Page 1

Tru Pointe

™

Refrigerant Leak Detector

Instruction 0019-9328

Operation & Maintenance

Rev. 3 – May 2010

Product Leadership • Training • Service • Reliability

Page 2

WARRANTY

Bacharach, Inc. warrants to Buyer that at the time of delivery this Product will be free from defects in mater ial

and manufac ture and will conform substan tially to Bach arach Inc.’s ap plicable spec i fi ca tions. Bacharach’s

li a bil i ty and Buyer’s remedy under this warranty are lim it ed to the repair or replacement, at Ba charach’s option,

of this Product or parts thereof returned to Seller at the factory of manufac ture and shown to Bacharach Inc.’s

reasonable satisfaction to have been defective; provided that written notice of the defect shall have been given

by Buyer to Bacharach Inc. within one (1) year after the date of delivery of this Product by Bacharach, Inc.

Bacharach, Inc. warrants to Buyer that it will convey good title to this Product. Bacharach’s liability and Buyer’s

remedy under this warranty of title are limited to the removal of any title defects or, at the election of Bacha rach,

to the replacement of this Product or parts thereof that are defective in title.

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND ARE GIVEN AND ACCEPTED IN LIEU OF (I) ANY

AND ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, IN CLUD ING WITH OUT LIMITATION THE IMPLIED WARRANTIES OF MERCHAN TABILITY AND FITNESS FOR A PARTICULAR PURPOSE: AND (II) ANY

OBLIGA TION, LIABILITY, RIGHT, CLAIM OR REM E DY IN CON TRACT OR TORT, WHETHER OR NOT ARISING FROM BACH A RACH’S NEGLIGENCE, ACTUAL OR IM PLIED. The remedies of the Buyer shall be limited

to those provided herein to the exclusion of any and all other remedies includ ing, without limita tion incidental or

consequen tial dam ag es. No agree ment varying or ex tend ing the foregoing warranties, remedies or this limitation will be binding upon Bacharach, Inc. unless in writing, signed by a duly au tho rized offi cer of Bacharach.

Declaration of Conformity

Manufacturer’s name: Bacharach, Inc.

Manufacturer’ address: 621 Hunt Valley Circle

New Kensington, PA 15068-7074

European Operations: Bacharach Europe

Sovereign House, Queensway

Royal Leamington Spa

Warwickshire CV31 3JR

United Kingdom

Product name: Tru Pointe

conforms to the following specifi cations:

EMC Directive 89/336/EEC EN50081-1:1992

EN61000-4-2:1995 EN61000-4-3:1995

EN50082-1:1997 Light Industrial EN50082-1:1998

EN55011:1998 Group 1,Class B

Notice:

Product improvements and enhancements are continuous, therefore the spec i fi ca tions and in for ma tion con-

tained in this document may change without notice.

Bacharach, Inc. shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing, performance, or use of this material.

No part of this document may be photocopied, reproduced, or translated to another language without the prior

written consent of Bacharach, Inc.

Copyright © 2003-2010, Bacharach, Inc., all rights reserved.

BACHARACH and Tru Pointe are registered trademarks of Bacharach, Inc. All other trademarks,

trade names, service marks and logos referenced herein belong to their respective companies.

A

Instruction 0019-9328

Page 3

Tru Pointe

Contents

Contents

Introduction .................................................................................................2

Features ......................................................................................................... 3

Technical Characteristics .........................................................................4

Operation ......................................................................................................6

Battery Installation ............................................................................ 6

Turning the Instrument ON / OFF .................................................... 7

Low Battery Indication .......................................................................8

Selecting High / Low Sensitivity Mode .............................................. 8

Procedure for Locating a Refrigerant Leak ....................................... 8

Sensor Failure Indication ................................................................... 9

False Refrigerant Indication ............................................................ 10

SAE Leak Detection Tips .................................................................10

Maintenance ...............................................................................................12

Routine Maintenance........................................................................12

Sensor Replacement .........................................................................13

Troubleshooting Guide ............................................................................14

Parts & Service ..........................................................................................16

Replacement Parts ............................................................................ 16

Sales/Service Centers .......................................................................16

