Page 1

Pressure Detectors

(Meter Bodies)

Model KKP/KFKB

User's Manual

OM2-5240-1100

Page 2

NOTICE

While the information in this manual is presented in good faith and

believed to be accurate, Azbil Corporation disclaims any implied

warranty of merchantability or fitness for a particular purpose and

makes no express warranty except as may be stated in its written

agreement with and for its customer.

In no event shall Azbil Corporation be liable to anyone for any

indirect, special or consequential damages. This information and

specications in this document are subject to change without notice.

© 2013 - 2020 Azbil Corporation. All Rights Reserved.

Page 3

Table of Contents

Chapter 1. Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1-1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-2. Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-3. Instructions for instruments (Transmitters and controllers) used in conjuncion . . . . . . . . . . . . 1

Chapter 2. Structures of meter bodies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2-1. External views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2-2. Structures and operating principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 3. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3-1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3-2. Bracket and bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3-3. Place of installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3-4. Installation method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3-5. Pressure piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3-6. Elevation and suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Chapter 4. Operation method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 5. Inspection and maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5-1. Check for leak from piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5-2. Blow and cleaning of meter body and piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

5-3. Notes for use in freesing season . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Appendix A. Specifications, Model No., External dimensions . . . . . . . . . . . . . . . . . . . . . A-1

i

Page 4

Page 5

Chapter 1. Description

1-1. General

The pressure detector (meter body) accepts a process pressure with its pressure receiver

element and converts the process pressure into a torque with its torque tube. The torque is

applied to a pneumatic transmitter (Model KKP or KFKB) or a pneumatic controller (Model

KFKB).

Some models of detectors have a flange incorporated with a diaphragm for connection to the

process.

1-2. Models

Measured pressures or

type of instrument

High gauge pressures Models KKP11/12/13/14

Low gauge pressures Models KKP15/16/17/18

Absolute pressures Models KKP25/26/27/28

Remote sealed diaphragm

type

Model numbers of

instruments used in

conjunction

Models KFKB11/12/13/14

Models KFKB15/16/17/18

Models KFKB25/26/27/28

Models KKP71/72/73/74/75/76

Models KFKB71/72/73/74/75/76

Operator’s Manual

used in conjunction

OM2-5220-0000 (KKP)

OM2-6220-0000 (KFKB)

1-3. Instructions for instruments (Transmitters and controllers) used in

conjuncion

For the instructions for instruments used in conjunction, refer to respective Operator’s

Manuals which cover the operating principles, service and unit replacement procedures, and

calibration and adjustment procedures of these instruments.

1

Page 6

Chapter 2. Structures of meter bodies

2-1. External views

Although external views of meter bodies differ by models as shown in Fig. 2-1, the bracket

mounting section and instrument connection section are identical for all models.

Models 11/12/13/14 Models 15/16

Models 17/18

Models 25/26/27/28

Models 71/72/73/74/75/76

(Meter bodies as coupled to respective instruments)

(Meter body as coupled to instrument)

Fig. 2-1.

2

Page 7

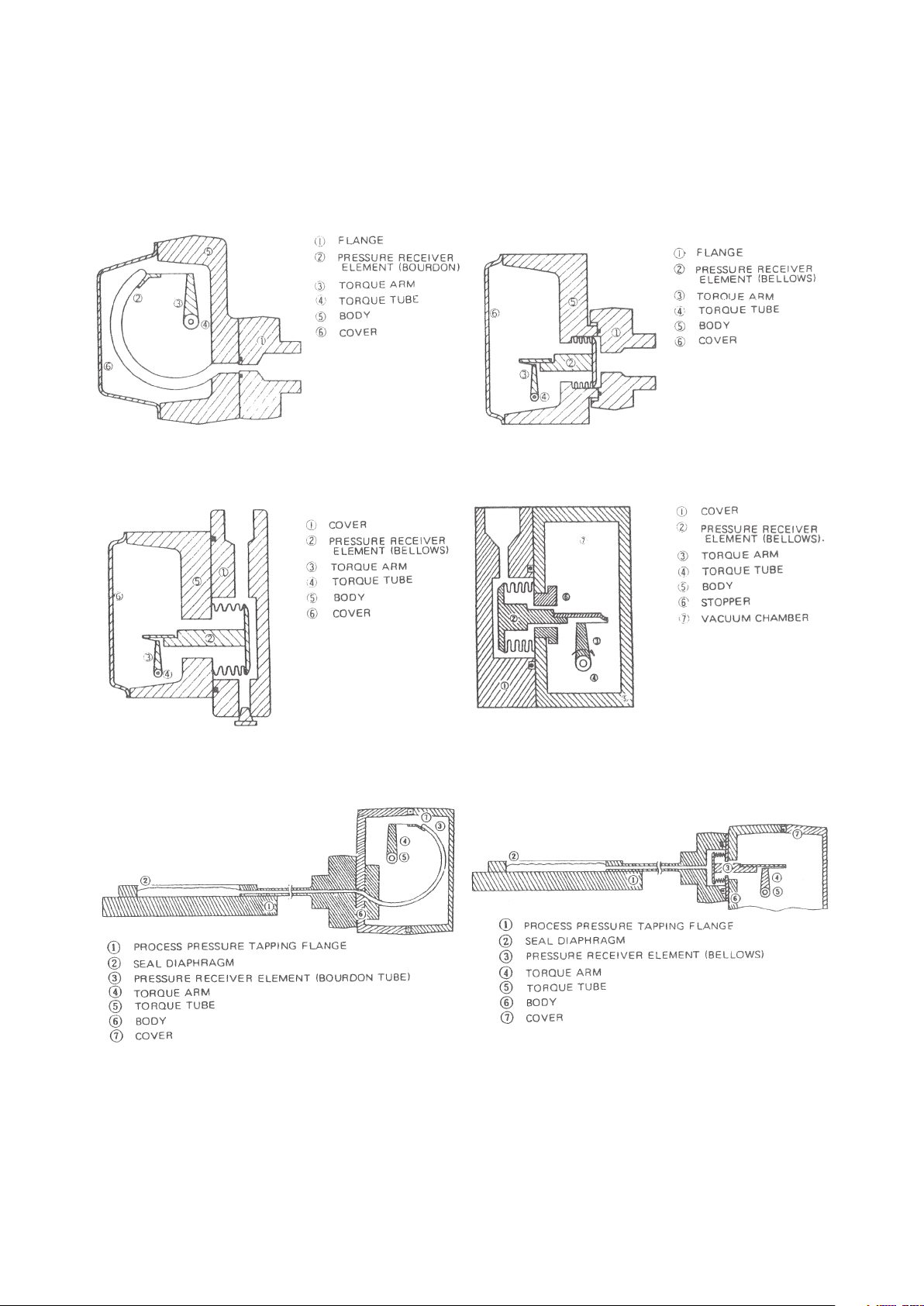

2-2. Structures and operating principles

The operating principles of the pressure detectors (meter bodies) are illustrated in Fig. 2-2

through Fig. 2-7.

Fig. 2-2. Operating principle of Model 11/12/13/14

meter body (Bourdon element)

Fig. 2-4. Operating principle of Model 17/18 meter body

(Bellows element)

Fig. 2-3. Operating principle of Model 15/16 meter body

(Bellows element)

Fig. 2-5. Operating principle of Model 25/26/27/28

meter body

Fig. 2-6. Operating principle of Model 71/72/73/74

meter body (Bourdon element)

Fig. 2-7. Operating principle of Model 75/76 meter body

(Bellows element)

3

Page 8

The process pressure is fed through the flange or cover (and via the seal liquid in the case of a

remote-sealed type) to the pressure receiver element which exercises a rotational force on the

torque arm. The torque arm drives the torque tube through which a torque force representing

the process pressure is applied to the beam of the instrument.

