Azbil VY5199J0080S, VY5199J0041S, VY5199J0101S, VY5199J0121S, VY5199J0040S Specifications And Instructions

...Page 1

AB-7353-U

Specifications/Instructions

ACTIVAL™

Motorized Two-Way Valve with Flanged-End Connection

for High Differential Pressure Application

<4-20 mA DC Input with 4-20 mA DC Feedback Output>

(ANSI Class125 equivalent / Gray cast iron)*

General

ACTIVAL™ Model VY5199J for high differential pressure

application is a series of motorized two-way valves with

flanged-end connection. Rotary valve and actuator are

integrated in a single unit.

Valve size ranges from

Actuator has a reversible synchronous motor, which

operates at a low voltage of 24 V AC.

4 to 20 mA DC input control signal provides proportional

control in combination with a single loop controller (e.g.,

Model SDC35/SDC36).

11/

” to 6”.

2

Features

Applicable to high differential pressure applications:

•

Water ow is controlled inside the valve to prevent over

pressure drop, leading to cavitation erosion resistance.

(See Fig. 1.)

Compact and lightweight:

•

Rotary motor actualizes small body and light weight.

Valve and actuator integrated in a single unit:

•

Pre-assembled body requires no adjustment.

Durable actuator with low power consumption

•

Modied linear ow characteristics

•

Valve applicable to high differential pressure, high Cv

•

value, wide rangeability, and low leakage

4 to 20 mA DC output available for position feedback.

•

Open/close changeover for input signal failure:

•

Actuator fully opens/closes valve in case that the control

signal is not input to the actuator. (Default: Fully open)

Direction changeover of control action:

•

Open/close action by 4 to 20 mA DC input signal is

reversely controllable.

Normal action 4 mA: 0 % to 20 mA: 100 %

Reverse action 20 mA: 0 % to 4 mA: 100 %.

(Default: Normal action)

Adjustable dead band*:

•

Dead band width can be narrowed to more precisely

operate valve actuator.

∗ Actuator is not operated by input signal changed less than a

certain amount. This amount of change is called dead band.

CE Marking certied:

•

ACTIVAL Model VY5199J conforms to all the applicable

standards of CE Marking.

* This product was designed and manufactured conforming to the ISO (International Organization for Standardization, PN16/GG-20).

© 2015–2016 Azbil Corporation All Rights Reserved.

1

Page 2

AB-7353-U

Safety Instructions

Please read instructions carefully and use the product as specied in this manual.

Be sure to keep this manual nearby for quick reference.

Restrictions

This product is targeted for general air conditioning. Do not use this product in a situation where human life

might be affected. Also, do not install this product in an atmosphere containing explosive gas or flammable gas.

If this product is used in a clean room or a place where particularly high reliability or control accuracy is required, please

contact our sales representative. Azbil Corporation will not bear any responsibility for the results produced by the

operators.

Warnings and Cautions

WARNING Alerts users that improper handling might cause death or serious injury.

CAUTION Alerts users that improper handling might cause minor injury or material loss.

Signs

Alerts users possible hazardous conditions caused by erroneous operation or erroneous use. The symbol inside

a

indicates the specic type of danger. (For example, the sign on the left warns of the risk of electric shock.)

Noties users that specic actions are prohibited to prevent possible danger. The symbol inside graphically

indicates the prohibited action. (For example, the sign on the left noties that disassembly is prohibited.)

Instructs users to carry out a specific obligatory action to prevent possible danger. The symbol inside

graphically indicates the actual action to be carried out. (For example, the sign on the left indicates general

instructions.)

a

a

a

WARNING

Some of the product models weigh more than 40 lb (18.1 kg). Carefully move the product with a vehicle or

•

enough manpower in an appropriate manner. Careless lift or accidental drop of the product might cause injury or

product damage.

Detach the cover only when wiring, setting the product or maintenance and reattach the cover after wiring,

•

setting the product or maintenance. Failure to do so might cause electric shock.

Before wiring, maintenance or setting the selector switches, be sure to turn off the power to the product

•

(including the optional devices). Failure to do so might cause electric shock or device failure.

CAUTION

Install and use this product under the operating conditions (for temperature, humidity, power, vibration, shock,

•

mounting direction, atmosphere, etc.) listed in the specifications. Failure to do so might cause fire or device

failure.

Installation and wiring must be performed by qualified personnel in accordance with all applicable safety

•

standards.

Use the product within its lifespan and avoid instrumentations that keep the product to operate excessively.

•

Continued use beyond the lifespan might cause re or device failure.

Keep the products in package for storage. Failure to do so might damage or stain the products.

•

Do not allow any shock on the product. Doing so might damage the product.

•

(1/2)

a

a

a

All wiring must comply with applicable codes and ordinances.

•

Provide circuit breaker/fuse protection when powering this product.

•

Provide a circuit protector (e.g., a fuse, circuit breaker) for the control panel to ensure your safety.

•

2

Page 3

AB-7353-U

a

a

a

a

CAUTION

Use full face gaskets for at face anges to prevent the product damage or uid leakage.

•

Set the selector switches using a pen nib or a nger. Do not use a tool such as a screwdriver. Such a tool might

•

damage the selector switches or the PCB.

For installation, do not mount the valve in an improper position or overtighten the bolts on the ange. Doing so

•

might damage the product.

After installation, make sure no uid leaks from the valve-pipe connections. Incorrect installation might cause

•

uid leakage.

Install the product so that no foreign objects remains inside the pipes. Be sure to provide a strainer on the inow

•

side of the piping. Flush the piping to remove the foreign objects after installation. Foreign objects inside the

piping might damage the product.

Do not allow the uid to freeze. Doing so might damage the valve body and cause uid leakage.

•

Do not put load or weight on the actuator of the product. Doing so might damage the product.

•

Do not install the product nearby a steam coil, pressurized hot-water coil, or any high heat source. High

•

temperature radiation might cause malfunction of its actuator.

Do not use the product in an atmosphere corrosive to the actuator, valve, and their components. Doing so might

•

damage the product.

Do not carelessly touch this product when being used to control hot water. The product temperature is hot, and

•

you might get burned.

Use crimp terminals with insulation for connections to the product terminals. Failure to do so might cause short

•

circuit leading to re or device failure.

(2/2)

Firmly tighten the terminal screws. Insufcient tightening of the terminal screws might cause re or overheating.

•

Do not touch the moving parts of the product. Doing so might cause injury.

•

S

Do not disassemble the product. Doing so might cause device failure.