Instruction 0019-9328

1

Page 4

Introduction

Tru Pointe

Introduction

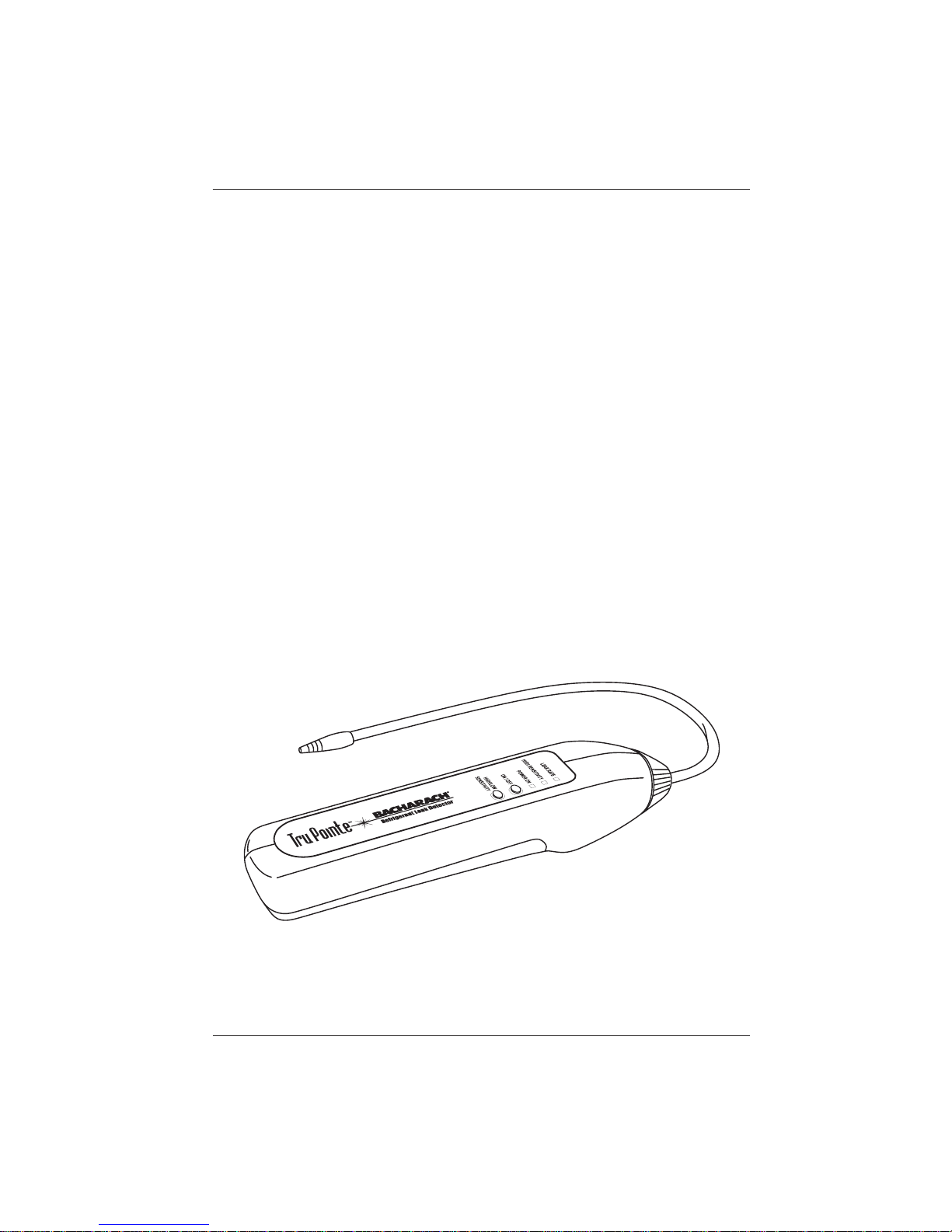

The Tru Pointe Refrigerant Leak Detector (Figure 1) is a portable, battery

powered instrument designed to pinpoint the location of refrigerant leaks

in air con di tion ing and re frig er ant sys tems, chillers, or cold storage units.

The use of heated-diode sensor technology allows the instrument to be

quickly responsive to all refrigerants, even when high background levels

of refrigerant vapors are present. No man u al sensitivity adjustments are

necessary during the inspection pro cess.

The instrument is suitable for HVAC Service Technicians, Refrigerant

Ser vice Technicians, Plant Maintenance Departments, Automotive Service

Facilities, and Refrigerant & Environmental Chamber Man u fac tures who

are in need of a small, lightweight and rugged instrument that is capable of

detecting and then pinpointing small to large gas leaks in tight spaces such

as those found in refrigeration units and automobile engine compartments.

