LLSS88000000 LLEEVVEELL SSWWIITTCCHH

OWNERS MANUAL

♦♦IINNSSTTAALLLLAATTIIOONN

♦♦CCAALLIIBBRRAATTIIOONN

♦♦TTRROOUUBBLLEESSHHOOOOTTIINNG

♦♦WWAARRRRAANNTTY

BABBITT

Page

INTERNATIONAL, INC.

1. Description-------------------------------------------------------------------1

TABLE OF CONTENTS

Y

G

P.O. Box 70094

Houston, Texas 77270

(713) 467-4438

TABLE OF CONTENTS

1. Description ----------------------------------------------------- 1

A. General Description ----------------------------------- 1

B. Specifications -------------------------------------------- 1

2. Theory of Operation/ Ordering Information ----------------- 2

3. Installation ----------------------------------------------------- 2

A. Inspection ----------------------------------------------------- 2

B. Physical Installation of Probe ----------------------------------- 2

C. Installing the Receiver ----------------------------------- 3

D. Typical Applications and Wiring Diagrams ----------------- 4

1) LS8000 Terminal Layout ----------------------------------- 4

2) Ladder Diagrams -------------------------------------------- 6

4. Calibration -------------------------------------------------------------- 10

A. Setting the Time Delay ----------------------------------- 10

B. Fail Safe Selection -------------------------------------------- 10

Page

C. Sensitivity Calibration ----------------------------------- 10

5. Maintenance and Troubleshooting ----------------------------------- 11

6. Warranty -------------------------------------------------------------- 12

LS8000 LEVEL SWITCH

1. DESCRIPTION

A. General Description

The LS8000 is a point level switch that detects the presence or absence of material in a bin, silo, tank or other

container.

The basic unit is made up of a solid stainless steel probe attached to an explosion proof housing. Inside the

explosion proof housing is a transmitter that is connected to the receiver board by a twisted, shielded pair of

wires.

The receiver board may be mounted up to one mile from the probe. All calibration adjustments and indicators

are at the receiver. The receiver also has the relay output and an on board fuse.

The unit is calibrated in the absence of material and an on board relay at the receiver changes state when

material is detected.

B. Specifications

Electrical

Power:

(12 VDC, 24 VDC or 230 VAC optional)

115 VAC (±15%) 50/60 Hz. 2 watts, standard.

Output: 2 Form C contacts, DPDT relay, 5 amp resistive

at 125, 250 VAC; 30 VDC

Fuse: On board, 250 mA @ 125 volts

Fail Safe: Selectable high or low level

Time Delay: Selectable: ON or OFF delay

Adjustable: 1/8 sec to 2 hrs.

RF Frequency: Approximately 1.3 MHz

Environmental

Hazardous Area: Transmitter: Class I- Group C, D

Class II- Group E, F, G

Receiver: Open printed circuit board can be put in

enclosure as required by application

Temperature: Probe: -30° F to 400° F

Electronics: -40° F to 185° F

Pressure: Probe: 1500 psi @ 75° F. Higher ranges available

upon request.

Construction: Probe: All wetted parts, 316 SS Teflon and Viton.

A Halar coating can be applied to the probe when

applicable.

Transmitter: Housed in cast aluminum explosion

proof enclosure

Receiver: Printed circuit board mounted on plastic

track provided with each unit.

Specifications subject to change without notice.

