Bürkert 0911 Operating Instructions Manual

Operating Instructions

Bedienungsanleitung

Instructions de Service

Type 0911

2 stage controller

2-Punkt-Regler

2 Régulateur Ponctuel

Id. No. 788 263

788 264

788 265

788 266

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous resérve de modification techniques.

© 2004 - 2017 Bürkert Werke GmbH & Co. KG

Operating Instructions 1706/03_EU-ml_00804604

2-STAGE CONTROLLER

TYPE 0911

1 GENERAL INFORMATION ........................................................................................................................ 2

1.1 Symbols ......................................................................................................................................................... 2

1.2 Safety notes ................................................................................................................................................ 2

1.3 Scope of delivery ...................................................................................................................................... 3

1.4 Warranty provisions ............................................................................................................................... 3

2 SYSTEM DESCRIPTION ............................................................................................................................ 4

2.1 General description ................................................................................................................................. 4

2.2 Operation ...................................................................................................................................................... 4

2.3 Before the installation ............................................................................................................................. 7

2.4 Parameters .................................................................................................................................................. 8

2.5 Controlling the loads ............................................................................................................................. 11

3 TECHNICAL DATA ..................................................................................................................................... 12

4 ASSEMBLY, INSTALLATION AND COMMISSIONING .......................................................... 13

4.1 General information regarding the installation and operation ......................................... 13

4.2 Assembly .................................................................................................................................................... 13

english

4.3 Electrical connections .......................................................................................................................... 14

5 HOT-KEY FUNCTION ................................................................................................................................. 16

6 FACTORY SETTING .................................................................................................................................. 17

7 MAINTENANCE ............................................................................................................................................18

8 REPAIR WORK .............................................................................................................................................. 19

8.1 Faults............................................................................................................................................................. 19

8.2 Ordering table for basic unit/accessories ................................................................................ 20

0911 - 1

1 GENERAL INFORMATION

1.1 Symbols

The following symbols are used in these operating instructions:

marks a work step that must be carried out.

ATTENTION!

english

NOTE indicates important additional information,

1.2 Safety notes

Please observe the notes in these operating instructions together with the

conditions of use and permitted data that are specified in the data sheets of

the 0911 controller, so that the device will function perfectly and will have a

long service life.

• Keep to the standard engineering rules when planning and operating the

device!

• Installation and maintenance work may only be carried out by specialist

personnel using the correct tools!

• Observe the current regulations on accident prevention and the safety

regulations for electrical devices during the operation and maintenance of

the device!

• Comply with the intended usage of the device.

• Only operate the device with its housing fitted.

• Before connecting the device, check that the power supply corresponds to

the values printed on the device.

• Check that the connections are correct before switching on the device.

• Observe the maximum load of the relay contacts (see technical data).

• Ensure that all sensors are installed with sufficient separation from voltageconducting lines. This will avoid incorrect temperature readings and will

protect the device from voltage interference at the sensor inputs.

• For applications in the industrial sector with critical environments, switch an

RC element in parallel (FT1).

• Always switch off the mains supply before carrying out manipulations on

the system.

• Take suitable measures to exclude unintended operation and damage by

unauthorised operation!

indicates information which, if ignored, could lead to a risk to

your health or to the functionality of the device.

tips and recommendations.

2 - 0911

• Please observe the prescribed environmental conditions with regard to

dampness and temperature limits. Malfunctions cannot be excluded if these

conditions are not complied with.

• Call in your authorised Bürket sales centre in case of doubt or faulty

functioning.

In the case of the non-observance of these notes or of unauthorised

manipulation of the device, we will accept no liability, and the guarantee on the

device and its accessories will become void!

1.3 Scope of delivery

Immediately after receiving the delivery, ensure that the contents agree with

the scope of the delivery. This includes:

• 1 Type 0911 controller

• 1 set of operating instructions (where required, on a data carrier)

• 1 front seal

• 2 Mounting clamps

In case of discrepancy, please contact our Customer centre immediately:

Bürkert Steuer- und Regelungstechnik

or your Bürkert Sales Centre.

1.4 Warranty provisions

english

Service-Abteilung

Chr.-Bürkert-Str. 13-17

D-76453 Ingelfingen

Tel. : 07940-10111

Bürkert provideds a guarantee of one year on the correct functioning of the

controller, under the precondition that the device is employed for its intended

use and under compliance with the specified conditions for use.

If the functions of the device are not in order, the respective device will be

repaired free of charge or will be replaced.

ATTENTION!

The warranty only covers the the controller and its components, but does not cover consequential damage of any kind

that could arise from the failure or malfunctioning of the device.

0911 - 3

2 SYSTEM DESCRIPTION

2.1 General description

2-point controller, 74 x 32 mm, with predefinable control function (e.g., heating/

cooling or moisten/dehumidify)

