Page 1

Operator Panel

for Infilex™ AC / Infilex™ GC / Infilex™ GD

Model QY5100W0000 (Panel Mount Type)

Model RY5001Q0000 (Integral Type)

General

Operator Panel is a user terminal for data display and

configuration, which can be connected to a remote unit:

Infilex AC, Infilex GC, or Infilex GD. Two types of Operator

Panel are available. Panel mount type (Model

QY5100W0000) is mounted on the door of the control

panel cabinet. Integral type (Model QY5100W0000) is

attached directly to the remote unit or to its I/O module to

integrate with the remote unit.

The Operator Panel can display all the points that the

remote unit has. Points to be modified (by changing their

data configuration) or operated, such as parameters, AO

(analog output), and DO (digital output), can be modified or

operated through the Operator Panel.

By connecting the Operator Panel to a remote unit (Infilex

AC, Infilex GC, or Infilex GD), the remote unit can be

managed not only through client PC of our BMS (building

management system), savic-net

Operator Panel at the installation site. This greatly

improves the efficiency of the building management.

Additionally, the Operator Panel facilitates status indication

of the points, and allows a remote unit to be easily used as

standalone.

Features

• Display of points:

All points of the remote unit can be managed through

the Operator Panel.

The Operator Panel displays the points as follows:

- Group-points mode

Points divided into up to 4 groups are displayed

per group.

- All-points mode

All the points of the remote unit are displayed.

The points that can be modified or operated through the

Operator Panel can be modified or operated in either

mode. Additionally, one point selected among the

ON/OFF points and the alarm points of the remote unit

can be continuously displayed.

• Operation restriction:

ON/OFF operation and data configuration change

through the Operator Panel can be restricted.

™

FX, but also through the

Specifications/Instructions

• Functions for a standalone remote unit:

When the remote unit connected to the Operator Panel

is standalone, an operation schedule of the point

specified to continuously display its status can be set

through the Operator Panel. Additionally, the Operator

Panel has a manual override function for AO and DO.

• LCD backlight and LED:

Model QY5100W000 is equipped with an LCD

backlight, and Model RY5001Q0000 is equipped with

a 7 segment LED. Operator Panel thus displays the

data and allows the operators to operate even in a

dark place.

• CE Marking certified product:

Operator Panel (both panel mount type and integral

type) conforms to all the applicable standards of CE

Marking (Class A).

Model QY5100W0000

(Panel mount type)

Model RY5001Q0000

(Integral type)

AB-6546

1

Page 2

AB-6546

Safety Instructions

Please read instructions carefully and use the product as specified in this manual. Be sure to keep this manual near by for

ready reference.

Usage Restrictions

This product is targeted for general air conditioning. Do not use this product in a situation where human life may be affected. If

this product is used in a clean room or a place where reliability or control accuracy is particularly required, please contact Azbil

Corporation’s sales representative. Azbil Corporation will not bear any responsibility for the results produced by the operators.

WARNING

• DANGER: To prevent the risk of severe or fatal electrical shock, always disconnect power source and product

power supply before performing any wiring.

• Be sure to ground with 100 Ω or lower ground resistance. Improper grounding may cause electrical shock or

equipment damages.

• Do not detach the terminal cover at any time except when wiring. After wiring, be sure to attach the terminal cover.

Before attaching/detaching the terminal cover, make sure that the wires are not current-carrying to prevent

electrical shock.

• Disconnect power before the product replacement to prevent electrical shock.

• Do not disassemble the product. Disassembly may result in electrical shock.

CAUTION

• Installation and wiring must be performed by qualified personnel in accordance with all applicable safety

Trademark information:

Infilex, savic-net, and Neopanel are trademarks of Azbil Corporation in Japan or in other countries.

standards.

• All wiring must comply with local codes of indoor wiring and electric installation rules.

• Use crimp terminal lugs with insulation for electric wires connected to the product screw terminals.

• Connect cables to the power source with terminals or the like for permanent connection.

• Make sure all the wires are tightly connected to prevent heat generation or equipment damages.

• Install a circuit breaker or circuit protector in the power supply circuit that supplies the power to the product.

• Lightning protection based on regional characteristics and building structure is needed in order to minimize

lightning damages.

• If more than the rated power supply voltage is applied, product replacement is required for safety.

• Noise protection is necessary when the product is installed in a location close to many noise sources.

• Do not block the vent holes on the upper or lower part of the product to prevent equipment damages. Remove

protective sheet after installation and wiring.

• This product must be operated under the operating conditions (power, temperature, humidity, vibration, shock,

installation position, atmospheric condition, etc) specified in this manual to prevent equipment damages.

• Install this product in a location out of reach of unauthorized people.

(e.g. Panel mount type: door of the control panel cabinet / Integral type: inside of the control panel cabinet)

• Do not incinerate this product for waste disposal . Do not reuse all or part of this product, either.