The reference-pressure chamber of the absolute-pressure detector (meter body) is kept

vacuum.

4

Page 9

Chapter 3. Installation

3-1. General

The meter body (detector), together with the instrument (transmitter) coupled to it, can be

installed on a 50-mm pipe stanchion by using the accessory bracket and U-shape bolt.

Model 61/62 meter body can be installed simply by fixing its flange to the process.

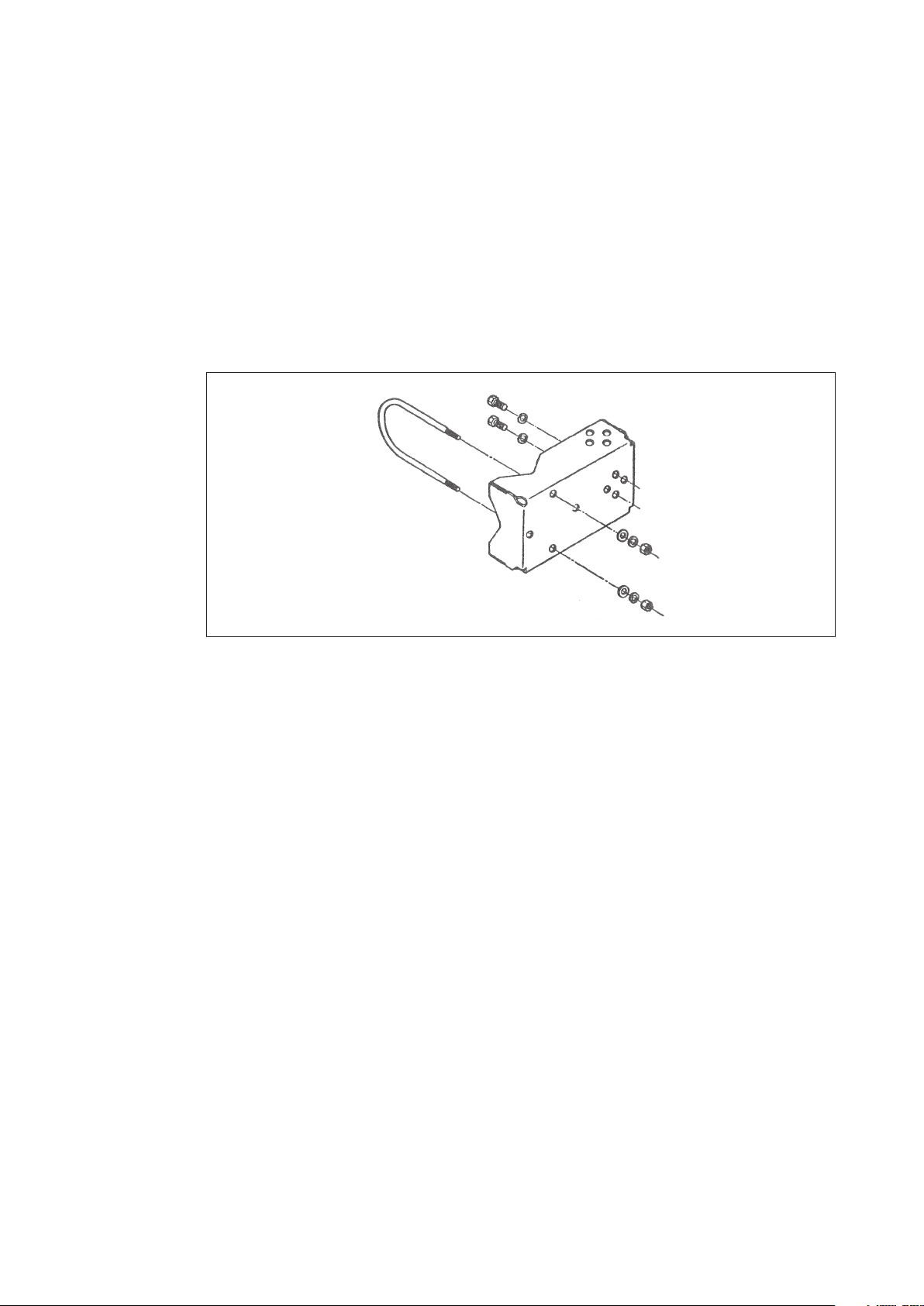

3-2. Bracket and bolts

The bracket and bolts for installation are supplied accompanying the meter body.

3-3. Place of installation

When selecting a place of installation for the instrument, take into consideration the matters

related to instrument inspection, maintenance, longevity, and operation safety as follows:

(1) Select a place where temperature change is small (within the limits of –30 °C to +80 °C).

Avoid a place where the instrument is exposed to high temperature by radiation from a

source of heat.

When water is measured, pay attention to freezing which may cause damage to the meter

body. Provide appropriate means to guard against freezing.

(2) Select a place where is reasonably free from humidity and vibration.

(3) Be sure to provide spaces for inserting a screwdriver for adjustment and span change.

Fig. 3-1.

5

Page 10

3-4. Installation method

3-4-1. Installation of regular-type meter body

The meter body, together with the transmitter coupled to it, can be installed in either one of

the following methods:

• Pipe stanchion mount

• Process pipe mount

In either case, fix the meter body to a 50-mm vertical or horizontal pipe using the mounting

bracket and U-shape bolt. Fix the pipe securely to a foundation so that the pipe does not sway.

(See Fig. 3-3.)

To install the meter body on a process pipe line, prepare brackets for mounting the 50-mm

pipe to the process pipe. (See Fig. 3-2.)

When installing a remote-sealed type of meter body, exercise care not to sharply bend or twist

the capillary tube and not to damage the diaphragm.

