Page 1

WARRANTY

Bacharach, Inc. warrants to Buyer that at the time of delivery this Product

will be free from defects in material and manufac ture and will conform

substan tially to Bacharach Inc.’s applicable speci cations. Bacharach’s

liability and Buyer’s remedy under this warranty are limited to the repair

or replacement, at Bacharach’s option, of this Product or parts thereof

returned to Seller at the factory of manufacture and shown to Bacharach

Inc.’s reason able satisfaction to have been defective; provided that written

notice of the defect shall have been given by Buyer to Bacharach Inc.

within one (1) year after the date of delivery of this Product by Bacharach,

Inc. For full details concerning this warranty, contact Bacharach Inc.

DRAFT GAUGE

Instruction 0013-9009

Rev. 5 - May 2010

World Headquarters

621 Hunt Valley Circle, New Kensington, PA 15068

Ph: 724-334-5000 • Fax: 724-334-5001 • Toll Free: 800-736-4666

Website: www.mybacharach.com • E-mail: help@mybacharach.com

Printed in U.S.A. ®Registered Trademark

Page 2

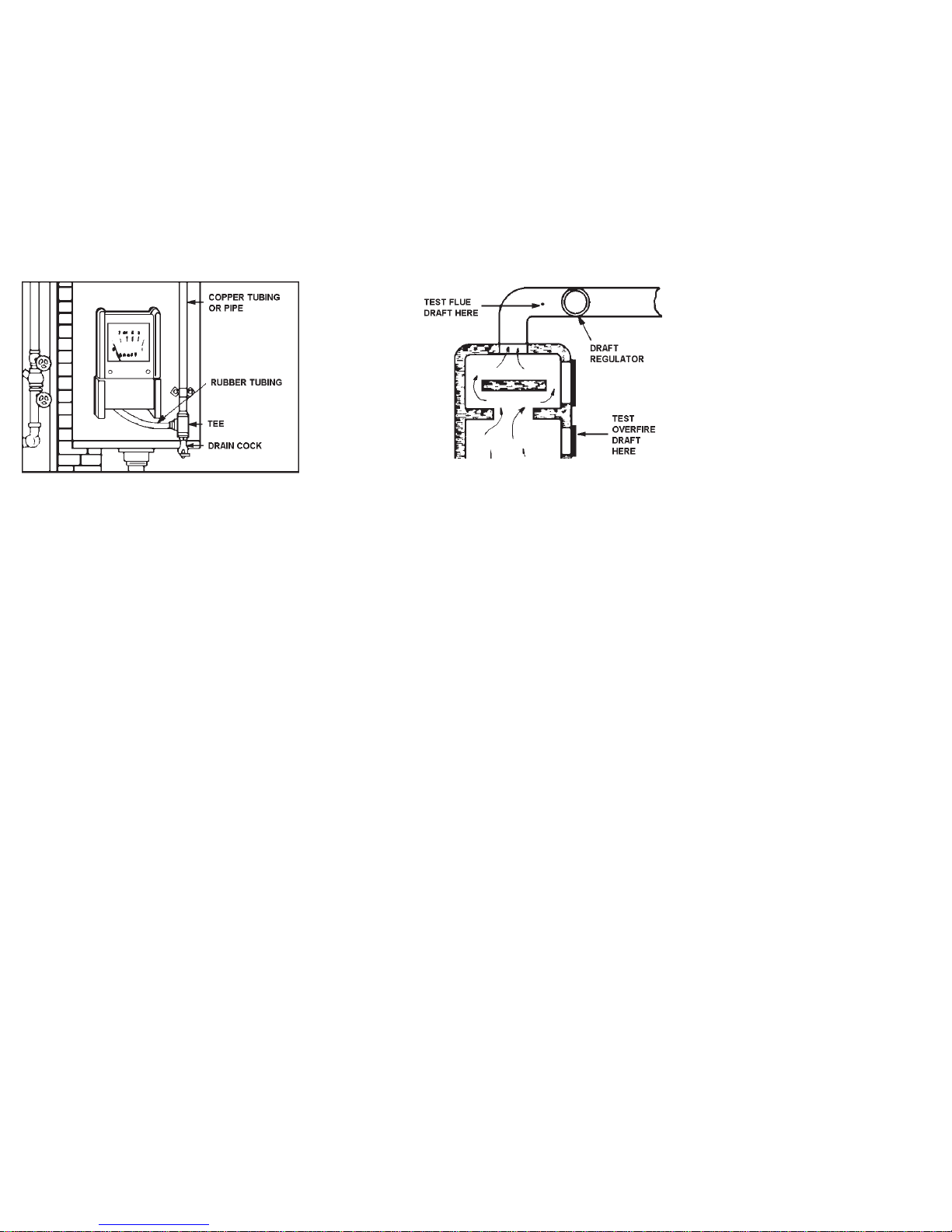

2 Figure 1. Draft Gauge

Mounting the Instrument

For portable use stand the gauge on a reasonably level surface

convenient to the location for checking draft. Gauge may also be

hung in an upright position using Ë(Slotted Recess) to receive a

nail or screw head. For permanent installation remove Ì (Screws)

and front cover, fasten to panel with two number 8 screws thru

Í(Mounting Holes), replace front cover and Ì (Screws). Never

locate gauge where temperature exceeds 110° F.

Connections

For portable use connect the gauge to a furnace with the 9 foot

length of rubber tubing and metal draft tube provided. For permanent installation, make connection from panel to draft measuring point with copper tubing or pipe, solid tubing (no fi ttings)

is preferred. At the end of the tubing provide a small tee with

a short piece of rubber tubing as shown in Figure 3. Connecting lines over 50 feet in length is not recommended. Use as few

bends as possible, and keep the connecting line to a minimum

length. The following tubing sizes are recommended:

Up to 10 foot length 1/4 inch ID tubing

Up to 25 foot length 3/8 inch ID tubing