2

Page 3

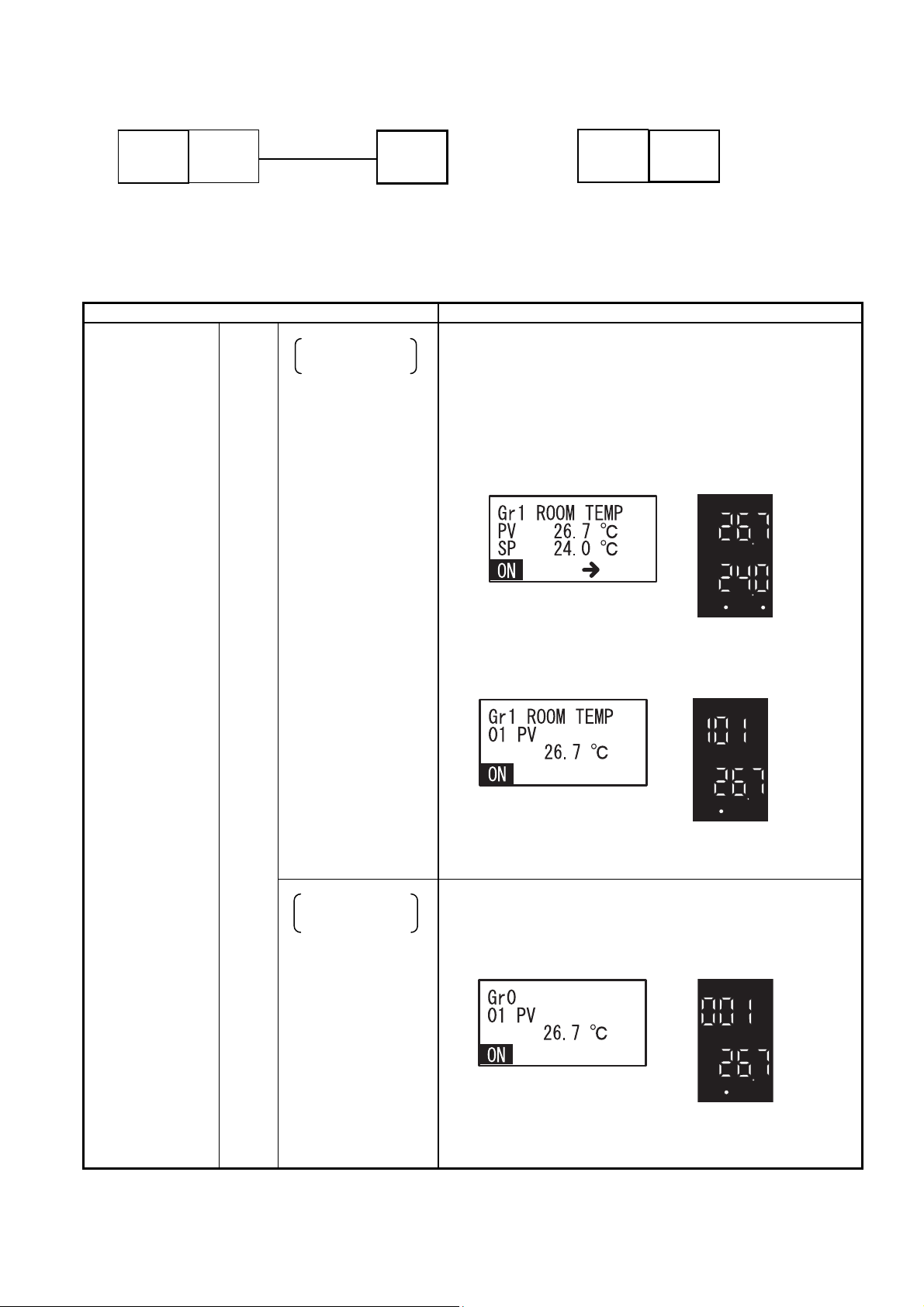

Connection

Infilex AC/

Infilex GC/

Infilex GD

Functions

Functions common

to:

- Operator Panel

connected with the

system

- Operator Panel

connected with the

standalone remote

unit.

and

AB-6546

UT (user

terminal)

module

DP-bus

(Display panel)

Model QY5100W0000

Operator

Panel

(Panel mount type)

Figure 1. Connection examples

Infilex AC/

Infilex GC/

Infilex GD

Model RY5001Q0000

(Integral type)

Operator

Panel

(1/2)

Function Description

Group-points mode

Display and

data configuration

Points classified by group are displayed. Up to 4 groups can be

configured, and up to 16 points per group can be registered in any

order. Two points (points 1 and 2) are displayed on the group top

display, and the points are respectively displayed on the group scroll

display.

Points to be modified (by changing their data configuration) or

operated, such as parameters, AO, and DO, can be modified or

ON

ALM

OFF

Model RY5001Q0000

(Integral type)

ON

ALM

OFF

Model RY5001Q0000

(Integral type)

ψ

ψ

Display and data configuration of the points

All-points mode

data configuration

Display and

operated in the group-points mode.