Figure 1. Tru Pointe Refrigerant Leak Detector

2

Instruction 0019-9328

Page 5

Tru Pointe

Features

• Quickly pinpoints the location of refrigerant leaks

• Patented heated-diode sensor that represents the latest

advancements in sensor technology

• Patented microprocessor-controlled circuitry

• High and low-sensitivity modes, push button selectable

• Automatic zero and background compensation that allows a

leak to be quickly found in contaminated atmospheres without requiring manual sensitivity adjustments

• Flexible probe 14 inches (356 mm) in length for locating

leaks in hard-to-reach areas

• One-handed operation

• No user calibration required

• Long life, DC brushless fan provides positive airfl ow past

sensor resulting in a faster response time

Introduction

• Batteries included

• One year warranty

• Extended warranty available

Instruction 0019-9328

3

Page 6

Technical Characteristics

Tru Pointe

Technical Characteristics

Power .......................................... Two ‘D’ Alkaline Batteries

Warm-Up Time ..........................10 seconds

Refrigerants Detected ................ All CFC, HCFC and HFC refrigerants

including: R-12, R-22, R-123, R-134a and

blends R-404A, R-408A, R-409A, and

R-410A

Sensor:

Type ......................................... Heated Diode, Dispersive Electron, Plug-In

Life Expectancy* ..................... Typically 150 hours or 1 year of normal use

Battery Life ................................ 11 hours min. high sensitivity mode,

20 hours min. low sensitivity mode,

as tested using Duracell Ultra MX1300

alkaline batteries

Response Time ...........................Instantaneous

Sensitivity................................... The instrument will detect a leak of at

least 0.5 oz/year (14 g/yr) as detected by

moving probe tip at 2" (50 mm) per sec-

ond, 0.2" (5 mm) above leak source. A leak

rate of less than 0.1 oz/year (3 g/yr) can

be de tect ed when probe tip is held steady

over leak source for at least 5 seconds.

Sensitivity Adjustment .............. Automatic

Weight ........................................ 1.16 lb (0.53 kg) w/ batteries

Size (excluding probe) ............... 2.12W x 9.5L x 2.4H inches

(53.8 x 241.3 x 61.0 mm)

Probe Length .............................. 14" (356 mm)

* Caution: Exposing the sensor to a steady stream of highly concentrated

refrigerant will severely reduce sensor life or damage the sensor.

Sensor life is directly proportional to the amount of refrigerant

that passes through the sensor.

4

Instruction 0019-9328

Page 7

Tru Pointe

Technical Characteristics

Operating Environment:

Position ....................................Any

Temperature ...........................32 to 122 °F (0 to 50 °C)

Humidity .................................10 to 90% RH, non-condensing

Approvals .................................... UL certifi ed to SAE J1627

CE Mark

Instruction 0019-9328

5

Page 8

Operation

Tru Pointe

Operation

Battery Installation

1. Remove battery cover by pressing down on the battery cover tab, and

then sliding the cover off the instrument. See Figure 2.

2. Install two ‘D’ alkaline batteries into the battery compartment, observ-

ing the polarity markings that are molded inside of the case.

3. Slide the battery cover back onto the instrument until its tab clicks

into place.

6

Figure 2. Battery Installation

Instruction 0019-9328

Page 9

Tru Pointe

Operation

Turning the Instrument ON / OFF

See Figure 3. The instrument is toggled ON and OFF by pressing the

ON/OFF button.

When the instrument is fi rst turned ON, observe that the green

LED will glow, and that the red

LEAK RATE LED fl ashes rapidly along with

POWER ON

the audible indicator producing a rapid ticking sound or constant tone.

The instrument requires a minimum of 10 seconds to warm up. After

which time both the LEAK RATE LED and audible indicator should slow

down to no more than 1 or 2 fl ashes/ticks per second.

Note that during the warm-up period, the instrument has zeroed out any

background concentration of refrigerant vapors that may have been present

in the area.

After the instrument is turned ON and allowed to warm up, it is ready

to perform leak testing as described in Section Procedure for Lo cat ing a

Refrigerant Leak.

Red LED:

Flash rate increases when the instrument

detects an increased level of refrigerant

Amber LED:

ON = High Sensitivity

OFF = Low Sensitivity

Blinking = Sensor Failure

Instruction 0019-9328

Green LED:

ON = Instrument turned ON

Blinking = Low battery condition

Press to toggle instrument ON and OFF

Press to toggle between high and low sensitivity

Figure 3. Indicators and Controls

7

Page 10

Operation

Tru Pointe

Low Battery Indication

A low-battery condition is indicated when the green POWER ON LED begins

to fl ash. Approximately 20 minutes of operation time remains from the

time this LED fi rst begins to fl ash; after which, the instrument’s operation

will gradually become erratic.

