Page 1

MagneW FLEX+/PLUS+

Electromagnetic Flowmeter

Converter

Model MGG10C/MGG14C

User’s Manual

CM2-MGG310-2001

Page 2

Copyright, Notices and Trademarks

© 2007-2018 Azbil Corporation. All Rights Reserved.

While the information in this manual is presented in good faith and

believed to be accurate, Azbil Corporation disclaims any implied war-

ranty of merchantability or tness for a particular purpose and makes no

express warranty except as may be stated in its written agreement with

and for its customer.

In no event shall Azbil Corporation be liable to anyone for any indirect,

special or consequential damages. This information and specications

in this document are subject to change without notice.

MagneW is a trademark of Azbil Corporation in Japan and/or other

countries.

®

HART

is a registered trademark of FieldComm Group.

Page 3

Safety

About this manual

This manual contains information and warnings that must be observed to keep the

model MGG10C/MGG14C MagneW

installation, correct operation and regular maintenance are essential to ensure safety

while using this device.

For the correct and safe use of this owmeter, it is essential that both operating and

service personnel follow generally accepted safety procedures in addition to the safety

precautions specied in this manual.

The following symbols are used in this manual to alert you to possible hazards:

Denotes a potentially hazardous situation which, if not avoided could result in

death or serious injury.

FLEX+/PLUS+ Flowmeter operating safely. Correct

WARNING

Denotes a potentially hazardous situation which, if not avoided could result in

minor injury or damage to device.

Safety messages

Carefully read this section before installing or operating this device.

ELECTRIC SHOCK HAZARD! Turn the power supply OFF before opening the

converter cover.

Switch the control equipment to manual control before terminating owmeter

operation and shutting o the output to the control equipment. This action

prevents the power shut-o from directly aecting the control equipment.

CAUTION

WARNING

CAUTION

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter i

Page 4

Safety Azbil Corporation

CAUTION

Install the owmeter in a location with an ambient temperature of -25 °C to

60 °C (-13 °F to 140 °F) and an ambient humidity of 5 to 100% RH to prevent

equipment malfunction or output errors.

CAUTION

Do not install the owmeter near high-current power lines, motors or transformers

to prevent damage from electromagnetic induction, which can cause equipment

malfunction or output errors.

CAUTION

Do not install the owmeter in a location subject to direct sunlight, wind, rain,

severe vibration, or in a highly corrosive atmosphere. The converter and detector

can be damaged.

CAUTION

Be sure to ground the welding power transformer when welding near the

owmeter to avoid output errors.

CAUTION

DO NOT use the owmeter to ground a welder. It can damage the owmeter.

ii Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 5

Azbil Corporation Safety

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter CE

Conformity Supplement

CE CONFORMITY: This product is in conformity with the protection requirements of the

following European Council Directive: 2014/30/EU, the EMC Directive and

2014/35/EU, Low Voltage Directive. Conformity of this product with any

other “CE Mark” Directive(s) shall not be assumed.

EMC Directive/Standard PC Conformity Notes

ELECTROMAGNETIC COMPATIBILITY: 2014/30/EU,

EMC Directive

EMISSIONS: EN61326-1:2013, Gr.1 Class A, Electrical

equipment for measurement, control and laboratory use

EN 55011:2009/A1: 2010, Gr.1, Class A, Industrial Control

Equipment, Radiated electromagnetic disturbances 30MHz -

1000MHz,

IMMUNITY: EN61326-1:2013, Electrical equipment for

measurement, control and laboratory use, EN 61326-2-3:2013,

Particular requirements

EN 61000-4-2: 2009, ESD, Electrostatic Discharge BB4 kV Contact

EN 61000-4-3:2006 + A2:2010, Radio-frequency

electromagnetic eld, amplitude modulated 80 -2700 MHz

EN 61000-4-4:2012, Electrical Fast Transients/Burst B 1kV 1

EN 61000-4-5: 2006, Surge B 1kV 1

EN 61000-4-6:2009, Conducted Radio-frequency, 150 KHz -

80 MHz

EN 61000-4-8: 2010, Power frequency magnetic eld A 30A/m

EN 61000-4-11:2004, Voltage Dip/short interruptions B

30MHz-230MHz quasi-peak limit 40dB(uV/m) at

10m

230MHz-1000MHz quasi-peak limit 47dB(uV/m)

at 10m

PERFORMANCE: Unless otherwise noted, the

performance of this product, at the specied levels

of electromagnetic interference, is within the

specications for for “Performance Under Rated

Conditions.”

8kV Air

A 1kHz, AM80%

10 V/m (80 -1000 MHz)

3V/m (1.0 -2.0 GHz)

1V/m (2.0 -2.7 GHz)

A 3V 1

50Hz

0.5, 1cycle 0% (100%)

10/12 cycle 40% (60%)

C

25/30 cycle 70% (30%)

C

250/300 cycle 0% (100%)

C

1

1

1

NOTES:

PC = Performance Criteria

1. Twist pair cables required for all I/O interface circuits.

In case of remote model,two core double shield cable in metal conduit pipe is required for the input line in

connection with detector.

Performance Criteria: Immunity includes the tests and severity levels specied in EN 61326-1-2013 and EN 61326-2-

3-2013.

LV Directive Conformity

LOW VOLTAGE DIRECTIVE: 2014/35/EU EN 61010-1: 2010, Safety requirements for electrical equipment for

measurement, control and laboratory use Part 1: General requirements

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter iii

Page 6

Safety Azbil Corporation

Internal

External

Internal

External

MagneW FLEX+/PLUS+ Electromagnetic Flowmeter

Documentation Supplement

1. Mains supply

The symbol for a.c. or d.c. on the name plate is as follows:

for a.c. power supply

for d.c. power supply

2. Fuse marking

The fuse cannot be replaced by the operator.

Fuse rating and electric characteristics are as follows:

Fuse rating: Voltage 250V

Current 3A

Manufacturer type: 239003 (LITTEL FUSE)

3. Grounding (Earthing)

Protective grounding (earthing) should be connected as shown in Operator's Manual.

The MagneW

FLEX+/PLUS+ has protective grounding (earthing) terminals in the terminal

box and on the external surface of its casing (see gure).

Remote models Integral models

An external switch or circuit-breaker must be installed near the MagneW

on the power line.

4. Equipment operation

Power line is connected to commercial power. The terminal cover

must not be opened when power is on.

FLEX+/PLUS+

iv Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 7

Chapter 1: Introduction

MagneW FLEX+/PLUS+ Flowmeter ................................................................................... 1-1

Main components ............................................................................................................1-1

Analog output and digital output .................................................................................. 1-3

System conguration for analog output (4 to 20 mA DC output) ................................. 1-4

System conguration WITHOUT the communication function ........................................1-5

System conguration WITH the HART communication function with the internal power

supply ..............................................................................................................................1-6

System conguration WITH the SFC or HART communication function with the external

power supply ...................................................................................................................1-7

System Conguration for Digital Output (DE Output) .................................................. 1-8

System conguration.......................................................................................................1-8

Approval of this Device................................................................................................ 1-10

Chapter 2: Installation

Site selection ............................................................................................................... 2-1

Unpacking and storage ............................................................................................... 2-2

Installation options....................................................................................................... 2-3

Changing the orientation of the converter .......................................................................2-4

Wiring .......................................................................................................................... 2-5

Integral wiring - 1 (1-contact input and 1- contact output) ........................................... 2-6

Integral wiring - 2 (2-contact input) .............................................................................. 2-7

Integral wiring - 3 (2-contact output)............................................................................ 2-8

Remote wiring - 1 (1-contact input and 1- contact output) .......................................... 2-9

Remote wiring - 2 (2-contact input) ............................................................................. 2-10

Remote wiring - 3 (2-contact output) ........................................................................... 2-11

Grounding .......................................................................................................................2-12

Signal and excitation cable specications .......................................................................2-12

Signal and excitation cable wiring ............................................................................... 2-14

Wiring cable................................................................................................................. 2-15

Wiring .......................................................................................................................... 2-16

Setting write protection ................................................................................................ 2-19

Setting the communication via the HART.................................................................... 2-21

Setting the empty detection function ........................................................................... 2-22

Setting the communication via the SFC ...................................................................... 2-23

Connecting power ....................................................................................................... 2-24

Table of Contents

Chapter 3: Operation

Start-up........................................................................................................................ 3-1

Shut down ................................................................................................................... 3-1

Using the display panel ............................................................................................... 3-2

Using the infrared touch sensor keys ..............................................................................3-3

Chapter 4: Using the display panel

About modes ............................................................................................................... 4-1

MEASURING MODE ................................................................................................... 4-4

LCD display ow.......................................................................................................... 4-5

Entering BASIC SETUP MODE .................................................................................. 4-11

Page 8

Table of Contents

Setting the TAG NO. ................................................................................................... 4-12

Default setting .......................................................................................................4-12

Setting range ........................................................................................................4-12

Damping time constant ...................................................................................................4-13

Default setting .......................................................................................................4-13

Setting range ........................................................................................................4-13

Auto zero .........................................................................................................................4-14

Flow counter - Reset value .............................................................................................4-16

Flow counter - Resetting .................................................................................................4-17

Detector data...................................................................................................................4-18

Default setting .......................................................................................................4-18

Setting the Number of Dummy Detectors .......................................................................4-20

Default setting .......................................................................................................4-20

Setting range ........................................................................................................4-20

Flow rate range ...............................................................................................................4-21

Setting range ........................................................................................................4-21

Flow rate indication .........................................................................................................4-22

Default setting .......................................................................................................4-22

Setting range ........................................................................................................4-22

Entering ENGINEERING / ADVANCED / MAINTENANCE MODE.................................4-23

Entering ENGINEERING MODE...........................................................................4-23

Entering ADVANCED MODE ................................................................................4-23

Entering MAINTENANCE MODE..........................................................................4-24

Selecting functions ..........................................................................................................4-25

Relations for setting function FXXXX ..............................................................................4-27

Range functions ..............................................................................................................4-30

Single range ..........................................................................................................4-30

Normal direction automatic dual range .................................................................4-31

Normal direction, external switching dual range ...................................................4-32

Normal/reverse automatic switching range ...........................................................4-33

[Built-in counter function] ......................................................................................4-35

[Contact input function] .........................................................................................4-36

[Contact output function] .......................................................................................4-37

Flow rate range .....................................................................................................4-40

Setting range ........................................................................................................4-40

Setting hysteresis .................................................................................................4-42

Selecting the current output method for dual range ..............................................4-43

Setting / Changing the preset value of the built-in ow counter ......................................4-44

Specic gravity ......................................................................................................4-45

Pulse weight .........................................................................................................4-46

Setting the pulse width ..........................................................................................4-47

Setting high and low limit alarms ..........................................................................4-49

Setting a 2-stage ow rate alarm ..........................................................................4-50

Selecting fail-safe mode for the analog output ................................................................4-52

Default setting .......................................................................................................4-52

Setting range ........................................................................................................4-52

Selecting fail-safe mode for the pulse output ..................................................................4-53

Default setting .......................................................................................................4-53

Setting range ........................................................................................................4-53

Setting the contact output status ..........................................................................4-54

Damping time constant ...................................................................................................4-56

Default setting .......................................................................................................4-56

Setting range ........................................................................................................4-56

Page 9

Table of Contents

Manual zeroing................................................................................................................4-57

Important ...............................................................................................................4-57

How to set .............................................................................................................4-57

Setting moving average ..................................................................................................4-58

Default setting .......................................................................................................4-58

Setting range ........................................................................................................4-58

Auto spike cut function ....................................................................................................4-60

Default setting .......................................................................................................4-60

Manual spike cut function ...............................................................................................4-61

Default setting .......................................................................................................4-61

Setting range ........................................................................................................4-61

Coecient of compensation ..................................................................................4-62

Setting the drop-out ..............................................................................................4-63

Setting the low ow cut .........................................................................................4-64

Setting decimal place ............................................................................................4-65

Change the excitation frequency ..........................................................................4-66

Setting the analog output limit ..............................................................................4-67

Change the ow direction .....................................................................................4-68

Error history check/clear .......................................................................................4-69

Chapter 5: Maintenance and Troubleshooting

Function check ............................................................................................................ 5-2

Input and output signal loop check .................................................................................5-2

Analog output check .................................................................................................... 5-3

Default setting .......................................................................................................5-3

Setting range ........................................................................................................5-3

Pulse output check ...................................................................................................... 5-4

Default setting .......................................................................................................5-4

Setting range ........................................................................................................5-4

Contact input/output loop check ......................................................................................5-5

Default setting .......................................................................................................5-5

Setting range ........................................................................................................5-5

Excitation current check ..................................................................................................5-8

Simulated signal by the calibrator ...................................................................................5-9

Preparation ...........................................................................................................5-9

Troubleshooting........................................................................................................... 5-10

Errors at startup........................................................................................................... 5-11

