Page 1

CM2-MGG31F-2001

MagneW PLUS+

Electromagnetic Flowmeter

F

oundation Fieldbus Transmitter

Model MGG14C

User’s Manual

Page 2

Copyright, Notices and Trademarks

© 2014–2018 Azbil Corporation All Rights Reserved.

Be sure that the user receives this manual before the product is used.

While this information is presented in good faith and believed to

be accurate, Azbil Corporation disclaims the implied warranties of

merchantability and tness for a particular purpose and makes no

express warranties except as may be stated in its written agreement

with and for its customer.

In no event shall Azbil Corporation be liable to anyone for any

indirect, special or consequential damages. is information and

specications in this document are subject to change without notice.

MagneW™ is a trademark of Azbil Corporation.

F™ Fieldbus is a trademark of FieldComm Group.

Precaution

is device is designed and manufactured for the use of general

applications.

Do not use this device for the nuclear applications and applications

which are directly related to the human life. Also do not use this

device in the radiation controlled area.

In case the device is used in the following applications, please

make sure to use the device with the system designed as failsafe/

redundant and the system should be maintained periodically.

• Safety device for human body protection

• Directly control the transport machine

• Aircra

• Space appliance

Azbil Corporation disclaims any liability for damages caused by

any of accidents/results by the above application.

Page 3

SAFETY PRECAUTIONS

About Icons

e safety precautions described in this manual are indicated by various icons.

Please be sure you read and understand the icons and their meanings described below before reading the

rest of the manual.

Safety precautions are intended to ensure the safe and correct use of this product, to prevent injury to the

operator and others, and to prevent damage to property.

Be sure to observe these safety precautions.

Warnings are indicated when mishandling this product might

WARNING

CAUTION

result in death or serious injury.

Cautions are indicated when mishandling this product might result in

minor injury to the user, or only physical damage to the product.

Examples

In describing the product, this manual uses the icons and conventions listed below

.

Use caution when handling the product.

The indicated action is prohibited.

Be sure to follow the indicated instructions.

SAFETY REQUIREMENTS

To reduce risk of electric shock which could cause personal injury, follow all safety notices in this

documentation.

WARNING

This symbol warns the user of a potential shock hazard where hazardous live voltages

may be accessible.

i

Page 4

Safety messages

Carefully read this section before installing or operating this device.

Cautions for installation

Installation of the device should be done by the expert from the safety perspective.

In case of the installation in the hazardous area, follow the regulation/guidance of the

explosion-proof.

In case of the installation in the hazardous area, select the explosion-protected apparatus.

Do not use the non-explosion-protected apparatus in the hazardous area.

Install the device in the environment where the following is within in the specifications

listed in the specification sheet.

• Ambient temperature, process fluid temperature

• Process fluid pressure

• Humidity

• Vibration

• Power supply voltage

Environment which exceeds the specifications may cause fire or device damage and it may

cause injury.

WARNING

CAUTION

DO NOT use the installed device as foot hold. It may cause the damage of the device.

DO NOT hit the glass of the device by tools. It may cause the damage of the device.

Install the device in a location with an ambient temperature of -25 °C to 60°C (-13 °F to

140 °F) and an ambient humidity of 5 to 100% RH to prevent device malfunction or output

errors.

DO NOT install the device near high-current power lines, motors, or transformers to prevent damage from electromagnetic induction, which can cause device malfunction or

output errors.

DO NOT use the device to ground a welder. It can damage the device.

Be sure to ground the welding power transformer when welding near the device to avoid

output errors.

DO NOT install the device in the severe vibration area or in corrosive environment. It may

damage the device, or cause the fume of the device.

DO NOT install the device on the bridge or deck of the ship.

DO NOT install the device on in the severe vibration area on the ship.

Be sure to use the metal conduit for the cables between the remote style transmitter and

flowtube.

Be sure to install the flowtube with a distance of 500mm minimum from the other flowtube. Magnetic field generated by a flowtube may affect the other flowtube and it may

cause the output errors.

DO NOT install the device in a location subject to direct sunlight, wind, rain, severe vibration, or in a highly corrosive atmosphere. The transmitter and flowtube can be damaged.

ii

Page 5

Cautions for wiring

DO NOT wire with wet hands. DO NOT wire while the circuit is alive. It may cause electrical

shock.

ELECTRIC SHOCK HAZARD! Turn the power supply OFF before opening the transmitter

cover.

Wiring of the device should be done by the expert from safety perspective.

Wire the cables to the correct terminal. Incorrect wiring may damage the device or cause

the fume of the device.

Connect the correct power supply. Incorrect power supply may damage the device or

cause the fume of the device.

Be sure to properly ground the device. Improper grounding may cause the output errors

DO NOT give impact to the device. It may cause the damage of the device.

WARNING

CAUTION

Be sure to use the power supply with the overcurrent protection function.

Be sure proper wiring. Incorrect wiring may cause the damage of the device.

Be sure to properly tighten the terminal cover on the terminal box so that water does not

penetrate in the terminal.

DO NOT connect AC power supply to the DC power supply model. The wrong power supply damages the device.

Turn off the Fieldbus power supply before connecting the Fieldbus cable to the transmitter. The transmitter or the Fieldbus power supply can be damaged. This type of damage is

not covered by Azbil Corporation’s warranty.

Be sure to plug all unused conduit connections with a water tight plug.

In case that a remote model is installed in a ship, the cables between the transmitter and

flowtube must be covered with a flexible metal conduit.

Switch the control equipment to manual control before terminating the device operation and shutting off the output to the control equipment. This action prevents the power

shut-off from directly affecting the control equipment.

iii

Page 6

iv

Page 7

Table of Contents

1. Introduction ...........................................................1-1

1.1 System configuration ..............................................................1-1

1.2 F Fieldbus .............................................................1-2

1.3 Main components .................................................................1-4

1.4 Local user interface ...............................................................1-5

2. Overview of MagneW PLUS+ Foundation Fieldbus .........................2-1

2.1 Overview ........................................................................2-1

2.2 Structure of MagneW PLUS+ F Fieldbus .....................................2-1

2.2.1 System/network Management VFD ............................................2-1

2.2.2 Function Block VFD ........................................................2-2

2.2.3 Function block .............................................................2-2

2.2.4 Transducer Block ...........................................................2-2

2.3 VFD/Object correlation diagram ....................................................2-3

2.4 Wiring .........................................................................2-4

2.5 Others .........................................................................2-5

3. Installation ............................................................3-1

3.1 Before installing electromagnetic flowmeter ..........................................3-2

3.2 Installation of transmitter ..........................................................3-3

4. Startup and Shutoff ....................................................4-1

4.1 Startup .........................................................................4-1

4.2 Steps before measurement ..........................................................4-2

4.3 Shutoff .........................................................................4-5

5. Basic Settings by Fieldbus Communication ...............................5-1

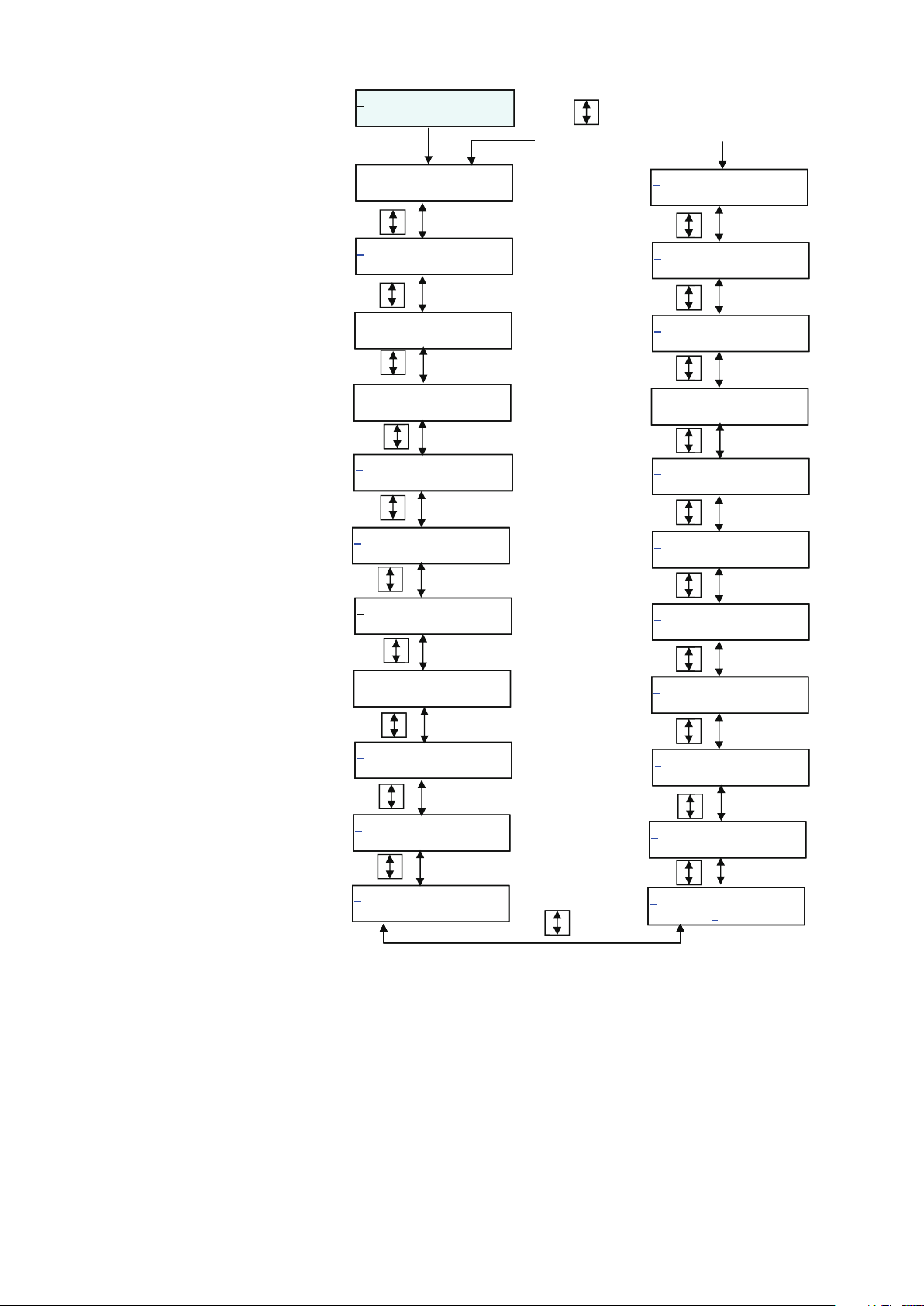

5.1 Fieldbus communication menu .....................................................5-2

5.2 Zero adjustment ..................................................................5-3

5.3 Basic settings .....................................................................5-4

6. Maintenance and Troubleshooting ......................................6-1

6.1 Troubleshooting ..................................................................6-1

6.2 Input of simulated signals from calibrator ............................................6-6

6.3 Measurement of excitation current ..................................................6-7

Appendix A. View List .................................................... A-1

Appendix B. Parameter List .............................................. B-1

Appendix C. Menu Configuration ..........................................C-1

v

Page 8

vi

Page 9

1. Introduction

This chapter contains an overview of the model MGG14C MagneW PLUS+ Flowmeter

and F Fieldbus system. It describes available configurations and provides

definitions for all the major parts of the transmitter.

MagneW PLUS+ Flowmeter

Thank you for purchasing the Azbil Corporation model MGG14C MagneW PLUS+

Flowmeter This system features:

• Advanced multi-variable capacity

• Digital panel display

• Intuitive, versatile operator interface with large characters and backlit liquid crystal

