Page 1

AZTECH CONVERTING SYSTEMS

212 W Lodge Drive

TEMPE, AZ 85283

PHONE (480) 951-8351

FAX (480) 998-5409

www.aztechconverting.com

DIE MASTER

User Manual

DM-40XX

Ver 1.3

Page 2

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

TABLE OF CONTENTS

SECTION 1: GENERAL INFORMATION 1-4

SECTION 2: MACHINE INSTALLATION 4-5

SECTION 3: MACHINE SETUP 6-18

SECTION 4: MACHINE OPERATION 19-28

SECTION 5: MAINTENANCE 29

SECTION 6: STATION DETAIL 30-52

SECTION 7: TROUBLESHOOTING 53

SECTION 8: WARRANTIES AND SERVICE 54

Page 3

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Section 1: General Information

1-1: Introduction

The AZTECH DieMaster Rotary Die Cutting Machine is available in 13 inch (33.02 cm), 18 inch

(45.72 cm) and 20 inch (50.8 cm) widths, with dual-spindle rewinds, and web speeds up to 500

feet/minute. The DieMaster is designed to be highly productive, versatile, and simple to operate

and maintain. Before operating your new DieMaster, fully read and understand all facets of this

manual. Following the procedures outlined in this manual will help assure maximum performance.

Keeping your machine properly set-up and maintained will assure years of productive and satisfactory service.

