Page 1

User’s Manual

for

Smart Loader Package

Model SLP-F7M

for

Micro Flow Rate Liquid Flow Meter

Model F7M

No. CP-SP-1423E

Thank you for purchasing this Azbil

Corporation product. This manual contains

information for ensuring the correct use of

the smart loader package.

Those designing, configuring, or

maintaining equipment that uses this

product should first read and understand

this manual. It provides necessary

information not only for initial setup,

but also for changing of settings,

troubleshooting, etc. Be sure to keep the

manual nearby for handy reference.

Page 2

NOTICE

Be sure that the user receives this manual before the product is used.

Copying or duplicating this user’s manual in part or in whole is forbidden.

The information and specifications in this manual are subject to change

without notice.

Considerable effort has been made to ensure that this manual is free from

inaccuracies and omissions. If you should find an error or omission, please

contact the azbil Group.

In no event is Azbil Corporation liable to anyone for any indirect, special or

consequential damages as a result of using this product.

© 2018-2019 Azbil Corporation. All Rights Reserved.

Page 3

Conventions Used in This Manual

The safety precautions explained in the following section aim to prevent injury to the operator and others, and to

prevent property damage.

Warnings are indicated when mishandling this

WARNING

product might result in death or serious injury.

CAUTION

product might result in minor injury to the user, or

only physical damage to the product.

In describing the product, this manual uses the icons and conventions listed below.

Handling Precautions:

Handling Precautions indicate items that the user should pay attention to when handling

the product.

Cautions are indicated when mishandling this

Note:

:

(1) (2) (3):

[OK] button: Indicates a selectable button on a personal computer screen.

[File]: Indicates messages and menus displayed on the personal computer.

[File] →

[Initialization]:

>> :

Notes indicate information that might benefit the user.

This indicates the item or page that the user is requested to refer to.

Numbers within parentheses indicate steps in a sequence or parts of an explanation.

Indicates menu selection on a personal computer.

Indicates the result of an operation, details displayed on the personal computer or other

devices, or the state of the device after operation.

[Ctrl] key: Indicates keys on the keyboard.

[Ctrl]+[A] key: Indicates the operation of pressing the [A]key on the keyboard while the [Ctrl]key is

pressed.

i

Page 4

Safety Precautions

To use loader communications, remove the cable from the F7M waterproof connector and

connect it to the adapter for loader communication cable. When handling the cable, make

sure that the electrodes of the connector are free from water drops and dust. Otherwise, a

failure or abnormal output might result. Also, be sure to turn off the F7M before removing

or connecting the connector. Otherwise, the F7M or the adapter for loader communication

cable may fail, and the power supply for the equipment may fail or catch fire.

The adapter for loader communication cable is not water resistant. Water drops or dust

entering inside or accumulating around the electrodes may damage the F7M or the adapter ,

or may cause external devices to catch fire or fail.

Do not apply excessive force to the plug of the USB loader cable when it is connected to the

adapter for loader communication cable. Doing so might damage the plug or the adapter.

After using loader communications, remove the cable for the F7M waterproof connector from

the adapter for loader communication cable, and insert it all the way into the waterproof

connector. If the cable is not inserted properly, the device's water resistance will be impaired,

the F7M or connected equipment may fail, and the connected equipment may catch fire.

CAUTION

ii

Page 5

The Role of This Manual

A total of 3 different manuals are available for Model SLP-F7M. Read them as necessary for your specific

requirements. If a manual you require is not available, contact the azbil Group or its dealer.

User’s Manual for Smart Loader Package Model SLP-F7M for Micro Flow Rate

Liquid Flow Meter Model F7M

Manual No. CP-SP-1423E

This manual.

The user can specify and check parameters of Model F7M on a PC using Model SLP-F7M

smart loader package.

Personnel in charge of the design or manufacture of equipment that incorporates

Model F7M should read this manual thoroughly.

This manual describes the installation of the software on a PC, the method for

connecting the loader to Model F7M, various functions and operations of Model SLPF7M, and procedures for configuring Model F7M.

Micro Flow Rate Liquid Flow Meter Model F7M User's Manual

Manual No. CP-SP-1421E

This manual describes the hardware and all the functions of Model F7M.

Personnel in charge of the design, manufacturing, operation, or maintenance of

equipment that incorporates Model F7M should read this manual thoroughly.

This manual covers installation, connections for wiring, all functions

and operating procedures of Model F7M, troubleshooting, and detailed

specifications.

Micro Flow Rate Liquid Flow Meter Model F7M9010/9030/9050 User’s Manual

Manual No. CP-UM-5922JE

This manual is supplied with the product.

Personnel in charge of the design or manufacture of equipment that

incorporates Model F7M and personnel in charge of installation of this device

should read this manual thoroughly.

The manual covers safety precautions, installation, wiring, and main

specifications.

iii

Page 6

Contents

Conventions Used in This Manual

Safety Precautions

The Role of This Manual

Chapter 1. INTRODUCTION

1 - 1 Overview

Features of the loader 1-1

Applicable versions 1-1

1 - 2 System Requirements 1-2

System Environment 1-2

Hardware Configuration 1-3

1 - 3 Installation 1-5

Installing the Loader 1-5

Installing the USB Loader Cable Device Driver 1-8

Installing the device driver 1-8

If the USB loader cable device driver cannot be installed 1-12

Checking and Installing Microsoft .NET Framework 1-14

1 - 4 Uninstallation 1-15

Uninstalling the Loader 1-15

Uninstalling the device driver 1-15

1-1

1-1

Chapter 2. STARTING AND EXITING THE LOADER 2-1

Starting the loader 2-1

Exiting the loader 2-2

Checking the communication port number 2-2

Chapter 3. HOW TO USE THE LOADER 3-1

3 - 1 Overview

Overview of functions 3-1

Components of the screen 3-1

Loader functions 3-2

3 - 2 Connecting the Loader to the Device 3-3

Procedures for device connection 3-3

3 - 3 Checking and Changing Parameters 3-6

Creating a parameter file without connecting the loader to the device 3-6

Checking parameters of the connected device 3-8

Writing parameters to the device 3-10

Saving parameters to a file 3-11

Checking saved parameters 3-11

3 - 4 List of Parameters 3-13

[Device info.] tab 3-13

[Parameters] tab 3-14

3 - 5 Checking Measured Values and Status 3-15

Displaying measured values and status of the device 3-15

3 - 6 Immediate Writing of Parameters 3-16

How to write monitoring parameters to the device immediately 3-16

3-1

iv

Page 7

3 - 7 List of Monitoring Parameters 3-18

[Monitor] tab 3-18

3 - 8 Operating the Device 3-20

Adjusting the zero point 3-20

Chapter 4. TROUBLESHOOTING 4-1

Types of abnormal status 4-1

Abnormal status and corrective actions 4-1

Error messages and corrective actions 4-4

Other troubleshooting 4-7

v

Page 8

-MEMO-

vi

Page 9

Chapter 1. INTRODUCTION

1 - 1 Overview

The SLP-F7M Smart Loader Package (hereafter “the loader”) is a simplified engineering tool for the F7M Micro Flow

Rate Liquid Flow Meter (“the device”). The user can configure various settings of the device and monitor the flow

rate and the operational status.

The loader runs on Windows 10 (32-bit and 64-bit) English version PCs. This user’s manual covers SLP-F7M ver.

2.0.0 and later. If an older version is being used, please download the latest loader from the Azbil Corporation

website.

Features of the loader

Functions Description

Configuration Various settings can be read from the device, checked or edited,

and written to the device.

In addition, parameter files can be created when the loader is not

connected to the device.

Monitoring The operational status of the device and alarms can be checked.

The settings for parameters that are shown with the [Write] button

can be written to the device immediately during monitoring.

Device operation The zero point of the device can be adjusted.

File functions Various settings and monitored data can be saved to a file.

Saved files can be opened to check the data.

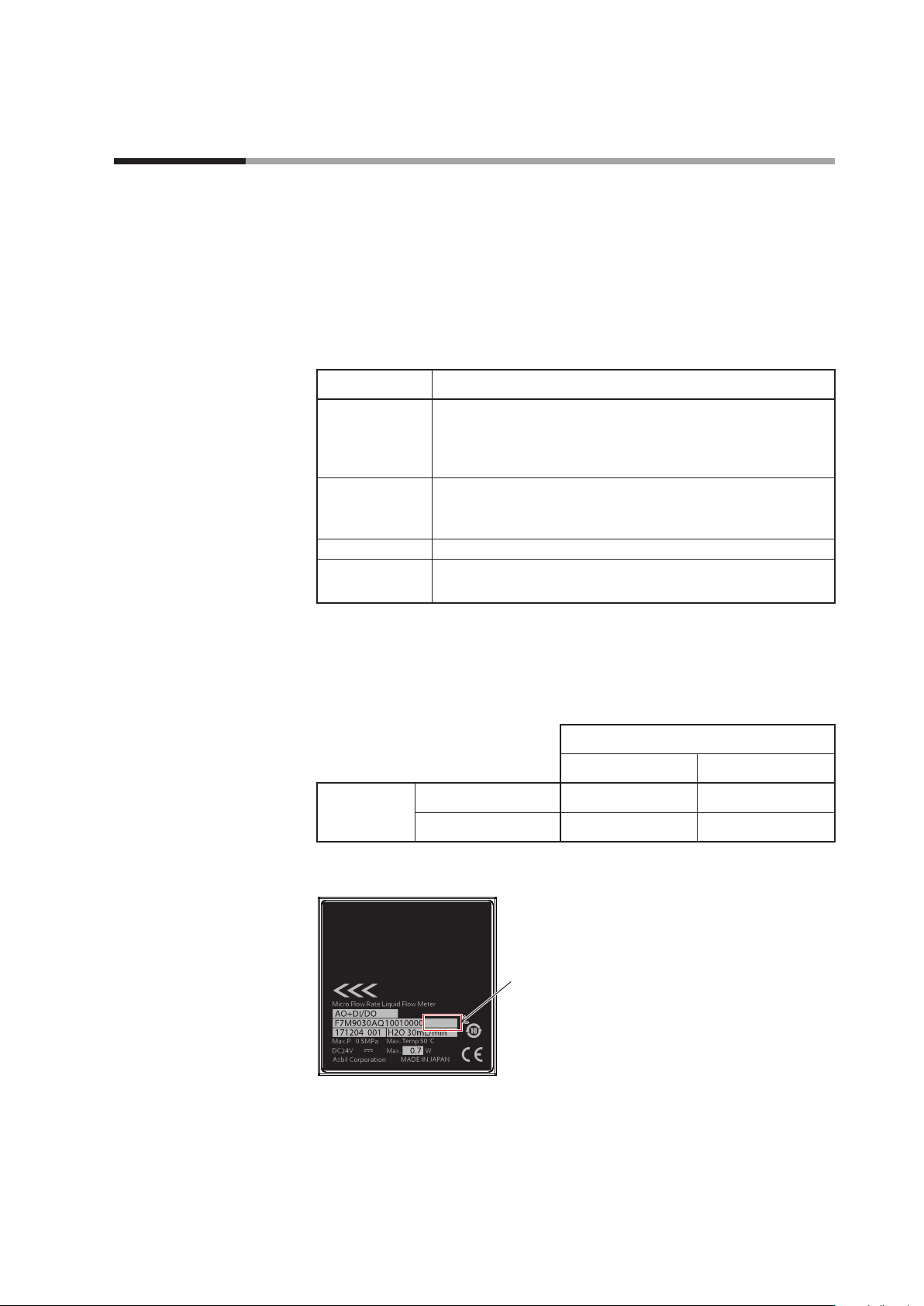

Applicable versions

Some combinations of loader version and F7M ID code are not possible. Be sure to

check the version of the loader and the F7M.*

ID code Ver. is not printed

Ver. b or later ×

*1. The ID code is printed on the label on the back of the device.