1

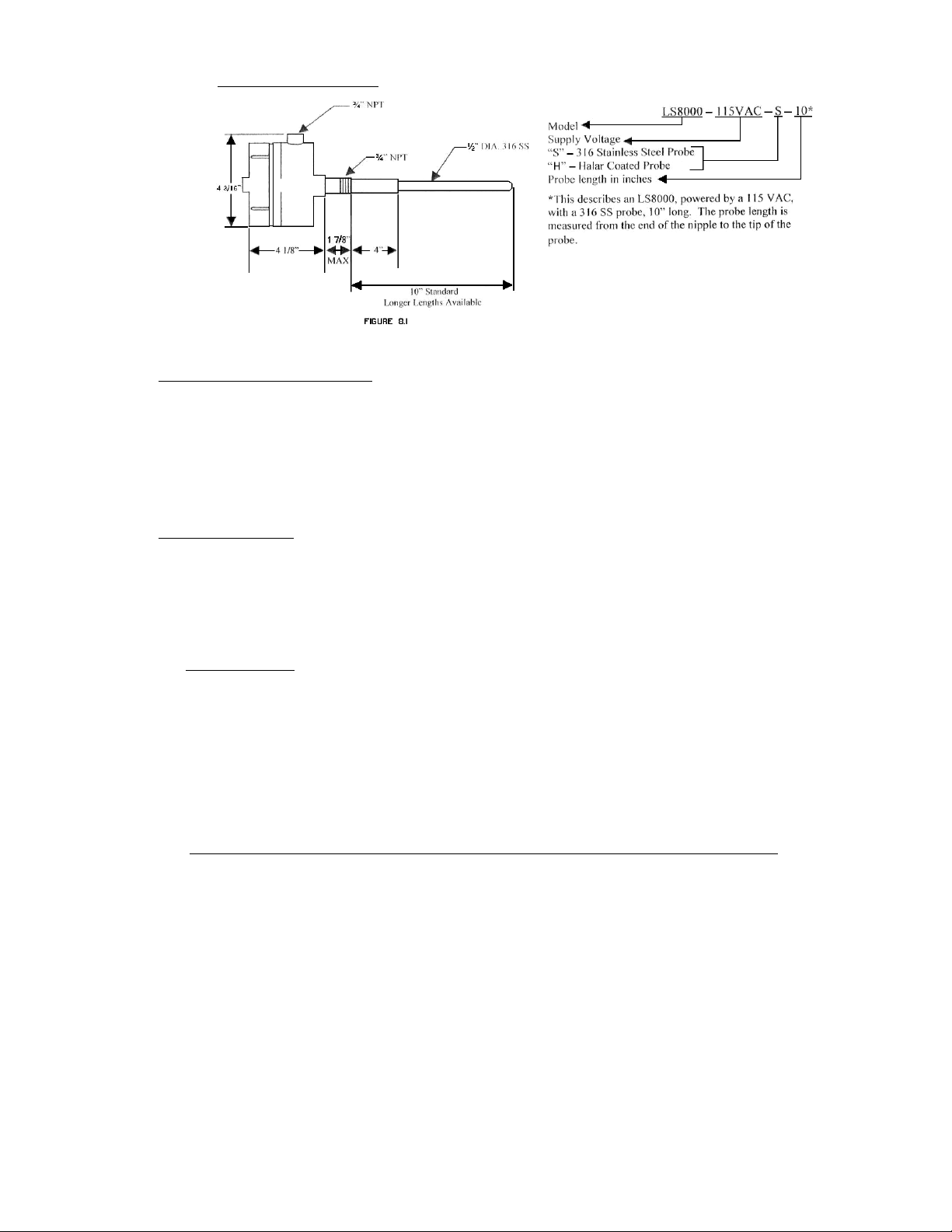

C. Ordering Information

2. THEORY OF OPERATION

The LS8000 employs a radio frequency (RF) balanced impedance bridge circuit to detect if the probe is in

contact with the material that is to be sensed.

When material is not in contact with the probe, the bridge is balanced by turning the adjustment pot to find the

threshold where the red led goes out.

When material is in contact with the probe, the bridge becomes unbalanced and the comparing circuit realizes

the change. This causes the relay to change state.

3. INSTALLATION

*CAUTION: ALL INSTALLATION AND WIRING MUST CONFORM TO NEC

AND ALL OTHER LOCAL ELECTRICAL CODES. TAKE SPECIAL CARE IN

OBSERVING HAZARDOUS AREA SAFETY PROCEDURES. WE ASSUME NO

LIABILITY FOR IMPROPERLY INSTALLED OR WIRED UNITS.

A. INSPECTION

After unpacking the LS8000, visually inspect the unit for any damages.

Please advise the factory or your local distributor of any damage.

A complete unit should consist of the following:

1. An explosion proof enclosure with probe attached

2. A transmitter module in the explosion proof enclosure

3. The LS8000/R receiver card

4. A plastic snaptrack to mount the receiver card

B. PHYSICAL INSTALLATION OF TRANSMITTER MODULE AND PROBE

1) The LS8000 is installed into the vessel wall using a ¾” NPT connection.

This can be either a threaded coupling or a tapped entry such as a flange.

2) The teflon insulator should always extend at least 2” through the vessel wall.

3) Always check for physical room around the location you have chosen to allow for installation. Allow 2 ¾”

turning radius to screw the probe in and clearance above for the length of the probe.

4) CAUTION: Always take the necessary safety precautions when cutting or welding in the

coupling for the LS8000.

a) Tag and lock out the electrical power to the equipment that services the vessels.

b) Check liquid or dry powders that create a gas in the vessel for oxygen as well as the explosion factor.

(All dust will explode.)

c) Vessels that are cross vented have to be isolated.

5) Screw the LS8000 into the connection provided. In dry material application, no sealant on threads is

required. In liquid, teflon or a good pipe thread sealant may be used.

2

6) The LS8000 has a ¾” NPT conduit entry. When wiring these units, conform to the National Electrical

Code and any other city or company codes.

7) Always install the electrical connection into the ¾” NPT on the LS8000 so water will not follow the

connection routing into the threads of the ¾” NPT

outside the unit, install an EYSM unilet before each LS8000 and fill with explosion proof sealing cement.

