Page 1

™

Digital Mass Flow Controller

Standard Gas Model

MQV9005/9020/9200/9500

0002/0005/0020/0050/0200/0500

User’s Manual

No. CP-SP-1204E

Thank you for purchasing an Azbil

Corporation product.

This manual contains information for

ensuring the correct use of this product.

It also provides necessary information

for installation, maintenance, and

troubleshooting.

This manual should be read by those who

design and maintain equipment that uses

this product. Be sure to keep this manual

nearby for handy reference.

Page 2

IMPORTANT

“Natural gas” in this document refers to city gas in Japan.

NOTICE

Be sure that the user receives this manual before the product is used.

Copying or duplicating this user’s manual in part or in whole is forbidden.

The information and specifications in this manual are subject to change

without notice.

Considerable effort has been made to ensure that this manual is free from

inaccuracies and omissions. If you should find an error or omission, please

contact the azbil Group.

In no event is Azbil Corporation liable to anyone for any indirect, special or

consequential damages as a result of using this product.

© 2006-2018 Azbil Corporation All Rights Reserved.

Micro Flow™, µF™ are trademarks of Azbil Corporation in Japan.

Page 3

Conventions Used in This Manual

The safety precautions explained in the following section aim to prevent injury to the operator and others, and to

prevent property damage.

Warnings are indicated when mishandling this product

WARNING

CAUTION

In describing the product, this manual uses the icons and conventions listed below.

Use caution when handling the product.

The indicated action is prohibited.

Always follow the indicated instructions.

might result in death or serious injury.

Cautions are indicated when mishandling this product

might result in minor injury to the user, or physical damage

to the product.

Handling Precautions:

Handling Precautions indicate items that the user should pay attention to when handling

the product.

Note:

(1)(2)(3): Numbers within parentheses indicate steps in a sequence or parts of an explanation.

0FF

>>: Indicates the result of an operation, details displayed on the personal computer or other

Notes indicate information that might benefit the user.

This indicates the item or page that the user is requested to refer to.

Indicates a selectable button on a personal computer screen.

devices, or the state of the device after operation.

ii

Page 4

Safety Precautions

Never allow gases that are within explosive limits to pass through this device. Doing so might

result in an explosion.

If the MQV is to be used for oxygen, make sure that it is a model designed for oxygen use.

Even if a device is designed for oxygen gas, do NOT use it for oxygen gas if it has been used

for some other gas even once. Oil contained in another gas may be deposited on the gascontacting parts and ignite upon reacting with oxygen.

If the device is used for burner air-fuel ratio control, take the necessary countermeasures

with the equipment to prevent the occurrence of backfire and to avoid any influence to the

device even if backfire occurs. Pressure increase or fire in the pipes caused by the backfire of

the burner could damage the controller.

This device cannot be used for measurement or control of hydrogen or helium gas. Use a

model specially designed for hydrogen and helium gases. For information on whether this

device can be used for gases other than the standard compatible gases, be sure to contact

the azbil Group in advance.

Prevent foreign matter from entering the device. If rust, water droplet, oil mist, or dust in the

pipes enters the device, measurement or control error or damage might occur.

If there is a possibility of foreign matter entering the device, provide a filter, strainer or mist

trap capable of eliminating foreign matter 0.1 µm or greater in diameter at the upstream. Be

sure to inspect and replace the filter at regular intervals.

Use this device within the operating differential pressure range. Not doing so may cause

hunting. Continuous hunting could damage the valve.

WARNING

CAUTION

Do not subject this device to pressure above its pressure resistance. Doing so might damage

it.

Be sure to use within the flow-rate range stipulated in the product specifications.

To prevent excessive flow, use a suitable means to control the supply pressure or use a

throttle valve or the like to control the flow rate.

If the flow rate exceeds the upper limit, both the flow rate display and the output voltage/

current may indicate considerably lower values than the actual flow rate.

If damage could result from the abnormal functioning of this device, include appropriate

redundancy in the system design.

iiii

Page 5

CAUTION

The valve on this device cannot completely shut a flow off. If complete shutoff is required,

provide a shutoff valve separately. When the external valve is closed, it is necessary also to

fully close the valve of the device using either of the following methods:

•

Set the flow rate setpoint to zero.

•

Make the valve operation mode to fully closed.

If this valve remains in normal control status when the external shutoff valve is closed (zero

flow rate), there will be an excessively large flow as soon as the external shutoff valve is

opened. For the MQV0050(J, K), MQV0200(J, K), and MQV0500(J, K), if the external shutoff

valve is closed continuously for 5 minutes or more in control mode or with the valve forced

fully open, the valve overheating limit (AL71) will be activated and the current to the valve

will be forcibly limited.

Before connecting pipes with Swagelok or VCR connections, check the precautions in the

instruction provided by the connecting joint manufacturer.

When separately purchasing a connecting joint, use the following made by Swagelok Co.,

Ltd:

1/4” Swagelok: SS-400-1-6ST (standard)

SS-400-1-6STSC11 (oil-inhibited)

1/2” Swagelok: SS-810-1-8ST (standard)

SS-810-1-8STSC11 (oil-inhibited)

1/4” VCR: SS-4-VCR-1-00032SC11

1/2” VCR: SS-8-VCR-1-8STSC11 or equivalent

Observe the following when using the device (oil-free model) for oxygen gas:

•

Piping should be carried out by a specialist skilled in handling oxygen gas.

•

Use oil-free pipes and parts.

•

Be sure to remove foreign matter, burrs, etc. from the pipes before connecting the device.

The device is a precision instrument. Do not drop it or subject it to impact, or it might be

damaged.

When installing joints (UNF connections), secure the lower part of the main unit in a vise or

the like gripped between rags to protect the finished surfaces, and turn the joint to tighten.

Mount securely in order to prevent vibration. Otherwise, equipment failure could result.

Mount the device horizontally. Do not mount it with the display facing down. Doing so might

cause measurement error or equipment failure.

For the MQV0050(J, K)/0200(J, K)/0500(J, K). use the largest pipe possible in order to reduce

pressure loss in the pipes, and do not install any equipment near the MQV that can cause a

large pressure loss. If there is a large pressure loss in the pipes or equipment, the pressure

of the gas supply to this device (operation differential pressure) will be affected and will

fluctuate greatly with the flow rate. This could result in unstable control.

When making the pipe connections, hold the hexagonal part of the connector section and

turn the pipe to tighten. After connecting, check that there are no gas leaks.

iiiiii

Page 6

CAUTION

If using Rc connections, take care not to coat with too much sealant. Foreign matter or burrs

in the pipes may also cause measurement errors.

Do not apply a negative voltage or a voltage exceeding 5 V to the external setup voltage

input terminal. Doing so might cause malfunction or equipment failure.

When using a relay for external contact input and/or external 3-way switching input, always

use a relay designed for micro-current use (with gold contacts). Failure to do so could cause

faulty contact, resulting in malfunction.

If there is a risk of a power surge caused by lightning, use a surge protector to prevent fire or

equipment failure.

Gas type switching by external contact input, flow rate switching, and analog input/output

voltage range switching by external 3-way input switching should be done only after

setting the operation mode to fully closed. Switching while controlling could cause large

fluctuations.

Be sure to check that the wiring is correct before turning the power on. Incorrect wiring could

cause damage or malfunction.

Do not apply excessive force to the cables or connector while the connector cable or the AC

adapter is connected. Doing so may damage the connector or the circuit board.

Do not operate the console keys using a sharp object such as a mechanical pencil or

screwdriver. Doing so might damage the console.

When discarding the device, dispose of it as industrial waste, following local regulations.

iviv

Page 7

The Role of This Manual

A total of 2 different manuals are available for the MQV. Read them as necessary for your specific requirements. If a

manual you require is not available, contact the azbil Group or its dealer.

Digital Mass Flow Controller Standard Gas Model

MQV9005/9020/9200/9500/0002/0005/0020/0050/0200/0500

Manual No. CP-SP-1204E

This manual.

First-time users of the MQV, and those in charge of maintenance or hardware design for

incorporating a MQV controller in instrumentation should read this manual.

This manual outlines the product, tells how to install, wire, and incorporate the product

into instrumentation, and describes its operation, inspection and maintenance,

troubleshooting, and hardware specifications.

MQV9005/9020/9050/9200/9500/0002/0005/0010/0020/0050/0100/0200/0500

Digital Mass Flow Controller User’s Manual for Communication Functions

Manual No. CP-SP-1197E

Personnel who use this device’s communications functions should read this

manual. The manual gives an overview of communications, describes wiring,

transmission protocols, communications data, and troubleshooting, and gives

communications specifications.

vv

Page 8

Organization of This User’s Manual

This manual is organized as follows.

Chapter 1. INTRODUCTION

This chapter briefly describes this device and its features, and gives a model

selection guide.

Chapter 2. NAMES AND FUNCTIONS OF PARTS

This chapter describes the names and functions of this device’s parts.

Chapter 3. MOUNTING AND WIRING

This chapter describes installation, mounting, wiring and initial settings of this

device.

Chapter 4. BASIC OPERATION

This chapter gives the basis of how to operate this device.

Chapter 5. ADVANCED OPERATION

This chapter describes how to set functions, parameters, controller information

display, and flow rate range.

Chapter 6. MAINTENANCE AND TROUBLESHOOTING

This chapter describes how to investigate and remedy trouble that may occur

during operation of this device.

Chapter 7. SPECIFICATIONS

This chapter describes the device’s specifications and external dimensions.

vivi

Page 9

Contents

Conventions Used in This Manual

Safety Precautions

The Role of This Manual

Organization of This User’s Manual

Chapter 1. INTRODUCTION

Introduction ...................................................................................................................................................... 1-1

Features ............................................................................................................................................................... 1-1

Functions ............................................................................................................................................................ 1-2

Model selection guide .................................................................................................................................. 1-7

Basic operation and advanced operation .........................................................................................1-10

Chapter 2. NAMES AND FUNCTIONS OF PARTS

Display ................................................................................................................................................................. 2-1

Main unit (MQV9005/9020/9200/9500/0002/0005/0020/0050) ............................................. 2-2

Main unit (MQV0050(J, K) /0200/0500) ................................................................................................ 2-2

Chapter 3. MOUNTING AND WIRING

Mounting ............................................................................................................................................................ 3-2

Piping.................................................................................................................................................................... 3-6

Wiring ................................................................................................................................................................... 3-7

Chapter 4. BASIC OPERATION

4 - 1 Switching Displays .............................................................................................................................................. 4-1

Basic operation ................................................................................................................................................ 4-1

4 - 2 Setting the Flow Rate ......................................................................................................................................... 4-4

Digital flow rate setup .................................................................................................................................. 4-5

Flow rate setup by external contact input (Advanced use) ........................................................ 4-7

Flow rate setup by external 3-way switching input (Advanced use) .....................................4-8

Analog flow rate setup ................................................................................................................................. 4-9

4 - 3 Selecting the Operating Mode ....................................................................................................................4-10

Operating mode selection ........................................................................................................................4-10

Operating mode display ............................................................................................................................4-10

Chapter 5. ADVANCED OPERATION

Setup mode transition operation ........................................................................................................... 5-1

5 - 1 Functions ................................................................................................................................................................. 5-2

Setup method ................................................................................................................................................... 5-2

Function setup items.....................................................................................................................................5-3

5 - 2 Parameters ............................................................................................................................................................5-11

Setup method .................................................................................................................................................5-11

Parameter setup item list ..........................................................................................................................5-12

viivii

Page 10

5 - 3 Device Information Display ......................................................................................................................... 5-15

Setup method ................................................................................................................................................ 5-15

Device information display item .......................................................................................................... 5-16

5 - 4 Flow Rate Range Change Function and Settings and Display Resolutions After

Change of Range ............................................................................................................................................... 5-17

Setup resolution in the analog setup................................................................................................. 5-18

Chapter 6. MAINTENANCE AND TROUBLESHOOTING

Alarm code display ......................................................................................................................................... 6-1

Troubleshooting guide ................................................................................................................................6-2

Chapter 7. SPECIFICATIONS

Specifications ...................................................................................................................................................7-1

Gas type and control range ..................................................................................................................... 7-11

Relationship between differential pressure and flow rate ..................................................... 7-12

Optional parts (sold separately) ........................................................................................................... 7-14

