Page 1

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifications

techniques.

© Bürkert SAS, 2011-2014

Operating Instructions

1408/01_EU-ml_00563282_Original_FR

Types 1078-1 / 1078-2

Timer without or with configuration module type 1077-2

Operating Instructions

Bedienungsanleitung

Manuel utilisateur

2

1. ABOUT THIS MANUAL ...........................................................3

2. INTENDED USE ..........................................................................5

3. BASIC SAFETY INFORMATION .........................................7

4. GENERAL INFORMATION .................................................. 10

5. AREA OF APPLICATION ......................................................11

6. TECHNICAL DATA .................................................................. 15

7. INSTALLATION AND WIRING ........................................... 20

8. COMMISSIONING .................................................................. 23

9. ADJUSTMENT ........................................................................... 25

10. MAINTENANCE AND TROUBLESHOOTING ............ 41

11. SPARE PARTS AND ACCESSORIES ........................... 42

12. PACKAGING, TRANSPORT ............................................... 43

13. STORAGE ................................................................................... 43

14. DISPOSAL OF THE DEVICE .............................................44

English

3

1. ABOUT THIS MANUAL

This manual describes the entire life cycle of the device.

Please keep this manual in a safe place, accessible to all

users and any new owners.

This manual contains important safety information.

Failure to comply with these instructions can lead to

hazardous situations.

• This manual must be read and understood.

1.1. Symbols used

danger

Warns you against an imminent danger.

• Failure to observe this warning can result in death or in

serious injury.

Warning

Warns you against a potentially dangerous situation.

• Failure to observe this warning can result in serious

injury or even death.

English

3

Page 2

4

caution

Warns you against a possible risk.

• Failure to observe this warning can result in substantial

or minor injuries.

note

Warns you against material damage.

• Failure to observe this warning may result in damage

to the device or system.

indicates additional information, advice or

important recommendations.

refers to information contained in this manual or in

other documents.

→ indicates a procedure to be carried out.

1.2. Definition of the word "device"

The term "device" used within the manual refers to the

timer type 1078-1 or 1078-2 (with or without configuration

module type 1077-2).

English

5

2. INTENDED USE

Use of the timer that does not comply with the

instructions could present risks to people, nearby

installations and the environment.

• The timer, with or without configuration module, allows

for controlling the activation/deactivation cycle of a

solenoid valve having a compatible supply voltage.

• Installation, adjustment and maintenance of the device

must be carried out by qualified staff with an electrical

certification for the 110/230 V AC energized versions.

• Protect the device from electromagnetic perturbations,

ultraviolet radiations and, when installed outside, from

the effects of climatic conditions.

• Use this device in compliance with the characteristics

and commissioning and use conditions specified in the

contractual documents and in the instruction manual.

• Requirements for safe and proper operation are proper

transport, storage and installation as well as careful

operation and maintenance.

• Only use the device as intended.

2.1. Restraints

Observe any existing restraints when the device is exported.

English

6

2.2. Foreseeable misuse

• Do not use this device in a potentially explosive atmosphere.

• Do not subject the device to mechanical loads (e.g. by

placing objects on top of it or by using it as a step).

• Do not make any external modifications to the device. Do

not paint or varnish any part of the device.

English

7

3. BASIC SAFETY INFORMATION

This safety information does not take into account:

• any contingencies or occurences that may arise during

assembly, use and maintenance of the devices.

• the local safety regulations that the operator must ensure

the staff in charge of assembly observe.

danger

Danger due to electrical voltage.

• Shut down the electrical power source of all the conductors and isolate it before carrying out work on the

system.

English

7

Page 3

8

Various dangerous situations

To avoid injury take care to:

• prevent any accidental power supply switch-on.

• carry out installation and maintenance by qualified and

skilled staff with the appropriate tools.

• guarantee a defined or controlled restarting of the

process, after a power supply interruption.

• use the device only if in perfect working order and in

compliance with the instructions provided in the user

manual.

• observe the general technical rules during the planning

and use of the device.

English

9

note

Elements / Components sensitive to electrostatic

discharges

• This device contains electronic components sensitive

to electrostatic discharges. They may be damaged

if they are touched by an electrostatically charged

person or object. In the worst case scenario, these

components are instantly destroyed or go out of order

as soon as they are activated.

• To minimise or even avoid all damage due to an electrostatic discharge, take all the precautions described

in the EN 61340-5-1 norm.

• Also ensure that you do not touch any of the energized

electrical components.

English

9

10

4. GENERAL INFORMATION

4.1. Manufacturer's address and

international contacts

To contact the manufacturer of the device, use following

address:

Bürkert SAS

Rue du Giessen

BP 21

F-67220 TRIEMBACH-AU-VAL

The addresses of our international branches can be found

on the last pages of this manual.

They can also be found on the Internet under:

www.burkert.com

4.2. Warranty conditions

The condition governing the legal warranty is the conforming use of the device in observance of the operating

conditions specified in this manual.

4.3. Information on the Internet

You can find the user manual and technical datasheets

regarding type 1078 or 1077 on the internet at:

www.burkert.com

English

11

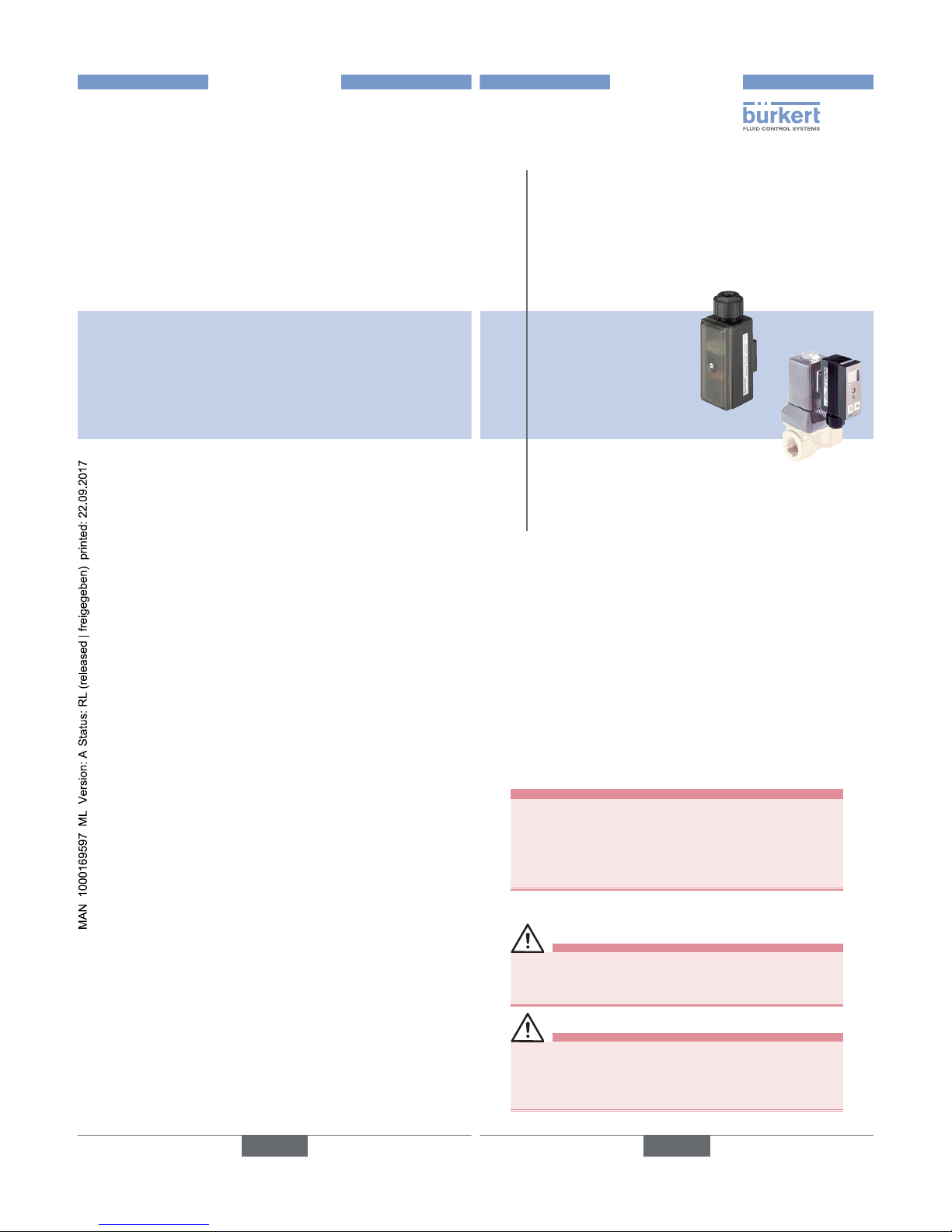

5. AREA OF APPLICATION

The timer 1078-1 or 1078-2 is plugged on a solenoid valve

by means of an EN 175301-803 form A fixed connector.

The timer allows for controlling the activation/deactivation

cycle of the solenoid valve.

5.1. General description

5.1.1. Construction

The timer 1078-1 or 1078-2 is a class II control device and

a Type 1 action device (see EN 60730-1 standard).

The timer 1078-1 or 1078-2 is an electronic module enclosed

in a housing with a transparent cover, a cable gland and an

EN 175301-803 female fixed connector, form A, with seal.

The timer is attached to the solenoid valve by means of a

screw.

• The timer 1078-1 is connected to the power supply

through the cable gland, by means of a 3-pole terminal

block in the housing.

• The timer 1078-2 is connected to the power supply

through the cable gland, by means of a 5-pole terminal

block in the housing.

The timer energizes the solenoid valve.

The timer 1078-2 can be configured by means of a configu-

ration module 1077-2, inserted onto the 1078-2 in place of

English

11

Page 4

12

its cover.

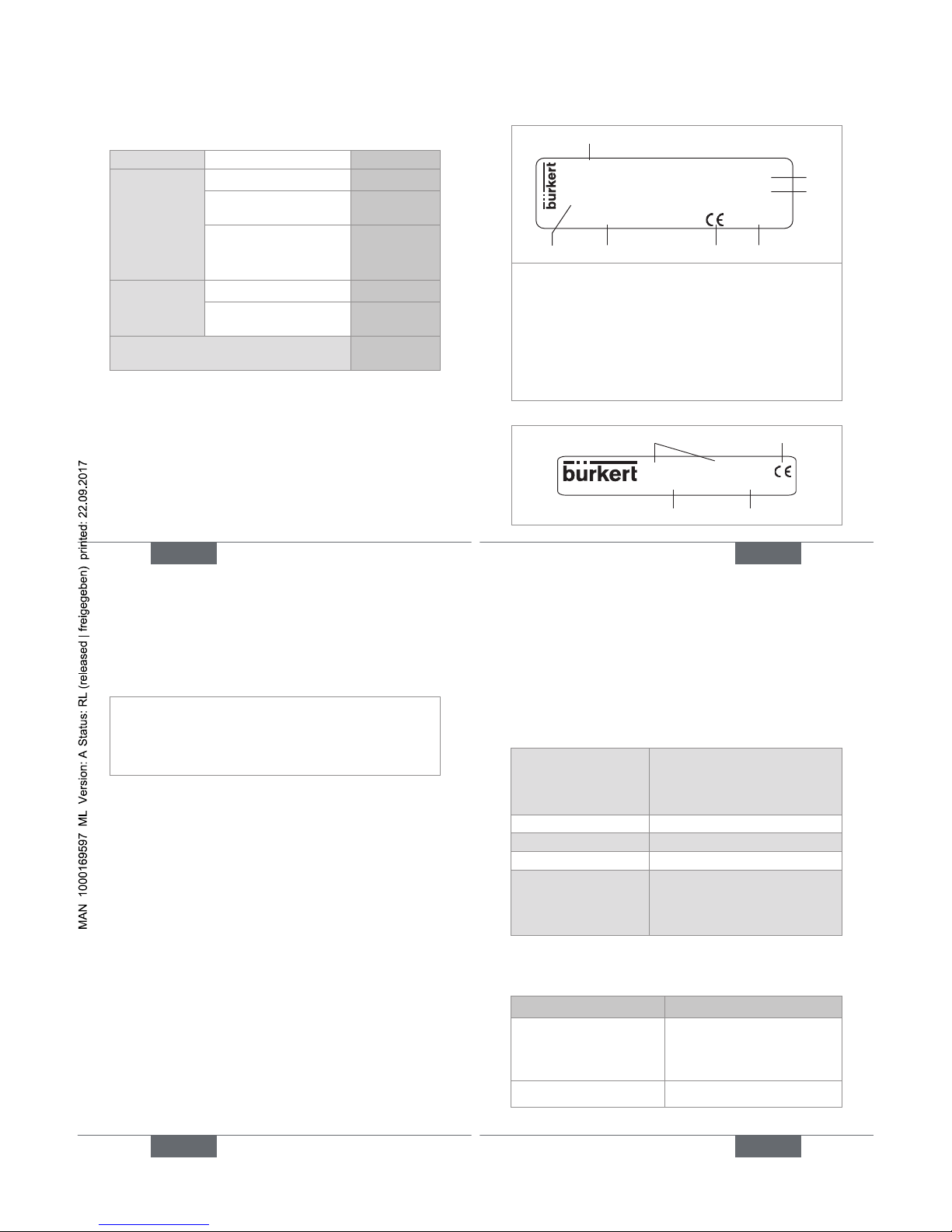

5.2. Available versions

Device Supply voltage Order code

Timer 1078-1

12-24 V DC 060647

24-48 V AC, 50-60 Hz,

24-48 V DC

060621

110-230 V AC,

50-60 Hz

060620

Timer 1078-2

12-24 V DC 060648

24-48 V AC, 50-60 Hz,

24-48 V DC

060629

Configuration module 1077-2 for timer

1078-2

060638

English

13

5.3. Description of the name plates

1078-1

Supply: 110-230V/50-60Hz 0,5A

Output: 110-230V/50-60Hz 0,5A

S/N 1000

00060620 W43ML

Made in France

1

2

3

6 5 47

1. Type of the device

2. Power supply data

3. Data of the power supplied to the solenoid valve

4. Construction code

5. Conformity logo

6. Order code

7. Serial number

Fig. 1: Nameplate of the 1078

1077-000-00-002-000-000

00060638 W45LP

Made in France

1 2

4 3

English

13

14

1. Type of the device

2. Conformity logo

3. Construction code

4. Order code

Fig. 2: Nameplate of the 1077

English

15

6. TECHNICAL DATA

6.1. Conditions of use

Ambient temperature

• 1078

• 1077

(in operation)

