Page 1

WARRANTY

Bacharach, Inc. warrants to Buyer that at the

time of delivery this Product will be free from

defects in material and manu-fac ture and will

conform substan tially to Bacharach, Inc.’s applicable speci cations. Bacharach’s liability and

Buyer’s remedy under this warranty are limited

to the repair or replacement, at Bacharach’s option, of this Product or parts thereof returned to

Seller at the factory of manu-facture and shown

to Bacharach, Inc.’s reason able satisfaction to

have been defective; provided that written

notice of the defect shall have been given by

Buyer to Bacharach within one (1) year after the

date of delivery of this Product by Bacharach,

Inc. For full details concerning this warranty,

contact Bacharach, Inc.

INSTRUCTION 0013-9008

DRAFTRITE

Rev.4 - May 2010

621 Hunt Valley Circle, New Kensington, PA 15068

Phone 724-334-5000 - Fax 724-334-5001

Made in U.S.A. ® Registered Trademark

Bacharach, Inc.

Page 2

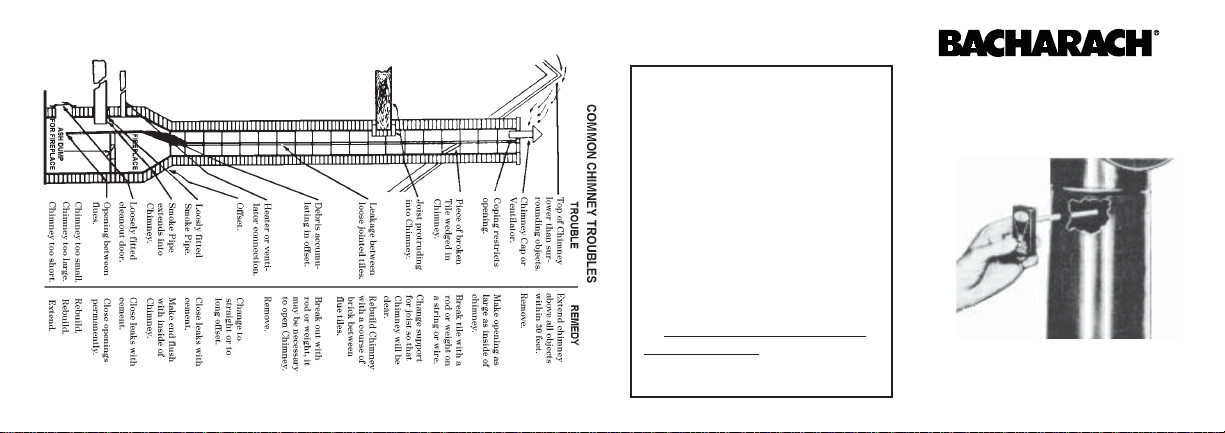

Assembly

Screw Draft Tube parts É& Êto-gether

then screw them into back of Draftrite

Ë. When required, extend Draft Tube

with length of ¼" copper tubing. Total

length of extended tube must not exceed

12 inches.

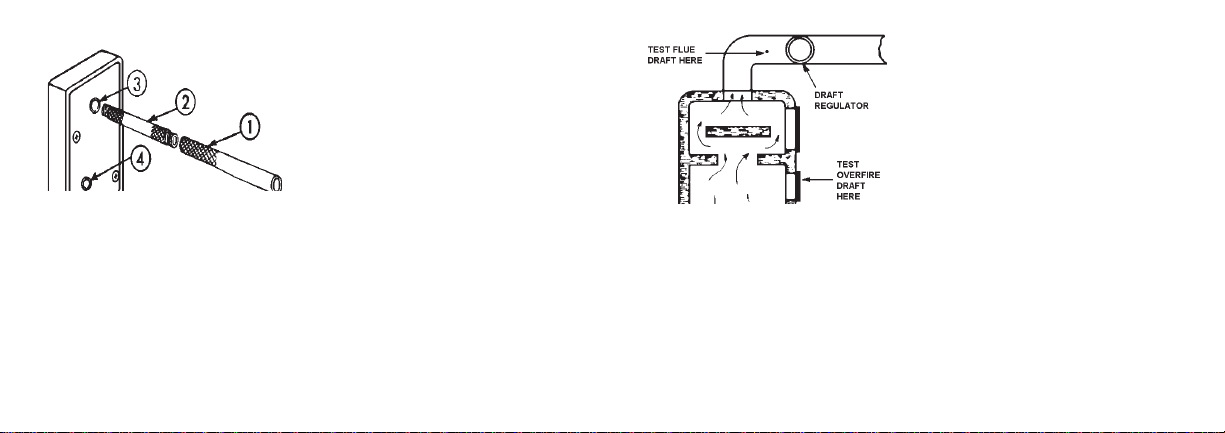

Location For Checking Draft

Heating Equipment Manufacturer may

require draft measurement (a) in fl ue

between furnace and draft regulator; (b)

overfi re between combustion space and heat

exchanger. Locate draft hole in fl ue at least

6" from draft regulator or damper toward

furnace. Use awl with ¼" shank to form hole

in fl ue or light sheet metal. Overfi re measure-

ment may be made through bolt hole or air

louvre in door or through observation port, if

necessary, drill a ¼" hole. In case of oversize

open-ing, Draft Tube should protrude several

inches minimum beyond inside wall, if necessary extend Draft Tube (see above).

Draft Measurement

Operate burner for several minutes and

while continuing to operate insert about half

of Draft Tube into draft hole. Cover Zero

Check hole Ìwith fi nger, level Draftrite until

(a) Draft Tube is horizon-tal and (b) pointer

is in line with zero scale mark, uncover Zero

Check hole without disturbing position of

Draftrite. Pointer instantly shows draft or

pressure reading. Use of the Draftrite is illustrated on front page.

Maintenance

Protect instrument from dirt, oil, and

lint. Do not oil. Keep gauge in case when

not in use, and keep case free of lint

or dirt. Clean Draft Tube occasionally

with pipe cleaner. Protect gauge against

excessive shock. Do not use as continuously indicating instrument. Draftrite is

designed for spot checking draft where

extreme portability is important.

Correct Draft

All combustion equipment requires correct

draft for best performance. Specifi c draft

recommendation should be obtained from

manufacturer.

IMPORTANT NOTE

Draftrite is furnished in two ranges for

measurement of updraft/downdraft of fuel

burning equipment as follows:

1. .10 inch water downdraft

to .14 inch water updraft.

2. .05 inch water downdraft

to .25 inch water updraft.

Neither of the above models can be used to

locate Neutral Pressure Point as required in

"Requirements for Instal-lation and Adjustment of Domestic Gas Conversion Burners"

(ANSI-Z21.8-1994).

Loading...

Loading...