Page 1

No.CP-SP-1148C

数字显示调节器

SDC15

使用说明书

详细篇

非常感谢您购买数字显示调节器SDC15。

本使用说明书中记述了正确安全使用

SDC15的必要事项。

对于承担使用SDC15的操作盘、装置的

设计、维护的工作人员,请务必在阅读

理解本书的基础上使用。

此外,本使用说明书不只在安装时,在维

护和故障维修时也是必不可少的。

请常备此手册以供参考。

Page 2

中英文版的内容如有差异,以英文版为准。

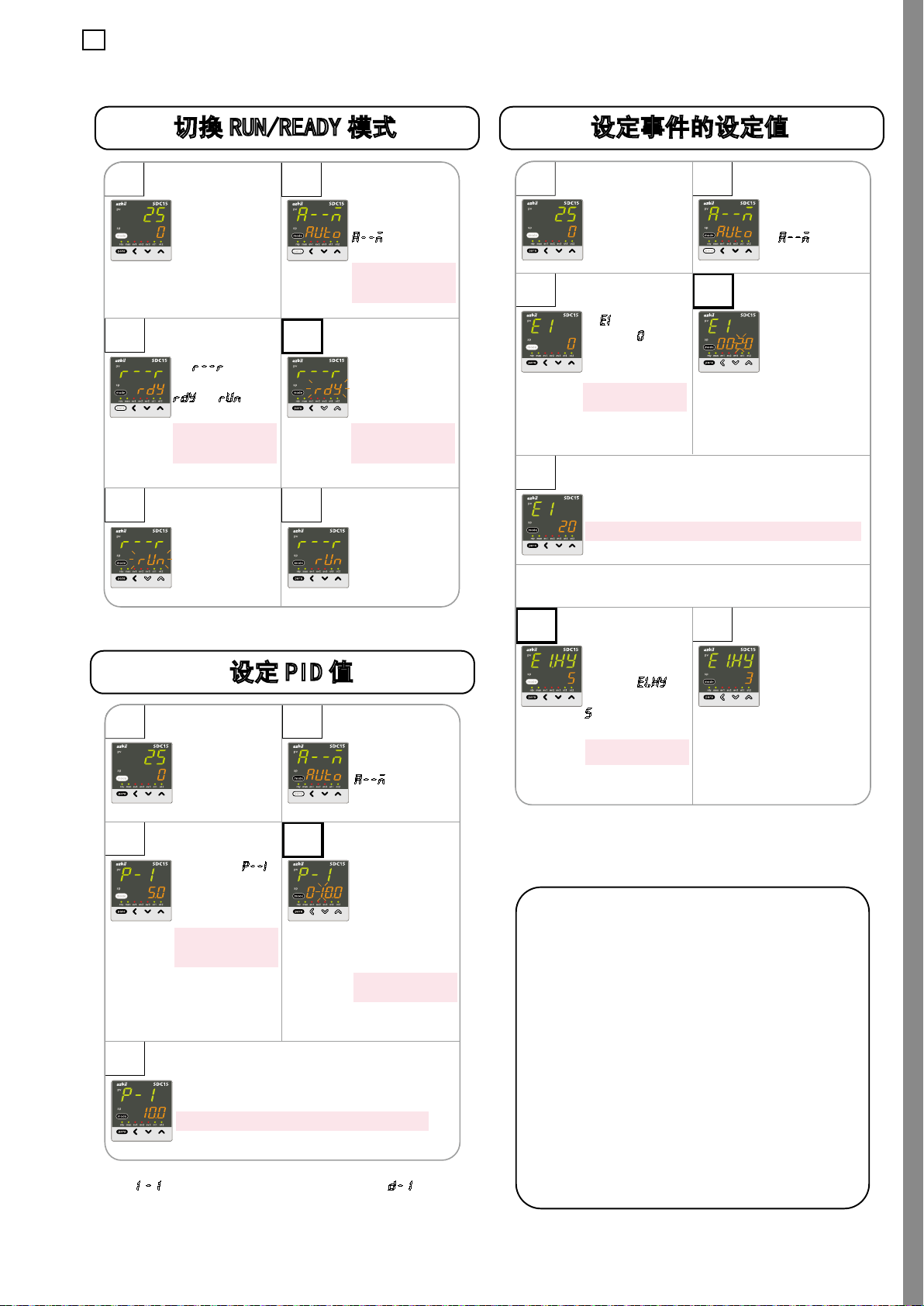

为了更好地理解 SDC15

D-1~D-8 页的「键操作指南」对参数的变化图、设定一览及具体的操作例等用图解方

式进行说明。

先阅读本页再阅读详细内容,效果更好。

另外,备有了采用了抗污能力强的纸制成的彩色版《键操作指南》,供在现场使用(资

料编号 CP-SP-1213C)。

如有需要,请与本公司或销售店联系。

请务必把本使用说明书送到本机使用者手中。

禁止擅自复印和转载全部或部分本使用说明书的内容。

今后内容变更时恕不事先通知。

本使用说明书的内容,经过仔细审查校对,万一有错误或遗漏,请向本

公司提出。

对客户应用结果,本公司有不能承担责任的场合,敬请谅解。

要求

C

○

2003 Yamatake Corporation ALL RIGHTS RESERVED

Page 3

安全要求事项(SAFETY REQUIREMENT)

为避免触电造成伤害危险,请依照本使用说明书中记载的所有安

全注全意事项进行操作。

此符号用于警示用户有因触摸而触电的危险。

未按本公司规定的使用方法进行操作的场合,会损坏本机的安全保护装置。

请勿用本公司指定以外的部件进行更换。

请在具有认证资格且经验丰富的工作人员的操作下,依照各地方条例进行所有配线作

业。

请务必在仪表操作员能够触及的范围内,设置本机主电源断电用开关。

AC电源型主电源配线时,请设置迟动类型(T)、额定电流200mA、额定电压250V的保

险丝。(IEC127)

机器的额定值

供给电压 100~240V(动作电源电压85~264Vac)

电源频率 50/60Hz

消耗功率 12VA以下

环境条件

请勿在有可燃性液体或者蒸气的环境下使用。

否则会损坏仪表的安全性。

使用温度范围 0~50℃

使用湿度范围 10~90%RH(无结露)

容许振动 2m/s2(10~60Hz)

过电压类型 Category Ⅱ(IEC60364-4-443, IEC60664-1)

污染度 Pollution degree 2

机器的设置

为避免仪表操作员触摸仪表背面端子,请务必将本机安装到安装板上。

除供给电源和继电器接点输出以外的输入输出的共模电压:对大地间的电压为

33V r.m.s.以下、46.7V峰值以下、70Vdc以下。

适合规格

EN61010-1、EN61326-1

i

Page 4

警告

注意

■ 图示说明

本安全注意事项的目的:为了正确安全使用本机,防患于未然,以免给您及他人造

成人体损害及财产损失,请务必遵守本安全注意事项。

本书中使用了各种图形符号,其显示的含义如下所示,请充分理解所述内容。

图示例

■

本符号表示使用上必须“注意”的内容。

安全注意事项

当错误使用本机时,可能会造成使用者死亡或重伤的危险

情况。

当错误使用本机时,可能会造成使用者轻伤或财物损失的

危险情况。

本符号表示必须“禁止”的内容。

本符号表示必须执行的“显示”内容。

ii

Page 5

警告

请勿分解本机。

否则有触电、发生故障的危险。

在对本机进行安装、拆除及配线作业时,请务必完全切断本机及连接设备的电

源。否则有触电的危险。

请勿触摸电源端子等带电部件。

否则有触电的危险。

注意

请在规格书中记载的使用条件(温度、湿度、电压、振动、冲击、安装方向、

环境等)范围内使用本机。

否则有发生火灾故障的危险。

请勿堵塞本机的通风孔。

否则有发生火灾、故障的危险。

请按照本机连线的标准、指定电源及施工方法,正确配线。

否则有发生火灾、故障的危险。

请勿让断线头、铁粉、水等进入机箱内。

否则有发生火灾、故障的危险。

请按规格书中记载的扭矩拧紧端子螺钉,端子螺钉没有拧紧时有触电、发生

火灾的危险。

请勿把本机中未使用的端子作为中继端子使用。

否则有触电,发生火灾、故障的危险。

盘安装型的场合,在接线完毕后,建议安装端子盖板。

否则有触电的危险。(本机备有另售的端子盖。)

请在规格书中记载的寿命范围内使用本机的继电器。超过使用寿命仍继

续使用的场合,有发生火灾、故障的危险。

有发生雷电涌危险的场合,请使用本公司生产的电涌放电器。

否则有发生火灾、故障的危险。

请勿错误配线。

错误配线,有导致机器发生故障的危险。

接通电源后,约6秒钟调节器无动作。

在调节器的继电器输出作为连锁信号使用的场合,请注意。

iii

Page 6

注意

控制输出1和控制输出2之间未隔离。

必要时请使用隔离器。

请勿在1台计算机上,使用多根编程器电缆,同时连接多台机器。

由于回流电流,可能产生PV值显示误差等可能。

RS-485接线时,请勿在通讯线路的两端处连接终端电阻。

否则可能造成通讯故障。

进行本机的电源配线时,请务必在操作者手可伸及的范围内设置本机主电源

断电用开关。另外,AC电源型仪表电源配线时,请设置迟动类型(T)、额

定电流0.2A、额定电压250V的保险丝。(IEC127)

请勿使用带尖物体(自动铅笔的头或者针等)进行键操作。

否则可能产生故障。

本机不仅有ON/OFF控制及原有的PID控制功能,还具有无需设定控制参数的

自适应控制功能。所谓自适应控制是指即使在SP值变更或者有干扰发生时,

也能够监视和学习控制仪表的特性、自动计算出控制常数,实现稳定控制。

使用前

本机前端的操作面板上覆盖着一层表面保护膜。当安装、配线作业完毕时,请在面板的一角粘贴玻璃纸带,

然后按箭头方向拉,揭下保护膜。

使用上的注意事项

用指甲等剥落保护膜,有可能划伤操作面板。

揭去

玻璃纸带

iv

Page 7

本使用说明书的定位

与数字显示调节器SDC15(以下简称本机)相关的使用说明书共有5册,请根据用途参阅相关的使用说明书。

如果您手中无相关的使用说明书时,请向本公司或代理店索取。

这些资料还可以从http://www.azbil.com/cn/网站下载。

本机的显示级别可以从“简单设定”、“标准设定”、“多功能设定”三种中选择。

有关「简单设定」可设定的功能,在「数字显示调节器SDC15使用说明书 基本篇」(CP-SP-1147C)中说

明。更高级应用的场合,请参阅本书。

本书是针对已经阅读完「基本篇」,并且使用过本公司的调节器产品,理解调节器的基本操作的人员为对象

编写的。

数字显示调节器SDC15 使用说明书 设置篇

使用本机进行装置设计、制作的人员,请务必阅读。

介绍本机使用上的安全注意事项、安装、接线及主要规格。详细的使用方法

请参阅《基本篇》或者《详细篇》。

数字显示调节器SDC15 使用说明书 基本篇

介绍本机在“简单设定”状态下可使用的功能。

使用本机进行装置设计、制作、操作、维护的人员,请务必阅读。

介绍本机安装、接线、主要功能、设定及操作方法、故障解决对策、详细

规格等。

数字显示调节器SDC15 使用说明书 详细篇

本书。

介绍本机的硬件及所有功能。使用本机进行装置设计、制作、操作、维护的

人员或者使用本机的通讯功能进行装置、通讯软件设计的人员,请务必阅

读。

介绍本机安装、接线、通讯连接、所有功能、设定及操作方法、与计算机

等主站的通讯方法、通讯地址、故障解决对策、详细规格等。

数字显示调节器SDC15/25/26/35/36 用智能编程软件包

使用说明书 资料编号 CP-UM-5290C

本书是关于使用计算机进行SDC15/25/26/35/36各种设定的软件的说明书。

请使用SDC15/25/35/36进行装置设计、设定的人员务必阅读。介绍了安装

到计算机上的方法、操作、各种功能、设定方法。

SDC15 键操作指南 资料编号 CP-SP-1213C

供初次使用SDC15的人员、现场的操作员在进行参数的设定及变更时用的资

料。以彩色和插图的方式,对键操作、显示的切换及参数设定一览进行说明。

v

资料编号 CP-UM-5287C

资料编号 CP-SP-1147C

资料编号 CP-SP-1148C

SLP-C35

Page 8

本使用说明书的构成

本使用说明书构成如下。

键操作指南

第1章 概 要

第2章 功能的概要

第3章 安 装

第4章 接 线

第5章 各功能的详细内容

第6章 显示·设定数据一览表

第7章 CPL通讯功能

第8章 MODBUS通讯功能

第9章 通讯数据一览表

第10章 维护及故障处理

第11章 校 正

第12章 产品废弃处理

第13章 规 格

参数的变化图、设定一览及具体的操作例等用图解归纳说明。

最先阅读本内容,有助于更好地理解本机。

对本机的用途或特长、型号构成、本机各部分的名称及功能进行说明。

在以后章节的说明中会使用到这些名称,所以请理解本章节的内容。

介绍本机的功能、动作的概要。

介绍本机设置的环境、安装尺寸、安装方法、必备工具。

介绍本机的接线方法、接线时的注意事项、连接示例。

介绍本机各功能的详细内容。

对本机的显示项目及其内容用一览表的形式归纳说明。

介绍使用本公司RS-485标准的CPL通讯,实现本机与计算机或PLC等上

位机通讯的方法。

介绍使用MODBUS通讯,实现本机与计算机或PLC等上位机通讯的

方法。

本机存储器内的通讯数据一览。

介绍本机的维修、检查、故障原因和解决对策。

介绍让本机始终保持高精度、正常运转的校正方法。

介绍本机失效后的废弃注意事项、废弃方法。

介绍本机的一般规格、性能规格、可选部件等。

vi

Page 9

目 录

安全要求事项

安全上的注意事项

要求

本使用说明书的定位

本使用说明书的构成

本使用说明书的标记

键操作指南

各部分的名称·······································································································D-1