8) When required, the LS8000 probe can be bent to meet your special application. Remember to allow 2” of

clearance between the probe and the

factory must bend the probe to your specifications.

9) Location of probes on high level installations is more critical on dry material than liquids. Note the

following:

a) For dry materials, mount the LS8000 in the top of the vessel whenever possible. (This allows you to

lengthen the probe if necessary.)

b) Avoid mounting the LS8000 near the product inlet, vent return lines, dust collectors and vessel

discharge openings on dry materials. Turbulence around these areas can cause erratic detection unless

the probe is long enough. On old installations it might be wise to fill the vessel first to determine the

length or location of the probe. We recommend a 36” top mounted high level probe in storage silos

and a 24” in smaller vessels such as use bins.

CAUTION: Always take safety precautions before opening vessels for such

c) On gravity filled vessels, take into consideration the angle of repose formed by the product.

d) On dry product that flows like water (starch), when using the LS8000 to stop the flow by means of a

butterfly valve or knifegate, make sure the probe is long enough to allow time to close these slow

moving valves.

e) In small vessels where a good location is hard to find, it may be

the probe and the product inlet to keep product off of the probe as it fills.

(A short time delay could also solve this problem.)

C. Installing the Receiver

hub. To guarantee that condensation and water will stay

vessel wall. If the probe is to be used in a pressure application, the

inspection.

necessary to put a baffle plate between

The receiver is a printed circuit board measuring 3” x 4 ½“. It is mounted in a plastic snap track that is

provided with each unit.

The snap track can be mounted in existing control panels or enclosures may be ordered from the factory.

1) Attach the snap track to the panel back pan or other surface using 2 small screws or a suitable adhesive.

2) Snap the LS8000/R receiver card into the snap track.

3) Connect shielded cable to the 3 terminals marked G,S, +. (See page 5

4) Connect the proper supply voltage and relay output wiring for your application. (See page 4)

NOTE: All wiring must conform to the National Electric Code or other enforcing authorities that

apply in your area.

D. Typical Applications and Wiring Diagrams Follow:

3

for wiring diagram.)

4

5

6

7

8

9

4. CALIBRATION

PLEASE READ THE ENTIRE CALIBRATION PROCEDURE BEFORE CALIBRATING THE LS8000.

If no time delay is required, turn the time adjustment pot completely CCW and set S1 down, S2 up. The

potentiometer has 20 turns and freewheels at the end of its travel without damage. You may hear “clicks” at the end

of travel.

A. Setting the Time Delay

1) Setting the timing mode, either on delay or off delay, is done by positioning S3 and S4 as shown in the

chart below.

NOTE: S3 and S4 also select fail safe high level (FSH) or fail safe low level (FSL).

2) Select the timing range using S1 and S2 as shown on the chart below.

3) Adjust the time adjustment potentiometer clockwise to increase time or CWW to decrease until the exact

time delay is reached. The test switch may be depressed to start the timing when checking timing

sequence.

NOTE: For long timing ranges you can set the timer for a shorter range, then

change the range switches (S1 and S2) to increase the time. For example, the desired

time delay is 15 minutes. This is equal to 900 seconds. By setting S1 down and S2 up

and adjusting the timer to approximately 28 seconds, the ratio on this range is 1. To

increase this range by 32, move S1 up and S2 up. 32x28 seconds equals approximately

15 minutes.

B. Fail Safe Selection

The fail safe feature provides a “false alarm” in case of power outage or major component failures. When

properly selected, the fail safe feature can protect equipment or alert you of a unit failure.

1) Fail Safe High

green led indicates relay status and is on when the relay is energized. When product comes into contact with

the probe, the relay is de-energized.

2) Fail Safe Low

NOTE: Due to the wide variety of applications and possible control or alarm functions, the proper fail safe

selection will depend on your circumstances. Please call your distributor or the factory if you need assistance.

TIMING RANGE

S1 S2 TIME RATIO S3 S4

DN UP 1/8 sec - 35 sec 1 UP UP ON FSL

UP DN 1/2 sec - 140 sec 4 DN UP DELAY FSH

UP UP 4 sec - 18 min 32 DN DN OFF FSL

DN DN 32 sec - 2 hrs 260 UP DN DELAY FSH

(FSH) means that the relay is energized when NO PRODUCT is touching the probe. The

(FSL) means that the relay is energized when PRODUCT IS touching the probe.

FAILSAFE TIMER MODE

C. Sensitivity Calibration

The LS8000 should be calibrated when no material is touching the probe and when the unit is installed where it

will be used.

1) Observe the red LED. If it is on, go to step 3.

2) If the red LED is off, turn the sensitivity adjustment potentiometer CW until it comes on.

