Page 1

CM2-MGN200-2001

MagneW PLUS+

Electromagnetic Flowmeter

Open Channel Flowmeter Detector

User’s Manual

Model: NNK140/941,NNK150/951

Page 2

NOTICE

© 2008-2019 Azbil Corporation All Rights Reserved.

While the information in this manual is presented in good faith and

believed to be accurate, Azbil Corporation disclaims any implied warranty of merchantability or tness for a particular purpose and makes

no express warranties except as may be stated in its written agreement

with and for its customer.

In no event shall Azbil Corporation be liable to anyone for any indirect,

special or consequential damages. is information and specications

in this document are subject to change without notice.

Page 3

Table of Contents

1 :Introduction ................................................................................................... 1

2 :External view ................................................................................................ 3

3 :Outline and standard specications ............................................................. 5

3-1 :Standard specications ................................................................... 5

3-2 :External dimensions ........................................................................ 6

3-3 :How to use model with an Elbow Flange ........................................ 14

3-4 :How to use the Dummy detector ..................................................... 15

4 :Installation .................................................................................................... 17

4-1 :Considerations on installation ......................................................... 17

4-2 :Transportation of owmeter to the installation site .......................... 18

4-3 :Example of installation work ........................................................... 19

4-4 :Examples of installation .................................................................. 20

5 :Wiring ........................................................................................................... 22

5-1 :Considerations on wiring ................................................................. 22

5-2 :Wiring .............................................................................................. 22

6 :Inspection ..................................................................................................... 24

6-1 :Flowmeter in general ...................................................................... 24

6-2 :Detector .......................................................................................... 24

Appendix .......................................................................................................... Appendix 1

Water level calculation (Bell mouth type) ............................................... Appendix 1

Water level calculation (Elbow ange type) ........................................... Appendix 3

Average ow velocity of detector (m/s) .................................................. Appendix 4

Page 4

Page 5

List of Figure

Figure 1 Open channel type Electromagnetic owmeter detector ............................................................... 2

Figure 2 State during ow rate measurement .................................................................................................. 2

Figure 3 Dimensional drawings of Bell mouth type detector ........................................................................ 6

Figure 4 Dimensional drawings of a detector with Elbow ange ................................................................. 8

Figure 5 Dimensional drawings of a Dummy ................................................................................................. 10

Figure 6 Drawing of a Dummy with Elbow ange ......................................................................................... 11

Figure 7 Detector with Elbow ange ................................................................................................................ 12

Figure 8 Dummy with Elbow ange ................................................................................................................. 12

Figure 9 Measuring a large ow rate using dummy detectors ...................................................................... 13

Figure 10 Examples of setting Dummy detector ............................................................................................... 13

Figure 11 Grounding terminal ............................................................................................................................. 14

Figure 12 Connection of converter and detector .............................................................................................. 20

Figure 13 Wiring to connection box ................................................................................................................... 20

Figure 14 Water level adjustment........................................................................................................................ 21

Figure A-1 Detector size selection graph .............................................................................................................. Appendix-2

Page 6

List of Table

Table 1: Tightening torque of detector ............................................................................................................ 14

Page 7

1 : Introduction

This manual describes how to install and operate the MagneWTM3000 FLEX/

PLUS NNK open channel electromagnetic owmeter detector. If you are using a

MagneW

operation manual of the converter.

Before installing a detector, make sure that its size is adequate by referring to the

“Diameter Selection Graph” in the appendix of this manual.