1-2: Machine Information and Specications

1

Page 4

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

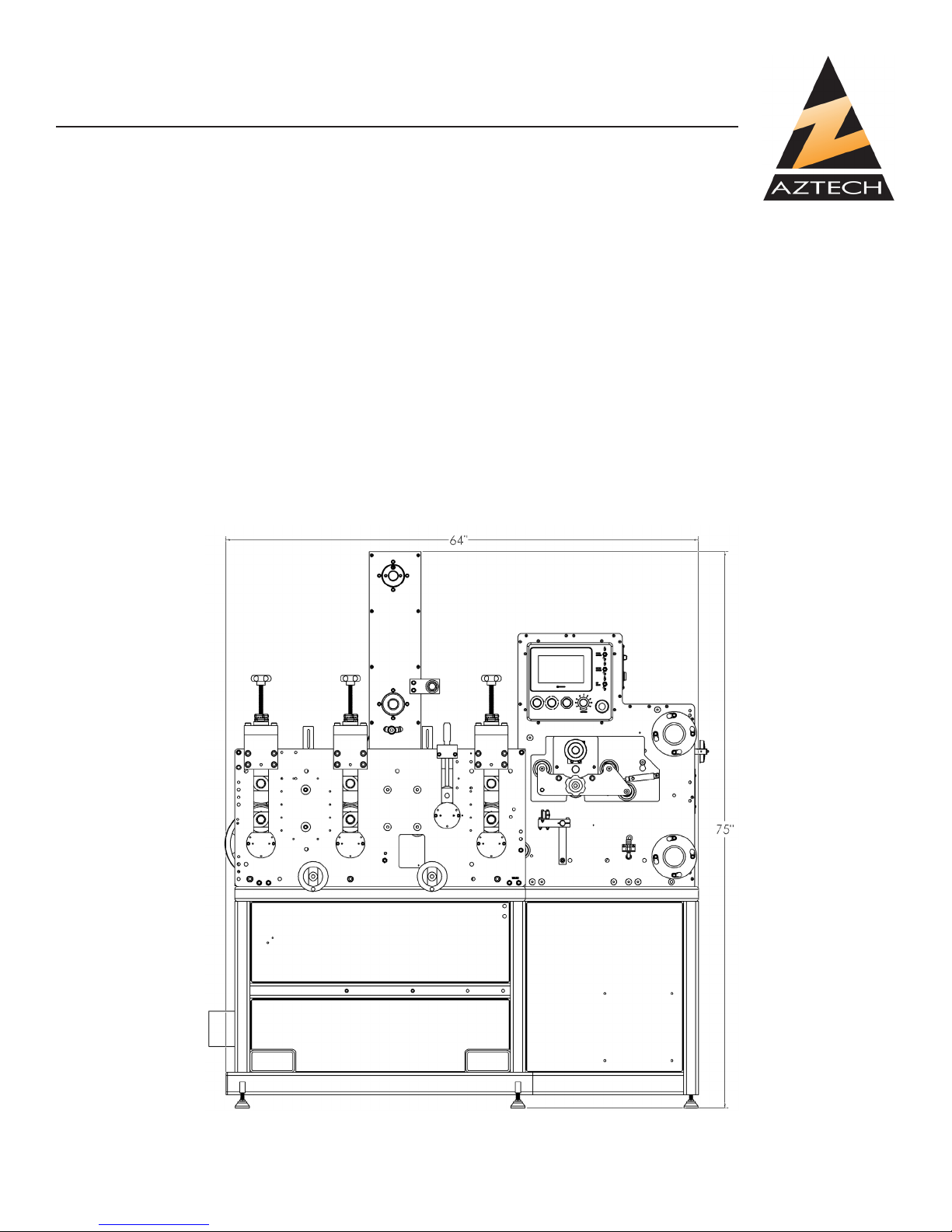

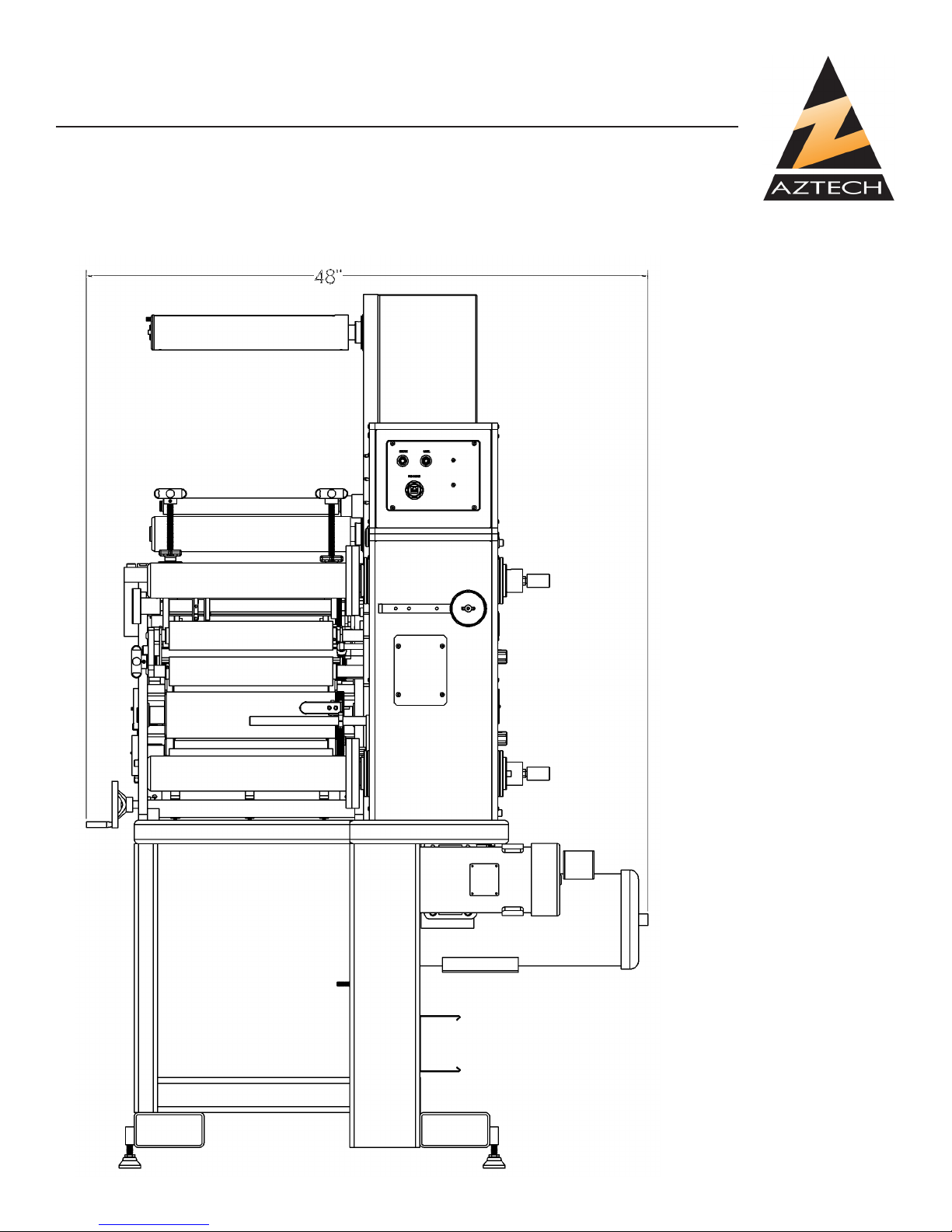

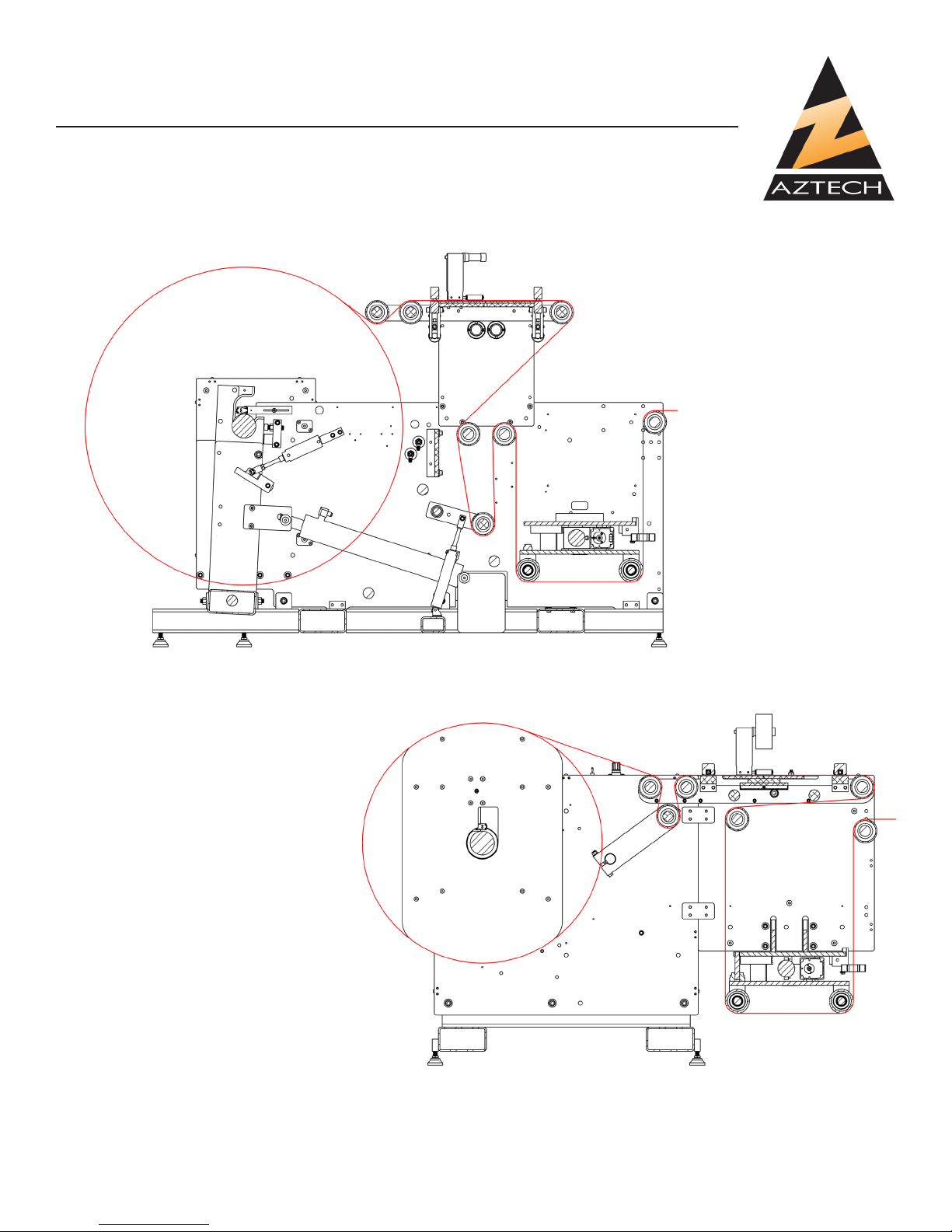

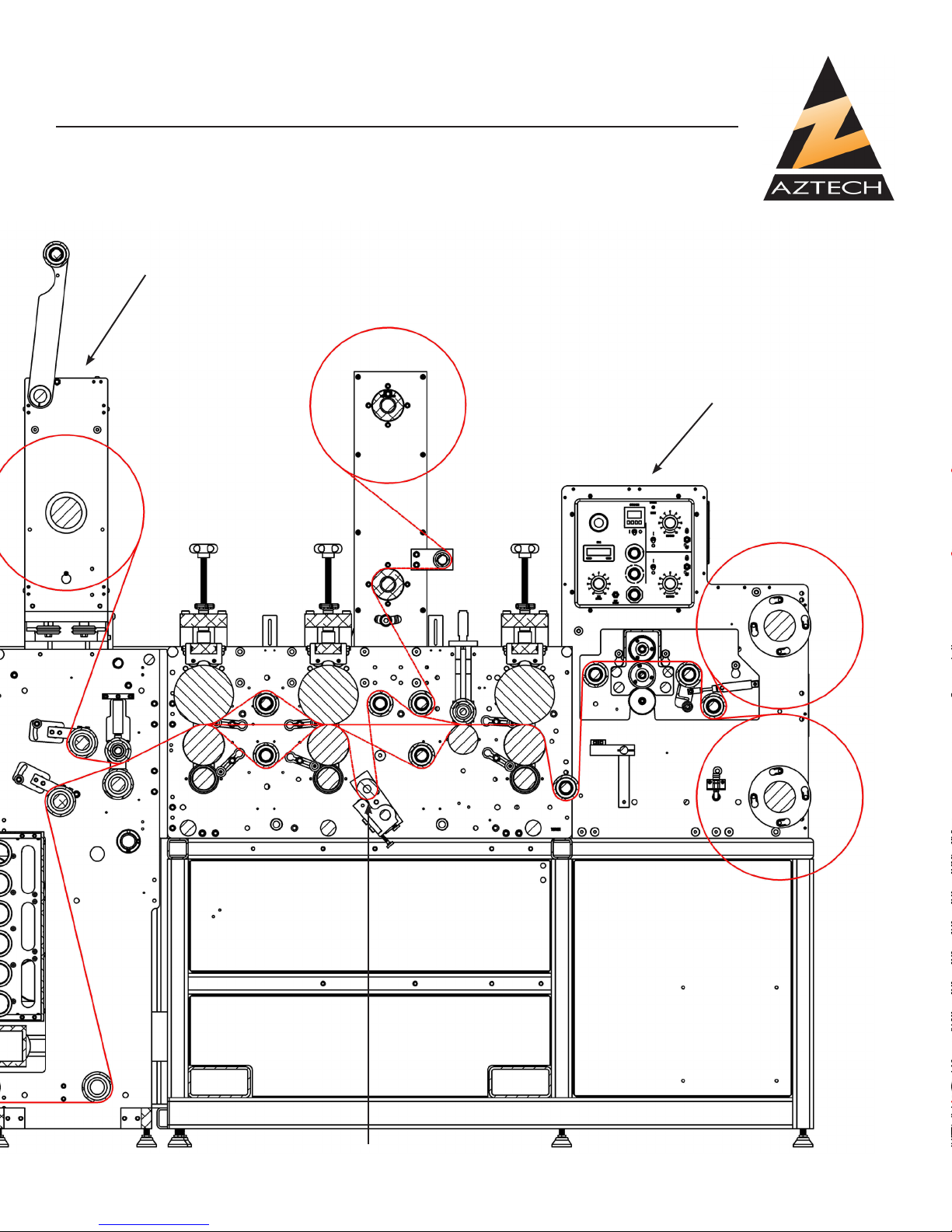

FRONT LAYOUT

(DIE MASTER ONLY)