•

Dispose of this product as industrial waste in accordance with your local regulations. Do not reuse all or part of

•

a

IMPORTANT:

In case an Azbil Corporation product fails, you are required to provide your Equipment with safety design

such as fool-proof design*

any occurrence of physical injuries, res, signicant damage, and so forth. Furthermore, fault avoidance*3,

fault tolerance*4, or the like should be incorporated so that the said Equipment can satisfy the level of

reliability and safety required for your use.

*1. A design that is safe even if the user makes an error.

*2. A design that is safe even if the device fails.

*3. Avoidance of device failure by using highly reliable components, etc.

*4. The use of redundancy.

the product.

During engineering work, do not touch the uninstructed area other than the setting switches. Doing so, you might

•

be burned. Temperature of some parts of the actuator becomes high.

1

, and fail-safe design*2 (anti-ame propagation design, etc.), whereby preventing

IMPORTANT:

When installing the product with a ange gasket, do not allow the gasket going inside the pipe.

•

The service life of ACTIVAL operated with small dead band can be shortened since the ACTIVAL operates

•

more frequently with small dead band than with normal dead band.

To operate the product with small dead band, provide shielded cable for input/output signal lines and power line.

•

Unshielded cable might cause error due to noise.

3

Page 4

AB-7353-U

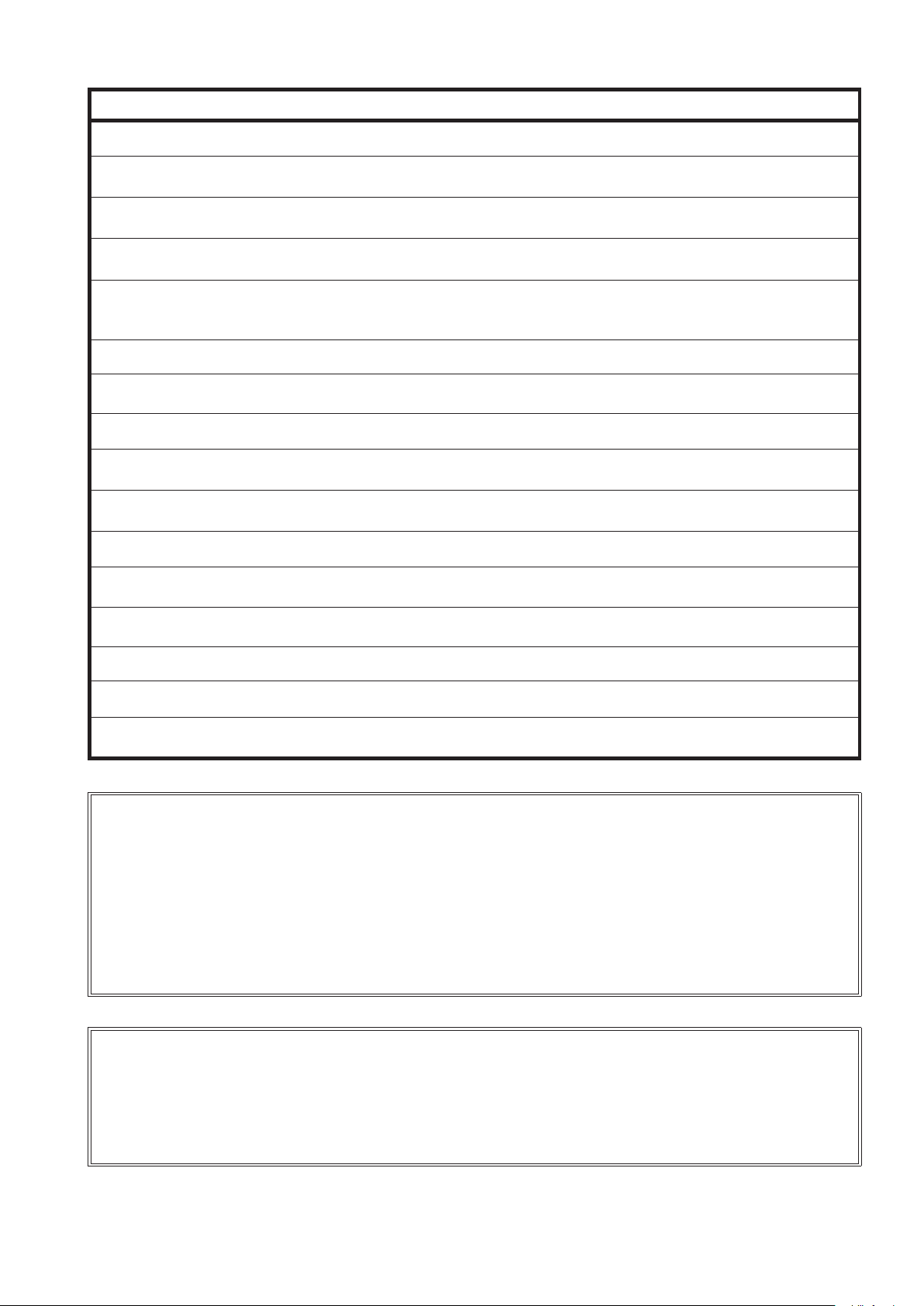

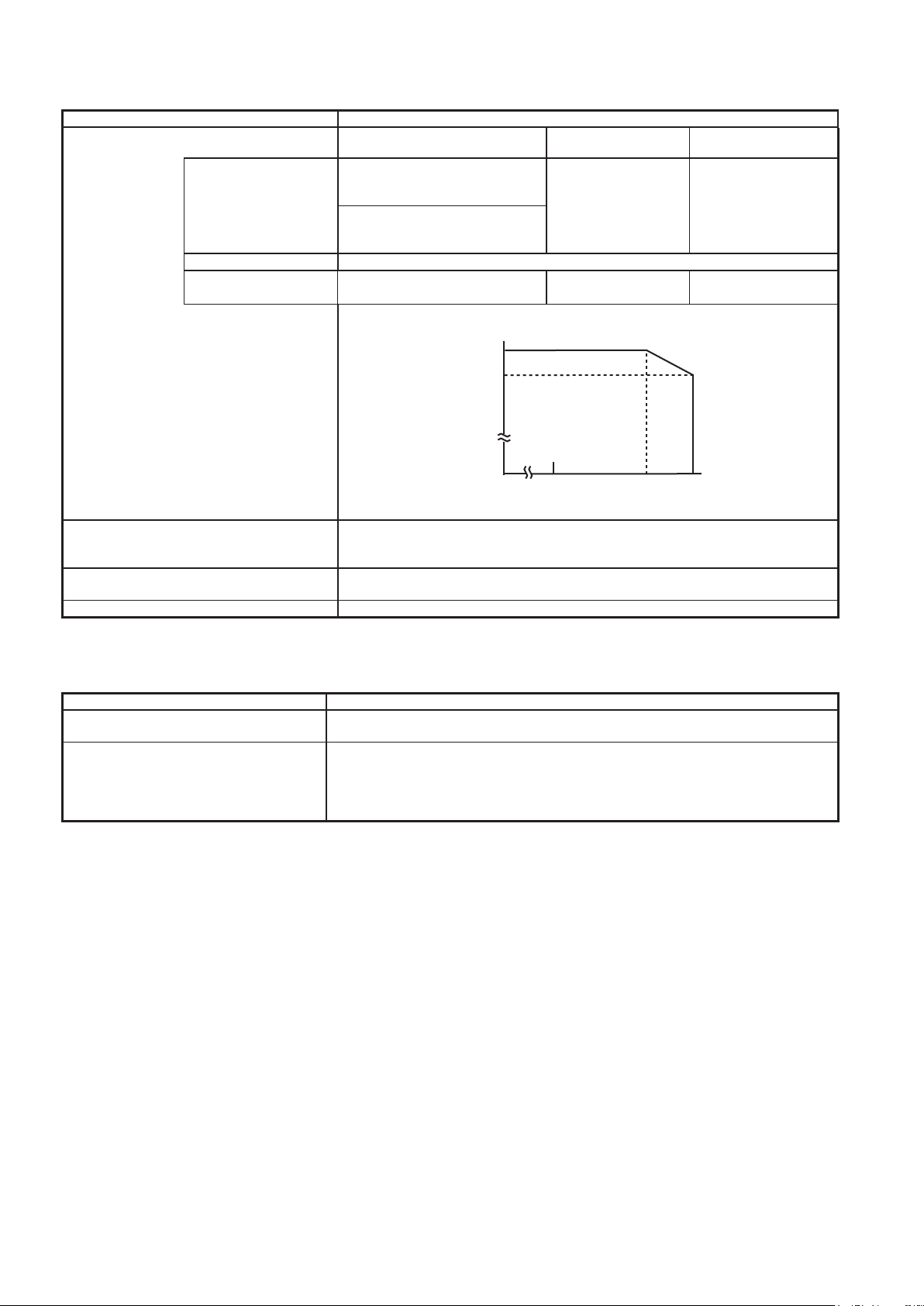

Mechanism of Cavitation Erosion Resistance

∗ Note:

Fig.1 shows the image of 1

1

/2” to 3'' valve model.

4'' to 6'' valve also has the cone as well.

Refer to the section Dimensions for the image of

4'' to 6'' valve model.

Cone

Figure 1. Mechanism of cavitation erosion resistance

Model Numbers

Model VY5199J0XXXS-146 is the model for the valve and actuator integrated into a single unit.

The model number label is attached to the yoke. The 4 to 20 mA control signal is indicated on the actuator label and on the

wiring diagram.

Base

model

number

VY51 Flanged motorized two-way valve

* This product was designed and manufactured conforming to the ISO (International Organization for Standardization, PN16 / GG-20).