External dimensions ................................................................................................................................... 7-15

viii

Page 11

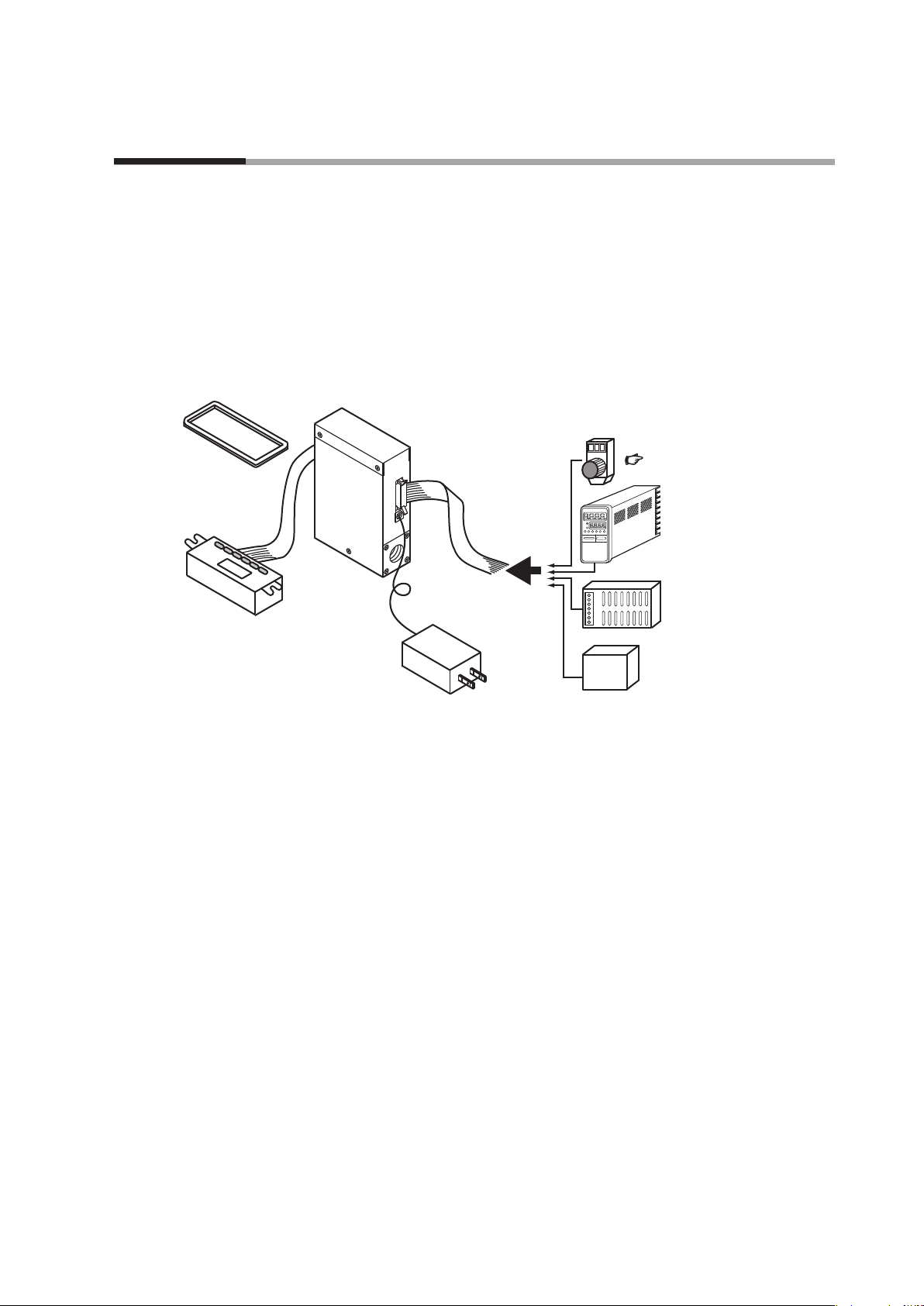

Chapter 1. INTRODUCTION

function)

Potentiometer (sold separately)

Separate display unit

Front cover for

Introduction

MQV high performance, digital mass flow controllers with advanced functions have

been developed for the general industrial application. They feature flow rate control

with high speed and wide rangeability. MQV controllers integrate three component

technologies: the ultra quick response µF (Micro Flow) thermal flow sensor, made

with proprietary Azbil Corporation technology, a proportional solenoid valve, and

advanced actuator control technology. Integrating these technologies has achieved

a high-speed control with low differential pressure.

separate display

(sold separately)

MQV

Features

Cable with dedicated

connector (sold separately)

AC adapter

(sold separately)

for setting ow rate

P.7-14

Controller

(e.g. SDC25/26)

24 V DC power supply

(e.g. WN790A)

RS-485 device

(for models supporting

optional RS-485

communications

Device Configuration

• High-speed controllability

Fast response of 300 ms or less*

(500 ms for the MQV9005/9020, 700 ms for the MQV0050(J, K), MQV0200, and

MQV0500.)

* Response time is the time required for the controlled flow rate to reach ±2 % of the

set value, starting from the fully closed state or from when the set value is changed

during control.

• Low differential pressure operation

MQV controllers can operate at a low differential pressure of 50 kPa or less.

• Wide control range

Wide control range of 1 to 100 % FS (2 to 100 % FS for the MQV9005)

• Wide product line-up

There are two types of models, those with integrated display and those with

separate display. On models with separate display, the display unit can be

detached to allow remote operation via the dedicated 2 m cable.

1-1

Page 12

Chapter 1. INTRODUCTION

• User-friendly

Runs on a general-purpose 24 V DC power supply, and the MQV's internal

power circuit and input/output circuits are isolated. When multiple MQV are

driven through the analog inputs and outputs, as with a PLC, they can all use

a common power supply even if the PLC's analog modules are not isolated by

channel. Therefore, even without individual power supplies for each device,

problems with one circuit do not affect adjacent ones. Also provided is a handy

AC adapter (sold separately) for easy use in the laboratory.

• Display direction can be changed (models with integrated display only)

The direction of the display can be rotated 180˚ to match the direction of the gas

flow, in case it was mounted the other way.

• Improved design (separate display model)

A front cover (sold separately) hides the mounting screws of the separate display

on the panel surface and improves the appearance.

Functions

• Various additional functions

The functions listed below are all standard.

All MQV models have the functions described below.

For function setup, Chapter 5. ADVANCED OPERATION.

• Multi-setup (function setup C-04)

Quickly switch to one of eight preset flow set value by key operation or external

input. If “Switching of SP No.” is set to external 3-way switching input, up to

three set values can be switched.

• Gas type switching (function setup C-18, C-26)

The gas type to be used can be selected from the standard compatible gases by

key operation. Additionally, two kinds of gas type settings can be changed by

external contact input.

• Gas type setup (function setup C-18)

The user can set gas type conversion factors for gases other than the standard

compatible gases, and for mixed gases.

For information on gas type conversion factors for various gases, contact the

azbil Group.

1-2

• Control flow range setting (function setup C-24, C-25)

The control flow range can be changed to the desired range (10 to 100 % of

the flow range at factory setting) in units of 1 % FS. The setup and display

resolution levels can be improved by reducing the control flow range.

Additionally, two kinds of control flow ranges can be switched through external

contact input.

• Direct setup (function setup C-2 1)

When changing the flow set value by key input, the controlled flow rate can

follow the set value while changes are being made (the flow set value can be

changed quickly). This function is useful when the user frequently changes set

value, for example when adjusting the flow set value during a trial run.

Page 13

Chapter 1. INTRODUCTION

• SP ramp control (function setup C-27)

This function is used to set the set value change ramp amount (the rate of

change per second) to a constant value for the start of control and for set value

changes. With this function, the set value change ramp amount can be set more

precisely than with the slow start function. Two different types of ramps can be

set, and there are the following 2 control modes:

•

SP ramp control 1

In SP ramp-up: Ramp 1

In SP ramp-down: Ramp 2

•

SP ramp control 2

In external contact OFF: Ramp 1

In external contact ON: Ramp 2

• SP limit (function setup C-35)

The lower and upper limits of the set value range can be set to desired levels.

(This prevents mistaken high/low settings.)

• Slow start (function setup C-1 7)

Sudden changes in the controlled flow rate, when control is started or when the

set value is changed, can be suppressed. The control speed can be changed in

eight stages within a range of about 1 to 6 seconds.

• Flow rate totalization (function setup C-09 to C-12)

MQV9005: in 0.1 mL units

MQV9020: in 1 mL units

MQV9200/9500: in 0.01 L units

MQV0002/0005: in 0.1 L units

MQV0020/0050: in 1 L units

MQV0050(J, K): in 0.001 m

MQV0200/0500: in 0.01 m3 units

Integrated flow count can be up to eight digits long (to 99,999,999) for each

unit. (Display alternates between first and last 4 digits.) The count can be

reset by key operation or external contact input. Use of external contact input

makes it possible to remotely operate the start, temporary stop, and reset of

totalization. When resetting the integrated count by key operation, the count

restarts automatically after it has been reset. On the other hand, when resetting

with the external contact input (by contact ON), the count restarts when the

contact is turned OFF.

3

units

• Event lamp lighting/output (function setup C-07, C-08)

Two of the event types listed below can be selected. Output ON delay time can

also be set (but delay cannot be set for totalizer pulse output).

•

Integrated flow event output (when the integrated flow event setting is

exceeded.)

•

Totalized pulse output (pulse can be output for each totalizing flow display

unit.)

•

OK output (the control flow rate is within the set value ± allowable range.)

1-3

Page 14

Chapter 1. INTRODUCTION

•

Flow rate upper or lower limit output (output in comparison with optional

upper or lower limit flow rate set value )

•

Output mode (The four modes — control / fully open / control or fully open /

fully closed — can be identified and output.)

• OK lamp ON/output (function setup C-07, C-08)

The OK lamp can be set to light when the control flow rate is within the set

value ± allowable range. This function is very handy for verifying at a glance

whether or not there is a proper response to a new set value after its value is

changed. OK lamp output can also be used as an interlock signal for subsequent

processes by assigning it to event output and including it in a sequence program.

• PV filter (function setup C-23)

This function is used to average the instantaneous flow rate (control flow rate)

detected value. Use of this function makes it possible to suppress effects of slight

pressure fluctuations.

• Control dead band setup (prevention of valve operation) (function setup

C-22)

This function is used to stop the valve from driving as long as the control flow

rate is within the OK range. Additionally, the OK range (width of dead band)

can be set to the desired level.

• Valve amperage display (function setup C-20)

The electric current supplied to the valve can be displayed in units of 0.0 to

100.0 %. Additionally, use of the valve amperage alarm detection function

makes it possible to detect an inlet pressure change or clogging of the piping at

the outlet.

• Gas type external switching (function setup C-10 to C-12, C-18, C-26)

Two preset types of gases (including one with a user-determined gas type

conversion factor) can be switched by external contact input.

• Control flow rate range external switching (function setup C-10 to C-12,

C-24, C-25)

Two preset control flow ranges can be switched by external contact input.

• PV forced zero (function setup C-29)

This function forcibly sets the detected instantaneous flow rate to 0 (zero) after

the delay time elapses when the flow rate setpoint has been set to 0 (zero) or the

valve mode has been changed to fully closed. This function makes it possible

to ignore the deviation of the instantaneous flow rate zero point caused by

inclination of the piping or the like.

1-4

• Flow rate display unit change (function setup C-37)

This function is used to change the flow rate display unit to L/min or mL/min of

the MQV9200/9500/0002/0005. When multiple devices are used side-by-side,

this function can make the flow rate display units uniform.

Page 15

Chapter 1. INTRODUCTION

• PV display decimal point change (function setup C-38)

This function is used to shift the decimal point position of the instantaneous

flow rate display one digit left or right. When multiple devices are used side-byside, the number of digits after the decimal point of the flow rate display can be

made uniform.

• Valve forcibly open or close (function setup C-02, C-09 to C-12)

This function is used to forcibly open or close the valve fully by key operation,

external contact input, or external 3-way switching input.

• Automatic shut-off (function setup C-13, C-16)

The valve can be shut off automatically under the following conditions:

•

When the totalized flow count reaches the preset value.

•

When one of the alarms, including flow rate alarms, is triggered.

• ALM (alarm) lamp ON/output/valve shut-off (function setup C-15, C-16 C-20)

The alarm output can be set for high and low deviations in the flow set value

and instantaneous flow rate. Additionally, an alarm judgment delay time can

also be set. If a flow rate alarm occurs or if an alarm occurs during self-diagnosis

of this controller, the valve can be forced fully closed or opened.