• -10°C...60°C

• 0°C...60°C

Air humidity < 85%, non condensated

Height above sea level max. 2000 m

Degree of pollution 2

Protection rating IP65, when screwed to the

solenoid valve at a torque rating

between 0,5 and 0,8 Nm, wired

and cable gland tightened

6.2. General technical data

6.2.1. Mechanical data

Part Material

Housing

• 1078

• 1077-2

• PA6 or polyarylamide

• Polyamide

Cover PSU

English

15

Page 5

16

Part Material

Female EN 175301-803

fixed connector

PA6

PG9 cable gland PA6 or polyarylamide

M3x45 or M3x55 screw 1, in stainless steel AL2

Seal for the female fixed

connector

NBR

32,5

90

M3x45

42,5

36

21

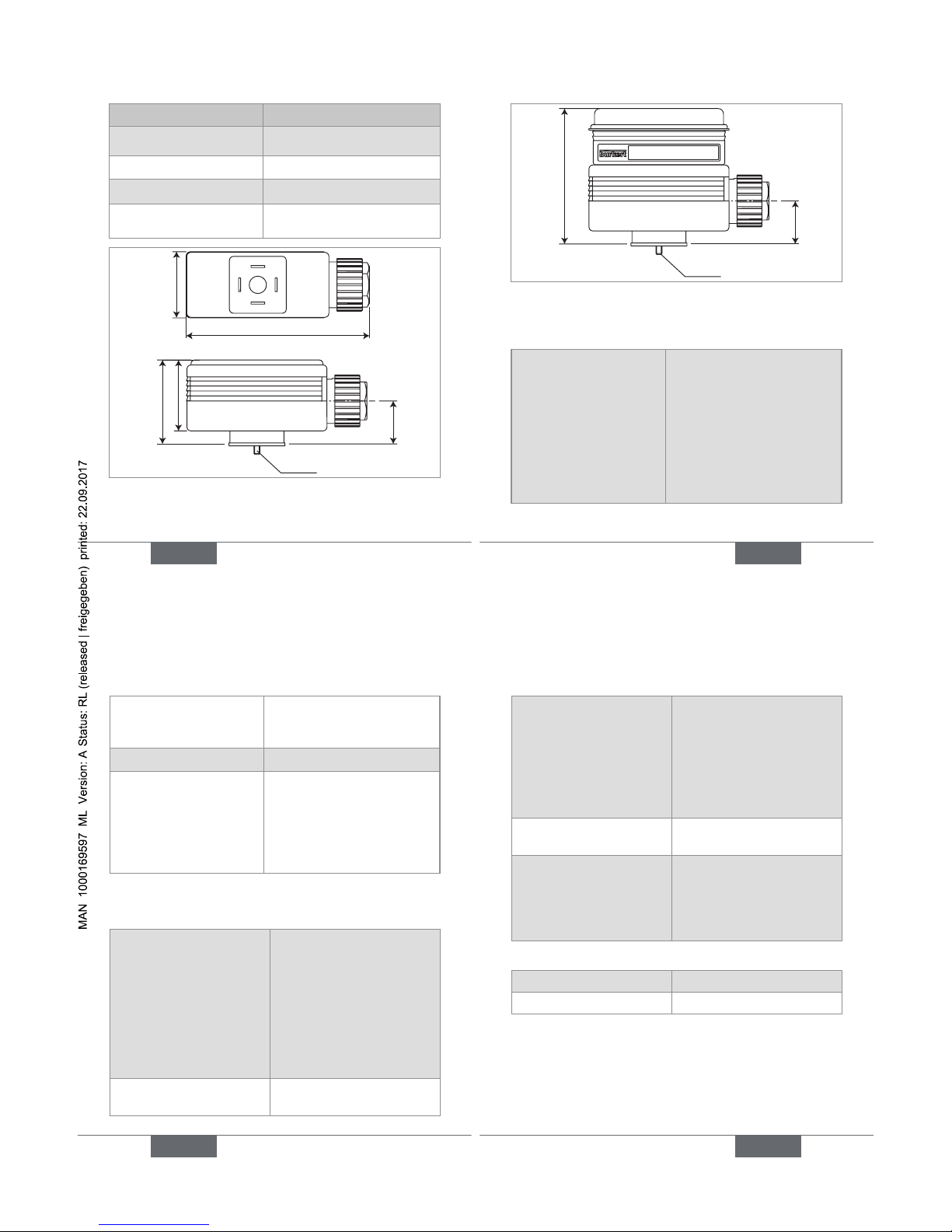

Fig. 3: Dimensions [mm] of the 1078

English

17

53,5

21

M3x55

Fig. 4: Dimensions [mm] of the 1078-2 combined with

the 1077-2

6.2.2. General features

Time range (1078-1)

(mechanical adjustment

using the 6 switches N°

1, 2, 3, 6, 7 and 8)

• 0,5 to 10 s (default setting)

• 1,5 to 30 s

• 5 to 100 s

• 0,5 to 10 min.

• 1,5 to 30 min.

• 5 to 100 min.

• 12 to 240 min.

• 0,5 to 10 h

English

17

18

Time range (

1078-2)

(digital adjustment through

module 1077-2)

0,2 s to 9999 h, continuous

Tolerance (1078-2) 1 %

Resolution (1078-2)

• up to 199 s

• up to 199 min.

• up to 99 h

• up to 9999 h

• 10 ms

• 1 s

• 1 min.

• 1 h

6.2.3. Electrical data

Table 1: Electrical data of the 1078

Power supply

• 1078-1

• 1078-2

Tolerance 10 %

• 12-24 V DC, max. 2 A

or 24-48 V AC/DC, max

1,5 A or 110/230 V AC,

max 0,5 A

• 12-24 V DC, max. 2 A

or 24-48 V AC/DC, max

1,5 A

Protection against polarity

reversal

No, for devices energized

with a direct voltage

English

19

Power supplied to the

solenoid valve

• Version 12-24 V DC

• Version 24-48 V AC/DC

• Version 110/230 V AC

• 12-24 V DC, max. 2 A

• 24-48 V DC, max. 1,5 A

• 110/230 V DC, max.

0,5 A

Clearance and leakage

path

Acc. to VDE 0100

Electrical connection

• Cable diameter

• Cross section of the

wires

Through PG9 cable gland

• 6 to 7 mm

• max. 1,5 mm

2

Table 2: Electrical data of the 1077-2

Supply voltage Energized by the 1078-2

Power consumed 5 mW

English

19

Page 6

20

7. INSTALLATION AND WIRING

7.1. Safety information

danger

Risk of injury due to electrical voltage.

• Shut down the electrical power source of all the conductors and isolate it before carrying out work on the

system.

• Do not unscrew the cover of a powered device.

• Observe all applicable accident protection and safety

guidelines for electrical equipment.

Warning

Risk of injury due to nonconforming installation.

• The electrical installation can only be carried out by

qualified and skilled staff with the appropriate tools.

• Install appropriate safety devices (correctly rated fuse

and/or circuit-breaker).

English

21

Warning

Risk of injury due to unintentional switch on of power

supply or uncontrolled restarting of the installation.

• Take appropriate measures to avoid unintentional activation of the installation.

• Guarantee a defined or controlled restarting of the

process subsequent to any intervention on the device.

Protect the power supply.

• Fit the power supply with a fuse of a value suited

to the load to be switched, if it is not protected

by default.

• Use a shielded cable with an operating temperature > +80 °C.

• Use a high quality electrical power supply,

filtered and regulated.

→ Loosen the screw of the housing cover.

→ Remove the cover.

→ Loosen the nut of the cable gland.

→ Insert the cable through the nut then through the cable

gland and refer to Fig. 5 or Fig. 6 for wiring.

→ Tighten the cable gland.

English

21

22

→ Install the cover and check for the correct position of

the seal.

→ Tighten the supplied screw at a torque rating between

0,5 and 0,8 Nm.

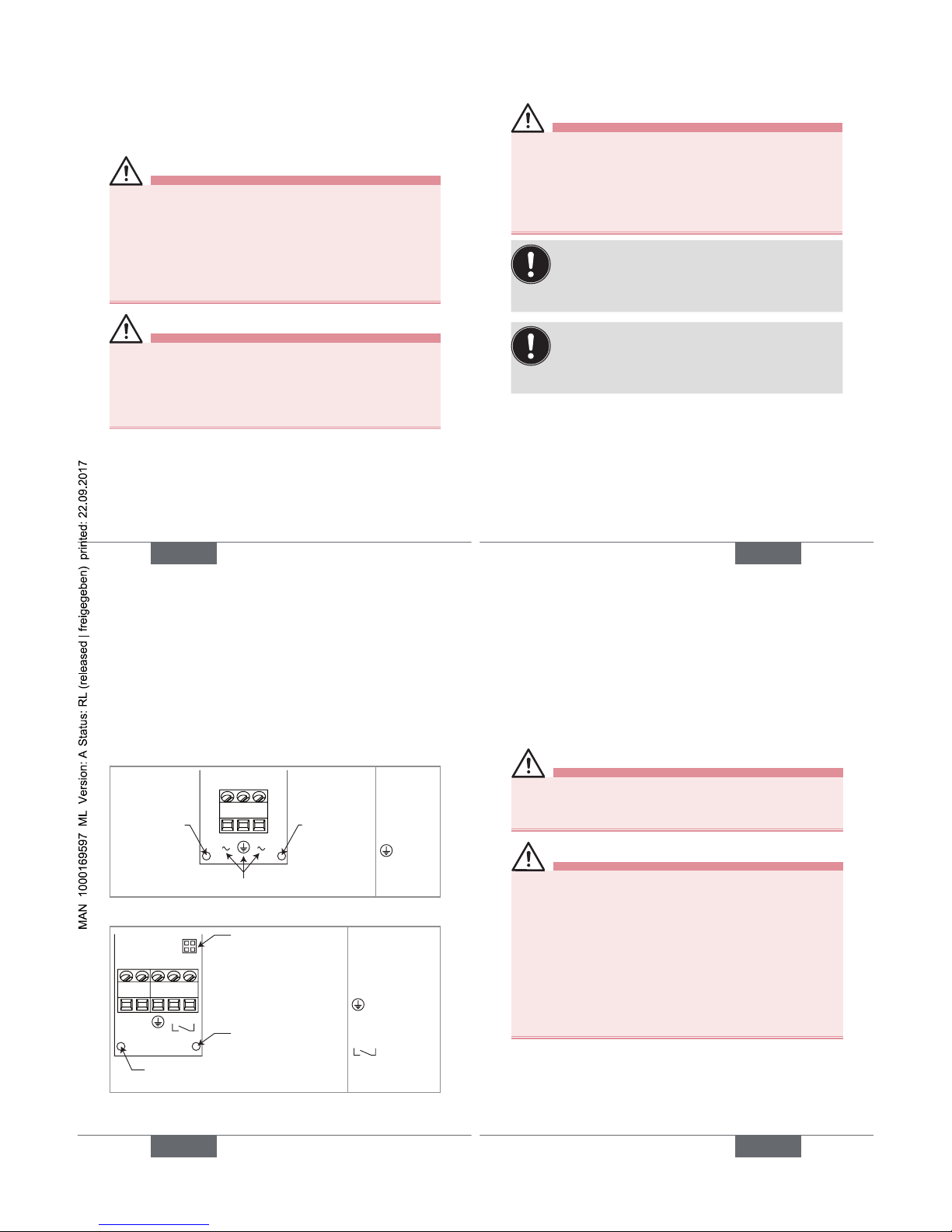

Connection of the power supply

Red LED: ON

during t

on

and

OFF during t

off

Red LED:

ON when

the device is

energized

(+) (-)

(+): V+

(-): 0V

: Protec-

tive earth

Fig. 5: Terminal assignment of the 1078-1

Connection of the

configuration module

1077-2

Red LED: ON when the

device is energized

Red LED: ON during t

on

and OFF during t

off

(+) (-)

Reset

(+): Power supply

(-): Power supply

: Protective

earth

Reset

: Binary input

(ON/OFF contact)

Fig. 6: Terminal assignment of the 1078-2

English

23

8. COMMISSIONING

8.1. Safety information

danger

Risk of electric shock.