TM

3000 FLEX/PLUS NNK in combination with a converter, refer to the

MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector 1

Page 8

Azbil Corporation

2 MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector

Page 9

Azbil Corporation

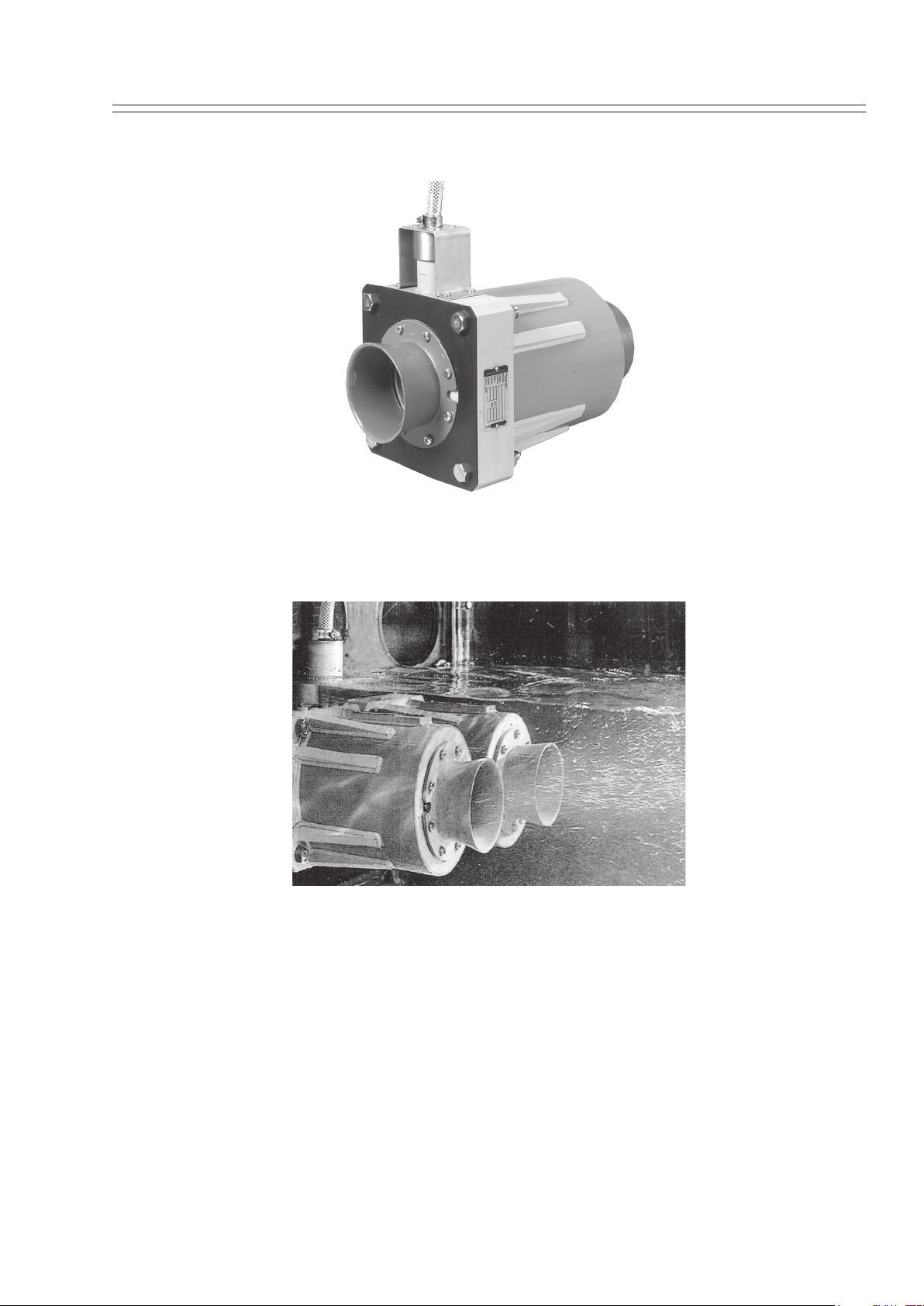

2 : External view

Figure 1 Open channel type Electromagnetic owmeter detector

Figure 2 State during ow rate measurement

MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector 3

Page 10

Azbil Corporation

4 MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector

Page 11

Azbil Corporation

3 : Outline and standard specications

This open channel type electromagnetic owmeter is used for measuring ow rates

in open channels or closed conduits such as drainage canals. It is used for a large

variety of ow rate measurements, such as drainage under total pollutant load

regulations, water and sewer service, and irrigation water. (This owmeter is ocially

listed in the “General Specications of Electric Work” of the Japan Sewage Works

Agency.)

3-1 : Standard specications

Overall specications

Flow velocity range: 0 - 0.3 to 0 - 10 m/s. (Continuously adjustable)

Accuracy (Combined with the MGG10/14C):

When detector is used

without dummy or dummies

When detector is used with

dummy or dummies

~Note

*Recommended condition of use

Without dummy: Straight channel section on the upstream side of

With dummy: Straight channel section on the upstream side of

Power supply: 90 to 250 V AC, 47 to 63 Hz

24V DC ± 10%, 110V DC ± 10%,

Power consumption: Approx. 10W (including detector and converter)

Detector

Material of body: Rigid vinyl chloride (parts in contact with uid: SUS304)

Within the recommended

condition *

+/- 1.0% F.S. +/- 2.0% F.S.

+/- 2.0% F.S. +/- 4.0% F.S.

detector is 3 times or more the nominal owmeter

diameter.

detector is twice or more the water channel width.

Outside of the

recommended condition

(Resisting {internal, external} pressure = 0.05MPa)

Materials of electrodes: SUS316L, Titanium

Structure: Open channel type (equivalent to JIS C 0920

Submersible Type) IEC IP68 equivalent

Cables (10m for each cable): One 4 core shielded cable (outer diameter 11.4 mm;

length 10 m) with cable protection vinyl tube (outer

diameter 22 mm; length 10 m)

Electrical conductivity of the measured uid: 5mS/cm

Ambient temperature: 0 to 40° C

MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector 5

Page 12

Azbil Corporation

W

Signal/Excitation cable

Signal/Excitation cable

Mass: 50 mm (detector;10 kg. dummy; 1.4 kg)

400 mm (detector;130 kg, dummy; 33.4 kg)