键操作及显示的切换 ················································································· D-2~D-3

具体的操作例···························································································· D- 4~D-5

参数一览 ··································································································· D- 6~D-7

PV量程表·············································································································D- 8

报警代码一览·······································································································D -8

事件的种类···········································································································D - 8

第 1 章 概 要

1-1 概 要···················································································································1 - 1

■ 型号构成·······································································································1 - 2

■ 附属品·可选部件 ························································································1 - 3

1-2 各部分的名称及功能·····························································································1 - 4

■ 本体及操作面板部 ························································································1 - 4

■ 底面 ··············································································································1 - 5

■ 背面 ··············································································································1 - 6

第 2 章 功能的概要

2-1 输入输出的构成 ····································································································2 - 1

2-2 键操作···················································································································2 - 2

■ 标准型···········································································································2 - 2

■ 特殊型···········································································································2 - 4

■ 数据设定方法································································································2 - 6

■ [mode]键操作方法 ·······················································································2 - 7

■ 显示级别·······································································································2 - 8

2-3 运行模式 ···············································································································2 - 9

第 3 章 安 装

■ 安装场所·······································································································3 - 1

■ 外形尺寸·······································································································3 - 2

■ 盘开孔图·······································································································3 - 2

■ 安装方法·······································································································3 - 3

vii

Page 10

第 4 章 接 线

4-1 接 线······················································································································· 4 - 1

■ 端子排列标签的记号 ························································································· 4 - 2

■ 接线时的注意事项·····························································································4 - 2

■ 数字输入的开路集电极输出的连接方法 ···························································· 4 - 5

■ 通讯(RS-485)的连接·························································································4 - 5

■ 与SSR(固态继电器)的连接 ···············································································4 - 7

■ 电流输入的接线 ································································································4 - 9

■ 干扰对策 ···········································································································4 -1 0

4-2 使用电缆····················································································································4- 11

第 5 章 各功能的详细内容

5-1 PV输入·······················································································································5 - 1

■ PV量程种类 ······································································································5 - 1

■ 温度单位 ···········································································································5 - 3

■ 冷接点补偿········································································································5 - 3

■ 开方运算小信号切除 ························································································· 5 - 3

■ 小数点位置········································································································5 - 4

■ PV量程下限·上限 ···························································································5 - 5

■ PV比率与PV偏置······························································································5 - 5

■ PV滤波··············································································································5 - 6

■ PV保持··············································································································5 - 6

■ PV下限·上限限幅及PV下限·上限报警··························································5 - 6

5-2 模式···························································································································5 - 7

■ AUTO/MANUAL模式 ·······················································································5 - 7

■ RUN/READY模式····························································································· 5 - 7

■ AT(自整定)停止/启动························································································ 5 - 8

■ 所有DO(数字输出)锁定解除··············································································5 - 8

■ 通讯DI(数字输入)1····························································································5 - 8

5-3 控 制······················································································································· 5 - 9

■ 控制方式 ···········································································································5 -1 1

■ 控制动作及加热冷却控制选择···········································································5 -1 2

■ 特殊控制输出····································································································5 -1 2

■ MANUAL模式切换时························································································5 - 13

■ ON/OFF控制·····································································································5 - 13

■ PID控制 ············································································································5 - 14

■ 加热冷却控制····································································································5 -1 5

■ ST(自适应) ······································································································5- 1 7

■ AT(自整定) ······································································································5- 1 8

■ Just-FiTTER ····································································································5 - 20

■ Ra-PID··············································································································5- 20

■ SP·····················································································································5 - 20

5-4 AT(自整定)功能··········································································································5 -2 1

■ 启动方法 ···········································································································5 -2 1

■ 停止方法 ···········································································································5 -2 1

viii

Page 11

5-5 ST(自适应) 功能

····································································································· 5 - 24

■ 启动方法········································································································ 5- 24

■ 停止方法········································································································ 5- 25

5-6 ST(自适应)使用上的注意事项················································································· 5- 2 6

5-7 SP··························································································································· 5- 27

■ 运行显示时的SP设定····················································································· 5- 28

■ LSP使用组数································································································· 5- 28

■ LSP1~4········································································································ 5-2 8

■ LSP组编号 ···································································································· 5-2 8

■ LSP组选择的DI分配······················································································ 5- 29

■ SP斜坡单位 ··································································································· 5- 30

■ SP斜坡上升斜率·下降斜率·········································································· 5- 30

■ SP下限限幅·上限限幅················································································· 5- 31

■ SP斜坡许可/禁止的DI分配 ············································································ 5- 31

5-8 DI(数字输入)·内部接点························································································· 5- 32

■ 动作种类········································································································ 5- 33

■ 内部事件编号指定 ························································································· 5- 34

■ 输入位运算 ···································································································· 5- 34

■ 输入分配········································································································ 5- 35

■ 输入分配的反转 ····························································································· 5- 3 6

■ 运算的反转 ···································································································· 5- 36

■ 智能编程软件包SLP-C35进行的DI分配的设定 ············································· 5- 37

5-9 内部事件 ················································································································ 5- 3 8

■ 动 作············································································································ 5- 3 9

■ 动作种类········································································································ 5- 45

■ 正逆·待机·READY时动作 ········································································· 5- 4 6

■ 报警OR·特殊OFF设定·延迟时间单位······················································· 5- 47

■ 主设定·副设定·回差 ·················································································· 5- 48

■ ON延迟·OFF延迟························································································ 5- 49

5-10 DO(数字输出) ····································································································· 5- 51

■ MV1·MV2处理····························································································· 5- 52

■ 动作种类········································································································ 5- 53

■ 输出分配········································································································ 5- 54

■ 输出分配的反转 ····························································································· 5- 5 6

■ 运算的反转 ···································································································· 5- 57

■ 锁定

··············································································································· 5- 57

■ 智能编程软件包SLP-C35进行的DO分配的设定············································ 5-5 8

5-11 应用例·················································································································· 5- 59

■ 使用分配功能的应用例 ·················································································· 5- 59

5-12 连续输出 ·············································································································· 5- 66

■ 输出量程········································································································ 5- 66

■ 输出种类········································································································ 5- 66

■ 输出量程下限·上限······················································································ 5- 6 7

■ MV量程幅 ······································································································ 5- 68

5-13 CT(变流器)输入 ···································································································· 5- 69

■ CT动作 ·········································································································· 5- 70

■ CT监视输出 ··································································································· 5- 70

■ CT测定等待时间···························································································· 5- 7 0

ix

Page 12

■ CT匝数及CT电力线贯通次数

5-14 操作面板显示及键操作····························································································5- 73

■ 键操作种类········································································································5- 7 3

■ [mode]键功能··································································································· 5 -7 3

■ 模式显示设定····································································································5 -7 4

■ PV/SP值显示设定·····························································································5 - 75

■ 操作量显示设定 ································································································5- 7 6

■ 事件设定值显示设定 ························································································· 5- 7 7

■ 事件剩余时间显示设定 ·····················································································5 -7 7

■ CT电流值显示设定 ··························································································· 5 -7 8

■ 显示级别 ···········································································································5 -7 8

■ LED监视 ···········································································································5 -7 8

■ 用户功能 ···········································································································5 -7 9

■ 键锁定·通讯锁定·编程器锁定·······································································5 - 83

■ 口令 ·················································································································· 5 -8 4

第 6 章 显示·设定数据一览表

6-1 运行显示一览 ············································································································6 - 1

■ 运行显示 ···········································································································6 - 1

6-2 参数设定显示一览·····································································································6 - 3

■ 模式库···············································································································6 - 3

■ SP库 ·················································································································6 - 3

■ 事件库···············································································································6 - 4

■ PID库················································································································ 6 - 5

■ 参数库···············································································································6 - 6

■ 扩展调整库········································································································6 - 7

6-3 设置设定显示一览·····································································································6 - 8

■ 设置库···············································································································6 - 8

■ 事件组态库········································································································6- 1 3

■ DI分配库 ···········································································································6 -1 6

■ DO分配库 ·········································································································6 - 19

■ 用户功能库········································································································6- 2 3

■ 锁定库···············································································································6- 2 3

■ 仪表信息库········································································································6- 2 4

第 7 章 CPL通讯功能

7-1 通讯的概要················································································································ 7 - 1

■ 特 长···············································································································7 - 1

■ 设 定···············································································································7 - 1

■ 通讯步骤 ···········································································································7 - 2

7-2 电文的构成················································································································ 7 - 3

■ 电文的构成········································································································7 - 3

■ 数据链层 ···········································································································7 - 3

■ 应用层···············································································································7 - 5

············································································5- 7 1

x

Page 13

7-3 命令的说明

·············································································································

■ 连续数据读出命令(RS命令) ········································································· 7 - 6

■ 连续数据写入命令(WS命令) ········································································ 7 - 7

■ 固定长连续数据读出命令(RD命令) ······························································ 7 - 8

■ 固定长连续数据写入命令(WD命令) ····························································· 7 - 9

■ 固定长随机读出命令(RU命令) ····································································· 7-10

■ 固定长随机写入命令(WU命令) ···································································· 7-11

7-4 数据地址的定义···································································································· 7-12

7-5 应用层的数值表现································································································ 7-13

7-6 结束代码一览 ······································································································· 7-14

7-7 送收信时间··········································································································· 7-15

■ 命令文、应答电文时间规格··········································································· 7-15

■ RS-485驱动控制时间规格 ············································································· 7-15

7-8 主站用通讯程序作成时的注意事项······································································· 7-16

■ 通讯例子程序································································································· 7-16

第 8 章 MODBUS通讯功能

8-1 通讯的概要············································································································· 8 - 1

■ 特 长············································································································ 8 - 1

■ 设 定············································································································ 8 - 1

■ 通讯步骤········································································································ 8 - 2

8-2 电文的构成············································································································· 8 - 3

■ 电文的构成 ···································································································· 8 - 3

■ 命令种类········································································································ 8 - 6

■ 其他规格········································································································ 8 - 6

8-3 命令的说明············································································································· 8 - 7

■ 读出命令(03H) ····························································································· 8 - 7

■ 写入命令(10H) ····························································································· 8 - 9

8-4 CPL通讯及共通规格 ···························································································· 8-11

■ 数据地址的定义 ····························································································· 8-11

■ 数值表现········································································································ 8-11

■ RS-485驱动控制时间规格 ············································································· 8-11

第 9 章 通讯数据一览表

第10章 维护及故障时处理

■ 通讯数据一览表 ····························································································· 9 - 1

■ 维 护 ··········································································································· 10-1

■ 报警显示及对策 ····························································································· 10-1

■ PV输入异常时的动作····················································································· 10-2

7-6

xi

Page 14

第11章 校 正

■ 校正的开始········································································································11 - 1

■ 校正的结束········································································································11 - 1

■ 校正前的注意事项·····························································································1 1 -2

■ 校正时必要的仪器·····························································································1 1 -2

■ 校正步骤 ···········································································································1 1- 2

第12章 产品废弃处理

第13章 规 格

■ 规 格·················································································································1 3- 1

■ 附属品·可选部件·····························································································1 3 -4

