Page 1

HGC000001000P

CM2-HGC100-2001

Heat Value Gas Chromatograph

Model HGC303

User's Manual

Page 2

NOTICE

While the information in this manual is presented in good faith and

believed to be accurate, Azbil Corporation disclaims any implied

warranty of merchantability or fitness for a particular purpose and

makes no express warranty except as may be stated in its written

agreement with and for its customer.

In no event shall Azbil Corporation be liable to anyone for any indirect,

special or consequential damages. is information and specications

in this document are subject to change without notice.

© 2009-2018 Azbil Corporation All Rights Reserved.

Page 3

Safety

Safety symbols

The Warning sign means that serious personal injury, even death, could result if the instructions

given are not strictly observed.

The Caution sign means that light personal injury and/or equipment damage could result if the

instructions given are not correctly observed.

Be sure to correctly operate the model HGC303 while strictly observing the

safety precautions provided in this manual-especially the Warnings and Cautions

indicated by the symbols as shown below.

The descriptions of the Warning and Caution signs used in this manual are as

follows.

WARNING

CAUTION

i

Page 4

Hazardous Areas Certifications

The model HGC303 complies with the type of protection, which based on the

following standards.

(1) ISSeP/ATEX Flameproof Certication

0344

II 2 GD

EEx d II C T6 -10°C ≤ Tamb ≤ +50°C IP65

ISSeP14ATEX0007X

Special conditions for safe use (symbol X)

e fastening screws of this apparatus are made of stainless steel and have a

yield stress of 500 N/mm2.

(2) FM Explosionproof / Flameproof Approval

Explosionproof for Class I, Division 1, Groups C and D, T4

Flameproof for Class I, Zone 1, AEx d IIB T4

Dust-ignitionproof for Class II and III, Division 1, Groups E, F and G, T4

(3) NEPSI Flameproof Certications

Flameproof

Ex d IIC T6 Gb at -10°C ≤ Tamb ≤ +50°C Dust-Ignition-proof

Ex tD A21 T85°C

erefore, the model HGC303 can be installed in various hazardous locations.

However, an explosion-protected electrical apparatus requires special care. Please

read all instruction and safety notes before installation.

WARNING

NEVER open the terminal box cover while the model HGC303 is energized in a hazardous location.

CAUTION

Use the model HGC303 only in an ambient temperature of -10 to 50°C (14 to 122°F)

CAUTION

Take precautions to prevent corrosion, deformation or damage to the housing or terminal box

cover.

CAUTION

See that all conduits are properly sealed. Otherwise, the model HGC303 cannot with- stand the

pressure that can result from explosion of an explosive gas inside the housing. Also, the model

HGC303 cannot prevent the explosion of any external explosive gas.

ii

Page 5

(1) Installation for ISSeP/ATEX Flameproof Apparatus

1. General

1.1 e apparatus protected by the ameproof enclosure in accordance with EN

60079-1 can be installed in such hazardous areas, for which the apparatus has

been certied, as an explosive atmosphere containing ammable substances in

the form of gas, vapour, mist or dust may be present.

Note: e apparatus has been certied to comply with EN 61241-0, EN 61241-1

(dust ignition protection).

1.2 The apparatus enclosure must be kept closed in the hazardous areas when

the apparatus is energized because the internal circuit of the apparatus is

capable of igniting the explosive atmosphere. (Never connect any hand-held

communicator to the apparatus terminals by opening the cover, except while no

explosive atmosphere is present.)

1.3 It is required to connect the external earthing terminal of the apparatus to

the equipotential bonding system which includes protective conductors,

metal conduits, metal cable sheaths, steel wire armouring and metallic parts of

structures, but does not include the neutral conductors of the power systems.

Note: e protective conductor to which exposed conductive parts of equipment

(machines, apparatus, devices, components and instrumentation thereof)

are connected, must be separated in the hazardous area from the neutral

conductor, and must be connected to the power systems earth point in the

non-hazardous area, if the power system is directly earthed.

For external earthing and bonding of the apparatus it is recommended to use

a cable lug so that the conductor is secured against loosening and twisting and

that the contact pressure is permanently secured.

1.4 Either cable systems (cable entry systems) or conduit systems can be employed

for wiring of the apparatus in the hazardous areas (see 2 or 3).

1.5 Non-sheathed single core cables are not permitted for live conductors unless

they are installed inside enclosures or conduit systems.

1.6 Conduits and, in special cases, cables (for example, where there is a pressure

difference) must be sealed so as to prevent the passage of the explosive

atmosphere.

1.7 Further information concerning installation and maintenance of apparatus

is given by relevant clauses of the following documents.

EN 60079-14 Electrical apparatus for explosive gas atmospheres

EN 60079-17 Part 17: Inspection and maintenance of electrical installations in

EN 50281-1-2 Electrical apparatus for use in the presence of combustible dust

Part 1-2: Electrical apparatus protected by enclosures

-- Selection, installation and maintenance

Part 14: Electrical installations in hazardous areas other than mines

hazardous areas.

iii

Page 6

2. Cable systems

2.1 Thermoplastic sheathed cables, thermosetting sheathed cables, or

elastomeric sheathed cables can be selected for xed wiring in the hazardous

areas.

2.2 Flameproof cable entry devices (cable glands) certified to comply with EN

60079-1 and appropriate to the type of cable employed, must be used for the

connection of cables to the apparatus.

3. Conduit systems

For conduit systems, relevant national standards or codes of practice are followed

prior to the following recommendations.

3.1 Screwed heavy gauge steel, solid drawn or seam welded conduit, or exible

conduit for protection of cables in explosive atmospheres (see ISO 10807) can

be selected for xed wiring in the hazardous areas.

3.2 Conduit must be threaded for connection to permit the full engagement of

ve threads.

3.3 Either conduit entry devices or sealing devices such as stopping boxes are

provided at the wall of the apparatus enclosure to limit the pressure piling eect

and to prevent hot gases from entering the conduit system from the enclosure

containing a source of ignition. Each type of both the devices must be certied

to comply with EN 60079-1.

3.4 The stopping boxes, if used, are filled with a compound which does not

shrink or setting and is impervious to, and unaected by, chemicals found in

the hazardous area. e depth of the compound in the stopping box is at least

equal to the internal diameter of the conduit, but in no case less than 10 mm.

3.5 When the conduit contains three or more non-seathed single or multi-core

cables, the total cross-sectional areas of cables, including insulation, are not

more than 40% of the cross-sectional area of the conduit.

4. Installation in explosive atmospheres caused by air / dust

mixtures

4.1 Conduit or cable glands, if employed to connect cables to the apparatus, must

be selected and used in such a way that an IP6X protection (dust-tight) is

guaranteed.

4.2 It is recommended to maintain the apparatus so that the dust layer will not

exceed a thickness of 5 mm.

Note: Where the ignition temperature of a dust layer up to 5 mm thickness is

equal to, or higher than, the value that is obtained by adding 75K to the

maximum surface temperature of the enclosure “T...°C” as marked on the

apparatus, the apparatus is incapable of causing ignition of the dust layer.

(T...°C is based on the maximum ambient temperature)

iv

Page 7

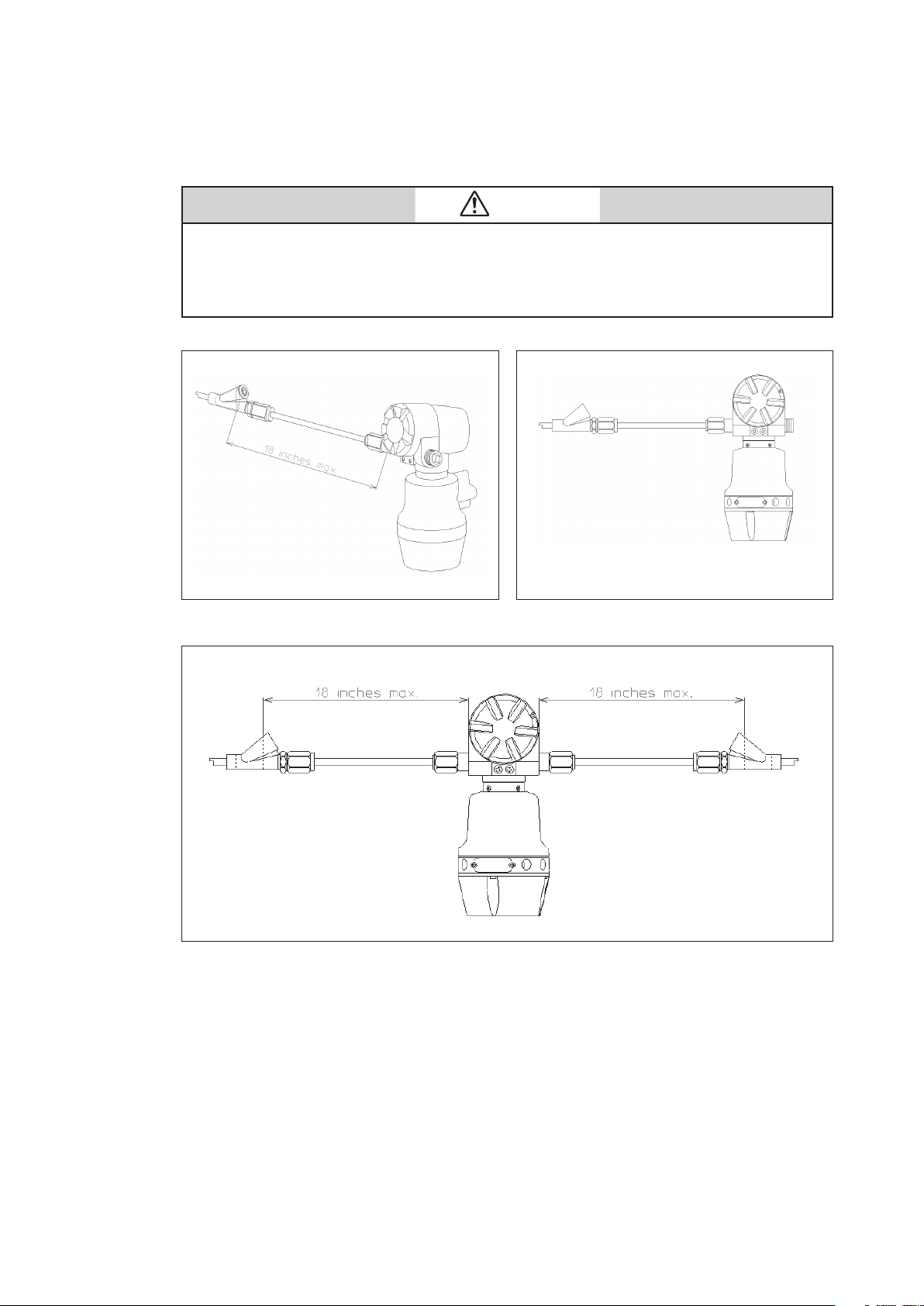

(2) Installation for FM Explosionproof / Flameproof Apparatus (in

accordance with NEC)

CAUTION

• Install the apparatus only in hazardous (classified) locations for which the apparatus has been

approved.

• Seal each conduit entering the apparatus enclosure within 18 in.(457 mm) from the enclosure.

• Do not open the apparatus enclosure when an explosive atmosphere is present.

Fig. S-1 An example of conduit seal (with stopping plug)

Fig. S-2 An example of conduit seals (without stopping plug)

v

Page 8

1. Class I, Division 1 locations

1.1 Wiring methods

• readed rigid metal conduit, threaded steel intermediate metal conduit,

or Type MI cable with termination ttings approved for the location, can

be employed

• readed joints must be made up with at least ve threads fully engaged.

• Boxes, ttings, and joints must be approved for Class I, Division 1.

1.2 Sealing

• Each conduit entering the apparatus enclosure is required to be sealed

within 18 in. (457 mm) from the enclosure.

• e sealing of each conduit can be provided with a sealing tting approved

for class I locations.

• Sealing compound must be approved and must not have a melting point of

less than 93° (200°F).