Operation errors .......................................................................................................... 5-12

Error messages ........................................................................................................... 5-13

Error codes for critical problems .....................................................................................5-13

Error codes for non-critical problems ..............................................................................5-14

Safety precautions....................................................................................................... 5-15

Operating precautions .....................................................................................................5-15

Examples of symbol ........................................................................................................5-15

Structure and functions of SFC .............................................................................5-16

Page 10

List of Figures

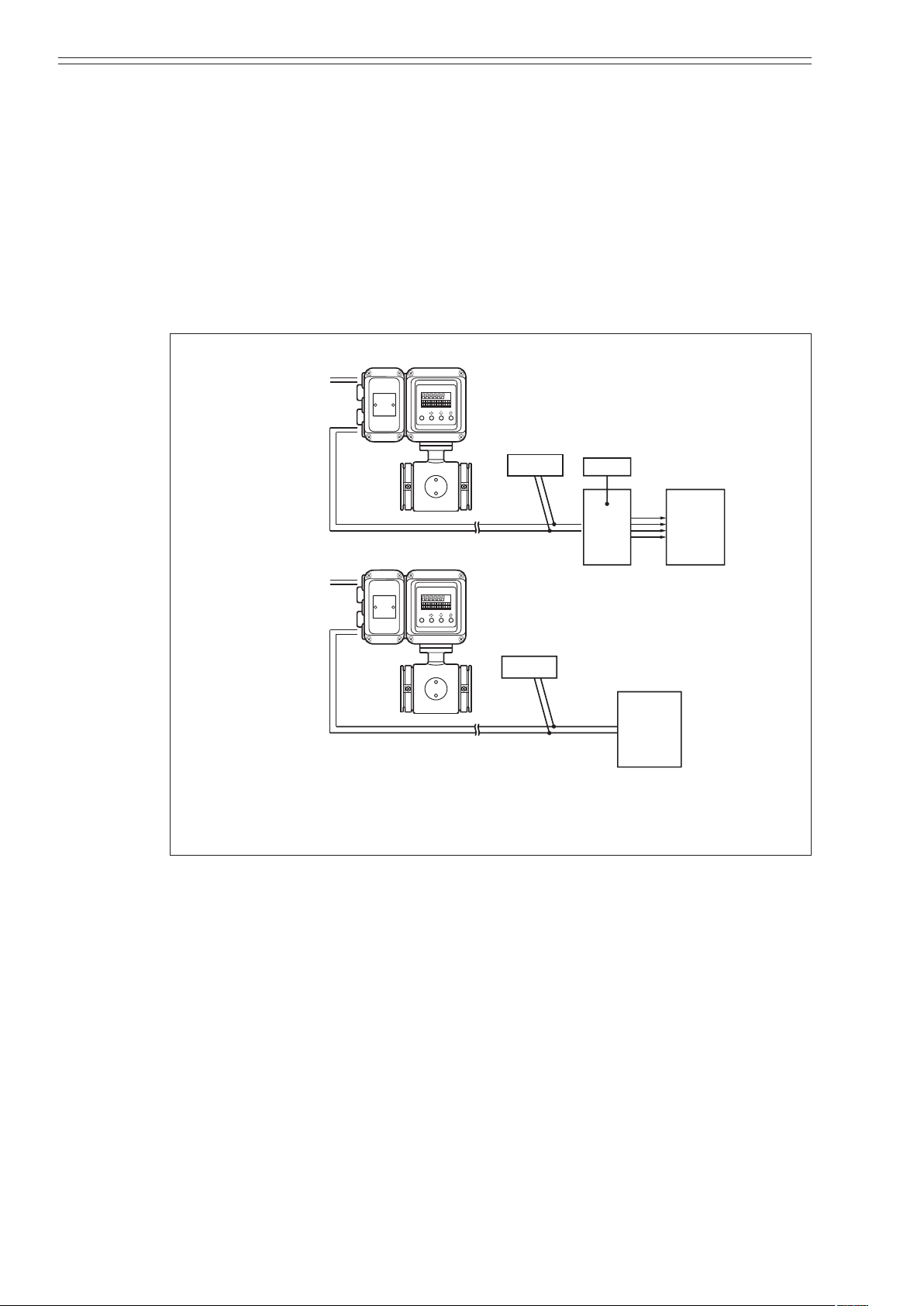

Figure 1-1 Integral System ................................................................................................. 1-1

Figure 1-2 Remote System ................................................................................................. 1-2

Figure 1-3 System conguration of analog output WITHOUT communication function ...1-5

Figure 1-4 System conguration of with the HART communication with internal power

supply ................................................................................................................ 1-6

Figure 1-5 System conguration for analog output WITH the communication function

(example setup) .................................................................................................1-7

Figure 1-6 System conguration for digital output ............................................................ 1-8

Figure 1-7 Parts of the converter ........................................................................................ 1-9

Figure 1-8 System conguration .......................................................................................1-11

Figure 2-1 Integral installation ........................................................................................... 2-3

Figure 2-2 Wall mounted remote installation .....................................................................2-3

Figure 2-3 Pipe mounted remote installation .....................................................................2-4

Figure 2-4 Integral converter terminal block ......................................................................2-6

Figure 2-5 Integral converter terminal block ......................................................................2-7

Figure 2-6 Integral converter terminal block ......................................................................2-8

Figure 2-7 Remote converter terminal block ......................................................................2-9

Figure 2-8 Remote converter terminal block ......................................................................2-10

Figure 2-9 Remote converter terminal block ......................................................................2-11

Figure 2-10 Cable usage ranges............................................................................................ 2-12

Figure 2-11 Signal Cable Dimensions .................................................................................. 2-13

Figure 2-12 Excitation Cable Dimensions............................................................................ 2-13

Figure 2-13 Signal and excitation cable construction .......................................................... 2-13

Figure 2-14 Detector to converter wiring diagram ............................................................... 2-14

Figure 2-15 Wiring diagram for current output .................................................................... 2-16

Figure 2-16 Wiring diagram for pulse output ....................................................................... 2-17

Figure 2-17 Switch locations on main card .......................................................................... 2-17

Figure 2-18 Wiring diagram for contact input...................................................................... 2-18

Figure 2-19 Wiring diagram for contact output.................................................................... 2-18

Figure 2-20 Switch locations on main card .......................................................................... 2-20

Figure 2-21 Write protection switch positions ..................................................................... 2-20

Figure 2-22 Switch locations on main card .......................................................................... 2-21

Figure 2-23 HART communication switch positions ........................................................... 2-21

Figure 2-24 Switch locations on main card .......................................................................... 2-22

Figure 2-25 Empty detection function switch positions ....................................................... 2-22

Figure 2-26 Switch locations on main card .......................................................................... 2-23

Figure 2-27 SFC communication switch positions .............................................................. 2-23

Figure 2-28 Name plate ........................................................................................................ 2-24

Figure 3-1 Start-up display ................................................................................................. 3-1

Figure 3-2 Display panel ....................................................................................................3-2

Figure 3-3 Touch sensor keys ............................................................................................. 3-3

Figure 3-4 Using the touch sensor keys..............................................................................3-3

Figure 4-1 Single range ......................................................................................................4-30

Figure 4-2 Normal direction automatic dual range ............................................................4-31

Figure 4-3 Normal/reverse automatic switching range ......................................................4-33

Figure 4-4 2-stage ow rate alarm output ..........................................................................4-39

Figure 4-5 Selecting the current output method for dual range ..........................................4-43

Page 11

List of Tables

Table 2-1 Remote converter terminal descriptions (1-contact input & 1-contact output) ............ 2-6

Table 2-2 Remote converter terminal descriptions (2-contact input) ...............................2-7

Table 2-3 Remote converter terminal descriptions (2-contact output) .............................2-8

Table 2-4 Remote converter terminal descriptions

Table 2-5 Remote converter terminal descriptions (2-contact input) ...............................2-10

Table 2-6 Remote converter terminal descriptions (2-contact output) .............................2-11

Table 2-7 Write Protection Levels .................................................................................... 2-19

Table 3-1 Touch Sensor key Functions ............................................................................. 3-4

Table 3-2 Default settings ................................................................................................. 3-5

Table 4-1 Mode functions ................................................................................................. 4-2

Table 4-2 Output selection ................................................................................................ 4-37

Table 5-1 Startup Errors .................................................................................................... 5-11

Table 5-2 Operation Errors ............................................................................................... 5-12

Table 5-3 Critical Errors ...................................................................................................5-13

Table 5-4 Non-critical ....................................................................................................... 5-14

(1-contact input & 1-contact output) ............ 2-9

Page 12

List of Tables

Page 13

Chapter 1: Introduction

Pulse output

Contact input/output

r

Converter

This chapter contains an overview of the model MGG10C/MGG14C MagneW FLEX+/

PLUS+ Flowmeter. It provides denitions for all the major parts of the converter.

MagneW FLEX+/PLUS+ Flowmeter

Thank you for purchasing the Azbil Corporation model MGG10C/MGG14C

Flowmeter. This system features:

• Digital panel display

• Intuitive, versatile operator interface with large characters and backlit liquid crystal

display (LCD)