附 录

索 引

用语集 ·······················································································································附-1

xii

Page 15

本使用说明书的标记

本使用说明书的标记如下。

使用上的注意事项:表示在使用时敬请注意的事项。

参考

①②③ :表示操作的顺序或对图等进行相应说明的部分。

[para]、[mode]等 :表示本机键盘的键、计算机画面的信息及菜单。

>> :表示操作的结果及操作后的状态。

● LED数值、文字显示

数字 7段LED显示如下。

0 1 2 3 4

5 6 7 8 9

英文 7段LED显示如下,有不能显示的英文字母。

A

a

:表示参照的项目及页码。

:表示知道该项内容后易于理解。

B

b

C

c

D

d

E

e

F

f

K

k

P

p

U

u

G

g

L

l

Q

q

V

v

H

h

M

m

R

r

Y

y

I

i

N

n

S

s

Z

z

J

j

O

o

T

t

-

使用上的注意事项

数字的2与英文字母的Z、数字的5与英文字母的S、数字的9与英文字母的

Q显示相同。

xiii

Page 16

Page 17

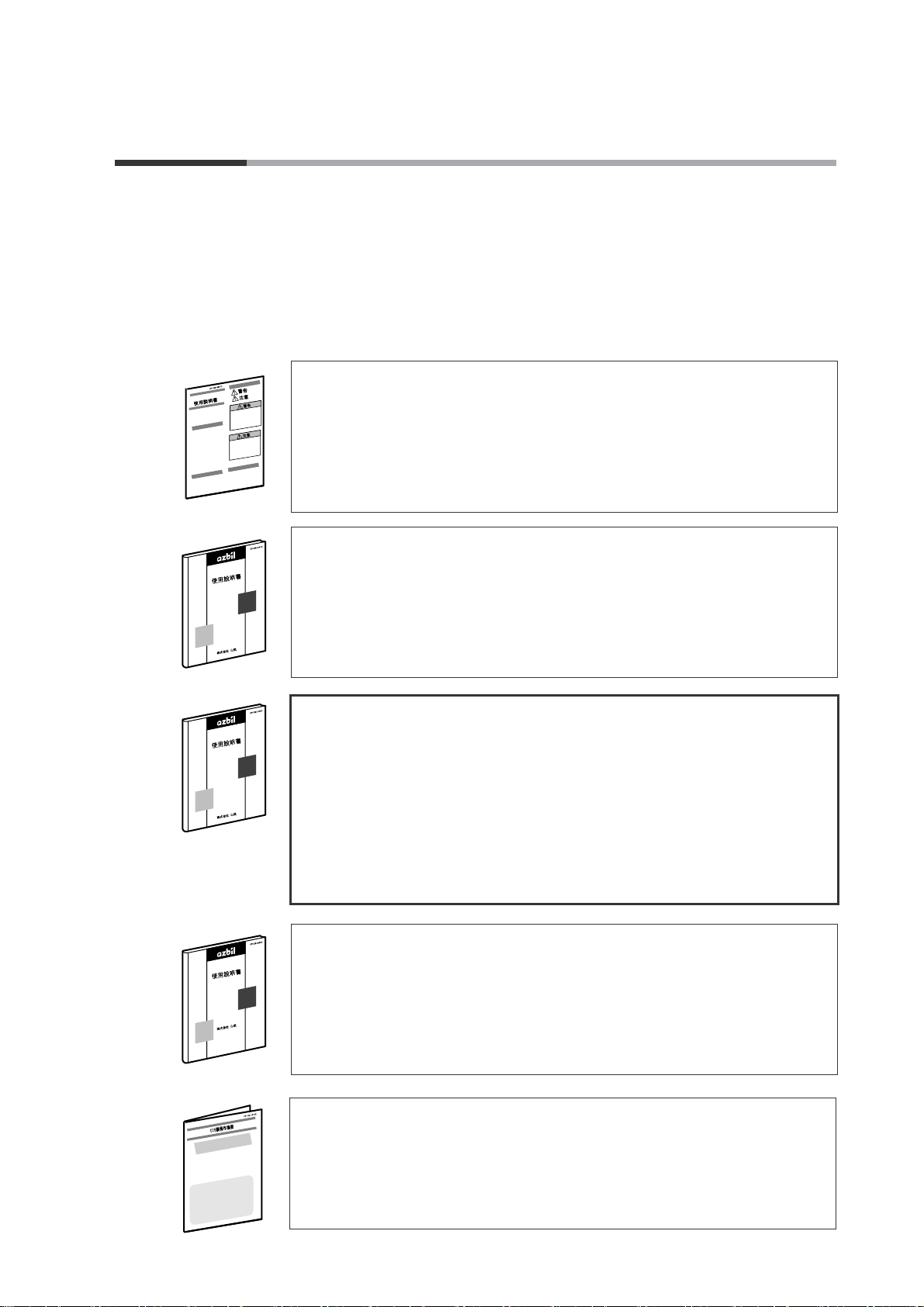

键操作指南

在D-1~D-8页上的“键操作指南”,是参数的变化图、设定一览及具体的操作例等的归纳说明。

详细内容请参阅正文。

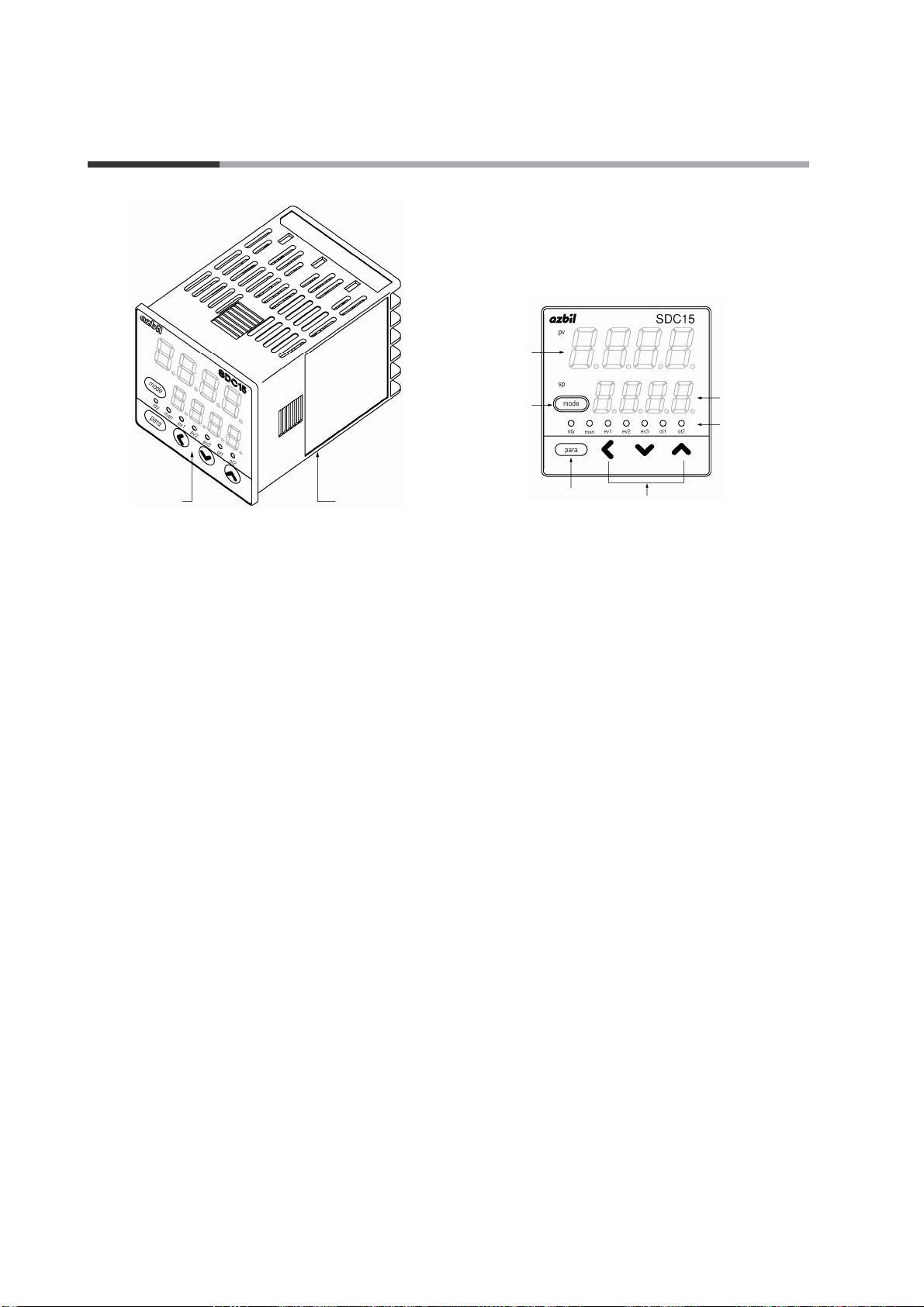

第1显示部

AT中显示灯

第2显示部

键

各种显示灯

模式显示灯

第1显示部

第2显示部

模式显示灯

[mode]键

键

编程器连接头(底部)

显示 PV 及各显示项目的显示值或设定值。

发生报警时,通常的显示与报警代码交替显示。

AT( 自整定 ) 执行时,右端位的小数点按亮 2 次灭 1 次显示。

显示 SP、MV、CT 及各显示项目的显示值或设定值。

根据设定,右端位的小数点可使 RUN/READY 模式灯或通讯状态灯亮。

rdy : READY 模式时灯亮 ( 灯灭时为 RUN 模式 )

man : MANUAL 模式时灯亮 ( 灯灭时为 AUTO 模式 )

ev1 ~ ev3 : 事件 1 ~ 3 输出 ON 时灯亮

ot1•ot2 : 控制 1 ~ 2 输出 ON 时灯亮 ( 电流输出及连续电压输出时

总为灯亮 )

运行显示状态下,连续按 1s 以上后,可进行下记预先设定好的 0 ~ 7 之一的

操作。

0 : 键操作无效 ( 初始值 ) 1: AUTO/MANUAL 模式切换

2 : RUN/READY 模式切换 3: AT( 自整定 ) 停止 / 启动切换

4 : LSP( 本地 SP) 组切换 5: 所有 DO( 数字输出 ) 锁定解除

6 : 键操作无效 7

• 设定显示状态下按 [mode] 键时,切换成运行显示。

: 通讯 DI( 数字输入 )1 的 ON/OFF 切换

键

[para]键

[<]�[∨]�[∧]键

编程器连接头

• 切换显示项目。

• 运行显示状态下连续按 2s 以上后,切换为库选择显示状态。

�

在数值的増减、位移动时使用。

编程器连接头位于底部,使用与智能篇程软件包同包装的专用电缆与计算机连

接。

D-1

Page 18

键操作及显示的变化

电源投入时

电源投入后6秒钟内灯灭,

模式显示灯依次灯亮,全

部灯亮后切换成运行显示

(AUTO时)

从MANUAL

变为AUTO时

去

2

2

按[para]键

【MODE库】

(MANUAL时)

从AUTO变

为MANUAL时

PV值

[para]键

SP值

注1

去

注3

)

LSP组编号

SP值

加热侧操作量

MV值 MV值

冷却侧操作量

MV值

1

)

【SP库】

【事件库】 【扩展调整 库】

【参数库】【PID库】

A

1

键

)

注3

键

按[para]

键2秒

去

D-2

Page 19

○ 根据有无可选项、型号、显示设定(C73~

○ 设定变更中按[para]键时,将取消操作

)、显示级别(

C78

C79

,显示下一个项目。

)的情况,有不能显示的项目。

运行显示

模

拟

输

入

按[para]

键2秒

PV值

AT进程值

定时器

剩余时间3

内部事件3

延迟时间

去

注2

SP

2

【设置库】

)

B

CT1

电流值

内部事件3

副设定

设定值

CT2

电流值

内部事件3

主设定

设定值

内部事件1

主设定

设定值

定时器

剩余时间2

内部事件2

延迟时间

内部事件1

副设定

设定值

内部事件2

副设定

设定值

定时器

剩余时间1

内部事件1

延迟时间

[para]

内部事件2

主设定

设定值

键

设定显示

【事件组态库】

【DI分配库】

【DO分配库】【用户功能库】

通

讯

【锁定库】 【仪表信息库】

键

连

控

制

动

续

输

出

作

操

作

·

显

键

示

去

注1)

显示UF(用户功能)登録的参数及数值

注2)

3分钟

以上不操作键时,自动返回PV显示②

注3)

按[para]键的同时按[<]时,可按各种显示•设定的显示切换相反的顺序进行操作

■ 箭头的说明

键

:

按[para]键

2秒

:

■ 各设定内的移动

键(正向位移动)

键+[<]键(反向位移动)

D-3

Page 20

具体的操作例

实心文字

白色黑边文字

: 初始设定的项目

: 运行状态下设定的项目

设定 PV 量程种类

1

3

从运行显示开始操

作

按 [mode] 键 1 次

置为运行显示

传感器未配线或断线的

场合,在第 1 显示部

上可能显示 PV 输入异

常的报警 (

之一 )

请再次连续按 [para]

键 2s 以上

变为设置设定显示

显示设定

量程 ) 的设定值

AL01~AL07

C01

(PV

2

4

,

请 连 续 按 [para]

键 2s 以上

变为 参 数 设 定显

示, 第 1 显 示部

闪烁显示

ON/OFF 控制的场合,

第 1 显示部上显示

按 [ <]、[∨ ]、[ ∧]

键之一后、第 2 显

示部的最右位闪烁

显示。

根据 PV 量 程表,

变更为希望的传感

器类型,不按键等

待 2s 以 上后, 显

示 从闪 烁 变 为 灯

亮,确定设定值

设定事件的动作种类

以在事件 1 上设定动作种类为「偏差上限」为例

1

从运行显示操作

请按 [display] 键 1

次置为运行显示

2

请连续按 [para] 键

2s 以上

变为参数设定显示

第 1 显 示 部 显 示

a--m

a--m

r--r

执行自整定 (AT)

AT 是强 制 性 地 重 复 MV 的 ON 及 OFF( 限幅 循环 ), 求 出 PID

的动作。

请确认这种动作对装置无影响后,再执行 AT。

1

3

5 6

在 AT 执行中,当有 READY 模式切换、MANUAL 模式切换、

PV 输入异常、发生停电时,AT 将不会变更 PID参数而自动停止。

另外,在 AT 执行中强制中止的场合,请按步骤 3,从

变更为

从运行显示开始操

作

按 [mode] 键 1 次

置为运行显示

按 [para] 键 2 次后,

在第 1 显示部上显

示at、 在 第 2 显

示部上显示

控制方式选择为「ON/

OFF 控 制 」 及 变更 了

设 置 数 据

示设定 ) 的场合, 将不

显示。

按 [ ∧ ] 键 1 次后,

第 2 显示部变为

at.On

at.Of

C73

的闪烁显示

。

at.Of

( 模 式 显

2

4

请 连 续 按 [para]

键 2s 以上

变 为 参数 设 定显

示, 第 1 显 示 部

闪烁显示

按 [ ∨ ] 键 或 [ ∧ ]

键 后,

烁显示。

只 有 在 RUN 模 式 且

AUTO 模式下,没有发

生 PV 输入异常时 才会

闪 烁, 另 外,DI 分 配

选择了「AT 停止 /启动」

的场合,不闪烁,不可

变更。

不 按 键 , 等 待 2s

以 上 后,

亮,AT 启动。

AT 执 行 中, 第 1

显示部的右端位的

小数点每灯亮 2 次

闪烁 1 次 (AT 结束

后灯灭,求出 PID)

a--m

at.Of

at.On

at.ON

将 闪

灯

3

5

同样,

的设定

再次持续按 [para]