display

• I/O Capacity

• Flexible digital communication using the F Fieldbus

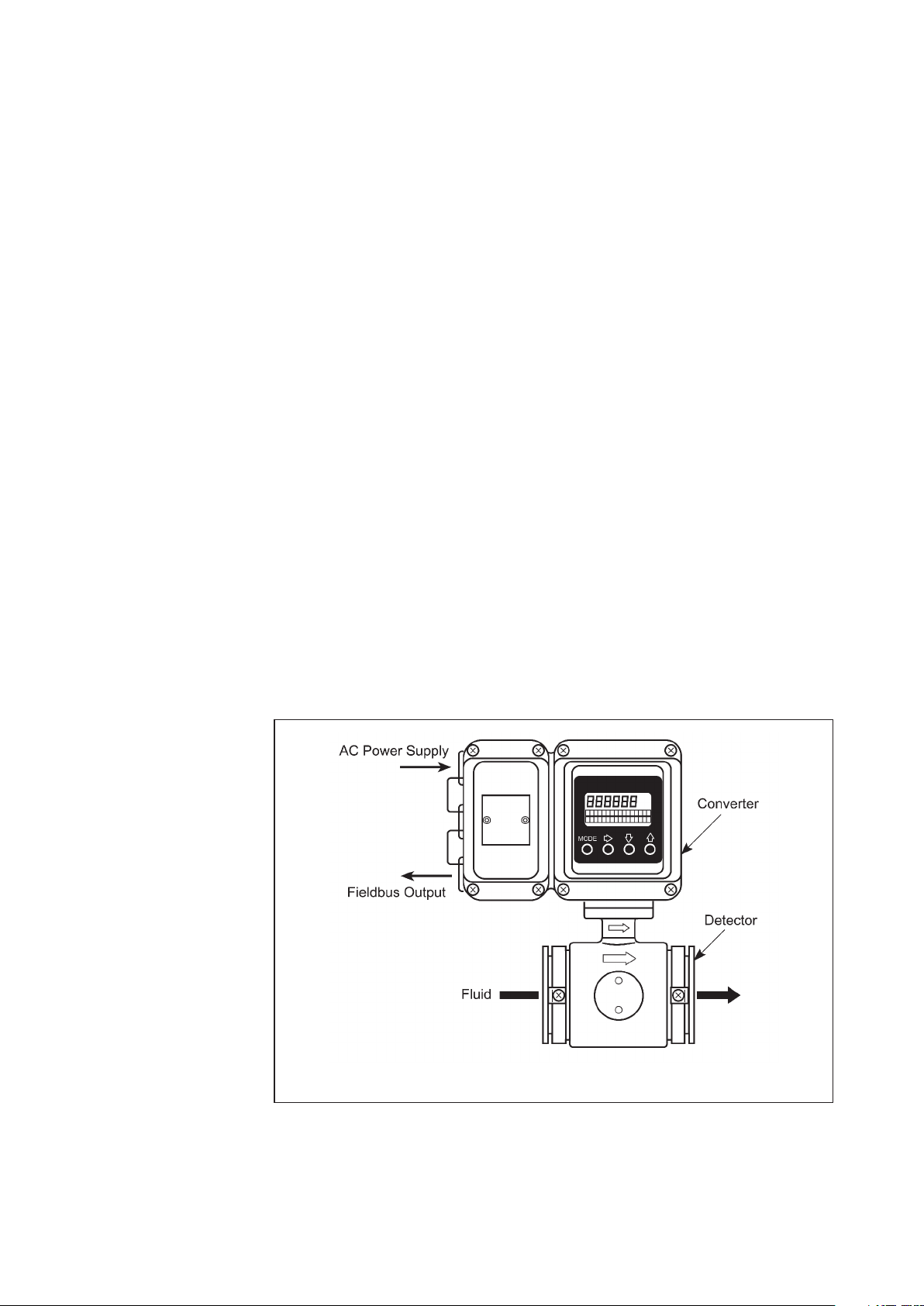

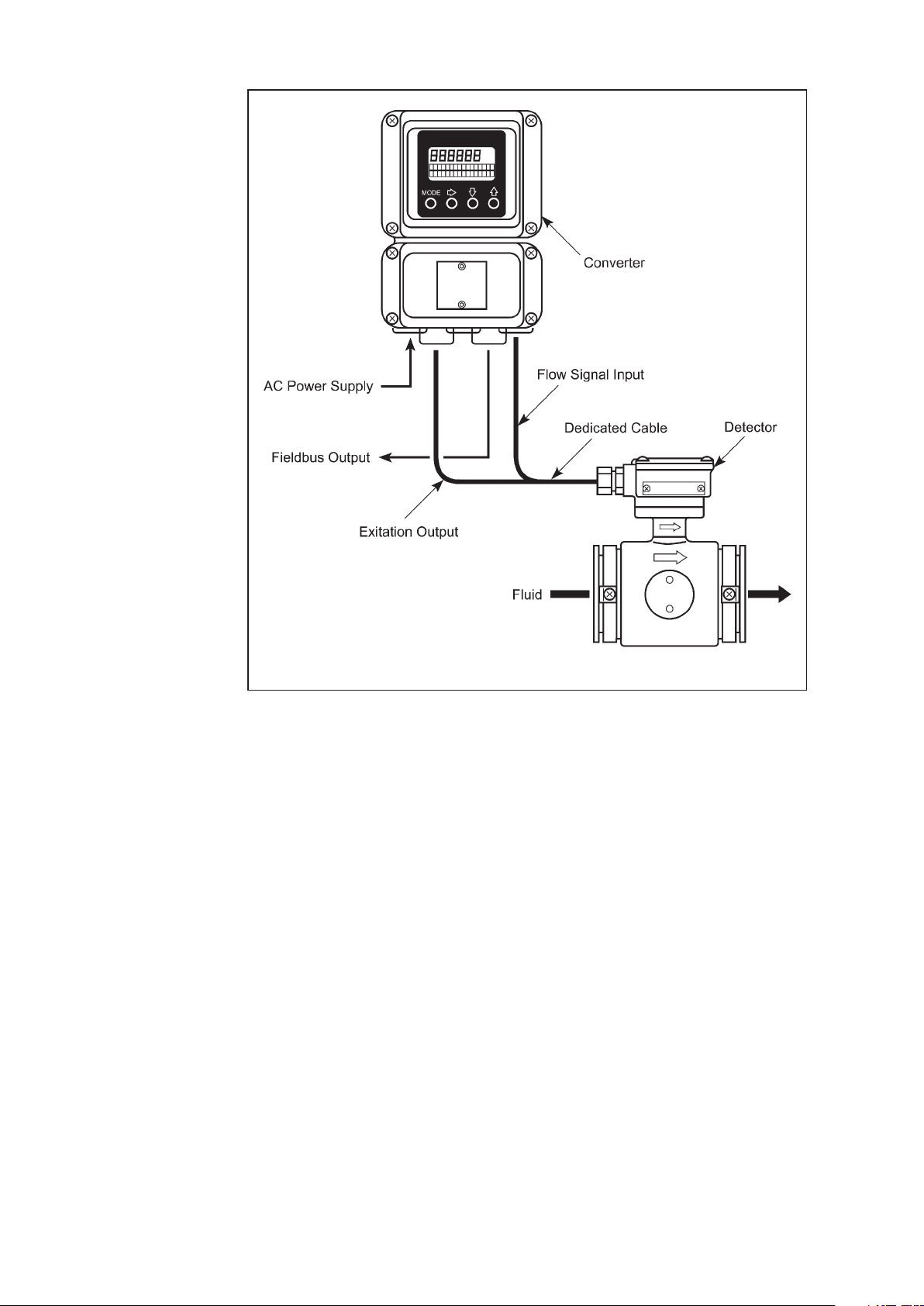

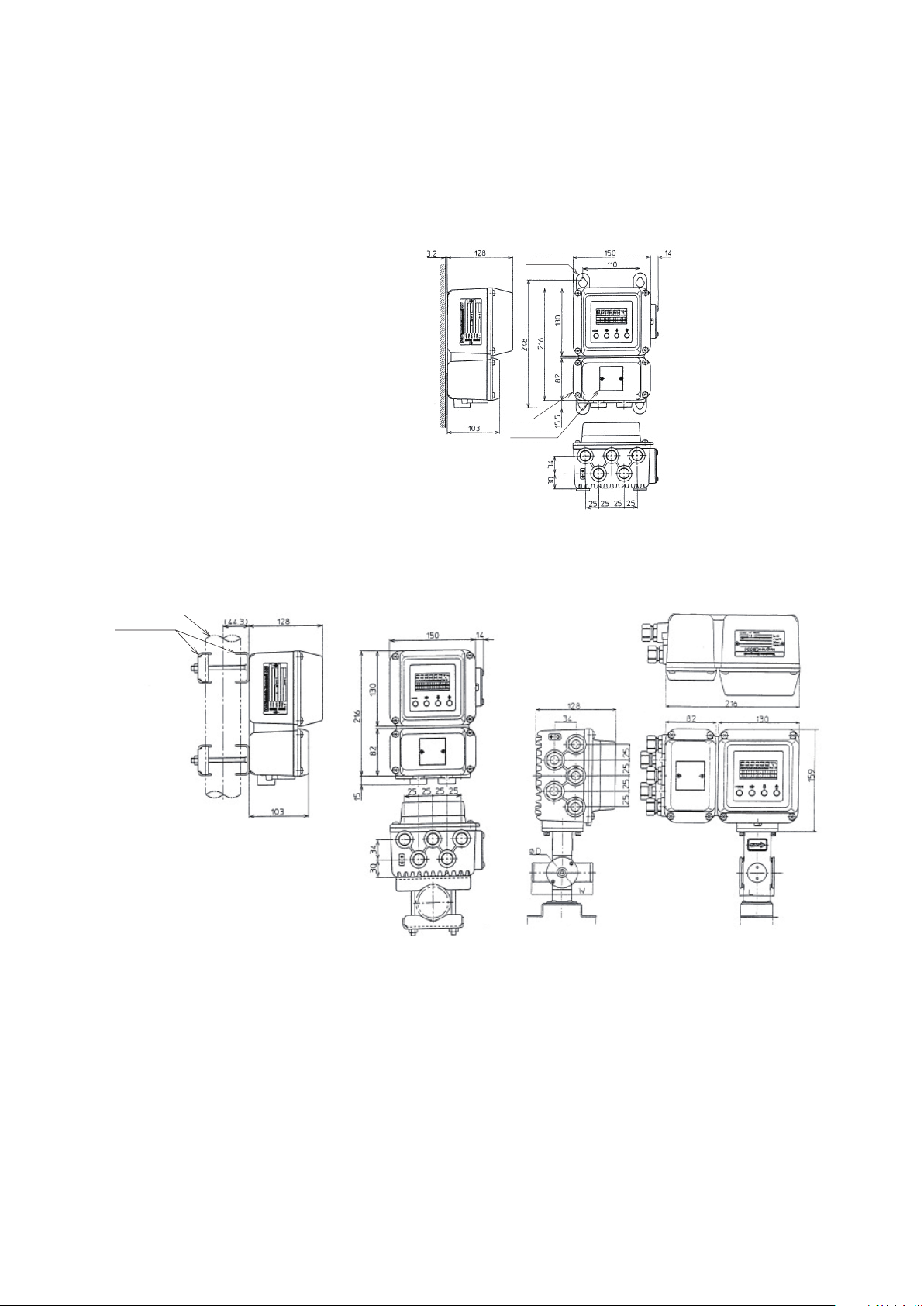

1.1 System configuration

The model MGG14C MagneW PLUS+ Flowmeter consists of a flowtube and a transmitter

which operate on the principles of Faraday’s law. The flowmeter is available in two

configurations:

Integral

Remote

– The transmitter is mounted directly on the flowtube and they are installed as an

integrated unit on the fluid pipe.

– The transmitter and flowtube are installed separately and connected together

via cables

Figure1-1 Indegral system

1-1

Page 10

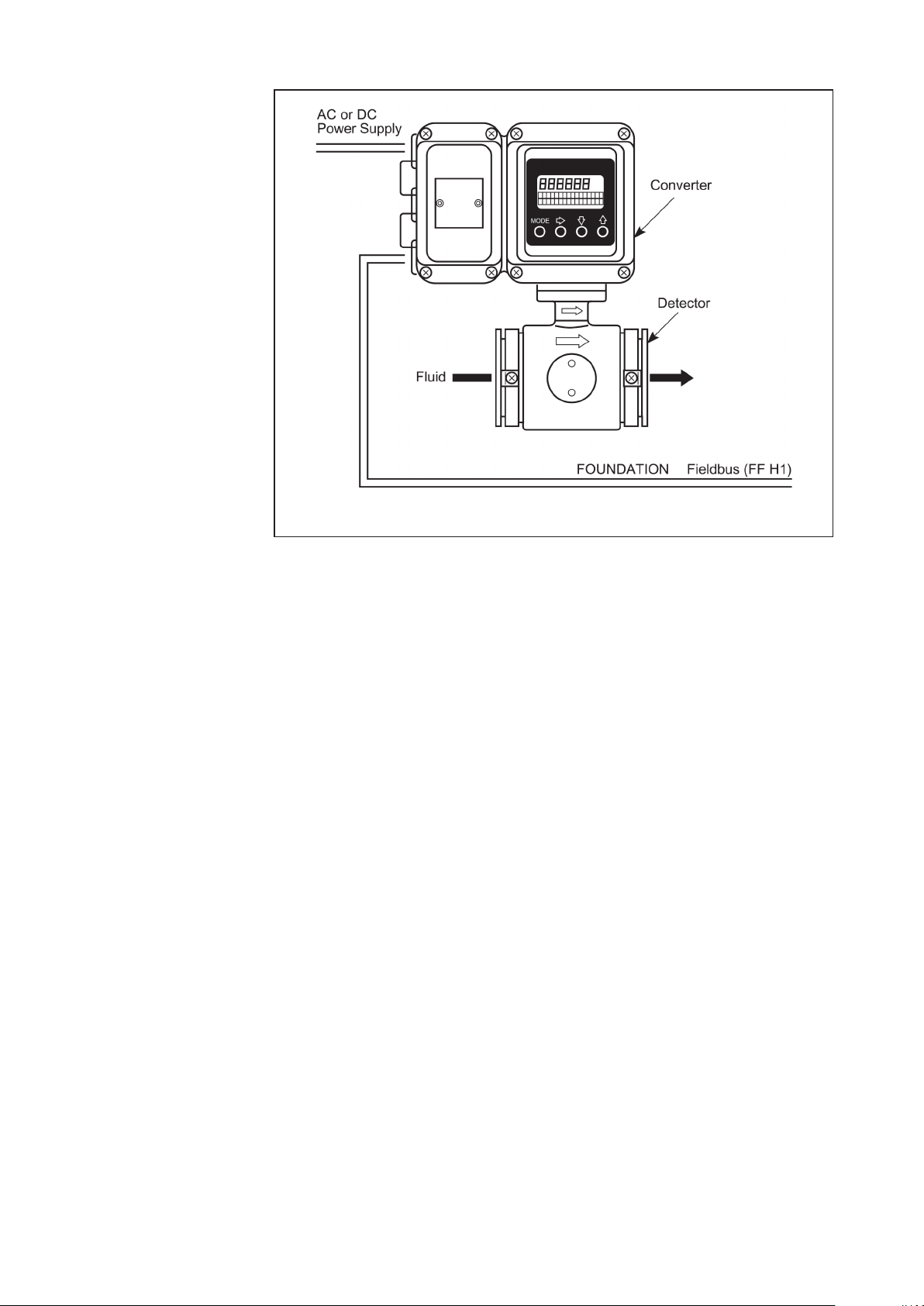

1.2 Foundation Fieldbus

The F Fieldbus provides communications and programmability for a single or

multiple flowmeter system. Some features of the fieldbus include:

• Complies with F Fieldbus H1 (31.25 kbps voltage mode bus)

specifications.

• Supports the standard Analog Input (AI) function block.

• Is an externally powered device – AC and DC powered models available.

• Comes with Enhanced Device Description (EDD) files and a Capability File (CF) for

automatic configuration.

The following figure shows a system in which the flow rate is output with a F

Fieldbus.

Figure1-2 Remote system

1-2

Page 11

Figure1-3 System using a Foundation Fieldbus

1-3

Page 12

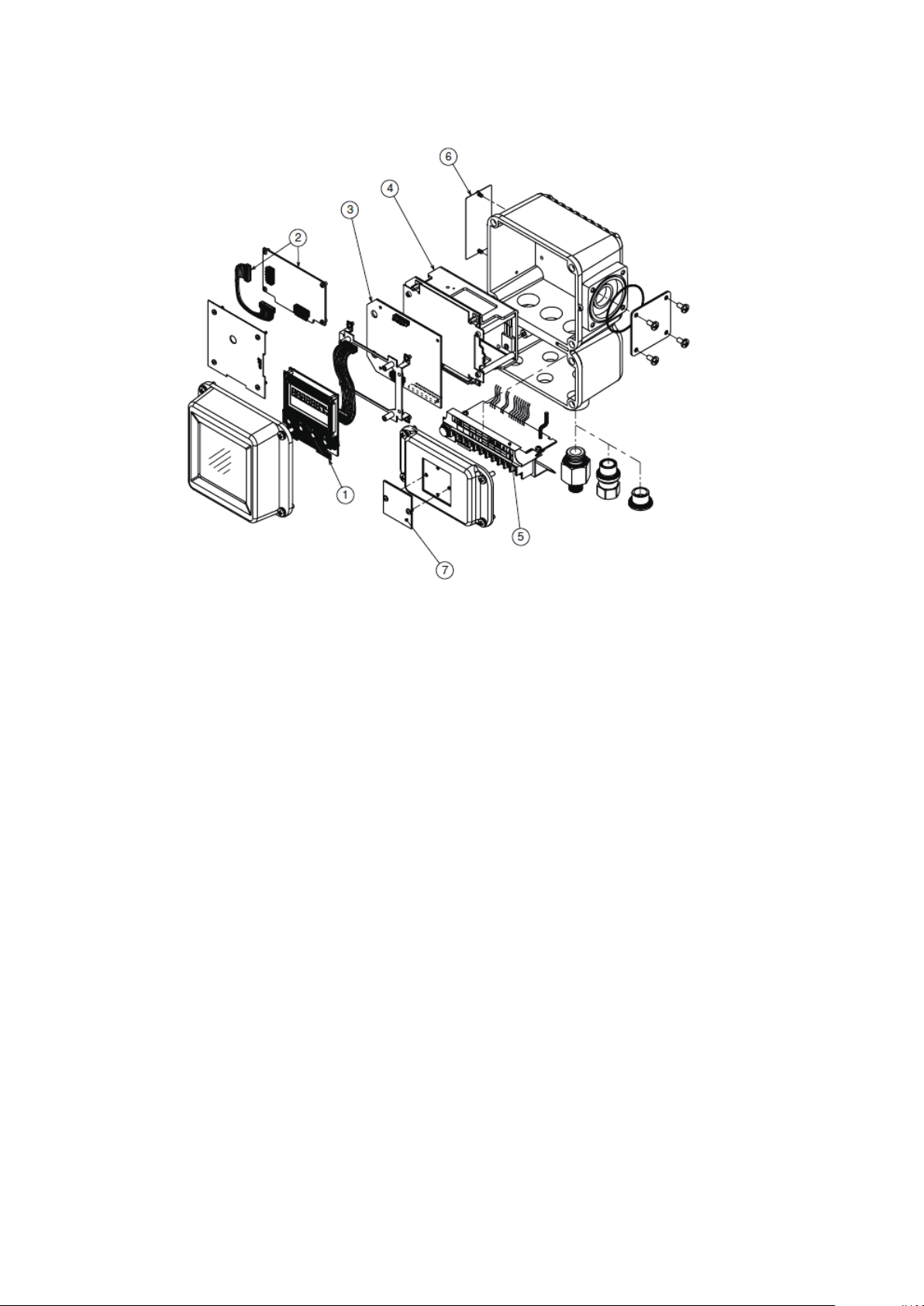

1.3 Main components

The transmitter consists of the components shown in the figure below.

