Page 1

CM2-MGG200-2001

MagneW FLEX+/PLUS+

Electromagnetic Flowmeter Detector

Model MGG11/18/MGG12/19/MGF11/MGS11U/28U

User’s Manual

Page 2

NOTICE

While the information in this manual is presented in good faith and

believed to be accurate, Azbil Corporation disclaims any implied

warranty of merchantability or tness for a particular purpose and

makes no express warranty except as may be stated in its written

agreement with and for its customer.

In no event shall Azbil Corporation be liable to anyone for any indirect,

special or consequential damages. is information and specications

in this document are subject to change without notice.

MagneW is a trademark of Azbil Corporation in Japan and/or other

countries.

© 1997-2019 Azbil Corporation. All Rights Reserved.

Page 3

Safety

About This Manual

This manual contains information and warnings that must be observed to keep the

model MGG/MGS Electromagnetic Flowmeter Detector operating safely. Correct

installation, correct operation and regular maintenance are essential to ensure safety

while using this device.

In addition to this model MGG/MGS detector user manual, please refer to model

MGG10C/14C converter user’s manual for start-up, calibration, trouble-shooting,

operation, and maintenance of the complete Electromagnetic Flowmeter.

For the correct and safe use of this device it is essential that both operating and

service personnel follow generally accepted safety procedures in addition to the safety

precautions specied in this manual.

The following symbols are used in this manual to alert you to possible hazards:

Denotes a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

WARNING

Failure to observe these precautions may produce dangerous conditions that could

result in operator injury or in physical damage to the device.

Safety Messages

Carefully read this section before in stalling or operating this device.

To prevent the gas or liquid in the pipe from escaping, do not remove the

electrode cover or the electrodes when the detector is installed on a pipe.

ELECTRIC SHOCK HAZARD! Turn the power supply o before wiring.

CAUTION

WARNING

WARNING

WARNING

This detector is heavy. Dropping it could cause personal injury or damage to the

device.

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector i

Page 4

Safety Azbil Corporation

WARNING

Before removing the unit, make sure that there is no residual liquid or pressure

inside the piping and the detector to avoid personal injury or damage to the unit.

CAUTION

The detector must be grounded (grounding reference is <100 W) to avoid output

uctuation, zero point instability or output drift.

CAUTION

The installation location must satisfy the following conditions to avoid output

errors and uctuations.

At the installation location:

• The electrical conductivity of the uid to be measured must match the stated

specication (specs vary according to the converter used) and be more or less

constant.

• The uid to be measured must be electrochemically homogenized. For example,

if two uids are mixed at an upstream point, the device should be installed at

a point so that the two uids can be evenly mixed by the time they reach the

measuring point.

• The distribution of additive matter, if any, must be nearly uniform.

CAUTION

To avoid measurement problems, do not use the MagneW

FLEX+/PLUS+ to measure

the following uids, even if their electrical conductivity, temperature and pressure

fall within the specications.

• Fluids that have sucient electrical conductivity at high temperatures but do not

satisfy the conductance requirements at room temperature (about 20°C (68°F)).

For example, fatty acids or soap.

• Certain uids that contain surfectants. For example, rinses, shampoos, CWM.

• Conductive adherents. For example, deposition of rosin or conductive material.

• Insulating adherents. For example, oil, kaolinite, kaolin, or calcium stearate.

CAUTION

This model MGG/MGS detector can only be connected to Azbil Corporation's

model MGG10C/14C converter.

No other types of converters can be used with the device.

ii MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 5

Azbil Corporation Safety

CAUTION

If the pipe is not lled, output errors will occur.

CAUTION

Do not rotate the unit more than 180° (one half rotation). Any further rotation can

disconnect wiring.

After removing the screws, do not pull on the terminal box. You can break the

lead wire.

When you move the terminal box, make sure the O-ring remains in the groove to

insure an air-tight seal when the unit is reassembled.

CAUTION

Before installing the detector, make sure any foreign matter is ushed from

the interior passage of the detector. Residual foreign matter could cause output

uctuations.

Do not touch the electrodes or allow oil or fat to come into contact with them to

avoid output uctuations.

Align the direction mark on the detector in the direction of the liquid ow.

Misalignment can result in a negative output.

CAUTION

The correct fastening torque must be used to prevent leakage. To avoid damage to

the detector, do not exceed the listed fastening torque.

CAUTION

Before installing the detector, make sure that the pipe is exactly straight and

centered. Any irregularity could cause leakage or other hazards.

CAUTION

Never attempt to force the detector between two anges if the space is too narrow.

It can damage the detector.

CAUTION

Make certain the bore diameters of the pipe and the detector are exactly the same

and install the detector so that the gasket does not protrude into the internal bore

of the pipe, as this could result in leakage or other hazards.

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector iii

Page 6

Safety Azbil Corporation

CAUTION

Tighten each bolt a little at a time and apply uniform pressure to all the bolts.

If leakage continues after tightening the bolts, make sure that the pipe is not o

center, then continue to tighten each bolt a little at a time.

CAUTION

Using a gasket with too small a diameter can aect the ow velocity distribution,

resulting in inaccurate measurement.

Using a gasket with too large a diameter can cause leakage. Also, any solid

substance in the uid to be measured could accumulate between the gasket and the

ange, resulting in inaccurate measurement.

CAUTION

The necessary materials and the installation method vary according to the material

of the ring and that of the pipe on which the detector is to be installed. Select the

appropriate method of installation from the following table after conrming the

specications of the detector to be installed and the conditions of installation.

Improper installation can result in leakage or damage to the pipe anges.

CAUTION

The use of anything other than the PTFE gaskets provided can result in leakage.

The use of rubber gaskets is not recommended and can cause leakage.

CAUTION

The use of rubber gaskets and a lower fastening torque is not recommended and

can cause insucient surface pressure between the lining and the grounding ring,

resulting in leakage.

CAUTION

Insucient grounding can cause output uctuations, instability of the zero point,

or output drift. Secure single point grounding with a grounding resistance of 100

W or less is recommended.

Do not ground a welder to the detector to avoid damaging the detector.

iv MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 7

Table of Contents

Chapter 1 : Introduction

1.1 : Principle of operation ......................................................................................... 1-1

1.2 : System operation ............................................................................................... 1-2

1.2.1: Integral type ........................................................................................................ 1-2

1.2.2: Remote type ........................................................................................................ 1-3

1.3 : Main components .............................................................................................. 1-4

1.3.1: Wafer type detector ............................................................................................. 1-5

1.3.2: Flange type detector ........................................................................................... 1-6

1.3.3: Union / Hose / Clamp type detector .................................................................... 1-7

1.3.4: Sanitary type detector ......................................................................................... 1-8

1.3.5: Detector terminal box .......................................................................................... 1-9

1.3.6: Approval of this device ........................................................................................ 1-10

Chapter 2 : Installation

2.1 : Unpacking .......................................................................................................... 2-1

2.1.1: Verifying specications ........................................................................................ 2-1

2.2 : Storage .............................................................................................................. 2-2

2.3 : Site selection ..................................................................................................... 2-3

2.3.1: Detector position ................................................................................................. 2-4

2.3.2: Changing the position of the terminal box ........................................................... 2-5

2.4 : Installing a wafer detector .................................................................................. 2-6

2.4.1: Determining the fastening torque ........................................................................ 2-7

2.4.2: Selecting the ange shape .................................................................................. 2-7

2.4.3: Necessary parts .................................................................................................. 2-9

2.4.4: Selecting an installation method ......................................................................... 2-12

2.4.5: Installation on a horizontal pipe ........................................................................... 2-13

2.4.6: Installation on a vertical pipe ............................................................................... 2-14

2.4.7: Installation on a metal pipe using SUS grounding ring material .......................... 2-15

2.4.8: Installation on a metal pipe using non-SUS grounding ring material .................. 2-16

2.4.9: Installation on a PVC pipe using SUS grounding ring material ........................... 2-19

2.4.10: Installation on a PVC pipe using non-SUS grounding ring material .................. 2-22

2.5 : Installing a anged detector ............................................................................... 2-25

2.5.1: Determining the fastening torque ........................................................................ 2-26

2.5.2: Necessary parts .................................................................................................. 2-31

2.5.3: Selecting an installation method ......................................................................... 2-32

2.5.4: Installation on a metal pipe using SUS grounding ring material .......................... 2-33

2.5.5: Installation on a metal pipe using non-SUS grounding ring material .................. 2-34

2.5.6: Installation on a PVC pipe using SUS grounding ring material ........................... 2-35

2.5.7: Installation on a PVC pipe using non-SUS grounding ring material .................... 2-39

2.6 : Installing a Union / Hose / Clamp Detector ........................................................ 2-43

2.6.1: Installation of Union and Hose assemblies basic installation method ................. 2-43

2.6.2: Installation of ISO-clamp/ Tri-clamp assembles basic installation method ......... 2-44

2.7 : Wiring the detector ............................................................................................. 2-46

2.7.1: Connecting the detector and converter (Remote models) .................................. 2-46

2.7.2: Grounding the detector (Remote models) ........................................................... 2-47

2.7.3: Installing the dedicated cable .............................................................................. 2-47

2.8 : Troubleshooting and maintenance .................................................................... 2-56

Page 8

Table of Contents

Page 9

Table of Contents

Page 10

List of Figure

Figure 1-1 Faraday’s law..................................................................................................... 1-1

Figure 1-2 Integral conguration......................................................................................... 1-2

Figure 1-3 Remote Conguration......................................................................................... 1-3

Figure 1-4 Wafer detector main parts .................................................................................. 1-5

Figure 1-5 Flange detector main parts ................................................................................ 1-6

Figure 1-6 Union / Hose / Clamp detector main parts......................................................... 1-7

Figure 1-7 Details of the clamp type detector ...................................................................... 1-8

Figure 1-8 Detector terminal box main parts ...................................................................... 1-9

Figure 2-1 Detector placement ............................................................................................. 2-4

Figure 2-2 Straight pipe section on upstream side of detector ............................................ 2-4

Figure 2-3 Space allowance required for maintenance ....................................................... 2-5

Figure 2-4 Repositioning the terminal box........................................................................... 2-5

Figure 2-5 Installing a wafer detector ................................................................................. 2-6

Figure 2-6 Flange Shapes .................................................................................................... 2-7

Figure 2-7 Unacceptable positioning ................................................................................... 2-8

Figure 2-8 Unacceptable placement of detector between anges ........................................ 2-8

Figure 2-9 Centering nut positioning for horizontal centering ............................................ 2-9

Figure 2-10 Centering nut positioning for vertical centering ................................................ 2-9

Figure 2-11 Installation on a metal pipe using SUS grounding ring material and a specied

torque................................................................................................................ 2-15

Figure 2-12 Installation on a metal pipe using non-SUS grounding ring material and a

specied torque................................................................................................. 2-16

Figure 2-13 Installation on a metal pipe using non-SUS grounding ring material with rubber

gaskets .............................................................................................................. 2-17

Figure 2-14 Incorrect installation ........................................................................................ 2-18

Figure 2-15 Installation on a PVC pipe using SUS grounding ring material ...................... 2-19

Figure 2-16 Installation on a PVC pipe using SUS grounding ring material and a protective

plate .................................................................................................................. 2-20