键 2s 以上

变 为 设置 设定 显

示, 显 示 设 置 数

C01

据

(PV 量程种

类 ) 的设定值

按 [ ∨ ] 键或 [ ∧ ] 键时,第 2 显示部的最右位闪烁

显示。

按 [ ∨ ] 键或 [ ∧ ] 键,变更成4的闪烁显示,不按

任何键,等待 2s 以上 后,从闪烁变为灯 亮,确定

设定值。

第 2 显示部的4是事件动作种类为「偏差上限」的设定

为事件 2 的动作种类、

e2.C1

4

e3.C1

数次按 [para] 键,

第 1 显 示 部 显 示

e1.c1

、第 2 显示 部

0

显示

第 2 显示部的

件动作种类设定为「无」

为事件 3 的动作种类

表示事

0

设定 SP 值

1

3

SP 限幅动作后,数值不能变更成大

于某个值以上的值。

要进行数值变更时,需变更 SP 限幅。

从运行显示开始操

作 ( 按 [mode] 键 1

次后 , 变为运行 显

示 )

按 [ < ]、[ ∨ ]、

[ ∧ ] 键之一后 , 第

2 显示部上的最右

位闪烁显示,变更

为 希 望 的 SP 值。

另外,数值闪烁状

态表示在内部尚未

进行数值的确定,

与数值变更前的状

态相同

2

4

请确认运行显示处

于 SP 显示状态( 数

次按 [para] 键后,

显示 )

不按键,等待 2s

以上后,显示从闪

烁变为灯亮,确定

设定值。

在闪烁状态下 , 按

[mode] 键后 , 回到步

骤 1 的状态

D-4

Page 21

•

步骤用粗框表示处需注意以下事项

4

设定有键锁的场合,数值不会闪烁,数值不可变更。

要进行数值变更时,请务必解除键锁。

切換 RUN/READY 模式

1

3

5 6

从运行模式开始操

作

请按 [display] 键 1

次置为运行显示

按 [para] 键 1 次后,

在第 1 显示部上显

r--r

示

显 示 部 上 显 示

rdY

RUN

RDY

表示当前的模式。

按 [ ∨ ] 键或 [ ∧ ]

键后,第 2 显示部

变成

闪烁显示。

, 第 2

run

( 或

)

是 RUN 模式,

是 READY 模式,

RUN

RDY

( 或

)

设定 PID 值

1

从运行显示开始

操作。

( 按 [mode] 键 1 次

后 , 变为运行显示 )

2

2

4

请持 续按 [para] 键

2s 以 上, 变 为 参

数 设 定 显 示, 在

第 1 显示部上显示

a--m

ON/OFF 控制的场合 ,

在第 1 显示部上显示

r--r

按 [ ∨ ] 键 或 [ ∧ ]

键后,第 2 显示部

闪烁显示。

DI 分配选择「RUN/

READY 切换」的场合 ,

不闪烁,不可变更。

不 按 键 等 待 2s 以

上后,显示从闪烁

变为灯亮,确定模

式切换。

请持续按 [para]

键 2s 以 上 , 变 成

参数设定显示 , 在

第 1 显示部上显示

A--M

设定事件的设定值

1

3

5

同样,E2是事件 2 的事件设定 值、E3是事件 3 的事件设

定值

6

从运行显示开始操

作。

( 按 [mode] 键 1 次

后 , 变为运行显示 )

数次按 [para] 后,

在第 1 显示部上显

E1

示

、在第 2 显示

部上显示0。

第 2 显示部的0表示事

件主设定为「0」

不按键等待 2s 以上后,显示从闪烁变为灯亮,确定

设定值。

在显示闪烁状态下按 [mode] 键,将回到步骤 1 的状态。

继续进行回差设定

的场合,按 [ ∨ ]

键 2 次或数次按

[ ∧ ] 键,第 1 显示

部上显示

第 2 显示部上显示

5

第 2 显示部的5表示事

件回差值设定为 5

e1.hY

2

4

7

、

请持 续按 [para] 键

2S 以 上, 变 为 参

数设定显示。

在第 1 显示部上显

A--M

示

按 [< ]、[ ∨ ]、[ ∧]

键之一,第 2 显示

部的最右位闪烁显

示 , 变更成希望 的

事件设定值。

另外 , 数值闪烁状

态表示在内部尚未

确定数值 , 与数值

变更前的状态相同

按 [< ]、[ ∨ ]、[ ∧]

键之一,第 2 显示

部的最右位闪烁显

示,变更为希望的

回差设定值。

不 按 键 , 等 待 2s

以上后,显示从闪

烁变为灯亮,确定

设定值。

3

5

同样

分时间(0 ~ 9999s)的设定值

请 数 次 按 [para] 键

后 , 在第 1 显示部上

显 示 比 例帯

第 2 显 示部 上 显 示

设定值。

控制 方 式 选 择 为「ON/

OFF 控制」的场合,将

不显示。

不按键等待 2s 以上时 , 显示从闪烁变为灯亮 , 确定

设定值。

在显示闪烁状态下按 [mode] 键,将回到步骤 1 的状态

是积分时间(0 ~ 9999s)的设定值、

1 - 1

P--I

、

4

按 [< ]、[ ∨ ]、[ ∧]

键之一后,第 2 显

示部的最右位闪烁

显示 , 变更比例 帯

为希望的设定值。

另外 , 数值闪烁 状

态表示在内部尚未

确定数值 , 与数 值

变 更 前 的 状 态 相

同。

比例帯的设定范围为

0.1 ~ 999.9%

是微

d- 1

D-5

同样,

E2.hY

回差设定值

Memo

是事 件 2 的 回差设定值、

E3.HY

是事 件 3 的

Page 22

参数一览

PV 测定及控制时必须的参数

:

基本的参数

:

:

使用可选项时的必须参数

运行显示一览

显 示

上段 : 第 1 显示部

下段 : 第 2 显示部

PV

SP

( 显示例 )

LSP1

LSP

PV

MV

HEAt

数值

Coo L

数值

PV

( 显示例 )

At1

Ct1

数值

Ct2

数值

E1

数值

E1.Sb

数值

( 显示例 )数值定时器剩余时间 1 不可设定

t1 .--

E2

数值

E2.Sb

数值

( 显示例 )数值定时器剩余时间 2 与定时器剩余时间 1 相同 -

t2 .--

E3

数值

E3.Sb

数值

( 显示例 ) 定时器剩余时间 3 与定时器剩余时间 1相同 -

t3 .--

项 目 内 容 初始值 设定值

SP( 目标值 ) SP 限幅下限~上限 0

LSP 组编号

( 第 1 位 = 最右位的数值 )

MV( 操作量 ) - 10.0 ~+ 110.0%

加热 MV( 操作量 ) 不可设定

冷却 MV( 操作量 )

AT 进程

( 第 1 位=最右位的数值 )

CT1 电流值 不可设定 -

CT2 电流值 不可设定 -

内部事件 1 主设定 - 1999~+ 9999U或 0~ 9999U 0

内部事件 1 副设定

内部事件 2 主设定 与内部事件 1主设定相同 0

内部事件 2 副设定 与内部事件 1副设定相同 0

内部事件 3 主设定 与内部事件 1主设定相同 0

内部事件 3 副设定 与内部事件 1副设定相同 0

1 ~ LSP 使用组数 ( 最大 4) 1

MANUAL 模式下可设定 ( 数值闪烁 )

- 10.0 ~+ 110.0%

不可设定 -

第 1 显示部上显示 ON延迟、OFF 延迟的区别

-

-

-

-

参数设定显示一览

【模式库】

MOde

显 示 项 目 内 容 初始值 设定值

A--M

r--r

At

do.Lt

C.dI

SP-1~SP-4

E1~E5

E1.Sb~E5.Sb

E1.HY~E5.HY

E1.on~E5.on

E1.of~E5.of

P-1

I-1

d-1

rE-1

oL-1

oH-1

P-1C

I-1C

d-1C

oL.1C

oH.1C

控

制

PV

时

间

比

例

输

出

SP

*1 0:1s 单位 1:0.5s 单位 2:0.2s 单位 3:0.1s 单位 U: Unit PV 量 程 的 工 业 量 (℃ , Pa,l/min 的 )

*2 输出含继电器输出的场合为 5 ~ 120s

AUTO/MANUAL

RUN/READY

AT停止/

所有DO锁定解除

1

通讯

【SP 库】

SP

显 示 项 目 内 容 初始值 设定值

LSP1~4组的SP SP

【事件库】

Ev

显 示 项 目 内 容 初始值 设定值

●

●

【PID 库】

PI D

显 示 项 目 内 容 初始值 设定值

●

●

●

●

【参数库】

PARA

显 示 项 目 内 容 初始值 设定值

CtrL

At.oL

At.oH

dIFF

oFFS

●

FL

rA

●

bI

CYU

CY

CYU2

CY2

tP.tY

SPU

SPd

●

●

●

●

●

切换

切换

启动切换

DI1

内部事件1~5主设定 -

内部事件1~5副设定

内部事件1~5回差

5 ON

内部事件1~

内部事件1~

比例帯 (PID1) 0.1 ~ 999.9%

积分时间 (PID1) 0 ~ 9999s (0 时无动作 )

微分时间 (PID1) 0 ~ 9999s 0 时无动作 )

手动复位 (PID1) - 10.0 ~+ 110.0%

操作量下限 (PID1) - 10.0 ~+ 110.0%

操作量上限 (PID1) - 10.0 ~+ 110.0%

冷却侧比例帯 (PID1) 0.1 ~ 999.9%

冷却侧积分时间 (PID1) 0 ~ 9999s (0 时无动作 )

冷却侧微分时间 (PID1) 0 ~ 9999s (0 时无动作 )

冷却侧操作量下限 (PID1) - 10.0~+ 110.0%

冷却侧操作量上限 (PID1) - 10.0~+ 110.0%

控制方式

AT 时操作量下限 -

AT 时操作量上限 -

ON/OFF 控制差动

ON/OFF 控制动作点偏移量 -

PV 滤波

PV 比率

PV 偏置 -

时间比例单位 1

时间比例周期 1

时间比例单位 2

时间比例周期 2

时间比例动作种类

SP 斜坡上升斜率

SP 斜坡下降斜率

5 OFF

延迟

延迟

AUTO(自动)

:

AUTo

RUN

:

RUN

:AT停止

At.oF

: 锁定继续

Lt.oN

dI.oF

OFF

:

限幅下限~上限

1999~+9999U或0~9999

(

小数点位置根据内部事件动作种类变化

0~9999

(

小数点位置根据内部事件动作种类变化

0.0~999.9或0~9999 0

0: ON/OFF控制 1: PID

2: ST( 自整定 )

10.0~+110.0

10.0~+110.0

0~9999U 5

1999~+9999U 0

0.0~120.0s 0.0

0.001~9.999 1.000

1999~+9999U 0

*1

0~3

5~120s或1~120s

*1

0~3

5~120s或1~120s

0:

控制性重视型

1:

操作端寿命重视型(时间比例周期内仅

动作1次)

0.0~999.9U(0.0U

:MANUAL(手动)

MAN

READY

:

RDY

:AT启动

At.oN

: 锁定解除

Lt.oF

dI.on

ON

:

固定

%

%

*2

*2

) 0.0

时无斜率

的最小单位

)

)

ON/OFF

AUTO

RUN

AT

停止

锁定继续

OFF

0

0

0

5

5.0

120

30

50.0

0.0

100.0

5.0

120

30

0.0

100.0

0

或

0.0

100.0

0

10

或

0

10

或

0

或

0.0

1

2

2

1

Et

At.tY

JF.b d

SP. LG

At-P

At-I

At-d

Ct r.A

JF.o v

St.SA

St.Sb

St.Hb

St.ud

【扩展调整库】

显 示 项 目 内 容 初始值 设定值

AT 种类 0: 通常 1: 立即响应 2 : 稳定

●

JF 整定幅 0.00 ~ 10.00

●

SP 拖位常数 0.0 ~ 999.9

●

AT 时比例帯调整系数 0.00 ~ 99.99

●

AT 时积分时间调整系数 0.00 ~ 99.99

●

AT 时微分时间调整系数 0.00 ~ 99.99

控制运算 0:PID( 旧型 PID) 1:Ra-PID( 高性能型 PID)

JF 超调抑制系数 0 ~ 100

●

ST 步执行判定幅 0.0 ~ 99.99

●

ST 步整定幅 0.0 ~ 10.00

●

ST 振荡整定幅 0.0 ~ 10.00

●

ST 步升降切换 0:PV 上升/下降时均执行 ST

1: 仅 PV 上升时执行 ST

*1

*1 通常 = 标准的控制特性 立即响应 = 迅速响应干扰的控制特性 稳定 =PV 上下波动小的控制。

设置设定显示一览

【设置库】

StUP

显 示 项 目 内 容 初始值 设定值

C01

模

拟

C02

输

C03

入

C04

C05

C06

C07

C08

C09

C14

控

C15

制

动

C16

作

C17

C18

C19

C20

C21

C22

C26

C27

C28

C29

C30

SP

C32

C36

C37

C38

C39

C40

C41

C42

连

C43

续

输

出

C44

C45

C46

C47

C48

C49

C50

C51

C64

通

讯

C65

C66

C67

C68

C69

C70

C71

键

C72

操

作

•

C73

显

示

C74

C75

C76

C77

C78

C79

C80

C90

C91

C92

C93

*1 热电偶的场合不可设定

PV 量程种类 参照量程表

温度单位 0: 摄氏 (℃) 1: 华氏 ( ℉ )