• When the device is switched on, the cover must be

closed.

Warning

Danger due to nonconforming commissioning.

Nonconforming commissioning could lead to injuries and

damage the device and its surroundings.

• Before commissioning, make sure that the staff in

charge have read and fully understood the contents of

the manual.

• In particular, observe the safety recommendations and

intended use.

• The device/installation must only be commissioned by

suitably trained staff.

English

23

Page 7

24

note

Risk of damage to the device due to the environment

• Protect the device from electromagnetic perturbations,

ultraviolet radiations and, when installed outside, from

the effects of climatic conditions.

English

25

9. ADJUSTMENT

9.1. Safety information

danger

Risk of injury due to electrical voltage

• Observe all applicable accident protection and safety

guidelines for electrical equipment.

• For the versions fed with 110-230 V AC power supply, shut down the electrical power source of all the

conductors and isolate it before carrying out work on

the system.

Warning

Risk of injury due to nonconforming adjustment.

Nonconforming adjustment could lead to injuries and

damage the device and its surroundings.

• The operators in charge of adjustment must have read

and understood the contents of this manual.

• In particular, observe the safety recommendations and

intended use.

• The device/installation must only be adjusted by suitably trained staff.

English

25

26

9.2. Adjustment of the 1078-1

danger

Risk of electric shock on a version fed with

110-230 V AC power supply.

• To adjust the potentiometers, use an insulated

screwdriver.

note

Risk of damage the electronic board

• To adjust the potentiometers, use an insulated

screwdriver.

The set operation mode starts when the device is

energized.

• Set the operation mode before energizing the

device combined with a solenoid valve.

To adjust the 1078-1:

→ Adjusting the valve operation mode.

English

27

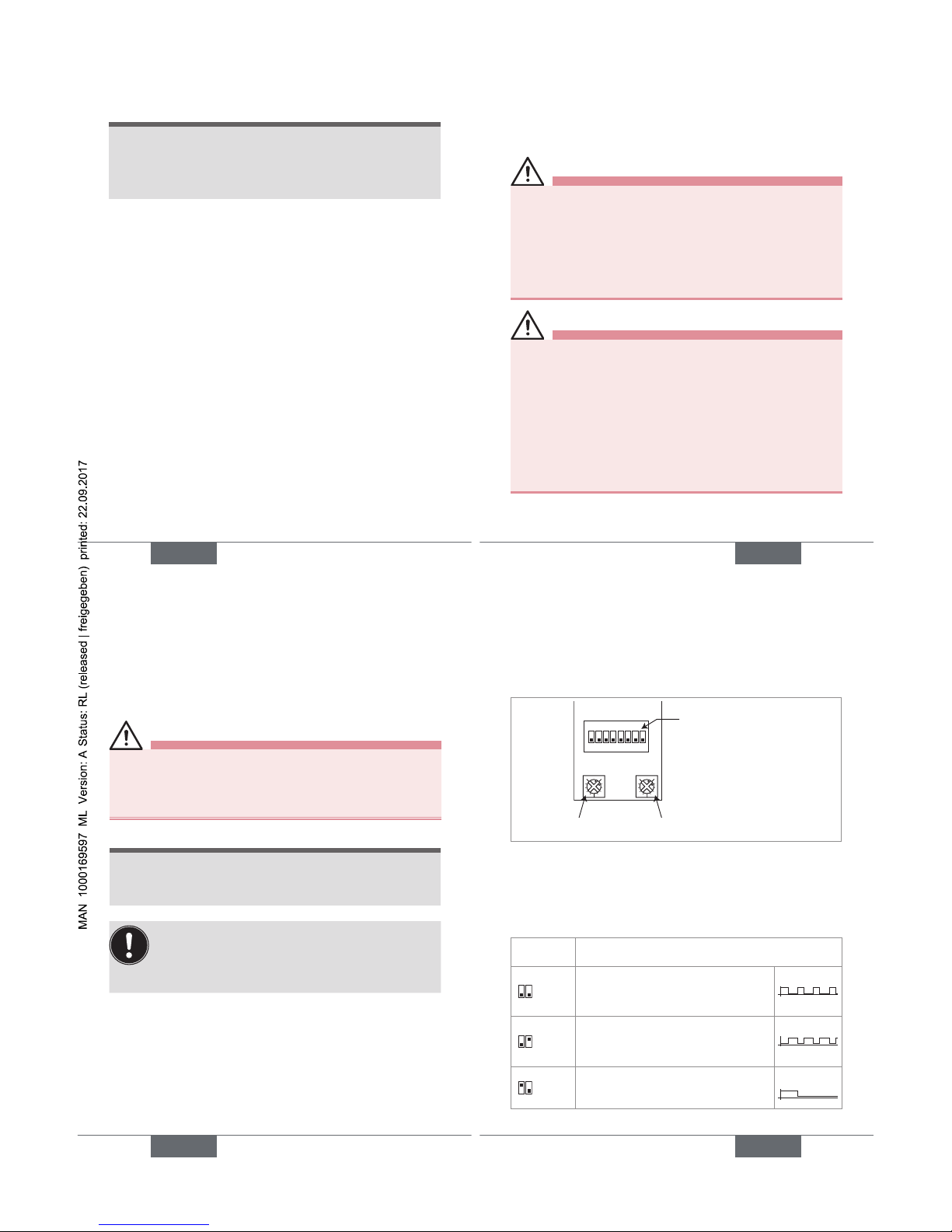

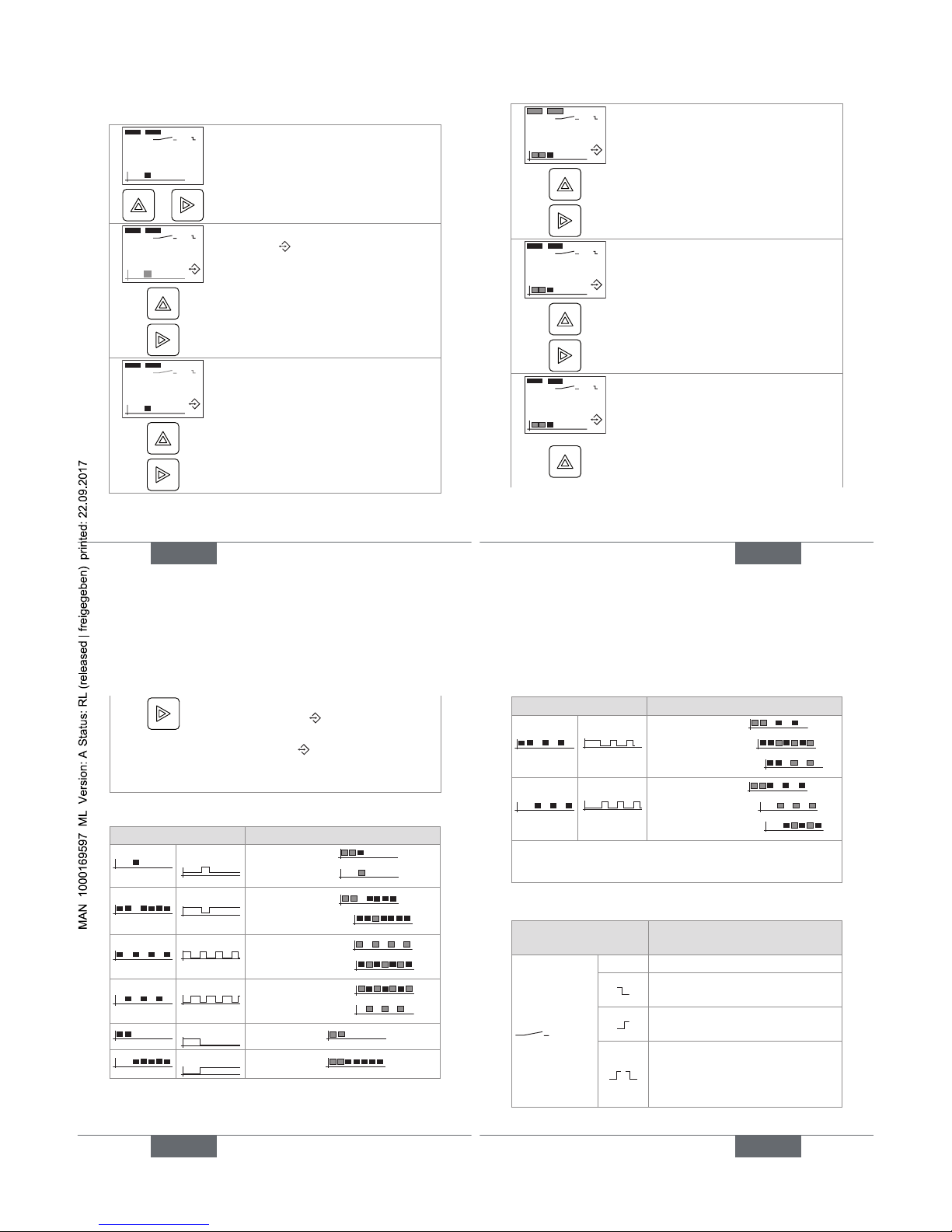

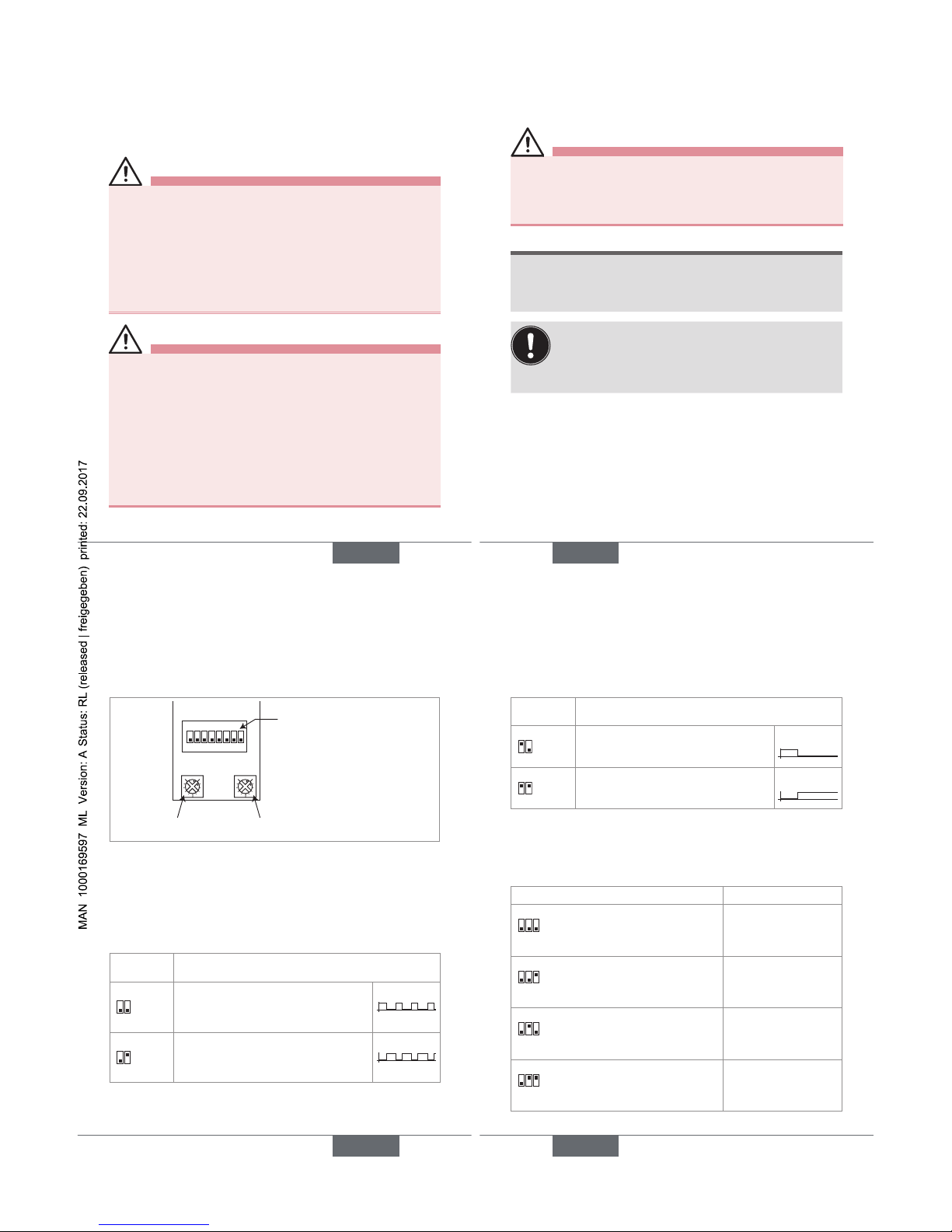

Switches 4 and 5: To choose the

operating mode of the solenoid

valve

Switches 1, 2 and 3: To adjust the

range t

on

.