100 mm (detector;23 kg. dummy; 3.4 kg)

600 mm (detector;220 kg, dummy; 59.4 kg)

200 mm (detector;45 kg. dummy; 10.4 kg)

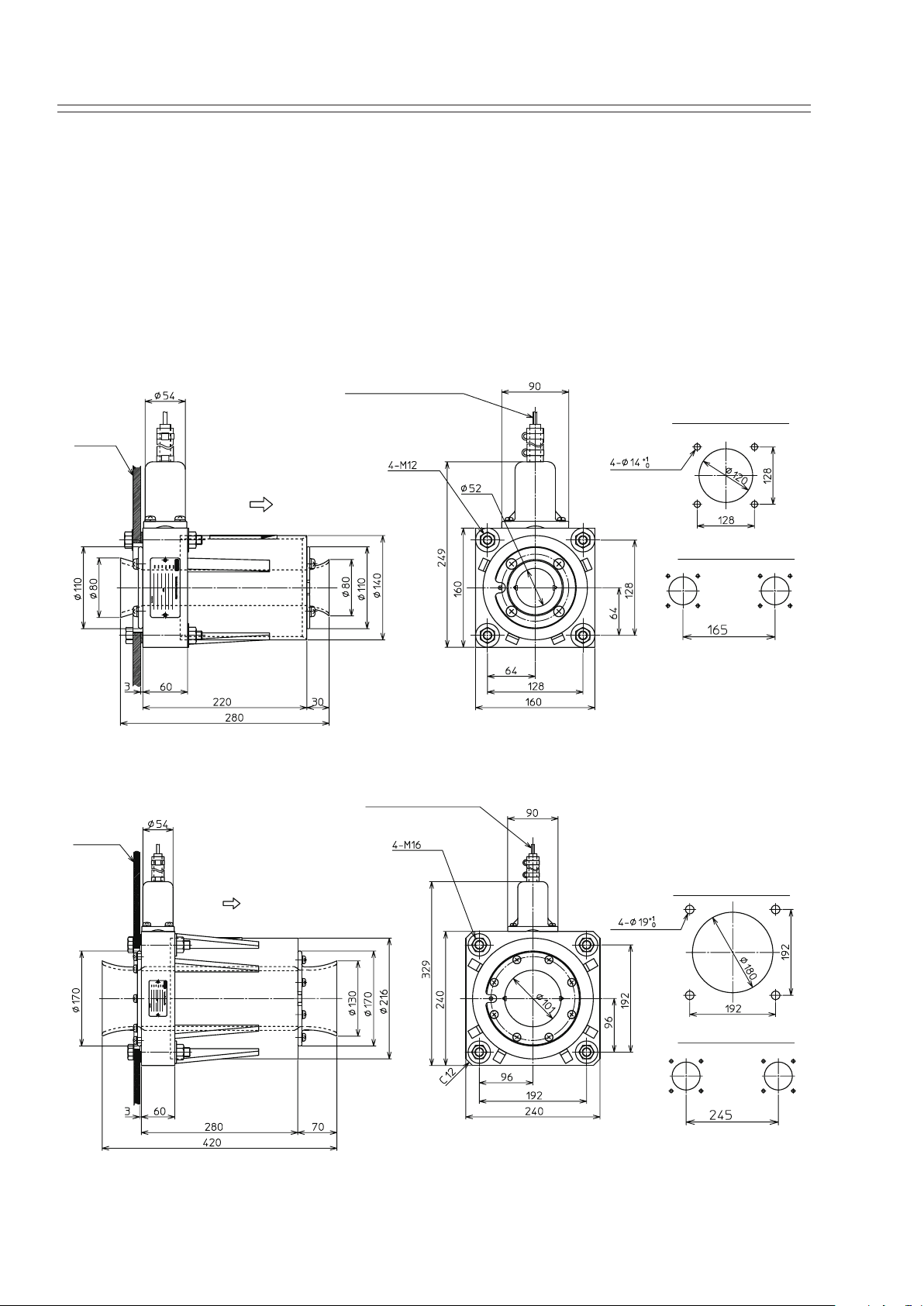

3-2 : External dimensions

Bell mouth type detector

Hole Dia. of Gate

eir/Gate

bolt

Flow direction

hole

Weir/Gate

Flow direction

Installation interval

or more

Size 50mm

bolt

Hole Dia. of Gate

hole

Installation interval

or more

Size 100mm

6 MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector

Page 13

Azbil Corporation

Signal/Excitation cable

Weir/Gate

Weir/Gate

bolt

Size 200mm

bolt

Signal/Excitation cable

hole

Hole Dia. of Gate

Installation interval

or more

Hole Dia. of Gate

Flow direction

Name plate

Material

hole

Installation interval

or more

Size 400mm

MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector 7

Page 14

Azbil Corporation

Weir/Gate

Flow direction

bolt

Name plate

Material

Size 600mm

Figure 3 Dimensional drawings of Bell mouth type detector

Hole Dia. of Gate

hole

Installation interval

or more

8 MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector

Page 15

Azbil Corporation

Signal/Excitation cable

Signal/Excitation cable

Detector with Elbow ange

Weir/Gate

Flow direction

bolt

Hole Dia. of Gate

hole

Installation interval

or more

Weir/Gate

Size 50mm

bolt

Hole Dia. of Gate

Flow direction

hole

Installation interval

or more

Size 100mm

MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector 9

Page 16

Azbil Corporation

Signal/Excitation cable

Weir/Gate

bolt

Size 200mm

Figure 4 Dimensional drawings of a detector with Elbow ange

Hole Dia. of Gate

hole

Installation interval

or more

10 MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector

Page 17

Azbil Corporation

Hole Dia. of Gate

Weir/Gate

Hole Dia. of Gate

Dummy

Weir/Gate

Bolt

Flow direction

hole

Installation interval

or more

Size 50mm

Weir/Gate

Flow direction

Flow direction

Size 100mm

bolt

bolt

Hole Dia. of Gate

hole

Installation interval

or more

Installation interval

or more

hole

Size 200mm

MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector 11

Page 18

Azbil Corporation

Flow direction

Weir/Gate

Weir/Gate

Hole Dia. of Gate

Flow direction

Size 400mm

bolt

bolt

Hole Dia. of Gate

hole

Installation interval

or more

hole

Installation interval

or more

Size 600mm

Figure 5 Dimensional drawings of a Dummy

12 MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector

Page 19

Azbil Corporation

Movable section

Dummy with an Elbow ange

Flow direction

H

T

L

Size 50mm, 100mm, 200mm

Figure 6 Drawing of a Dummy with Elbow ange

Size 50mm 100mm 200mm

L 367 to 388 569 to 590 876 to 897

H 73 to 94 136 to 157 281 to 302

T 112 to 133 212 to 233 407 to 428

MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector 13

Page 20

Azbil Corporation

Cover

3-3 : How to use model with an Elbow Flange

When no weir plate can be installed on the downstream side of a detector, use a

model with an Elbow ange.

(a) The water level (+ 7mm) can be adjusted since the elbow ange length can