When a low-battery indication occurs, replace the batteries as described

under the previous Section Battery Installation.

Selecting High / Low Sensitivity Mode

When the Tru Pointe is fi rst turned ON it defaults to its low-sensitivity

mode.

Place the instrument into its high-sensitivity mode by pressing the HIGH/

LOW SENSITIVITY button until the HIGH SENSITIVITY LED turns ON (HIGH

SENSITIVITY amber LED glows).

Tip: Use the low-sensitivity mode to extend battery and sensor

life. Use the high-sensitivity mode, if necessary, to pinpoint leaks.

Return the instrument to its low-sensitivity mode by pressing the HIGH/

LOW SENSITIVITY button until the HIGH SENSITIVITY LED turns OFF.

Procedure for Locating a Refrigerant Leak

After the instrument is turned ON and allowed to warm up, observe that

both the LEAK RATE LED and the audible indicator should be fl ashing/tick-

ing at no more than 1 or 2 times a second, indicating that the instrument

is in its idle state and currently not detecting an increasing concentration

of refrigerant.

Important: The instrument’s function is to detect a change

in refrigerant level, and not to make a quantitative mea sure ments. The technique of locating a leak by detecting a change

in level allows an op er a tor to quickly locate the source of a

leak without making manual sensitivity ad just ments, or being concerned about the background refrigerant level in the

sur round ing area.

Begin by slowly moving the probe tip toward the area of the suspected leak

source. If surfaces are dirty or wet, wipe them off with a shop towel. Avoid

allowing dirt to clog the probe tip, or allowing water to enter the instrument.

8

Instruction 0019-9328

Page 11

Tru Pointe

Operation

When the instrument fi rst detects an increase in the refrigerant level, the

LEAK RATE LED begins fl ashing and the audible indicator begins ticking

at a faster rate. If movement of the probe is stopped for more than 10 seconds, the instrument will self-zero and return to its idle state even though

refrigerant is still present.

Once the presence of refrigerant has been determined and the instrument

allowed to self-zero, moving the probe toward the leak source will once

again cause the instrument to respond in a positive manner. The instrument’s audible and visual indications will fall if the probe is moved away

from the leak source.

Caution: Exposing the sensor to a steady stream of highly

concentrated refrigerant will severely reduce sensor life or

damage the sensor. Sensor life is directly proportional to the

amount of refrigerant that passes through the sensor.

Use the following general procedure to pinpoint the source of a leak:

1. Move the probe tip along the refrigerant lines and around the fi ttings

until the

LEAK RATE LED begins fl ashing and the audible indicator

starts ticking at a faster rate.

2. Continue moving the probe tip in a direction that keeps the instrument responding in a positive manner.

3. Once the source of the leak has been passed, the instrument’s visual and

audible indications will fall. At this point, reverse the di rec tion of probing

so that the instrument once again responds in a positive manner.

4. Repeat Step 3 until a small movement of the probe tip over the leak

source results in the rapid indication of increasing and decreasing

refrigerant levels.

Sensor Failure Indication

A failed sensor is indicated when the HIGH SENSITIVITY LED begins to fl ash.

Refer to the Trou ble shoot ing Guide Section of this manual for information

on how to remedy this condition.

Instruction 0019-9328

9

Page 12

Operation

Tru Pointe

False Refrigerant Indication

False refrigerant indications are usually caused by abnormal changes in

sensor temperature. These temperature changes are typically due to a sudden change in air fl ow past the sensor, or the sensor being heated or cooled

by an outside source. To avoid false re frig er ant indications, DO NOT . . .

• allow the probe tip to become clogged with dirt,

• allow the probe to suck in hot gases.

SAE Leak Detection Tips

The following was derived from SAE Surface Vehicle Standard J1628,

Technician Procedure for Using Electronic Refrigerant Leak Detectors for

Service of Mobile Air-Conditioning Systems:

• The electronic leak detector shall be operated in accordance with the

equipment manufacturer’s operating instructions.

• Leak test with the engine not in operation.

• The air conditioning system shall be charged with suffi cient refrigerant

to have a gauge pressure of at least 340 kPa (49 psi) when not in op er a tion. At temperatures below 15 °C (59 °F), leaks may not be mea sur able,

since this pressure may not be reached.