Handling Precautions

•

The valve on this device cannot completely shut off.

•

If complete shutoff is required, provide a shutoff valve separately.

• Automatic reset of cumulative count at start of control function (function

setup C-14)

Start of control and reset of totalized flow count can be done simultaneously by

a single action (by key or external switching input). Combining this function

with the automatic shut-off function described above is handy for shutting the

valve off in cases where a fixed totalized flow amount is counted repeatedly.

• Analog scaling (function setup C-28)

This function is used to optionally change the flow rate (between 10 % FS and

100 % FS) corresponding to 100 % FS analog input/output (5 V or 20 mA).

• Analog input (flow set value) range selection (function setup C-05, C-09)

In analog setup, the desired input range can be selected from those shown below

either by key operation or by external 3-way switching input. When doing so,

the voltage input and current input are selected automatically, as they are linked

with the settings of function setup C-06 (analog output type selection). For

example, when the voltage output (0 to 5 V or 1 to 5 V) is selected in C-06,

the voltage input is selected automatically. Likewise, when the current output

(0 to 20 mA or 4 to 20 mA output) is selected, the current input is selected

automatically.

1-5

Page 16

Chapter 1. INTRODUCTION

•

Internal reference 0 to 5 V input*/External reference 0 to 20 mA input

•

External reference 0 to 5 V input/External reference 0 to 20 mA input

•

External reference 1 to 5 V input/External reference 4 to 20 mA input

* The internal reference 0 to 5 V is used when the 5 V output terminal voltage

(pin No. 20) of this controller is used as the reference.

• Analog output type/range selection (function setup C-06, C-09)

Output can be set either to instantaneous flow rate (PV) or flow set value (SP).

Furthermore, a voltage/current output range can be selected from (1) to (4)

shown below by key operation. Additionally, (1)/(2) or (3)/(4) can be changed

through the external 3-way switching input. (Combinations are switched

because of linkage with the analog input range selection.)

Instantaneous flow rate (PV) output Flow set value (SP) output

(1) 0 to 5 V output

(1) 0 to 5 V output

(2) 1 to 5 V output

(3) 0 to 20 mA output

(4) 4 to 20 mA output

(2) 1 to 5 V output

(3) 0 to 20 mA output

(4) 4 to 20 mA output

1-6

Page 17

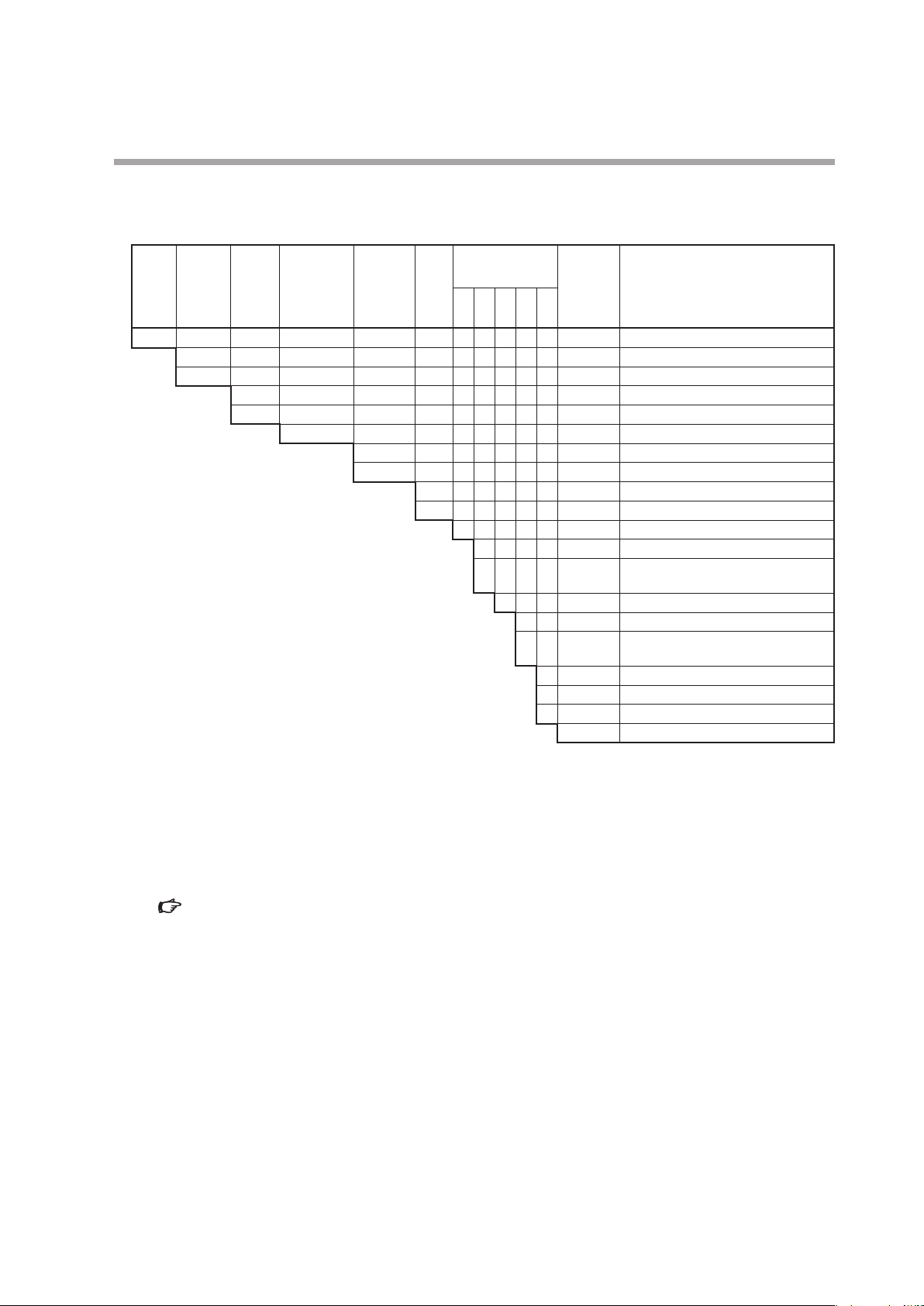

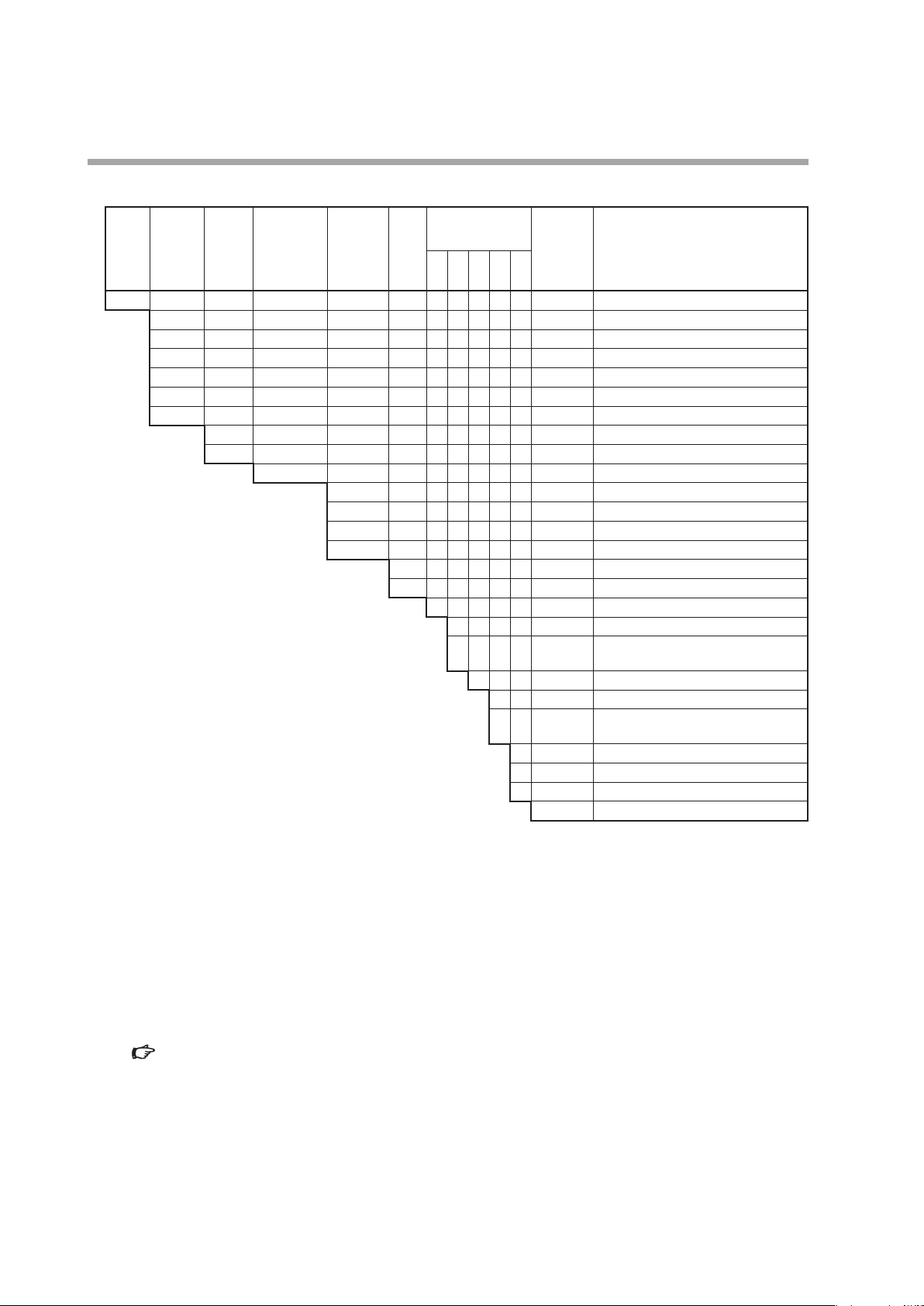

Model selection guide

MQV9005/9020

z

Chapter 1. INTRODUCTION

Standard

Basic

model

control

flowrate

No.

range

MQV Digital mass flow controller, MQV

9005 0.10 to 5.00 mL/min (standard)

9020 0.2 to 20.0 mL/min (standard)

Display

Material of

gascontacting

parts

B Integrated display (body length 90 mm)

C Separate display (body length 90 mm)

S SUS316

Connection

method

Gas

type

S 1/4" Swagelok

V 1/4" VCR

N Air, nitrogen

S Oxygen

Optional

functions

1 2 3 4 5

0 Without optional functions

0 Without optional functions

1 Model with RS-485 communications

0 Without optional functions

Appended

No.

(CPL) function

0 Without optional functions

1 Gas-contacting parts treated to be oil

0 Without optional functions

D With inspection certificate

Y With traceability certificate

0 Product version

free

*5

Description

*2, *4

*3, *4

*1, *4

*1, *4

*1. mL/min (standard) indicates the volumetric flow rate per minute (mL/min) converted to conditions of 20 ˚C and

101.325 kPa (1 atm). The reference temperature can be changed to 0, 25, or 35 ˚C.

*2. Air/nitrogen is the factory setting. By changing the setting, this model can be used for argon.

*3. Oxygen is the factory setting. By changing the setting, this model can be used for air/nitrogen, argon. However, once

this device has been used for gas other than oxygen, never reuse it for oxygen.

*4. The flow rate ranges in the table are for use of this device with air. The controllable flow range may vary depending

on the type of gas.

Gas type and control range (P.7-11).

*5. When oxygen is selected as the gas type, selection “1,” “gas-contacting parts treated to be oil free,” must be selected

for Optional function 4.