●

冷接点补偿 0: 执行 ( 内部 ) 1: 不执行 ( 外部 )

小数点位置 0: 无小数点 1 ~ 3: 小数点以下 1~ 3位

PV 量程下限

PV 量程上限

●

SP 限幅下限

●

SP 限幅上限

●

开方运算小信号切除

控制动作 ( 正逆 )

●

PV 异常时操作量选择

●

PV 异常时操作量

●

READY 时操作量

( 加热冷却控制的场合为加热侧 )

●

READY 时操作量 ( 冷却侧 )

●

MANUAL 变更时动作

●

预置 MANUAL 值 - 10.0 ~+ 110.0% 0.0

●

PID 运算初始化功能选择

●

PID 运算初始操作量 - 10.0 ~+ 110.0% 0.0

加热冷却控制选择

●

加热冷却切换

加热冷却控制死区

●

加热冷却控制切换点

LSP 使用组数

●

SP 斜坡单位

CT1 动作

CT1 监视输出

CT1 测定等待时间

CT2 动作

CT2 监视输出

CT2 测定等待时间

控制输出 1 量程

控制输出 1 种类 0: MV 1: 加热 MV 2: 冷却 MV 3:PV

控制输出 1 量程下限 - 1999 ~+ 9999U 0.0

控制输出 1 量程上限

控制输出 1MV 量程幅 0 ~ 9999( 控制输出 1 种类为10、11 时有效 ) 200

控制输出 2 量程 与控制输出 1 量程相同 1

控制输出 2 种类 与控制输出 1 种类相同 3

控制输出 2 量程下限 与控制输出 1 量程下限相同 0

控制输出 2 量程上限 与控制输出 1 量程上限相同 1000

控制输出 2MV 量程幅 与控制输出 1MV量程幅相同 200

通讯种类 0:CPL 1:MODBUS ASCII 形式

机器地址 0 ~ 127(0时无通讯 ) 0

传送速度 (bps) 0:4800 1:9600 2 :19200 3:38400 2

数据形式 ( 数据长 ) 0:7 位 1:8 位 1

数据形式 ( 校验 ) 0: 偶数 1: 奇数 2 : 无 0

数据形式 ( 停止位 ) 0:1 位 1:2 位 0

●

通讯最小应答时间 1 ~ 250ms 3

●

键操作种类 0: 标准型 1: 特殊型 0

Mode 键功能 0: 无效 1: AUTO/MANUAL 切换

●

模式显示设定 ( 权重之和 ) 位 0:AUTO/MANUAL 显示 ( 有 : + 1)

●

PV/SP 值显示设定 ( 权重之和 )

●

操作量显示设定 ( 权重之和 ) 位 0:MV显示 (有 :+ 1)

●

事件设定值显示设定

( 运行显示 )

●

事件剩余时间显示设定

( 运行显示 )

●

CT 输入电流值显示设定

( 运行显示 )

显示级别 0: 简单 1: 标准 2: 多功能 0

●

LED 监视

●

CT1 匝数 0:800 匝

●

CT1 电力线贯通次数 0:1 次 1 ~ 6: 次数 1

●

CT2 匝数 与 CT1匝数相同 8

●

CT2 电力线贯通次数 与 CT1 电力线贯通次数相同 1

PV 量程种类为直流电压、直流电流的场合

- 1999 ~+ 9999U

PV 量程下限~ PV 量程上限

0.0 ~ 100.0%(0.0 时无开方运算 ) 0.0

0: 加热控制 ( 逆动作 ) 1: 冷却控制 (正动作 ) 0

0: 控制运算继续 1:PV 异常时输出操作量 0

- 10.0 ~+ 110.0% 0.0

- 10.0 ~+ 110.0% 0.0

- 10.0 ~+ 110.0% 0.0

0: 无扰 1: 预置 0

0: 自动 1: 不初始化 2 : 初始化 0

0: 不使用 1: 使用 0

0: 通常 1: 省电 0

- 100.0 ~+ 100.0% 0.0

- 10.0 ~+ 110.0% 50.0

1 ~ 4 1

0:0.1U/s 1:0.1U/min 2 :0.1U/h 1

0: 加热器断线检测 1: 电流值测量 0

0 ~ 1: 控制输出 1 ~2 2 ~ 4: 事件输出 1 ~

30 ~ 300ms 30

与 CT1 动作相同 0

与 CT1 监视输出相同 0

CT1 测定等待时间

1:4 ~ 20mA 2 :0 ~ 20mA 1

4: 比率 • 偏置 • 滤波前 PV

5: SP 6: 偏差 7:CT1 电流值 8:CT2 电流值

10: SP + MV 11:PV + MV

2:MODBUS RTU 形式

2: RUN/READY 切换 3: AT 停止 / 启动

4: LSP 组切换 5: 所有 DO 锁定解除

6: 无效 7: 通讯 DI1 切换 8: 无效

位 1:RUN/READY 显示 ( 有 : + 2)

位 3:AT 停止 / 启动显示 ( 有 : + 8)

位 4:DO 锁定解除显示 ( 有 : + 16)

位 5: 通讯 DI1ON/OFF 显示 ( 有 : + 32)

其它无效设定 0、+ 4、+ 64、+ 128

位 0:PV 显示 ( 有 : + 1)

位 1:SP 显示 ( 有 : + 2)

位 2 :LSP 组编号显示 ( 有 : + 4)

其它无效设定 0、+ 8

位 1: 加热 MV/ 冷却 MV 显示 ( 有 : + 2)

位 3:AT 进程显示 ( 有 : + 8)

其它无效设定 : 0、+ 4

0: 不显示

1: 显示内部事件 1

2: 显示内部事件 1 ~ 2

3: 显示内部事件 1 ~ 3

0: 不显示

1: 显示内部事件 1

2: 显示内部事件 1 ~ 2

3: 显示内部事件 1 ~ 3

0: 不显示 1: 显示 CT1

2: 显示 CT1 ~ 2

0: 不使用 1:RS-485 通讯发信时闪烁

2:RS-485 通讯收信时闪烁

3: 全 DI 状态的 OR( 逻辑和) 4:READY 时闪烁

1 ~ 40: 匝数按设定值的 100 倍

按型号

或 50.0

或 50.0

3 0

1

0.30

0.0

1.00

1.00

1.00

0

0

10.0

0.50

1.00

0

1000

30

100.0

255

15

15

0

0

0

0

0

0

0

0

0

0

0

8

D-6

Page 23

○ 表中的「●」是多功能设定及标准设定下显示的项目。

○ 要变更显示级别时,请参阅右下的

【事件组态库】

EUCF

显 示 项 目 内 容 初始值 设定值

E1.C1

~

E1.C2~E5.C2

E1.C3~E5.C3

DI

显 示 项 目 内 容 初始值 设定值

dI

1.1~dI 3.1

dI

1.2~dI 3.2

dI

1.3~dI 3.3

1.4~dI 3.4

dI

dI

1.5~dI 3.5

dI

1.6~dI 3.6

dI

1.7~dI 3.7

1.8~dI 3.8

dI

1.9~dI 3.9

dI

内部事件 1 ~ 5 组态 1 动作种类

E5.C1

内部事件 1 ~ 5 组态 2

第 1 位 : 正逆

第 2 位 : 待机

第 3 位 :READY 时动作

第 4 位未定义

内部事件 1 ~ 5 组态 3

●

第 1 位 : 报警 OR

第 2 位 : 特殊 OFF

第 3 位 : 延迟时间单位

第 4 位 : 未定义

【DI分配库】

内部接点

●

内部接点 1~3 输入位运算

●

内部接点 1~3 输入分配 A

●

内部接点 1~3 输入分配 B

●

内部接点 1~3 输入分配 C

●

内部接点 1~3 输入分配 D

●

内部接点 1~3 反转 A~D

第1位:反转

第2位:反转

第3位:反转

第4位:反转

●

内部接点 1~5 反转

●

内部接点 1~5

内部事件编号指定

参照事件的种类

从右侧开始1、2、3、4位

0:正 1:

逆

0:无 1:待机 2:

0:继续 1:强制OFF 0

0 0

从右侧开始1、2、3、4位

0:无 1:正(OR动作) 2:正(AND动作)

3:逆(OR动作) 4:逆(AND动作)

0:

通常

1:

事件设定值(主

0:0.1s 1:1s 2:1min 0

0 0

3

1

动作种类

~

A

B

C

D

0: 无功能 1:LSP 组选择 (0/ + 1)

2 :LSP 组选择 (0/ + 2) 3:LSP 组选择(0/ + 4)

4: 无效 5: 无效

6: 无效 7:RUN/READY 切换

8:AUTO/MANUAL 切换 9:LSP/RSP 切换

10:AT 停止 / 启动 11:ST 禁止/无效

12: 控制动作正逆切换 13:SP 斜坡许可 / 禁止

14:PV 値保持 15:PV 最大値保持

16:PV 最小値保持 17: 定时器停止 / 启动

18: 所有 DO 锁定解除 ( 继续 /解除)

19: 无效 20: 无效

0: 不使用 ( 缺省的输入 )

1: 运算 1((A and B) or (C and D))

2: 运算 2((A or B) and (C or D))

3: 运算 3(A or B or C or D)

4: 运算 4(A and B and C and D)

0: 常开 1: 常闭 2 :DI1 3:DI2

4 ~ 9: 未定义 10 ~14: 内部事件 1 ~ 5

15 ~ 17: 未定义 18 ~21: 通讯 DI1 ~ 4

22:MANUAL 23:READY 24: 未定义

25:AT 启动中 26:SP 斜坡中 27:未定义

28: 有报警 29: 有 PV 报警

30: 未定义 31:mode 键按下状态

32: 事件输出 1 端子状态

33: 控制输出 1 端子状态

从右侧开始 1、2、3、4 位

0: 不反转 1: 反转

0: 不反转 1: 反转

0: 全部内部事件

1 ~ 5: 内部事件编号

待机+SP变更时待机

)=0

时事件

显示级别的变更方法

0

0

0

0

2~4

或

0

0

0

0

0

0

0

0

0

0

OFF

Id01

Id02

Id03

Id04

Id05

Id06

Id07

Id08

【仪表信息库】

ID

显 示 项 目 初始值 初始值 设定值

●

仪表种类编号 0: 固定 不可设定

●

ROM 版本1 XX.XX(

●

ROM 版本2 XX.XX(

●

SLP

对应版本 不可设定

●

EST

对应版本 不可设定

●

日期代码 年 公历

●

日期代码 月日 月+(日

●

制造编号 不可设定

小数点以下2位

小数点以下2位

-2000 例: 2003

÷100) 例:12月1

)

)

年为「3」 不可设定

12.01

日为「

不可设定

不可设定

」 不可设定

设定时的注意事项

• AT 的种类由 [ 扩展调整库 ] 的

(AT 种类 ) 变更。请根据控制特性设定。

At.tY

Memo

【DO分配库】

Do

显 示 项 目 内 容 初始值 设定值

Ot1.1~Ot2.1

Ev1.1~Ev3.1

Ot1.2~Ot2.2

Ev1.2~Ev3.2

Ot1.3~Ot2.3

Ev1.3~Ev3.3

Ot1.4~Ot2.4

Ev1.4~Ev3.4

Ot1.5~Ot2.5

Ev1.5~Ev3.5

Ot1.6~Ot2.6

Ev1.6~Ev3.6

Ot1.7~Ot2.7

Ev1.7~Ev3.7

Ot1.8~Ot2.8

Ev1.8~Ev3.8

UF-1~UF-8

LOC

LoC

C.LoC

L.LoC

PASS

PS1A

PS2A

PS1b

PS2b

●

动作种类(控制输出1~2、

事件输出1~

●

输出分配A(控制输出1~2、

事件输出1~

●

输出分配B(控制输出1~2、

事件输出1~

●

输出分配C(控制输出1~2、

事件输出1~

●

输出分配D(控制输出1~2、

事件输出1~

●

控制输出1~2、事件输出

~

第1位:反转

第2位:反转

第3位:反转

第4位:反转

●

反转(控制输出1~2、

事件输出1~

●

锁定(控制输出1~2、

事件输出1~

【用户功能库】

UF

显 示 项 目 内 容 初始值 设定值

用户功能定义 1~8

3)

3)

3)

3)

3)

3 反转A~D

A 0:

B

C

D

3)

3)

0:

3~6:运算1~4

0: 常开 1: 常闭

2 ~ 6: 内部事件 1 ~ 5 7 ~ 9: 无效

10 ~ 13: 未定义 14 ~ 15: MV1 ~2

16 ~ 17: 未定义 18 ~ 21: DI1 ~4

22 ~ 25: 未定义 26 ~ 30: 内部接点 1 ~ 5

31 ~ 33: 未定义 34 ~ 37: DI1 ~4

38: MANUAL 39: READY 40: 无效

41: AT启动中 42: SP 斜坡中

43: 未定义 44: 有报警

45: 有 PV 报警 46: 未定义

47: 按下 mode 键状态

48: 事件输出 1 端子状态

49: 控制输出 1 端子状态

1

从右侧开始1、2、3、4位

0:

0:无 1:有(ON

2:有(OFF

-

1~2: MV1~2

缺省的输出

1:

不反转

反转

1:

不反转

反转

时锁定

时锁定,电源投入初始化时除外

)

)

0

14~15

或

2~4

0

0

0

0

0

0

0

-

【锁定库】

显 示 项 目 初始值 初始值 设定值

●

●

键锁

通讯锁定

编程器锁定

口令显示

1A

口令

2A

口令

1B

口令

2B

口令

0:

无

1:

模式、事件、运行显示、SP、UF、锁定、手动

MV

、[mode] 键可设定

2:

运行显示、SP、UF、锁定、手动MV、[mode]

键可设定

3: UF

、锁定、手动MV、[mode] 键可设定

0: read/write 可能 1: read/write 不可

0: read/write 可能 1: read/write 不可

0 ~ 15(5: 显示口令 1A ~ 2B)

0000 ~ FFFF(16 进制数 )

0000 ~ FFFF(16 进制数 )

0000 ~ FFFF(16 进制数 )

0000 ~ FFFF(16 进制数 )

0000

0000

0000

0000

0

0

0

0

显示级别的变更方法

本机的显示级别通过设置设定数据 C79: 显示级别可从 3 种类中选择。

显示级别按多功能设定>标准设定>简单设定的顺序 , 可显示 • 设

定的項目增多。另外,多功能设定下可显示所有项目。

1

3

按 [mode] 键 1 次, 置

为运行显示

请连续按 [para] 键 2 秒

以上

变为参数设定显示

第 1 显示部上显示

或

a--m

R--R

请数次按 [para] 键,变

更为

(C79: 显示 级

C79

别 )

2

4

请再次持续按 [para] 键

2s 以 上, 在 第 1 显 示

部上显示

C01

按 [ < ]

[ ∨ ]、[ ∧ ]

、

键之一的任一键 , 使第

2 显示部闪烁

按 [ ∨ ]

[ ∧ ] 键 , 变

、

更为希望的数值 , 手指

离开键 2s 后 , 数值灯

亮 , 确定。

0: 简单设定 ( 初始值 )

1: 标准设定

2: 多功能设定

D-7

Page 24

PV

SP

PV 量程表 事件的种类

【热电偶】 【热电阻】

传感器

C01

设定值

注 1) PL Ⅱ热电偶是 2003 年 7 月以后产品追加的量程。

注 2) B 热电偶的显示値下限为 20℃。但当仪表信息库的 ROM 版本 1(

注 3) 热电偶、热电阻、直流电压 • 直流电流根据 PV No. 型号决定。

类型

1

K - 200 ~+ 1200℃

2

K 0 ~ 1200℃

3

K 0 ~ 800℃

4

K 0 ~ 600℃

5

K 0 ~ 400℃

6

K - 200 ~+ 400℃

9

J 0 ~ 800℃

10

J 0 ~ 600℃

11

J - 200 ~+ 400℃

13

E 0 ~ 600℃

14

T - 200 ~+ 400℃

15

R 0 ~ 1600℃

16

S 0 ~ 1600℃

17

B 0 ~ 1800℃

18

N 0 ~ 1300℃

19

PL II 0 ~ 1300℃

20

WRe5-26 0 ~ 1400℃

21

WRe5-26 0 ~ 2300℃

24

DIN U - 200 ~+ 400℃

25

DIN L - 100 ~+ 800℃

: 初始值

为- 180℃。

量程

C01

设定值

41 Pt100 - 200 ~+ 500℃

42 JPt100 - 200 ~+ 500℃

43 Pt100 - 200 ~+ 200℃

44 JPt100 - 200 ~+ 200℃

45 Pt100 - 100 ~+ 300℃

46 JPt100 - 100 ~+ 300℃

51 Pt100 - 50.0 ~+ 200.0℃

52 JPt100 - 50.0 ~+ 200.0℃

53 Pt100 - 50.0 ~+ 100.0℃

54 JPt100 - 50.0 ~+ 100.0℃

63 Pt100 0 ~ 200.0℃

64 JPt100 0 ~ 200.0℃

67 Pt100 0 ~ 500℃

68 JPt100 0 ~ 500℃

【直流电压• 直流电流】

C01

设定值

84 0 ~ 1V 86 1 ~ 5V

87 0 ~ 5V

88 0 ~ 10V

89 0 ~ 20mA

90 4 ~ 20mA

报警代码一览

输

入

异

常

仪

表

异

常

报警

代码

AL01

AL02

AL03

AL1 1

A L7 0

AL9 5

AL9 6

AL97

AL9 8

AL9 9

异常名称 原 因 处 理

PV 输入异常

( 上超量程 )

PV 输入异常

( 下超量程 )

传感器断线、误接线

PV 量程种类误设定

传感器断线、误接线

PV 量程种类误设定

CJ 异常 端子温度异常 ( 热电偶 ) 环境温度的确认

PV 输入异常

( 热电阻 )

CT 输入异常

( 上超量程 )

(CT 输入 1/2 的单

侧或两侧 )

传感器断线、误接线 接线的确认

测量超过显示范围上限

的电流、CT 匝数误设定、

CT 电力线贯通次数误

设定、误接线

A/D 变换异常 A/D 变换部故障 更换本体

参数异常

调整数据异常

参数异常

(RAM 领域 )

调整数据异常

(RAM 领

域 )

数据确定中电源断开

干扰等造成数据破坏

数据确定中电源断开

干扰等造成数据破坏

干扰等造成数据破坏

干扰等造成数据破坏

ROM 异常 ROM( 内存 ) 故障

传感器

类型

传感器

类型

量程

量程

1999~+9999

的范围内定标小数

点位置可变

) 是 2.04」以前的场合,

ID02

接线确认

PV 量程种类的再设定

使用匝数与显 示范围符合 的

CT

CT 匝数的再设定

CT 电力线贯通次数的再设定

接线确认

• 重新加电

• 数据的再设定

(AL95/97 是设定数据、

AL96/98 是调整数据 )

• 更换本体

• 重新加电

• 更换本体

动作的种类

主

设

●: 在该值处变化 ●:

定

○: 在经过1U点后该值变化 ○:

无事件

PV上限 1

PV下限 2

PV上下限 3

ON

ON

HYS

主设定 * 副设定 *

偏差上限 4

偏差下限 5

偏差上下限 6

偏差上限 7

(最终SP基准)

偏差下限 8

(最终SP基准)

偏差上下限

( )

最终SP基准

加热器1断线 16

/过电流

ON

9

ON

ON

主设定

测量CT1电流值前为OFF

加热器1短路 17

测量CT1电流值前为OFF

加热器2断线 18

/过电流

ON

主设定 *

测量CT2电流值前为OFF

加热器2短路 19

测量CT2电流值前为OFF

报警状态 23

: 初始值

*: 主设定>副设定的场合,自动对调主设定 / 副设定进行动作。

报警(报警代码AL01~99)

发生时为ON、除此之外为OFF

ONHYS

主设定

PV

HYS

主设定 主设定

ON

HYS

主设定

SP+主设定

ON

HYS

主设定

HYS

*

HYS

ONHYS

SP+主设定

HYS

SP+主设定

副设定

ONHYS

HYS

SP+主设定

副设定

SP

输出ON时的CT1

ONHYS

主设定

输出OFF时的CT1

输出ON时的CT2

ONHYS

主设定

输出OFF时的CT2

PV

PV

PV

PV

PV

PV

PV

副设定

副设定 *

ONHYS

ONHYS

ONHYS

ONHYS

*

ONHYS

上记以外的事件种类

动 作 动 作

种 类 设定值

SP

上限

SP

下限

SP

上下限

MV

上限

MV

下限

MV

上下限

10

11

12

13

14

15

种 类 设定值

1 20

回路诊断

2 21

回路诊断

3 22

回路诊断

READY

状态

MANUAL

状态

逆动作正动作

在该值处变化

在经过1U点后该值变化

常OFF常OFF0

ON

HYS

ONHYS

主设定 * 副设定 *

ON

HYS

SP+主设定

SP+主设定

ONHYS

主设定

SP

ON

HYS

SP+主设定

ONHYS

主设定

SP

ONHYS

主设定 *副设定

ON

HYS

输出OFF时的CT1

主设定 *

ON

输出OFF时的CT2

种 类 设定值

AT

中状态

SP

斜坡中

控制正动作状态

ST

整定等待状态

定时器状态

输出ON时的CT1

ONHYS

输出ON时的CT2

HYS

动 作

测量CT1电流值前为OFF

测量CT1电流值前为OFF

测量CT2电流值前为OFF

测量CT2电流值前为OFF

报警(报警代码AL01~99)

发生时为ON、除此之外为OFF

24

25

主设定

ONHYS

PV

HYS

ONHYS

PV

HYS

副设定

SP+主设定

ONHYS

PV

HYS

副设定

主设定

副设定 *

主设定

HYS

HYS

PV

PV

PV

PV

PV

PV

*

27

28

29

30

32

使用上的注意事项

• 仪表信息库的 ROM 版本 1(

不显示。

) 为「2.04」以前的场合,CT 输入异常报警 (

id02

AL11

)

D-8

Page 25

第1章 概 要

1 - 1 概 要

本机是带48×48mm面板的小型调节器,具备如下特长。

• 进深60mm,节省空间。

• 面板厚2mm,薄型设计。

• 显示部大,可视性好。

• 面板上配置[mode]键、[pare]键、位移动键,设定简单。

• 输入种类有热电偶(K、J、E、T、R、S、B、N、PL Ⅱ、WRe5-26、

DIN U、DIN L)、热电阻(Pt100、JPt100)、电流信号(4~20mAdc、

0~20mAdc)、电压信号(0~1Vdc、1~5Vdc、0~5Vdc、0~10Vdc)。

• 控制输出种类有继电器、电压脉冲、电流输出,在控制输出1及2中可组合

使用。

• 使用控制输出2或事件继电器,能够对应加热冷却控制。

• 可进行ON/OFF控制、固定PID、自适应控制。

• 除了PID控制,还配置有Ra-Pid(RationaLOOP)及Just-FiTTER两种算

法,控制性能优越。

• 选项功能中,能够组合选择2点(独立接点)或者3点事件、2点CT输入、

2点数字输入、RS-485。

• 标准配置有计算机编程器端口,通过计算机编程器,设定更简便。

• 使用另售的智能编程软件包(SLP-C35),可以很容易地实现参数读写操

作。

除表形式的设定之外,可在运行时进行操作或在趋势画面上对控制状态进

行监视,不需上位机器的程序就可执行本机的操作。

• 符合IEC指令、CE标准。

(适合规格:EN61010-1、EN61326-1)

1-1

Page 26

第1章 概 要

■ 型号构成

本机的型号构成如下表。

基本型号 安装 控制输出 PV输入 电 源 可选项 追加处理 规 格

C15

(注1)

(注1) 底座需要单独订货。

(注2) C15S场合为1a接点。

(注3) C15S无此项选择。

(注4) 变流器需要单独订货。

(注5) DC电源型不可选择。

T

S

(注2)

(注3)

(注3)

(注3)

R0

V0

VC

VV

C0

CC

T

R

L

A

D

00

01

(注3)

(注4)

(注3)

(注4)

(注5)

(注3)

(注4)

(注5)

(注3)

(注4)

(注5)

02

03

04

05

06

仪表盘安装型

底座安装型

控制输出1

继电器输出

电压脉冲输出

(SSR驱动用)

电压脉冲输出

(SSR驱动用)

电压脉冲输出

(SSR驱动用)

电流输出

电流输出

热电偶输入

(K,J,E,T,R,S,B,N,PLⅡ,WRe5-26,DINU,DINL)

热电阻输入(Pt100/JPt100)

直流电压/电流输入(0~1Vdc, 1~5Vdc,

0~5Vdc, 0~10Vdc, 0~20mAdc, 4~20mA DC)

AC电源(100~240Vac)

DC电源(24Vac/24~48Vdc)

无

事件继电器输出3点

事件继电器输出3点

变流器输入2点

数字输入2点

事件继电器输出3点

变流器输入2点

RS-485通讯

事件继电器输出2点(独立接点)

事件继电器输出2点(独立接点)

变流器输入2点

数字输入2点

事件继电器输出2点(独立接点)

变流器输入2点

RS-485通讯

无追加处理

00

带检查报告书

D0

带跟踪证明

Y0

控制输出2

无

无

电流输出

电压脉冲输出

(SSR驱动用)

无

电流输出

1-2

Page 27

■ 附属品·可选部件

名称 型号

安装件(C15T用) 81446403-001(附属品)

垫片

变流器(孔径5.8mm)

变流器(孔径12mm)

底座(C15S用)

硬保护盖

软盖

端子盖

智能编程软件包

L型插头适配器

81409657-001(附属品)

