Page 1

CP-UM-5289JE

①

⑥

⑨

②

⑤

⑧⑧ ⑦⑦

注 意

デジタル指示調節計

SDC35/36

取扱説明書 設置編

このたびは当社製品をご購入いただき、まことにありがとうございます。

この製品を正しく安全にお使いいただくために、この取扱説明書を必ず

お読みになり、理解したうえでお使いください。

本書は、いつもお手元においてご使用ください。

ご注文・ご使用に際しては、下記URLより「ご注文・ご使用に際して

のご承諾事項」を必ずお読みください。

https://www.azbil.com/jp/product/factory/order.html

お願い

この取扱説明書は、本製品をお使いになる担当者のお手元に確実

に届くようにお取りはからいください。

この取扱説明書の全部、または一部を無断で複写、または転載す

ることを禁じます。この取扱説明書の内容を将来予告なしに変更

することがあります。

この取扱説明書の内容については、万全を期しておりますが、

万一ご不審な点や記入もれなどがありましたら、当社までご連絡

ください。

お客さまが運用された結果につきましては、責任を負いかねる場

合がございますので、ご了承ください。

© 2003–2018 Azbil Corporation. All Rights Reserved.

本書は使用上の注意事項と取り付け・結線・PVレンジ種類・パラメー

タ一覧・主な仕様などを説明したものです。詳しい取り扱い方法・設

定方法などは、別冊の「詳細編」をご覧ください。

各種機能の操作については次の説明書があります。必要に応じてお読

みください。

デジタル指示調節計 SDC35/36 取扱説明書 詳細編 CP-SP-1150

デジタル指示調節計 SDC15/25/26/35/36用

スマートローダパッケージ SLP-C35 取扱説明書 CP-UM-5290

デジタル指示調節計 SDC35/36 キー操作ダイジェスト CP-SP-1203

これらの資料は https://www.compoclub.com からダウンロードする

こともできます。

確認してください

お買い上げいただいたSDC35/36は次のものが同梱されています。

・ 取付器具 81409654-001 2個

・ 取扱説明書(本書) CP-UM-5289JE 1部

安全上の注意

この安全上の注意は、製品を安全に正しくお使いいただき、あなたや他の人々

への危害や財産への損害を未然に防止するためのものです。安全上の注意は

必ず守ってください。また、内容をよく理解してから本文をお読みください。

● 警告表示の意味

警告

注意

取り扱いを誤った場合に、使用者が死亡または 重傷を

負う危険の状態が生じることが想定される場合。

取り扱いを誤った場合に、使用者が軽傷を負うか、ま

たは物的損害のみが発生する危険の状態が生じること

が想定される場合。

警 告

導電性の汚染が生ずる環境、もしくは結露などによって導電

性となる乾燥した非導電性の汚染が生ずる環境で使用しない

でください。トラッキング現象などにより部品故障や故障に

起因する火災のおそれがあります。

本器の電源配線には仕様に記載されているヒューズを設けて

ください。トラッキング現象や部品故障に起因する火災のお

それがあります。

本器への通電前に配線が正しく行われていることを確認して

ください。本器への配線間違いは故障の原因になり、また危

険な災害を招く原因にもなります。

本器へ結線や取り付け、取り外しは電源の供給元を切った状

態で行ってください。

感電、故障の原因になります。

電源端子などの充電部には触らないでください。

感電のおそれがあります。

本器を分解しないでください。感電、故障のおそれがあります。

J1

本器は、仕様に記載された使用条件(温度、湿度、電圧、振動、

衝撃、取付方向、雰囲気など)の範囲内で使用してください。

火災、故障のおそれがあります。

本器の通風穴をふさがないでください。

火災、故障のおそれがあります。

本器への結線は定められた基準に従い、指定された電源、お

よび施工方法で正しく配線してください。

火災、感電、故障のおそれがあります。

本器ケース内部に線くず、切粉、水などが入らないようにし

てください。火災、故障のおそれがあります。

端子ねじは仕様に記載されたトルクで確実に締め付けてくだ

さい。締め付けが不完全だと火災、感電のおそれがあります。

本器の未使用端子を中継端子として使用しないでください。

火災、感電、故障のおそれがあります。

本器の結線後は端子カバーを取り付けることをお勧めします。

感電のおそれがあります。

(本器は別売品の端子カバーを用意しています)

本器のリレーは仕様に記載された寿命の範囲内で使用してく

ださい。範囲を超えて使い続けると火災、故障のおそれがあ

ります。

雷サージのおそれがある場合には、サージアブソーバ(サージ

防止器)を使用してください。火災、故障のおそれがあります。

キー操作の際には先のとがったもの(シャープペンシルの先や

針など)で押さないでください。故障の原因となります。

設置からPV レンジ・SPの設定まで

設置から最低限の初期設定までのフローを示します。

手順1 設 置

手順2 結 線

設定操作

J2ページ

J2ページ

J3ページ

手順3 PVレンジ種類の設定(PVレンジ表)

手順4 SP の設定

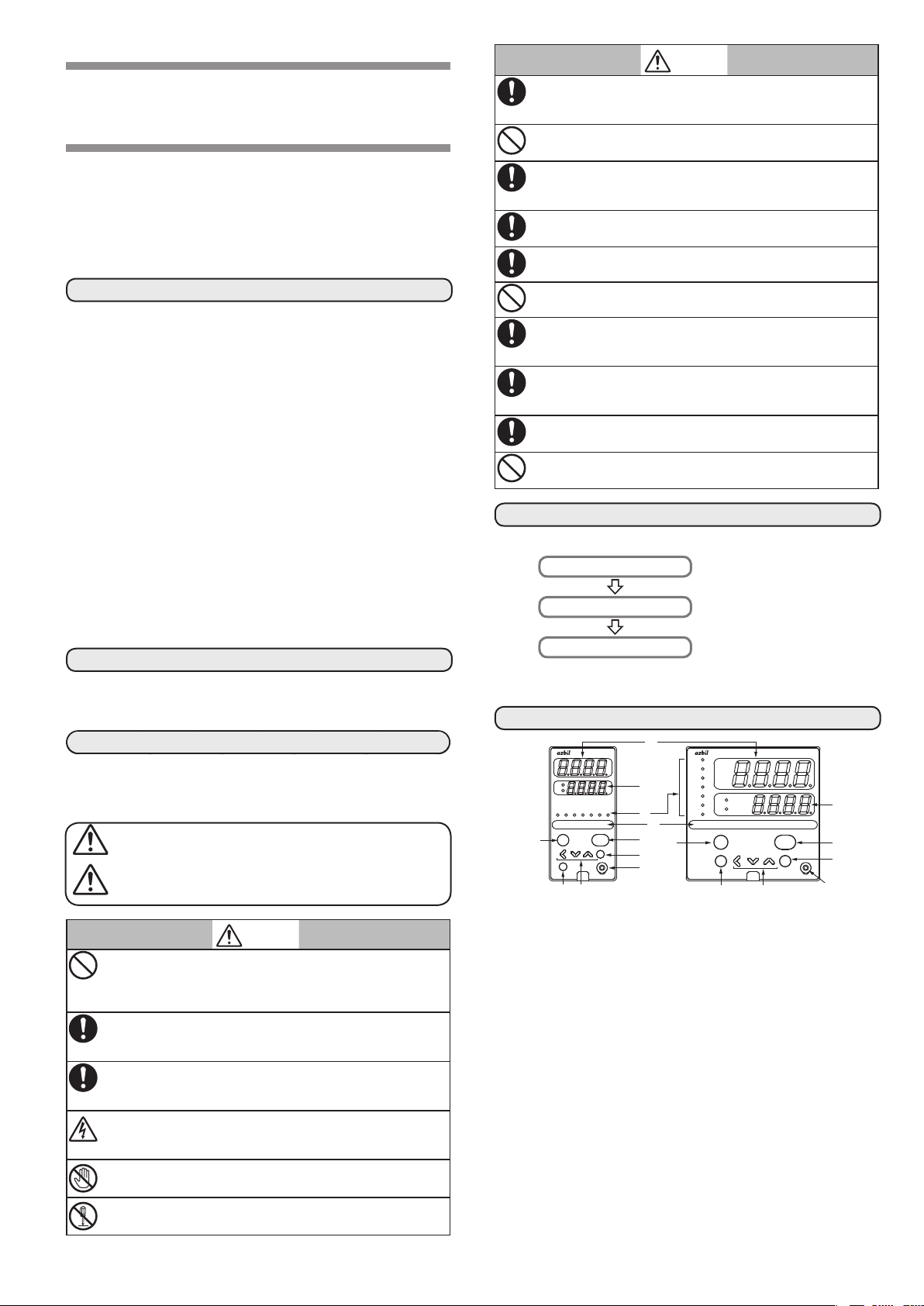

各部の名称と機能

pv

sp

out

man rsp ev1 ev2 ev3 ot1 ot2

display

mode

enter

para

②

③

⑥

⑨

⑩

man

pv

rsp

ev1

ev2

ev3

sp

ot1

out

ot2

④

⑤

mode

para

① 第1 表示部 : PV値(現在の温度など)や設定項目を表示します。

② 第2表示部 : SP値(設定温度など)や各設定項目の設定値を表

示します。第 2 表示部が SP を表示しているときは、

spが点灯し、操作量(MV)を表示しているときは、

out が点灯します。

③ モード表示灯

man : MANUALモード(手動)のとき点灯します。

rsp

: RSP(リモート設定入力)モードのとき点灯します。

ev1〜ev3

: イベントリレー出力がONしているとき点灯します。

ot1・ot2 : 制御出力が ON しているとき点灯します。

④ MS(マルチステータス)表示灯

:

点灯条件と点灯状態を組みにして、優先度のつい

た 3 組を設定できます。

⑤ [mode]キ ー :

1 秒以上押し続けると、あらかじめ設定してある

操作ができます。

⑥ [display]キー : 運転表示で表示内容を切り替えます。バンク設定

表示から運転表示に戻します。

⑦ <、∨、∧キー : 数値の増減、桁送りに使用します。

⑧ [para]キー : 表示の切り替えをします。

⑨ [enter]キー :

設定の変更開始と変更中の数値の確定を行います。

⑩ ローダコネクタ : スマートローダパッケージに同梱されている専

用ケーブルを使用してパソコンと接続します。

SDC36SDC35

display

enter

⑩

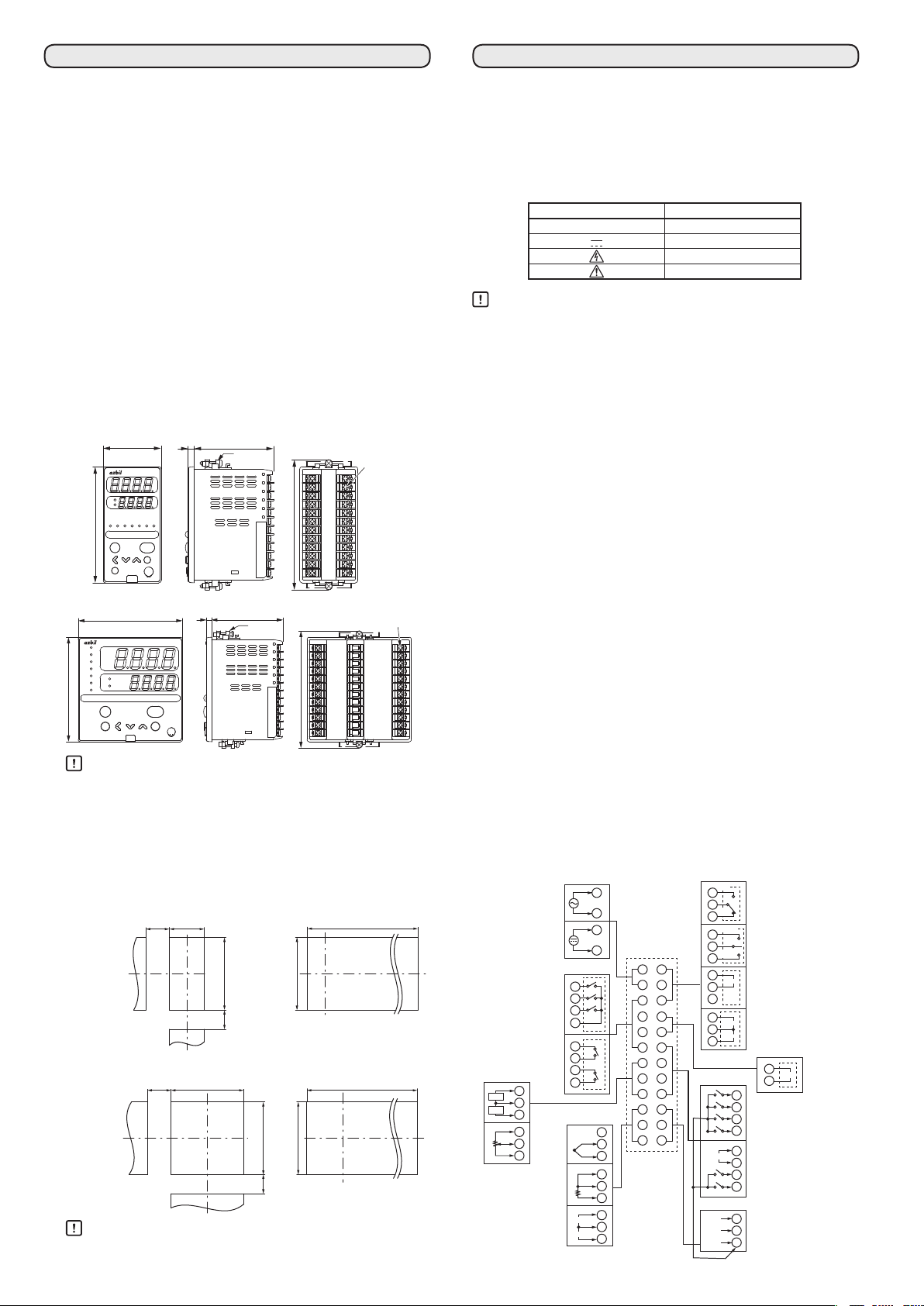

Page 2

端子ねじ M3

5

65

96

48

65

5

96

96

密着取付

個別取付

密着取付

個別取付

電圧パルス/電流/連続電圧

電流/連続電圧/電圧パルス

電圧パルス/電流/連続電圧

制御出力

電 源

CT入力

手順1 設 置

■

取付場所

本器を取り付けるときは、次のような場所に設置してください。

• 供給電源およびリレー接点出力を除く入出力のコモンモード電

圧:対大地間の電圧は、30 Vrms以下、424 Vピーク以下、

DC60 V以下としてください。

• 高温、低温、高湿度、低湿度にならないところ

• 硫化ガスなど腐食性ガスやシリコンガスのないところ

• 粉じん、油煙などの少ないところ

•

直射日光および風雨の当たらないように適切な処理のされたところ

• 機械的振動、衝撃の少ないところ

• 高圧線の下、溶接機の近くおよび電気的ノイズの発生源の近く

でないところ

• ボイラなどのような高圧点火装置から15 m 以上離れたところ

• 電磁界の影響の少ないところ

• 可燃性の液体や蒸気のないところ

• 屋内

■

取付方法

•

取付角度は水平位置から、後下がり10 度以内、後上がり10 度以

内としてください。

• パネルは板厚9 mm 以下で剛性のあるものをご使用ください。

■

外形寸法

●

C35

取付器具

+0.5

0

(付属品)