Actuator/valve Actuator Valve

Control

signal

Rating/

material

9 4 to 20 mA DC input with 4 to 20 mA DC feedback output

Type

9

J

Nominal

size / Cv

0

040 1

041 1

050 2” / 40 Cv

060 2

080 3” / 95 Cv

101 4” / 145 Cv

121 5” / 234 Cv

151 6” / 350 Cv

Fixed Description

ANSI Class125 equivalent / Gray cast iron*

with cavitation erosion resistant mechanism

S-146

NEMA 4X and IEC IP54 protected and standard torque type actuator with

terminal block for 1

NEMA 4X and IEC IP54 protected and high torque type actuator with

terminal block for 6'' valve

1

/2” / 16 Cv

1

/2” / 25 Cv

1

/2” / 65 Cv

1

/2” to 5'' valve

4

Page 5

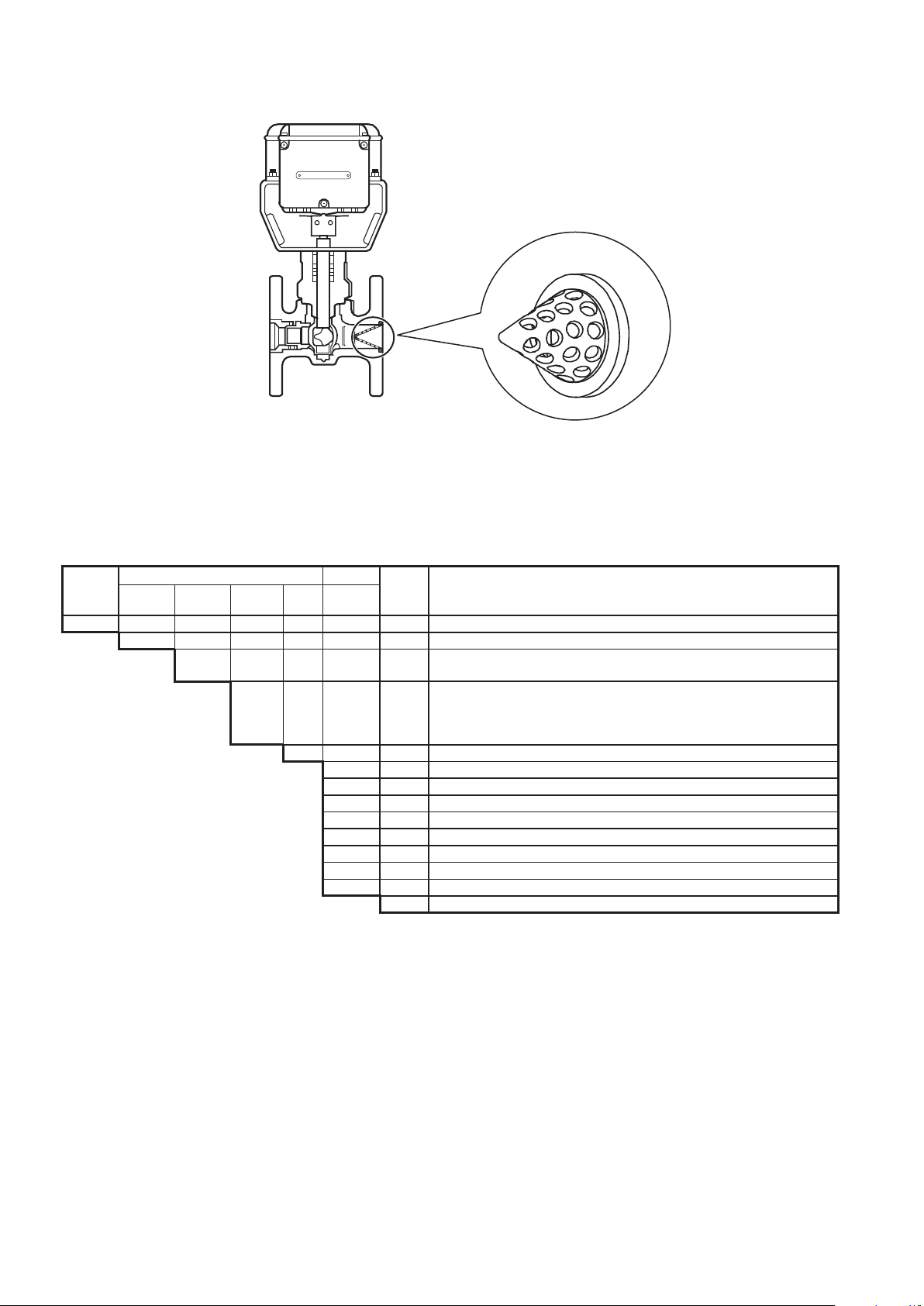

Speci cations

For weight, refer to the table shown in the section Dimensions.

Valve speci cations

Item Speci cation

Model Two-way valve with anged-end connection proportional control

ANSI Class125 equivalent (Max. working pressure: 230 psig)

(ASTM A126 class B ASME 16.1-2010)

Body pressure rating

260

220

180

140

Max working pressure 230 psig at 32 to 266°F : 4" to 6"

100

Use the product within the hatched range.

Pressure psig

60

32 68 104 140 176 212 248 284 320 356

Temperature °F

End connection ANSI Class125 Bolt pattern anges, at face ange (FF)

Size, Cv, close-off rating

Model number

VY5199J0040S-146 1

VY5199J0041S-146 1

VY5199J0050S-146 2” 50 40 145 psig

VY5199J0060S-146 2

Nominal size

Inch DN

1

/2” 40 16 145 psig

1

/2” 40 25 145 psig

1

/2” 65 65 145 psig

VY5199J0080S-146 3” 80 95 145 psig

VY5199J0101S-146 4” 100 145 72.5 psig

VY5199J0121S-146 5” 125 234 72.5 psig

VY5199J0151S-146 6” 150 350 72.5 psig

Materials Body Gray cast iron

Plug, stem Stainless steel

Cone

1

1

/2” to 3'' valve: Stainless steel

4'' to 6'' valve: Cast iron

Seat ring Heat-resistant PTFE

Gland packing Inorganic ber

Gasket Non-asbestos joint sheet

Applicable uid Chilled/hot water, high-temperature water, ethylene glycol solutions (50 % max.)

Allowable uid temperature Model VY5199J00XX(1

1

/2" to 3"): 32 to 347 °F (0 to 175 °C)

Model VY5199J01X1(4" to 6"): 32 to 266 °F (0 to 130 °C)

Flow characteristics Modi ed linear characteristic

Rangeability 100 : 1

Seat leakage 0.01 % or less of rated Cv value

Paint Gray

Actuator to be combined Integrated with the valve

Class125

at 32 to 347℉: 1 1/2" to 3"

Cv Close-off ratings

AB-7353-U

Actuator speci cations

Item Speci cation

Power supply 24 V AC ± 15 %, 50 Hz/60 Hz

Applicable valve size Standard torque type 1

1

/2” to 5''

High torque type 6''

Power consumption Standard torque type 12 VA

High torque type 13 VA

Timing 63 ± 5 sec (50 Hz) / 53 ± 5 sec (60 Hz)

Control signal input 4 mA DC to 20 mA DC input (Input impedance: 100 Ω)

Feedback signal output Range: 4 mA DC (0 % position) to 20 mA DC (100 % position)

Max. load resistance: 500

Ω

Materials Case Cast aluminum alloy

Top cover, terminal cover Polycarbonate resin (Color: gray)

Yoke Steel plate

Surface nishing Case None

Yoke Electro-galvanized (Bright chromate nish)

Valve position indication Pointer located at the bottom of the actuator shows the position by pointing at the value (0:

close to 100: open) of the scale on front, rear, and bottom sides.

Manual operation Available. Refer to the section Manually opening/closing the ACTIVAL.

Wires connection M3.5 screw terminal connection

Enclosure rating NEMA 4X, IEC IP54

Insulation resistance Between terminal and case: 5 MΩ or higher at 500 V DC

Dielectric strength Between terminal and case: 500 V AC/min with 5 mA or less leakage current