• e minimum thickness of the sealing compound should not be less than the

trade size of the conduit and, in no case, less than 5/8 in.(16 mm).

• Splices and taps cannot be made in the ttings.

2. Class I, Division 2 locations

2.1 Wiring methods

• readed rigid metal conduit, threaded steel intermediate metal conduit,

enclosed gasketed busways, or Type PLTC cable in accordance with the

provisions of remote-control, signaling, and power-limited circuits (see

NEC, Article 725), or Type ITC cable in cable trays, in raceways, supported

by messenger wire, or directly buried where the cable is listed for this use;

Type MI, MC, MV, or TC cable with approved termination ttings can be

employed.

• Boxes, ttings, and joints are not required to be explosionproof.

2.2 Sealing

• Each conduit entering the apparatus enclosure is required to be sealed as

shown in 1.2.

3. Class II, Division 1 locations

3.1 Wiring methods

• readed rigid metal conduit, threaded steel intermediate metal conduit,

or Type MI cable with termination ttings approved for the location, can

be employed.

• Boxes and ttings must be dusttight.

3.2 Sealing

• Where a raceway provides communication between the apparatus enclosure

and an enclosure that is not required to be dust-ignitionproof, suitable means

must be provided to prevent the entrance of dust into the dust-ignitionproof

enclosure through the raceway. One of the following means can be used: (1)

a permanent and eective seal; (2) a horizontal raceway not less than 10

(3.05 m) long; or (3) a vertical raceway not less than 5 (1.52 m) long and

extending downward from the dust-ignitionproof enclosure.

• Seals are not required to be explosionproof.

vi

Page 9

4. Class II, Division 2 locations

4.1 Wiring methods

• Rigid metal conduit, intermediate metal conduit, electrical metallic

tubing, dust-tight wireways, or Type MC or MI cable with approved

termination fittings, or Type PLTC in cable trays, or Type ITC in cable

trays, or Type MC or TC cable installed in ladder, ventilated trough,

or ventilated channel cable trays in a single layer, with a space not less

than the larger cable diameter between the two adjacent cables, can be

employed.

• All boxes and ttings must be dusttight.

4.2 Sealing

• Sealing means must be provided as shown in 3.2.

5. Class III, Division 1 locations

5.1 Wiring methods

• Rigid metal conduit, rigid non-metallic conduit, intermediate metal

conduit, electrical metallic tubing, dust-tight wireways, or Type MC or

MI cable with approved termination ttings, can be employed.

• All boxes and ttings must be dusttight.

5.2 Sealing

• Sealing means are not required.

6. Class III, Division 2 locations

6.1 Wiring methods

• Wiring methods must comply with 5.1.

6.2 Sealing

• Sealing means are not required.

vii

Page 10

(3) NEPSI Flameproof and Dust Certications

Heat Value Gas Chromatograph model HGC303, manufactured by Azbil

Corporation, has been approved by National Supervision and Inspection Center for

Explosion Protection and Safety of Instrumentation (NEPSI) in accordance with

the following standards:

GB3836.1-2010 Electrical apparatus for explosive gas atmospheres

Part 1: General requirements

GB3836.2-2010 Electrical apparatus for explosive gas atmospheres

Part 2: Flameproof enclosure “d”

GB12476.1-2013

Part 1: General requirements

GB12476.5-2013

Part 5: Protection by enclosure “tD”

The apparatus are approved with Ex marking of Ex d IIC T6; Ex tD A21 T85°C

IP65. e certicate number is GYJ15.1324X.

1. Requirements for safe use

1.1 e external earthing terminal shall be connected to the ground reliably at site.

1.2 e ambient temperature range is -40°C to +60°C.

1.3 e cable entry holes have to be connected by means of suitable cable entries

with type of protection of Ex d IIC and Ex tD A21, which are covered by a

separate examination certicate. Unwanted entry holes shall be blocked by blind

plugs. Aer installation of the cable entry, the whole apparatus shall reach IP65.

1.4 Rated supply voltage: (24±15%)Vd.c

1.5 e warning “Do not open while the circuit is alive” must be obeyed when the

product is used in the explosive gas area.

1.6 Regular cleanness shall be conducted to avoid the deposit of the dust.

1.7 The gas that may cause the corrosion effect to the aluminum alloy shall be

excluded at site.

1.8 End users are forbidden to change the configuration to ensure the explosion

protection performance of the product.

1.9 When installation, operation and maintenance the product, users should

comply with the relevant requirements of the product instruction manual and

the following standards:

GB3836.13-2013 “Electrical apparatus for explosive gas atmospheres Part 13: Repair

GB3836.15-2000 “Electrical apparatus for explosive gas atmospheres Part 15:

GB3836.16-2006 “Electrical apparatus for explosive gas atmospheres Part 16: Inspection

GB50257-1996 “Code for construction and acceptance of electric device for

GB12476.2-2010 “Electrical apparatus for use in the presence of combustible dust

GB15577-2007 “Safety regulations for the protection of dust explosion”.

Electrical apparatus for use in the presence of combustible dust

Electrical apparatus for use in the presence of combustible dust

and overhaul for apparatus used in explosive gas atmospheres”

Electrical installations in hazardous area (other than mines)”

and maintenance of electrical installation (other than mines)”.

explosion atmospheres and fire hazard electrical equipment

installation engineering”

Part A-1: Electrical apparatus protected by enclosures and surface

temperature limitation-Selection, installation and maintenance”

2. Special condition for safe use

e cover has at least 7.9 engaged threads.

viii

Page 11

EMC caution

1. Electromagnetic environment

The model HGC303 is intended to be used in an industrial electromagnetic

environment.

2. Electromagnetic immunity conditions

Specication: During test, SCV deviation is less than or equal to 1MJ/m3.

ix

Page 12

x

Page 13

Table of Contents

Chapter 1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1-1. Definition of terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3. Model HGC303 measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-4. Model No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-5. Model HGC303 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-6. Fieldbus communication system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Chapter 2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2-1. Unpacking and storing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-2. Installing the model HFA100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-3. HGM Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-3-1. Computer system requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2-3-2. Settings for Windows 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2-3-3. HGM software installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2-3-4. .NET framework 4.0 installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2-3-5. Microsoft Visual C++ runtime installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

2-3-6. Setting the folder access rights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

2-4. Fieldbus installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2-4-1. Fieldbus requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

2-4-2. Fieldbus wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

2-5. Model HGC303 installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

2-5-1. Installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-29

2-5-2. Model HGC303 dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

2-5-3. Model HGC303 installation example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

2-5-4. Model HGC303 piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

2-5-5. Model HGC303 wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-34

Chapter 3. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3-1. Starting up the model HGC303 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-1-1. Secondary pressure and flow set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-1-2. Piping leak check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-1-3. Power on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3-1-4. Model HGC303 leak check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3-2. Stopping the model HGC303 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3-3. HGM operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3-3-1. HGM connection with model HFA100 and HDM303 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3-3-2. Starting up the HGM with model HFA100 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3-3-3. HGM Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3-3-4. Set up HGM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

3-3-5. User’s mode menu and commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

3-3-6. Main displays of HGM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-20

3-3-7. Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

3-3-8. Configuration mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

3-3-9. HGM shut down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-40

3-4. Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

3-4-1. Calibration gas requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

3-4-2. Calibration procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-42

3-4-3. Calibration function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

3-4-4. Description of component data table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

xi

Page 14

3-4-5. Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

3-4-6. Calibration methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

3-5. GPA mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-52

3-5-1. Setting the HGM to GPA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-52

3-5-2. Data save . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-53

3-5-3. Data edit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-53

3-5-4. File auto saving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-54

3-5-5. Configuration mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

3-5-6. User’s mode (GPA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-63

3-5-7. Main display panels of HGM (GPA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-65

3-5-8. Report (GPA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-70

Chapter 4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4-1. Checking and changing the carrier gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2. Checking and changing the filters in model HGC303 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-3. Periodical check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Chapter 5. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5-1. Connection with PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5-2. HGC status on HGM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Terms and Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S1

xii

Page 15

Chapter 1. Introduction

1-1. Definition of terms

Heat Value Gas Chromatograph (Model HGC303)

The Heat Value Gas Chromatograph measures process gases (N2, CO2,

C1~C6+) that are mainly contained in natural gas, calculates heat value,

density, Wobbe index and compressibility factor, and converts them into

a Fieldbus signal in the field and transmits the signal to a receiver.

Parameters can all be remotely set, adjusted, and self-diagnosed by

using the HGM.

Measuring and calculating methods comply with ISO 6974 Part 4, ISO

6976 and GPA2172.

HGC Data Manager (Model HDM303)

Model HDM303 is Modbus interface unit for model HGC303.

Model HDM303 covers all the function of model HMU303. Model

HDM303 also has a powerful functions.

HGC000

The functions are local display, data storage function, multi

Modbus serial port, multi stream switching, and analog output.

HMU can not be connected together with HDM in the same FB

loop. Only one HMU can be connected in one FB loop with the

HGC. Two or more HDM can be connected in the same FB loop.

For this application, the HDM must be configured first.

Please refer to the model HDM303 User’s Manual for more details.

Heat Value Gas Chromatograph Fieldbus Adaptor (Model HFA100)

HFA is an interface used to connect the HGM (HGC

monitor), Windows-based PC application, to Azbil

Corporation’s state of the art analyzer, HGC (Heat value

Gas Chromatograph) that operates on F

fieldbus H1 network. Users are able to configure, monitor

and maintain the HGC all from the PC by simply

connecting the HFA to the Fieldbus network.

OUNDATION

TM

1-1

Page 16

HGC Monitor (HGM)

HGM software is provided as a standard accessory

with the model HGC303.

The model HGC303 Monitor allows the user to

configure and calibrate the model HGC303 as well as

allowing one to monitor a heat value-trend graph.

Moreover, HGM also has a report function for

concise management.

SP (Set Point)

The set value of each variable.

PV (Process variable)

The present value of each variable.

SCV, GCV

Superior Calorific Value, Gross Calorific Value

These parameters are same value of different name.

HGM000001000P

ICV, NCV

Inferior Calorific Value, Net Calorific Value

These parameters are same value of different name.

TCD

Thermal Conductivity Detector

URV

Upper Range Value

LRV

Lower Range Value

Total (Raw)

Total of raw concentration

Component name

C6+: Hexane and heavier gas

C3H8: Propane

i-C4H10: i-Butane

n-C4H10: n-Butane

neo-C5H12: neo-Pentane

i-C5H12: i-Pentane

n-C5H12: n-Pentane

N2: Nitrogen

CH4: Methane

CO2: Carbon dioxide

C2H6: Ethane

1-2

Page 17

1-2. General

The model HGC303 is a gas chromatograph designed to analyze natural gas and is able to

transmit a process variable via a Fieldbus signal.

One can easily adjust configuration data and monitor values such as the heat value by using

the HGM.

The heat value monitoring system, which can be controlled from both the model HGC303 and

HGM, will substantially minimize time, cost and maintenance.

This chapter first describes the measuring system and structure of the model HGC303. After

that, the characteristics and the specifications of Fieldbus are described in detail.

First time users of the model HGC303 should read this chapter carefully and thoroughly.

Components of the model HGC303 system

Before installing the model HGC303, the following components must be prepared:

Hardware

Model HGC303

Model HDM303

Model HFA100

Power supply (24 V DC, 4A min.), Power supply cable

Fieldbus cable (See “2-4-1. Fieldbus requirements” on page 2-25)

Flow meter for process gas

(A flow meter for methane should be used scale: 0 - 100 ml/min.)

Laptop or desktop PC

(See “2-3-1. Computer system requirements” on page 2-3 for detail)

Helium gas for carrier gas and valve operating gas

Calibration gas

1/8 or 1/4 inch stainless steel (SS) tubing

Fitting for piping (1/4 NPT male connector 5 or 6 pieces.... For HGC)*

Software

Microsoft Windows 7 (32-bit type, 64-bit type) / Microsoft Windows 10 (64-bit type)

HGM

Note *: For satisfying TestSafe Flameproof Certification or IP65, six 1/4 NPT male connectors

are required.