Switches 6, 7 and 8: To adjust the

range t

off

.

Potentiometer t

off

Potentiometer t

on

1ON2345678

13

13

Fig. 7: Adjustment elements of the 1078-1

The timer 1078-1 allows for controlling the ON (called t

on

) /

OFF (called t

off

) cycle of a solenoid valve.

Four operation modes can be set with switches 4 and 5.

See Fig. 7 and Fig. 8.

Switches 4

and 5

Operation mode of the solenoid valve

4ON5

ON (ton)/OFF (t

off

) cycle of the valve: Set the

time ton and the time t

off

T

on

T

off

4ON5

OFF (t

off

)/ON (ton) cycle of the valve: Set the

time ton and the time t

off

T

on

T

off

4ON5

Timed-out activation of the valve: Only set

the time t

on

T

on

T

off

English

27

Page 8

28

Switches 4

and 5

Operation mode of the solenoid valve

4ON5

Delayed activation of the valve: Only set the

time delay t

off

T

on

T

off

Fig. 8: Operation modes of the 1078-1

→ Set the time range for t

on

with switches 1, 2 and 3 and/

or t

off

with switches 6, 7 and 8. See Fig. 7 and Fig. 9.

Switches 1, 2, 3 (ton) and 6, 7, 8 (t

off

)

Time range

1

ON

23

678

0,5-10 seconds

1

ON

23

678

1,5-30 seconds

1

ON

23

678

5-100 seconds

1

ON

23

678

0,5-10 minutes

1

ON

23

678

1,5-30 minutes

English

29

Switches 1, 2, 3 (ton) and 6, 7, 8 (t

off

)

Time range

1

ON

23

678

5-100 minutes

1

ON

23

678

12-240 minutes

1

ON

23

678

0,5-10 hours

Fig. 9: Time ranges for ton and t

off

→ Set the ON time t

on

with potentiometer ton and/or the

OFF time t

off

with potentiometer t

off

, with a flat screw-

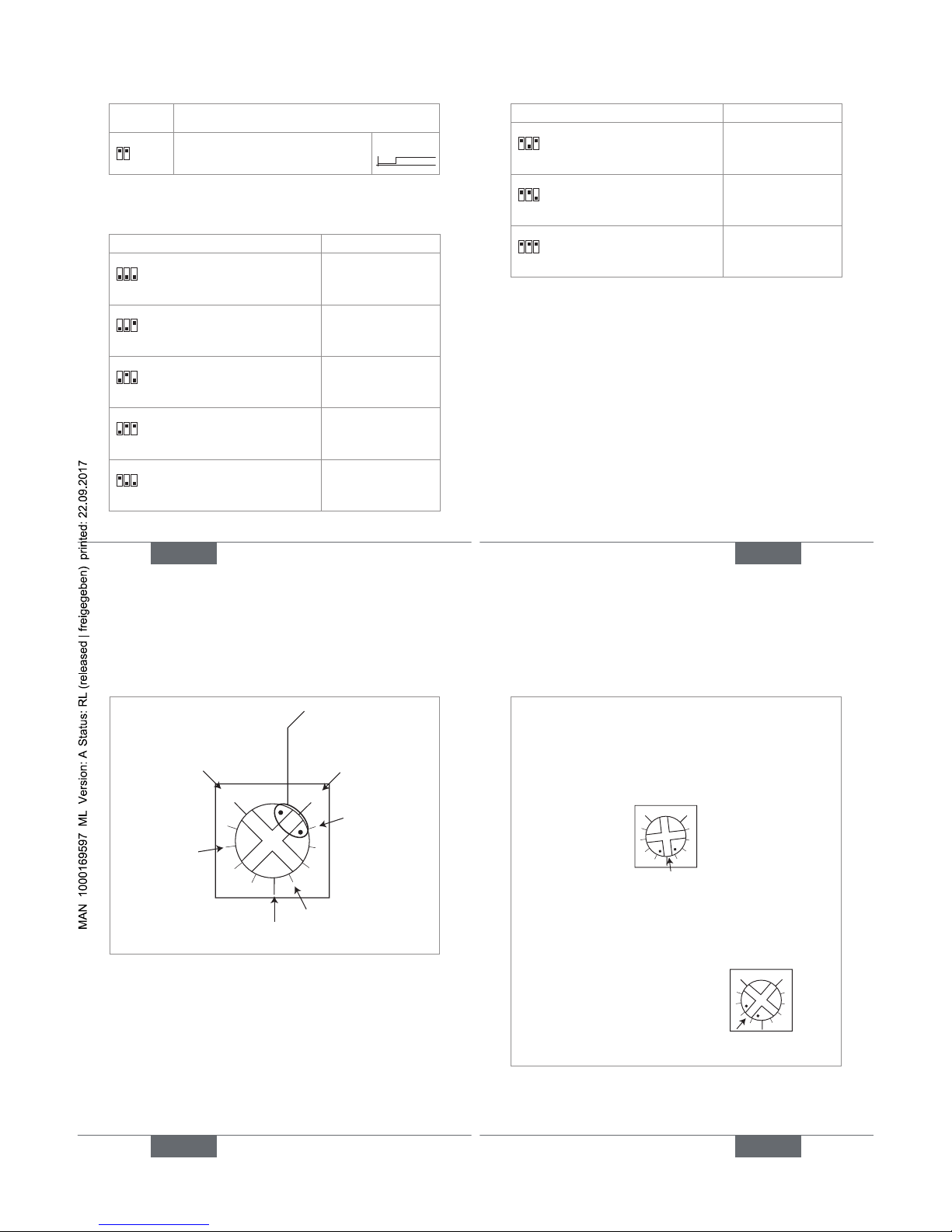

driver of correct size. See Fig. 7 and Fig. 10.

English

29

30

13

Position 1 of the potentiometer = minimum value

of the selected time range

(default position)

Position 3 of the poten-

tiometer = full scale of

the selected time range

min. value of the time

range + 10 % of the

time range

Cursor

min. value of the time range +

40 % of the time range

min. value of the time range +

50 % of the time range

min. value of the

time range +

80 % of the time

range

Fig. 10: Using the potentiometers of the 1078-1

English

31

For example:

The time range for t

on

is set to 5-100 seconds and the

time range for t

off

is set to 1,5-30 minutes.

→ If t

on

= 50 seconds = min. value of the range (5 s)

+ 45 s (45/95*100 = 47 % of the range), set the

cursor of the t

on

potentiometer as follows:

ton = min. value of the range + 47 % of the time range

13

→ If t

off

= 20 seconds = min. value of the range (1,5

min.) + 18,5 min. (18,5/28,5*100 = 65 % of the

range), set the cursor of the t

off

potentiometer as

follows:

13

t

ooff

= min. value of the range + 65 % of

the time range

Fig. 11: Setting example of potentiometers ton and t

off

of

the 1078-1

English

31

Page 9

32

9.3. Adjustment of the 1078-2

danger

Risk of electric shock.

• Shut down the electrical power source of all the conductors and isolate it to avoid modifying the parameters of the 1078-2 before inserting the configuration

module type 1077-2 on the timer 1078-2.

To change the parameters of the 1078-2, install a configuration module type 1077-2 on the timer 1078-2.

→ Check that both red LEDs are OFF.

→ Loosen the screw from the 1078-2.

→ Remove the cover.

→ Install the 1077-2 with its seal onto the 1078-2, in any

position. See Fig. 6, page 22.

→ Insert the screw supplied with the 1077-2.

→ Tighten the screw at a torque rating between 0,5 and

0,8 Nm.

English

33

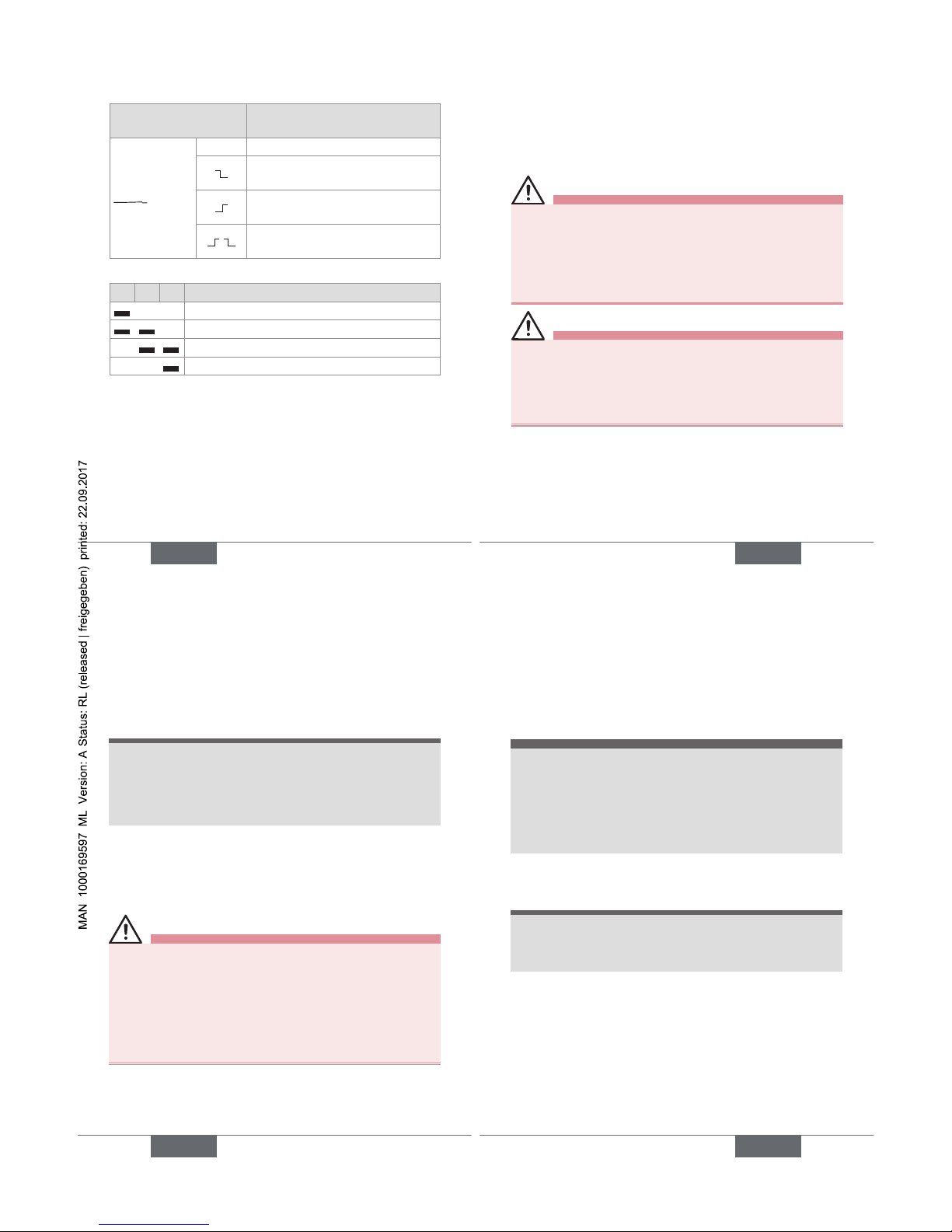

9.3.1. Adjustment keys of the 1077-2

+

To access the Settings level.

• From the Read level to go to the next time.

• From the Settings level to go to the next

function.

• To validate the setting of each function.

• At the end of the adjustment, to transfer the

new settings to the timer.

At the Settings level:

• To change the flashing numerical value.

• To go to the next choice of a function.

Fig. 12: Adjustment of the 1077-2

English

33

34

9.3.2. Display elements of the 1077-2

hms

199:99

Time units for the displayed time:

hours, minutes and/or seconds

- At the Read level:

Shows that the output is

closed

- At the Settings level:

Shows that the ON/OFF

contact is normally open

Setting for the reset

input

Shows a time. If "--:--"

is displayed the set

cycle is completed.

Shows that the device

is beeing adjusted

Shows the operating

mode

- At the Read level:

Shows that the output

is open

- At the Settings level:

Shows that the ON/OFF

contact is normally closed

Fig. 13: Display of the 1077-2

9.3.3. Operating levels

The configuration module has two operating levels: The

Read level and the Settings level.

English

35

• The Read level allows for reading the different times that

have been set and for following their count down.

• The Settings level allows for setting the operating mode,

the reset type and the times (units and values).

9.3.4. Navigating within the Read level

99:00

99:01

10:10

When the device is energized

or when the Settings level

is left, the display shows

the first running time (which

depends on the set operating

mode).The count-down of

that time starts.

The next screens show the

other set times.The number

of times depends on the set

operating mode.

Fig. 14: Navigation at the Read level

English

35

Page 10

36

9.3.5. Accessing the Settings level

99:00

Read level

+

To access the Settings level.

99:01

a) Symbol is dispalyed and the

operating mode flashes.

→ Change the operating mode. See

Fig. 16.

→ Validate the displayed choice and

go to the next function.

99:01

b) The reset type flashes.

→ Change the reset type. See Fig.

17.

→ Validate the displayed choice and

go to the next function.

English

37

99:01

c) The time units and the first time to

be set flash.

→ Choose the time units for the first

time to be set. See Fig. 18.

