Page 1

Multifunction

Pulse-to-Pneumatic

Pressure Converter

Model J-APN11

CM2-APN100-2001

User's Manual

Page 2

Copyright, Notices and Trademarks

1997-2015 Azbil Corporation All Rights Reserved.

While this information is presented in good faith and believed to be accurate,

Azbil Corporation disclaims the implied warranties of merchantability and

fitness for a particular purpose and makes no express warranties except as

may be stated in its written agreement with and for its customer.

In no event is Azbil Corporation liable to anyone for any indirect, special or

consequential damages, The information and specifications in this document

are subject to change without notice.

Page 3

For Safe Operation

Preface

Checkup

Message Con-

ventions

Safe equipment use requires accurate installation, operation and maintenance. Be

sure to read and understand the section on "Important Items" thoroughly before

attempting installation, operation or maintenance.

• Upon arrival, check equipment specifications and ensure there is no damage in

transit. Equipment is tested by strict quality control programs before shipment.

For oversights in quality or specifications, contact Azbil Corporation, providing

equipment information and serial No.

• The nameplate is on the top of the case.

This manual uses the following message conventions:

Warning

Personal injury could occur if procedures are not

followed closely.

Other indications

Caution

An illustration in a white circle with a back slash ○ indicates an action

to avoid.

A detailed explanation of the action is given in the circle or near the

mark.

An illustration in a black circle ● indicates an instruction regarding a

specific action to avoid.

A detailed explanation is given in the circle. The illustration at left

means to pull the plug from the socket.

Minor personal injury could occur if procedures are not

followed closely. Inconvenience such as equipment

damage could occur if procedures are not followed

closely.

Page 4

Notes on Handling

Notes

on Installation

Notes on

Wiring

Warning

• Do not use equipment outside the range determined in the specifications. Serious accident could occur.

Caution

• After installation, do not step or climb on this product. Equipment

may be damaged or personal injury occur.

• Do not press or hit door glass. Glass may be broken or personal

injury occur.

• Ground correctly. Incomplete grounding violates rules and may

cause output errors.

• Equipment is heavy. Wear safety shoes.

Warning

• Electrical shock may occur if working with wet hands or power on.

Notes on

Maintenance

Caution

• Perform wiring according to wiring specifications. Incorrect wiring

may damage equipment or lead to operation errors.

• Operate the power supply according to specifications. Incorrect

operation may damage equipment.

Caution

• Do not modify equipment. Modification may damage equipment.

Page 5

Contents

1. Outline ....................................................................................................... 1-1

2. Converter Configuration and Parts ........................................................... 2-1

3. Installation and Operation ......................................................................... 3-1

3-1 Installation ................................................................................................... 3-1

3-2 Operation .................................................................................................... 3-1

3-3 Connection .................................................................................................. 3-2

3-4 Wiring Procedure ........................................................................................ 3-3

4. Adjustment and Setting ............................................................................. 4-1

4-1 Preparation .................................................................................................. 4-1

4-2 Adjustment of Pneumatic Pressure Output (Figure 4-2) ............................. 4-2

4-3 Adjustment of Current Output (Figure 4-3) .................................................. 4-4

4-4 Setting Pneumatic Pressure Monitor ........................................................... 4-5

4-5 Setting Output Speed .................................................................................. 4-6

4-6 Manual Operation (with A/M switch) ............................................................ 4-7

5. Parts List ................................................................................................... 5-1

6. Maintenance ............................................................................................. 6-1

6-1 Regular Maintenance .................................................................................. 6-1

6-2 Periodical Maintenance and Checking ........................................................ 6-1

Page 6

1. Outline

The J-APN 11 Multifunction Rulse-to-Pneumatic Pressure Converter responds to up (upward)and down

(downward)pulse signals. It drives pulses and a (four-phase) motor to send out pneumatic pressure

signals of 20 to 100[kPa] and current signals of 4 to 20 [mA] DC via a nozzle and a flapper mechanism.

In case of power failure, the converter automatically keeps the pneumatic pressure signal at its pre-failure

position (provided that the pneumatic source is in normal operation).