• I/O Capacity

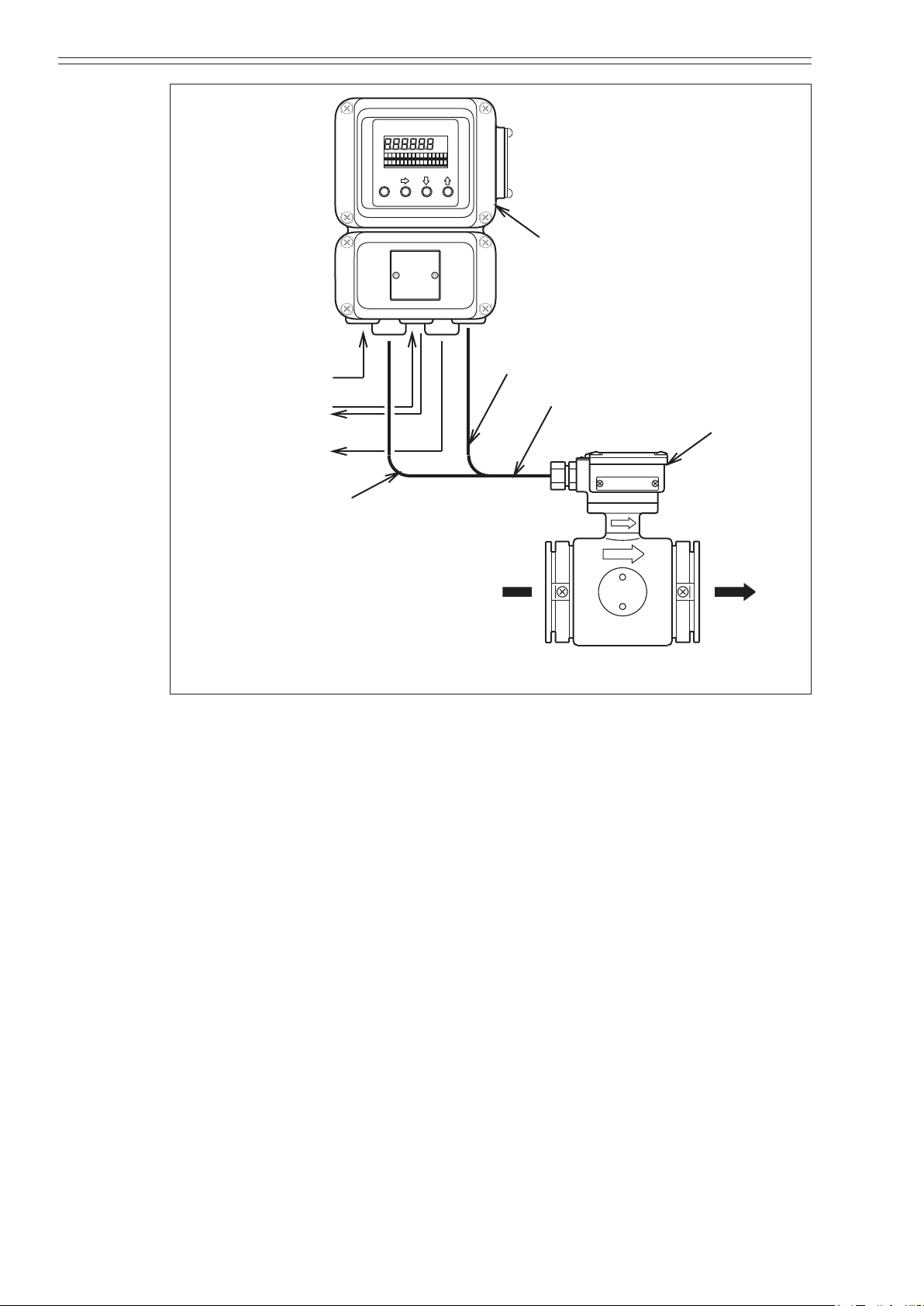

Main components

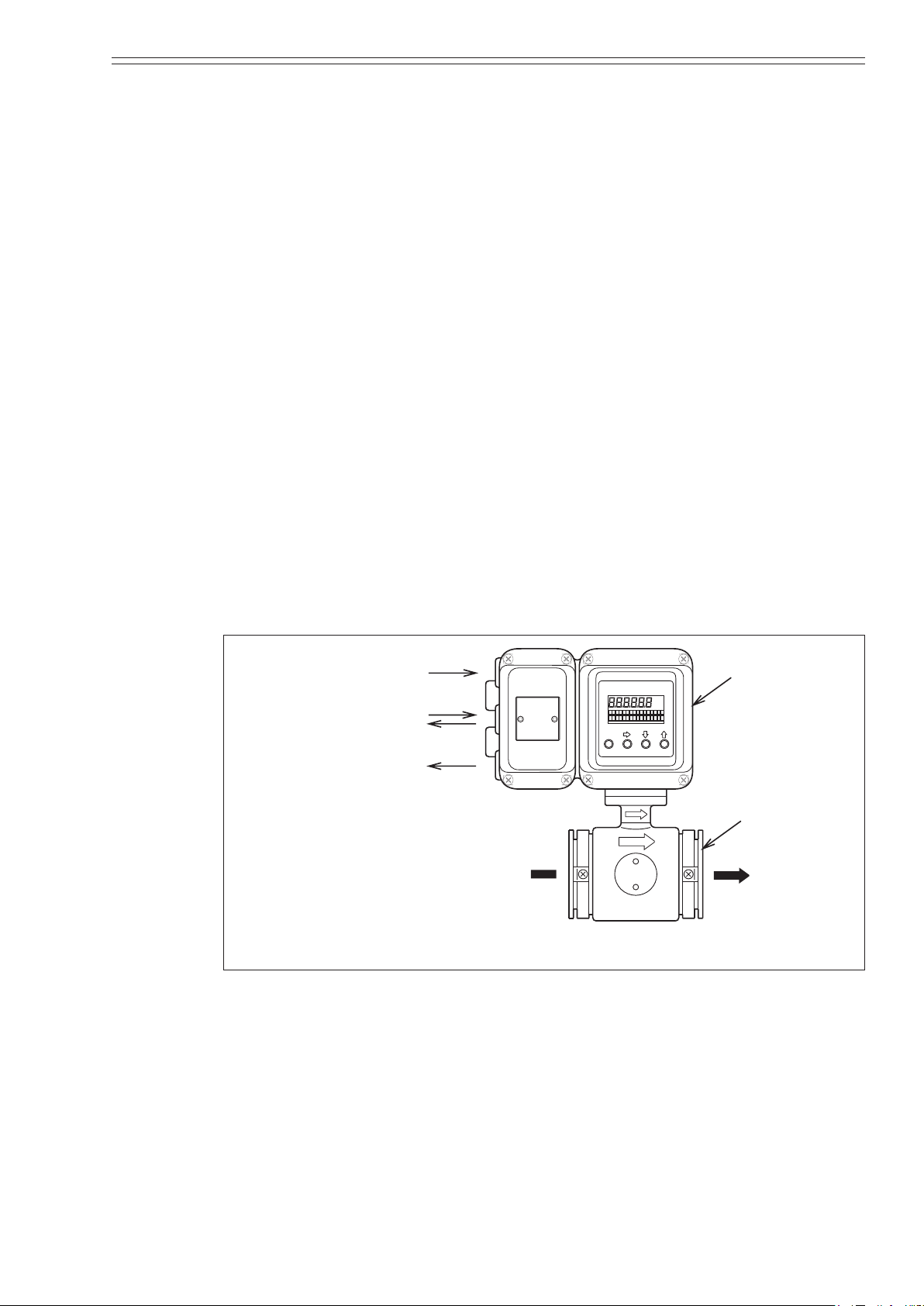

The model MGG10C/MGG14C MagneW FLEX+/PLUS+ Flowmeter consists of a

detector and a converter which operate on the principles of Faraday’s law.

Integral - The converter is mounted directly on the detector and they are installed as

an integrated unit on the uid pipe.

Remote - The converter and detector are installed separately and connected together

via cables

AC power supply

Analog output

Digital output

Detecto

Fluid

Figure 1-1 Integral System

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 1-1

Page 14

Introduction Azbil Corporation

P

Co

A

Analog output/

Digital output

Converter

C power supply

ulse output

ntact input/output

Excitation output

Flow signal input

Dedicated cable

Detector

Fluid

Figure 1-2 Remote System

1-2 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 15

Azbil Corporation Introduction

Analog output and digital output

Introduction

The choice of either an analog output or digital output system conguration depends

on whether or not you want to use the digitally enhanced (DE) communication mode.

Analog output (4 to 20 mA DC output)

In analog mode, the owmeter sends the instantaneous ow rate as a proportional 4 to

20 mA output signal to a controller or a recorder in the control system.

Digital output (DE output)

A owmeter in the DE mode can communicate in a direct digital fashion with Azbil

Corpotation or Honeywell DCS system. The digital signal can include ow rate,

owmeter database, and self-diagnostics.

Switching output mode

The analog/digital output mode is selectable.

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 1-3

Page 16

Introduction Azbil Corporation

System conguration for analog output (4 to 20 mA DC output)

Introduction

In the analog mode, the owmeter can be congured with or without SFC

communciations.

WITHOUT the communication function

The DC power supply that transmits the analog output, when the owmeter is used

without SFC communications, is built into the product.

The analog output signal is transmitted directly to the host control system.

• Analog output range: 0.8 to 22.4 mA (-20 to +115%)

• Resistive load: 0 to 600 W

WITH HART communication function

The DC power supply that transmits the analog output and HART communication,

when the owmeter is used with the HART communications, is built into the product.

• Analog output range: 3.2 to 22.4 mA (-5 to +115%)

• Resistive load: 0 to 600 W

WITH the communication function (SFC or HART)

When the owmeter is used in the analog mode with SFC communications, an

external power supply (DC power) and external resistive load (minimum 250 W) is

required. HART communication is also available with the external power supply and

resistive load.

• Analog output range: 3.2 to 22.4 mA (-5 to +115%)

• DC power: 16 to 45V DC

• Maximum value of external resistive load is calculated:

CAUTION

For systems WITH the SFC communication function, failure to install the external

power supply and the external resistive load, will prevent the analog output from

being accepted on the receiving instrument side. Be sure to install the external

power supply and the external resistive load as specied.

1-4 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 17

Azbil Corporation Introduction

A

power

supply

Device

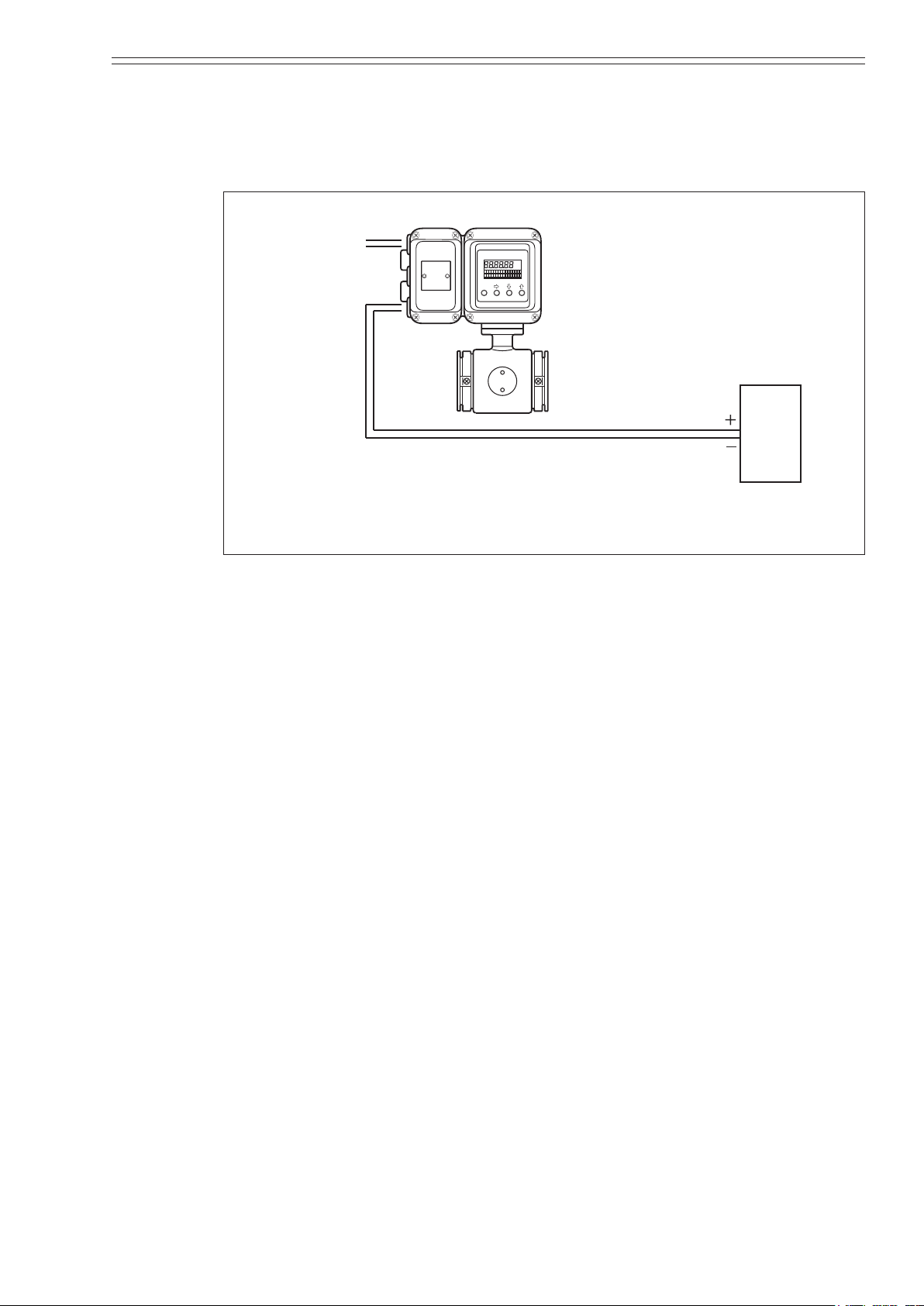

System conguration WITHOUT the communication function

Figure 1-3 shows a sample system conguration without the communication. In this

system, the device measures the ow rate and outputs analog 4 to 20mA DC signal to

the Host Control System.

C or DC

Host

control

system

Figure 1-3 System conguration of analog output WITHOUT communication

function

Smart Electromagnetic Flowmeter (device)

• Measures ow rate and outputs an analog signal.

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 1-5

Page 18

Introduction Azbil Corporation

A

power

supply

Device

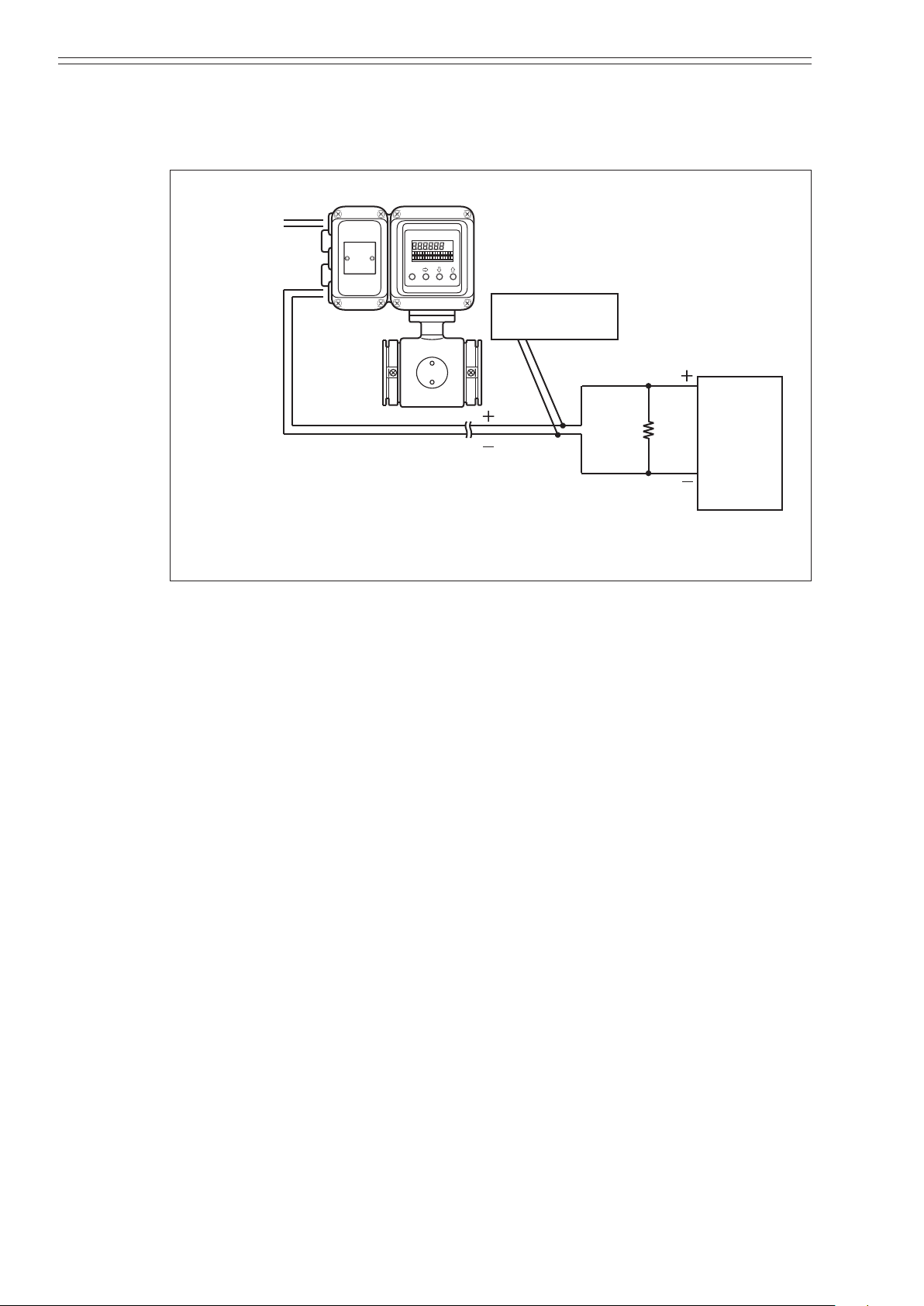

System conguration WITH the HART communication function with

the internal power supply

Figure 1-4 shows a sample system conguration in with the HART communication.