→ Validate the displayed choice and

go to the next function.

99:01

d) The part of the time, that is associated to the greatest time unit, flashes.

→ Set the time associated to the

greatest time unit. See Fig. 18.

→ Validate the set value and go to the

next function.

99:01

d) The part of the time, that is associated to the smallest time unit, flashes.

→ Set the time associated to the

smallest time unit. See Fig. 18.

English

37

38

→ Validate the set value and end the

adjustment ( goes out and the

settings are saved) or go to the

next time ( is still displayed).

→ To set each additional time, repeat

steps c), d) and e).

Fig. 15: Adjustment of the 1078-2

Function Values to be set

T

on

T

off

• the delay T

off

( )

• the pulse T

on

( )

T

off

T

on

• the pulse Ton ( )

• the duration T

off

( )

T

on

T

off

• the duration T

on

( )

• the duration T

off

( )

T

on

T

off

• the duration T

off

( )

• the duration T

on

( )

T

on

T

off

the pulse Ton ( )

T

on

T

off

the delay T

off

( )

English

39

Function Values to be set

Ton1

T

off

Ton2

T

off

• the pulse Ton1 ( )

• the duration T

off

( )

• the duration T

on

2 ( ).

T

on

T

off1Toff

2

• the delay T

off

1 ( )

• the duration T

on

( )

• the duration T

off

2 ( ).

T

on

= ON duration of the valve

T

off

= OFF duration of the valve

Fig. 16: Operating modes

Symbols chosen at the

Settings level

The reset occurs...

No reset.

when the ON/OFF contact is

opened.

when the ON/OFF contact is

closed.

when the ON/OFF contact is

closed but the parametered

cycle only begins when the ON/

OFF contact is opened.

English

39

Page 11

40

Symbols chosen at the

Settings level

The reset occurs...

No reset.

when the ON/OFF contact is

closed.

when the ON/OFF contact is

opened.

at each change of state of the

ON/OFF contact.

Fig. 17: Possible resets

h m s Setting range for the time

00:00h to 9999h

00:00h to 99h:59min.

00:00min. to 199min.:59s

00:00s to 199s:99

Fig. 18: Time units and associated setting ranges

English

41

10. MAINTENANCE AND

TROUBLESHOOTING

10.1. Safety information

danger

Risk of injury due to electrical voltage.

• Shut down the electrical power source of all the conductors and isolate it before carrying out work on the

system.

• Observe all applicable accident protection and safety

guidelines for electrical equipment.

Warning

Risk of injury due to non-conforming maintenance.

• Maintenance must only be carried out by qualified and

skilled staff with the appropriate tools.

• Guarantee a defined or controlled restarting of the

process subsequent to any intervention on the device.

English

41

42

10.2. Maintenance and cleaning

note

The device may be damaged by the cleaning

product.

• Clean the device with a cloth slightly dampened with

water or a cleaning product compatible with the materials from which it is made.

Please feel free to contact your Bürkert supplier for any

additional information.

11. SPARE PARTS AND

ACCESSORIES

caution

Risk of injury and/or damage by the use of incorrect

parts.

Incorrect accessories and unsuitable spare parts may

cause injuries and damage the device and the surrounding area.

• Use only original accessories and original spare parts

from Bürkert.

English

43

12. PACKAGING, TRANSPORT

note

Damage due to transport

Transport may damage an insufficiently protected device.

• Transport the device in shock-resistant packaging and

away from humidity and dirt.

• Avoid the effects of heat and cold, which could cause

the storage temperature range to be exceeded.

13. STORAGE

note

Poor storage can damage the device.

• Store the device in a dry place away from dust.

• Ambient storage temperature: -10 to +60 °C.

English

43

Page 12

44

14. DISPOSAL OF THE DEVICE

→ Dispose of the device and its packaging in an environ-

mentally-friendly way.

note

Damage to the environment caused by products

contaminated by fluids.

• Keep to the existing provisions on the subject of waste

disposal and environmental protection.

Note

Comply with the national and/or local regulations

which concern the area of waste disposal.

English

Page 13

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifications

techniques.

© Bürkert SAS, 2011-2014

Operating Instructions

1408/01_EU-ml_00563282_Original_FR

Types 1078-1 / 1078-2

Zeitsteuerung ohne oder mit Bedieneinheit Typ 1077-2

Bedienungsanleitung

deutsch

2

1. DIE BEDIENUNGSANLEITUNG .........................................3

2. BESTIMMUNGSGEMÄSSE VERWENDUNG................6

3. GRUNDLEGENDE SICHERHEITSHINWEISE ..............8

4. ALLGEMEINE HINWEISE .................................................... 10

5. ANWENDUNGSBEREICH ................................................... 11

6. TECHNISCHE DATEN ..........................................................15

7. INSTALLATION UND VERKABELUNG ......................... 21

8. INBETRIEBNAHME ................................................................ 24

9. BEDIENUNG ............................................................................. 26

10. WARTUNG, FEHLERBEHEBUNG ...................................42

11. ERSATZTEILE, ZUBEHÖR .................................................43

12. VERPACKUNG, TRANSPORT ........................................... 44

13. LAGERUNG ................................................................................44

14. ENTSORGUNG ........................................................................45

deutsch

3

1. DIE BEDIENUNGSANLEITUNG

Die Bedienungsanleitung beschreibt den gesamten Lebenszyklus des Gerätes. Bewahren Sie diese Anleitung so auf,

dass sie für jeden Benutzer zugänglich ist und jedem neuen

Eigentümer des Gerätes wieder zur Verfügung steht.

Die Bedienungsanleitung enthält wichtige Informationen zur Sicherheit!

Das Nichtbeachten dieser Hinweise kann zu gefährlichen

Situationen führen.

• Die Bedienungsanleitung muss gelesen und verstanden werden.

1.1. Darstellungsmittel

GEFAHR!

Warnt vor einer unmittelbaren Gefahr!

• Bei Nichteinhaltung sind Tod oder schwere Verletzungen die Folge.

WARNUNG!

Warnt vor einer möglicherweise gefährlichen

Situation!

• Bei Nichteinhaltung drohen schwere Verletzungen

oder auch der Tod.

deutsch

Page 14

4

VORSICHT!

Warnt vor einer möglichen Gefährdung!

• Nichtbeachtung kann mittelschwere oder leichte Verletzungen zur Folge haben.

HINWEIS!

Warnt vor Sachschäden!

• Bei Nichtbeachtung kann das Gerät oder die Anlage

beschädigt werden.

bezeichnet wichtige Zusatzinformationen, Tipps

und Empfehlungen, die für Ihre Sicherheit und die

einwandfreie Funktion des Gerätes wichtig sind.

bezeichnet wichtige Zusatzinformationen, Tipps

und Empfehlungen.

verweist auf Informationen in dieser Bedienungsanleitung oder in anderen Dokumentationen.

→ markiert einen Arbeitsschritt, den Sie ausführen

müssen.

deutsch

5

1.2. Begriffsdefinition "Gerät"

Der in dieser Anleitung verwendete Begriff "Gerät“ steht

immer für die Zeitsteuerung Typ 1078-1 oder 1078-2 (mit

oder ohne Bedieneinheit Typ 1077-2).

deutsch

6

2. BESTIMMUNGSGEMÄSSE

VERWENDUNG

Bei nicht bestimmungsgemäßem Einsatz der Zeitsteuerung können Gefahren für Personen, Anlagen in

der Umgebung und die Umwelt entstehen.

• Die Zeitsteuerung, ohne oder mit Bedieneinheit, dient

zur Steuerung des On/Off-Zyklus eines Magnetventils

mit kompatibler Versorgungsspannung.

• Installation, Inbetriebnahme, Bedienung und Wartung

des Geräts müssen nur durch geschultes Personal mit

elektrischer Berechtigung für die mit 110/230 V AC

versorgten Geräte durchgeführt werden.

• Schützen Sie das Gerät vor elektromagnetischen Störungen, U.V.-Bestrahlung und bei Außenanwendung

vor Witterungseinflüssen.

• Für den Einsatz sind die in den Vertragsdokumenten

und der Bedienungsanleitung spezifizierten zulässigen Daten, Betriebs- und Einsatzbedingungen zu

beachten.

• Voraussetzungen für den sicheren und einwandfreien

Betrieb sind sachgemäßer Transport, sachgemäße

Lagerung und Installation sowie sorgfältige Bedienung

und Instandhaltung.

• Setzen Sie das Gerät nur bestimmungsgemäß ein.

deutsch

7

2.1. Beschränkungen

Beachten Sie bei der Ausfuhr des Gerätes gegebenenfalls

bestehende Beschränkungen.

2.2. Vorhersehbarer Fehlgebrauch

• Dieses Gerät nicht in explosionsgefährdeten Bereichen

einsetzen.

• Belasten Sie das Gehäuse nicht mechanisch (z. B. durch

Ablage von Gegenständen oder als Trittstufe).

• Nehmen Sie keine äußerlichen Veränderungen an den

Gerätegehäusen vor. Lackieren Sie keinen Teil des Geräts.

deutsch

Page 15

8

3. GRUNDLEGENDE

SICHERHEITSHINWEISE

Diese Sicherheitshinweise berücksichtigen keine:

• Zufälligkeiten und Ereignisse, die bei Montage, Betrieb und

Wartung der Geräte auftreten können.

• Ortsbezogene Sicherheitsbestimmungen, für deren Einhaltung, auch in Bezug auf das Installations- und Wartungspersonal, der Betreiber verantwortlich ist.

Gefahr durch elektrische Spannung!

• Schalten Sie vor Beginn der Arbeiten in jedem Fall alle

existierenden am Gerät angeschlossenen SpannungsVersorgungen ab, und sichern Sie diese vor unbeabsichtigtem Wiedereinschalten!

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten,

• dass die Anlage nicht unbeabsichtigt betätigt werden

kann.

• Installations- und Instandhaltungsarbeiten dürfen nur

von autorisiertem Fachpersonal mit geeignetem Werkzeug durchgeführt werden.

deutsch

9

Allgemeine Gefahrensituationen.

Zum Schutz vor Verletzungen ist zu beachten,

• Nach einer Unterbrechung der elektrischen Versorgung ist ein definierter oder kontrollierter Wiederanlauf

des Prozesses zu gewährleisten.

• Betreiben Sie das Gerät nur in einwandfreiem Zustand

und unter Beachtung der Bedienungsanleitung.

• Bei der Einsatzplanung und dem Betrieb des Gerätes

die allgemeinen Regeln der Technik einhalten.

HINWEIS!

Elektrostatisch gefährdete Bauelemente / Baugruppen!

• Das Gerät enthält elektronische Bauelemente, die

gegen elektrostatische Entladung (ESD) empfindlich

reagieren. Berührung mit elektrostatisch aufgeladenen Personen oder Gegenständen gefährdet diese

Bauelemente. Im schlimmsten Fall werden sie sofort

zerstört oder fallen nach der Inbetriebnahme aus.

• Beachten Sie die Anforderungen nach EN 61340-5-1, um

die Möglichkeit eines Schadens durch schlagartige elektrostatische Entladung zu minimieren bzw. zu vermeiden!

• Achten Sie ebenso darauf, dass Sie elektronische

Bauelemente nicht bei anliegender Versorgungsspannung berühren!

deutsch

10

4. ALLGEMEINE HINWEISE

4.1. Herstelleradresse und

internationale Kontaktadressen

Sie können mit dem Hersteller des Gerätes unter folgender

Adresse Kontakt aufnehmen:

Bürkert SAS

Rue du Giessen

BP 21

67220 TRIEMBACH-AU-VAL

Die Kontaktadressen finden Sie auf den letzten Seiten

dieser Bedienungsanleitung.

Außerdem im Internet unter:

www.burkert.com

4.2. Gewährleistung

Voraussetzung für die Gewährleistung ist der bestimmungsgemäße Gebrauch des Gerätes unter Beachtung der im

vorliegenden Handbuch spezifizierten Einsatzbedingungen.

4.3. Informationen im Internet

Bedienungsanleitungen und Datenblätter zum Typ 1078 oder

1077 finden Sie im Internet unter:

www.buerkert.de

deutsch

11

5. ANWENDUNGSBEREICH

Die Zeitsteuerung 1078-1 oder 1078-2 wird mittels einer

EN 175301-803-Steckdose, Form A, an ein Magnetventil

angeschlossen.

Die Zeitsteuerung dient zur Steuerung des On/Off-Zyklus

des Magnetventils.

5.1. Allgemeine Beschreibung

5.1.1. Aufbau

Die Zeitsteuerung 1078-1 oder 1078-2 ist ein Klasse II

Schaltgerät und ein Typ 1 Funktionsgerät (siehe Norm

EN 60730-1).

Die Zeitsteuerung 1078-1 oder 1078-2 ist eine Elektronikeinheit, die in einem Gehäuse mit durchsichtigem Deckel, eine

Kabelverschraubung und eine EN 175301-803-Steckdose,

Form A mit Dichtung, eingebaut ist. Die Zeitsteuerung wird

auf das Magnetventil mittels einer Schraube festgehalten.

