Page 1

Instruction 2072-0400

Operation & Maintenance

Rev. 0 – March 2002

Product Leadership • Training • Service • Reliability

Page 2

WARRANTY

Bacharach, Inc. warrants to Buyer that at the time of delivery this Product will be free from defects in material

and manufacture and will conform substantially to Bacharach Inc.’s applicable specifications. Bacharach’s

liability and Buyer’s remedy under this warranty are limited to the repair or replacement, at Bacharach’s

option, of this Product or parts thereof returned to Seller at the factory of manufacture and shown to

Bacharach Inc.’s reasonable satisfaction to have been defective; provided that written notice of the defect shall

have been given by Buyer to Bacharach Inc. within one (1) year after the date of delivery of this Product by

Bacharach, Inc.

Bacharach, Inc. warrants to Buyer that it will convey good title to this Product. Bacharach’s liability and

Buyer’s remedy under this warranty of title are limited to the removal of any title defects or, at the election of

Bacharach, to the replacement of this Product or parts thereof that are defective in title.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN AND ACCEPTED IN LIEU OF (I)

ANY AND ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WITHOUT LIMITATION

THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE:

AND (II) ANY OBLIGATION, LIABILITY, RIGHT, CLAIM OR REMEDY IN CONTRACT OR TORT,

WHETHER OR NOT ARISING FROM BACHARACH’S NEGLIGENCE, ACTUAL OR IMPLIED. The remedies

of the Buyer shall be limited to those provided herein to the exclusion of any and all other remedies including,

without limitation incidental or consequential damages. No agreement varying or extending the foregoing

warranties, remedies or this limitation will be binding upon Bacharach, Inc. unless in writing, signed by a duly

authorized officer of Bacharach.

Note: The Filter Drier and Refrigerant Identifier Filter are considered consumable items, and are therefore not

covered under the terms of this warranty.

Register Your Warranty by Visiting

www.bacharach-inc.com

Notice:

Product improvements and enhancements are continuous; therefore the specifications and information

contained in this document may change without notice.

Bacharach, Inc. shall not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

No part of this document may be photocopied, reproduced, or translated to another language without the prior

written consent of Bacharach, Inc.

Copyright © 2002, Bacharach, Inc., all rights reserved.

®

BACHARACH

service marks and logos referenced herein belong to their respective owners.

is a registered trademark of Bacharach, Inc. All other trademarks, trade names,

A Instruction 2072-0400

Page 3

Contents MAC 2000

Table of Contents

1 Introduction .......................................................................................................... 1

1.1 Glossary of Terms..................................................................................................... 2

1.2 General Operating Guidelines................................................................................. 2

1.3 Component Location and Description .....................................................................3

1.4 Using the Function Keys..........................................................................................7

1.5 Using the Up/Down, Increase, Decrease, and Back/Forward Arrow Keys............7

2 Initial Set-Up ......................................................................................................... 9

2.1 Initial Set-Up Instructions ......................................................................................9

2.2 Checking Vehicles for Possible Contaminated Systems......................................11

2.3 External Source Tank Testing...............................................................................11

3 Operation ............................................................................................................. 13

3.1 MAC2000 Operational Overview...........................................................................13

3.2 Diagnosing A/C System Operation Using the Snap-Shot Mode ......................... 15

3.3 Recovery Mode........................................................................................................18

3.4 Vacuum Mode (Evacuation)...................................................................................19

3.5 Charge Mode........................................................................................................... 20

3.6 System Flush Mode (Oil Flush) .............................................................................22

3.7 Refrigerant Management System .........................................................................24

3.8 Internal Tank Manual Refill .................................................................................25

3.9 System Set Up ........................................................................................................ 26

3.10 Identify Refrigerant ...............................................................................................26

3.11 Check Internal Tank for Air .................................................................................. 27

4 Maintenance ........................................................................................................ 29

4.1 Changing the Filter Drier......................................................................................29

4.2 Replacing the External Source Tank ....................................................................30

4.3 Replacing the Printer Paper ..................................................................................31

4.4 Replacing the Refrigerant Identifier Filter...........................................................32

5 Parts and Service ............................................................................................... 33

5.1 Parts........................................................................................................................33

5.2 Service Centers....................................................................................................... 34

Instruction 2072-0400 i

Page 4

MAC2000

SERIES: MAC2000 Refrigerant: 134a

KENT MOORE: J-055000

Air Conditioning and Refrigerant

Service Solution

WARNING

PRESSURIZED TANK CONTAINS LIQUID REFRIGERANT. OVERFILLING OF THE TANK MAY CAUSE

VIOLENT EXPLOSION AND POSSIBLE INJURY OR DEATH. Safety devices require the use of only authorized

refillable tanks. Refer to the instruction manual for tank specifications and ordering information. Do not recover

refrigerants in a non-refillable storage container! Regulations require refrigerant to be transported only in

specifically authorized containers.

ALL HOSES MAY CONTAIN LIQUID REFRIGERANT UNDER PRESSURE. Contact with refrigerant may cause

injury. Wear proper protective equipment, including safety goggles. Disconnect hoses with extreme caution.

HIGH VOLTAGE ELECTRICITY INSIDE PANELS. RISK OF ELECTRICAL SHOCK. Disconnect power before

service unit. Refer to the instruction manual.

TO REDUCE RISK OF FIRE, avoid the use of an extension cord. The extension cord may

overheat. If you must use an extension cord, the cord must be 14 AWG minimum and as short as possible. Do not

use this equipment in the vicinity of spilled or open containers of gasoline or other flammable substances.

Use this equipment in locations with mechanical ventilation that provides at least four air changes per hour or

locate the equipment at least 18 inches above the floor.

Make certain that all safety devices are functioning properly before operating the unit. Before operating, read and

follow the instructions and warnings in the manual.

CAUTION: SHOULD BE OPERATED BY QUALIFIED PERSONNEL. Technician must be familiar with air

conditioning and refrigeration systems, refrigerants and the dangers of pressurized components.

Use with the R-134a refrigerant only. This equipment is not designed for any other purpose other than recovering,

recycling and charging refrigerants. Do not mix refrigerant types.

OPERATING NOTES

Change the filter-drier when the display shows Change Filter message. Follow the instructions for the changeover.

At temperatures exceeding 120 °F / °C, wait 10 minutes between recovery jobs.

R-134a WARNINGS!

Use the MAC2000 unit only with R-134a refrigerants. Cross-contamination with other refrigerant types will cause

severe damage to the A/C systems and to service tools and equipment. Do not mix refrigerant types through a

system or in the same container.

Avoid breathing A/C refrigerant and lubricant vapor mist. Exposure may irritate eyes, nose and throat. To remove

R-134a from the system, use service equipment certified to meet the requirements of SAE-J2210 (R-134a

recycling equipment). If accidental system discharge occurs, ventilate work area before resuming service.

HFC-134a service equipment or vehicle A/C systems should not be pressured tested or leak tested with

compressed air. Some mixtures of air/HFC-134a have been shown to be combustible at elevated pressures.

These mixtures are potentially dangerous and may result in fire or explosion causing injury or property damage.

Additional health and safety information may be obtained from refrigerant and lubricant manufacturers.

Instruction 2072-0400 ii

Page 5

MAC2000 Introduction

1 Introduction

Important! These instructions are for qualified personnel, trained and

experienced in the handling of refrigerants. Federal and state laws

may require the licensing of refrigerant handling personnel. Failure to

follow proper operating procedures may cause personal injury and

equipment damage

The Bacharach Test System’s Mobile Air Conditioning MAC2000 is

the most advanced refrigerant management system on the market

today. It is a complete automotive A/C service tool that will identify,

recover, recycle, flush and troubleshoot automotive R-134a A/C

systems in a fully automatic manner.

A large liquid crystal diode (LCD) display screen prompts the

technician for input and displays system status. An internal 30 pound

recovery tank and electronic scale ensure convenient refrigerant

storage and accurate refrigerant management.

Upon power up, the unit performs a self-test and, if necessary, a selfevacuation routine. The technician may then select the specific

function required for the job. During operation, the MAC2000 checks

for error conditions and alerts the technician if any exist.

The entire service procedure can be done with one hook-up to the

vehicle. A built-in refrigerant identifier checks for contaminated

refrigerant prior to recovery. Pressures are shown on the high and low

side gauges, and other operating information is shown on the screen.