For ver. b and later,

the code is printed as “Ver. _.”

Ver. b

*2. Please download the latest version of the loader from the following website.

https://www.azbil.com/products/factory/factory-product/flowmeter/rate-liquid/

f7m/software/index.html

1

Loader version

Earlier than 2.0.0 2.0.0 or later

*2

1-1

Page 10

Chapter 1. INTRODUCTION

1 - 2 System Requirements

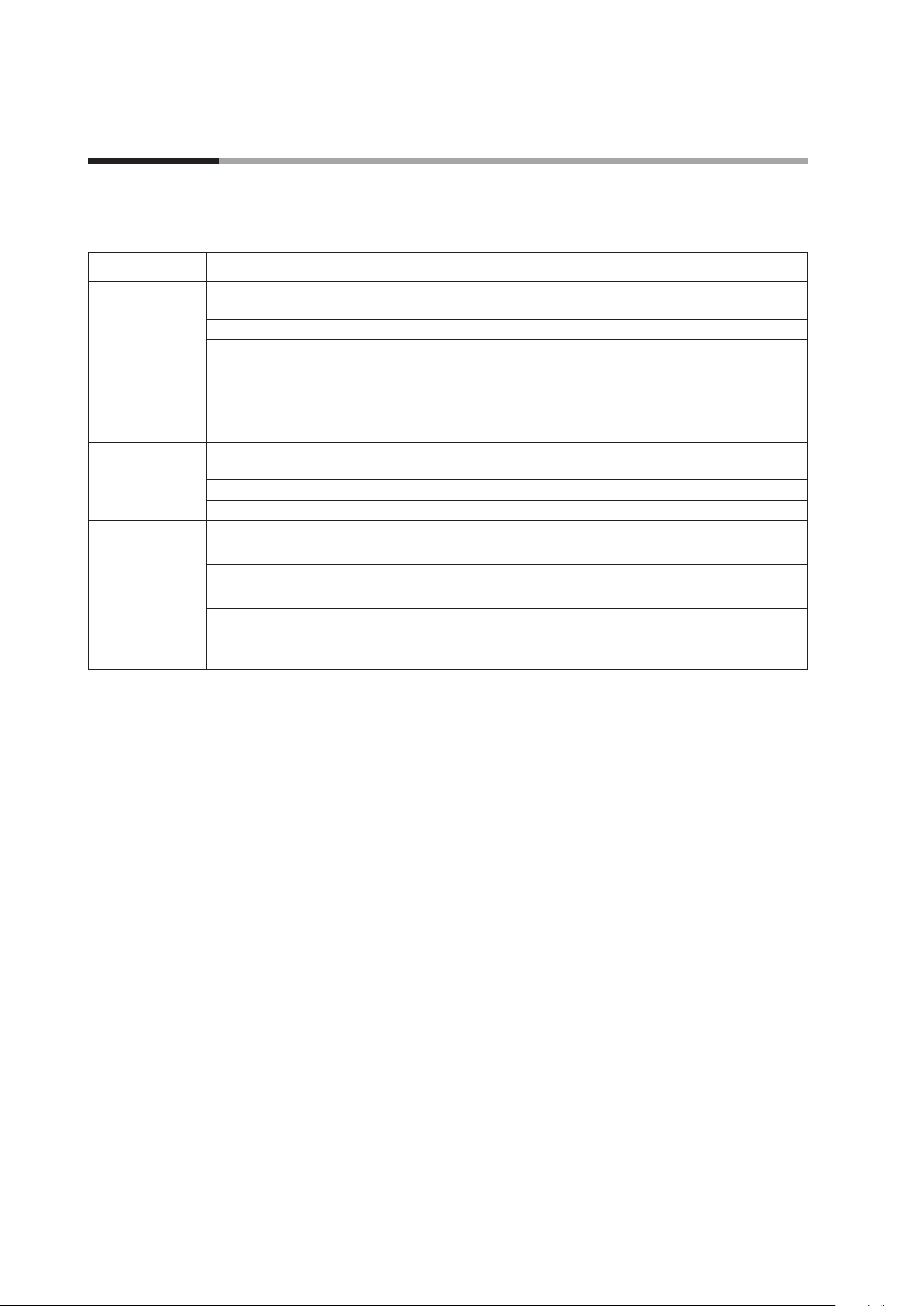

The following system environment is required for use of the loader.

System Environment

Item Description

PC Compatible equipment Windows PC with an Intel CPU

Recommended: Core i3–i7, 1.5 GHz or more. Minimum: 1 GHz

Operating system*

Memory Recommended: 4 GB or more. Minimum: 2 GB

Hard disk Recommended free space: 20 GB or more. Minimum: 10 GB or more

Display Recommended: 1366 × 768 dot or more, 32-bit color or more

Pointing device A mouse or an equivalent device compatible with Windows.

USB port 1 port

Other hardware Adapter for loader

communication cable

USB loader cable USB loader cable (azbil brand, model No. 81441177-001)*

Cable for waterproof connector Cable (azbil brand, model No. F9Y7H_1)

Software Microsoft .NET Framework 4.6

If this software is not installed on the PC, download it from the Microsoft website*

USB loader cable device driver

Install the driver using its installation software, which is different from the installer for the loader.

Adobe Acrobat Reader XI or later version

This software is necessary for viewing PDF user's manuals. If the software is not installed on the PC,

download it from the Adobe's website and install it.

1 *2

Windows10 (64-bit and 32-bit English versions)

Adapter for loader communication cable (azbil brand, model No.

F9Y7A1)

3

4

and install it.

*1. The performance of the loader cannot be guaranteed if it is used on other operating systems.

*2. Specify “Smaller – 100%” (default) as the font size on Windows. Otherwise, loader windows may not be displayed

properly.

*3. Use Rev. 05 or later version of the USB loader cable.

*4. English versionWindows https://www.microsoft.com/en-US/download/details.aspx?id=48130 (as of 3/26/2019)

1-2

Page 11

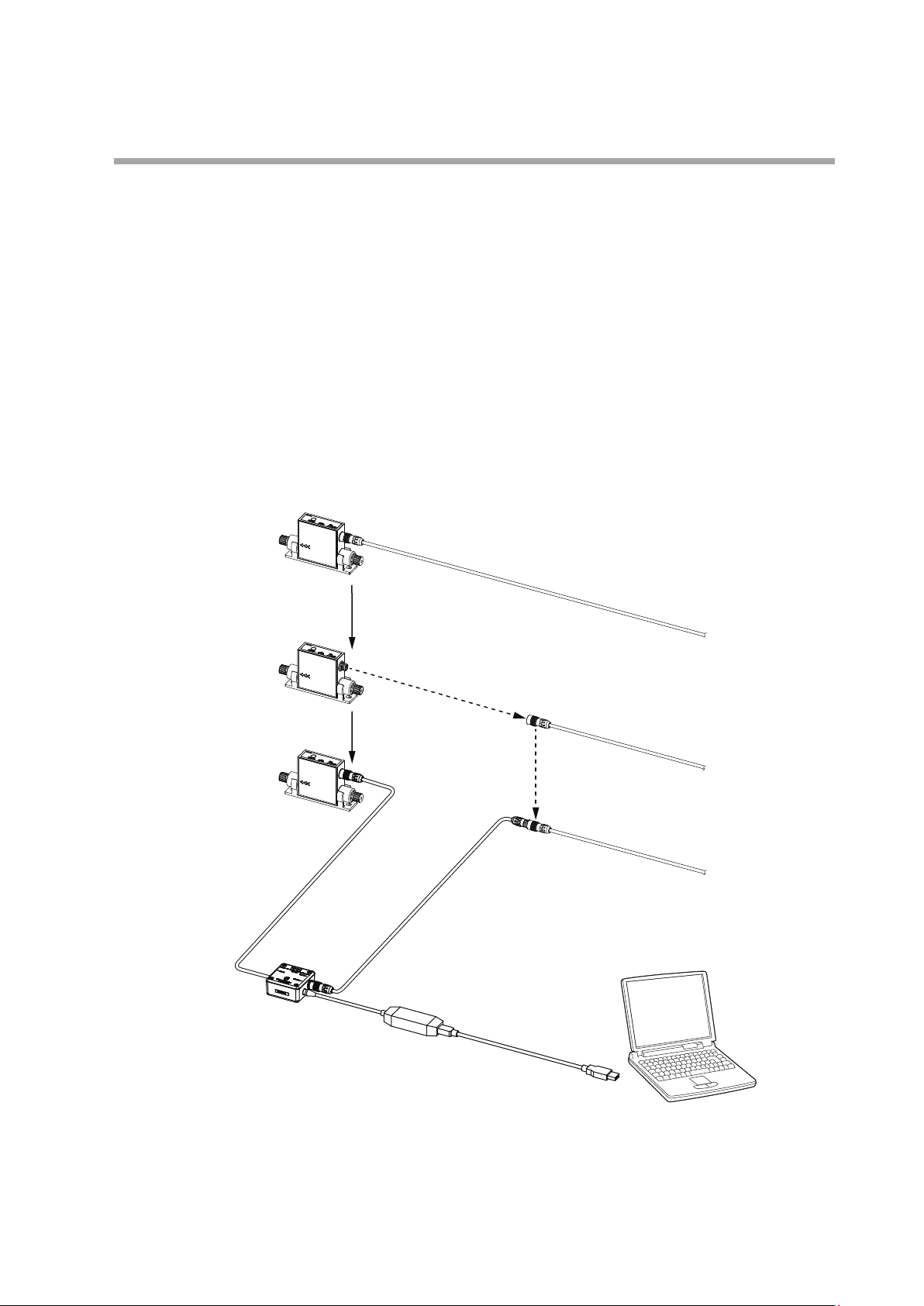

Hardware Configuration

Connection method

z

Chapter 1. INTRODUCTION

The hardware configuration for loader communication is explained below.

• Turn off the supply of power to the device.

• Remove the cable from the waterproof connector on the device, and connect

the cable to the adapter for loader communication cable with cable B, which is

supplied with the adapter.

• Connect cable A, which is also supplied with the adapter, to the waterproof

connector on the device and to the adapter for loader communication cable.

• The device can now be turned on or off with the power switch on the adapter for

loader communication cable.