• Die Zeitsteuerung 1078-1 wird an die Spannungs-

versorgung über die Kabelverschraubung und eine

dreipolige Klemmleiste innerhalb des Gehäuses

angeschlossen.

• Die Zeitsteuerung 1078-2 wird an die Spannungs-

versorgung über die Kabelverschraubung und eine

fünfpolige Klemmleiste innerhalb des Gehäuses

deutsch

Page 16

12

angeschlossen.

Die Zeitsteuerung versorgt das Magnetventil mit Strom.

Die Zeitsteuerung 1078-2 kann mittels der Bedieneinheit

1077-2, die Anstelle des Deckels auf den 1078-2 eingesteckt

wird, parametriert werden.

5.2. Verfügbare Ausführungen

Gerät Betriebsspannung

BestellNummer

Zeitsteuerung

1078-1

12-24 V DC 060647

24-48 V AC, 50-60 Hz,

24-48 V DC

060621

110-230 V AC,

50-60 Hz

060620

Zeitsteuerung

1078-2

12-24 V DC 060648

24-48 V AC, 50-60 Hz,

24-48 V DC

060629

Bedieneinheit 1077-2 für Zeitsteuerung

1078-2

060638

deutsch

13

5.3. Beschreibung der

Typenschilder

1078-1

Supply: 110-230V/50-60Hz 0,5A

Output: 110-230V/50-60Hz 0,5A

S/N 1000

00060620 W43ML

Made in France

1

2

3

6 5 47

1. Typ des Geräts

2. Daten der Betriebsspannung

3. Daten der an das Magnetventil versorgte Spannung

4. Herstellungscode

5. Konformitäts-Logo

6. Bestellnummer

7. Serien-Nummer

Bild 1: Typenschild Typ 1078

deutsch

14

1077-000-00-002-000-000

00060638 W45LP

Made in France

1 2

4 3

1. Typ des Geräts

2. Konformitäts-Logo

3. Herstellungscode

4. Bestellnummer

Bild 2: Typenschild Typ 1077

deutsch

15

6. TECHNISCHE DATEN

6.1. Betriebsbedingungen

Umgebungstemperatur

• 1078

• 1077

(im Betrieb)

• -10 °C...60 °C

• 0 °C...60 °C

Luftfeuchtigkeit < 85%, nicht kondensiert

Höhe über

Meeresspiegel

max. 2000 m

Verschmutzungsgrad 2

Schutzart IP65, wenn auf ein Magnetventil

mit einem Drehmoment

zwischen 0,5 und 0,8 Nm

angeschraubt, verkabelt

und Kabelverschraubung

festgeschraubt

deutsch

Page 17

16

6.2. Allgemeine technische Daten

6.2.1. Mechanische Daten

Teil Werkstoff

Gehäuse

• 1078

• 1077-2

• PA6 oder Polyarylamid

• Polyamid

Deckel PSU

EN 175301-803-Steckdose PA6

PG9-Kabelverschraubung PA6 oder Polyarylamid

M3x45- oder M3x55-Schraube 1, aus Edelstahl AL2

Dichtung der Steckdose NBR

deutsch

17

32,5

90

M3x45

42,5

36

21

Bild 3: Abmessungen [mm] des 1078

deutsch

18

53,5

21

M3x55

Bild 4: Abmessungen [mm] des 1078-2 mit 1077-2

6.2.2. Allgemeine technische Daten

Zeitbereich (1078-1)

(mechanische

Einstellung mittels den 6

Auswahlschaltern N° 1, 2,

3, 6, 7 und 8)

• 0,5 bis 10 s

(Grundeinstellung)

• 1,5 bis 30 s

• 5 bis 100 s

• 0,5 bis 10 min.

• 1,5 bis 30 min.

• 5 bis 100 min.

• 12 bis 240 min.

• 0,5 bis 10 h

deutsch

19

Zeitbereich (

1078-2)

(digitale Einstellung mittels

Bedieneinheit 1077-2)

0,2 s bis 9999 h,

kontinuierlich

Toleranz (1078-2) 1 %

Auflösung (1078-2)

• Bereich bis 199 s

• Bereich bis 199 min.

• Bereich bis 99 h

• Bereich bis 9999 h

• 10 ms

• 1 s

• 1 min.

• 1 h

6.2.3. Elektrische Daten

Tabelle 1: Elektrische Daten der 1078

Betriebsspannung

• 1078-1

• 1078-2

Toleranz 10 %

• 12-24 V DC, max. 2 A

oder 24-48 V AC/DC, max.

1,5 A oder 110/230 V AC,

max. 0,5 A

• 12-24 V DC, max. 2 A

oder 24-48 V AC/DC,

max. 1,5 A

Schutz gegen Verpolung Nein, bei Ausführungen mit

direkter Betriebsspannung

deutsch

Page 18

20

An das Magnetventil

versorgte Spannung

• Ausführung 12-24 V DC

• Ausführung

24-48 V AC/DC

• Ausführung

110/230 V AC

• 12-24 V DC, max. 2 A

• 24-48 V AC/DC, max.

1,5 A

• 110/230 V AC, max.

0,5 A

Luft- /Kriechstrecken Nach VDE 0100

Elektrischer Anschluss

• Durchmesser des

Kabels

• Querschnitt der Ader

über PG9-Kabelverschraubung

• 6 bis 7 mm

• max. 1,5 mm

2

Tabelle 2: Elektrische Daten des 1077-2

Betriebsspannung über den 1078-2 versorgt

Verbrauch 5 mW

deutsch

21

7. INSTALLATION UND

VERKABELUNG

7.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch Stromschlag!

• Schalten Sie vor Beginn der Arbeiten in jedem Fall alle

existierenden am Gerät angeschlossenen SpannungsVersorgungen ab, und sichern Sie diese vor unbeabsichtigtem Wiedereinschalten!

• Den Deckel nicht öffnen, wenn das Gerät unter Spannung steht.

• Beachten Sie die Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Installation!

• Elektrische Installation darf nur durch autorisiertes

Fachpersonal und mit geeignetem Werkzeug durchgeführt werden!

• Verwenden Sie unbedingt geeignete Sicherheitsvorrichtungen (ordnungsgemäß dimensionierte Sicherungen und/oder Schutzschalter).

deutsch

22

WARNUNG!

Verletzungsgefahr durch ungewolltes Einschalten

der Anlage und unkontrollierten Wiederanlauf!

• Anlage vor unbeabsichtigtem Betätigen sichern.

• Nach jedem Eingriff an dem Gerät einen kontrollierten

Wiederanlauf gewährleisten.

Die Spannungsversorgung schützen.

• Die Spannungsversorgung mit einer der zu schaltende Last geeignete Sicherung schützen, wenn

sie noch nicht entsprechend abgesichert ist.

• Ein abgeschirmtes Kabel mit einer Betriebsgrenztemperatur höher als + 80 °C verwenden.

• Eine hochwertige gefilterte und geregelte Spannungsversorgung verwenden.

→ Die Schraube des Deckels lausschrauben.

→ Den Deckel entfernen.

→ Die Überwurfmutter der Kabelverschraubung losschrauben.

→ Das Kabel durch die Überwurfmutter dann durch die

Kabelverschraubung führen und gemäß Bild 5 oder

Bild 6 verkabeln.

→ Die Überwurfmutter zurückschrauben.

deutsch

23

→ Den Deckel aufsetzen, dabei die Dichtung richtig

einsetzen.

→ Die Schraube mit einem Drehmoment zwischen 0,5

und 0,8 Nm festziehen.

Anschluss der Betriebsspannung

Rote LED:

während t

on

ein

und während

t

off

aus

Rote LED: ein

bei eingeschaltetem Gerät

(+) (-)

(+): V+

(-): 0V

:

Schutzerde

Bild 5: Klemmenbelegung des 1078-1

Anschluss der Bedieneinheit 1077-2

Rote LED: ein bei eingeschaltetem Gerät

Rote LED: während t

on

ein und während

t

off

aus

(+) (-)

Reset

(+): Versorgungsspannung

(-): Versorgungsspannung

: Schutzerde

Reset

: Binäreingang zum

externen Reset

(Ein/Aus-Kontakt)

Bild 6: Klemmenbelegung des 1078-2

deutsch

Page 19

24

8. INBETRIEBNAHME

8.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch Stromschlag!

• Wenn das Gerät unter Spannung steht, muss der

Deckel geschlossen sein.

WARNUNG!

Verletzungsgefahr bei unsachgemäßer

Inbetriebnahme!

Nicht sachgemäßer Betrieb kann zu Verletzungen sowie

Schäden am Gerät und seiner Umgebung führen.

• Vor der Inbetriebnahme muss gewährleistet sein, dass

der Inhalt der Bedienungsanleitung dem Bedienungspersonal bekannt ist und vollständig verstanden wurde.

• Besonders zu beachten sind die Sicherheitshinweise

und die bestimmungsgemäße Verwendung.

• Das Gerät/die Anlage darf nur durch ausreichend

geschultes Personal in Betrieb genommen werden.

deutsch

25

HINWEIS!

Gefahr der Beschädigung des Geräts durch die

Umgebung!

• Schützen Sie das Gerät vor elektromagnetischen

Störungen, vor Ultraviolettbestrahlung und bei einer

Außenanwendung vor den Wetterbedingungen.

deutsch

26

9. BEDIENUNG

9.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch Stromschlag!

• Beachten Sie die Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

• Bei einer mit 110-230 V AC gespeisten Version

schalten Sie vor Beginn der Arbeiten in jedem Fall alle

existierenden am Gerät angeschlossenen SpannungsVersorgungen ab, und sichern Sie diese vor unbeabsichtigtem Wiedereinschalten!

WARNUNG!

Verletzungsgefahr bei unsachgemäßer Bedienung!

Nicht sachgemäße Bedienung kann zu Verletzungen,

sowie Schäden am Gerät und seiner Umgebung führen.

• Das Bedienungspersonal muss den Inhalt der Bedienungsanleitung kennen und verstanden haben.

• Besonders zu beachten sind die Sicherheitshinweise

und die bestimmungsgemäße Verwendung.

• Das Gerät/die Anlage darf nur durch ausreichend

geschultes Personal bedient werden.

deutsch

27

9.2. Bedienung des 1078-1

GEFAHR!

Verletzungsgefahr durch Stromschlag bei einer mit

110-230 V AC gespeisten Version!

• Zur Einstellung der Potentiometer einen nicht leitenden

Schraubendreher verwenden.

HINWEIS!

Schaden an der Elektronikplatine!

• Zur Einstellung der Potentiometer einen nicht leitenden

Schraubendreher verwenden.

Die eingestellte Funktion wird gestartet sobald das

Gerät unter Spannung gesetzt wird.

• Die Funktion einstellen, bevor das mit einem Magnetventil verbundene Gerät unter Spannung gesetzt wird.

deutsch

Page 20

28

Zur Einstellung des 1078-1:

→ Die Funktion einstellen.

Schalter 4 und 5: Auswahl der

Funktion des Magnetventils

Schalter 1, 2 und 3: Einstellung

des Zeitbereichs t

on

.

Schalter 6, 7 und 8: Einstellung

des Zeitbereichs t

off

.

Potentiometer t

off

Potentiometer t

on

1ON2345678

13

13

Bild 7: Elemente zur Parametrierung des 1078-1

Die Zeitsteuerung 1078-1 dient zur Steuerung von Ein(t

on

) und Aus- (t

off

) -Schaltzeiten des Magnetventils.

Vier Funktionen können mittels der Schalter 4 und 5 eingestellt werden. Siehe Bild 7 und Bild 8.

Schalter 4

und 5

Funktion des Magnetventils

4ON5

Ein-(ton) / Aus (t

off

) -Zyklus des Magnetventils: Einen Wert für ton und einen Wert

für t

off

einstellen

T

on

T

off

4ON5

Aus- (t

off

) / Ein- (ton) ) -Zyklus des Magnetventils: Einen Wert für ton und einen Wert

für t

off

einstellen

T

on

T

off

deutsch

29

Schalter 4

und 5

Funktion des Magnetventils

4ON5

Einschaltimpuls des Magnetventils: Nur

einen Wert für ton einstellen

T

on

T

off

4ON5

Einschaltverzögerung des Magnetventils:

Nur einen Wert für die Verzögerung t

off

einstellen

T

on

T

off

Bild 8: Funktionen des 1078-1

→ Den Zeitbereich für t

on

mittels der Schalter 1, 2 und 3

und/oder t

off

mittels der Schalter 6, 7 und 8 einstellen.

Siehe Bild 7 und Bild 9.