5

Page 6

AB-7353-U

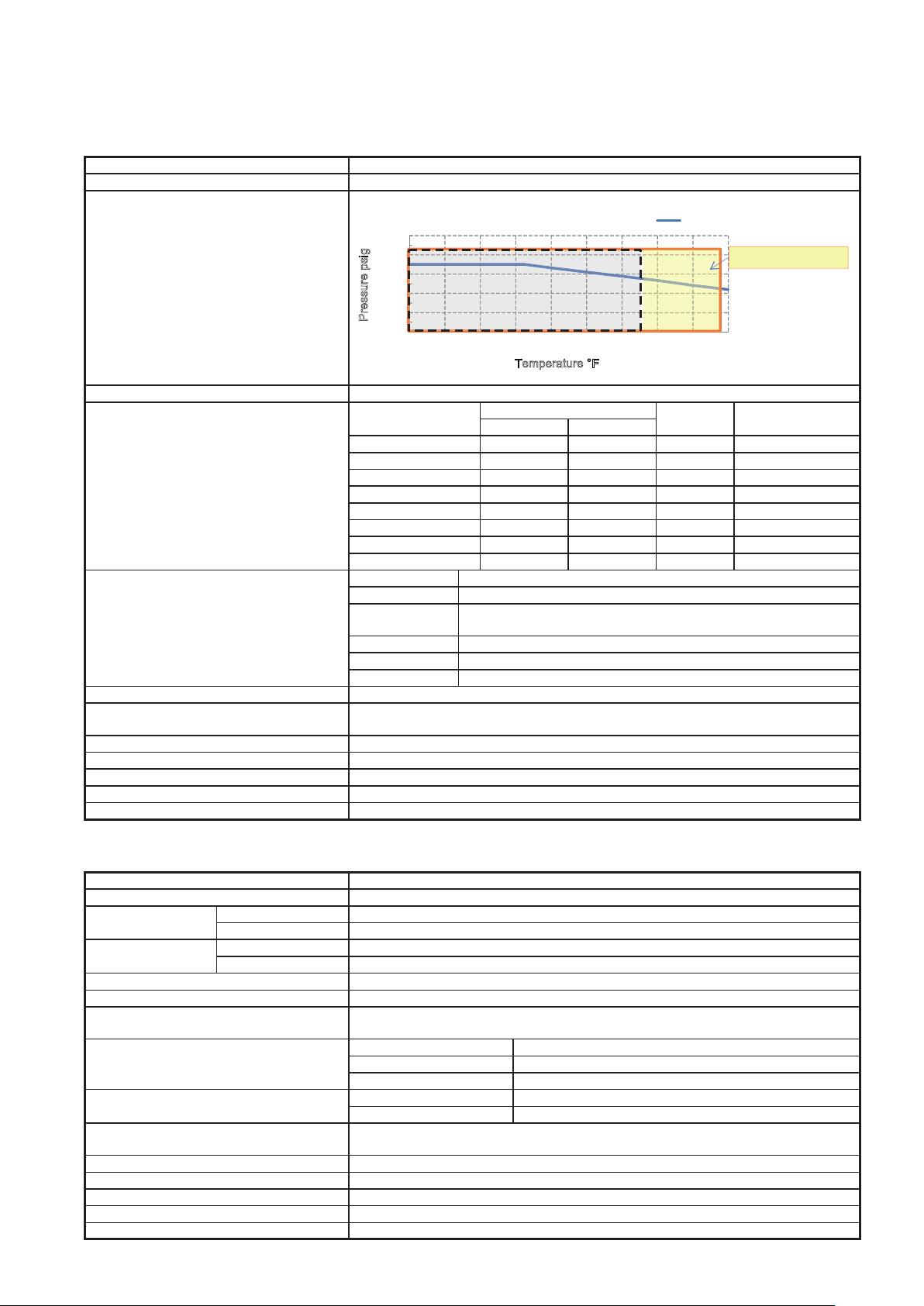

Valve and actuator (as a single unit) specications

Item Specication

Environmental conditions

Ambient temperature*

Ambient humidity 5 % RH to 95 % RH

Vibration

Installation locations Indoor (salt air, corrosive gas, and organic solvent must be avoided.)

Installation orientation Installable in any position ranging from upright to sideways (90° tilted.)

Position for shipment 100 % (fully open) preset at factory.

1

Rated operating condition Limit operating condition

-4 to 122 °F (-20 to 50 °C)

(Fluid temperature 32 to 302 °F

(0 to 150 °C))

-4 to 104 °F (-20 to 40 °C)

(Fluid temperature 302 to 347 °F

(150 to 175 °C))

2

16.1 fps

(10 Hz to 150 Hz)

Notes: ∗1 Do not allow the uid to freeze.

(4.9 m/s2)

2 Actuator shall be packed during transport and storage.

∗

-4 to 140 °F

(-20 to 60 °C)

32.2 fps2 (9.8 m/s2)

(10 Hz to 150 Hz)

conditions (packaged*

-4 to 158 °F

(-20 to 70 °C)

64.3 fps2 (19.6 m/s2)

(10 Hz to 150 Hz)

122

104

Ambient temperature °F

-4

32 212 302 347

Fluid temperature °F

Outdoor (the optional outdoor cover must be used. Direct sunlight, salt air, corrosive gas,

and organic solvent must be avoided.)

* Always install in upright position outdoors.

Transport/storage

2

)

Options

For options, separate order is required.

Item Specication

Seal connector

(Part No. 83104346-003)

Auxiliary switch*

(Part No.83165274-001)

CE Marking Conformity

1

Applicable wire size: 0.28" Dia. to 0.35" Dia. (7 mm Dia. to 9 mm Dia.)

(Seal connector is necessary for NEMA 4X and IEC IP54 protection)

Number of switches: 2 (SW A and SW B)

Max. applied voltage/current: 30 V DC / 3 A

Actuating position

SW A: Adjustable between 0 % (fully closed) and 100 % (fully open)

SW B:.Adjustable between 0 % (fully closed) and 100 % (fully open)

This product complies with the following Electromagnetic Compatibility (EMC).

EMC: EN61000-6-2, EN55011 Class A

6

Page 7

Dimensions and Maintenance Clearance

Valve size: 1 ” to 3''

1

/

2

5.43"

(138 mm)

2.76"

(70 mm)

2.76"

(70 mm)

H

1

H

L

1

L

t

Flow direction

Valve size: 4'' to 6''

2.76"

(70 mm)

2.76"

(70 mm)

C Dia.

Min. 12"

(305 mm)

3.23"

(82 mm)

3.35"

(85 mm)

Min. 20" (508 mm)

(See Note.)

N × h Dia.

D Dia.

∗ Note:

Leave a clearance of 4" (100 mm) if you do not open the top cover

(to set the selector switches after the ACTIVAL is installed).

Min. 12"

(305mm)

3.23"

(82mm)

3.35"

(85mm)

AB-7353-U

Min. 20"

(508mm)

(See Note.)

5.43"

(138 mm)

H

1

H

Model number

VY51X9J004XS-146

VY51X9J0050S-146

VY51X9J0060S-146

VY51X9J0080S-146

VY51X9J0101S-146

VY51X9J0121S-146

VY51X9J0151S-146

N × h Dia.

C Dia.

C Dia.

D Dia.

L

Flow direction

∗ Note:

t

Leave a clearance of 4" (100 mm) if you do not open the

L

1

top cover (to set the selector switches after the

ACTIVAL is installed)

Valve

size

1

1

DN40 mm 241 103 165 82.5 18 99.2 125 16 9.5 kg

2" in 9.65 4.21 7.01 3.50 0.79 4.72 5.91 0.75

DN50 mm 245 107 178 89 20 120 150 19 11.5 kg

1

2

DN65 mm 262 124 190 90 20 140 180 19 16 kg

3" in 10.35 4.92 7.99 3.94 0.87 6.00 7.48 0.75

DN80 mm 263 125 203 100 22 152.4 190 19 20 kg

4" in 11.14 5.71 13.78 6.42 0.94 7.46 8.66 0.75

DN100 mm 283 145 350 163 24 189.5 220 19 28.6 kg

5" in 12.19 6.75 15.75 6.65 1.02 8.46 9.84 0.87

DN125 mm 309.5 171.5 400 169 26 215 250 22.2 38 kg

6" in 12.52 7.09 18.90 8.35 1.02 9.50 11.02 0.87

DN150 mm 318 180 480 212 26 241.3 280 22.2 50.6 kg

Unit H H1 L L1 t C D h N Weight

/2" in 9.49 4.06 6.50 3.25 0.71 3.91 4.92 0.63

/2" in 10.31 4.88 7.48 3.54 0.79 5.51 7.09 0.75

4

4

4

4

8

8

8

Figure 2. Dimensions and maintenance clearance (inch/mm)