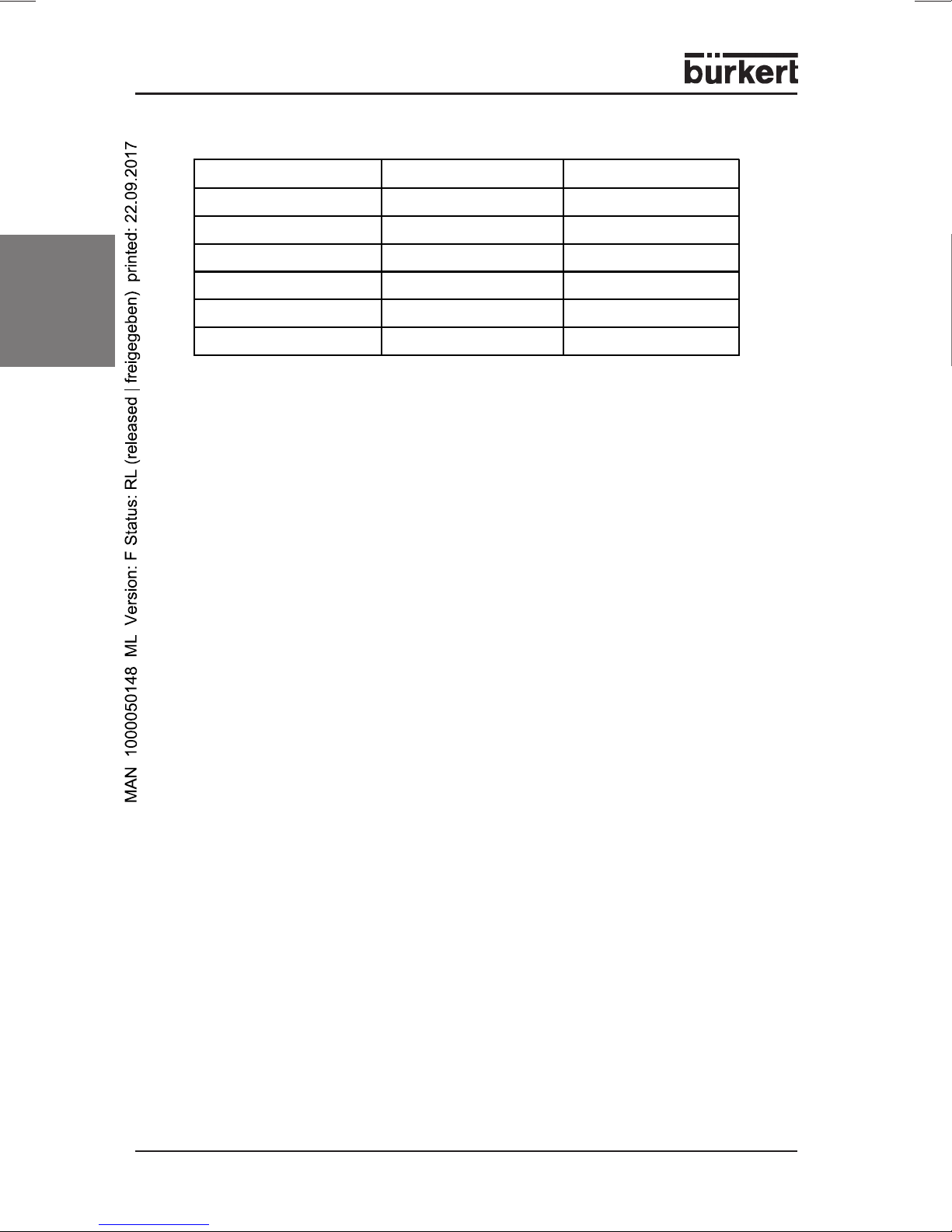

The following models are available:

Type Configurable Input Parameter UDM

english

TU

Temperature

controller

PTC, NTC, Pt100

Thermoelements J, K, S

(Defined by display unit)