be changed. A water level error caused by the use of a dummy detector can be

corrected by adjusting the arm.

Water level adjusting arm

(Shrinkable)

Figure 7 Detector with Elbow ange

(b) The measurement range can be increased in provision for a future ow rate

increase by installing a model with an elbow ange (with cover).

The cover can be mounted and removed easily with a buttery screw.

Movable section

Flow direction

Figure 8 Dummy with Elbow ange

14 MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector

Page 21

Azbil Corporation

[1 flowmeter] 1 flowmeter

1 flowmeter

qq

Dummy

3-4 : How to use the Dummy detector

The measurable ow rate can be doubled, tripled, or quadrupled by installing 1,2,3

dummy detectors, respectively. A detector must be combined with dummy detectors

of the similar shape. If the ow rate is to be increased in future, the measurable

range can be expanded easily by installing a model with an elbow ange. (with a

cover).

1 dummy

2 dummies

Q=q Q=2q Q=3q

qq

Dummy

Detector

Detector

qq

Figure 9 Measuring a large ow rate using dummy detectors

Flow rate measurement in trunk sewerage

(400mm: one detector and three dummies)

MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector 15

Flow rate measurement in sewage treatment

plant

(600mm: one detector and nine dummies)

Figure 10 Examples of setting Dummy detector

Page 22

Azbil Corporation

16 MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector

Page 23

Azbil Corporation

Grounding terminal

4 : Installation

4-1 : Considerations on installation

Before the installation of a open channel type electromagnetic owmeter, observe

the following considerations.

• If you are asking a subcontractor to install a owmeter, you are advised to check

the procedure of installation work in writing in advance.

• Protect the ends of the dedicated cables attached to the body from water by

wrapping them with tape.

• When locating a owmeter on a gate, assign one worker to the upstream side

of the gate and another to the downstream side. Suspend the owmeter with a

chain block and lock its body with bolts with the specied tightening torque. Make

sure that the electrode is situated horizontally.

• Ground the owmeter with the grounding terminal. (The placement of the

grounding terminal is shown in Figure 11.)

• After mounting a detector, make sure that neither the body, nor the cables are

damaged.

• The gate board on which the elbow ange–type detector and dummy detectors

are installed must bear the weight of the detectors and of the water that ows

through them. Therefore, use a board that is strong enough and that will not

warp. If the gate board warps, leakage will occur between the board and the

detectors, and measurement will be incorrect.

• When removing and reinstalling the submersible electromagnetic owmeter from

the gate board for replacement, recalibration, or other purposes, check that the

board is not deformed and that there is no rust or foreign matter on the sealant

between the board and the detector.

MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector 17

Figure 11 Grounding terminal

Page 24

Azbil Corporation

Table 1: Tightening torque of detector

Nominal size Tightening torque Nominal size Tightening torque

50mm

100mm

200mm

10 to 20

11 to 21

25 to 35

400mm

600mm

25 to 35

25 to 35

4-2 : Transportation of owmeter to the installation site

• Weigh the owmeter and post the weight in a place where one can see it.

• Check to see if a crane can be used.

• If rollers are to be used for moving a owmeter, encase the owmeter in a

wooden frame.

• Provide a chain block scaolding.

• Use a jack or a stepladder if necessary.

18 MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector

Page 25

Azbil Corporation

A

Gate

4-3 : Example of installation work

Chief field supervisor

Meeting about installation

Flowmeter mounting

Assigned to unloading

the unit from a crane,

chain block etc.

<Example of personnel assignment>

Unloading worker

C

worker

Installation supervisor

Detailed supervision

from the beginning to

completion of installation

CD

Flowmeter mounting

worker

Support on upstream

side of the gate

B

Flowmeter mounting

worker

Bolt tightening on

downstream side of

the gate

Installation supervisor

B

E

Mounting worker

D

Upstream side

Detector

Downstream side

Chief field supervisor

A

Mounting worker

E

MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector 19

Page 26

Azbil Corporation

4-4 : Examples of installation

Schematic drawings

1) It is recommended that a

Mounting

Gate

Weir

Flow measurement with a NNK

detector installed in an open

channel.

Flow measurement with a NNK

detector installed on the intake

end of channel.

gate with a lifting device be

used. If there is a possibility that

the upstream water level will

become lower than the inlet port

of the detector, a downstream

wirer plate or a adaptor must be

installed to avoid exposing the

measuring pipe in to air.

2) MagneW™3000 FLEX/

PLUS, the NNK detector, can

be mounted in direct or reverse

direction. However, wiring

connections must be made

accordingly.

Flow measurement with

submersible electromagnetic

ormeter installed in a pit.

Flow measurement with a NNK

detector installed in a discharge

tube.

Flow measurement with a NNK

detector installed in a discharge

end channel.

Discharge ow measurement with

a NNK detector with an elbow

ange installed in a profabrication

sewage disposal plant.

20 MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector

Page 27

Azbil Corporation

Pictures of owmeter installation

Measurement with one 200mm detector

and one 200mm dummy

Installed on a water tank outlet (600mm) Installed in a discharge pipe of the plant (400mm)

High accuracy measurement with two 200mm

detectors

MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector 21

Page 28

Azbil Corporation

5 : Wiring

5-1 : Considerations on wiring

(a) Since the root of the 4-core cabtyre cable (including cores for signal and

excitation) is a watertight structure, do not pull them.

(b) The standard length of each cable of the detector is 10m. If the cable length

between a detector and a converter is over 10m, use a cable connection box

(Model No. NNZ 102-X-X)*. (See Figure 9.) Since the uid conductivity of the

water and drain is over 100 mS/cm, the cable can be extended to a maximum

of 100m. * Optional (Model SMC 11-HC)

(c) Make sure that the cable between the detector and the converter is laid at a

place where it cannot be damaged.

(d) Screw the tightening gland into the wire connection port of the converter in

order to ensure airtightness between the cabtyle cable and the wire connection

port.

(e) Cable should be as far from a large current cable as possible, and they should

not be laid in parallel.

5-2 : Wiring

(a) Install the converter in a place where it will not be exposed to direct sunshine.

(b) If to be used for a ow running reverse to the ow direction marked on the

(c) Ground the detector using the grounding terminal (Figure 11) (ground

(d) Never short-circuit the exciting terminals (X,Y) of the converter. Do not connect

detector (See the arrows in Figure 7 and Figure 8.), reverse the white and black

signal lines (White - B, Black - A)

resistance needs to be less than 100 W).

anything but a detector to the converter.

22 MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector

Page 29

Azbil Corporation

Category D ground

10m long cables as standard accessories.

Category D ground

The cable can be extended to 100m.

A detector is used in combination with a Open channel type detector (Type NNK)

and a converter (Type MGG10C/14C). Its output signals are instantaneous ow rate

signals (4 to 20mA DC), totalized output (pulse) and contact output (open collector).

Submersible detector

(Type NNK)

MGG10C/14C

Converter

P+ / P-

(Pulse output)

-

+

Green

Pulse

100V AC

or

Selected power

supply

Power

Exciting current

XY

HNG

Category D

A submersible electromagnetic flowmeter has

Red

ground

Figure 12 Connection of converter and detector

I+ / I-

(analog output)

-

+

4 to 20mA

Input signal

ABC

White

Contact output

-

+

Black

Shield

Contact input

-

+

Detector

Connected with standard 10mm long cable

A B C X Y

Cable connection box

(Model No NNZ102-X-X)

Wiring diagram when a cable connection box is used

for connecting more than 10m long cables.