1 - 1

Page 7

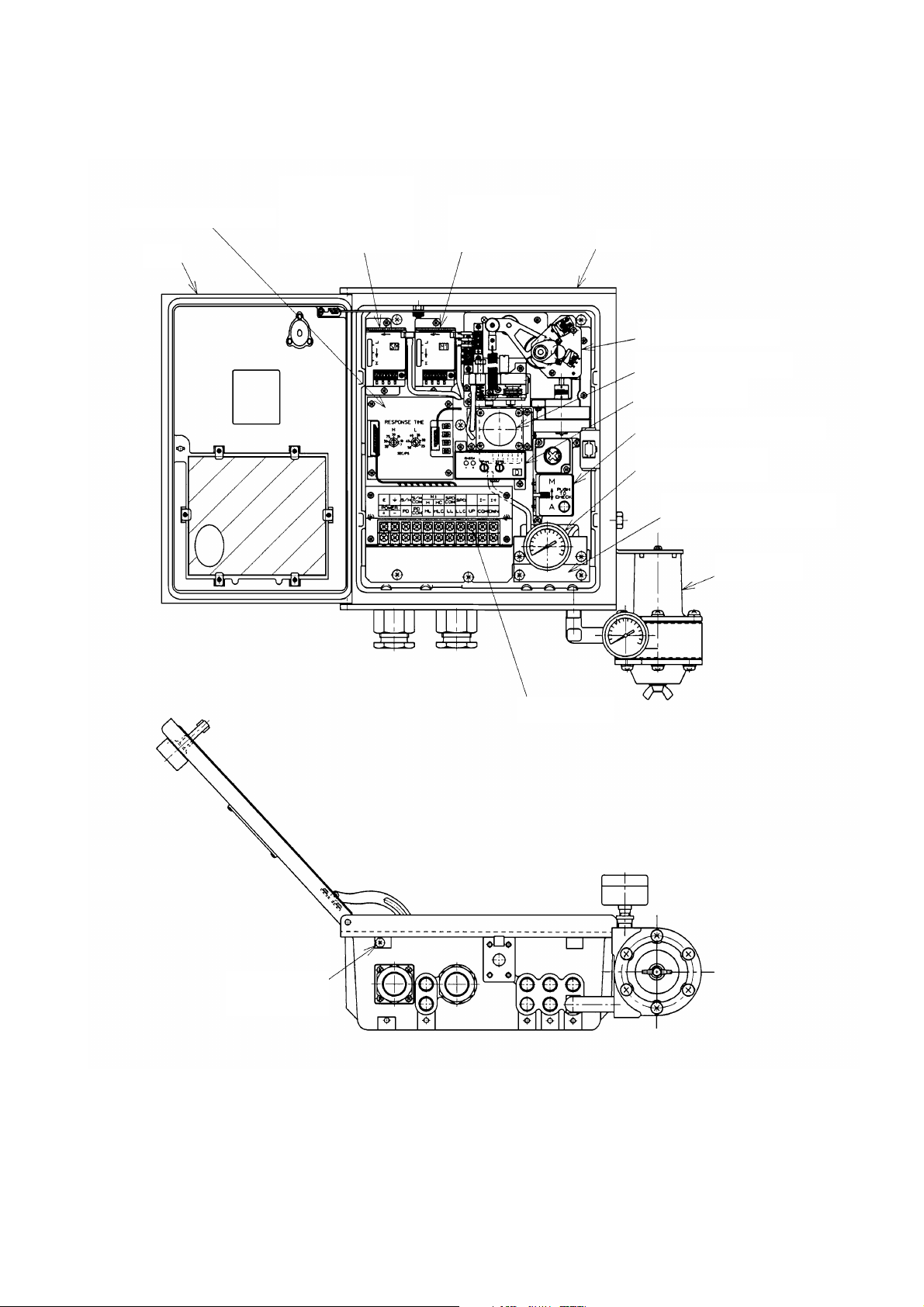

2. Converter Configuration and Parts

Main printed plate

assembly

Door

S/M pneumatic

pressure drop

monitor

M1 Pneumatic

pressure signal

monitor

Case

Mechanical part assembly

Pilot valve installed

P/I unit

Manual operation mechanism

(*)

Output pneumatic pressure

indicator

Relay block for internal

piping

Air set

Customer

terminals

External ground

terminal (M4)

(*): If manual operation is not used, a pneumatic pressure signal monitor (M2) can be installed.

Figure 2-1 Converter configuration and parts

2 - 1

Page 8

3. Installation and Operation

3-1. Installation

Mount the converter securely on a 2-inch pipe or on a wall. (refer to Specification Sheets

:SS2-APN100-0100, the figure for externaldimensions.)