QN206A

QN212A

81446391-001

81446442-001

81446443-001

81446898-001

SLP-C35J50

81441057-001

第1章 概 要

1-3

Page 28

[

p

第1章 概 要

1 - 2 各部分的名称及功能

■ 本体及面板部

面板部

● 面板部

本体部

本体部:内装仪表的输入输出信号的电气回路或CPU、内存等

面板部:装有显示数值或状态的显示部及用于操作的键。

[mode]键

在运行显示状态下,持续按1s以上后,可进行下述预先设定好的操作。

• AUTO/MANUAL模式切换

• RUN/READY模式切换

• AT(自整定)停止/启动切换

• LSP(本地SP)组切换

• 所有DO(数字输出)锁定解除

• 通讯DI(数字输入)1的ON/OFF切换

在设定显示状态下按[mode]键后,切换成运行显示。

[para]键

切换显示项目。

运行显示状态下持续按2s以上后,切换成设定显示。

[<]·[∨]·[∧]键

数值的增减、位移动时使用。

第1显示部

[mode]键

ara]键

操作面板部

[<], [∨], [∧]键

。

第2显示部

模式显示灯

1-4

Page 29

■ 底部

第1章 概 要

第1显示部

显示PV的数值或各显示项目(显示值·设定值)的名称。

运行显示下发生报警时,将交替进行通常的显示及报警代码显示。

右端位的小数点显示AT( 自整定)或 ST(自适应) 的状态。AT执行时灯

亮·闪烁各2次、ST执行时灯亮·闪烁各1次。

第2显示部

显示SP的数值或各显示项目的显示值或设定值。

右端位的小数点可显示通讯状态等。

模式显示灯

rdy : RUN/READY模式显示 READY模式时灯亮。

man : AUTO/MANUAL模式显示 MANUAL模式时灯亮。

ev1•ev2•ev3 : 事件1~3输出显示 输出ON时灯亮。

ot1•ot2 : 控制1~2输出显示 输出ON时灯亮。对电流输出,灯

常亮。

使用上的注意事项

• 用[mode]键进行LSP组切换时,需要把「LSP使用组数」设定在2以上。

• 要使第2显示部右端位的小数点显示通讯状态等内容时,需要设为「多

功能设定」下的「LED 监视」。

• 请勿用带尖的物品(活动铅笔尖或针等)进行键操作,否则容易造成故障。

编程器接口: 使用与智能

编程器接口

编程软件包同包装的专用缆线与计算机连接。

1-5

Page 30

第1章 概 要

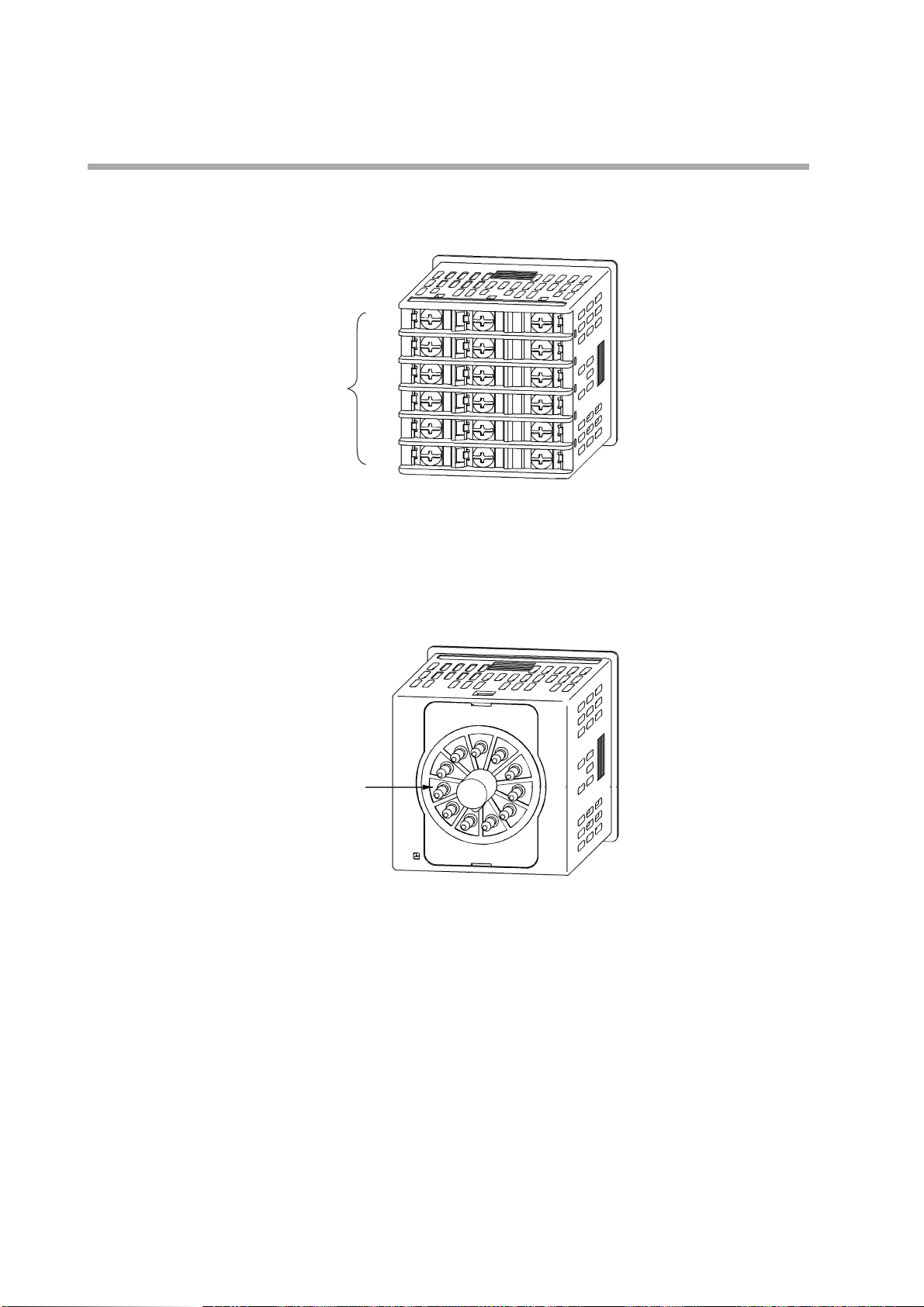

■ 背部

● 盘安装型(C15T)

● 底座安装型(C15S)

端子部

端子部: 连接电源、输入、输出等。

M3螺丝。连接时请务必使用与M3螺丝匹配的压接端子。

端子螺丝的拧紧扭矩为0.4~0.6N·m。

底座部

底座部: 插入另售的底座,从底座处连接电源、输入、

底座的接线请使用与M3.5螺丝匹配的压接端子。

底座的端子螺丝的拧紧扭矩为0.78~0.98N·m。

输出等。

1-6

Page 31

第2章 功能的概要

2 - 1 输入输出的构成

● PV输入

● 控制输出

● 事件输出

● DI(数字输入)

● CT(变流器)输入

PV输入

数字输入1, 2

CT输入1, 2

可选择PV输入的传感器或量程,选择的范围根据型号的输入种类(T:热电

偶、R:热电阻、L:直流电流·直流电压)有差异。

型号的控制输出种类为R:继电器、V:电压脉冲时为ON-OFF控制输出、或

时间比例输出,时间比例输出的场合可设定时间比例周期。型号的控制输

出种类为C:电流时为连续输出(模拟输出),可设定输出的量程。控制输出

有2个时,只要设定成「简单设定」就能进行加热冷却控制。

型号中带事件的场合,由事件种类设定的警报或控制模式作为DO(数字输

出)输出。

型号中带DI的场合,可进行由DI分配设定的功能切换。

型号中带CT输入的场合,从事件输出可把加热器断线警报输出。

PV处理

内部接点

处理

CT处理

其他

其他

控制处理

(ON/OFF控制、

PID控制)

内部事件

处理

其他

模拟

输出处理

数字

输出处理

控制输出1,2

(电流输出)

控制输出1,2

(继电器输出、

电压脉冲输出)

事件输出1~3

(继电器输出)

2-1

Page 32

第2章 功能的概要

2 - 2 键操作

通过键操作,可在面板上调出各种显示或设定。

键操作全流程分为标准型与特殊型2种,可由设置设定选择。

• 标准型: 基本上与旧机型C10的键操作相同。

• 特殊型: 在旧机型C10的键操作基础上,增加了一部份旧机型C30的键操作。

键操作全流程分别如下所示。

■ 标准型

设置设定的键操作种类 C71=0时为标准型。

标准型的显示·设定数据的排列方法如下树型结构所示。

运行显示

PV及SP AUTO/MANUAL切换 PV量程种类

LSP组选择 RUN/READY切换 温度单位

MV AT停止/启动切换

加热MV 全DO锁定解除

冷却MV 通讯DI1

AT进程

CT输入1电流值

CT输入2电流值

内部事件1主设定

内部事件1副设定

内部事件1剩余时间

内部事件2主设定

内部事件2副设定

内部事件2剩余时间

内部事件3主设定

内部事件3副设定

内部事件3剩余时间

5-75

5-28

5-76

5-76

5-76

5-76

5-78

5-78

5-48

5-48

5-77

5-48

5-48

5-77

5-48

5-48

5-77

用户功能(利用)

用户功能1

用户功能2

用户功能3

用户功能4

用户功能5

用户功能6

用户功能7

用户功能8

5-79

5-79

5-79

5-79

5-79

5-79

5-79

5-79

模式

SP

LSP1组SP

LSP2组SP

LSP3组SP

LSP4组SP

事件

内部事件1 主设定

内部事件1 副设定

内部事件1 回差

·

·

·

内部事件5 ON延迟

内部事件5 OFF延迟

PID

比例带

积分时间

微分时间

手动复位

·

·

·

冷却侧操作量下限

冷却侧操作量上限

参数

控制方式

AT时操作量下限

AT时操作量上限

ON/OFF控制差动

SP斜坡上升斜率

SP斜坡下降斜率

扩展调整

AT种类

JF整定幅

SP拖位常数

·

·

·

ST步整定幅

ST振荡整定幅

ST步升降切换

5-7

5-7

5-8

5-8

5-8

5-28

5-28

5-28

5-28

5-48

5-48

5-48

5-50

5-14

5-14

5-14

5-14

5-14

5-14

5-11

5-18

5-18

5-13

5-30

5-30

5-18

5-20

5-20

5-17

5-17

5-17

内部接点1 输入位运算

内部接点3内部事件编号指定

设定

·

·

·

显示级别

LED监视

事件组态

内部事件1 组态1

内部事件1 组态2

·

·

·

内部事件5 组态2

内部事件5 组态3

DI分配

内部接点1 动作种类

·

·

·

内部接点3 反转

DO分配

控制输出1 动作种类

控制输出1 输出分配A

·

·

·

事件输出3 反转

事件输出3 锁定

用户功能

用户功能定义1

用户功能定义2

·

·

·

用户功能定义7

用户功能定义8

键锁

键锁

通讯锁定

·

·

·

口令1B

口令2B

仪表信息

ROM ID

ROM版本1

·

·

·

日期代码 月日

制造编号

5-2

5-3

5-78

5-78

5-45

5-46

5-46

5-47

5-33

5-34

5-36

5-345-50

5-53

5-54

5-57

5-57

5-79

5-79

5-79

5-79

5-83

5-83

5-84

5-84

6-24

6-24

6-24

6-24

(注) 树型构造的显示·设定栏右边的数字表示对应的页。

2-2

Page 33

第2章 功能的概要

使用上的注意事项

·有关运行显示、参数设定显示、设置设定显示的显示·设定内容,

请参阅

6-1 运行显示一览表 (6-1页)

6-2 参数设定显示一览表 (6-3页)

6-3 设置设定显示一览表 (6-8页) 。

·也可在按住[para]键的同时按[<]键,来取代按[para]键,对各种

显示·设定的显示按相反顺序进行切换。但按[para]键及[<]键

超过2s以上的操作无效。

2-3

Page 34

第2章 功能的概要

■ 特殊型

冷却MV

AT进程

运行显示

PV及SP

LSP组选择

MV

加热MV

CT输入1电流值

CT输入2电流值

内部事件1主设定

内部事件1副设定

内部事件1剩余时间

内部事件2主设定

内部事件2副设定

内部事件2剩余时间

内部事件3主设定

内部事件3副设定

内部事件3剩余时间

用户功能(利用)

用户功能1

用户功能2

用户功能3

用户功能4

用户功能5

用户功能6

用户功能7

用户功能8

设置设定的键操作种类C71=1时为特殊型。

特殊型的显示·设定数据的排列方法如下树型结构所示。

5-75

5-28

5-76

5-76

5-76

5-76

5-78

5-78

5-48

5-48

5-77

5-48

5-48

5-77

5-48

5-48

5-77

5-79

5-79

5-79

5-79

5-79

5-79

5-79

5-79

DI分配

库选择

模式

事件

PID

参数

扩展调整

设置

事件组态

DO分配

用户功能

锁定

仪表信息

SP

AUTO/MANUAL切换

RUN/READY切换

AT停止/启动切换

所有DO锁定解除

ROM ID

模式库

通讯DI1

SP库

LSP1组SP

LSP2组SP

LSP3组SP

LSP4组SP

各种库

·

·

·

锁定库

键锁

·

·

·

口令1B

口令2B

仪表信息库

ROM版本1

·

·

·

日期代码 月日

制造编号

5-7

5-7

5-8

5-8

5-8

5-28

5-28

5-28

5-28

5-83

5-83

5-84

5-84

6-24

6-24

6-24

6-24

注) 树型构造的显示·设定栏的右边的数字表示对应的页。

2-4

Page 35

第2章 功能的概要

使用上的注意事项

·运行显示、库选择显示、库设定显示的显示·设定内容,请参阅

6-1 运行显示一览表(6-1页)

6-2 参数设定显示一览表(6-3页)

6-3 设置设定显示一览表(6-8页) 。

这些一览表中,记述有各设定项目附属库相关的说明。

·对运行显示及设定项目显示,也可在按住[para]键的同时按[<]键,

来取代按[para]键,对各种显示•设定的显示按相反顺序进行切换。

但按[para]键及[<]键超过2s以上的操作无效。

2-5

Page 36

第2章 功能的概要

■ 数据设定方法

① 请操作[para]键,显示设定的数据。

(有关[para]键的操作,请参阅前述的「键操作全流程」)

pv

sp

mode

本图是设置设定「C01」设定

(

为PV量程种类的场合)

② 请按[<]·[∨]·[∧]键的任一键。

≫

第2显示部为数值的场合,第1位开始闪烁。

pv

sp

mode

(本图是参数设定「r - - r」设定

为RUN/Ready切换的场合)