1-7

Page 18

Chapter 1. INTRODUCTION

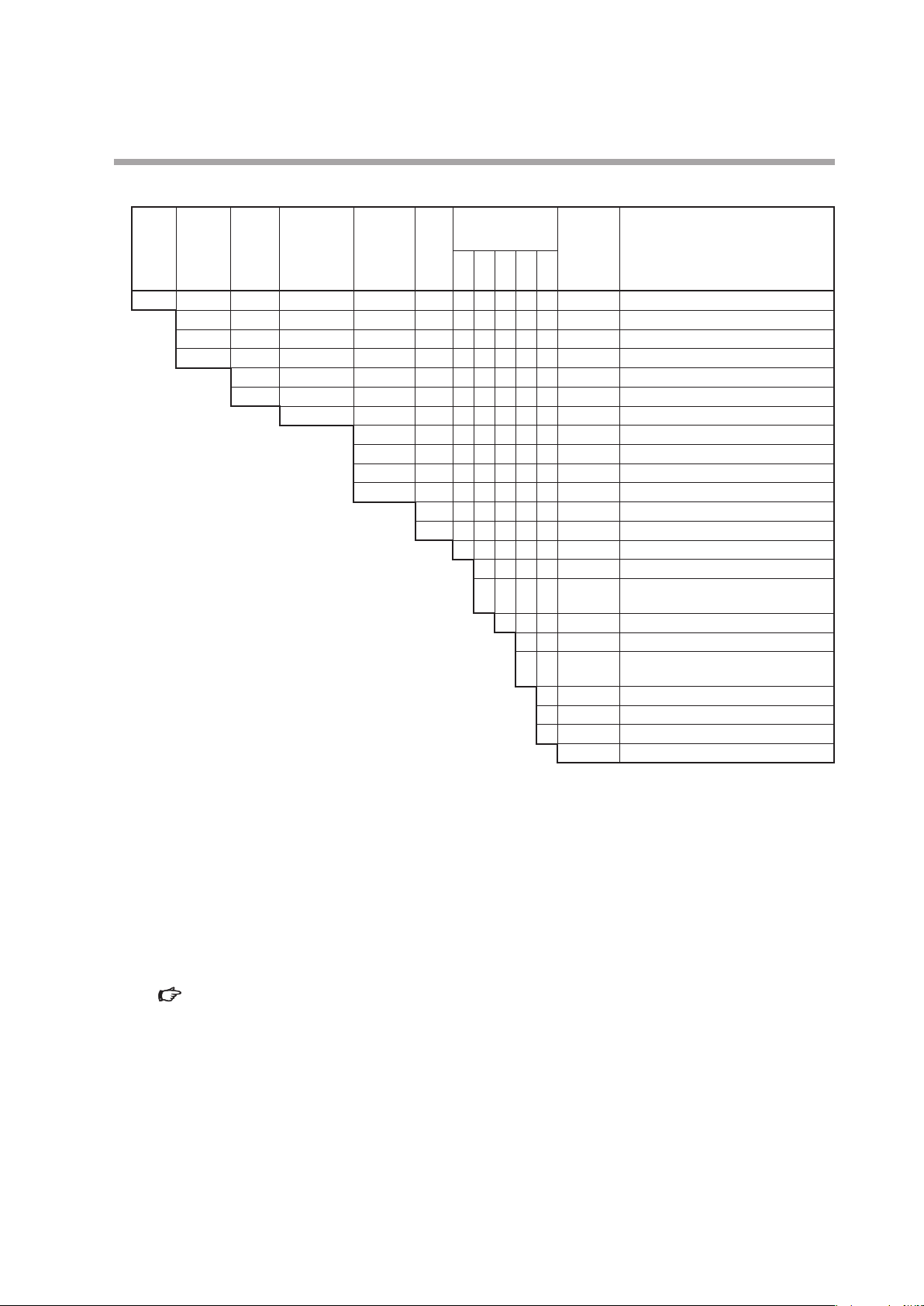

MQV9200/9500/0002/0005/0020/0050

z

Basic

model

No.

Standard

control

flowrate

range

Display

Material of

gascontacting

parts

Connection

method

Gas

type

Optional

functions

1 2 3 4 5

Appended

No.

Description

MQV Digital mass flow controller, MQV

9200 2 to 200 mL/min (standard)

*1, *4

9500 0.004 to 0.500 L/min (standard)

0002 0.02 to 2.00 L/min (standard)

0005 0.04 to 5.00 L/min (standard)

0020 0.2 to 20.0 L/min (standard)

0050 0.4 to 50.0 L/min (standard)

*1, *4

*1, *4

*1, *4

*1, *4

B Integrated display (body length 90 mm)

C Separate display (body length 90 mm)

S SUS316

R Rc 1/4"

S 1/4" Swagelok

V 1/4" VCR

U 9/16-18UNF

N Air, nitrogen

S Oxygen

*2, *4

*3, *4

0 Without optional functions

0 Without optional functions

1 Model with RS-485 communications

(CPL) function

0 Without optional functions

0 Without optional functions

1 Gas-contacting parts treated to be oil

*5

free

0 Without optional functions

D With inspection certificate

Y With traceability certificate

0 Product version

*1, *4

*1. L/min (standard) and mL/min (standard) indicate the volumetric flow rate per minute (L/min and mL/min) converted

to conditions of 20 ˚C and 101.325 kPa (1 atm). The reference temperature can be changed to 0, 25, or 35 ˚C.

*2. Air/nitrogen is the factory setting. By changing the setting, this model can be used for argon, carbon dioxide (CO

city gas 13A (LNG: 46 MJ/m

3

), city gas 13A (LNG: 45 MJ/m3), propane 100 %, methane 100 %, or butane 100 %.

Additionally, semi-standard gas models that can be used for ammonia or acetylene (seal material: EPDM) can also be

manufactured.

*3. Oxygen is the factory setting. By changing the setting, this model can be used for air/nitrogen, argon, carbon dioxide

(CO

), city gas 13A, propane 100 %, methane 100 %, or butane 100 %. However, once this device has been used for

2

gas other than oxygen, never reuse it for oxygen.

*4. The flow rate ranges in the table are for use of this device with air. The controllable flow range may vary depending

on the type of gas.

Gas type and control range (P.7-11).

*5. When oxygen is selected as the gas type, selection “1,” “gas-contacting parts treated to be oil free,” must be selected

for Optional function 4.

1-8

),

2

Page 19

MQV0050(J, K)/0200/0500

z

Chapter 1. INTRODUCTION

Standard

Basic

model

control

flowrate

No.

range

MQV Digital mass flow controller, MQV

0050 0.4 to 50.0 L/min (standard)

0200 2 to 200 L/min (standard)

0500 4 to 500 L/min (standard)

Display

Material of

gascontacting

parts

J Integrated display (body length 150 mm)

K Separate display (body length 150 mm)

S SUS316

Connection

method

Gas

type

R Rc 1/2"

S 1/2" Swagelok

V 1/2" VCR

U 3/4-16UNF

N Air, nitrogen

S Oxygen

Optional

functions

1 2 3 4 5

0 Without optional functions

0 Without optional functions

1 Model with RS-485 communications

0 Without optional functions

Appended

No.

(CPL) function

0 Without optional functions

1 Gas-contacting parts treated to be oil

0 Without optional functions

D With inspection certificate

Y With traceability certificate

0 Product version

free

*5

Description

*1, *4

*1, *4

*2, *4

*3, *4

*1, *4, *6

*1. The notations mL/min (standard) and L/min (standard) indicate the volume flow rate per minute converted to 20 ˚C,

one atmosphere (101.3 kPa (abs)). The reference temperature can also be changed to 0 ˚C, 25 ˚C or 35 ˚C.

*2. Air/nitrogen is the factory setting. By changing the setting, this model can be used for argon, carbon dioxide (CO

city gas 13A (LNG: 46 MJ/m

3

), city gas 13A (LNG: 45 MJ/m3), propane 100 %, methane 100 %, or butane 100 %.

),

2

Additionally, semi-standard gas models that can be used for ammonia or acetylene (seal material: EPDM) can also be

manufactured. (MQV0200/0500 only)

*3. Oxygen is the factory setting. By changing the setting, this model can be used for air/nitrogen, argon, carbon dioxide

(CO

), city gas 13A (LNG: 45 MJ/m3), propane 100 %, methane 100 %, or butane 100 %. However, once this device has

2

been used for a gas other than oxygen, never reuse it for oxygen.

*4. The flow rate ranges in the above table are for use of this device for air. The controllable flow range may vary

depending on the type of gas.

Gas type and control range (P.7-11).

*5. When oxygen is selected as the gas type, selection “1,” “gas-contacting parts treated to be oil free,” must be selected

for Optional function 4.

*6. The MQV0050(J, K) is for low differential pressure and is controllable to a high flow rate range with lower differential

pressure than the MQV0050(B, C).

1-9

Page 20

Chapter 1. INTRODUCTION

Basic operation Advanced operation

DISP key

Basic operation and advanced operation

This device provides two kinds of operations, basic operation and advanced

operation. Basic operation is the state of the device during normal use. In

basic operation, the contents of the 7-segment display can be changed to show

instantaneous flow rate, flow set value, totalized flow value, or amperage to the

valve in normal operation mode. Also, how to set the flow set value is described in

the basic operation part.

Advanced operation is for selecting various functions or setting parameters of the

device. When the device is used with the factory settings, no setup operation is

needed. However, to change the gas type, set a range, set an external contact input,

set upper and lower alarm limits, or set communication conditions (for models

with communication functions), it is necessary to configure various settings using

advanced operation. The diagram below gives an outline of operation flow. Basic

and advanced operation are described in Chapters 4 and 5, respectively.

Power ON

Instantaneous

ow rate display

DISP key

Flow set value

display

DISP key

Totalized ow

display

DISP key

Valve amperage

display

DISP key

key+ENT key

(3 s or more)

key (3 s or more)

key (3 s or more)

Function setup mode

Parameter setup mode

Controller information

display mode

1-10

Page 21

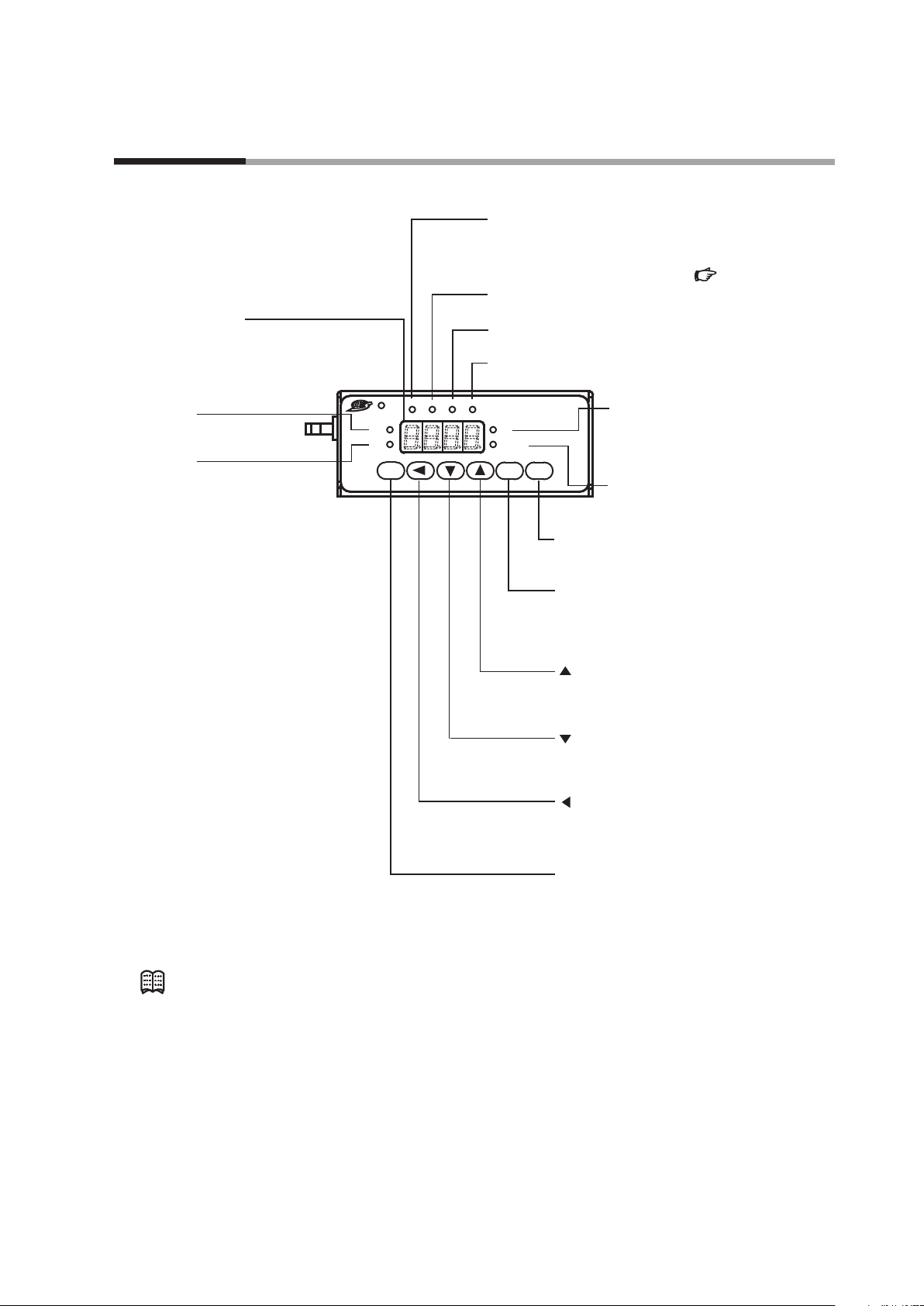

Chapter 2. NAMES AND FUNCTIONS OF PARTS

PV lamp:

OK lamp:

Use this key to change the operating mode.

reset alarm and move to the function setup mode.