• Take care not to contaminate the detector probe tip if the part being

tested is contaminated. If the part is particularly dirty, it should be

wiped off with a dry shop towel or blown off with shop air. No cleaners

or solvents shall be used, since many electronic detectors are sensitive to

their ingredients.

• Visually trace the entire refrigerant system, and look for signs of airconditioning lubricant leakage, damage, and corrosion on all lines, hoses, and components. Each questionable area shall be carefully checked

with the detector probe, as well as all fi ttings, hose-to-line couplings,

re frig er ant controls, service ports with caps in place, brazed or welded

areas, and areas around attachment points and hold-downs on lines and

components.

10

Instruction 0019-9328

Page 13

Tru Pointe

Operation

• Always follow the refrigerant system around in a continuous path so

that no areas of potential leaks are missed. If a leak is found, always

continue to test the remainder of the system.

• At each area checked, the probe shall be moved around the location, at

a rate no more than 25 to 50 mm/sec (1 to 2 in./sec), and no more than

5 mm (0.2 inch) from the surface completely around the position. Slower

and closer movement of the probe greatly improves the likelihood of

fi nding a leak.

• An apparent leak shall be verifi ed at least once by blowing shop air into

the area of the suspected leak, if necessary, and repeating the check of

the area. In cases of very large leaks, blowing out the area with shop air

often helps locate the exact position of the leak.

• Leak testing of the evaporator core while in the air conditioning module

shall be accomplished by turning the air conditioning blower on high for

a period of 15 seconds minimum, shutting it off, then waiting an ad di tion al 15 seconds minimum for the refrigerant to accumulate in the case,

then inserting the leak detector probe into the blower resistor block or

condensate drain hole if no water is present, or into the closest opening

in the heating/ventilation/air conditioning case to the evap o ra tor, such

as the heater duct or a vent duct. If the detector activates, a leak ap par ent ly has been found.

• Following any service to the refrigerant system of the vehicle, and any

other service which disturbs the refrigerant system, a leak test of the

repair and of the service ports of the refrigerant system shall be done.

Instruction 0019-9328

11

Page 14

Maintenance

Tru Pointe

Maintenance

By following the procedures outlined below, The Tru Pointe will provide

many years of trouble-free and dependable operation.

Routine Maintenance

• Replace the batteries per Section Battery Installation when the green

POWER ON LED begins to fl ash.

• Periodically check the instrument’s sensitivity by exposing it to a source

of refrigerant gas. DO NOT check sensitivity by cracking open a bottle

of refrigerant or Schrader valve and exposing the sensor to a stream

of pure refrigerant. This will severely reduce sensor life or damage the

sensor.

• Keep the instrument case and probe clean by wiping them with a shop

towel. If necessary, moisten the towel with a mild detergent solution.

Avoid using any type of solvents that may either attack the instrument’s

ABS plastic case, or leave behind a hydrocarbon residue that may de sen si tize the sensor.

12

Instruction 0019-9328

Page 15

Tru Pointe

Maintenance

Sensor Replacement

Over time the sensor will become less responsive to refrigerant gas as it

nears the end of its useful life. A sensor’s average life expectancy is approximately 150 hours or 1 year of normal use, but will vary depending on

the amount of refrigerant that passes through the sensor.

Replace the sensor as follows (see Figure 4):

Material Required:

• Sensor (refer to Section Replacement Parts)

Procedure:

1. Turn OFF instrument.

2. Grasp nose cone of probe assembly and pull probe away from case

using a slight twisting motion.

3. Sensor may be hot! Pull spent sensor from its socket and discard.

4. Plug in new sensor.

5. Push probe assembly back into case.

6. Turn ON the instrument and check that it responds in a positive manner to a source of refrigerant gas.

'RASPPROBEASSEMBLYSNOSE

CONEANDPULLPROBEAWAYFROM

CASEWHILEAPPLYINGASLIGHT

TWISTINGMOTION

2%&2)'%2!.4

3%.3/2

Figure 4. Sensor Replacement

Instruction 0019-9328

13

Page 16

Troubleshooting

Tru Pointe

Troubleshooting Guide

The following table lists the causes and remedies for the most common

problems that may occur with the instrument.

If the information in Table 1 does not solve the problem, or for help with

any prob lem that is not listed, please contact one of the Bacharach Sales/

Service Cen ters listed in Section Parts & Service.