+0.5

0

92

30

以上

+0.5

0

取付器具

(付属品)

+0.5

0

92

30

以上

108

108

(48×N-4)

+0.5

0

92

(96×N-4)

+0.5

0

92

●

■

パネル穴あけ図

●

●

SDC35

pv

sp

out

ot2ot1ev3ev2ev1rspman

display

mode

enter

para

C36

man

pv

rsp

ev1

ev2

ev3

sp

ot1

out

ot2

mode

para

取り扱い上の注意

• 付属の取付器具のねじを締めて、取付器具が動かなくなっ

たガタのない状態からさらに半回転だけねじを回してパネ

ルに固定してください。

ねじを締めすぎるとケースが変形するおそれがあります。

• 本器を操作される方が背面端子に触らないように、必ずパ

ネルに取りつけてください。

SDC36

display

enter

C35

30以上 44

C36

30以上 92

取り扱い上の注意

• 3台以上密着して取り付ける場合は、周囲温度は 40 ℃を

超えないようにしてください。

単位:mm

端子ねじ M3

単位:mm

+0.5

0

+0.5

0

手順2 結 線

すべての配線作業は、それぞれの地域の規則に従って、認定された経

験のある作業者が行ってください。

本器を操作される方の手が届く範囲内に、本器の主電源遮断用のス

イッチを必ず設けてください。

また、AC電源モデルの本器の電源配線には遅動タイプ(T)の定格電

流05 A、定格電圧250 Vのヒューズを設けてください。(IEC127)

本器側面の端子配列ラベルで使用している記号の意味は下表のとおり

です。

記 号 内 容

取り扱い上の注意

AC24 V/DC24 V

CT1

CT2

MFB

J2

〜 交 流

• 結線は本器の形番と端子番号を本体側面のラベルで確認してか

ら行い、必ず間違いのないことを確認してください。

• 端子の接続にはM3のねじに適合する圧着端子を使ってください。

• 入出力信号線は動力線や電源線から50 cm 以上離してください。

また、同一の配線管やダクト内を通さないでください。

• 圧着端子などが隣の端子と接触しないようにしてください。

• 一つの端子ねじに複数の圧着端子を配線する場合は、あらかじめ

圧着端子を曲げ、2 枚までの接続としてください。

• カレントトランスにはヒータ電流の流れる導線を貫通させてくだ

さい。また、ヒータ電流は仕様に記載した許容電流を超えて使用

しないでください。本器を破損することがあります。

• カレントトランス入力は位相制御に使用できません。

• 本器の電源がOFF のときは電流入力回路が切断されます。複数

台の電流入力を直列計装し、本器の電源を個別にON/OFFさせ

たい場合は、別売の抵抗(81401325)をつけて電圧入力レンジ

で受けてください。

• 制御出力1 と制御出力 2 の間は絶縁されていません。必要に応じ

てアイソレータを使用してください。

• RS-485の伝送路の両端に終端抵抗をつけないでください。通信

できなくなります。

• モータ駆動リレー出力に接続するモータ電源がAC100/200 V

用のモータを使用する場合は、外部に補助リレーを使用するこ

とをお勧めします。補助リレーを使用しない場合は、お客様の

ご使用条件(モータの使用電圧や突入電流、開閉頻度など)で、

十分ご確認のうえご使用ください。

• モータ駆動端子⑬、⑭、⑮とMFB 入力端子⑦、⑧、⑨は、同一

ダクト内に配線したり、6心ケーブルで配線しないでください。

モータ起動時のノイズなどで本器の故障の原因になります。

• 本器に接続する機器または装置は、本器の電源、入出力部の最

高使用電圧に適した強化絶縁が施されているものを使用してく

ださい。

• 本器は電源投入後、安定のため最大5 秒間は機能しないように

なっています。その後運転状態に入りますが、規定の精度を満

足させるためには、ウォームアップ時間が30分以上必要です。

AC電源

AC100~240 V

DC電源

(無極性)

リレ ー

リレ ー

独立接点

入 力

7

8

9

Y

7

T

8

熱電対

G

9

測温抵抗体

直流電流

直流電圧

1

2

1

2

イ ベ ント 出 力

3

3

2

4

1

5

COM

6

3

2

4

5

1

6

PV入力

-

+

C

B

A

+

mA

-

V

+

10

11

12

10

11

12

10

11

12

直 流

注意、感電の危険

注 意

1

13

2

14

3

15

4

16

5

17

6

18

7

19

8

20

9

21

10

22

11

23

12

24

NO

13

14

NC

15

OPEN

13

14

CLOSE

15

13

14

13

14

15

DI

COM

RSP

mA/V

COM

通 信

DA

DB

SG

+

-

+

1

-

2

+

4

18

3

19

2

20

1

21

18

+

-

19

2DI

20

1

21

22

23

24

リレ ー

モ ータ 駆 動リレ ー

補助出力

16

+

-

17

デジタル 入力

RSP/DI

RSP入力

デジタル 入力

RS-485

電 流また は

連続電圧

Page 3

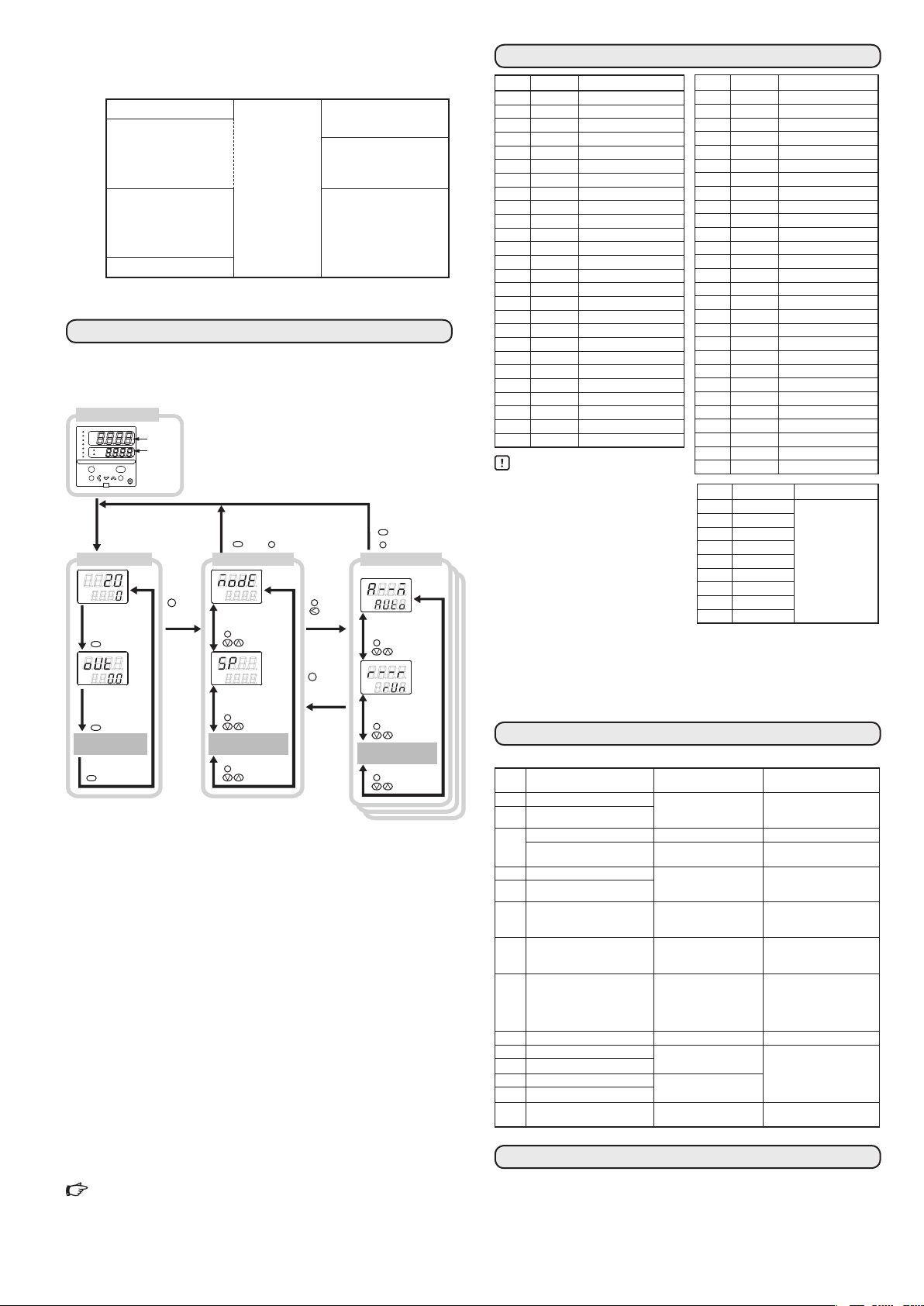

●

電源投入時表示

この図に書いてある表示や設定の状態は、説明のための例です。

実際には形番や設定内容により表示しない表示や設定があります。

入出力間アイソレーション

実線で囲まれたものは他の信号と絶縁されています。入出

力の有無は形番によります。

電 源

PV入力

CT入力1

CT入力2

MFB入力

ローダ通信

デジタル入力1

内部回路

デジタル入力2

デジタル入力3

デジタル入力4

RS-485通信

RSP入力

* 独立接点の場合、イベント出力1 とイベント出力 2 の間は絶縁され

ています。

設定操作

●

キー操作フロー図

データの設定方法には、標準タイプと特殊タイプがあります。

ここでは標準タイプで説明しています。

SDC36

man

pv

rsp

ev1

ev2

ev3

sp

ot1

out

ot2

mode

para

運転表示 バンク選択表示 バンク設定表示

PV/SP表示

display

MV表示

display

その他の表示・設定

(displayキー操作の繰り返し)

display

キーを 押す

手順3 PV レンジ種類の設定(PV レンジ表参照)

バンク選択表示が

キーを押して

キーを押してください。

≫第1 表示部にC0 1 が表示されます。

[enter]キーを押してください。

≫第2 表示部が点滅します。

PVレンジ表を参照し[<][∨][∧]キーを押して、希望のセン

サタイプのC0 1設定値を表示させてください。

[enter]キーを押してください。

≫点滅が終了し、設定が確定します。

手順4 SP の設定

運転表示のときに[enter]キーを押してください。

≫第2 表示部の SP 値が点滅します。

[∨][∧]キーを押して、希望の SP 値に設定してください。

[enter]キーを押してください。

≫点滅が終了し、設定したSP 値が点灯し確定します。

取り扱い方法、設定方法の詳細は、別冊の

デジタル指示調節計 SDC35/36 詳細編 CP-SP-1150

または、デジタル指示調節計SDC35/36 キー操作ダイジェ

スト CP-SP-1203 をご覧ください。

display

enter

キーを 押す

キーを 押す

消 灯

電源投入後 5~6 秒 の間は、第1表示部・第2表示部

消 灯

が 消 灯 の ま ま 、モ ー ド 表 示 灯 が 順 に 点 灯 し て い き ま す 。

すべてが点灯すると、運転表示に切り替わります。

3分以上キーを押さない

display

mode

または キーを押す

para

キーを

2秒以上

押す

Stup

モ ード バ ン ク 選 択

para

キーを 押す

キーを 押す

SPバンク選択

para

キーを 押す

キーを 押す

その他のバンク

(para、∨、∨キー操作の繰り返し)

para

キーを 押す

キーを 押す

MOdE

(モードバンク選択)のときに[∨][∧]

(セットアップバンク)を表示させ、[enter]

制御出力1

制御出力2

補助出力

イベント出力1

イベント出力2

イベント出力3

各 バンク

選択表示で

enter

または

キーを

押す

para

キーを

2秒以上

押す

*

*

3分以上

キーを 押さない

display

または

mode

キーを 押す

( モ ード バ ン ク の 例 )