For normal operation

Remove the cable from

the waterproof connector

For loader communication

Cable A

(included with the adapter)

The device (F7M)

Cable (F9Y7H_1)

Cable B

(included with the adapter)

Cable (F9Y7H_1)

Windows PC

(with the loader installed)

←

Output

→

←

24 V DC

24 V DC

Adapter for loader communication cable

(F9Y7A1)

Note 1. During loader communication, output from the F9Y7H_1 cable cannot be checked with the loader.

Note 2. The underscore represents a digit that tells the material of the cable.

USB loader cable

(81441177-001)

USB port

1-3

Page 12

Chapter 1. INTRODUCTION

Note

Handling Precautions

• It is also possible, without using cable B, to directly connect the adapter for loader

communication cable to the cable removed from the waterproof connector on the

device.

• To use loader communications, remove the cable from the device waterproof

connector and connect it to the adapter for loader communication cable.

• When handling the cable, make sure that the electrodes of the connector are

free from water drops and dust. Otherwise, a failure or abnormal output might

result. Also, be sure to turn off the device before removing or connecting the

connector. Otherwise, the device or the adapter for loader communication

cable may fail, and the power supply for the equipment may fail or catch fire.

Separately sold products

z

• The adapter for loader communication cable is not water resistant. Water

drops or dust entering inside or accumulating around the electrodes may

damage the device or the adapter, or may cause external devices to catch fire

or fail.

• After using loader communications, remove the cable for the device

waterproof connector from the adapter for loader communication cable,

and insert it all the way into the waterproof connector. If the cable is not

inserted properly, the device's water resistance will be impaired, the device or

connected equipment may fail, and the connected equipment may catch fire.

• Application of excessive force to the plug of the USB loader cable might

interfere with communications. If this happens, reconnect the plug correctly

and restart communications.

• Adapter for loader communication cable (F9Y7A1)

• USB loader cable (81441177-001)

• Cable (F9Y7H_1)*

* The underscore represents a digit that tells the material of the cable.

1-4

Page 13

Chapter 1. INTRODUCTION

1 - 3 Installation

Please download the installer for the loader from the following website (in Japanese only):

https://www.compoclub.com/ The installer file is compressed. Expand it before use. (Expanded file name example:

setup_SLPSP7_en_V1_0_15.msi)

Installing the Loader

The following explanation of the loader installation and screens use 64-bit

Windows 10 as an example.

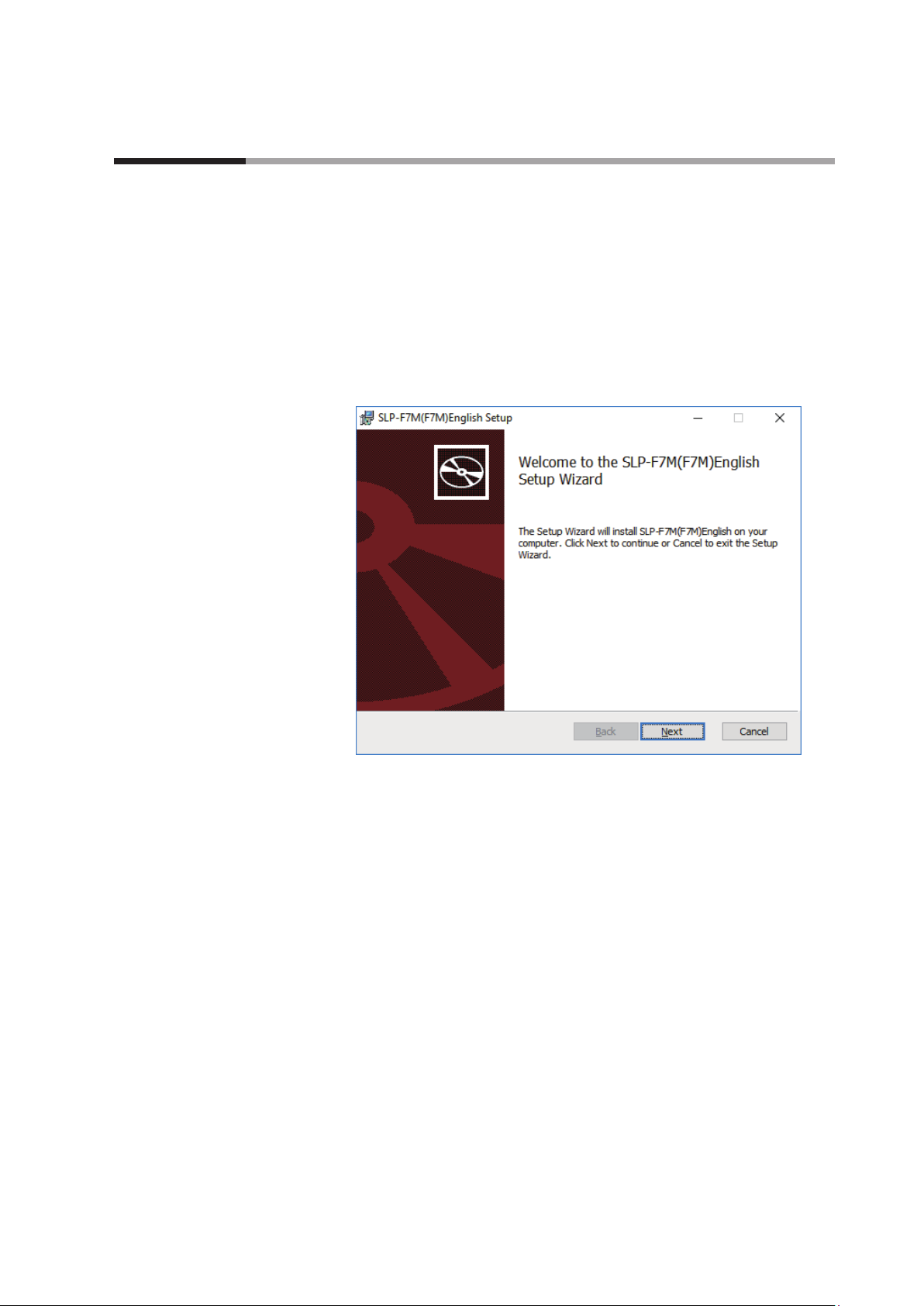

(1) Double-click setup_SLPF7M_en_V☐_☐_☐.msi* to launch the installer.

>> The setup wizard opens.

* ☐ represents a number. For example: setup_SLPF7M_en_V1_0_09.msi

(2) Click the [Next] button.

1-5

Page 14

Chapter 1. INTRODUCTION

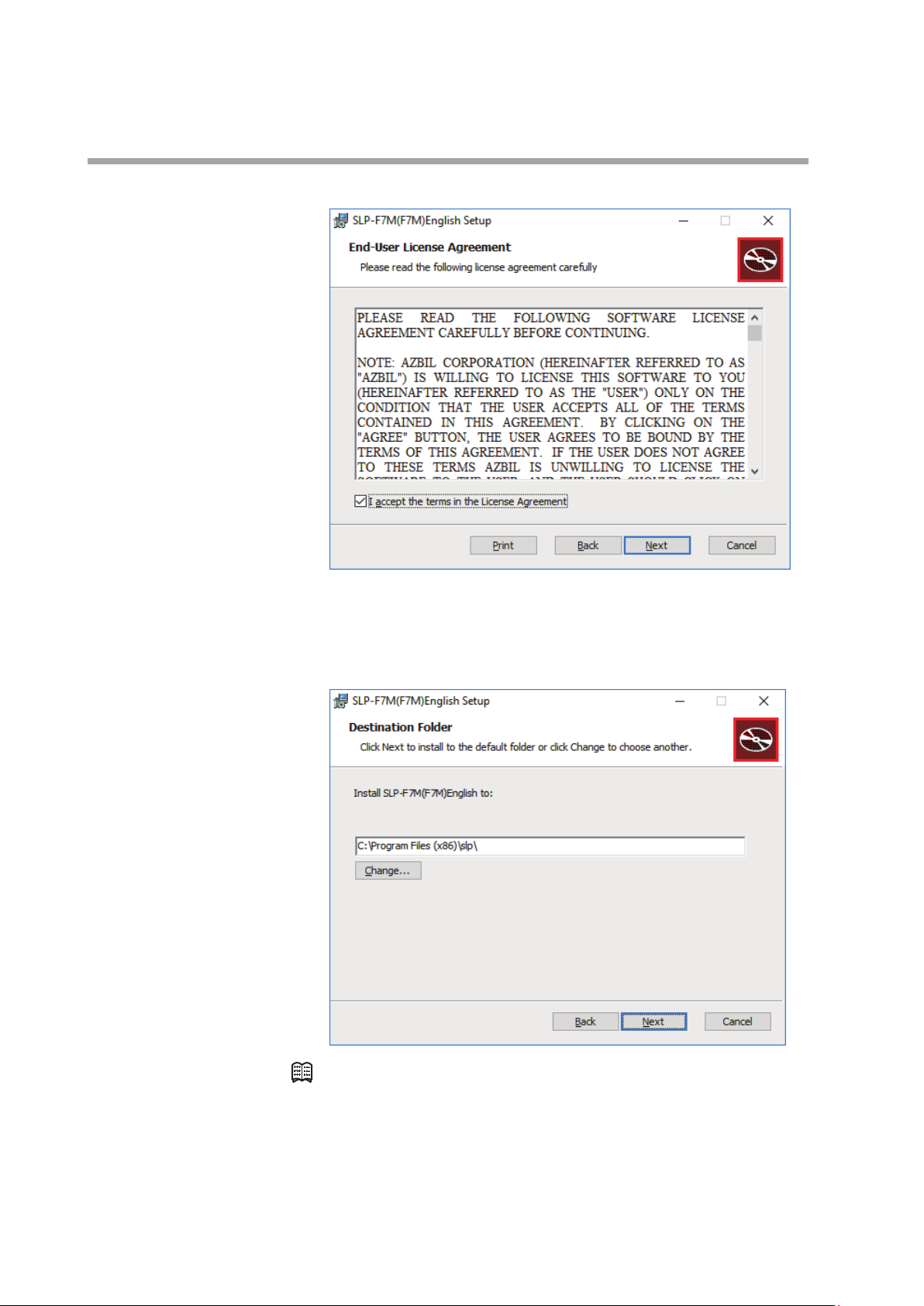

>> The following screen is displayed.

(3) If you accept the software license agreement and wish to install the software,

check the check box for [I accept the terms in the License Agreement] and

click the [Next] button.

>> The following screen is displayed.

1-6

Note

• Click the [Change...] button to change the destination folder.

(4) Click the [Next] button.