1-3

Page 18

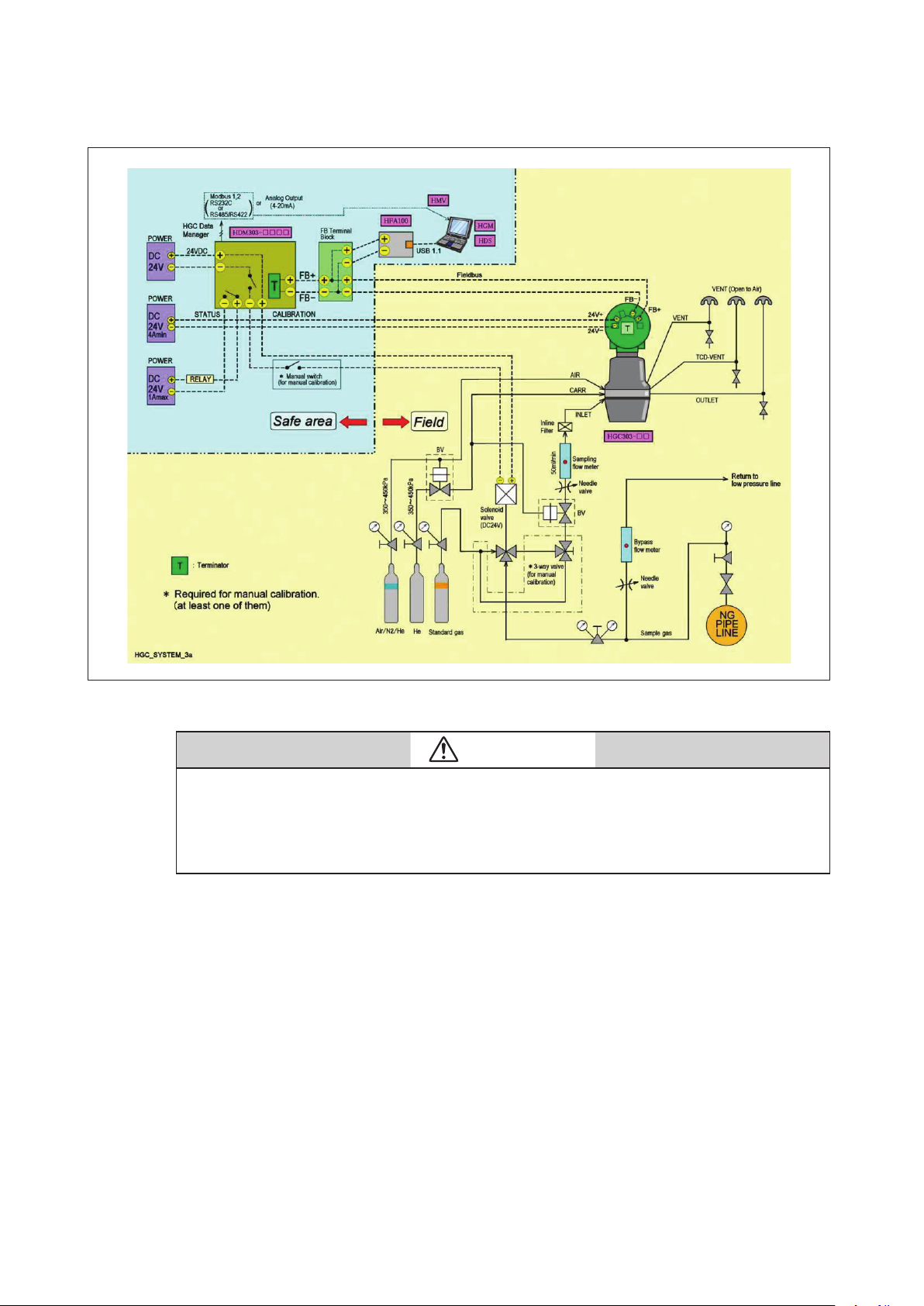

1-3. Model HGC303 measuring system

Fig. 1-1 Model HGC303 measuring system diagram

CAUTION

A block valve is a kind of air actuator valve. It is used mainly for the protection of the TCD and

columns.

It works as sample shut-off valve when the pressure of the carrier gas or air supply is lower than

approximately 294 kPa.

Azbil Corporation recommends that it should be installed.

The Heat Value Gas Chromatograph measures process gases (N2, CO2, C1~C6+) that

are mainly contained in natural gas, calculates heat value, density, Wobbe index and

compressibility factor, and converts them into a Fieldbus signal in the field and trans- mits the

signal to receivers.

Parameters can be remotely set, adjusted, and self-diagnosed with the HGM.

1-4

Page 19

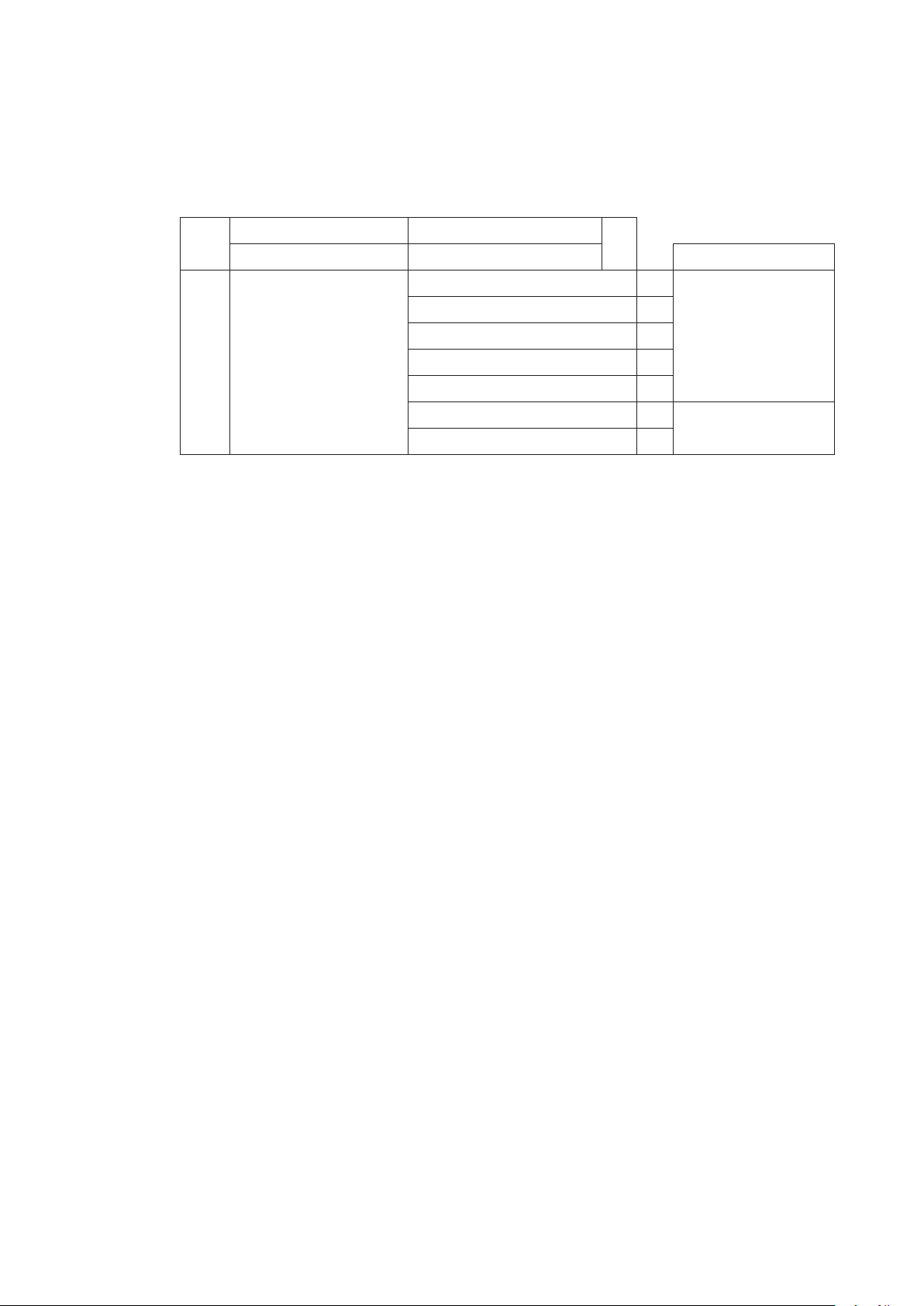

1-4. Model No.

HGC303-I II

I Conduit entry 1/2 NPT female 1

II Explosion-protection ISSeP/ATEX flameproof E ISO

Heat Value Gas Chromatograph

Gas connection 1/4 NPT female Calculation method

NEPSI flameproof N

TestSafe flameproof S

JIS flameproof *

Ordinary type

FM flameproof F GPA

CSA flameproof C

Note *: Special model.

Note +: Default range is suitable for High calorie LNG.

+

+

J

H

1-5

Page 20

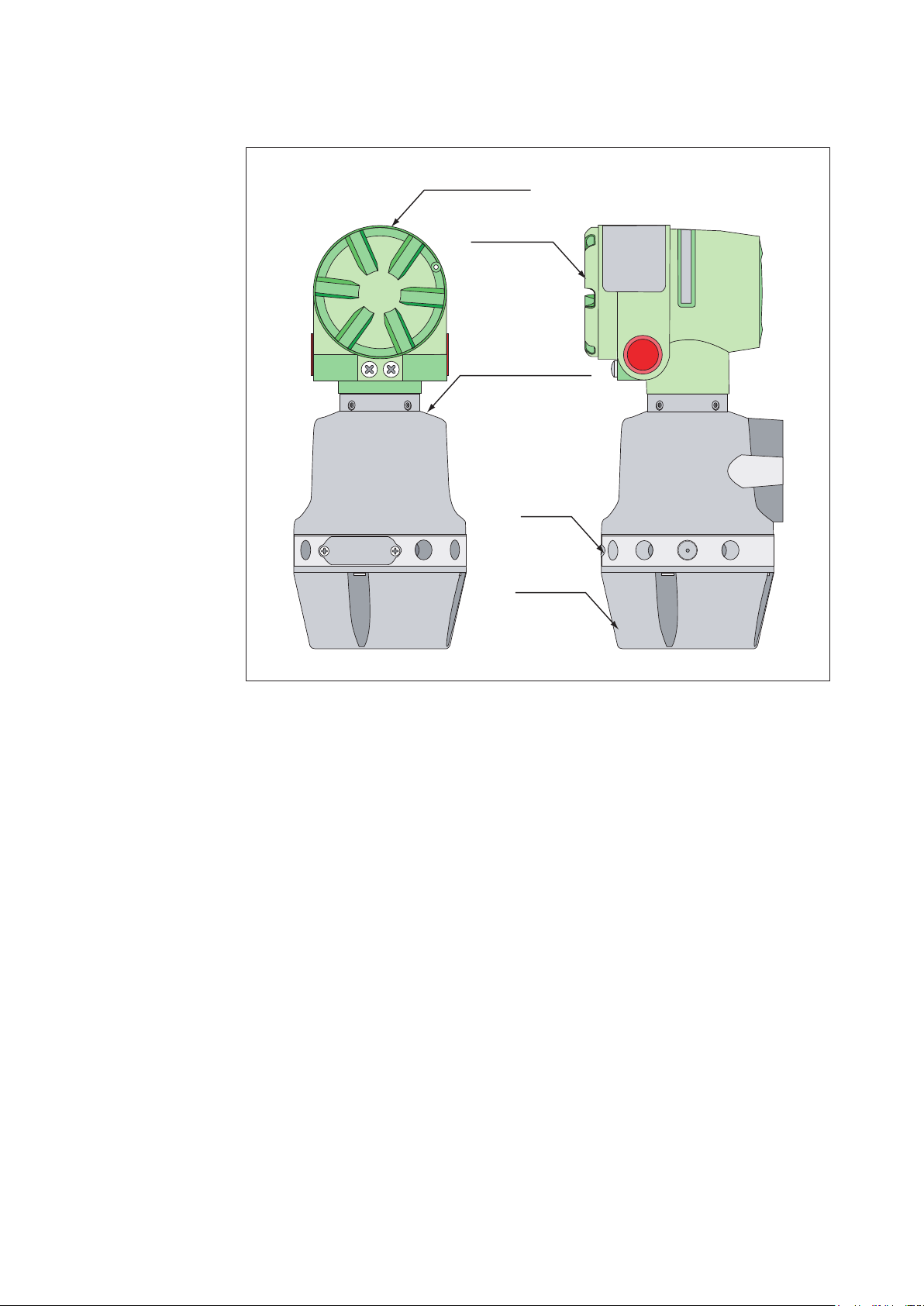

1-5. Model HGC303 Structure

HGC000004000D

Terminal housing

Terminal cover

Analyzer unit housing

Manifold

Oven cover

Fig. 1-2 Main parts of Model HGC303

1 Terminal housing ..........Terminal box for wiring.

2 Analyzer unit housing ..Proportional valve, solenoid valve, TCD sensor are located here.

3 Manifold .........................Connection parts for gas inlet and outlet line

4 Oven cover .....................Analyzer valve and column system are found inside the cover.

1-6

Page 21

1-6. Fieldbus communication system

The model HGC303 uses F

between other devices.