AUTO/MANUAL

切り替え

para

キーを 押す

キーを 押す

RUN/READY

切り替え

para

キーを 押す

キーを 押す

その他の設定

(para、∨、∨キー操作の繰り返し)

para

キーを 押す

キーを 押す

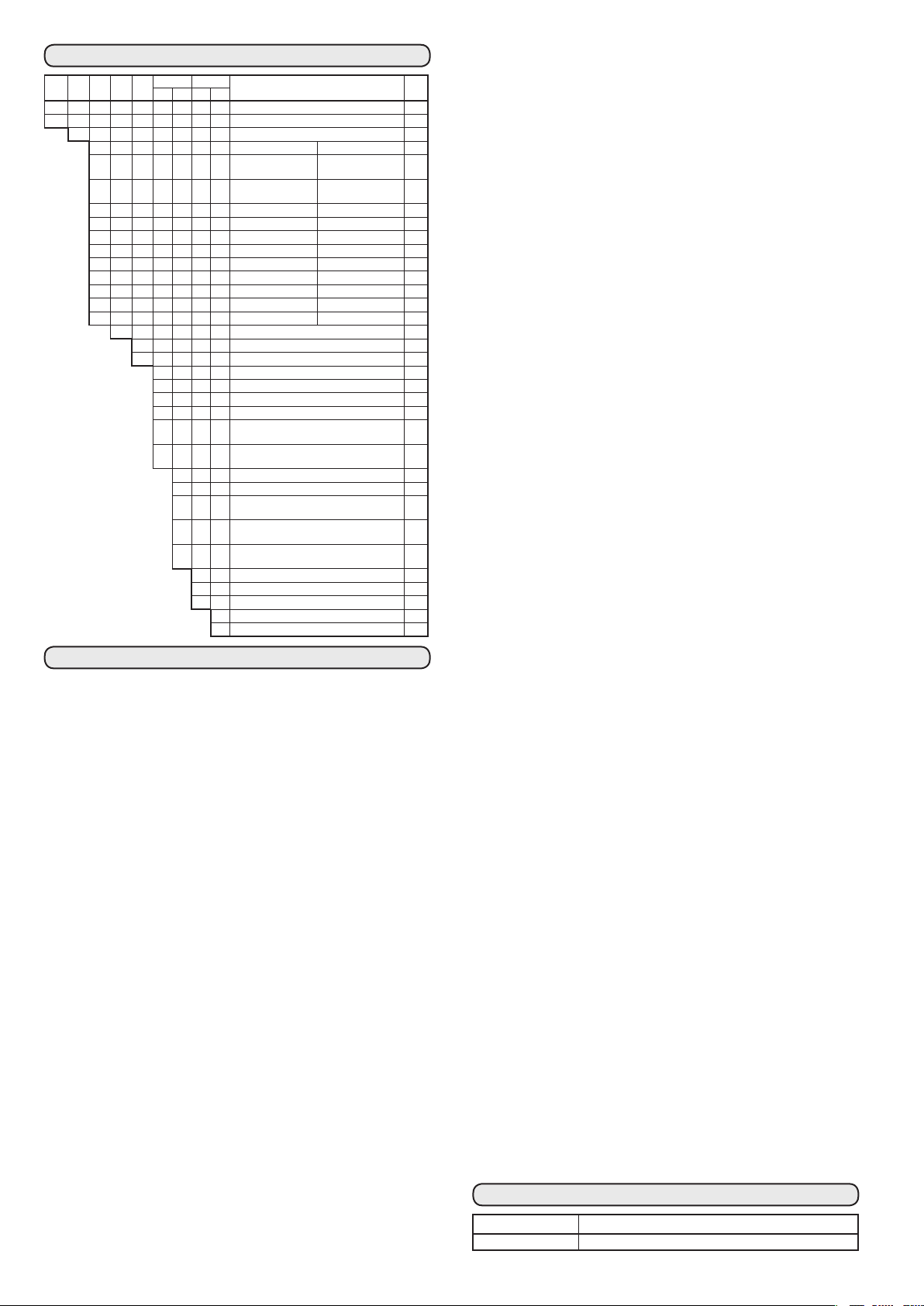

PVレンジ表

C01

設定値

C01

設定値

センサ タイプ

レンジ

1 K -200〜+1200 ℃

2 K 0〜1200 ℃

3 K 0.0〜800.0 ℃

4 K 0.0〜600.0 ℃

5 K 0.0〜400.0 ℃

6 K -200.0〜+400.0 ℃

7 K -200.0〜+200.0 ℃

8 J 0〜1200 ℃

9 J 0.0〜800.0 ℃

10 J 0.0〜600.0 ℃

11 J -200.0〜+400.0 ℃

12 E 0.0〜800.0 ℃

13 E 0.0〜600.0 ℃

14 T -200.0〜+400.0 ℃

15 R 0〜1600 ℃

16 S 0〜1600 ℃

17 B 0〜1800 ℃

18 N 0〜1300 ℃

19 PL II 0〜1300 ℃

20 WRe5-26 0〜1400 ℃

21 WRe5-26 0〜2300 ℃

22 Ni-Ni・Mo 0〜1300 ℃

23 PR40-20 0〜1900 ℃

24 DIN U -200.0〜+400.0 ℃

25 DIN L -100.0〜+800.0 ℃

26

金鉄クロメル

0.0K〜360.0K

取り扱い上の注意

• 精度はレンジにより異なります。

• No.17(センサタイプ B)は、

260 ℃以下:±4.0 %FS、

260 〜 800 ℃:± 0.4 %FS、

800 〜 1800 ℃:± 0.2 %FS

20 ℃未満は表示されません。

No.15(センサタイプR)、

No.16(センサタイプS)は、

100 ℃以下:±0.2 %FS、

100 〜 1600 ℃:± 0.15 %FS

No.23(センサタイプ PR40-20)は、0 〜

300 ℃:±2.5 %FS、

センサ タイプ

41 Pt100 -200.0〜+500.0 ℃

42 JPt100 -200.0〜+500.0 ℃

43 Pt100 -200.0〜+200.0 ℃

44 JPt100 -200.0〜+200.0 ℃

45 Pt100 -100.0〜+300.0 ℃

46 JPt100 -100.0〜+300.0 ℃

47 Pt100 -100.0〜+200.0 ℃

48 JPt100 -100.0〜+200.0 ℃

49 Pt100 -100.0〜+150.0 ℃

50 JPt100 -100.0〜+150.0 ℃

51 Pt100 -50.0〜+200.0 ℃

52 JPt100 -50.0〜+200.0 ℃

53 Pt100 -50.0〜+100.0 ℃

54 JPt100 -50.0〜+100.0 ℃

55 Pt100 -60.0〜+40.0 ℃

56 JPt100 -60.0〜+40.0 ℃

57 Pt100 -40.0〜+60.0 ℃

58 JPt100 -40.0〜+60.0 ℃

59 Pt100 -10.00〜+60.00 ℃

60 JPt100 -10.00〜+60.00 ℃

61 Pt100 0.0〜100.0 ℃

62 JPt100 0.0〜100.0 ℃

63 Pt100 0.0〜200.0 ℃

64 JPt100 0.0〜200.0 ℃

65 Pt100 0.0〜300.0 ℃

66 JPt100 0.0〜300.0 ℃

67 Pt100 0.0〜500.0 ℃

68 JPt100 0.0〜500.0 ℃

C01

設定値

入力タイプ レンジ

81 0 〜 10 mV -1999〜+9999

-10〜+10 m V

82

83 0 〜 100 mV

84 0 〜 1 V

の範囲でスケー

リング

小数点位置可変

86 1 〜 5 V

87 0 〜 5 V

88 0 〜 10 V

89 0 〜 20 mA

90 4 〜 20 mA

300 〜 800 ℃:± 1.5 %FS、800 〜 1900 ℃:±0.5 %FS

No.26(センサタイプ金鉄クロメル)は、± 1.5 K となります。

No.55 〜 62(センサタイプPt100または JPt100)、

No.81(センサタイプ0 〜 10 mV)は、± 0.15 %FS ±1digit。

• 小数点表示のあるレンジは、小数点以下一桁表示ができます。

• 使用するセンサのタイプとレンジのC0 1設定値を正しく設定してください。大

きな温度誤差などで異常な出力をする場合があります。

アラームコード一覧表

本器異常時のアラーム表示と対策を示します。

アラーム

コード

AL0 1

AL02

AL03

AL05

AL06

AL07

AL 10

AL 1 1

(CT入力1/2 の片方または

AL70

AL95

AL96

AL97

AL98

AL99

*

RSPモード時だけ表示

異常名称 原 因 処 置

PV入力異常(オーバーレンジ) • センサ断線

PV入力異常(アンダーレンジ)

• 誤配線

• PV レンジ種類誤設定

• 配線の確認

• PV レンジ種類の再設定

CJ異常 • 端子温度異常(熱電対) • 周囲温度の確認

PV入力異常 • センサ断線

RSP入力異常*(オー バーレンジ )

RSP入力異常*(アン ダーレンジ )

MFB入力異常 • 断線

モータ調整異常 • 断線

CT入力異常(オーバーレンジ)

両方)

• 誤配線(測温抵抗体)

• センサ断線

• 誤配線

• RSP レンジ種類誤設定

• 誤配線

• 誤配線

• モータ電源断

• 表示範囲上限を超える

電流を測定

• CT ターン数誤設定

• CT 電力線貫通回数誤設定

• 誤配線

• 配線の確認

• 配線の確認

• RSP レンジ種類の再設定

• 配線の確認

• MFB 入力値の確認

• 全開調整値、全閉調整値の確認

• 配線の確認

• モータ電源の確認、再調整

• 全開調整値、全閉調整値の確認

• 表示範囲に合ったターン

数のCT使用

• CT ターン数の再設定

• CT 電力線貫通回数の再設定

• 配線の確認

A/D変換異常 • A/D変換部故障 • 本体交換

パラメータ異常 • データ確定中に電源断

調整データ異常

パラメータ異常(RAM 領域)

• ノイズなどでデータ破壊

• ノイズなどでデータ破壊

調整データ異常(RAM 領域)

ROM異常 • ROM(メモリ)故障 • 電源再投入

• 電源再投入

• データの再設定(

は設定データ、

は調整データ)

• 本体交換

• 本体交換

保 守

清 掃 :

部品交換 :部品交換は、おやめください。

ヒューズ交換:AC電源モデルで電源配線に設けたヒューズを交換するときは、

J3

本器の汚れを取る場合は、柔らかい布での乾拭きを行ってください。

シンナー、ベンゼンなどの有機溶剤や洗剤は使用しないでください。

必ず指定の規格品を使用してください。規格 IEC127、

遮断速度 遅動タイプ(T)、定格電圧 250 V、定格電流 05 A

レンジ

AL95/97

AL96/98

Page 4

形番構成表

基本形番取り 付け制御出力PV入力電源

C35 マスクサイズ48 mm× 96 mm

C36 マスクサイズ96 mm× 96 mm

T パネル取付形

R0 リレー出力 NO なし(制御出力 1 の

*1

R1 モータ駆動リレー 出

V0 電圧パ ルス出力

VC 電圧パル ス出力

VD 電圧パル ス出力

VV 電圧パ ルス出力

C0 電流出力 なし

CC 電流出力 電流出力

CD 電流出力 連続電圧出力

D0 連続電圧出力 なし

DD 連続電圧出力 連続電圧出力

*

1 DC 電源では選択できません

*

2 SSR 駆動用

*

3 カレントトランスは別売です

*

4 制御出力がR1の場合は、カレン

トトランス入力はつきません

MFB入力になります

オプ ション

追加処理 仕 様 備考

1 2 1 2

制御出力1 制御出力 2

力OPEN側

U

A AC 電源(AC100 〜 240 V)

D DC電源(AC24 V/DC24 V)

1

2

3

*1

4 イベントリレー出力2 点(独立接点)

*1

5 イベントリレー出力 2点(独立接点)、

*1

6 イベントリレー出力 2点(独立接点)、

0 なし

*3 *4

1

*3 *4

2 カレントトランス入力2 点、

*3 *4

3 カレントトランス入力2 点、

*3 *4

4 カレントトランス入力2 点、

ユニバーサル

イベ ントリレー出力 3 点

イベントリレー出力 3 点、補助出力(電流出力)

イベントリレー出力 3 点、補助出力(電 圧出力)

補助出力(電流出力)

補助出力(電圧出力)

カレントトランス入力2点、デジタル入力4点

デジタル入力4点、RS-485 通信

デジタル入力2点、RSP 入力

デジタル入力2点、RSP入力、RS-485 通信

0 追加処理なし

D 検査成績書添付

Y トレーサビリティ証明対応

0 なし

A UL 対応品

リレー出力NC)

モータ駆動リレー 出

力CLOSE側

*2

*2

*2

連続電 圧出力

*2

電圧パ ルス出力

なし

電流出力

*2

仕 様

zPV入力

熱電対 : K、J、E、T、R、S、B、N(JIS C 1602-1995)

測温抵抗体 :Pt100(JIS C 1604-1997)、JPt100(JIS C 1604-1989)

直流電圧 :0 〜 10 mV、−10 〜+10 mV、0 〜 100 mV、0 〜 1 V、

直流電流 :0 〜 20 mA、4 〜 20 mA

サン プリング 周 期

指示精度 :± 01 % FS±1digit、熱電対の負の領域は

冷接点補償精度 :± 05 ℃(周囲温度23± 2 ℃にて)

冷接点補償方法 :

許容入力 :• −05〜+12 V(熱電対、測温抵抗体、直流電圧)

zデジタル入力

点 数 : 2 点または4点

入力形式 :無電圧接点またはオープンコレクタ

許容ON接点抵抗

許容OFF接点抵抗

許容ON残留電圧

ON時端子電流 :約75 mA(短絡時)、約50 mA(接点抵抗 250 Ω時)

最小ホールド時間

zカレントトランス入力

点 数 : 2点

入力対象 :

計測電流下限 :AC04 A(800 ターン、電力線貫通回数 1にて)

計測電流上限 :AC500 A(800 ターン、電力線貫通回数 1にて)

許容計測電流 :

表示範囲下限 :AC00 A

表示範囲上限 :AC700 A(800 ターン、電力線貫通回数 1にて)

表示精度 :± 5 %FS

表示分解能 :AC01 A

PL II(Engelhard Industries 資料(ITS90))

WRe5-26(ASTM E988-96(Reapproved 2002))

Ni-Ni・Mo(ASTM E1751-00)

PR40-20(Johnson Matthey 資料)

DIN U、DIN L(DIN 43710-1985)

金鉄クロメル(林電工資料)

1 〜 5

V、0 〜 5 V、0 〜 10 V

:100 ms

2 % FS± 1digit(周囲温度23 ± 2 ℃にて)

±0

±10 ℃(周囲温度 15 〜 35 ℃にて)

±15 ℃(周囲温度 0 〜 15 ℃、35 〜 50 ℃にて)

本器内にて補償、および本器外での補償(0 ℃のみ)選択可能

• 30 mA以下または4 V以下(直流電流)

許容入力値以上の電圧または電流が入力されると破損す

ることがあります。

:250 Ω以下

:100 kΩ以上

:10 V以下

:200 ms以上

カレントトランス 巻数100〜4000ターン(100ターン単位で対応)

計算式(ターン数÷(2000 ×電力線貫通回数))

計算式(ターン数÷(16 ×電力線貫通回数))

AC700 A 以下(800 ターン、電力線貫通回数1にて)

計算式(ターン数÷(16 ×電力線貫通回数)×14)

計算式(ターン数÷(16 ×電力線貫通回数)×14)

MFB

付き

zモータフィードバックポテンショメータ入力(R1モデル)

許容抵抗値 :100 〜 2500 Ω

断線検出 :

AL07

表示

zRSP入力

入力種類 :リニア 0〜20 mA/4〜20 mA または

サンプリング周期 :100 ms

指示精度 : ±01 %FS±1 digit(周囲温度23±2 ℃にて)

入力断線時動作 :ダウンスケール+

リニア0〜5

V/1〜5 V/0〜10 V

AL06

z制御出力

• リレー出力

接点定格 :

制御出力1 NO側AC250 V/DC30 V、3 A(抵抗負荷)