Figure1-4 Main components

(1)

Local user interface

can be accessed using the four infrared sensor keys on the panel.

(2)

Fieldbus interface board

(3)

Main board

(4)

Power supply board

(5)

Terminal

(6)

Name plate

manufacture and the flowtube constant (EX) for the flowmeter.

(7)

Tag number plate

– This board includes fundamental functions of the flow measurement.

– Encloses the input/output terminals. Contains an integrated 12 kV, 1000A isolator.

– Indicates model numbers and production numbers, power supply requirements, date of

– Indicates the instantaneous flow rate or the totalized valve. The flowmeter functions

– Includes the fieldbus communication function.

– There are two types, AC power supply, and DC power supply type.

– Indicates the tag number as specified in the product order.

1-4

Page 13

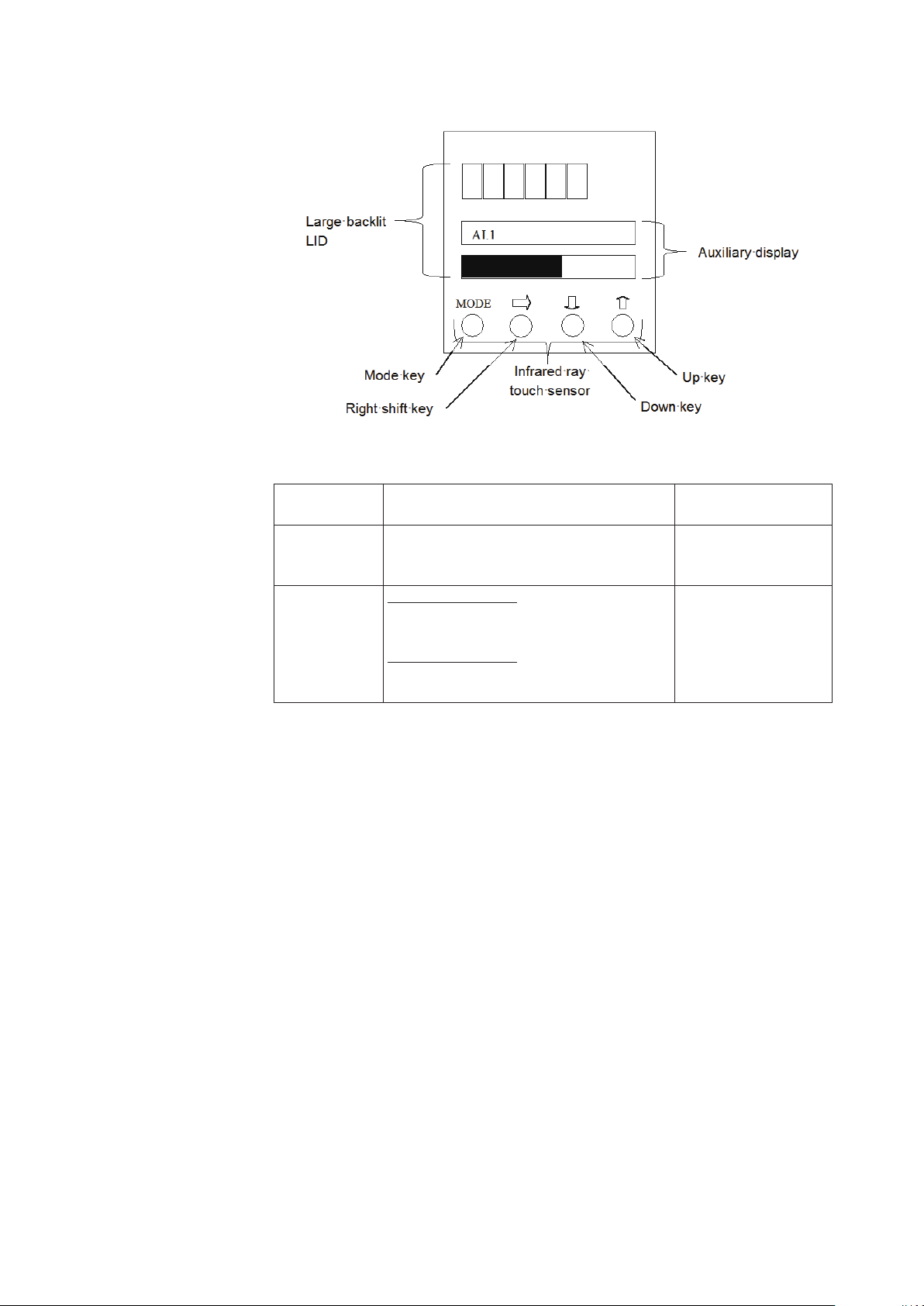

1.4 Local user interface

Figure1-5 Local user interface

Display MEASURING MODE

Main display Indicates a value set by PARAM_SELECTION

under the block selected by BLOCK_TAG_SEL.

Indicates maximum four values cyclically.

Auxiliary display

Upper auxiliary display

Indicates the information of [Tag, unit, or status]

set by DISPLAY_INFO_SEL cyclically.

Lower auxiliary display

Indicates percent flow rate with bar indicator.

Range is set by EU_100, and EU_0.

Other than MEASURING

MODE

Indicates flow velocity.

Indicates procedures for

the parameter setting or

adjustment.

1-5

Page 14

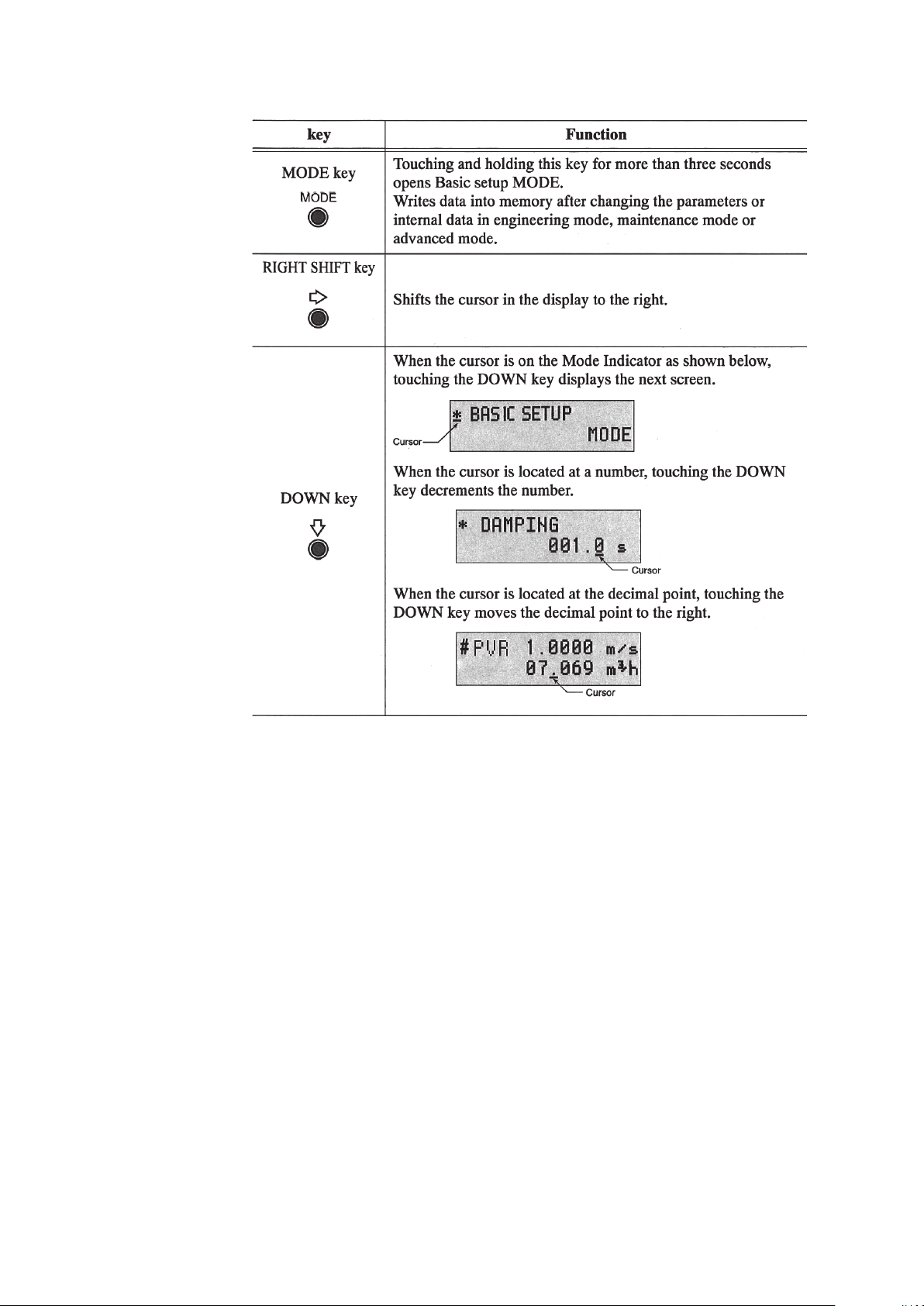

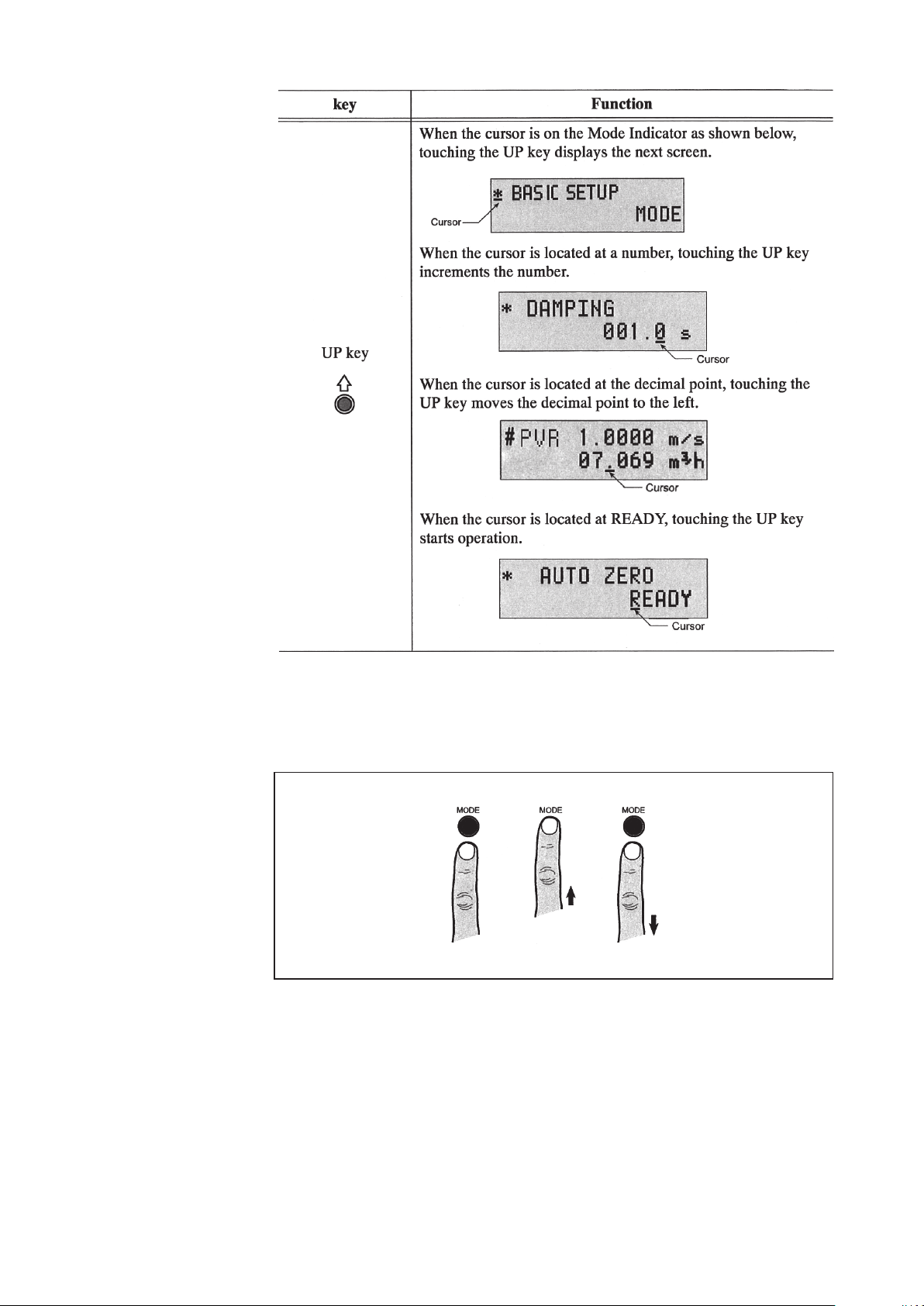

The following table is a summary of the functions of each of the keys.

1-6

Page 15

How to operate the infrared touch sensor

For best results, approach the key from below and completely cover the circle. Then move

your finger straight down to its original position. These motions ensure correct operation.

Moving sideways across the keys can accidentally activate the wrong control.

Figure1-6 Using the touch senser keys

1-7

Page 16

Local user interface operation

The following table describes the functions available in each mode.

Display

MEASURING MODE This is the normal operational mode and indicates the measuring

BASIC SETUP MODE This mode is used to change data settings that must be recorded or

MAINTENANCE MODE

ADVANCED MODE This mode is used to apply some specific noise immunity functions.

MEASURING MODE

Other than MEASURING MODE

status.

Each time the MEASURING MODE is selected, data is written into

memory. Settings entered in other modes are held in temporary

memory for two minutes, but will return to the previously saved

value unless the MEASURING MODE is selected to save the data.

The only exception is the counter, which is always saved into memory

immediately.

changed frequently. These settings include:

TAG NO.