Refrigerant is recovered into and charged out of an internal storage

tank. The MAC2000 unit automatically refills this tank with

refrigerant from an external source tank as needed in order to

maintain a constant 12–15 lbs (5.45–6.82kg) of refrigerant available

for charging. One quick connection is all that’s needed to replace the

source tank when it is empty.

Other time saving features include automatic air purge, single pass

recycling, and automatic oil drain. The unit also automatically clears

refrigerant from its high- and low-side hoses after every job. A red

light on top of the unit flashes whenever a process is complete or when

the unit needs attention from the technician.

The MAC2000 is ETL listed to UL standards and meets SAE

specifications for recycled refrigerant.

Instruction 2072-0400 1

Page 6

Introduction MAC2000

1.1 Glossary of Terms

A/C Air conditioner or air conditioning

A/C System The vehicle’s air conditioning system

Unit The MAC2000 itself

Screen LCD Display

Contaminated Refrigerant that has been mixed with some

other type of refrigerant.

1.2 General Operating Guidelines

• The MAC2000 monitors the AC line voltage and disables itself if

the voltage drops below 100 VAC or rises above 135 VAC. An error

message will be displayed on screen when the line voltage is out of

tolerance. The unit must be turned OFF and then back ON to reset

the voltage monitoring circuitry. Extension cords must be a

minimum of 14 AWG and kept as short as possible.

Common causes for electrical problems include:

- Long extension cords

- Faulty, overloaded electrical circuits

- Drop lights

- Improper ground or improper polarity

• The screen shows options and gives instructions for most service

and maintenance tasks. Read the on-screen prompts and follow

their instructions.

• The MAC2000 prompts a technician to check the system oil drain

bottle on the side of the unit for recovered oil. Any system oil that is

lost is automatically drained during recovery. A technician must

measure and record the lost amount of oil in order to know how

much new oil to add during charging. Refer to the A/C system

manufacturer’s service manuals for oil specifications. Dispose of

used oil properly.

• In general, it is best to leave the MAC2000 turned ON throughout

the workday. This allows the unit time to purge itself of air and

refill the internal storage tank. Turn the unit OFF at the end of the

day.