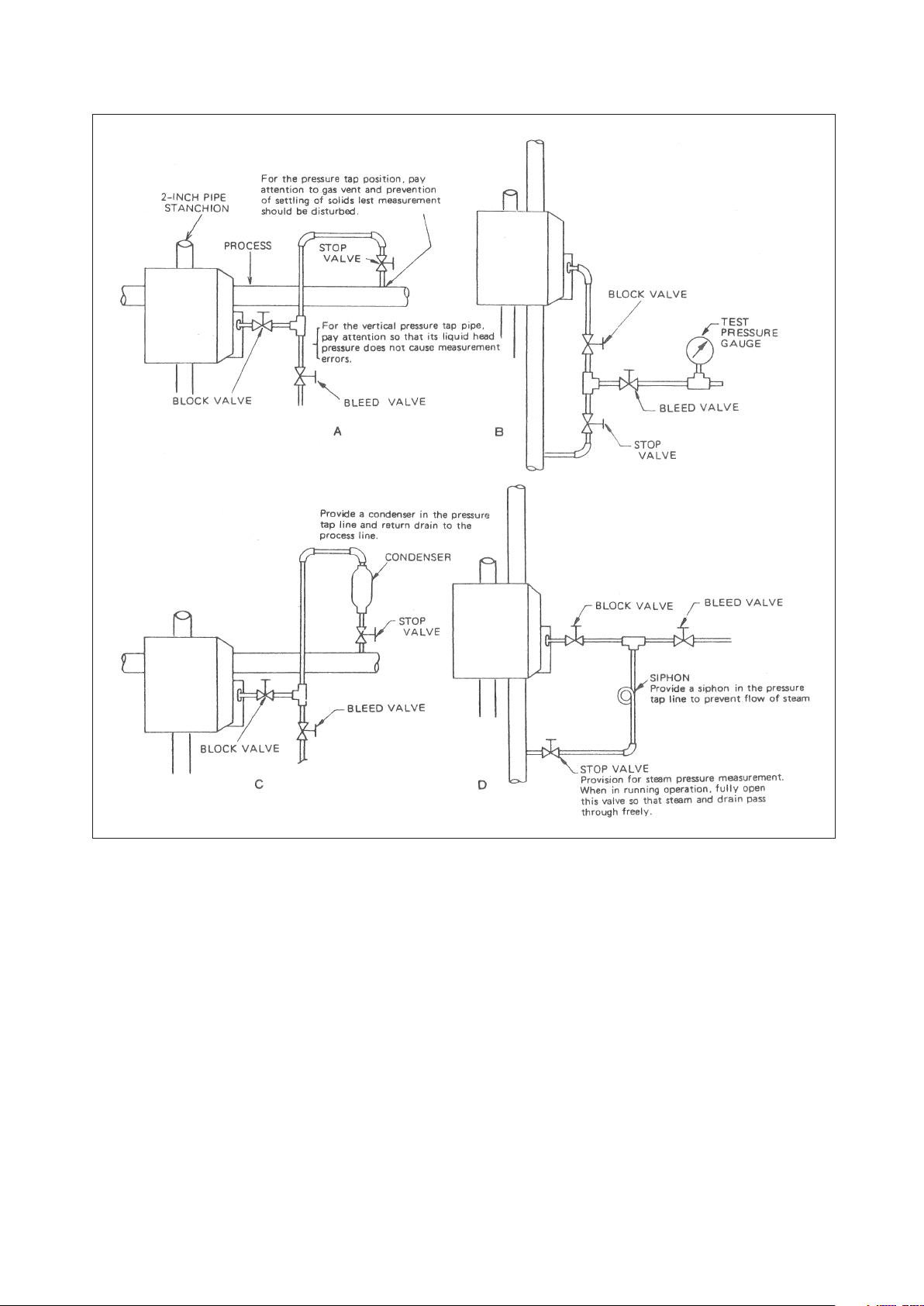

Fig. 3-2. Example of line mount bracket

Note: When installing the transmitter (meter body) on a 50-mm pipe, note that the order of

mountings (transmitter, bracket, and 50-mm pipe) differs depending on the mounting

direction.

Fig. 3-3. Installation examples

6

Page 11

3-4-2. Installation of remote-sealed diaphragm type meter body

This type of meter body can be fixed to a pipe stanchion in the same manner as in the case of

the regular type of meter body. For connection to the process, proceed as follows:

(1) Connect the tapping flange to the process flange with the bolts and gasket. Evenly tighten

the bolts to prevent leak. Lay the capillary tube so that it is less subjected to temperature

change and fix it so that it does not move.

It is recommendable to install the transmitter at a location lower than the flange.

(2) If the zero point shift has been caused by the head pressure of the seal liquid due to

the difference in height between the center of the flange and the center of the pressure

receiver, adjust zero by means of the ZERO control (or ELEVATION or SUPPRESSION

control). The specific-gravity of the seal liquid is 0. 935 at 20 °C (For temperature

compensation, use a factor of 0.001/°C).

(3) For installation of the button diaphragm, refer to its dimension drawing.

When the installed button diaphragm is required to be pulled out, set the collar available

as an option to the groove at the rear end of the element (capillary tube side) and retract

the screw.

7

Page 12

3-5. Pressure piping

3-5-1.

The pressure piping method (tapping pressure connection method) for the meter body

(transmitted) differs by installation position of the meter body, by the type of the process pipe,

and other conditions of measurement.

3-5-2.

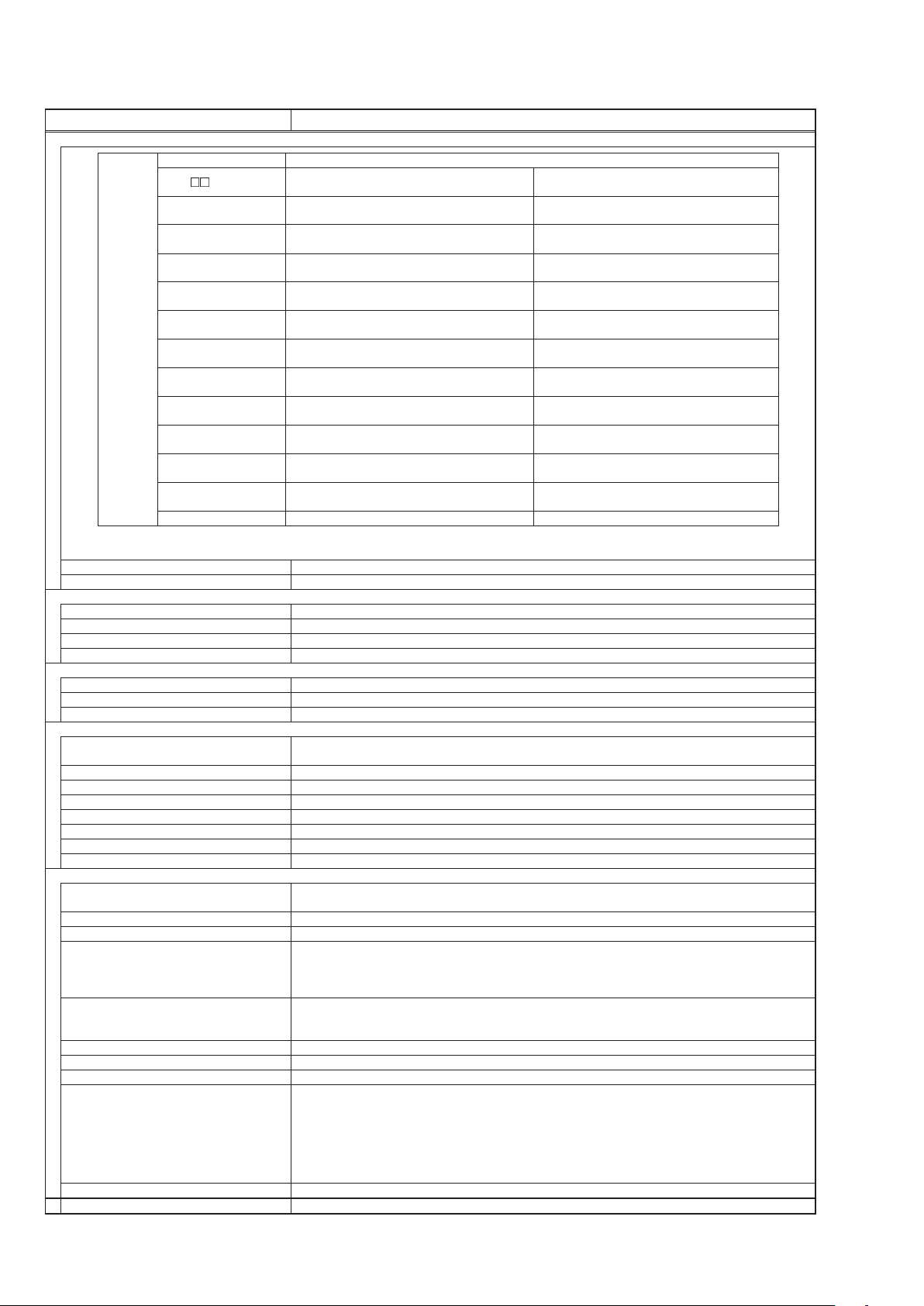

Typical examples of pressure piping methods are shown in Fig. 3-4. For piping, observe the

following instructions.

(1) Install a tee joint in the pressure tap line.

(2) Install a stop valve between the pressure tap point and the tee joint.

(3) For the pressure connection piping from the tap point of a horizontal process pipe to

the meter body, provide a gradient so that drain is returned through the tap point to the

process pipe.

Note: To measure a high pressure, pay attention to the types of joints, and pipe

(4) For pressure piping from the process pipe to the transmitter, use an appropriate type

(appropriate schedule number and nominal thickness) of pipes depending on the process

pressure and other measuring conditions. An example is a 1/2 inch Schedule 80 steel pipe.

Copper pipes are used in general for measurement of water or steam pressures.

dimensions and materials.

3-5-3. Auxiliary devices

(1) Oil seal and air purge

When it is undesirable to lead directly the measured pressure medium (fluid with

suspension, highly viscous fluid, or corrosive fluid) to the pressure transmitter, use liquid

seal or air purge.

Various liquid seal and air purge methods are possible. For details, please consult an Azbil

Corp. representative.

(2) Pulsation damping

When the process pressure pulsates or otherwise varies abnormally rapidly, install a

restriction valve in the pressure piping in order to smooth out such rapid pressure change.

8

Page 13

Fig. 3-4. Examples of pressure tap piping

9

Page 14

3-6. Elevation and suppression

3-6-1. Definitions of elevation and suppression

The terms “elevation” and “suppression” as used in this publication are defined as follows:

Elevation: Synonymous with “suppressed zero range”

An input range whose low end value is higher than zero.

For example, a range of 20 to 100.

Suppression: Synonymous with “elevated zero range”

An input range whose low end value is lower than zero.

For example, a range of –20 to 0.

3-6-2. Setting of elevation/suppression

For setting of elevation/suppression, refer to Section “CALIBRATION AND ADJUSTMENT”

of Operator’s Manual for Pneumatic Transmitter OM2-5220-0000.

When calculating the head pressure of the seal liquid of Model 71/72/73/74/75/76, multiply

the level difference between the center of diaphragm and the center of detector by the specificgravity of seal liquid (0.935*) and take the product value for the elevation.

See 3-4-2 (2)

*

Fig. 3-5.

Note: Elevation alone is applicable to Model 25/26/27/28. To other models, suppression is

applicable for vacuum pressures.

10

Page 15

Chapter 4. Operation method

The meter body, together with the transmitter coupled to it, starts operating as the air supply

and process input are fed to it. (It is recommendable to check the operation of the transmitter

before starting the running operation.)

(1) Measurement of liquid or gas pressure (Except vacuum pressure process)

Close the block valve, open the bleed valve, and then open the stop valve in order to blow

the pressure piping to eliminate foreign matter from inside the piping. Next, close the

bleed valve, wait until the pressure piping is cooled off if process temperature is high, and

then open the block valve to lead process liquid or gas to the meter body. (No bleed is

required for vacuum pressure processes.)

(2) Measurement of steam pressure

The operating procedure is the same as that for liquid or gas pressure measurement of (1),

except the following: After blowing the pressure piping to eliminate foreign matter and

closing the bleed valve, condense steam so that the pressure piping and siphon are filled

with water, and then open the block valve.

(3) Correction for Installation height of transmitter

When a liquid pressure is measured or when there is condensed steam in the pressure

piping, correction should be made, as required, for the head pressure which depends

on the height of installation of the transmitter. (This will be required especially when

measuring low pressures.) For this correction, shift the zero point of the transmitter by

an amount corresponding to the differential height between pressure tapping point and

transmitter installation position multiplied by the specific gravity of the liquid. (Elevation)

(4) Zero point check

When the instrument has become the measuring state, check and adjust the zero point

with the receiver connected to the transmitter.

11

Page 16

Chapter 5. Inspection and maintenance

For routine inspection and maintenance, pay attention to the following:

5-1. Check for leak from piping

Check that there is no leak in the piping from the pressure tap points to the meter body. If any

loose connections are found, tighten them securely.

5-2. Blow and cleaning of meter body and piping

To maintain constantly the instrument at its best performances meeting its specification

accuracy, keep clean the meter body and its piping. If sediment or other foreign matters are

entrapped in the pressure chambers of the meter body, measuring errors may be caused. To

blow and clean the meter body and piping, proceed as mentioned in the following referring to

3-5. Pressure piping of Chapter 3. Installation.

1. Close the stop valve.

2. With the block valve kept open, rapidly open the bleed valve.

3. Close the bleed valve and open the stop valve.

For a vacuum pressure process, blow the piping only when the process is at a positive pressure.

No blowing is necessary for the remote-sealed diaphragm type of meter bodies.

5-3. Notes for use in freesing season

When the transmitter used for measurement of water or other freezable liquid is paused

in a freezing season or area, loosen the bleed valve and drain out liquid from the pressure

chambers to prevent freezing.

12

Page 17

Appendix A. Specifications, Model No., External dimensions

KF Series

Pressure Indicating Controller

Model KFK

OVERVIEW

The KF Series instruments are field installed

type of pneumatic indicating controllers which are

used to measure and control the various types of

process variables such as temperatures, pressures,

flows and liquid levels.

Model KFK Pressure Indicating Controllers

(adjustable range type) indicate and control a

process variable by converting its pressure into

mechanical displacement of a bellows or a spiral

pressure receiving element.

Indicating transmitters and indicating

transmitting controllers also are available as well as

indicating controllers. The controllers are available

either in the local type to set the set-point value

with the knob on the instrument or in the cascade

type (remote type) to set the set-point value with a

pneumatic signal.

No. SS2-KFK100-0100

FEATURES

• A wide variety of measuring elements and

control mechanisms are available to meet

various applications.

• A pneumatic circuit board and a heat-resistant

weatherproof sturdy case are used, thereby

greatly improving the durability and reliability.

• The pneumatic circuit board system allows to

readily add or eliminate control mechanisms and

units, thereby enhancing the system

modifications and expansion flexibility

• Interchangeable parts are used to the maximum

practicable extent, thereby reducing the number

of parts to be kept in stock.

• The detecting section is identical with that of the

pressure transmitter of PREX3000 Pneumatic

Transmitter Series.

A-1

Page 18

SPECIFICATIONS

Standard Specifications

Item Specifications

Detector

Model

No.

11

12

13

14

15

16

17

18

25

26

27

28

71

72

73

74

75

76

Pressure

element

Bourdon

tube

Bellows

Bellows

(absolute

pressure)

Remote

seal

diaphragm

Measuring range Process connection Pressure limit Allowable overload

0-5 to 0-70 MPa

{0-50 to 0-700 kgf/cm

0-1.25 to 0-25 MPa

{0-12.5 to 0-250 kgf/cm

0-0.35 to 0-7 MPa

{0-3.5 to 0-70 kgf/cm

0-0.175 to 0-3.5 MPa

{0-1.75 to 0-35 kgf/cm

0-35 to 0-686 MPa

{0-0.35 to 0-7 kgf/cm

0-10 to 0-196 kPa

{0-0.1 to 0-2 kgf/cm

0-3.4 to 0-66.6 kPa

{0-25 to 0-500 mmHg}

0-0.7 to 0-13.3 kPa

{0-5 to 0-100 mmHg}

0-35 to 0-686 kPa abs.

{0-0.35 to 0-7 kgf/cm

0-10 to 0-196 kPa abs.

{0-0.1 to 0-2 kgf/cm

0-3.4 to 0-66.6 kPa abs.

{0-25 to 0-500 mmHg}

abs.

0-0.7 to 0-13.3 kPa abs.

{0-5 to 0-100 mmHg}

abs.

0-5 to 0-70 MPa

{0-50 to 0-700 kgf/cm

0-1.25 to 0-25 MPa

{0-12.5 to 0-250 kgf/cm

0-0.35 to 0-7 MPa

{0-3.5 to 0-70 kgf/cm

0-0.175 to 0-3.5 MPa

{0-1.75 to 0-35 kgf/cm

0-35 to 0-686 kPa

{0-0.35 to 0-7 kgf/cm

0-10 to 0-196 kPa

{0-01 to 0-2 kgf/cm

Welding nipple

2

}

connection (13.6 x 50)

2

}

2

}

2

}

2

}

2

}

Rc½ or Rc¼ internal

Thread

½NPT or ¼NPT internal

thread

2

} abs.

2

} abs.