Figure 2-17 Installation on a PVC pipe using SUS grounding ring material with rubber

gaskets (Not recommended) ............................................................................. 2-21

Figure 2-18 Installation on a PVC pipe using non-SUS grounding ring material .............. 2-22

Figure 2-19 Installation on a PVC pipe using non-SUS grounding ring material and a

protective plate ................................................................................................. 2-23

Figure 2-20 Installation on a PVC pipe using non-SUS grounding ring material with rubber

gaskets .............................................................................................................. 2-24

Figure 2-21 Installing a anged detector ............................................................................. 2-25

Figure 2-22 Flange Shapes .................................................................................................. 2-30

Figure 2-23 Unacceptable Placement of Detector Between Flanges .................................. 2-30

Figure 2-24 Installation on a metal pipe using SUS grounding ring material and a specied

torque................................................................................................................ 2-33

Figure 2-25 Installation on a metal pipe using non-SUS grounding ring material and a

specied torque................................................................................................. 2-34

Figure 2-26 Incorrect installation ........................................................................................ 2-35

Figure 2-27 Installation on a PVC pipe using SUS grounding ring material and a specied

torque................................................................................................................ 2-36

Page 11

List of Figure

Figure 2-28 Installation on a PVC pipe using SUS grounding ring material and a protective

plate .................................................................................................................. 2-37

Figure 2-29 Installation on a PVC pipe using SUS grounding ring material with rubber

gaskets (not recommended) .............................................................................. 2-38

Figure 2-30 Installation on a PVC pipe using Non-SUS grounding ring material and a

specied torque................................................................................................. 2-40

Figure 2-31 Installation on a PVC pipe using non-SUS grounding ring material and a

protective plate ................................................................................................. 2-41

Figure 2-32 Installation on a PVC pipe using non-SUS grounding ring material with rubber

gaskets .............................................................................................................. 2-42

Figure 2-33 Example of installation (union assembly) ........................................................ 2-44

Figure 2-34 Example of installation ..................................................................................... 2-44

Figure 2-35 Connection using a dedicated cable ................................................................. 2-46

Figure 2-36 Grounding via the external grounding terminal .............................................. 2-47

Figure 2-37 Connection using a dedicated cable ................................................................. 2-47

Figure 2-38 Dedicated cable structure ................................................................................ 2-48

Figure 2-39 Trimming the outside sheath ............................................................................ 2-48

Figure 2-40 Attaching the C-wire ........................................................................................ 2-49

Figure 2-41 Trimming the outside shield ............................................................................. 2-49

Figure 2-42 Trimming the inside sheath .............................................................................. 2-50

Figure 2-43 Attaching the lead wires (SA and SB) .............................................................. 2-50

Figure 2-44 Trimming the inside shield ............................................................................... 2-51

Figure 2-45 Removing the conductive tube .......................................................................... 2-51

Figure 2-46 Trimming the insulator ..................................................................................... 2-51

Figure 2-47 Terminal connections ....................................................................................... 2-52

Figure 2-48 Trimming the outside sheath ............................................................................ 2-53

Figure 2-49 Attaching the C-wire ........................................................................................ 2-53

Figure 2-50 Trimming the outside shield ............................................................................. 2-54

Figure 2-51 Trimming the inside sheath .............................................................................. 2-54

Figure 2-52 Attaching the lead wires (SA and SB) .............................................................. 2-54

Figure 2-53 Attaching the lead wires (SA and SB) .............................................................. 2-55

Figure 2-54 Terminal connections ....................................................................................... 2-56

Page 12

List of Figure

Page 13

List of Table

Table 2-1 Fastening torque for wafer detectors ............................................................................... 2-7

Table 2-2 Recommended inner diameters of gaskets ...................................................................... 2-10

Table 2-3

Table 2-4

Table 2-5 Wafer detector installation methods ................................................................................ 2-12

Table 2-6 Fastening torque for anged detectors ............................................................................ 2-26

Table 2-7 Recommended inner diameters of gaskets ...................................................................... 2-31

Table 2-8 Flange detector installation methods ............................................................................... 2-32

Table 2-9 Fastening torque .............................................................................................................. 2-43

Table 2-10 Cable continuity .............................................................................................................. 2-52

Table 2-11 Cable continuity .............................................................................................................. 2-52

Table 2-12 Cable continuity .............................................................................................................. 2-56

Table 2-13 Cable continuity .............................................................................................................. 2-56

Inner and outer diameters of rubber gaskets of thickness 0.5 to 1 mm (0.02 to 0.04 inches)

Inner and outer diameters of rubber gaskets of thickness 3 to 4 mm (0.12 to 0.16 inches)

... 2-11

...... 2-11

Page 14

List of Table

Page 15

Chapter 1 : Introduction

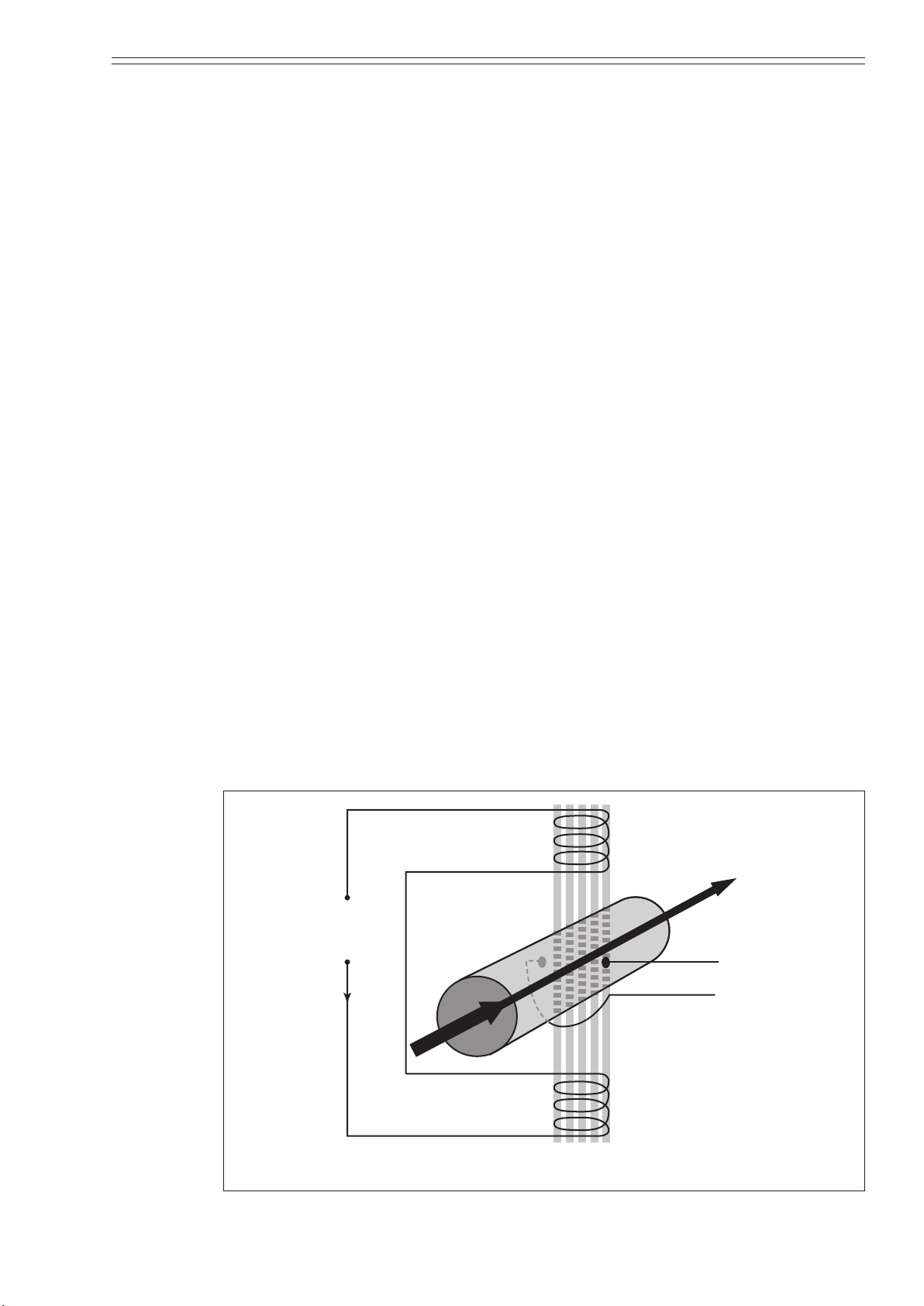

Induced voltage (E)

Excitation

1.1 : Principle of operation

The owmeter consists of two parts: a detector which is mounted in the pipeline and

through which the measured liquid ows, and a converter which may be mounted

either integral with the detector or separately. The converter conditions and outputs

the electrical signal from the detector or separately. The converter conditions and

outputs the electrical signal from the detector.

The owmeter works based on the principle of Faraday’s law of electromagnetic

induction, which states that if an electrical conductor, in this case the measured

conductive liquid, passes through a magnetic eld a small electromotive force (EMF)

is induced perpendicular to the eld and ow (refer to Figure 1-1).

Faraday’s law:

E = k BDV when

E = Induced voltage (EMF)

B = Strength of the magnetic eld

D = Conductor width (electrode spacing)

V = Velocity of the conductor

k = Correction factor

This induced EMF is proportional to the average ow rate and is detected by

two electrodes (E

converter.

The only variable in this application of Faraday’s law is the ow rate (V) of the

conductive measured liquid, because eld strength (B), is controlled constant and

electrode spacing (D) is xed.

Therefore, the output electromotive force is directly proportional to liquid ow rate,

resulting in the linear output of a magnetic owmeter.

and E2) mounted in the wall of the detector and then fed to the

1

Magnetic

field (B)