制御出力2 NC側AC250 V/DC30 V、1 A(抵抗負荷)

寿 命 : NO 側5万回以上、NC 側 10 万回以上

最小開閉仕様 :5 V、100 mA

最小開時間/閉時間

:250 ms

• モータ駆動リレー出力(R1 モデル)

接点形式

接点定格 : AC250 V、8 A(抵抗負荷)

寿 命 : 12万回以上(定格時の抵抗負荷にて)

最小開閉仕様

:1c 2 回路(a 接点側だけ)

AC250 V、2 A(cos φ= 04)

DC24 V、25 A(L/R = 07 ms)

10万回以上(定格時の誘導負荷にて)

:DC24 V、40 mA

• 電圧パルス出力(SSR 駆動用)

開放時端子間電圧

:DC19 V ± 15 %

内部抵抗 : 82 Ω± 05 %

許容電流 : DC24 mA 以下(これ以上の電流を出力すると出力回路が

最小OFF時間/ON時間

破損する場合があります)

:時間比例周期 10 s 未満のとき 1 ms

時間比例周期10 s以上のとき250 ms

• 電流出力

出力形式 : DC0〜20 mAまたは4〜20 mA電流出力

許容負荷抵抗 :600 Ω以下

出力精度 :

±01 % F S( 周 囲 温 度 2 3 ± 2 ℃ に て )た だ し 0 〜 1 mAは±1 %FS

• 連続電圧出力

出力形式 : DC0〜5 V/1〜5 Vまたは0〜10 V電圧出力

許容負荷抵抗 :1000 Ω以上

出力精度 :

±01 % F S( 周 囲 温 度 2 3 ± 2 ℃にて)ただし0〜005 Vは±1 %FS

z補助出力

• 電流出力

出力形式 : DC0〜20 mAまたは4〜20 mA電流出力

許容負荷抵抗 :600 Ω以下

出力精度 :

±01 %FS(周囲温度23±2 ℃ に て )た だ し 0 〜 1 mAは±1 %FS

• 連続電圧出力

出力形式 : DC0〜5 V/1〜5 Vまたは0〜10 V電圧出力

許容負荷抵抗 :1000 Ω以上

出力精度 :

±01 %FS(周囲温度23±2 ℃にて)ただし0〜005 Vは±1 %FS

zイベントリレー出力(ev1〜ev3)

接点定格 :AC250 V/DC30 V 2 A(抵抗負荷)

寿 命 :10 万回以上

最小開閉仕様 :5 V、10 mA(参考値)

zRS-485通信

伝送路 : 3 線式

伝送速度 :4800、9600、19200、38400 bps

通信 プロトコル :CPL、Modbus 準拠

終端抵抗 :接続禁止

z環境条件

• 動作条件

周囲温度 : 0〜50 ℃(密着取付の場合は0〜40 ℃)

周囲湿度 : 10〜90 %RH(結露なきこと)

定格電源電圧 :AC 電源モデル AC100 〜 240 V 50/60 Hz

電源電圧範囲 :

DC電源モデル AC24 V 50/60 Hz、DC24 V

AC電源モデル AC85〜264 V 50/60±2 Hz

DC電源モデル AC216〜264

V 50/60±2 Hz、DC216〜264 V

• 輸送条件

周囲温度 : − 20〜+ 70 ℃

周囲湿度 : 10〜95 %RH(結露なきこと)

zその他仕様

消費電力 :

停電不感時間 :

高 度 : 2000 m 以下

質 量 :

端子 ねじ 締付トルク :

適合規格 : EN61010-1、

過電圧カテゴリ :Category Ⅱ(IEC60364-4-443、IEC60664-1)

許容汚染度 : Pollution degree2

AC 電源モデル 12 VA以下

DC 電源モデル 12

AC電源モデル 20

DC電源モデル 停電なきこと

C35 48×96 約 250

C36 96×96 約 300

N・m

04〜06

EN61326-1(For use in industrial locations)

EMC試験中、±10

動が生じる場合があります。

VA以下(AC24 V ) 8 W以下(DC24 V)

ms以下

g(専用取付器具を含む)

g(専用取付器具を含む)

%FSに相当する指示値や出力値の変

付属品一覧表

名 称 形 番

取付器具 81409654-001(付属品)

J4

Page 5

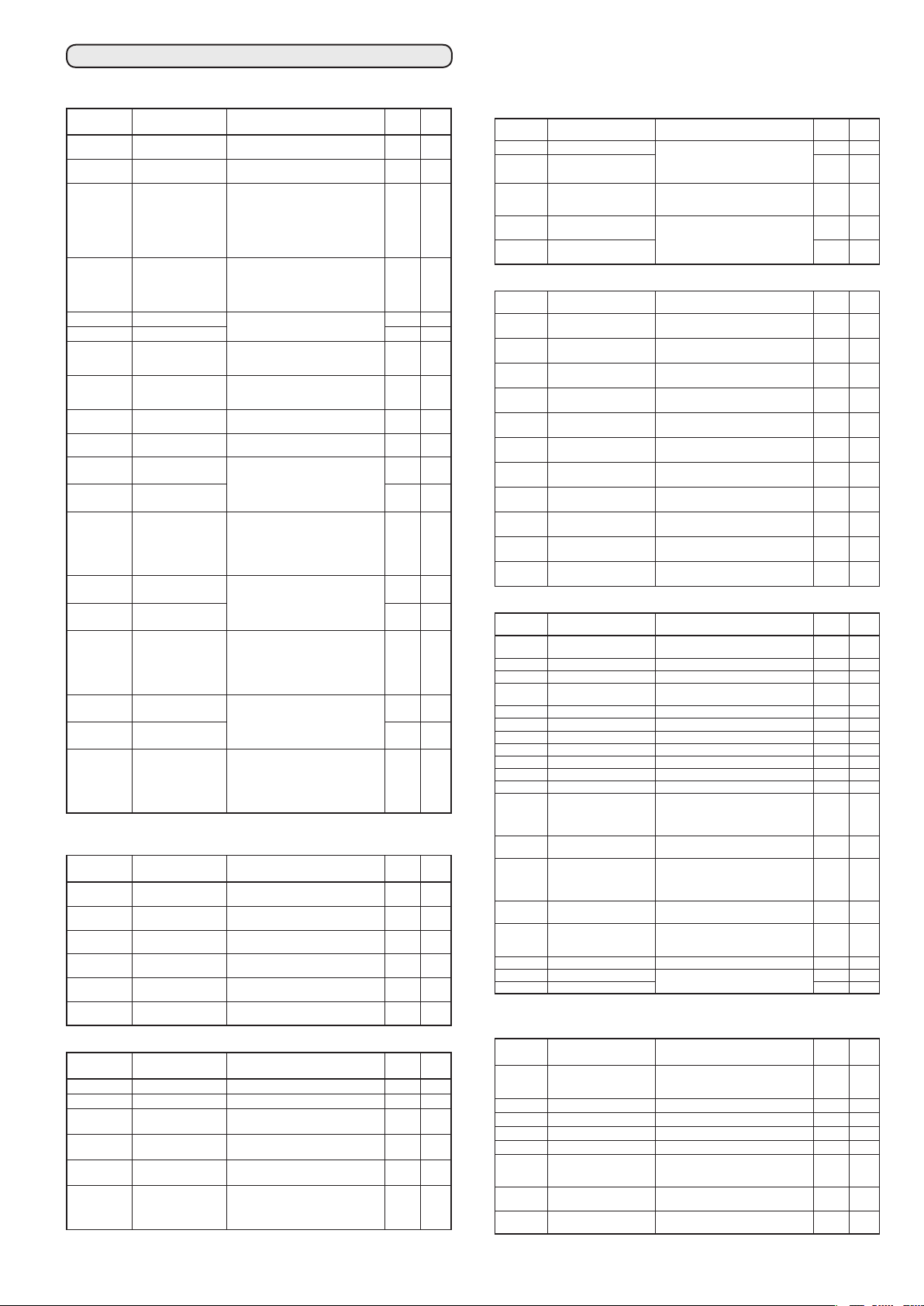

SDC35/36パラメータ一覧表

【運転表示一覧表】

■

運転表示

表 示 項 目 内 容 初期値 表 示

第1表示:PV

第2表示:SP

LSP 1

第2表示:LSP

ST. 1-�

(表示例)

ステップ番号

第2表示:

ステップ残り時間

第1表示:PV

第2表示:MV

HEAt

COOL

Fb

第1表示:PV

(表示例)

At 1

Ct 1

Ct2

E 1

E 1.Sb

t 1.--�

(表示例)

E2

E2.Sb

t2.--�

(表示例)

E3

E3.Sb

t3.--�

(表示例)

SP(目標値) SPリミット下限(

LSP組番号(第1桁=

(表示例)

最右桁の数値)

ステップ運転残り時間 設定不可

MV(操作量) -10.0 〜+110.0 %

加熱MV(操作量) 設定不可

冷却MV(操作量) — 0

MFB(モータ開度

フィードバック値)

AT進捗(第1桁=最右

桁の数値)

CT(カレントトランス)

入力1電流値

CT(カレントトランス)

入力2電流値

内部イベント1

主設定

内部イベント1

副設定

タイマ残り時間1 設定不可

内部イベント2

主設定

内部イベント2

副設定

タイマ残り時間2 設定不可

内部イベント3

主設定

内部イベント3

副設定

タイマ残り時間3 設定不可

上 限(

1 〜 LSP使用組数(

第1表示:「St.」の横にステップ番号と、

上昇ランプ、下降ランプ、ソークの区別

を表示

第2表示:ステップ運転時間単位(

に従った単位(0.1 s、min. s、h. min の

どれか)で表示

AUTOモードで設定不可

(数値の点滅なし)

MANUALモードで設定可能

(数値の点滅あり)

-10.0 〜+ 110.0 %

設定不可

-10.0 〜+ 110.0 %

推定の場合、0.0 〜 100.0 %で点滅表示

設定不可

1 〜 :AT 起動中(値が減っていく)

0 :AT 終了

設定不可 — 0

設定不可 — 0

内部イベント動作種類により設定可能な

範囲が異なる

-1999 〜+ 9999 U:下記以外の場合

0 〜 9999 U:設定値が絶対値の場合

-199.9 〜+ 999.9 %:MVの場合

第1表示:「t 1.」の横に ONディレイ、

OFFディレイの区別を表示

第2表示:内部イベント 1 ディレイ

時間単位(E

(0.1 s、s、minのどれか)で表示

内部イベント動作種類により設定可能な

範囲が異なる

-1999 〜+ 9999 U:下記以外の場合

0 〜 9999 U:設定値が絶対値の場合

-199.9 〜+ 999.9 %:MVの場合

第1表示:「

OFFディレイの区別を表示

第2表示:内部イベント 2 ディレイ

時間単位(

(0.1 s、s、minのどれか)で表示

内部イベント動作種類により設定可能な

範囲が異なる

-1999 〜+ 9999 U:下記以外の場合

0 〜 9999 U:設定値が絶対値の場合

-199.9 〜+ 999.9 %:MVの場合

第1表示:「

OFFディレイの区別を表示

第2表示:内部イベント 3 ディレイ時

間単位(

(0.1 s、s、minのどれか)で表示

【パラメータ設定表示一覧表】

■

モードバンク:

表 示 項 目 内 容 初期値 表 示

A--M

r--r

L--r

At

dO.Lt

C.dI 1

■

SPバンク:

表 示 項 目 内 容 初期値 表 示

RSP

PI d.r

〜

SP- 1

SP-8

〜

PI d. 1

PI d.8

〜

rMP. 1

rMP.8

〜

TI M. 1

TI M.8

MOdE

AUTO/MANUAL

モード切り替え

RUN/READYモード

切り替え

LSP/RSPモード

切り替え

AT停止/ 起動切り替え

全DOラッチ解除

通信DI1

AUTO

MAN

:MANUAL(手動)モード

RUN

:RUN モード

RDY

:READY モード

LSP

:LSP モード

RSP

:RSP モード

At.OF

At.ON

Lt.ON

Lt.OF

dI .OF

dI .On

SP

RSP 設定不可 - 0

PID組番号(RSP用) 1〜8 1 1

LSP1 〜 8組の SP SP リミット下限(

PID組番号

(LSP1 〜 8用)

勾配(LSP1 〜 8用) 0 〜 9999(小数点位置は PVの小数点位

時間(LSP1 〜 8用) 0.0 〜 999.9(ステップ運転時間単位が

上 限(

1〜8 1 1

置とSPランプ単位で決まる)

0.1 sの場合)

0 〜 9999(ステップ運転時間単位が 1 s

または1 minの場合)

C07

C08

E3.C3

:AUTO(自動)モード

:AT停止

:AT起動

:ラッチ継続

:ラッチ解除

:OFF

:ON

C08

)〜 SPリミット

)

C30

、最大8) 1 0

1.C3

の3桁目)に従った単位

t2.

」の横に ONディレイ、

E2.C3

の3桁目)に従った単位

t3.