2 Rev 1.3

Page 5

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

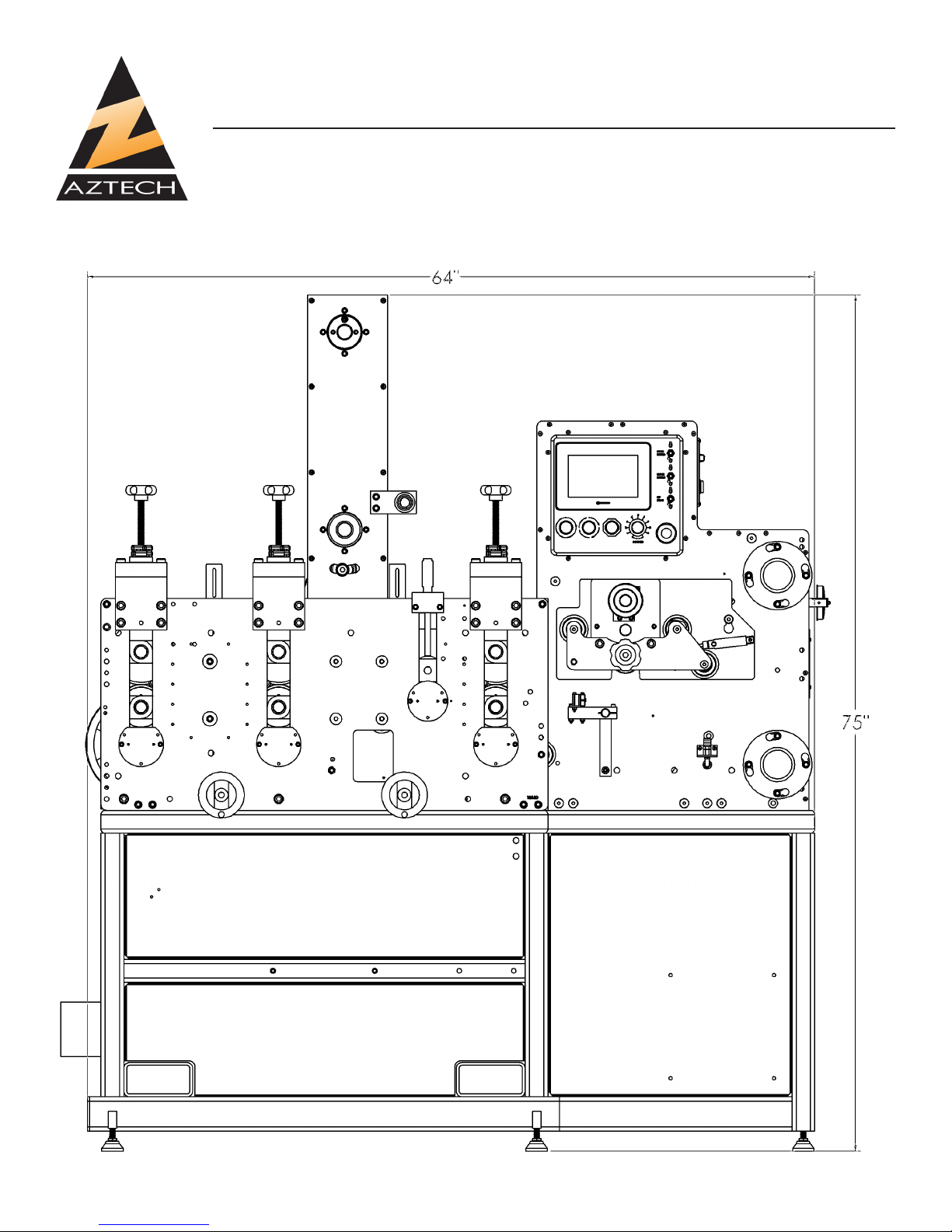

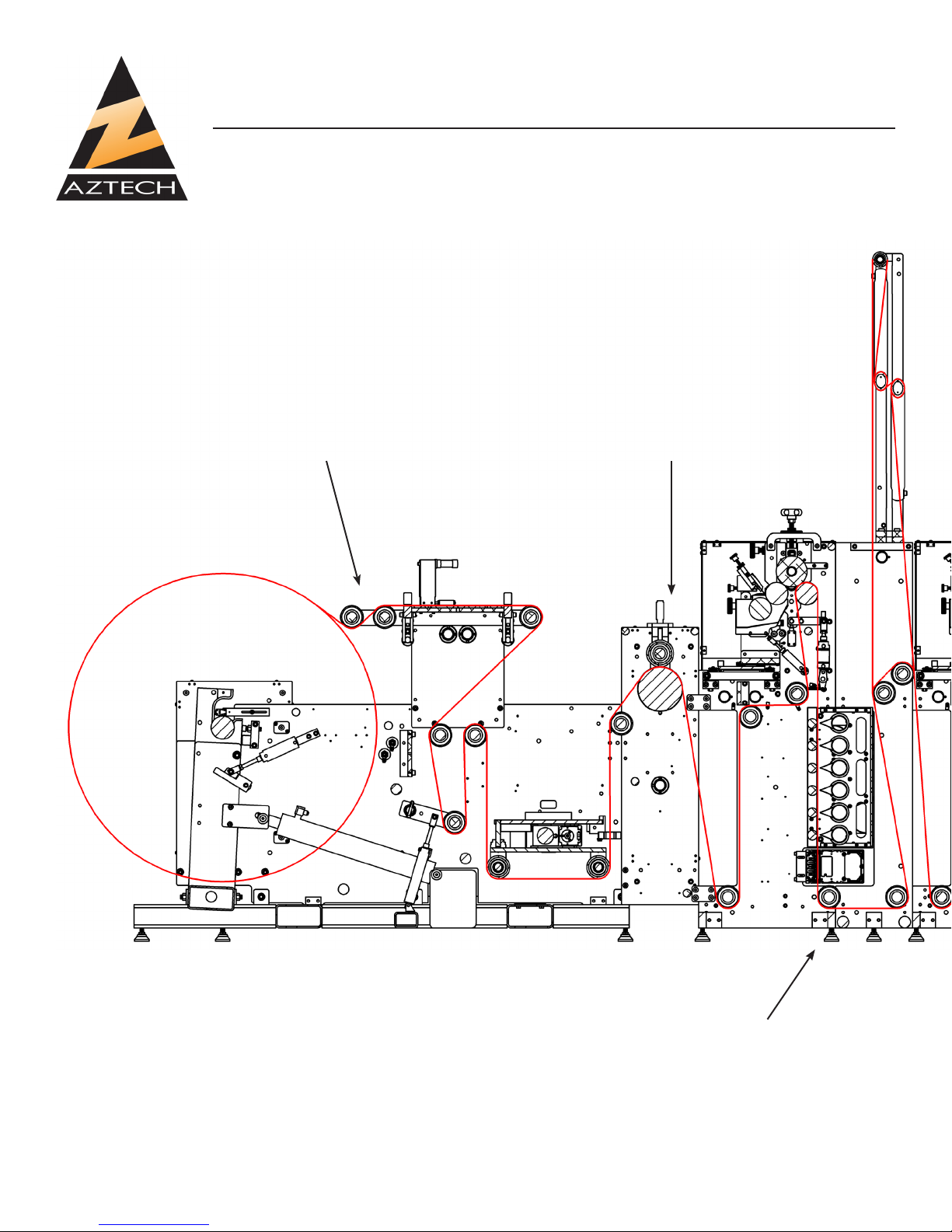

SIDE LAYOUT

(DIE MASTER ONLY)

(13” Shown, 18” and 20” are

similar)

3

Page 6

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

1-3: Care and Maintenance

To assure maximum performance and longevity of your Die Master, it is very important to perform periodic maintenance. Read

Chapter 5 for more information.

1-4: Safety

The DieMaster is designed to operate at high rates of speed, employing rollers, gears, pulleys, and

other moving parts. Where possible, guards are provided to protect operator from injury. Operators

must keep their hands clear of the machine when it is in operation. Making all operators aware of

potential safety hazards will help minimize any chances of operator injury.

Section 2: Machine Installation

2-1: Preparation

It is important that your DieMaster Rotary Die Cutter be situated on solid and level ground. Make

sure that site allows for access to machine from all 4 sides. If the machine is placed on unstable or

un-level ground, it may tip over risking damage or serious personal injury.

2-2: Un-crating Machine

To avoid damage to your new DieMaster, begin by unfastening the latches on the front panel and

removing the panel to expose the machine. Carefully remove all boxes from inside the crate and

set aside to avoid damage. Remove all 4 lag bolts which hold the machine to the base.

2-3: Removal and Positioning

It is critical that the DieMaster be removed from the crate using a fork lift, making sure that the forks

t directly inside the 2 slots at base of the machine. Lift and remove from crate, and if equipped with

adjustable feet, thread all 4 feet into threaded holes at machine’s base, and lower into desired position. Machine may be leveled by turning adjustable feet until level.

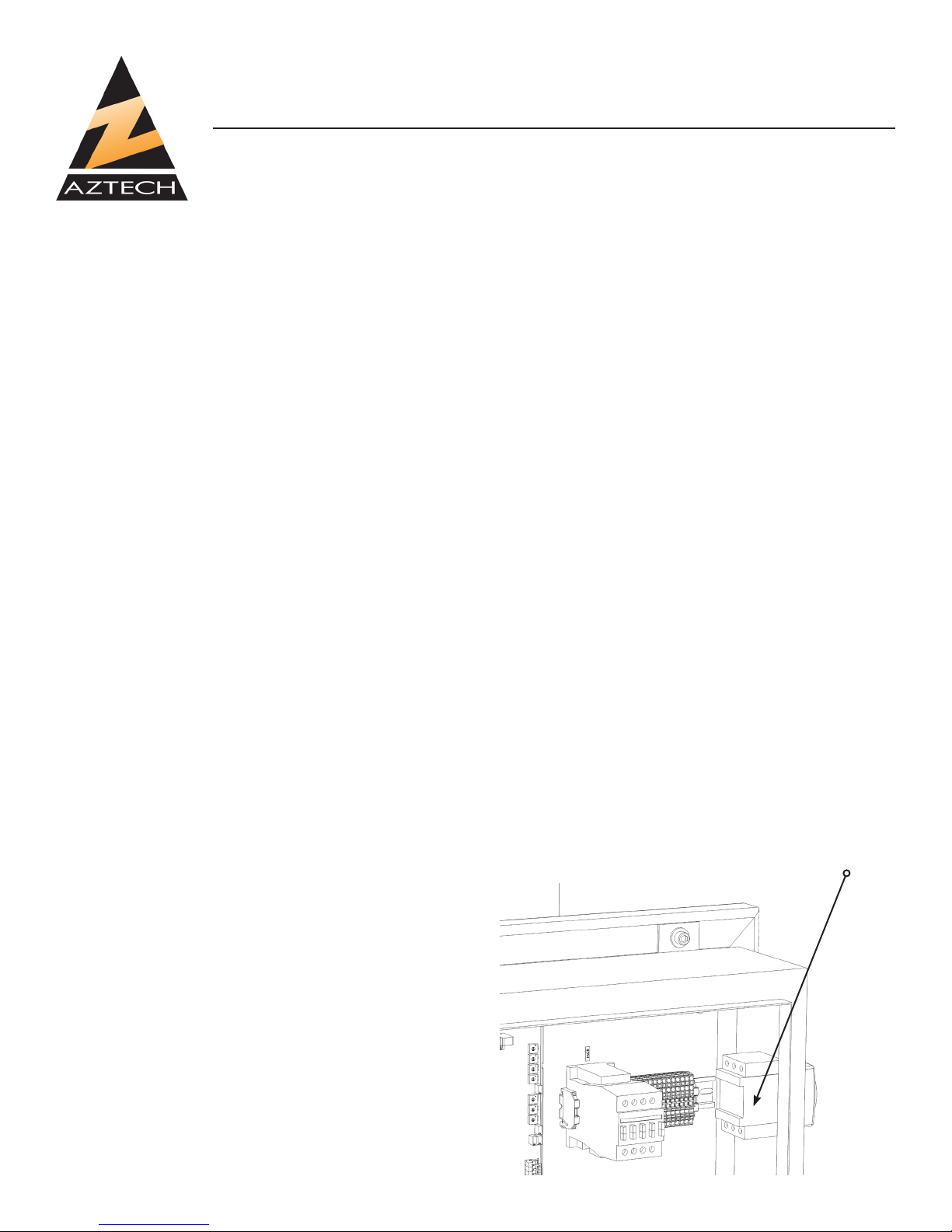

2-4: Electrical and Pneumatic Connections

50A 220VAC

THREE PHASE

TO DISCONNECT

ELECTRICAL CONNECTIONS: Your DieMaster uses

a power supply of 220 volts, 50 amps AC 3PH. Improper connections or mishandling may cause serious personal injury. AZTECH highly recommends that

electrical service be performed only by a qualied

electrician.

Electrical connection to the machine is performed

by bringing electrical service to the electrical box at

the back of the machine and making connections as

shown.