TABLE 1. TROUBLESHOOTING GUIDE

Symptom Probable Cause & Remedy

Instrument does not turn

ON.

The POWER ON LED is

fl ashing.

The HIGH SENSITIVITY LED

is fl ashing in clean air.

The LEAK RATE LED is

turned on steady, and the

audible indicator is producing a steady tone.

Instrument does not respond to the presence of

refrigerant.

a. Batteries are dead or installed back-

ward. Install two fresh ‘D’ alkaline batteries per Section Battery Installation.

b. Faulty refrigerant sensor. Remove sen-

sor and turn ON instrument. If instrument now operates, replace sensor per

Section Sensor Replacement.

Low battery indication. Replace batteries

per Section Battery Installation.

a. Sensor depleted or faulty. Replace sensor

per Section Sensor Replacement.

b. Batteries are nearly depleted. Replace

per Section Battery Installation.

a. This is normal during warm up. After

warm up the fl ash/tick rate should slow

down to less than 1 or 2 times per second.

b. Probe tip clogged, not allowing air to

fl ow over sensor. Unclog probe tip.

a. Sensor nearly depleted or faulty. Replace

sensor per Section Sensor Replacement.

b. Probe assembly loose. Push nose cone of

probe assembly back into instrument.

c. Probe tip clogged, not allowing air to

fl ow over sensor. Unclog probe tip.

d. Crack in rubber sheathing that covers

the probe’s fl exible tube, allowing air to

enter through the crack. Replace probe

assembly.

14

Instruction 0019-9328

Page 17

Tru Pointe

Troubleshooting

TABLE 1. TROUBLESHOOTING GUIDE (Cont.)

Symptom Probable Cause & Remedy

Short sensor life. Senor has often been exposed to high levels

of refrigerant. Avoid exposing sensor to

pure refrigerant for long periods of time.

Erratic refrigerant leak

indication.

a. Windy conditions. Shut off surrounding

fans; protect probe tip from wind; switch

to low-sensitivity mode per Section

High/Low Sensitivity Mode.

b. Probe assembly loose. Push nose cone of

probe assembly back into instrument.

c. Low batteries. Replace batteries per Sec-

tion Battery Installation.

d. Loose sensor. Remove probe and ensure

that the sensor is being held fi rmly in its

socket (see Figure 4.)

e. Sensor faulty. Replace sensor per Sec-

tion Sensor Replacement.

Instruction 0019-9328

15

Page 18

Parts & Service

Tru Pointe

Parts & Service

Complete Kit: Includes detector, instruction manual,

2 ‘D’ batteries, and a hard carrying case ........................................0019-8106

Replacement Parts

Battery Door .................................................................................... 0019-0548

Hard Carrying Case........................................................................ 0019-0501

Probe Assembly ............................................................................... 0019-0553

Screw, Case, #4-20 x 1" Self Tapping ............................................. 0102-1982

Sensor .............................................................................................. 0019-0559

Sales/Service Cen ters

United States

Pennsylvania

621 Hunt Valley Circle

New Kensington, PA 15068

Phone: 1-800-736-4666

Fax: 724-334-5723

Email: help@mybacharach.com

Canada

Bacharach of Canada, Inc.

20 Amber St. Unit# 7

Markham, Ontario L3R SP4 Canada

Phone: 905-470-8985

Fax: 905-470-8963

Email: bachcan@idirect.com

16

Instruction 0019-9328

Page 19

Warranty Registration

Please fi ll out the following information and FAX to Bacharach's

Warranty Department at 724-334-5001. Or register online at www.

mybacharach.com /warranty-registration.htm

Name

Title Company # of Employees

Address

City State Zip

Phone Fax E-mail

Product Purchased Part No. Serial No.

Date Purchased Purchased From

1. What can Bacharach do to better serve you? ___________________________

__________________________________________________________________

2. My Application:

Combustion Analysis Leak Detection Emission Monitoring

Appliance Service Indoor Air Quality

Other (Please Specify) _____________________________________________

3. Future Applications May Include/Please Send More Information About:

Combustion and IAQ Analyzers Training Programs

Emissions Monitors Service Programs

Refrigeration Products

Page 20

Ph: 724-334-5000 • Fax: 724-334-5001 • Toll Free: 1-800-736-4666

Web site: www.mybacharach.com • E-mail: help@mybacharach.com

Printed in U.S.A.

621 Hunt Valley Circle, New Kensington, PA 15068-7074

World Headquarters

Loading...

Loading...