」の横に ONディレイ、

の3桁目)に従った単位

C07

)〜SP リミット

)

C33

)

レベル

0 0

— 0

— 0

— 0

— 0

— 0

0 0

0 0

— 0

0 0

0 0

— 0

0 0

0 0

— 0

レベル

AUTO 0

RUN 0

LSP 0

AT停止 0

ラッチ 継続0

OFF 0

レベル

0 0

0 1

0 1

表示レベルの意味 0:C79=0、1、2で表示

1:C79=1、2で表示

2:C79=2で表示

初期値は形番により変わるものがあります。

■

イベントバンク:Ev (EvCF設定後のEv設定値)

表 示 項 目 内 容 初期値 表 示

E 1〜E8

E 1.Sb

E8.Sb

E 1.Hy

E8.Hy

E 1.On

E8.On

E 1.Of

E8.Of

P- 1

P-8

I - 1

I -8

d- 1

d-8

rE- 1

rE-8

OL- 1

OL-8

OH- 1

OH-8

P- 1C

P-8C

I- 1C

I-8C

d- 1C

d-8C

OL. 1C

OL.8C

OH. 1C

OH.8C

CtrL

At.OL

At.OH

dI FF

OFFS

FL

rA

bI

FL2

rA2

bI 2

CyU

Cy

CyU2

Cy2

tP.ty

OUtL

SPU

SPd

*

1 出力にリレー出力を含む場合

*

2 出力にリレー出力を含まない場合

At.ty

JF.bd

SP.LG

At-P

At-I

At-d

Ctr.A

JF.Ov

*

内部イベント1 〜 8 主設定 - 1999 〜+9999

〜

内部イベント1 〜 8 副設定 0 0

〜

内部イベント1 〜 8

ヒステリシス

〜

内部イベント1 〜 8

ONディレイ

〜

内部イベント1 〜 8

OFFディレイ

■

PIDバンク:PI

表 示 項 目 内 容 初期値 表 示

〜

〜

〜

〜

(PID1 〜 8組)

〜

〜

〜

(PID1 〜 8組)

〜

(PID1 〜 8組)

〜

(PID1 〜 8組)

〜

(PID1 〜 8組)

〜

(PID1 〜 8組)

■

パラメータバンク:

表 示 項 目 内 容 初期値 表 示

■

拡張調整バンク:

表 示 項 目 内 容 初期値 表 示

位置比例制御 (R1)モデル:1.00、位置比例制御以外のモデル:0.00

d

比例帯(PID1 〜 8組) 0.1 〜 999.9 % 5.0 0

積分時間(PID1 〜 8組)

微分時間(PID1 〜 8組)

マニュアルリセット

操作量下限(PID1〜8組)

操作量上限(PID1〜8組)

冷却側比例帯

冷却側積分時間

冷却側微分時間

冷却側操作量下限

冷却側操作量上限

制御方式 0:ON/OFF制御

AT時操作量下限 - 10.0 〜+ 110.0 % 0.0 0

AT時操作量上限 - 10.0 〜+ 110.0 % 100.0 0

ON/OFF制御

ディファレンシャル

ON/OFF制御動作点オフセット

PVフィルタ 0.0 〜 120.0 s 0.0 0

PVレシオ 0.001 〜 9.999 1.000 1

PVバイアス - 1999 〜+9999 U 0 0

RSPフィルタ 0.0 〜 120.0 s 0.0 1

RSPレシオ 0.001 〜 9.999 1.000 1

RSPバイアス - 1999 〜+9999 U 0 1

時間比例単位1

時間比例周期1 5 〜 120 s

時間比例単位2

時間比例周期2 5 〜 120 s

時間比例動作種類 0:制御性重視型

操作量変化リミット 0.0 〜 999.9 %/s(0.0 はリミットなし) 0.0 2

SPランプ上昇勾配 0.0 〜 999.9 U(0.0Uは勾配なし) 0.0 2

SPランプ下降勾配 0.0 2

Et

AT種類 0:通常(標準的な制御特性)

JF整定幅 0.00 〜 10.00 0.30 2

SPラグ定数 0.0 〜 999.9 0.0 2

AT時比例帯調整係数 0.00 〜 99.99 1.00 2

AT時積分時間調整係数

AT時微分時間調整係数

制御アルゴリズム 0:PID(従来型 PID)

JFオーバーシュート

抑制係数

小数点位置は内部イベント動作種類に合

うように変わります

一部の動作種類では、0〜9999となります

0 〜 9999

小数点位置は内部イベント動作種類に合

うように変わります

0.0 〜 999.9(ディレイ時間単位 0.1 sの

場合)

0 〜 9999(ディレイ時間単位 0.1 s以外

の場合)

0 〜 9999 sまたは 0.0 〜 999.9 s

(0で積分動作なし)

0 〜 9999 sまたは 0.0 〜 999.9 s

(0で微分動作なし)

-10.0 〜+ 110.0 % 50.0 0

-10.0 〜+ 110.0 % 0.0 1

-10.0 〜+ 110.0 % 100.0 1

0.1 〜 999.9 % 5.0 0

0 〜 9999 sまたは 0.0 〜 999.9 s

(0で積分動作なし)

0 〜 9999 sまたは 0.0 〜 999.9 s

(0で微分動作なし)

-10.0 〜+ 110.0 % 0.0 1

-10.0 〜+ 110.0 % 100.0 1

PArA

1:PID固定

0 〜 9999 U 5 0

-1999 〜+ 9999 U 0 2

0:1 s 単位

1:0.5 s固定(サイクルタイム設定不可)

2:0.25 s固定(サイクルタイム設定不可)

3:0.1 s固定(サイクルタイム設定不可)

*1

*2

1 〜 120 s

0:1 s 単位

1:0.5 s固定(サイクルタイム設定不可)

2:0.25 s固定(サイクルタイム設定不可)

3:0.1 s固定(サイクルタイム設定不可)

*1

*2

1 〜 120 s

1: 操作端寿命重視型(時間比例周期内

では1回だけの ON/OFF 動作)

即応(外乱に速やかに反応する制御特性)

1:

2: 安定(PV の上下動が少ない制御特性)

0.00 〜 99.99 1.00 2

0.00 〜 99.99 1.00

1:Ra-PID(高性能型 PID)

0 〜 100 0 1

J5

0 0

5 0

0 2

0 2

120 0

30 0

120 0

30 0

0

または1

0 2

10

または2

0 2

10

または2

0

または1

0 0

または

*

0.00

0 1

レベル

レベル

レベル

0

0

0

2

レベル

2

Page 6

■

ゾーンバンク:

表 示 項 目 内 容 初期値 表 示

ZN- 1

ZN-2

ZN-3

ZN-4

ZN-5

ZN-6

ZN-7

ZN.df

ゾーン1 - 1999 〜+9999U 9999U 2 ゾーン PID

ゾーン2 9999U 2

ゾーン3 9999U 2

ゾーン4 9999U 2

ゾーン5 9999U 2

ゾーン6 9999U 2

ゾーン7 9999U 2

ゾーン用ヒステリシス 0 〜 9999 5U 2

ZONE

レベル

【セットアップ設定表示一覧表】

■

セットアップバンク:

表 示 項 目 内 容 初期値 表 示

C 0 1

C 02

C 03

C 04

C 05

C 06

C 07

C 08

C 09

C 10

C 1 1

C 12

C 13

C 14

C 15

C 16

C 17

C 18

C 19

C 20

C 2 1

C 22

C 23

C 24

C 26

C 27

C 28

C 29

C 30

C 3 1

C 32

C 33

C 34

C 35

C 36

PVレンジ種類 熱電対のレンジ:1 〜 26

温度単位 0:摂氏(℃)

冷接点補償 0:冷接点補償を行う(内部)

小数点位置 0: 小数点なし

PVレンジ下限 PVレンジ種類が熱電対、測温抵抗体の場

PVレンジ上限 PVレンジ種類が熱電対、測温抵抗体の場

SPリミット下限 PVレンジ下限〜 PVレンジ上限 0 1

SPリミット上限 1000 1

開平演算ドロップアウト 0.0 〜 100.0 %(0.0で開平演算なし) 0.0 2

RSPレンジ種類 0:4 〜 20 mA

RSPレンジ下限 -1999 〜+ 9999 U 0 0

RSPレンジ上限 1000 0

PID演算補正 0:有効

制御動作(正逆) 0:加熱制御(逆動作)

PV異常時操作量選択 0:制御演算を継続する

PV異常時操作量 -10.0 〜+110.0 % 0.0 2

READY時操作量(加熱冷

却制御の場合は加熱側)

READY時操作量(冷却側) -10.0 〜+110.0 % 0.0 1

MANUAL変更時動作 0:バンプレス

プリセットMANUAL値 - 10.0 〜+110.0 %

PID演算初期化機能選択 0:自動

PID演算初期操作量 -10.0 〜+ 110.0 % 0.0

制御パラメータ小数点 0:小数点なし

ゾーンPID動作選択 0:使用しない

加熱冷却制御選択 0:使用しない

加熱冷却切り替え 0:通常

加熱冷却制御不感帯 - 100.0 〜+ 100.0 % 0.0 0

加熱冷却制御切り替え点 - 10.0 〜+110.0 % 50.0 2

LSP使用組数 1〜8 1 0

SPランプ種類 0: 標準

SPランプ単位 0:0.1 U/s

ステップ運転時間単位 0: 0.1 s

ステップ運転

PVスタート

ステップ運転ループ 0:停止(ループしない)

CT1動作 0:ヒータ断線検出

StUP

測温抵抗体のレンジ:41 〜 68

直流電圧・直流電流のレンジ:

81 〜 84、86 〜 90

1:使用しないでください

1:冷接点補償を行わない(外部)

1: 小数点以下 1 桁

2: 小数点以下 2 桁

3: 小数点以下3桁

(熱電対/測温抵抗体の小数点付きレン

ジの場合、0 〜 1)

合、レンジの下限を表示するが、設定不可

PVレンジ種類が直流電圧、直流電流の場

合、-1999〜+9999 U

合、レンジの上限を表示するが、設定不可

PVレンジ種類が直流電圧、直流電流の場

合、-1999〜+9999 U

1:0 〜 20 mA

2:0 〜 5 V

3:1 〜 5 V

4:0 〜 10 V

1:無効

1:冷却制御(正動作)

1:PV異常時操作量を出力する

-10.0 〜+ 110.0 % 0.0 1

1:プリセット

(電源ON時に、MANUAL モードだった

ときも使用する)

1:初期化しない

2: 初期化する(現在値と異なる SP値を

入力したとき)

1: 小数点以下 1桁

(積分時間、微分時間の小数点)

1:SPによる切り替え

2:PVによる切り替え

1:使用する

1:省エネ

1: マルチランプ

2: ステップ運転 電源再投入時

ステップ停止(READY)

3: ステップ運転 電源再投入時復帰

1:0.1 U/min

2:0.1 U/h

1: 1s(コンソールは min. sで表示)

2: 1min(コンソールは h. minで表示)

0:なし

1:上昇スタート

2:下降スタート

1:ループする

2:最終ステップ継続(ループしない)

1:電流値測定

1000 0

または

50.0

または

50.0

備 考

動作選択を

使用する

C24

(

≠0)

の場合、

表示

レベル

88 0

0 0

0 2

0 0

0 0

0 0

0 2

0 0

0 2

0 1

0.0

0 2

0 2

0 2

0 0

0 1

0 2

1 2

0 2

0 2

0 2

0 0

表 示 項 目 内 容 初期値 表 示

C 37

C 38

C 39

C 40

C 4 1

C 42

C 43

C 44

C 45

C 46

C 47

C 48

C 49

C 50

C 5 1

C 52

C 53

C 54

C 55

C 56

C 57

C 58

C 59

C 60

C 6 1

C 62

1

C 63

C 64

C 65

C 66

2

C 67

C 68

C 69

C 70

C 7 1

C 72

C 73

* 制御出力の形番が R1(モータ駆動リレー出力)の場合、セットアップバンクC57の設定を「0」また

は「1」に設定した場合は「C60=1」と設定し、位置比例制御自動調整を必ず行ってください

CT1監視出力 0:制御出力1

CT1測定待ち時間 30 〜 300 ms 30 0

CT2動作 0:ヒータ断線検出

CT2監視出力 0:制御出力1

CT2測定待ち時間 30 〜 300 ms 30 0

制御出力1 レンジ 電流出力の場合

制御出力1 種類 0:MV

制御出力1 スケーリング下限

制御出力1 スケーリング上限

制御出力1

MVスケーリング幅

制御出力2 レンジ 制御出力 1 と同じ 1 0

制御出力2 種類 3 0

制御出力2 スケーリング下限

制御出力2 スケーリング上限

制御出力2

MVスケーリング幅

補助出力レンジ 制御出力 1と同じ 1 0

補助出力種類 3 0

補助出力 スケーリング下限 - 1999 〜+ 9999(小数点位置と単位

補助出力 スケーリング上限 1000 0

補助出力

MVスケーリング幅

位置比例制御方法選択 0: MFB 制御+推定位置制御

位置比例制御デッドゾーン 0.5 〜 25.0 % 10.0 0

位置比例制御長寿命 0:制御性重視

位置比例制御

自動調整

位置比例全閉調整値 0 〜 9999 1000 0

位置比例全開調整値 0 〜 9999 3000 0

位置比例全開時間 5.0 〜 240.0 s 30.0 0

通信種類 0:CPL

機器アドレス 0 〜 127(0 のとき通信しない) 0 0

伝送速度 0:4800 bps

データ形式

(データ長)

データ形式

(パリティ)

データ形式

(ストップビット)

通信最小応答時間 1 〜 250 ms 3 2

キー操作種類 0:標準タイプ

modeキー機能 0:無効

モード表示設定 モードバンクの設定表示有無を下記の重

1:制御出力2

2:イベント出力1

3:イベント出力2

4:イベント出力3

1:電流値測定

1:制御出力2

2:イベント出力1

3:イベント出力2

4:イベント出力3

1:4 〜 20 mA

2:0 〜 20 mA

連続電圧出力の場合

1:1 〜 5 V

2:0 〜 5 V

3:0 〜 10 V

1:加熱MV(加熱冷却制御用)

2:冷却MV(加熱冷却制御用)

3:PV

4:レシオ・バイアス・フィルタ前PV

5:SP

6:偏差(PV -SP)

7:CT1電流値

8:CT2電流値

9:MFB(推定 MFBを含む)

10:SP+MV

11:PV+MV

-1999 〜+ 9999(小数点位置と単位

は、制御出力1の種類によって変わる)

0 〜 9999

(制御出力1種類が 10、11 のとき有効)

-1999 〜+ 9999(小数点位置と単位

は、制御出力2の種類によって変わる)

0 〜 9999

(制御出力2種類が 10、11 のとき有効)

は、補助出力種類によって変わる)

0 〜 9999

(補助出力種類が10、11のとき有効)

1: MFB 制御

2: 推定位置制御(MFB使わない)

3: 推定位置制御(MFB 使わない)+電源

1:ポテンショメータ寿命重視

0:停止

1:開始

1:Modbus/ASCII形式

2:Modbus/RTU形式

1:9600 bps

2:19200 bps

3:38400 bps

0:7ビット

1:8ビット

0:偶数パリティ

1:奇数パリティ

2:パリティなし

0:1ビット

1:2ビット

1:特殊タイプ

1:AUTO/MANUAL切り替え

2:RUN/READY切り替え

3:AT停止/ 起動

4:LSP組切り替え

5:全DOラッチ解除

6:LSP/RSP切り替え

7:通信DI1切り替え

8:無効

み付けの和で決める

ビット0: AUTO/MANUAL表示

なし:0、あり:+1

ビット1: RUN/READY表示

なし:0、あり:+2

ビット2: LSP/RSP表示

なし:0、あり:+4

ビット3: AT停止 / 起動表示

なし:0、あり:+8

ビット4: DOラッチ解除表示

なし:0、あり:+16

ビット5: 通信DI1 ON/OFF 表示

なし:0、あり:+32

その他無効な設定 0、+64、+128

*

投入時位置合わせ

*

レベル

0 0

0 0

0 0

1 0

0 0

0.0 0

100.0 0

200 0

0 0

1000 0

200 0

0 0

200 0

0 0

1 0

0 0

0 0

2 0

1 0

0 0

0 0

0 2

1 0

255 1

J6

Page 7

表 示 項 目 内 容 初期値 表 示

C 74

C 75

C 76

C 77

C 78

C 79

C 80

C 8 1

C 82

C 83

C 84

C 85

C 86

C 87

C 88

C 89

C 90

C 9 1

C 92

C 93

C 97

PV/SP値表示設定 基本表示の表示有無を下記の重み付けの

操作量表示設定 基本表示の表示有無を下記の重み付けの

イベント設定値

表示設定

イベント残り時間

表示設定

CT入力電流値

表示設定

表示レベル 0:簡単設定

LEDモニタ 0:使用しない

MS表示灯点灯条件

(第1優先)