Damping time constant

Auto zero

Detector data

This mode is used when adjustment or verification is required for

regular maintenance of the system or when troubleshooting the

system. This mode includes:

Shipping information

Output adjustment

Gain adjustment

This mode is further divided into the following two modes:

OUTPUT CHECK MODE

CALIBRATION MODE

This mode includes:

Damping

Manual zero

Averaging

Auto spike Cut

Coefficient

Drop out

Low-flow cut off

Flow direction change

1-8

Page 17

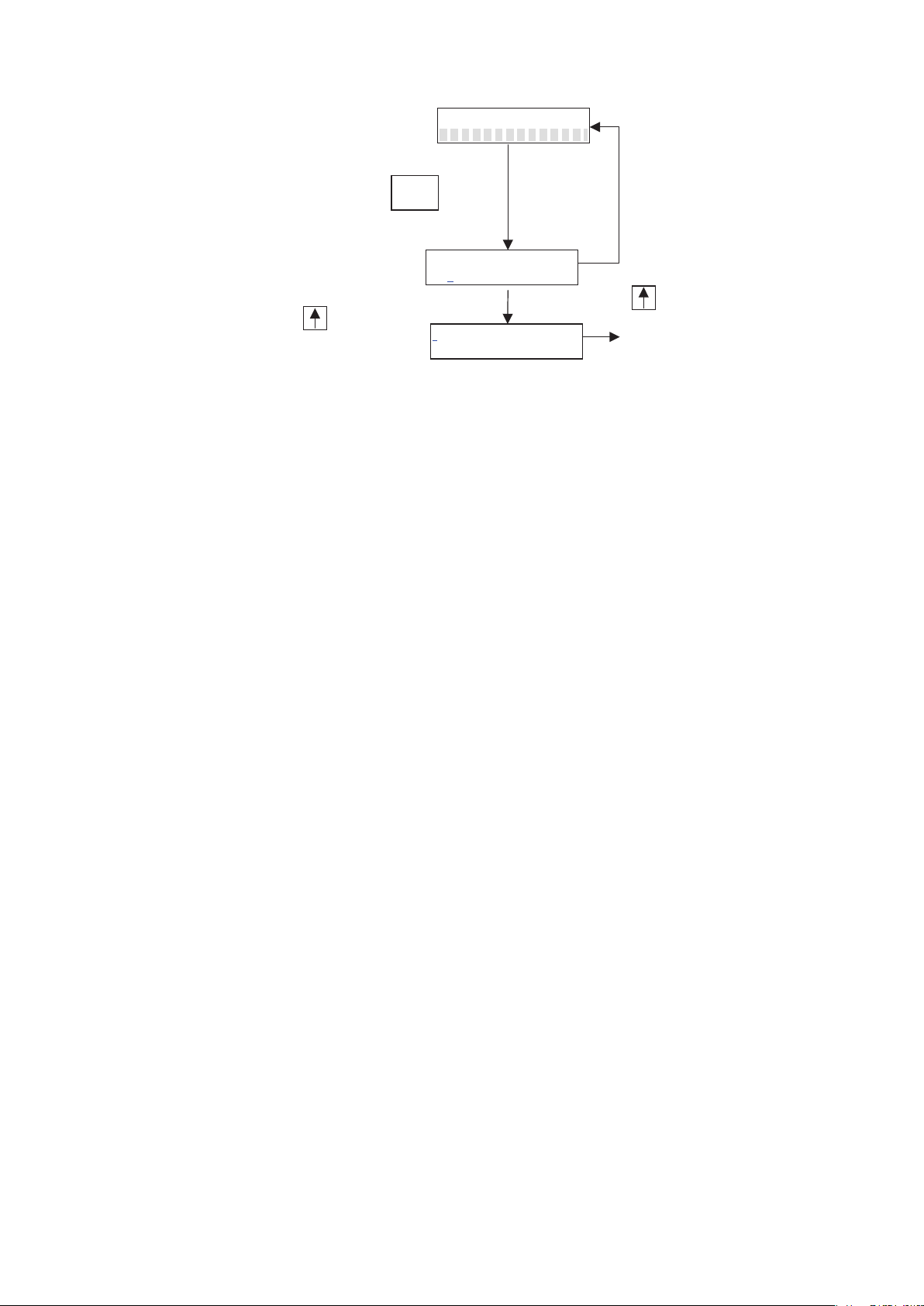

AI – 01 PV

The screen returns to MEASURING mode

MEASURING MODE

to BASIC SETUP

Move the cursor under “Y” and

press key.

Push 3

seconds

MODE

ENTER BASIC SET

YES OR

NO

in case of no operation for 8 seconds.

Move the cursor under “N” and

* BASIC SETUP

MODE

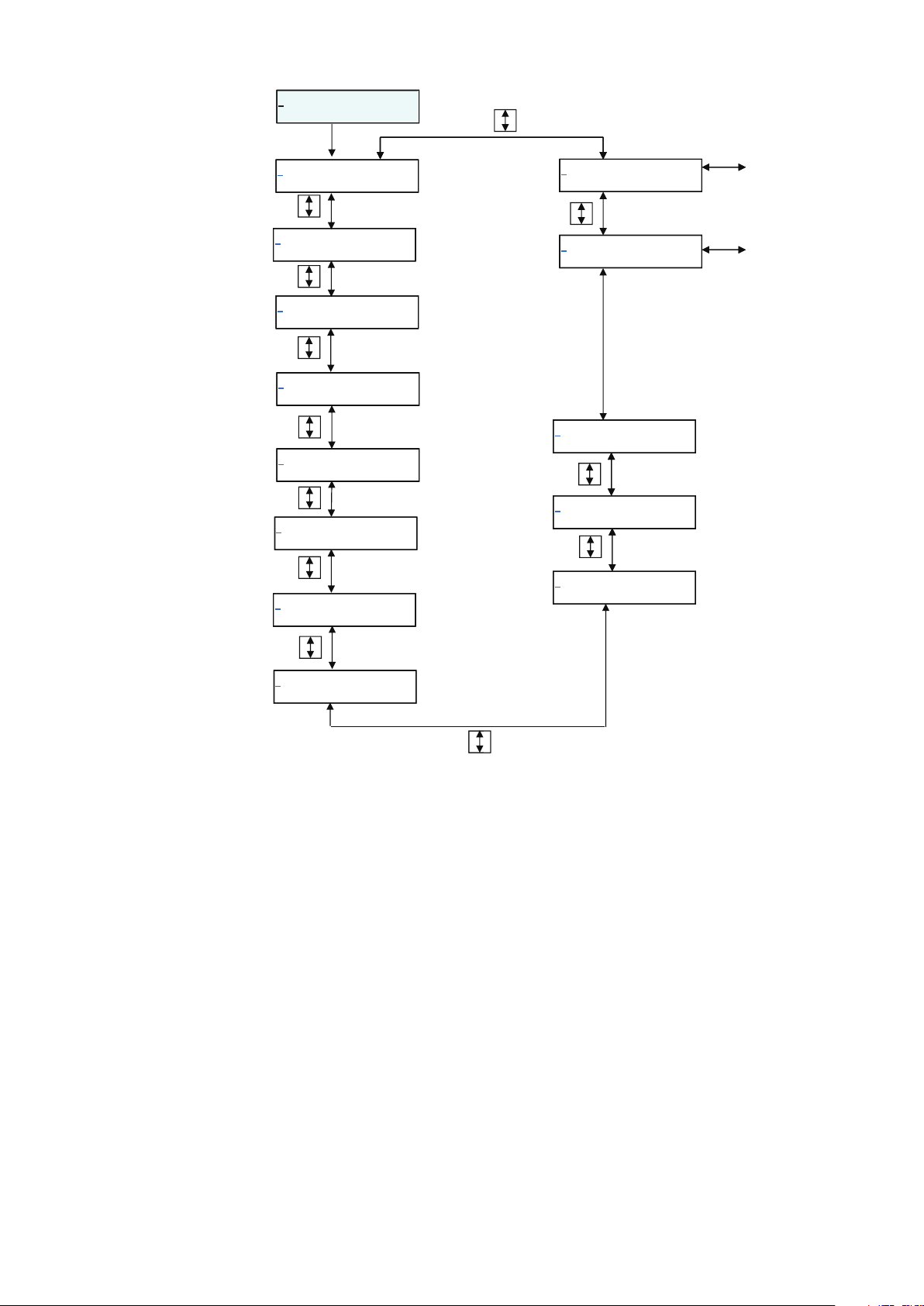

Figure1-7 How to enter BASIC SETUP

* In the BASIC SETUP mode, flow velocity in m/s appears on the upper auxiliary display.

* After entering the BASIC SETIP mode, if do not operate anything for 10 minutes, the

screen automatically returns from BASIC SETUP mode to MEASURING MODE.

1-9

Page 18

*

2 seconds later

BASIC SETUP

to Fig1-11 screen

*

PD TAG 1/2

YA – RC - 001

*

PD TAG 2/2

YA – RC - 001

*

NODE ADRESS

FFh

*

MEMO

*

DAMPING

*

AUTO ZERO

READY

MODE

XXXXXXXX

003.0 s

s

*

MODE ENTER

ADVANCED

*

MODE ENTER

MAINTENANCE

*

DENSITY

*

SVR 10.000 m/s

1.0000

70.686 t/h

to Fig1-10 screen

*

MGG DIA

M

*

DUMMY

EX 300.0

50.0

0

Figure1-8 BASIC SETUP MODE

*

PVR 10.000 m/s

70.686

m3/h

1-10

Page 19

2 seconds later

& ADVANCED

MODE

& COEFFICIENT

1.0000

& MANUAL ZERO

READY

& AVARAGING

OFF

& PV SPIKE CUT

OFF

& PV SPIKE CUT

TIME 00.0 s

& PV SPIKE CUT

LEVEL 00.0 %

& SV SPIKE CUT

OFF

& MODE RETURN

BASIC SETUP

& FLOW SWITCH 2

HYSTERISIS

& FLOW SWITCH 2

SP

.00000 t/h

& FLOW SWITCH 2

MODE LOW

& FLOW SWITCH 2

SOURCE SV

& FLOW SWITCH 1

HYSTERISIS 0%

& FLOW SWITCH 1

SP

.00000 m3/h

0%

& SV SPIKE CUT

TIME 00.0S

& SV SPIKE CUT

& PV L-FLOW CUT

LEVEL

& SV L-FLOW CUT

LEVEL

LEVEL 00.0 %

10%

10%

Figure1-9 ADVANCED MODE

& FLOW SWITCH 1

MODE LOW

& FLOW SWITCH 1

SOURCE

& FLOW DIRECTION

& EX FREQUENCY

PV

FORWARD

12.5 Hz

1-11

Page 20

> MAINTENANCE

MODE

> CALIBRATION

> SHIPPING INFO

> MODE RETURN

BASIC SETUP

OFF

OFF

Figure1-10 MAINTENANCE MODE

1-12

Page 21

2. Overview of MagneW PLUS+ Foundation Fieldbus

2.1 Overview

This chapter contains an overview of the model MGG14C MagneW PLUS+ F

Fieldbus transmitter.

Model MGG14C MagneW

MagneW PLUS+ flowtube and measures the conductive fluid flow rate. It outputs the

following with the F Fieldbus protocol.

Primary value of Flow TB: volumetric flow rate

Secondary value of Flow TB: mass flow rate

Primary value of Diag TB: scale level by scale diagnostic

Those outputs are displayed on the following Display panel.

Fieldbus is a widely used bi-directional digital communication protocol for field devices

that enable the simultaneous output to many types of data to the process control system.

PLUS+ F Fieldbus transmitter is coupled with the

MODE

The MagneW

by the FieldComm Group, and provides interoperability between Azbil devices and those

produced by other manufacturers.

Fieldbus comes with software consisting of three AI function blocks that enable the

flexible implementation of systems.

PLUS+ Fieldbus communication type employs the specification standardized

2.2 Structure of MagneW PLUS+ Foundation Fieldbus

The MagneW PLUS+ contains two Virtual Field Devices (VFD), one is System/network

Management VFD and the other is Function block VFD.

2.2.1 System/network Management VFD

• Sets node addresses and Physical Device tags (PD Tag) necessary for communication.

• Controls the execution of function blocks.

• Manages operation parameters and communication resources (Virtual Communication

Relationship:VCR).

2-1

Page 22

2.2.2 Function Block VFD

It includes some objects to execute function block applications. Resource block, Function

block, and Transducer block are one of the objects.

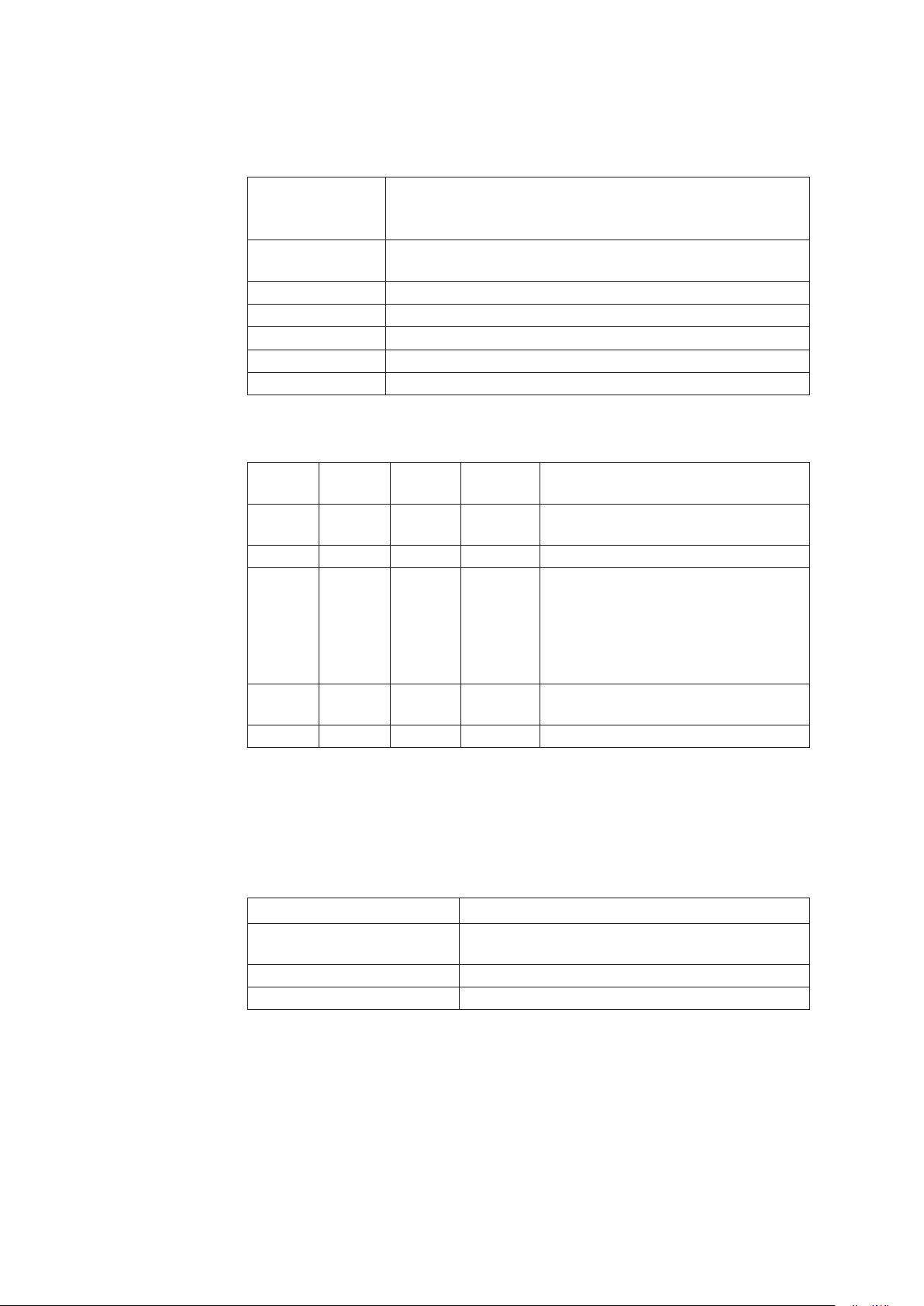

Transducer block

2.2.3 Function block

AI * 2 (3) 30

DI 2 30 1800, 1900 For flow limit switches

PID 1 45 2000

AR 1 30 2100

TOT 2 30 2200, 2300 For totalization volume

Resource block

Function block

Alert object

Trend object

View object

Link object

Block

name

Number

• Manages the status of The

• Automatically informs the host of any detected faults or other problems

based on the NAMUR NE107.