Figure 13 Wiring to connection box

MGG10C/14C

Converter

XY ABC

Red

Green

(Model No. SMC11- HC)

Black

White

Shield

MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector 23

Page 30

Azbil Corporation

Elbow flange

W

(Fluid overflows from one.)

hen the two are the same height.

6 : Inspection

Inspect the following parts.

6-1 : Flowmeter in general

(a) Check to see if the detector and the converter are mounted as specied.

…. See “Considerations on installation” on page 17. “Examples of

installation” on page 20 and “Considerations on wiring” on page 22.

“Wiring” on page 22 in this manual.

(b) Check to see if the detector and the converter are connected correctly.

…. See “Considerations on wiring” on page 22. in this manual.

6-2 : Detector

(a) Are all the bolts tightened?

…. Make sure that all the bolts are tightened.

(b) Is the detector grounded?

…. Refer to the instructions related to the ground terminal in “Grounding

terminal” on page 17.

(c) Are the dummy detector and the detector installed at the same height?

…. If detectors with elbow anges are used, stop the ow and ll the elbow

anges with liquid and make sure that no uid comes out from either of the

detectors. If they are not installed at the same height, adjust it using the

water level adjusting arm. (See “Figure 14 Water level adjustment”.)

(d) Is the detector or the dummy detector size large enough for the maximum

ow rate?

… See “Detector size selection graph” on page 2 for checking this.

(e) Are oily suspended substances stuck to the inner wall?

…. Wipe with a cloth

Water level

error*

hen the two are not the same height.

24 MagneW PLUS+ Electromagnetic Flowmeter Open channel Flowmeter Detector

* Correct the error using the water level adjusting arm by referring to 3-(4)

“Instructions relating to the Elbow Flange”.

W

Figure 14 Water level adjustment

Page 31

Appendix

1

Water level calculation (Bell mouth type)

Example:

Mounting

Gate

Weir

Conversion of water head dierential (H1) to water level

in which : Water head dierential conversion coecient 0.053

(Example)

Size and number of detector : 200mm, 1unit

Size and number of dummy detector : 200mm, 1unit

Width of weir plate (W) : 2m

H

Maximum ow rate (Qt.) : 500m3/h

Average ow velocity per detector (V) : 2.21m/s

H2

When the average ow velocity of the detector is 2.21[m/s]

Conversion of overow water depth (H2O) to water level

(Example)

When the maximum ow rate is 500[m

3

/h] and the sheathing board width is 2[m]

NNK-MagneW 3000 FLEX/PLUS Smart Electromagnetic Flowmeter Open channel Type Detector Appendix-1

Page 32

Appendix Azbil Corporation

Figure A-1 Detector size selection graph

~Note

The expression “200mm(3)” refers to the structure consisting of one 200mm

detector and two 200mm dummies. (“200mm” referts to the detector’s size

or aperture and “(3)“means that the total number of detectors including

dummy detectors.)

[How to use the graph]

The ow rate is graduated from left to right along the lower horizontal axis.

If a line is drawn perpendicular to his axis, up wards to the top of this graph

by drawing a lines directly left from the points of intersection.

[Example] Water head dierential and ow velocity at ow rate of 500m

3

Draw a line upward from the point of 500mm

/hr, and it will intersect with

the following diagonal lines:

400mm(4), 400mm(3), 600mm(2) {=200mm(8), 400mm(1) {=200mm(4)},

200mm(3), 200mm(2) {=100mm(8)}, 200mm(1) {=100mm(4)}

When the line intersects with 200mm(2), the water head dierential H1 is

found to be about 0.26m and the ow velocity per detector V(m/s) is about

2.2m/s.

Example for a maximum ow rate of 500 (m

3

/h) and weir plate width of 2

(m):

3

/hr

Appendix-2 NNK-MagneW 3000 FLEX/PLUS Smart Electromagnetic Flowmeter Open channel Type Detector

Page 33

Azbil Corporation Appendix

45 elbow

Gate

Water level calculation (Elbow ange type)

Example

Size and number of detector: 200mm, 1 unit

H3

H4

H5

Water level calculation of head dierence ( )

where : Water head conversion coecient of the elbow ange: 0.055

Size and number of dummy detector: 200mm, 1 unit

Maximum ow rate (Qt.): 500m3/h

Average ow velocity per detector (V): 2.21m/s

Example: For a detector average ow velocity of 2.21 (m/s):

Elbow spouting height ( )

Where : Conversion coecient of elbow spouting height: 0.028

Example: For a detector average ow velocity of 2.21 (m/s):

Nominal size 50mm 100mm 200mm

Dimension of

49mm 92mm 196mm

Consequently, THE head can be calculated as

NNK-MagneW 3000 FLEX/PLUS Smart Electromagnetic Flowmeter Open channel Type Detector Appendix-3

Page 34

Appendix Azbil Corporation

Average ow velocity of detector (m/s)

Flow velocity conversion table

Where

: Flow velocity (m/s), : Flow rate (m3/h)

: Flow velocity conversion coecient

(Example)

Detector size: 200(mm)

Flow rate per detector: 250(m

3

/h)

Nominal size

(mm)

50 0.1415

100 0.03537

200 0.00842

400 0.002210

600 0.0009824

Flow velocity conversion

coecient K

Appendix-4 NNK-MagneW 3000 FLEX/PLUS Smart Electromagnetic Flowmeter Open channel Type Detector

Page 35

Page 36

Terms and Conditions

We would like to express our appreciation for your purchase and use of Azbil Corporation’s products.