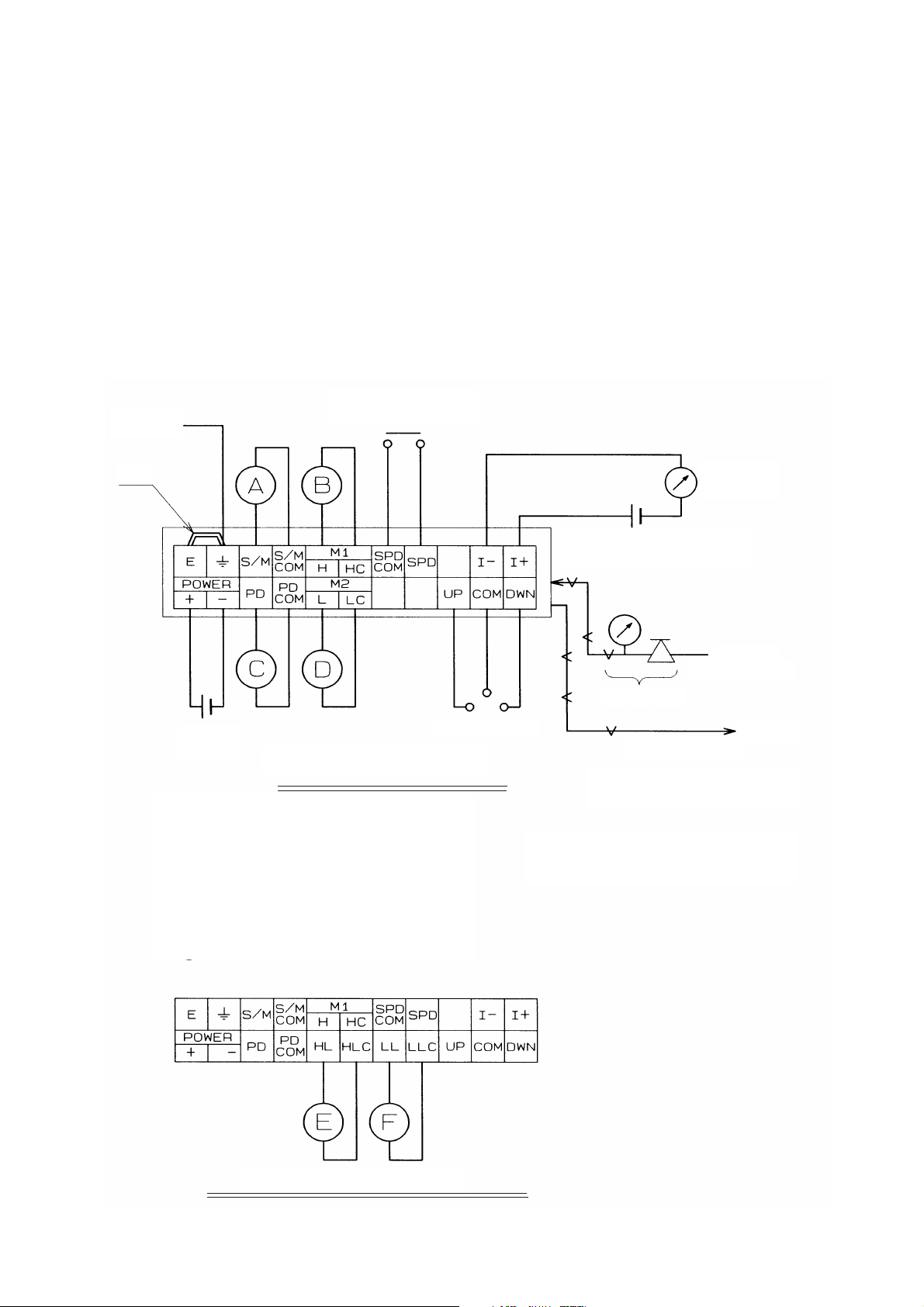

3-2. Operation

Complete wiring and piping according to Figure 3-2-1. Warm up the converter for about 30 minutes

before operating.

For air supply, please use the prescribed instrumentation air.

Class 3

grounding

(*1)

Power supply

24V DC

Contact for changing speed

High speed when contact is on

Contact for pulse input

Distribution frame with two pneumatic

pressure monitors

Contacts

A: Supplied air drop monitor

B: Output pneumatic pressure signal monitor

(high)

C: Power supply down monitor

D: Output pneumatic pressure signal monitor

(low)

E: High

F: Low

Ammeter

(4 to 20mA)

Power supply for current

output 24VDC

Supplied air

200 to 990kPa

Air set

Output air

20 to 100kPa

Apply load of ø4 and 3m +20cc.

(*1): Remove jumper plate when testing

withstand voltage or insulation

resistance.

Distribution frame with limit contact output

Figure 3-2-1 Customer terminal wiring and air piping

3 - 1

Page 9

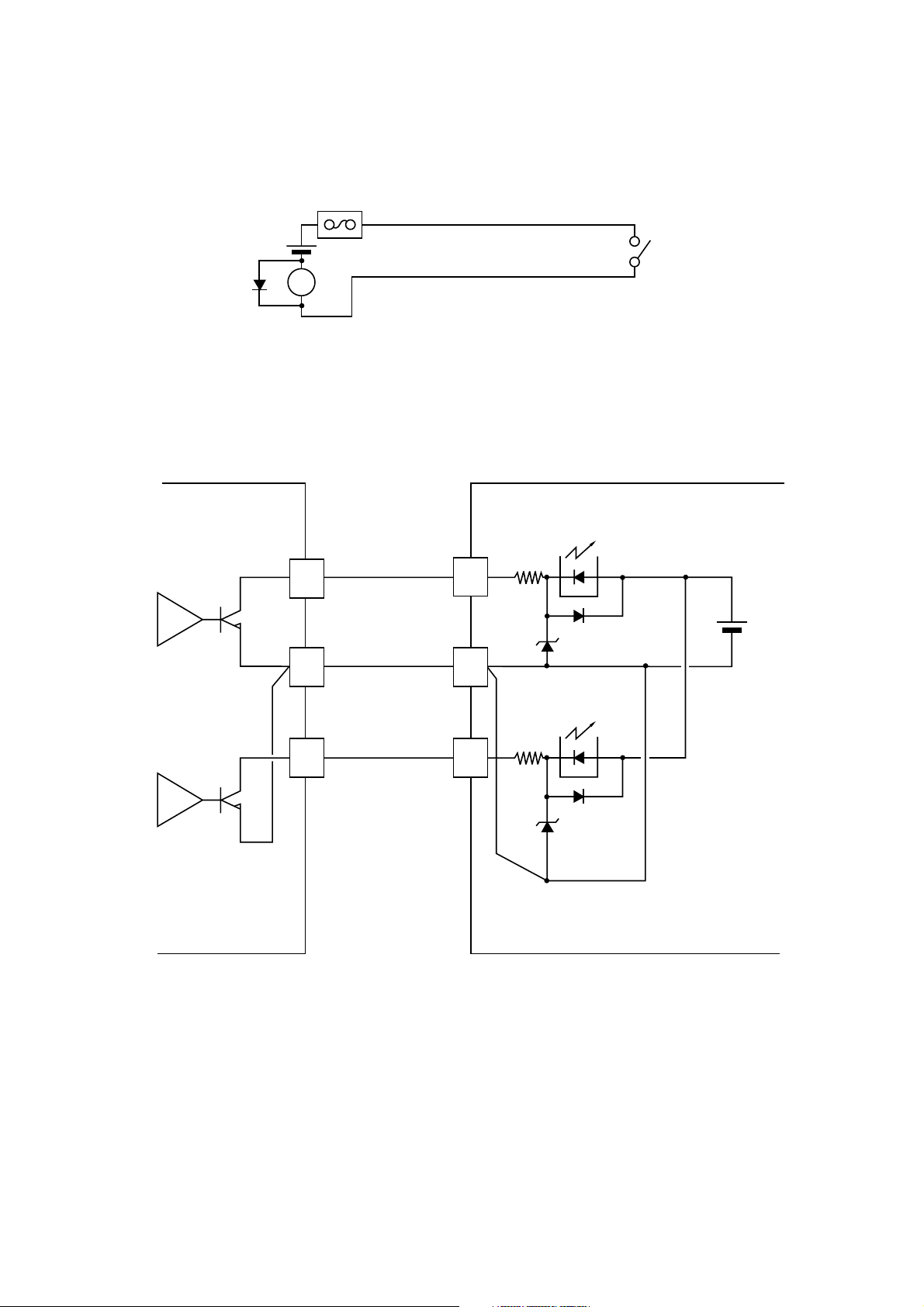

3-3. Connection

(a) Contact output

Fuse or MCB

Figure 3-3-1

Combine the contact with a surge suppression device for safety.