It links together with Transducer block or other function block and

provides arithmetic processing and transmits.

It provides interface function between the hardware and function block.

It provides processing for the event or alarm generated in function block.

Object to transmit trend data collected in short time

Object that provides information of each parameter in the function block.

Objects that links the above mentioned objects.

Execution

time (ms)

INDEX Note

1500, 1600,

(1700)

MagneW PLUS+

For volumetric flow rate and mass flow rate

PID function block execute a control

algorithm to minimize the error as the

difference between a measured process

variable and desired setpoint.

It also has functions of cascade control, feed

forward control, and alarm detection.

Arithmetic block perform an arithmetical

operation to the flow measurement value.

hardware.

* Number of AI becomes three when selecting flow signal analysis function.

Flow signal analysis function will be provided as call factory basis. Consult your azbil

representative.

2.2.4 Transducer Block

Flow transducer block

Display transducer block Block that controls the LCD display

Diag transducer block Block that executes the diagnosis

Block name Description

Block that calculates the flow speed, volumetric flow rate,

and mass flow rate

2-2

Page 23

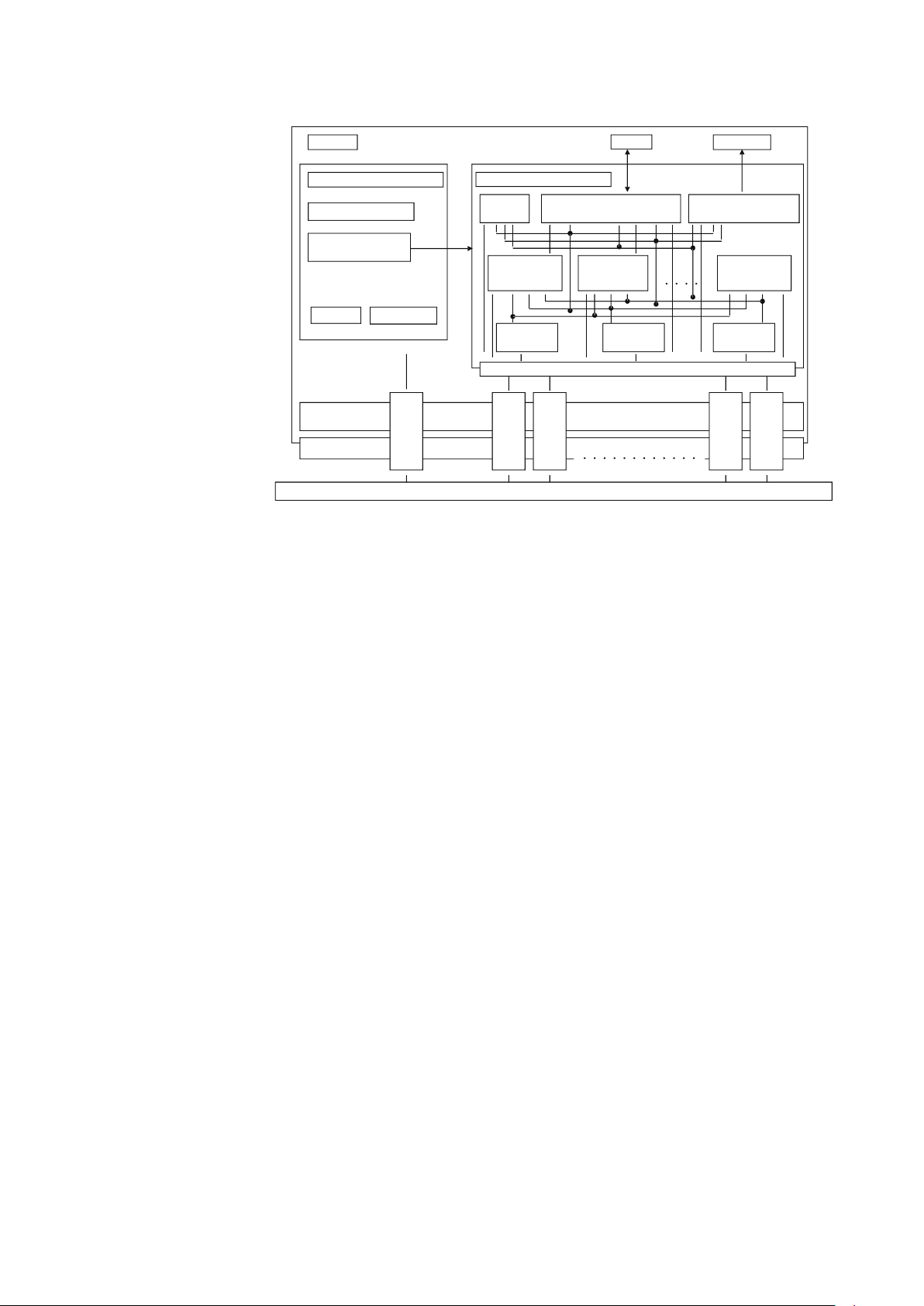

2.3 VFD/Object correlation diagram

Device

Basic information control

Function block

Control function

LAS

Communication stack

(FMS/FAS/DLL)

Physical layer (PHL)

H1 Fieldbus Line

/

VCR control

VCR VCR VCR VCR VCR

Function block VFD

Resource

block

AI

Function

Link object

FF standard transducer block

(FLOW/Positioner/Pressure)

View

Object

2-3

Figure2-1 VFD/Object correlation diagram

DI

Function

Senso r

Trend

Object

Display

Display transducer block

PID

Function

Alert

Object

2-3

Page 24

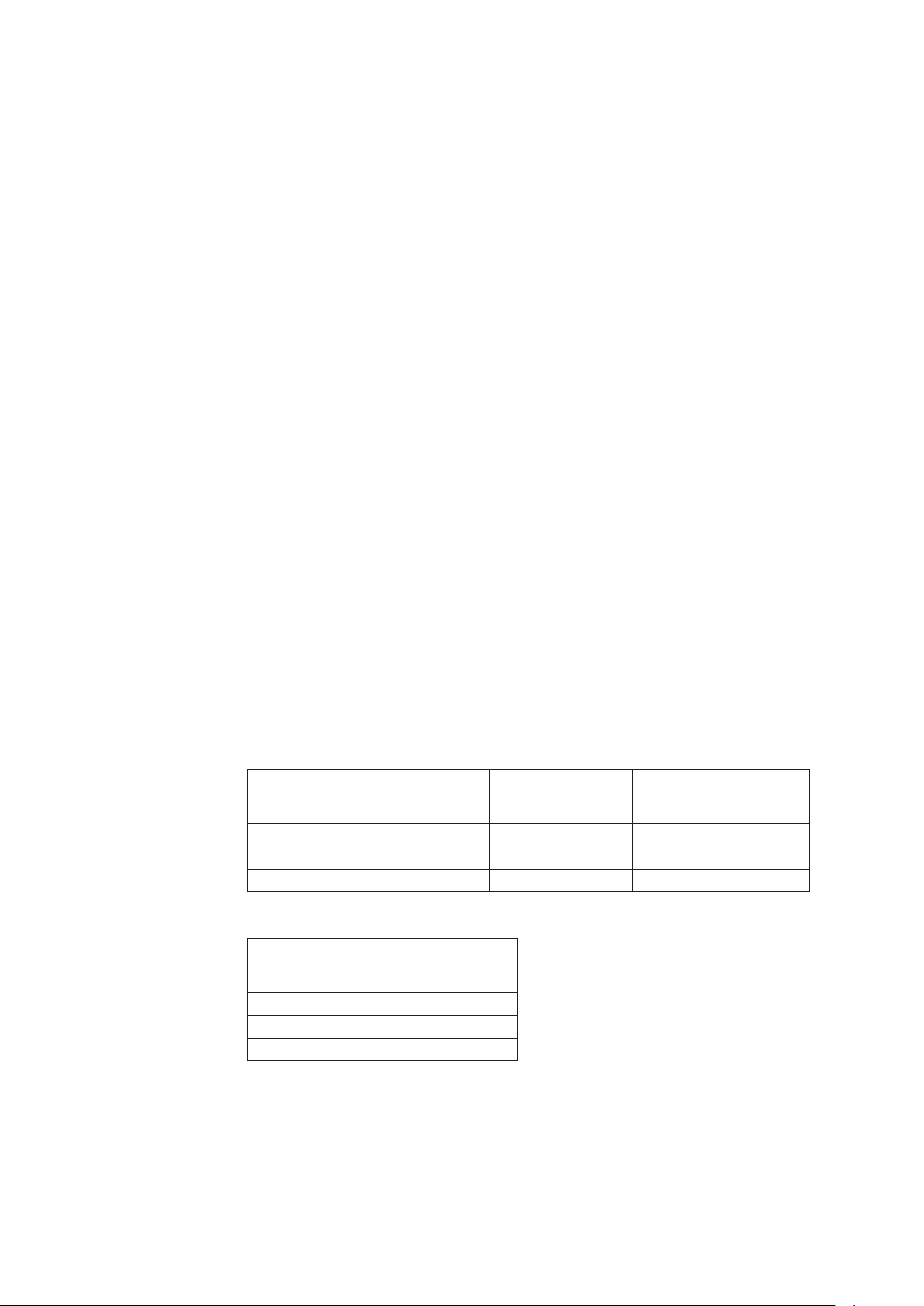

2.4 Wiring

The number of devices that can be connected to a single bus and the cable length vary

depending on system design. When constructing systems, both the basic and overall

design must be carefully considered to achieve optimal performance.

Fig 2-2 shows typical wiring to the Fieldbus network. The following are required for use

with Fieldbus devices:

• Terminator:

Fieldbus requires two terminators. Refer to the supplier for details of terminators that are

attached to the host.

• Field devices:

Connect Fieldbus communication type MagneW

PLUS+. Two or more MagneW PLUS+

devices or other devices can be connected.

• Host:

Used for accessing field devices. A dedicated host (such as DCS) is used for an

instrumentation line while dedicated communication tools are used for experimental

purposes. For operation of the host, refer to the instruction manual for each host. No

other details on the host are given in this manual.

• Cable:

Used for connecting devices. For laboratory or other experimental use, a twisted pair cable

2

two to three meters in length with a cross section of 0.9 mm

or more and a cycle period

of within 5 cm (2 inches) may be used. Termination processing depends on the type of

device being deployed. For MagneW PLUS+, use an M4 screw terminal claw. Some hosts

require a connector. Refer to Azbil Corporation when making arrangements to purchase

the recommended equipment. Connect the devices as shown in Figure 2-2. Connect

the terminators at both ends of the trunk, with a minimum length of the spur laid for

connection.

Table 2-1 Fieldbus cable

Classification Description Size Maximum length

2

A Type A Fieldbus cable 0.8 mm

B Type B Fieldbus cable 0.32 mm

C Type C Fieldbus cable 0.13 mm

D Type D Fieldbus cable 1.25 mm

(18AWG) 1900m

2

(22AWG) 1200m

2

(26AWG) 400m

2

(16AWG) 200m

Table 2-2 Resistance of the Fieldbus cable

Classification Maximum resistance @ 25ºC

A 22 /Km

B 56 /Km

C 132 /Km

D 20 /Km

2-4

Page 25

2.5 Others

Figure2-2 Cabling

Connect/disconnect the fieldbus devices

Before connecting/disconnecting the fieldbus device to the network, make sure this

activity does not affect the process.

Fieldbus network allows device connection/disconnection to the network while the device

circuit is alive. However from the process safety perspective, the device connection/

disconnection to the network after turn off the power is suggested.

Make sure to properly isolate the wires after disconnecting the device.

Non-fieldbus device

Non-fieldbus device is not allowed to connect to the fieldbus network.

Communication error and miss-wiring

If communication error appears, the device repeats sending the signal/message until it

is received by the host system. This kind of the communication error appears when the

wiring is improper.

Check the wiring if communication error appears.

2-5

Page 26

2-6

Page 27

3. Installation

Overview

Installation of the device should be done by the expert from the safety perspective.

In case of the installation in the hazardous area, follow the regulation/guidance of the

explosion-proof.

In case of the installation in the hazardous area, select the explosion-protected apparatus.

Do not use the non-explosion-protected apparatus in the hazardous area.

Install the device in the environment where the following is within in the specifications

listed in the specification sheet.

• Ambient temperature, process fluid temperature

• Process fluid pressure

• Humidity

• Vibration

• Power supply voltage

Environment which exceeds the specifications may cause fire or device damage and it may

cause injury.

This chapter describes the installation and wiring of the device in the following order:

- Criteria for selecting the installation environment

- Overview of the device installation

- Wiring of signal cables

WARNING

CAUTION

DO NOT use the installed device as foot hold. It may cause the damage of the device.

DO NOT hit the glass of the device by tools. It may cause the damage of the device.

Install the device in a location with an ambient temperature of -25 °C to 60°C (-13 °F to

140 °F) and an ambient humidity of 5 to 100% RH to prevent device malfunction or output

errors.

DO NOT install the device near high-current power lines, motors, or transformers to prevent damage from electromagnetic induction, which can cause device malfunction or

output errors.

DO NOT use the device to ground a welder. It can damage the device.

Be sure to ground the welding power transformer when welding near the device to avoid

output errors.

DO NOT install the device in the severe vibration area or in corrosive environment. It may

damage the device, or cause the fume of the device.

DO NOT install the device on the bridge or deck of the ship.

DO NOT install the device on in the severe vibration area on the ship.

Be sure to use the metal conduit for the cables between the remote style transmitter and

flowtube.

Be sure to install the flowtube with a distance of 500mm minimum from the other flowtube. Magnetic field generated by a flowtube may affect the other flowtube and it may

cause the output errors.

DO NOT install the device in a location subject to direct sunlight, wind, rain, severe vibration, or in a highly corrosive atmosphere. The transmitter and flowtube can be damaged.

3-1

Page 28

3.1 Before installing electromagnetic flowmeter

Criteria for selecting the installation environment Getting started Select the optimal

location for installing the device according to the following criteria in order to maximize

its performance.

Note:

- Install the device in a location with an ambient temperature of -25 °C to 60 °C (-13 °F

to 140 °F) and an ambient humidity of 5 to 100% RH to prevent device malfunction or

output errors.

- DO NOT install the device near high-current power lines, motors, or transformers to

prevent damage from electromagnetic induction, which can cause device malfunctions

or output errors.

- DO NOT use the device to ground a welder. Doing so can damage the device.

- Be sure to ground the welding power transformer when welding near the device.

- DO NOT install the device in an area with severe vibrations or in a corrosive

environment. Doing so may cause damage the device.

- DO NOT install the device in a location subject to direct sunlight, wind, or rain.

WARNING

Use this product under the conditions as defined in the specifications (e.g., protection against explosion, pressure rating, temperature,

humidity, voltage, vibration, shock, mounting direction, and atmosphere) to avoid failure of the device or harmful physical effects such

as fire damage.

WARNING

In case of the installation in the hazardous area, select the explosionprotected apparatus. Do not use the non-explosion-protected apparatus in the hazardous area.

3-2

Page 29

3.2 Installation of transmitter

Mounting bracket

Material: SPCC

(Zinc plating)

2B-pipe

2B-pipe mounting

Installation of transmitter

Basic mounting methods

The transmitter can be mounted in three ways—integrated mounting with the

flowtube, wall-mounting, and 2B-pipe mounting

Mounting plate

Terminal box

Tag number plate

Figure3-1 Wall-mounting of transmitter

Figure3-2 2B-pipe mounting of transmitter and Integrated mounting

3-3

Page 30

Electrical wiring (1)

DO NOT wire with wet hands. DO NOT wire while the circuit is alive. It may cause electrical

shock.

ELECTRIC SHOCK HAZARD! Turn the power supply OFF before opening the transmitter

cover.

Wiring of the device should be done by the expert from safety perspective.

Wire the cables to the correct terminal. Incorrect wiring may damage the device or cause

the fume of the device.

Connect the correct power supply. Incorrect power supply may damage the device or

cause the fume of the device.

Be sure to properly ground the device. Improper grounding may cause the output errors

DO NOT give impact to the device. It may cause the damage of the device.

WARNING

CAUTION

Be sure to use the power supply with the overcurrent protection function.

Be sure proper wiring. Incorrect wiring may cause the damage of the device.

Be sure to properly tighten the terminal cover on the terminal box so that water does not

penetrate in the terminal.

DO NOT connect AC power supply to the DC power supply model. The wrong power supply damages the device.

Turn off the Fieldbus power supply before connecting the Fieldbus cable to the transmitter. The transmitter or the Fieldbus power supply can be damaged. This type of damage is

not covered by Azbil Corporation’s warranty.

Be sure to plug all unused conduit connections with a water tight plug.

In case that a remote model is installed in a ship, the cables between the transmitter and

flowtube must be covered with a flexible metal conduit.

Switch the control equipment to manual control before terminating the device operation and shutting off the output to the control equipment. This action prevents the power

shut-off from directly affecting the control equipment.

Introduction

The electromagnetic flowmeter needs to be connected to the main power supply (AC or

DC 24 V) for proper operation.

The following items are described in relation to the electrical wiring of the electromagnetic

flowmeter.

3-4

Page 31

- Connection points on the main unit of the electromagnetic flowmeter

- Terminal layout

- Transmitter terminal table

- Cables between flowtube and transmitter

- Cable specifications

- Connection between flowtube and transmitter

- Selection of wiring cable

- Installation of wiring cable

- Connection to the Fieldbus output

Note:

- Do not directly connect the AC power supply to the main unit of the electromagnetic

flowmeter if the main power supply is designed to be 24 V DC. AC power supplied

to the main unit of the electromagnetic flowmeter causes irreversible damage in the

internal measurement circuit.

Connection points on the main unit of the electromagnetic flowmeter

Figure 3-4 presents the terminal block of the main unit of the electromagnetic flowmeter.

WARNING

· In wiring, turn off the power before opening the cover to avoid electric shock.

· DO NOT perform wiring work when current is being applied. Doing so may

cause electric shock.

Note:

- Properly align the wiring position as indicated. Improper wiring can damage the

device.

- Especially, check the wiring position of the power lines again as they carry a high

capacity current.

3-5

Page 32

Terminal layout

Figure3-3 Terminal layout of remote transmitter

Integral transmitter: Terminal layout

Unlike a remote transmitter, an integral transmitter does not use the terminals X, Y, SB,

SA, A, B, C, and E. These terminal symbols are thus erased from the layout.

DC-24V transmitter: Terminal wiring diagram

The power terminal of the DC-24V remote transmitter is indicated as POWER DC

24V. Check carefully if the polarity is positive or negative.

Transmitter terminal table

Terminals for a remote transmitter Terminals for an integral transmitter

Symbol Description Symbol Description

A

B -

C

SA N

SB

FIELDBUS

X

Y

POWER AC

E Not used

Flow signal input

+

Fieldbus output

-

Excitation output

L

N

Power supply

Grounding

(grounding

resistance must be

FIELDBUS

POWER AC

<100)

+

Fieldbus output

L

Power supply

Grounding

(grounding resistance

must be <100)

3-6

Page 33

Electrical wiring (2)

Cable length (m)

Cable length (m)

Cables between flowtube and transmitter

Please use a special cable (MGA12W) designated for connecting the flowtube and

transmitter.

Select a signal cable (Azbil’s special cable or a commercially-available shielded cable)

depending on the fluid conductance, cable length, and the diameter of the flowtube. Refer

to the figure below.

- Range where Azbil’s special cable can be used: A and B

- Range where a commercially-available cable can be used: Only A

2.5mm and 5mm Diameter Cable >10mm Diameter Cable

B. Usage range of dedicated

cable, model MGA12W

A. Usage range of

commercially

available cable

Fluid Conductivity (µs/cm)

B. Usage range

of dedicated

cable, model

MGA12W

Fluid Conductivity (µs/cm)

Figure3-4 Relationship between the fluid conductance and cable length

Specifications of cables between flowtube and transmitter

Cable (between remote flowtube and transmitter):

Length: Maximum 300 m (depends on the fluid conductance)

Outer diameter: φ 10–12 mm

2

Signal cable: Special cable (diameter of 11.4 mm, 0.75 mm

), or an equivalent among

commercially-available shielded cables (e.g., CVVS, CEEV)

Excitation cable: Special cable (φ 10.5 mm, 2 mm2), or an equivalent among

commercially-available shielded cables (e.g., CVV)

Note:

- Always use a shielded cable as a signal cable.

A. Usage range of

commercially

available cable

3-7

Page 34

Signal cable

Designed for an M4 screw

Conductive wire

(Model: MGA12W)

Cable termination on the owtube side

Cable termination on the transmitter side

Designed for an M4 screw

Designed for an M4 screw

Designed for an M4 screw

Designed for an M4 screw

Flowtube

side

(type code A)

(type code B)

Cable termination on the owtube side

(type code B)

Transmitter

side

Flowtube

side

Flowtube

side

Cable termination on the Zener barrier side

Flowtube

side

Flowtube

side

Zener barrier side

Zener barrier side

Designed for an M4 screw

Designed for an M3 screw

(type code E)

Designed for an M3 screw

(type E)

Designed for an M3 screw

Designed for an M3 screw

(type code E)

Designed for an M4 screw

Designed for an M4 screw

Cable termination on the Zener barrier side

(type code D)

Flowtube

side

(type code E) (type code C)

Flowtube

side

(type code E)

Outer sheath

Inner sheath

Inner shield

Outer shield

Cable termination on the transmitter side

Zener barrier side

Zener barrier side

Conductive tube

Insulator

Note) Remove the conductive tubes (black) of conductive cables for terminals A and B up

to the edge s of the inner shields.

Figure3-5 Structural drawing of signal cable

3-8

Page 35

Excitation cable

Designed for an M4 screw

(Model: MGA12W)

Designed for an M4 screw

Insulator

60

Flowtube

side

Transmitter

side

70

Designed for an M4 screw

70L60

Designed for an M4 screw

Designed for an M4 screw

Designed for an M4 screw

Cable termination on the owtube side

Black

White

Flowtube

side

50

50

(Model code: A)

Black

White

Flowtube

side

50

50

(Model code: A)

Black

White

Black

White

Flowtube

side

Flowtube

side

60

39

(Model code: B)

60

39

(Model code: B)

Sheath

Insulator

Conductive wire

Fabric tape

Figure3-6 Structural drawing of excitation cable

3-9

Page 36

Electrical wiring (3)

Dedicated cable model MGA12W

Commercially available cable

Connection between flowtube and transmitter

Detector

A

Signal cable

model MGA12W

Signal cable 2-core

Single shielded cable

Converter

SA

A

C

B

X

Y

Excitation cable

model MGA12W

Signal cable 2-core

Single shielded cable

Detector

A

C

B

X

Y

Excitation cable

Figure3-7 Connection between flowtube and transmitter

C

B

SB

X

Y

Converter

A

C

B

X

Y

3-10

Page 37

4. Startup and Shutoff

Overview

This chapter describes the procedure for starting up the device and performing zero

adjustment.

Follow the instructions in this chapter when you start up and operate the device for the

first time.

Zero adjustment can be made in one of the following ways:

Using the device’s LUI

Using a fieldbus configurator to communicate with the device

This chapter describes how to perform zero adjustment using the local user interface (LUI).

Refer to Chapter 5 for the alternative method using Fieldbus communication.

4.1 Startup

Start up the device

Procedure

Start up the electromagnetic flowmeter according to the following procedure.

Step Procedure

Make sure that the flowtube of the electromagnetic flowmeter is properly

1

connected to the piping.

Make sure that the flowtube and transmitter of the electromagnetic flowmeter are

2

securely wired.

Fill the flowtube of the electromagnetic flowmeter with a measurement fluid and

3

pause the flowtube.

Check for any fluid leakage from the flange, to which the flowtube of the

4

electromagnetic flowmeter is attached.

5 Apply current to the transmitter of the electromagnetic flowmeter.

Make sure that the LUI display is turned on.

Image

6

This completes the startup of the electromagnetic flowmeter.

. . . . .

4-1

Page 38

4.2 Steps before measurement

m3/h

m3/h

m3/h

m3/h

m3/h

Setting up flowtube data

Getting started

Select and configure the constant of the flowtube used in combination with the

transmitter, flowtube type, and diameter.

Default settings

The settings of EX 300.0, MGG, and DIA 050.0 are applied when no flowmeter is specified

for the combined use with the transmitter.

Note:

If you have purchased a combination set including a transmitter and a flowtube, the

flowtube data are already configured by real current calibration. Note that any change

will result in an output error from the flowmeter. Refer to Table 4-1.

Improper setting of flowtube information can result in

output errors from the flowmeter.

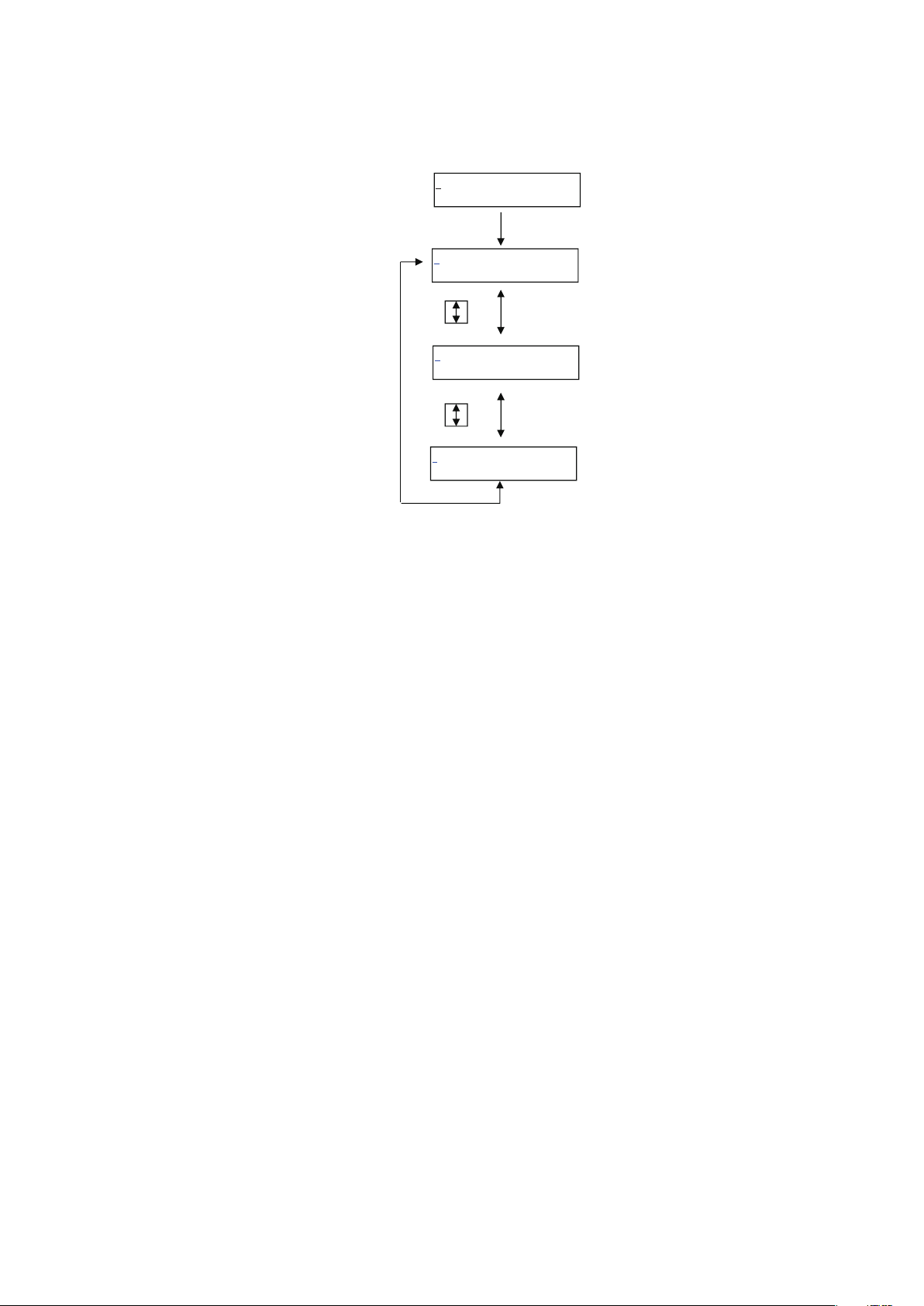

Step Procedure Screen

WARNING

Follow the procedure for entering BASIC SETUP MODE

1

to display the screen for setting up the flowtube data.

Touch the key to set up the constant for the flowtube.

Use the and keys to enter the value for the EX section

2

which is printed on the name plate of the flowtube to be

used in combination with the transmitter.

Next, touch the key to select the flowtube type.#Use

the and keys to select the MODEL number which is

3

printed on the name plate of the flowtube to be used in

combination with the transmitter.

Next, touch the key to select the diameter.#Use the

4

and keys to select the diameter of the flowtube used in

combination with the transmitter.

Touch the key to move the cursor underneath the *

5

mark.

4-2

Page 39

Zero adjustment

m3/h

m3/h

m3/h

m3/h

m3/h

m3/h

Getting started

Make sure to perform zero adjustment after starting up the device. There are three ways to

do so.

Using the device’s LUI

Using the parameter list by communicating with the device

Using the menu by communicating with the device

Adjust the measured instantaneous flow rate value to zero when the fluid inside the

flowtube is sitting still.

Note:

Zero adjustment is extremely important for ensuring accurate measurement of flow

rate. Make sure to perform this adjustment when you first operate the device.

Before performing zero adjustment, make sure that Class D grounding is reliably

performed with the flowtube and that the flowtube is filled with a measurement fluid

which is sitting still.

Zero adjustment is possible when the flow velocity falls below 0.2 m/s. Wait until the

fluid comes to a complete rest (a flow velocity of 0.0 m/s) to avoid output errors.

Zero adjustment requires O/S to be selected for the Actual MODE in Flow Transducer

Block.

Configure the setting from the host system in advance.

Step Procedure Screen

Touch the MODE key for 3 seconds or longer.

Note: The screen as shown on the right is displayed only

1

for 8 seconds. Perform the following operations within 8

seconds. Touch the

Touch the

key to move the cursor underneath YES and

key four times.

touch the ke y.

2

is displayed before the screen

switches to the one shown on the

right in 2 seconds.

Touch the

3

the right.

Touch the key once to move the cursor underneath

4

READY.

key once to display the screen as shown on

Touch the key to start zero adjustment. During the

adjustment, the value of 0.0 blinks for displaying the large

7-segment flow rate. Once the adjustment is complete,

5

the value stops blinking and the screen returns from ON

to READY.

This period is about 30 seconds.

At the very end, make sure to touch the MODE key to

6

complete the adjustment.

4-3

Page 40

Checking the operation of Fieldbus

Check to see if the device operates properly with Fieldbus.

Prior to operating Fieldbus, the DD file (device description) and the CF file (capability) of

the device need to be copied to the host.

Download the DD file and CF file from the official website of the FieldComm Group.

Operation of Fieldbus requires the following settings in the host.

Ensure that PD_TAG and NODE_ADRS can be set up by configuring the following

settings.

1) Network parameter settings for link active scheduler (LAS)

Symbol Parameter name Description and setting value

V(ST) Slot time Set a value of 5 or greater.

V(MID) Gap between minimum frames Set a value of 10 or greater.

V(MRD) Maximum response delay time

V(FUN)

V(NUN) Total number of unpolled nodes

The number of the first unpolled

node

Set the value so that V(MRD)

V(ST) is 20 or greater.

Set the value immediately next to

the address used by the host. Set

a value of 12 or greater in 16-bit

representation.

The number represents the range

of unused addresses. Set the value

of the minimum address used by

the device in the work site minus

the value of V(FUN).

1) Checking PD_TAG (physical device tag) and address

Parameter name Parameter name Setting value

PD_TAG Physical device tag

NODE_ADRS Node address

The same address setting as another device cannot be selected for NODE_ADRS. (Such an

entry is changed into the default address [0xF8–0xFB])

Assign a different address for each unit.

Up to 32 ASCII

characters

Set the minimum

address of the BASIC

device in hexadecimal

notation and F7 or less

Data when shipped

from the factory

Specified by customers

Hexadecimal notation

and F8

4-4

Page 41

4.3 Shutoff

CAUTION

· Make sure to switch the controller to manual control mode in order to

shut off the device and stop the output to the controller.

This safeguards the controller from direct impacts caused by the suspended output from the device.

· Do not turn off the power within 60 seconds of any data being rewritten using the LUI or another communication method, to avoid possible errors in saving the data.

Procedure

Take the following procedure to shut off the device.

Step Procedure

1 Switch the controller of the device you want to shut off to manual control mode.

2 Turn off the power of the device.

4-5

Page 42

4-6

Page 43

5. Basic Settings by Fieldbus Communication

Overview

This chapter outlines zero adjustment as an operation performed using Fieldbus

communication, each Transducer block, as well as basic parameter settings.

Some parameters require O/S to be selected for the Block MODE parameter in order to

change the settings.

Mode parameters can be switched with MODE_BLK in each block.

In order to use each block after the settings are changed, select AUTO for MODE-BLK.

Note

- The device supports Version 3.8 or later versions of 475.

Version 3.6 or earlier versions cannot properly display some parameters.

- The device supports host authentication, HTK 6.1.a or later versions, and Standard

Dictionary 3.70 or later versions.

Other versions may fail to display some parameters.

- Some parameters may not be properly displayed when some hosts are used.

- METHOD may not work with some hosts.

In such cases, access the parameter from the parameter list to configure the settings.

5-1

Page 44

5.1 Fieldbus communication menu

There are four types of menu structures for Fieldbus communication depending on the

host being used.

This section describes the device menu for communicators.

- Device menu for communicators

This menu displays parameters such as setup and adjustment of the positioner.

A host supporting the device menu can display this menu. (Example: 475 Field

Communicator by Emerson)

- Block menu for communicators

A communicator capable of Fieldbus communication can display this block menu. A

menu prepared for each block displays parameters such as setup and adjustment of the

positioner. (Example: 475 Field Communicator by Emerson)

- Block menu for PCs

A compatible host (PC) can display this block menu. A menu prepared for each block

displays parameters such as setup and adjustment of the positioner. (Example: Azbil's

device management system - InnovativeField Organizer)

- Parameter list

All parameters are displayed by block.

Appendix C presents a list of parameters for Flow Transducer Block, Resource Block,

and Display Transducer Block.

5-2

Page 45

5.2 Zero adjustment

Getting started

Once the device has started up, make sure to perform zero adjustment in one of the

following three ways.

Adjust the measured instantaneous flow rate value to zero when the fluid inside the

flowtube is sitting still.

Note:

- Zero adjustment is extremely important for ensuring accurate measurement of flow

rate. Make sure to perform this adjustment when you first operate the device.

- Before performing zero adjustment, make sure that Class D grounding is reliably

performed with the flowtube and that the flowtube is filled with a measurement fluid

which is sitting still. Zero adjustment is possible when the flow velocity falls below 0.2

m/s. Make sure to wait until the fluid comes to a complete rest (a flow velocity of 0.0

m/s) to avoid output errors.

- Zero adjustment requires O/S to be selected for the Actual MODE in Flow Transducer

Block.

Configure the setting from the host system in advance.

Accessing the option from the menu

Note: Use METHOD in the menu to perform zero adjustment. METHOD may not

operate with some hosts.

In such cases, perform zero adjustment by accessing the option through the

parameter list.

- Device menu for communicators

Perform zero adjustment by selecting Device Maintenance Auto Zero Adjustment

(METHOD).

- Block menu for communicators or Block menu for PCs

Perform zero adjustment by selecting FLOW Transducer Block Block Maintenance

Auto Zero Adjustment (METHOD).

Accessing the option from the parameter list

Set TARGET in MODE_BLK of FLOW Transducer Block to O/S (Out of Service).

1

Set “1” (Execute) to AUTO_ZERO_CALIBRATION_CMD in FLOW Transducer

Block.

Zero adjustment starts.

2

Set “4” (Canceled) to AUTO_ZERO_CALIBRATION_CMD in FLOW Transducer

Block in order to cancel zero adjustment.

Execution results of automatic zero adjustment can be checked at

MANUAL_ZERO_CALIBRATION_CMD in FLOW Transducer Block.

3

While “1” (Executing) is displayed during execution of zero adjustment, “2” (Success) is

displayed when zero adjustment is completed successfully.

For flow measurement, set TARGET of Transducer Block in FLOW Transducer Block to

4

AUTO.

5-3

Page 46

5.3 Basic settings

Sensor value

Flow Transducer Block

Overview of function

Flow Transducer Block enables calculation of flow velocity, volume flow rate, and mass

flow rate based on the sensor outputs of the electromagnetic flowmeter.

The calculated volume flow rate and mass flow rate are output to AI Function Block

and TOT Function Block. A flow switch is prepared for turning the transducer on or off

depending on the volume flow rate and mass flow rate. The value assigned to the flow

switch is output to DI Function Block.

Function Block diagram

The following diagram shows the configuration of Flow Transducer Block.

Calculation function

Self-diagnosis history

Adjustment function

SENSOR_VALUE (ow velocity)

Conguration function

PRIMARY_VALUE

(volume ow rate)

SECONDARY_VALUE

(mass ow rate)

FLSW1_VALUE

FLSW2_VALUE

Figure5-1 Function Block diagram

Parameters

Major parameters for Flow Transducer Block are described as follows.

Refer to the attached Parameter List for more descriptions of parameters.

Output

SENSOR_VALUE

Indicates the flow velocity (m/s) of the measurement fluid.

PRIMARY_VALUE

Indicates the volume flow rate and the status.

Channel 1 corresponds to this parameter.

Select 1 for CHANNEL of Function Block you want to use in order to connect to AI

Function Block or TOT Function Block.

SECONDARY_VALUE

Indicates the mass flow rate and the status.

Channel 2 corresponds to this parameter.

Select 2 for CHANNEL of Function Block you want to use in order to connect to AI

Function Block or TOT Function Block.

FLSW_1_VALUE_D

Indicates the output value of Flow Switch 1 and the status.

Channel 100 corresponds to this parameter.

Select 100 for CHANNEL of Function Block you want to use in order to connect to DI

Function Block.

FLSW_2_VALUE_D

Indicates the output value of Flow Switch 2 and the status.

Channel 101 corresponds to this parameter.

Select 101 for CHANNEL of Function Block you want to use in order to connect to DI

Function Block.

Settings

PRIMARY_VALUE_RANGE

5-4

Page 47

Indicates setting values for the upper and lower range limits, unit, and the position of

the decimal point for the volume flow rate.

The unit for the flow rate must be identical to the unit assigned for XD_SCALE in AI

Block.

Refer to Table 5-1 for the units that can be set up.

SECONDARY_VALUE_RANGE

Indicates setting values for the upper and lower range limits, unit, and the position of

the decimal point for the mass flow rate.

The unit for the flow rate must be identical to the unit assigned for XD_SCALE in AI

Block.

Refer to Table 5-2 for the units that can be set up.

DENSITY_CONSTANT

Fluid density setup

The assigned value is applied to the calculation of SECONDARY_VALUE (mass flow

rate).

FLOWTUBE_SIZE

Flowtube diameter setup

FLOWTUBE_TYPE

Flowtube type setup

EMPTY_PIPE_DETECTOR

Indicates whether the empty detection function is enabled or disabled.

Calculation function

DAMPING_CONSTANT

A damping constant can be set up when a tiny variation component needs to be cut off

from the measured instantaneous flow rate value.

PRIMARY_VALUE_LOW_FLOW_CUT

A low cut-off threshold can be set for the volume flow rate.

Available range is 0 to 10% (percentage of PRIMARY_VALUE_RANGE.EU100).

SECONDARY_VALUE_LOW_FLOW_CUT

A low cut-off threshold can be set for the mass flow rate.

Available range is 0 to 10% (percentage of SECONDARY _VALUE_RANGE.EU100).

Adjustment function

AUTO_ZERO_CALIBRATION_CMD

This command executes automatic zero adjustment.

Run this command in order to perform zero adjustment when the fluid is filled

and sitting still in the flowtube.

GAIN_CALIBRATION_CMD

This command executes gain adjustment of the transmitter.

Run this command in order to perform zero adjustment of the transmitter using a

calibrator, etc.

Self-diagnosis history

FLOW_TB_STATUS_RECORD_1–10

Saves self-diagnosis history.

5-5

Page 48

Table 5-1. Units that can be set up for volume flow rate

Unit of

volume

flow rate

3

cm

3

m

cm3/d (1514) cm3/h (1513) cm3/min (1512) cm3/s (1511)

m3/d (1350) m3/h (1349) m3/min (1348) m3/s (1347)

d h min s

L L/d (1354) L/h (1353) L/min (1352) L/s (1351)

bbl bbl/d (1374) bbl/h (1373) bbl/min (1372) bbl/s (1371)

mgal/h (1457)

gal/h (1364)

kgal/h (1458)

mImpGal_h (1472)

ImpGal/h (1369)

kImpGal/h (1473)

gal

ImpGal

mgal/d (1461)

gal/d (1365)

kgal/d (1462)

mImpGal_d (1476)

ImpGal/d (1370)

kImpGal/d (1477)

Unit of time

mgal/min (1453)

GPM (1363)

kgal/min (1454)

mImpGal_min (1468)

ImpGal/min (1368)

kImpGal/min (1469)

mgal/s (1459)

gal/s (1362)

kgal/s (1450)

mImpGal_s (1464)

ImpGal/s (1367)

kImpGal/s (1465)

Table 5-2. Units that can be set up for mass flow rate

Unit of

volume

flow rate

g

g/d (1321)

kg/d (1325)

d h min s

g/h (1320)

kg/h (1324)

t t/d (1329) t/h (1328) t/min (1327) t/s (1326)

lb lb/d (1333) lb/h (1332) lb/min (1331) lb/s (1330)

Unit of time

g/min (1319)

kg/min (1323)

g/s (1318)

kg/s (1322)

5-6

Page 49

Display Transducer Block

Overview of function

Display Transducer Block controls the display of measurement values and alarm

indication in the local user interface (LUI).

Input and output signal values for function blocks installed in the device can be displayed,

such as OUT of AI Block and PRIMARY_VALUE and SECONDARY_VALUE of Flow

Transducer Block.

Parameter

Major parameters of Display Transducer Block are described as follows.

Refer to the attached Parameter List for more descriptions of parameters.

DISPLAY_PARAM_SELECTION

Select the parameter you want to display from among the parameters configured in the

display setting 1 to 4.

Up to four parameters can be displayed in chronological order.

If all of the parameters for 1 to 4 are unselected, O/S is set for MODE_BLK._Actual in

Display Transducer Block.

DISPLAY_INFO_SELECTION

Adjunct data (tag, status, and unit) that are commonly assigned for parameters in the

display setting 1 to 4 can be configured. Factory default is 0x07 (Tag, Unit, Status

are all selected)

For example, if not displaying Tag and Status, and displaying only Unit, change the

setting to 0x02.

If all the adjunct data are unselected, O/S is set for MODE_BLK._Actual in Display

Transducer Block.

DISPLAY_CYCLE

The cycle for updating the display can be set in units of seconds, in a range from 1 to 10

seconds. Factory default is 0x05(5 sec).

BLOCK_TAG_SELECTION_n

Enter BLOCK_TAG for the block to which the parameter is to be displayed in the

display setting n. Enter the BLOCK_TAG of the block that has the parameters to be

displayed into BLOCK_TAG_SELECTION_n. If an incorrect value is entered, the block

cannot be identified and display settings cannot be set up.

PARAM_SELECTION_n

Select a parameter you want to display in the display setting n.

Available values are presented in Table 5-3.

*1

*2

*2

Note: When writing is not possible for BLOCK_TAG_SELECTION_n (n=1 to 4), or

PARAMETER_SELECTION_n (n=1 to 4), switch the settings of RB FEATURE_SEL

Bit_12 (Deferral of Inter-Parameter Write Checks) to ON (enabled).

DISPLAY_TAG_n

*2

Enter the text you want to display in the indicator as a tag for the display setting n.

Up to 16 characters can be entered.

5-7

Page 50

UNIT_SELECTION_n

*2

You can select whether the parameter in display setting n will be displayed using the

unit associated with it or another desired unit.

Select Auto (0) in order to display the parameter with the associated unit as assigned

for the displayed value, and select Custom (1) in order to display the parameter with

another desired unit.

Please refer to the parameter list, which includes the display parameter, and section in

Table 5-4, “LUI Display Unit String.”

CUSTOM_UNIT_n

*2

Enter the text you want to display as the unit.

This parameter is displayed only when Custom is selected in UNIT_SELECTION_n.

Up to 16 characters can be entered for CUSTOM_UNIT_n.

*1 If changing the display time, change the parameter setting.

*2 If changing the display detail from the factory default PV value of the Flow Transducer Block to

other parameter, change these parameters.

Regular Display

With the factory default setting, the PV value of Flow Transducer Block is displayed.

With the factory default setting, it gets displayed periodically according to the following

sequence.

Seq. No. 1 2 3

Main Disp.

Aux. Disp

DisplayTime

FTB:PV value FTB:PV value FTB:PV value

PRIMARY_VALUE (Specified Unit) (Status)

5 5 5

For example, if you wish to change the display detail to Out value of AI Function Block,

1. Set AI_FB_01 in BLOCK_TAG_SELECTION_1. (AI_FB_01 of Block Tag is

the factory default value. If it has been changed since factory shipment, set this

modified value)

2. Verify that BLOCK_TYPE_SELECTION_1 is now AI Function Block(0x0101).

3. Select 8:OUT for PARAM_SELECTION_1

4. For example, change DISPLAY_TAG_1, which is the tag to be displayed, to OUT.

For other displayable parameters, please refer to Table 5-3.