C or DC

HART375

communicator

250Ω

Host

control

4 - 20 mA

analog output

system

Figure 1-4 System conguration of with the HART communication with internal

power supply

Smart Electromagnetic Flowmeter (device)

• Measures ow rate and outputs an analog signal.

HART Communicator:

• Communicate with the MagneW

FLEX+/PLUS+. For the HART communication by the HART 375 communicator, the

FLEX+/PLUS+ and congure the data of the MagneW

necessary DD le needs to be downloaded.

1-6 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 19

Azbil Corporation Introduction

A

power

supply

Device

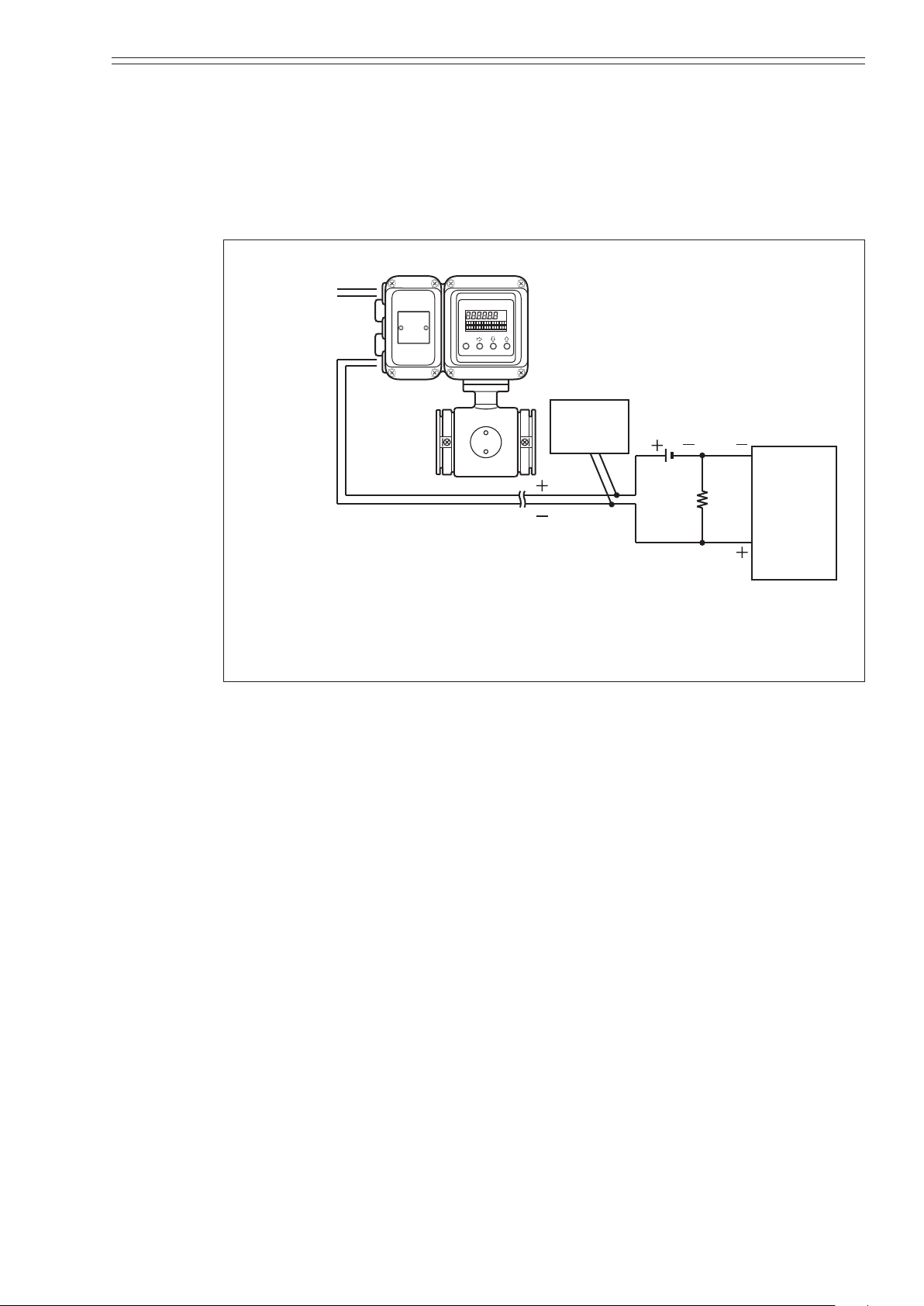

System conguration WITH the SFC or HART communication function

with the external power supply

Figure 1-5 shows a sample system conguration in which the instantaneous ow rate

measured by the unit is output with a 4 to 20 mA DC analog signal.

In order to enable communications, a DC power supply and a resistance of 250W or

more must be installed on the receiving side.

C or DC

Smart

communicator

SFC or

HART

4 - 20 mA

analog output

Figure 1-5 System conguration for analog output WITH the communication

function (example setup)

Smart Electromagnetic Flowmeter (device)

• Measures ow rate and outputs an analog signal instantaneous ow rate.

Smart Communicator (SFC):

• Communicates with the device to read data and change the device settings.

• The SFC version must be V7.0 or later.

HART Communicator:

• For the HART communications by the HART 375 communicator, the neccesary DD

le needs to be downloaded.

DC24V power supply

250Ω

resistance

Host

control

system

(1 - 5 V

input)

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 1-7

Page 20

Introduction Azbil Corporation

A

power

supply

Device

System Conguration for Digital Output (DE Output)

System conguration

Figure 1-5 shows a system conguration in which the ow rate measured by the

unit, the database in the unit, and self-diagnostics are output using the DE (Digital

Enhancement) protocol (rules for digital signal communication).

In this system, the DE protocol-based digital signal transmitted from the unit is

output to the control system after conversion to an analog signal at the smart protocol

converter (SPC). Or, the digital signal is directly transmitted to the control system, if

it is capable of receiving the DE protocol-based signal directly.

AC or DC

power

supply

SFC

Device

C or DC

SFC

SHL

SPC

Control

system

PM100,

PM300,

or

A-MC

Figure 1-6 System conguration for digital output

Smart Electromagnetic Flowmeter (device)

Measures ow rate and outputs the instantaneous ow rate and unit self-diagnostics

using a digital signal.

Smart protocol converter (SPC)

Converts the DE protocol-based digital signal into a 4 to 20 mA or 1 to 5 V DC

analog signal for output.

Smart handy loader (SHL)

Used to change the SPC settings.

Smart communicator (SFC)

• Used to communicate with the device to read data and change the device settings.

PM100

• Simultaneously executes such functions as process control on the UCN, regulatory

control, sequencing, calculation, and process input/output.

1-8 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 21

Azbil Corporation Introduction

C

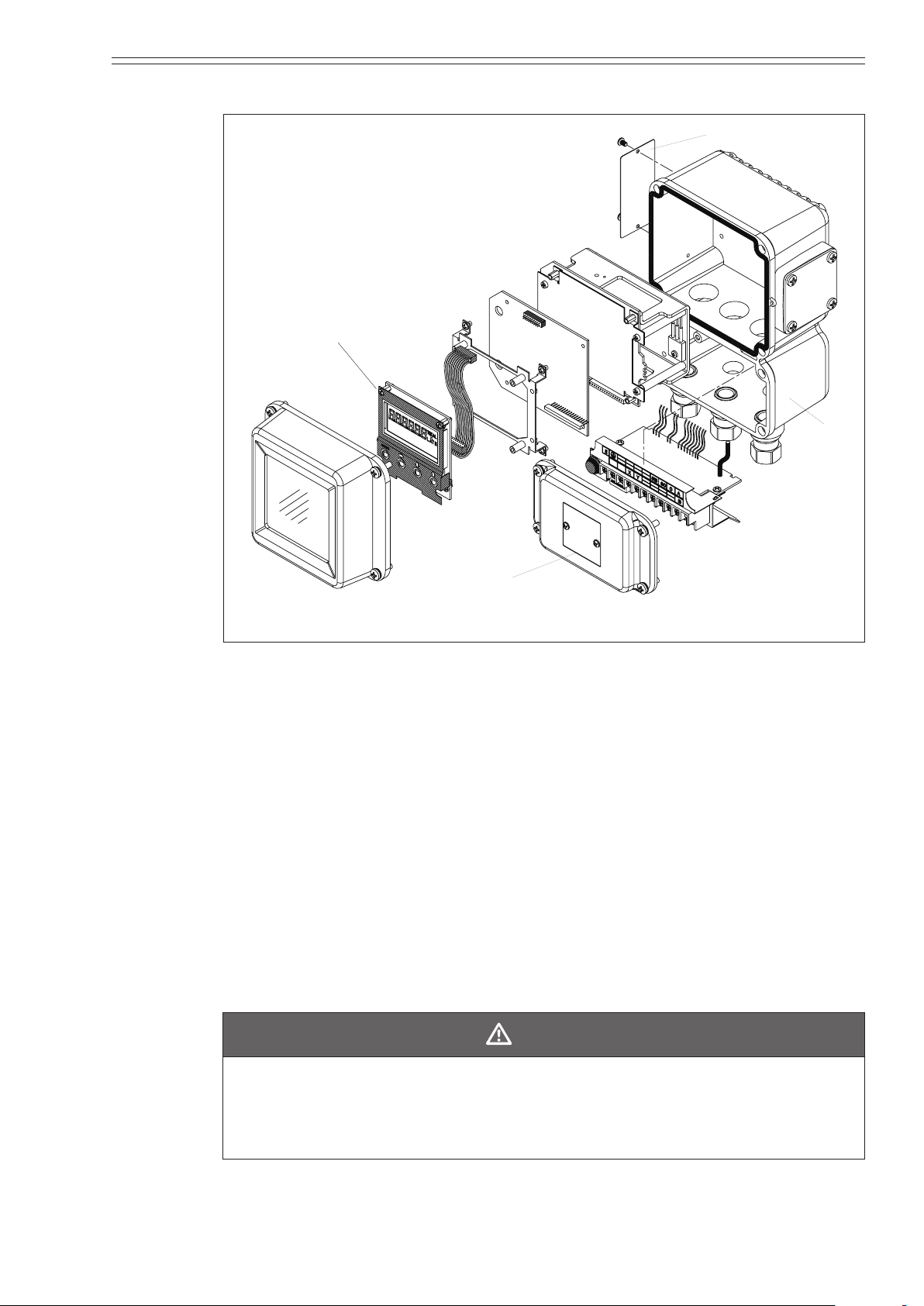

The converter consists of the components shown in the gure below.

A

B

D

Figure 1-7 Parts of the converter

Converter

• Converts electromotive force by the detector to the ow rate signal.

• Transmits the analog output or the digital output as the ow rate signal.

Data setting device (A)

• Displays the ow rate and the totalized value.

• The Data can be congured through the four infrared sensor keys.

Terminal box (B)

• Encloses the inputs/outputs terminals.

• Equipped with lightning arrestor.

Name plate (C)

• Indicates model numbers, product numbers and the detector factor (EX).

Tag number plate (D)

• Indicates the tag number as specied in the product order.

CAUTION

Do not apply over-voltage that exceed following lightning arrestor specication.

The converter may be damaged.

• Power supply terminal: series mode 1kV, common mode 2kV

• Input/Output terminal: series mode 1kv, common mode 1kV

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 1-9

Page 22

Introduction Azbil Corporation

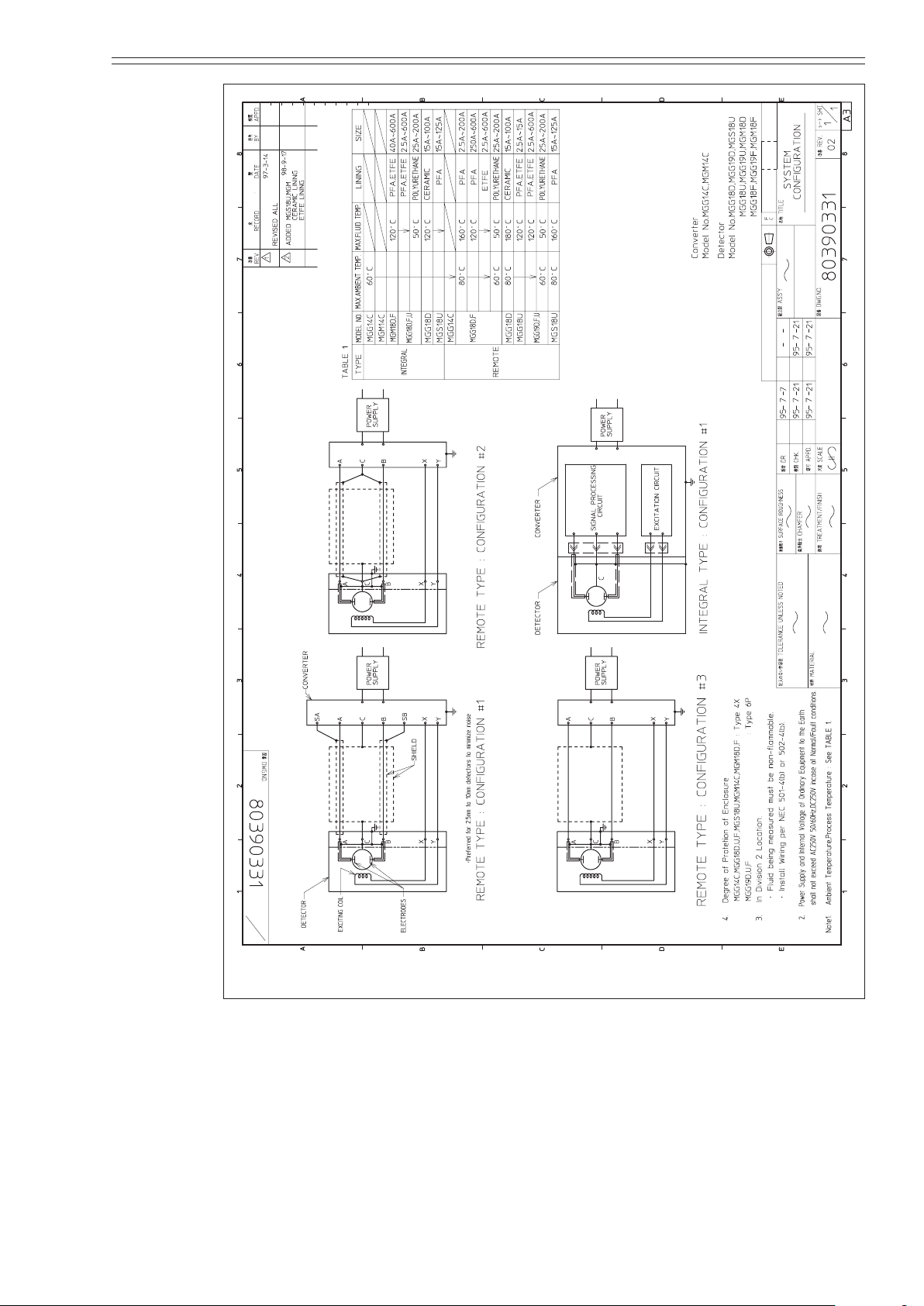

Approval of this Device

Overview

If the basic model number is MGG14C and 1/2 NPT wiring connection is selected

and style code is selected as “N”, this device functions as an FM, non-incentive-

approved model. In this case, the installation standards described in this section must

be followed.

Installation of this device

FM Nonincendive model

THIS EQUIPMENT IS SUITABLE FOR USE IN CLASS I, DIVISION 2,

GROUPS(A, B, C, D), CLASS II/III, DIVISION 2, GROUPS (F, G), OR NONHAZARDOUS LOCATIONS ONLY.

CAUTION

• Power supply and internal voltage of ordinary equipment to the earth shall not

exceed AC250V 50/60HZ, DC250V in case of normal /formal conditions.

• Ambient temperature is from - 25 to 60C

• Process temperature is from -40 to 160C (Remote model).

• Process temperature is from -40 to 120C (Integral model)

1-10 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 23

Azbil Corporation Introduction

Figure 1-8 System conguration

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 1-11

Page 24

MEMO

Page 25

Chapter 2: Installation

This chapter describes the installation and wiring procedures for the owmeter.

WARNING

ELECTRIC SHOCK HAZARD! DO NOT perform wiring work while the power

is ON!

Site selection

When selecting an installation site for the owmeter, observe the following safety

measures:

CAUTION

Install the owmeter in a location with an ambient temperature of -25 °C to

60 °C (-13 °F to 140 °F) and an ambient humidity of 5 to 100% RH to prevent

equipment malfunction or output errors.

CAUTION

Do not install the owmeter near high-current power lines, motors or transformers

to prevent damage from electromagnetic induction, which can cause equipment

malfunction or output errors.

CAUTION

Be sure to ground the welding power transformer when welding near the

owmeter to avoid output errors.

CAUTION

DO NOT use the owmeter to ground a welder. It can damage the owmeter.

CAUTION

Do not install the owmeter on the bridge or deck of the ship.

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 2-1

Page 26

Installation Azbil Corporation

Unpacking and storage

The model MGG10C/MGG14C MagneW FLEX+/PLUS+ Flowmeter is a precision

instrument and should be handled with care to prevent damage or breakage.

After unpacking the owmeter, verify that the following items are included:

• Model MGG10C/MGG14C converter

• Standard accessories

• MagneW setting data sheet

• Test report

If you have questions regarding the technical specications of the owmeter, contact

your nearest Azbil Corporation oce or Azbil Corporation representative. When

making an inquiry, make sure to provide the model number and product number of

your owmeter.

Storage

When storing the owmeter before use:

• Store indoors at room temperature (77 °F or 25 °C) within a humidity level of

approximately 65%.

• Store away from vibration or shock.

• Store the converter and detector in the original packaging.

In addition, when storing the converter after use:

• Attach the display cover, Terminal box cover and Waterproof gland(s) to prevent

moisture ingression into the device.

2-2 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 27

Azbil Corporation Installation

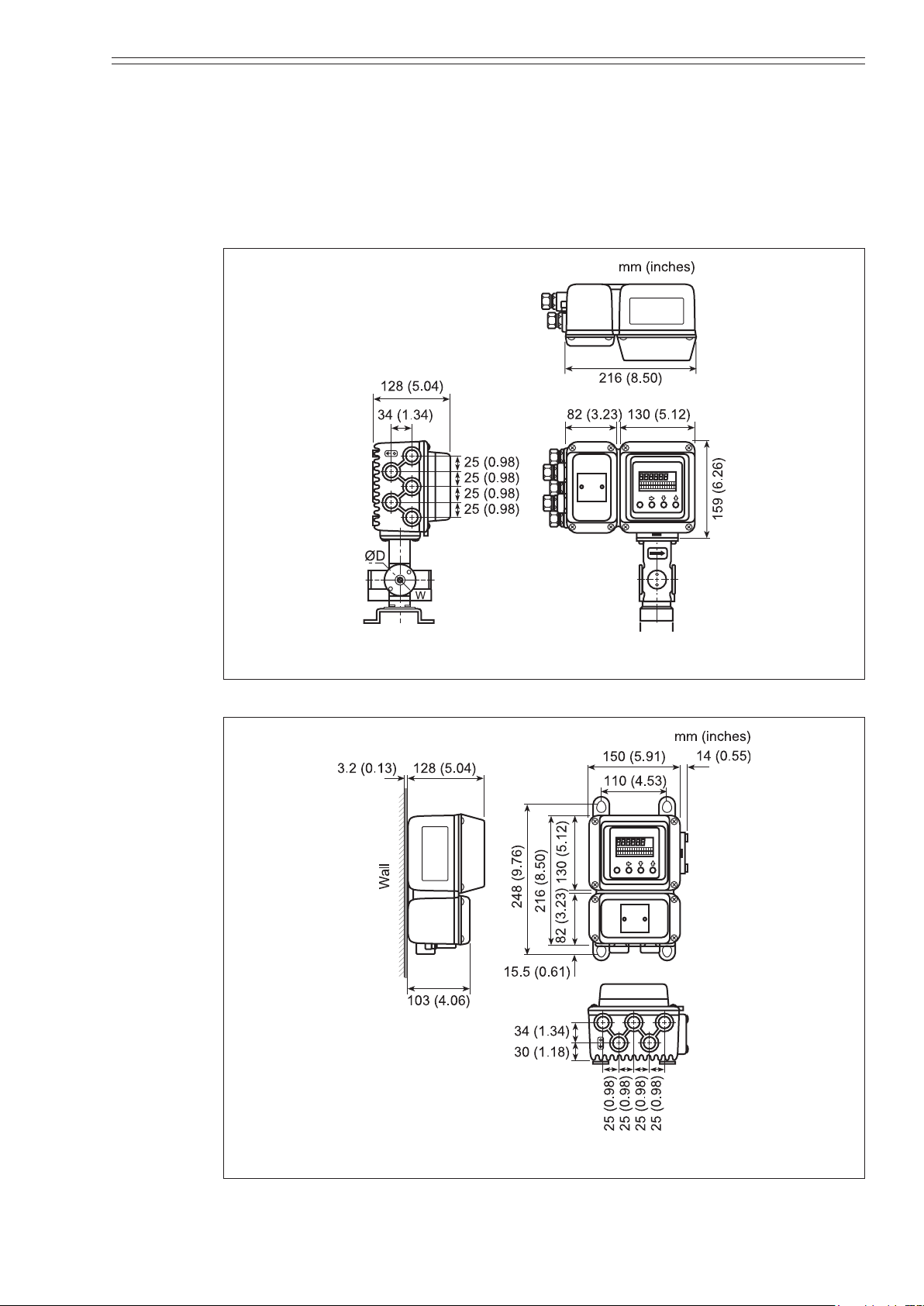

Installation options

There are three ways to install the owmeter. Integral systems are pre-assembled

with the converter attached to the detector; remote systems allow you to install the

converter in a remote location - wall mounted or mounted directly to a two inch (50.8

mm) pipe. The following illustrations provide dimensions for the three dierent

installation options.

Figure 2-1 Integral installation

Figure 2-2 Wall mounted remote installation

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 2-3

Page 28

Installation Azbil Corporation

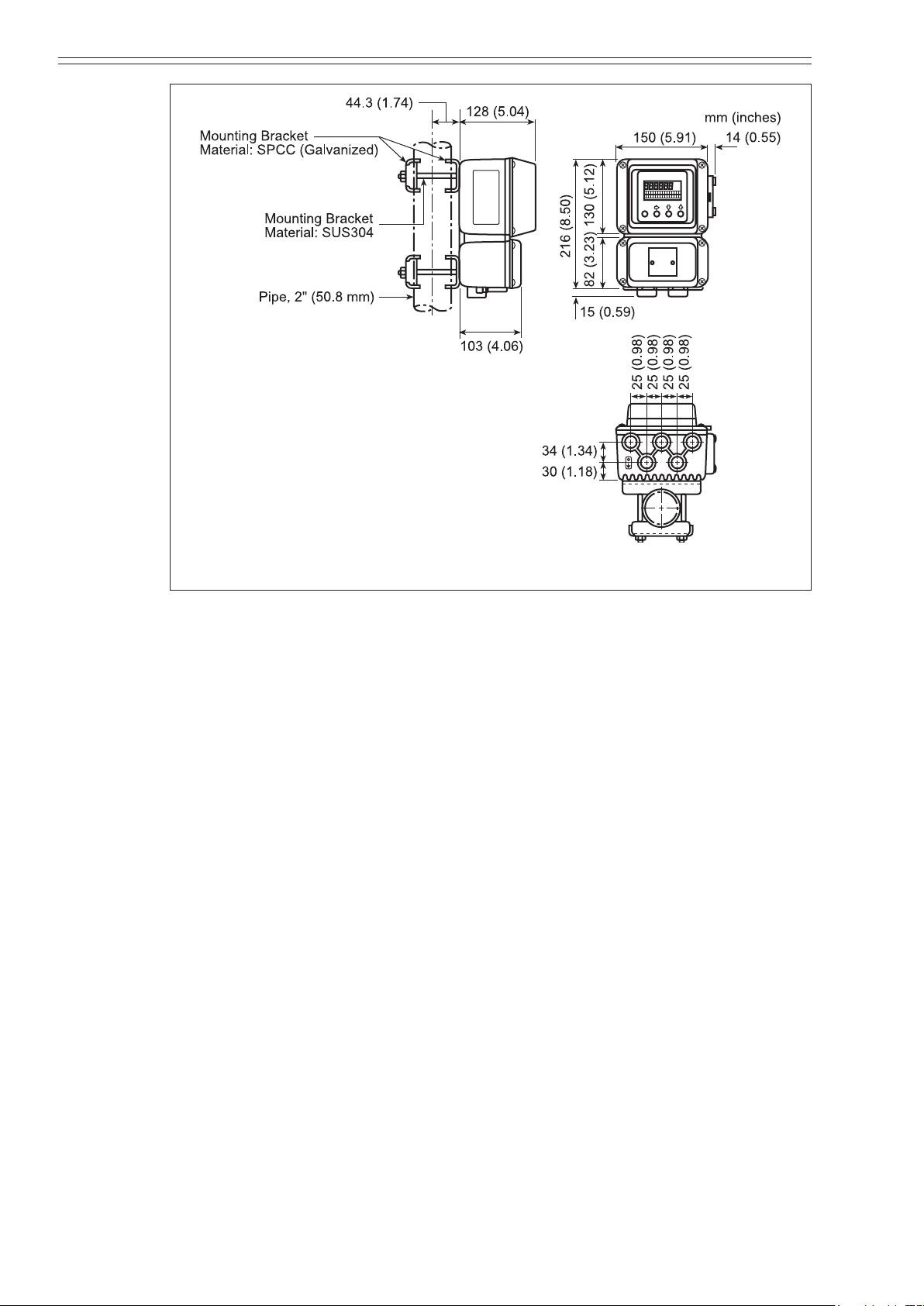

Figure 2-3 Pipe mounted remote installation

Changing the orientation of the converter

The model selected when the owmeter is purchased determines the orientation of the

display. It is possible, however, to change the horizontal or vertical orientation of the

converter.

To change the orientation of the converter:

1. Remove the four screws holding the display cover to the main body and remove

the cover.

2. Remove the four screws holding the display panel to the main body.

3. Remove and rotate the display panel to the required orientation.

4. Replace the four screws and tighten.

5. Rotate the display cover so that the openings for the LEDs are correctly aligned

with the Display Panel.

6. Replace the four screws and tighten.

2-4 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 29

Azbil Corporation Installation

Wiring

CAUTION

Use electrical tube and duct to prevent water entry and protect the cable from

external damage.

CAUTION

Be sure to use a waterproof gland at the conduit connection to prevent water entry

inside of the terminal box and prevent output errors.

CAUTION

Turn o the power supply before connecting the cables to the converter.

The converter can be damaged. This type of damage is not covered by Azbil

Corporation’s warranty.

CAUTION

Be sure to plug all unused conduit connections with a water tight plug.

CAUTION

In case that a remote model is installed in a ship, the cables between the converter

and detector must be covered with a exible metal conduit.

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 2-5

Page 30

Installation Azbil Corporation

STATUS IN STATUS OUT

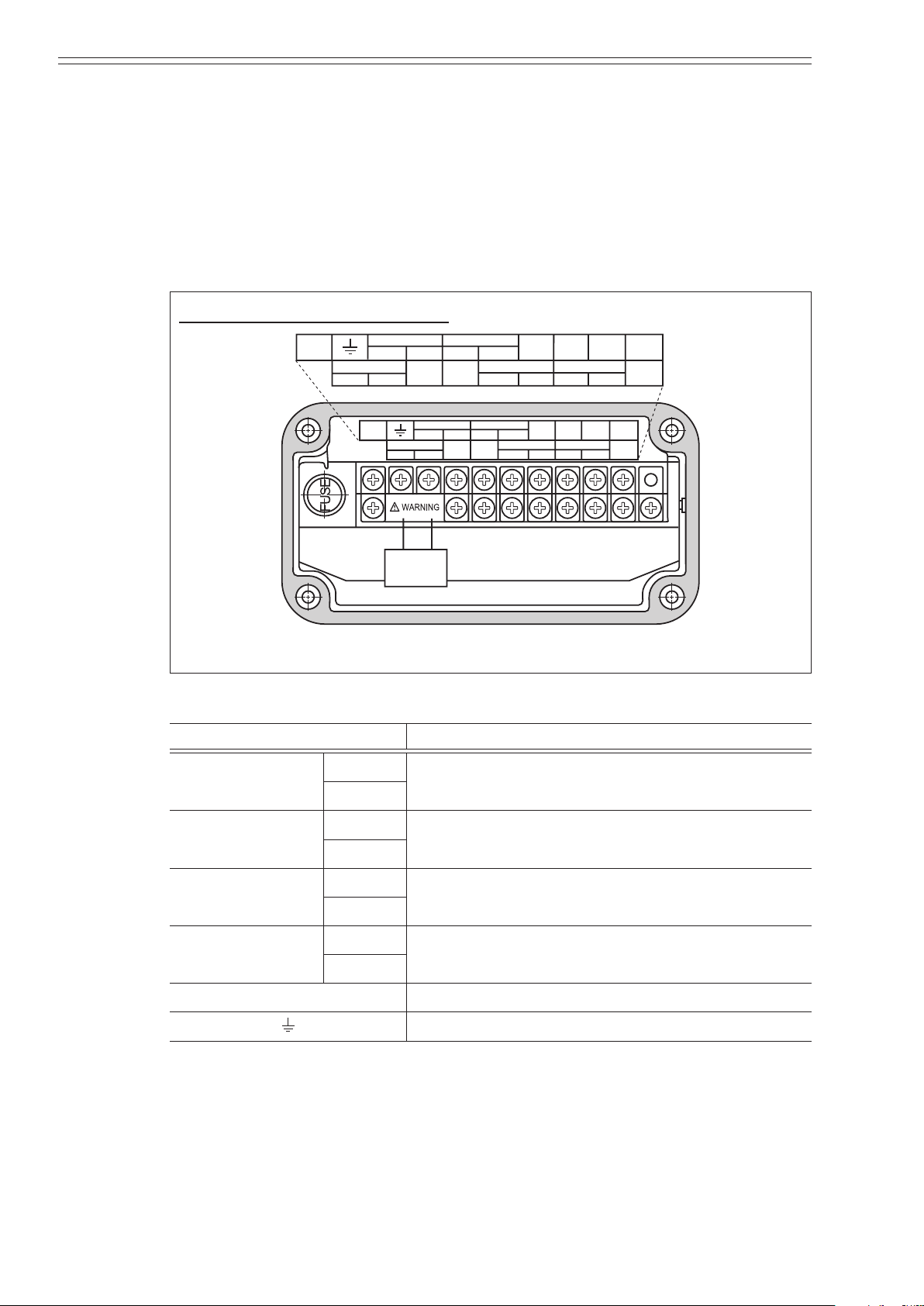

Integral wiring - 1 (1-contact input and 1- contact output)

To wire a remote system, the following cables are required:

• Analog output cable - see page 2-16

• Pulse output cable - see page 2-17

• Contact input/output cable - see page 2-17

The following pages provide information on selecting the correct cables and wiring

the system. A diagram of the terminal block for a remote system is shown below.

1-contact input and 1-contact output

E

+-+-

POWER AC

LN

E

STATUS IN STATUS OUT

+-+-

POWER AC

LN

SB SA CA

+-+-

SB SA CA

+-+-

AC

POWER

Figure 2-4 Integral converter terminal block

Table 2-1 Remote converter terminal descriptions

Symbol Description

+

I. OUT

Analog output

–

I. OUTP. OUT

I. OUTP. OUT

(1-contact input & 1-contact output)

BXY

BXY

P. OUT

Pulse output

–

+

+

STATUS IN

Contact input

–

+

STATUS OUT

Contact output

–

E Not used

~ Note

In case of DC24V and DC110V power supply, the symbol of the “L” and “N” of the

Grounding (grounding resistance must be <100W)

power supply become “+” and “–”.

2-6 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 31

Azbil Corporation Installation

STATUS IN 1STATUS IN 2

Integral wiring - 2 (2-contact input)

To wire a remote system, the following cables are required:

• Analog output cable - see page 2-16

• Pulse output cable - see page 2-17

• Contact input/output cable - see page 2-17

The following pages provide information on selecting the correct cables and wiring

the system. A diagram of the terminal block for a remote system is shown below.

2-contact input

E

POWER AC

+-+-

LN

E

STATUS IN 1STATUS IN 2

+-+-

POWER AC

LN

SB SA CA

+-+-

+-+-

I. OUTP. OUT

SB SA CA

I. OUTP. OUT

BXY

BXY

AC

POWER

Figure 2-5 Integral converter terminal block

Table 2-2 Remote converter terminal descriptions (2-contact input)

Symbol Description

+

I. OUT

Analog output

–

P. OUT

Pulse output

–

+

+

STATUS IN 1

Contact input 1

–

+

STATUS IN 2

Contact input 2

–

E Not used

~ Note

In case of DC24V and DC110V power supply, the symbol of the “L” and “N” of the

Grounding (grounding resistance must be <100 W)

power supply become “+” and “–”.

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 2-7

Page 32

Installation Azbil Corporation

STATUS OUT 2STATUS OUT 1

Integral wiring - 3 (2-contact output)

To wire a remote system, the following cables are required:

• Analog output cable - see page 2-16

• Pulse output cable - see page 2-17

• Contact input/output cable - see page 2-17

The following pages provide information on selecting the correct cables and wiring

the system. A diagram of the terminal block for a remote system is shown below.

2-contact output

E

+-+-

POWER AC

LN

STATUS OUT 2STATUS OUT 1

E

+-+-

POWER AC

LN

SB SA CA

+-+-

+-+-

I. OUTP. OUT

SB SA CA

I. OUTP. OUT

BXY

BXY

AC

POWER

Figure 2-6 Integral converter terminal block

Table 2-3 Remote converter terminal descriptions (2-contact output)

Symbol Description

+

I. OUT

Analog output

–

P. OUT

Pulse output

–

+

+

STATUS OUT 1

Contact output 1

–

+

STATUS OUT 2

Contact output 2

–

E Not used

~ Note

In case of DC24V and DC110V power supply, the symbol of the “L” and “N” of the

Grounding (grounding resistance must be <100 W)

power supply become “+” and “–”.

2-8 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 33

Azbil Corporation Installation

STATUS IN STATUS OUT

Remote wiring - 1 (1-contact input and 1- contact output)

To wire a remote system, the following cables are required:

• Signal cable - see page 2-12

• Excitation cable - see page 2-12

• Analog output cable - see page 2-16

• Pulse output cable - see page 2-17

• Contact input/output cable - see page 2-17

The following pages provide information on selecting the correct cables and wiring

the system. A diagram of the terminal block for a remote system is shown below.

1-contact input and 1-contact output

E

POWER AC

+-+-

LN

E

XY

STATUS IN STATUS OUT

+-+-

POWER AC

LN

AC

POWER

XY

SB SA CA

+-+-

SB SA CA

+-+-

Figure 2-7 Remote converter terminal block

Table 2-4 Remote converter terminal descriptions

Symbol Description

A

B

C

Flow rate signal input

SA

SB

I. OUT

P. OUT

STATUS IN

STATUS OUT

+

–

Analog output

+

–

+

–

+

–

Contact input

Contact output

X

Y

E Not used

Grounding (grounding resistance must be <100W)

I. OUTP. OUT

I. OUTP. OUT

(1-contact input & 1-contact output)

B

B

Pulse output

Excitation

~ Note

In case of DC24V and DC110V power supply, the symbol of the “L” and “N” of the

power supply become “+” and “–”.

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 2-9

Page 34

Installation Azbil Corporation

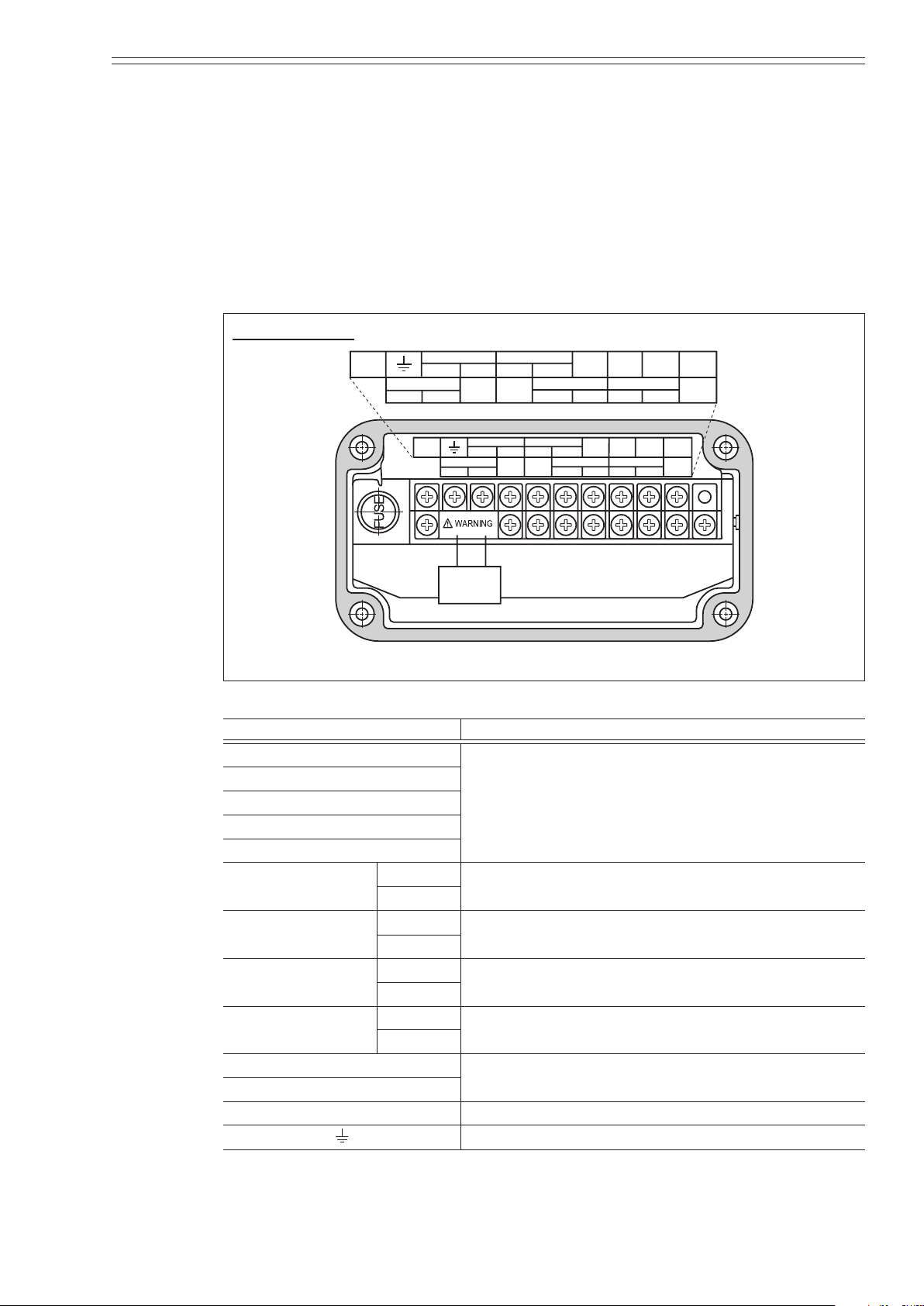

STATUS IN 1STATUS IN 2

Remote wiring - 2 (2-contact input)

To wire a remote system, the following cables are required:

• Signal cable - see page 2-12

• Excitation cable - see page 2-12

• Analog output cable - see page 2-16

• Pulse output cable - see page 2-17

• Contact input/output cable - see page 2-17

The following pages provide information on selecting the correct cables and wiring

the system. A diagram of the terminal block for a remote system is shown below.

2-contact input

Table 2-5 Remote converter terminal descriptions (2-contact input)

I. OUT

P. OUT

STATUS IN 1

STATUS IN 2

E

+-+-

POWER AC

LN

E

XY

STATUS IN 1STATUS IN 2

+-+-

POWER AC

LN

AC

POWER

XY

SB SA CA

+-+-

+-+-

I. OUTP. OUT

SB SA CA

I. OUTP. OUT

B

Figure 2-8 Remote converter terminal block

Symbol Description

A

B

C

Flow rate signal input

SA

SB

+

–

+

–

+

–

+

–

X

Y

Analog output

Pulse output

Contact input 1

Contact input 2

Excitation

E Not used

Grounding (grounding resistance must be <100 W)

B

~ Note

In case of DC24V and DC110V power supply, the symbol of the “L” and “N” of the

power supply become “+” and “–”.

2-10 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 35

Azbil Corporation Installation

STATUS OUT 2STATUS OUT 1

Remote wiring - 3 (2-contact output)

To wire a remote system, the following cables are required:

• Signal cable - see page 2-12

• Excitation cable - see page 2-12

• Analog output cable - see page 2-16

• Pulse output cable - see page 2-17

• Contact input/output cable - see page 2-17

The following pages provide information on selecting the correct cables and wiring

the system. A diagram of the terminal block for a remote system is shown below.

2-contact output

E

POWER AC

+-+-

LN

E

XY

STATUS OUT 2STATUS OUT 1

+-+-

POWER AC

LN

AC

POWER

XY

SB SA CA

+-+-

+-+-

I. OUTP. OUT

SB SA CA

I. OUTP. OUT

B

B

Figure 2-9 Remote converter terminal block

Table 2-6 Remote converter terminal descriptions (2-contact output)

Symbol Description

A

B

C

Flow rate signal input

SA

SB

I. OUT

P. OUT

STATUS OUT 1

STATUS OUT 2

X

Y

+

–

+

–

+

–

+

–

Analog output

Pulse output

Contact output 1

Contact output 2

Excitation

E Not used

Grounding (grounding resistance must be <100 W)

~ Note

In case of DC24V and DC110V power supply, the symbol of the “L” and “N” of the

power supply become “+” and “–”.

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 2-11

Page 36

Installation Azbil Corporation

Grounding

CAUTION

ELECTRIC SHOCK HAZARD! Grounding is essential for accurate

measurement. The grounding resistance must be less than 100W.

Signal and excitation cable specications

For remote installations, the converter and detector are connected using a set of

dedicated cables (Model MGA12W). The signal cable connects the output signal

of the detector to the converter and the excitation cable feeds the excitation current

to the detector. You can obtain these cables from Azbil Corporation or purchase

commercially available cables. Integral owmeters already contain the converter to

detector connections.

The cables between the detector and converter should be no longer than 300 m (984

ft.), but the actual length depends on conductivity of the uid being measured.

The following cable diameters apply:

2

Signal cable - 11.4 mm (0.45 in.), 0.75 mm

(.0011625 sq. in.) or equivalent

commercially available cable (CVVS or CEEV, for example)

2

Excitation cable - 10.5 mm (0.41 in.), 2 mm

(.0031 sq. in.) or equivalent

commercially available cable (CVV, for example)

Cable dimensions and construction are shown on the following pages.

The following graphs show the ratio of uid conductivity to cable length and show

cable usage ranges for dierent diameter cables. The acceptable usage range for Azbil

Corporation’s cable Model MGA12W cables encompass both areas A and B in the

graphs below while commercially available cables are limited to area A only.

Figure 2-10 Cable usage ranges

2-12 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 37

Azbil Corporation Installation

Detector side Converter side

Detector side Converter side

Out

ath

ath

d

)

Conduct

e

ator

Out

er shiel

d

Sheath

pe

ator

Conduct

e

Si

g

citation cable

mm (inches)

To M4

Screw

To M4

Screw

Model A

To M4

Screw

Model B

60 (2.36)

60 (2.36)

L 90 (3.54)

60 (2.36)

60 (2.36)

65 (2.56)

70 (2.76)

40 (1.57)

60 (2.36)

Figure 2-11 Signal Cable Dimensions

90 (3.54)

65 (2.56)

60 (2.36)

To M4

Screw

60 (2.36)

mm (inches)

60 (2.36)

To M4

Screw

60 (2.36)

Figure 2-12 Excitation Cable Dimensions

nal cable

er she

Inner she

Inner shiel

Conductive tube (Black

ive wir

Insul

Figure 2-13 Signal and excitation cable construction

~ Note

Strip the conductive tubing (black) down to the ends of the inner shields on the

conductive wires for terminals A and B of the signal cable.

70 (2.76)

To M4

L

70 (2.76)

Cloth ta

Insul

Screw

ive wir

Ex

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 2-13

Page 38

Installation Azbil Corporation

ctor

e

W

Co

r

C

tation cable

W

ctor

tation cab

g

e

e

r

Dedi

cated cabl

e model MGA12

W

Commerciall

y

e

Signal and excitation cable wiring

The following gure shows the proper terminal connections for the signal and

excitation cables for both model MGA12W cables and commercial cable.

Signal cabl

model MGA12

nverte

Dete

Exci

model MGA12

Dete

available cabl

nal cable 2-cor

Si

Single shielded cabl

Exci

le

Figure 2-14 Detector to converter wiring diagram

nverte

2-14 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 39

Azbil Corporation Installation

Wiring cable

Selecting the cable

The recommended wiring cable is a 600V vinyl sheath electrical wire CVV (JIS C

2

3401) with a conductor section of 2 mm

equivalent or higher capacity.

Shielded wire is recommended for wiring at locations subject to electromagnetic

noise interference.

Select a sheath material suitable for the cable installation environment (consider

ambient temperature, corrosive gas, corrosive uid, etc.)

Run the cable into the terminal block through the conduit connection (G1/2 internal

thread, CM20 external thread, Pg13.5 or 1/2NPT internal thread).

f

An outer diameter of

outer diameters is

A crimp terminal (M4 screw) with an insulation sleeve is recommended for the

terminal connections.

11(0.433 inch) is optimum. (The applicable range of cable

f

10(0.394 inch) - f12(0.4724 inch).)

(0.0031 inch2), or a twisted cable with an

~ Note

The maximum length of the wiring cable is 1500 m(4921 ft). However, the maximum

length between converter and detector is 300 m(984 ft).

Wiring the cable

When wiring the cable between this product and the control equipment, the following

precautions must be observed.

• Run the wiring away from equipment that may generate noise, such as highcapacity transformers, motors, or power supplies. DO NOT install the cable in the

same tray or duct as other power cables. Output errors may result.

• For water proong and damage prevention of the wire, we recommend cabling

work using conduits and ducts. Use a water proof cable gland.

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 2-15

Page 40

Installation Azbil Corporation

With SFC communications

* An external power supply is needed.

With HART communications(internal power supply)

Wiring

Analog output wiring

The current output wiring method depends on HART or SFC communication.

An external power supply is required to communicate with the SFC.

(Change dip switch settings only after turing power supply OFF.)

Position of dip switch pins

I OUT

SFC

~ Note

Converter

Converter

Brack

Brack

Red

HART375 Communicator

*

DC power

supply

24V/42V

Red

SFC

Receiving

instrument

Receiving

instrument

(Move the switches to

the blackened positions.)

Position of dip switch pins

I OUT

(Move the switches to

the blackened positions.)

SFC

Figure 2-15 Wiring diagram for current output

• Check and conrm that the polarity of the wiring is correct. Incorrect polarity may

cause damage to the equipment.

• In case of not using communication function, the position of dip switch pins should

be set as the HART communication. HART Communication works with the wiring

for the SFC communication.

• The communication type (HART or SFC) must be specied when ordering. In case

of communication change, the following two congurations are necessary.

1) According to the communication type, switch position should be changed.

(Refer to the Figure 2-15).

2) Change communication type in the “COM SELECT” screen in the “Shipping

Info” screen.

2-16 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 41

Azbil Corporation Installation

Protective diode

S6 switch

Empty detection function switch

Wr

protec

switch

Main car

C

switch

Pulse output wiring

The pulse output is an open collector output.

Pay close attention to voltage and polarity when wiring.

200mA max.

Load

~ Note

External

power supply

30V max.

Avoid this polarity

Figure 2-16 Wiring diagram for pulse output

Check and conrm that the polarity of the wiring is correct. Incorrect polarity may

cause damage to the equipment.Use an external power supply that meets the voltage

and capacity specications. Pulse may be output when the power is turned ON or

OFF. Pulse output protection circuit causes voltage drop. Some counters may not

pick up the pulses due to this voltage drop. In such case, turn On S6 switch. Refer to

the Figure 2-17.

ite

tion

ommnication

Pulse output

protection

circuit

d

S6 ON

Figure 2-17 Switch locations on main card

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 2-17

Page 42

Installation Azbil Corporation

Withstand voltage 30V min.

Contact input wiring

Either a semi conductive contact or a no-voltage contact can be used as the contact

input.

The contact input terminals are not available when a 2-contact output model has been

selected.

STATUS IN

24V

24V

STATUS IN

STATUS IN

STATUS IN

Required specications for the

semi - conductive contact.

OFF:

Leak current 0.1mA max.

ON : Saturation voltage 3V max.

ON current 15mA max.

Required specications for

No-voltage contact.

OPEN: Resistance 100k min.

CLOSE : Resistance 400 max.

Figure 2-18 Wiring diagram for contact input

Contact output wiring

Pay close attention to voltage and polarity when wiring for an open collector output.

Protective diode

Load

External

power supply

30V max.

Avoid this polarity

Figure 2-19 Wiring diagram for contact output

~ Note

Check and conrm that the polarity of the wiring is correct. Incorrect polarity may

cause damage to the equipment.

Use an external power supply that meets the voltage and capacity specications.

2-18 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 43

Azbil Corporation Installation

Setting write protection

Write protection settings allow you to control the level at which data conrmation

and manipulation are possible. The system has four modes:

Basic setup mode - used to run the owmeter on a day-to-day basis.

Engineering mode - used by those who are responsible for owmeter conguration.

Maintenance mode - used when system maintenance is required.

Advanced mode - used to apply some specic noise immunity functions, and other

advanced functions.

Write protection settings are changed by setting the switch positions of the write

protection switch on the main card in the converter. When the owmeter is shipped,

settings can be made in any mode (Level 0). The following table shows the write

protect levels available by resetting the switch:

Table 2-7 Write Protection Levels

Level

Basic setup/

Engineering

mode

Advanced

mode

Maintenance

mode

Remarks

0

1

2

3 – –

a - Both data conrmation and manipulation are possible.

– - Only data conrmation is possible.

r - Neither data conrmation nor manipulation are possible.

a a a

a a r

a

–

r

r

Default setting

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 2-19

Page 44

Installation Azbil Corporation

Empty detection function switch

C

switch

Level 0

Level 1

Level 2

Level 3

To set the write protection level:

1. Remove the four screws holding the display cover to the main body of the

converter and remove the cover.

2. Locate the write protection switch.

Write

protection

switch

Main card

ommnication

Figure 2-20 Switch locations on main card

3. Set the write protection switch positions to the required level of protection.

Write

protect

Write

protect

Write

protect

Write

protect

OFF

ON

(Move the switches to the white positions)

Figure 2-21 Write protection switch positions

2-20 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 45

Azbil Corporation Installation

Empty detection function switch

Wr

protec

switch

Main car

C

switch

OFF ON

I SFC

Setting the communication via the HART

To check the communication switch position on the main card:

1. Remove the four screws holding the display cover to the main body of the

converter and remove the cover.

2. Locate the communication switch

ite

tion

d

ommunication

3. Make sure that position of the I switch (1-4) are ON and positions of the SFC

switch (5-8) are OFF.

Figure 2-22 Switch locations on main card

5678

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 2-21

~ Note

FSKOFF

(Move the switches to the white positions)

Figure 2-23 HART communication switch positions

Refer to the Figure 2-15 Wiring diagram for current output for the wiring

Page 46

Installation Azbil Corporation

Empty detection function switch

Wr

protec

switch

Main car

C

switch

Empty detec

function ON

function OFF

EPEP

Setting the empty detection function

This function xes the analog output and latches the display to zero when the detector

is empty.

To set the empty detection function:

1. Remove the four screws holding the display cover to the main body of the

converter and remove the cover.

2. Locate the empty detection function switch.

ite

tion

d

ommunication

Figure 2-24 Switch locations on main card

3. Set the empty detection function switch positions to the required setting.

2-22 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

tion

Empty detection

(Move the switches to the white positions)

Figure 2-25 Empty detection function switch positions

OFF ON

Page 47

Azbil Corporation Installation

Empty detection function switch

Wr

protec

switch

Main car

OFF ON

I SFC

Setting the communication via the SFC

To check the communication switch position on the main card:

1. Remove the four screws holding the display cover to the main body of the

converter and remove the cover.

2. Locate the communication switch

ite

tion

d

Communication

switch

3. Make sure that position of the I switch (1-4) are OFF and positions of the SFC

switch (5-8) are ON.

Figure 2-26 Switch locations on main card

5678

OFF ON

Figure 2-27 SFC communication switch positions

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 2-23

Page 48

Installation Azbil Corporation

Connecting power

WARNING

ELECTRIC SHOCK HAZARD! DO NOT perform wiring work while the power

is ON!

Commercial power (AC100~120, 200~240V, 50-60Hz) or a 24 VDC ± 10% power

supply is required for this system. The power supply specication is shown on the

name plate of your converter.

Figure 2-28 Name plate

The 24 VDC converter has a terminal marked “POWER DC24V” instead of

“POWER,” as on the remote converter.

2-24 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 49

Chapter 3: Operation

This chapter describes the procedure for starting and shutting down the owmeter and

using the display panel and the infrared touch sensor keys.

Start-up

To start operation of the owmeter:

1. Conrm that the detector is correctly installed on the pipe.

2. Conrm that the wiring between the converter and the detector has been properly

completed according to the installation instructions specied in this manual. In

case of using a HART/SFC communication function, verify an appropriate wiring

according to the wiring in this users manual.

3. Begin and then stop uid ow through the detector so that uid is present in the

detector in a static condition.

4. Conrm that there is no leakage at the anges of the detector.

5. Apply power to the converter.

6. The following display appears seven seconds after the power is ON.:

7. Zero the owmeter using the procedure on page 4-14.

Shut down

Switch the control equipment to manual control before terminating owmeter

operation and shutting o the output to the control equipment. This action

prevents the power shut-o from directly aecting the control equipment and

causing the valve positioner to malfunction.

WPO 0000000020

Figure 3-1 Start-up display

The owmeter is now on and operational.

CAUTION

To stop operation of the owmeter:

1. Switch the control equipment connected to the owmeter to manual control.

2. Turn o power to the converter.

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 3-1

Page 50

Operation Azbil Corporation

E

/h

L

Main displa

y

y

y

y

y

Auxillar

y

y

Using the display panel

The display panel is shown below, followed by a description of each feature. The

infrared touch sensor keys are described in the next section.

Totalized value displa

Percent flow rate displa

displa

LCD displa

MOD

123456TOTA

Actual flow rate displa

Figure 3-2 Display panel

Main display

- Indicates the ow rate selected in basic setup mode.

Auxiliary display

- Several values are displayed in this area:

• During measurement mode, indicates a ow rate to supplement the ow rate

selected in the basic setup mode.

• Indicates the totalized value

• When not in measurement mode, indicates the procedures for parameter setting,

adjustment, etc.

Percent ow display

- When lit, indicates that the percent ow rate is currently being displayed on Main

display.

Actual ow rate display

- When lit, indicates that the actual ow rate is currently being displayed on Main

display.

Totalized value display

- When lit, indicates that the totalized value is currently being displayed on Main

display.

3-2 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 51

Azbil Corporation Operation

E

L

00

/h

56

M

O

button

RIGHT SHIFT

button

Infrared touch

Using the infrared touch sensor keys

The infrared touch sensor keys allow you to make selections by simply touching the

display panel.

MagneW3000

.

1234

MOD

DE

Figure 3-3 Touch sensor keys

For best results, approach the key from below

and completely cover the circle. Then move

your nger straight down to its original

position. These motions ensure correct

operation. Moving sideways across the keys

can accidently activate the wrong control.

FLEX

TOTA

sensor button

UP button

DOWN button

Figure 3-4 Using the touch sensor keys

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 3-3

Page 52

Operation Azbil Corporation

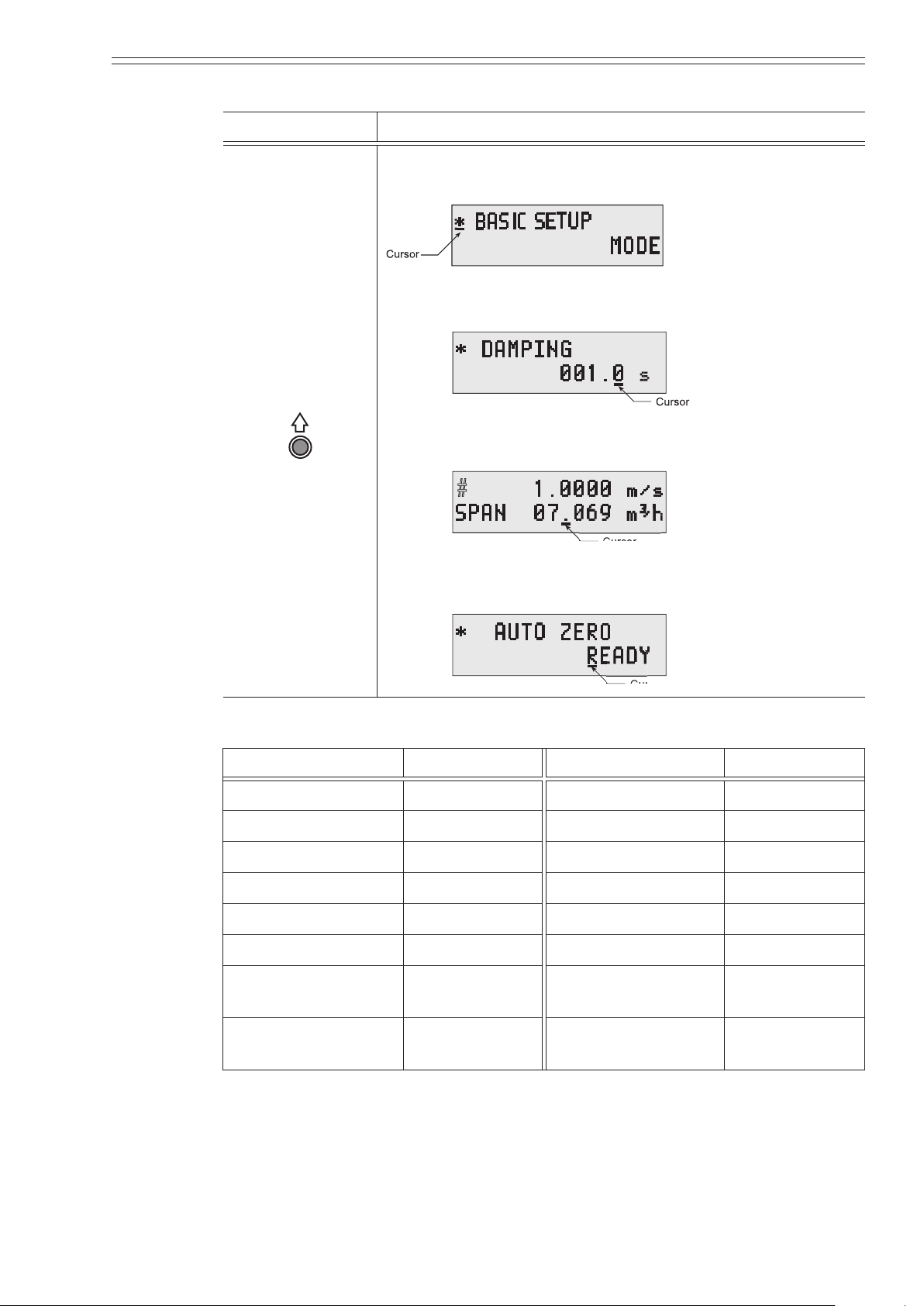

The following table is a summary of the functions of each of the keys.

Table 3-1 Touch Sensor key Functions

key Function

Touching and holding this key for more than three seconds

MODE key

RIGHT SHIFT key

opens Basic setup MODE.

Writes data into memory after changing the parameters or

internal data in engineering mode, maintenance mode or

advanced mode.

Shifts the cursor in the display to the right.

When the cursor is on the Mode Indicator as shown below,

touching the DOWN key displays the next screen.

DOWN key

When the cursor is located at a number, touching the DOWN

key decrements the number.

When the cursor is located at the decimal point, touching the

DOWN key moves the decimal point to the right.

#

3-4 Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter

Page 53

Azbil Corporation Operation

#

Table 3-1 Touch Sensor key Functions

key Function

When the cursor is on the Mode Indicator as shown below,

touching the UP key displays the next screen.

When the cursor is located at a number, touching the UP key

increments the number.

UP key

When the cursor is located at the decimal point, touching the

UP key moves the decimal point to the left.

When the cursor is located at READY, touching the UP key

starts operation.

Table 3-2 Default settings

Parameter Default Parameter Default

TAG XXXXXXXX HI-ALM +115%

DAMPING 3.0s LO-ALM -115%

SPAN as specied FALL SAFE MODE LOW

DISPLAY SELECT as specied ST. OUT MODE CLOSE

HYSTERESIS 0 AVERAGING OFF

GRAVITY 1.0000 COEFFICIENT 1.0000

PLS SCL

(PULSE SCALE)

as specied or

1.0000 l/p

DROP OUT 2%

PLS WID

(PULSE WIDTH)

Model MGG10C/14C - MagneW FLEX+/PLUS+ Converter 3-5

DUTY 50 LOW FLOW CUT OFF