Model QY5100W0000

(Panel mount type)

Model QY5100W0000

(Panel mount type)

Group top display

Group scroll display

All points of the remote unit (max. 99 points) are displayed. The

points are respectively displayed.

Points to be modified (by changing their data configuration) or

operated, such as parameters, AO, and DO, can be modified or

operated in the all-points mode.

Model QY5100W0000

(Panel mount type)

ON

OFF

Model RY5001Q0000

(Integral type)

ψ

ALM

3

Page 4

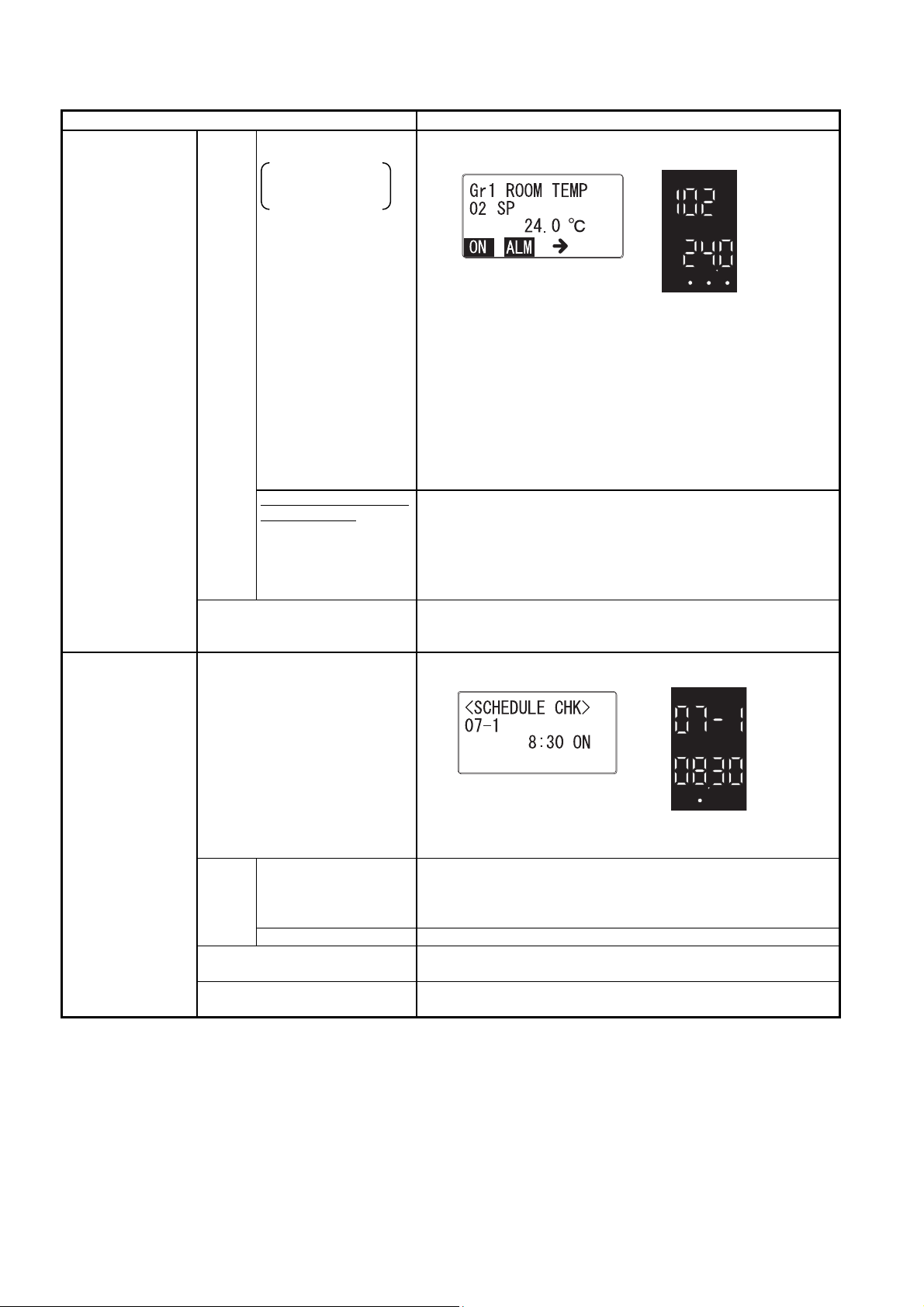

AB-6546

(2/2)

Function Description

Functions common

to:

- Operator Panel

connected with the

system

and

- Operator Panel

connected with the

standalone remote

unit.

Group-points mode

All-points mode

Display of:

- operating status

- alarm status

One point among the ON/OFF and alarm points is specified to

continuously display its status on the bottom line of the screen.