3) Turn the sensitivity adjustment pot CCW until the red LED just goes out and continue to turn the pot CCW

at least ¾ of a turn. This sets the unit to its maximum stable sensitivity. If in your application this is too

sensitive, you can turn the sensitivity adjustment pot further CCW. Always bring the product into contact

with the probe after calibration to assure proper performance.

Note the green LED indicates relay status. The relay is energized when the green LED is on.

SPECIAL CALIBRATION NOTES:

For some products, the LS8000 can be calibrated with product touching the probe. To do this, turn the

sensitivity adjust pot CW until the red LED just comes on

ALWAYS CHECK TO SEE IF THE UNIT RESETS IN THE ABSENCE OF PRODUCT.

and continue CW for ¼ to ½ of a turn.

10

5. MAINTENANCE AND TROUBLESHOOTING

No routine maintenance is required other than keeping the interior of the unit clean and free of dirt, dust and other

contaminants.

The LS8000 consists of three main sub-assemblies. These are the enclosure with the antenna probe, the transmitter

module and the receiver card. The following troubleshooting guide will assist in determining how to correct most of

the problems which may occur in the field. Review the Installation and Calibration procedures in sections 3 and 4.

PROBLEM POSSIBLE CAUSE SOLUTION

RED LED cannot be adjusted to

turn on.

RED LED remains on at all times Antenna probe is shorted to case

Unit triggers when material

touches probe, but will not reset

when material recedes from probe

or unit and gives false alarm.

Unit will not detect material. Improper calibration.

Unit will not stay in calibration. Poor grounding of transmitter

Relay operates properly, but no

signal at terminals.

Transmitter module not connected

to probe.

No power to unit.

Blown on-board fuse

Bad receiver card.

or ground.

Shielded cable not correctly

hooked up.

Shielded cable broken or shorted.

Improper mount of probe.

Improper calibration procedure.

Excessive material build-up on

probe.

Probe is mounted in flow of

material.

Transmitter module not plugged

into probe.

Unit was calibrated with material

touching probe.

housing to vessel.

Burned or broken lands on

receiver printed circuit board.

Bad relay contacts.

Plug transmitter into probe.

Check for correct power.

Replace fuse.

Repair or replace card.

Unplug banana plug and position

it so that the bare end is not

touching anything. Turn

calibration pot 20 turns CCW.

LED should go out. If it does,

repair, replace or clean antenna

probe. If LED does not go out,

replace electronics.

Check shielded cable for proper

connection.

Check shielded cable for shorts or

open circuits.

Contact factory or dist.

See section 4 C.

Perform “dirty probe calibration”:

Recalibrate with built up material

on probe. See section 4C.

Revise mounting or use time

delay. See section 4C.

See calibration instructions,

section 4.

Plug transmitter module into

probe.

Be sure material is not touching

probe and recalibrate.

Provide secure ground connection.

Turn off power. Remove module

from housing and inspect lands on

printed circuit for damage.

Replace if necessary.

Replace relay or return for repair.

PLEASE CONTACT THE FACTORY OR YOUR DISTRIBUTOR IF YOU HAVE ANY

QUESTIONS OR NEED ASSISTANCE.

11

6. WARRANTY

All components of the LS8000 are warranted to be free from defects in material and workmanship for a

period of two years from the date of purchase. This warranty applies to general purchaser and to

components installed, serviced and operated according to instructions.

Babbitt International, Inc. will repair or replace, at its option, FOB at its plant or any other location

designated, any part which proves to be defective in manufacture or workmanship.

All claims must be made in writing within the warranty period. No claims outside of the warranty period

will be honored.

Warranties are not applied to any components which have been damaged by improper installation, use,

exposure to unusual atmospheric conditions or components which have been misused, abused, damaged

by neglect or accident. This warranty shall not apply to any components which have been altered or

repaired without the prior written consent of Babbitt International, Inc.

Babbitt International, Inc. assumes no responsibility or liability for any labor or material back charges,

without written authorization. Any products returned must be with prior written authorization.

THE FOREGOING IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING ANY WARRANTIES OF MERCHANTABILITY AND/OR FOR FITNESS FOR

PARTICULAR PURPOSE, AND BABBITT INTERNATIONAL, INC. ASSUMES NO OTHER

LIABILITIES EXPRESSED OR IMPLIED. BABBITT INTERNATIONAL, INC. SHALL NOT BE

LIABLE FOR NORMAL WEAR AND TEAR, NOR FOR DIRECT, INCIDENTIAL OR

CONSEQUENTIAL DAMAGES. IN NO EVENT SHALL BABBITT INTERNATIONAL

INCORPORATED’S LIABILITY EXCEED THE PRICE OF ITS PRODUCT AT THE TIME OF

PURCHASE.

12

Loading...

Loading...