Flow rate (V)

voltage

supply

Measuring fluid

E1

E2

Figure 1-1 Faraday’s law

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 1-1

Page 16

Introduction Azbil Corporation

1.2 : System operation

Introduction

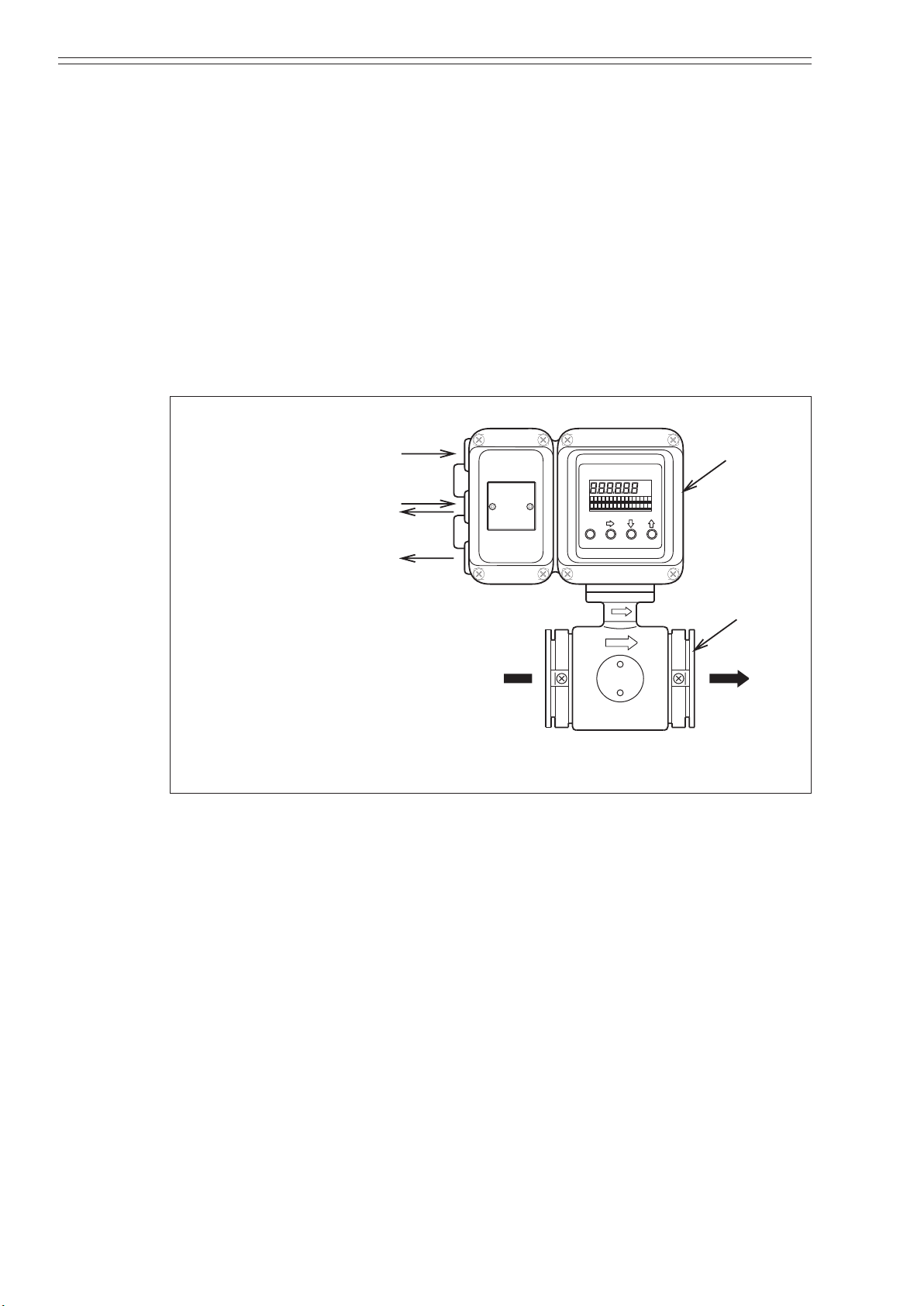

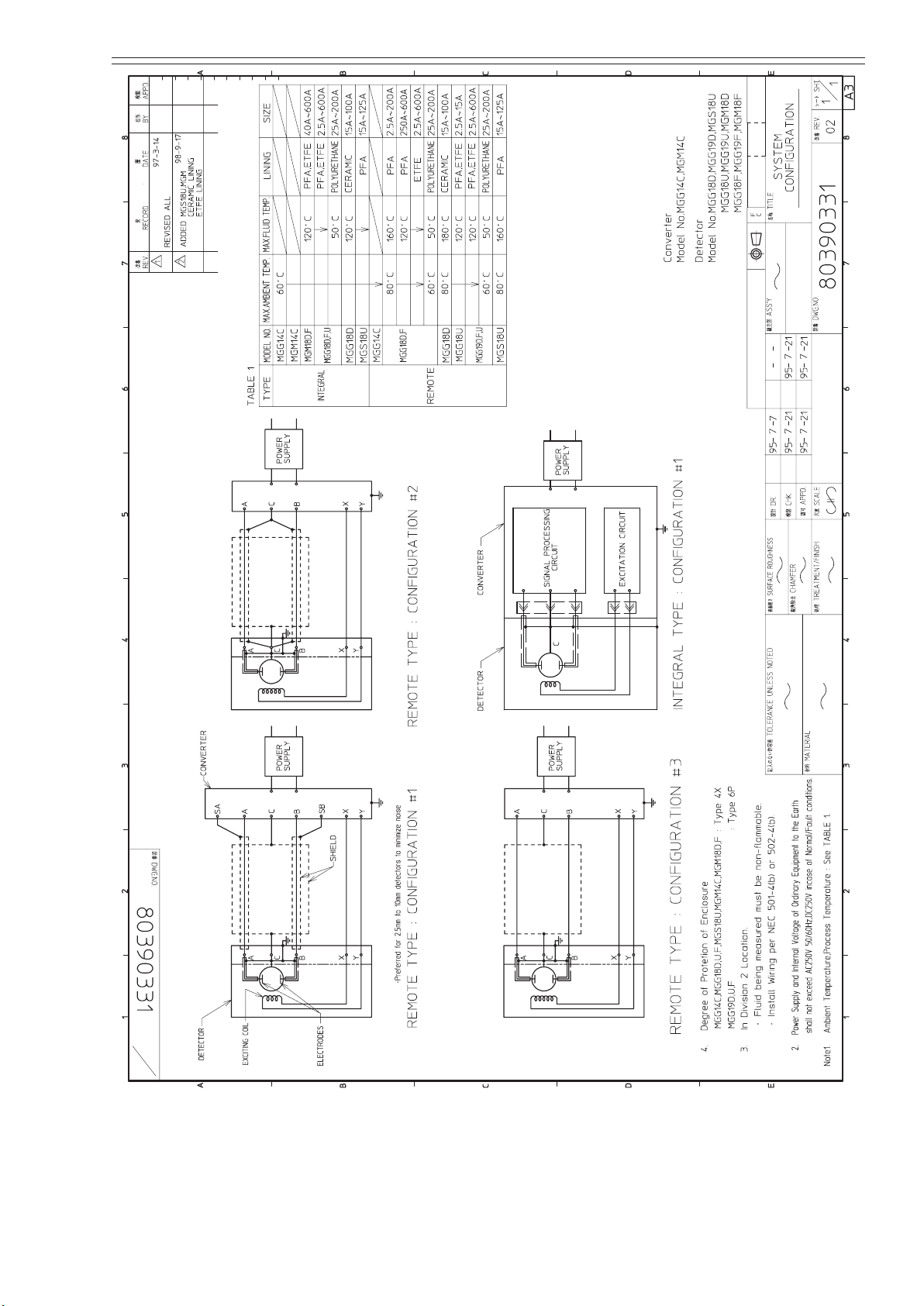

Depending on how it is combined with the converter, this product is available in two

congurations, integral and remote.

• Integral: Detector and converter are installed as an integrated unit on a pipe.

• Remote: Detector and converter are installed connected by cable.

1.2.1: Integral type

Figure 1-2 and Figure 1-3 show examples of measurement systems using the device.

/

Figure 1-2 Integral conguration

1-2 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 17

Azbil Corporation Introduction

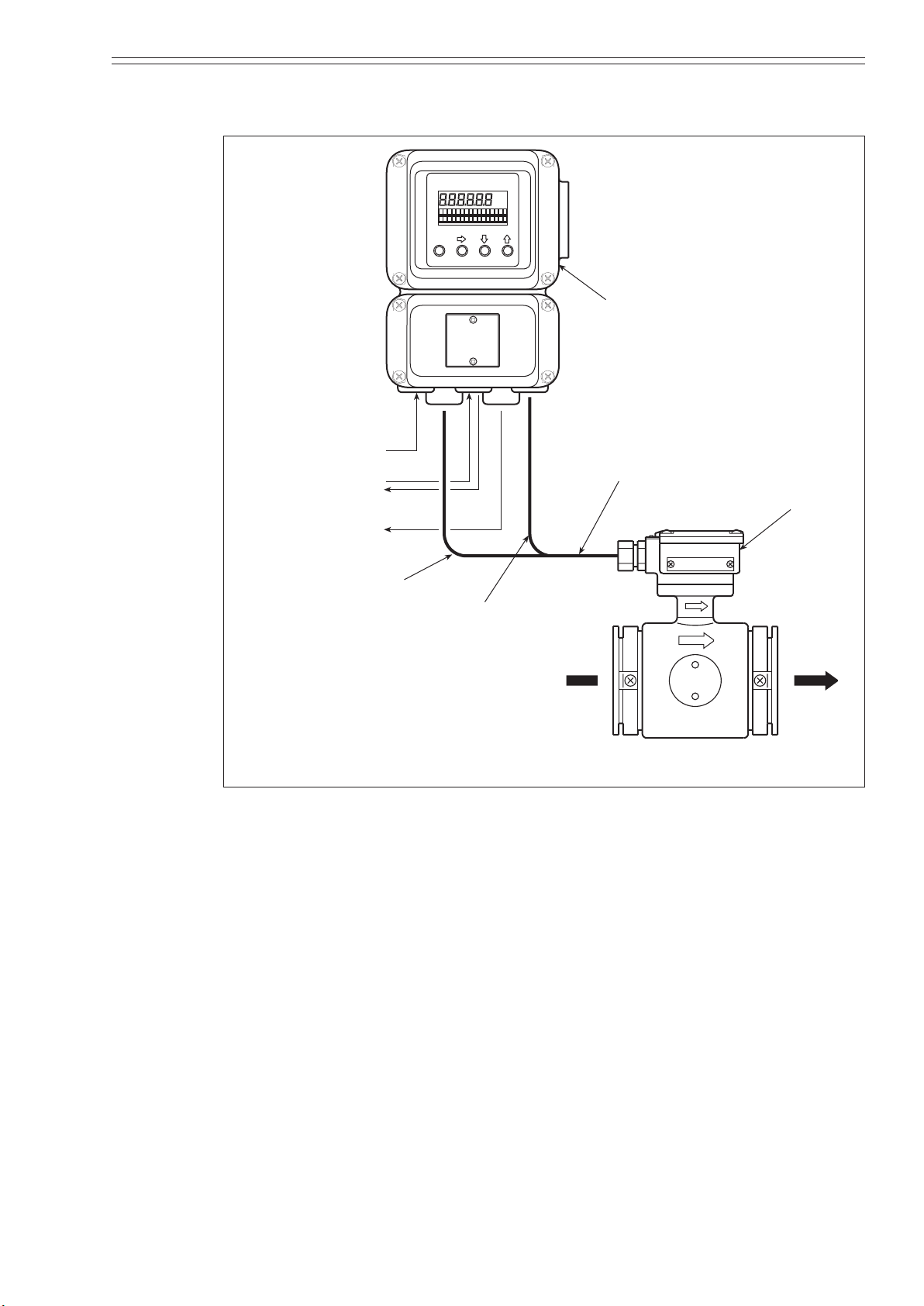

Contact input/output

1.2.2: Remote type

Converter

AC power supply

Pulse output,

Analog output/

Digital output

Dedicated cable

Detector

Excitation output

Flow signal input

Direction of fluid

Figure 1-3 Remote Conguration

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 1-3

Page 18

Introduction Azbil Corporation

1.3 : Main components

Detector

There are three types of model MGG/MGS Electromagnetic Flowmeter Detectors:

Wafer detectors, Flange detector, and Union / Hose / Clamp detector. The type of

detector you choose depends on your specic installation requirements. All types of

detectors function such that when a conductive uid passes through the detectors, an

electromotive force signal proportional to the ow rate is generated.

WARNING

To prevent the gas or liquid in the pipe from escaping, do not remove the

electrode cover or the electrodes when the detector is installed on a pipe.