G1½ external thread

2

}

(34 button diaphragm)

G1½ external thread

(34 button diaphragm)

2

}

or 2 in. ANSI wafer

2 in. -ANSI wafer

2

}

2 in. -ANSI wafer

80 mm-JIS30K flush

diaphragm

100 mm-JIS30K

2

}

extended diaphragm

3 in. -ANSI300 flush

diaphragm

4 in. -ANSI300

extended diaphragm

80 mm-JIS10K flush

diaphragm

100 mm-JIS10K

extended diaphragm

2

}

3 in. -ANSI150 flush

diaphragm

4 in. -ANSI150

extended diaphragm

80 mm-JIS10K flush

diaphragm

100 mm-JIS10K

extended diaphragm

2

}

3 in. -ANSI150 flush

diaphragm

4 in. -ANSI150

extended diaphragm

-0.1 to +70 MPa

{-1 to +700 kgf/cm2}

-0.1 to +30 MPa

{-1 to +300 kgf/cm2}

-0.1 to +10.5 MPa

{-1 to +105 kgf/cm2}

-0.1 to +5.25 MPa

{-1 to +52.5 kgf/cm2}

-0.1 to +1.05 MPa

{-1 to +10.5 kgf/cm2}

-100 to +300 kPa

{-1 to +3 kgf/cm2}

-66.6 to +66.6 kPa

{-500 to +500 mmHg}

-13.3 to +13.3 kPa

{-100 to +100 mmHg}

0 to 686 kPa abs.

{0 to 7 kgf/cm2} abs.

0 to 196 kPa abs.

{0 to 2 kgf/cm2} abs.

0 to 66.6 kPa abs.

{0 to 500 mmHg} abs.

0 to 13.3 kPa abs.

{0 to 100 mmHg} abs.

-0.05 to +70 MPa

{-0.5 to +700 kgf/cm2}

-0.05 to +30 MPa

{-0.5 to +300 kgf/cm

-0.05 to +10.5 MPa

{-0.5 to +105 kgf/cm

-0.05 to +5.25 MPa

{-0.5 to +52.2 kgf/cm

-0.05 to +5.1 MPa

{-0.5 to +51 kgf/cm

-0.05 to +3.82 MPa

{-0.5 to +37 kgf/cm

2

2

-0.05 to +1.05 MPa

{-0.5 to +10.5 kgf/cm2}

-0.05 to +0.3 MPa

{-0.5 to +3 kgf/cm2}

-0.1, 75 MPa

{-1, 750 kgf/cm2}

-0.1, 32 MPa

{-1, 320 kgf/cm2}

-0.1, 14 MPa

{-1, 140 kgf/cm2}

-0.1, 7 MPa

{-1, 70 kgf/cm2}

-0.1, 1.4 MPa

{-1, 14 kgf/cm2}

-100, 400 kPa

{-1, 4 kgf/cm2}

-66.6, 400 kPa

{-500 mmHg, 4 kgf/cm

-13.3, 400 kPa

{-100 mmHg, 4 kgf/cm

-1.4 MPa abs

{14 kgf/cm2} abs.

0.6 MPa abs.

{6 kgf/cm2} abs.

0.4 MPa abs.

2

} abs.

{4 kgf/cm

0.4 MPa abs.

2

} abs.

{4 kgf/cm

-0.05, 70 MPa

{-0.5, 750 kgf/cm2}

-0.05, 32 MPa

2

}

{-0.5, 320 kgf/cm2}

-0.05, 14 MPa

2

}

{-0.5, 140 kgf/cm2}

-0.05, 7 MPa

2

}

{-0.5, 70 kgf/cm2}

-0.05, 5.1 MPa

}

{-0.5, 51 kgf/cm2}

-0.05, 3.82 MPa

}

{-0.5, 37 kgf/cm2}

-0.05, 1.4 MPa

{-0.5, 14 kgf/cm2]

-0.05, 0.4 MPa

{-0.5, 4 kgf/cm2}

No. SS2-KFK100-0100

Suppression

(max.)

-100 kPa

{-1 kgf/cm

-66.6 kPa

2

}

{-500 mm Hg}

-13.3 kPa

2

}

{-100 mm Hg}

-0.05 MPa

{-0.5 kgf/cm

-0.05 MPa

{-0.5 kgf/cm

⎯

⎯

⎯

⎯

2

}

2

}

2

}

Elevation

(max.)

65 MPa

{650 kgf/cm2}

28.75 MPa

{287.5 kgf/cm2}

10.15 MPa

{101.5 kgf/cm2}

5.075 MPa

{50.75 kgf/cm2}

1.015 MPa

{10.15 kgf/cm2}

290 kPa

{2.9 kgf/cm

63.2 kPa

{475 mmHg}

12.6 kPa

{95mmHg}

653 kPa abs.

{6.65 kgf/cm

abs.

186 kPa abs.

{1.9 kgf/cm2} abs.

63.2 kPa abs.

{475 mmHg} abs.

12.6 kPa abs.

{95 mmHg} abs.

65 MPa

{650 kgf/cm2}

28.75 MPa

{287.5 kgf/cm2}

10.15 MPa

{101.5 kgf/cm2}

5.075 MPa

{50.75 kgf/cm2}

4.925 MPa

{49.25 kgf/cm2}

3.525 MPa

{35.25 kgf/cm

1.015 MPa

{10.15 kgf/cm2}

0.29 MPa

{2.9 kgf/cm

2

}

2

}

2

}

2

}

Note 1) Elevation + Span ≤ Max. span.

2) Refer to the annexed table about Max. working pressure on Remote seal diaphragm.

A-2

Page 19

No. SS2-KFK100-0100

Max working pressure

Note 1 : Max working pressure depends on flange rating, flange materials and operating temperature. Please refer to the following data.

Operating range of temperature depends on specification of transmitters.

Note 2 : In case of remote sealed type (KKP75, KFKB

following data.

Carbon Steel

-75), Max working pressure depends on the smaller value of either 1.05 MPa or

JIS JPI/ANSI

SUS304

SUS316

SUS316L

A-3

Page 20

No. SS2-KFK100-0100

Item Specifications

Function

Model No. Measuring range

KFKB

11/71

″ 12/72

″ 13/73

″ 14/74

″ 15/75

Accuracy

″ 16/76

″ 17

″ 18

″ 25

″ 26

″ 27

″ 28

Transmission/Indication ±1.0%FS/±1.5%FS ±0.5%FS/±1.0%FS

Note: *1) Transmitting accuracy : ± 0.75%FS Indicating accuracy : ± 1.25%FS

*2) Transmitting accuracy : ± 0.75%FS Indicating accuracy : ± 1.25%FS

Repeatability Within 0.3% FS

Dead band Within 0.1% FS

Indication

Angle 44 degrees

Scale length 150 mm

Pointe Process variable ; Red Set-point value; Green

Output indicator (40 mm) Scale range; 0 to 200 kPa {0 to 2 kgf/cm2}, Indicator accuracy; 3% FS

Set-point Section

Local setting Internal or external setting by setting knob

Remote setting Pneumatic pressure setting of 20 to 100 kPa {0.2 to 1.0 kgf/cm2}

Setting range 0 to 100% FS

Controller

Control action

Proportional band (P) 5-500% (direct or reverse action)

Integral (I) 0.05 to 30 min.

Derivative (D) 0.05 to 30 min.

Differential gap 1 to 100% FS, adjustable

Batch setting pressure 60 to 110 kPa {0.6 to 1.1 kgf/cm2}, adjustable

External reset pressure 20 to 100 kPa {0.2 to 1.0 kgf/cm2}

Manual reset 0 to 100% FS, adjustable (by pneumatic pressure setting.)

General Specification

Output

Minimum load I.D. 4 mm x 3 m + 20 cm

Supply air pressure 140 ± 14 kPa {1.4 ± 0.14 kgf/cm2}

Air consumption

(50% output balanced)

Saturated air supply capacity

Air connection Rc ¼ or ¼ NPT internal thread

Ambient temperature At meter body (process fluid) ; -40 to +120 °C At transmitter (ambient) ; -30 to +80 °C

Relative humidity 10-90% RH

Case, Door Enclosure ; Rain-tight and dust tight, meets JIS F 8001 class 3 splash-proof, NEMA 3, IEC IP 54

Mounting Panel or 2 inch pipe mounting

Weight Approx. 9.3 kg (model KFKB12-1412A1T-X)

0-5

to 0- less than 10 MPa

{0-50

to 0- less than 100 kgf/cm

0-1.25

to 0- less than 2.5 MPa

{0-12.5

to 0- less than 25 kgf/cm

0-0.35

to 0- less than 0.7 MPa

{0-3.5

to 0- less than 7 kgf/cm

0-0.175

to 0- less than 0.35 MPa

{0-1.75

to 0- less than 3.5 kgf/cm

0-35

to 0- less than 68.6 kPa

{0-0.35

to 0- less than 0.7 kgf/cm

0-10

to 0- less than 19.6 kPa

{0-0.1

to 0- less than 0.2 kgf/cm

0-3.4

to 0- less than 6.66 kPa

{0-25

to 0- less than 50mmHg}

0-0.7

to 0- less than 1.33 kPa

{0-5

to 0- less than 10mmHg}

0-35

to 0- less than 68.6 kPa abs.

{0-0.35

to 0- less than 0.7 kgf/cm

0-10

to 0- less than 19.6 kPa abs.

{0-0.1

to 0- less than 0.2 kgf/cm

0-3.4

to 0- less than 6.66 kPa abs.

{0-25

to 0- less than 50mmHg} abs.

0-0.7

to 0- less than 1.33 kPa abs.

{0-5

to 0- less than 10mmHg} abs.

2

}

2

}

2

}

2

}

2

}

2

}

2

} abs.

2

} abs.

0-10

to 0-70 MPa

{0-100

to 0-700 kgf/cm2}

0-2.5

to 0-25 MPa

{0-25

to 0-250 kgf/cm2}

0-0.7

to 0-7 MPa

{0-7

to 0-70 kgf/cm2}

0-0.35

to 0-3.5 MPa

{0-3.5

to 0-35 kgf/cm2}

0-68.6

to 0-686 kPa

{0-0.7

to 0-7 kgf/cm2}

0-19.6

to 0-196 kPa

0-0.2

to 0-2 kgf/cm2}

0-6.66

to 0-66.6 kPa

{0-50

to 0-500mmHg}

0-1.33

to 0- less than 9.3 kPa (*1)

{0-10

to 0- less than 70 nmHg}

0-68.6

to 0-686 kPa abs.

{0-0.7

to 0-7 kgf/cm2} [abs.]

0-19.6

to 0-196 kPa abs.

{0-0.2

to 0-2 kgf/cm2} [abs.]

0-6.66

to 0-66.6 kPa

{0-50

to 0-500mmHg} [abs.]

0-1.33

to 0- less than 9.3 kPa abs. (*2)

{0-10

to 0- less than 70 nmHg} [abs.]

P + Manual reset, PI, PID, PD + Manual reset, PI + Batch, On-Off, Differential gap,

P + External reset, PD + External reset

2

20 to 100 kPa {0.2 to 1.0 kgf/cm

control action)

}, 0 or Corresponding to supply air pressure (when on-off or differential gap

3

Indicating transmitter (A0) ; 5 L/min [N]

Indicating controller (A1, A3) ; 9 Lmin [N]

Indicating transmitting controller (A2, A4) ; 9 L/min [N]

Manual controller (M) ; 3 L/min N]

Transmitter output : 40 L/min [N]

Controller Output ; 40 L/min [N]

Manual control output ; 30 L/min [N]

Materials ; Case ........................................Aluminum die-cast

Door.........................................Polyester with fiberglass

Door-glass ............................... Reinforced glass (3 mm thick)

Case finish ; Acryl baking finish

(for corrosion-resistant and silver finish, refer to the optional specification.)

Color of finish ; Dark beige (Munsell 10YR 4.7 / 0.5)

A-4

Page 21

No. SS2-KFK100-0100

Optional Specifications

Item Specifications

(1) External SP setting knob (for local setting) A setting knob is mounted on the door. SP can be adjusted from outside.

(2) Built-in manual controller

(with auto/manual transfer switch)

(3) Elevation, Suppression

(4) Air set

(not applicable to panel mounting type)

Consists of manual control regulator , two position transfer switch and balance check button.

Elevation; The lower limit of input range is above zero.

Suppression; The lower limit of input range is below zero.

Pressure regulator with filter plus 40 mm pressure gauge.

(supply pressure; 200 to 970 kPa {2 to 9.7 kgf/cm

200 kPa {0 to 2 kgf/cm

2

})

2

}, output; 140 kPa {1.4 kgf/cm2}, pressure gauge; 0 to

Optional Semi-standard and Special Specifications

Item Applicable Models Specifications

Max. operating pressure; 5 MPa {50 kgf/cm

(1) Steam block (Y29) Except remote seal diaphragm type

(2) High temperature use (Y62) Remote seal diaphragm type

(3) Stainless steel bolts (Y66) Model ; KFKB -11 to16 SUS304 stainless steel is used for meter body fixing bolts.

(4) For oil-free (Y67) Except remote seal diaphragm type Liquid-contacting sections are degreased.

(5) Corrosion-resistant and

silver finish (Y138)

(6) For oxygen measurement

(Y182)

(7) For chlorine gas measurement

(Y183)

(8) Special order items (the items

mentioned in the right are

available as special order

items.)

All the KFK models

Remote seal diaphragm type (when

measuring element material is

SUS316 or SUS316L)

Model ; KFKB

(when measuring element material

is tantalum.)

All the KFK models

-74~76

Max. operating temperature ; 250 °C (below 120 °C at meter body)

Steam piping connection ; PT¼ or ¼NPT internal thread

Material ; Carbon steel (SF45A)

Operating temperature; Fluid -10 to +200 ºC

Ambient -10 to +80 ºC

Sealing liquid ; Special silicon oil

Corrosion-resistant finish with baked acryl (Y138A):

Resistant against corrosive gases.

Corrosion-proof finish with baked epoxy resin (Y138B):

Resistant against corrosive liquids.

Regular silver finish with baked acryl (Y138C):

To suppress temperature rise caused by direct sunlight or other cause.

Corrosion-resistant silver finish with baked acryl (Y138D):

To suppress temperature rise caused as above and to be resistance against

corrosive gases.

(note: silver finish is not resistant against alkaline gases.)

Liquid-fill ; Fluorine oil

Operating temperature (both fluid and ambient) ; -10 to +60 ºC

Wet-parts treatment ; Treated for degreasing

Liquid-fill ; Fluorine oil

Operating temperature (both fluid and ambient) ; -10 to +80 ºC

Wet-parts treatment ; Treated for degreasing.

1) Door lock

2) Stainless steel tag plate

3) AUTO/MAN switch viewing window

4) Pressure gauge (40 mm) for transmitting signal.

2

}

A-5

Page 22

No. SS2-KFK100-0100

MODEL SELECTION

Ex.: KFKB12-7112050210A1T-M, K, 6, 7

KFKB12-1122A1T-M, K, 6, 7

Basic model no. Selectable specifications

Type

Func-

tion

Control

action

Type of

detector

Cover, flange or

mounting screw

materials

Element

materials

Flange or

mounting

screw

rating

Capillary

tube

length

KFK I II III IV V VI VII VIII IX X XI XII

Length of

extended

parts of

flange

Air

connec-

tion

Output

pressure

unit

Mounting

method

Options

I B0 Indicating transmitter

B1 Indicating controller (local type)

B2 Indicating transmitting controller (local type)

B3 Indicating controller (cascade type)

B4 Indicating transmitting controller (cascade type)

II 0 No selection 5 PI + Batch

1 P + Manual reset 6 On-Off

2 PI 7 Differential gap

3 PID 8 P + External reset

4 PD + Manual reset 9 PD + External reset

III -11 Bourdon tube type

-12 Bourdon tube type

-13 Bourdon tube type

-14 Bourdon tube type

-15 Bellows type

-16 Bellows type

-17 Bellows type

-18 Bellows type

-25 Bellows type (abs. press.)

-26 Bellows type (abs. press.)

-27 Bellows type (abs. press.)

-28 Bellows type (abs. press.)

-71 Remote seal diaphragm type

-72 Remote seal diaphragm type

-73 Remote seal diaphragm type

-74 Remote seal diaphragm type

-75 Remote seal diaphragm type

-76 Remote seal diaphragm type

Carbon steel (SF45A) (applicable to type 17/18/2

IV 1

excluding wafer type and diaphragm type)

2 SUS316 (except flange type and button diaphragm type)

7 SUS304 (applicable to type 7 detector except wafer)

SUS316L (applicable to type 7

8

phragm and flange)

V 2 SUS316 (seal diaphragm; SUS316L)

3 Monel

4 Tantalum

8 SUS316L (applicable to type 7 detector)

(applicable to type 11-28 or 7

extended flange, wafer and button diaphragm type)

0-5

{0-50

0-1.25

{0-12.5

0-0.35

{0-3.5

0-0.175

{0-1.75

0-35

{0-0.35

0-10

{0-0.1

0-3.4

{0-25

0-0.7

{0-5

to 0-70 MPa

to 0-700 kgf/cm

to 0-25 MPa

to 0-250 kgf/cm

to 0-7 MPa

to 0-70 kgf/cm

to 0-3.5 MPa

to 0-35 kgf/cm

to 0-686 MPa

to 0-7 kgf/cm

to 0-196 kPa

to 0-2 kgf/cm

to 0-66.6 kPa

to 0-500 mm Hg}

to 0-13.3 kPa

to 0-100 mm Hg}

0-35

{0-0.35

0-10

{0-0.1

0-3.4

{0-25

0-0.7

{0-5

0-5

{0-50

0-1.25

{0-12.5

0-0.35

{0-3.5

0-0.175

{0-1.75

0-35

{0-0.35

0-10

{0-0.1

detector except button dia-

2

}

2

}

to 0-686 kPa abs.

to 0-7 kgf/cm

to 0-196 kPa abs.

to 0-2 kgf/cm

to 0-66.6 kPa abs.

to 0-500 mm Hg}

to 0-13.3 kPa abs.

to 0-100 mm Hg} abs.

to 0-70 MPa

to 0-700 kgf/cm

to 0-25 MPa

to 0-250 kgf/cm

to 0-7 MPa

to 0-70 kgf/cm

to 0-3.5 MPa

to 0-35 kgf/cm

to 0-686 kPa

to 0-7 kgf/cm

to 0-196 kPa

to 0-2 kgf/cm

detector except

2

}

2

}

2

}

2

}

/7 detector

VI Blank (applicable to type 1 or 2 detector)

01 Flush diaphragm type

80mm-JIS 10K (RF) equiv. flange

02 Flush diaphragm type

80mm-JIS 30K (RF) equiv. flange

03 Flush diaphragm type

3 in.-ANSI 150 (RF) equiv. flange

04 Flush diaphragm type

3 in.-ANSI 300 (RF) equiv. flange (applicable

05 Extended diaphragm type to type 7

100 mm-JIS 10K (RF) equiv. flange detector)

06 Extended diaphragm type

100 mm-JIS 30K (RF) equiv. flange

07 Extended diaphragm type

4 in.-ANSI 150 (RF) equiv. flange

08 Extended diaphragm type

4 in.-ANSI 300 (RF) equiv. flange

09 2 in.-ANSI 1500 (RF) equiv. wafer

11 PF 1½ external thread (button diaphragm type)

VII Blank (applicable to type 1 or 2 detector)

02 2m (applicable to type 7 detector)

03 3m (applicable to type 7 detector)

05 5m (applicable to type 7 detector)

VIII Blank (applicable to type 1 or 2 detector)

00 Applicable to flush diaphragm, wafer or button diaphragm type.

10 Length; 100 mm (applicable to extended diaphragm)

2

}

2

}

2

}

2

}

2

}

2

}

2

}

2

}

15 Length; 150 mm (applicable to extended diaphragm)

IX A Rc¼ internal thread (instruction plate: Japanese)

B ¼NPT internal thread (instruction plate: English)

X 1 0.2 to 1.0 kgf/cm2

2 3 to 15 PSI

3 0.2 to 1.0 bar

4 20 to 100 kPa

8 19.6 to 98.1 kPa (equality to 0.2 to 1.0 kgf/cm2)

XI P Panel mounting (Pressure regulator with filter cannot be installed)

T 2-inch pipe mounting

XII -X No option

Built-in manual controller (with auto/manual switch)

-M

(applicable to type B1, B2, B3 or B4 controller.)

With external SP setting knob

-K

(applicable to type B1 or B2 controller)

-5 Elevation or high elevation

-6 Suppression

-7 With Pressure regulator with filter

[Note] When specifying semi-standard option (Y ) not listed in

model no table, please write as: KFKB12-1122A1T-M,K,6,7

(Y67, Y 138) (Please consult with factory in case of a multiple

of “Y” spec. are required.)

A-6

Page 23

DIMENSIONS

(Unit:mm)

AIR CONNECTIONS (Refer to note 1, 3)

o : Rc ¼ internal

• : ¼ NPT internal

ESP : EXTENAL SP SIGNAL

REGEND

(FOR CASCADE TYPE ONLY)

× : TRANSMITTING SIGNAL

(FOR

TRANSMITTER ONLY

OUT : CONTROLLED SIGNAL

RES : EXTERNAL RESET SIGNAL

(FOR EXTERNAL RESET TYPE ONLY)

SUP : SUPPLY AIR PRESSURE

)

Notes:

1) The holes not to be used for connection are plugged.

2) These holes in the bracket enable the controller to be mounted in various position.

3) For manual reset provision, “SUP” and “RES” have been preconnected.

4) This dimensions are of bourdon type detector. (detector model nos 11 to 14).

Caution must be taken to dimensions which depend on the shape of elements.

(refer to the reference specification sheets at the rear of this sheet.)

A-7

Page 24

Terms and Conditions

We would like to express our appreciation for your purchase and use of Azbil Corporation’s products.

You are required to acknowledge and agree upon the following terms and conditions for your purchase of Azbil Corporation’s products (system

products, field instruments, control valves, and control products), unless otherwise stated in any separate document, including, without limitation,

estimation sheets, written agreements, catalogs, specifications and instruction manuals.

1. Warranty period and warranty scope

1.1 Warranty period

Azbil Corporation’s products shall be warranted for one (1) year from the date of your purchase of the said products or the delivery of the

said products to a place designated by you.

1.2 Warranty scope

In the event that Azbil Corporation’s product has any failure attributable to azbil during the aforementioned warranty period, Azbil

Corporation shall, without charge, deliver a replacement for the said product to the place where you purchased, or repair the said

product and deliver it to the aforementioned place. Notwithstanding the foregoing, any failure falling under one of the following shall

not be covered under this warranty:

(1) Failure caused by your improper use of azbil product (noncompliance with conditions, environment of use, precautions, etc. set

forth in catalogs, specifications, instruction manuals, etc.);

(2) Failure caused for other reasons than Azbil Corporation’s product;

(3) Failure caused by any modification or repair made by any person other than Azbil Corporation or Azbil Corporation’s

subcontractors;

(4) Failure caused by your use of Azbil Corporation’s product in a manner not conforming to the intended usage of that product;

(5) Failure that the state-of-the-art at the time of Azbil Corporation’s shipment did not allow Azbil Corporation to predict; or

(6) Failure that arose from any reason not attributable to Azbil Corporation, including, without limitation, acts of God, disasters, and

actions taken by a third party.