另外,第2显示部为文字列的场合,文字列全体开始闪烁。

数值的场合,用[<] • [∨] • [∧]键可对闪烁位进行移动或对闪烁位的值

进行增减。

文字列的场合,用[∨] • [∧]键可对闪烁中的文字列全体进行变更。

pv

sp

mode

(本图是「0001」的第1位闪烁的状态)

③ 手指离开键并等待。

≫

2s后闪烁停止,确定数据的变更。

pv

sp

mode

使用上的注意事项

pv

sp

mode

(本图是「rUn」全体闪烁的状态)

pv

sp

mode

·即使按[<]·[∨]·[∧]键,也不闪烁的场合,其数据不会变更。

例如:DI分配了RUN/READY切换时,面板键不能进行RUN/READY

的切换。

2-6

Page 37

■ [mode]键操作方法

第2章 功能的概要

• 文字列全体闪烁的场合,如果[∨]键不能变更时,请按

[∧]键。

[∧]键不能变更时,请按 [∨]键。

• 显示闪烁时,按[para]键后,数据并不变更而显示下一个数据。另

外,显示闪烁时,按[mode]键后,数据并不会变更而回到运行显

示。

• MANUAL模式下的MV(操作量)显示,即使不按键,闪烁也会继续。

另外,这种场合,闪烁中的值作为MV输出。

运行显示下按[mode]键1s以上后,可进行由设置设定的[mode]键功能(C72)

所设定的切换操作。

右图是RUN/READY切换(C72=2)的设

定下,按[mode]键时的例子。

① 运行显示的PV/SP显示的状态下,现在

为 READY 模式的场合,按[mode] 键

后,第2显示部显示闪烁的「rUn」文字

列。

pv

sp

mode

② 按[mode]键1s以上后,从READY模式

切换成RUN模式,「rUn」文字列不再

闪烁。

pv

sp

mode

③ 停止按[mode]键后,回到原来的显示。

pv

sp

mode

使用上的注意事项

• 设置设定的[mode]键功能设定为无效(C72=0)的场合或设定的切换

操作无效的场合,不能用[mode]键进行切换操作。

• 不在运行显示下,而在参数设定显示或设置设定显示下,按[mode]

键后,将回到运行显示。但即使一直持续按[mode]键,也不能进行

切换操作。这种场合,请先停止按键后再按[mode]键。

2-7

Page 38

第2章 功能的概要

■显示级别

本机的显示级别可由设置设定的显示级别(C79)从「简单设定」、「标准

设定」、「多功能设定」3种中选择。

各设定项目可显示的显示级别,请参阅

第6章 显示·设定数据一览表。

使用上的注意事项

即使变更显示级别,设定显示以外的功能不会改变。显示级别置为

「标准设定」或「多功能设定」,当设定完更具应用性的功能后回

到简单设定的场合,该功能的设定虽不能显示,但该功能自身仍动

作。

2-8

Page 39

2 - 3 运行模式

运行模式的切换如下。

RUN : 控制状态

READY: 控制停止状态

AUTO : 自动运行(由本机自动决定操作量)

MANUAL: 手动运行(操作量可手动操作)

AT: 自整定(通过限幅循环法自动设定PID常数)

ST: 自适应(控制继续、自动设定PID常数)

RUN+AUTO模式

AT启动中 ST启动中

RUN+MANUAL模式

AT停止

ST停止

AUTO/MANUAL切换

AT停止

ST停止

RUN/READY

RUN/READY

切换

切换

第2章 功能的概要

READY+AUTO模式

READY+MANUAL模式

AT停止

ST停止

AUTO/MANUAL切换

AT停止

ST停止

2-9

Page 40

Page 41

第3章 安 装

请在规格记载的使用条件(温度、湿度、电压、振动、冲击、安装方向、环境

等) 的范围内使用本机。

■ 安装场所

否则,会发生火灾、故障。

请勿遮挡本机的通风孔。

否则,会发生火灾、故障。

请在下述场所安装本机。

·除供给电源及继电器接点输出外,输入输出的共模电压必须满足以下条件。

对大地间的电压为:

AC :33Vr.m.s.以下、峰值46.7V以下、

DC :70Vdc以下。

·非高温、非低温、非高湿度、非低湿度的场所

·无硫化气等腐蚀性气体或无硅气体的场所

·粉尘、油烟等较少的场所

·无直射阳光及风雨不直接吹淋的场所

·机械振动、冲击较少的场所

·远离高压线、焊接机附近及电气干扰发生源的场所

·远离锅炉等高压点火装置15m以上的场所

·电磁干扰较少的场所

·无可燃性液体或蒸气的场所

注意

3-1

Page 42

0

0

第3章 安 装

■ 外形尺寸

● 盘安装型(C15T)

● 底座安装型(C15S)

■ 盘开孔图

安装件(附属品)

固定件 底座

2-M4用安装孔

81446391-001 (另售)

端子螺丝 M3.5

底座

盘安装型的场合,请按下述尺寸开孔。

单独安装 密集安装

+0.5

30以上

使用上的注意事项

·3台以上密集安装的场合,请把环境温度控制在40℃以内。

·上下方向请保持50mm以上的间隔。

45

5

.

0

0

+

(48xN-3)

+0.5

45

5

.

0

+

0

45

50以上

(N为安装台数)

单位 :mm

端子螺丝

M3

单位 :mm

3-2

Page 43

■ 安装方法

·安装角度从水平位置向后仰10度以内,向前倾10度以内。

·盘安装型的场合,请使用板厚在9mm以下的钢板。

● 盘安装型(C15T)的场合

准备的物品 : 十字螺丝刀

垫片(附属品) 安装件用螺丝

本体

图是使用垫片的防水安装示例。

通常的盘安装时不使用垫片。

① 请把本机从盘前面插入。

② 请从盘的后面嵌入安装件。

③ 请把安装件按到盘上,直到安装件的插件可靠地插入本体的漕内。

④ 请紧固安装件上下的螺丝。

防水安装的场合

盘孔

盘安装型(C15T)可进行防水安装。

这种场合,在开始上述步骤①前,请先安装本体附属的垫片。

安装了垫片的本体从上述步骤①开始安装。

使用上的注意事项

紧固附属安装件的螺丝,在安装件处于不能活动的状态时再继续拧一

圈螺丝固定在

安装件

上。螺丝拧得过紧时会引起外壳变形。

仪表盘

第3章 安 装

卡销

盘

3-3

Page 44

第3章 安 装

● 盘安装型(C15T)使用硬保护盖的场合

盘安装型的场合,可在面板部安装硬保护盖。

以防止不经意操作本机使设定变更或在设置环境恶劣时使用,盖板盖住时也

能看见显示。

操作键时,请往上掀开盖后操作。

准备的物品:

硬保护盖 部件编号 81446442-001 (另售品)

硬保护盖

盘

使用本体附属的垫片及硬保护盖附属的垫片两种,两者相同。

① 如图所示,就像用2枚垫片挟住硬保护盖那样,按垫片、硬保护盖、垫片

的顺序,分别安装到本体上。

② 请把本机从盘前面插入。

③ 请从盘的后面嵌入安装件。

④ 请把安装件按到盘上,直到安装件的插件可靠地插入本体的漕内。

⑤ 请紧固安装件上下的螺丝。

本体

垫片

垫片

使用上的注意事项

·拧紧附属安装件的螺丝,在安装件处于不能活动的状态时再继续拧半

圈螺丝,固定到盘上。

螺丝拧得过紧时会引起外壳变形。

·如果只是为了防止误操作,不需要防水功能的场合,2枚垫片可以不安

装。

3-4

Page 45

● 盘安装型(C15T)使用软保护盖的场合

盘安装型的场合,前面面板部可安装软保护盖。

在安装有软保护盖的情况下,也可操作键。

另外,安装软保护盖起到与使用垫片防水相同的功能。

准备的物品 :

软保护盖 部件编号 81446443-001 (另售品)

本体

软保护盖

不使用本体附带的垫片。

① 就像包住本体的面板部那样安装软保护盖。

② 把安装了软保护盖的本机从盘的前面插入。

③ 请从盘的后面嵌入安装件。

④ 请把安装件按到盘上,直到安装件的插件可靠地插入本体的漕内。

⑤ 请紧固安装件上下的螺丝。

使用上的注意事项

拧附属安装件的螺丝,在安装件处于不能活动的状态时再继续拧半圈螺

丝,固定到盘上。螺丝拧得过紧时会引起外壳变形。

第3章 安 装

盘

本体

软保护盖

盘

3-5

Page 46

第3章 安 装

● 底座安装型(C15S)的场合

固定用孔

本体

准备的物品: 十字螺丝刀

底座

DIN导轨

固定件

图为DIN导轨安装时的示例。

① 请把底座安装在盘内。(用螺丝固定时,直接安装底座)

② 请进行底座的接线。

③ 把本机按入在底座上。

④ 把底座上下的固定件插入本机固定件用孔中。

使用上的注意事项

底座安装型的场合,把本机安装到底座前,请先完成配线工作。

3-6

Page 47

第4章 接 线

4 - 1 接 线

在对本机进行安装、拆除及配线作业时,请务必完全切断本机及连接设备的电源。

否则有触电的危险。

请勿触摸电源端子等带电部件

否则有触电的危险。

请按规定的标准、指定的电线及施工方法正确配线。

否则有发生火灾、触电、故障的危险。

请勿让断线头、铁粉、水进入机箱内。

否则有发生火灾、故障的危险。

请按规格记载的扭矩可靠地拧紧端子螺丝。

如果没有完全拧紧,有触电、发生火灾的危险。

请勿把本机未使用的端子作为中继端子使用。

否则有触电、发生火灾、故障的危险。

盘安装型的场合,建议在本机接线后盖上端子盖。

否则有触电的危险。(本机备有另售的端子盖)

请在规格记载的寿命范围内使用本机的继电器。

超过寿命继续使用时,有发生火灾、故障的危险。

有雷击可能的场合,请使用本公司产的浪涌吸收器。

否则有发生火灾、故障的危险。

请勿误接线。

接线错误时会造成机器故障。

电源投入后约6秒钟内调节器不动作。

调节器的继电器输出作为联锁信号使用的场合,敬请注意。

控制输出1与控制输出2之间未隔离。

请根据需要,使用隔离器。

1台计算机与多台调节器连接时,请勿用多根编程器缆线连接。

产生的回流电流,会使PV值发生显示误差等可能性。

RS-485接线时,请勿在通讯路的两端连接终端电阻。

否则有无法通讯的可能。

在进行本机的电源配线时,请务必在操作人员能触及的地方设置主电源切断

开关。

另外,对AC电源型的调节器进行电源配线时,请采用额定电流为0.2A、额

定电压为250V的迟动型(T)保险丝(IEC127)

警告

注意

4-1

Page 48

第4章 接 线

■ 端子排列标签的记号

■ 接线时的注意事项

本机侧面的端子排列标签中使用的记号有以下含义。

记 号 内 容

~

·接线前请务必确认本机的型号及端子编号没有错误。

·盘安装型(C15T)的场合,请使用与M3适合的压接端子与端子连接。

端子螺丝的拧紧扭矩为0.4~0.6N·m。

·底座安装型(C15S)的场合,请使用与M3.5螺丝适合的压接端子与端子连接。

端子螺丝的拧紧扭矩为0.78~0.98N·m。

·请注意压接端子等不能与相邻的端子接触。

·盘安装型(C15T)、2个压接端子接线到一个端子螺丝上的场合,

请预先将压接端子弯曲后再接线。

·盘安装型(C15T)的场合,1~6、13~18号端子请按照从端子台侧看左方向

接线。

A : 5.8mm以下 B : 5.5~7.6mm

(参考)推荐压接端子:日本压接端子制造(株)V1.25-MS3

·输入输出信号线与动力线或电源线保持50cm以上的间距,而且不能放在同

一线槽或配线管内。

直流

交流

注意、触电的危险

注意

·与其他仪表的并联连接时,在设置前请查清其他仪表的限制条件。

·数字输入请按无电压型、接点按微小电流使用。

·请把加热器用电流流过的导线贯通于变流器中。

另外,加热器电流须在规格书规定的容许电流内。

否则会烧毁本机。

·变流器输入不能使用位相角控制。

·盘安装型(C15T)的场合,还备有防触电的端子盖(另售品,型号:

81446898-001)

本体外壳凹部

端子盖

4-2

Page 49

·

控制输出1与控制输出2间未隔离,请根据需要使用隔离器

第4章 接 线

。

● C15T的接线

㒻⬉఼

⬉㛝ކ

⬉㛝ކ

⬉⌕

⬉㛝ކ

⬉㛝ކ

⬉⌕

⬉⌕

⬉⌕

⛁⬉ي

⛁⬉䰏

⬉⌕

⬉

·RS-485通讯线路的两端处,请勿安装终端电阻,否则可能造成通讯故障。

·请对与本机连接的机器或装置实施与本机的电源、输入输出部最高使用电

压符合的基础绝缘。

·

本机在电源投入后,为了进入稳定状态,在最大6秒钟内将不起作用

。其后

进入运行状态,但为了获得规定的精度,需要预热30分钟以上。

·DC电源型使用的场合,请采用强化绝缘的电源。

ࠊ䕧ߎ CT䕧ܹ

1

2

3

1

+

ϋ

2

3

1

+

1

ϋ

2

2

+

3

1

+

1

ϋ

2

2

+

3

1

+

ϋ

2

3

1

+

1

ϋ

2

2

+

3

PV䕧ܹ

1

13

7

2

14

8

3