The F

OUNDATION

communication system which interconnects field equipment such as sensors, actuators and

controllers.

The F

OUNDATION

manufacturers in Europe, North America and Asia Pacific.

OUNDATION

TM

fieldbus is an open, 2-wire, multi-drop, two-way digital

TM

fieldbus is supported by a worldwide network of customers and

TM

fieldbus technology to transfer information

F

OUNDATION

F

OUNDATION

(1) F

OUNDATION

TM

fieldbus http://www.fieldbus.org/

TM

fieldbus literature

TM

fieldbus Technical overview (FD-043)

(2) Fieldbus Installation & Planning Guide (AG-165)

(3) F

OUNDATION

TM

fieldbus Application Guide

31.25kbit/s Wiring and Installation (AG-140)

(4) F

OUNDATION

TM

fieldbus Application Guide

31.25kbit/s Intrinsically Safe Systems (AG-163)

1-7

Page 22

1-8

Page 23

Chapter 2. Installation

This chapter guides you through the procedures for installing of your hardware and software.

2-1. Unpacking and storing

Unpacking the model HGC303

Your model HGC303 is a precision instrument and should be handled with care to prevent any

damage to it or breaking it.

After unpacking the model HGC303, verify that the following items are included

Package items

(1) Model HGC303

(2) Mounting bracket set

(3) Wrench for seal plug

(4) Tag number plate set

(5) CD-ROM including HGM software

and user’s manual

(6) EC declaration of conformity and

safety instructions *

Note *: It is packed with model HGC303-_E only.

CAUTION

Exposing the model HGC303 to the atmosphere might cause deterioration of the column.

Therefore, the model HGC303 has been packed and shipped in a protective bag with a desiccant.

Install and operate the model HGC303 immediately after breaking the seal.

Inquires

If you have any questions regarding the specifications of your model HGC303, contact one

of the Azbil Corporation products service offices or contact your nearest Azbil Corporation

representative.

When making an inquiry, make sure to provide the model number and product number of

your model HGC303.

2-1

Page 24

Storing the model HGC303

The model HGC303 should be stored:

- indoor at storage temperature (-40 to 70°C); humidity (up to 95%RH)

- in a place safe from vibration or shock.

- in the same packing as it was shipped in.

Model HGC303 that has been used should be stored by following procedures below.

Step Action

1 Make sure no process gas remain in the model HGC303.

2 Purge the model HGC303 with helium gas.

Insert metal plugs into all the inlets and outlets for carrier gas, valve operating

3

gas and process gas except VENT (valve operating gas outlet) in order to keep

moisture out.

4 Pack it as it was when it was originally received.

Store the model HGC303 indoors at normal temperature and humidity in a

5

place safe from vibration or shock.

2-2

Page 25

2-2. Installing the model HFA100

To collect data from HGC, HGM needs the HFA100 (Heat value gas chromatograph fieldbus

adapter) as a data converter. First, for hardware installation, see the user’s manual for

HFA100.

Note: This manual is for the use of HFA100 version 3.0 or later. For combinations of HFA100

versions and corresponding PC software versions, see “Software Compatibility” in the

Appendix.

2-3. HGM Installation

2-3-1. Computer system requirements

(1) Operating system: Windows 7 (32-bit type, 64-bit type) / Windows 10 (64-bit type)

(2) Disk storage: 20 GB free space minimum

(3) CD-ROM drive (used only during installation)

(4) USB 2.0 or later

Note: For Windows 7, use Service Pack 1 and the latest updates. For Windows 10, use

Professional or Enterprise Edition version 1709 or later.

2-3

Page 26

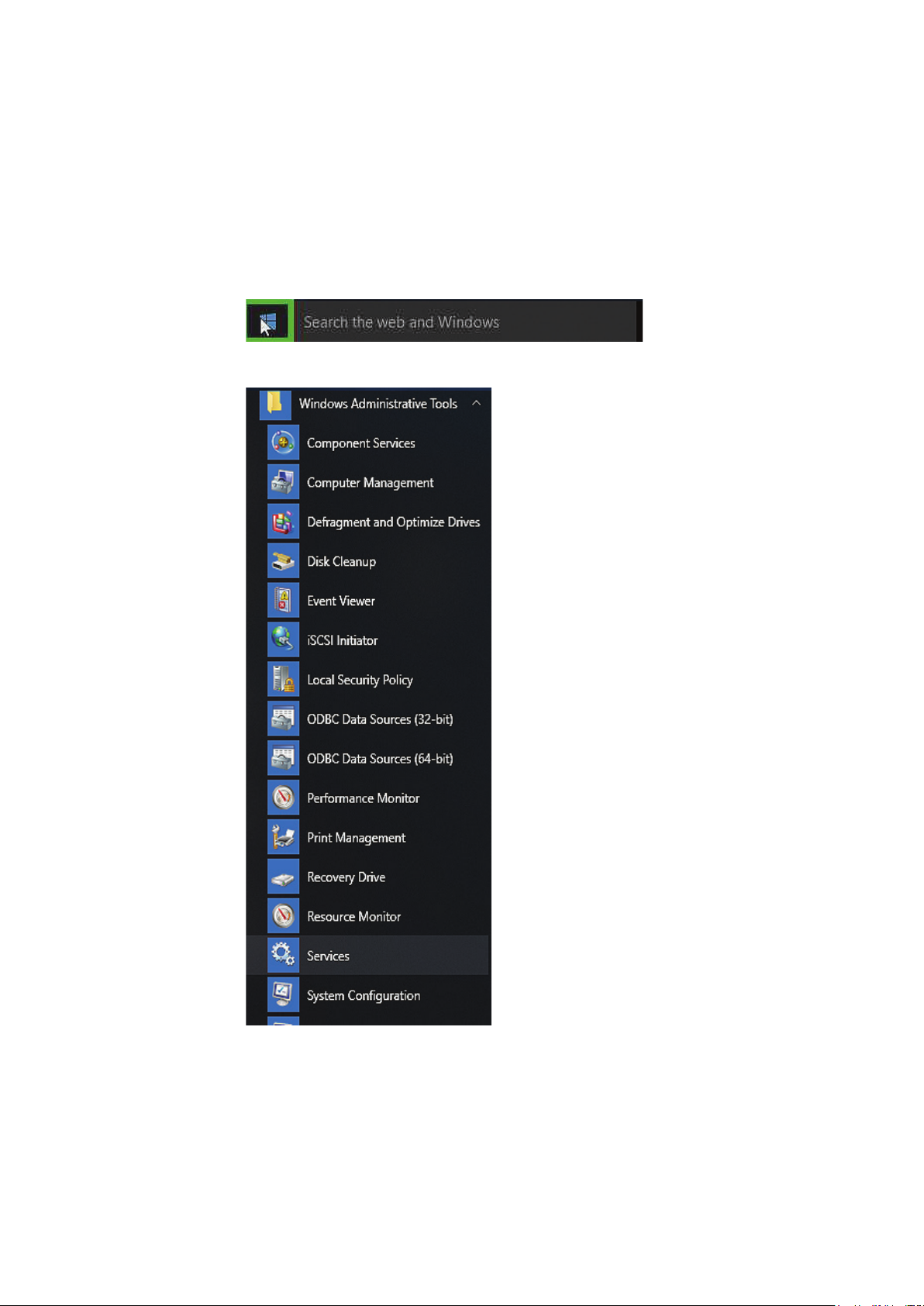

2-3-2. Settings for Windows 10

When using Windows 10 and running the HGM online, make sure to configure the Windows

Update setting so that the Internet is not connected.

Stopping services

(1) Left-click the [Start] icon and then click the [Services] menu from the

[Windows Administrative Tools]menu.

2-4

Page 27

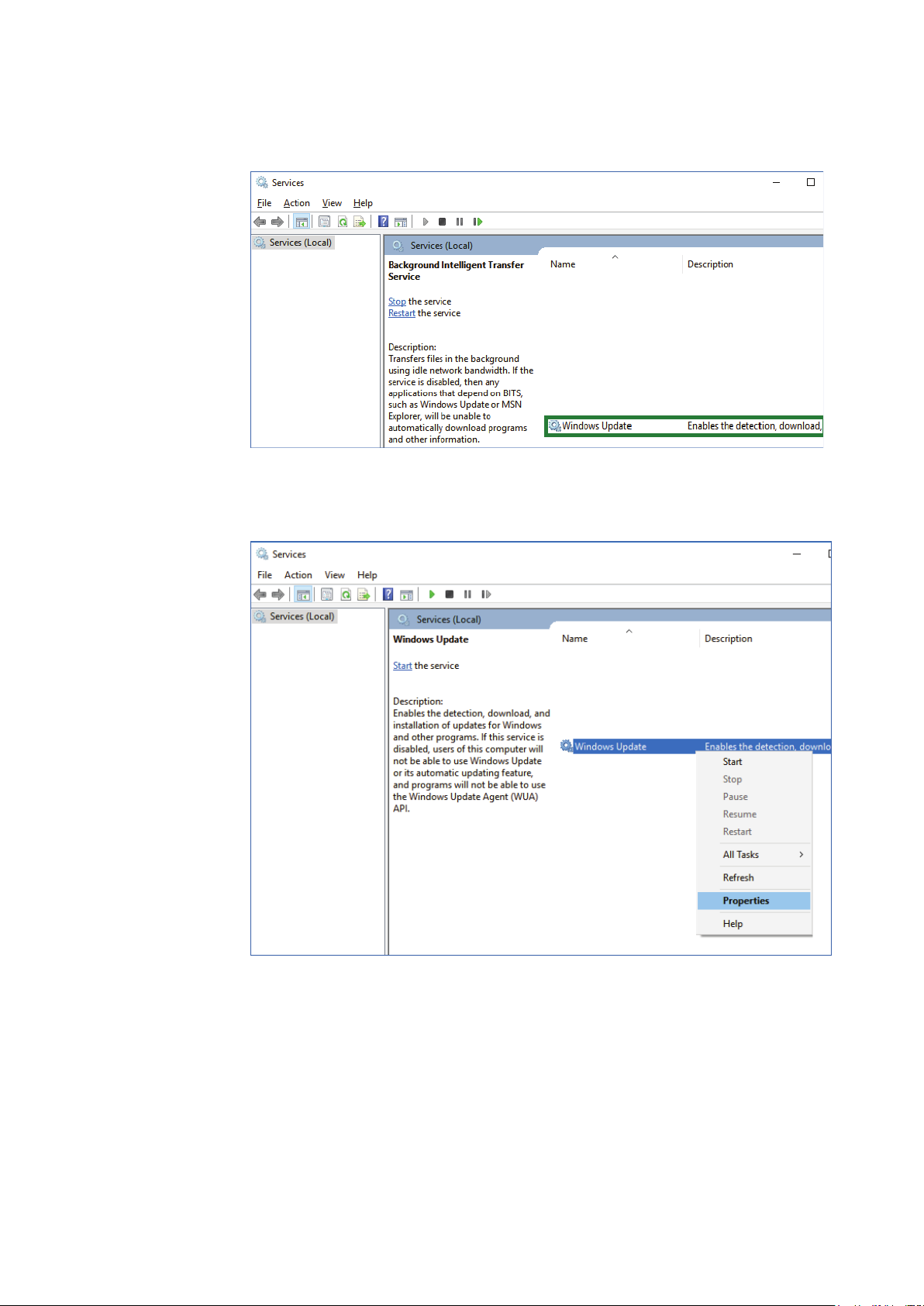

(2) Click in the [Services] screen, and then right-click [Windows Update].