4 Rev 1.3

Page 7

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

90PSI

INCOMING

HP AIR

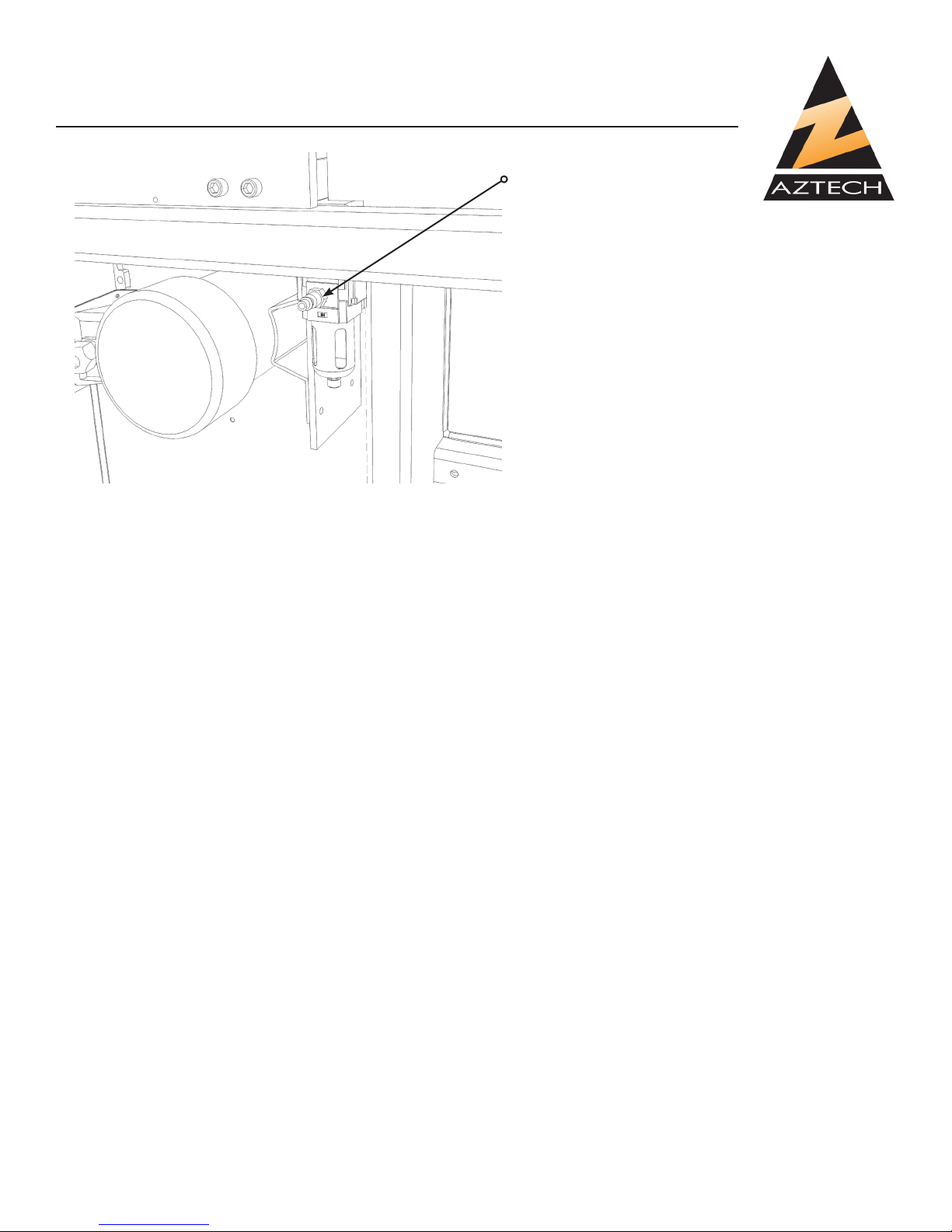

PNEUMATIC CONNECTIONS: Although

your machine has been thoroughly tested

before shipment, connections on occasion

may loosen during shipment. Visually inspect

all pneumatic to assure that each is tted

securely. Connect airline to the pneumatic

control panel at the back of the machine (see

gure 2-B), and listen for any air leaks that

may exist. Check all switches by switching

back and forth from on and off to make sure

they are operating properly.

NOTE: Red lines on air dials indicate proper default settings.

2-5: Testing Before Operation

Make sure the area around your machine is clear of any objects which may impair the machine.

Also inspect and make sure all belts, pulleys, rollers, and spindles are free and clear of any

objects which may impede operation, and risk machine damage. Before threading your machine,

accelerate and decelerate your machine through a full range of speeds, and make sure acceleration is smooth and free of any unnatural sounds or movements. Using control switches, switch

Unwind and Rewind Spindle(s) from on and off positions making sure the pneumatic system is

performing properly. Then turn power on, run machine at low speed to assure machine is working

properly. Then with speed set at maximum setting, press the stop button to assure that the brake is

working properly.

5

Page 8

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Section 3: Machine Setup

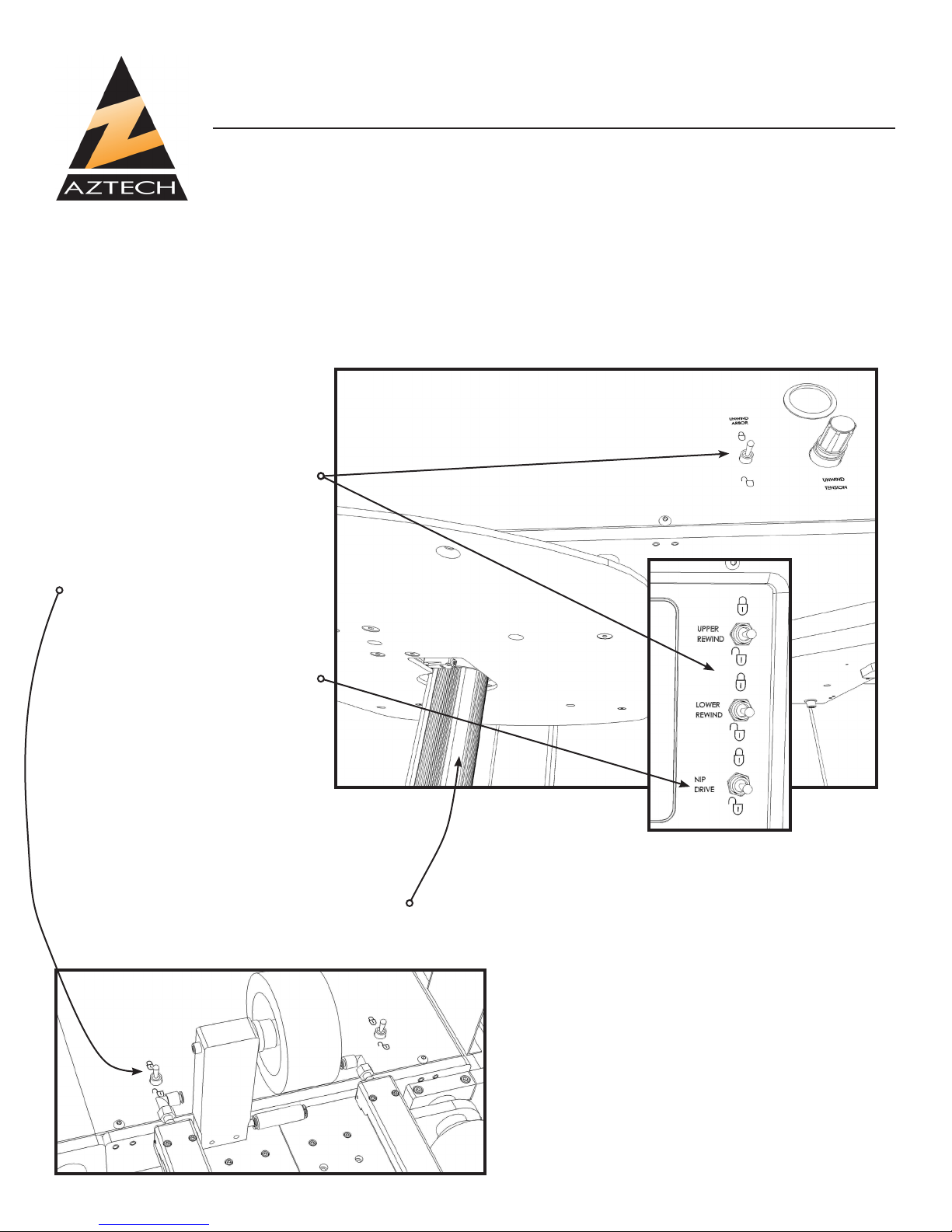

3-1: Webbing the Machine

Proper webbing of your DieMaster is vital to optimal machine performance. The proper way to

thread your machine for various substrates is shown on the following page. Any improper webbing

of the machine may cause tension problems that will impede operation.

To web the machine:

1. Turn unwind arbor switch to

“DEFLATE” position.

2. Assure that the rewind and

unwind switches on main panel are in the “OFF” position

3. Assure that both splice-table

clamps are released into the

up position.

4. Assure that the pneumatic nip

roll is disengaged in the up

position.

5. Assure that the slitting blades

are disengaged. BE SURE

TO USE CAUTION WHEN

NEAR RAZOR SLITTING

BLADES AS THEY ARE

EXTREMELY SHARP AND

MAY CAUSE SERIOUS INJURY.

6. Load roll onto unwind spindle and carefully thread the web through the machine making sure to

follow web paths on the following page.