Instruction 2072-0400 2

Page 7

MAC2000 Introduction

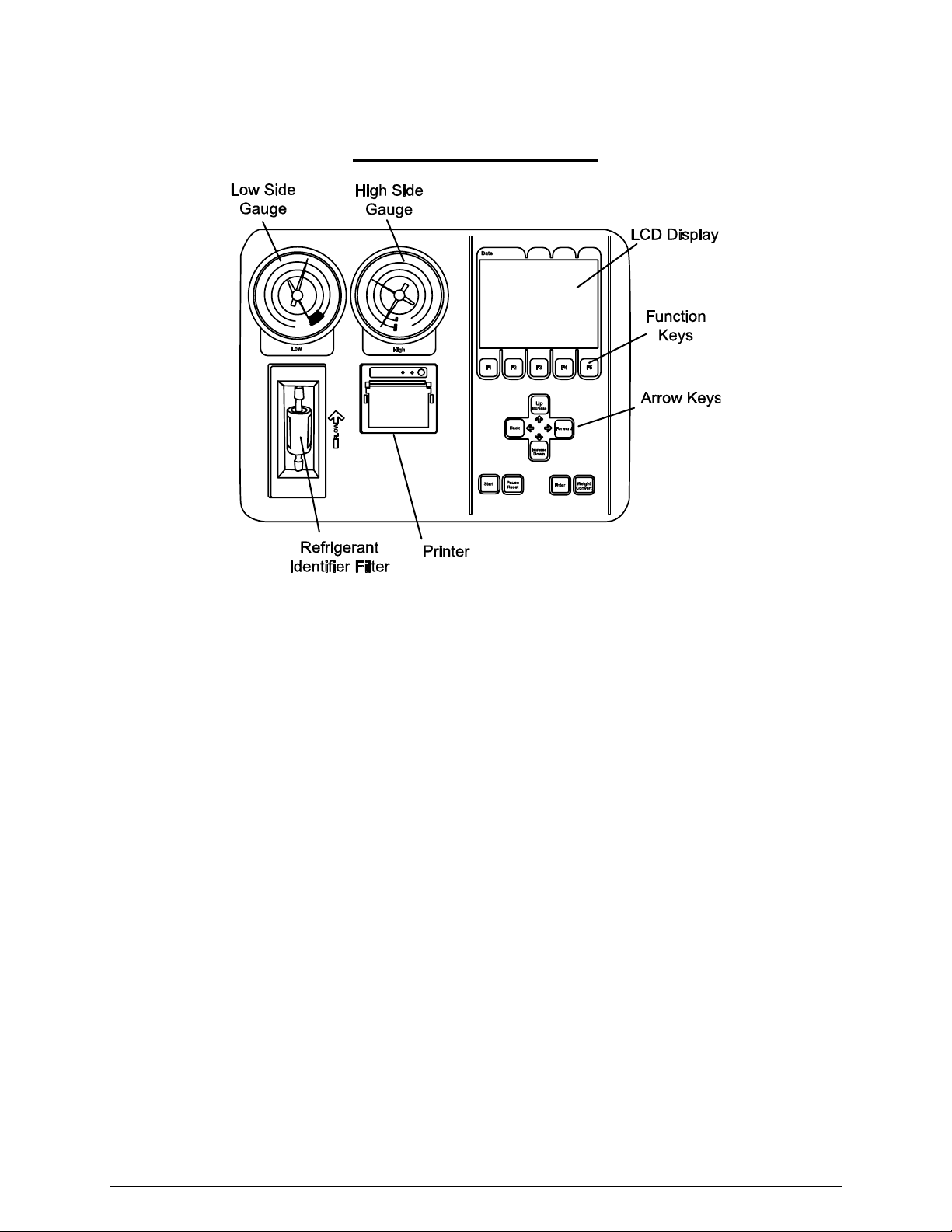

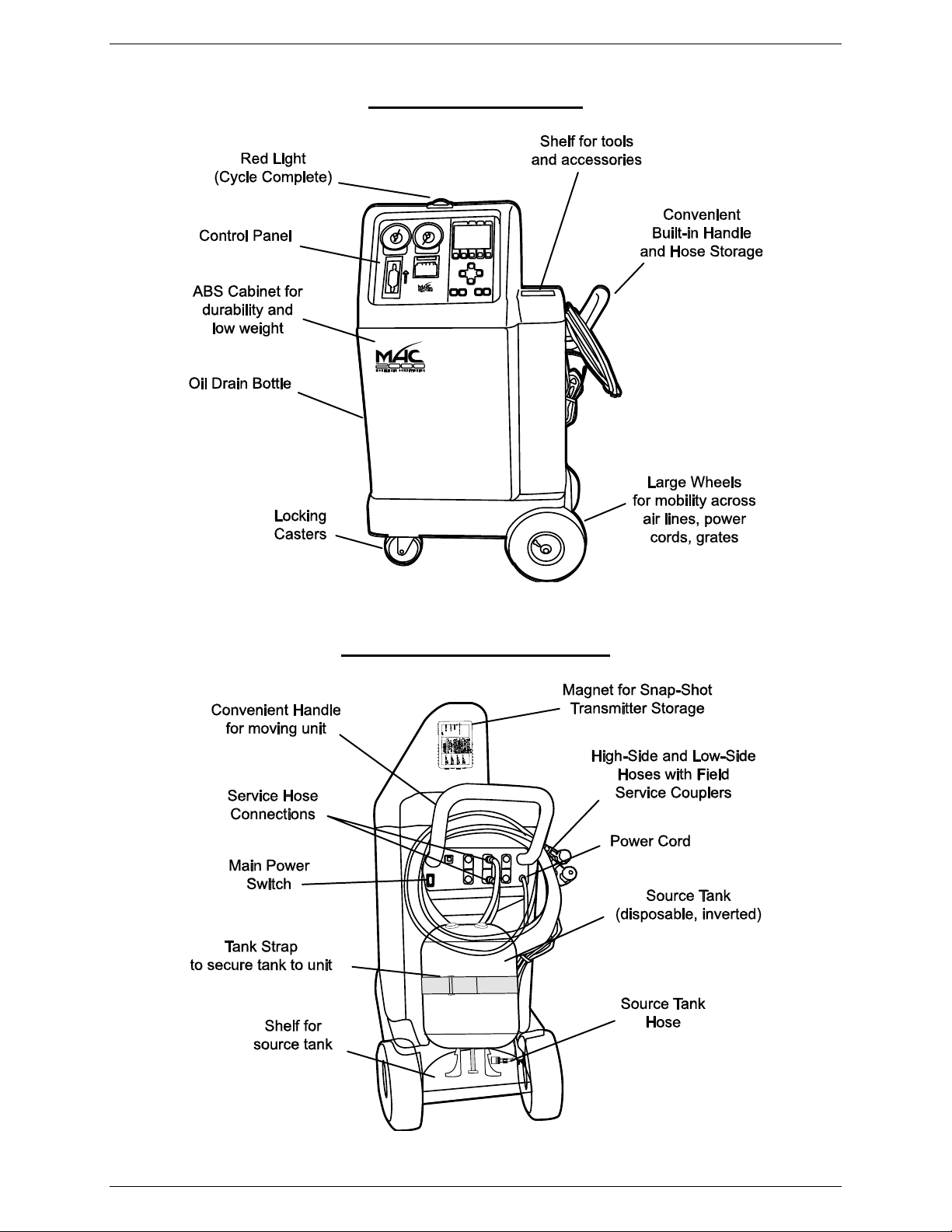

1.3 Component Location and Description

MAC2000 Control Panel

High Side Gauge – Shows the pressure in

the high side of the vehicle’s A/C system.

Low Side Gauge – Shows the pressure in

the low side of the vehicle’s A/C system.

LCD Display (Screen) – Displays all

operational, error, and maintenance

messages.

Refrigerant Identifier Filter – Protects the

refrigerant identifier sensor from

contaminants.

Printer – Provides a printed record of the

functions performed by the MAC2000. The

printer can print the record of the

MAC2000’s last operation as well as other

refrigerant management data and

operational statistics.

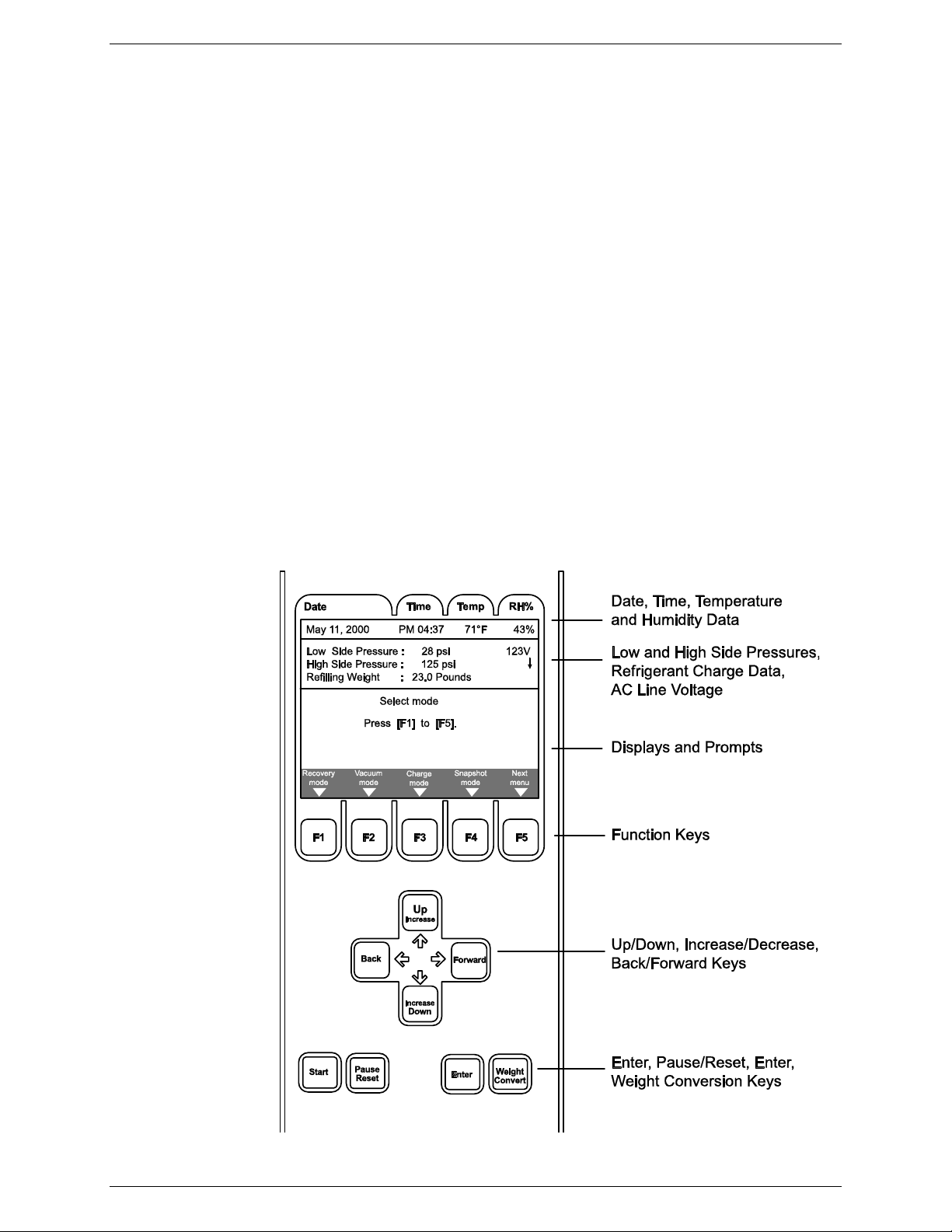

Start Key – Press to start a function.

Pause/Reset Key – Press to either pause,

reset, or abort a function and return the

display to the Main menu.

Enter Key – Press to accept a value as

displayed on the screen.

Weight Convert Key – Press to change

the charge amount between pounds,

pound & ounces, and kilograms. Pushing

this key allows a technician to scroll

through the different weight units.

Arrow Keys – Use these keys to select

variables and adjust values such as

charge weight and vacuum time. The

Increase and Decrease keys are used to

adjust numerical values, while the Back,

Forward, Left and Right keys are used to

move between values displayed on the

screen.

F1 – F5 Function Keys – Use these keys to

select various modes and functions on the

MAC2000. A key’s current function is

described directly above it on the screen.

Instruction 2072-0400 3

Page 8

Introduction MAC2000

MAC2000 Front View

MAC2000 Right-Side View

Instruction 2072-0400 4

Page 9

MAC2000 Introduction

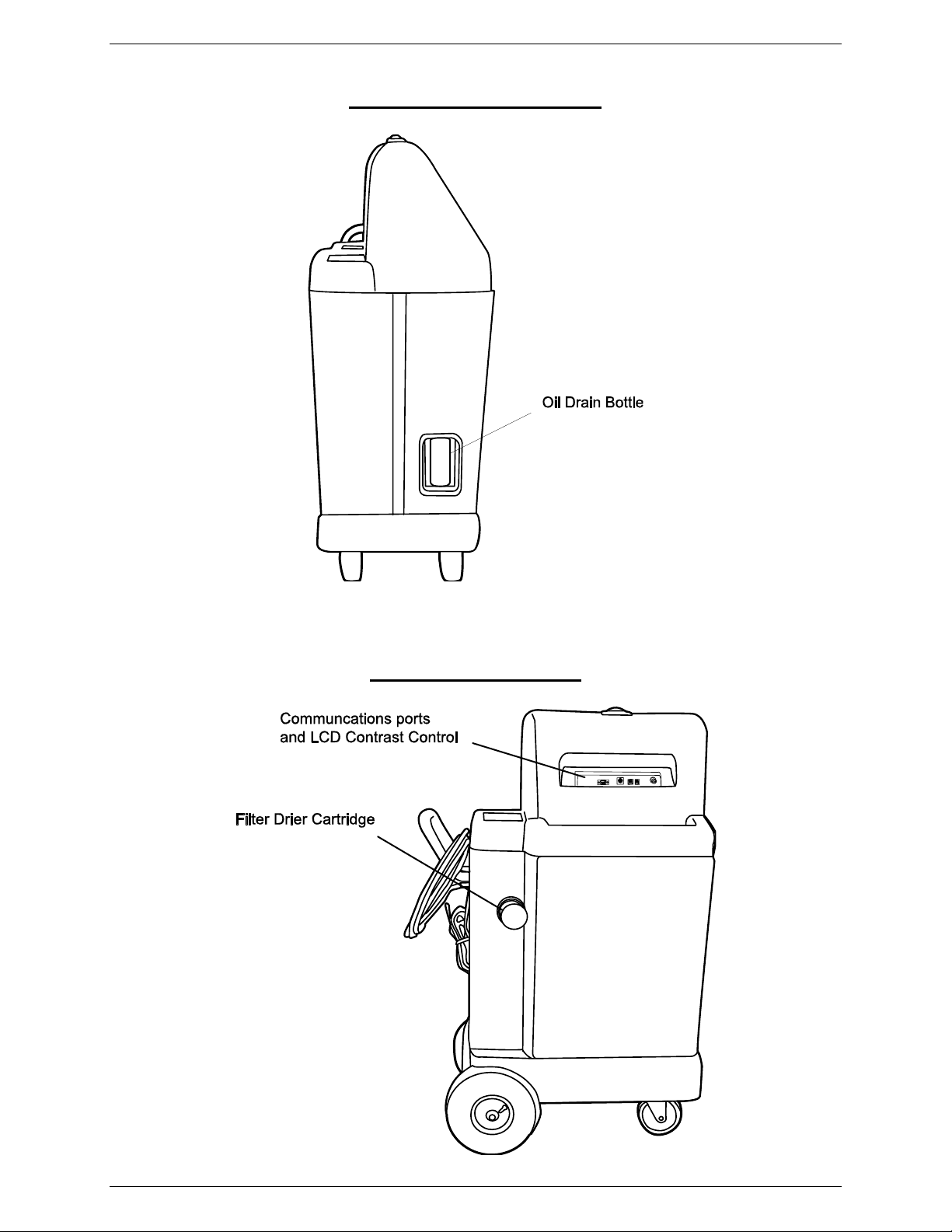

MAC2000 Left-Side View

MAC2000 Back View

Instruction 2072-0400 5

Page 10

Introduction MAC2000

Closeup of MAC2000 Handle Panel

Note: The auxiliary tank ports are not used as this time.

Temperature and Velocity Data Ports

Note: The communications ports are used for software updates and

future options, and are not used during normal operation.

Instruction 2072-0400 6

Page 11

MAC2000 Introduction

1.4 Using the Function Keys

The operation of each function key (F1–F5) depends on the service

operation and unit status. The display shows five labels along the

bottom of the screen pointing to the function keys below. Each label

shows the action the key will activate. To make a selection, press the

function key immediately below the arrow.

The Next menu function key takes the technician to the next set of

menu items. There will always be a menu item to take the technician

back to the main menu.

1.5 Using the Up/Down, Increase, Decrease, and Back/Forward Arrow Keys

Pressing the Up/Down and Back/Forward keys moves the cursor on

the screen in that direction. In addition, when entering numeric data,

pressing the Increase key will increase the number, while pressing

the Decrease key will decrease the number.

Instruction 2072-0400 7

Page 12

Introduction MAC2000

Notes:

Instruction 2072-0400 8

Page 13

MAC2000 Initial Set-Up

2 Initial Set-Up

2.1 Initial Set-Up Instructions

It is extremely important to follow these instructions! Improper

setup will result in potential inaccuracies when operating the unit.

1. Un-box the MAC2000.

2. Open the accessory box that contains the rear and side tray mats,

the high- and low-side service hoses, the snap-shot transmitter,

and one spare printer paper roll.

3. Drop the mats into the side and rear storage trays.

4. Attach the blue low-side service hose to the service-hose fitting

with the blue label, and attach the red high-side service hose to the

red service fitting.

5. Attach the snap-shot transmitter to its magnetic storage plate.

6. Install an external source tank of R-134a refrigerant on the lower

shelf of the unit, below the handle. The external source tank

should be inverted so liquid refrigerant is supplied to the internal

tank. The MAC2000 can handle 30 lb (14kg) or 50 lb (23kg)

commercial tanks. Secure the tank to the unit by placing the strap

around the tank and tightening it. WARNING: Failure to

secure the source tank properly could result in injury!

WARNING

Instruction 2072-0400 9

Page 14

Initial Set-Up MAC2000

7. Attach the yellow refill hose coming from behind the tank to the

source tank fitting. Open the source tank valve. To avoid the

possible of lost refrigerant, the external source tank should be

checked for leakage around the tank valve. If leakage is found,

close the valve and keep it closed at all times except during a

manual tank refill operation as described in Section 3.8.

Bacharach Test Systems does not reimburse for lost refrigerant.

8. Attach the unit’s power cord to 115VAC 50/60 Hz, 15 Amp

grounded outlet. Avoid using long extension cords.

9. Set the main Power switch (located under the handle) to ON.

10. There is a brief initialization period of several seconds. The

technician will be prompted to set-up the following parameters.

(This initial set-up procedure occurs only once when a new unit is

turned on. Subsequent changes can be made using the System SetUp mode per Section 3.9 at any time.)

a) Set Date & Time: Press the Enter key to change the date. Use

the Left/Right and Up/Down keys to make adjustments. Press

the Enter key again to save the changes.

b) Select Language: Select the preferred Language.

c) Select Units: English or Metric (English is the Default).

d) Calibrate the Pressure Transducers: Remove high- and low-

side hoses from side of unit; then follow on-screen prompts to

calibrate the pressure sensors.

e) Set Elevation: Enter the unit’s elevation above sea level for

your location ± 500 feet.

11. The MAC2000 now automatically evacuates all air from the

internal circuit and tank, and pre-charges the tank with 12 lbs of

R-134a. This process takes approximately 15 – 20 minutes.

Instruction 2072-0400 10

WARNING

Always wear eye protection when working with refrigerants.

Refrigerants can cause injury. Read and follow all warnings at the

beginning of this manual before operating this unit.

CAUTION! R-134a systems have special fittings (per SAE

specifications) to avoid cross contamination with R12 systems. Do not

attempt to adapt your unit for another refrigerant type system, or

failure will result!

12. The MAC2000 is now set-up and ready for operation.

Page 15

MAC2000 Initial Set-Up

2.2 Checking Vehicles for Possible Contaminated Systems

Before every recovery, the MAC2000 automatically samples the

refrigerant in the vehicle’s A/C system. If the system fails the purity

level required, the unit tests a second time. In the event the system

fails a second time, the unit prompts that the hoses be disconnected

from the vehicle. Follow the on-screen prompts in order to clean out

the MAC2000.

Note: The MAC2000 must be disconnected from the vehicle before

starting the cleaning process. It is illegal to knowingly vent or allow

refrigerant to vent to the atmosphere. This illegal venting will occur if

the unit is left attached to the vehicle.

Please refer to your shop’s policy for dealing with contaminated

refrigerant.

2.3 External Source Tank Testing

The MAC2000 features an exclusive source tank refrigerant

identification process that checks the source refrigerant before it is

added to the unit’s internal tank. This testing is automatic and does

not require any action by the technician. This feature prevents

contaminated refrigerant from entering the MAC2000, thus rendering

it inoperable.

Instruction 2072-0400 11

Page 16

Initial Set-Up MAC2000

Notes:

Instruction 2072-0400 12

Page 17

MAC2000 Operation

3 Operation

3.1 MAC2000 Operational Overview

The MAC2000 is an EPA-approved, ETL-listed, single-pass recycling

system. During the recovery operation, refrigerant is removed from

the vehicle and passed through an oil separator and filter drier before

entering the storage tank.

The MAC2000’s refrigerant weighing system is extremely accurate. It

has sophisticated error correction capability that minimizes incorrect

readings caused by bumps or vibration. Even with this protection,

however, the MAC2000 should be placed on level ground and out of

the way of foot traffic. Do not touch or move the unit while it is

operating!

To ensure that the displayed reading of recovered refrigerant is

accurate, the unit will perform a low side clearing routine, if

necessary, when the power is turned on. If refrigerant is sensed in the

accumulator, the screen will display “Clearing System”. This

indicates refrigerant in the accumulator is being transferred to the

storage tank.

At any time during system operation, pressing the Weight Convert

key can change the weight units. The available units are pounds only,

pounds & ounces, or kilograms.

Power Up – When power is applied, the unit performs a selfdiagnostics. When these tests are complete, the display shows “Select

mode.”

Main Data Display – (See illustration of Main Data Display in

Section 1.5 on Page 7.) Shows the date, time, ambient temperature,

RH%, AC line voltage, low- and high-side pressures, and the amount

of refrigerant available for charging. Use the function keys (F1 – F5)

to select the desired mode as described in the following paragraphs.

Instruction 2072-0400 13

Page 18

Operation MAC2000

Main Menu

Recovery Vacuum Charge Snapshot Next

mode mode mode mode menu

• Recovery mode – Recovers and recycles refrigerant from a vehicle’s

A/C system. This mode is most often used prior to opening an A/C

system to atmosphere to replace a system component.

• Vacuum mode – Removes residual air and moisture from a system

previously opened to the atmosphere. This mode also allows a

technician to verify that the A/C system will hold a vacuum for a

certain length of time.

• Charge mode – Select this mode to add refrigerant to an A/C

system; also most commonly used to “top off” the system.

• Snap-Shot mode – Monitors and records important operating

information including the high- and low-side pressures, ambient

temperatures, A/C vent temperatures, ambient humidity, and

(optionally) vent air flow velocities. This information is used to

diagnose and measure A/C performance before and after service.

• Next menu – Displays Menu 2.

Menu 2

Main System Tank System Next

menu flush refill set-up menu

• Main menu – Returns display to the Main menu.

• System flush – Removes all oil and refrigerant from an A/C system.

This mode is often used prior to retrofitting a system to R-134a.

• Tank refill – Overrides the automatic tank refill function of the

MAC2000 and transfers refrigerant from the external source tank

to the internal storage tank.

• System set-up – Sets up certain operating parameters in order for

the MAC2000 to operate correctly. The set-up information must be

entered prior to operating the MAC2000.

• Next menu – Displays Menu 3.

14 Instruction 2072-0400

Page 19

MAC2000 Operation

Menu 3

Main Identify Check Refri Filter

menu mode tank air data change

• Main menu – Returns display to the Main menu.

• Identify mode – Identifies refrigerant in a vehicle’s A/C system

without having to recover the refrigerant. After the unit is finished

identifying the refrigerant the display returns to the Main menu.

• Check tank air – This option allows a technician to manually check

the internal source tank for air and other non-condensables, and

then purges the tank if too much air is present.

• Refri data – Accesses the unit’s historical refrigerant data.

• Filter change – Removes refrigerant from the filter dryer prior to

its replacement.

3.2 Diagnosing A/C System Operation Using the Snap-Shot Mode

WARNING

Always wear eye protection and protective clothing when working

with refrigerants. Observe all warnings at the beginning of this

manual. Be sure the vehicle is in PARK before turning on the engine.

Provide adequate ventilation or pipe exhaust to outside. Vehicle

exhaust fumes can cause injury or death.

To assist in system diagnostics, the MAC2000’s Snap-Shot mode

allows a technician to monitor and record the following key operating

information from the vehicle being serviced. This data can be collected

before and after servicing to show any changes in performance of a

vehicle’s A/C system.

• Date and Time

• Ambient Temperature & Humidity

• Low Side System Pressure, minimum and maximum values

• High Side System Pressure, minimum and maximum values

• Front Duct Temperature, minimum value

• Rear Duct Temperature, minimum value

• Refrigerant Identifier Results

Instruction 2072-0400 15

Page 20

Operation MAC2000

Data is collected from inside the vehicle’s passenger compartment by

means of the snap-shot transmitter (shown below). This transmitter is

powered from the vehicle’s cigarette-lighter, and wirelessly transmits

temperature (and optional air flow) data to the MAC2000.

Snap-Shot Transmitter

Red Temperature Sensor – This sensor should be used on the front

A/C vent in the vehicle. The temperature is displayed as “RED

TEMPERATURE” on the Snap-Shot mode screen.

Blue Temperature Sensor – This sensor should be used on the rear

A/C vent. The temperature is displayed as “BLUE TEMPERATURE”

on the Snap-Shot mode screen.

Anemometer (optional) – The optional Anemometer measures airflow.

This sensor can be purchased separately.

Communications Port – Used to connect the transmitter directly to

the MAC2000 via a cable (instead of transmitting data wirelessly).

This port is not normally used, and requires a cable (not included).

Enter the Snap-Shot mode as follows:

1. If not already done, plug the MAC2000 into a properly grounded

AC outlet; set the Power switch to ON; then wait until the unit

completes its self diagnostics. The screen will display “Select

mode” when ready.

2. Press the Snapshot mode function key to select the Snap-Shot

mode.

16 Instruction 2072-0400

Page 21

MAC2000 Operation

3. Follow the instructions on the screen. A technician will be

instructed to connect the high- and low-side service hoses to their

respective service ports on the vehicle’s A/C system and open the

A/C system’s service-port valves. Connect the red and blue

temperature sensors, start the vehicle, then turn the vehicle’s A/C

system to its maximum cool or re-circulating setting.

4. Press the unit’s Start key.

5. After identifying the refrigerant in the vehicle, the MAC2000

displays and updates the minimum and maximum values as

shown on the display. The snap-shot display can now be used to

monitor the performance of the vehicle’s A/C system.

6. While in the snap-shot mode, the following operations can be

performed:

Main Capture Reset Recover

menu (Print)

• Main menu – Returns display to the Main menu.

• Capture (Print) – Prints the following data:

Date :May 18, 2001

Time :PM 02:14

Low PSI :(min) 17 (max) 18

High PSI :(min) 17 (max) 18

Duct Air Flow. : (max) 0 ft/m

Blue vent. Temp.: (min) 8 F

Red vent Temp. : (min) 73 F

Ambient Temp. : 73 F

Ambient Humidity: 49 RH%

RECOVERABLE

R134a: 99.9% R12 : 0.0%

R-22: 0.0% HC : 0.0%

AIR: 1.5%

---Snap-shot report--

---Identifier result ---

---Snap-shot encrypted code--001 Q54 L6G 028 M94 H29

• Reset Values – Resets and begins tracking new min. and max.

values.

• Recover – Starts a recovery operation.

Instruction 2072-0400 17

Page 22

Operation MAC2000

3.3 Recovery Mode

The recovery mode removes all refrigerant from the vehicle’s A/C

system and stores it in the unit’s internal storage tank. Before

recovery begins, however, there must be pressure in the hoses. This

prevents inadvertent recovery of air or other contaminants from a

leaking system. The MAC2000 will automatically sense the presence

of refrigerant and confirm that it is not contaminated before starting

the recovery process.

Begin the refrigerant recovery process as follows:

1. If not already done, plug the MAC2000 into a properly grounded

AC outlet; set the Power switch to ON; then wait until the unit

completes its self diagnostics. The screen will display “Select

mode” when ready.

2. Press the Recovery mode function key and observe the following

message: “Hook-up the service hoses to vehicle.”

3. At this time hook up the service hoses, open the A/C system’s

service-port valves, and then press the unit’s Start key. The

refrigerant identifier will warm up, zero itself, and then display

the message “Analyzing sample, please wait . . .”

If the refrigerant is contaminated (meaning that it has somehow

been mixed with some other kind of refrigerant), the results will be

displayed along with the word “contaminated.” Note that the

unit will not allow the recovery operation to proceed when

refrigerant is contaminated.

If the refrigerant is found to meet specifications, the unit will

automatically proceed to recover the refrigerant. During the

recovery operation, refrigerant is removed from both the high and

low side of the vehicle’s A/C system. The screen will display

“Recovering refrigerant” along with showing the amount of

refrigerant being recovered.

4. When the A/C system has been recovered to a minimum vacuum of

9 inHg, the recovery process automatically stops. The following

events then occur:

• The unit’s red light flashes and the beeper sounds, signaling

the technician that recovery is complete.

• The screen reads “Recovery complete” and shows the weight

of the recovered refrigerant.

• System oil is automatically drained into the oil drain bottle (see

MAC2000 Left-Side View, Page 5).