(3) On the [Services] screen, right-click [Windows Update] and then click [Properties] in the

menu that is displayed.

2-5

Page 28

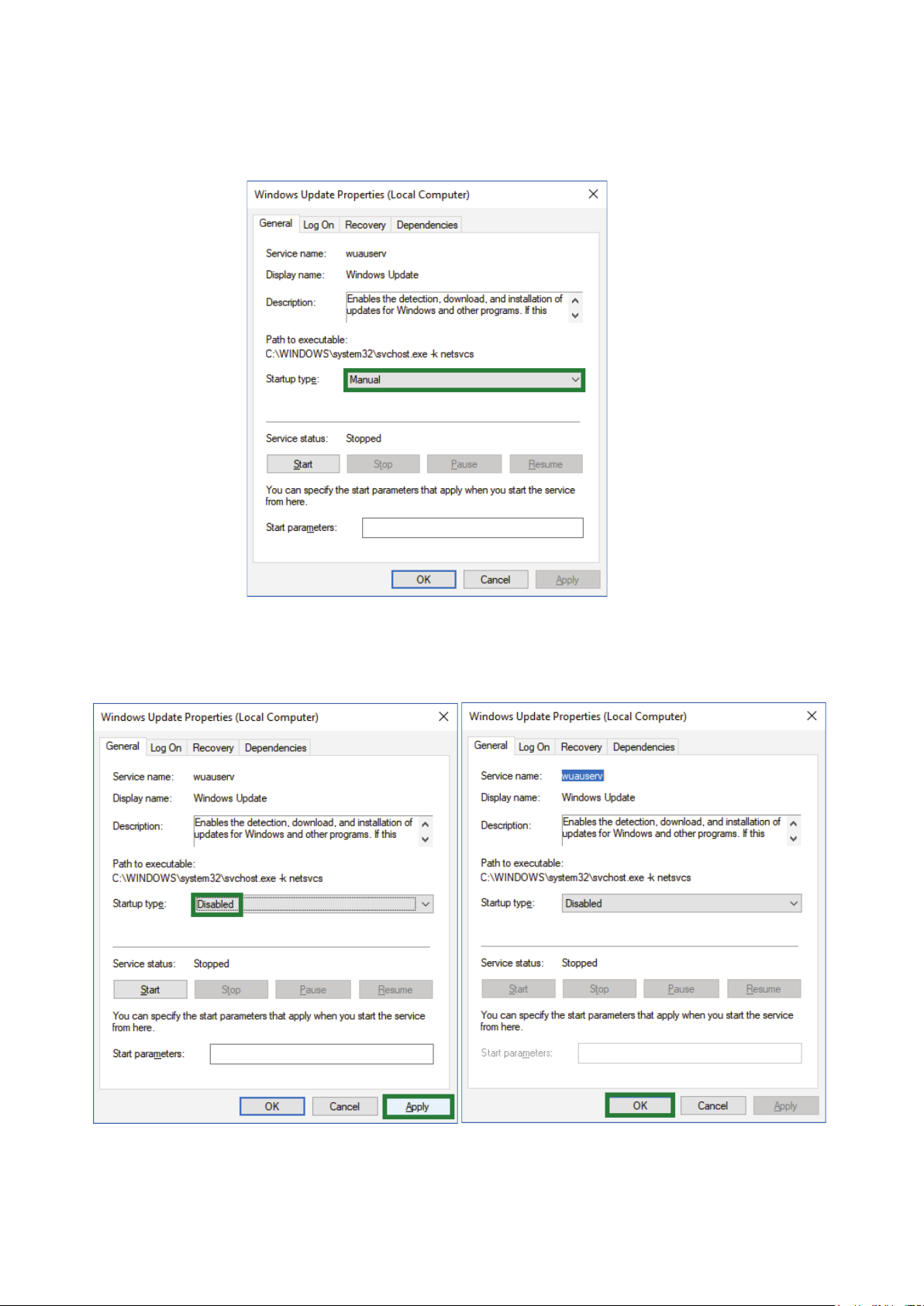

(4) On the [Windows Update Properties] screen, click [Startup type] and then switch it to [Disabled].

If [Service Status] is [Run], switch it to [Stopped].

(5) On the [Windows Update Properties] screen, with the [Startup type] selected as

[Disabled], click the [Apply] button and then the [OK] button.

2-6

Page 29

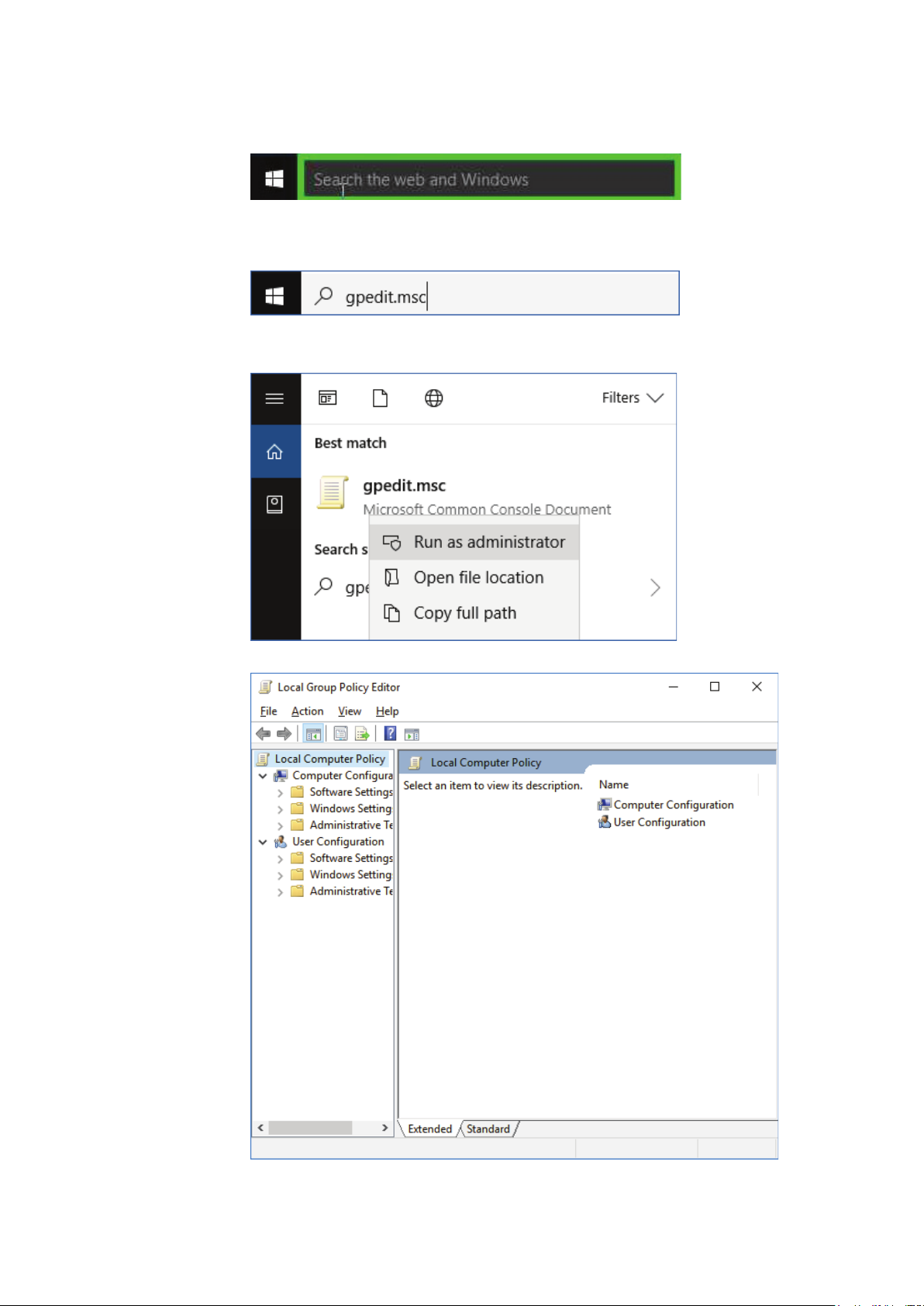

(6) Click on the search section at the bottom left of the window.

(7) Click in the Search screen and enter “gpedit.msc.”

(8) Right-click the displayed program and click “Run with Administrator Privileges.”

(9) The [Local Group Policy Editor screen] opens.

2-7

Page 30

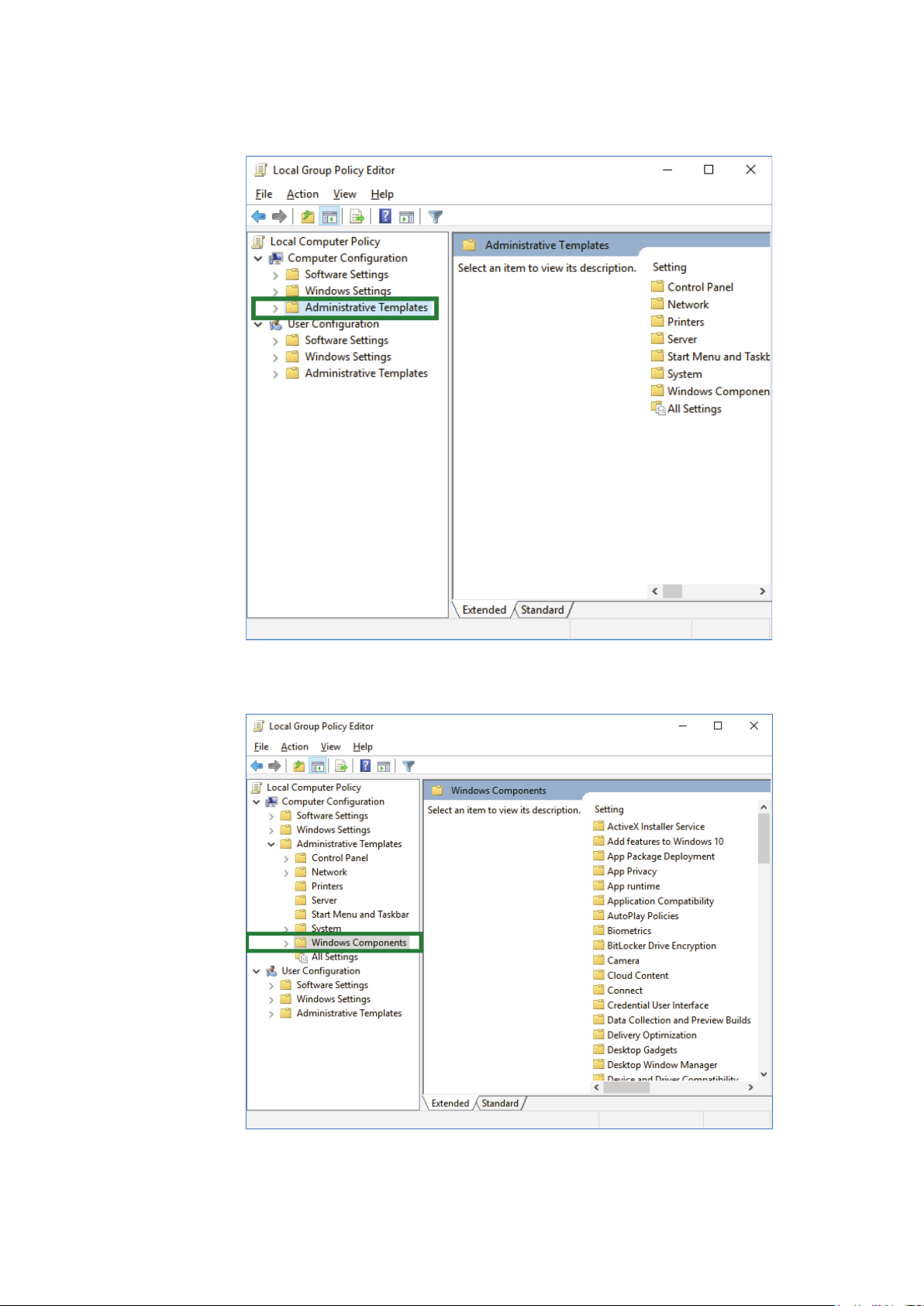

(10) In the [Local Group Policy Editor] screen, click [Computer Configuration] >

[Administrative Templates] in the menu tree on the left.