Page 15

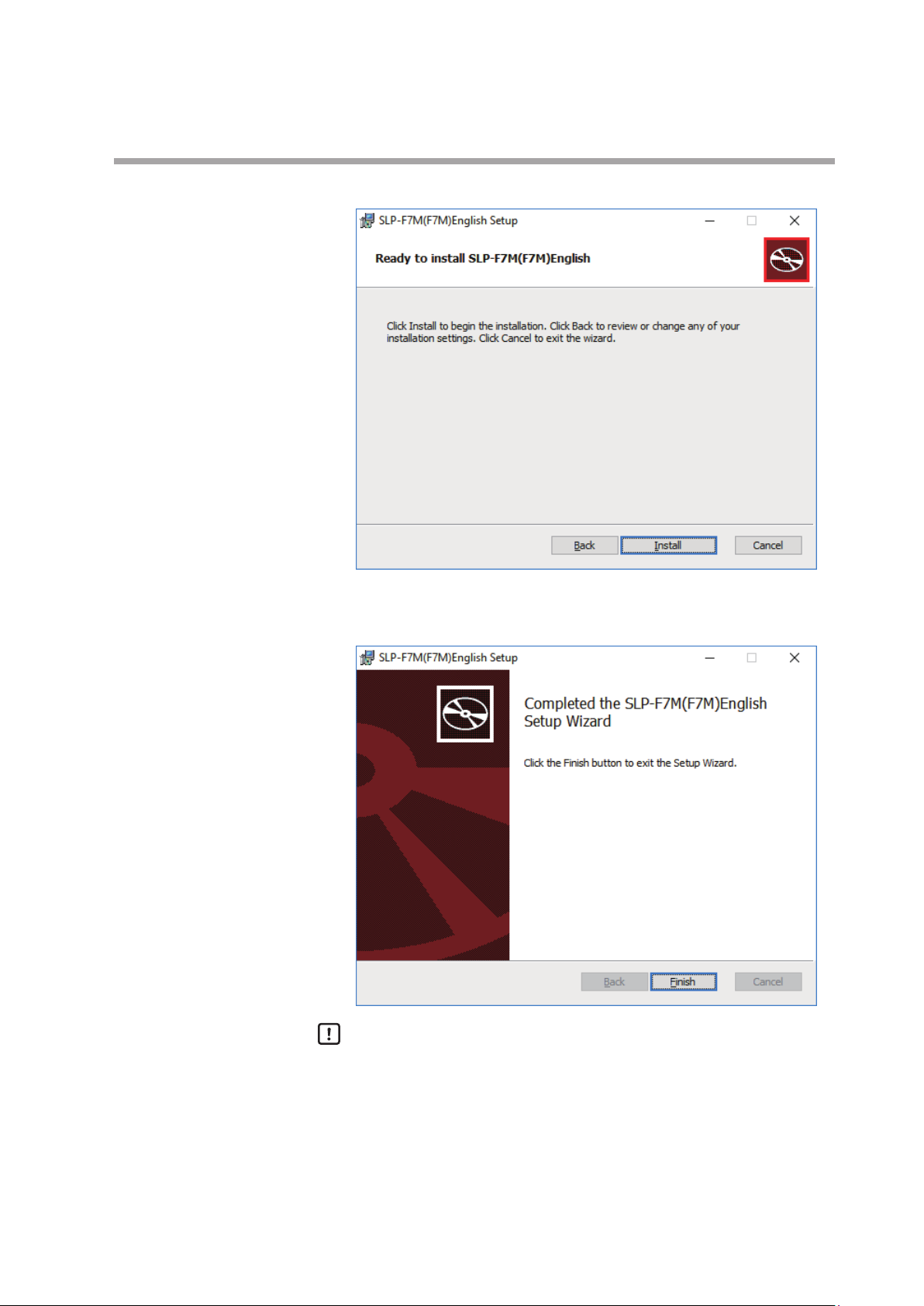

>> The following screen is displayed.

Chapter 1. INTRODUCTION

(5) Click the [Install] button.

>> When installation is complete, the following screen is displayed.

Handling Precautions

• A warning message about user account control might appear, depending

on the PC settings. Allow the software to make changes to the computer.

(6) Click the [Finish] button.

This completes the loader installation. Close the installer.

(7) If the installation files are no longer needed, delete the entire folder.

1-7

Page 16

Chapter 1. INTRODUCTION

Installing the USB Loader Cable Device Driver

A device driver must be installed before using the USB loader cable. Follow the

procedure below to install the device driver on the PC.

Installing the device driver

Handling Precautions

• Before installing the device driver, unplug the USB loader cable from the PC.

• Be sure to follow the procedure below when installing the device driver. The

USB cable may not be recognized if the procedure is not followed. If the loader

cable is not recognized, uninstall the device driver and reinstall it.

• If a problem occurs and installation is not successful, uninstall the driver and

reinstall it.

• To install the device driver, administrator rights on the computer are required.

Installation should be done by the administrator or by a user who belongs to

the administrator group.

• A USB loader cable with a label that does not indicate a revision number is not

compatible with Windows 10. (As of 12/11/2017, available USB loader cables have a

label saying “REV.06,” and are compatible with Windows 10.)

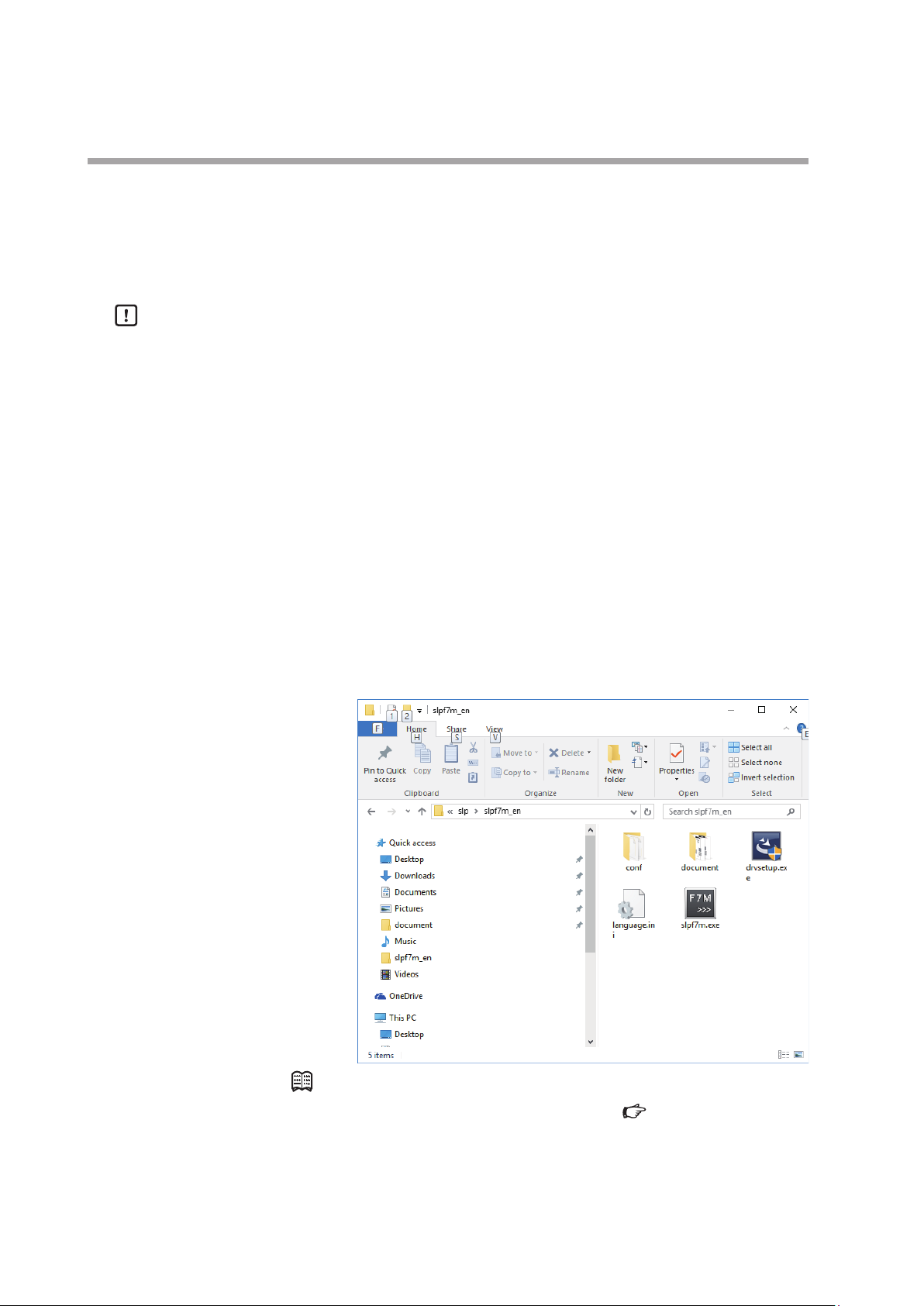

(1) Open the [slpf7m_en] folder where the loader was installed and double-click

drvsetup.exe.

1-8

Note

• If you did not change the destination folder in

(P.1-5), the file is stored in the following default folder:

• 64-bit Windows: C:\Program Files(x86)\slp\slpf7m_en

• 32-bitWindows: C:\Program Files\slp\slpf7m_en

Installing the Loader

Page 17

Chapter 1. INTRODUCTION

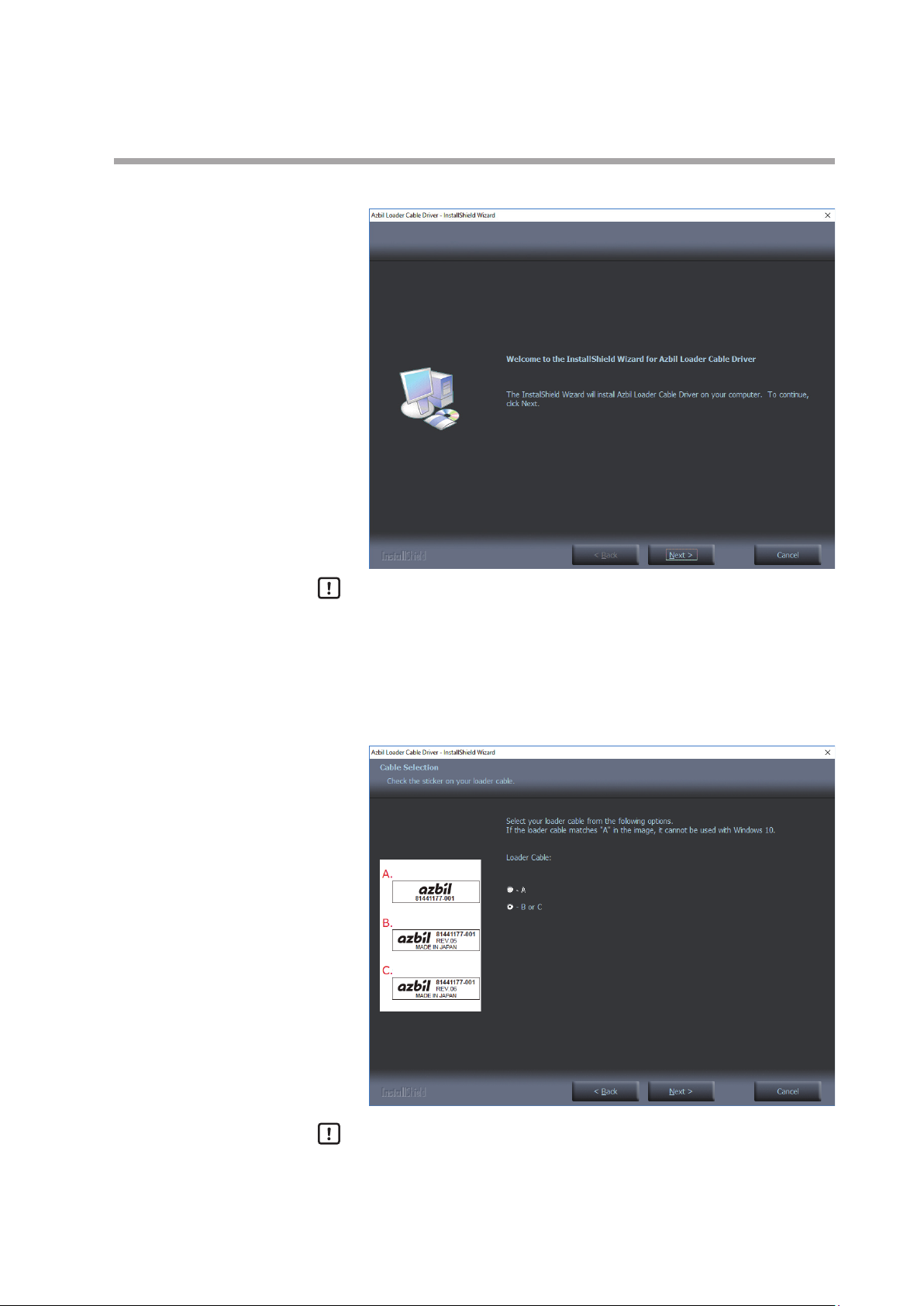

>> The installer is launched and the following window is displayed.