18 Instruction 2072-0400

Page 23

MAC2000 Operation

Note: The MAC2000 will automatically restart the recovery process

if the unit senses a rise in the A/C system’s pressure.

5. After recovering the refrigerant from the A/C system, close the

service-port valves, and then remove the hoses from the vehicle.

Observe that the service hoses should remain under vacuum. This

ensures that no contaminants are introduced into the A/C system

during a recharge process.

6. The technician can now begin repairs on the A/C system.

3.4 Vacuum Mode (Evacuation)

The Vacuum mode is used to remove residual air and moisture from

the vehicle’s A/C system by pulling the system into a deep vacuum.

This mode is most often used after completing a repair that required

opening the A/C system to the atmosphere. Moisture and/or air in an

A/C system can cause erratic operation and must be removed before

recharging the system with refrigerant.

Evacuate a vehicle’s A/C system as follows:

1. If not already done, plug the MAC2000 into a properly grounded

AC outlet; set the Power switch to ON; then wait until the unit

completes its self diagnostics. The screen will display “Select

mode” when ready.

2. Connect the high- and low-side service hoses to their respective

service ports on the vehicle’s A/C system; then open the A/C

system’s service-port valves.

3. Press the Vacuum mode function key and observe that the screen

reads “Set VACUUM TIME now.” The minimum evacuation time

is 3 minutes. To change this time, press and hold the Increase key

until the desired time is shown.

4. Press the Start key to begin the evacuation process.

Note: Before evacuation begins, the MAC2000 checks if pressure is

present in the vehicle. If pressure is sensed, the unit will display the

message: “Error: You have pressure in the hoses. You must

first recover this refrigerant before proceeding.” If this error

message appears, first abort the evacuation process by pressing the

Reset key, recover the system per Section 3.3, then restart the

evacuation process by pressing the Vacuum mode function key.

5. The evacuation process continues for the amount of time set in

Step 3. If a vacuum level of at least 27 inHg is not achieved within

the prescribed time, the evacuation process automatically

continues for a maximum of 7 minutes, or until 27 inHg is

Instruction 2072-0400 19

Page 24

Operation MAC2000

achieved. When the A/C system reaches the proper vacuum, the

unit’s red light and beeper signal evacuation is complete, and the

screen reads “Vacuum complete.” If the proper vacuum is not

achieved after 7 minutes of evacuation, the process stops, and the

technician is prompted to check for a leak.

Note: Depending on the altitude, the A/C system may not be able to

achieve 27 inHg. It is important that the altitude setting in the SetUp menu is correct for your location. The MAC2000 uses this

information to calculate and provide an equivalent set point for

your altitude. (For instance, at 6000 feet the equivalent set point

for your altitude pulls to 22 inHg before completing evacuation).

6. Press the Reset key to return to the Main menu.

7. The technician can now proceed to charge the system.

3.5 Charge Mode

The Charge mode is designed to add a precise amount of refrigerant to

the vehicle’s A/C system. This mode can be used to either “top off” a

system, or do a complete recharge after the system has been evacuated

or flushed. The unit has a built-in default charge amount of 2 pounds

(0.91 kg). Other charge amounts can be entered in increments of

either 0.06 pounds, 1 ounce, or 0.02 kg.

1. If not already done, plug the MAC2000 into a properly grounded

AC outlet; set the Power switch to ON; then wait until the unit

completes its self diagnostics. The screen will display “Select

mode” when ready.

2. Press the Charge mode function key and observe that the message

“Hook-up the service hoses to vehicle” should appear. If not

already done, connect the high- and low-side service hoses to their

respective service ports on the vehicle’s A/C system, and then open

the system’s service-port valves.

Note that at the start of this step, before the service hoses are

connected, the MAC2000 first checks if the service hoses are under

a vacuum. This prevents air and other contaminants from being

introduced into the A/C system. If the message “The vehicle is

not properly evacuated” appears, perform one of the following:

• If the refrigerant in the A/C system has just been recovered,

evacuate both the system and the service hoses per Section 3.4.

• If the A/C system needs to be “topped off,” first ensure that the

service hoses are disconnected from the vehicle; then either

recover the hoses per Section 3.3 if they contain refrigerant, or

evacuate the hoses per Section 3.4 if they contain air.

20 Instruction 2072-0400

Page 25

MAC2000 Operation

3. After entering the Charge mode, the following options are

available:

• Press the Enter key to accept the 2.00 pound Default.

• Press the Weight Convert key to change the “Set charge

weight” units.

• Use the Increase or Decrease keys to set the desired charge

amount. Select the next higher value if the exact charge

amount cannot be entered. Press Enter to accept the charge

amount shown on the screen.

Note: The MAC2000 charges in one-ounce increments, regardless of

which unit of measure is selected. This means that sometimes the

exact charge amount cannot be entered. For example, the A/C

system may require a 1.03 kg charge. The MAC2000 will only allow

a setting of 1.02 kg or 1.04 kg. In this instance, always select the

next higher value. This difference is only 0.3 of an ounce, which will

not affect the vehicle’s A/C performance.

4. By default the MAC2000 charges liquid refrigerant directly into

the high side of the A/C system. A technician, however, may choose

to charge into both the high and low side by pressing the Low side

ON-OFF function key. Pressing this key toggles the low-side option

on and off. Important! Charging liquid directly into the low side of

the compressor could slug the compressor and cause permanent

damage. Check with the compressor manufacture before proceeding.

5. The screen should now show the amount of refrigerant set for

charging. Press the Start key to begin the charging process.

During the charging process, liquid refrigerant is drawn from the

unit’s internal storage tank and charged through the high side

(and optionally the low side) of the vehicle’s A/C system. The

screen will show the progress of this charging process.

Important! Do not disturb or bump the MAC2000 during charging

as any jarring movement can affect the charge accuracy.

Note: If an insufficient pressure differential exists between the tank

and the system, charging suspends and the MCR2000 goes into a

power-charge mode to increase tank pressure to complete the

charge. This normally occurs only when the unit has been in a very

cold environment prior to use.

6. When charging is complete, the red light and beeper signal that

the process is complete. The MAC2000 automatically goes into the

Snap-Shot mode, thus allowing a technician to obtain an afterservice snap-shot of important operating parameters of the A/C

system. Refer to Section 3.2 for details.

Instruction 2072-0400 21

Page 26

Operation MAC2000

7. If more refrigerant needs to be added, press the Additional Charge

function key. Otherwise, press the Done function key to exit the

Snap-Shot mode.

8. Close the service-port valves; remove the service hoses from the

vehicle; then press the Start key to recover the hoses.

Important!

Start key is pressed, the refrigerant in the vehicle will be recovered!

If the hoses are not removed from the vehicle before the

9. If any oil was removed during the recovery or evacuation process,

make sure that the proper amount of oil is added back into the

vehicle’s A/C high side port in accordance with the vehicle

manufacturer’s recommendations. Add an amount of new oil equal

to the amount collected in the oil drain bottle (see MAC2000 LeftSide View, Page 5).

3.6 System Flush Mode (Oil Flush)

The System Flush mode is designed to be used on General Motors

vehicles using their Oil Flush Adapter and Filter accessory. This

accessory is attached inline with the vehicle’s compressor and is used

to flush the A/C system with refrigerant. In this mode, refrigerant is

circulated through both the A/C system and the MAC2000 where an

oil separator removes the oil and returns oil-free refrigerant back into

the A/C system for further flushing. At the end of the cycle, the

refrigerant is completely removed from the A/C system and stored in

the unit’s internal storage tank. The flushing process can take up to

30–45 minutes to complete. Because of the variety of A/C system

configurations currently in service, the flush may bypass certain

sections of the A/C system. To ensure the complete system is flushed,

the technician may need to pinch off certain hoses to force the

refrigerant flush throughout the system.

1. Before beginning the flushing process, recover all refrigerant from

the vehicle’s A/C system per Section 3.3 Recovery Mode.

2. From the Main menu, press the Next menu function key to display

Menu 2, and then press the System flush function key to select the

System Flush mode. The unit reminds the technician to “Please

empty the purge oil bottle prior to flushing.”

3. Press Start to continue. The unit now reminds the technician to

install the inline flushing adapter and remove the orifice tube or

TXV valve before continuing.