(b) UP/down signals

UP

Amplifer

UP

Amplifer

Output side

UP

COM

DWN

J-APN

Figure 3-3-2 Connection method

24V DC

24V DC

For isolated

models,this 24V DC is

generated inside the

instrument.

Open collector output is desirable for up/down signals.

For contact output, use a mercury relay.

3 - 2

Page 10

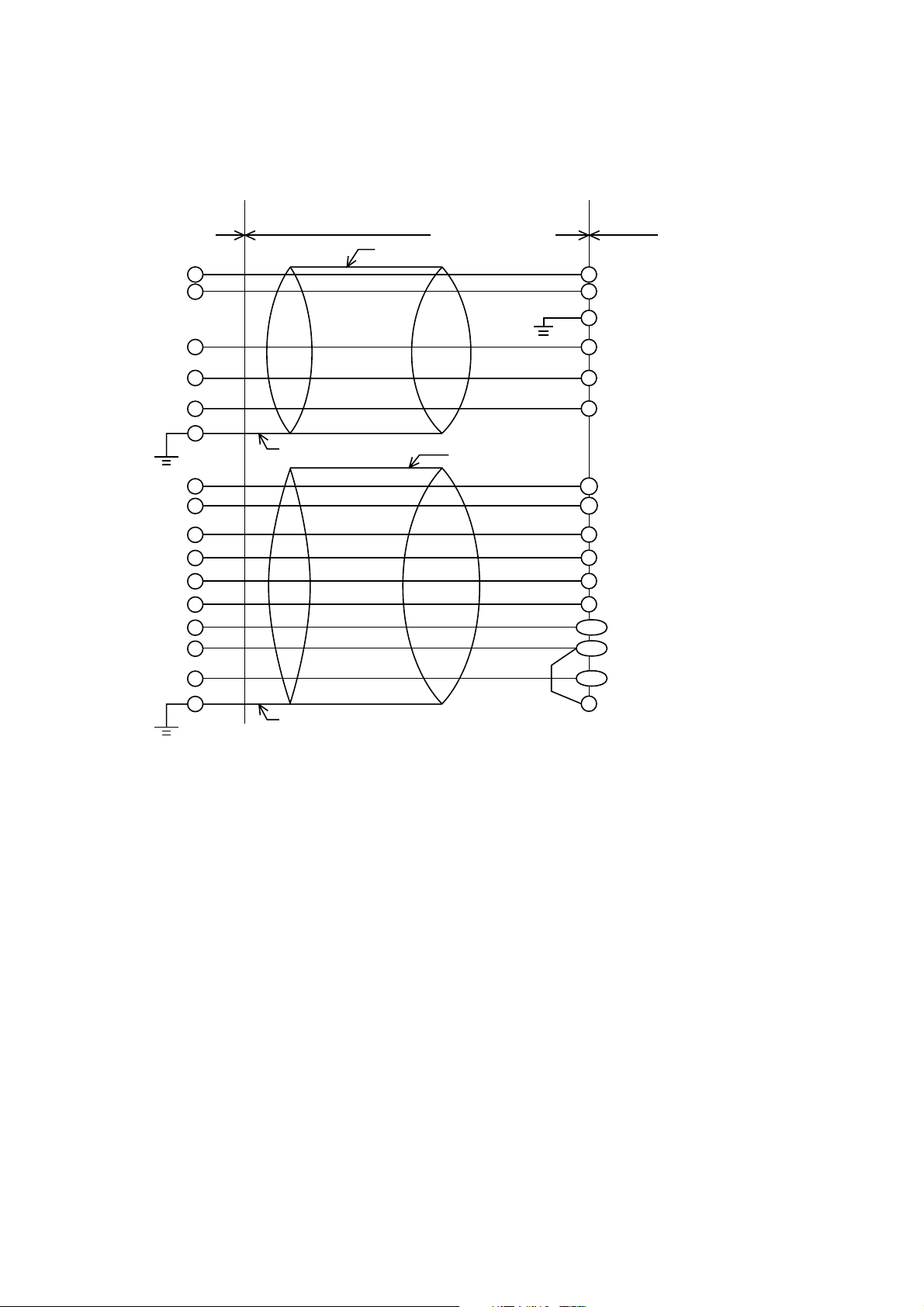

3-4. Wiring Procedure

1) Recommended wiring for pulse width input

Instrument

room

Shield Note 1

CVV - S

External wiring

CVV - S

+

-

E

U

D

C

I +

I -

H

C

L

C

P/D

P/D

ˇ´

ˇ

Pulse-to-pneumatic

pressure converter

+24V

} power supply

0V

E

Up signal

Down signal

COM

Feedback signal

+

}

(4 to 20 mA DC or

–

20 to 4 mA DC)

High limit

Common

Low limit

Common

Supply power down

}

monitor signal

*Jumper

S/D

C

Supply pneumatic pressure down

}

signal

Shield Note 1

Note 1: Ground the cable shield only on the instrument room side (Class 3 or higher).

Note 2: Install the jumpers on the external wiring.

Note 3: Although a large number of additional functions can be selected on the pulse-to-

pneumatic pressure converter, the number of external wires may be limited depending

on the conduit dimensions. The cable shapes and the number of wire cores should be

your guides when selecting functions.

Note 4: Ground the main unit to Class 3 or higher.

