Page 1

INSTRUCTION 2772-0803

REMOTE INTELLIGENT SENSOR

AREA MONITOR

Installation/Operation/Maintenance

Rev. 14 – February 2004 (CN #3252)

®

251 Welsh Pool Road

Website: www.scottinstruments.com • www.bacharach-inc.com

Ph: 610-363-5450 • Fax: 610-363-0167

Printed in U.S.A. ®Registered Trademark

Exton, PA 19341

Page 2

Declaration of Conformity

Manufacturer's Name: SCOTT INSTRUMENTS

Manufacturer's Address: 251 Welsh Pool Road

Exton, PA 19341 USA

Product Name: Remote Intelligent Sensor

Conforms to the following product specifications

EMC: European Directive 89/336/EEC

EN 500081-1 (Emissions)

EN 500082-1 (Immunity)

A

Page 3

REMOTE INTELLIGENT SENSOR - AREA MONITOR

CONTENTS

Page #

FEATURES .................................................................................................................................... v

PRODUCT SPECIFICATION ...........................................................................................................vi

RIS CATALOG NUMBERS & DATA ............................................................................................. viii

1 INTRODUCTION ........................................................................................................................... 1-1

1.1 SYSTEM DESCRIPTION .......................................................................................................... 1-1

1.2 BASIC PRINCIPLES ................................................................................................................. 1-1

1.3 GENERAL DESCRIPTION ....................................................................................................... 1-1

1.3.1 ENCLOSURE................................................................................................................ 1-1

1.3.2 CABLE GLANDS .......................................................................................................... 1-1

1.3.3 MAIN SYSTEM BOARD .............................................................................................. 1-1

1.3.4 SYSTEM POWER SWITCH SW1 ............................................................................... 1-2

1.3.5 MECHANICAL CHASSIS ............................................................................................ 1-2

1.3.6 BACK-UP BATTERY ................................................................................................... 1-2

1.3.7 BASE BOARD ............................................................................................................... 1-2

1.3.8 SAMPLE INLET........................................................................................................... 1-3

2 INSTALLATION AND SYSTEM CHECK .................................................................................. 2-1

2.1 UNPACKING ............................................................................................................................. 2-1

2.2 BATTERY CONNECTION........................................................................................................ 2-1

2.3 MECHANICAL INSTALLATION ............................................................................................ 2-1

2.4 ELECTRICAL INSTALLATION .............................................................................................. 2-1

2.4.1 CABLE RECOMMENDATION .................................................................................... 2-1

2.4.1.1 PSU to RIS Input ................................................................................................... 2-1

2.4.1.2 PSU to Alarm Module ........................................................................................... 2-1

2.4.1.3 RIS Relay Output to Alarm Module ..................................................................... 2-1

2.4.1.4 0 – 1V Analog Output ............................................................................................ 2-1

2.4.1.5 4 – 20 mA Analog Output ..................................................................................... 2-1

2.4.2 POWER SUPPLY AND INPUT CONNECTIONS ................................................... 2-1

2.4.3 OUTPUT CONNECTIONS ......................................................................................... 2-2

2.4.4 RELAY OUTPUTS ....................................................................................................... 2-2

2.4.5 ANALOG OUTPUTS ................................................................................................... 2-2

2.5 SYSTEM POWER SUPPLY CONSIDERATION & SELECTION ........................................ 2-2

2.5.1 RIS POWER SUPPLIES .............................................................................................. 2-2

2.5.1.1 ‘Single Point’ .......................................................................................................... 2-2

2.5.1.2 ‘Multi Point’ ........................................................................................................... 2-2

2.5.2 POWER REQUIREMENTS, RIS & ALARM MODULE ........................................... 2-3

2.5.2.1 Low Flow RIS Models ............................................................................................ 2-3

2.5.2.2 High Flow RIS Models ........................................................................................... 2-3

2.5.2.3 ‘Worst Case’ Currents ........................................................................................... 2-3

2.5.2.4 Alarm Module......................................................................................................... 2-3

2.5.2.5 Summary ‘Worst Case’ Input Currents .............................................................. 2-3

2.6 SAMPLE LINES ........................................................................................................................ 2-3

2.6.1 GENERAL ..................................................................................................................... 2-3

2.6.2 LESS REACTIVE GASES ............................................................................................ 2-3

2.6.3 REACTIVE GASES ....................................................................................................... 2-4

2.6.4 SYSTEM PERFORMANCE WITH EXTENDED SAMPLE LINES ........................ 2-4

2.7 0 – 1 VOLT CONVERSION ...................................................................................................... 2-4

2.7.1 TOOLS & MATERIALS REQUIRED ......................................................................... 2-4

2.7.2 PROCEDURE................................................................................................................ 2-4

Instruction 2772-0803 Page i

Page 4

REMOTE INTELLIGENT SENSOR - AREA MONITOR

CONTENTS (continued)

2.8 SYSTEM CHECK ....................................................................................................................... 2-4

2.8.1 TAPE CASSETTE LOADING ..................................................................................... 2-4

2.8.2 CHECK AND ADJUST SYSTEM PARAMETERS .................................................... 2-5

2.8.2.1 V, System Voltage ................................................................................................. 2-5

2.8.2.2 mA, ‘Charger Current’ ......................................................................................... 2-5

2.8.2.3 Alarm Set Points .................................................................................................. 2-5

2.8.2.4 Alarm Level 1 and 2 ............................................................................................. 2-5

2.8.2.5 Gas Curve .............................................................................................................. 2-6

2.8.2.6 Multi Gas Curve Systems .................................................................................... 2-6

2.8.2.7 Light Levels Track 1 & 2 .................................................................................... 2-6

2.8.2.8 Flow Rate ............................................................................................................... 2-6

2.8.2.9 Date & Time ......................................................................................................... 2-6

2.8.2.10 Interruption of TEST Mode Cycle ...................................................................... 2-7

2.8.2.11 Completion of Checks .......................................................................................... 2-7

2.9 OPTION PCB INSTALLATION .............................................................................................. 2-7

2.9.1 PRINTER (OPTION) INTERFACE INSTALLATION ............................................. 2-7

2.9.2 PORTABLE PRINTER ................................................................................................. 2-7

2.9.3 ALARM MODULE CONNECTION ............................................................................ 2-7

2.9.4 RELAY ALARM INSTALLATION ............................................................................. 2-7

3 SYSTEM OPERATION AND FEATURES ................................................................................ 3-1

3.1 COMPLETE SAMPLING SEQUENCE ................................................................................... 3-1

3.1.1 AUTOMATIC PURGE CYCLE ................................................................................... 3-1

3.1.2 TWIN TRACK TAPE SAMPLING ............................................................................. 3-1

3.1.3 TAPE REFERENCE MEASUREMENT ..................................................................... 3-1

3.2 DENSITY AND TIME OPERATING MODES ........................................................................ 3-2

3.2.1 DENSITY MODE .......................................................................................................... 3-2

3.2.2 TIME MODE ................................................................................................................. 3-2

3.3 CHANGE-OVER FROM DENSITY TO TIME MODE ........................................................... 3-2

3.4 MIMINUM SAMPLE TIME ..................................................................................................... 3-2

3.5 TAPE CASSETTE LIFE ............................................................................................................ 3-2

3.6 DATA POINT STORAGE .......................................................................................................... 3-2

3.7 SYSTEM DISPLAY .................................................................................................................... 3-2

3.7.1 SYSTEM NORMAL, GAS CONCENTRATION ZERO OR LOW. ........................... 3-2

3.7.2 SYSTEM NORMAL, GAS CONCENTRATION ABOVE THE

ALARM THRESHOLD ................................................................................................. 3-3

3.7.3 OVERRANGE ALARM ................................................................................................. 3-3

3.7.4 SYSTEM FAULT .......................................................................................................... 3-3

3.8 SYSTEM ALARMS ..................................................................................................................... 3-3

3.8.1 GAS ALARM ................................................................................................................. 3-3

3.8.2 ADDITIONAL GAS ALARM SET POINT ................................................................. 3-3

3.8.3 FAULT RELAY ............................................................................................................ 3-4

3.9 DIAGNOSTICS .......................................................................................................................... 3-4

3.10 TEST MODE ............................................................................................................................ 3-4

3.11 KEYPAD FUNCTION ............................................................................................................ 3-4

3.11.1 ‘HOLD/RELEASE’ KEY ............................................................................................... 3-4

3.11.2 ‘PRINT’ KEY ................................................................................................................. 3-4

3.11.3 ‘15 MIN TWA (DECADE)’ KEY .................................................................................. 3-4

3.11.4 ‘8 HR TWA (DIGIT SET)’ KEY .................................................................................... 3-4

3.12 USING THE KEYBOARD ....................................................................................................... 3-4

Page ii Instruction 2772-0803

Page 5

REMOTE INTELLIGENT SENSOR - AREA MONITOR

CONTENTS (continued)

3.13 OPTIONAL FEATURES ......................................................................................................... 3-4

3.13.1 RELAY ALARM OPTION............................................................................................ 3-4

3.13.2 PRINTER INTERFACE OPTION ..............................................................................3-4

3.13.3 TEST CARD ..................................................................................................................3-4

3.14 PRINTER OPERATION & USE (OPTIONAL FEATURE) ................................................. 3-5

3.14.1 GENERAL ..................................................................................................................... 3-5

3.14.2 PRINTER SPECIFICATION ...................................................................................... 3-5

3.14.3 PRINTOUT MODES ..................................................................................................... 3-6

3.14.3.1 Printing 'On Line' ................................................................................................. 3-6

3.14.3.2 Print at Intervals ..................................................................................................3-6

3.14.3.3 Print on Command ................................................................................................ 3-6

3.14.3.4 Printed Date Format ............................................................................................ 3-7

3.14.3.5 Data Storage up to 7 Days ....................................................................................3-7

3.14.3.6 Preventing Data Loss ........................................................................................... 3-7

3.14.4 PRINTER CARD DESCRIPTION .............................................................................. 3-7

3.14.4.1 Real Time Clock .................................................................................................... 3-7

3.14.4.2 Data Storage .......................................................................................................... 3-7

3.14.4.3 Data Communication ............................................................................................ 3-7

3.14.4.4 Selection of Printer Baud Rate ............................................................................ 3-7

3.14.5 CONNECTING A PRINTER ....................................................................................... 3-7

3.14.5.1 GMD Printer Connection ..................................................................................... 3-7

3.14.5.2 Connecting a Non-GMD Printer .......................................................................... 3-8

3.14.5.3 Portable Use of a Non-GMD Printer ....................................................................3-8

4 MAINTENANCE AND TROUBLESHOOTING ................................................................... 4-1

4.1 MAINTENANCE GENERAL.......................................................................................... 4-1

4.2 VERIFYING THAT A GAS ALARM WAS CAUSED BY GAS .................................... 4-1

4.3 CLEARING A SPURIOUS ALARM ............................................................................... 4-1

4.4 ADJUST LIGHT LEVELS .............................................................................................. 4-1

4.5 CHECKING AND ADJUST SYSTEM FLOW RATE .................................................. 4-2

4.6 DISABLING THE ‘DOOR OPEN’ ALARM ................................................................... 4-2

4.7 ADJUST THE DOOR SWITCH ..................................................................................... 4-2

4.8 MEASURING PUMP CURRENT .................................................................................. 4-3

4.9 RESETTING THE PRINTER OPTION STORAGE .................................................... 4-3

4.10 CLEANING THE SAMPLING INPUT AND OPTICS BLOCK ................................. 4-3

4.10.1 INTRODUCTION............................................................................................. 4-3

4.10.2 LIGHT LEVEL ADJUSTMENT ..................................................................... 4-3

4.10.3 WHEN TO CLEAN .......................................................................................... 4-3

4.10.4 HOW TO CLEAN ............................................................................................. 4-4

4.10.5 DIRECT CLEANING OF THE LED’S AND PHOTO DIODES .................. 4-4

4.10.6 REPLACING THE OPTICS BLOCK ............................................................. 4-4

4.10.7 WHAT TO DO IF CLEANING DOES NOT RECTIFY THE PROBLEM .. 4-5

4.11 CHANGING A PUMP. .................................................................................................... 4-5

4.11.1 PREPARATION ................................................................................................ 4-6

4.11.2 REMOVAL OF THE MECHANICAL CHASSIS ........................................... 4-6

4.11.3 PUMP REMOVAL ............................................................................................ 4-6

4.14.4 FITTING THE NEW PUMP........................................................................... 4-6

4.14.5 REPLACING THE MECHANICAL CHASSIS AND

SETTING PUMP FLOW ................................................................................ 4-6

Instruction 2772-0803 Page iii

Page 6

REMOTE INTELLIGENT SENSOR - AREA MONITOR

CONTENTS (continued)

4.12 EXTERIOR CLEANING ................................................................................................. 4-6

4.13 KEY PARAMETER CHECKS ......................................................................................... 4-6

4.14 MECHANICAL TIGHTNESS ......................................................................................... 4-7

4.14.1 CABLE GLANDS ............................................................................................. 4-7

4.14.2 DOOR SWITCH ................................................................................................ 4-7

4.14.3 DOOR SEALS ................................................................................................... 4-7

4.14.4 SAMPLE INLET .............................................................................................. 4-7

4.14.5 INTERFACE TERMINAL SCREWS .............................................................. 4-7

4.15 INPUT PATH CLEANING ............................................................................................ 4-7

4.16 PUMP CHECK ................................................................................................................ 4-7

4.17 CHARCOAL FILTER & TUBING CHECK .................................................................. 4-7

4.18 TROUBLESHOOTING GENERAL ............................................................................... 4-7

4.19 EXCESSIVE INPUT CURRENT ................................................................................... 4-7

4.19.1 HIGH CHARGING CURRENT....................................................................... 4-7

4.19.2 HIGH PUMP CURRENT ................................................................................ 4-7

4.20 LOW PUMP FLOW ........................................................................................................ 4-7

4.20.1 A FAULTY PUMP ........................................................................................... 4-8

4.20.2 A BADLY FITTED INPUT TUBE ................................................................. 4-8

4.20.3 A FAULTY TAPE GATE SEAL...................................................................... 4-8

4.20.4 LEAKING OR LOOSE TUBING .................................................................... 4-8

4.21 EXCESSIVE TAPE USE ................................................................................................. 4-8

4.21.1 MONITORED CONCENTRATION LEVELS HIGH .................................... 4-8

4.21.2 EXCESSIVE STEP LENGTH ......................................................................... 4-8

4.22 TAPE BREAKAGE .......................................................................................................... 4-8

4.23 LIGHT FAULTS .............................................................................................................. 4-8

4.24 DOOR FAULT ................................................................................................................. 4-8

5 SYSTEM SPARE PARTS ........................................................................................................ 5-1

5.1 MODEL DEPENDENT PARTS ..................................................................................... 5-1

5.1.1 CASSETTE ........................................................................................................ 5-1

5.1.2 OPTICS BLOCK ............................................................................................... 5-1

5.1.3 BACK-UP BATTERY ....................................................................................... 5-1

5.1.4 PUMP ASSEMBLY .......................................................................................... 5-1

5.2 SYSTEM POWER SUPPLIES ....................................................................................... 5-1

5.2.1 ‘SINGLE POINT’ ............................................................................................. 5-1

5.2.2 ‘MULTIPOINT’ ................................................................................................ 5-1

5.3 RECOMMENDED SPARES ............................................................................................ 5-1

5.4 COMMON PARTS ........................................................................................................... 5-2

5.5 OPTIONS AND SUPPLIES ........................................................................................... 5-2

5.6 SERVICE CENTERS ....................................................................................................... 5-2

SUPPLEMENT A ............................................................................................................................ S-A1

A1 EARLIER IRS BASE BOARDS ....................................................................................... S-A1

A1.1 ADJUSTING LIGHT LEVELS ON PHASE 1 RIS UNITS ......................... S-A1

RIS TEST/FAULT PARAMETER LOG SHEET

Page iv Instruction 2772-0803

Page 7

REMOTE INTELLIGENT SENSOR - AREA MONITOR

FEATURES

• TRUE CONTINUOUS MONITORING WITH RELIABLE PAPER TAPE DETECTION

Using GMD developed, optimized and proven tape technology.

• MICROPROCESSOR CONTROLLED AND SOLID STATE LOGIC

For reliability, flexibility and calibration stability.

• QUICK RESPONSE & AUTORANGING

Sophisticated, dynamic control of the sampling sequence provides a response time as low as 15

seconds, excellent resolution of short term peaks and economic use of tape.

• LOCAL OR REMOTE WARNING

Highly visible display of measured concentration, system status, gas and system fault alarms.

Remote warnings of gas and fault alarms via solid state relay interface. Optional audible and visual

alarm module provides high impact additional warning.

• CONTINUOUS DIAGNOSTICS & SYSTEM TEST MODE

Monitors the status of key parameters and enables the system to be kept in optimum condition.

• BATTERY BACKUP

Integral backup battery automatically provides supply failure protection.

• USER SELECTABLE ALARM SET POINTS

The default values assigned may be set at any value in the detection range through the system

keyboard.

• UP TO FOUR WEEK CASSETTE WITH INTEGRAL PURGE FILTER

One piece design eliminates tape handling and provides economy of use.

• SYSTEM EXPANSION

Comprehensive area monitor schemes can be built one point at a time, each selected to measure

the gas required.

• OPTIONAL FEATURES

Printer option with storage of up to 7 days worth of data points.

Instruction 2772-0803 Page v

Page 8

REMOTE INTELLIGENT SENSOR - AREA MONITOR

PRODUCT SPECIFICATION

ACCURACY

PHYSICAL

Dimensions: 7" Depth x 11.75" Width x 7.875" Height

Weight: 11.5 lbs. (5.2 Kg.).

Enclosure: IP-55 with sealed glands (NEMA 4).

Cable Glands: 3 x for input/output cables. Pre-wired connector for Optional Printer.

POWER INPUT REQUIREMENTS

External Power Supply: 12VDC

Input Current: Depends upon model and conditions.

Low Flow models: (200cc/min or less) Cat.# 2772-0010/015/020/030/035/040/060/

High Flow models: (700cc/min or less) Cat.#272-0120/160/175 etc.

ppb Ranges: ± 15 % of reading ± 1 ppb.

ppm Ranges: ± 15 % of reading ± 0.01 ppm.

2772-0020: ± 20 % of reading ± 0.01 ppm.

2772-0035: ± 20 % of reading ± 0.02 ppm.

(178mm D x 298mm W x 200mm H)

090/095/100/110/150 etc.

Normal run current (charged battery) =150–200mA

Run current (discharged battery) =500–700mA

Normal run current, (charged battery) =250–300mA

Run current (discharged battery) =600–800mA

OUTPUTS

Solid State ‘Relay’ Output:

Standard System: 1 Combined Gas/ Fault Alarm.

Optionally: 2 Gas Alarms plus 1 Fault Alarm, or

Devices rated @ 1A./60 V DC max.

Surge current (1 second) = 5A peak.

Turn on/off time = 50, ms.

On state voltage = 1.5V DC

Off state leakage at 60 V DC across the load = 200, µA

Logic: Device normally ‘closed’, opens on alarm

(with standard system software).

Analog Output:

Standard: 4–20 mA is default on the instrument.

0–1 V DC can be hardware selected.

In both cases the minimum = zero concentration,

and the maximum value = system range maximum.

(Other configurations available. Contact Customer Service)

Page vi Instruction 2772-0803

Page 9

DISPLAY

Custom LCD Display: Area measures 5.7" (145mm) x 3.2" (81 mm).

Displayed parameters

include:

In the TEST Mode, display

includes:

Alpha/Numeric characters: 0.92" (23.4mm) high.

KEYBOARD

Membrane Switch Panel: Four switches for the following functions:

REMOTE INTELLIGENT SENSOR - AREA MONITOR

PRODUCT SPECIFICATION (continued)

System Readiness status,

Measured Concentration (3 decades of ppb or ppm),

Tape Remaining, and Icons for Gas & Fault alarms.

Alarm Set Point(s), System Current (mA),

Alarm Type, Regulated Voltage (V), Active Gas Type,

Track 1 & 2 Light Levels, and, Date & Time (with optional

Serial Printer Interface PCB, Section 5).

PRINT, 8 HR. TWA /DIGIT SET, 15 MIN TWA/DECADE,

& HOLD/RELEASE.

INTERNAL BACK-UP BATTERY

Sealed Lead Acid Battery: 6 v / 1.1 Ah Charge maintained with external power connected.

(the internal power switch SW1 can be on or off).

ENVIRONMENTAL

Temperature Range: –10 °C to +40 °C ( operating)

(Instrument Only) Relative Humidity (System Hardware): 5–95% (non-condensing).

SAMPLING INPUT

FEP: Teflon input tubes

OPTIONS

Printer option: TTL serial interface and 7-Day memory.

Three (3) Relay option: 2 x gas alarm outputs with adjustable set point and 1 x fault

alarm output.

CATALOG #, CASSETTE #,

RANGES and MODEL

DEPENDENT PARAMETERS: See RIS Catalog Numbers and Data (Table #1).

Instruction 2772-0803 Page vii

Page 10

REMOTE INTELLIGENT SENSOR - AREA MONITOR

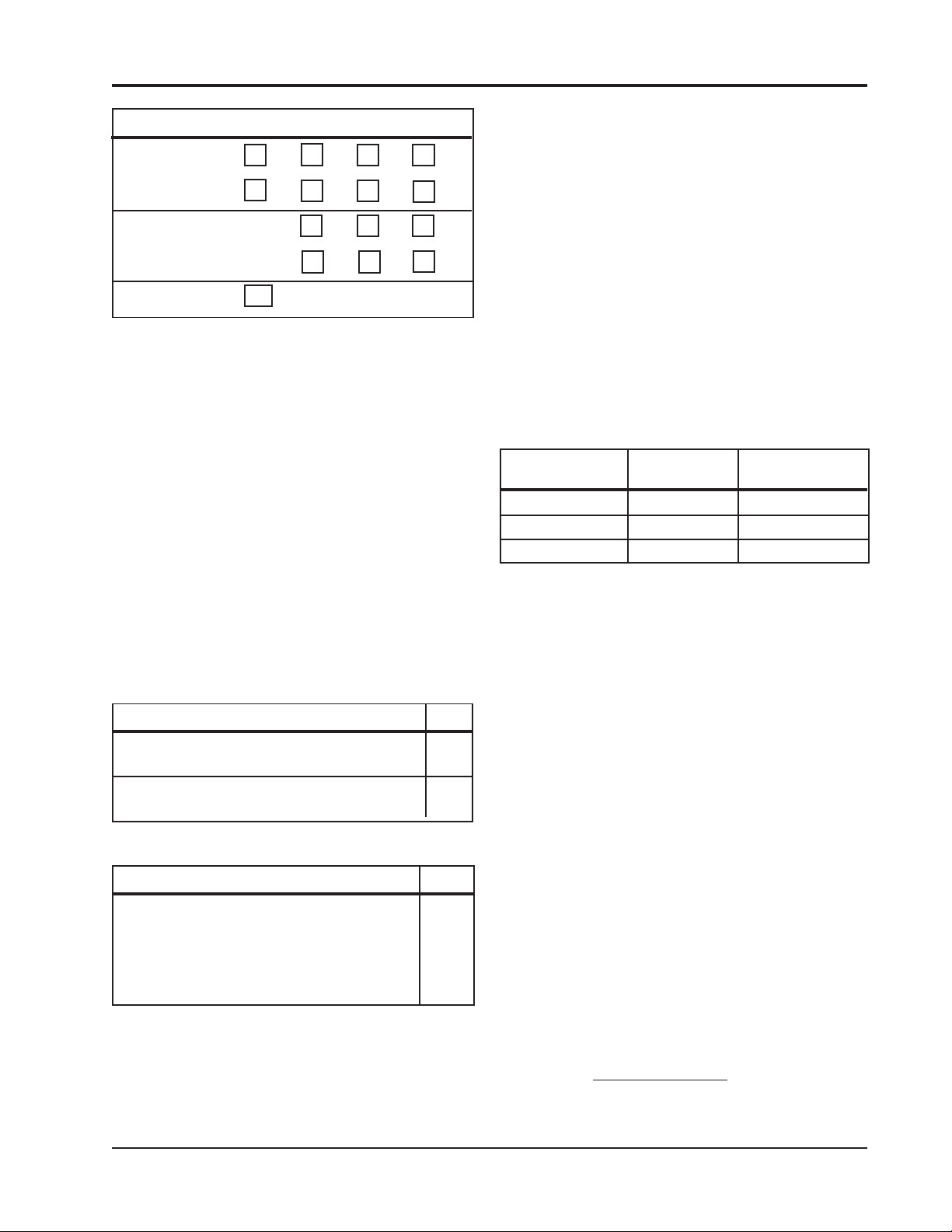

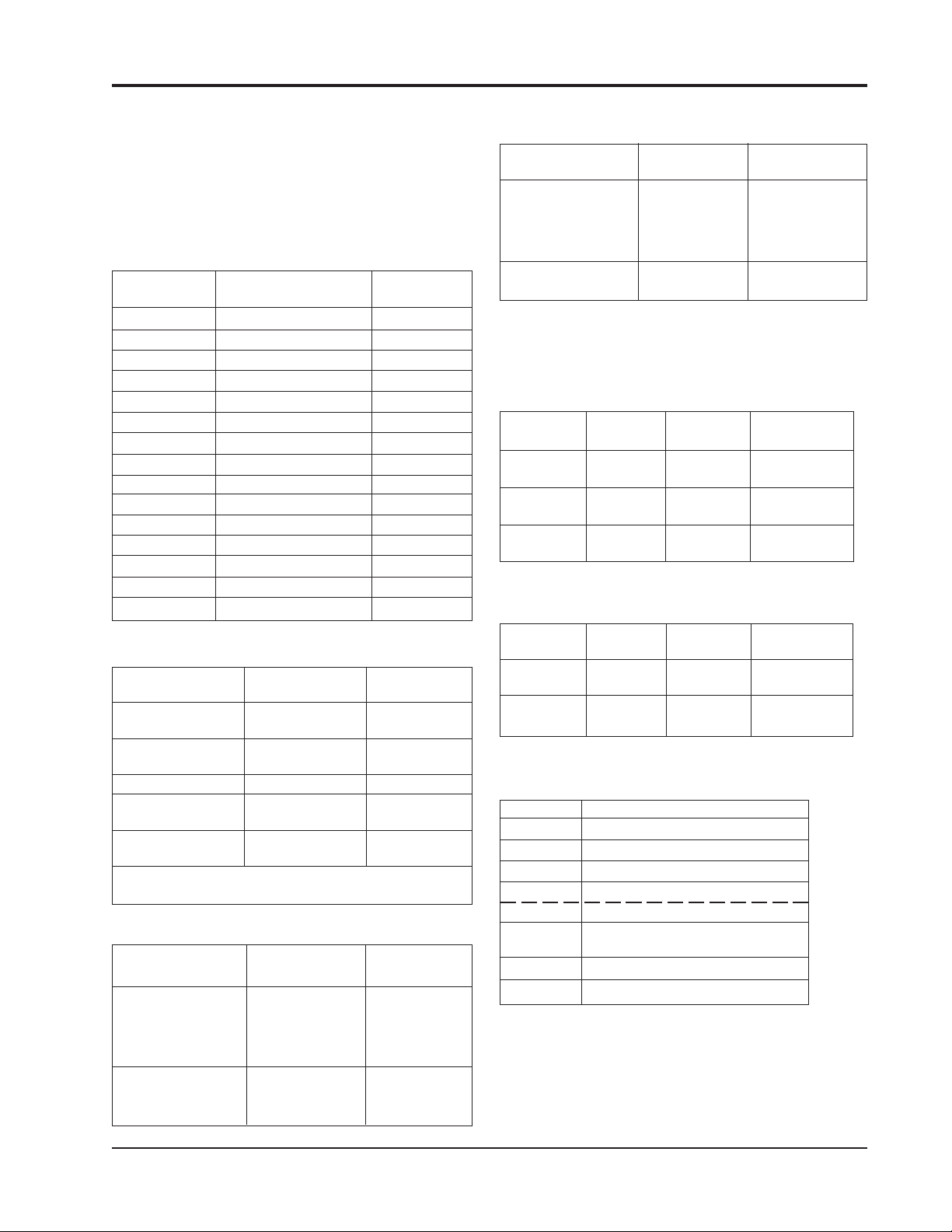

TABLE #1

RIS CATALOG NUMBERS & DATA

CATALOG

NUMBER

2772-0010 TDI 0 1000 ppb 200 5 10 100

2772-0015 TDI HIGH RANGE 5 2000 ppb 200 5 10 2000

2772-0020 HYDRAZINES 1 2.00 ppm 200 0.05 0.10 2.00

2772-0030 PHOSGENE (A) 3 5.00 ppm 100 0.05 0.10 0.30

2772-0035 VELCORIN® 35 2.00 ppm 200 0.05 0.10 2.00

2772-0040 CHLORINE 7 2.00 ppm 170 0.05 0.10 2.00

2772-0060 ARS INE 8 1000 ppb 200 25 50 100

2772-0090 ACID GASES 9 2.00 ppm 150 0.05 0.10 2.00

2772-0095 HCl HIGH RESOLUTION 10 100 ppb 250 5 10 100

2772-0100 HDI 2 500 ppb 200 5 10 500

2772-0110 PHOSGENE (B) 4 5.00 ppm 100 0.05 0.10 5.00

2772-0120* MDI 6 200 ppb 700 5 10 200

2772-0150 IPDI 12 1000 ppb 200 5 10 100

2772-0160* MDI, TDI, IPDI 97

2772-0175* TDI HIGH FLOW* 14 100 ppb 700 5 10 100

GAS TYPE

GAS

CODE

RANGE UNITS

200 MDI

100 TDI

200 IPDI

ppb 700 5 10 200

FLOW

RATE

ALARM

LEV EL 1

ALARM

LEVEL 2

ANALOG

OUTPUT

* High Flow, all others are Low Flow

Page viii Instruction 2772-0803

Page 11

REMOTE INTELLIGENT SENSOR - AREA MONITOR

1 INTRODUCTION

1.1 SYSTEM DESCRIPTION

A range of Remote Intelligent Sensors (RIS) are

available. Each is designed to measure low concentrations of a specific gas. Multiple RIS systems can

be connected into a control network to provide an

area monitoring capability with central supervision.

The RIS is a single point, microprocessor

controlled, instrument for use in a fixed location.

Two RIS versions were produced (see Supplement A

for units built before April '92).

The RIS is housed in an environmentally sealed

enclosure and is line-powered, via a DC power

supply, for continuous monitoring. An internal

backup battery is provided as protection against

power interruptions.

The standard system provides clear visual

indication of status, concentration level, 4-20 ma

analog output, gas, and fault alarm conditions.

TWA’s, 15 minute and 8 hour, are displayed at the

touch of a keyboard button.

Reliable and effective operation is assured by

on-line self-diagnostic routines. An easy-to-use

TEST Mode allows key parameters to be checked

and adjusted.

Optional features provide storage, and printout,

of up to one week’s data points, two independently

selectable (via keypad) alarm relays with a separate

fault indication relay and a hardware selectable 0-1

VDC analog output (Sections 2.4.5 & 2.7).

This combination of operating features gives long

tape cassette life at low sampling levels, and a rapid

response with excellent tracking of short term peaks

as levels rise.

The detection of a gas concentration that is higher

than the user-adjustable alarm set point, results in a

highly visible warning on the RIS's large custom

display. In addition, local and remote external warning

devices or systems can be activated via interface

signals.

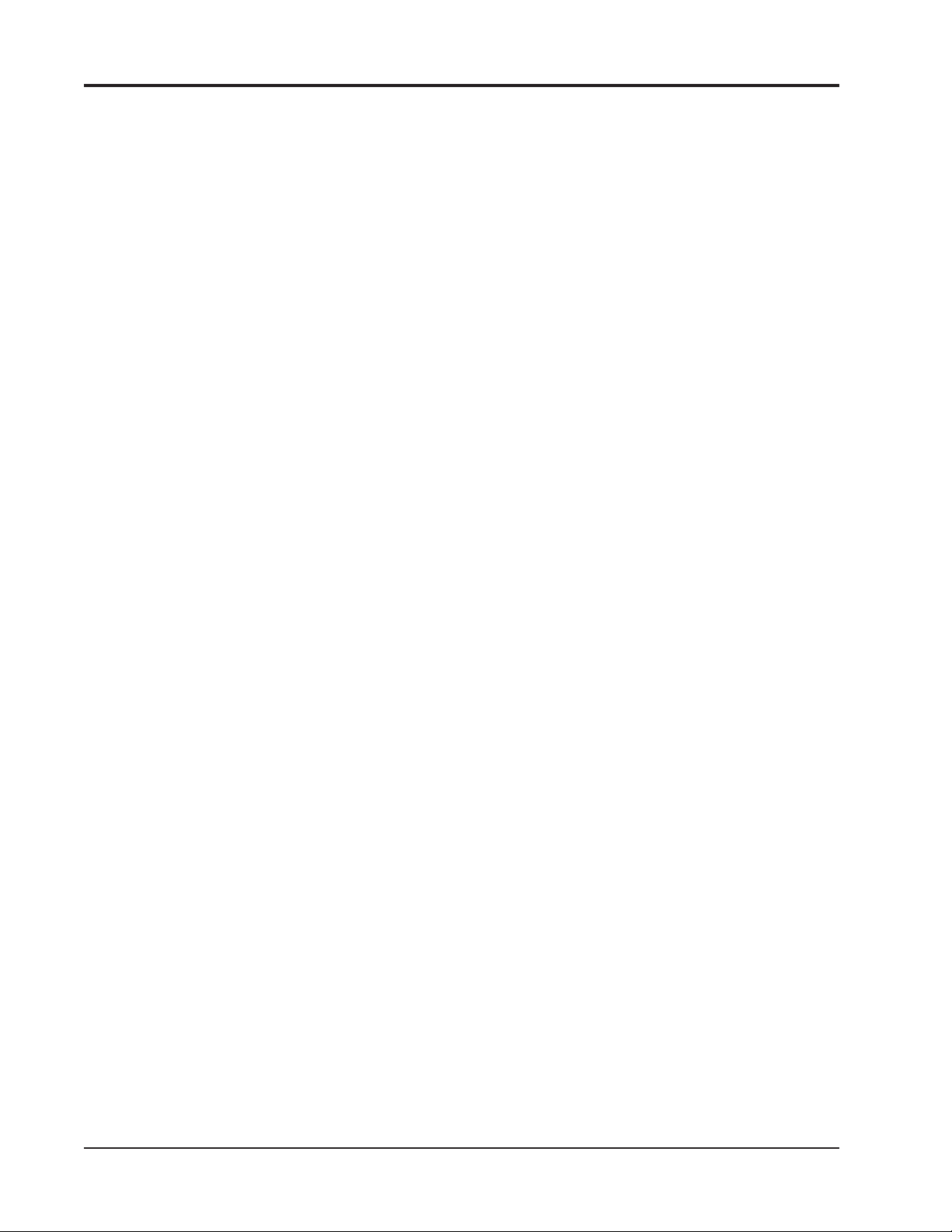

1.3 GENERAL DESCRIPTION

1.3.1 ENCLOSURE. The instrument is contained

within a tough, IP-55 rated, enclosure that is

suitable for installation inside and out. A large

liquid crystal display (LCD) is mounted in the front

face of the door next to a membrane keyboard that is

used for programming certain functions.

1.2 BASIC PRINCIPLES

A measured sample volume is drawn into the

RIS and passed through a chemically impregnated

paper tape. The tape reacts to the presence of a

specific gas by developing a stain whose intensity is

proportional to the sample concentration.

A beam of light is bounced off the tape and the

reflected light is measured. The difference in

reflected light values, developed before and after

the stain, is used to calculate stain intensity,

enabling the sampled gas concentration to be

determined.

The measurement of low gas concentration

levels takes place during a fixed four minute sample

period. If the sample concentration rises above a

predetermined value, the operating mode changes

and the system measures the time taken for a given

stain value to develope.

This technique provides a wide dynamic range,

good resolution and a rapid response to rising gas

levels. In addition, the tape never becomes saturated

which ensures accurate measurement, and toxic gases

are prevented from breaking through the tape into the

system. A double track, tape management system

gives maximum tape economy.

Figure 1-1. Enclosure

The door is hinged on one side and secured shut

by two screw fasteners, which are opened with a

special key to discourage unauthorized tampering.

The door hinges are easily disengaged and removal of

the door from the base is quick and simple, should

this ever be required.

A door-open fault display icon, and relay output

provide warnings and help ensure that RIS is only

operated when the enclosure is secured shut.

There are threaded mounting holes in the base

of the enclosure. The mounting brackets are supplied with the system.

1.3.2 CABLE GLANDS. Three sealed glands are

provided for cable entry and exit. A socket is

provided at one end to allow the connection of an

optional printer.

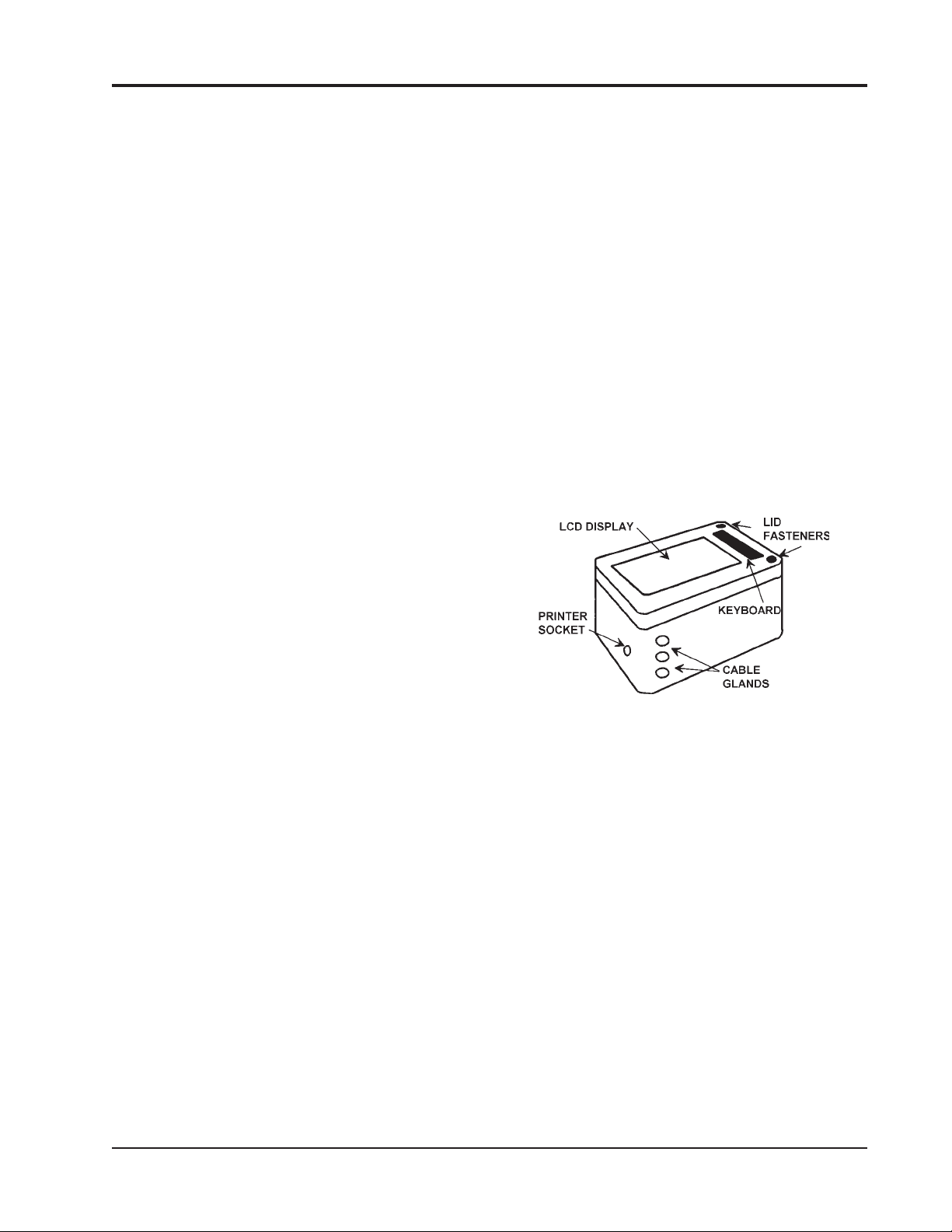

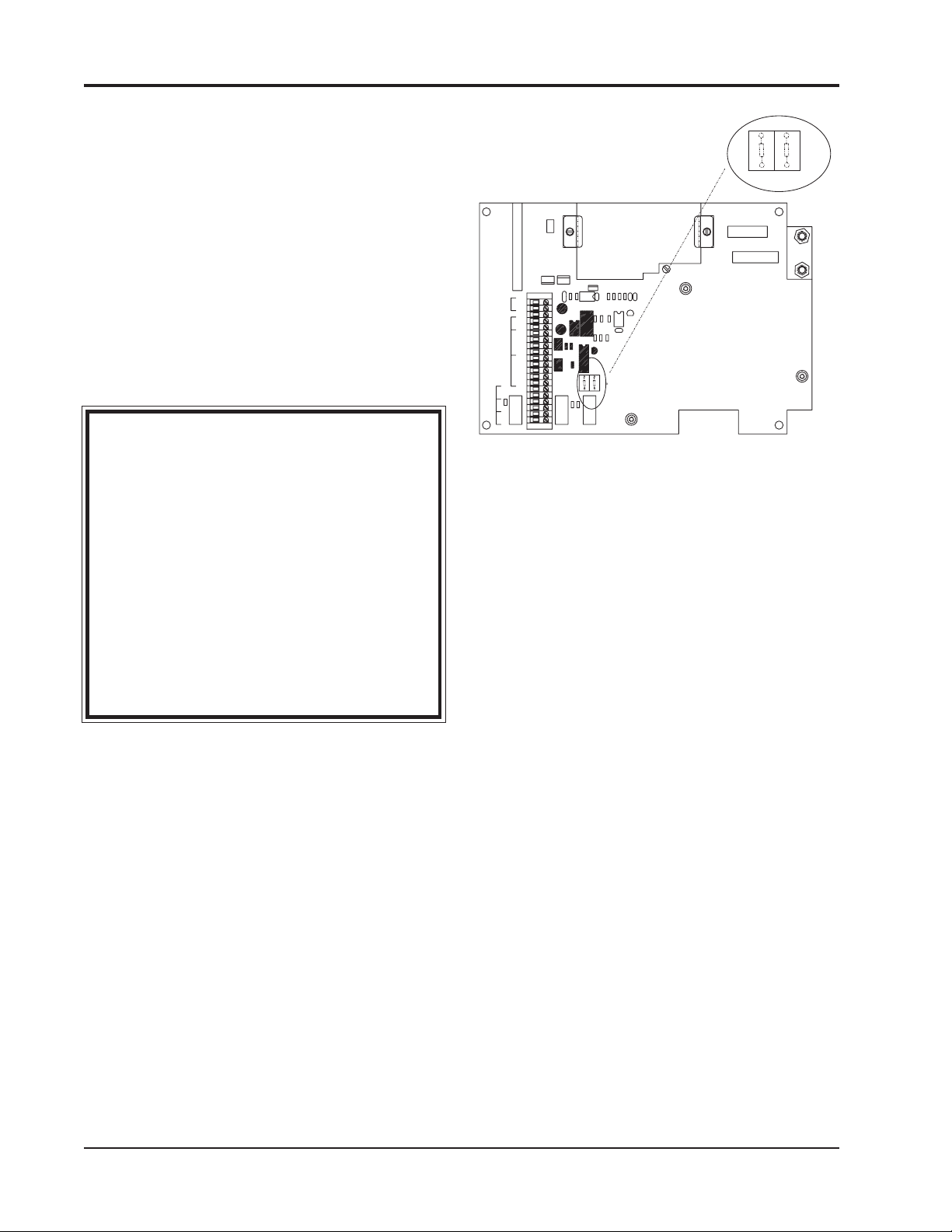

1.3.3 MAIN SYSTEM BOARD. The board is

mounted on the rear face of the door and is accessible when the door is open. The red push-button

TEST Mode switch is in the bottom left-hand corner,

as viewed with the door open.

Instruction 2772-0803 Page 1-1

Page 12

DIP SWITCH 1

DO NOT TOUCH !!

LCD

ADJUST

POT.

EPROMS

DOOR

PROMIXITY

SWITCH

RED TEST BUTTON

REMOTE INTELLIGENT SENSOR - AREA MONITOR

DIP SWITCH 2

ON/OFF SWITCH SW1

VOLTAGE REGULATOR VR1

BATTERY

J5

FILTER

J1

CASSETTE

PRINTER

SOCKET

BATTERY PLUG

RIBBON

CABLE

INTERFACE

CABLE

OPTION

BOARD

B

A

MAIN BOARD

FLOW ADJUST POT.

CABLE GLANDS

TAPE GATE LEVER

TAPE

RESET

BUTTON

LIGHT

LEVEL

ADJUST

Figure 1-2. Door Open and Cover Removed from Back of Door

PNEUMATIC

HOSES AND

CONNECTOR

DOOR SWITCH

MAGNET

ADJUSTMENT

MECHNICAL

CHASSIS

On the main board are mounted several potentiometers and ‘dip’ switches. These should not normally be touched, particularly dip switch 1.

However, a potentiometer (POT) is provided for user

adjustment of the pump flow rate. The location of

the POT is shown in Figure 1-2 and an explanation

of how the flow rate is adjusted is provided in

Section 4.5.

System operating software is stored in two

EPROM’s that are fitted on the board and marked

with the version number. These devices should not

be normally touched or removed except if a factory

upgrade is received.

The main board is protected by a black molded

cover held on by two screws and two pegs.

1.3.4 SYSTEM POWER SWITCH SW1. RIS

operation is controlled by a switch mounted on the

base board. SW1 is located at the top left of the

right hand unit, see Figure 1-2.

When SW1 is ‘OFF’, the system is off. With the

switch ‘ON’, the system will operate from the external 12 volts input, or the systems back-up battery if the external power is disconnected, or fails.

1.3.5 MECHANICAL CHASSIS. This subassembly carries the optic block and its associated

PCB, the tape drive mechanism and take-up drive

clutch.

Also mounted on the chassis is the pump, with

the pneumatic elements and plumbing necessary for

the track switching and purge functions. The tape

cassette is mounted directly on the front face of the

chassis.

1.3.6 BACK-UP BATTERY. The lead acid battery is

located immediately above the mechanical chassis and is

secured to the system base board with metal clips. It is

connected to the system via a short cable plug and

socket (J5).

The battery is automatically ‘float charged’

whenever the RIS is connected to a 12 VDC supply.

The battery is charged with SW1 off or on. If the

RIS supply fails, the back-up battery will keep the

system running for 2-3 hours. The support time

depends upon the system type, specification, and the

battery condition.

If the RIS is being shipped, or will remain unused

and disconnected from the input supply for more than a

few days, it is good practice to disconnect the battery, at

the plug and socket.

NOTE: If the internal system switch, SW1,

is left on and the RIS input supply is

disconnected, the battery will discharge.

If the RIS input supply is disconnected, the

battery will discharge, irregardless of SW1

being on or off.

1.3.7 BASE BOARD. This is a printed circuit

board fixed to the base of the enclosure. It provides

the interconnection between the subassemblies

mounted on it and the main circuit board on the door.

Other circuit elements located on this board

include; the analog output, solid state output

‘relays’, interface terminal strip J1, voltage regulator potentiometer VR1 and system switch SW1.

The current Phase 2 boards have 3 solid state

‘relay’ devices. Terminal identification and numbering have varied and the appropriate interface

diagram should be used. Both versions are shown in

Figure 2-3.

NOTE: The earlier (Phase 1) versions

(Produced before April '92) are described in

Supplement A, in the rear of this manual.

The 3 ‘relay’ devices are standard, but only one

‘relay’ output is active and available unless the

optional Alarm Relay PCB (Section 5.5) is installed.

Page 1-2 Instruction 2772-0803

Page 13

REMOTE INTELLIGENT SENSOR - AREA MONITOR

1.3.8 SAMPLE INLET. The sample is brought

into the RIS through the short length of black FEP

tube and into the optic block. There are two types of

input tube; one has a single 0.25 inch (6 mm)

diameter tube, the other is a double tube arrangement used for systems that monitor aerosols.

NOTE: It is essential that the input tube is

correctly fitted, if incorrectly fitted, the

measurement will be inaccurate (Figures

2-4 & 2-5).

Instruction 2772-0803 Page 1-3

Page 14

REMOTE INTELLIGENT SENSOR - AREA MONITOR

NOTES

Page 1-4 Instruction 2772-0803

Page 15

REMOTE INTELLIGENT SENSOR - AREA MONITOR

2 INSTALLATION AND

SYSTEM CHECK

The RIS may be installed inside or out. It

should be mounted and connected according to the

instructions provided below, and in an environment

that is within the specified limits detailed in the

Product Specification.

WARNING

Failure to comply with these recommendations may void the warranty.

2.1 UNPACKING

Carefully check for shipping damage by examination inside and out. In case of damage, retain

packing and make an appropriate claim against the

carrier.

2.2 BATTERY CONNECTION

Open the RIS door with the key provided and

reconnect the battery lead at J5 (see Figure 1-2).

NOTE: Do not turn the main system

switch, SW1, on at this stage.

2.4 ELECTRICAL INSTALLATION

2.4.1 CABLE RECOMMENDATION. When

deciding cable size and length, the following criteria

should be used.

The maximum permissible volt drop across

supply cables and termination at an assumed

500 mA = 1 volt. Therefore cable length and size

should be selected so that the maximum resistance

of cable and termination is 2 Ohms.

This requirement is achieved by the cable

recommendations given below. The voltage measured at J1 terminals 1 and 2 with a system taking a

‘normal’ current of 150-250 mA should be not less

than 11.5 volts.

The following guidance on cable size and maximum length should be observed:

2.4.1.1 PSU to RIS Input. 18 AWG stranded,

screened, copper wire x 300 ft. maximum, or 16 AWG

stranded screened copper wire x 450 ft. maximum.

2.4.1.2 PSU to Alarm Module. 18 AWG stranded,

screened, copper wire x 600 ft. maximum, or 16 AWG

stranded screened copper wire x 900 ft. maximum.

2.3 MECHANICAL INSTALLATION

See Figure 2-6 for enclosure dimensions and

mounting points. When deciding mounting arrangements and position, consider the following requirements:

It should be possible to fully open door for

cassette replacement, service and maintenance.

Adequate clearance is required for connection

of external wires and pipes through the glands

provided.

RIS must be located so that the sampling

input tube(s) does not require extending (Section

2.6).

The mounting position should be such that

the installation of other equipment will not subsequently interfere with enclosure access.

It should not be possible for strong light,

natural or artificial, to shine directly up the input

tube(s). Servicing will be aided if suitable lighting is

provided.

NOTE: Ensure the sample inlet tube(s) are

correctly inserted in the optics block (see

Figures 2-4 & 2-5).

2.4.1.3 RIS Relay Output to Alarm Module.

Approximately 5,000 ft. maximum of 18 AWG

stranded, screened, copper wire.

2.4.1.4 0 - 1V Analog Output. Dependent upon the

input impedance of the device being driven. Check

with manufacturer. As guidance, with a device

having an input impedance of 10 megohm, a run of

up to 1,000 ft. of 18 AWG stranded, screened, copper

wire should be satisfactory.

2.4.1.5 4 - 20 mA Analog Output. 18 AWG

stranded, screened, copper wire x 500 ft. maximum.

2.4.2 POWER SUPPLY AND INPUT CONNECTIONS. The power supply enclosure can be mounted

adjacent to the RIS, or in some other convenient

location. Advice on power supply selection is provided in Section 2.5.

Connect the 12 volt DC input from the external

power supply to the J1 interface terminals #1 (0V)

and #2 (+12V). Connect external devices/alarms as

required.

Instruction 2772-0803 Page 2-1

Page 16

REMOTE INTELLIGENT SENSOR - AREA MONITOR

When input connections have been made, and

12 volts DC is available at J1 terminals #1 & 2,

leave the system connected overnight with system

switch, SW1, off during the recharge.

WARNING

Each RIS power supply must be connected

to line voltage by a separate circuit back to

a main distribution point. The connection

should not be to a circuit that is liable to

be switched off at, say, the end of a shift.

Failure to observe this advice can result in

a deeply discharged battery, interrupted

RIS operation, and premature battery

failure. This is because an external

interruption of power will result in RIS

running on internal battery until it is

discharged, unless power is restored before

total discharge.

The circuit should be fused according to normal

practice and provided with a switch for use during

maintenance.

2.4.3 OUTPUT CONNECTIONS. Connect

external wiring to standard and optional features

as required and according to the interface Figures

2-2 and 2-3. Observe the general guidance below.

2.5 SYSTEM POWER SUPPLY

CONSIDERATION & SELECTION

2.5.1 RIS POWER SUPPLIES. The following

standard power supplies are available, higher

output alternatives can be offered where necessary.

See Chapter 5 for proper Power Supplies and Part

Numbers.

2.5.1.1 ‘Single Point’. This power supply is

suitable for permanent installation to supply one

RIS plus one GMD Alarm Module.

Specification:

AC Input: 100/120/220 VAC + 10% - 13%

230-240 VAC (47-63HZ) + 15% - 10%

Regulation:

Line: ± .05% for a 10% I/P change

Load: ± .05% for a 50% load change

Output Ripple: 5 mV peak to peak

Short Circuit and Overload Protection:

Auto current limit fold back

Temperature Rating: 0 to 50 °C full rated,

de-rate linearly to 40% at 70 °C

Enclosure:

NEMA 3R rain tight

Meets US 50 type 3R LEC 529.IP32

Size 6.75" H x 4.375" W x 4.375" D

(172mm x 111mm x 111mm).

2.4.4 RELAY OUTPUTS. The alarm and fault

relays, combined into a single output in a basic RIS,

are solid state semiconductor devices. The outputs

normally present the equivalent of a closed contact

to the external circuit and open on alarm or fault.

The output terminals at J1 terminal strip are

polarized and care is required when making connection to the external circuit.

The semiconductor device specification is

included in the Product Specifications and ratings

should be observed.

It is recommended that external relay coils, or

other devices, controlled by the RIS interface are

not energized from the 12 VDC input supply to the

RIS. This will avoid a possibility of overloading the

power supply.

2.4.5 ANALOG OUTPUTS. A 4 - 20 mA analog

output is available (as default) at the interface

terminal strip J1. An external analog instrument

may be connected to provide remote indication of

the measured concentration.

An optional 0 - 1 Volt analog output is available. To set the 0 - 1 Volt output, follow the procedure in Section 2.7. The 20 mA, (or 1 Volt if appropriate), represents the maximum concentration

value for the particular RIS monitor.

2.5.1.2 ‘Multi Point’. This power supply is suitable

for permanent installation to supply multiple RIS/

Alarm combinations.

Specification:

AC Input: 104-127 VAC, 208-254 VAC,

both 50-60 Hz.

Regulation: Combined Line & Load = ± 0.1%

Output Ripple: 10mV RMS

Short Circuit and Overload Protection: Auto

current limit fold back

Temperature Rating: 0 to 55 °C ambient

Temperature Coefficient: 0.03%/°C

Max. Output Current: 120% rated current

= 1.8x 120%=2.16A

Enclosure: NEMA 4X

Size* 10"H x7"Wx6.25"D

(254mm x 178mm x 159mm)

*including flanges and connectors.

The following table shows the combination of

RIS’s and Alarms that may be connected to one

‘Multi Point’ supply. Practical worst case conditions

are assumed to apply. See Table #1 for the High

Flow models.

Page 2-2 Instruction 2772-0803

Page 17

REMOTE INTELLIGENT SENSOR - AREA MONITOR

RIS TYPE Acceptable Combinations

Standard 4321

and + or+or+or+

Alarm Module 0248

High Flow 3 2 1

and + or + or +

Alarm Module 0 4 7

Alarm Module 10

NOTE: In large applications physical

layout and distance between RIS’s and

Alarms may make it more convenient to

use some small local power supplies.

2.5.2 POWER REQUIREMENTS, RIS &

ALARM MODULE. Typical current consumption

under a range of operating conditions are:

2.5.2.1 Standard RIS Models. All Standard

systems (See Table #1) have Flow Rates of 200 cc/

min. or less. This list may be incomplete because of

new models introduced after publication.

The input current taken by an RIS depends

upon the following factors. The battery charge

state, its condition and age, the operating point in

the cycle, pump current and the options fitted.

Typical input current, under several conditions:

Normal conditions, well charged battery.

Conditions and Comment mA

System running, no pump (as measured 60 in the TEST Mode, mA test) 90

System running, pump on (measure at J1 150 terminal #2, or as shown on print header) 200

Battery discharged, power just restored.

Conditions and Comment mA

System running, pump on. (Current 500 shown is short term peak and would 700

only occur after a prolonged power

disruption. An old battery tends to take

a lower charging current)

2.5.2.2 High Flow RIS Models. All of these

systems (Table #1) have a the larger pump taking

an additional current of, typically, 100 mA. All

other factors are as detailed under Section 2.5.2.1.

2.5.2.3 ‘Worst Case’ Current.

Low Flow RIS. A practical ‘worst case’ current

of 500 mA may be considered reasonable under most

situations. Where long-term power disruptions (more

than 2 hours) are likely, it may be prudent to

assume 550 - 700 mA ‘worst case’.

High Flow RIS. A practical ‘worst case’ current

of 600 mA is reasonable in most circumstances; in

severe conditions 650 - 800 mA may be prudent.

2.5.2.4 Alarm Module. With both horn and flasher

alarms operating and a well charged battery, the

input current is typically 100 mA.

After a power interruption, with the battery

discharged, and the alarm in the ‘standby’ state

(both horn and flasher off), a practical ‘worst case’

current of 200 mA is considered reasonable.

2.5.2.5 Summary: 'Worst Case' Input Currents.

Model ‘Practical’ ‘Extreme’

Worst Case Worst Case

Low Flow 500 mA 700 mA

High Flow 600 mA 800 mA

Alarm Module 200 mA 250 mA

2.6. SAMPLE LINES

2.6.1 GENERAL. The RIS is designed, tested and

calibrated to give accurate measurement of the

target gas when used as supplied and as directed in

this manual. This particularly includes using the

short input tube fitted to the RIS. The input tube,

material, diameter and length have been carefully

selected so that no attenuation of the sample occurs

as it is drawn into the monitor for measurement.

NOTE: GMD Strongly Recommends

only the original input tube be used. Refer

to Section 5.3 (Recommended Spares).

2.6.2 LESS REACTIVE GASES. They are less

liable to be ‘lost’ in sample lines but many factors

are involved. These include temperature, humidity,

and sample velocity.

It may be possible with some of these gases, and

under specific circumstances, to use somewhat

extended sample lines. It is not possible to give more

specific guidance on this subject than the following

comments:

The less reactive gases referred to above include,

PHOSGENE, HYDRIDES and CHLORINE. In

some circumstances, it may be possible to use an

input tube of

(0.91 meters) in length. The material MUST be

black FEP Teflon fitted to the RIS as supplied.

up to a maximum of about 36 inches

Instruction 2772-0803 Page 2-3

Page 18

REMOTE INTELLIGENT SENSOR - AREA MONITOR

2.6.3 REACTIVE GASES. Many gases are

extremely liable to attenuation and no extension

of input tube should be attempted. These

gases include ISOCYANATES, HYDRAZINES

and ACID GASES such as HF and HCI.

2.6.4 SYSTEM PERFORMANCE WITH

EXTENDED SAMPLE LINES. Bacharach will not

guarantee system performance and accuracy if

extended sample lines are fitted, except where the

company has expressly given written approval.

NOTE: Without such specific approval,

the user must determine that performance

is not adversely affected under the

particular application conditions.

WARNING

Extended input lines should never be

used when sampling low vapor pressure compounds such as MDI. These

compounds are present in aerosol

form, and sampling efficiency will be

drastically reduced if the sample line

is extended. Instruments intended for

aerosol sampling have a dual input

tube approximately 1" (25 mm) long

protruding from the bottom of the

instrument.

0 - 1 V

J 4

P O W E R

S W 1

O N

V R 1

1

J 5

J 1

-

1 2 V D C

IN P U T

+

A O V

A N A L O G

O U T P U T

A O P

A I N

N E T W O R K

A O U T

C O M M S

IN T E R F A C E

B

S

P I

P O

S E R IA L

P R IN T E R

P R D Y

IN T E R F A C E

P P R S

O V

+

R L A 1

R 1 6

-

R L A 2

+

R L F

-

+

R L A 2

-

2 0

T R 1

R 1 R 2

C 1

IC 1

1

+

2

L 1

R 8 R 9

C 7

3

IC 2

4

C 5

+

V R 2 Z E R O

R 7

IC 4

R 1 2

R 1 1

Q 1

V R 3 S P A N

R 1 3

1 3

1 4

0 -1 V

1 5

R L F

R L A 1

R 1 7

R 1 8

B A T T E R Y P A C K

R 5 R 6

R 3 R 4

C 3 C 4

C 2

R 1 0

IC 3

D 1

C 6

R 1 4

R 1 5

4 -2 0 M A

G M D 1 17 6 0

J 3

1

J 2

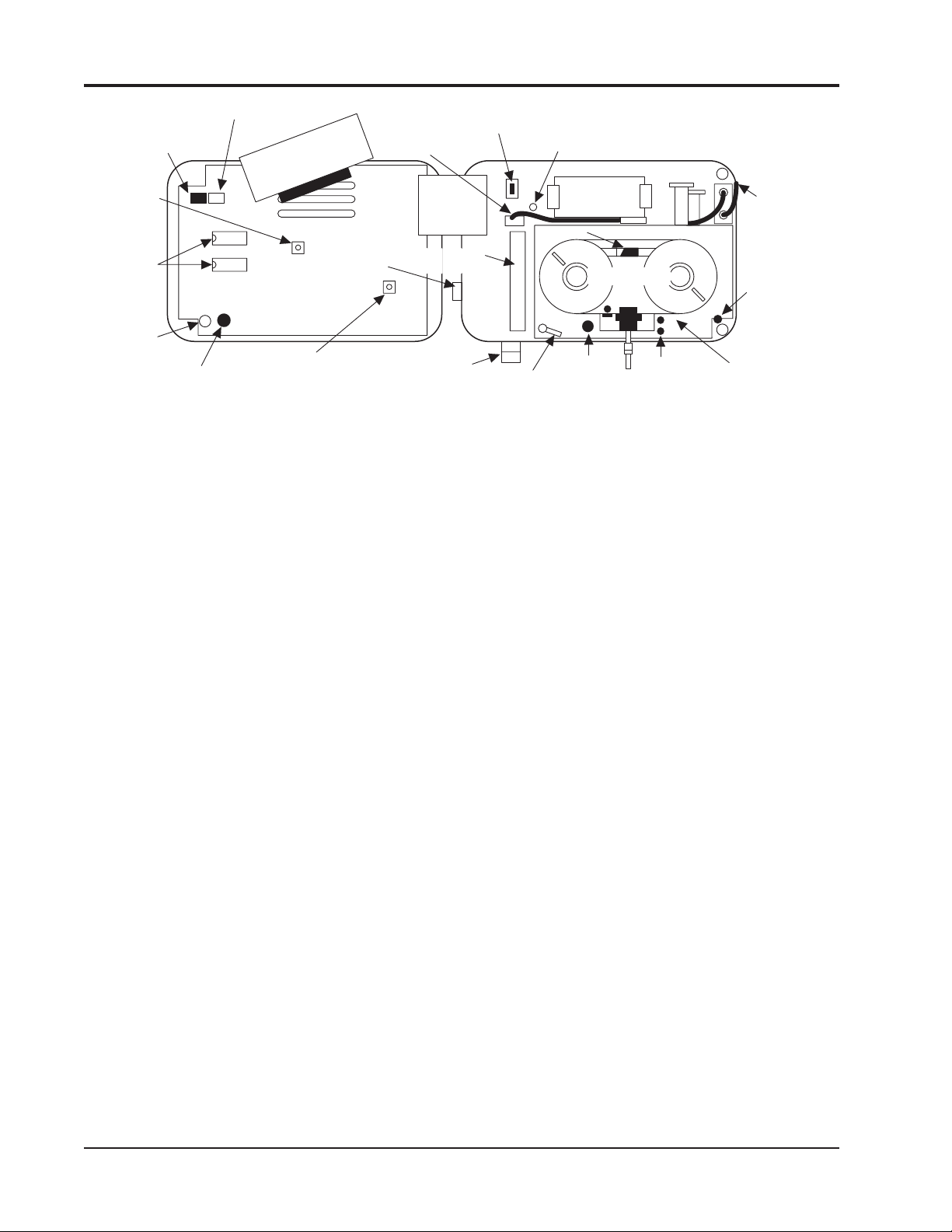

Figure 2-1. 0 - 1 Volt Conversion

2.8 SYSTEM CHECK

NOTE: This procedure should be followed

every time a new cassette is installed, to

insure the system is operating correctly.

During the initial system check of this unit,

and at least on a yearly basis there after,

the sample inlet tube should be checked for

proper installation.

2.8.1 TAPE CASSETTE LOADING

4 - 2 0 M A

1

WARNING

2.7. 0 - 1 VOLT CONVERSION

This involves opening the RIS door, which

automatically initiates the door-open

alarm. Before opening the door to load or

2.7.1 TOOLS & MATERIALS REQUIRED

change a cassette, ensure that any external

warning system is disabled or that those

• 2.5 mm Hex Key

• Soldering Iron

involved are aware of your intended

actions.

• Solder

• Wire Cutter (Small)

• Buss Wire (#22 AWG, 1/2" Long)

Open the door with the key provided. Leave the

system switch on. Press the TEST Mode switch on

the bottom left inside corner of the door. Open the

2.7.2 PROCEDURE. Remove main power from

RIS System: then set ON/OFF switch SW1 to OFF.

Follow the removal of the mechanical chassis from

Section 4.11.2.

Remove link (0 Ohm resistor) from the 4 - 20

tape gate with the lever and remove the old cassette, if installed. The cassette and its mounting

spigots are designed to fit tightly; use a firm and

direct pull to disengage the cassette. See Figure 1-2

for the location of the items referred to.

OUTPUT position using wire cutters to cut both

ends of the link. Solder buss wire link into the 0-1

Volt position per Figure 2-1.

Reinstall the mechanical chassis, cables, and

hoses using the first two paragraphs of Section

NOTE: Make sure that the ‘O’ ring

installed in the cassette molding, (and

which seals purge connections), is not left

behind when the cassette is removed.

4.11.5.

Page 2-4 Instruction 2772-0803

Page 19

REMOTE INTELLIGENT SENSOR - AREA MONITOR

If the ‘O’ ring is left on the purge spigot the

new cassette will not seat fully and faulty tape

handling will occur.

Push the new cassette firmly into position.

When doing so make sure that the tape enters the

open gate and does not catch on the side and break.

If the tape is not tight and in the correct

position to enter the gate, carefully tighten it by

turning the take up spool.

It is not necessary to touch the tape directly.

Touching the tape with bare fingers is undesirable

because of chemicals used to impregnate the tape.

When the cassette is in position, close the tape

gate and press the tape reset button to reset the

tape counter (to 99%) and initiate a new cycle.

NOTE: It is recommended that before

exiting TEST Mode, the System

Parameters are checked as described in

Section 2.8.2. The check takes a few

minutes and ensures that the system is in

optimum adjustment.

Exit the TEST Mode by pressing the red button

inside (on the door) again and close the door.

Tighten the door screws and take care not to over

tighten them. The above procedure is summarized

in the following:

Disable external alarms & warn staff.

Open door and enter TEST Mode.

Remove old cassette, check for retained ‘O’

ring.

Fit new cassette and close gate.

Press tape reset button & observe tape step.

Check system parameters.

Exit TEST Mode and close the door.

2.8.2 CHECK AND ADJUST SYSTEM

PARAMETERS. This procedure can be carried out

if a system fault is reported, as a routine check

after cassette replacement, or at any other time it

is necessary. The full sequence of data displayed in

the TEST Mode depends upon the options fitted to

the particular system. All tests are given below for

completeness.

The parameters that are normally checked at

cassette change are: V system voltage, mA the

current, Light Levels track 1 & 2, and Flow

Rate. The others are set values that do not change

unless the system is switched off.

Entering the TEST Mode. Open the RIS

door, having taken precautions against causing

unnecessary alarms, and enter the TEST Mode by

pressing the red button on the rear of the door.

Each of the TEST Mode displays remains for 3

seconds before stepping to the next parameter.

This cycling of data repeats continuously until

the HOLD/RELEASE key is pressed to hold a

displayed parameter; or the TEST Mode button is

again pressed to exit the mode; or five minutes

passes. After five minutes an automatic return to

the NORMAL mode occurs.

2.8.2.1 V, System Voltage. The first displayed data

is system voltage. This is the regulated voltage

derived from the nominal 12 VDC external supply at

the system interface. The displayed value should be

6.9 ± 0.1V.

If adjustment is required, first press the HOLD/

RELEASE key to hold the display. Adjust by turning

potentiometer VR1 located on the base board near

the system switch SW1 (NOTE: See Supplement A

for older version PCB's). When adjusting, do so

cautiously and allow time for the battery voltage to

settle to the new value. Recheck the voltage 10

minutes after adjustment.

2.8.2.2 mA, ‘Charger Current’. This display shows

the system current taken under the test conditions.

Pump current is not included because the pump is

not running during this part of the test cycle.

The displayed current, in mA, is the total of that

taken by the system, (excluding pump), and the

battery charging current. A ‘normal’ reading is about

60-90 mA. This assumes a well charged battery and

an average specification system.

Note that if the system voltage is lower than

6.9 V, the charge current will be proportionately

higher. A mA reading that is much higher than the

range shown above suggests a discharged or faulty

battery if the system volts are correct.

2.8.2.3 Alarm Set Point. The numerical value in

ppb, or ppm, (system dependent) is shown with the

‘flashing bells’ icon. If the set point has not been

changed, the default value will be active. Default

values are shwon in Table #1.

To change the set point value, ‘hold’ display with

the HOLD/RELEASE key. At this point the least

significant digit will flash and it can be changed as

required by pressing the DIGIT key. Each press steps

one digit more. Press firmly.

When the first digit is selected, step to the next

higher decade by pressing the DECADE key. Again

use the DIGIT key to select the required number, and

so on. On completion, press the HOLD/RELEASE key

to allow the sequence of test data to continue.

2.8.2.4 Alarm Level 1 and 2. When the Relay alarm

option is fitted, there are two Alarm Levels and each

may be user adjusted. Both Alarm Level set ponts

are displayed in sequence when the option is fitted.

Instruction 2772-0803 Page 2-5

Page 20

REMOTE INTELLIGENT SENSOR - AREA MONITOR

Alarm Level 1 is displayed first and is identified by

the number 1 which is shown in addition to the

numerical set point value. Similarly, the Alarm level

2 set point which follows, is identified by a 2.

IMPORTANT: Be aware that if the RIS is

switched off at SW1, the alarm set point(s)

will be return to their default at system

switch on. It will therefore be necessary to

reestablish set points if they differ from the

default values.

2.8.2.5 Gas Curve. The gas curve for the system is

displayed as a number. Systems are fitted with an

alpha numeric display and the active gas curve

shown directly (e.g., MDI or TDI etc.). Most systems

have only one gas curve programmed in the software and that curve is permanently active.

2.8.2.6 Multi Gas Curve Systems. In special

‘multicurve’ systems, a curve can be selected by:

1. Pressing TEST switch to enter the TEST Mode.

2. Wait until the display scrolls to the gas curve.

3. Press HOLD key to freeze the display.

4. Press DIGIT key to select the required curve.

5. Exit the test mode.

NOTE: The ‘default’ curve is MDI and is

automatically selected at system power up.

Be aware that each system has its particular

Flow Rate as shown in Table #1. After track 1 flow

has been read, press the HOLD/RELEASE key to

‘release’ the display. Allow it to step to track 2 and

press the key again to ‘hold’ that reading.

Flow to both tracks is supplied by one pump and

switched to the active channel by solenoid valves.

The flow measured at each track should therefore

be similar. Adjustment to the pump flow is made

with the potentiometer located on the main board as

shown in Figure 1-2 and is described in Section 4.5.

2.8.2.9 Date & Time. If the Optional Printer card

is installed, the data displayed in the Test sequence

automatically includes the date and time. The date

and time are reset to zero, with any stored data

point information, when the system is switched off

at SW1. It is necessary to set the date & time when

the system is installed, and if it is switched off

subsequently.

'HOLD' Setting Date & Time. To set the date

and time, ‘hold’ the display and use the digit and

decade keys to select the required values. The

decade that flashes after the display is ‘held’ is

adjusted first in each case.

If the number required is stepped past, keep

going until the desired number comes round again.

Note that the date & time is not lost if the input

supply fails, providing the back-up battery is not

discharged and SW1 remains on.

2.8.2.7 Light Levels Track 1 & 2. The next

display in sequence, is track 1 light level value.

This is a numerical value between, approximately,

200 and 254. Also displayed is a separate 1 (for

track one). This is followed by the next display with

a similar reading and a 2 (for track two).

The ‘correct’ value for both light levels is 220.

However, variations occur normally because of

small changes in the reflective property of the tape

along its length. These variations do not normally

exceed ±2 or 3. If the light level reading is 220 ±2 or

3, do not adjust. If it is approaching 200, or more

than 235 it should it be reset to 220.

NOTE: The light level may vary slightly

tape to tape. It is essential that checking

and adjustment is only made with a tape

in the gate and the gate closed. See Section

4.4 for detailed instructions on adjustment.

2.8.2.8 Flow Rate. While the light level test cycles

are active, the pump is running and ‘sample Flow

Rate’ can be checked. This is done by HOLD-ing the

display at 1. (and afterwards at 2.), and measuring

Flow Rate with a suitable flow meter connected in

series with the sample inlet tube.

2.8.2.10 Interruption of TEST Mode Cycle. If

5 minutes have elapsed since entering the Test

Mode, the display will revert to “normal”. To

complete the adjustments, press TEST Mode switch

again to reenter the mode and carry on.

2.8.2.11 Completion of Checks. Exit the TEST

MODE by pressing the red TEST BUTTON again on

the rear of the door.

NOTE: It is occasionally possible to

initiate a display that contains both

‘normal’ and ‘test’ data simultaneously. If

this occurs when exiting the TEST Mode,

press red TEST MODE button to reenter

the mode and then again to exit it cleanly.

When installing a new tape, press the red TAPE

RESET button on the left of the tape gate to reset

the system and the tape counter.

Close the door and tighten the securing screw

fasteners. The display should now show: SYSTEM

OK and a zero NUMERICAL ppm/ppb value

(assuming monitored atmosphere is zero) alternating with 99% which indicates the cassette life

available. There should be no fault icons shown.

Page 2-6 Instruction 2772-0803

Page 21

REMOTE INTELLIGENT SENSOR - AREA MONITOR

2.9 OPTION PCB INSTALLATION

Under the cover on the main board are three

slots for mounting option boards. An option board

can be inserted in any available slot. The two

option cards available are the Serial Printer

Interface PCB, and the Alarm Relay PCB (See

Section 5.5 for order numbers).

2.9.1 PRINTER (OPTION) INTERFACE

INSTALLATION. A suitable external printer can

be connected when the printer option is fitted. This

is a ‘plugable’ option and may be added any time.

Section 3.14 explains the user selectable aspects.

The Printer option is a user installed feature

for which the external printer socket is pre-wired.

To install, proceed as follows:

The following parts are required: Printer PCB,

Portable Printer (See Chapter 5 for part numbers)

complete with charger and lead.

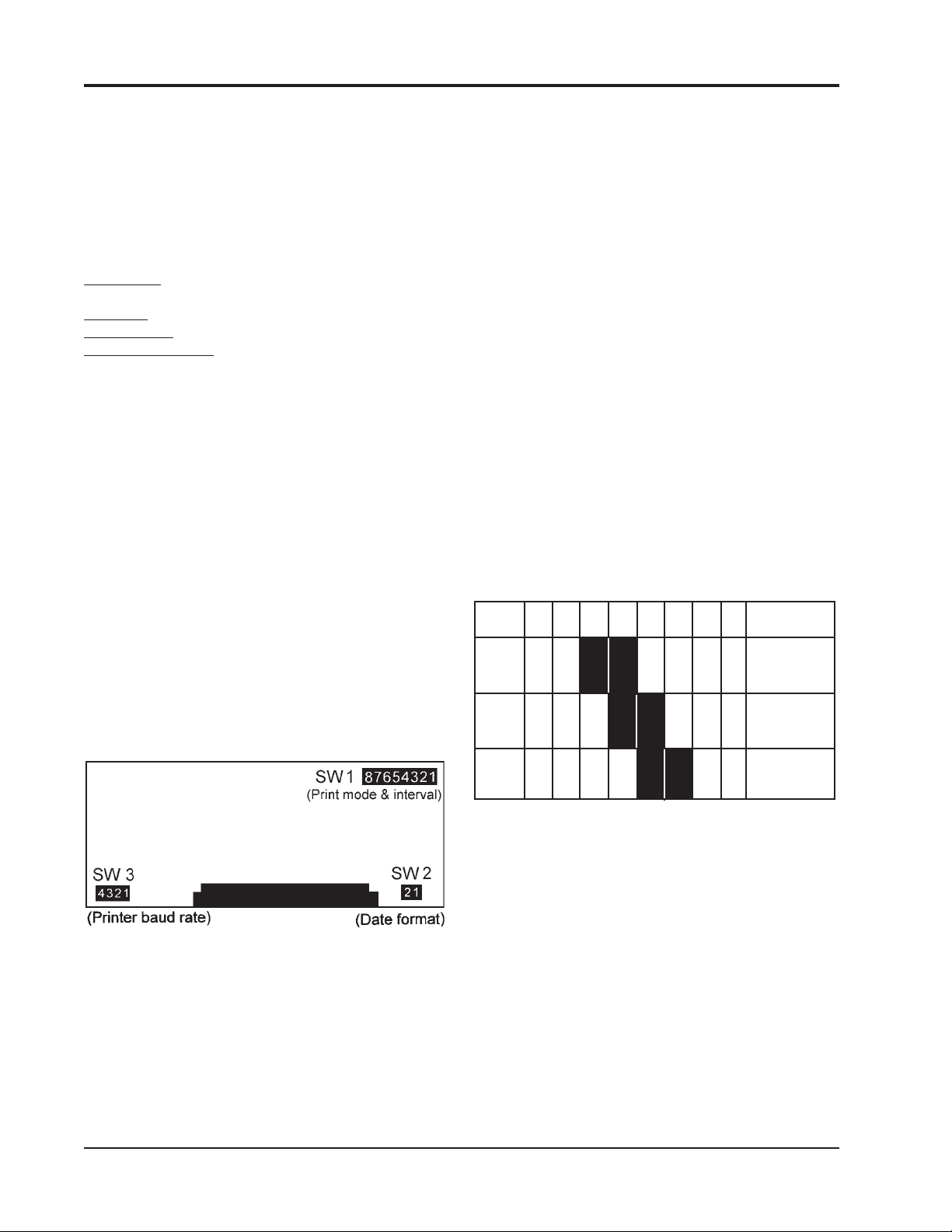

Refer to Sections 3.14.3 and 3.14.4 and set the

switches on the Printer board to select the desired

date format, printer interval and the baud rate.

When handling the option board wear a wrist strap

with the clip grounded at RIS common.

Disable external warning systems controlled

by the RIS to avoid unnecessary alarms.

Open the RIS door and switch off the system at

SW1. Before fitting the option board, wear a wrist

strap with the clip grounded at RIS common.

Terminal # 1 on J1 can be used.

If a wrist strap is not available, avoid touching

components on the option board and the main

board.

Slide the Printer option board into a slot and

engage the connectors. If the board is not put in

correctly, the connectors will not mate.

Set the date and time using the procedure in

Section 2.8.2.9.

Replace the cover on the main board, plug

printer into external socket provided, turn on the

printer, wait for the printer to print "Ready", and

check printer operation by pressing the PRINT key.

2.9.3 ALARM MODULE CONNECTION. The

GMD Alarm Module is available for connection

directly to an RIS’s interface terminals. Single or

multiple Alarm and RIS combinations are possible

and are described in the Alarm Module Manual

(2701-1982). Basic connection of an Alarm to an RIS

is shown in that manual.

2.9.4 RELAY ALARM INSTALLATION. To

install, follow the steps below:

Disable external warning systems controlled by

the RIS and route additional cabling for the extra

relay outputs that will be made available.

Open the RIS door and switch off the system at

SW1. Disconnect the single relay output wiring from

terminal strip J1 inside the RIS. Remove the black

main board cover on the door rear to expose the

option board slots.

Check that the two EPROM’s are Version 30-xx03 or higher, where xx is the gas curve code (e.g. 00

for TDI, 06 for MDI etc.). 03 at the end of the version

# confirms that the relays are normally closed in the

‘off' state and open on alarm.

Slide the Relay Alarm Option board into a slot

and engage the connectors. If the board is not put in

correctly, the connectors will not mate. When

handling the option board wear a wrist strap

with the clip grounded at RIS common. Termi-

nal # 1 on J1 can be used. If a wrist strap is not

available, avoid touching components on the option

board and the main board. Replace the cover on the

main board.

Bring the new interface wires into the system

and connect them according to the Figure 2-2.

Ensure correct polarity is observed. Switch the

system on at SW1 and check for correct operation of

the externally connected alarm system/s.

The gas alarms can be checked with the use of a

Test Card, (see Section 3.13.3), or by opening the

tape gate with the system operating.

2.9.2 PORTABLE PRINTER. This printer is

supplied complete with internal battery, charger

and interconnecting cable. A fully charged printer

battery allows for printing a complete 7 days worth

of data. The printer can also be used ‘on line’ via

the supplied charger. See Section 3.14 for printer

operation.