Model QY5100W0000

(Panel mount type)

ψ

ON

ALM

OFF

Model RY5001Q0000

(Integral type)

The above illustration shows that a point with ON/OFF and alarm

status is specified and continuously displayed, indicating the

Display and data configuration of the points

operating status ‘ON’ and the alarm status ‘reported.’

When the operating status is ‘OFF’ and the alarm status is ‘not

reported,’

- Model QY5100W0000: [ON] or [ALM] is not displayed.

- Model RY5001Q0000: Green dot above [OFF] is on and

the green dot above [ALM] is off.

Available only for Model

QY5100W0000

Display of:

- Group name

- Point abbreviated

name

- Engineering unit

Operation restriction

Group names, abbreviated point names, and engineering unit are

displayed.

Note that an abbreviated point name is displayed using up to 4

alphanumeric characters, and a group name is displayed using up

to 12 alphanumeric characters.

Operation and data configuration functions can be restricted to

prevent careless configuration change or undesirable ON/OFF

operation.

Functions of

Operator Panel

connected with the

standalone remote

unit

Schedule display*

Operation schedules for current day and the following day are

displayed.

Operation schedule

The operation schedule can be set through the Operator Panel

Model QY5100W0000

(Panel mount type)

ψ

ON

ALM

OFF

Model RY5001Q0000

(Integral type)

when it is connected to the standalone remote unit. Up to 8

setting*

Schedule

Holiday schedule

Current date and time setting

schedules per day can be set and displayed for 8 days of the week

(Monday through Sunday and one holiday).

Dates for the holiday operation schedule can be set and displayed.

Current date and time (year, month, day, hour, and minute) can be

set.

Manual override

For inspection and maintenance, manual operation and setting can

be set to override the output signals from the remote unit.

∗Note:

Schedule display and setting functions are applicable only to the ON/OFF point specified to continuously display its status. If an alarm

point is specified, the schedule display and setting function is not applicable.