Figure 3-4-1 Wiring Procedure (for pulse width input)

3 - 3

Page 11

2) Recommended wiring for pulse train input

Use KPEV-S for up and down signals and CVV-S for other signals.

Instrument

room

Shield Note 1

KREV-S

External wiring

CVV-S

+

+24V

--

0V

E

E

U

Up signal

D

Down signal

C

COM

I+

+

I-

H

C

L

C

P/D

P/D

}

–

High limit

Common

Low limit

Common

Supply power down

}

monitor signal

Pulse-to-pneumatic

pressure converter

} power supply

Feedback signal

(4 to 20 mA DC or

20 to 4 mA DC)

Supply pneumatic pressure down

*Jumper

S/D

C

}

signal

Shield Note 1

Note 1: Ground the cable shield only on the instrument room side (Class 3 or higher).

Note 2: Install the jumpers on the external wiring.

Note 3: Although a large number of additional functions can be selected on the pulse-to-

pneumatic pressure converter, the number of external wires may be limited depending

on the conduit dimensions. The cable shapes and the number of wire cores should be

your guides when selecting functions.

Note 4: Ground the main unit to Class 3 or higher.

Figure 3-4-2 Wiring Procedure (for pulse train input)

3 - 4

Page 12

3) Recommended cables

Up and down signals

Pulse train input cable : KPEV-S.

Pulse width input cable : CVV-S.

Signals other than up and down signals : CVV-S.

1 KPEV-S cable specifications

(Used for up and down signals for pluse train input)

Polyethylene insulated vinyl sheath cable for shielded instrumentation

Performance :

Conductor : twisted soft copper wire for electrical use (JIS C 3102)

Insulator : polyethylene

Pair twisting : two wire cores twisted together at a proper pitch

Structure: 2P 3, blanket shielding

Electrical characteristics

Conductor : Nominal cross area: 2 mm

2

Structure : 7 cores/0.6 mm

Conductor resistance : 9.61 ohms/km

Line capacity (reference value) : 0.08 µF

Sheath thickness : 1.5 mm

External diameter : 15.0 mm

2 CVV-S cable specifications

(Used for signals other than up and down signals for pulse train input)

Vinyl insulated vinyl sheath cable for shielded instrumentation

Performance :

Conductor : twisted soft copper wire for electrical use (JIS C 3102)

Insulator : vinyl

Structure : 6 cores or 8 cores, blanket shielding

Electrical characteristics

Conductor : Nominal cross area : 2 mm

2

Structure : 7 cores/0.6 mm

Outside shape : 1.8 mm

Conductor resistance : 9.42 ohms/km

Line capacity (reference value) : 0.12 µF/km

Sheath thickness : 1.5 mm

External diameter : 14.0 to 15.0 mm

(depends on the number of cores)

3 - 5

Page 13

4) Outside cable diameter and number of wire cores

Structure table CVV-S (2-301.25 mm2)

Structure table CVV-S (2-302 mm2)

Packings applicable to waterproof glands

Use one of three kinds : 12,13, and 15 in diameter.

3 - 6

Page 14

4. Adjustment and Setting

4-1. Preparation

Connect as shown below.

To stabilize, warm up for at least 30 minutes before operation.

Note 1.

Speed

changeover

switch

High speed when on

Power

supply

When testing contact for

conductivity, connect to terminal

indicated by asterisk (*).

Class 3 grounding

Pulse-to-Pneumatic Pressure Converter

Distribution frame with two

pneumatic pressure monitors

Current output (4 to 20 mA)

Ammeter

Power supply for current output

(P/I power externally supplied)

Supplied pneumatic pressure

200 to 990 kPa

Reducing valve

Digital

manometer

Pneumatic pressure output

20 to 100 kPa

Apply load of ø 4, 3m+20cc

Tester

Pulse generator

Note 1 Remove jumper plate when testing withstand voltage

or insulation resistance.

Distribution frame with limit contact output

Figure 4-1 Instrument connection

Tools

1. Digital manometer

2. Ammeter

3. 24VDC power supply

4. Pulse generator for up and down

signals

5. Switch (for changing speed)

6. Air supply: 200 to 990kPa with air set

140kPa without air set

7. Tester for checking contact (output)

4 - 1

Page 15

4-2. Adjustment of Pneumatic Pressure Output (Figure 4-2)

Perform zero and span adjustments of pneumatic output with mechanical stoppers for upper and lower

limits (between the 56T helical gear and base) in contact.

Use the fine-zero adjustment screw and fine-span adjustment nuts on the transmitter.

1) At the lower contact with mechanical stopper

Pneumatic pressure output: 16kPa (-5%F.S.) ±1%F.S.

2) At the upper limit of contact with mechanical stopper

Pneumatic pressure output: 104kPa (105%F.S.) ±1%F.S.

Repeat zero and span adjustments until conditions (1) and (2) are met.

• Turn off power and remove the pulse motor connector, so that coupling can be done easily by hand.

• Pneumatic pressure output is measured by connecting a tube to the pneumatic pressure output check

plug.

Note 1 : Upper and lower limits are set to -3+/-1%F.S. and 103+/-1%F.S. The output value

must not exceed the mechanical stopper range.

Cap for pneumatic pressure output check plug

Terminal block for upper limit

Rough-zero

adjustment screw

(zero rise)

Input spring

Terminal block for

lower limit

Fine-zero

adjustment screw

Set screw for fixing cam, (Note 1.)

2 each for upper and lower limits (M3)

Cam for upper limit

Microswitch for upper limit

Microswitch for lower limit

Pulse motor

Span adjustment nut

Figure 4-2 Mechanical assembly

Pneumatic pressure

transmitter

4 - 2

Cam for lower limit

Page 16

4-2-1. Changing contact of limit contact signal

The following are contacts between the limit contact signal terminal block and customer terminal

connection cables.

Customer terminal cables

HL

........... Upper limit contact cable

HL .C ...... Upper limit common cable

LL............ Lower limit contact cable

LL .C ....... Lower limit common cable

Upper limit contact (terminal block)

• When using at NC (normally closed) (type H or E)

HL → NC (terminal board)

HL .C → C (terminal board)

• When using at NO (normally opened) (type K or F)

HL → NO (terminal block)

HL .C → C (terminal block)

Lower limit contact (terminal block)

• When using at NC (normally closed) (type H or E)

LL → NC (terminal board)

LL .C → C (terminal board)

• When using at NO (normally opened)

LL → NO (terminal board)

LL .C → C (terminal board)

Terminal block for lower limit

Red

Brown

Yellow

Blue

To customer terminal block

Terminal block for upper limit

Mechanical assembly

Figure 4-2-1 Connecting limit contact signal terminal block with customer terminals

4 - 3

Page 17

4-3. Adjustment of Current Output (Figure 4-3)

4-3-1. For direct feature

Conduct wiring and piping as shown in Figure 3-2-1.

1) Adjust input up and down so that pneumatic pressure output is about (*1) 20kPa (0% F.S.), then zeroadjust the P/I converter to attain current output corresponding to pneumatic pressure output (*2).

2) Adjust input up and down so that pneumatic pressure output is about 100kPa (100% F.S.), then spanadjust the P/I converter to attain current output corresponding to pneumatic pressure output.

Repeat steps (1) and (2) until the specified accuracy is achieved.

For reverse characteristics, start from step (3) below.

(*1): Pneumatic pressure output cannot be set precisely since it changes with a pulse motor.

(*2): To calculate the current output corresponding to pneumatic pressure output:

I = 4 + ( ) 16

P – 20

80

I : corresponding current output [mA DC]

P: pneumatic pressure output [kPa]

4-3-2.

For reverse feature

1) Set pneumatic pressure output to about 20kPa (0% F.S.). Zero-adjust so that current output becomes

20mA.

2) Set pneumatic pressure output to about 100kPa (100% F.S.). Span-adjust so that current output

becomes 4mA. (See (2) note (*2) of Section 4-3-1.)

Repeat steps (1) and (2) until the specified accuracy is achieved.

I = 20 – ( ) 16 (For reverse feature)

P – 20

80

4 - 4

Page 18

Zero adjustment

Span adjustment

Current output check terminal

Figure 4-3 P/I conversion unit

4-4. Setting Pneumatic Pressure Monitor

1) For models with both a pneumatic-pressure signal monitor (set at M1 (upper limit): 90±1%F.S., M2

(lower limit): 10±1%F.S.when shipping) and a supplied-air pressure drop monitor (set at 110kPa

when shipping), alarm settings are changed by adjusting the setting wheel on each unit. To raise the

set value, turn the setting wheel counterclockwise.

When only one monitor is used, select the upper limit or lower limit alarm.

2) Connect the monitor unit terminal and customer terminal connection cable as shown below.

(When used as an upper limit alarm) M1 monitor

Monitor terminal block

Orange

Common

(When used as a lower limit alarm) M2 monitor (or when used M1 monitor as a lower limit alarm)

Monitor terminal block

Orange

Common

Purple

Purple

(Purple)

Alarm contact is NC

Alarm contact is NO

(Purple)

Alarm contact is NO

Alarm contact is NC

4 - 5

Page 19

(When used as a supplied pneumatic pressure drop monitor) S/M monitor

Monitor terminal block

Green

Common

Black

(Black)

Alarm contact is NO

Alarm contact is NC

4-5. Setting Output Speed

1) Setting high speed output

Turn on the section between the customer terminal block (SPD COM) and (SPD). Adjust the variable

resistor for high speed on the main printed plate assembly to set the specified speed.

2) Setting low speed output

Turn off the section between customer terminal block (SPD COM) and (SPD). Adjust the variable

resistor for low speed on the main printed plate assembly to set the specified speed.

External terminal block connector

Connector for pulse motor

High-speed control

Figure 4-5 Setting output speed

4 - 6

Low-speed control

Page 20

4-6. Manual Operation (with A/M switch)

A manually-operated unit has a reducing valve for manual pneumatic-pressure setting and auto/manual

switch.

From this unit, switch A → M and M → A following the procedure below.

Under automatic operation (lever set to A), the automatic adjustment output pneumatic pressure is

displayed on the output pneumatic-pressure manometer. Pressing the check button displays output

(manual adjustment output pressure) of the reducing valve. To switch to manual operation, operate the

setting knob of the reducing valve to set the manual output to be the same as the automatic output, then

switch the mode.

Under manual operation (lever set to M), the reducing valve output is displayed on the output pneumaticpressure manometer, and remote operation of the valve is enabled. Pressing the check button displays

automatic adjustment output. To switch to automatic operation, set automatic output to the same as

manual output, then switch the mode.

Setting knob

Automatic output

Manual output

Reducing valve

Switch lever

Auto/Manual switch

Balance check button

Figure 4-6 Manual operation

Output pneumatic

pressure

Manual operation unit circuit

Check button

Output pneumaticpressure manometer

Supplied pneumatic

pressure

4 - 7

Page 21

5. Parts List

KEY NO. Part No. Name Quantity

1 80345502–ITEM Case Assembly 1a 10

2 80345454–001 Door Assembly 1a 7

3 80345503–001 Mechanical part assembly 1a 5

4 80345504–001 Pilot valve installed 1a 5

5 80250366–ITEM Output pneumatic pressure indicator 1a 7

6 80345505–001 S/M pneumatic pressure drop monitor 1a 7

7 80345505–002 Pneumatic pressure signal monitor(M1) 1a 7

8 80345505–003 Pneumatic pressure signal monitor(M2) 1a 7

9 80353282–001 Manual operation mechanism 1a 5

10 80513486–ITEM KF Air set 1a 5

11 80345506–ITEM P/I 1a 7

12 80345437–ITEM Main printed plate assembly 1a 5

13 80345442–ITEM Customer terminals 1a 7

Recommendation

exchange period

(years)

14 80510478–ITEM SUS water-proof gland 1 10

80510497–001 Plastic water-proof gland 1 10

Note 1: "-ITEM" depends on instrument specifications.

5 - 1

Page 22

Fig 5-1. Parts key No.

5 - 2

Page 23

6. Maintenance

6-1. Reguler Maintenance

1) Check the supplied air pressure

Keep the supplied air pressure unit clean. Drain unit and check filters regularly. Check the

compressor, the air cleaning and dehumidifying unit, and the tank.

6-2. Periodical Maintenance and Checking

1) Check for air leaks

Make sure that there is no air leak from the air pipe or the connection joints.

2) Check the nozzle flapper for staining

Remove stains on the nozzle flapper of the pneumatic pressure sending unit (mechanical parts

assembly, see Figure 4-2, with a cloth impregnated with a solvent such as petroleum, naphtha

or chlorosene 1, 1, 1-Trichloroethane (Chloroethene). Wipe gently to prevent damage to the

flapper beam (plate spring).

3) Check the gear mechanism of the pulse motor for wear

Damaged or worn gears, especially the worm gears and worm wheels must be replaced.

4) Check the pilot relay (Figure 6-1)

(1) Remove the pilot relay from the manifold : remove the two screws (14), the spring

washers (15), and the gaskets.

(2) Disassemble the pilot relay : remove the two flat-head screws (13).

(3) Dismount parts (6) to (12). Parts (2) to (5) need not be dismounted unless they need

replacing.

(4) Clean the metal parts with a solvent such as petroleum, naphtha or chlorosene. 1, 1, 1-

Trichloroethane (Chloroethene).

Do not stain the diaphragms with the solvent.

Clean the valve stem (2) on the seal surface and the hole. Let solvent be absorbed by

pressing the conic spring (4) to push the valve stem (2) in the compression direction.

(5) Check the inside of the exhaust ring (10) for stains. If stained, clean with a cloth

impregnated with a solvent.

(6) Dry all the parts with clean compressed air.

(7) Replace the rubber diaphragms (8) and (11) if they are worn or damaged.

(8) Reassemble the pilot relay : replace all parts in correct order and tighten them with two

flat-head screws (13).

(9) Remount the pilot relay on the manifold, position the gasket (1) correctly.

(10) Fix the pilot relay on the manifold using mounting screws (14) and two spring washers

(15).

6 - 1

Page 24

5) You are recommended to replace rubber parts (such as the diaphragms and gaskets on the pilot

relay, the tube for piping, and the O-ring for the check plug of the pneumatic pressure sending

unit) at intervals of about five years, though this may vary depending on conditions.

Figure 6-1 Pilot relay disassembled

6 - 2

Page 25

Page 26

Terms and Conditions

We would like to express our appreciation for your purchase and use of Azbil Corporation's products.

You are required to acknowledge and agree upon the following terms and conditions for your purchase of Azbil Corporation's

products (system products, field instruments, control valves, and control products), unless otherwise stated in any separate

document, including, without limitation, estimation sheets, written agreements, catalogs, specifications and instruction manuals.

1. Warranty period and warranty scope

1.1 Warranty period

1.2 Warranty scope

Azbil Corporation's products shall be warranted for one (1) year from the date of your purchase of the said products or

the delivery of the said products to a place designated by you.

In the event that Azbil Corporation's product has any failure attributable to azbil during the aforementioned warranty

period, Azbil Corporation shall, without charge, deliver a replacement for the said product to the place where you

purchased, or repair the said product and deliver it to the aforementioned place.

Notwithstanding the foregoing, any failure falling under one of the following shall not be covered under this warranty:

(1) Failure caused by your improper use of azbil product

(noncompliance with conditions, environment of use, precautions, etc. set forth in catalogs, specifications,

instruction manuals, etc.);

(2) Failure caused for other reasons than Azbil Corporation's product;

(3) Failure caused by any modification or repair made by any person other than Azbil Corporation or Azbil

Corporation's subcontractors;

(4) Failure caused by your use of Azbil Corporation's product in a manner not conforming to the intended usage of

that product;

(5) Failure that the state-of-the-art at the time of Azbil Corporation's shipment did not allow Azbil Corporation to

predict; or

(6) Failure that arose from any reason not attributable to Azbil Corporation, including, without limitation, acts of God,

disasters, and actions taken by a third party.

Please note that the term “warranty” as used herein refers to equipment-only-warranty, and Azbil Corporation shall not

be liable for any damages, including direct, indirect, special, incidental or consequential damages in connection with or

arising out of Azbil Corporation's products.

2. Ascertainment of suitability

3. Precautions and restrictions on application

You are required to ascertain the suitability of Azbil Corporation's product in case of your use of the same with your

machinery, equipment, etc. (hereinafter referred to as “Equipment”) on your own responsibility, taking the following

matters into consideration:

(1) Regulations and standards or laws that your Equipment is to comply with.

(2) Examples of application described in any documents provided by Azbil Corporation are for your reference

purpose only, and you are required to check the functions and safety of your Equipment prior to your use.

(3) Measures to be taken to secure the required level of the reliability and safety of your Equipment in your use

Although azbil is constantly making efforts to improve the quality and reliability of Azbil Corporation's

products, there exists a possibility that parts and machinery may break down.