Schalter 1, 2, 3 (ton) und 6, 7, 8 (t

off

)

Zeitbereich

1

ON

23

678

0,5-10 Sekunden

1

ON

23

678

1,5-30 Sekunden

1

ON

23

678

5-100 Sekunden

1

ON

23

678

0,5-10 Minuten

deutsch

30

Schalter 1, 2, 3 (ton) und 6, 7, 8 (t

off

)

Zeitbereich

1

ON

23

678

1,5-30 Minuten

1

ON

23

678

5-100 Minuten

1

ON

23

678

12-240 Minuten

1

ON

23

678

0,5-10 Stunden

Bild 9: Zeitbereiche für ton und t

off

→ Einschaltzeit t

on

über Potentiometer ton und/oder Aus-

schaltzeit t

off

über Potentiometer t

off

mittels eines geeig-

neten Schraubendreher einstellen. Siehe Bild 7 und

Bild 10.

deutsch

31

Stelle 1 des Potentiometers = Mindestwert des

eingestellten Zeitbereichs

(Grundeinstellung)

Stelle 3 des Potentiometers =

Bereichsende des eingestellten

Zeitbereichs

Mindestwert des Zeitbereichs + 10 % des

Zeitbereichs

Zeiger

Mindestwert des Zeitbereichs +

40 % des Zeitbereichs

Mindestwert des Zeitbereichs +

50 % des Zeitbereichs

Mindestwert des

Zeitbereichs +

80 % des Zeitbe-

reichs

13

Bild 10: Verwendung der Potentiometer des 1078-1

deutsch

Page 21

32

Zum Beispiel:

Bei Einstellung des 5-100 Sekunden-Zeitbereichs für t

on

bzw. 1,5-30 Minuten-Zeitbereichs für t

off

.

→ Bei t

on

= 50 Sekunden = Mindestwert des Bereichs

(5 s) + 45 s (45/95*100 = 47 % des Bereichs) den

Zeiger des Potentiometers ton wie folgt einstellen:

ton = Mindestwert des Zeitbereichs + 47 % des Zeitbereichs

13

→ Bei t

off

= 20 Minuten = Mindestwert des Bereichs

(1,5 min.) + 18,5 min. (18,5/28,5*100 = 65 % des

Bereichs) den Zeiger des Potentiometers t

off

wie folgt

einstellen:

13

t

off

= Mindestwert des Zeitbereichs +

65 % des Zeitbereichs

Bild 11: Einstellungsbeispiel der Potentiometer ton und t

off

des 1078-1

deutsch

33

9.3. Bedienung des 1078-2

GEFAHR!

Verletzungsgefahr durch Stromschlag!

• Bevor die Bedieneinheit 1077-2 auf die Zeitsteuerung

1078-2 eingesetzt wird, alle existierende am Gerät

angeschlossenen Spannungs-Versorgungen abschalten, und diese vor unbeabsichtigtem Wiedereinschalten sichern, damit die Einstellungen des 1078-2 nicht

geändert werden!

Zur Einstellung der Parameter des Geräts 1078-2 die

Bedieneinheit 1077-2 auf die Zeitsteuerung 1078-2

einsetzen.

→ Sicherstellen, dass die 2 roten Lichtanzeigen aus sind.

→ Die Schraube des 1078-2 lösen.

→ Den Deckel abnehmen.

→ Die Bedieneinheit 1077-2 inkl. Dichtung auf die Zeit-

steuerung 1078-2 in jener Richtung einsetzen. Siehe

Bild 6, Seite 23.

→ Die Schraube, die mit der Bedieneinheit 1077-2 mitge-

liefert ist, einsetzen.

→ Die Schraube mit einem Drehmoment zwischen 0,5

und 0,8 Nm festziehen.

deutsch

34

9.3.1. Bedienungstasten des 1077-2

+

Zugriff auf die

Einstellungs-Ebene.

• Auf der Lese-Ebene: Zur nächsten Zeit

ablesen.

• Auf der Einstellungs-Ebene: Zur nächsten

Funktion zugreifen.

• Die Einstellung jeder Funktion bestätigen.

• Am Ende des Einstellungszyklus alle Parameter

in die Zeitsteuerung übertragen.

Auf der Einstellungs-Ebene:

• Die blinkende Ziffer ändern.

• Zugriff auf die nächste Auswahl einer Funktion.

Bild 12: Bedienungstasten des 1077-2

deutsch

35

9.3.2. Anzeige des 1077-2

hms

199:99

Zeiteinheiten für die angezeigte

Zeit: Stunden, Minuten und/oder

Sekunden

- Auf der Lese-Ebene:

Zeigt an, dass der Aus-

gang eingeschaltet ist

- Auf der Einstellungs-

Ebene: Zeigt an, dass der

Resetkontakt stromlos

geöffnet ist

Parametrierung de

Reset-Eingangs

Zeigt eine Zeit an. Bei

Anzeige von "--:--" ist

der eingestellte Zeitzyklus beendet.

Zeigt an, dass das

Gerät eingestellt wird

Zeigt die Funktion an

- Auf der Lese-Ebene:

Zeigt an, dass der Aus-

gang ausgeschaltet ist

- Auf der Einstellungs-

Ebene: Zeigt an, dass der

Resetkontakt stromlos

geschlossen ist

Bild 13: Anzeige des 1077-2

deutsch

Page 22

36

9.3.3. Betriebsebenen

Die Bedieneinheit verfügt über zwei Betriebsebenen: Die

Lese-Ebene und die Einstellungs-Ebene.

• Auf der Lese-Ebene werden die eingestellten Zeiten und

die laufende Restzeit abgelesen.

• Auf der Einstellungs-Ebene werden die Funktion, den

Reset-Typ und die Zeiten (Einheit und Werte) eingestellt.

9.3.4. Navigation auf der Lese-Ebene

99:00

99:01

10:10

Beim Einschalten des

Gerätes oder bei Verlassen

der Einstellungs-Ebene wird

die ablaufende Zeit angezeigt

(hängt von der eingestellten

Funktion ab). Diese Zeit läuft

ab.

Die nächsten Bildschirme

zeigen die weiteren

eingestellten Zeiten an.

Ihre Anzahl hängt von der

eingestellten Funktion ab.

Bild 14: Navigation auf der Lese-Ebene

deutsch

37

9.3.5. Zugriff auf die

Einstellungs-Ebene

99:00

Lese-Ebene

+

Zum Zugriff auf die Einstellungs-Ebene.

99:01

a) Symbol wird angezeigt und die

Funktion blinkt.

→ Funktion ändern. Siehe Bild 16.

→ Angezeigte Auswahl bestätigen und

zum nächsten Parameter zugreifen.

99:01

b) Reset-Typ blinkt.

→ Reset-Typ ändern. Siehe Bild 17.

→ Angezeigte Auswahl bestätigen und

zum nächsten Parameter zugreifen.

deutsch

38

99:01

c) Zeiteinheit und erste zu einstellende

Zeit blinken.

→ Zeiteinheit der ersten Zeit aus-

wählen. Siehe Bild 18.

→ Angezeigte Auswahl bestätigen und

zum nächsten Parameter zugreifen.

99:01

d) Teil der Zeit, der der größten Einheit

entspricht, blinkt.

→ Teil der Zeit, der der größten Einheit

entspricht, einstellen. Siehe Bild 18.

→ Eingestellter Wert bestätigen und

zum nächsten Parameter zugreifen.

99:01

e) Teil der Zeit, der der kleinsten

Einheit entspricht, blinkt.

→ Teil der Zeit, der der kleinsten Einheit

entspricht, einstellen. Siehe Bild 18.

deutsch

39

→ Eingestellter Wert bestätigen und

Parametrierung beenden ( erlischt

und die Einstellungen werden

gespeichert) oder zur nächsten

Zeit-Einstellung ( bleibt angezeigt).

→ Zur Einstellung der nächsten Zeit

die Stufen c), d) und e) wiederholen.

Bild 15: Parametrierung des 1078-2

Funktion Zu einstellende Werte

T

on

T

off

• Verzögerung T

off

( )

• Puls T

on

( )

T

off

T

on

• Puls Ton ( )

• Zeit T

off

( )

T

on

T

off

• Zeit T

on

( )

• Zeit T

off

( )

T

on

T

off

• Zeit T

off

( )

• Zeit T

on

( )

T

on

T

off

Puls Ton ( )

T

on

T

off

Verzögerung T

off

( )

deutsch

Page 23

40

Funktion Zu einstellende Werte

Ton1

T

off

Ton2

T

off

• Puls Ton1 ( )

• Zeit T

off

( )

• Zeit T

on

2 ( ).

T

on

T

off1Toff

2

• Verzögerung T

off

1 ( )

• Zeit T

on

( )

• Zeit T

off

2 ( ).

T

on

= Einschaltzeit des Ventils

T

off

= Ausschaltzeit des Ventils

Bild 16: Funktionen

Auf der EinstellungsEbene ausgewählte

Symbole

Reset erfolgt...

Reset ausgeschaltet.

beim Öffnen des Resetkontaktes.

beim Schließen des

Resetkontaktes.

beim Schließen des Reset-

kontaktes aber die eingestellte

Funktion startet erst beim Öffnen

des Resetkontaktes.

deutsch

41

Auf der EinstellungsEbene ausgewählte

Symbole

Reset erfolgt...

Reset ausgeschaltet.

beim Schließen des

Resetkontaktes.

beim Öffnen des Resetkontaktes.

bei jeder Statusänderung des

Resetkontaktes.

Bild 17: Mögliche Resetdefinitionen

h m s Zeit-Einstellungsbereich

00:00h bis 9999h

00:00h bis 99h:59min.

00:00min. bis 199min.:59s

00:00s bis 199s:99

Bild 18: Zeiteinheiten und entsprechende

Einstellungsbereiche

deutsch

42

10. WARTUNG,

FEHLERBEHEBUNG

10.1. Sicherheitshinweise

GEFAHR!

Verletzungsgefahr durch Stromschlag!

• Schalten Sie vor Beginn der Arbeiten in jedem Fall alle

existierenden am Gerät angeschlossenen SpannungsVersorgungen ab, und sichern Sie diese vor unbeabsichtigtem Wiedereinschalten!

• Beachten Sie die Unfallverhütungs- und Sicherheitsbestimmungen für elektrische Geräte!

WARNUNG!

Gefahr durch unsachgemäße Wartungsarbeiten!

• Wartungsarbeiten dürfen nur durch autorisiertes Fachpersonal und mit geeignetem Werkzeug durchgeführt

werden!

• Nach jedem Eingriff an dem Gerät einen kontrollierten

Wiederanlauf gewährleisten.

deutsch

43

10.2. Wartung und Reinigung

HINWEIS!

Das Gerät kann durch Reinigungsmittel beschädigt

werden.

• Das Gerät nur mit einem Lappen reinigen, der leicht

mit Wasser oder einem Reinigungsmittel angefeuchtet

ist, das sich mit den Werkstoffen verträgt, aus denen

das Gerät besteht.

Für weitere Auskünfte steht Ihnen Bürkert zur Verfügung.

11. ERSATZTEILE, ZUBEHÖR

VORSICHT!

Verletzungsgefahr, Sachschäden durch ungeeignete

Teile!

Falsches Zubehör und ungeeignete Ersatzteile können

Verletzungen und Schäden am Gerät und dessen

Umgebung verursachen.

• Verwenden Sie nur Originalzubehör sowie Originalersatzteile der Fa. Bürkert.

deutsch

Page 24

44

12. VERPACKUNG, TRANSPORT

HINWEIS!

Transportschäden!

Ein unzureichend geschütztes Gerät kann durch den

Transport beschädigt werden.

• Transportieren Sie das Gerät vor Nässe und Schmutz

geschützt in einer stoßfesten Verpackung.

• Das Gerät keinen Temperaturen außerhalb des zulässigen Temperaturbereichs für die Lagerung aussetzen.

13. LAGERUNG

HINWEIS!

Falsche Lagerung kann Schäden am Gerät

verursachen!

• Lagern Sie das Gerät trocken und staubfrei!

• Lagerungstemperatur: -10 bis +60 °C.

deutsch

45

14. ENTSORGUNG

→ Entsorgen Sie das Gerät und die Verpackung

umweltgerecht.

HINWEIS!

Umweltschäden durch Teile, die durch Flüssigkeiten

kontaminiert wurden!

• Geltende Entsorgungsvorschriften und Umweltbestimmungen einhalten!

Hinweis!

Beachten Sie die nationalen

Abfallbeseitigungsvorschriften.

deutsch

46

deutsch

Page 25

www.burkert.com

We reserve the right to make

technical changes without notice.

Technische Änderungen

vorbehalten.

Sous réserve de modifications

techniques.

© Bürkert SAS, 2011-2014

Operating Instructions

1408/01_EU-ml_00563282_Original_FR

Types 1078-1 / 1078-2

Temporisateur sans ou avec module de paramétrage

1077-2

Manuel d‘utilisation

Français

2

1. A PROPOS DE CE MANUEL ................................................ 3

2. UTILISATION CONFORME ...................................................5

3. CONSIGNES DE SÉCURITÉ DE BASE .......................... 7

4. INFORMATIONS GÉNÉRALES ............................................9

5. SECTEUR D‘APPLICATION ................................................ 10

6. CARACTÉRISTIQUES TECHNIQUES .......................................................................................................14

7. INSTALLATION ET CÂBLAGE ..........................................19

8. MISE EN SERVICE ................................................................. 22

9. RÉGLAGE.................................................................................... 24

10. MAINTENANCE ET DEPANNAGE ..................................40

11. PIÈCES DE RECHANGE ET ACCESSOIRES ........... 41

12. EMBALLAGE ET TRANSPORT ......................................... 42

13. STOCKAGE ................................................................................42

14. ELIMINATION DE L'APPAREIL ......................................... 43

français

3

1. A PROPOS DE CE MANUEL

Ce manuel décrit le cycle de vie complet de l‘appareil.