Note: If you change the Block Tag of the block that you are trying to set the display for, the

setting will not get properly implemented.

If you had changed the Block Tag, turn the device power off and then on again, or

write “4{Restart Processor}” to Resource Block’s RESTART section and then restart

your device.

5-8

Page 51

Several Parameter Display

Display Transducer Block can display a maximum of 4 parameters sequentially and

periodically. This section will explain the setting of displaying two parameters as an

example.

This explains how to set it to display the PV value of Flow Transducer Block and OUT

value of AI Function Block periodically.

- The factory default setting sets it so that it only displays the PV value of Flow

Transducer Block. In addition, if adding OUT value of AI Function Block as the second

parameter, enable bit1:Parameter 2 of the DISPLAY_PARAM_SELECTION.

DISPLAY_PARAM_SELECTION will change from the factory default 0x01 to 0x03.

- Next you will set BLOCK_TAG_SELECTION_2 to AI_FB_01. Verify that BLOCK_

TYPE_SELECTION_2 is now set to 0x0101 AI Function Block (AI_FB_01 of Block

Tag is the factory default value. If it has been changed since factory shipment, set this

modified value).

- Select 8:OUT for PARAM_SELECTION_2.

- Set the DISPLAY_TAG_2, a display tag, to OUT for example.

By conducting the above setting, it gets displayed periodically according to the following

sequence.

Seq. No. 1 2 3 4 5 6

Main Disp.

Aux. Disp

DisplayTime

FTB:PV

value

PRIMARY_

VALUE

5 5 5 5 5 5

FTB:PV

value

(Specified

Unit)

FTB:PV

value

(Status) OUT

AI:OUT

value

AI:OUT

value

(Specified

Unit)

AI:OUT

value

(Status)

Set the following to display the third parameter along with the above.

DISPLAY_PARAM_SELECTION: 0x07 (enable bit2:Parameter 3 as well)

BLOCK_TAG_SELECTION_3: set the Block Tag to be displayed

PARAM_SELECTION_3: select the parameter to be displayed

DISPLAY_TAG_3: set the Tag to be displayed

Set the following to display the fourth parameter as well.

DISPLAY_PARAM_SELECTION: 0x0f (enable bit3:Parameter 4 as well)

BLOCK_TAG_SELECTION_4: set the Block Tag to be displayed

PARAM_SELECTION_4: select the parameter to be displayed

DISPLAY_TAG_4: set the Tag to be displayed

Please refer to Appendix B for detail on Display Transducer Block parameters.

Note: If you change the Block Tag of the block that you are trying to set the display for, the

setting will not get properly implemented.

If you had changed the Block Tag, turn the device power off and then on again, or

write “4{Restart Processor}” to Resource Block’s RESTART section and then restart

your device.

5-9

Page 52

Status Display

Please refer to Table 5-5 for the status displayed by the string part.

Alarm Display

When an alarm is activated, the alarm display strings of Table 5-6 will get periodically

displayed.

Irregular Display

During OOS and main board communication error, the regular display will be switched to

irregular display.

OOS Display

When Display Transducer Block is OOS (Out Of Service), it will display the following.

Main Disp.

Aux. Disp

(upper)

(lower)

DISPLAY OFF

DISP TB O/S

Main Board Communication Error Display

When a main board communication error occurs inside the transmitter, the following

gets displayed.

Main Disp.

Aux. Disp

(upper)

(lower)

HW ERROR

COMM ERROR

Table 5-3 Display Transducer Block Displayable Parameter List

Block ProfileNumber Parameter Index Range Index

FlowTB 0x0113 PRIMARY_VALUE 15 PRIMARY_VALUE_RANGE 16

SECONDARY_VALUE 18

DiagTB 0x8018 SCALE_LEVEL 15 SCALE_LEVEL_RANGE 16

AI 0x0101 OUT 8 OUT_SCALE 11

PID 0x0108 OUT 9 OUT_SCALE 11

IN 15 PV_SCALE 10

CAS_IN 18 PV_SCALE 10

BKCAL_IN 27 OUT_SCALE 11

BKCAL_OUT 31 PV_SCALE 10

RCAS_IN 32 PV_SCALE 10

ROUT_IN 33 OUT_SCALE 11

RCAS_OUT 35 PV_SCALE 10

ROUT_OUT 36 OUT_SCALE 11

TRK_VAL 39 TRK_SCLAE 37

FF_VAL 40 FF_SCALE 41

AR 0x0127 OUT 8 OUT_RANGE 11

IN 14 PV_SCALSE 10

IN_LO 15 PV_SCALSE 10

IN1 16 PV_SCALSE 10

IN2 17 PV_SCALSE 10

IN3 18 PV_SCALSE 10

TOTALIZER 0x0144 OUT 9 OUT_RANGE 12

PRESET_IN 20 XD_RANGE 11

SECONDARY_VALUE_

RANGE

19

5-10

Page 53

Table 5-4 LUI Display Unit String List

Unit Code Unit String Displayed in LUI Description

1000 K Kelvin

1001 degC degree Celsius

1002 degF degree Fahrenheit

1003 degR degree Rankine

1034 m3 cubic meter

1036 cm3 cubic centimeter

1038 L liter

1048 gal US gallon

1049 ImpGal Imperial gallon

1051 bbl barrel

1088 kg kilogram

1089 g gram

1092 t metric ton

1094 lb pound (mass)

1130 Pa pascal

1131 GPa gigapascal

1132 Mpa megapascal

1133 kPa kilopascal

1134 mPa millipascal

1135 uPa micropascal

1136 hPa hectopascal

1137 bar bar

1138 mbar millibar

1139 torr torr

1140 atm atmospheres

1141 psi pounds per square inch

1142 psia pounds per square inch absolute

1143 psig pounds per square inch gauge

1144 gcm2 gram per square centimeter

1145 kgcm2 kilogram per square centimeter

1146 inH2O inches of water

1147 inH2O_4C inches of water at 4°C

1148 inH2O_68F inches of water at 68°F

1149 mmH2O millimeters of water

1150 mmH2O_4C millimeters of water at 4°C

1151 mmH2O_68F millimeters of water at 68°F

1152 ftH2O feet of water

1153 ftH2O_4C feet of water at 4°C

1154 ftH2O_68F feet of water at 68°F

1155 inHg inches of mercury

1156 inHg_0C inches of mercury at 0°C

1157 mmHg millimeters of mercury

1158 mmHg_0C millimeters of mercury at 0°C

1318 g/s gram per second

1319 g/min gram per minute

1320 g/h gram per hour

1321 g/d gram per day

1322 kg/s kilogram per second

1323 kg/min kilogram per minute

1324 kg/h kilogram per hour

1325 kg/d kilogram per day

1326 t/s metric ton per second

1327 t/min metric ton per minute

1328 t/h metric ton per hour

1329 t/d metric ton per day

1330 lb/s pound per second

5-11

Page 54

Unit Code Unit String Displayed in LUI Description

1331 lb/min pound per minute

1332 lb/h pound per hour

1333 lb/d pound per day

1334 STon/s short ton per second

1335 STon/min short ton per minute

1336 STon/h short ton per hour

1337 STon/d short ton per day

1338 LTon/s long ton per second

1339 LTon/min long ton per minute

1340 LTon/h long ton per hour

1341 LTon/d long ton per day

1342 % percent

1347 m3/ s cubic meter per second

1348 m3/min cubic meter per minute

1349 m3/ h cubic meter per hour

1350 m3/ d cubic meter per day

1351 L/s liter per second

1352 L/min liter per minute

1353 L/h liter per hour

1354 L/d liter per day

1355 ML/d megaliter per day

1356 CFS cubic feet per second

1357 CFM cubic feet per minute

1358 CFH cubic feet per hour

1359 ft3/d cubic feet per day

1360 SCFM standard cubic feet per minute

1361 SCFH standard cubic feet per hour

1362 gal/s US gallon per second

1363 GPM US gallon per minute

1364 gal/h US gallon per hour

1365 gal/d US gallon per day

1366 Mgal/d mega US gallon per day

1367 ImpGal/s Imperial gallon per second

1368 ImpGal/min Imperial gallon per minute

1369 ImpGal/h Imperial gallon per hour

1370 ImpGal/d Imperial gallon per day

1371 bbl/s barrel per second

1372 bbl/min barrel per minute

1373 bbl/h barrel per hour

1374 bbl/d barrel per day

1449 mgal/s milli US gallon per second

1450 kgal/s kilo US gallon per second

1451 Mgal/s mega US gallon per second

1453 mgal/min milli US gallon per minute

1454 kgal/min kilo US gallon per minute

1455 Mgal/min mega US gallon per minute

1457 mgal/h milli US gallon per hour

1458 kgal/h kilo US gallon per hour

1459 Mgal/h mega US gallon per hour

1461 mgal/d milli US gallon per day

1462 kgal/d kilo US gallon per day

1463 Mgal/d mega US gallon per day

1464 mImpGal/s milli imperial gallon per second

1465 kImpGal/s kilo imperial gallon per second

1466 MImpGal/s mega imperial gallon per second

1468 mImpGal/min milli imperial gallon per day

1469 kImpGal/min kilo imperial gallon per day

5-12

Page 55

Unit Code Unit String Displayed in LUI Description

1470 MImpGal/min mega imperial gallon per day

1472 mImpGal/h milli imperial gallon per hour

1473 kImpGal/h kilo imperial gallon per hour

1474 MImpGal/h mega imperial gallon per hour

1476 mImpGal/d milli imperial gallon per day

1477 kImpGal/d kilo imperial gallon per day

1478 MImpGal/d mega imperial gallon per day

1482 Mbbl/s megabarrel per second

1486 Mbbl/min megabarrel per minute

1490 Mbbl/h megabarrel per hour

1494 Mbbl/d megabarrel per day

1496 mm3/s cubic millimeter per second

1497 km3/s cubic kilometer per second

1498 Mm3/s cubic megameter per second

1500 mm3/min cubic millimeter per minute

1501 km3/min cubic kilometer per minute

1502 Mm3/min cubic megameter per minute

1504 mm3/h cubic millimeter per hour

1505 km3/h cubic kilometer per hour

1506 Mm3/h cubic megameter per hour

1508 mm3/d cubic millimeter per day

1509 km3/d cubic kilometer per day

1510 Mm3/d cubic megameter per day

1511 cm3/s cubic centimeter per second

1512 cm3/min cubic centimeter per minute

1513 cm3/h cubic centimeter per hour

1514 cm3/d cubic centimeter per day

1518 kL/min kiloliter per minute

1519 kL/h kiloliter per hour

1520 kL/d kiloliter per day

1522 Nm3/s Normal cubic meter per second

1523 Nm3/min Normal cubic meter per minute

1524 Nm3/h Normal cubic meter per hour

1525 Nm3/d Normal cubic meter per day

1527 Sm3/s Standard cubic meter per second

1528 Sm3/min Standard cubic meter per minute

1529 Sm3/h Standard cubic meter per hour

1530 Sm3/d Standard cubic meter per day

1532 NL/s Normal liter per second

1533 NL/min Normal liter per minute

1534 NL/h Normal liter per hour

1535 NL/d Normal liter per day

1537 SL/s Standard liter per second

1538 SL/min Standard liter per minute

1539 SL/h Standard liter per hour

1540 SL/d Standard liter per day

1589 mL/min milliliters per minute

1617 ML/h megaliter per hour

1618 ML/min megaliter per minute

1619 kL/s kiloliter per second

1620 kft3/ d cubic kilofeet per day

1621 kCFH cubic kilofeet per hour

1622 kCFM cubic kilofeet per minute

1623 kCFS cubic kilofeet per second

1624 mft3/ d cubic millifeet per day

1625 mCFH cubic millifeet per hour

1626 mCFM cubic millifeet per minute

5-13

Page 56

Unit Code Unit String Displayed in LUI Description

1627 mCFS cubic millifeet per second

1648 kgal kilogallon

1649 kImpGal kilo-imperial gallon

1653 Mft3/ d cubic Megafeet per day

1654 Mm3/ d cubic Megameters per day

Table 5-5 Display Transducer Block Display Status List

Quality Substatus Display String Status Detail

0 : Bad 0 Bad-Non_spec Non-specific

1 Bad-ConfigError Configuration Error

2 Bad-NotConnected Not Connected

3 Bad-DeviceFailur Device Failure

4 Bad-SensorFailur Sensor Failure

5 Bad-NoCommWitL No Comm, with LUV

6 Bad-NoCommWitN No Comm, no LUV

7 Bad-OutOfService Out of Service

8 Bad-TrnsducInMA Transducer in MAN

1 : Uncertain 0 Uncertn-Non_spec Non-specific

1 Uncertn-LUV Last Usable Value

2 Uncertn-Substtut Substitute / Manual Entry

3 Uncertn-InitValu Initial Value

4 Uncertn-S-CvNotA Sensor Conversion not Accurate

5 Uncertn-EgUnRaV Engineering Unit Range Violation

6 Uncertn-SubNoma Sub-normal

7 Uncertn-TrdInMA Transducer in MAN

2 : GOOD(NC) 0 GOOD-NC-Non_sp Non-specific

1 GOOD-NC-ActBkA Active Block Alarm

2 GOOD-NC-ActAdA Active Advisory Alarm

3 GOOD-NC-ActCrA Active Critical Alarm

4 GOOD-NC-UakBk Unack Block Alarm

5 GOOD-NC-UakAd Unack Advisory Alarm

6 GOOD-NC-UakCr Unack Critical Alarm

8 GOOD-NC-IFS Initiate Fault State(IFS)

3 : GOOD(C) 0 GOOD-C-Non_spec Non-specific

1 GOOD-C-InitAck Initialization Acknowledge

2 GOOD-C-InitReq Initialization Request

3 GOOD-C-NotInvit Not Invited

4 GOOD-C-NotSelct Not Selected

6 GOOD-C-LoclOvrr Local Override

7 GOOD-C-FaltStAc Fault State Active

8 GOOD-C-IFS Initiate Fault State(IFS)

5-14

Page 57

Table 5-6 Display Transducer Block Display Alarm List

FD_xxx_ACTIVE Bit Display String Description

0 Check Check Function Bit

1 Not used

2 Not used

3 Not used

4 Gain Calibration Gain Calibration

5 Zero Calibration Zero Calibration

6 Fixed EX Current Fixed EX Current

7 Touch-Key Active Touch-Key Active

8 Not used

9 Not used

10 Not used

11 Not used

12 Not used

13 Zero Calib. Fail Zero Calib. Failure

14 Scale Detected Scale Detected

15 Not Calibrated Not Calibrated

16 Not used Not used

17 Not used Not used

18 Not used Not used

19 Not used Not used

20 Not used Not used

21 Not used Not used

22 Empty Detected Empty Detected

23 Flow Rate Over Flow Rate Over

24 Not used Not used

25 Not used Not used

26 Not used Not used

27 Not used Not used

28 MainBoardCommErr MainBoardCommunicationError

29 Extube Coil Open Extube Coil Open

30 Main Board Fail Main Board Failure

31 FFopt Board Fail FF Option Board Failure

5-15

Page 58

Diag Transducer Block

S

Overview of function

Diag Transducer Block calculates values for diagnosing the integrity of the flow rate signal

based on the sensor output from the electromagnetic flowmeter.