UDM = °C

UDM = °F

AU

Control device with

current / voltage

input

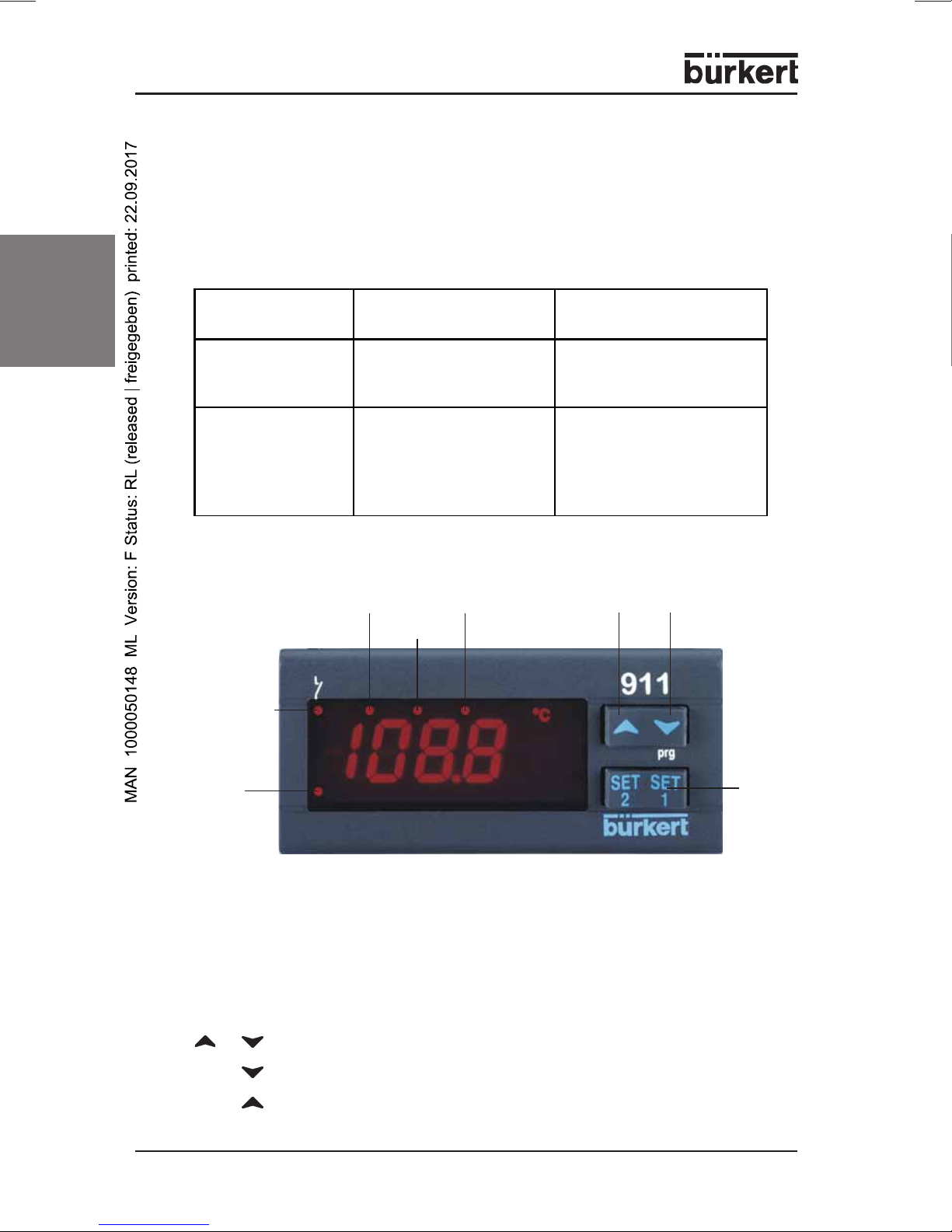

2.2 Operation

Output 1

Alarm

LED

4 ... 20 mA

0 ... 1 V

0 ... 10 V

LED1

ES LED

LED 2

0 = °C; 1 = °F

2 = % RH

3 = bar

4 = PSI

5 = without units

upwards

downwards

SET

button

BUTTONS

SET Display of the set-value,

Changing and confirming a default during the programming phase

BUTTON COMBINATIONS

+

SET+ Selecting the programming level

SET+ Return to the room temperature display

4 - 0911

Locking and unlocking the keypad

LED MESSAGES

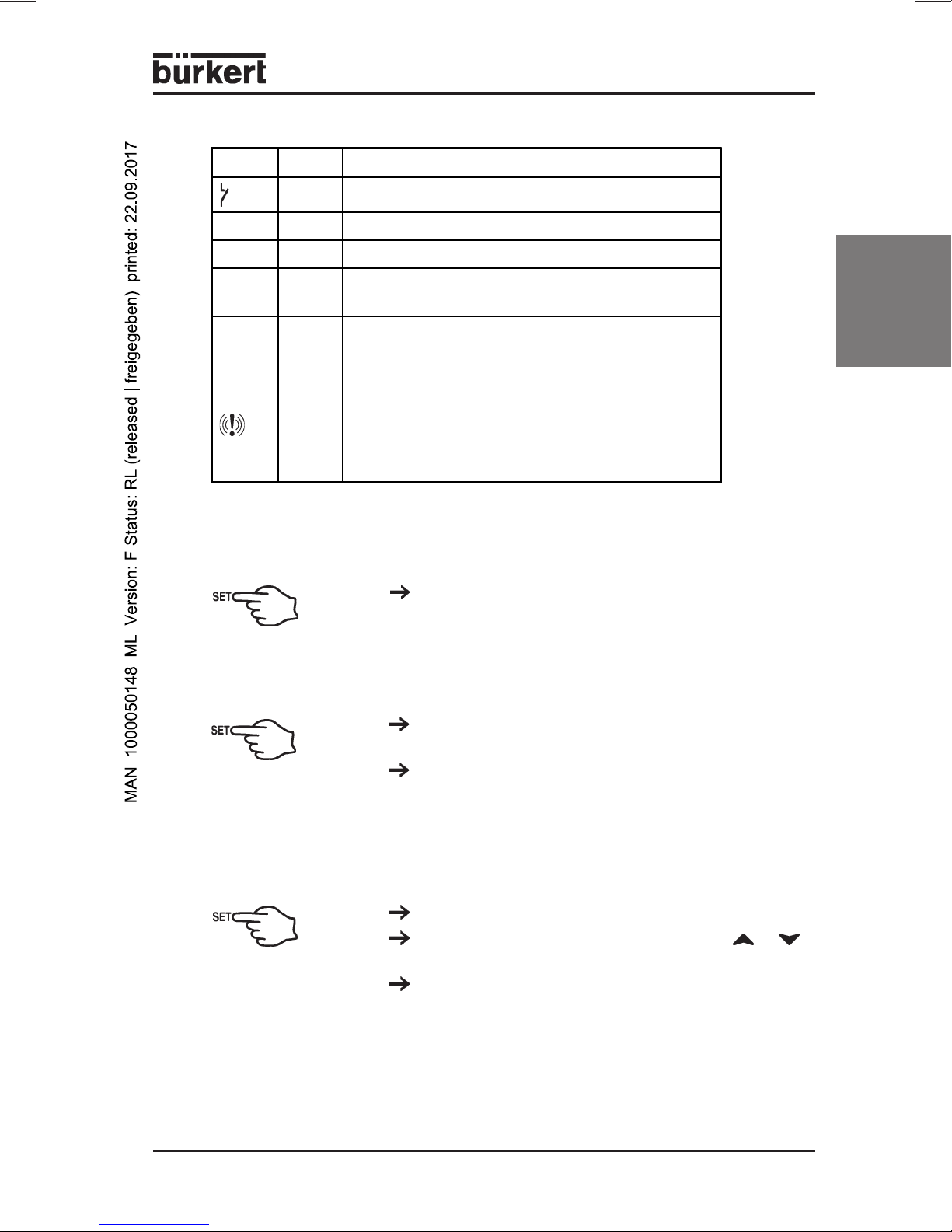

LED Mode Meaning

on Output active

LED1 blinks Programming level (blinks together with LED2)

LED2 blinks Programming level (blinks together with LED1)

E.S. on

Alarm

LED on

SWITCH DEVICE ON/OFF

SET-VALUE DISPLAYS

Energy-saving mode (second set-value) has

been activated by the digital input

- Signals an Alarm state

- If you are in the lower programming level

"Pr2", which can only be accessed using

a password, the lighting up of the Alarm LED

signals that the displayed parameters can

also be accessed in the first level Pr1

(without password).

english

Hold the SET button down for at least 4 sec

(only for parameter OnF = yes).

Briefly press the SET button once. The set-value

display appears in the display.

Briefly press the SET button again, or wait 5

seconds in order to display the room temperature.

CHANGE THE SET VALUE

Hold the SET button down for 2 seconds.

Change the set-value within 10 s with the or

buttons.

You can save the new set-value by briefly pressing

the SET button or by waiting 10 seconds.

0911 - 5

ENTER PROGRAMMING LEVEL

english

USER LEVEL PR1

Hold the SET + buttons down for at least 3

seconds

Select with Pr2 and then confirm with the SET

button.

Enter the password 321 and then confirm with the

SET button.

Enter the „3“ and then 1x SET button

Enter the „2“, and then 1x the SET button

Enter the „1“, and then 1x the SET button

You are now in the Parameter List.

Press down the SET + buttons for 3 seconds.

PR1 contains all the parameters accessible to the

user. The device shows the first parameter that is

available in the user level.

SERVICE LEVEL PR2 (PASSWORD 321)

See:

Accessing the programming level.

ADDING/REMOVING PARAMETERS IN THE USER LEVEL „PR1“

Accessing the programming level

The status can be changed with the SET +

buttons.

If a parameter is not visible in the PR1 level, this will

be indicated by an LED point.

CHANGING THE DEFAULT PARAMETERS

Enter a desired value with SET + or .

Then confirm with the SET button.

Enter a desired parameter with or .