20.9 lb

25.4 lb

35.3 lb

44.1 lb

63.1 lb

83.8 lb

112 lb

7

Page 8

AB-7353-U

Parts Identication

Valve size: 1 " to 3''

1

/

2

Top cover

Gland packing

Bonnet

Seat ring

Plug

Valve size: 4'' to 6''

Terminal cover

Knockout hole

Pointer

Joint

Yoke

O-ring

Stem

Cone

Top cover

Terminal cover

Model number

VY5199JXXXX

Actuator

S-146

Valve body

Bonnet

Plug

Seat ring

Pointer

Joint

Yoke

O-ring

Gland packing

Stem

Cone

Figure 3. Parts identication

Model number

VY5199JXXXX

: Heat insulation

S-146

8

Page 9

AB-7353-U

Recommended Criteria to Prevent Cavitation Erosion

Cavitation erosion is likely to occur in the case that the pressure ratio XF calculated by the following formula overreaches the

criterion value.

P1 - P

P1 - Pv

2

: Pressure ratio

F

: Absolute pressure of valve inlet [psig (abs)]

1

: Absolute pressure of valve outlet [psig (abs)]

2

X

=

F

X

P

P

Pv: Saturated vapor pressure of uid* [psig (abs)]

Saturated vapor pressure of uid varies depending on the uid temperature.

∗

Always keep the pressure ratio X

< 0.7 (criterion value).

F

If the pressure ratio does not meet this criterion, cavitation erosion may occur. This value is thus necessary to prevent

cavitation erosion. Note that cavitation itself may be generated even if the pressure ratio is kept below 0.7.

IIn addition to the pressure ratio, the ow velocity at the valve in 100 % position is another criterion for cavitation erosion.

Flow velocity [fps] = 263.5 x

Q

2

d

Q = Flow rate [GPM]

d = Valve size [DN (mm)]

Always keep the ow velocity < 23.0 fps (7.0 m/s) (criterion value) for chilled water and < 16.4 fps (5.0 m/s) (criterion value)

for hot water.

If the ow velocity does not meet these criteria, cavitation erosion may occur.

9

Page 10

AB-7353-U

Setting

On the PCB (printed circuit board) of the actuator, the selector switches are provided.

WARNING

Before wiring, maintenance or setting the selector switches, be sure to turn off the power to the product

•

a

(including the optional devices). Failure to do so might cause electric shock or device failure.

Detach the cover only when wiring, setting the product or maintenance and reattach the cover after wiring,

•

setting the product or maintenance. Failure to do so might cause electric shock.

CAUTION

Set the selector switches using a pen nib or a nger. Do not use a tool such as a screwdriver. Such a tool might

•

damage the selector switches or the PCB.

During engineering work, do not touch the uninstructed area other than the setting switches. Doing so, you

•

might be burned. Temperature of some parts of the actuator will become high.

IMPORTANT:

The service life of ACTIVAL operated with small dead band can be shortened since the ACTIVAL operates

•

more frequently with small dead band than with normal dead band.

To operate the product with small dead band, provide shielded cable for input/output signal lines and power line.

•

Unshielded cable can cause error due to noise.

Identication of the selector switches

Open/close selector switch

for input signal failure

(Initially set at ‘close’.)

Direction selector switch

for control action of 4-20 mA input signal

(Initially set at normal action

(4mA:0% to 20mA:100%))

Normal/small selector switch

for dead band width

(Initially set at ‘normal’ dead band.)

Figure 4. Selector switches

Open/close selector switch for input signal failure:

If no control signal is input, the actuator automatically closes (0 %) or opens (100 %) the valve by setting the selector switch

at ‘open’ (100 %) or ‘close’ (0 %).

Direction selector switch for control action of 4 to 20 mA input signal:

Direction of control action by 4-20 mA DC input signal can be reversely switched.

Normal action: 4 mA for 0 % to 20 mA for 100 %

Reverse action: 20 mA for 0 % to 4 mA for 100 %

Normal/small selector switch for dead band width:

To more precisely operate the valve, smaller dead band (than the normal) of the control signal input can be set. Two selector

switches are provided for the normal/small dead band width. Always set the both switches at the same mode (‘normal’ or

‘small’).

10

Page 11

AB-7353-U

Installation

Precautions for installation

WARNING

Before wiring, maintenance or setting the selector switches, be sure to turn off the power to the product

•

a

a

ACTIVAL Model VY5199J is the valve and actuator integrated into a single unit. Do not combine the valve with any other

•

actuator, or do not combine the actuator with any other valve.

To remove foreign substances inside the pipes, install a strainer (with 40 or more meshes) on the inflow side of each

•

valve. In case that the strainers cannot be installed on the inow side of each valve, install it on the pipe diverting sections

(sections diverting from main piping system to sub piping system).

Install the valve so that the ow direction of process uid agrees with the arrow indicated on the valve body.

•

After installation, remove buffer material wrapped around the valve (4'' to 6'' model).

•

(including the optional devices). Failure to do so might cause electric shock or device failure.

CAUTION

After installation, make sure no uid leaks from the valve-pipe connections. Incorrect installation might cause

•

uid leakage.

For installation, do not mount the valve in an improper position or overtighten the bolts on the ange. Doing so

•

might damage the product.

Install the product so that no foreign objects remains inside the pipes. Be sure to provide a strainer on the inow

•

side of the piping. Flush the piping to remove the foreign objects after installation. Foreign objects inside the

piping.

Installation location

CAUTION

Do not install the product nearby a steam coil, pressurized hot-water coil, or any high heat source.

•

IMPORTANT:

The covers might be corroded by some chemical and organic solvent/vapor. Do not clean the ACTIVAL using

•

such substances, or do not expose the ACTIVAL to such substances.

Although the ACTIVAL can be used in high humidity environments (max. 95 % RH), do not immerse the

•

actuator in water.

Although the ACTIVAL can also be used outdoors, be sure not to expose the ACTIVAL to direct sunlight.

•

Install the ACTIVAL in a position allowing easy access for maintenance and inspection. Fig. 2 shows the minimum

•

clearance for maintenance and inspection. When installing the ACTIVAL in a ceiling space, provide an access hole within

the 20" (508 mm) radius of the ACTIVAL. And, place a drain pan under the valve.

Do not mount the ACTIVAL on a pipe where water hammer occurs, or where solid objects including slug may accumulate.