1-4 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 19

Azbil Corporation Introduction

Grounding terminal

Waterproof gland

Grounding ring

Mounting screw (4 places)

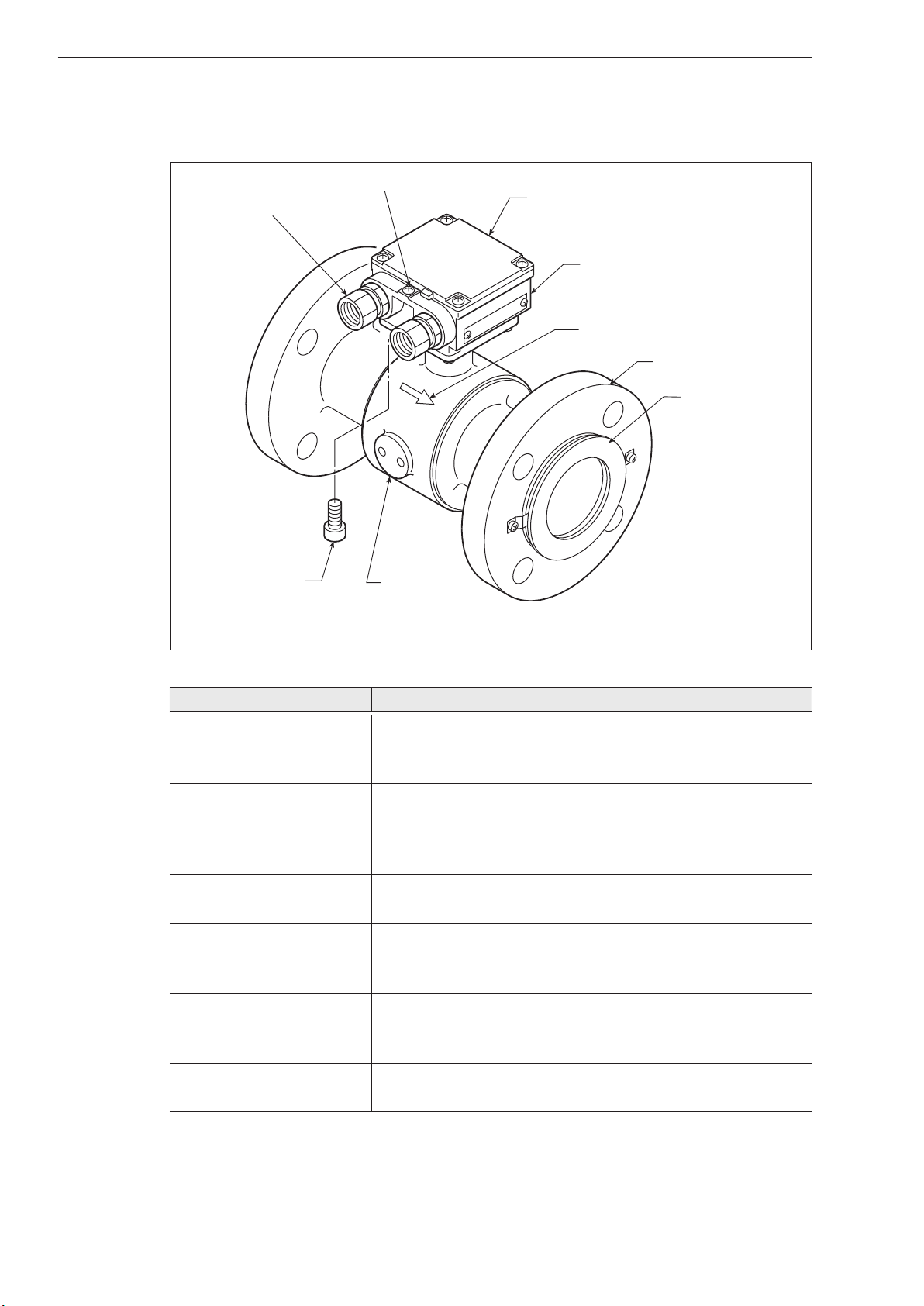

1.3.1: Wafer type detector

A wafer detector consists of the components shown in the gure below.

Terminal box cover

Terminal box

Flow direction mark

Electrode cover

Figure 1-4 Wafer detector main parts

Name Function

Flow direction mark Indicates the direction of uid ow.

Mount the detector so that the measured uid ows in the

direction indicated by this mark.

Electrodes Detect an electromagnetic force signal proportional to the

ow rate of the uid passing through the detector.

The electrode material varies depending on the corrosion

characteristics of the uid to be measured.

Electrode cover Houses the electrodes. Do not remove the cover with the

detector installed on a pipe.

Grounding rings Keep reference voltage as zero by grounding the unit.

The grounding ring material varies depending on the

corrosion characteristics of the uid to be measured.

Terminal box

(Remote model only)

Houses the connection terminals used for applying

a standard voltage. Houses the excitation and signal

terminals.

Terminal box cover

(Remote model only)

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 1-5

Keeps the terminals dry and protected. Keep the terminal

box cover on during operation.

Page 20

Introduction Azbil Corporation

Mounting screw

(4 places)

Grounding terminal

Grounding ring

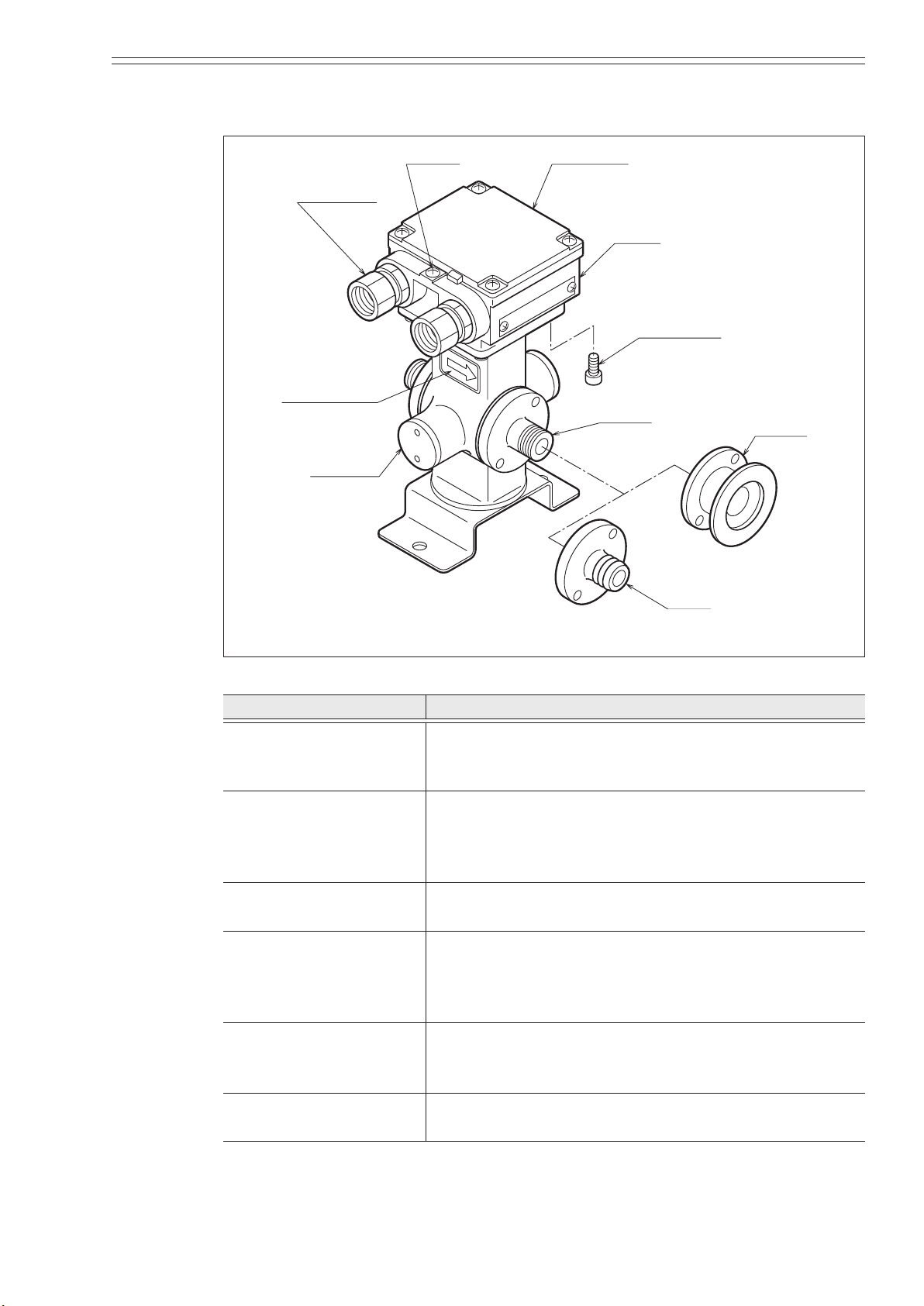

1.3.2: Flange type detector

A Flange detector consists of the components shown in the gure below.

Waterproof gland

Terminal box cover

Terminal box

Flow direction mark

Flange

Electrode cover

Figure 1-5 Flange detector main parts

Flow direction mark Indicates the direction of uid ow. Mount the detector

Electrodes Detect an electromagnetic force signal proportional to

Electrode cover Houses the electrodes. Do not remove the cover with the

Grounding rings Keep reference voltage as zero by grounding the unit.

Terminal box

(Remote model only)

Terminal box cover

(Remote model only)

Name Function

so that the measured uid ows in the direction indicated

by this mark.

the ow rate of the uid passing through the detector.

The electrode material varies depending on the corrosion

characteristics of the uid to be measured.

detector installed on a pipe.

The grounding ring material varies depending on the

corrosion characteristics of the uid to be measured.

Houses the connection terminals used for applying

a standard voltage. Houses the excitation and signal

terminals.

Keeps the terminals dry and protected. Keeps the

terminal box cover on during operation.

1-6 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 21

Azbil Corporation Introduction

Grounding terminal

Terminal box cover

1.3.3: Union / Hose / Clamp type detector

Waterproof

gland

Terminal box

Mounting screw(4 places)

Flow direction

mark

Union

Electrode

cover

Clamp

Hose

Figure 1-6 Union / Hose / Clamp detector main parts

Name Function

Flow direction mark Indicates the direction of uid ow.

Mount the detector so that the measured uid ows in the

direction indicated by this mark.

Electrodes The electrodes generate an electromotive force signal

proportional to the ow rate of the uid passing through

the detector. The electrode material varies depending on

the corrosion characteristics of the uid to be measured.

Electrode cover Houses the electrodes. Do not remove the cover with the

detector installed on a pipe.

Union (Connected by

screws)

Hose

The connection uses a union, hose, and clamp. The

material is SUS316.

Applicable for detector bore diameters of 2.5 to 15 mm.

Clamp

Terminal box

(Remote model only)

Houses the connection terminals used to apply a standard

voltage.

Houses excitation and signal terminals.

Terminal box cover

Keeps the terminals box cover on during operation.