Handling Precautions

• A warning message about user account control might appear, depending

on the PC settings. Click the [Yes] button to allow the software to make

changes to the computer.

(2) Click the [Next ] button.

>> The following screen is displayed.

Handling Precautions

• The USB loader cable with label A cannot be used with Windows 10.

(USB loader cables that are available as of 12/11/2017 have label C with

“REV.06” printed, so they can be used for Windows 10.)

1-9

Page 18

Chapter 1. INTRODUCTION

(3) Select the label code A, B, or C of your USB loader cable in the window, and

click the [Next] button.

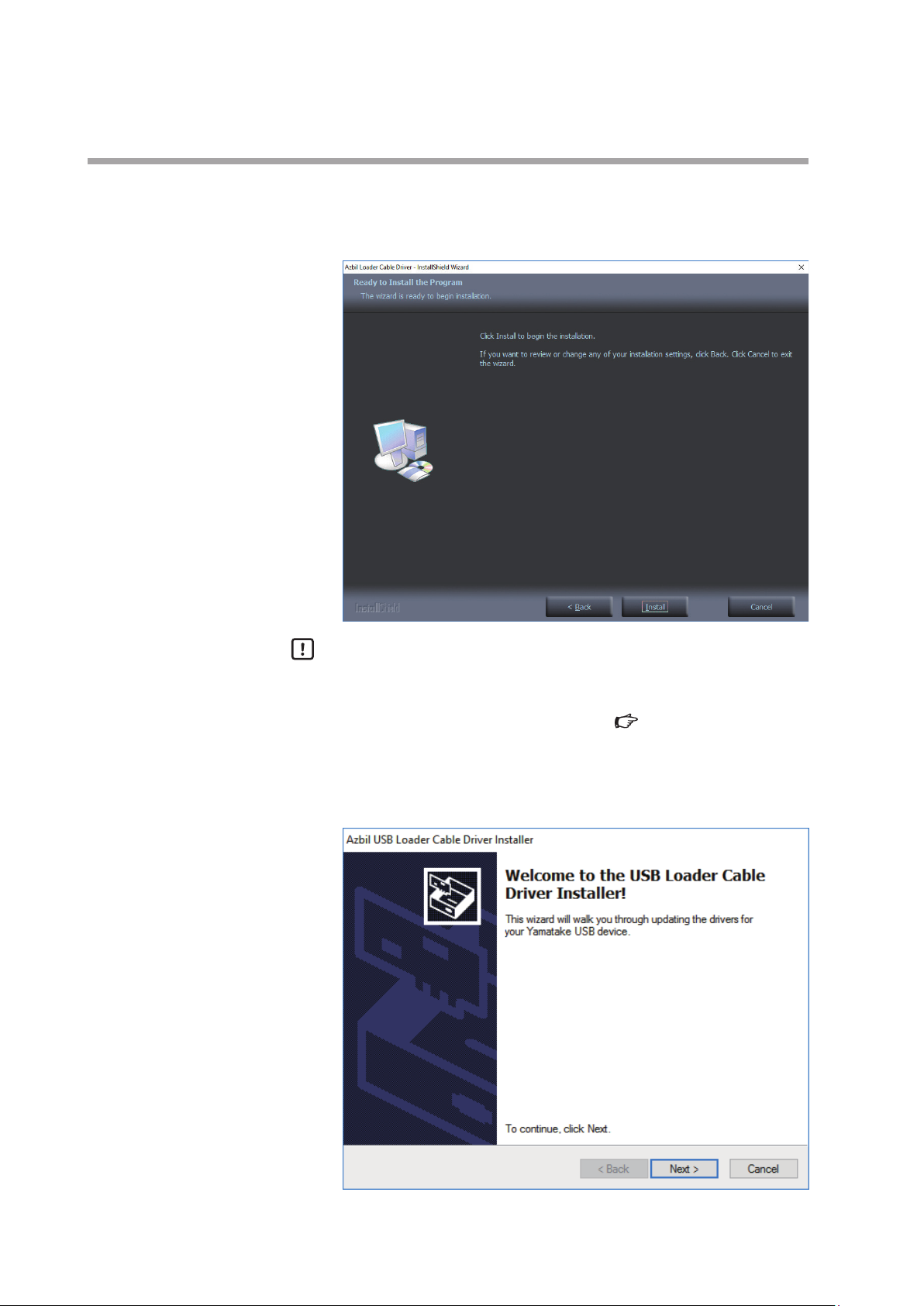

>> The following screen is displayed.

Handling Precautions

• If a message saying that the USB loader cable driver has already been

installed on your computer appears even if you uninstalled the driver in

the past, follow the procedure described in

device driver cannot be installed (P.1-12).

(4) Click the [Install] button.

>> The following screen is displayed.

If the USB loader cable

1-10

Page 19

(5) Click the [Next ] button.

>> The following screen is displayed.

Chapter 1. INTRODUCTION

(6) If you accept the software license agreement and wish to install the software,

select [AGREE] and click the [Next] button.

>> Installation of the device driver starts and the following window is

displayed.

1-11

Page 20

Chapter 1. INTRODUCTION

(7) Click the [Finish] button.

>> The following screen is displayed.

(8) Click the [Finish] button.

Installation of the device driver is complete.

If the USB loader cable device driver cannot be installed

When attempting to install the device driver on a PC on which a USB loader cable

was used in the past, the following window may appear, and it may not be possible

to install the driver, even if the previous device driver has already been uninstalled.

In this case, follow the procedure below.

Step 1. Install tools other than the driver as instructed in the window.

1-12

Page 21

Chapter 1. INTRODUCTION

(1) Click the [Next ] button.

>> Once the installation process is complete, the following screen is displayed.

(2) Click the [Finish] button.

>> The installer for the device driver closes.

Step 2. Follow the procedure described in

(P.1-15).

Step 3. Install the driver following the procedure described in

the USB Loader Cable Device Driver (P.1-8).

Uninstalling the device driver

Installing

1-13

Page 22

Chapter 1. INTRODUCTION

Checking and Installing Microsoft .NET Framework

(1) Right-click the [Start] button and select [Programs and Features].

>> The following screen is displayed.

(2) Select [Turn Windows features on or off ].

>> The following screen appears:

(3) Check that .NET Framework is enabled.

If not, click the checkbox to enable .NET Framework. If “.NET Framework” is

not displayed, the software has not been installed.

After confirming that .NET Framework is enabled, close the window.

Note

• If the software has not been installed on the PC, download it from the

Microsoft website* and install it.

Windows Update to make sure that Windows is in up to date.

* .NET Framework for English versionWindows https://www.microsoft.com/en-

US/download/details.aspx?id=48130 (as of 3/26/2019)

Before installing .NET Framework, execute

1-14

Page 23

1 - 4 Uninstallation

Uninstalling the Loader

(1) Right-click the [Start] button and select [Programs and Features].

(2) Double-click “SLP-F7M (F7M) English” under [Name].

Chapter 1. INTRODUCTION

>> The following screen is displayed.

>> The following screen is displayed.

(3) Click the [Yes] button. The program and related files will be deleted.

Handling Precautions

• A warning message about user account control might appear, depending

Uninstalling the device driver

Handling Precautions

• Before uninstalling the device driver, unplug the USB loader cable from the PC.

• After uninstalling the driver, restart the computer.

• To uninstall the driver, administrator rights on the computer are required.

Installation should be done by the administrator or by a user who belongs to

the administrator group.

on the PC settings. Click the [Yes] button to allow the software to make

changes to the computer.

1-15

Page 24

Chapter 1. INTRODUCTION

(1) Right-click the [Start] button and select [Programs and Features].

>> The following screen is displayed.

(2) Double-click “Azbil Loader Cable Driver.”

>> The following screen is displayed.

(3) Click the [Yes] button.

>> The device driver is deleted and the following window is displayed.

1-16

(4) Click the [Finish] button.

(5) Restart the computer.

Page 25

Chapter 2. STARTING AND EXITING THE LOADER

Handling Precautions

• If there are multiple USB ports, connect the USB loader cable to the same port

every time. If it is connected to a different port, driver reinstallation might be

required.

• Do not unplug the loader cable from the PC while the loader is running. Doing

so may cause faulty loader operation.

• Before starting the loader, close all other application software. Otherwise,

the loader may not work properly due to a particular combination of other

applications and drivers.

• In the Windows settings, select [Control Panel] → [Region] and press the

[Additional settings] button to check that ".” is set for [Decimal symbol]. If any

other symbol is set, the loader will not work properly.

• Check the Windows power option settings and make sure that the PC will not

automatically enter sleep mode. If the PC enters sleep mode, communication

with the device will stop.

Starting the loader

• For details on Windows and PC settings, refer to the user’s manuals provided

with Windows and your PC.

• Do not start multiple instances of the loader program at the same time. Doing

so may cause faulty loader operation.

Double-click the [SLP-F7M (F7M) English] icon on the desktop, or click the [Start]

button at the bottom left of the screen and select [All Apps] → [SLP] → [SLP-F7M

(F7M) English].

>> The following splash screen is displayed for 3 seconds.

>> After 3 seconds, the following initial screen is displayed.

2-1

Page 26

Chapter 2. STARTING AND EXITING THE LOADER

Note

• For details on the OS or the mouse, see the user’s manuals provided with

those products.

Exiting the loader

Select [File] → [Exit] or click the [×] icon in the upper right corner of the screen.

>>The loader closes.

Checking the communication port number

Select [Control Panel] → [Device Manager] and see [Port (COM and LPT)] to check

the COM number for “Yamatake USB Loader Comm.port.”