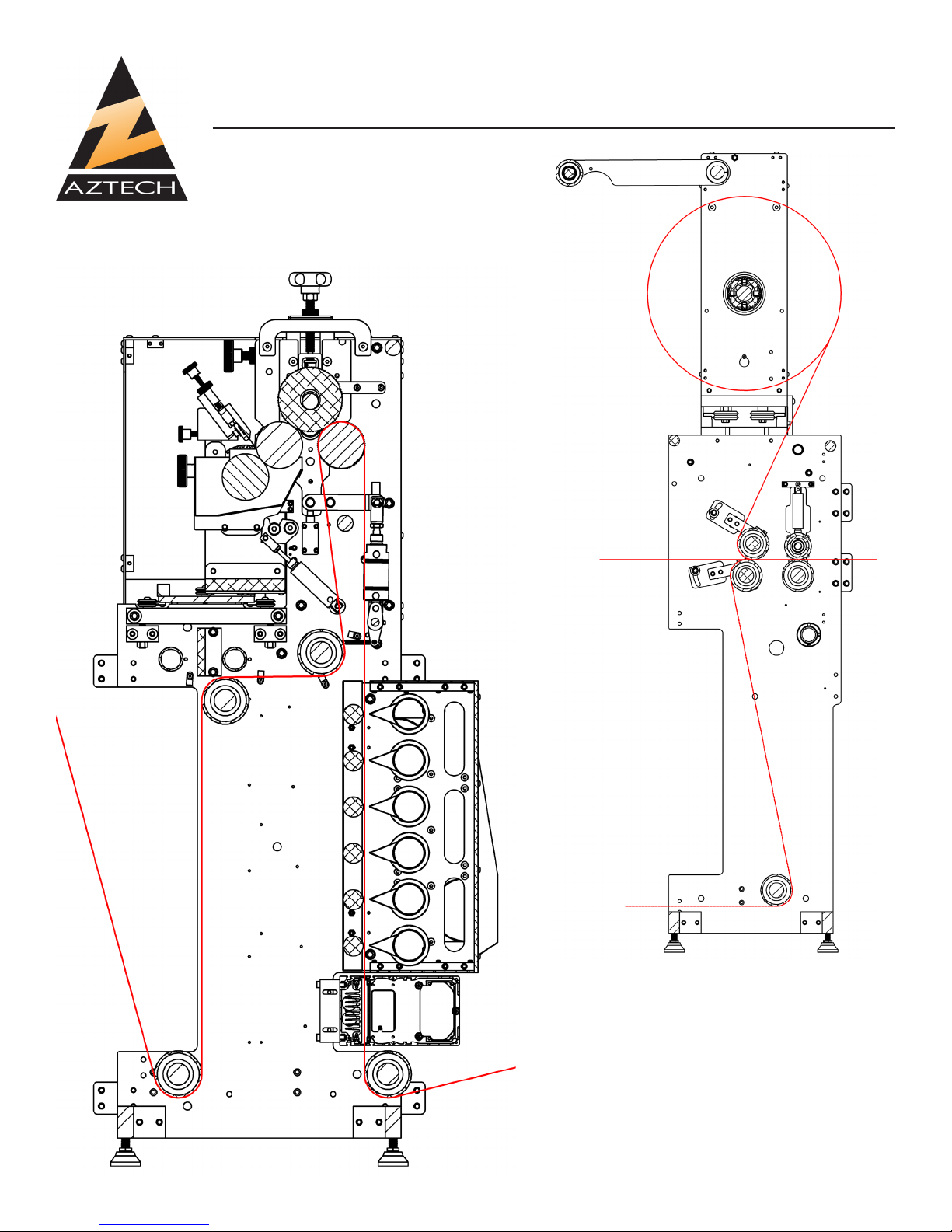

Modular Design

6 Rev 1.3

The Die Master press is designed

in modular sections to allow a

press to be tailored for an application. The various sections are

shown on the following pages.

Page 9

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Unwind Sections

Cradle Mount

Unwind

CMU

Unwind Disc Brake

UDB

7

Page 10

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Flexo Print Station

8 Rev 1.3

Lamination Tower

ACCESSORY MODULES

Page 11

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

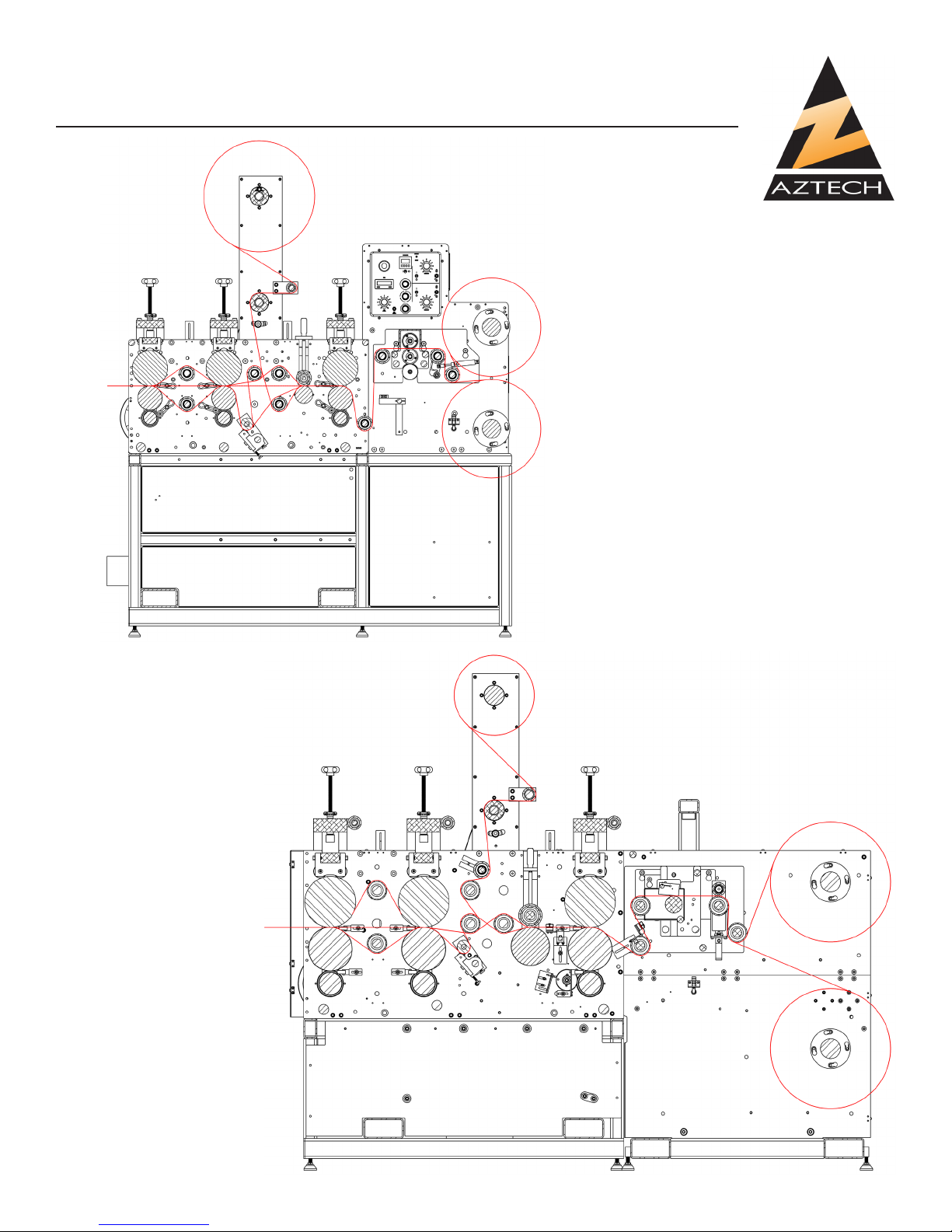

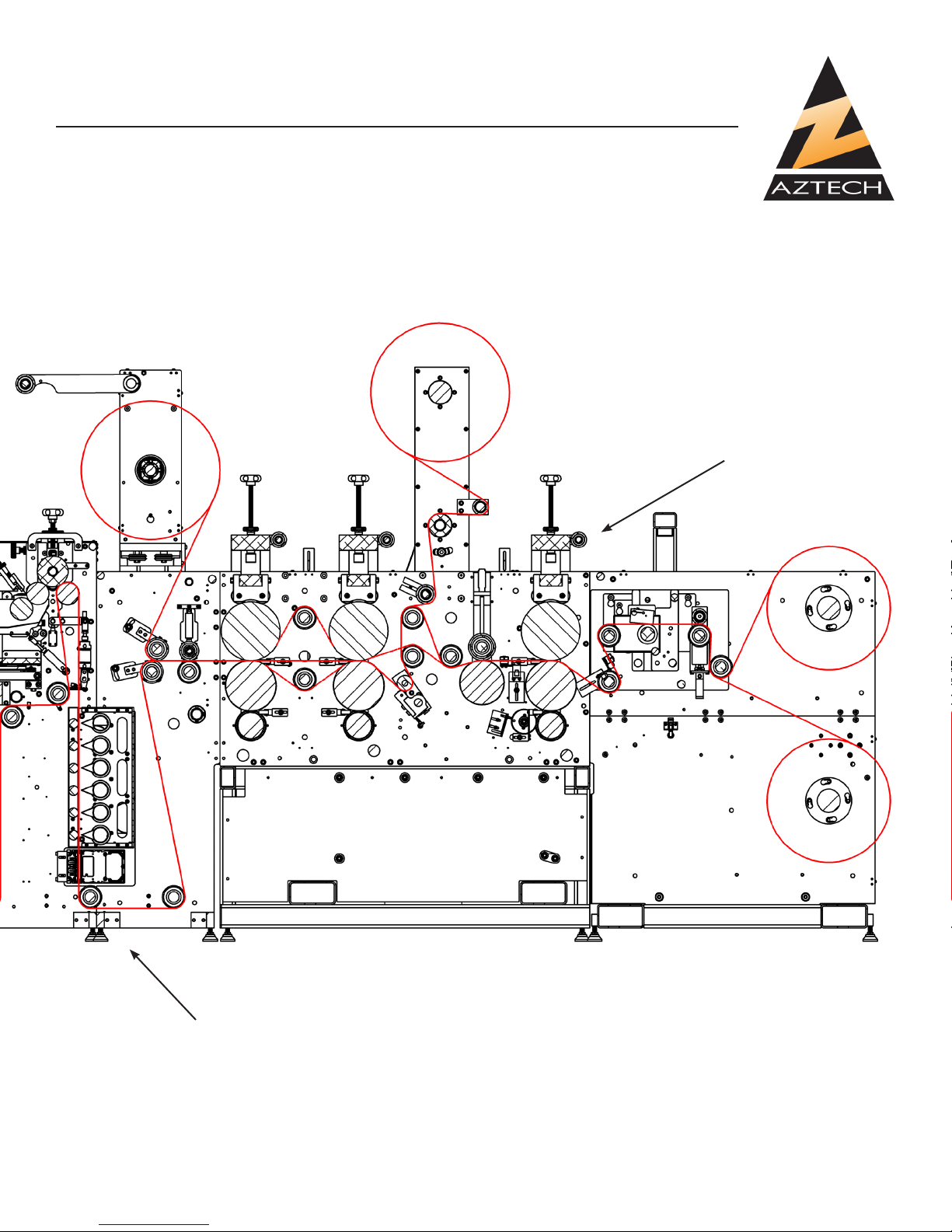

DIE SECTIONS

13” - 18” DIE MASTER

20” DIE MASTER

9

Page 12

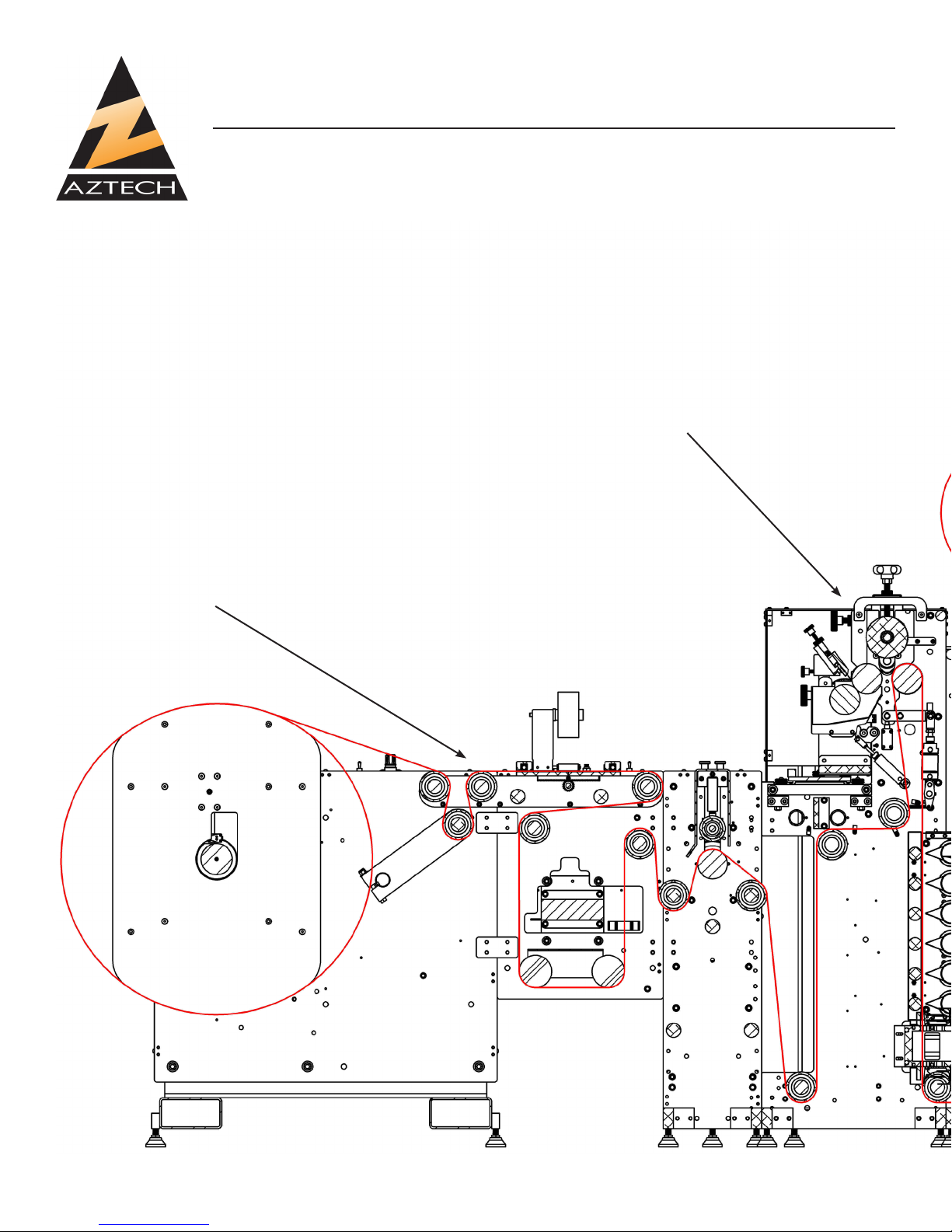

13” Die Master Shown

-UDB

-Print Station

-Lamination Tower

-13” Die Section

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

DieMaster w/ UDB Web Path

PRINT STATION

UDB

10 Rev 1.3

Page 13

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

OPTIONAL WEB PATHS

LAMINATION TOWER

REWIND MODULE

SHOWN DASHED

UNDERSCORE

11

Page 14

13” Die Master Shown

-CMU

-2x Print Stations

-Lamination Tower

-20” Die Section

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

CMU INFEED NIP

SAMPLE 20” PRESS

12 Rev 1.3

PRINT STATIONS

Page 15

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

OPTIONAL WEB PATHS

20” DIE SECTIONS

SHOWN DASHED

Lamination Tower

13

Page 16

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

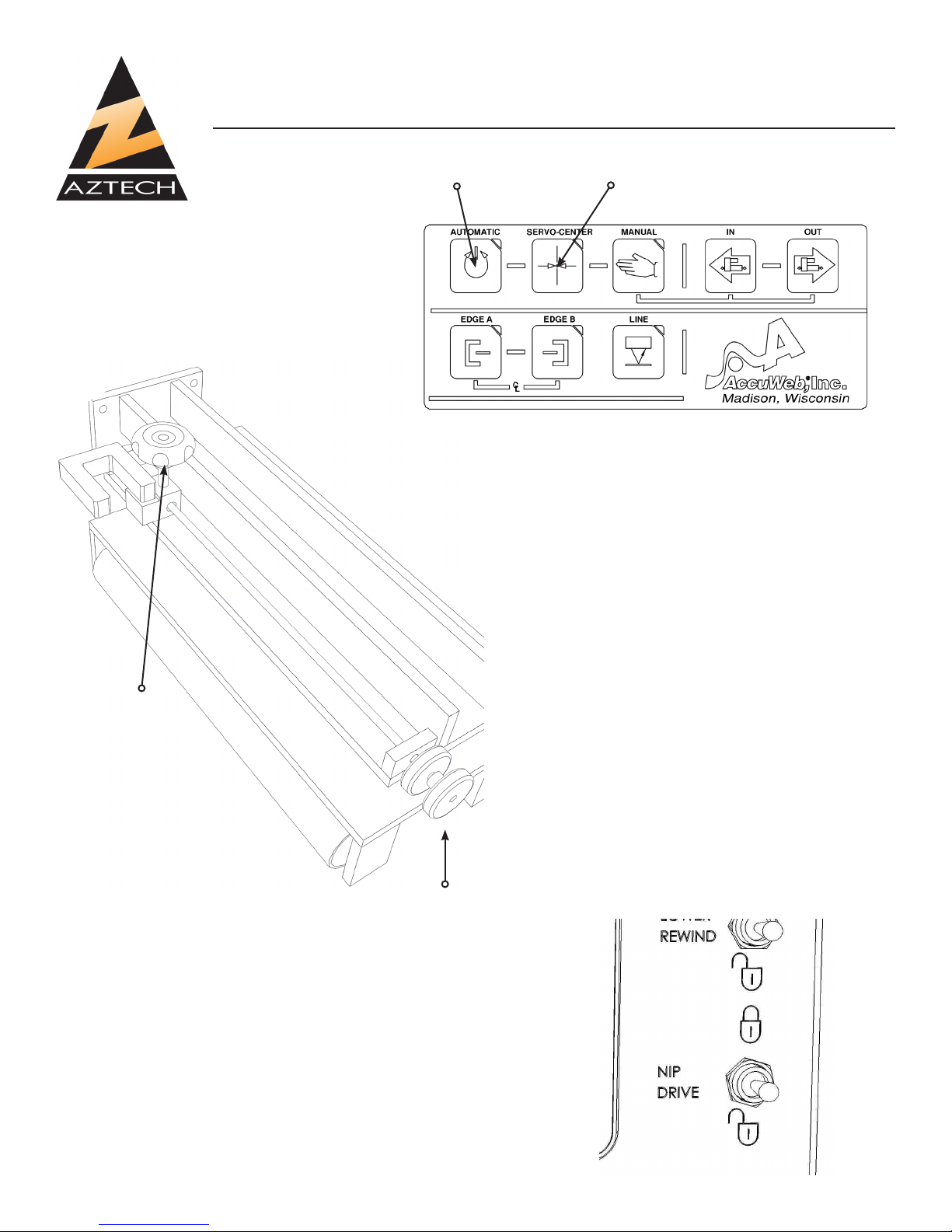

AUTOMATIC SERVO CENTER

3-2: Web Guide Setup

The web guide is located in the center of

the machine between the unwind and rewind stations. After webbing the machine,

set the web by doing the following:

COARSE

SENSOR

POSITIONING

Setting the Web Guide:

1. Press the “SERVO-CENTER” button on the

front of the web guide.

2. Align the sensor with the inside edge of the

web. For ne alignment adjustment, turn

knob on outside of web guide.

3. Jog the machine briey to assure that the

web is moving smoothly.

4. Press the “AUTOMATIC” button which

will engage the sensor and allow the web

guide to adjust itself to the movement of

the web.

5. For more specic instructions about the

features of the web guide, refer to the Accu-Web manual included with this manual.

3-3: Nip Roll Operation

The Nip Roll is pneumatically controlled using control switch and

must be in the up position while machine is running, and in the

down position when threading machine.

14 Rev 1.3

FINE

SENSOR

POSITIONING

Page 17

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

3-4: Splice Table Operation

The splice table on your Sidewinder BSR is located just above the

Unwind Station, just after the optional Inspection Tower. To operate

the Splice Table, simply follow the following steps:

WEB CLAMP

SWITCHES

SLITTING CHANNEL

1. Turn off machine and engage both web clamp switches.

2. Using a razor blade, carefully cut the web along the slicing channel. Disengage the clamp nearest the unwind station. Be sure to leave the other clamp engaged.

3. After waste has been removed, pull through new web, carefully align with web, and lower the

handle to hold.

4. Again using a razor blade, cut the web, discard waste, pull tape under webs, fold to secure and

cut tape.

5. Disengage both switches to release web clamps.

15

Page 18

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

3-5: ROTARY SHEAR SET-UP

Step 1 Set lower blades for

desired slit-widths and tighten

set-screws, making sure upper

blades are up and not in lock

position.

TURN TO UNLOCK

Step 2 Lower upper blade

assembly by turning handle

counter-clockwise and snap

into lock position, making sure

that the upper blades are clear

of lower blades to avoid blade

damage.

Step 3 Gently slide upper

blade(s) into cutting position

ush against the lower blade(s)

by pushing on both sides of the

blade to avoid wobble. Hold upper blade against lower blade

and tighten set-screw.

SLITTER

TIGHTEN SET SCREWS

TO LOCK BLADES

16 Rev 1.3

Page 19

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

LOOSEN SET

SCREW HERE

SLIDE FORWARD

TO REMOVE

3-6: Changing Rewind Spindle

Your Die Master may be equipped with Convertech pneumatically inatable modular rewind spindles. These spindles are easily removed by loosening the hex-screw at the machine side and pulling away from machine. To insert new spindle, simply insert spindle into rewind station and tighten

hex-screw rmly.