6 - 0911

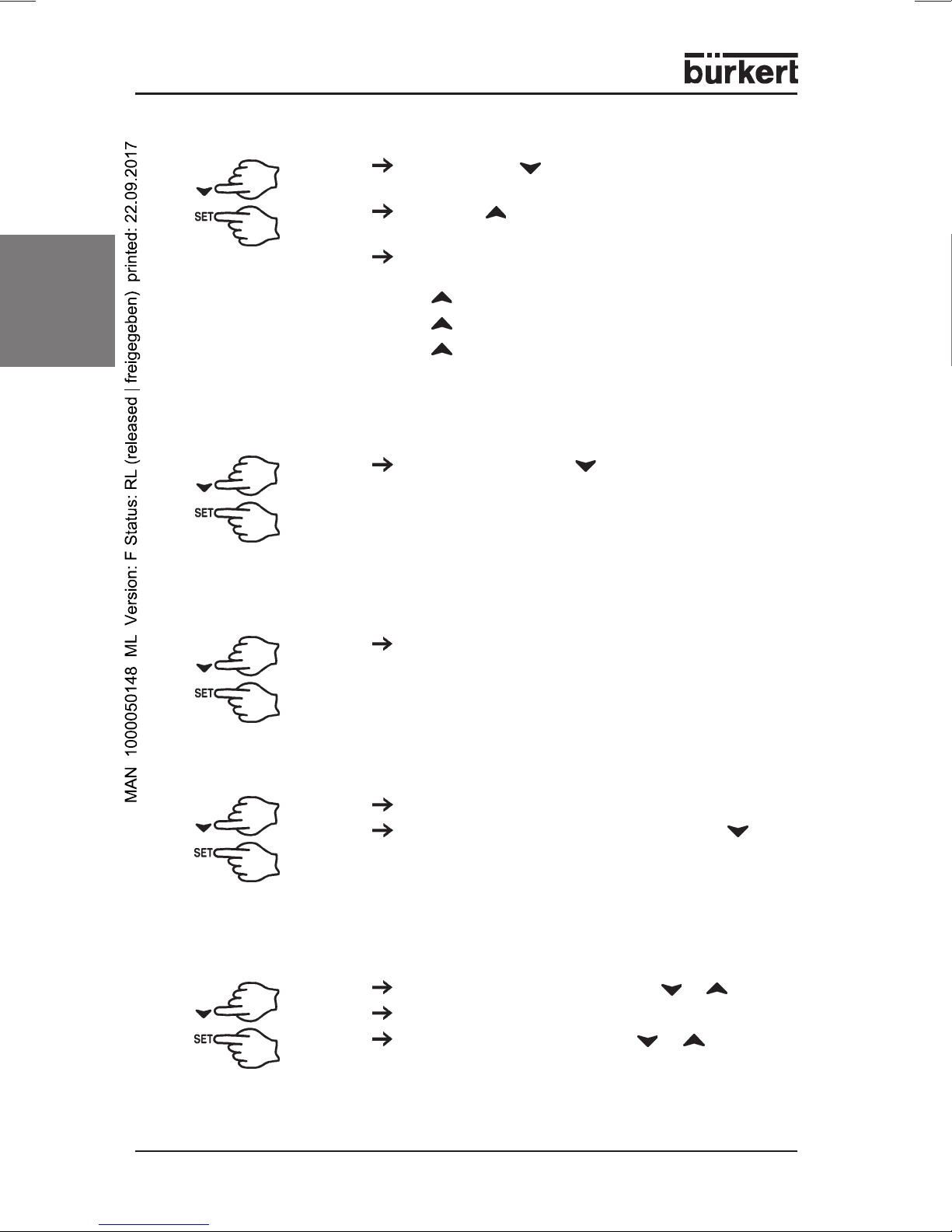

NOTE

All parameter values can be seen by repeatedly pressing the

SET buttons.

LOCKING AND UNLOCKING THE KEYPAD

2.3 Before the installation

PREDEFINE THE SENSOR TYPE

The configurable input type is noted on the controller

label. Please enter this input type if it does not

corresponds to the connected sensor type.

Hold down the buttons and for at least 3

seconds. The POF message appears on the

display.

The keyboard is locked. You can only view the

set-value and the minimum and maximum

temperature. The POF message also appears if you

hold down a button for longer than 3 s.

The keyboard will be unlocked if you hold down

the buttons and for 3 s. POn appears in the

display for a few seconds.

english

Hold down the SET + button for at least 3

seconds.

Select the parameter Pbc (sensor type) and then

confirm with the SET button to see the current

default.

Type TU (temperature controller):

J = Thermoelement J; Pt = Pt100;

C = Thermoelement K; Ptc = PTC;

S = Thermoelement S; ntc = NTC

Type AU

(control devices with voltage/current input):

cur = 4...20 mA; 0-1 = 0...1 V; 10 = 0...10 V

Confirm the default with the SET button.

Briefly switch off the power to the device.

0911 - 7

MEASUREMENT LIMITS FOR THE SENSOR TYPES

Sensor Lower limit Upper limit

NTC -40°C 110°C

PTC -50°C 150°C

Pt100 -200°C 600°C

TcK 0°C 1300°C

TcJ 0°C 600°C

english

2.4 Parameters

Control

Hy1

LS1

US1

S1C

AC

on

ono

TcS 0°C 1400°C

Hysteresis 1

Lowest set-value setting

Highest set-value setting

control effect

Minimum switch duration

Minimum switch-on period

Minimum delay

Switch hysteresis of Set-value 1 with

positive or negative values. The default

range is dependent on the input type.

The parameter may not be entered as

zero.

Set-value limits for operator

Set-value limits for operator

in = inverse (heating, humidification)

dir = direct (cooling, dehumidification)

0...250 sec relay switch-off duration

0...250 sec relay switch-on period

0...120 min; minimum delay between two

activations of the control relay.

Alarms

ALC

Configuration

Temperature alarm

ALL

ALU

ALd

Low temperature alarm

Over-temperature alarm

Alarm delay

at temperature

Overshoot/Undershoot

8 - 0911

rE = relative to the set-value (in Kelvin)

Ab = absolute values (in °C)

If SET - ALL is undershot,

a low temperature alarm will be triggered

after the delay time ALd.

If SET + ALU exceeded, a high

temperature alarm will be triggered after

delay time ALd.

0...999 min; Minimum time in which the

conditions for an alarm situation

must be present.

Alarms

ALH

Hysteresis for the

Limit value alarms

ALL and ALU

dAO

Alarm delay at

with Mains ON

S01

Status of the control relay

with sensor fault

tbA

Status of the control relay

after acknowledgement (by

(any button) in an

alarm situation

AS

Configuration of the alarm

relay at an alarm

Measured value display

LCI

Lower analog

Display value

(-1999...1999)

Automatic alarm acknowledgement:

With high alarm undershot by

ALU - ALH and with low alarm with

under shooting of ALL + ALH

(0.1 K...upper measurement range)

0...23.5 hours; suppression of

Alarms after commissioning.

oFF = opened

on = closed

oFF = Relay deactivated

on = Relay activated

cL = Terminal 4-5 closed

oP = Terminal 4-6 closed

Lower display value for current input

4 mA or with voltage input 1 V

or 10 V (only for inputs 4-20

mA, 0-1V, 0-10 V)

english

UCI

OPb

rES

UdM

PbC

P3F

Upper analog

Display value

(-1999...1999)

calibration of the sensor

Resolution

Units

Type of sensor

Temperature sensor U):

Current / voltage input

(AU)

Third terminal of a

Pt100 sensor

Upper display value for current input

20 mA or for voltage input 1 V or 10 V

(only for the 4-20 mA, 0-1V, 0-10 V

inputs)

regardless of the measurement range

in = only whole numbers

dE = also tenths

ce = hundreths

Display of the units directly in the

illuminated display. Regardless of which

controller type is being used:

see

General description

Type of inout

J = Thermoelement „J“; Pt = Pt100;

C = Thermoelement „K“; Ptc = PTC;

S = Thermoelement „S“; ntc = NTC

cur = 4...20 mA; 0-1 = 0...1 V;

10 = 0...10 V

(if present)

no = Pt100 2-wire wired

yES = Pt100 3-wire wired

0911 - 9

Digital inputs

HES

i1F

english

i1P

did

Miscellaneous

Adr

Temperature increase/

Reduction

Function of the digital

Input

Polarity of the digital

input

Alarm delay time

of the digital input

(1...120 min)

Serial address RS485

(1...247)

Set-value is increased/lowered by HES

during the energy saving phase.

EAL = external alarm; OFF = unused;

bAL = serious external alarm;

Es = Energy saving mode Start/Stop;

onF = switch the device ON/OFF

externally;

C-H = reverse the control effect

CL: active with closed contact

OP: active with opened contact

For i1F = EAL or i1F = bAL.

The corresponding alarm

display or message then takes place

Address for XJ500 recording

system. Identifies the device if it

is linked into a ModBUS-compatible

system.

OnF

Ptb

rEL

Pr2

NOTE

Set device to STAND-BY

Number of the parameter-

no = not possible via keyboard

yes = STAND-BY can be activated by

holding down the SET button of at least

4 sec. During a STAND-BY, OFF is

displayed.

only read-out value

table

Version

Display of the parameters in

only read-out value

display only

Level Pr2

You can access hidden paramaters by holding down the keys

SET + for 3 sec in the programming level HY. The message Pr2

appears.

10 - 0911

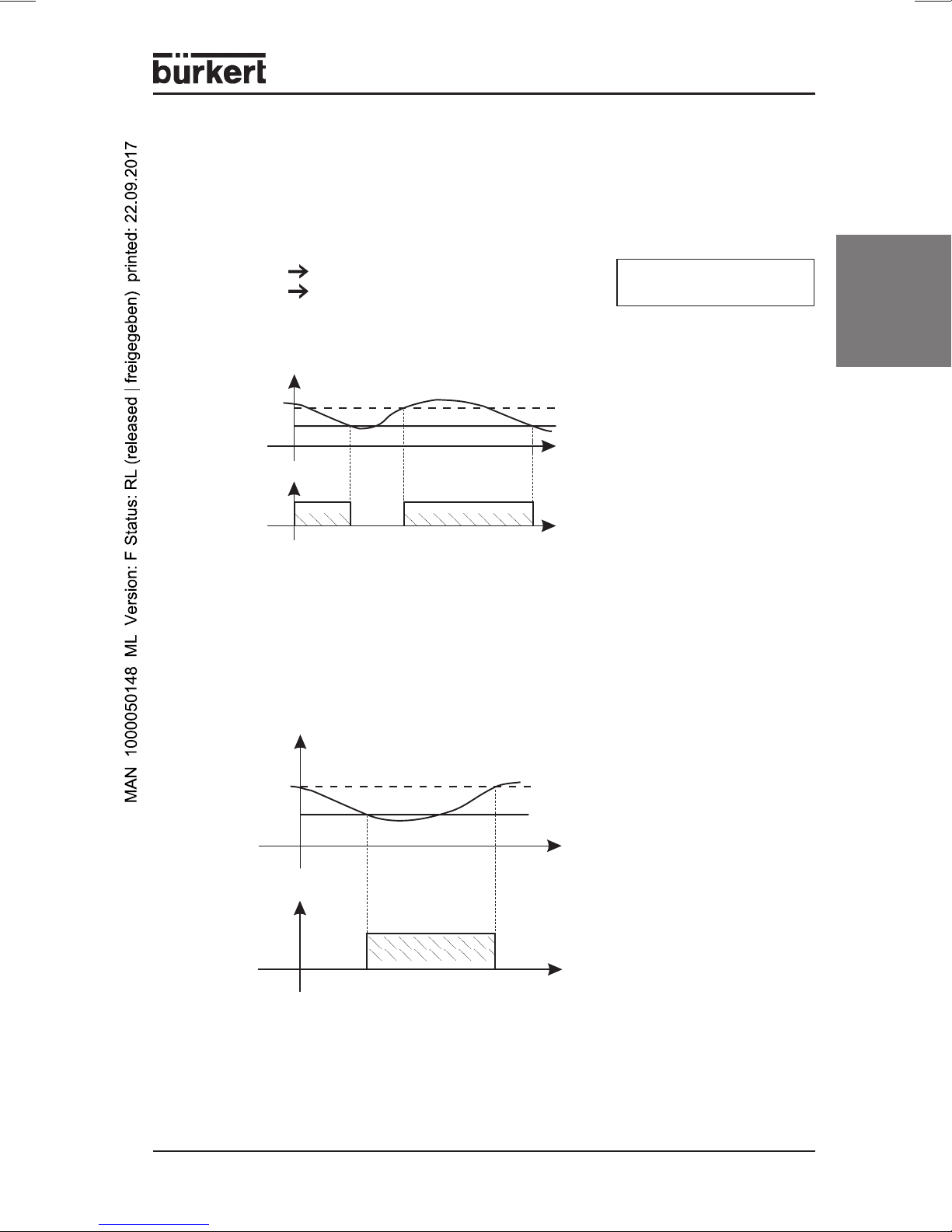

2.5 Controlling the loads

CONTROLLER OUTPUT

The control is dependent on the measured temperature (= sensor

temperature). Program the control direction (heating or cooling) with the

parameter S1C.

S1C = dir Cooling SET = Set-value

S1C = in Heating Hy = Switch hysterisis

COOLING

temperature

SET+HY

SET

t

compressor

ON

t

Parameter S1C = dir; The value HY has been preset to 2 K in the factory.

If the temperature exceeds the value SET + HY, the compressor will be

switched on and will be switched off again when the temperature is below SET.

HEATING

temperature

SET

english

SET-HY

heat

ON

Parameter S1C = in; The value HY has been preset to 2 K in the factory.

If the temperature falls below the value SET-HY, the controller output will be

switched on and will be switched off again when SET is exceeded.

t

t

0911 - 11

3 TECHNICAL DATA

• Housing ABS, self-extinguishing

• Dimensions Front 74 x 32 mm, Depth 60 mm

• Assembly Panel-mounting unit for 29 x 71 mm cutout

• Protection class IP65 from front, only with front seal RG-C

• Connections Screw terminals

• Pipe cross-section ≤ 2.5 mm

english

• Auxiliary energy depending on model

• Power consumption max. 3 VA

• Display three digits, red LED, height 12 mm

• Inputs configurable NTC / PTC or

• Relay outputs Changeover 8(3) A, 250 V AC

• Other outputs acoustic alarm (optional)

• Data memory EEPROM

• Ambient temperature 0 ... +60°C / +32 ... +140°F

• Storage temperature -30 ... +85°C / -22 ... +185°F

• Air humidity 20 ... 85% (non-condensing)

• Measurement range according to sensor

• Resolution 0.1°C or 1°F

• Accuracy at + 25 °C better than 0.5% of the measurement range

IP20

2

12...24 V AC / DC; ± 10%

230 V AC; ± 10%; 50 / 60 Hz

optional 110 V AC; ± 10%; 50 / 60 Hz

NTC / PTC / Pt100 / Thermoelement J, K, S

or 4...20 mA / 0...1 V / 0...10 V

12 - 0911

4 ASSEMBLY, INSTALLATION AND COMMISSIONING

4.1 General information regarding the installation and operation

ATTENTION!