2-2

Page 27

Chapter 3. HOW TO USE THE LOADER

3 - 1 Overview

Overview of functions

Connect the loader to the device in order to change the parameters, monitor the

flow rate and device status, and for other operations (zero point adjustment, etc.).

Parameters and monitoring results can be saved to a file. The saved file can be

opened to check the data, and parameters can be written to the device.

In addition, with the device not connected, it is possible to edit new parameter

settings and save them to a file, and connect the device afterward to write the

parameters to the device.

Handling Precautions

• As a result of internal calculation (rounding), the value of the least significant

digit displayed on the loader might differ from the value the device has

internally.

• As a result of internal calculation, the least significant digit near either the

range high or range low limit may be judged to be outside the range limit,

with the result that the number cannot be input.

Components of the screen

Menu bar

Toolbar

Tab

Tree view

Status bar Panel view

Name Description

Menu bar All functions of the loader can be accessed from here by selecting any of the

Toolbar Icons for frequently used functions of the loader are provided for easy access to

Tab Information on the device is sorted into tabs.

Tree view Items in the tab are grouped by the device functions.

Panel view Information on the device (status, parameters, etc.) is displayed. Parameter

Status bar The status of communications between the loader and the device is displayed.

menus with the mouse or keys.

the necessary function.

Clicking any of the tabs displays the tree of related items.

Device info.: Model No., etc.

Parameters: Device parameters (configurable in this tab)

Monitor: Process values, abnormal status, etc., of the device

Selecting any of the groups displays related device information in the panel

view.

settings can be changed, with the exception of the items with a gray background.

3-1

Page 28

Chapter 3. HOW TO USE THE LOADER

Loader functions

The table below shows the functions of the loader. They can be executed from

the menu bar.

The functions with icons can also be executed from the toolbar.

parameters)

• File (F): The submenu includes file operations and exit from the

• Comm. (E): The submenu includes the function to execute before

• Parameters (P): The submenu includes functions for reading all

• Monitor (M): The submenu includes functions for starting and

• Device operation (O): Certain device functions can be executed from the

• Help (H): Loader information, etc., can be displayed from the

3 - 4 List of Parameters (P.3-13)(for device information and a list of

loader.

starting communications with the device.

parameters from the device and writing all parameters

to the device.

stopping monitoring.

submenu.

submenu.

Menu bar

Menu Submenu

File New Creates a file of parameters to be written to a device, while

the loader is not connected to the device.

Open Reads parameters that were saved to a file and displays them

on the loader screen. The parameters can be changed and

written to the device.

Save Saves the current parameters. Ctrl + S

Rename and save... Saves the current parameters to a file with a different file

name.

Exit Ends the loader program.

Comm. Comm. settings Communication settings of the loader can be changed. Ctrl + G

Activate comm. Execute this function before starting communication. Ctrl + A

Parameter

Read all parameters

Reads device information and parameters from the device. F1

Overview of functions Toolbar Shortcut keys

Ctrl + N

Ctrl + O

Shift + Ctrl + S

–

Alt + F4

from device

Write parameters to

device

Monitor Start monitoring Reads the process value and device status from the device

End monitoring Ends updating of values on the monitor screen. F5

Device

operation

Help User's Manual for SLP-F7M

Zero point adjustment Automatically adjusts the zero point of the instantaneous flow

Smart Loader Package for

F7M (PDF)

F7M Micro Flow Rate

Liquid Flow Meter User’s

Manual (PDF)

Version information The version information for the loader, etc., is displayed.

Writes only parameters to the device.

Device information is not written.

Settings cannot be written if the model No. of the connected

the device differs from the number in the loader.

and updates the monitoring display.

–

rate.

The user's manual for the loader can be viewed.* – –

The user's manual for the device can be viewed.* – –

– –

F2

F4

F6

* Adobe Acrobat Reader XI or later version is required to view the document.

3-2

Page 29

Chapter 3. HOW TO USE THE LOADER

3 - 2 Connecting the Loader to the Device

In order to check or change the data on the device, the loader must first be connected to the device.

The procedure for connection is as follows.

Steps 1–2: Connect the PC to the device.

Step 3: Start the loader.

Steps 4–5: Set the communication conditions.

Steps 6–8: Execute “Activate comm.”

Handling Precautions

• After the above procedure, a different device can be connected without

exiting the loader. To do so, change the device that is connected to the PC, and

activate communication with the device using steps (6)–(8).

Procedures for device connection

In order to connect the loader to the device, it is necessary to specify

communication settings for the loader and activate communication with the device.

(1) Turn the device off.

(2) Connect the device to the PC.

(3) Start the loader.

(4) Select [Comm. (E) ] → [Comm. settings] on the menu bar, or click the

button on the toolbar.

>> The following screen is displayed.

3-3

Page 30

Chapter 3. HOW TO USE THE LOADER

(5) In the COM port field, select the COM number for the USB loader cable, and

click the [OK] button.

>> The window closes.

Note

• To identify which of multiple communication ports is used, in Windows select

[Control Panel] → [Device Manager] and view [Ports (COM & LPT)] to check

the communication port number for “Yamatake USB Loader Comm. Port.”

(6) Select [Comm. (E)] → [Activate comm.] on the menu bar, or click the

button on the toolbar.

>> The following screen is displayed.

(7) Turn off the power switch on the adapter for loader communication cable.

Power switch

3-4

(8) Turn on the power switch and click the [OK] button within 10 seconds.

>> If communication activation is successful, the following screen is displayed.

Click the [End] button. Now you can execute functions that require

communication with the device.

Page 31

Chapter 3. HOW TO USE THE LOADER

>> If communication activation failed, the following screen is displayed.

Click the [End] button. Check the communication settings of the loader, the

state of the device, and the connection to the device, and then repeat steps

(1)–(8).

3-5

Page 32

Chapter 3. HOW TO USE THE LOADER

3 - 3 Checking and Changing Parameters

Parameters can be checked or changed by the following methods.

· Create a parameter file

· Open a parameter file

· Read all parameters from the device*

Changed parameters can be written to the device or saved by the following methods.

· Write all parameters to the device*

· Save the file

· Rename and save the file

* It is necessary to connect the loader to the device in advance. ( 3 - 2 Connecting the Loader to the Device (P.3-3))

Creating a parameter file without connecting the loader to the device

It is possible to create a parameter file for a device before connecting it to the loader,

and to write the saved parameters to the device afterward.

(1) Select [File] → [New] on the menu bar, or click the

>> The following window is displayed:

button on the toolbar.

3-6

(2) Select the model number of the device whose parameter file is to be created,

and click the [OK] button.

>> The following screen is displayed.

Handling Precautions

• The last letter is the ID code. Please select the model number that is

followed by the ID code printed on the label on the back of the device.

Page 33

Chapter 3. HOW TO USE THE LOADER

Handling Precautions

• The following device information is displayed after a model number is

selected.

Model No.: The model number selected in the [Select model number]

window.

(The digits representing the device specifications that do not affect the

loader function are displayed with hyphens.)

Serial No.: 0

Signal type: Analog output + DI + DO

Firmware version: 0000

(3) Check that the model number and the signal type are correct. Click the

[Parameters] tab and select a parameter group in the tree view, and make

necessary changes to the parameters.

(4) Select [File] → [Rename and save...] on the menu bar, or click the button on

the toolbar.

3-7

Page 34

Chapter 3. HOW TO USE THE LOADER

(5) Enter any name in the [File name] field (example: F7M_N1_1.f7m) and click

>> The following screen is displayed.

the [Save] button.

Note

•

Checking parameters of the connected device

The method of reading and displaying all parameters of the connected device is

explained below.

“All parameters” means all data on the [Device info.] and [Parameters] tabs.

(1) Connect the loader to the device. (

Device (P.3-3))

(2) On the menu bar, select [Parameters] → [Read all parameters from device].

>> The following screen is displayed.

Writing parameters to the device (P.3-10), Saving parameters to

a file (P.3-11) (for opening saved files and writing parameters to the device)

3 - 2 Connecting the Loader to the

3-8

(3) Click the [OK] button.

Page 35

>> The following screen is displayed.

(4) Click the [OK] button.

>> The following screen is displayed.

Chapter 3. HOW TO USE THE LOADER

(5) Click the [Parameters] tab and select the item to check in the tree view.

>> The following screen is displayed.

3-9

Page 36

Chapter 3. HOW TO USE THE LOADER

Writing parameters to the device

This section describes the procedure for writing parameters to the device.

After reading parameters to the loader, perform the following operations.

Handling Precautions

• Parameters cannot be written to the device if the model number of the device

is different from the number in the [Device info.] tab.

However, because the underlined digits in the following example represent

the device specifications that do not affect the loader function, even if there

are discrepancies in these digits, parameters can be written to the device.

Example: F7M9010AQ100100Y0

(1) Activate communication with the device.

(

3 - 2 Connecting the Loader to the Device (P.3-3))

(2) On the menu bar, select [Parameters] → [Write parameters to the device], or

click the

>> The following screen is displayed.

(3) Click the [OK] button.

>> The following screen is displayed.

button on the toolbar.

3-10

(4) Click the [OK] button.

Page 37

Saving parameters to a file

Parameters that were read from the device or that were changed can be saved to a

file using the following procedure.

Chapter 3. HOW TO USE THE LOADER

(1) Select [File] → [Rename and save...] on the menu bar, or click the

the toolbar.

>> The following screen is displayed.

button on

(2) Enter any name in the [File name] field and click the [Save] button.

Checking saved parameters

This section describes the procedure for displaying data (parameters) that have

been saved to a file.

(1) Select [File] → [Open] on the menu bar, or click the

button on the toolbar.

>> The following screen is displayed.

3-11

Page 38

Chapter 3. HOW TO USE THE LOADER

(2) Select the parameter file to open (extension: f7m) and click the [Open] button.

>> The following screen is displayed.

(3) Select a tab and an item in the tree view to check parameter settings.

3-12

Page 39

Chapter 3. HOW TO USE THE LOADER

3 - 4 List of Parameters

The following tables show the parameters that can be accessed by the loader.

Note

• F7M Micro Flow Rate Liquid Flow Meter User’s Manual CP-SP-1421E (for

details on parameters)

[Device info.] tab

Displays information such as model number. The settings of these parameters

cannot be changed.

Parameters Unit Description Factory default

Model No. – Device model No. (17 chars.) + ID code (1 alphabetical

char.) (In some cases, the ID code is not printed.)

Example: F7M9030AQ10010000b

Serial No. – Serial number of the device represented by a 9-digit

number

Signal type – Indicates the signal type of the device. Analog output + DI + DO

Firmware version – Indicates the firmware version of the device. –

Depends on the device

specifications.

Depends on the device.