You are required to acknowledge and agree upon the following terms and conditions for your purchase of Azbil Corporation’s products (system

products, field instruments, control valves, and control products), unless otherwise stated in any separate document, including, without limitation,

estimation sheets, written agreements, catalogs, specifications and instruction manuals.

1. Warranty period and warranty scope

1.1 Warranty period

Azbil Corporation’s products shall be warranted for one (1) year from the date of your purchase of the said products or the delivery of the

said products to a place designated by you.

1.2 Warranty scope

In the event that Azbil Corporation’s product has any failure attributable to azbil during the aforementioned warranty period, Azbil

Corporation shall, without charge, deliver a replacement for the said product to the place where you purchased, or repair the said

product and deliver it to the aforementioned place. Notwithstanding the foregoing, any failure falling under one of the following shall

not be covered under this warranty:

(1) Failure caused by your improper use of azbil product (noncompliance with conditions, environment of use, precautions, etc. set

forth in catalogs, specifications, instruction manuals, etc.);

(2) Failure caused for other reasons than Azbil Corporation’s product;

(3) Failure caused by any modification or repair made by any person other than Azbil Corporation or Azbil Corporation’s

subcontractors;

(4) Failure caused by your use of Azbil Corporation’s product in a manner not conforming to the intended usage of that product;

(5) Failure that the state-of-the-art at the time of Azbil Corporation’s shipment did not allow Azbil Corporation to predict; or

(6) Failure that arose from any reason not attributable to Azbil Corporation, including, without limitation, acts of God, disasters, and

actions taken by a third party.

Please note that the term “warranty” as used herein refers to equipment-only-warranty, and Azbil Corporation shall not be liable for any

damages, including direct, indirect, special, incidental or consequential damages in connection with or arising out of Azbil Corporation’s

products.

2. Ascertainment of suitability

You are required to ascertain the suitability of Azbil Corporation’s product in case of your use of the same with your machinery,

equipment, etc. (hereinafter referred to as “Equipment”) on your own responsibility, taking the following matters into consideration:

(1) Regulations and standards or laws that your Equipment is to comply with.

(2) Examples of application described in any documents provided by Azbil Corporation are for your reference purpose only, and

you are required to check the functions and safety of your Equipment prior to your use.

(3) Measures to be taken to secure the required level of the reliability and safety of your Equipment in your use

Although azbil is constantly making efforts to improve the quality and reliability of Azbil Corporation’s products, there exists

a possibility that parts and machinery may break down. You are required to provide your Equipment with safety design such

as fool-proof design,*

physical injuries, fires, significant damage, and so forth. Furthermore, fault avoidance,*3 fault tolerance,*4 or the like should be

incorporated so that the said Equipment can satisfy the level of reliability and safety required for your use.

*1. A design that is safe even if the user makes an error.

*2. A design that is safe even if the device fails.

*3. Avoidance of device failure by using highly reliable components, etc.

*4. The use of redundancy.

3. Precautions and restrictions on application

3.1 Restrictions on application

Please follow the table below for use in nuclear power or radiation-related equipment.

Nuclear power quality*5 required Nuclear power quality*5 not required

Within a radiation

controlled area*

Outside a radiation

controlled area*

Cannot be used (except for limit switches for

6

nuclear power*7)

Cannot be used (except for limit switches for

6

nuclear power*7)

1

and fail-safe design*2 (anti-flame propagation design, etc.), whereby preventing any occurrence of

Cannot be used (except for limit switches for

nuclear power*7)

Can be used

*5. Nuclear power quality: compliance with JEAG 4121 required

*6. Radiation controlled area: an area governed by the requirements of article 3 of “Rules on the Prevention of Harm from

Ionizing Radiation,” article 2 2 4 of “Regulations on Installation and Operation of Nuclear Reactors for Practical Power

Generation,” article 4 of “Determining the Quantity, etc., of Radiation-Emitting Isotopes,”etc.

*7. Limit switch for nuclear power: a limit switch designed, manufactured and sold according to IEEE 382 and JEAG 4121.

Any Azbil Corporation’s products shall not be used for/with medical equipment.

The products are for industrial use. Do not allow general consumers to install or use any Azbil Corporation’s product. However, azbil

products can be incorporated into products used by general consumers. If you intend to use a product for that purpose, please contact

one of our sales representatives.