(Remote model only)

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 1-7

Page 22

Introduction Azbil Corporation

Terminal box

Grounding

Mounting screw

Flow direction mark

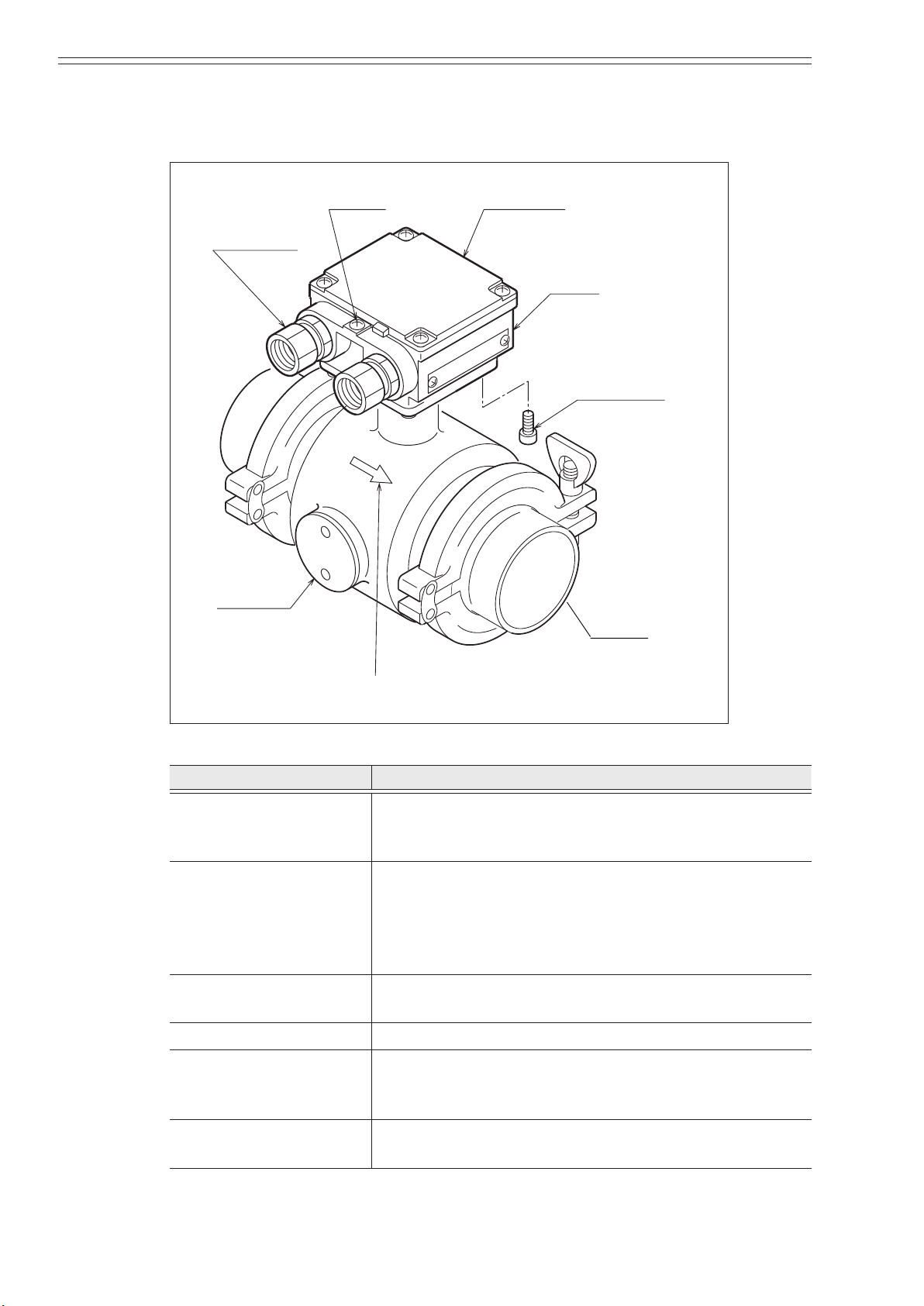

1.3.4: Sanitary type detector

Figure 1-7 shows the structure of the detector and the names of its major parts.

Waterproof

gland

Electrode

cover

terminal

cover

Terminal

box

(4 places)

Ferrule

Figure 1-7 Details of the clamp type detector

Name Function

Flow direction mark Indicates the direction of uid ow.

Mount the detector so that the measured uid ows in the

direction indicated by this mark.

Electrodes The electrodes generate an electromotive force signal

proportional to the ow rate of the uid passing through

the detector.

The electrode material varies depending on the corrosion

characteristics of the uid to be measured.

Electrode cover Houses the electrodes. Do not remove the cover with the

detector installed on a pipe.

Clamp Clamp structure varies IDF clamp and tri-clamp.

Terminal box

(Remote model only)

Houses the connection terminals used to apply a standard

voltage.

Houses excitation and signal terminals.

Terminal box cover

Keeps the terminals box cover on during operation.

(Remote model only)

1-8 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 23

Azbil Corporation Introduction

Grounding terminal

Excitation terminals

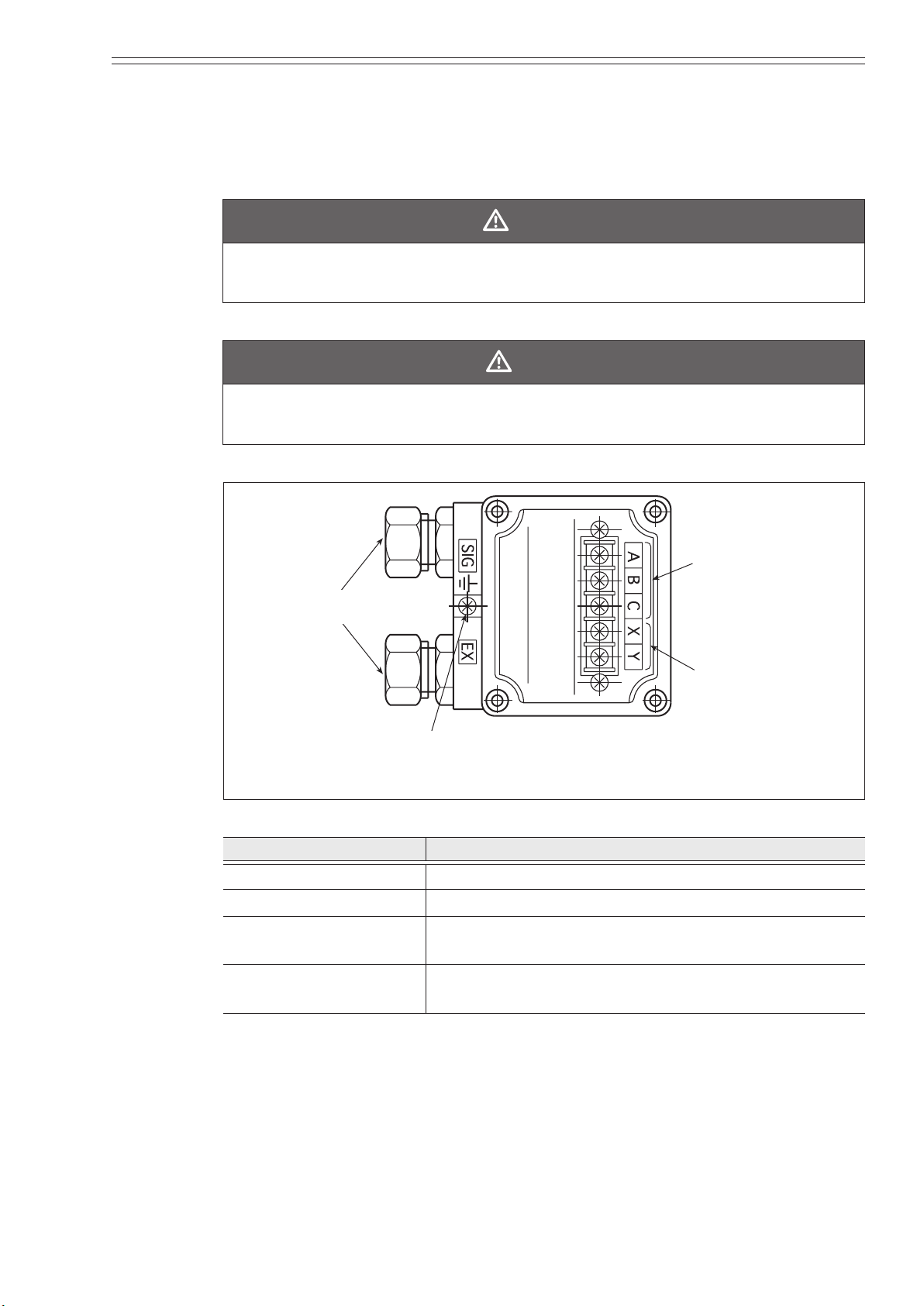

1.3.5: Detector terminal box

The detector terminal box houses the connection terminals used for applying a

standard voltage. Houses the excitation and signal terminals.

WARNING

ELECTRIC SHOCK HAZARD! Turn o power to the converter side before

wiring.

CAUTION

The detector must be grounded (grounding resistance is <100 W) to avoid output

uctuation, zero point instability or output drift.

Signal terminals

Conduit wiring

connectors

Figure 1-8 Detector terminal box main parts

Name Function

Signal terminals Marked A, B and C.

Excitation terminals Marked X and Y.

Conduit wiring

connectors

The excitation cable and the signal cable are wired

through these connectors.

Grounding terminal This terminal is used to ground the detector (grounding

resistance is <100 W).

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 1-9

Page 24

Introduction Azbil Corporation

1.3.6: Approval of this device

Overview

If 1/2 NPT wiring connection is selected, this device functions as an FM/CSA, nonincendive -approved model. In this case, the installation standards described in this

section must be followed.

Installation of this device

FM/CSA Nonincendive model

THIS EQUIPMENT IS SUITABLE FOR USE IN CLASS I, DIVISION 2, GROUPS

(A, B, C, D), CLASS II/III, DIVISION 2, GROUPS (F, G), OR NON-HAZARDOUS

LOCATIONS ONLY.

CAUTION

(1) Power supply and internal voltage of ordinary equipment to the earth shall not

exceed 250 V AC 50/60 Hz, 250 V DC in case on normal / formal conditions.

(2) Ambient temperature is from -25 to 60°C

(3) Process temperature is from -40 to 160°C (Remote model).

Process temperature is from -40 to 120°C (Integral model)

1-10 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 25

Azbil Corporation Introduction

If an MGG18/19 detector is used with an MGG14C converter as an FM-approved

nonincendive product, both the detector and the converter should be FM-approved

nonincendive products.

If they are not, the MGG18/19 detector cannot be used as an FM-approved

nonincendive product.

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 1-11

Page 26

Introduction Azbil Corporation

1-12 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 27

Chapter 2 : Installation

This section describes unpacking, installation and wiring of the MagneW FLEX+/

.

PLUS+

Depending on the grounding ring or piping material, the required parts or the method

of device installation vary.

2.1 : Unpacking

This device is a precision instrument and should be handled with care to prevent

damage or breakage.

WARNING

This detector is heavy. Dropping it could cause personal injury or damage to the

device.

After unpacking the unit, verify that the following items are present:

• MagneW

• Standard accessories

• Precautions for installation sheet

FLEX+/PLUS+ Detector

2.1.1: Verifying specications

The specications for this device are written on its attached identication plate.