3-13

Page 40

Chapter 3. HOW TO USE THE LOADER

[Parameters] tab

Parameters Unit Description Factory default

DI settings DI function – Zero point adjustment

Error reset

Liquid type selection*

DO settings DO function – Flow rate event 1

Flow rate event 2

Error indication output

Totalizer pulse output

DO polarity – Direct (normally open)

Reverse (normally closed)

Analog output

settings

Flow rate

correction

Totalizer pulse flow

rate

Upper limit validity – Invalid

Flow rate upper limit % FS 0.00–100.00 100.00

Hysteresis upper limit % FS 0.00–10.00 0.00

Delay upper limit s 0.0–60.0 0.0

Lower limit validity – Invalid

Flow rate lower limit % FS 0.00–100.00 0.00

Hysteresis lower limit % FS 0.00–10.00 0.00

Delay lower limit s 0.0–60.0 0.0

Span correction factor – 0.000–2.000 1.000

Zero-point correction V -1.000 to +1.000 0.000

Output at error – Present value

Voltage at error V 0.600–6.000 0.600

Flow rate CCF 1 – These parameters cannot be changed

Zero point adjustment 1mW 0.00

Flow rate CCF 2* – 1.000

Zero point adjustment 2*mW 0.00

mL/pulse 0.01, 0.1, 1, 10 0.1

Valid

Valid

Last good value (before error)

Specified value (set in [Voltage at error])

using the [Write parameters to the

device] menu. Write the settings from

the [Monitor] tab.

Error reset

Flow rate event 1

Direct

Valid

Valid

Present value

1.000

Offset correction value mL/min -10.00 to +10.00 0.00

Low-flow cutoff value % FS 0.0–100.0 1.0

Filter time constant s 0.0–60.0 0.0

Function

settings*

*Available on devices with ID code “b” or later

Automatic setting of

flow rate correction

factor (CCF)*

Temperature-based

correction (for water)*

Display ON/OFF using

DI status*

– ON

OFF

– ON

OFF

– ON

OFF

OFF

ON

OFF

3-14

Page 41

3 - 5 Checking Measured Values and Status

Displaying measured values and status of the device

(1) Connect the loader to the device. ( 3 - 2 Connecting the Loader to the

Device (P.3-3))

Chapter 3. HOW TO USE THE LOADER

(2) Obtain device information by executing steps 1 to 4 in

parameters of the connected device (P.3-8). If you have already executed

steps 1 to 4, this process is unnecessary.

(3) Click the [Monitor] tab and select the item to display in the tree view.

Monitoring information has not yet been read from the device. (The following

are the screens displayed when [Monitor] → [Process value] is selected)

(4) Click the [Monitor] → [Start monitoring] on the menu bar, or click the

button on the toolbar.

Checking

>> The following screen is displayed. The loader starts updating values and

information. When monitoring is in progress, “Monitoring” at the bottom

left of the screen is displayed in green and the word “Communicating...”

blinks.

3-15

Page 42

Chapter 3. HOW TO USE THE LOADER

3 - 6 Immediate Writing of Parameters

How to write monitoring parameters to the device immediately

Only when monitoring is in progress, parameters with the [Write] button can be

written to the device immediately.

(1) Connect the loader to the device. (

Device (P.3-3))

(2) Obtain device information by executing steps 1 to 4 in

parameters of the connected device (P.3-8). If you have already executed

steps 1 to 4, this process is unnecessary.

(3) Click the [Monitor] tab and select the desired item in the tree view. At this

point monitoring information has not yet been read from the device. [Write]

buttons are disabled and the monitoring parameters cannot be written to the

device immediately.

(The following figure shows the screen after clicking [Monitor] → [Fluid

settings correction].)

3 - 2 Connecting the Loader to the

Checking

(4) Click the [Monitor] → [Start monitoring] on the menu bar, or click the

button on the toolbar.

>> The following screen is displayed.

3-16

Page 43

Chapter 3. HOW TO USE THE LOADER

The loader starts updating values and information.

When monitoring is in progress, “Monitoring” at the bottom left of the screen

is displayed in green and the word “Communicating...” blinks.

Under these conditions, monitoring parameters can be written to the device

immediately by pressing the [Write] button.

(5) Change the value or option selection for the desired monitoring parameter

and press the [Write] button next to it. Only the setting for that monitoring

parameter is written to the device.

3-17

Page 44

Chapter 3. HOW TO USE THE LOADER

3 - 7 List of Monitoring Parameters

[Monitor] tab

Parameters Unit Description

Process value Instantaneous

flow rate

Abnormal status – Indicates the type of abnormal status. –

Fluid settings

correction*

Instantaneous

1

flow rate

Totalized flow mL Indicates the total volume of flow at that point in time.*

Totalized flow

count up

Liquid type – Indicates the currently selected liquid type. The type can be

Flow rate CCF 1 – Indicates the flow rate correction factor for liquid type 1. The

Zero point

adjustment 1

Flow rate CCF 2 – Indicates the flow rate correction factor for liquid type 2. The

Zero point

adjustment 2

Abnormal

Error – An error has a significant impact on the operation of the device.

status

Alarm – An alarm affects the measurement of flow rate.

Warning – A warning has a small impact on the measurement of flow rate.

Information – This is not technically an abnormal status. Information is

Sensor

information

Flow path

temperature

Circuit

temperature

Heater power mW Displays power consumption by the heater used for flow rate

Factory

default

mL/min Indicates the value calculated from the measured flow rate signal. –

mL/min Indicates the value calculated from the measured flow rate signal. –

1

– Totalizing of the flow volume can be started or stopped.*

1 *2

Stop

Start

Stop

Stop and reset counter to 0

Liquid

changed.*

1 *2

type 1

Liquid type 1

Liquid type 2

1.000

value can be changed.*

1 *3

0 to 100.000

mW Indicates the amount of zero point adjustment for liquid type 1.

The value can be changed.*

1 *3

0.00

-5.00 to +5.00

1.000

value can be changed.*

1 *3

0 to 100.000

mW Indicates the amount of zero point adjustment for liquid type 2.

The value can be changed.*

1 *3

0.00

-5.00 to +5.00

Chapter 4. TROUBLESHOOTING (for details and corrective

actions)

Chapter 4. TROUBLESHOOTING (for details and corrective

actions)

Chapter 4. TROUBLESHOOTING (for details and corrective

actions)

displayed for reference.

Chapter 4. TROUBLESHOOTING (for details and corrective

actions)

°C Displays an approximate temperature in the flow path. –

°C Displays the approximate temperature of the circuit. –

measurement.

–

–

–

–

–

–

3-18

Page 45

Chapter 3. HOW TO USE THE LOADER

Parameters Unit Description

Abnormal

status code

*1. Available on devices with ID code “b” or later.

*2. The setting can be changed only when monitoring is in progress.

Changes are temporary and the parameter is reset to the setting at the time when the device was shipped if the device

is turned off and back on.

*3. The setting can be changed only when monitoring is in progress.

Abnormal status

code 0

Abnormal status

code 1

Abnormal status

code 2

Abnormal status

code 3

Abnormal status

code 4

Abnormal status

code 5

Abnormal status

code 6

Abnormal status

code 7

– For maintenance –

– For maintenance –

– For maintenance –

– For maintenance –

– For maintenance –

– For maintenance –

– For maintenance –

– For maintenance –

Factory

default

3-19

Page 46

Chapter 3. HOW TO USE THE LOADER

3 - 8 Operating the Device

Adjusting the zero point

Note

• To reset the zero point of a device with ID code “b” or later to the value at the

time when the device was shipped, set [Zero point adjustment 1] and [Zero point

adjustment 2] to “0.00” (the value at the time of shipment).

( 3 - 6 Immediate Writing of Parameters

• If a device’s ID code is not indicated, it is not possible to restore the zero point

setting at the time when the device was shipped using the loader.

Instead, use the switch on the device to restore the setting.

For details, please refer to Micro Flow Rate Liquid Flow Meter Model F7M User’s

Manual (CP-SP-1421E).

• If [Automatic setting of flow rate correction factor (CCF)] is enabled, the CCF

based on the amount of adjustment after zero point adjustment is automatically

set. If this function is used to automatically set the CCF, flow rate accuracy is not

guaranteed. For higher accuracy, use the set value as a guideline for setting the

CCF manually.

Handling Precautions

• When zero point adjustment is in progress, do not turn off the device.

• Parameters other than zero point adjustment are written to the device by

[Writing all parameters], but the amount of zero point adjustment is written to

the device when zero point adjustment is complete.

The procedure for adjusting the zero point of the instantaneous flow rate after

connecting the loader to the device is given below.

(1) Connect the loader to the device. (

(2) Obtain device information by executing steps 1 to 4 in

(3) Select [Device operation] → [Zero point adjustment] on the menu bar.

3 - 2 Connecting the Loader to the

Device (P.3-3))

Checking

parameters of the connected device (P.3-8). If you have already executed

steps 1 to 4, this process is unnecessary.

3-20

>> The following screen is displayed.

Page 47

Chapter 3. HOW TO USE THE LOADER

(4) Check that the pipe is full of fluid and that the fluid is not moving, and then

click the [OK] button.

>> The following window is displayed.

>> When zero point adjustment is complete, the following screen is displayed.

(5) Pressing the [OK] button returns the display to the original screen.

3-21

Page 48

-MEMO-

Page 49

Chapter 4. TROUBLESHOOTING

Types of abnormal status

There are four types of abnormal status of the device: Error, alarm, warning, and

information.

Abnormal status can be checked by the loader.

Abnormal status of the device Description

Error An error has a significant impact on the operation of this device. If an error occurs,

flow rate measurement stops.

If the problem is caused by a transient failure such as electrical noise, the device may

return to normal after the power is turned off and back on. If not, request repair.

Alarm An alarm affects the measurement of flow rate.

If an alarm occurs, flow rate measurement continues, but the accuracy of the flow

rate is not guaranteed.

Warning A warning has a small impact on the measurement of flow rate.

If a warning occurs, digital output remains off when “DO function" is set to “Error

indication output.”

Whether a warning has occurred can be checked with the LED indicator or by the

loader.

If a warning occurs, flow rate measurement continues.

Information This is not technically an abnormal status. Information is displayed for reference.

Abnormal status can be checked by the loader.

Abnormal status and corrective actions

Type Er : Error

Al : Alarm

Wn : Warning

Inf : Information

Automatic recovery ✓ : Yes (when the cause is removed, the abnormal status

indication disappears)

– : No

No. Type Description Likely cause Corrective action

0 Al Zero point adjustment

error

(correction of more than

±40 % FS)

Wn Zero point adjustment

completed

(correction of more than

±25 % FS)

Inf Zero point adjustment

completed.

(succeeded)

The zero point was adjusted when

the fluid was moving.

Zero point adjustment succeeded. –

Check that the pipe is full of the

fluid to be measured and that

the fluid is not moving, and try

again.

Automatic

recovery

✓

4-1

Page 50

Chapter 4. TROUBLESHOOTING

No. Type Description Likely cause Corrective action

1 Wn Empty (flow path not full) The flow path of this device has

Fill the flow path with the fluid.

Automatic

recovery

not been full for some time.

Inf Flow rate measurement

error

A flow rate measurement error

occurred due to a cause such as

bubbles in the flow path of the

Check for problems in the

installation environment or

instrumentation.

device.

2 Wn Accuracy-guaranteed

flow rate exceeded

Fluid is flowing at a rate greater

than the rated (accuracy-

Use this device within the rated

flow rate range.

guaranteed) flow rate.

3 Wn Analog output range

exceeded

4 Wn Parameter error

(1) Checksum error

(2) Number of write

cycles exceeded

The rated flow rate was exceeded,

or an analog output correction

parameter value is invalid.

(1) A checksum error occurred

during parameter data reading

or writing.

(2) Parameters were written more

than the specified number of

Use this device within the rated

flow rate range.

Set a valid parameter value.

(1) Write parameters again.

(2) Replace the product.

times.

5 Wn Watchdog time-out A reset by a communication

command, or malfunction due to

electrical noise, etc.

6 Al Flow path or circuit

temperature out of range

Wn The fluid temperature or the

The sensor unit has failed.

ambient temperature does not

meet the specified operating

conditions.

If the warning persists after

turning the power off and back

on, request repair.

•

Check that the fluid

temperature and the

ambient temperature meet

the specified operating

conditions.

•

If the alarm persists after

turning the power off and

back on, request repair.

7 Al Measurable flow rate

exceeded

8 Al Totalizer pulse output

error (flow over range)

The flow rate is greater than 115

% of the measurable range.

When totalizer pulse was being

output, the flow rate exceeded

Use this device within the rated

flow rate range.

Use this device within the rated

flow rate range.

the rated measurable range for a

certain period of time.

Wn When totalizer pulse was being

output, the flow rate far exceeded

the rated measurable range for a

certain period of time.

9 – (Not used) – – –

10 Al Heater control error The heater, temperature sensor,

or electric circuit has failed, so the

heater cannot be controlled.

11 Er Parameter error A type of parameter not

supported by this device, or

an illegal parameter value, was

downloaded by the loader.

Al Parameter mismatch Parameter values are abnormal,

If the alarm persists after turning

the power off and back on,

request repair.

If the error, alarm, or information

persists after changing the

parameter and turning the

power off and back on, request

repair.

etc.

Inf Out-of-range parameter Parameter values are out of range.

✓

✓

✓

–

–

–

✓

✓

✓

–

4-2

Page 51

Chapter 4. TROUBLESHOOTING

No. Type Description Likely cause Corrective action

12 Er Nonvolatile memory error The data in the device is corrupt. If the error or information

Inf Backup parameter error The data in the backup area is

corrupt.

persists after changing the

parameter setting and turning

the power off and back on,

request repair.

13 Er Software execution error

14 Er Hardware error

15 Er Program ROM error A data discrepancy was detected

•

The heater or temperature

sensor has failed.

•

The electric circuit has failed.

•

The heater or temperature

sensor has failed.

•

The electric circuit has failed.

in a cyclic redundancy check

(CRC) of the ROM.

If the error persists after turning

the power off and back on,

request repair.

If the error persists after turning

the power off and back on,

request repair.

If the error persists after turning

the power off and back on,

request repair.

Automatic

recovery

–

–

–

–

–

4-3

Page 52

Chapter 4. TROUBLESHOOTING

Error messages and corrective actions

Menu Message Description Corrective action

[Comm. (E)] →

[Comm. settings]

[Comm. (E)] →

[Activate comm.]

[File] → [New] No model number has been

[File] → [Open] The model is not supported by

No COM port has been selected. The [OK] button was pressed

Communication activation failed.

Please check the communication

settings of the loader, the state of

the device, and the connection to

the device, and then try again.

selected.

the loader.

Reading of the file failed.

The read data contains errors. The file could not be opened

[File name]

File not found.

Check the file name and try again

with no COM port selected.

Communication activation

failed and the loader cannot

communicate with the device.

The [OK] button was pressed

with no model number

selected.

The selected file is for a model

that is not supported by the

loader, so the file could not be

opened.

due to errors in the file.

The file is probably corrupt.

The specified file cannot be

opened because the loader

cannot find it.

Select the COM port that is

assigned for communications

with the device, and click the

[OK] button.

Please check the

communication settings of the

loader, the state of the device,

and the connection to the

device, and then try again.

A model number must be

specified. Select the model

number of the device to be

connected and press the [OK]

button.

If a new version of the loader is

available on the Azbil website

(Compo Club), it might be

possible to open the file by

upgrading the loader.

If the file still cannot be opened,

it might be corrupt. Take the

same corrective action as for

“The read data contains errors.”

Specify the parameters again

and save them to a file.

(Execute [Read all parameters

from device] or select [File] →

[New] to display parameters,

change the settings, and save

them to a file.)

Please enter the correct file

name.

[File] → [Save]

[File] → [Rename

and save...]

4-4

No file is open. The user attempted to save a

[File name] already exists.

Do you want to replace it?

[File name]

This file is set to read-only

Try again with a different file

name.

[File name]

You don't have permission to save

in this location.

Contact the administrator to

obtain permission.

Would you like to save in the

[Document] folder instead?

file but no file was open.

A file with the same name was

found when [Rename and

save...] was executed.

It is possible to overwrite

the file data with the current

parameter settings.

The specified file is read-only

and cannot be overwritten.

You do not have access rights

for the specified destination

folder.

Execute [Rename and save...].

To overwrite the data, press the

[Yes] button.

If you wish not to overwrite

the data, press the [No] button,

change the file name, and save

it.

Change the file name and save

it.

To save the file to the

Documents folder, press the

[Yes] button.

To save the file to another

folder, select a folder that you

are permitted to access and

save the file.

Page 53

Chapter 4. TROUBLESHOOTING

Menu Message Description Corrective action

[Parameters]

→ [Read all

parameters from

device]

The model is not supported by

the loader.

Reading of parameters failed.

A product other than the

device is connected or the

device model not supported

by the loader is specified, so

parameters cannot be read

from the device.

Check the connected product.

Download the latest version of

the loader software from the

Azbil website (Compo Club),

install the loader, and try again.

[Parameters] → [Write

parameters to the

device]

Reading of parameters failed. Reading of parameters from

the device was aborted

because a communication

error, etc., occurred.

Parameters could not be written

to the device because the model

number of the device is different

from the number specified by the

loader.

The model number in the loader’s

device information must be the

same as the model number of the

connected device.

Model number specified by the

loader: F7M _ _ _ _ _ _ _ _

Model number of the connected

device: F7M _ _ _ _ _ _ _ _

Parameters could not be written

to the device because some of the

values were invalid.

Please specify valid values for

the following items and then try

again.

Writing of parameters failed. Writing parameters to the

Parameters could not be

written to the device because

the model number of the

connected device is different

from the model number

currently specified for work

using the loader.

Parameters could not be

written to the device because

the specified parameters

include out-of-range values,

or because the combination

of the specified parameters is

prohibited.

device was aborted because

a communication error, etc.,

occurred.

Please check the

communication settings for the

loader, the power to the device,

and the cable connections, and

then try again.

The model number in the

loader’s device information

must be the same as the model

number of the connected

device.

Please correct the value of the

parameter(s) displayed under

the message

and try again.

Please check the

communication settings for the

loader, the power to the device,

and the cable connections, and

then try again.

4-5

Page 54

Chapter 4. TROUBLESHOOTING

Menu Message Description Corrective action

[Monitor] → [Start

monitoring]

[Device operation]

→ [Zero point

adjustment]

[Help] → Menu

to open a user’s

manual

Parameter values The value is out of range. The entered value could not be

Monitoring could not be started

because the model number of

the device is different from the

number specified by the loader.

Please execute reading of all

parameters from the device and

try again.

Model number specified by the

loader: F7M _ _ _ _ _ _ _ _

Model number of the connected

device: F7M _ _ _ _ _ _ _ _

A communication error occurred.

Monitor startup failed.

Monitoring stopped due to a

communication error.

Zero point adjustment failed.

Zero point cannot be adjusted if

the flow rate exceeds the range

(±40 % FS).

Zero point adjustment failed.

Zero point cannot be adjusted if

an error or alarm occurred or if

zero point adjustment has already

been executed by pressing the

operation switch on the device.

Or, a communication error

occurred.

The specified file cannot be

opened.

The input value is invalid. The specified value could not

The number of characters exceeds

the limit.

Monitoring could not begin

because the model number

of the connected device is

different from the model

number currently specified for

work using the loader.

A communication error

occurred during monitor

startup.

A communication error

occurred during monitoring.

The flow rate is outside the

adjustment range.

The zero point cannot be

adjusted if an error or alarm

occurred, if zero point

adjustment is in progress, or if a

communication error occurred.

The software required to

display the user's manual (a

PDF file) is not installed on the

PC.

set because it is out of range.

be set because it includes

non-numeric values such as

letters or double-width Asian

characters, which are not

treated as numeric values.

The character string is too long. The number of characters must

The model number in the

loader’s device information

must be the same as the model

number of the connected

device.

Please check the

communication settings for the

loader, the power to the device,

and the cable connections, and

then try again.

Please check the

communication settings for the

loader, the power to the device,

and the cable connections, and

then try again.

Check that the pipe is full of

fluid and that the fluid is not

moving, and try again.

Remove all errors or alarms, if

any.

If zero point adjustment is

in progress, wait until it is

complete.

If a communications

error occurred, check the

communication settings for the

loader, the power to the device,

and the cable connections.

Then, try again.

Download Adobe Acrobat

Reader XI or later version from

Adobe’s website, install it, and

try again.

Enter a value that is between

the lower and upper limits

that are indicated within

the parentheses next to the

parameter.

Enter a numeric value.

be within the limit.

4-6

Page 55

Chapter 4. TROUBLESHOOTING

Other troubleshooting

Type Message Description Corrective action

Display Values are not displayed properly.

Files cannot be opened.

Other Some or all functions of the

loader (screen display, operation,

etc.) cannot be executed.

If a symbol other than “.” is set

as the decimal point symbol

in the Windows settings, the

loader will not work properly.

Due to unknown errors, the

loader does not operate

properly.

In the Windows settings, select

[Control Panel] → [Region]

and press the [[Additional

settings] button.

Check that “.” is set as the decimal

point symbol.

Exit the loader using the

following procedure and then

restart the loader:

Press the Ctrl + Alt + Delete keys.

Click [Task Manager].

Select [SLP-F7MJ91 for F7M

(32bit)] and click the [End Task]

button.

4-7

Page 56

-MEMO-

Page 57

Revision History of CP-SP-1423E

Date Rev. Revised pages Description

Apr. 2018 1

Apr. 2019 2

1-1 Description was added. Added “Applicable versions”.

1-3 Added notes to the figure.

1-14 Changed the URL in “Note.”

3-6 Changed a screenshot. Added “Handling Precautions.”

3-7, 3-9 Changed a screenshot.

3-13, 3-14 Changed the table in “[Device info.] tab.” Changed the table in “[Parameter]

t a b.”

3-15 Moved from p. 3-14.

3-15 Changed a screenshot.

3-16 Added “How to write monitoring parameters to the device immediately” in

section 3-6.

3-18 Changed the table in “List of Monitoring Parameters.”

3-20 Added descriptions to “Note” in “Adjusting the zero point.”

Page 58

1-12-2 Kawana, Fujisawa

https://www.azbil.com

Kanagawa 251-8522 Japan

Specifications are subject to change without notice.

1st edition: Apr. 2018 (V)

2nd edition Apr. 2019 (V)

(11)

Loading...

Loading...