MS表示灯点灯状態

(第1優先)

MS表示灯点灯条件

(第2優先)

MS表示灯点灯状態

(第2優先)

MS表示灯点灯条件

(第3優先)

MS表示灯点灯状態

(第3優先)

MS表示灯偏差範囲 0 〜 9999 U 5 2

特殊機能 0 〜 15(電源 ON時に 0になる) 0 2

ツェナーバリア調整 調整による書き替えは可能

CT1ターン数 0:800ターン

CT1電力線貫通回数 0:1 回

CT2ターン数 0:800ターン

CT2電力線貫通回数 0:1 回

測定入力異常(アンダー

レ ン ジ )発 生 種 類

和で決める

ビット0: PV表示

なし:0、あり:+1

ビット1: SP表示

なし:0、あり:+2

ビット2: LSP組番号表示

なし:0、あり:+4

その他無効な設定 0、+8

和で決める

ビット0: MV表示

なし:0、あり:+1

ビット1: 加熱MV/ 冷却 MV表示

なし:0、あり:+2

ビット2: MFB表示

なし:0、あり:+4

ビット3: AT進捗表示

なし:0、あり:+8

0: 運転表示に内部イベント設定値を表

示しない

1: 運転表示に内部イベント1設定値を

表示する

2: 運転表示に内部イベント1 〜 2設定

値を表示する

3: 運転表示に内部イベント1 〜 3設定

値を表示する

0: 運転表示に内部イベントのON/OFF

ディレイ残り時間を表示しない

1: 運転表示に内部イベント1の ON/

OFFディレイ残り時間を表示する

運転表示に内部イベント1 〜 2の

2 :

ON/OFF ディレイ残り時間を表示する

3 :

運転表示に内部イベント1 〜 3の

ON/OFF ディレイ残り時間を表示する

0 :

運転表示にCTの電流値を表示しない

1: 運転表示にCT1電流値を表示する

運転表示にCT1、CT2電流値を表示する

2 :

1:標準設定

2:多機能設定

1:RS-485通信送信時点滅

2:RS-485通信受信時点滅

3:全DI状態の OR(論理和)

4:READY時点滅

0:常時開(常時 OFF=0)

1:常時閉(常時 ON=1)

2 〜 9:内部イベント1 〜 8

10 〜 13:未定義

14: MV1(ON/OFF、時間比例 1、加熱

側、OPEN側出力)

15: MV2(時間比例 2、冷却側、CLOSE

側出力)

16 〜 17:未定義

18 〜 21:DI1 〜 DI4

22 〜 25:未定義

26 〜 30:内部接点1 〜 5

31 〜 33:未定義

34 〜 37:通信DI1 〜 DI4

38:MANUAL

39:READY

40:RSP

41:AT

42:ランプ中

43:未定義

44:アラーム

45:PVアラーム

46:未定義

47:modeキー押し状態

48:イベント出力1端子の状態

49:制御出力1端子の状態

0:点灯

1:遅い点滅

2:2回点滅

3:速い点滅

4:左→右

5:右→左

6:左右往復

7:偏差OK

8:偏差グラフ

9:MVグラフ

10:加熱側MVグラフ

11:冷却側MVグラフ

12:MFBグラフ

13:DIモニタ

14:内部接点モニタ

15:内部イベントモニタ

MS表示灯点灯条件(第1優先)と同じ 44 2

MS表示灯点灯状態(第1優先)と同じ 6 2

MS表示灯点灯条件(第1優先)と同じ 1 2

MS表示灯点灯状態(第1優先)と同じ 9 2

手動による数値入力は不可

1 〜 40:設定値の100 倍をターン数とする

1 〜 6:回数

1 〜 40:設定値の100 倍をターン数とする

1 〜 6:回数

0:-10 %FS

1: - 5 mV(C0 1:PV レンジ種類の値

が17、23のときだけ有効)

15 1

15 1

0 1

0 1

0 1

1 0

0 2

39 2

1 2

0.00 2

8 2

1 2

8 2

1 2

0 0

レベル

■

イベントコンフバンク:

表 示 項 目 内 容 初期値 表 示

〜

E 1.C 1

E8.C 1

E 1.C2

E8.C2

E 1.C3

E8.C3

dI 1. 1

dI 5. 1

dI 1.2

dI 5.2

内部イベント1 〜 8

コンフ1

動作種類

〜

内部イベント1 〜 8 コンフ2

1桁目:正逆 0:正

2桁目:待機 0:なし

3桁目:READY時動作 0:継続

4桁目:未定義 0 0

〜

内部イベント1 〜 8 コンフ3

1桁目:アラームOR 0:なし

2桁目:特殊OFF 0: 通常どおり

3桁目:ディレイ時間単位 0:0.1 s

4桁目:未定義 0 0

■

DI割り付けバンク:

表 示 項 目 内 容 初期値 表 示

〜

内部接点1 〜 5

動作種類

〜

内部接点1 〜 5

入力ビット演算

EvCF

0:イベントなし

1:PV上限

2:PV下限

3:PV上下限

4:偏差上限

5:偏差下限

6:偏差上下限

7:偏差上限(最終 SP基準)

8:偏差下限(最終 SP基準)

9:偏差上下限(最終 SP基準)

10:SP上限

11:SP下限

12:SP上下限

13:MV上限

14:MV下限

15:MV上下限

16:CT1ヒータ断線/ 過電流

17:CT1ヒータ短絡

18:CT2ヒータ断線/ 過電流

19:CT2ヒータ短絡

20:ループ診断1

21:ループ診断2

22:ループ診断3

23:アラーム(状態)

24:READY(状態)

25:MANUAL(状態)

26:RSP(状態)

27:AT起動中(状態)

28:SPランプ中(状態)

29:制御正動作(状態)

30:無効

31:モータ開度推定中(状態)

32:タイマ(状態)

33: MFB 上下限

右側から1、2、3、4桁とする 0000 0

1:逆

1:待機

2:待機+SP変更時待機

1:強制OFF

右側から1、2、3、4桁とする 0000 2

1:アラーム正+OR動作

2:アラーム正+AND動作

3:アラーム逆+OR動作

4:アラーム逆+AND動作

1: イベント設定値(主)=0 の場合、イ

ベントOFF

1:1 s

2:1 min

dI

0:機能なし

1:LSP組選択(0/+1)

2:LSP組選択(0/+2)

3:LSP組選択(0/+4)

4:PID組選択(0/+1)

5:PID組選択(0/+2)

6:PID組選択(0/+4)

7:RUN/READY切り替え

8:AUTO/MANUAL切り替え

9:LSP/RSP切り替え

10:AT停止/ 起動

11:無効

12: 制御動作正逆切り替え

(設定どおり/設定の反対)

13:SPランプ許可/ 禁止

14: PV 値ホールド

(ホールドせず/ホールド)

15: PV 最大値ホールド

(ホールドせず/ホールド)

16: PV 最小値ホールド

(ホールドせず/ホールド)

17:タイマ停止/起動

18:全DOラッチ解除(継続/ 解除)

19: アドバンス

(アドバンスせず/アドバンス)

20: ステップホールド

(ホールドせず/ホールド)

0:使用しない(デフォルトの入力)

1:演算1((A and B)or(C and D))

2:演算2((A or B)and(C or D))

3:演算3(A or B or C or D)

4:演算4(A and B and C and D)

J7

レベル

0 0

0

0

0

0

0

0

レベル

0 0

0 2

Page 8

表 示 項 目 内 容 初期値 表 示

〜

dI 1. 3

dI 5. 3

dI 1. 4

dI 5. 4

dI 1. 5

dI 5. 5

dI 1. 6

dI 5. 6

dI 1. 7

dI 5. 7

dI 1.8

dI 5.8

dI 1.9

dI 5.9

■

Ot 1. 1

Ot2. 1

Ev 1. 1

Ev3. 1

Ot 1.2

Ot2.2

Ev 1.2

Ev3.2

Ot 1.3

Ot2.3

Ev 1.3

Ev3.3

Ot 1.4

Ot2.4

Ev 1.4

Ev3.4

Ot 1.5

Ot2.5

Ev 1.5

Ev3.5

Ot 1.6

Ot2.6

Ev 1.6

Ev3.6

内部接点1 〜 5

入力割り付けA

〜

内部接点1 〜 5

入力割り付けB

〜

内部接点1 〜 5

入力割り付けC

〜

内部接点1 〜 5

入力割り付けD

〜

内部接点1〜5 反転A〜D 右側から1、2、3、4 桁とする 0000 2

1桁目:反転A

(入力割り付けAの反転)

2桁目:反転B

(入力割り付けBの反転)

3桁目:反転C

(入力割り付けCの反転)

4桁目:反転D

(入力割り付けDの反転)

〜

内部接点1 〜 5 反転 0:反転しない

〜

内部接点1 〜 5

内部イベント番号指定

DO割り付けバンク:

表 示 項 目 内 容 初期値 表 示

制御出力1 〜 2、

〜

イベント出力1 〜 3

動作種類

〜

制御出力1 〜 2、

〜

イベント出力1 〜 3

出力割り付けA

〜

制御出力1 〜 2、

〜

イベント出力1 〜 3

出力割り付けB

〜

制御出力1 〜 2、

〜

イベント出力1 〜 3

出力割り付けC

〜

制御出力1 〜 2、

〜

イベント出力1 〜 3

出力割り付けD

〜

制御出力1 〜 2、

〜

イベント出力1 〜 3

反転A〜D

〜

1桁目:反転A 0:反転しない

2桁目:反転B 0

3桁目:反転C 0

4桁目:反転D 0

0:常に開(OFF、0)

1:常に閉(ON、1)

2:DI1

3:DI2

4:DI3

5:DI4

6 〜 9:未定義

10:内部イベント1

11:内部イベント2

12:内部イベント3

13:内部イベント4

14:内部イベント5

15:内部イベント6

16:内部イベント7

17:内部イベント8

18:通信DI1

19:通信DI2

20:通信DI3

21:通信DI4

22:MANUALモード

23:READYモード

24:RSPモード

25:AT起動中

26:SPランプ中

27:未定義

28:アラームあり

29:PVアラームあり

30:未定義

31:modeキー押し状態

32:イベント出力1端子状態

33:制御出力1端子状態

0:反転しない

1:反転する

1:反転する

0:すべての内部イベント

1 〜 8:内部イベント番号

dO

0: デフォルトの出力

1: MV1(ON/OFF制御出力、時間比例

出力、加熱冷却制御の加熱側時間比

例出力)

2: MV2(加熱冷却制御の冷却側時間比

例出力)

3: 演算 1((A and B)or(C and D))

4: 演算 2((A or B)and(C or D))

5: 演算 3(A or B or C or D)

6: 演算 4(A and B and C and D)

0:常に開(OFF、0)

1:常に閉(ON、1)

2:内部イベント1

3:内部イベント2

4:内部イベント3

5:内部イベント4

6:内部イベント5

7:内部イベント6

8:内部イベント7

9:内部イベント8

10 〜 13:未定義

14:MV1

15:MV2

16、17:未定義

18:DI1

19:DI2

20:DI3

21:DI4

22 〜 25:未定義

26:内部接点1

27:内部接点2

28:内部接点3

29:内部接点4

30:内部接点5

31 〜 33:未定義

34:通信DI1

35:通信DI2

36:通信DI3

37:通信DI4

38:MANUALモード

39:READYモード

40:RSPモード

41:AT起動中

42:SPランプ中

43:未定義

44:アラームあり

45:PVアラームあり

46:未定義

47:modeキー押し状態

48:イベント出力1端子状態

49:制御出力1端子状態

右側から1、2、3、4桁とする 0000 2

1:反転する

2〜5

または

0

0 2

0 2

0 2

0

0

0

0

0 2

0 2

0 2

14、15

または

2〜4

0 2

0 2

0 2

0

レベル

2

レベル

2

表 示 項 目 内 容 初期値 表 示

Ot 1.7

Ot2.7

Ev 1.7

Ev3.7

Ot 1.8

Ot2.8

Ev 1.8

Ev3.8

■

UF- 1

UF-2

UF-3

UF-4

UF-5

UF-6

UF-7

UF-8

■

LOC

C.LOC

L.LOC

PASS

PS 1A

PS2A

PS 1b

PS2b

■

I d0 1

I d02

I d03

I d04

I d05

I d06

I d07

I d08

イベント出力1 〜 3

反転

〜

制御出力1 〜 2、

〜

イベント出力1 〜 3

ラッチ

〜

ユーザーファンクションバンク:

表 示 項 目 内 容 初期値 表 示

ユーザーファンクション

定義1

ユーザーファンクション

定義2

ユーザーファンクション

定義3

ユーザーファンクション

定義4

ユーザーファンクション

定義5

ユーザーファンクション

定義6

ユーザーファンクション

定義7

ユーザーファンクション

定義8

ロックバンク:

表 示 項 目 内 容 初期値 表 示

LOC

キーロック 0: すべて設定が可能

通信ロック 0:RS-485通信 read/write可能

ローダロック 0:ローダ通信read/write 可能

パスワード表示 0〜15

パスワード1A 0000 〜 FFFF(16 進数) 0000 0

パスワード2A 0000 〜 FFFF(16 進数) 0000 0

パスワード1B 0000 〜 FFFF(16 進数) 0000 0

パスワード2B 0000 〜 FFFF(16 進数) 0000 0

計器情報バンク:I

表 示 項 目 内 容 初期値 表 示

ROM ID 2固定 — 2

ROM バージョン1 XX. XX(小数点以下 2桁) — 2

ROM バージョン2 XX. XX(小数点以下 2桁) — 2

SLP対応バージョン — 2

EST対応バージョン — 2

デートコード 年 西暦-2000 例:2003 年は「3」 — 2

デートコード 月日 月+(日÷ 100)

製造番号 — 2

制御出力1 〜 2、

〜

0:反転しない

1:反転する

0: なし

1: あり(ONでラッチ)

2: あり(OFF でラッチ、電源投入

初期化時は除く)

UF

各設定の第1表示部の表示で、設定

例外は下記のとおり

----

: 未登録

□

P-

: 使用中PID 組の比例帯

□

I-

: 使用中PID 組の積分時間

□

d-

: 使用中PID 組の微分時間

□

rE-

: 使用中 PID組のマニュアル

リセット

□

OL-

: 使用中PID 組の操作量下限

□

OH-

: 使用中PID 組の操作量上限

□

C

P-

: 使用中 PID組の冷却側比例帯

□

C

I-

: 使用中 PID組の冷却側

積分時間

□

C

d-

: 使用中 PID組の冷却側

微分時間

□

C

Ol.