Display

Lit when the deviation between the ow set value

and instantaneous ow rate is in the allowable range.

Set the allowable range in the parameter setup.

7-segment display:

Displays the instantaneous ow rate,

ow set value, totalized ow, amperage

to the valve and the operating mode.

It also displays parameter setup values, function

setup values and details of alarms.

SP lamp:

Lit when the ow rate

setpoint is displayed.

Lit when the instantaneous ow

rate is displayed.

ALM lamp:

Lit when an alarm occurs.

EV1 lamp

Lit when event 1 output is ON.

EV2 lamp:

Lit when event 2 output is ON.

OK ALM EV1 EV2

SP

PV

RUN ENT DISP

(For details on how to set parameters, )

:

L

L/min

Digital

Mass Flow

Controller

DISP key:

Use this key to switch the details displayed

on the 7-segment display.

ENT key:

Use this key to x and store the set value

to memory.

Also use it to reset the cumulative ow and to

L lamp

*1:

Lit when the totalized ow is

displayed.

Blinks when the cumulative

ow event occurs.

L/min lamp

Lit when the instantaneous ow rate

or ow set value is displayed.

P.5-11

*2:

Note

key:

Use this key to increment the setting value.

Additionally, this key is used to change to

the device information display mode.

key:

Use this key to decrement the setting value.

Also use it to move to the function setup mode.

key:

Use this key to move to a desired digit

when changing setting value. Also use it to

move to the parameter setup mode.

RUN key:

*1. This lamp is used for mL or m3 instead of L on some models.

*2. This lamp is used for mL/min instead of L/min on some models.

•

Technical terms used in this manual are defined as follows:

•

SP (setpoint): The flow set value (or flow rate setpoint)

•

PV (process variable): Instantaneous flow rate (or controlled flow rate)

•

Operating mode: 3 modes (valve fully closed/valve control/ valve fully

open)

2-1

Page 22

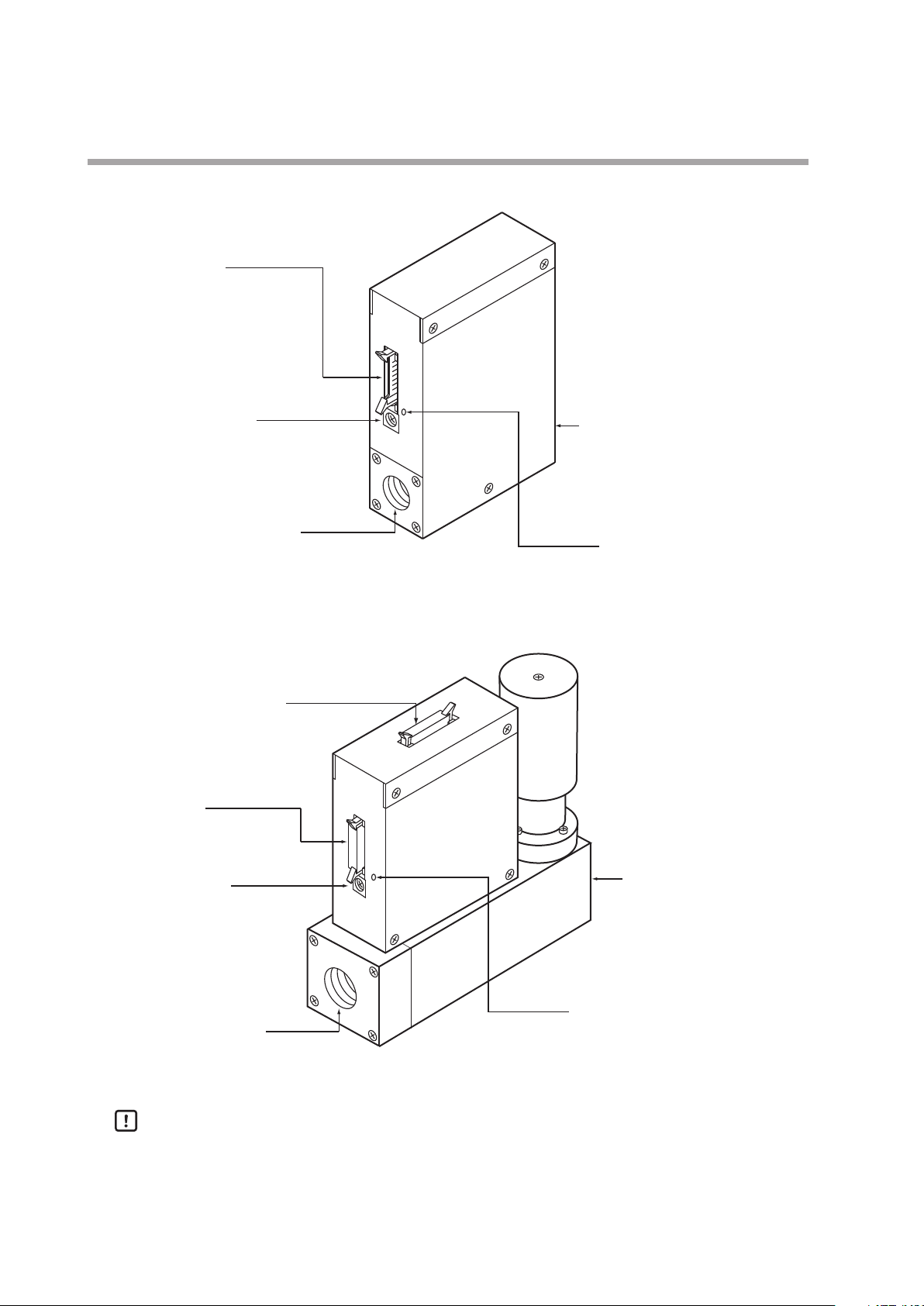

Chapter 2. NAMES AND FUNCTIONS OF PARTS

gas enters.

Jack for PC loader connection

Connector port:

This is used for I/O signals.

Use cable with dedicated

connector.

Jack for AC adapter:

Connect dedicated adapter here.

Model No.: 81446957-001

(24 V DC, 750 mA)

Pipe connection port (inlet):

This is the port through which

gas enters.

Pipe connection port (outlet):

Connector port:

This is used for I/O signals.

Use cable with dedicated

connector.

Connector for separate display:

This is used for connecting the

separate display unit.

Main unit (MQV9005/9020/9200/9500/0002/0005/0020/0050)

Jack for AC adapter:

Connect dedicated adapter here.

Model No.: 81446957-001

(24 V DC, 750 mA)

Pipe connection port (inlet):

This is the port through which

Main unit (MQV0050(J, K) /0200/0500)

Pipe connection port (outlet):

This is the port from which

gas is discharged.

2-2

Handling Precautions

This is the port from which

gas is discharged.

Jack for PC loader connection

•

The former AC adapter (model No. 81446682-001, 15 V DC/350 mA) can not be

used with MQV.

Page 23

Chapter 3. MOUNTING AND WIRING

Never allow gases that are within explosive limits to pass through this device. Doing so might

result in an explosion.

If the MQV is to be used for oxygen, make sure that it is a model designed for oxygen use. Even

if a device is designed for oxygen gas, do NOT use it for oxygen gas if it has been used for some

other gas even once. Oil contained in another gas may be deposited on the gas-contacting

parts and ignite upon reacting with oxygen.

Prevent foreign matter from entering the device. If rust, water droplet, oil mist, or dust in the

pipes enters the device, measurement or control error or damage might occur.

If there is a possibility of foreign matter entering the device, provide a filter, strainer or mist

trap capable of eliminating foreign matter 0.1 µm or greater in diameter at the upstream. Be

sure to inspect and replace the filter at regular intervals.

Use the device within the operating differential pressure range. Also, do not subject it to

pressure beyond the rated pressure resistance range. Doing so might damage it.

Do not subject this device to pressure above its pressure resistance. Doing so might damage it.

Be sure to use within the flow-rate range stipulated in the product specifications.

To prevent excessive flow, use a suitable means to control the supply pressure or use a throttle

valve or the like to control the flow rate.

If the flow rate exceeds the upper limit, both the flow rate display and the output voltage/

current may indicate considerably lower values than the actual flow rate.

If damage could result from the abnormal functioning of this device, include appropriate

redundancy in the system design.

The valve on this device cannot completely shut a flow off. If complete shutoff is required,

provide a shutoff valve separately. When the external valve is closed, it is necessary also to

fully close the valve of the device using either of the following methods:

If this valve remains in normal control status when the external shutoff valve is closed (zero

flow rate), there will be an excessively large flow as soon as the external shutoff valve is

opened. For the MQV0050(J, K), MQV0200(J, K), and MQV0500(J, K), if the external shutoff

valve is closed continuously for 5 minutes or more in control mode or with the valve forced

fully open, the valve overheating limit (AL71) will be activated and the current to the valve will

be forcibly limited.

WARNING

CAUTION

•

Set the flow rate setpoint to zero.

•

Make the valve operation mode to fully closed.

3-1

Page 24

Chapter 3. MOUNTING AND WIRING

Before connecting pipes with Swagelok or VCR connections, check the precautions in the

instruction provided by the connecting joint manufacturer.

When purchasing a connecting joint, use the following made by Swagelok Co., Ltd:

1/4" Swagelok: SS-400-1-6ST (standard)

1/2" Swagelok: SS-810-1-8ST (standard)

1/4" VCR: SS-4-VCR-1-00032SC11

1/2" VCR: SS-8-VCR-1-8STSC 11 or equivalent

When controlling oxygen flow, use an oxygen model and observe the following:

The device is a precision instrument. Do not drop it or subject it to impact, or it might be

damaged.

SS-400-1-6STSC11 (oil-inhibited)

SS-810-1-8STSC11 (oil-inhibited)

•

Piping should be carried out by a specialist skilled in handling oxygen gas.

•

Use oil-free pipes and parts.

•

Be sure to remove foreign matter, burrs, etc. from the pipes before connecting the device.

CAUTION

Mounting

Installation locations

z

Avoid mounting the device in the following locations:

•

Locations subject to high and low temperature and humidity

•

Locations whose atmospheres contain large amounts of dirt and dust, salt, conductive

substances such as iron powder, water droplet, oil mist or organic solvents

•

Locations subject to direct sunlight and rain

•

Locations directly subject to mechanical vibration or shock

•

Locations close to sources of electrical noise

•

Locations where strong magnetic or electrical fields are generated

Handling Precautions

•

The valve of this device cannot completely shut a flow off. If complete

shutoff is required, provide a shutoff valve separately.

Changing the display direction (models with integrated display only)

z

The display can be turned 180˚, in case the controller has been mounted with the

display upside-down.