Compare these specications with those listed in Appendix A, device standard

specications and model numbers, and verify that all specications on the plate are

correct, paying special attention to the following:

• Detector size

• Electrode material

• Lining material

• Flange rating

• Grounding ring material

If you have questions regarding the specications of your device, contact your nearest

Azbil Corporation oce or the azbil Group representative. When making an inquiry,

be sure to provide the model number and product number of this device.

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-1

Page 28

Installation Azbil Corporation

2.2 : Storage

WARNING

Before removing the unit, make sure that there is no residual liquid or pressure

inside the piping and the detector to avoid personal injury or damage to the unit.

When storing this device:

• Store the device indoors at room temperature and humidity, in a place safe from

vibration or shock.

• Store the device in the same condition as it was shipped.

When storing this device after use:

(1) Rinse the inside of the detector with water to remove residual uids and then

allow it to dry.

(2) Firmly attach the terminal box cover and the electrode cover in order to keep out

moisture.

(3) Replace the detector in its original packaging.

(4) Store the device indoors at room temperature and humidity, in a place safe from

vibration or shock.

2-2 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 29

Azbil Corporation Installation

2.3 : Site selection

In order to make full use of the functions of the device, select an optimal installation

site by following the selection criteria below.

CAUTION

Install the unit in a location with an ambient temperature of -30 to +80°C (-22 to +

176°F) and a relative humidity of 5% to 100%. Failing to meet these requirements

could cause damage to the device or cause output errors.

Install the unit away from high-current power lines, motors and transformers to

prevent damage from electromagnetic induction. Failing to meet this requirement

could cause output errors.

Do not install the unit in a location subject to severe vibration or a highly

corrosive atmosphere. Failing to meet this requirement could break the neck of the

detector or cause other damage.

Install the unit as far from direct sunlight as possible to avoid output errors.

CAUTION

The installation location must satisfy the following conditions to avoid output

errors and uctuations.

At the installation location:

• The electrical conductivity of the uid to be measured must match the stated

specication (specs vary according to the converter used) and be more or less

constant.

• The uid to be measured must be electrochemically homogenized. For example,

if two uids are mixed at an upstream point, the device should be installed at

a point so that the two uids can be evenly mixed by the time they reach the

measuring point.

• The distribution of additive matter, if any, must be nearly uniform.

CAUTION

To avoid measurement problems, do not use the MagneW

the following uids, even if their electrical conductivity, temperature and pressure

fall within the specications.

Fluids that have sucient electrical conductivity at high temperatures but do not

satisfy the conductance requirements at room temperature (about 20°C (68°F)).

For example, fatty acids or soap.

• Certain uids that contain surfectants. For example, rinses, shampoos, CWM.

• Conductive adherents. For example, deposition of rosin or conductive material.

• Insulating adherents. For example, oil, kaolinite, kaolin, or calcium stearate.

FLEX+/PLUS+ to measure

CAUTION

This model MGG/MGS detector can only be connected to Azbil Corporation's

model MGG10C/14C converter.

No other types of converter can be used with the device.

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-3

Page 30

Installation Azbil Corporation

Pump

May not ll

Good

2.3.1: Detector position

• Position the detector so that its inner detector passage is continuously lled with

the uid being measured. The following gure provides examples.

Air is easily trapped may not ll with uid

Bad

with uid

Good

Figure 2-1 Detector placement

CAUTION

The detector must be positioned as shown by the circled areas in the gure shown

above. If the pipe is not lled, output errors will occur.

• When measuring high viscosity uid, connecting the pipe to a vertical detector is

recommended (in order to secure an axial symmetrical ow).

• Install a straight pipe section on the upstream side of the detector. The following

gure shows the length of the straight pipe section (D = nominal bore diameter of

the detector).

Upstream

Right angle joint

Detector

> 5D

T-joint

Detector

> 5D

Gate valve (Completely open)

Detector Detector

> 5D

Diffuser with cone angle >15

(<15 Considered straight pipe section)

Detector

> 5D

Concentrator

(Considered straight pipe section)

Detector

> 5D

Any type of valve

> 10D

Figure 2-2 Straight pipe section on upstream side of detector

• Although a pipe section is not necessary on the downstream side, secure a section

of at least 2D if eccentric ow appears.

• Select an installation site where there is no major pulsation or vibration (away

from a pump).

• Make sure that there is adequate space around the detector after installation to

perform maintenance.

2-4 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 31

Azbil Corporation Installation

(15.75 inches)

400 mm

(15.75 inches)

400 mm

Figure 2-3 Space allowance required for maintenance

2.3.2: Changing the position of the terminal box

In some locations, the direction of the terminal box may be unsuitable if the detector

is installed as it is shipped. In this case, the terminal box can be repositioned before

installation.

After selecting an installation site, adjust the direction of the terminal box using the

method described below.

To change the position of the terminal box:

(1) Using an M5 wrench, remove the four screws securing the terminal box to the

detector.

(2) Holding the detector, rotate the terminal box horizontally to the required position.

CAUTION

Do not rotate the terminal box more than 180° (one half rotation). Any further

rotation can disconnect wiring.

After removing the screws, do not pull on the terminal box. The lead wire can be broken.

When you move the terminal box, make sure the O-ring remains in the groove to

insure an air-tight seal when the unit is reassembled.

(3) Using a hex wrench, retighten the four screws.

Bottom view

Hexagonal wrench

Figure 2-4 Repositioning the terminal box

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-5

Page 32

Installation Azbil Corporation

Nuts (optional)

material grounding

a

supplied.)

2.4 : Installing a wafer detector

CAUTION

Before installing the detector, make sure any foreign matter is ushed from

the interior passage of the detector. Residual foreign matter could cause output

uctuations.

Do not touch the electrodes or allow oil or fat to come into contact with them to

avoid output uctuations.

Align the direction mark on the detector in the direction of the liquid ow.

Misalignment can result in a negative output.

The following gure shows the basic installation method for installing a wafer

detector.

Through-bolts (optional)

Pipe

Gasket (Required

when using SUS

rings. Otherwise,

gasket is

Centering nuts (supplied)

Figure 2-5 Installing a wafer detector

2-6 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 33

Azbil Corporation Installation

2.4.1: Determining the fastening torque

The following table shows the fastening torque for each pipe bore.

CAUTION

The correct fastening torque must be used to prevent leakage. To avoid damage to

the detector, do not exceed the listed fastening torque.

Table 2-1 Fastening torque for wafer detectors

Nominal detector bore diameter

mm (inch)

2.5 - 15 (0.1 - 3/8) 13 - 18 (9.6 -13.3)

25 (1) 20 - 30 (14.8 - 22.1)

40 - 80 (1½ - 3.1) 30 - 50 (22.1 - 36.9)

100 (4) 50-70 (36.9 - 51.6)

125 - 150 (5 - 6) 80 -100 (59.0 - 73.8)

200 (4) 90 -100 (66.4 - 73.8)

2.4.2: Selecting the ange shape

The anges used for installation should maximize the area of contact with the gasket.

O Acceptable X Unacceptable

Flange

Fastening torque

N•m (ft•lb)

Welding

Pipe

Welding

(The liquid could leak because of the

small area of contact with the gasket.)

Figure 2-6 Flange Shapes

CAUTION

Before installing the detector, make sure that the pipe is exactly straight and

centered. Any irregularity could cause leakage or other hazards.

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-7

Page 34

Installation Azbil Corporation

Tilted pipe Off-center Off-center

Figure 2-7 Unacceptable positioning

CAUTION

Never attempt to force the detector between two anges if the space is too narrow.

It can damage the detector.

Figure 2-8 Unacceptable placement of detector between anges

CAUTION

Make certain the bore diameters of the pipe and the detector are exactly the same

and install the detector so that the gasket does not protrude into the inner bore of

the pipe, as this could result in leakage or other hazards.

CAUTION

Tighten each bolt a little at a time and apply uniform pressure to all the bolts.

If leakage continues after tightening the bolts, make sure that the pipe is not o

center, then continue to tighten each bolt a little at a time.

2-8 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 35

Azbil Corporation Installation

Flange

position

Flange

Position

2.4.3: Necessary parts

You will need the following parts to install a wafer detector:

• Centering nuts (four supplied)

• Connecting bolts and nuts (available separately)

• Gaskets: Required when using grounding rings made of SUS material. Not

required when using grounding rings made of hastelloy, titanium, tantalum, or

platinum.

• Protective Plate: Required when connecting the detector to polyvinyl chloride

(PVC) piping.

Centering nuts

The centering nuts create the exact alignment of the pipe and detector. These nuts

are positioned on through-bolts and the detector is set on top of the nuts to properly

position it against the anges.

The position of the centering nuts depends on the direction in which the detector is

installed. For horizontal centering of the detector, position two centering nuts against

each ange. For vertical centering of the detector, position the four centering nuts on

the bottom ange. The following gures show horizontal and vertical centering nut

positions.

Centering nut

Figure 2-9 Centering nut positioning for horizontal centering

Centering Nut

Figure 2-10 Centering nut positioning for vertical centering

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-9

Page 36

Installation Azbil Corporation

Gaskets

Gaskets are supplied with the grounding ring, except when it is made of SUS

material. If you are using SUS material, you must provide the gaskets. Azbil

Corporation recommends joint sheet or polytetraouroethylene (PTFE) gasket

material. For the inner (bore) diameters of the gaskets, see the following table.

Rubber gaskets are not recommended.

CAUTION

Using a gasket with too small a diameter can aect the ow velocity distribution,

resulting in inaccurate measurement.

Using a gasket with too large a diameter can cause leakage. Also, any solid

substance in the uid to be measured could accumulate between the gasket and the

ange, resulting in inaccurate measurement.

Table 2-2 Recommended inner diameters of gaskets

Nominal

detector

bore

diameter

Gasket

inner

diameter

mm

(inch)

mm

±

(inch)

±

2.5 5 10 15 25 40 50 65 80 100 125 150 200

0.1 0.2 3/8 1/2 1 1½ 2 2½ 3 4 5 6 8

6161111161251401511641761101112411481196

1

0.24

0.24

0.43

0.63

0.98

1.57

2.01

2.52

2.99

3.98

4.88

5.83

7.72

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

If you install the detector at a lower torque level using rubber gaskets, you must use

gaskets with the bore and outer diameters for the respective pipe bore shown in the

following table. Depending on the grounding ring material, two gaskets of dierent

thicknesses may be required. The following two tables provide the inner and outer

diameters for the two dierent gasket thicknesses.