4. If not already done, connect the high- and low-side service hoses to

their respective service ports, and ensure that the service-port

valves are open.

22 Instruction 2072-0400

Page 27

MAC2000 Operation

5. Again press Start to continue. The unit now displays “Set Flush

Time.” Set the flush time by pressing and holding down the

Increase or Decrease key until the desired time is shown. Press

Start to accept the flush time shown on the screen. A minimum

flush time of 30 minutes is recommended.

Important! There must be a minimum of 12 pounds of refrigerant in

the internal storage tank in order to complete the System Flush

process. A message will be displayed if additional refrigerant needs

to be added. Add additional refrigerant by following the procedure

described in Section 3.8 Internal Tank Manual Refill.

6. Press the Start key to begin flushing. The MAC2000 begins

flushing the A/C system in the following manner:

• The A/C system is first completely filled with refrigerant,

during which time the screen shows “Flushing – Charging.”

• The system is now flushed for the time duration set in Step 5,

during which time the screen shows “Flushing system.”

• After the system is flushed, all refrigerant is automatically

recovered. The screen shows “Recovering refrigerant”

during this process.

• The flush cycle completes by draining the oil that was removed

during the flushing process into the unit’s oil drain bottle (see

MAC2000 Left-Side View, Page 5). The screen shows

“Draining oil” during this process.

Important! All oil was removed from the A/C system during the

System Flush operation. Be sure that the proper amount of oil is

added back into the vehicle’s A/C high side port in accordance with

the vehicle manufacturer’s recommendations.

7. The unit beeps and its red light flashes to indicate that the

flushing cycle is complete. The screen now reminds the technician

to remove the inline flushing adapter, and to reinstall the orifice

tube or TXV valve.

8. Evacuate and then recharge the A/C system per Sections 3.4

and 3.5.

Instruction 2072-0400 23

Page 28

Operation MAC2000

3.7 Refrigerant Management System

The MAC2000’s Refrigerant Management System tracks all aspects of

refrigeration usage, which can significantly help in the management

of an A/C repair business. In addition, the unit’s software allows a

business to meet new federal regulations requiring strict records of

refrigerant usage.

Refrigerant measurement during charging is extremely accurate. In

the recovery mode, however, accuracy is plus or minus 3 ounces based

on variations in air temperature and pressure.

Uses of the refrigerant data include:

• Improved record keeping

• Accurate determination of net profits for your business

• Reduced billing errors

• Minimized refrigerant loss from leaks and theft

• Reduced technician errors

Enter the Refrigerant Management mode as follows:

From the Main menu, press the Next menu function key twice to

display Menu 3; then press Refri Data to select the Refrigerant

Management Mode.

The first screen displays the following information in the “Last job

refrigerant management data” screen:

• Date & time ......Date and time the job was started

• Mode .................Lists what job was performed: recovery, charging,

vacuum, or flush

• Run time ...........Time it took to complete the job

• Status ...............Describes whether the job was normally completed

or interrupted

• Recovered .........Weight of refrigerant recovered from vehicle

• Charged ............Weight of refrigerant charged into vehicle

• Added ................Weight of refrigerant transferred from the external

source tank to the internal storage tank

Pressing Next displays the following data in the “Total refrigerant

management data” screen:

• Total # Of Jobs ..Total time spent doing all jobs, and number of all

jobs that were performed

• Total Recovery...Time spent doing recovery and number of times it

was performed

• Total Vacuum....Time spent doing evacuation and number of times

it was performed

• Total Charge .....Time spent charging and number of times it was

performed

24 Instruction 2072-0400

Page 29

MAC2000 Operation

• Total Flush ........Time spent flushing and number of times it was

performed

• Recovered .........Total amount of refrigerant recovered

• Charged ............Total amount of refrigerant charged

• Added ................Total amount of refrigerant transferred from the

external virgin tank to the internal storage tank

• Filter life left .....Weight of refrigerant that can be charged before

the Filter Dryer needs replaced

Pressing Next again displays the “Job history” screen, which

contains the history of each job performed. A technician can press the

UP and Down keys to scroll through the last 75 jobs.

Tips: Holding down the Up or Down key speeds up scrolling.

The total screen can be cleared by entering the Set-up mode and

selecting “Clear totals?”

Job history can be cleared by entering the Set-up mode and selecting

“Clear job history?”

3.8 Internal Tank Manual Refill

When the MAC2000 remains turned ON during the day, the unit

automatically refills the internal tank with refrigerant from the

external source tank. An operator, however, can manually add

refrigerant as follows:

1. If not already done, plug the MAC2000 into a properly grounded

AC outlet; set the Power switch to ON; then wait until the unit

completes its self diagnostics. The screen will display “Select

mode” when ready.

2. Press the Next menu function key to display Menu 2. Then press

the Tank refill function key to begin the refill process.

Note: If the tank is already filled with 12 lbs or more of refrigerant,

then the message “Tank already full” appears.

3. Press the Start key to continue. The screen will then display “The

internal tank is now being refilled.” When the internal tank is

filled, the screen displays “Tank refill complete.”

4. Press the Reset key to return to the Main menu.

Instruction 2072-0400 25

Page 30

Operation MAC2000

3.9 System Set Up

When the MAC2000 is initially turned on for the first time, the unit

automatically enters its System Set-Up mode. The unit must then be

set up by following the on-screen prompts before it can be used.

To change the data that was entered during the initial set-up process,

or to perform other functions such as clearing job history or

recalibrating the pressure transducers, re-enter the System Set-Up

mode as follows:

1. If not already done, plug the MAC2000 into a properly grounded

AC outlet; set the Power switch to ON; then wait until the unit

completes its self diagnostics. The screen will display “Select

mode” when ready.

2. Press the Next menu function key to display Menu 2. Then press

the System set-up function key.

3. Follow the on-screen prompts to enter the following data or

perform the following procedures:

• Time & Date

• Language

• Use Metric units (Yes or No)

• Calibrate Pressure Transducers (remove service hoses from the

unit’s Service Hose Fittings and follow on-screen prompts)

• Elevation above sea level

• Clear error flags

• Clear job totals

• Clear job history

• Print data after every job

4. Press the Reset key at any time to save the settings and return to

the Main menu.

3.10 Identify Refrigerant

Before performing any maintenance work a technician can determine

the following information about the vehicle’s refrigerant

• Whether the refrigerant in the A/C system

can or cannot be recovered

• % R-134a

• % R-22

• % R12

• % Air

• % HC (Hydrocarbons)

26 Instruction 2072-0400

Page 31

MAC2000 Operation

Perform a refrigerant identity check as follows:

1. If not already done, plug the MAC2000 into a properly grounded

AC outlet; set the Power switch to ON; then wait until the unit

completes its self diagnostics. The screen will display “Select

mode” when ready.

2. Press the Next menu function key twice to display Menu 3. Then

press the Identify mode function key.

3. Hook up the service hoses, open the A/C system’s service-port

valves, and then press the unit’s Start key. At this time the

refrigerant identifier will warm up, zero itself, and then display

the message “Analyzing sample, please wait . . .” When

complete, the results of the identification process will be displayed.

4. Press Reset to exit the identification screen.

5. Close service-port valves, and remove service hoses from vehicle.

6. Press Start to begin recovering the hoses. During the recovery

process the message “Clearing hoses, please wait . . .” is

displayed. After recovery is complete, the Main menu will appear.

3.11 Check Internal Tank for Air

When the MAC2000 remains turned ON during the day, air is

automatically purged from the internal storage tank. A technician,

however, can manually check and purge the internal tank of air and

any other non-condensable gases as follows:

1. If not already done, plug the MAC2000 into a properly grounded

AC outlet; set the Power switch to ON; then wait until the unit

completes its self diagnostics. The screen will display “Select

mode” when ready.

2. Press the Next menu function key twice to display Menu 3. Then

press the Check Tank Air function key.

3. Press the Start key. The refrigerant identifier will first warm up,

zero itself, and then display the message “Analyzing sample,

please wait …” When complete, the results of the identification

process will be displayed.

Instruction 2072-0400 27

Page 32

Operation MAC2000

4. Depending on the percentage of air found in the internal tank,

perform one of the following:

• If the display shows “Identifier result: EXCESSIVE,” then

purge the tank by first pressing the Reset key to display the

message “Would you like to purge air?” Then press the Start

key to begin purging air. When complete, the Main menu will

appear. Repeat Steps 2, 3, and 4 until the percentage of air

within the internal tank is at an acceptable level.