NOTE

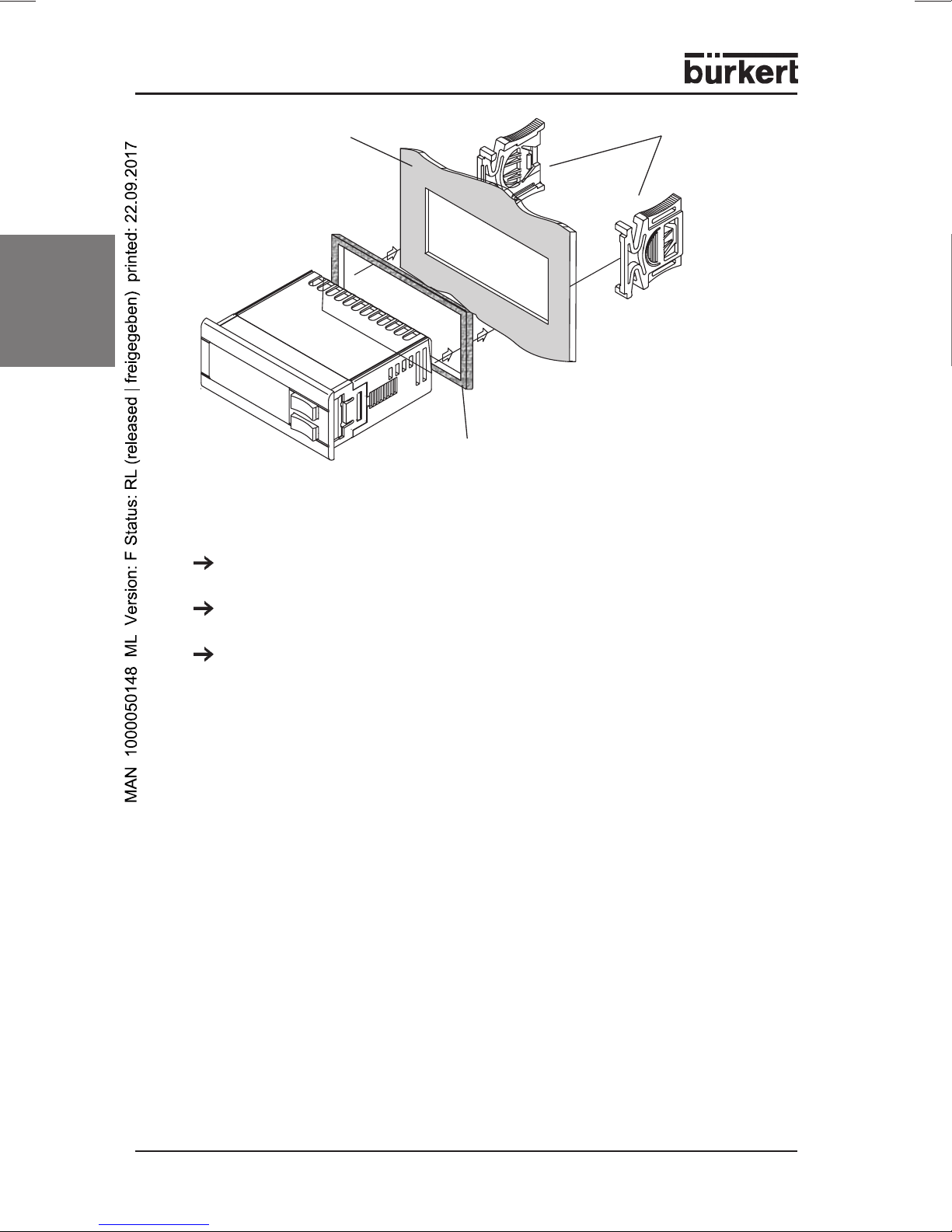

4.2 Assembly

The device is designed for panel mounting in a 71 x 29 mm cutout, and is

secured with a mounting clamp.

In order to guarantee the front protection of IP65, a rubber seal must be fitted

behind the mounting frame (optional for RG-C).

• Do not lay cables for inputs next to lines carrying voltage.

• Avoid heavy vibrations, aggressive gases, heavy soiling

and damp.

• Before connecting the device, check that the power supply

corresponds to the values shown on the rating plate.

• Observe the maximum loading of the relay contacts (see

Technical data

• Ensure that you install all sensors with sufficient separation

from lines carrying voltage, in order to avoid incorrect

temperature measurements and to protect the device from

voltage interference over the sensor inputs.

).

english

Thje ambient temperature form problem-free operation lies in the range from

0 ... +60°C.

Ensure sufficient ventilation through the cooling slots.

Panel

Mounting clamp

0911 - 13

english

4.3 Electrical connections

Use cable with a cross-section of max. 2.5 mm2. The device is provided

with the corresponding screw terminals.

Panel Mounting frame

Front seal

Check the auxiliary energy before you connect the power supply

(see

Technical data

Do not load the relay contacts higher than permitted. If necessary, use a

contactor.

).