Up to 50 foot length 1/2 inch ID tubing

Zero Adjusting

When checking for zero, hold the draft tube near gauge or if

permanently connected, break connecting line at panel. Zero is

adjusted by moving É(Adjusting Tab) until the pointer is in line

with the scales zero. For portable use, check zero each time the

gauge is set up for use. For permanent installations (always disconnect the hose from the gauge before making the zero check)

check zero at one or two week intervals. 3

Page 3

Figure 2. Draft Gauge Parts

5

4

Parts List for the Draft Gauge

0013-0014 Scale +.05 <0> –.25” H2O

0013-0015 Scale +.05 <0> –1.0” H2O

0013-0016 Scale +1 <0> –25mm H2O

0013-0017 Scale +1 <0> –5mm H2O

0013-0159 Scale +1 <0> –15mm H2O

0013-0056 Leaf Spring Assembly for +.05” <0> –.25” or +1 <0> –5mm H2O Range

0013-0057 Leaf Spring Assembly for +.05” <0> –1.0” or +1 <0> –25mm H2O Range

0013-0058 Leaf Spring Assembly for +1” <0> –15” H

2

O Range

0013-0006 Window

0013-0024 Screw

0013-0025 Screw

0013-0029 Pointer Assy

0013-0033 Calibrating Arm

0013-0034 Slide Stud

0013-0036 Washer

0013-0046 Draft Tube

0013-0047 Tubing

0013-0049 Cradle & Zero Adjuster

0013-0050 Diaphragm Cover

0013-0055 Diaphragm Assy

0013-0060 Back Cover

0013-0128 Front Cover

0013-0134 Front Cover Assy

0001-0627 Screws

0001-1636 Screws

0001-1974 Screws

0001-2486 Screw

0001-5107 Screw

0001-5110 Screw

0002-2160 Screws

0002-2986 Lock Nuts

0002-2990 Hex Nut

0002-3735 Speed Nuts

0002-4708 Washer

0005-4703 Pointer Stops

Page 4

Locations for Checking Draft

Furnace manufacturer may require measurement of draft (a) in

fl ue between regulator and furnace or (b) overfi re between com-

bustion space and heat exchanger (Figure 4). Locate sampling

hole in fl ue 6” or more from draft regulator or damper toward

furnace. Use awl with ¼ shank for forming draft hole in light

sheet metal. Make overfi re measurement through blot hole in

door or through air louvers. If necessary, drill ¼ hole. In case of

over sized hole or masonry setting, draft tube (replace with

1/8’ pipe if necessary) should be inserted several inches beyond

inside surface of fl ue pipe or furnace wall. For detailed instruc-

tions on check locations, see manufacturer’s service or installation manual.