•

To set the selector switches after installation, leave a enough clearance above the top cover of the actuator, as shown in

•

Figs. 2 to 4.

Mounting position

The ACTIVAL can be mounted in any position ranging from upright to sideways (90° tilted). The ACTIVAL should be installed

with its actuator vertically positioned above the valve body. (See Fig. 5.) However, the ACTIVAL must be installed always in

upright position outdoors.

High temperature radiation might cause malfunction of its actuator.

Correct mounting Incorrect mounting

Figure 5. ACTIVAL mounting positions

11

Page 12

AB-7353-U

Piping

Check that the model number of the product is what you ordered. The model number is shown on the label attached to the

•

yoke.

Install a bypass pipe and gate valves on the inow, outow, and bypass sides. Also, install a strainer on the inow side.

•

When installing the ACTIVAL to pipes, do not allow any object, such as chips, to get inside a pipe or valve. Valve cannot

•

fully closes, or the valve seat may get damaged causing uid leakage, due to an object jammed inside the valve.

When piping, do not apply too much sealing material, such as solidifying liquid and tape, to the pipe connection sections so

•

that these materials ow into the valve. Valve cannot fully closes, or the valve seat may get damaged causing uid leakage,

due to the sealing material jammed inside the valve.

Before activating the ACTIVAL, fully open (in 100 % position) the valve and ush the pipes at the maximum ow rate to

•

remove all the foreign substances. (Factory preset position: 100 %)

Heat insulation

Do not apply heat insulation to the actuator or to the yoke, as shows in Fig. 3. If the yoke and the actuator are

covered with insulation material, the pointer cannot be checked and may be distorted.

Factory preset position

The actuator shaft is positioned at 100 % (in fully open position) for shipment. The shaft is thus completely turned

counterclockwise, and the pointer points at ‘100’. (See Fig. 6.)

Pointer

Figure 6. Preset pointer position for shipment

Manually opening/closing the ACTIVAL

IMPORTANT:

might

Manually opening/closing the ACTIVAL with the power (24 V AC) applied

•

To manually open/close the ACTIVAL, do not turn the joint beyond the fully open/closed mark.

•

To manually open/close the ACTIVAL, slowly turn the joint. If shock is sent to the actuator, the actuator

•

damage the actuator.

might

get damaged.

Disconnect the power from the ACTIVAL before manually operating the ACTIVAL. As shown in Fig. 7, from the front of the

ACTIVAL, hold the joint using a tool such as a wrench, and turn the joint slowly toward the set position.

Joint

Hold the joint using a wrench

and turn slowly.

Figure 7. Manual operation

12

Page 13

AB-7353-U

Auxiliary switch (optional)

IMPORTANT:

The auxiliary switch is installed on site. Refer to the instructions supplied with the auxiliary switch for

•

installation.

Do not open the top cover except when adjusting the auxiliary switch. Close the top cover instantly after

•

adjusting the auxiliary switch.

Do not put any load on the top cover.

•

Procedure to change the actuator mounting position

IMPORTANT:

Do not change the combination of the valve, yoke, and actuator.

•

Set the ACTIVAL (actuator and valve) in 100 % position before changing the mounting position. If the valve

•

in 0 % position is assembled with the actuator in 100 % position, the actuator put torque on the closed valve,

and the gear of the actuator get damaged.

1) Remove the screws connecting the actuator and the yoke. Lift the actuator and detach it from the yoke. Make sure that the

groove on the top of the valve stem is parallel to the pipes (indicating the valve in 100 % position). <Step 1 in Fig. 8>

2) Remove the screws connecting the yoke and the valve. <Step 2 in Fig. 8>

3) Change the facing direction of the yoke. The yoke and actuator can be horizontally rotated every 90° (0°/90°/180°/270° from

the factory preset position) to mount onto the valve.

4) A thermal insulation sheet is inserted between the yoke and the valve. When changing the mounting positions, reinsert the

sheet and then t the yoke into the new mounting position.

5) Before xing the yoke to the valve with the screws, check that the actuator engages correctly with the valve stem (at the

new mounting position). Check that the pointer of the actuator indicates 100 % position as well. Then, x the yoke to the

valve. <Step 3 in Fig. 8>

6) Mount the actuator. Place the actuator, with its facing direction changed, on the yoke, and x with the screws. <Step 4 in

Fig. 8>

7) Check that the ACTIVAL with the mounting position changed operates smoothly (from 0 % to 100 %).

1.

Step 1 Step 4

Lift off the actuator.

2.

Step 2 Step 3

Detach the yoke from the

valve.

Thermal insulation sheet

Groove

Valve stem

Figure 8. Changing the actuator mounting position

Change the actuator mounting

position, and remount the

actuator on the yoke.

Change the yoke mounting

position and remount the yoke

on the valve.

4.

3.

13

Page 14

AB-7353-U

Wiring

WARNING

Before wiring, maintenance or setting the selector switches, be sure to turn off the power to the product

•

a

IMPORTANT:

The ACTIVAL is designed for 24 V AC power supply voltage.

•

Do not apply any other power voltage (e.g., 120 V AC, 240 V AC) to the ACTIVAL.

Make sure the polarity of the power supply and 4 to 20 mA DC feedback output referring to the wiring

•

diagrams. Incorrect wiring

To prevent damage, cover the terminals except when connecting/disconnecting wires.

•

Do not leave any refuse including metal chips after cutting a knockout hole and after connecting the wires

•

inside the actuator.

Do not connect 24 V AC power to the terminals 4 to 7.

•

(including the optional devices). Failure to do so might cause electric shock or device failure.

Detach the cover only when wiring, setting the product or maintenance and reattach the cover after wiring,

•

setting the product or maintenance. Failure to do so might cause electric shock.

CAUTION

Installation and wiring must be performed by qualified personnel in accordance with all applicable safety

•

standards.

might

result in PCB (print circuit board) burnout.

To keep NEMA 4X and IP54 protection

Use a water-proof connector for the ACTIVAL in a high-humidity environment or outdoor location.

Be sure to completely close the terminal cover and the top cover.

•

Waterproof the wiring port.

•

- For cable connection, use a water-proof connector. (Seal connector Part No. 83104346-003 is recommended.)

- For conduit connection, use a water-proof plica tube or the like.

Wiring procedure

1) To lead the wires into the terminals, cut out a knockout hole for a wiring port. Two knockout holes are provided on the

bilateral sides of the actuator terminals. Select a knockout hole according to the conduit mounting direction, and cut it out by

lightly knocking the hole using a screwdriver.

Knockout hole for wiring port

Figure 9. Knockout hole for wiring port

14

Page 15

2) Unscrew the 3 setscrews (M4 × 10) of the terminal cover and remove the terminal cover, as shown in Fig. 10.

AB-7353-U

Set screws

1. Unscrew the setscrews. 2. Remove the terminal cover.

Figure 10. Terminal cover removal

Terminal cover

3) Correctly connect the wires to the terminals with M3.5 screw terminal lugs, referring to Figs 11 to 13.

4) Attach the terminal cover by the 3 original screws.

Terminals connection

24 V AC

power supply

1 2 3 4 5 6 7

T1 T

Vacant-+

2

4 to 20 mA DC

controller

4 to 20 mA DC inputs from

feedback output

-

+

∗Note:

Terminals 2, 5, and 7 are

connected inside the actuator.

Figure 11. Terminals connection of Model VY5199J0XXXS-146

15

Page 16

AB-7353-U

Connection Examples (Connection to Azbil Corporation's SDC series controller)

Connection to Model SDC35TC0/SDC36TC0 Connection to Model SDC35TC0/SDC36TC0 (Parallel operation)

Isolation

transformer

Power

supply

+ 13

- 14

Model SDC35/SDC36TC0

+

-

Position indicator

+ +

- -

Isolator

1 T

1

2

T

2

4 +

5

-

6 +

7

-

Model VY5199J

(4-20 mA DC input with

4-20 mA DC output)

Isolation example:

If the position indicator is not isolated inside, provide

an isolator. If isolated, an isolator is not required.

Figure 12. Connection example: Single Model VY5199J

with Model SDC35/SDC36TC0

Power

supply

+ 13

- 14

Model SDC35/SDC36TC0

+

-

Position indicator

Power

supply

Isolation

transformer

+ +

- -

Isolator

Isolation

transformer

1 T

2

4 +

5

6 +

7

1 T

2

4 +

5

1

T

2

-

-

1

T

2

-

6 +

7

-

Isolation example:

If the position indicator is not isolated inside, provide

an isolator. If isolated, an isolator is not required.

+

-

Position indicator

+ +

- -

Isolator

2 × Model VY5199J

(4-20 mA DC input with

4-20 mA DC output)

Figure 13. Connection example: Two Model VY5199J

with Model SDC35/SDC36TC0 (Parallel operation)

Notes:

Input impedance of the actuator is 100 Ω.

∗

For connecting multiple ACTIVAL to one controller (e.g., Model SDC35/SDC36), provide a transformer (two in total) for each ACTIVAL

∗

since 4 to 20 mA input is not isolated from other terminals.

Terminals 2, 5, and 7 are connected inside the actuator. To connect to a device (PLC, position indicator, etc.) with its terminals not isolated

∗

inside, externally isolate (between the ACTIVAL and the device). Otherwise, a loop is formed for the common line and can damage the

circuit of the ACTIVAL. (SDC series controllers including Model SDC35/SDC36 shown in Figs. 12 and 13 are isolated inside.)

Isolation transformer is required for ACTIVAL. Transformer without isolation may damage the ACTIVAL and other devices connected to

∗

ACTIVAL.

16

Page 17

Internal Connection of Auxiliary Switch

Auxiliary switch Part No. 83165274-001

N.C.

OP1

OP2

OP3

OP4

OP5

OP6

Switches A and B actuating position: Adjustable between 0 % (fully closed) and 100 % (fully open)

Figure 14. Internal connection of Part No. 83165274-001

Common

N.O.

N.C.

Common

N.O.

AB-7353-U

Switch A Switch B

17

Page 18

AB-7353-U

Inspection and Maintenance

CAUTION

Do not carelessly touch this product when being used to control hot water.

•

Inspect the ACTIVAL according to Table 1.

•

Manually open/close the ACTIVAL at least once a month if it is left in inactive state for a long period.

•

Visually inspect the uid leakage of the valve and the actuator operations every six months.

•

If any of the problems described in Table 2 are found, take corresponding actions shown in the table.

If your problem is not solved by the corresponding action, please contact Azbil Corporation near you.

Visual inspection Semiannual

Operating status Semiannual

Routine inspection Any time

The product temperature is hot, and you might get burned.

Table 1. Inspection items and details

Inspection item Inspection interval Inspection detail

Fluid leakage from the gland and the ange face

•

Loosened bolts

•

Valve and actuator damages

•

Unstable open/close operation

•

Abnormal noise and vibration

•

Fluid leakage to the outside

•

Abnormal noise and vibration

•

Unstable open/close operation

•

Valve hunting

•

Table 2. Troubleshooting

Problem Part to check Action

Fluid leaks from the ange face. Loosened ange bolts

Gasket on the ange face

Misaligned piping

Fluid leaks from the gland.

Fluid leaks from the bonnet. Loosened bolts Tighten the bolts.

Valve does not operate smoothly /

valve stops halfway /

valve does not operate at all.

Fluid leaks to the outside of the valve

when the ACTIVAL is in fully closed

position.

The valve vibrates or produces an

abnormal noise.

The auxiliary switch does not actuate. Auxiliary switch (cam switch) condition

Valve hunting occurs. Secondary pressure condition

Input signal disagrees with the feedback

output signal.

Conditions of the power applied and of the input

signal applied

Loosened terminals

Wiring conditions / disconnected wires

Actuator pointer not pointing to fully closed position Fully close the ACTIVAL.

Primary pressure condition

Differential pressure condition

Loosened terminals

Wiring condition / disconnected wires

Differential pressure condition

Control stability

To completely shut off the valve, valve open and close (0-100% position) operation is controlled

by 10-90 % range of actuator voltage/current input signal. Input signal therefore disagrees with

the feedback signal, and this is not an error.

Tighten the ange bolts.

Replace the gasket.

Redo piping.

Consult with our sales personnel.

Check the power supply and the controller

connected to.

Tighten the terminals.

Check the wiring.

Adjust the mounting position and change

the installation location.

Redo the cam switch setting.

Tighten the terminals.

Check the wiring.

Adjust the mounting position and change

installation location.

Connect the control parameters setting for

controller.

18

Page 19

This blank page is added for page layout purposes.

AB-7353-U

19

Page 20

AB-7353-U

ACTIVAL is a trademark of Azbil Corporation in Japan or in other countries.

Azbil North America, Inc.

9033 N. 24th Ave., Suite 6

Phoenix, AZ 85021

888-262-4639

602-216-8199

http://us.azbil.com/

Rev.4.0 Jun. 2016

20

Specications are subject to change without notice.

Building Systems Company

1-12-2 Kawana, Fujisawa, Kanagawa

251-8522 JAPAN

http://www.azbil.com/

AB-7353-U

Loading...

Loading...