14 - 0911

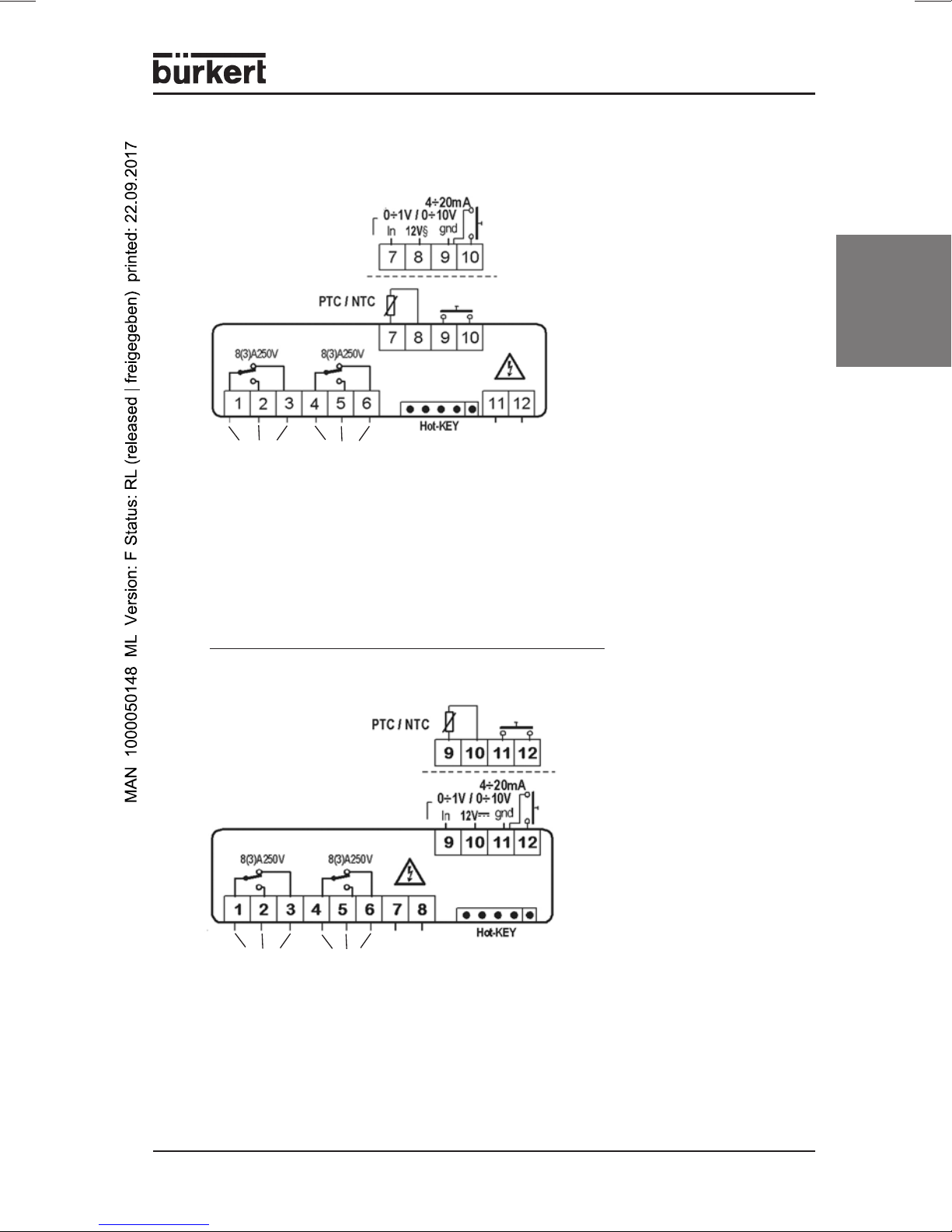

PIN ASSIGNMENT

12 V AC/DC or 24 V AC/DC

english

operating

contacts

(1, 2, 3)

alarm

contacts

(4, 5, 6)

Standard signal input: 0...1 V; 0...10 V = 7(+), 9(-)

4...20 mA = 7(+), 9(-)

Thermoelement J, K, S = 7(+) - 9(-)

sensor: Pt100 = 7 - 9(8)

voltage supply: 24 V AC/DC = 11 - 12

230 V AC

operating

contacts

(1, 2, 3)

Standard signal input: 0...1 V; 0...10 V = 9(+), 11(-)

Thermoelement J, K, S = 9(+) - 11(-)

sensor: Pt100 = 9 - 11(10)

voltage supply: 230 V AC = 7 - 8

alarm

contacts

(4, 5, 6)

4...20 mA = 9(+), 11(-)

0911 - 15

5 HOT-KEY function

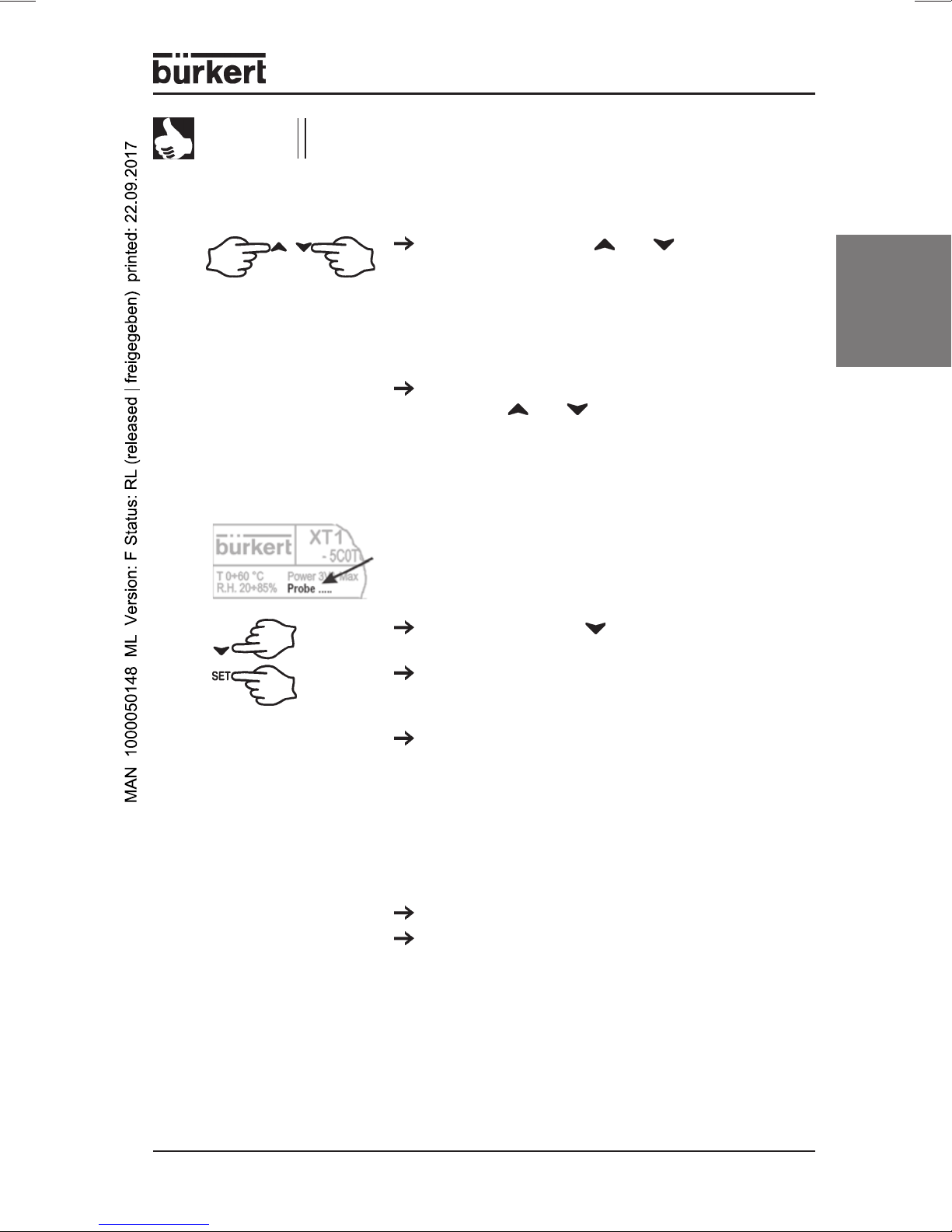

DOWNLOAD (HOT-KEY CONTROL DEVICE)

Writing the stored parameter set from the HOT-KEY into the control device:

Switch off the electrical power to the controller, or set it to STAND-BY.

Insert the HOT-KEY up to the stop in the marked position on the controller.

Re-activate the controller.

english

The default parameters in the HOT-KEY will be automatically written into the

controller. During this time, the message DoL blinks in the display. The

programming procedure is finished after 10 seconds, and normal operation

starts automatically with the new parameter set.

The HOT-KEY can be removed.

The following messages are possible at the end of the data transfer:

end for a correct data transfer

err for a failed data transfer

In this case, briefly switch off the power to the device to repeat the

procedure. If you want to cancel the procedure, simply remove the HOTKEY.

UPLOAD (CONTROL DEVICE HOT-KEY)

Writing the current default parameters of the control device into the HOT-KEY:

Insert the HOT-KEY into the provided position when the controller is

switched on again.

Operate 1x with . The message uPL can be seen in the display.

Press the SET button in order to start the data transfer. uPL starts to blink.

You can remove the HOT-KEY again after about 10 seconds.

The following messages are possible at the end of ther data transfer:

end for a correct data transfer

err for a failed data transfer

In this case, press the SET button again to repeat the procedure. If you

want to cancel the procedure, remove the HOT-KEY.