3.2 Precautions on application

you are required to conduct a consultation with our sales representative and understand detail specifications, cautions for operation,

and so forth by reference to catalogs, specifications, instruction manual, etc. in case that you intend to use azbil product for any purposes

specified in (1) through (6) below. Moreover, you are required to provide your Equipment with fool-proof design, fail-safe design, antiflame propagation design, fault avoidance, fault tolerance, and other kinds of protection/safety circuit design on your own responsibility

to ensure reliability and safety, whereby preventing problems caused by failure or nonconformity.

Page 37

(1) For use under such conditions or in such environments as not stated in technical documents, including catalogs, specification,

and instruction manuals

(2) For use of specific purposes, such as:

* Nuclear energy/radiation related facilities

[When used outside a radiation controlled area and where nuclear power quality is not required]

[When the limit switch for nuclear power is used]

* Machinery or equipment for space/sea bottom

* Transportation equipment

[Railway, aircraft, vessels, vehicle equipment, etc.]

* Antidisaster/crime-prevention equipment

* Burning appliances

* Electrothermal equipment

* Amusement facilities

* Facilities/applications associated directly with billing

(3) Supply systems such as electricity/gas/water supply systems, large-scale communication systems, and traffic/air traffic control

systems requiring high reliability

(4) Facilities that are to comply with regulations of governmental/public agencies or specific industries

(5) Machinery or equipment that may affect human lives, human bodies or properties

(6) Other machinery or equipment equivalent to those set forth in items (1) to (5) above which require high reliability and safety

4. Precautions against long-term use

Use of Azbil Corporation’s products, including switches, which contain electronic components, over a prolonged period may degrade

insulation or increase contact-resistance and may result in heat generation or any other similar problem causing such product or switch

to develop safety hazards such as smoking, ignition, and electrification. Although acceleration of the above situation varies depending

on the conditions or environment of use of the products, you are required not to use any Azbil Corporation’s products for a period

exceeding ten (10) years unless otherwise stated in specifications or instruction manuals.

5. Recommendation for renewal

Mechanical components, such as relays and switches, used for Azbil Corporation’s products will reach the end of their life due to wear by

repetitious open/close operations.

In addition, electronic components such as electrolytic capacitors will reach the end of their life due to aged deterioration based on

the conditions or environment in which such electronic components are used. Although acceleration of the above situation varies

depending on the conditions or environment of use, the number of open/close operations of relays, etc. as prescribed in specifications

or instruction manuals, or depending on the design margin of your machine or equipment, you are required to renew any Azbil

Corporation’s products every 5 to 10 years unless otherwise specified in specifications or instruction manuals. System products, field

instruments (sensors such as pressure/flow/level sensors, regulating valves, etc.) will reach the end of their life due to aged deterioration

of parts. For those parts that will reach the end of their life due to aged deterioration, recommended replacement cycles are prescribed.

You are required to replace parts based on such recommended replacement cycles.

6. Other precautions

Prior to your use of Azbil Corporation’s products, you are required to understand and comply with specifications (e.g., conditions and

environment of use), precautions, warnings/cautions/notices as set forth in the technical documents prepared for individual Azbil

Corporation’s products, such as catalogs, specifications, and instruction manuals to ensure the quality, reliability, and safety of those

products.

7. Changes to specifications

Please note that the descriptions contained in any documents provided by azbil are subject to change without notice for improvement

or for any other reason. For inquires or information on specifications as you may need to check, please contact our branch offices or

sales offices, or your local sales agents.

8. Discontinuance of the supply of products/parts

Please note that the production of any Azbil Corporation’s product may be discontinued without notice. After manufacturing is

discontinued, we may not be able to provide replacement products even within the warranty period.

For repairable products, we will, in principle, undertake repairs for five (5) years after the discontinuance of those products. In

some cases, however, we cannot undertake such repairs for reasons, such as the absence of repair parts. For system products, field

instruments, we may not be able to undertake parts replacement for similar reasons.

9. Scope of services

Prices of Azbil Corporation’s products do not include any charges for services such as engineer dispatch service. Accordingly, a separate

fee will be charged in any of the following cases:

(1) Installation, adjustment, guidance, and attendance at a test run

(2) Maintenance, inspection, adjustment, and repair

(3) Technical guidance and technical education

(4) Special test or special inspection of a product under the conditions specified by you

Please note that we cannot provide any services as set forth above in a nuclear energy controlled area (radiation controlled area) or at a

place where the level of exposure to radiation is equivalent to that in a nuclear energy controlled area.

AAS-511A-014-10

Page 38

Page 39

Document Number: CM2-MGN200-2001

Document Name: MagneW PLUS+ Electromagnetic Flowmeter

Open Channel Flowmeter Detector User’s

Manual

Model NNK140/941, NNK150/951

Date: 1st edition: Nov. 2008

3rd edition: Nov. 2019

Issued/Edited by: Azbil Corporation

Page 40

Loading...

Loading...