3-2

Page 25

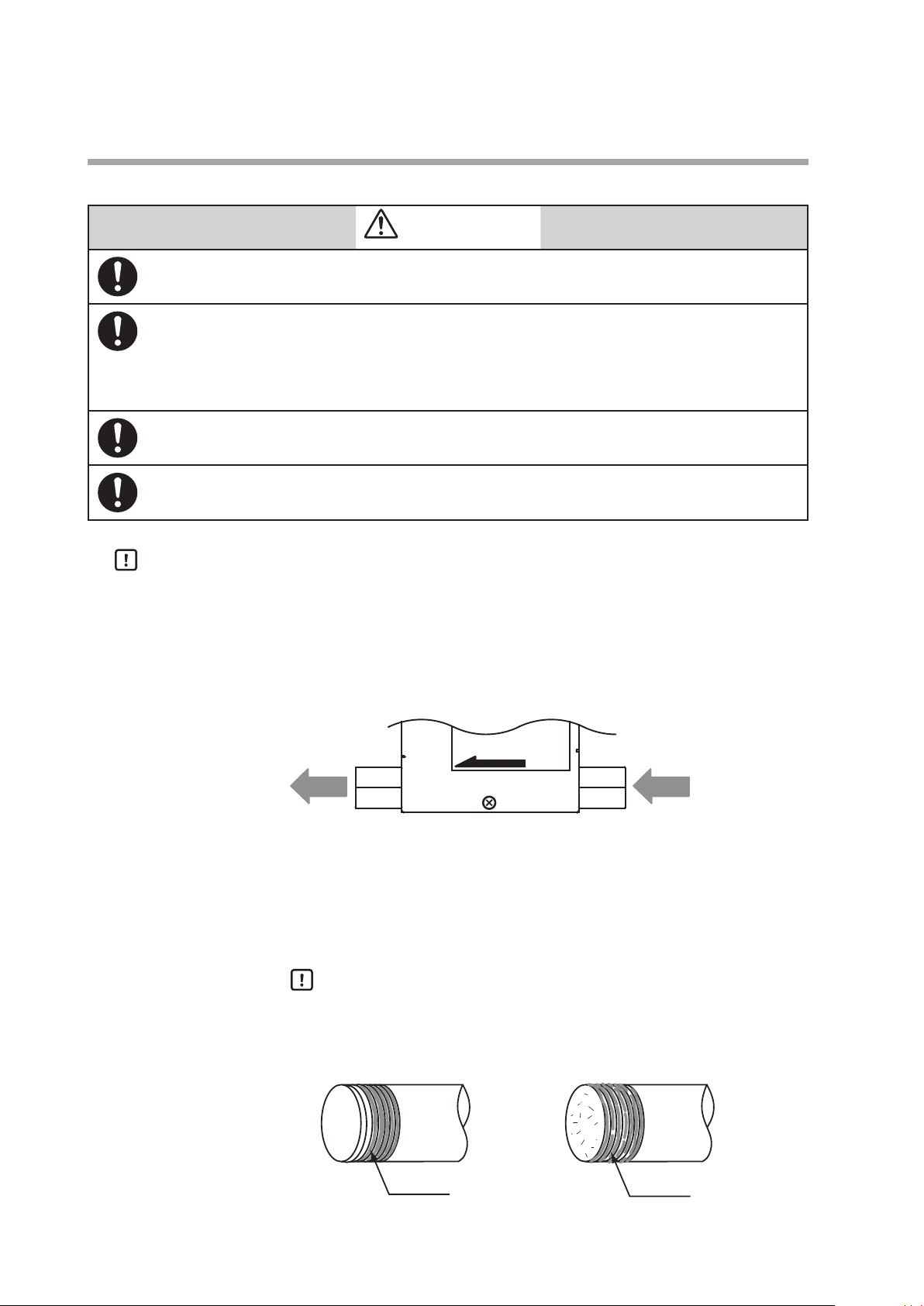

Chapter 3. MOUNTING AND WIRING

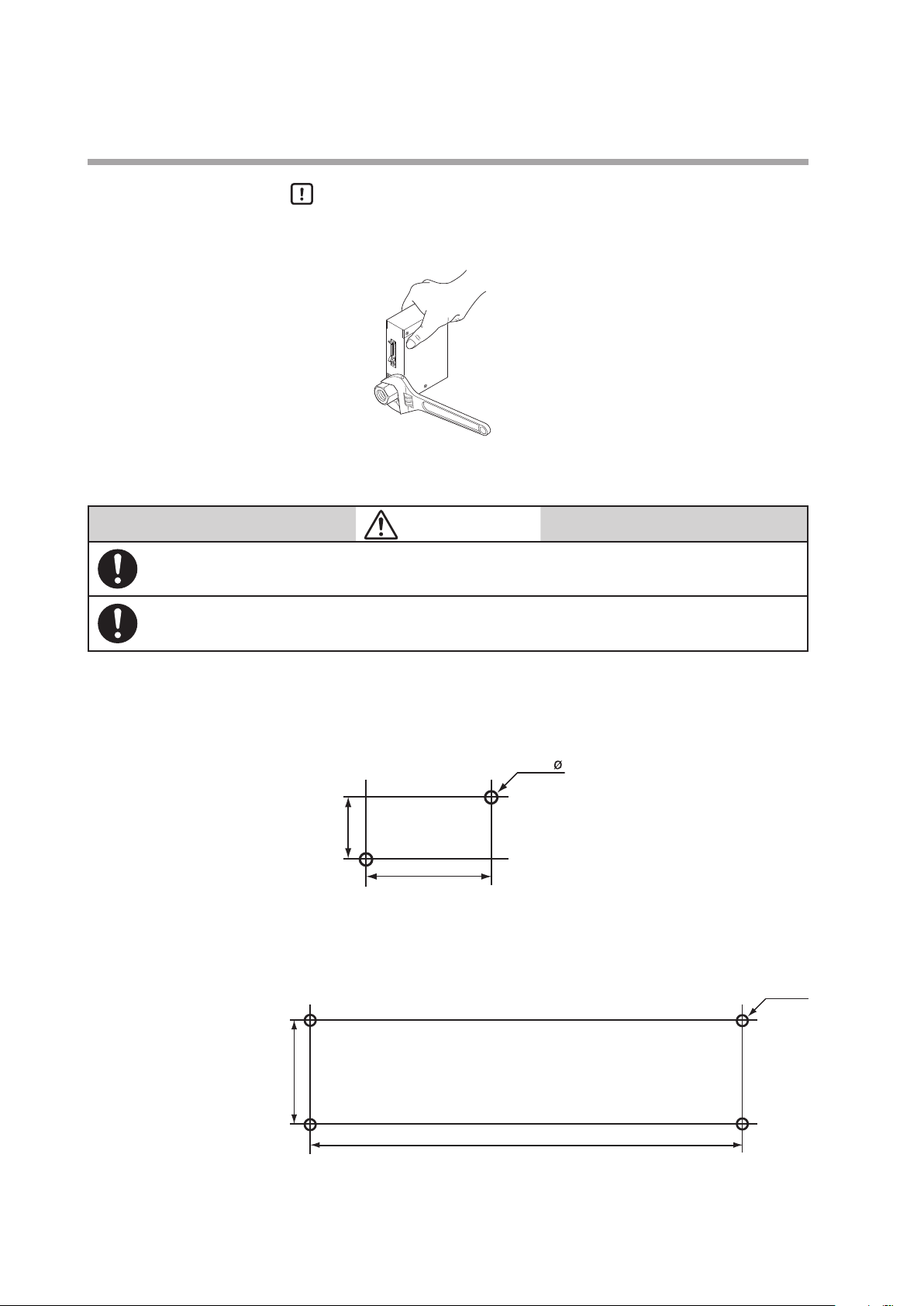

When installing joints (UNF connections), secure the lower part of the main unit in a vise or the

like gripped between rags to protect the finished surfaces, and turn the joint to tighten. The

device may be damaged if the lower main unit is not secured.

Connector latches

Main unit

•

Procedure

(1) Turn the power OFF.

(2) Remove the four screws holding the display.

(3) Lift up the display from the main unit, and turn it 180˚ counterclockwise.

(4) Put the display back on the main unit, and fasten with the four screws

(5) To return the display to its original position on the body, turn it 180˚

Handling Precautions

•

Before changing the display direction, be sure to turn the power OFF.

•

Prevent foreign objects from falling inside the main unit when the display

is taken off. Failure to do so might cause trouble or malfunction.

•

Do not remove the connectors used inside the main unit.

Installing joints (UNF) connections

z

taken off in step (2).

clockwise.

CAUTION

Rag

3-3

Page 26

Chapter 3. MOUNTING AND WIRING

Incorrect

Mount securely in order to prevent vibration. Otherwise, equipment failure could result.

Mount the device horizontally. Do not mount it with the display facing down. Doing so might

cause measurement error or equipment failure.

15

4.5

27

4.5 ø

Installation procedure

z

Handling Precautions

•

Do not hold the top part of the main unit with your hand. Doing so might

deform the case.

•

Take special care not to damage the connector latches.

CAUTION

z MQV9200/9500/0002/0005/0020/0050

Install the device with two M4 screws using the mounting holes on the base of the

device.

z MQV0050(J, K)/0200/0500

Install the device with four M4 screws using the mounting holes on the base of the

device.

unit: mm

30

unit: mm

110

3-4

Page 27

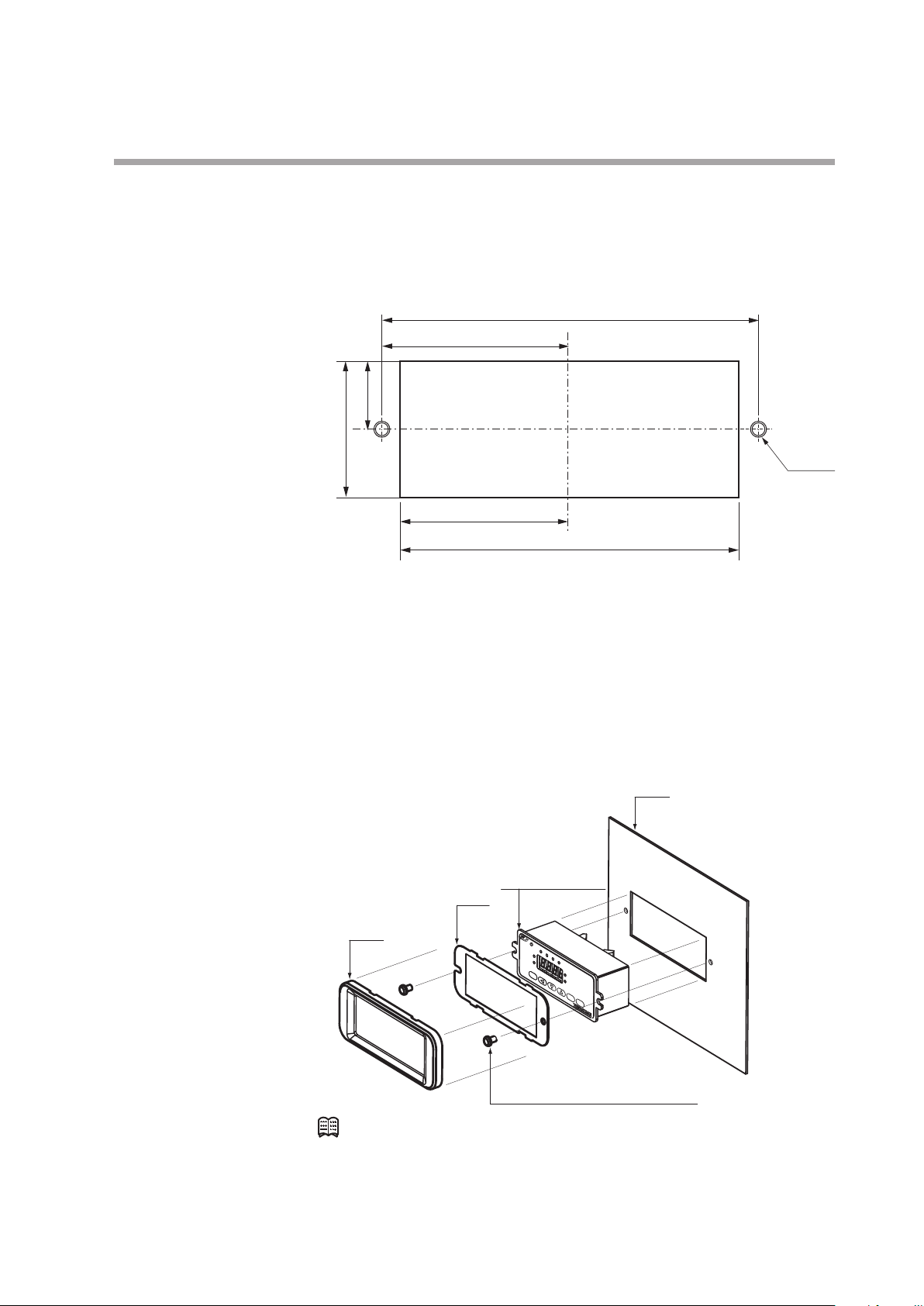

Installing the separate display unit

35 ±0.2

Panel cutout dimensions

(cross recessed head machine screws)

Panel

z

For models with a separate display

(1) Make mounting holes in the panel according to the panel cutout dimensions.