: 使用中PID 組の冷却側

操作量下限

□

C

Oh.

: 使用中PID 組の冷却側

操作量上限

1: モード、イベント、運転表示、SP、

UF、ロック、マニュアルMV の設定

が可能

2: 運転表示、SP、UF、ロック、マニュ

アルMV の設定が可能

3: UF、ロック、マニュアル MVの設

定が可能

1:RS-485通信read/write 不可

1:ローダ通信read/write不可

5:パスワード1A 〜 2B表示

d

例:12月1 日は「12.01」

0 2

0 2

- - - - 1

- - - - 1

- - - - 1

- - - - 1

- - - - 1

- - - - 1

- - - - 1

- - - - 1

0 0

0 2

0 2

0 0

— 2

〔ご注意〕 この資料の記載内容は、お断りなく変更する場合もありますので

ご了承ください。

本 社 〒100-6419 東京都千代田区丸の内 2-7-3 東京ビル

北海道支店

東北支店

北関東支店

東京支社

☎(011)211 ー 1136

☎(022)290 ー 1400

☎(048)621 ー 5070

☎(03)6432 ー 5142

製品のお問い合わせは…

中部支社

関西支社

中国支店

九州支社

☎(052)324 ー 9773

☎(06)6881 ー 3383 ~ 4

☎(082)554 ー 0750

☎(093)285 ー 3530

コー ル センター : 0466-20-2143

〈アズビル株式会社〉 https://www.azbil.com/jp/

〈COMPO CLUB〉 https://www.compoclub.com

2003年 9月 初版発行

2018年10月 改訂 28 版(V)

J8

レベル

レベル

レベル

レベル

(28)

Page 9

CP-UM-5289JE (Not for use in Japan)

(1)

(6)

(9)

(2)

(5)

(8)(8) (7)(7)

WARNING

SDC35/36

Single Loop Controller

User’s Manual for Installation

Thank you for purchasing an Azbil Corporation product.

Before operating this product described in this User’s Manual,

please take note of the following points regarding safety.

Be sure to keep this manual nearby for handy reference.

Please read “Terms and Conditions” from the following URL before ordering and use.

https://www.azbil.com/products/factory/order.html

NOTICE

Be sure that the user receives this manual before the product is used.

Copying or duplicating this user’s manual in part or in whole is forbidden. The information and specifications in this manual are subject to change without notice.

Considerable effort has been made to ensure that this manual is free

from inaccuracies and omissions. If you should find an error or omission, please contact the azbil Group.

In no event is Azbil Corporation liable to anyone for any indirect,

special or consequential damages as a result of using this product.

© 2003–2018 Azbil Corporation. All Rights Reserved.

This manual explains the handling precautions, mounting, wiring,

PVrange type, list of parameters and main specifications only. See the

separate Installation & Configurations manual listed below for the detail

handling procedures and the setting methods, etc. These manuals also

contain information on using various functions. Please read if necessary.

SDC35/36 Single Loop Controller User’s Manual for Installation &

Configuration CP-SP-1150E

SLP-C35 Smart Loader Package for SDC15/25/26/35/36 Single Loop

Controller User’s Manual CP-UM-5290E

SDC35/36 Quick Reference Guide CP-SP-1203E

UNPACKING

Check the following items when removing the SDC35/36 from its package:

Name Part No. Q'ty Remarks

Mounting Bracket

User's Manual

81409654-001

CP-UM-5289JE

2

1 This Manual

SAFETY PRECAUTIONS

The use of this product in a manner not specified by the manufacturer

will impair its built-in safety features.

z Key to symbols

WARNING

Warnings are indicated when mishandling this product

might result in death or serious injury to the user.

CAUTION

Cautions are indicated when mishandling this product

might result in minor injury to the user, or only physical

damage to this product.

WARNING

Do not use this device in an environment with conductive pollution, or with dry non-conductive pollution which can become

conductive due to condensation, etc. Otherwise, problems such

as tracking phenomena may damage parts, resulting in fire.

Be sure to use the fuse described in the specifications for the

power wiring of this device. Otherwise, tracking phenomena or

parts failure due to other factors may cause fire.

Note that incorrect wiring of the SDC35/36 can damage the

SDC35/36 and lead to other hazards. Check that the SDC35/36 has

been correctly wired before turning the power ON.

Before wiring, or removing/mounting the SDC35/36, be sure to

turn the power OFF.

Failure to do so might cause electric shock or faulty operation.

Do not touch electrically charged parts such as the power terminals. Doing so might cause electric shock.

E1

Do not disassemble the SDC35/36.

Doing so might cause electric shock or faulty operation.

CAUTION

Use the SDC35/36 within the operating ranges recommended

in the specifications (temperature, humidity, voltage, vibration,

shock, mounting direction, atmosphere, etc.).

Failure to do so might cause fire or faulty operation.

Do not block ventilation holes.

Doing so might cause fire or faulty operation.

Wire the SDC35/36 properly according to predetermined standards. Also wire the SDC35/36 using specified power leads according to recognized installation methods. Failure to do so might

cause electric shock, fire or faulty operation.

Do not allow lead clippings, chips or water to enter the controller

case. Doing so might cause fire or faulty operation.

Firmly tighten the terminal screws at the torque listed in the specifications. Insufficient tightening of terminal screws might cause

electric shock or fire.

Do not use unused terminals on the SDC35/36 as relay terminals.

Doing so might cause electric shock, fire or faulty operation.

We recommend attaching the terminal cover (sold separately) after

wiring the SDC35/36. Failure to do so might cause electric shock.

Use the relays within the recommended service life.

Failure to do so might cause fire or faulty operation.

If there is a risk of a power surge caused by lightning, use a surge

absorber (surge protector) to prevent fire or device failure.

Do not operate the keys with a mechanical pencil or other sharptipped object. Doing so might cause faulty operation.

QUICK START GUIDE

From installation to PV and SP setup

Step 1. Mount ....................................... PageE2

Step 2. Wire ......................................... PageE2

Step 3. Set the PV range ............................. PageE3

Step 4. Set the SP ....................................PageE3

PART NAMES AND FUNCTIONS

SDC35

pv

sp

out

man rsp ev1 ev2 ev3 ot1 ot2

display

mode

enter

para

(2)

(3)

(4)

(6)

(9)

(10)

man

pv

rsp

ev1

ev2

ev3

sp

ot1

out

ot2

(5)

mode

para

(1) Upper display: Displays PV values (present temperature etc.) or setting

items.

(2) Lower display: Displays SP values (set temperature, etc.) and other pa

rameter values. When the lower display shows the SP

va

lue, the “sp” lamp lights up. When the display shows the

manipulated variable (MV), the “out” lamp lights up.

(3) Mode indicator man: Lights when MANUAL (manual mode)

rsp:

ev1 to ev3

ot1 to ot2

(4) MS (Multi-status) indicator:

In the combination of the lighting condition and the light-

Lights when RSP mode (remote setup input).

: Lights when event relays are ON.

: Lights when the control output is ON.

ing status as a group, the priority 3 groups can be set.

(5) [mode] key: The operation which has been set beforehand can be done

by pushing the key for 1s or more.

(6) [display] key: Used to change the display contents in the operation dis

play mode. Display is returned from bank setup display to

o

(7)

[<], [ ], [ ] keys:

peration display.

Used for incrementing numeric values and performing

arithmetic shift operations.

(8) [para] key: Switches the display.

(9) [enter] key: Used to set the setup values at the start of change and dur

ing the change.

(10) Loader connector:

Connects to a personal computer by using a dedicated

cable supplied with the Smart Loader Package.

SDC36

display

enter

(10)

-

-

-

Page 10

Location

96

5

65

screw M3

96

65

5

Terminal screw M3

Individual mounting

Gang-mounting

Gang-mounting

Individual mounting

transformer

Current or

Voltage pulse/Current/Voltage

Current/Voltage/Voltage pulse

Control outputs

Install the controller in a location that meets the following criteria:

•

Common mode voltages for I/O except power supply and relay contact

output: The voltage to ground is 30Vr.m.s. max., 42.4V peak max., and

60VDC max.

•

Neither high nor low temperature/humidity.

•

Free from silicone gas and other corrosive gases such as sulfide gas.

•

Little dust or soot.

•

Protected from direct sunlight, wind or rain.

•

Little mechanical vibration and shock.

•

Not close to a high voltage line, welding machine or other source of

electrical noise.

•

At least 15 meters away from a high voltage ignition device for a boiler.

•

No strong magnetic field.

•

No flammable liquid or gas.

•

Indoors

Mounting Procedure

•

The mounting must be horizontal within 10 degrees tilted in back side

lowering or within 10 degrees tilted in back side rising.

•

The mounting panel should be used with a thickness of less than 9mm

of firm board.

External Dimensions

z C35 (unit: mm)

z C36 (unit: mm)

Panel Cutout Dimensions

z C35 (unit: mm)

z C36 (unit: mm)

STEP 1. MOUNTING

+0.5

0

92

min.

Mounting

bracket

(Accessory)

Mounting bracket

(Accessory)

+0.5

0

92

30

min.

108

108

(48×N−4)

+0.5

0

92

(96×N−4)

+0.5

0

92

Terminal

+0.5

0

+0.5

0

48

SDC35

pv

sp

out

ot2ot1ev3ev2ev1rspman

display

mode

enter

para

96

man

pv

rsp

ev1

ev2

ev3

sp

ot1

out

ot2

mode

para

SDC36

display

enter

Handling Precautions

•

To fasten this controller onto the panel, tighten a mounting

bracket screws, and turn one more half turn when there is no

play between the bracket and panel. Excessively tightening the

screws may deform the controller case.

•

Be sure to mount the unit in a panel so that operators do not

touch the rear terminal block.

30

+0.5

44

min.

0

30

30

+0.5

92

0

min.

Handling Precautions

•

When three or more units are gang-mounted horizontally, the

maximum allowable ambient temperature is 40°C.

STEP 2. WIRING

All wiring should follow local regulations and be carried out by certified and

experienced personnel. Be sure to provide a switch within operator reach for

shutting OFF the main power supply to the controller in the main supply wir

ing. Also, in case of AC power supply models, the main supply wiring also

r

equires a time-lagged type (T) fuse (rated current: 0.5A, rated voltage: 250V).

(IEC127) The following table shows the meaning of the symbols in the termi

nal wiring label on the controller side:

Handling Precautions

•

Before wiring the SDC35/36, verify the controller’s model No. and terminal Nos. written on the label on the side of the body. Inspect all

wiring once wiring work for the SCD35/36 has been completed.

•

Use M3 crimp-type terminal lugs for wiring to terminal.

•

Leave at least 50 cm between I/O signal wires and power wires.

Do not put them in the same electrical conduit or duct.

•

Be careful not to allow any crimp-type terminal lugs to touch adjacent terminals.

•

To connect 2 (max.) crimp terminals to the same terminal screw, bend

the crimp terminals beforehand.

•

Prepare a heater current conductor to send a heater current through

the current transformer. Do not use a heater current that exceeds the

specified permissible current as this may damage the controller.

•

The current transformer input cannot be used for phase control.

•

If multiple current-input type SDCs are connected in series and you

want to turn them on/off individually, convert them to voltage input

by adding resistors (No. 81401325, sold separately) to the circuit.

•

There is no isolation provided between control output 1 and control

output 2. Install an isolator as required.

•

Do not connect a terminating resistor to either end of the RS-485

communications line. Doing so may interfere with communication.

•

If the motor connected to the motor drive relay output is used with

a 100/200VAC power supply, the use of an external auxiliary relay is

recommended. If an auxiliary relay is not used, thoroughly check the

operating conditions (operating voltage of the motor, inrush current,

frequency of switching, etc.) before use.

•

Do not wire in the same duct for the motor drive terminals (13), (14),

(15) and the MFB input terminals (7), (8), (9) and also do not use 6-core

cable. Failure to follow the instruction might cause controller malfunction due to noise during motor startup operation.

•

Make sure that devices and equipment connected to this device have

reinforced insulation suitable for the maximum operating voltage of

this device’s power supply and input/output ports.

•

The controller requires maximum 5 seconds to start up once the

power is turned ON. The controller can be used once it has started up.

However, it is recommended to allow a warm-up time of at least 30

minutes to attain the specified accuracy.

AC power supply

100 to 240 V AC

DC power supply

24 V AC/24 V DC

(independent contact)

CT1

Current

CT2

inputs

MFB

Thermocouple

E2

Symbols Meaning

Power supply

1

2

(non polar)

Relay

Relay

Inputs

7

8

9

Y

7

T

8

G

9

RTD

DC current

DC voltage

1

2

Event outputs

3

3

2

4

1

5

COM

6

3

2

4

5

1

6

PV inputs

10

−

11

+

12

C

10

B

11

A

12

+

10

mA

−

11

V

+

12

AC power supply

DC power supply

Caution, there is danger of electric shock

Caution

NO

13

Relay

14

NC

15

OPEN

13

Relay for

14

motor drive

CLOSE

1

13

2

14

3

15

4

16

5

17

6

18

7

19

8

20

9

21

10

22

11

23

12

24

15

13

+

Voltage pulse /

−

14

Current / Voltage

13

+

1

−

14

2

+

15

DI

4

18

3

19

2

20

1

21

COM

RSP

18

+

mA/V

−

19

2DI

20

1

21

COM

Communication

DA

22

DB

23

24

SG

Auxiliary output

16

17

Digital input

RSP/DI

RSP input

Digital input

RS-485

-

-

+

Voltage

−

Page 11

z I/O isolation

The display and setup status shown above are examples for explanation.