4

Page 5

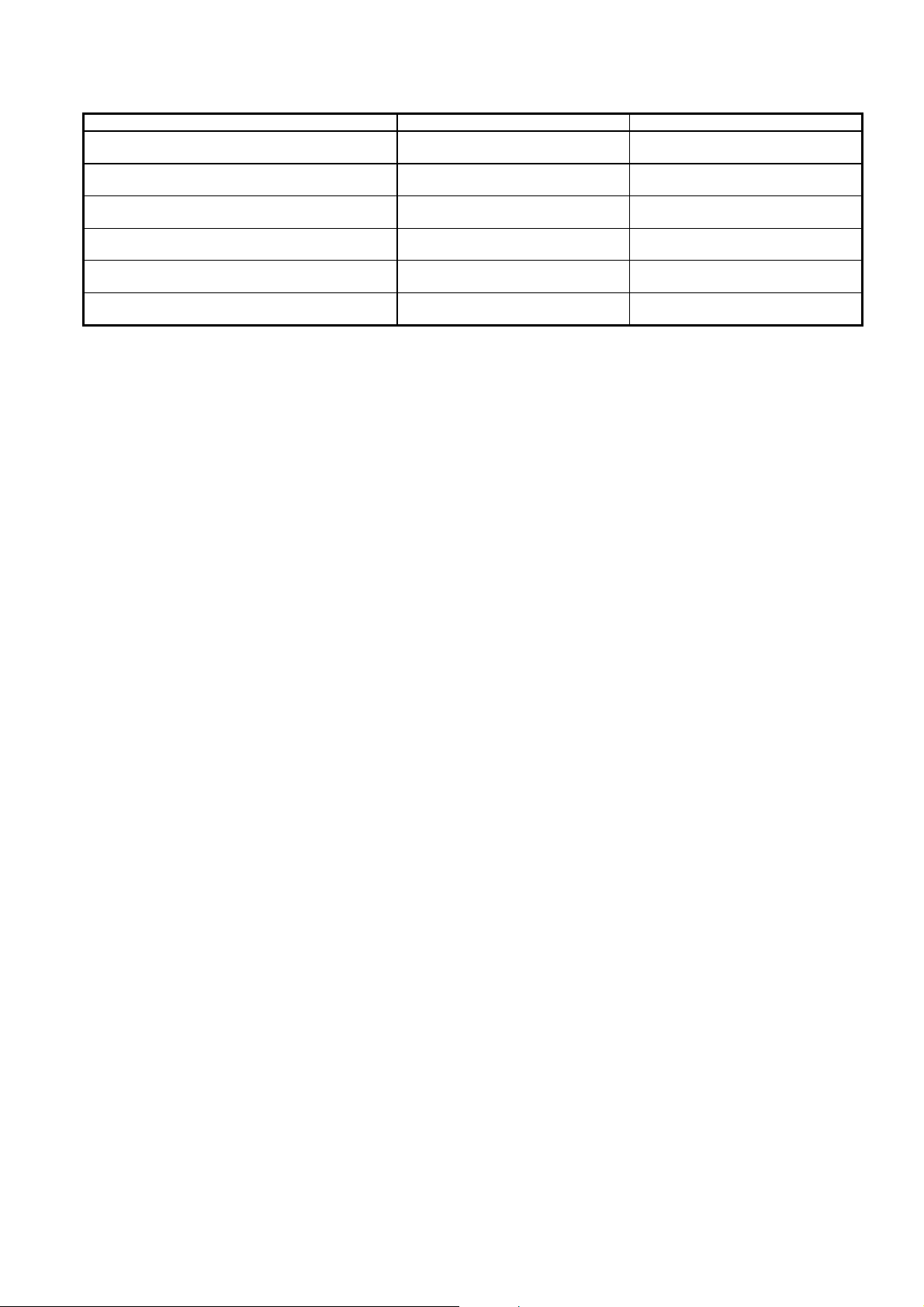

Points to be continuously displayed on the screen (point types with their operating/alarm status)

Point type Operating status Alarm status

SAP

(Status Alarm Point)

CAP

(Command with Status Alarm Point)

SOP*

1

(Status Only Point)

COP

(Command Only Point)

CCP

(Command with COS (Change of Status) Point)

AOP

(Alarm Only Point)

Notes:

∗1 Status Only Point, which does not have any command, can be specified to continuously display on the screen.

∗2 If CCP or CAP disagrees with its COS, its indicator [ON] or [OFF] flashes.

9 9

2

9*

9

9

9

2

9*

9

AB-6546

5

Page 6

AB-6546

Specifications: Model QY5100W0000 (Panel Mount Type)

Main unit specifications

Item Specification

Power supply Model QY5100W0000

Environmental

conditions

Status indication LED (Green) Power ON: Power ON, OFF: Power OFF

Communication DP-bus

Display

Weight 400 g

Material / color Modified PPE / light gray

connection

Rated operating

conditions

Transport and storage

conditions

LCD

Key

Power M3 screw Terminal

Communication (DP-bus) M3 screw (Modular connection*)

Rated voltage 100 V AC to 240 V AC, 50 Hz/60 Hz

Allowable voltage range 85 V AC to 264 V AC

Power consumption 8 VA

Ambient temperature 0 °C to 50 °C

Ambient humidity 10 %RH to 85 % RH (Non-condensing)

Altitude 2000 m or lower

Vibration 5.9 m/s

Ambient temperature -20 °C to 60 °C

Ambient humidity 5 %RH to 85 % RH (Non-condensing)

Vibration (for storage) 5.9 m/s2 or less (at 10 Hz to 150 Hz)

Vibration (for transport) 9.8 m/s

Transmission system RS-485

Transmission speed 4800 bps

Transmission distance 10 m

Number of remote units to

be connected

Resolution 128 × 64 (dots)

Gradation 2 tones: black and white

Backlight LED backlight

Contrast adjustment Trimmer

Material Silicon rubber Input

Key names [mode], [<], [>], [→], [∧], [∨], [enter]

2

or less (at 10 Hz to 150 Hz)

2

or less (at 10 Hz to 150 Hz)

1

∗ Modular adaptor is pre-connected to the M3 screw terminals.

Wiring specifications

Item Wiring Wiring length Condition

Power supply JIS* IV 2.0 mm2 or JIS CVV 2.0 mm2 or greater ⎯ ⎯

Ground JIS IV 2.0 mm2 or JIS CVV 2.0 mm2 or greater ⎯ Ground resistance: 100 Ω or lower

DP-bus Model DY7210 Connector cable,

Model DY7220 Short connector cable, or

Cable compliant to EIA/TIA-568 Category 5 or above

∗JIS: Japanese Industrial Standards

10 m ⎯

Model Numbers: Model QY5100W0000 (Panel Mount Type)

Base model number Power ⎯ Description

QY5100

W 100 V AC to 240 V AC

Note:

Operation manual for Model QY5100W0000 (AB-6547) is available. When you order the product, request the manual if necessary.

Operator Panel for Infilex AC / Infilex GC / Infilex GD

Panel mount type (Mounted on the door of the control panel cabinet.)

0000 ⎯

6

Page 7

AB-6546

Specifications: Model RY5001Q0000 (Integral Type)

Main unit specifications

Item Specification

Environmental

conditions

Display

Weight 170 g

Material / color Modified PPE / light gray

Rated operating

conditions

Transport and

storage

conditions

LED

Key

Ambient temperature 0 °C to 50 °C

Ambient humidity 10 %RH to 90 %RH (Non-condensing)

Altitude 2000 m or lower

Vibration When assembled with Infilex AC:

5.9 m/s

When assembled with Infilex GC/Infilex GD:

3.2 m/s

Ambient temperature -20 °C to 60 °C

Ambient humidity 5 %RH to 95 %RH (Non-condensing)

Vibration (for storage) When assembled with Infilex AC:

Vibration (for transport) 9.8 m/s

7 segment LED

Dot LED for status indication [OFF], [ON], and [→] in green

Material Silicon rubber Input

Key names [MODE], [∧], [∨], [ENTER], [→]

5.9 m/s

When assembled with Infilex GC/Infilex GD:

3.2 m/s

2

or less at 10 Hz to 150 Hz

4 digit × 2 lines (Upper line in green, lower line in red)

Upper line: Point number is displayed.