Instruction 2772-0803 Page 2-7

Page 22

REMOTE INTELLIGENT SENSOR - AREA MONITOR

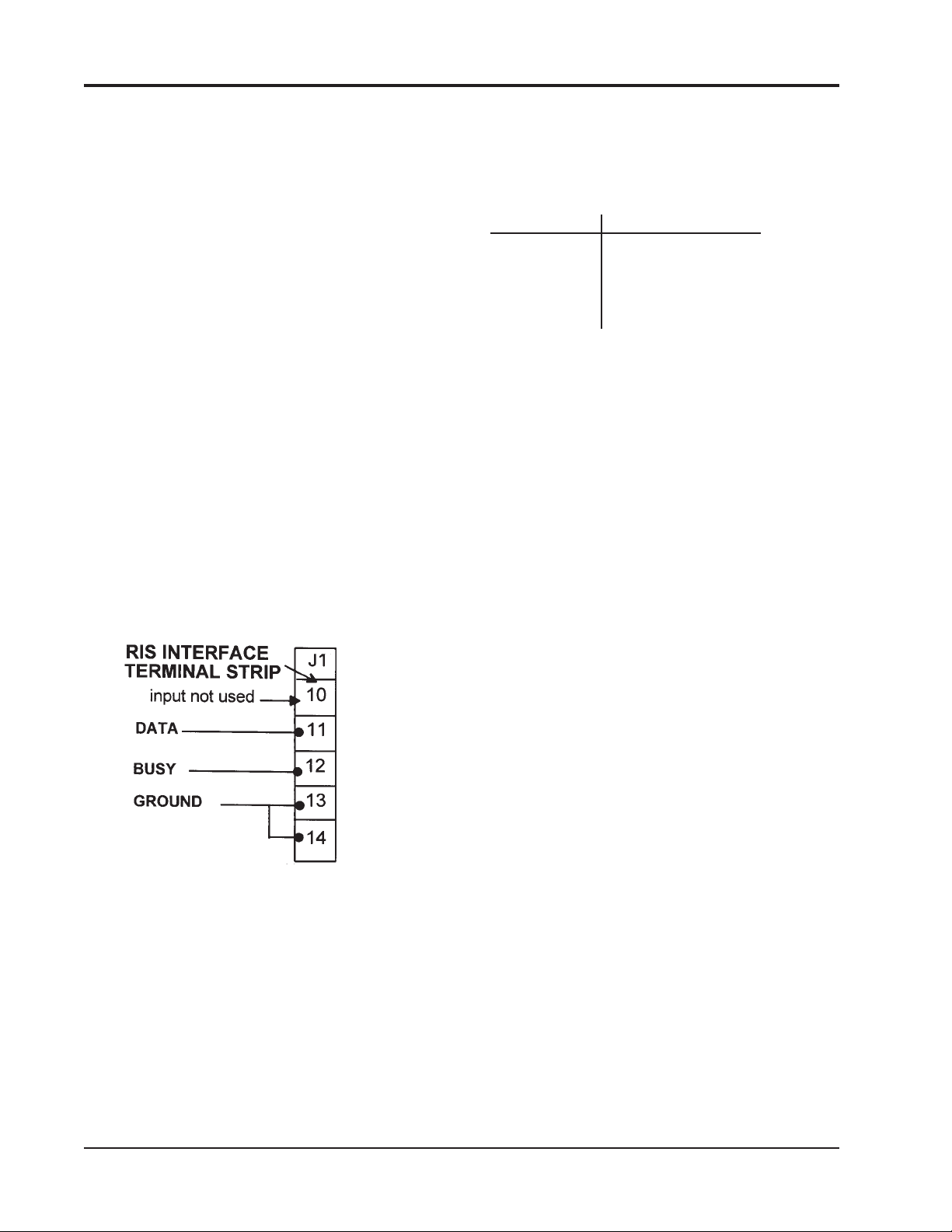

TERMINAL USE AND TERMISILKSCREEN IDENTS NAL

12 VDC – 1

INPUT + 2

(Connected internally to #1) 3

ANALOG – A 0V 4

OUTPUT + A OP 5

NET- A IN 6

WORK A OUT 7

COMMS B 8

INTERFACE S 9

PI 10

SERIAL PO 11 DATA Non GMD

PRINTER PRDY 12 BUSY Printer

INTERFACE PPRS 13 GROUND see Sec. 3.14

0V 14

COMBINED GAS RLA1 + 15 + Fault/Alarm

& FAULT ALARM GAS ALARM 1 – 16 RLA1 O/P or Relay O/P

NOT RLF +17+

ACTIVE FAULT ALARM – 18 RLF O/P

NOT RLA2 +19+

ACTIVE GAS ALARM – 20 RLA2 O/P

s s

RELAY ACTION RELAY ACTION

WITHOUT WITH

2701-1761 2701-1761

OPTION CARD OPTION CARD

INSTALLED INSTALLED

GMD PRINTER: When purchased as an option, the

printer is usually plugged into the pre-wired external socket provided. Alternatively it can be hardwired into the system through the J1 interface using

the information provided in Section 3.14 of this

manual.

RELAY OUTPUTS: Observe polarity. The

outputs present a closed circuit that opens

on fault or alarm.

With a single combined output, the ‘relay’

toggles position on fault and remains open

on alarm. Adding the optional three-relay

board option enables the three-relay

option.

CONNECT CABLE

SCREEN(S) ONE

END ONLY

To 12 VDC

+PSU

CURRENT RIS J1 INTERFACE CONNECTIONS WITH

SYSTEMS USING VERSION 30-XX-03 AND HIGHER

SOFTWARE.

Figure 2-2. Hookup for Phase 2 Base Board Terminal Strip

Page 2-8 Instruction 2772-0803

Page 23

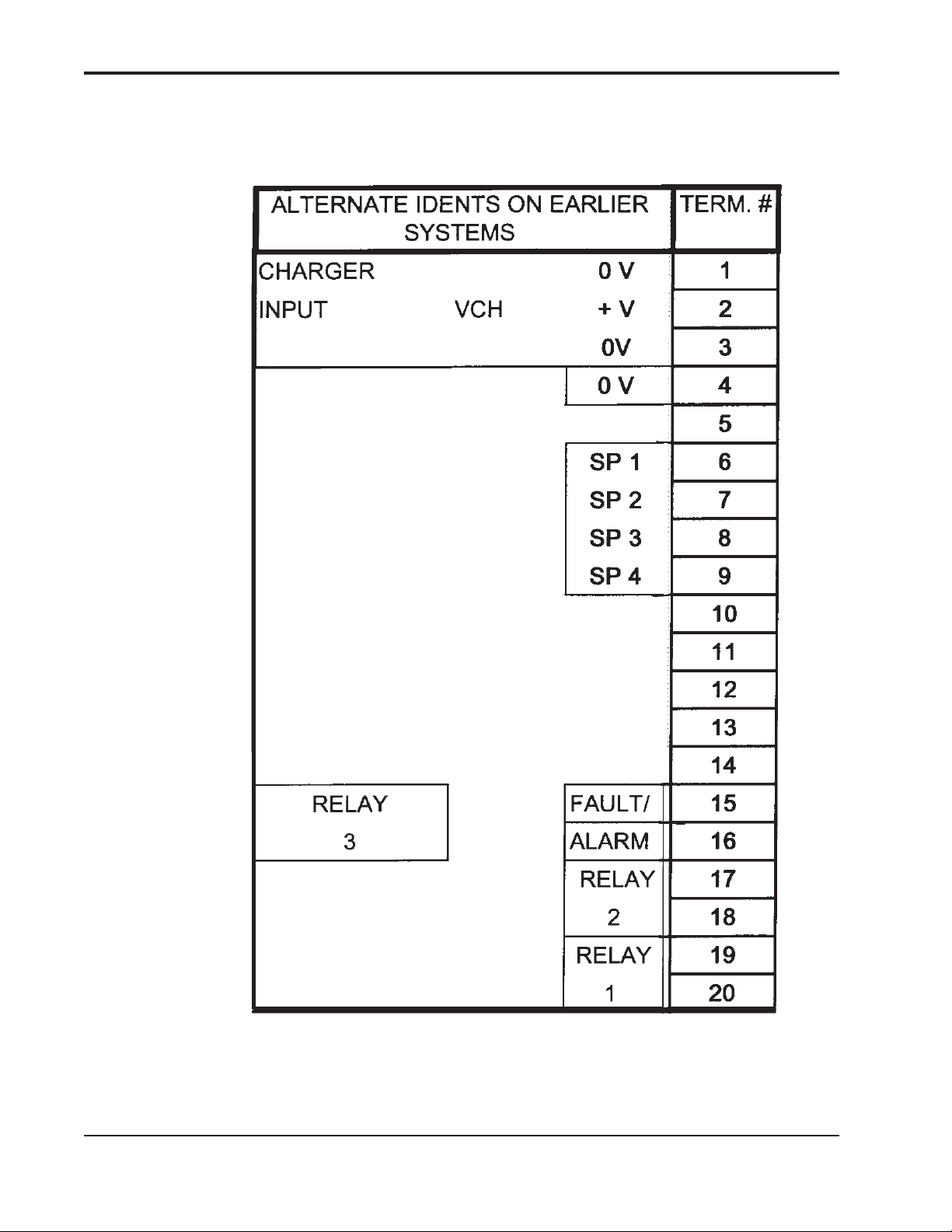

REMOTE INTELLIGENT SENSOR - AREA MONITOR

Figure 2-3. Phase 2 Base Board Terminal Strips

Instruction 2772-0803 Page 2-9

Page 24

REMOTE INTELLIGENT SENSOR - AREA MONITOR

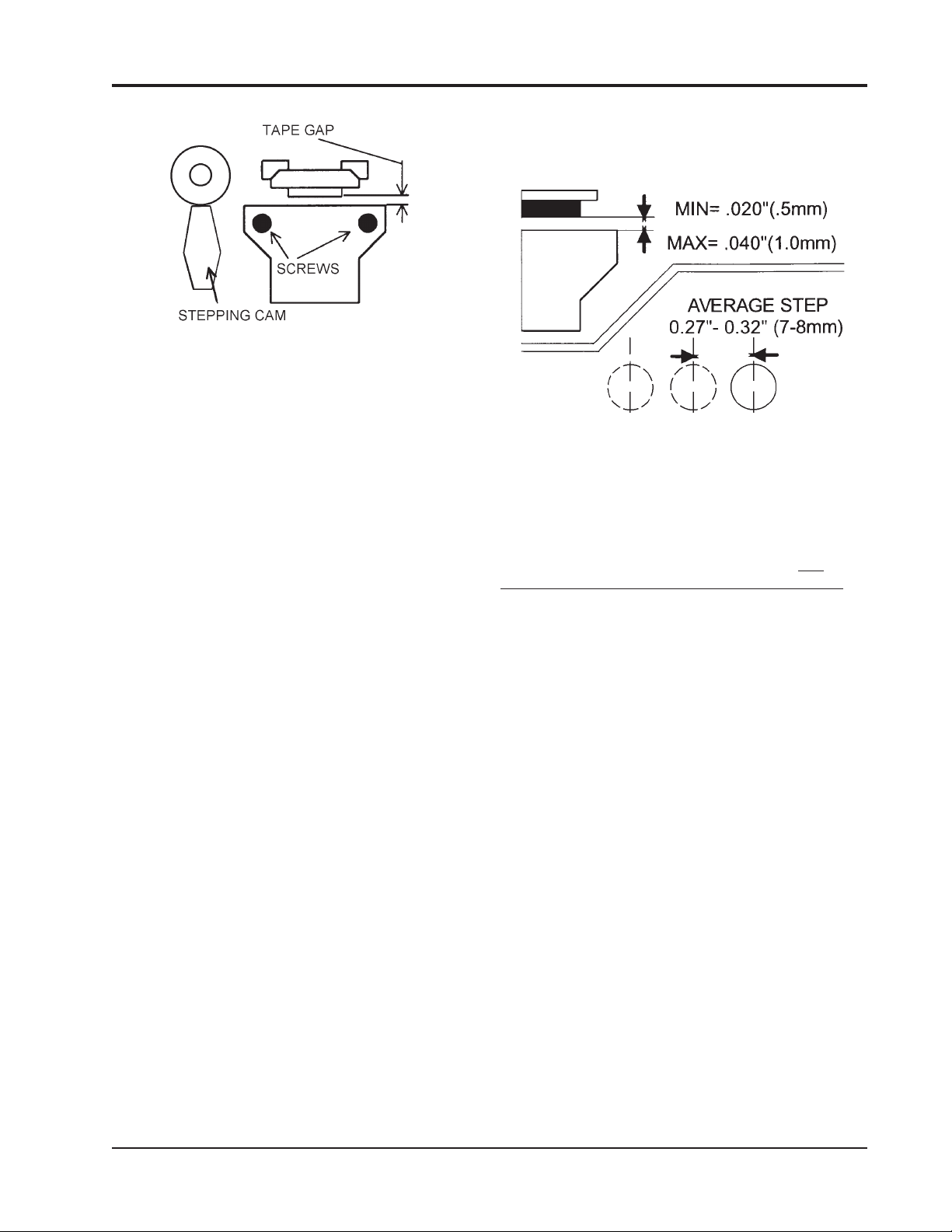

Figure 2-4. Figure 2-5.

Page 2-10 Instruction 2772-0803

Page 25

REMOTE INTELLIGENT SENSOR - AREA MONITOR

Figure 2-6.

Instruction 2772-0803 Page 2-11

Page 26

REMOTE INTELLIGENT SENSOR - AREA MONITOR

Figure 2-7 Figure 2-8

Page 2-12 Instruction 2772-0803

Page 27

REMOTE INTELLIGENT SENSOR - AREA MONITOR

K

3 SYSTEM OPERATION

AND FEATURES

3.1 COMPLETE SAMPLING

SEQUENCE

The sequence starts with system and cassette being

purged before gas sampling starts. In addition, a

reference light level reading is taken from the fresh

tape spot under the optics block.