2-10 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 37

Azbil Corporation Installation

Table 2-3 Inner and outer diameters of rubber gaskets of thickness 0.5 to 1 mm

(0.02 to 0.04 inches)

Nominal

detector

bore

diameter

Gasket

inner

diameter

Gasket

outer

diameter

mm

(inch)

mm

±

(inch)

±

mm

±

(inch)

±

2.5 5 10 15 25 40 50 65 80 100 125 150 200

0.1 0.2 3/8 1/2 1 1½ 2 2½ 3 4 5 6 8

6161111161251401511641761101112411481196

1

0.24

0.24

0.43

0.63

0.98

1.57

2.01

2.52

2.99

3.98

4.88

5.83

7.72

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

34134134134150175191111111211146117712071257

1

1.34

1.34

1.34

1.34

1.97

2.95

3.58

4.37

4.76

5.75

6.97

8.15

10.12

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

Table 2-4 Inner and outer diameters of rubber gaskets of thickness 3 to 4 mm

(0.12 to 0.16 inches)

Nominal

detector

bore

diameter

mm

(inch)

2.5 5 10 15 25 40 50 65 80 100 125 150 200

0.1 0.2 3/8 1/2 1 1½ 2 2½ 3 4 5 6 8

Gasket

inner

diameter

Gasket

outer

diameter

mm

±

(inch)

±

mm

±

(inch)

±

6161111161251391511641761101112411481196

1

0.24

0.24

0.43

0.63

0.98

1.54

2.01

2.52

2.99

3.98

4.88

5.83

7.72

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

34134134134150168184110411141139116611901240

1

1.34

1.34

1.34

1.34

1.97

2.68

3.31

4.09

4.49

5.47

6.54

7.48

9.45

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

0.04

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-11

Page 38

Installation Azbil Corporation

2.4.4: Selecting an installation method

To select an installation method you must determine the following:

• Horizontal or vertical placement of the detector

• Mounting pipe material

• Grounding ring material

• Need for a protective plate

• Use of rubber gaskets

CAUTION

The necessary materials and the installation method vary according to the material

of the ring and that of the pipe on which the detector is to be installed. Select the

appropriate method of installation from the following table after conrming the

specications of the detector to be installed and the conditions of installation.

Improper installation can result in leakage or damage to the pipe anges.

Table 2-5 Wafer detector installation methods

Pipe

material

Grounding ring

material

Installation Requirements See Page

Metal SUS material With specied fastening torque page 2-15

With rubber gaskets and low

page 2-17

fastening torque

Non-SUS material With specied fastening torque page 2-16

With rubber gaskets and low

page 2-17

fastening torque

PVC SUS material With specied fastening torque page 2-19

With a protective plate page 2-20

With rubber gaskets and low

page 2-21

fastening torque

Non-SUS material With specied fastening torque page 2-22

With a protective plate page 2-23

With rubber gaskets and low

page 2-24

fastening torque

2-12 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 39

Azbil Corporation Installation

Flange

f

fluid flow

2.4.5: Installation on a horizontal pipe

To install a wafer detector on a horizontal pipe:

Follow this procedure to install the detector on a horizontal pipe.

Step Action Drawing

1 • Insert through-bolts in the ange holes

shown by black dots in the drawing. Slip

two centering nuts onto each through-bolt

before inserting the bolts.

2 • Turn the detector so that the direction mark

on the detector matches the direction of

uid ow.

• Insert the detector and gaskets between the

pipe anges.

• Position the detector so that it sits on top of

the centering.

3 • Make sure that the detector remains

properly centered.

• Make sure that the gaskets do not protrude

beyond the edges of the pipe anges.

• When you have checked these items, insert

the remaining through-bolts into the ange

holes and tighten the bolts evenly using the

appropriate fastening torque given on page

2-7.

Gasket

Direction o

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-13

Page 40

Installation Azbil Corporation

Flange

Centering nuts

Direction of

Direction of

2.4.6: Installation on a vertical pipe

Follow this procedure to install the detector on a horizontal pipe.

Step Action Drawing

1 • Of the ange holes shown by black dots in the

drawing, insert through-bolts into the two holes

at the back and fasten them lightly with nuts.

Slip one centering nut onto each through bolt

before inserting the bolts.

2 • Turn the detector so that the direction mark on

the detector matches the direction of uid ow.

• Insert the detector and gaskets between the pipe

anges.

fluid flow

Terminal

box side

Back

Gaskets

3 • Insert through-bolts tted with one centering

nut each into the remaining two ange holes

shown by black dots in steps 1 and 2.

4 • Make sure that the detector remains properly

centered.

• Make sure that the gaskets do not protrude

beyond the edges of the pipe anges.

• When you have checked these items, insert

the remaining through-bolts into the ange

holes and tighten the bolts evenly using the

appropriate fastening torque given on page

2-7.

fluid flow

Gaskets

2-14 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 41

Azbil Corporation Installation

Grounding ring

2.4.7: Installation on a metal pipe using SUS grounding ring material

The installation method described in this section is for installation on a metal pipe

using SUS grounding ring material. For the installation method corresponding to any

other combination of materials, refer to Table 2-5 on page 2-12.

For installation using SUS grounding ring material, Azbil Corporation recommends

non-rubber gaskets such as joint sheet or PTFE. Although rubber gaskets can be used,

it is not possible to reduce the fastening torque. See page 2-17 for installation using

rubber gaskets.

CAUTION

The use of rubber gaskets is not recommended and can cause leakage.

To install a wafer detector on a metal pipe using SUS grounding ring material

and a specied torque:

• Install the detector as shown in the following illustration. The torque level for

tightening the bolts is not related to the gasket material.

See Table 2-1 on page 2-7 for the appropriate torque.

See Table 2-2 on page 2-10 for the inner diameter of the gasket.

Pipe side

flange

Lining

Gasket

Figure 2-11 Installation on a metal pipe using SUS grounding ring material and a

specied torque

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-15

Page 42

Installation Azbil Corporation

Grounding ring

2.4.8: Installation on a metal pipe using non-SUS grounding ring material

The installation methods described in this section are for installation on a metal pipe

using non-SUS grounding ring material. For the installation method corresponding to

any other combination of materials, refer to Table 2-5 on page 2-12.

PTFE gaskets are provided for this type of installation. Although rubber gaskets

can be used, it is not possible to reduce the fastening torque. See page 2-17 for

installation using rubber gaskets.

CAUTION

The use of anything other than the PTFE gaskets provided can result in leakage.

The use of rubber gaskets is not recommended and can cause leakage.

To install a wafer detector on a metal pipe using non-SUS grounding ring

material and a specied torque:

• Install the detector as shown in the following illustration. The torque level for

tightening the bolts is not related to the gasket material.

See Table 2-1 on page 2-7 for the appropriate torque.

See Table 2-2 on page 2-10 for the inner diameter of the gasket.

Lining

Figure 2-12 Installation on a metal pipe using non-SUS grounding ring material

and a specied torque

2-16 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

PTFE gasket

Page 43

Azbil Corporation Installation

(0.02 to 0.04 inch)

To install a wafer detector on a metal pipe using non-SUS grounding ring

material with rubber gaskets:

CAUTION

The use of anything other than the PTFE gaskets provided can result in leakage.

The use of rubber gaskets is not recommended and can cause leakage.

(1) Remove the grounding ring from the detector and insert a rubber gasket 0.5 to 1.0

mm (0.02 to 0.04 inch) thick between the lining and the grounding ring.

(2) Reinsert the grounding ring on top of the rubber gasket.

(3) Remove the PTFE gasket and insert a rubber gasket 3.0 to 4.0 mm (0.12 to 0.16

inch) to replace it.

(4) With the rubber gaskets in the position shown in the following gure, attach the

detector to the pipe. Both rubber gaskets should be made of the same material.

See Table 2-3 on page 2-11 and Table 2-4 on page 2-11 for the rubber gasket

dimensions.

Rubber gasket

Lining

Grounding ringRubber gasket

0.5 to 1 mm

3 to 4 mm

(0.12 to 0.16 inch)

Figure 2-13 Installation on a metal pipe using non-SUS grounding ring material

with rubber gaskets

(5) Fasten the bolts with a torque that provides a leakproof joint.

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-17

Page 44

Installation Azbil Corporation

Grounding ring

Gasket

Lining

PTFE gasket

Figure 2-14 Incorrect installation

2-18 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 45

Azbil Corporation Installation

Grounding ring

2.4.9: Installation on a PVC pipe using SUS grounding ring material

The installation methods described in this section are for installation on a PVC pipe

using SUS grounding ring material. For the installation method corresponding to any

other combination of materials, refer to Table 2-5 on page 2-12.

PTFE gaskets are provided for this type of installation. If you supply the gaskets,

Azbil Corporation recommends non-rubber gaskets such as joint sheet or PTFE.

Although rubber gaskets can be used, they are not recommended. See page 2-21 for

installation using rubber gaskets.

CAUTION

The use of rubber gaskets and a lower fastening torque is not recommended and

can cause insucient surface pressure between the lining and the grounding ring,

resulting in leakage.

If tightening the bolts at the specied torque threatens to warp or damage the PVC

pipes, you will need to use a protective plate. See page 2-20 for installation of the

protective plate.

To install a wafer detector on a PVC pipe using SUS grounding ring material

with a specied fastening torque:

• Install the detector as shown in the following illustration. The torque level for

tightening the bolts is not related to the gasket material.

See Table 2-1 on page 2-7 for the appropriate torque.

See Table 2-2 on page 2-10 for the inner diameter of the gasket.

Lining

Figure 2-15 Installation on a PVC pipe using SUS grounding ring material

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-19

Gasket

Page 46

Installation Azbil Corporation

Grounding ring

Protective plate

To install a wafer detector on a PVC pipe using SUS grounding ring material

and a protective plate:

Use this method to install the detector using a protective plate to prevent the PVC

pipe from being deformed or damaged when the bolts are tightened with the specied

torque.

• Install the protective plate between the outer side of the PVC ange and the

detector, as shown in the gure below. The protective plate protects the PVC

pipe. The torque level for tightening the bolts is not related to the gasket material.

See Table 2-1 on page 2-7 for the appropriate torque.

See Table 2-2 on page 2-10 for the inner diameter of the gasket.

Lining

Gasket

Figure 2-16 Installation on a PVC pipe using SUS grounding ring material and a

protective plate

2-20 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 47

Azbil Corporation Installation

(0.02 to 0.04 inch)

To install a wafer detector on a PVC pipe using SUS grounding ring material

with rubber gaskets and a low fastening torque:

CAUTION

The use of rubber gaskets and a lower fastening torque is not recommended and

can cause insucient surface pressure between the lining and the grounding ring,

resulting in leakage.

(1) Remove the grounding ring from the detector and insert a rubber gasket 0.5 to 1.0

mm (0.02 to 0.04 inch) thick between the lining and the grounding ring.

(2) Reinsert the grounding ring on top of the rubber gasket.

(3) With the rubber gasket in the position shown in the following gure, attach the

detector to the pipe. In the example shown, both rubber gaskets are made of the

same material.

Rubber gasket

Lining

Grounding ringRubber gasket

0.5 to 1 mm

3 to 4 mm

(0.12 to 0.16 inch)

Figure 2-17 Installation on a PVC pipe using SUS grounding ring material with

rubber gaskets (Not recommended)

(4) Fasten the bolts with a torque that provides a leakproof joint.

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-21

Page 48

Installation Azbil Corporation

Grounding ring

2.4.10: Installation on a PVC pipe using non-SUS grounding ring material

The installation methods described in this section are for installation on a PVC pipe

using non-SUS grounding ring material. For the installation method corresponding to

any other combination of materials, refer to Table 2-5 on page 2-12.

PTFE gaskets are provided for this type of installation. If you supply the gaskets,

Azbil Corporation recommends non-rubber gaskets such as joint sheet or PTFE.

Although rubber gaskets can be used, they are not recommended. See page 2-24 for

installation using rubber gaskets.

CAUTION

The use of rubber gaskets and a lower fastening torque is not recommended and

can cause insucient surface pressure between the lining and the grounding ring,

resulting in leakage.