Lower line: Max. 6 digit number is displayed. (Upper 2 digits are

displayed first, and lower 4 digits are displayed with [∧] key.) For the

decimal number, max. 3 digits after the decimal point are displayed.

[ALM] in red.

2

or less at 10 Hz to 150 Hz

2

or less at 10 Hz to 150 Hz

2

or less at 10 Hz to 150 Hz

2

or less at 10 Hz to 150 Hz

Wiring specifications

Item Wiring Wiring length Condition

Remote Controller bus Model DY7210 Connector cable,

Model DY7220 Short connector cable, or

EIA/TIA-568 Category 3 or over

50 m ⎯

Model Numbers: Model RY5001Q0000 (Integral Type)

Base model number ⎯ ⎯ Description

RY5001

Q ⎯

Note:

Operation manual for Model RY5001Q0000 (AB-6642) is available. When you order the product, request the manual if necessary.

Operator Panel for Infilex AC / Infilex GC / Infilex GD

Integral type (Assembled with Infilex AC / Infilex GC / Infilex GD)

0000 ⎯

CE Marking Conformity

This product must be installed in a panel cabinet. Besides, the product in the panel cabinet must be out of reach of

unauthorized people who are not well-trained for electric facilities.

This product complies with the following Electromagnetic Compatibility (EMC) and the Low Voltage Directive (LVD).

EMC: EN61326-1 Class A, Table 2 (For use in an industrial electromagnetic environment)

LVD: EN61010-1 Overvoltage category II

Pollution degree 2

7

Page 8

AB-6546

r

r

Dimensions: Model QY5100W0000 (Panel Mount Type)

<Main unit dimensions>

<Mounting panel cutout dimensions>

91.8

91

70

Figure 2. Main unit dimensions (mm): Model QY5100W0000

+0.5

92

30 or wide

Figure 3. Mounting panel cutout dimensions (mm): Model QY5100W0000

0

91.8

96

+0.5

0

92

30 or wide

96

8

Page 9

Dimensions: Model RY5001Q0000 (Integral Type)

<Main unit dimensions>

Figure 4. Main unit dimensions (mm): Model RY5001Q0000

30

AB-6546

90

140

9

Page 10

AB-6546

A

Parts Identification: Model QY5100W0000 (Panel Mount Type)

Displays the operation status

and/or alarm status of the

selected point.

Contrast adjustment trimmer

djusts the contrast of the LCD by

turning the trimmer.

(To darken, turn the trimmer

clockwise. To lighten, turn it

counterclockwise.)

Is lit when the power is ON.

Data display panel

Displays the point data,

schedule, operation

restriction, etc.

Operation status display

Alarm status display

Power LED (green)

1) 2) 3) 4) 5) 6) 7)

(1) [mode] key Changes over the point display modes (group-points modes (groups

1 to 4) and all-points mode).

When the Operator Panel is connected to a standalone remote unit,

changes over the schedule display/setting, and current day/time

setting modes.

(2) [<] key Changes to display the point data to the previous point data.

(3) [>] key Changes to display the point data to the next point data.

(4) [→] key For a configuration changeable point, switches the normal display

(5) [∨] key For numeric data configuration, decreases the selected numeric

(6) [∧] key For numeric data configuration, increases the selected numeric digit.

(7) [enter] key Fixes the configured point data.

Figure 5. Parts identification: Model QY5100W0000

(display only) to the configuration change display.

In the configuration change display, selects a digit of the point data to

change.

digit. (The digit (9 to 0) descends one by one. After 0, the digit

returns to 9.)

For ON/OFF operation, switches ON to OFF.

For positive/negative numeric data configuration, changes + to -.

(The digit (0 to 9) ascends one by one. After 9, the digit returns to 0.)

For ON/OFF operation, switches OFF to ON.

For positive/negative numeric data configuration, changes - to +.

When the [enter] and [mode] keys are concurrently kept pressed for

an extended period of time, a point display mode (or a mode unique to

the Operator Panel connected to a standalone remote unit) is

changed to the operation restriction mode.

Configuration changeable/

unchangeable status indicator

Indicates that the currently

displayed point data is changeable.

Point data displayed without the

indicator is unchangeable.

Operation keys

10

Page 11

Parts Identification: Model RY5001Q0000 (Integral Type)

(5)

g

™

(1)

(2)

(3)

(4)

(1) [MODE] key Changes over the point display modes (group-points modes (groups 1

(2) [∧] key Changes to display the point data to the previous point data.