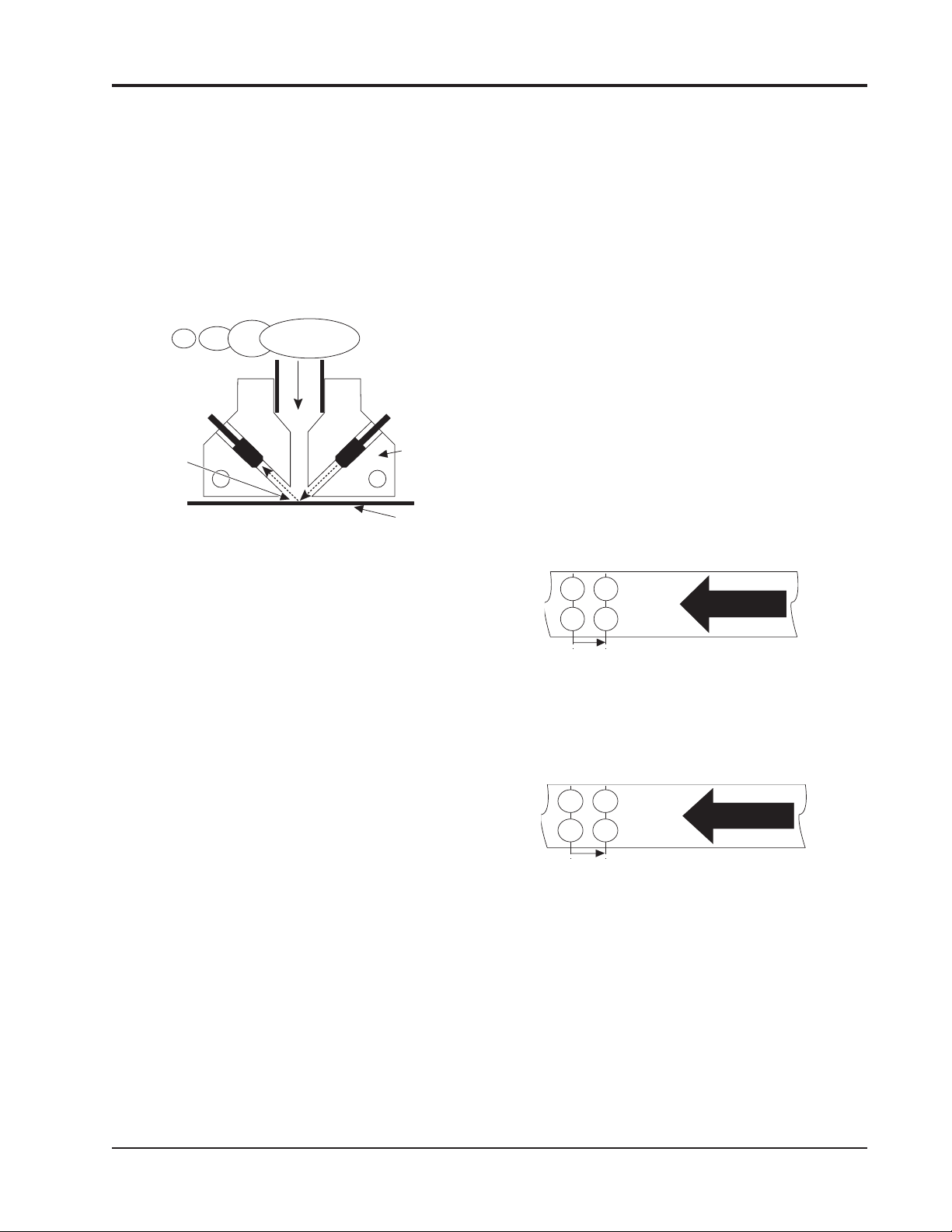

INCOMING

SAMPLE

PHOTO

DIODE

LIGHT

REFLECTED

OFF TAPE

SURFACE

Figure 3-1. Sampling Sequence

During the sampling period the tape spot is

scanned every two seconds. This frequent scanning

detects the change in the reflected light value that

occurs if a stain develops.

If no stain, or a low density stain, is detected,

sampling continues for a fixed four minutes. At the

end of this time calculated concentration for that

cycle is displayed and the next cycle starts.

The development of a significant stain shortens

the sampling cycle and the concentration value is

displayed immediately, as described in more detail

below.

When a concentration above alarm set point is

detected, the gas alarm relay/s opens to initiate

external alarm systems and warning devices. This

is in addition to the visual warning display.

3.1.1 AUTOMATIC PURGE CYCLE. A purge

sequence occurs after every tape step. The pump

runs at a higher Flow Rate for 10 seconds; air

inside the tape cassette, and the enclosure, is

exchanged for filtered air. The incoming air is

filtered as it passes through a ‘scrubber’ filter in

the cassette. This is shown in the diagram in

Figure 2-8.

Purging prevents the build up of gas in the

system, and in the cassette where it could preexpose the tape. The ‘scrubber’ filter is automatically renewed at each cassette change.

LIGHT

EMITTING

DIODE

TAPE

OPTIC

BLOC

Effective purging requires the enclosure to be

properly sealed. Ensure that the cable glands and

the door are air tight. Unused cable glands can be

tightened onto a short piece of cable.

Purge inlet and exhaust ports can be piped to a

remote location, where this is necessary.

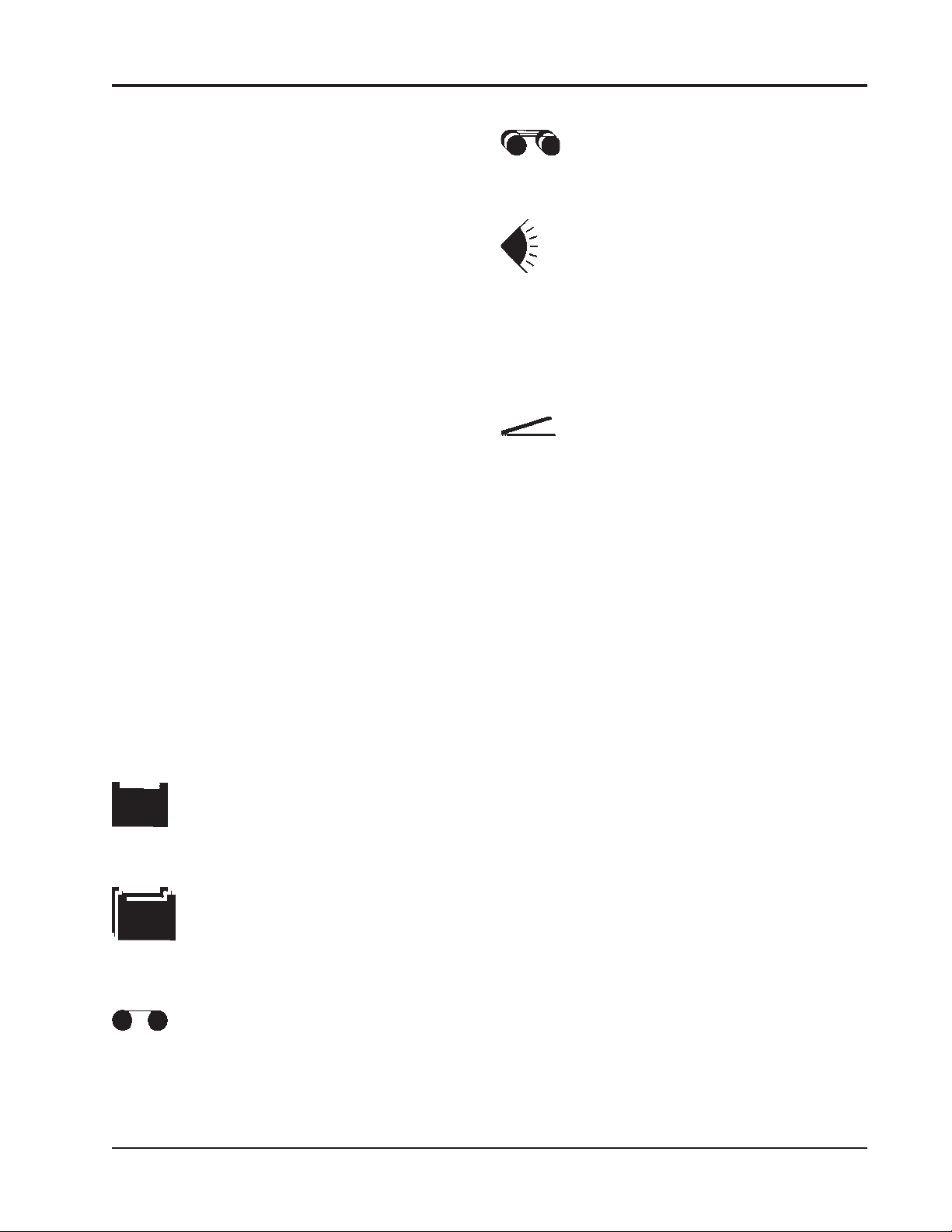

3.1.2 TWIN TRACK TAPE SAMPLING. At

start-up the incoming sample is passed through the

lower tape half (track 1). When that sampling period

is complete, the microprocessor decides if a stain has

formed on the tape. If not, the next sample is again

passed through the same spot on track 1. Conversely

if a stain was formed, the second sample is switched

to pass through the upper half (track 2). The same

sequence occurs at the end of that sample period and

track 2 is reused if no stain is detected.

At this point the tape is stepped on and the next

sample passed through the next track 1 spot. Figure

3-2 shows the sequence where no stain develops and

the maximum of four sample periods occurs before

the tape is stepped.

3/4 7/8

1/2 5/6

STEP

4 SAMPLE PERIODS OF 4 MINUTES EACH

= 16 MINUTES PER TAPE STEP

TRACK 2

TRACK 1

TAPE

Figure 3-2. No Stain, Both Tracks Used Twice

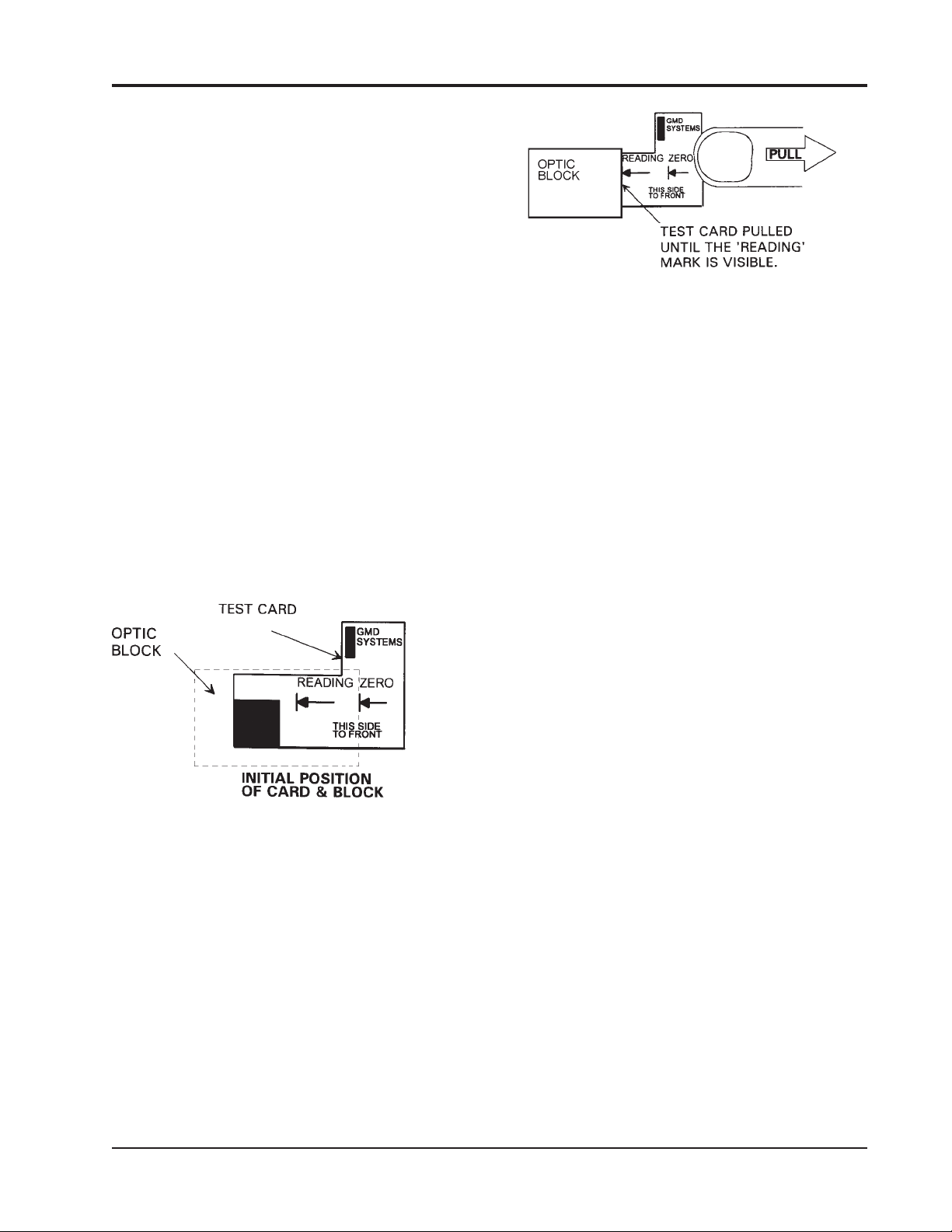

Figure 3-3 shows that only two sample periods

per tape step occur if significant stains develop on

the tape.

2 4

1 3

STEP

2 SAMPLE PERIODS PER STEP. EACH SAMPLE

PERIOD IS A MAX OF 4 MINUTES, OR LESS IF

THE STAIN IS SIGNIFICANT = 8 MINUTES PER

TAPE STEP

TRACK 2

TRACK 1

TAPE

Figure 3-3. Stain On Tape, Both Tracks Used Once

3.1.3 TAPE REFERENCE MEASUREMENT. At

the start of each sample period, the tape spot being

used is scanned by the light pulse (generated by the

optics system), see Figure 3-1. The value of the

reflected light is measured and stored as the reference against which the light value, during and at the

end of the sample period, is assessed..

Instruction 2772-0803 Page 3-1

Page 28

REMOTE INTELLIGENT SENSOR - AREA MONITOR

This method eliminates the ‘zero drift’ that

could otherwise occur with slight variation in the

reflective value of the tape. It also ensures that