Therefore, some displays or settings are not shown actually according to

the model and/or setup contents.

Items surrounded by solid lines are insulated from other signals.

Availability of input or output is based on a model number.

Power supply

PV input

Current transformer input 1

Current transformer input 2

Motor feedback input

Loader communication

Digital input 1

Digital input 2

Digital input 3

Digital input 4

RS-485 communication

RSP input

* In case of independent contact, the part between the event

output 1 and the event output 2 is isolated.

SETTING THE PV RANGE TYPE

z Flowchart of key operations

There are the standard type and special type in the data setup

method. Here, the method is explained in the standard type.

Display when the power is turned ON.

SDC36

man

pv

rsp

ev1

ev2

ev3

sp

ot1

out

ot2

mode

para

Operation display Bank selection display Bank setup display

PV/SP display

display

key.Press the

MV display

display

display

key.Press the

key.Press the

Other display and setup

(Operate the [display]

key repeatedly.)

display

enter

Keep the

para

key

pressed

for 2 sec.

or longer.

OFF

OFF

Step 3. Setting the PV range ( PV RANGE TABLE)

In the mode bank MOdE, press the [

Stup, and then press the [enter] key.

>> C0 1 will be displayed on the upper display. Press the [enter] key again.

>> The lower display will be flashing.

Referring to the PV range table, press the [<] [

sired sensor type for C0 1.

Press the [enter] key.

>> The flashing will stop and the settings will go into effect.

Step 4. Setting the SP

In the mode bank MOdE, press the [enter] key.

>> The lower display will be flashing.

Press the [

] [ ] keys to display the desired SP setting.

Press the [enter] key.

>> The flashing will stop and the settings will go into effect.

SDC35/36 Single Loop Controller User’s Manual for Basic

Operations CP-SP-1150E and SDC35/36 Quick Reference Guide

CP-SP-1203E.

The mode indicators are lit sequentially form

the left during a period of 5 to 6 sec after the

power has been turned ON while both the

upper display and lower display are OFF.

When all mode indicators have been lit, the

display is changed to the operation display.

No key operation for 3 minutes

or more.

display

Press the or key.

Mode bank selection

para

key.Press the

key.Press the

SP bank selection

para

key.Press the

key.Press the

Other banks

(Operate the [para], [ ]

and [ ] keys repeatedly.)

para

key.Press the

key.Press the

] [ ] keys to display the setup bank

Control output 1

Control output 2

Auxiliary output

Internal

Circuit

Event output 1*

Event output 2*

Event output 3

No key operation for

3 minutes or more.

mode

Press the

enter

or

key.

Keep the

para

key

pressed

for 2 sec.

or longer.

Press the or key.

(example. mode bank)

AUTO/MANUAL

change

RUN/READY change

Other setup

(Operate the [para], [ ]

and [ ] keys repeatedly.)

] [ ] keys to display the de-

PV RANGE TABLE

Input

C0 1

type

set

value

41 Pt100 −200.0 to +500.0°C −300 to +900°F

42 JPt100 −200.0 to +500.0°C −300 to +900°F

43 Pt100 −200.0 to +200.0°C −300 to +400°F

44 JPt100 −200.0 to +200.0°C −300 to +400°F

45 Pt100 −100.0 to +300.0°C −150 to +500°F

46 JPt100 −100.0 to +300.0°C −150 to +500°F

47 Pt100 −100.0 to +200.0°C −150 to +400°F

48 JPt100 −100.0 to +200.0°C −150 to +400°F

49 Pt100 −100.0 to +150.0°C −150 to +300°F

50 JPt100 −100.0 to +150.0°C −150 to +300°F

51 Pt100 −50.0 to +200.0°C −50 to +400°F

52 JPt100 −50.0 to +200.0°C −50 to +400°F

53 Pt100 −50.0 to +100.0°C −50 to +200°F

54 JPt100 −50.0 to +100.0°C −50 to +200°F

55 Pt100 −60.0 to +40.0°C −60 to +100°F

56 JPt100 −60.0 to +40.0°C −60 to +100°F

57 Pt100 −40.0 to +60.0°C −40 to +140°F

58 JPt100 −40.0 to +60.0°C −40 to +140°F

59 Pt100 −10.00 to +60.00°C −10 to +140°F

60 JPt100 −10.00 to +60.00°C −10 to +140°F

61 Pt100 0.0 to 100.0°C 0 to 200°F

62 JPt100 0.0 to 100.0°C 0 to 200°F

63 Pt100 0.0 to 200.0°C 0 to 400°F

64 JPt100 0.0 to 200.0°C 0 to 400°F

65 Pt100 0.0 to 300.0°C 0 to 500°F

66 JPt100 0.0 to 300.0°C 0 to 500°F

67 Pt100 0.0 to 500.0°C 0 to 900°F

68 JPt100 0.0 to 500.0°C 0 to 900°F

C0 1

Input type Range

set value

81 0 to 10mV The scaling and

82 −10 to +10mV

83 0 to 100mV

84 0 to 1V

86 1 to 5V

87 0 to 5V

88 0 to 10V

89 0 to 20mA

90 4 to 20mA

display

mode

Input

C0 1

type

set

value

1 K −200 to +1200°C −300 to +2200°F

2 K 0 to 1200°C 0 to 2200°F

3 K 0.0 to 800.0°C 0 to 1500°F

4 K 0.0 to 600.0°C 0 to 1100°F

5 K 0.0 to 400.0°C 0 to 700°F

6 K −200.0 to +400.0°C −300 to +700°F

7 K −200.0 to +200.0°C −300 to +400°F

8 J 0 to 1200°C 0 to 2200°F

9 J 0.0 to 800.0°C 0 to 1500°F

10 J 0.0 to 600.0°C 0 to 1100°F

11 J −200.0 to +400.0°C −300 to +700°F

12 E 0.0 to 800.0°C 0 to 1500°F

13 E 0.0 to 600.0°C 0 to 1100°F

14 T −200.0 to +400.0°C −300 to +700°F

15 R 0 to 1600°C 0 to 3000°F

16 S 0 to 1600°C 0 to 3000°F

17 B 0 to 1800°C 0 to 3300°F

18 N 0 to 1300°C 0 to 2300°F

19 PLII 0 to 1300°C 0 to 2300°F

20 Wre5-26 0 to 1400°C 0 to 2400°F

21 Wre5-26 0 to 2300°C 0 to 4200°F

22 Ni-Ni·Mo 0 to 1300°C 0 to 2300°F

23 PR40-20 0 to 1900°C 0 to 3400°F

24 DIN U −200.0 to +400.0°C −300 to +700°F

25 DIN L −100.0 to +800.0°C −150 to +1500°F

26 Gold iron

0.0K to 360.0K 0 to 360K

chromel

Range

Handling Precautions

•

The accuracy varies according to

the range. The accuracy of the B

thermocouple is ±4.0%FS for a

range of 260°C or less, ±0.4%FS

for 260 to 800°C and ±0.2%FS for

800 to 1800°C.

The PV values under 20°C are not

shown. The accuracy of the No.15

(sensor type R) or No.16 (sensor type

S) is ±0.2%FS for a range of 100°C or less, and ±0.15%FS for 100 to 1600°C.

The accuracy of the No.23 (sensor type PR40-20) is ±2.5%FS for 0 to of

300°C, and ±1.5%FS for 300 to 800°C, ±0.5%FS for 800 to of 1900°C.

The accuracy of the No.26 (sensor type gold iron chromel) is ±1.5K.

The accuracy of the No. 55 to 62 and 81 are ±0.15%FS ±1digit for each

para

key.Press the

key.Press the

ranges. The accuracy of the No.19 (sensor type PLII) in the range of 0 to

32°F does not meet the indication accuracy.

•

The ranges with a decimal point show figures under decimal point.

•

Make sure to set the correct number in setup display C0 1, according to

the type and range of the sensor used. If the setting is wrong, problems

such as large temperature errors in the output may occur.

para

key.Press the

key.Press the

ALARM CODE TABLE

This table shows the alarm display and measures for the abnormal operation of this controller.

para

key.Press the

key.Press the

Alarm

code

AL01

AL02

AL03

AL05

AL06

AL07

AL10

AL11

AL70

AL95

AL96

AL97

AL98

AL99

*1. Displays in RSP mode *2. RAM area

Error Cause Corrective action

PV input failure

(over range)

PV input failure

(under range)

CJ failure Terminal temperature is faulty

PV input failure Sensor line break, incorrect wiring (RTD) Checking wiring.

RSP input failure *

(over range)

RSP input failure *

(under range)

MFB input failure Motor line break, incorrect wiring Checking wiring or conrm

Motor adjustment failure M otor line break, incorrect wiring,

CT input failure

(over-range)

(CT input 1 or 2, or both)

A/D conversion failure Defective A/D converter Replace unit.

Parameter failure Power turned OFF during xing data

Adjustment data

Parameter failure *

Adjustment data failure *

ROM failure ROM (memory) error Re -start the system.

Sensor line break, incorrect wiring,

incorrect PV range type setting

(thermocouple).

1

Sensor line break, incorrect wiring,

incorrect RSP range setting

1

motor power supply failure.

2

rent exceeding the upper limit of

A cur

the display range was measured. The

number of CT turns or the number of

CT power wire loops is incorrectly set,

or wiring is incorrect.

Data corrupted due to noise, etc.

Data corrupted due to noise, etc.

2

Range

the decimal point

position can be

changed variably in

a range of −1999 to

+9999.

Checking wiring or reset PV

range type.

Checking the ambient

temperature.

Checking wiring or reset RSP

range code.

the MFB input.

Checking wiring, conrm the

motor power supply, reset.

Use a CT with the correct

number of turns for the dis

play range, reset the number

of CT turns, reset the number

of CT power wire loops,

and/or check the wiring.

Re-start the system.

Reset data or replace unit.

(AL95/97: setting data,

AL96/98: tuning data)

Replace unit.

-

MAINTENANCE

Cleaning:

Parts replacement: Do not replace the parts.

Fuse replacement: On AC models, when replacing the fuse for the power, make sure

E3

When wiping out the SDC35/36, use the soft and dried cloth. Do not

use a detergent or an organic solvent like thinner or benzene.

that the replacement fuse complies with applicable standards. Use a

time lag fuse (T) compliant with IEC127 and rated at 250V, 0.5A.

Page 12

MODEL SELECTION TABLE

Basic

Mounting Control

model

No.

C35 48 × 96 size model

C36 96 × 96 size model

*1 Can not be selected for DC model.

*2 For SSR drive

*3 A current transformer is sold separately.

*4 When the control output is R1, the current

transformer input is not applied. MFB input

is applied.

outputPVinput

T Panel mounting type

*1 R1

Power

Optional

supply

R0 Relay contact output

V0 Voltage pulse output*

VC Voltage pulse output*

VD Voltage pulse output*

VV Voltage pulse output*

C0 Current output —

CC Current output Current output

CD Current output Voltage output

DO Voltage output —

DD Voltage output Voltage output

U Universal

A AC model (100 to 240VAC) 50/60Hz

D DC model (24VAC/24VDC)

*1 4

*1 5

*1 6

Additional

functions

processing

1 2 1 2

Control output 1 Control output 2

N.O.

Relay contact output for

motor drive OPEN side

1 Event relay output: 3 points

2 Event relay output 3 points,

3 Event relay output 3 points,

0

*3, *4 1 Current transformer input: 2 points

*3, *4 2

*3, *4 3 Current transformer input: 2 points

*3, *4 4 Current transformer input: 2 points

Auxiliary output (current output)

Auxiliary output (voltage output)

Event output: 2 points (independent contact)

Event output: 2 points (independent contact)

Auxiliary output (current output)

Event output: 2 points (independent contact)

Auxiliary output (voltage output)

None

Digital input: 4 points

Current transformer input: 2 points

Digital input: 4 points, RS-485 communication

Digital input: 2 points, RSP input

Digital input: 2 points, RSP input, RS-485

communication

0 No additional treatment

D Inspection certificate provided

Y

Complying with the traceability certification

0

None

A UL-marked product

SPECIFICATIONS

z PV input

Thermocouple:

Resistance temperature detector (RTD):

DC voltage:

DC current:

Sampling cycle:

Indication accuracy:

Cold junction compensation accuracy:

Cold junction compensation method:

Allowable input:

z Digital input

Number of inputs: 2 or 4 points

Input type:

Allowable ON contact resistance:

Allowable OFF contact resistance:

Allowable ON residual voltage:

Terminal current (ON):

Minimum hold time:

z Current transformer input

Number of inputs:

Input object:

Current measurement lower limit:

Current measurement upper limit:

Allowable measured current:

Display range lower limit:

Display range upper limit:

Display accuracy:

K, J, E, T, R, S, B, N (JIS C1602-1995)

PL II (Engelhard Industries Data (ITS90))

WRe5-26 (ASTM E988-96(Reapproved 2002))

Ni-Ni·Mo (ASTM E1751-00)

PR40-20 (Johnson Matthey Data)

DIN U, DIN L (DIN 43710-1985)

Gold iron chromel (Hayashidenko Data)

Pt100 (JIS C1604-1997), JPt100 (JIS C1604-1989)

0 to 10mV, −10 to +10mV, 0 to 100mV,

0 to 1V, 1 to 5V, 0 to 5V, 0 to 10V

0 to 20mA, 4 to 20mA

100ms

±0.1%FS±1digit, ±0.2%FS±1digit for a negative

area of the thermocouple (at ambient temperature

23±2°C)

±0.5°C (at ambient temperature 23±2°C)

±1.0°C (at ambient temperature 15 to 35°C)

±1.5°C (

at ambient temperature 0 to 15°C or 35 to 50°C)

The compensation in the controller or the compensation at the outside of the controller (0°C only)

can be selected.

−0.5 to +12V (thermocouple, RTD, DC voltage)

30mA max or 4V max (DC current)

More than the allowable input voltage or current

may damage this device.

Dry contact or open collector

Max. 250Ω

Min. 100kΩ

Max. 1.0V

Approx. 7.5mA (in case of short circuit).

Approx. 5.0mA

200ms or more

2 points

Current transformer with 100 to 4,000 turns

(availability is by 100-turn units)

0.4A AC (800 turns, 1 time)

Formula; Number of turns ÷ (2000 × number of

power wire loops)

50.0A AC (800 turns, 1 time)

Formula; Number of turns ÷ (16 × number of

power wire loops)

70.0A AC (800 turns, 1 time)