• If the display shows “Identifier result: RECOVERABLE,”

then the amount of air within the tank is at an acceptable

level. Press the Reset key to display the message “Would you

like to purge air?” Then press the Reset key again to return

to the Main menu.

28 Instruction 2072-0400

Page 33

MAC2000 Maintenance

4 Maintenance

Field maintenance of the MAC2000 is limited to the following:

• Changing the filter drier

• Tracking of refrigerant using the unit’s Refrigerant Management

System

• Replacing the external refrigerant source tank

• Replacing the printer paper

• Replacing the refrigerant identifier filter

All other maintenance should be performed by an authorized

Bacharach Service Center (Section 5.2).

4.1 Changing the Filter Drier

The MAC2000 has a unique filtering system that ensures the

refrigerant transferred to the storage tank is clean and moisture-free.

The filter drier must be changed periodically to ensure that the

system will work properly.

The MAC2000 will automatically indicate when the filter needs to be

changed. If the “Change Filter” message appears when the Recovery

mode is selected, it is best to complete that job before changing the

filter drier. “Change Filter” will be displayed on the screen

whenever the recovery mode is selected until the filter has been

replaced.

All refrigerant must be evacuated from the old filter before it is

removed from the unit. Follow the filter change procedures carefully

to minimize refrigerant loss and ensure only clean, moisture-free

refrigerant is transferred into the storage tank.

Instruction 2072-0400 29

Page 34

Maintenance MAC2000

Caution: The filter drier should not be changed with the MAC2000

still connected to the vehicle. Disconnect the unit by closing the vehicle’s

service-port valves and disconnecting the high- and low-side hoses from

the vehicle.

1. If not already done, plug the MAC2000 into a properly grounded

AC outlet; set the Power switch to ON; then wait until the unit

completes its self diagnostics. The screen will display “Select

mode” when ready.

2. From the Main menu, press the Next menu function key to display

Menu 2.

3. Follow the on-screen prompts; then press the Start key to begin

evacuating the filter.

4. When completely evacuated, follow the on-screen prompts and

remove the old filter drier by unscrewing it counterclockwise.

Dispose of the used filter in a proper manner.

5. Lubricate the O-rings of a new filter drier with a light grease or

saliva; then hand tighten until it bottoms out.

6. Press the Reset key after the new filter has been installed. This

will remove any air that may have entered the system during the

changeover process.

4.2 Replacing the External Source Tank

The internal storage tank contains enough refrigerant for several jobs,

but it’s important to replace the external source tank soon after the

message “Source Tank empty” is displayed so that the internal

storage tank isn’t depleted during a charge operation.

30 Instruction 2072-0400

Page 35

MAC2000 Maintenance

To replace the external source tank:

1. Close tank valve; remove yellow hose from tank valve; release tank

strap; then remove tank from side of unit.

2. Place a new source tank on the shelf and secure it with the tank

strap. The tank strap must be set up to supply liquid – this

usually means the tank is inverted.

3. Reconnect the yellow hose to the tank fitting; then open the tank

valve.

4. The unit’s automatic tank refill function will add refrigerant to the

internal storage vessel as the unit is used. A technician may fill it

immediately, however, by pressing the Next menu function key to

display Menu 2, and then pressing the Tank refill function key to

immediately begin filling the internal storage tank.

4.3 Replacing the Printer Paper

1. Open the printer cover by first squeezing together the cover’s two

plastic latches, and then pulling the cover forward.

2. Remove the old paper-roll core.

3. Insert the new paper roll so that it unrolls over-the-top. Then pull

out several inches of paper and position the paper so that it rests

against the paper cutter.

4. Close the printer cover.

5. Press and hold the feed button to ensure that the paper feeds

properly; then tear off the excess paper.

Instruction 2072-0400 31

Page 36

Maintenance MAC2000

4.4 Replacing the Refrigerant Identifier Filter

Caution: Visually inspect the Refrigerant Identifier Filter every day. If

it begins to turn red, replace it immediately! You risk damaging the

identifier sensor if the filter is not replaced.

The refrigerant identifier filter is located on the control panel, directly

under the Low Side pressure gauge. The filter’s function is to protect

the refrigerant identifier sensor from contaminates. When this filter

starts to develop red spots, replace the filter immediately!

1. Remove the filter from its holder; then remove the tubing from

each end.

2. Position the new filter so that its flow-arrow points in the same

direction as the flow-arrow on the control panel.

3. Attach the tubing to the new filter, and press the filter back into

its holder.

32 Instruction 2072-0400

Page 37

MAC2000 Parts and Service

5 Parts and Service

5.1 Parts

Model MAC2000, 115VAC 50/60 Hz ........................................2000-4200

Model MAC2000, 220–240VAC, 50/60 Hz ...............................2000-4206

Bottle, Oil Drain........................................................................2055-0150

Filter Drier ................................................................................2037-0030

Filter, Refrigerant Identifier .................................................... 2068-0010

Power Cord (for Snap-Shot Data Transmitter) .......................2066-0040

Printer........................................................................................2017-0080

Printer Paper............................................................................. 2075-0060

Sensors (for Snap-Shot Data Transmitter):

Anemometer (air flow) ............................................................ 2064-0010

Temperature (blue) .................................................................2062-0020

Temperature (red) ................................................................... 2062-0010

Service Coupler – Red (High Side) ...........................................2022-1240

Service Coupler – Blue (Low Side) ........................................... 2022-1230

Service Hose – Red (High Side) ................................................ 2035-0170

Service Hose – Blue (Low Side) ................................................ 2035-0180

Snap-Shot Data Transmitter....................................................2001-0001

Instruction 2072-0400

33

Page 38

Parts and Service MAC2000

5.2 Service Centers

Service and replacement parts can be obtained by contacting a Bacharach Service Center at

the following locations:

California

7281 Garden Grove Blvd.,

Suite H

Garden Grove, CA 92841

Phone: 714-895-0050

Fax: 714-895-7950

E-mail: calservice@bacharach-inc.com

Indiana

8618 Louisiana Place

Merrillville, IN 46410

Phone: 219-736-6178

Fax: 219-736-6269

E-mail: indservice@bacharach-inc.com

New Jersey

7300 Industrial Park

Rte. 130, Bldg. 22

Pennsauken, NJ 08110

Phone: 856-665-6176

Fax: 856-665-6661

E-mail: njservice@bacharach-inc.com

Pennsylvania

621 Hunt Valley Circle

New Kensington, PA 15068

Phone: 724-334-5051

Fax: 724-334-5723

E-mail: help@bacharach-inc.com

Texas

5151 Mitchelldale, B-4

Houston, TX 77092

Phone: 713-683-8141

Fax: 713-683-9437

E-mail: txservice@bacharach-inc.com

Canada

Bacharach of Canada, Inc.

151 Bentley Street Unit #6

Markham, Ontario L3R 3X9 Canada

Phone: 905-470-8985

Fax: 905-470-8963

E-mail: bachcan@idirect.com

México

Bacharach de México

Playa Regatas No. 473 Tercer Piso

Col. Militar Marte

Delegación Iztacalco, 08830

México D.F.

México

Phones: 011-5255-5634-7740

011-5255-5634-7741

FAX: 011-5255-5634-7738

E-mail: bacharach@prodigy.net.mx

Denmark

Bacharach Instruments Int'l

P.O. Box 44

39 Lindegade

DK 6070 Christiansfeld

Denmark

Phone: 011/45 74 563171

Fax: 011/45 74 563178

E-mail: mail@bacharach.dk

Europe

Bacharach Europe

Sovereign House, Queensway

Leamington Spa

Warwickshire CV31 3JR

England

Phone: (01926) 338111

Fax: (01926) 338110

34 Instruction 2072-0400

Page 39

Page 40

Printed in U.S.A.

World Headquarters

621 Hunt Valley Circle, New Kensington, PA 15068-7074

Ph: 724-334-5000 • Fax: 724-334-5001 • Toll Free: 1-800-736-4666

Website: www.bacharach-inc.com • E-mail: help@bacharach-inc.com

Loading...

Loading...