Please note that the term “warranty” as used herein refers to equipment-only-warranty, and Azbil Corporation shall not be liable for any

damages, including direct, indirect, special, incidental or consequential damages in connection with or arising out of Azbil Corporation’s

products.

2. Ascertainment of suitability

You are required to ascertain the suitability of Azbil Corporation’s product in case of your use of the same with your machinery,

equipment, etc. (hereinafter referred to as “Equipment”) on your own responsibility, taking the following matters into consideration:

(1) Regulations and standards or laws that your Equipment is to comply with.

(2) Examples of application described in any documents provided by Azbil Corporation are for your reference purpose only, and

you are required to check the functions and safety of your Equipment prior to your use.

(3) Measures to be taken to secure the required level of the reliability and safety of your Equipment in your use

Although azbil is constantly making efforts to improve the quality and reliability of Azbil Corporation’s products, there exists

a possibility that parts and machinery may break down. You are required to provide your Equipment with safety design such

as fool-proof design,*

physical injuries, fires, significant damage, and so forth. Furthermore, fault avoidance,*3 fault tolerance,*4 or the like should be

incorporated so that the said Equipment can satisfy the level of reliability and safety required for your use.

*1. A design that is safe even if the user makes an error.

*2. A design that is safe even if the device fails.

*3. Avoidance of device failure by using highly reliable components, etc.

*4. The use of redundancy.

3. Precautions and restrictions on application

3.1 Restrictions on application

Please follow the table below for use in nuclear power or radiation-related equipment.

Nuclear power quality*5 required Nuclear power quality*5 not required

Within a radiation

controlled area*

Outside a radiation

controlled area*

Cannot be used (except for limit switches for

6

nuclear power*7)

Cannot be used (except for limit switches for

6

nuclear power*7)

1

and fail-safe design*2 (anti-flame propagation design, etc.), whereby preventing any occurrence of

Cannot be used (except for limit switches for

nuclear power*7)

Can be used

*5. Nuclear power quality: compliance with JEAG 4121 required

*6. Radiation controlled area: an area governed by the requirements of article 3 of “Rules on the Prevention of Harm from

Ionizing Radiation,” article 2 2 4 of “Regulations on Installation and Operation of Nuclear Reactors for Practical Power

Generation,” article 4 of “Determining the Quantity, etc., of Radiation-Emitting Isotopes,”etc.

*7. Limit switch for nuclear power: a limit switch designed, manufactured and sold according to IEEE 382 and JEAG 4121.

Any Azbil Corporation’s products shall not be used for/with medical equipment.

The products are for industrial use. Do not allow general consumers to install or use any Azbil Corporation’s product. However, azbil

products can be incorporated into products used by general consumers. If you intend to use a product for that purpose, please contact

one of our sales representatives.

3.2 Precautions on application

you are required to conduct a consultation with our sales representative and understand detail specifications, cautions for operation,

and so forth by reference to catalogs, specifications, instruction manual, etc. in case that you intend to use azbil product for any purposes

specified in (1) through (6) below. Moreover, you are required to provide your Equipment with fool-proof design, fail-safe design, antiflame propagation design, fault avoidance, fault tolerance, and other kinds of protection/safety circuit design on your own responsibility

to ensure reliability and safety, whereby preventing problems caused by failure or nonconformity.

Page 25

(1) For use under such conditions or in such environments as not stated in technical documents, including catalogs, specification,

and instruction manuals

(2) For use of specific purposes, such as:

* Nuclear energy/radiation related facilities

[When used outside a radiation controlled area and where nuclear power quality is not required]

[When the limit switch for nuclear power is used]

* Machinery or equipment for space/sea bottom

* Transportation equipment

[Railway, aircraft, vessels, vehicle equipment, etc.]

* Antidisaster/crime-prevention equipment

* Burning appliances

* Electrothermal equipment

* Amusement facilities

* Facilities/applications associated directly with billing

(3) Supply systems such as electricity/gas/water supply systems, large-scale communication systems, and traffic/air traffic control

systems requiring high reliability

(4) Facilities that are to comply with regulations of governmental/public agencies or specific industries

(5) Machinery or equipment that may affect human lives, human bodies or properties

(6) Other machinery or equipment equivalent to those set forth in items (1) to (5) above which require high reliability and safety

4. Precautions against long-term use

Use of Azbil Corporation’s products, including switches, which contain electronic components, over a prolonged period may degrade

insulation or increase contact-resistance and may result in heat generation or any other similar problem causing such product or switch

to develop safety hazards such as smoking, ignition, and electrification. Although acceleration of the above situation varies depending

on the conditions or environment of use of the products, you are required not to use any Azbil Corporation’s products for a period

exceeding ten (10) years unless otherwise stated in specifications or instruction manuals.

5. Recommendation for renewal

Mechanical components, such as relays and switches, used for Azbil Corporation’s products will reach the end of their life due to wear by

repetitious open/close operations.

In addition, electronic components such as electrolytic capacitors will reach the end of their life due to aged deterioration based on

the conditions or environment in which such electronic components are used. Although acceleration of the above situation varies

depending on the conditions or environment of use, the number of open/close operations of relays, etc. as prescribed in specifications

or instruction manuals, or depending on the design margin of your machine or equipment, you are required to renew any Azbil

Corporation’s products every 5 to 10 years unless otherwise specified in specifications or instruction manuals. System products, field

instruments (sensors such as pressure/flow/level sensors, regulating valves, etc.) will reach the end of their life due to aged deterioration

of parts. For those parts that will reach the end of their life due to aged deterioration, recommended replacement cycles are prescribed.

You are required to replace parts based on such recommended replacement cycles.

6. Other precautions

Prior to your use of Azbil Corporation’s products, you are required to understand and comply with specifications (e.g., conditions and

environment of use), precautions, warnings/cautions/notices as set forth in the technical documents prepared for individual Azbil

Corporation’s products, such as catalogs, specifications, and instruction manuals to ensure the quality, reliability, and safety of those

products.

7. Changes to specifications

Please note that the descriptions contained in any documents provided by azbil are subject to change without notice for improvement

or for any other reason. For inquires or information on specifications as you may need to check, please contact our branch offices or

sales offices, or your local sales agents.

8. Discontinuance of the supply of products/parts

Please note that the production of any Azbil Corporation’s product may be discontinued without notice. After manufacturing is

discontinued, we may not be able to provide replacement products even within the warranty period.

For repairable products, we will, in principle, undertake repairs for five (5) years after the discontinuance of those products. In

some cases, however, we cannot undertake such repairs for reasons, such as the absence of repair parts. For system products, field

instruments, we may not be able to undertake parts replacement for similar reasons.

9. Scope of services

Prices of Azbil Corporation’s products do not include any charges for services such as engineer dispatch service. Accordingly, a separate

fee will be charged in any of the following cases:

(1) Installation, adjustment, guidance, and attendance at a test run

(2) Maintenance, inspection, adjustment, and repair

(3) Technical guidance and technical education

(4) Special test or special inspection of a product under the conditions specified by you

Please note that we cannot provide any services as set forth above in a nuclear energy controlled area (radiation controlled area) or at a

place where the level of exposure to radiation is equivalent to that in a nuclear energy controlled area.

AAS-511A-014-10

Page 26

Page 27

Document Number:

OM2-5240-1100

Document Name:

Date:

Issued/Edited by:

Pressure Detectors (Meter Bodies)

Model KKP/KFKB

User's Manual

6th edition: Jan. 2020

Page 28

Loading...

Loading...