17.5 ±0.2

Chapter 3. MOUNTING AND WIRING

unit: mm

100 ±0.2

50 ±0.2

M4 (2)

45 ±0.2

(2) Mount the display and secure it by tightening the screws.

Installing the front cover for the separate display unit

z

For models with a separate display, a front cover (decorative frame) can be

mounted. Use of this cover makes it possible to hide the mounting screws,

improving the appearance.

Items needed for installation

• Front cover (81446858-001), 1 set

• Phillips screwdriver

Plate

Mask

90 ±0.2

Separate display

unit

Procedure

(1) As shown in the figure, put the plate over the display panel, and then secure it

(2) Fit the mask onto the display to mount it.

Mounting screws

Note

•

The front cover set includes one mask, one plate, and two mounting screws.

to the display by tightening the screws.

3-5

Page 28

Chapter 3. MOUNTING AND WIRING

Mount this device horizontally. However, do not mount with the display facing down. Doing so

might cause measurement error or device failure.

For the MQV0050(J, K)/0200(J, K)/0500(J, K), use the largest pipe possible in order to reduce

pressure loss in the pipes, and do not install any equipment near the device that can cause

a large pressure loss. If there is a large pressure loss in the pipes or equipment, the pressure

of the gas supply to this device (operation differential pressure) will be affected and will

fluctuate greatly with the flow rate. This could result in unstable control.

When making the pipe connections, hold the hexagonal part of the connector section and turn

the pipe to tighten. After connecting, check that there are no gas leaks.

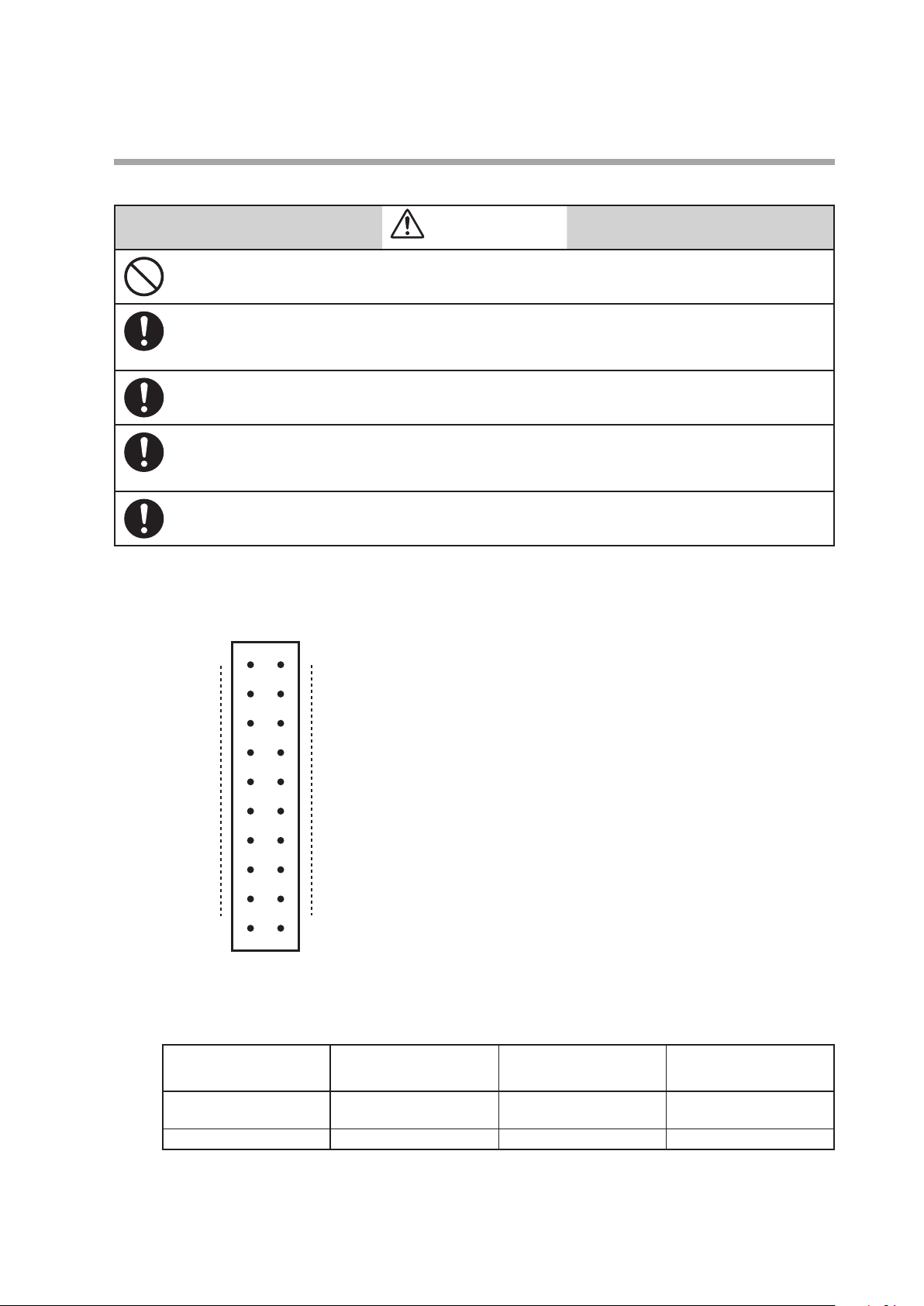

If using Rc connections, take care not to coat with too much sealant. Foreign matter or burrs in

the pipes may also cause measurement errors.

Correct

Incorrect

Sealant

Piping

CAUTION

Handling Precautions

•

Make sure that the gas flows into the device in the direction indicated by the

FLOW arrow on the main unit. Otherwise, the flow rate cannot be controlled

correctly.

•

Do not touch the pipe sections of a controller treated to be oil-free with your

bare hands. Doing so will degrade the oil-free treatment.

•

Do not hold the top part of the main unit with your hand when connecting

piping. Doing so might deform the case.

Fasten and connect pipes to the body using a wrench (spanner) or similar tool on

the hexagonal sections of the joints.

Coating sealant (Rc connection)

z

Handling Precautions

•

FLOW

GasGas

Coat with an appropriate amount of sealant. Do not coat the top two

threads. Remove any dirt or burrs from inside the pipes.

3-6

Sealant

Page 29

Wiring

Do not apply a negative voltage or a voltage exceeding 5 V to the external setup voltage input

terminal. Doing so might cause malfunction or equipment failure.

When using a relay for external contact input and/or external 3-way switching input, always

use a relay designed for micro-current use (with gold contacts). Failure to do so could cause

faulty contact, resulting in malfunction.

If there is a risk of a power surge caused by lightning, use a surge protector to prevent fire or

equipment failure.

Gas type switching by external contact input, flow rate switching, and analog input/output

voltage range switching by external 3-way input switching should be done only after setting

the operation mode to fully closed. Switching while controlling could cause large fluctuations.

Be sure to check that the wiring is correct before turning the power on. Incorrect wiring could

cause damage or malfunction.

View from connector insertion side

Chapter 3. MOUNTING AND WIRING

CAUTION

Connector pin layout

z

Connector model No. (device side): HIF3BA-20PA-2.54DS

20 19

2

Table of compatible connectors (all made by HIROSE ELECTRIC CO., LTD.)

z

1

Manufacturer: HIROSE ELECTRIC CO., LTD.

Connector type

Contact crimp type HIF3BA-20D-2.54C HIF3-2226SCC AWG#22 to #26

Cable clamp type HIF3BA-20D-2.54R Not required AWG#28 (flat cable only)

Compatible connector

model No.

Compatible contact

model No.

Compatible wire

(single wire allowed)

3-7

Page 30

Chapter 3. MOUNTING AND WIRING

4

24 V DC

POWER GND

POWER (24 V)

POWER (24 V)

or 9 D.GND

DB

8

6

DB

DA

SG

Connector signal names

z

Pin number Signal name Description Remarks

20 +5 V (5 mA max.) 5 V DC reference voltage outputa 5 mA max.

19 FLOW OUT Instantaneous flow rate (PV) or

18 A.GND Analog ground Analog signal common

17 FLOW SP INPUT Setpoint flow rate (SP) voltage

16 MODE INPUT External 3-way switching input 3-stage switching input

15 DI3 External contact input 3 2-stage switching input

14 DI2 External contact input 2

13 DI1 External contact input 1

12 EV2 OUT Event output 2 Open collector non-insulated output

11 EV1 OUT Event output 1

10 ALM OUT Alarm output

9 D.GND Digital ground Digital signal common

8 DB RS-485 communications DB Do not connect on models without the

7 DA RS-485 communications DA

6 D.GND Digital ground Digital signal common

5 TEST For test Do not use.

4 POWER GND Power supply ground Connect two wires each in parallel to the

3 POWER GND Power supply ground

2 POWER (24 V) Power supply + (24 V DC)

1 POWER (24 V) Power supply + (24 V DC)

flow rate setpoint (SP) output

input

0 to 5 V/1 to 5 V/0 to 20 mA/ 4 to 20 mA

output

0 to 5 V/1 to 5 V/0 to 20 mA/ 4 to 20 mA

input

(OPEN/GND/5 V)

(OPEN/GND)

communications function.

power supply to reduce voltage drop

caused by wiring resistance.

Wiring

z

• Power supply

POWER GND

3

+-

2

1

• RS-485 communications (for models with optional RS-485 only)

7

DA

Note

•

For details on wiring for RS-485 communication, Digital Mass Flow

Controller User's Manual: Communications, CP-SP-1197E.

3-8

Page 31

• Alarm output/event output

12

Load

EV2 OUT

or 6 D.GND

15

9

DI3

or 6 D.GND

19

0 to 5 V/1 to 5 V

0 to 20 mA/4 to 20 mA

0 to 5 V/1 to 5 V

0 to 20 mA/4 to 20 mA

FLOW OUT

FLOW SP INPUT

20

+5 V

FLOW SP INPUT

Chapter 3. MOUNTING AND WIRING

Load

Load

+ -

11

EV1 OUT

10

ALM OUT

9

Handling Precautions

•

Take special care that the event and alarm outputs do not exceed the

output rating of the device. Additionally, when driving a relay, use an

appropriate coil surge absorption diode built-in relay. Failure to do so

might cause the device to malfunction.

• External contact input

DI2

14

13

DI1

Handling Precautions

•

When switching by relay contact, use an appropriate relay intended for

micro-current use (with gold contacts). Failure to do so could cause faulty

contact, resulting in malfunction.

• Analog I/O

+

Output

—

+

Input

—

• When using potentiometer (0 to 5 V)

18

A.GND (0 V)

17

18

17

A.GND

3-9

Page 32

Chapter 3. MOUNTING AND WIRING

20

OPEN

+5 V

MODE INPUT

• External 3-way switching input

0 V

Operation of external 3-way switching input

18

5 V

A.GND (0 V)

16

Handling Precautions

•

When switching by relay, use an appropriate relay intended for microcurrent use (with gold contacts). Failure to do so could cause faulty

contact, resulting in malfunction.

Input state of pin No.16

Assigned function

Switching of operating mode 1 Control Fully closed Fully open

Switching of operating mode 2 Fully closed Control Fully open

Switching of SP No. SP-0 SP-1 SP-2

Switching of totalizing operation Continue

Switching of analog I/O

voltage range

* "Internal reference" refers to the use of the 5 V DC reference voltage pin (No. 20) on

this device, and is used when the setting value is set by an externally connected

potentiometer.

Input Internal

Output

OPEN GND 5V

Reset Stop counting

counting

External

reference

0 to 5 V or

0 to 20 mA

0 to 5 V/0 to

20 mA

reference

0 to 5 V or

external

reference

0 to 20 mA

0 to 5 V/0 to

20 mA

*

External

reference

1 to 5 V or

4 to 20 mA

1 to 5 V/4 to

20 mA

Note

•

For details on how to assign external 3-way switching input functions,

Chapter 5, ADVANCED OPERATION Function setup items

C-09

(P.5-4).

3-10

Page 33

Example of wiring

Input/output circuit

Instantaneous owrate output

z

Chapter 3. MOUNTING AND WIRING

Potentiometer

(5 kΩ)

Event output 2

Event output 1

Alarm output

(Output common)

0 V

+

-

OPEN

+5 V

DB

DA

SG

+5 V (5 mA max.)