CAUTION: Utilizing Rewind Spindles less than 1.5” in diameter require the use of Outboard

Support Apparatus which is NOT included in the standard equipment. Operating the machine without the support apparatus and with spindles less than 1.5” may result in serious

injury.

17

Page 20

ADJUST EOR HEIGHT

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

LOOSEN SET

SCREW HERE

CMU EOR Sensor Mounting

3-7: End-of-Roll (EOR) Sensor Adjustment

The unwind unit will come equipped with an end-

of-roll sensor. When this sensor is switched on,

the machine will not RUN if there is insufcient

material on the unwind roll. To adjust the sensor:

1: Loosen the screw retaining the EOR sensor

mount.

2: Move the sensor into a position where it is just

“OFF” with an empty core.

3: Tighten the retaining screw.

ADJUST EOR HEIGHT

18 Rev 1.3

UDB EOR Sensor Mounting

Page 21

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Section 4: Machine Operation

4-1: Operator Control Layout

13”- 18” Standard model DieMaster

START PB

JOG PB

STOP PB

SPEED KNOB

REWIND CONTROLS

COUNTER CONTROL

E-STOP

20” Standard model DieMaster

19

Page 22

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

4-1: Operator Control Layout

TOUCH

SCREEN

PLC

The Die-Master is also available with a PLC machine control with

a touch-screen interface. The operation of the HMI interface is

described in the next section.

20 Rev 1.3

START PB

JOG PB

STOP PB

SPEED KNOB

REWIND CONTROLS

AIR CONTROLS

E-STOP

Page 23

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

4-2: PLC OPERATION

THE MAIN MENU

On power-up of the machine, the PLC will boot. This is analogous to a home PC booting. It can be

expected to take a minute or two.

When the PLC has nished booting, the MAIN MENU will be displayed.

When the MAIN MENU is displayed, the PLC will lock-out the operator buttons and the machine will

not run.

The menu jumps displayed in white may be accessed by the user, the yellow MACHINE DIAGNOSTICS jump is password protected.

The PLC may be setup to have controls labeled in Spanish or German. Pressing the ags at the

bottom changes between these languages.

21

Page 24

MAIN MENU

Buttons to acess primary ma-

chine functions are displayed

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

RUN SCREEN

on the MAIN MENU.

Menú principal en Español Hauptmenu auf Deutsch

22 Rev 1.3

Page 25

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

RUN MENU

Set Torque. Press

to set manually

Machine Running Status

Enabled/Disabled Indicator

Adjustor / Indicator

Increment by 1 and 10

Counter ON/OFF

Exit to Main Menu Prompt Rewind Setup

Progress BarDistance Units

Count Sensor Selection

23

Page 26

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

COUNTER STATUS

DISPLAY

The user is prompted to con-

rm reset. The prompt clears in

5 seconds.

The Batch Count increments

every time the set count is

reached and the counter is on.

Press here to turn the

counter on and off.

The current count is displayed The Set count is displayed

The count progress is visually

represented as a percentage

scale.

The count sensor selection is

shown. If in distance, the units

are displayed.

24 Rev 1.3

Page 27

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Press the box to change between

Over and Underwind.

DO NOT SWITCH WHILE RUNNING

TORQUE COMPENSATION

The Torque Compensation feature mimics the act of slowly increasing rewind torque by gradually

turning up the knob while the roll grows. To set up the feature, enter the core diameter as the Start-

ing Diameter. Enter the nished roll size as the Finishing Diameter. Subtract the torque setting

used to start the roll from the setting used to nish the roll and enter this as the % to ADD. When

the TQ COMP is on, a text will be displayed above the rewind torque bar.

25

Page 28

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Press to set the nish count.

Press to set the slowdown

point. IF THE SLOWDOWN

POINT IS GREATER THAN

THE SET COUNT, THE

MACHINE WILL NOT SLOWDOWN.

When in distance count, press

to set the units.

26 Rev 1.3

Press to toggle between

count sensors.

Press to turn the EOR on

and off.

When the End of Roll sensor is

on, an indicator showing its status

will show on the Run Menu.

Page 29

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

4-3: Mounting Rotary Die(s) in Die Station

Recapping the set-up procedures as outlined in Chapter 3, carefully follow the web path diagram in 3.1-2, web the DieMaster,

and adjust the web guide if needed (see diagram 3-2).

ALWAYS USE CAUTION WHEN HANDLING ROTARY TOOLING

AS DAMAGE MAY OCCUR IF MISHANDLED. WHEN LAYING A

ROTARY DIE DOWN, ALWAYS MAKE SURE TO SET ON SOFT

SURFACE TO HELP AVOID DAMAGE.

To correctly mount a rotary die:

1) Use spacer washer(s) on journal on gear side to assure that

the die gear is properly aligned to the anvil roll gear.

2) Slide square bearing block onto gear side journal and slide die

into place. If gears are not aligned properly, remove die, and add

or remove washers until aligned.

3) Use spacer washer(s) on outboard side, and slide quarter-turn

bearing block onto shaft and turn counter-clockwise, making certain that the die is snug and does not slide around.

4) With die in proper position, set die truck onto die making certain the bearings ride against the rotary die bearers.

5) Slide die bridge into place, tighten all 4 hex screws, and turn

both assist knobs clockwise until snug. Secure die by turning the

lock knobs clockwise until tight.

6) Using the pre-drilled holes near the die station, secure the 4

die wipers against the die bearers and lubricate all 4 with oil to

help keep debris away from die.

27

Page 30

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

4-4: Using the Waste-Windup

With die properly positioned, slide a core onto the waste-windup

spindle, inate using the switch and perform the following steps:

1) Jog the machine to briey begin cutting and

than stop.

2) Peel the waste away from the web, using

caution by keeping hands away from the die,

and hold with one hand while jogging the

machine to produce enough length of waste to

reach the waste wind-up.

3) Thread the waste by wrapping around the

capstain roll, then around the knurled idler roll,

before securing to the waste windup spindle.

4) Adjust both lower capstan and waste-windup spindle tensions using the pneumatic dials.

CAUTION: ALWAYS KEEP HANDS OR LOOSE CLOTHING AWAY FROM THE DIE WHEN THE

MACHINE IS IN MOTION TO AVOID THE POTENTIAL FOR SERIOUS PERSONAL INJURY.

4-5: Adjusting Die Timing

The cranks at the front of the machine may be used

to adjust the die timing.

Timing position is shown by the bar and scale are

the top rear of the machine.

28 Rev 1.3

Page 31

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Chapter 5: Maintenance

The DieMaster Rotary Die Cutting Machine is rigidly constructed to provide your company many

years of reliable productivity, however regular and periodic maintenance is required to keep it running to its full potential and to avoid damage. To assure maximum performance and longevity, the

following maintenance is essential:

REGULAR MAINTENANCE:

• Lubricate Die and Anvil Roll bearing blocks by applying oil into holes at the top of the bearing

blocks.

• Apply oil to all ber wiper rolls to keep dies and rollers free of debris.

• Apply heavy viscosity gear grease to all roller gears.

• Apply grease to the die trucks using the (4) ttings and apply oil to the felt pads between the bear-

ings and trucks.

• Clean blades on slitting station.

PERIODIC MAINTENANCE:

• Turn off power and remove back cover to inspect all belts assuring they are tightened sufciently.

• Clean the web guide sensor to assure that it is free of dust and debris.

• Clean counter sensors inside the machine under the pace roller to assure that they are free of

dust and debris.

• Assure that all belts are sufciently tight and tighten any loose belts.

29

Page 32

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Chapter 6: Station Detail

UDB Main Assembly

30 Rev 1.3

Page 33

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

31

Page 34

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

UBD: Brake Assembly

32 Rev 1.3

Page 35

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

33

Page 36

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

UDB: Brake Assembly

34 Rev 1.3

Page 37

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

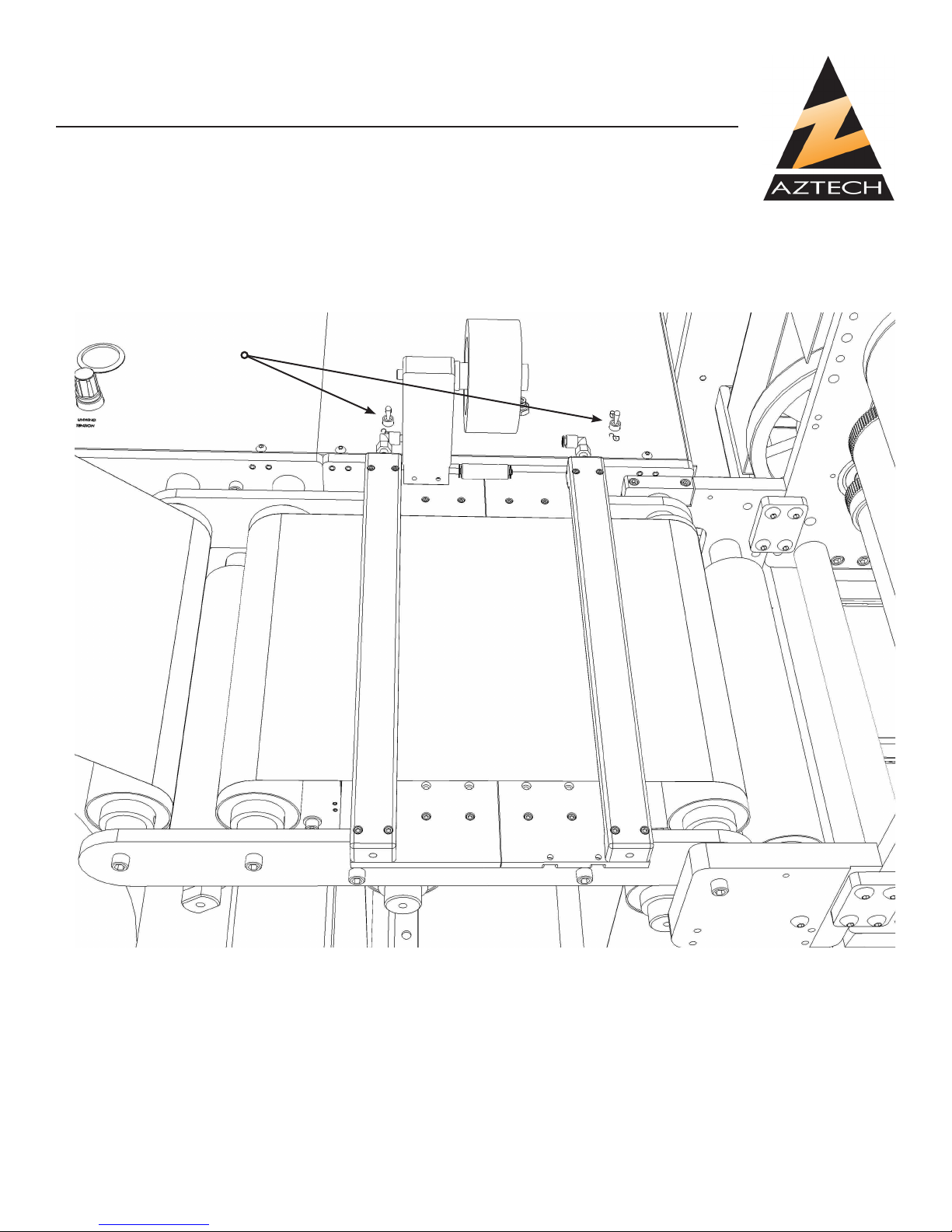

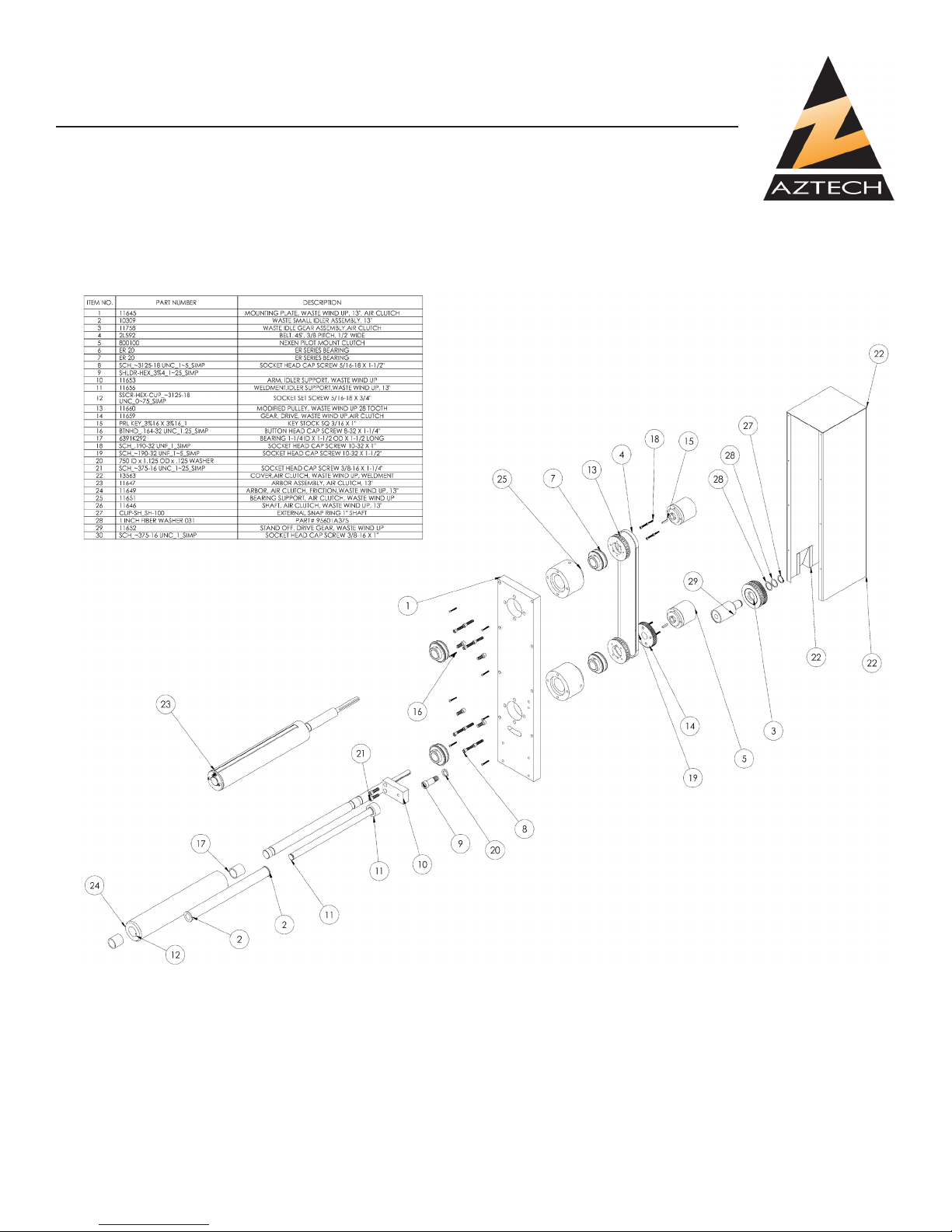

Waste Windup Assembly

35

Page 38

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Rotary Die Station: Support Roll Assembly

36 Rev 1.3

Page 39

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Rotary Die Station: Anvil Roll Assembly

37

Page 40

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Rotary Die Station: Die Truck Assembly

38 Rev 1.3

Page 41

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Main Drive: Nip Roll Assembly

39

Page 42

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Main Drive: Pace Roll Assembly

40 Rev 1.3

Page 43

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Slitting Station: Main Assembly

41

Page 44

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Slitting Station: Rotary Shear Assembly

42 Rev 1.3

Page 45

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Press Controls, PLC OPTION

43

Page 46

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Main Electrical Cabinet, PLC

44 Rev 1.3

Page 47

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Label Sensor Panel

Operator Panel, PLC

45

Page 48

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Cradle Mount Unwind Controls

46 Rev 1.3

Page 49

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

47

Page 50

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Press Controls, STANDARD

48 Rev 1.3

Page 51

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Press Schematic, STANDARD

49

Page 52

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Press Schematic, STANDARD

50 Rev 1.3

Page 53

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

51

Page 54

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Press Schematic, STANDARD

52 Rev 1.3

Page 55

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Section 7: Troubleshooting

7-1: Why doesn’t the machine turn on?

First check to make sure that the main power switch on the back electrical panel is turned on. Then

make sure that the emergency stop button on control panel is

disengaged.

7-2: The counter is not counting accurately.

Inspect and clean both counter sensors located in the machine on the gear underneath the pace

roller.

7-3: Why is the counter not counting inches?

Make sure that the counter sensor below the web guide is ashing red which assures that it is properly connected to the machine. Be sure that the setting on the PLC is “Distance”.

7-4: Why is the counter not counting labels?

If your machine is equipped with the optional label counter and is not doing so, after assuring that

the counter sensor below the web guide is ashing red which assures

that it is properly connected, assure that the PLC is set to “LABELS”.

7-5: Why isn’t the end-of-roll sensor working?

If your DieMaster is equipped with the optional end-of-roll shut-down and it is not shutting down

the machine when the unwind roll is near the end, or if it is shutting down prematurely, perform the

following:

1. Assure that the light on the sensor (see gure 7-B)

located near the unwind spindle is illuminated.

2. If not illuminated, check wiring for proper connections or damage. If wiring is set up properly, the

sensor may need to be replaced.

3. If illuminated, the sensor may be in need of adjustment. If the machine is shutting down prematurely, the sensor needs to be moved closer to the

unwind spindle, where if it is not shutting down

the machine at all, the sensor needs to be moved

away from the unwind spindle. To adjust the sensor, simply loosen the set screw, slide bracket in

either direction, and re-tighten

Adjust Sensor

Height

Set Screw

53

Page 56

AZTECH CONVERTING SYSTEMS

DM-40XX

USER MANUAL

Section 8: Warranties and Service

8-1: Warranties & Provisions

WARRANTIES: All equipment manufactured and sold by AZTECH Converting Systems (Seller) is

warranted to be free of defective materials and workmanship under normal use and service for a

period of one (1) year from the date of delivery to Buyer's premises. All commercial components not

manufactured by Seller carry the original manufacturer's warranty. At Seller's discretion, Seller may

provide on-site warranty service for a period of ninety (90) days from the aforementioned date.

REMEDIES If within the Warranty Period any such Equipment is proven to Seller's satisfaction to

be defective in either material or workmanship, Seller, at its sole discretion, shall (a) repair or re-

place defective parts on the Equipment at Seller's cost, or (b) grant a reasonable allowance on

account of such a breach. If within the Warranty Period the Seller receives notice from Buyer of

defects in parts or materials. Seller will ship (ground, prepaid) replacement parts) and invoice Buyer

for the full cost of the replacement parts). Buyer will receive a Return Authorization (RA) from seller,

and return defective parts or materials to Seller, who at its sole discretion shall determine whether

defective parts or materials are or are not subject to exclusion from this warranty as provided herein. Any defective parts or material not excluded from the Warranty Period will then be fully credited

to Buyer.

EXCLUSIONS

THE FOLLOWING ITEMS ARE EXCLUDED FROM THIS WARRANTY:

• Defects or damage caused by careless or improper use.

• Parts that need periodic replacement from wear during normal operation.

• Routine maintenance and adjustment.

• Failure or damage caused by improper

installation or inadequate maintenance by Buyer.

• Failure or damage caused by equipment modications by Buyer.

• Equipment damage resulting from an accident, or abnormal conditions of operation.

DISCLAIMER OR WARRANTY

NO OTHER WARRANTY IS EXPRESSED OR IMPLIED INCLUDING WARRANTIES OF MER-

CHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE. SELLER IS NOT LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGE SUCH AS, BUT NOT LIMITED TO LOSS IN

PROFITS, LOSS OF USE OF EQUIPMENT, OR INCREASED IN OPERATING COSTS OR EXPENSES.

8-2: Technical Service

In the event that your DM is not functioning properly or if you have any technical questions, an AZTECH Technical Service representative is available to assist you. Contact information is as follows:

Phone: 1-480-951-8351

1-800-829-8351

Fax: 1-480-998-5409

E-Mail: techservice@aztechconverting.com

54 Rev 1.3

Loading...

Loading...