Conservez-le de sorte qu‘il soit accessible à tout utilisateur

et à disposition de tout nouveau propriétaire.

Ce manuel contient des informations importantes

relatives à la sécurité.

Le non-respect de ces consignes peut entraîner des

situations dangereuses.

• Ce manuel doit être lu et compris.

1.1. Symboles utilisés

DANGER

Met en garde contre un danger imminent.

• Son non-respect peut entraîner la mort ou de graves

blessures.

AVERTISSEMENT

Met en garde contre une situation éventuellement

dangereuse.

• Son non-respect peut entraîner de graves blessures,

voire la mort.

français

Page 26

4

ATTENTION

Met en garde contre un risque éventuel.

• Son non-respect peut entraîner des blessures légères

ou de gravité moyenne.

REMARQUE

Met en garde contre des dommages matériels.

• Son non-respect peut entraîner des dommages sur

l'appareil ou l'installation.

désigne des informations supplémentaires, des

conseils ou des recommandations importants.

renvoie à des informations contenues dans ce

manuel ou dans d'autres documents.

→ indique une opération à effectuer.

1.2. Définition du terme "appareil"

Le terme "appareil" utilisé dans ce manuel se rapporte

au temporisateur type 1078-1 ou 1078-2 (avec ou sans

module de paramétrage 1077-2).

français

5

2. UTILISATION CONFORME

L‘utilisation non conforme du temporisateur peut

présenter des dangers pour les personnes, les installations proches et l‘environnement.

• Le temporisateur, sans ou avec module de paramétrage, permet de contrôler le cycle d'activation /

désactivation d'une électrovanne ayant une tension

d'alimentation compatible.

• L'installation, la mise en service, le réglage et la

maintenance de cet appareil doivent être réalisés

par du personnel qualifié, titulaire notamment de

l'habilitation électrique pour les versions alimentées en

110/230 V AC.

• Protéger cet appareil contre les perturbations électromagnétiques, les rayons ultraviolets et, lorsqu'il est installé à l'extérieur, des effets des conditions climatiques.

• Utiliser cet appareil conformément aux caractéristiques et conditions de mise en service et d'utilisation

indiquées dans les documents contractuels et dans le

manuel utilisateur.

• L'utilisation en toute sécurité et sans problème de

l'appareil repose sur un transport, un stockage et une

installation corrects ainsi que sur une utilisation et une

maintenance effectuées avec soin.

• Veiller à toujours utiliser cet appareil de façon

conforme.

français

6

2.1. Restrictions

Respecter les restrictions éventuelles lorsque l‘appareil est

exporté.

2.2. Mauvaise utilisation prévisible

• Ne pas utiliser cet appareil dans une atmosphère explosible.

• Ne pas soumettre l‘appareil à des contraintes mécaniques

(par ex. en y déposant des objets ou en l‘utilisant comme

marchepied).

• N‘apporter aucune modification extérieure au corps. Ne

laquer aucune partie de l‘appareil.

français

7

3. CONSIGNES DE SÉCURITÉ DE

BASE

Ces consignes de sécurité ne tiennent pas compte :

• des imprévus pouvant survenir lors du montage, de

l‘utilisation et de l‘entretien des appareils.

• des prescriptions de sécurité locales que l‘exploitant est

tenu de faire respecter par le personnel chargé du montage.

DANGER

Danger dû à la tension électrique.

• Couper l'alimentation de tous les conducteurs et

consigner l'alimentation électrique avant d'intervenir

sur l'installation.

Situations dangereuses diverses

Pour éviter toute blessure, veiller à :

• empêcher toute mise sous tension involontaire de

l'installation.

• ce que les travaux d'installation et de maintenance

soient effectués par du personnel qualifié et habilité,

disposant des outils appropriés.

• garantir un redémarrage défini et contrôlé du process,

après une coupure de l'alimentation électrique.

français

Page 27

8

Situations dangereuses diverses

Pour éviter toute blessure, veiller à :

• n'utiliser l'appareil qu'en parfait état et en tenant

compte des indications du manuel utilisateur.

• respecter les règles générales de la technique lors de

l'implantation et de l'utilisation de l'appareil.

REMARQUE

Eléments / Composants sensibles aux décharges

électrostatiques

• Cet appareil contient des composants électroniques

sensibles aux décharges électrostatiques. Ils peuvent

être endommagés lorsqu'ils sont touchés par une personne ou un objet chargé électrostatiquement. Dans

le pire des cas, ils sont détruits instantanément ou

tombent en panne sitôt effectuée la mise en route.

• Pour réduire au minimum voire éviter tout dommage

dû à une décharge électrostatique, prenez toutes les

précautions décrites dans la norme EN 61340-5-1.

• Veiller également à ne pas toucher les composants

électriques sous tension.

français

9

4. INFORMATIONS GÉNÉRALES

4.1. Adresse du fabricant et

contacts internationaux

Le fabricant de l‘appareil peut être contacté à l‘adresse

suivante :

Bürkert SAS

Rue du Giessen

BP 21

67220 TRIEMBACH-AU-VAL

Les adresses des filiales internationales figurent sur les

dernières pages de ce manuel imprimé.

Elles sont également disponibles sur internet sous :

www.burkert.com

4.2. Conditions de garantie

La condition pour bénéficier de la garantie légale est

l‘utilisation conforme de l‘appareil dans le respect des conditions d‘utilisation spécifiées dans le présent manuel.

4.3. Informations sur internet

Retrouvez sur internet le manuel utilisateur et la fiche technique relatifs au type 1078 ou 1077 sous :

www.burkert.fr

français

10

5. SECTEUR D‘APPLICAT ION

Le temporisateur 1078-1 ou 1078-2 se connecte sur une

électrovanne grâce à une embase EN 175301-803 forme A.

Le temporisateur permet de contrôler le cycle d'activation /

désactivation de l'électrovanne.

5.1. Description générale

5.1.1. Construction

Le temporisateur 1078-1 ou 1078-2 est un dispositif de

commande de classe II et d'action de type 1 (voir la norme

EN 60730-1).

Le temporisateur 1078-1 ou 1078-2 est un module électronique contenu dans un boîtier avec un couvercle transparent,

un presse-étoupe, une embase électrique EN 175301-803

femelle, de forme A, et son joint d'étanchéité. Le temporisateur

est maintenu sur l'électrovanne grâce à une vis.

• Le temporisateur 1078-1 est raccordé à l'alimentation

électrique via le presse-étoupe, par l'intermédiaire d'un

bornier à 3 vis à l'intérieur du boîtier.

• Le temporisateur 1078-2 est raccordé à l'alimentation

électrique via le presse-étoupe, par l'intermédiaire d'un

bornier à 5 vis à l'intérieur du boîtier.

Le temporisateur alimente l'électrovanne en électricité.

français

11

Le temporisateur 1078-2 peut être paramétré à l'aide du

module de configuration 1077-2, inséré sur le 1078-2 à la

place du couvercle de ce dernier.

5.2. Versions disponibles

Appareil Tension d'alimentation

Référence de

commande

Temporisateur

1078-1

12-24 V DC 060647

24-48 V AC, 50-60 Hz,

24-48 V DC

060621

110-230 V AC,

50-60 Hz

060620

Temporisateur

1078-2

12-24 V DC 060648

24-48 V AC, 50-60 Hz,

24-48 V DC

060629

Module de paramétrage 1077-2 pour

temporisateur 1078-2

060638

français

Page 28

12

5.3. Description des étiquettes

d‘identification

1078-1

Supply: 110-230V/50-60Hz 0,5A

Output: 110-230V/50-60Hz 0,5A

S/N 1000

00060620 W43ML

Made in France

1

2

3

6 5 47

1. Type de l'appareil

2. Caractéristiques de l'alimentation électrique

3. Caractéristiques de l'alimentation électrique fournie à

l'électrovanne

4. Code de construction

5. Logo de conformité

6. Référence de commande

7. Numéro de série

Fig. 1 : Etiquette d’identification du 1078

français

13

1077-000-00-002-000-000

00060638 W45LP

Made in France

1 2

4 3

1. Type de l'appareil

2. Logo de conformité

3. Code de construction

4. Référence de commande

Fig. 2 : Etiquette d’identification du 1077

français

14

6. CARACTÉRISTIQUES TECHNIQUES

6.1. Conditions d'utilisation

Température ambiante

• 1078

• 1077

(en fonctionnement)

• -10 °C...60 °C

• 0 °C...60 °C

Humidité de l'air < 85 %, non condensée

Altitude 2000 m max.

Degré de pollution 2

Indice de protection IP65, vissé sur une électrovanne

avec un couple de serrage

compris entre 0,5 et 0,8 Nm,

câblé et presse-étoupe serré

6.2. Caractéristiques techniques

générales

6.2.1. Caractéristiques mécaniques

Elément Matériau

Boîtier

• 1078

• 1077-2

• PA6 ou polyarylamide

• Polyamide

français

15

Elément Matériau

Couvercle PSU

Embase électrique femelle

EN 175301-803

PA6

Presse-étoupe PG9 PA6 ou polyarylamide

Vis M3x45 ou M3x55 1, en acier inoxydable AL2

Joint de l'embase

électrique femelle

NBR

32,5

90

M3x45

42,5

36

21

Fig. 3 : Dimensions [mm] du 1078

français

Page 29

16

53,5

21

M3x55

Fig. 4 : Dimensions [mm] du 1078-2 associé au 1077-2

6.2.2. Caractéristiques générales

Plage de temps (1078-1)

(paramétrage mécanique

à l'aide des 6 sélecteurs

N° 1, 2, 3, 6, 7 et 8)

• 0,5 à 10 s (réglage par

défaut)

• 1,5 à 30 s

• 5 à 100 s

• 0,5 à 10 min.

• 1,5 à 30 min.

• 5 à 100 min.

• 12 à 240 min.

• 0,5 à 10 h

français

17

Plage de temps (

1078-2)

(paramétrage numérique

par module 1077-2)

0,2 s à 9999 h en continu

Tolérance (1078-2) 1 %

Résolution (1078-2)

• jusqu'à 199 s

• jusqu'à 199 min.

• jusqu'à 99 h

• jusqu'à 9999 h

• 10 ms

• 1 s

• 1 min.

• 1 h

6.2.3. Caractéristiques électriques

Table 1 : Caractéristiques électriques des 1078

Alimentation électrique

• 1078-1

• 1078-2

Tolérance 10 %

• 12-24 V DC, max. 2 A

ou 24-48 V AC/DC, max

1,5 A ou 110/230 V AC,

max 0,5 A

• 12-24 V DC, max. 2 A

ou 24-48 V AC/DC, max

1,5 A

Protégé contre l'inversion

de polarité

Non, versions alimentées en

tension continue

français

18

Alimentation électrique

fournie à l'électrovanne

• version 12-24 V DC

• version 24-48 V AC/DC

• version 110/230 V AC

• 12-24 V DC, max. 2 A

• 24-48 V AC/DC, max

1,5 A

• 110/230 V AC, max 0,5 A

Distance d'isolement et

lignes de fuite

Selon VDE 0100

Raccordement électrique

• Diamètre du câble

• Section des fils

via presse-étoupe PG9

• 6 à 7 mm

• max. 1,5 mm

2

Table 2 : Caractéristiques électriques du 1077-2

Tension d'alimentation Alimenté par le 1078-2

Puissance consommée 5 mW

français

19

7. INSTALLAT ION ET CÂBLAGE

7.1. Consignes de sécurité

DANGER

Risque de blessure par décharge électrique.

• Couper l'alimentation de tous les conducteurs et

consigner l'alimentation électrique avant d'intervenir

sur l'installation.

• Ne pas dévisser le couvercle lorsque l'appareil est

sous tension.

• Respecter la réglementation en vigueur en matière de

prévention des accidents et de sécurité relative aux

appareils électriques.

AVERTISSEMENT

Risque de blessure dû à une installation non

conforme.

• L'installation électrique ne peut être effectuée que par

du personnel habilité et qualifié, disposant des outils

appropriés.

• Utiliser impérativement les dispositifs de sécurité

adaptés (fusible correctement dimensionné et/ou

coupe-circuit).

français

Page 30

20

AVERTISSEMENT

Risque de blessure dû à une mise sous tension

involontaire de l'installation et à un redémarrage

incontrôlé.

• Protéger l'installation contre toute mise sous tension

involontaire.

• Garantir un redémarrage contrôlé de l'installation,

après toute intervention sur l'appareil.

Protéger l'alimentation électrique.

• Equiper l'alimentation avec un fusible adapté à

la charge à commuter, si l'alimentation n'est pas

protégée par défaut.

• Utiliser un câble blindé avec une température

limite de service > +80 °C.

• Utiliser une alimentation électrique de qualité,

filtrée et régulée.

→ Desserrer la vis du couvercle du boîtier.

→ Retirer le couvercle.

→ Desserrer l'écrou du presse-étoupe.

→ Insérer le câble dans l'écrou puis dans le presse-

étoupe et câbler selon la Fig. 5 ou la Fig. 6.

→ Resserrer le presse-étoupe.

français

21

→ Mettre en place le couvercle, en veillant à la position