FLOW OUT

A.GND

FLOW SP INPUT

MODE INPUT

DI3

DI2

DI1

EV2 OUT

OUT

EV1

ALM OUT

D.GND

DB

DA

D. GND

TEST

Internal circuit

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

Handling Precautions

•

Do not input any signal to pin No. 5.

•

The power circuit is isolated from the input/output circuit inside this device.

•

Even though the analog GND and digital GND are connected internally, always

carry out the grounding wiring individually.

•

When the AC adapter plug is inserted into the AC adapter power supply

terminal, the power supply changes from the DC power supply to the AC

adapter.

•

The former AC adapter 81446682-001 (15 V DC, 350 mA) cannot be used with

this device.

+

-

Power supply

(24 V DC)

POWER GND

POWER GND

POWER (24 V)

POWER (24 V)

AC adapter input

4

3

2

1

Power circuit

+

-

3-11

Page 34

Chapter 3. MOUNTING AND WIRING

20

Connector terminal block

z

Sometimes two or more connections must be made to the same pin during wiring.

In this case, use a connector terminal block. If you need a 20-core cable for the

connectors on the device and connector terminal block, contact the azbil Group or

your dealer.

Note

•

Recommended connector terminal block

Manufacturer: Toyo Giken

Model: PCN-1H-20

M ounting connector

HIROSE ELECTRIC CO., LTD., HIF3BA-20PA-2.54DSA

Compatible connector (other side)

HIROSE ELECTRIC CO., LTD., HIF3BA-20D-2.54R

This terminal block can be mounted directly on a DIN rail.

The following table shows the correspondence between connector pin Nos. and

terminal block Nos:

Handling Precautions

•

For details regarding the cable with connector on both ends, contact

the azbil Group. (The optional dedicated connector, 81446681-001 or

81446951-001, cannot be used to connect to the connector terminal

block.)

•

The specifications of the recommended connector terminal block are

subject to change. Contact the manufacturer beforehand for details.

Pin No. Terminal block No.

20 B-10

19 A-10

18 B-9

17 A-9

16 B-8

15 A-8

14 B-7

13 A-7

12 B-6

11 A-6

10 B-5

9 A-5

8 B-4

7 A-4

6 B-3

5 A-3

4 B-2

3 A-2

2 B-1

1 A-1

2

19

Cable with connector

on both ends

Connector terminal

block

1

MQV

3-12

Page 35

Chapter 4. BASIC OPERATION

Do not operate the console keys using a sharp object such as a mechanical pencil or

screwdriver. Doing so might damage the console.

Power ON

go out)

4 - 1 Switching Displays

CAUTION

Basic operation

Basic operation is used to change the display to instantaneous flow rate (PV), flow

set value (SP), totalized flow value, or valve amperage.

Normally, when the power is turned ON, the instantaneous flow rate is displayed

in basic operation mode. When this is the case, operating the DISP key changes the

contents of the 7-segment display as described below.

Instantaneous ow rate display (PV and L/min lamps lit)

DISP key

Flow set value display (SP and L/min lamps lit)

DISP key

Totalized ow display (L lamp lit)

DISP key

Valve amperage display (SP, PV, L, and L/min lamps

DISP key

Handling Precautions

•

If there is no operator input for approximately 10 seconds while the flow set

value is being displayed, the display automatically reverts to the instantaneous

flow rate display.

•

On the MQV9005/9020/9200, the mL/min lamp replaces the L/min lamp.

On the MQV9005/9020, the mL lamp replaces the L lamp, and on the

MQV0050(J, K)/0200/0500, the m3 lamp replaces the L lamp.

Indicating instantaneous flow rate (PV display)

z

When the power is turned ON, the PV and L/min lamps light, and the

instantaneous flow rate is indicated on the display.

Handling Precautions

•

When the operating mode is set to fully closed, and the flow rate is zero,

and when the operating mode is switched to the control mode or fully

open mode, the operating mode (

one second.

•

When an alarm occurs, the alarm code and the PV are displayed

alternately.

OFF/ON/FULL

) is displayed for about

4-1

Page 36

Chapter 4. BASIC OPERATION

Indicating the flow set value (SP display)

z

If DISP key is pressed while the instantaneous flow rate is displayed, the PV lamp

goes out, the SP lamp lights and the flow set value (SP) is indicated on the display.

Handling Precautions

•

If the SP value is not changed for about 10 seconds while the flow

set value is displayed, the instantaneous flow rate is redisplayed

automatically. For details on how to change the flow rate, 4 - 2 S etting

the Flow Rate (P.4-4).

•

When multiple setpoints (2 to 8 SPs) have been selected in

function setup, when switching by external input, the flow set value (SP

value) is displayed for about one second, and then the display switches to

the SP No.

c-04

in the

Indicating the totalized flow

z

When the DISP key is pressed while the flow set value (SP) is displayed, the SP and

L/min lamps go out, the L lamp lights up, and the totalized flow value is indicated

on the display.

When the totalized flow value is 10,000 or higher, the number is displayed in two

parts, the last four digits, followed by the first four digits. When the value is the last

four digits, the decimal point on the display is lit up.

For example, when the totalized flow value is "123,456L", "3 4 5 6." is displayed.

Press the DISP key to display " 1 2". To alternately display the first and last four

digits, press the

Handling Precautions

•

When an alarm occurs, the alarm code and the totalized flow value are

displayed alternately.

Resetting the totalized flow count

z

The totalized flow value is reset to zero by holding down the ENT key for two

seconds or more while the totalized flow value is displayed.

Note (Advanced operation)

•

Totalized flow event output function

When "1: Totalized flow rate count up ON" is selected as the event output

type for function setup

totalized flow value reaches the totalized flow event setting. This threshold

value for the totalized flow event is set in the parameter setup mode.

key.

C-07

or

, the event output turns ON when the

C-08

4-2

•

Totalized flow event automatic valve shut-off function

When "1: Function enabled" is set for the automatic valve shut-off function

in function setup C-13, the valve will be automatically closed fully if the

totalized flow value reaches the preset value.

The threshold value for the totalized flow event is set in the parameter setup

mode.

For details on function setup and parameter setup, Chapter 5.

ADVANCED OPERATION.

Page 37

Valve amperage display

z

Chapter 4. BASIC OPERATION

If DISP key is pressed while the totalized flow is displayed, the PV, SP, L and L/

min lamps go out, and the electrical current to the valve (

indicated on the 7-segment display.

Note (Advanced operation)

•

When "1: Only upper limit alarm used," "2: Only lower limit alarm used,"

or "3: Upper and lower limit alarm used" is selected for valve amperage

alarm type (

activated if the valve current exceeds the upper limit set value or goes below

the lower limit value. The valve amperage upper and lower limits are set in

the parameter setup mode.

For details on function setup and parameter setup, Chapter 5.

ADVANCED OPERATION.

in the function setup), the valve amperage alarm will be

C-20

0.0

to 1

00.0

[ %]) is

Handling Precautions

•

The valve amperage can vary greatly according to the differential

pressure even at the same flow rate. The valve amperage alarm function

cannot be used unless the differential pressure is stable.

•

Even under stable differential pressure conditions, the relationship

between the valve amperage and flow rate has hysteresis characteristics

(amperage may vary even at the same flow rate).

When using the valve amperage alarm, be sure to test sufficiently under

operating conditions. That way, an appropriate alarm current setting can

be determined.

4-3

Page 38

Chapter 4. BASIC OPERATION

*

Factory setting

4 - 2 Setting the Flow Rate

Set the ow rate as shown below.

Digital setup

Flow set value Selection from function setup C-03

Analog setup

*

Selection from function setup C-04

Multi-setup

Voltage setup

Selection from function setup C-05 and C-06

Current setup

Two kinds of setup methods, that is, digital and analog setup, are provided to set

the flow rate. Additionally, the digital setup further provides two kinds of setup

methods, single setup and multi-setup.

In single setup, the flow rate is set through key input or communications. In multisetup, the flow rate is set through the key input, communications, external contact

input, or external 3-way switching input. One flow set value can be set in the single

setup while up to eight flow set values can be set in the multi-setup.

*

Key input or communicationsSingle setup

Key input or communications

External contact inputs

External 3-way switching input

Internal reference 0 to 5 V input

External reference 0 to 5 V/1 to 5 V input

External reference

0 to 20 mA/4 to 20 mA input

In the analog setup, the flow rate is set through the external voltage/current input.

The factory setting is digital setup.

Either digital setup or analog setup is selected as the flow rate setup method (

in the function setup).

0: Digital setup (flow rate is set through the key input or communication.)

1: Analog setup (flow rate is set through the external analog voltage/current.)

For further detailed setup, make selections in

For details on function setup,

Handling Precautions

•

Setup by communications is available only for models with RS-485

communications.

C-04

to

in the function setup.

C-06

Chapter 5. ADVANCED OPERATION.

C-03

4-4

Page 39

Digital flow rate setup

Chapter 4. BASIC OPERATION

Up to eight SP values can be set on this device. The operating procedure may vary

depending on the number of SP values to be set.

Single setup (number of SPs in function setup

z

Follow the procedure below to change the SP value:

(1) Press the DISP key.

>> The SP (flow rate setpoint) is shown on the 7-segment display

(2) Change the SP value by pressing the

be changed by pressing the key.

>> The digit currently being changed starts blinking.

(3) When you have reached the target value, press the ENT key.

>> The SP value is set, and saved.

Note (Advanced use, direct setup function)

•

Control can be executed using an SP value currently being changed

(indicated by blinking display) when the direct setup function is enabled

for the instantaneous flow rate direct setup function ON/OFF (

function setup). In this case, the ENT key need not be pressed to enter the SP

value.

Handling Precautions

•

When switching the display by pressing the DISP key, first press the ENT

key to enter the SP value, and switch the display.

For details on how to set up functions, Chapter 5. ADVANCED

OPERATION.

C-04

is 1)

or keys. You can move to the digit to

in the

C-2 1

Multi-setup (number of SPs in function setup

z

In multi-setup, up to eight SP values can be switched by key operation and by

external contact input.

Follow the procedure below to change the SP No. and SP value:

(1) Press the DISP key.

>> The display switches to SP No.

(2) Press the

>> The SP No. is entered.

(3) Change the SP value by pressing the

be changed by pressing the key.

>> The digit currently being changed blinks while the SP value is being changed.

(4) When you have reached the target value, press the ENT key to enter the new SP

value.

>> The SP value and SP No. are updated, and the SP value of the selected SP No. is

new the active SP.

or keys to change the SP No. and press the ENT key.

C-04

is 2 to 8)

SP-0

to

after about one second.

SP-7

or keys. You can move to the digit to

4-5

Page 40

Chapter 4. BASIC OPERATION

Note (Advanced use, direct setup function)

•

Control can be executed using an SP No. or SP value currently being

changed (indicated by blinking display) when the direct setup function

is enabled for the instantaneous flow rate direct setup function ON/OFF

(

in the function setup). In this case, the ENT key need not be pressed

C-21

to enter the SP value.

Handling Precautions

•

When switching the display by pressing the DISP key, first press the ENT

key to enter the SP value.

For details on how to set up functions, Chapter 5. ADVANCED

OPERATION.

Handling Precautions (Common to single setup and multi-setup)

•

When "1: Analog setup" is selected as the flow rate setup method (

in the function setup) and the SP value is controlled by external voltage

input, the SP value and SP No. cannot be changed with the or key.

C-03

•

If no operation is made for approximately 10 s after the operation stated

in (1) has been performed, the display automatically returns to the

instantaneous flow rate display.

•

If the DISP key is pressed during the operations in steps (2) and (3)

(setting is blinking), the SP No. and SP value return to their previous

values without saving of new values.

•

When the SP value is updated in step (3) for single setup or in step (4) for

multi-setup, the display automatically returns to the instantaneous flow

rate display after approximately 2 s have elapsed.

4-6

Page 41

Flow rate setup by external contact input (Advanced use)

When assigning "3: Switching of SP No." at external contact input function

assignment C- 1 0 to C- 1 2 in the function setup, up to eight SP values can be

changed by means of external contact ON and OFF combinations.

Chapter 4. BASIC OPERATION

(1) When the number of preset SP values is set to 5 to 8 in function setup