You are required to provide your Equipment with safety design such as fool-proof design, *1 and fail-safe

design*2 (anti-flame propagation design, etc.), whereby preventing any occurrence of physical injuries, fires,

significant damage, and so forth. Furthermore, fault avoidance, *3 fault tolerance,*4 or the like should be

incorporated so that the said Equipment can satisfy the level of reliability and safety required for your use.

*1. A design that is safe even if the user makes an error.

*2. A design that is safe even if the device fails.

*3. Avoidance of device failure by using highly reliable components, etc.

*4. The use of redundancy.

Azbil Corporation's products other than those explicitly specified as applicable (e.g. azbil Limit Switch For Nuclear Energy)

shall not be used in a nuclear energy controlled area (radiation controlled area).

Any Azbil Corporation's products shall not be used for/with medical equipment.

The products are for industrial use. Do not allow general consumers to install or use any Azbil Corporation's product.

However, azbil products can be incorporated into products used by general consumers. If you intend to use a product for

that purpose, please contact one of our sales representatives.

In addition,

you are required to conduct a consultation with our sales representative and understand detail specifications, cautions

for operation, and so forth by reference to catalogs, specifications, instruction manual, etc. in case that you intend to use

azbil product for any purposes specified in (1) through (6) below.

Moreover, you are required to provide your Equipment with fool-proof design, fail-safe design, anti-flame propagation

design, fault avoidance, fault tolerance, and other kinds of protection/safety circuit design on your own responsibility to

ensure reliability and safety, whereby preventing problems caused by failure or nonconformity.

(1) For use under such conditions or in such environments as not stated in technical documents, including catalogs,

specification, and instruction manuals

(2) For use of specific purposes, such as:

* Nuclear energy/radiation related facilities

[For use outside nuclear energy controlled areas] [For use of Azbil Corporation's Limit Switch For Nuclear

Energy]

* Machinery or equipment for space/sea bottom

* Transportation equipment

[Railway, aircraft, vessels, vehicle equipment, etc.]

* Antidisaster/crime-prevention equipment

Page 27

* Burning appliances

* Electrothermal equipment

* Amusement facilities

* Facilities/applications associated directly with billing

(3) Supply systems such as electricity/gas/water supply systems, large-scale communication systems, and traffic/air

traffic control systems requiring high reliability

(4) Facilities that are to comply with regulations of governmental/public agencies or specific industries

(5) Machinery or equipment that may affect human lives, human bodies or properties

(6) Other machinery or equipment equivalent to those set forth in items (1) to (5) above which require high reliability

and safety

4. Precautions against long-term use

Use of Azbil Corporation's products, including switches, which contain electronic components, over a prolonged period

may degrade insulation or increase contact-resistance and may result in heat generation or any other similar problem

causing such product or switch to develop safety hazards such as smoking, ignition, and electrification.

Although acceleration of the above situation varies depending on the conditions or environment of use of the products,

you are required not to use any Azbil Corporation's products for a period exceeding ten (10) years unless otherwise

stated in specifications or instruction manuals.

5. Recommendation for renewal

Mechanical components, such as relays and switches, used for Azbil Corporation's products will reach the end of their life

due to wear by repetitious open/close operations.

In addition, electronic components such as electrolytic capacitors will reach the end of their life due to aged deterioration

based on the conditions or environment in which such electronic components are used.

Although acceleration of the above situation varies depending on the conditions or environment of use, the number of

open/close operations of relays, etc. as prescribed in specifications or instruction manuals, or depending on the design

margin of your machine or equipment, you are required to renew any Azbil Corporation's products every 5 to 10 years

unless otherwise specified in specifications or instruction manuals.

System products, field instru ments (sensors such as pressure/flow/level sensors, regulating valves, etc.) will reach the end

of their life due to aged deterioration of parts.

For those parts that will reach the end of their life due to aged deterioration, recommended replacement cycles are

prescribed. You are required to replace parts based on such recommended replacement cycles.

6. Other precautions

Prior to your use of Azbil Corporation's products, you are required to understand and comply with specifications (e.g.,

conditions and environment of use), precautions, warnings/cautions/notices as set forth in the technical documents

prepared for individual Azbil Corporation's products, such as catalogs, specifications, and instruction manuals to ensure

the quality, reliability, and safety of those products.

7. Changes to specifications

Please note that the descriptions contained in any documents provided by azbil are subject to change without notice for

improvement or for any other reason.

For inquires or information on specifications as you may need to check, please contact our branch offices or sales offices,

or your local sales agents.

8. Discontinuance of the supply of products/parts

Please note that the production of any Azbil Corporation's product may be discontinued without notice.

For repairable products, we will, in principle, undertake repairs for five (5) years after the discontinuance of those

products. In some cases, however, we cannot undertake such repairs for reasons, such as the absence of repair parts.

For system products, field instruments, we may not be able to undertake parts replacement for similar reasons.

9. Scope of services

Prices of Azbil Corporation's products do not include any charges for services such as engineer dispatch service.

Accordingly, a separate fee will be charged in any of the following cases:

(1) Installation, adjustment, guidance, and attendance at a test run

(2) Maintenance, inspection, adjustment, and repair

(3) Technical guidance and technical education

(4) Special test or special inspection of a product under the conditions specified by you

Please note that we cannot provide any services as set forth above in a nuclear energy controlled area (radiation

controlled area) or at a place where the level of exposure to radiation is equivalent to that in a nuclear energy controlled

area.

AAS-511A-014-04

Page 28

Page 29

Page 30

Page 31

Document Number : CM2-APN100-2001

Document Name : Multifunction Pulse-to-Pneumatic

Pressure Converter Model J-APN11

Date : 1st edition: Mar. 1997

3rd editoin: Mar. 2015

Issued / Edited by : Azbil Corporation

Page 32

Loading...

Loading...