6

Figure 3. Mounting Draft Gauge

Figure 4. Draft Gauge Locations

Measuring Draft

Allow furnace to operate for several minutes, unwrap hose, place

gauge on reasonably level surface, check zero, insert metal draft

tube through draft hole. After about 30 seconds read draft from

gauge scale.

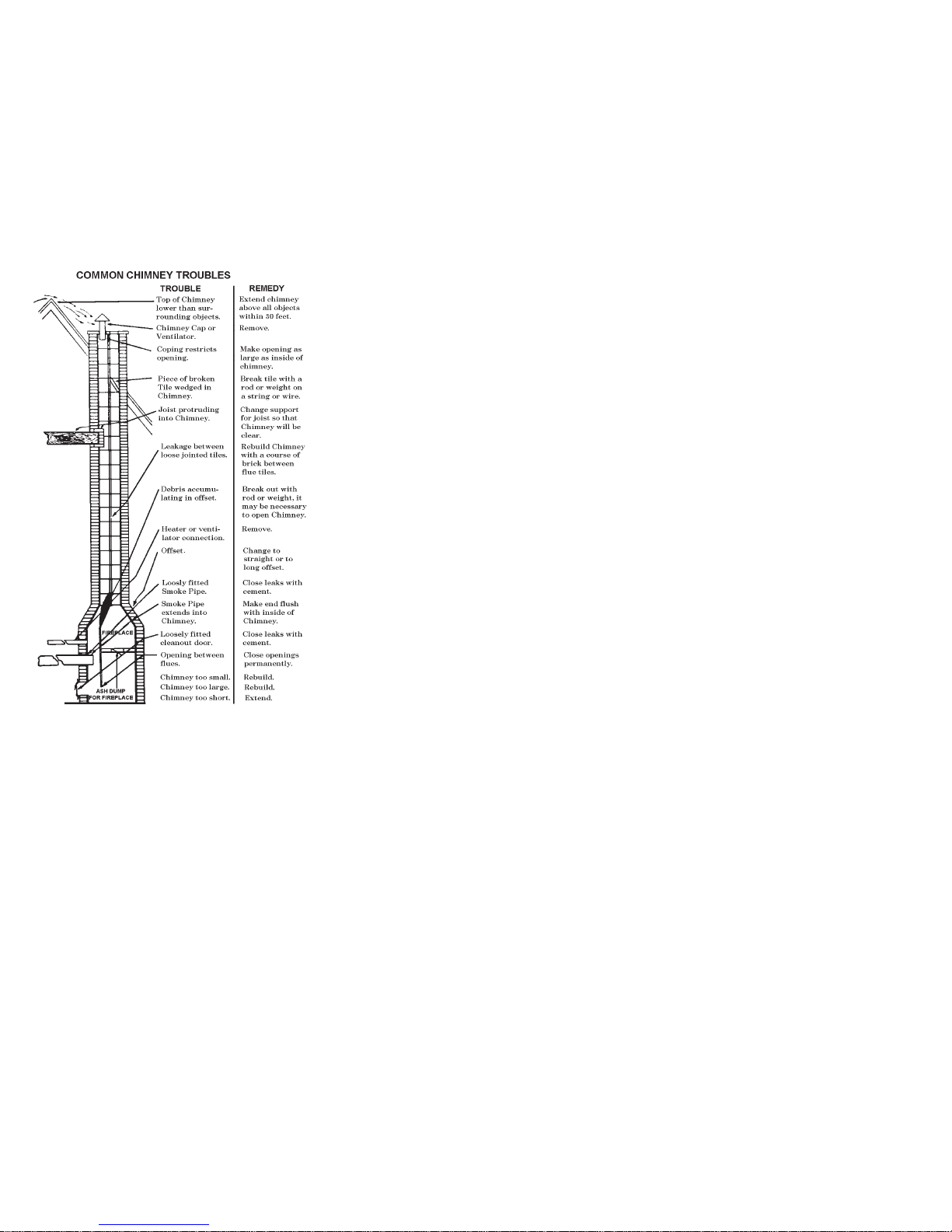

Correct Draft

Recommendations for draft required for good performance must

be obtained from the heating equipment manufacturer’s installation or service manual. Some common causes of poor draft are

shown in “Common Chimney Troubles”.

Maintenance

Do not oil this gauge. Protect the gauge from shock, vibration

and exposure to excessively high temperatures. 7

Page 5

8

Loading...

Loading...