(11) Click [Windows Components] in the [Local Group Policy Editor] screen.

2-8

Page 31

(12) Double-click [Windows Update] in the [Local Group Policy Editor] screen.

(13) Double-click [Configure Automatic Update] in the [Local Group Policy Editor] screen.

(14) Click the [Disabled] button in the [Configure Automatic Update] screen.

2-9

Page 32

(15) Click the [OK] button in the [Configure Automatic Update] screen.

(16) In the Settings screen, click the [Update & security] icon.

2-10

Page 33

(17) Open the [Windows Update] item list.

(18) In the [Windows Update] items list, click [Advanced options].

2-11

Page 34

(19) Below the [Choose how updates are installed] section, if “Some settings are managed by

your organization” is displayed and grayed out, the settings for Windows 10 are complete.

2-12

Page 35

2-3-3. HGM software installation

Installing the HGM.

Note: We recommend always using the latest version of the HGM software. It is supplied in

HGC CD-ROM.

(1) Make sure Windows has been installed.

(2) Start PC. Be sure to Log On your PC with Administrator Account.

(3) Insert the CD-ROM that is supplied with HGC into the CD-ROM drive.

(4) Double-click the [HGMx.xx_setup] folder.

(5) Double-click the [setup.exe] file.

(6) If the User Account Control dialog box appears, click [Yes] button.

Fig. 2-1 UAC dialog box

2-13

Page 36

(7) HGM installer will appear, click [OK] button.

Fig. 2-2 Setup message

(8) The following screen will appear, click PC figure button.

Fig. 2-3 HGM installation location

2-14

Page 37

(9) The following screen will appear, click [Continue] button.

Fig. 2-4 Group name

If a version conflict message appears, select [Yes].

(10) Installation is complete once the message below appears on your screen. Click [OK]

button.

Fig. 2-5 Complete installation

2-15

Page 38

2-3-4. .NET framework 4.0 installation

Do the installation if the OS is Windows 7

Microsoft .NET framework 4.0 or later is required to run HGM. If Microsoft .NET framework

4.0 or later is not installed on the PC, install it using the following proce- dure.

(1) Make sure Windows has been installed.

(2) Start PC. Be sure to Log On your PC with Administrator Account.

(3) Insert the CD-ROM that is supplied with HGC into the CD-ROM drive.

(4) Double-click the [dotNet Framework 4.0] folder.

(5) Double-click the [dotNetFx40_Full_x86_x64.exe] file.

(6) If the User Account Control dialog box appears, click [Yes] button.

Fig. 2-6 UAC dialog box

2-16

Page 39

(7) Setup program will start.

Fig. 2-7 .NET framework 4.0 installation progress

Check the license acceptance check box and click the [Install] button.

(8) Installation will start. It may take a few minutes until completion.

Fig. 2-8 .NET framework 4.0 installation progress

2-17

Page 40

(9) Installation is complete once the message below appears on your screen. Click [Finish]

button.

Fig. 2-9 Complete installation

2-3-5. Microsoft Visual C++ runtime installation

The runtime component for Microsoft Visual C++ 2010 is required for HGM execution. If it is

not installed on the PC, install it using the following procedure.

(1) Make sure Windows has been installed.

(2) Start PC. Be sure to Log On your PC with Administrator Account.

(3) Insert the CD-ROM that is supplied with HGC into the CD-ROM drive.

(4) Double-click the [vc_runtime2010] folder.

(5) Double-click the [vcredist_x86.exe] file.

(6) If the User Account Control dialog box appears, click [Yes] button.

2-18

Page 41

Fig. 2-10 UAC dialog box

(7) Setup program will start.

Fig. 2-11 VC++2010 runtime license agreement

Check the license acceptance check box and click the [Install] button.

2-19

Page 42

(8) Installation will start. Please wait a moment.

Fig. 2-12 VC++2010 runtime installation progress

(9) Installation is complete once the message below appears on your screen. Click [Finish]

button.

Fig. 2-13 Complete installation

2-20

Page 43

2-3-6. Setting the folder access rights

When executing HGM on a Windows 7 or later PC, full access rights for the following

program folders are required.

32bit type operation system: C:\Program Files (x86)\HGM

64bit type operation system: C:\Program Files\HGM

Note: Executing the program without this setting will cause a virtual folder problem caused

by Windows User Account Control (UAC). Refer to troubleshooting “5-1. Connection

with PC.”

Set the access rights by taking the following steps.

(1) Start PC. Be sure to Log On your PC with Administrator Account.

(2) Use Windows Explorer, select [HGM] folder, right click and select [Properties].

Fig. 2-14 HGM folder

2-21

Page 44

(3) HGM Properties, select [Security] tab and click [Edit] button.

Fig. 2-15 HGM folder properties

2-22

Page 45

(4) Permissions for HGM, select [Users] in Group or user names.

Fig. 2-16 Permissions for HGM folder

2-23

Page 46

(5) Permissions for HGM, check Allow Full control in Permissions for Users, then click

[Apply] button and click [OK] button.

Fig. 2-17 Permissions for HGM folder

2-24

Page 47

(6) HGM Properties, click [OK] button.

Note: If the HGM folder has already been created under C:\Users\User_name\AppData\Local\

VirtualStore, the HGM software may not work properly. Move the data in the HGM

folder to other place, or delete the HGM folder.

2-4. Fieldbus installation

2-4-1. Fieldbus requirements

Fieldbus components and characteristics

Cable

Various types cables are usable for fieldbus.

Type A is the preferred fieldbus cable.

Azbil Corporation recommends type A as the fieldbus cable to use.

Fig. 2-18 HGM folder properties

2-25

Page 48

The table below describes the type of cable and its maximum length, which is specified in the

IEC 1158-2/ISA S50.02 Physical Layer Standard.

Table 2-1. Fieldbus cable description

Type Cable description Size Maximum length

2

A Shielded, twisted pair #18 AWG (0.8 mm

Structure: twisted pair cable with overall shield

Detailed specifications of the Type A cable at 25°C are as follows;

a) Characteristic impedance: Z0 at 31.25 kHz = 100 ohm +/- 20%

b) Maximum attenuation at 39 kHz = 3.0 db/m

c) Maximum capacitive unbalance to shield = 2 nF/km

d) Maximum DC resistance (per conductor) = 22 ohm/km

e) Maximum propagation delay change 7.8 kHz to 39 kHz = 1.7 us/km

f) Conductor cross-sectional area (wire size) = 0.8 mm

g) Minimum shield coverage shall be 90%

) 1900m (6232 ft.)

2

(#18 AWG)

Support

Conductor

Insulator

Taping

Shield foil

Shield wire

Shield net

Jacket

Fig. 2-19 Example of Type A fieldbus cable structure

Terminators

A terminator is an impedance matching module used near or at the end of a transmission line.

Terminators prevent distortion and signal loss.

A terminator shall be located at both ends of a trunk cable, connected from one signal

conductor to the other.

A trunk is the longest cable path between any two devices on the fieldbus network. ONLY

TWO terminators are required per fieldbus segment.

No connection shall be made between the terminator and cable shield.

2-26

Page 49

The terminator impedance value shall be 100 ohm +/- 2% over a frequency range of 7.8 kHz to

39 kHz.

The model HGC303 and model HDM303 have a terminator at the fieldbus connection port

therefore an additional terminator is not required.

Terminal blocks

The terminal blocks can be the same as those used for 4-20mA.

Connectors

D-sub 9P connector is as specified for standard fieldbus connectors in the IEC/ISA Standard.

Contact No. Signal

6 Data +

7 Data -

2-27

Page 50

2-4-2. Fieldbus wiring

Signal wire

A Fieldbus signal is transmitted via 2-wire isolated signal lines.

Please keep in mind that the Fieldbus signal has polarity, positive (+) and negative (-). All of

the (+) terminals must be connected to each other and similarly, all of the (-) terminals must

be connected each other.

An important aspect of fieldbus is that neither of the signal wires are grounded.

Shielding

The preferred type of cable for fieldbus is a shielded cable.

Assemble a lugged shield wire connected to the metallized shield of each cable. Connect all

shield wires together to the terminal block.

In addition, connect the overall shield to the ground at one point in instruments room to

protect against field noise.

Do not ground the shield at multiple points.

Termination

A terminator shall be connected at both ends of the signal wire pair, at the field device end and

the host device end.

Connect the terminator between signal (+) and (-).

ONLY TWO terminators are needed per fieldbus segment.

Never connect a terminator between the signal (+ or -) and cable shield.

Twisted pair wire

Fig. 2-20 Example of cable finish

Heat shrink sleeve

Jacket

Overall shield

Shield wire

Wire terminal

2-28

Page 51

2-5. Model HGC303 installation

2-5-1. Installation site

Conditions for selecting a location for installation.

- A sheltered location conforming to class C as defined by IEC654-1.

This is so to protect the model HGC303 from direct sunlight, wind, and rain.

Select a site that allows for the installation of a housing structure or protective panels.

- A location which is free from sudden changes in temperature or humidity and which has an

ambient temperature within the range of -10 to 50°C and a relative humidity range of 95%

maximum.

- A location not subject to electromagnetic induction, as such as that generated by large-scale

transformers and high-frequency furnaces.

- A location not subject to severe vibration.

- A location with minimal exposure to corrosive gases or dust and with good air circulation.

2-29

Page 52

2-5-2. Model HGC303 dimensions

The dimensions of the model HGC303 are given below.

[Unit: mm (inch)]

77 (3.0)

100 (3.9)

Fig. 2-21 Model HGC303 dimension

115 (4.5)

97 (3.8)82 (3.2)

244 (9.6)

A workspace should be selected taking into consideration facilitation of wiring, piping, and

maintenance.

Table 2-2. Conduit type

Model No. Gas connection Conduit entry

HGC303-1_ 1/4 NPT female 1/2 NPT female

2-30

Page 53

2-5-3. Model HGC303 installation example

Install the model HGC303 as shown in following diagrams.

The weight of the model HGC303 with mounting bracket is 5kg / 11lbs.

2in. pipe

Fig. 2-22 Example of model HGC303 installation with mounting bracket

Mounting position: Mount the model HGC303 horizontally.

Hexagon head bolt

Mounting bracket

HGC000008000D

2-31

Page 54

2-5-4. Model HGC303 piping

Refer to this section before designing and installing the gas inlet, gas outlet and vent lines.

The mark [N] on the manifold refers to 1/4 NPT connection.

Table 2-3. Piping description

HGC000009000P

Left side view Front view Right side view

Fig. 2-23 Piping location

Model

Part

HGC303

Description

marking

Carrier gas inlet Carr

Valve operating gas

inlet

Valve operating gas

outlet

AIR

VENT

Inlet for introducing the carrier gas into the

column of the analyzer unit.