If tightening the bolts at the specied torque threatens to warp or damage the PVC

pipes, you will need to use a protective plate. See page 2-23 for installation of the

protective plate.

To install a wafer detector on a PVC pipe using non-SUS grounding ring

material with a specied fastening torque:

• Install the detector as shown in the following illustration. The torque level for

tightening the bolts is not related to the gasket material.

See Table 2-1 on page 2-7 for the appropriate torque.

See Table 2-2 on page 2-10 for the inner diameter of the gasket.

Lining

Figure 2-18 Installation on a PVC pipe using non-SUS grounding ring material

2-22 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

PTFE gasket (supplied)

Page 49

Azbil Corporation Installation

Grounding ring

Protective plate

To install a wafer detector on a PVC pipe using non-SUS grounding ring

material and a protective plate:

Use this method to install the detector using a protective plate to prevent the PVC

pipe from being deformed or damaged when the bolts are tightened with the specied

torque.

• Install the protective plate between the outer side of the PVC ange and the

detector, as shown in the gure below. The protective plate protects the PVC

pipe. The torque level for tightening the bolts is not related to the gasket material.

See Table 2-1 on page 2-7 for the appropriate torque.

See Table 2-2 on page 2-10 for the inner diameter of the gasket.

Lining

PTFE gasket

(Supplied)

Figure 2-19 Installation on a PVC pipe using non-SUS grounding ring material

and a protective plate

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-23

Page 50

Installation Azbil Corporation

(0.02 to 0.04 inch)

To install a wafer detector on a PVC pipe using non-SUS grounding ring

material with rubber gaskets and a low fastening torque:

CAUTION

The use of rubber gaskets and a lower fastening torque is not recommended and

can cause insucient surface pressure between the lining and the grounding ring,

resulting in leakage.

(1) Remove the grounding ring from the detector and insert a rubber gasket 0.5 to 1.0

mm (0.02 to 0.04 inch) thick between the lining and the grounding ring.

(2) Reinsert the grounding ring on top of the rubber gasket.

(3) Remove the PTFE gasket and insert a rubber gasket 3.0 to 4.0 mm (0.12 to 0.16

inch) to replace it.

(4) With the rubber gaskets in the position shown in the following gure, attach the

detector to the pipe. Both rubber gaskets should be made of the same material.

See Table 2-3 on page 2-11 and Table 2-4 on page 2-11 for the appropriate

dimensions.

Rubber gasket

Lining

Grounding ringRubber gasket

0.5 to 1 mm

3 to 4 mm

(0.12 to 0.16 inch)

Figure 2-20 Installation on a PVC pipe using non-SUS grounding ring material

with rubber gaskets

(5) Fasten the bolts with a torque that provides a leakproof joint.

2-24 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

Page 51

Azbil Corporation Installation

Nuts (optional)

2.5 : Installing a anged detector

CAUTION

Before installing the detector, make sure any foreign matter is ushed from

the interior passage of the detector. Residual foreign matter could cause output

uctuations.

Do not touch the electrodes or allow oil or fat to come into contact with them to

avoid output uctuations.

Align the direction mark on the detector in the direction of the liquid ow.

Misalignment can result in a negative output.

The following gure shows the basic installation method for installing a anged

detector.

Through-bolts (optional)

Pipe

Gasket (Required when

using SUS material

grounding rings.

Otherwise, a gasket is

supplied.)

Figure 2-21 Installing a anged detector

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-25

Page 52

Installation Azbil Corporation

2.5.1: Determining the fastening torque

The following table shows the fastening torque for each pipe bore.

CAUTION

The correct fastening torque must be used to prevent leakage. To avoid damage to

the detector, do not exceed the listed fastening torque.

Table 2-6 Fastening torque for anged detectors

Nominal

detector bore

diameter

mm (inch)

2.5 - 15 mm

(0.1 - 3/8 inch)

25 mm

(1 inch)

Flange ratings

JIS 10K

JIS 20K

JIS 30K

JPI 150

JPI 300

ANSI 150

ANSI 300

DIN PN10/16

DIN PN25/40

JIS 10K

JIS 20K

JIS 30K

JPI 150

JPI 300

ANSI 150

ANSI 300

6 - 9

6 - 9

18 - 31

6 - 9

6 - 9

6 - 9

9 - 14

21 - 31

21 - 32

23 - 36

11 - 17

22 - 34

Fastening torque

N•m (ft•lb)

(4.4 - 6.6)

(4.4 - 6.6)

(13.3 - 22.9)

(4.4 - 6.6)

(4.4 - 6.6)

(4.4 - 6.6)

(6.6 - 10.3)

(15.5 - 22.9)

(15.5 - 23.6)

(17.0 - 26.6)

(8.1 - 12.5)

(16.2 - 25.1)

kgf•cm

61 - 92

61 - 92

184 - 316

61 - 92

61 - 92

61 - 92

92 - 143

214 - 316

214 - 326

235 - 367

112 - 173

224 - 347

40 mm

(1½ inches)

DIN PN10/16

DIN PN25/40

JIS 10K

JIS 20K

JIS 30K

10 - 14

12 - 18

22 - 32

22 - 34

41 - 65

(7.4 - 10.3)

(8.9 - 13.3)

(16.2 - 23.6)

(16.2 - 25.1)

(30.2 - 47.9)

102 - 143

122 - 184

224 - 326

224 - 347

418 - 663

JPI 150

JPI 300

ANSI 150

ANSI 300

DIN PN10/16

DIN PN25/40

2-26 MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector

13 - 18

36 - 57

22 - 32

25 - 38

(9.6 - 13.3)

(26.6 - 42.0)

(16.2 - 23.6)

(18.4 -28.0)

133 - 184

367 - 581

224 - 326

255 -387

Page 53

Azbil Corporation Installation

Table 2-6 Fastening torque for anged detectors

Nominal

detector bore

diameter

mm (inch)

50 / 65 mm

(2 / 2½ inches)

80 mm

(3 inches)

Flange ratings

JIS 10K

JIS 20K

JIS 30K

JPI 150

JPI 300

ANSI 150

ANSI 300

DIN PN10/16

DIN PN25/40

JIS 10K

JIS 20K

JIS 30K

JIS G3451 F12

JPI 150

JPI 300

ANSI 150

ANSI 300

24 - 34

19 - 31

22 - 34

23 - 32

20 - 32

24 - 34

28 - 42

20 - 31

37 - 61

42 - 66

18 - 37

26 - 35

37 - 57

Fastening torque

N•m (ft•lb)

(17.7 - 25.1)

(14.0 - 22.9)

(16.2 - 25.1)

(17.0 - 23.6)

(14.8 - 23.6)

(17.7 - 25.1)

(20.7 - 31.0)

(14.8 - 22.9)

(27.3 - 45.0)

(31.0 - 48.7)

(13.3 - 27.3)

(19.2 - 25.8)

(27.3 - 42.0)

kgf•cm

245 - 347

194 - 316

224 - 347

235 - 326

204 - 326

245 - 347

286 - 428

204 - 316

377 - 622

428 - 673

184 - 377

265 - 357

377 - 581

100 mm

(4 inches)

125 / 150 mm

(5 / 6 inches)

DIN PN10/16

DIN PN25/40

JIS 10K

JIS 20K

JIS 30K

JIS G3451 F12

JPI 150

JPI 300

ANSI 150

ANSI 300

DIN PN10/16

DIN PN25/40

JIS 10K

JIS 20K

JIS 30K

JIS G3451 F12

JPI 150

JPI 300

ANSI 150

ANSI 300

20 - 31

25 - 39

22 - 33

41 - 66

61 - 95

21 - 41

21 - 31

43 - 66

22 - 33

48 - 74

47 - 67

58 - 91

80 - 123

23 - 45

42 - 60

50 - 74

(14.8 - 22.9)

(18.4 - 28.8)

(16.2 - 24.3)

(30.2 - 48.7)

(45.0 - 70.1)

(15.5 - 30.2)

(15.5 - 22.9)

(31.0 - 48.7)

(16.2 - 24.3)

(35.4 - 54.6)

(34.7 - 49.4)

(42.8 - 67.1)

(59.0 - 90.7)

(17.0 - 33.2)

(31.0 - 44.3)

(36.9 - 54.6)

204 - 316

255 - 398

224 - 337

418 - 673

622 - 969

214 - 418

214 - 316

438 - 673

224 - 337

489 - 755

479 - 683

591 - 928

816 - 1254

235 - 459

428 - 612

510 - 755

DIN PN10/16

DIN PN25/40

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter Detector 2-27

47 - 67

97 - 97

(34.7 - 49.4)

(71.5 - 71.5)

479 - 683

989 - 989

Page 54

Installation Azbil Corporation

Table 2-6 Fastening torque for anged detectors

Nominal

detector bore

diameter

mm (inch)

200 mm

(8 inches)

250 mm

(10 inches)

Flange ratings

JIS 10K

JIS 20K

JIS 30K

JIS G3451 F12

JPI 150

JPI 300

ANSI 150

ANSI 300

DIN PN10/16

DIN PN25/40

JIS 10K

JIS 20K

JIS G3451 F12

JPI 150

JPI 300

ANSI 150

ANSI 300

44 - 65

66 - 102

94 - 142

24 - 44

42 - 59

81 - 120

47 - 68

123 - 189

51 - 63

81 - 99

73 - 89

69 - 85

82 - 97

Fastening torque

N•m (ft•lb)

(32.5 - 47.9)

(48.7 - 75.2)

(69.3 - 104.7)

(17.7 - 32.5)

(31.0 - 43.5)

(59.7 - 88.5)

(34.7 - 50.2)

(90.7 - 139.4)

(37.6 - 46.5)

(59.7 - 73.0)

(53.8 - 65.6)

(50.9 - 62.7)

(60.5 - 71.5)

kgf•cm

449 - 663

673 - 1040

959 - 1448

245 - 449

428 - 602

826 - 1224

479 - 693

1254 - 1927

520 - 642

826 - 1010

744 - 908

704 - 867

836 - 989

300 mm

(12 inches)

350 mm

(14 inches)

DIN PN10/16

DIN PN25

JIS 10K

JIS 20K

JIS G3451 F12

JPI 150

JPI 300

ANSI 150

ANSI 300

DIN PN10/16

DIN PN25

JIS 10K

JIS 20K

JIS G3451 F12

JPI 150

JPI 300

ANSI 150

ANSI 300

DIN PN10/16

DIN PN25

57 - 69

108 - 127

50 - 62

79 - 97

49 - 59

56 - 68

116 - 136

45 - 55

105 - 122

54 - 66

143 - 167

66 - 80

80 - 98

116 - 136

42 - 52

160 - 189

(42.0 - 50.9)

(79.7 - 93.7)

(36.9 - 45.7)

(58.3 - 71.5)

(36.1 - 43.5)

(41.3 - 50.2)

(85.6 - 100.3)

(33.2 - 40.6)

(77.4 - 90.0)

(39.8 - 48.7)

(105.5 - 123.2)

(48.7 - 59.0)

(59.0 - 72.3)

(85.6 - 100.3)

(31.0 - 38.4)

(118.0 - 139.4)

581 - 704

1101 - 1295

510 - 632

806 - 989

500 - 602

571 - 693

1183 - 1387

459 - 561

1071 - 1244

551 - 673

1458 - 1703

673 - 816

816 - 999