER. Change the data at other locations

by scrolling up or down and repeating the procedure. To go back to the default setting, select

RESET FORMAT.

MyBachar ach.com • Fyrite® InSIght • Instruction 24-9460

10

Page 12

Performing Tests

Performing a Combustion Test Using the Fyrite® INSIGHT

After the analyzer is powered up and the appropriate

fuel selected, insert the probe in the proper sample

location for the equipment being tested. Contact

the manufacturer of specific equipment or consult

the manufacturers’ literature to determine the

proper sample locations for combustion/carbon

monoxide, stack temperature and draft tests. The

following are recognized as generally accepted

locations for testing heating equipment, consult

with the manufacturer of specific equipment to

make cer tain.

The measuremen t for gases and temperature

should be taken at the same point. Typically, this

is done by selecting a sample location ‘upstream’

from the draft diverter/hood, barometric control

or any othe r openi ng, whi ch allows room air

to enter and dilute flue gases in the stack. In

larger installations it may also be necessary to

extr act a number of sample s from inside the

flue to determine the area of greatest flue gas

concentration. Another common practice is to

take the flue gas sample from the ‘Hot Spot’ or the

area with the highest temperature.

Atmospheric furnace

draft

O2, CO air

free and stack

temperature

Instruction 24-9460 • Fyrite® InSIght • MyBacharach.com

11

Page 13

Performing Tests

Co nden sing furnac e s / b oile r s can be te s ted th r ough a

hole drilled in the plastic vent pipe (when allowed by the

manufacturer or ‘local authority of jurisdiction) or taken from

the exhaust termination.

In order to obtain an accurate Steady State Efficiency reading,

an auxiliary thermocouple must be inserted in the combustion

air intake so that a true net stack temperature is used in the

calculation.

It is important to remember that the vent system on these units

operates under a positive pressure. As a result, any holes in

the vent need to be sealed.

Domestic hot water heaters with the ‘bell’ shaped draft

diverter on top can be accurately tested by at taching a

section of copper tubing to the probe or using a flexible

probe which is then inserted directly into the top of the

fire tube below the diverter.

Another common practice is to insert the probe in the hole

drilled for the draft test, direct it down and push it below

the level of the draft hood.

MyBachar ach.com • Fyrite® InSIght • Instruction 24-9460

12

Page 14

Performing Tests

Pressure

1. To measure draft, gas pressure, External Static Pressure, differential pressure, troubleshoot

pressure sensors, etc, press the F2 button to go to the MAIN MENU. Press the scroll down

button once to Highlight PRESSURE and press the center, green, ENTER button. Press the

F2 button to ZERO the pressure channel and follow the prompts in the screen.

2 Press the ESC button at any time to return to the previous screen.

Temperature (Differential)

1. Select the TEMPERATURE feature in the main menu to record/document temperature

differences (ie temperature rise). Two ‘K’ type thermocouples must be plugged into the bottom

of the instrument to use this feature. Press the F2 button to zero the temperature channels.

a. Note: Thermocouple should be located in same area to zero.

Saving test results

1. To save test results, simply press the F3 Ke y. To ac ce ss t he sa ve d te st re su lt s, g o t o th e MAIN

MENU, scroll down to MEMORY and press the green ENTER button. Press the MEMORY

DIRECTORY and up to 100 sets of test results will load up. Scroll down to find the time/dated

set of test results and press the ENTER button to recall that information.

Documenting Test Results

1. To print a set of test results, point the IR transmitter located in the top of the INSIGHT, and

press the F1 or PRINT KEY. Flue gas test results or diagnostic information in the screen will

be printed.

2. To download the test results to the Bacharach Software through the supplied USB cable,

follow the instructions included with that package.

Instruction 24-9460 • Fyrite® InSIght • MyBacharach.com

13

Page 15

Connecting the INSIGHT

Computer to INSIGHT Connection

& USB Device Driver Configuration

Connect the USB cable (P/N 104-4032) that was supplied with the InSIght, and, if necessary,

install the analyzer’s USB device driver as follows:

1. With both the Insight and computer turned ON, insert the

appropriate ends of the USB cable into the USB connectors

on the InSIght and computer as seen below.

2. If this is the first time the Insight is being connected to the

computer, then the “Found New Hardware Wizard” should

shortly appear. Select “No, not this time” and click NEXT.

(Note: The USB device driver only needs to be installed

once. It does not require to be re-installed each time

the Insight is connected to the the computer.)

3. Select “Install from a list or specific location (Advanced)”

and click NEXT.

4. Select to search for the best driver and then browse to folder

C:\Program Files\InSightData. Click NEXT.

5. At the Hardware Installation window, click CONTINUE

AN Y WAY. Our dri ver has been thoro ughly tes ted in

Windows for stability. This message appear s because

Microsoft has not tested this product through WHQ L

certification.

6. After the Found New Hardware Wizard has finished

installing the software, click FINISH to close the Wizard.

* Only available with the Reporting Kit

MyBachar ach.com • Fyrite® InSIght • Instruction 24-9460

14

Page 16

Potential Error Messages

1. O2 SENSOR MISSING - The O2 sensor is not installed.

2. T-STK DISCONNECTED - The probe thermocouple is not connected to the analyzer’s T-Stack

connector. Plug the probe thermocouple plug into the T-Stack connector at the bottom of the

instrument.

3. BAD SENSOR - O

replaced.

4. LOW SENSORS - O

replaced in the near future. Message will indicate which sensor(s) were in warning.

5. WARMUP SENSOR ERROR - CO sensor was not zeroed at warm-up because of high output.

Run instrument on fresh air then restart instrument to re-zero sensor. If message persists CO

sensor may need to be replaced.

a. Stack or Air temperature channel is measuring temperature outside the range of -4 to 212˚F

at startup. Make sure that the Stack and Air thermocouples are sampling ambient room

air within the temperature range at startup.

b. Pressure sensor is measuring pressure outside the range of ± 3 in wc at startup. Ensure

that the analyzer is sampling atmospheric pressure and restart the instrument.

c. The analyzer was turned on with the probe sampling flue gas. Move the probe to fresh air

and restar t the instrument.

d. Message will indicate which channel is in error.

6. LOW BATTERY - Battery voltage is low. Replace the batteries.

7. XXXX - Occurs in the number fields of sensors that are in over-range.

8. **** Occurs in the number fields of sensors and the calculated values that depend on the

sensors that were in error coming out or warm-up.

9. **** Occurs in the number fields of calculated values when Oxygen is above 16%.

sensor is too low and can not be calibrated in the instrument and needs

2

or CO sensor outputs were low but still usable. Sensor(s) may need to be

2

Instruction 24-9460 • Fyrite® InSIght • MyBacharach.com

15

Page 17

Parts and Service

Replacement Parts:

DESCRIPTION PART NO.

O2 Sensor ............................................. 24-0788

CO Sensor .............................................24 -7265

B-Smart™ CO Sensor...........................24-1467

O2 Sensor Cover ................................... 24-1421

CO Sensor Cover ..................................24-1484

Probe and Hose Assembly .................. 24-3004

Water Trap . .........................................19-3265

Filter (pkg of 3) .....................................07-1644

Thermocouple Replacement (12 in.) .... 24- 8414

Probe Stop ............................................19-30 37

Gas Connector ..................................... 24-0877

Draf t Connector................................... 24-0878

Connector Plate Assembly ..................24-1483

O-Ring Kit (2 sets) ................................ 24-1471

USB cable .......................................... 104-4032

Carry Case ........................................... 24-0865

Replacement Pump ............................. 24-3049

PC Software ......................................... 24-1470

Battery / Sensor Cover ........................24-145 3

MyBachar ach.com • Fyrite® InSIght • Instruction 24-9460

Accessories:

DESCRIPTION PART NO.

IrDA Printer ................................... 24 -1400

Printer Paper (pkg. of 5) ..................24-1310

Printer Paper (pkg. of 1) ................. 06-8733

Boot ................................................ 24-1461

AC Adapter .................................... 24-125 4

Calibration Kit ................................ 24 -7059

Calibration Gas, 500 ppm CO. ........24-0492

Calibration Gas, 100 ppm CO ..........51-1994

Thermocouple, 1 IN ...................... 104-1798

Thermocouple, 10 FT ................... 10 4-1797

Smoke Kit ......................................21-700 6

Pressure Kit ................................... 24-8214

16

Page 18

Service Centers

Replacement parts and service can be obtained by contacting

one of the following Bacharach Service Centers:

United States

Headquarters

621 Hunt Valley Circle

New Kensington, Pennsylvania 15068

Phone: 724-334-5051

Fax: 724-334-5723

Email: help@bacharach-inc.com

Markham, Ontario L3R 9W7 Canada

México

Bacharach de México

Playa Regatas No. 473 Tercer Piso

Col. Militar Marte

Delegación Iztacalco, 08830

México D.F. México

Phones: +52-555-634-7740

+52-555-634-7741

Fax: +52-555-634-7738

Email: bacharach@prodigy.net.mx

Instruction 24-9460 • Fyrite® InSIght • MyBacharach.com

17

Canada

Bacharach of Canada, Inc.

250 Shields Court Unit #3

Phone: 905-470-8985

Fax: 905-470-8963

Email: bachcan@idirect.com

Page 19

Page 20

m

o

r

f

y

l

e

v

i

s

u

l

c

x

E

Headquarters: 621 Hunt Valley Circle

New Kensington, Pennsylvania 15068-7074 U.S.A.

Phone: 1-800-736-4666 • www.MyBacharach.com

BAC1-5461 - Rev.0

Loading...

Loading...