Inlet for introducing the valve operating gas into

the analyzer unit.

Outlet valve operating gas.

Do not remove this vent plug. *

Process gas inlet INLET Inlet for introducing the process gas.

Process gas outlet OUTLET Outlet for process gas.

Measured gas outlet TCD-VENT

Outlet for mixture of measured gas and carrier gas

after analysis.

Note *: Remove the vent plug then connect the fitting and pipe when IP65 is required or

when HGC model No. is ‘HGC303-1S’.

2-32

Page 55

WARNING

Purge the carrier gas line before performing any piping, and then verify that there is no dust

remaining in the piping.

Release the gas from the vent line to the air through the header.

There is a possibility that back-pressure from vent line has a lot of influence.

Prepare the carrier gas and valve operating gas as specified in the table below.

Table 2-4. Gas specifications

Gas type Purity Secondary supply pressure

Carrier gas Helium

Valve operating

gas

Process gas Natural gas -

Helium, Air,

Nitrogen

99.99% or

higher

99.99% or

higher

400 ± 50 kPa

(58 ± 7 psi)

400 ± 50 kPa

(58 ± 7 psi)

50 - 490 kPa (7 - 71 psi)

at flow meter inlet

2-33

Page 56

2-5-5. Model HGC303 wiring

Remove the terminal cover and wiring while referring to the figure and table below.

Fig. 2-24 Wiring location

Either internal grounding (earthing) terminal (A) or external grounding (earthing) terminal

(B) can be used.

At least one grounding (earthing) terminal connection is recommended.

Table 2-5. Wiring description

Terminal No. Description

1 Power supply (-)

2 Power supply (+)

3 No connection

4 FB terminal (-)

5 FB terminal (+)

6 No connection

7 Terminator (-)

8 Terminator (+)

A Internal GND

B External GND

Note: Azbil Corporation recommends cable of conductor cross-sectional area 2 (mm

equivalent for power supply connection and GND connection.

2-34

2

) or

Page 57

WARNING

Only a 24V DC supply may be used to operate the model HGC303.

CAUTION

Confirm that the supply voltage is within 24VDC+/-15% (20.4~27.4V) at the HGC terminal.

CAUTION

HGC requires the current of 4A minimum on 24VDC as the power supply.

CAUTION

Use a power supply which has overcurrent protection capability for this product.

2-35

Page 58

2-36

Page 59

Chapter 3. Operation

3-1. Starting up the model HGC303

3-1-1. Secondary pressure and flow set

Adjust the pressure of the following gas types as specified by the corresponding pressure on

the right.

Table 3-1. Gas specifications

Gas type Secondary supply gas pressure and flow rate

Carrier gas 400 ± 50 kPa (58 ± 7 psi)

Valve operating gas

Process gas 50 ± 20 ml/min.

3-1-2. Piping leak check

Before starting up the model HGC303, conduct a leak test to verify there is no leakage of gas

from the piping connection.

A leak test using soap bubbles will be sufficient.

If a leak found:

(1) Tighten the fittings.

(2) Replace the fittings.

400 ± 50 kPa (58 ± 7 psi)

3-1

Page 60

3-1-3. Power on

Supply the power to operate the model HGC303 system according to the following action.

Table 3-2. The procedure to start up the model HGC303 system

Step Action

1 Supply the valve operating gas

2 Supply the carrier gas pressure

3 Supply the power to the model HGC303

4 Supply the power to the model HDM303

5 Wait until the model HGC303 system becomes stable.

6 Supply the process/standard gas*+

Note: After turning on the power, allow 2 hours for the device to warm up.

The carrier gas pressure SP and oven temperature SP have already been factory set in the

model HGC303, therefore, the user doesn’t have to worry about setting this data.

Carrier gas pressure SP: less than 300 kPa (43.5 psi)

(SP differs with each model HGC303)

Oven temperature SP: 58°C (136.4°F)

Analyzing cycle: 300 sec.

Note: When the power is supplied to the model HGC303, a model HGC303 status error will

appear on HGM monitoring system (oven temperature error message etc.

This is because of a self-diagnostic system error, not a model HGC303 system error.

The model HGC303 status will automatically return to normal once the oven

temperature reaches 58°C (136.4°F).

Note *: Recommend supplying the standard gas if it is the first time set-up after delivery or

a long-period storage.

Note +: If the output value from HGC seems strange after several cycles supplying the

process gas, try to do followings:

1. Check the process/standard gas supplies properly and the vent line is not blocked. If

there are problems, rectify them and check the output value again.

2. Run the HGM program, and make it “on-line”, then start “User’s mode”.

3. Check whether the peaks are small or normal, the peak shapes are strange or not by

chromatogram.

4. If the phenomena in section above are observed, stop the process gas and quite the

HGM program.

5. Connect blind plugs or shut the vent lines, then connect Helium gas cylinder at the

‘INLET’ port of HGC.

6. Charge Helium gas at 400kPa (58psi) to ‘INLET’ then leave it for about one hour.

7. Return the connection normal and supply process/standard gas for checking again.

3-2

Page 61

3-1-4. Model HGC303 leak check

After turning the model HGC303 on, conduct a leak test to verify that there is no leakage of

gas from the model HGC303.

The following procedures are for a simple leak test for the carrier gas line. Carry out the leak

test for the valve operating gas line in the same way.

(A)

(B)

Fig. 3-1 Leak check

Table 3-3. Model HGC303 leak test procedure

Step Action

1 Check that the valve operating gas is being supplied.

2 Check the carrier gas has a secondary pressure (A) of 400 ± 50 kPa (58 ± 7 psi).

Verify that the carrier gas line valve off and observe the rate of fall in the

3

indicated primary pressure (B).

Leak evaluation procedure.

After introducing the carrier gas into the model HGC303, a normal condition is

confirmed by a rate of fall of less than 1500 kPa (217 psi) per every 5 minutes.If

more than 1500 kPa (217 psi) is observed, immediately contact an Azbil

4

Corporation products service office or the nearest distributor.

If the carrier gas is being used for valve operating gas at the same time, the

carrier gas consumption will be doubled. (less than 3000 kPa (435 psi) per 5

minutes)

HGC000011000D

CAUTION

Verify that there is no leak from all connections.

3-3

Page 62

3-2. Stopping the model HGC303

To stop model HGC303 operation, follow the procedures listed below.

Table 3-4. Stopping model HGC303 operation

Step Action

1 Shut off the process gas line.

2 Turn off the model HDM303 power.

3 Turn off the model HGC303 power.

4 Shut off the carrier gas line.

5 Shut off the valve operating gas line.

Refer to “ Storing the model HGC303” on page 2-2 when removing the model

6

HGC303 from the field.

Do not leave the model HGC303 in the sampling system without plugs or seals at the connections

to vent.

CAUTION

3-4

Page 63

3-3. HGM operation

Introduction

The functions of the HGM are described in this chapter.

The HGM is a calibration, configuration and maintenance tool for the model HGC303.

Analysis statuses, process variables and a chromatogram are displayed on its screen, and

information is stored in a database to facilitate routine management and tuning.

Note 1: There is a possibility that this software will not function properly if another

Note 2: Please use a period “.” as a decimal symbol.

There is a possibility that analysis data will not save properly if a comma “,” is used.

Select Start >> Settings >> Control Panel >> Regional Settings and then click on

Set decimal symbol to period “.”.

Functions

(1) Monitoring heat value, chromatogram and carrier gas pressure / oven temperature control

(2) Data save (load)

(3) User report

(4) Calibration

(5) Self-diagnostics

(6) Hold model HGC303 outputs to host control system

application software is used at the same time.

Number Tag

3-5

Page 64

3-3-1. HGM connection with model HFA100 and HDM303

HGM connection is possible at any location along the FB line. Connect the HGM as shown in

the picture below.

Fig. 3-2 Model HGC303-HGM connection example (combination of model HGC303,

model HDM303 and model HFA100)

Refer to the model HDM303 user’s manual regarding the details of each part of the model

HDM303.

3-6

Page 65

3-3-2. Starting up the HGM with model HFA100

The procedure to start the HGM up are given below.

(1) Make sure that both the model HGC303 and the model HDM303 are running normally.

(2) Prepare a personal computer, which has the HGM installed.

(3) Verify that font size is [Small font] and the display resolution 1024 Å ~ 768 pixels.

(4) Connect the model HFA100 along the FB line. (Refer to Fig. 3-2.)

(5) Connect the USB cable to the USB port of your PC.

(6) Make sure that the model HFA100 installation is correct.

(7) Check that you have implemented section "2-3-6. Setting the folder access rights"

(8) Run the HGM port set program [ComSetHGM.exe].

All program> HGM> HGM Port Setting

3-7

Page 66

(8) Port setting combo box will appear, click [], and select COM port for use, and click

[OK] button.

Fig. 3-3 HFA Port setting

These settings will be stored in the settings file in the program folder.

3-8

Page 67

(9) Run the driver program [hfadrv2.exe]

All program> HGM> hfadrv2

(10) Driver program will start, and please wait for periodical running begin.

Fig. 3-4 hfadrv2 comand window

Note: When the driver program doesn’t operate properly, please Refer to troubleshooting “5-1.

Connection with PC.”

3-9

Page 68

(11) Run the HGM program [hgmXXX.exe].

All program> HGM> HGM VersionX.XX

HGM Program will start.

Fig. 3-5 start HGM

3-10

Page 69

HGM operation flow chart

Here is a flow chart showing how to get the HGM online and it also gives an overview of the

HGM’s functions.

[hfadrv2.exe]

[hgmXXX.exe]

[hgmXXX.exe]

[hfadrv2.exe]

Below is a flowchart showing HGM functions that are available offline.

[hgmXXX.exe]

[hgmXXX.exe]

3-11

Page 70

3-3-3. HGM Main menu

The contents of the main menu are described in this section.

The screen shown below is displayed once the HGM is started up.

(OFFLINE) (ONLINE)

Fig. 3-6 Main menu

The HGM main menu is divided into six functions

Table 3-5. Main menu description

Display Description

Offline (Online) Displays the Online/Offline status.

Set up HGM Select Online/Offline mode, Data saving interval.

User‘s Mode

Configuration mode

Quit Exit from the HGM application.

Monitoring heat value trend graph and chromatogram. You can

also perform calibrations using this mode.

The model HGC303 can be configured from here can be done

here.

3-12

Page 71

3-3-4. Set up HGM

Before the HGM can communicate with the model HGC303, an initial setup must be

performed as follows.

a. Initial screen b. After clicking the [Change password] button.

c. Normalization method setting

Fig. 3-7 Set up HGM display

3-13

Page 72

Table 3-6. Set up HGM description

Display Description

Analyzer Status

Refresh The latest update information for communication is displayed.

Maintenance mode

product key

Data Saving Interval

Auto Saving

Calculation mode

Normalization

method

Follow the procedures given below in order for the HGM to communicate with the model

HGC303.

Analyzer Status shows whether the HGM is online or not. The

HGM is online if [HGC] is shown.

Authorized service personnel use only.

HV1, CV1 and SV1 files are stored onto your PC according to the

set data saving interval.

The HGM automatically saves files according to the set auto

saving interval

The HGM can calculate heat values using either [ISO] or [GPA]

calculation method.

Note: When calculation method is changed, normalization

method will return to the default value.

The HGM displays the value of after normalization, by following

the method which has set. See section “3-3-8. Configuration

mode” to set HGM to HGC.

3-14

Page 73

Table 3-7. Set up online mode

Step Action

[Analyzer Status]

Select [HGC] in Analyzer Status

1

If [HGC] cannot be selected from the pull-down menu, click the [Refresh]

button. The HGM searches for the model HGC303 again along the Fieldbus line.

[Data saving interval]

Select “data saving interval” from pull-down menu;

5 min. / 5 sec. [Default]

10 min. / 10 sec.