16 - 0911

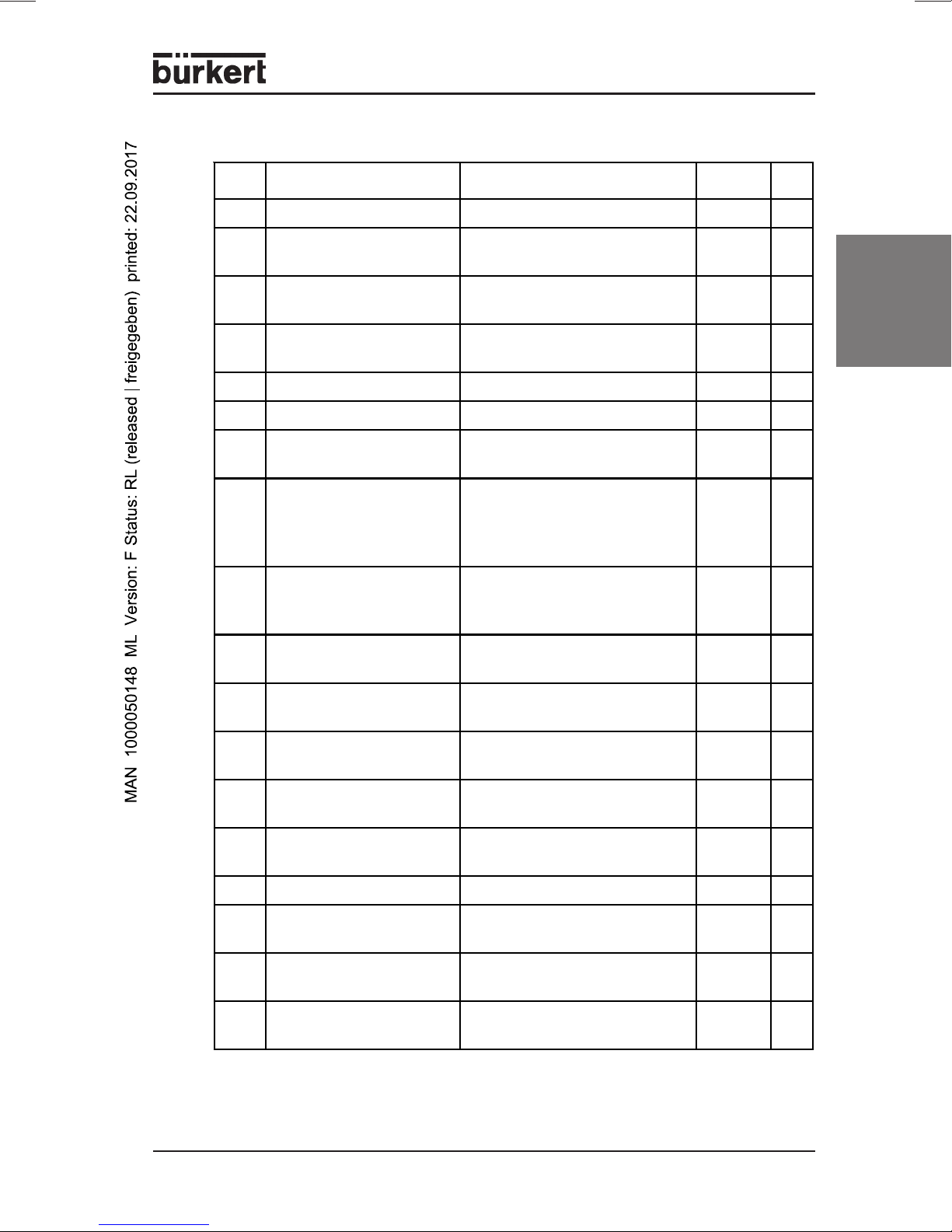

6 FACTORY SETTING

1

PA

Description Range Default PE

SET Set-value LS1 + US1 0 Pr1

HY1 Switch hysterisis 1

LS1 Lowest set-value 1

US1 Largest set-value 1

dependent on measurement

range

Lower measurement range +

SET1

Upper measurement range +

SET1

-1 Pr1

min Pr2

max Pr2

S1C Control effect Output 1 in = inverse; dir = direct in Pr2

Ac Delay time for the relay 0...250 sec 0 Pr2

Minimum switch-on time

on

for a relay

0...250 sec 0 Pr2

Minimum waiting time

between two consecutive

ono

activations of the same

0...120 min 0 Pr2

load

Alarm limits are absolute

ALC

values or related to the

rE = relative; Ab = absolute rE Pr2

set-value

2

english

ALL

ALU

ALH

ALd

dAO

Lower Alarm Limit

(ALC = rE; ALC = Ab)

Upper Alarm Limit

(ALC = rE; ALC = Ab)

Switch hysterisis for

temperature alarms

Alarm delay time during

the operation

Alarm delay time after

commissioning

dependent on measurement

range

dependent on measurement

range

dependent on measurement

range

0...999 min 15 Pr2

0...23.5 h 1.3 Pr2

10 Pr2

10 Pr2

2Pr2

So1 Output 1 for sensor error oFF = open; on = closed oFF Pr2

tbA

AS

LCI

1

Parameter

2

Programming level

3

Only for devices with voltage and current input

Alarm relay can be

acknowledged

Polarity of the Alarm

relay

Lower analog display

3

value

no; yES yES Pr2

CL...oP oP Pr2

depending on sensor var. Pr2

0911 - 17

PA

UCI

1

3

Description Range Default PE

Upper analog display

value

2

depending on sensor var. Pr2

english

Opb Sensor calibration

depending on measurement

range

0Pr1

rES Resolution in = NO; dE = 0.1; cE = 0.01 in Pr2

Type TU: °C = °C, °F = °F;

UdM Units

Type AU: 0 = °C, 1 = °F;

2 = RH, 3 = bar, 4 = PS,

var. Pr1

5 = without display

Pt = Pt100; J = tcJ; c = tck;

PbC Type of sensor

S = tcS; Ptc = PTC;

ntc = NTC; 0.1 = 0...1 V;

var. Pr1

10 = 0...10 V; cur = 0...20 mA

rd

P3F 3

sensor present no = no; yES = yes no Pr2

HES Energy-saving mode Down scale / Full scale 0 Pr2

i1F

i1P

did

Configuration of the

digital input

Polarity of the digital

input

Alarm delay of the digital

input

c-H / oFF / off / HES /

EAL / bAL

cL = closed;

oP = open

0...120 min 0 Pr2

EAL Pr2

cL Pr2

Adr Serial address for XJ500 RS485 address 1 Pr2

OnF

Activate Standby

function

Ptb Parameter table Read value - Pr2

rEL Software version Read value - Pr2

Pr2 Parameter access to Pr2 Read value 321 Pr1

1

Parameter

2

Programming level

3

Only for devices with voltage and current input

7 MAINTENANCE

When operated in accordance with the instruction in this handbook, the 0911

controller is maintenance-free.

no = no; oFF = active no Pr2

18 - 0911

Loading...

Loading...