(3) [∨] key Changes to display the point data to the next point data.

(4) [ENTER] key Fixes the configured point data.

(5) [→] key For a configuration changeable point, switches the normal display

to 4) and all-points mode).

When the Operator Panel is connected to a standalone remote unit,

changes over the schedule display/setting, and current day/time setting

modes.

For numeric data configuration, increases the selected numeric digit.

(The digit (0 to 9) ascends one by one. After 9, the digit returns to 0.)

For ON/OFF operation, switches OFF to ON.

For positive/negative numeric data configuration, changes - to +.

For numeric data configuration, decreases the selected numeric digit.

(The digit (9 to 0) descends one by one. After 0, the digit returns to 9.)

For ON/OFF operation, switches ON to OFF.

For positive/negative numeric data configuration, changes + to -.

When the [ENTER] and [MODE] keys are concurrently kept pressed for

an extended period of time, the normal display mode (or a mode unique

to the Operator Panel connected to a standalone remote unit) is

changed to the operation restriction mode.

(display only) to the configuration change display.

In the configuration change display, selects a digit of the point data to

change.

Data display panel

Displays the point data, schedule, operation restriction, etc.

uration changeable/unchangeable status indicator

Confi

Indicates that the currently displayed point data is changeable.

Point data displayed without the indicator is unchangeable.

Operation status display / Alarm status display

Displays the operation status and/or alarm status of the selected point.

Indicates the start-up time with ON LED and the shut-down time with OFF LED when

schedule is displayed.

Port for Remote Controller bus

Connects to Neopanel

Ask Azbil Corporation’s sales personnel for details regarding Neopanel and

Attachment hole for the point assignment list holder

Holds the point assignment list holder* indicating point names and their engineering

units/status.

∗ Note:

Point assignment list holder (Part No. 83167015-001)

is optional requiring separate order.

For a poing assignment list, photocopy the blank point

assignment list included in AB-6642 operation manual

of Model RY5001Q0000 and fill out the list.

Also, digital data (in spreadsheet format) of point

assignment list is available. Ask Azbil Corporation’s

sales personnel for details.

Figure 6. Parts identification: Model RY5001Q0000

or Neoplate with LAN cable.

AB-6546

11

Page 12

AB-6546

f

r

Installation

IMPORTANT:

Do not install Operator Panel in a high temperature environment including locations exposed to heat radiation

from heating/cooling system equipment or to the direct sunlight. Also, install in a location where the displaying

contents can be seen clearly.

Model QY5100W0000 (panel mount type)

Precautions

• Use a minimum of 2 mm thick steel plate for the

mounting panel. (e.g., door of a control panel

cabinet where the Operator Panel is installed.)

• The allowable mounting angle is ranging from

upright position to 10° tilted upwards or

downwards.

• The angle of visibility is 80° (vertical and

horizontal). Be sure to install Model

QY5100W0000 in a location where its LCD is

visible.

• Do not remove the protective sheet until the

wiring work is completed.

Installation procedure

1) Insert Model QY5100W0000 from the front of the

mounting panel.

2) From the rear of the mounting panel, attach the

mounting brackets to Model QY5100W0000.

3) Keep the mounting brackets pushed until its

claws are engaged with the grooves on Model

QY5100W0000.

4) Tighten the screws of the mounting brackets attached to the top and the bottom of Model QY5100W0000.

Mounting bracket screws

Mounting brackets

Cutout portion o

the mounting panel

Mounting panel

Grooves on the top and

bottom sides fo

mounting brackets

Min. 2 mm thick

Main unit of Model QY5100W0000

Figure 7. Model QY5100W0000 installation

IMPORTANT:

Tighten the screws supplied with the mounting brackets until the mounting brackets get unshaken. Then, rotate (to tighten)

the screws once to fix Model QY5100W0000 on the mounting panel.

If the screws are tightened excessively, the case of Model QY5100W0000 may get deformed.

Model RY5001Q0000 (integral type)

Model RY5001Q0000, as well as the other modules (I/O and UT) connected to the Infilex GC/Infilex GD/Infilex AC basic unit,

is mounted on a DIN rail. The connectable modules including Model RY5001Q0000 vary because the power supplied by the

basic unit is limited. For details about installing Model RY5001Q0000, please refer to the respective

Specifications/Instructions and Installation Manual.

Product Document number Document type

Infilex AC (for NC-bus) AB-6438 Specifications/Instructions

Infilex AC (for LonTalk protocol) AB-6584 Specifications/Instructions

Infilex AC (for IP) AB-6489 Specifications/Instructions

Infilex GC (for NC-bus) AB-6528 Specifications/Instructions

Infilex GC (for LonTalk protocol) AB-6580 Specifications/Instructions

Infilex GC (for IP) AB-6541 Specifications/Instructions

Infilex GD (for NC-bus) AB-6529 Specifications/Instructions

Infilex GD (for LonTalk protocol) AB-6581 Specifications/Instructions

Infilex GD (for IP) AB-6542 Specifications/Instructions

Modules (I/O, UT, Operator Panel) AB-6527 Specifications/Instructions

Infilex Series for LonTalk Protocol AB-6651 Installation Manual

12

Page 13

AB-6546

Wiring: Model QY5100W0000 (Panel Mount Type)

WARNING

• Be sure to ground with 100 Ω or lower ground resistance. Improper grounding may cause electrical shock or

equipment damages.

CAUTION

• Install a circuit breaker or circuit protector in the power supply circuit that supplies the power to the product.

IMPORTANT:

• Use max. φ5.8 mm (outer diameter) crimp terminal lugs.

• Multiple cables cannot be connected together to the power supply terminal. Avoid daisy-chain connection for the power

supply terminals of Model QY5100W0000.

Connecting procedure

1) Connect the UT (user terminal) module and Model QY5100W0000 with the modular cable. Then, connect power supply.

2) After the wiring installation is completed, peel off the protective sheet before supplying the power.

Power supply terminals

arrangement

H

G

E

Operator Panel Model QY5100W0000

(Rear side)

13

∼

14

15

Figure 8. Connection to UT module

Figure 9. Protective sheet

2. Connect.

1. Connect.

UT module

Modular cable

Protective sheet

Wiring: Model RY5001Q0000 (Integral Type)

Model RY5001Q0000 is directly attached to a Infilex GC/Infilex GD/Infilex AC basic unit or to its I/O module, etc. Wires

connection therefore is not necessary unless Neopanel or Neoplate is connected to Model RY5001Q0000.

(Neopanel/Neoplate is connected to Model RY5001Q0000 with LAN cable. A modular jack (port for Remote Controller bus) is

provided on the front lower side of Model RY5001Q0000. (Refer to Fig. 6.)

13

Page 14

AB-6546

Maintenance

Model QY5100W0000 (panel mount type)

Wipe off the LCD with dry soft cloth when needed.

Any periodic part replacement is required. However, if the

brightness or contrast of the LCD deteriorates, replace the

LCD module.

LCD module: Part No. 83167012-001

If any part other than LCD module gets damaged (e.g. fuse

disconnection), the whole unit requires to be replaced.

LCD module replacement

IMPORTANT:

• Only authorized service personnel are allowed to

replace the LCD.

• Do not touch the power supply part during LCD

replacement.

• Before replacing the LCD, be sure to turn off the

power completely. Always replace the LCD with

the power disconnected.

• Plastic screws are used to prevent static

electricity. Be sure not to excessively tighten them

so as not to break the screws, or be sure not to

lose them. Metal screws cannot be substituted for

the plastic screws.

• Be sure to discharge static electricity charged in

your body (by touching the unpainted metal part of

the panel, etc.) before and during the LCD module

installation.

Required tools:

• Slotted screwdriver

• Phillips screwdriver

1) Remove the front panel using a slotted screwdriver.

Figure 10. Front panel removal

Front panel

2) Remove the transparent cover. Insert a slotted

screwdriver in the clearance on the right, and pry the

transparent cover.

Transparent

cover

Figure 11. Transparent cover removal (1/2)

Hold the pried cover with fingers to pull it out.

Figure 12. Transparent cover removal (2/2)

3) Remove the screw at the lower left of the LCD board.

Figure 13. Screw removal

4) Remove the upper portion of the LCD module. At this

time, note that the LCD module is connected to the LCD

board with the connector.

Figure 14. LCD module removal

Connector

LCD module

14

Page 15

AB-6546

5) Disconnect the connector to remove the LCD module.

Connector

Figure 15. Connector disconnection

6) Mount a new LCD module.

Connect the connector and hook the LCD module with

the claws of the LCD board.

Insert the screw into the hole located at the lower left of

the LCD board, and then engage the LCD module with

the boss at the lower right of the LCD board.

Claw

Boss

Figure 16. LCD module mounting

Screw

7) When the LCD module fits to the LCD board, tighten the

screw at the lower left of the LCD board (in one location).

Model RY5001Q0000 (integral type)

Any part replacement is not available for Model

RY5001Q0000. If any part of Model RY5001Q0000 gets

damaged, the whole unit requires to be replaced.

For details regarding the maintenance, ask Azbil

Corporation’s sales personnel.

IMPORTANT:

Screw-tightening torque is 0.07 N⋅m (0.7 kgf⋅cm).

Larger torque than 0.07 N⋅m may break the screw.

8) Attach the transparent cover to the LCD module. (The

wider side surface (to be inserted into the LCD module)

needs to be located on the right.)

9) Mount the front panel.

15

Page 16

AB-6546

Specifications are subject to change without notice.

Building Systems Company

http://www.azbil.com/

Rev. 5.0 Sep 2015 AB-6546

(J: AI-6546 Rev. 3.4) Printed in Japan.

16

Loading...

Loading...