15 min. / 15 sec.

30 min. / 30 sec.

2

60 min. / 60 sec.

5 min.: Heat value and Total (Raw) data (text file extension:.hv1)

5 sec.: Oven temperature and Carrier gas pressure data (text file extension:.sv1)

Refer to “ Data save” on page 3-16 and “ Editing data” on page 3-17 for details on

how to save and edit the data.

[Auto saving interval]

Check the box to select an interval as required.

3

Selection: Min. 1 day, Max 10 day

Refer to “ Automatic file saving” on page 3-18 for details on the auto saving

mechanism.

[Calculation Mode]

4

Select [ISO] or [GPA] from Calculation Mode.

ISO [Default]

[Password]

Some screens require a password to access them.

However, if you want to change a password, click the [Change password>>]

button. The password-setting screen appears on the setup HGM display (See “Fig.

3-7 Set up HGM display” on page 3-13). Click the [specified] button, and then

enter the “Old password”, which has been stored in the HGM and then enter a

“New password”.

The new password becomes active once you click the [OK] button in the

password-setting screen.

5

Default passwords are as follows (Maximum letters: 16):

Calibration : password1

Configuration mode : password2

Maintenance mode : password3

Field work : password4

Calibration data change* : password5

Note: *This refers to the [Advanced>>] button in “Fig. 3-17 Calibration setting panel” on

page 3-46.

If necessary, click the [Extended setup] button, and select normalization method.

6

Default is “Standard normalization”.

7 Click the [OK] button to return to the main menu.

8 Click on [User’s mode] in the main menu.

3-15

Page 74

Table 3-8. Analyzer status and available functions

Analyzer Status Print Save Load Report

Calibration

Online OK OK NA OK OK

Offline OK NA OK OK NA

NA: not available

Note: For details on [GPA mode] selected in Calculation mode, refer to “3-5. GPA mode” on

page 3-52.

Data save

The last 4000 items of data are automatically stored in the RAM of your PC at each data saving

interval.

You can also save data by using the save function (See Table 3-12 or Table 3-14).

The data are saved as text files (.hv1 or.cv1 or.sv1) in C:\program files\hgm\data (default)

folder.

Table 3-9. Save data description

Text file

extension

.hv1 Table 3-12

Save

button

No.3

Data saving interval

(Default)

5 minutes

(1day =288 data)

4000/288=13.8 days

Content

for HGM version less than 4.70

Date and time,

ICV(Ideal)(MJ/m3), ICV(Real)(MJ/m3),

SCV(Ideal)(MJ/m3), SCV(Real)(MJ/m3),

Total raw(mol%)

for HGM version 4.70 or later

Date and time,

ICV(Ideal)(MJ/m3), ICV(Real)(MJ/m3),

SCV(Ideal)(MJ/m3), SCV(Real)(MJ/m3),

Total raw(mol%),

ICV(Ideal)(kJ/m3), ICV(Real)(kJ/m3),

SCV(Ideal)(kJ/m3), SCV(Real)(kJ/m3),

ICV(Ideal)(kWh/m3), ICV(Real)(kWh/m3),

SCV(Ideal)(kWh/m3), SCV(Real)(kWh/m3)

.cv1 Table 3-12

No.3

.sv1 Table 3-14

No.3

5 seconds

(1 hour =720 data)

Date and time, PV1-PV20

(PV1-11; Raw data)

Date and time, PV17, PV18

4000/720=5.5 hours

Text files (.hv1 and. cv1) are saved at the same time with the save function, which is described

in Table 3-12 No.3.

3-16

Page 75

Editing data

HGM000011000S

If you want to edit saved data, open a saved file using to following procedure. You can edit data

using software such as Microsoft ExcelTM.

1 Start Microsoft Excel

2 Select [Open]

3 Select the directory where the saved file is stored.

(Default directory C:\program files\hgm\data)

4 Select [All files] in “Files of type”.

5 Select a saved file, then click [open].

6 Follow the messages that come up on screen. (Click [Comma] at “delimiters”.)

TM

Fig. 3-8 Example of saved data files (.hv1)

3-17

Page 76

Automatic file saving

The HGM can be set to automatically save data files. This is done by activating the setting

from the [setup HGM] panel.

Default directory; C:\program files\hgm\data.

Files with the extensions;.hv1,.cv1, and.sv1 and.cg1(chromatogram) are saved.

All.cg1 files are saved as named YYYYMMDDHHMMas.cg1.

YYYY = year, MM = month, DD = date, HH = hour, MM = minute, as = auto saving,

.cg1 = chromatogram extension file.

Data saving interval of.cg1 files is fixed to 5minutes.

Example:

Auto saving interval:1day (Selection: min. 1day, max. 10 days)

Data saving interval:5 min. and 5 sec.

(Selection: min. 5 min. and 5 sec., max 60 min. and 60 sec.)

(1) HGM data saving starts at 2001/07/25 19:00.

(This function starts after checking the box in [Setup HGM] then clicking the [OK]

button.)

(2) Analysis data and chromatograms

(2001/07/25 19:00-2001/07/25 23:59) is saved at 2001/07/26 0:00.

Saved file names: 010725as.hv1, 010725as.hv2, 010725as.cv1, 010725as.sv1,

010725as.sv2, 20010725HHMMas.cg1.

“as” stands for auto saving.

(3) Analysis data and chromatograms

(2001/07/26 0:00-2001/07/26 23:59) are saved at 2001/07/27 0:00.

Saved file names: 010726as.hv1, 010726as.hv2, 010726as.cv1, 010726as.sv1,

010726as.sv2, 20010726HHMMas.cg1.

3-18

Page 77

3-3-5. User’s mode menu and commands

Click on [User’s Mode] and you will see the following display.

The display size is fixed (full screen).

Fig. 3-9 User’s mode display

This screen is divided into three graphs. On the right hand side is the measurement data.

Table 3-10. Description of user’s mode display

Screen Description

Top (blue) This graph shows heat value and the total of raw concentration

Center (white) Chromatogram

Bottom (red) This graph shows carrier gas pressure and oven temperature

Right panel Process gas analysis data

3-19

Page 78

3-3-6. Main displays of HGM

Indication panel

Data is updated every 5 minutes.

Table 3-11. Description of the indication panel

No. Panel Description

1 Date time Present date and time

2 Status

3 Data box

4 Calculated Value

Communication status appears when HGM

is communicating with model HGC303.

Select a data type.

Default: Retention time (sec.)

Select values for Ideal gas or Real gas and its unit

Default: Real

SCV: Superior Calorific Value

ICV: Inferior Calorific Value

1

2

3

Oven Temp. and

5

Carr. Pres.

6 Chromatogram

7 [Field work]

8 [Calibration]

9 [Report]

10 HGC Status

11 Return Menu

Display oven temperature and carrier gas

pressure

The last 300 chromatograms are stored in

RAM. Save the data as required. Select

[previous XX] or [latest] to view the

chromatogram.

If [previous XX] is selected, the auto reload

function stops. XX: 01-299

Return to [latest] to monitor the latest

chromatogram.

Auto reload function starts again.

Model HGC303 holds outputs to the host

control system during field maintenance.

Click the [Field work] button then [ON], to

set the holding time to [24hrs]. [Field work]

button blinks while performing fieldwork.

Click the [Calibration] button to perform

calibration. The [Calibration] button blinks

during auto calibration.

Refer to “3-4. Calibration” on page 3-41

Click the [Report] button to create a report.

Refer to “3-3-7. Report” on page 3-25.

Green means that model HGC303 is

analyzing normally.

If this signal changes to red, click this button

to read the error message.

Refer to “Chapter 5. Troubleshooting” on

page 5-1.

Exit from User’s mode

Return to Main Menu

4

5

6

8

9

7

10

11

3-20

Page 79

Heat value and total raw concentration

This graph shows the heat value and the total raw concentration.

The left vertical axis represents the heat value and the right vertical axis represents the total

raw concentration.

The horizontal axis represents the time range.

Fig. 3-10 Trend graph of SCV and the total concentration (Raw)

Table 3-12. Trend graph of SCV and total raw concentration description

No. Display Description

1 URV (SCV)

2 Load (Offline)

3 Save (Online)

4 Print Verify that your printer is connected and working properly.

Upper Range Value for SCV, default value: 42 MJ/m

Click the [URV] button to change the URV value

Recall saved data

File name extension:.hv1

The latest data is saved

Default directory is “C:\Program files\hgm\data”.*

HGM000016000S

3

30min.

5

(The time range

select)

6 LRV(SCV)

URV

7

(Total raw conc.)

LRV

8

(Total raw conc.)

9 Black circle

This indicates the time range of the horizontal axis.

Select a time range from the pull-down menu:

30 min., 60 min., 3 hour, 6 hours, 12 hours, 1 day, 2 days, 3 days, 6 days, 12 days

Default: 30 min.

Lower Range Value for SCV, default value: 38 MJ/m

3

Click the [LRV] button to change the LRV value

Upper Range Value for Total, default value: 103%

Click the [URV] button to change the URV value

Lower Range Value for Total, default value: 97%

Click the [LRV] button to change the LRV value

Black indicates SCV graph.

Click the [Disp data] button (No.11) to select a data type. Default: SCV (Real)

10 Red circle Red indicates Total raw conc. graph.

11 Disp. data Select a data type for heat value.

12 Time

Online: Date and time of the latest data (data is reloaded every 5 min.)

Offline: Date and time of when the data was saved.

* In case of 64bit type operation system, data are saved in c:\Program files (x86)\hgm\data.

3-21

Page 80

Chromatogram

Chromatogram is updated every 5 minutes.

9

1

2

3

4

5

6

7

8

Table 3-13. Chromatogram description

No. Display Description

Upper Range Value for vertical axis

1 URV

Click the [URV] button to change the URV value

Default value is 1

2 Load (Offline) Recall saved data. File name extension:.cg1

3 Save (Online)

The latest data is saved.

Default directory is “C:\Program files\hgm\data”.*

4 Print Verify that your printer is connected and working properly.

10

11

13

Fig. 3-11 Trend chromatogram (online)

12

HGM000017000S

5 Over write Overlapped chromatograms are displayed.

Click the [reverse] button to invert the display and [No.9] [Forward]

6 Reverse

changes the display to [Reverse].

Default: [Forward]

Lower Range Value for vertical axis

7 LRV

Click the [LRV] button to change the LRV value.

Default value: -1

8 Disp Components When the box is checked, the name of each component will be dis- played.

9 Forward-Reverse Display [Forward] or [Reverse]

10 Upper gate marker Gate start marker of each component.

11 Lower gate marker Gate end marker of each component.

12 Time

13 Status bar (Online)

Online: Date and time of the latest data (data is reloaded every 5 min.)

Offline: Date and time of when the data was saved.

Status bar range: 5minutes

Chromatogram data is updated every 5minutes.

* In case of 64bit type operation system, data are saved in c:\Program files (x86)\hgm\data.

3-22

Page 81

Zoom function (2 × 2)

Click on a peak of interest to get a detailed view (display only).

Fig. 3-12 Zoom box

3-23

Page 82

Trend graph of carrier gas pressure and oven temperature control

9

1

2

3

4

5

6

Fig. 3-13 Trend graph of carrier pressure and oven temp. control

This data is displayed according to the set data saving interval

(Refer to “3-3-4. Set up HGM” on page 3-13).

Default interval: 5 sec.

Table 3-14. Description of trend graph of carrier gas pressure and oven temperature control

No. Display Description

Upper Range Value for oven temperature.

Click the [URV] button to change the URV value

Default value: 62 deg.C.

1

URV (Oven

Temp.)

2 Load (Offline) Recall saved data. File name extension:.sv1

3 Save (Online)

The latest data is saved.

Default directory is “C:\Program files\hgm\data”.*

4 Print Verify that your printer is connected and working properly.

10

7

8

HGM000019000S

11

This indicates the time range of the horizontal axis.

30min

5

(Time range select)

Select a time range from pull-down menu: