Page 1

Control Valve

Model HLS_ _ _/HTS_ _ _/HPS_ _ _/HLC_ _ _/HSC_ _ _/HAV_ _ _

User's Manual

OM2-8113-0201

Page 2

NOTICE

While this information is presented in good faith and believed to

be accurate,Azbil Corporation disclaims the implied warranties of

merchantability andfitness for a particular purpose and makes no

express warranties except asmay be stated in its written agreement with

and for its customer.

In no event is Azbil Corporation liable to anyone for any indirect,

special orconsequential damages. e information and specications in

this documentare subject to change without notice.

© 2012 - 2018 Azbil Corporation All Rights Reserved.

Page 3

Table of Contents

Chapter 1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1-1. Scope 1-1

1-2. Major components of control valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-3. Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-4. Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Chapter 2. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2-1. Maximum lifting loads of eyebolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-1. Installing valve in process pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2-1. Item to be checked after installation and before starting operation . . . . . . . . . . . . . . . . . . . . . 2-2

Chapter 3. Inspection and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Chapter 4. Disassembly and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4-1. Detaching actuator from valve body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-2. Disassembly and assembly of valve body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4-3. Disassembly and assembly of actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

4-4. Disassembly and assembly of model PSA 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

4-5. Disassembly and assembly of model HA2, HA3, or HA4 actuator . . . . . . . . . . . . . . . . . . . . . . . 4-19

4-6. Disassembly and assembly of model PSA6 actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-25

4-7. Disassembly and assembly actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Chapter 5. Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Chapter 6. Direct/Reverse Action Type Conversion and Spring Range Change of Actuator 6-1

6-1. Direct/Reverse action change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6-2. Stroke and range spring change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Chapter 7. Instructions for Top Handwheel of Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7-1. Model PSA1 actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-1-1. Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7-1-2. Disassembly and Assembly of Top Handwheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7-2. Model HA2, HA3, or HA4 actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7-2-1. Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7-2-2. Disassembly and assembly of top handwheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Chapter 8.

Instructions for Side Handwheel of Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-1. Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-2. Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

8-3. Disassembly of side assembly of side handwheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

i

Page 4

Chapter 9. Instructlons for Bellows Sealed Type of Control Valves . . . . . . . . . . . . . . . .9-1

9-1. Model HLS control valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9-1-1. Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

9-1-2. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

9-2. Model HTS control valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9-2-1. Structures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

9-2-2. Disassembly and assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Chapter 10. Azbil Low Emission standard-compliant gland packing . . . . . . . . . . . . 10-1

10-1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10-2. Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

10-3. Installation into the gland . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

10-3-1. Preparation for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

10-3-2. Start of installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

10-3-3. Retightening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

10-4. Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

Chapter 11. Certified ISO 15848-1 compliant low emission gland packing . . . . . . 11-1

11-1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

11-2. Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

11-3. Starting Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

11-4. Assembling the parts of the gland . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-3

11-4-1. Preparation for assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-3

11-4-2. Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-5

11-5. Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-9

11-6. Application to existing control valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-13

11-7. Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-13

Chapter 12. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Chapter 13. Recommended Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

ii

Page 5

Chapter 1. General

1-1. Scope

This manual covers the instructions for the following Control Valves.

Model HLS : Small-port single-seated control valves

Model HLC : Small-port cage guide type single-single seated control valves

Model HTS : Top-guide single-seated control valve

Model HSC : Cage type single-seated control valve

Model HPS : Top-guide high-pressure single-seated control valves

Model HAV : Venturi throat type angle control valves.

For the valve positioners, refer the following operators manuals.

Model VPE OM2-8310-0410 Pneumatic valve positioner for small actuators

Model HTP OM2-83 10-0200 Pneumatic valve positioner (Single Acting type)

Model HEP 15, l6, l7 OM2-8313-0100 Electro-Pneumatic Valve Positioner (Single Acting

Model AVP 300/301/302/200/201/202 CM2-AVP300-2001 Electro-pneumatic positioner

Model AVP 303/203 CM2-AVP303-2001 Electro-pneumatic positioner

Model AVP 701/702 CM2-AVP702-2001 Smart valve positioner 700 series (HART)

Model AVP 703 CM2-AVP703-2001 Smart valve positioner 700 series

Type)

(F

OUNDATION

fieldbus)

1-2. Major components of control valves

Each control valve is comprised of two major components, namely, a valve body and an

actuator. Various combinations of valve body and actuator are available to meet various type

of uses with different valve sizes, pressure ratings, types of connections, types of materials, and

actuator sizes.

(For details of specifications, refer to Specification Sheets SS2-8113-0200, -0210, .0300, -0310,

-0400, and -2600.)

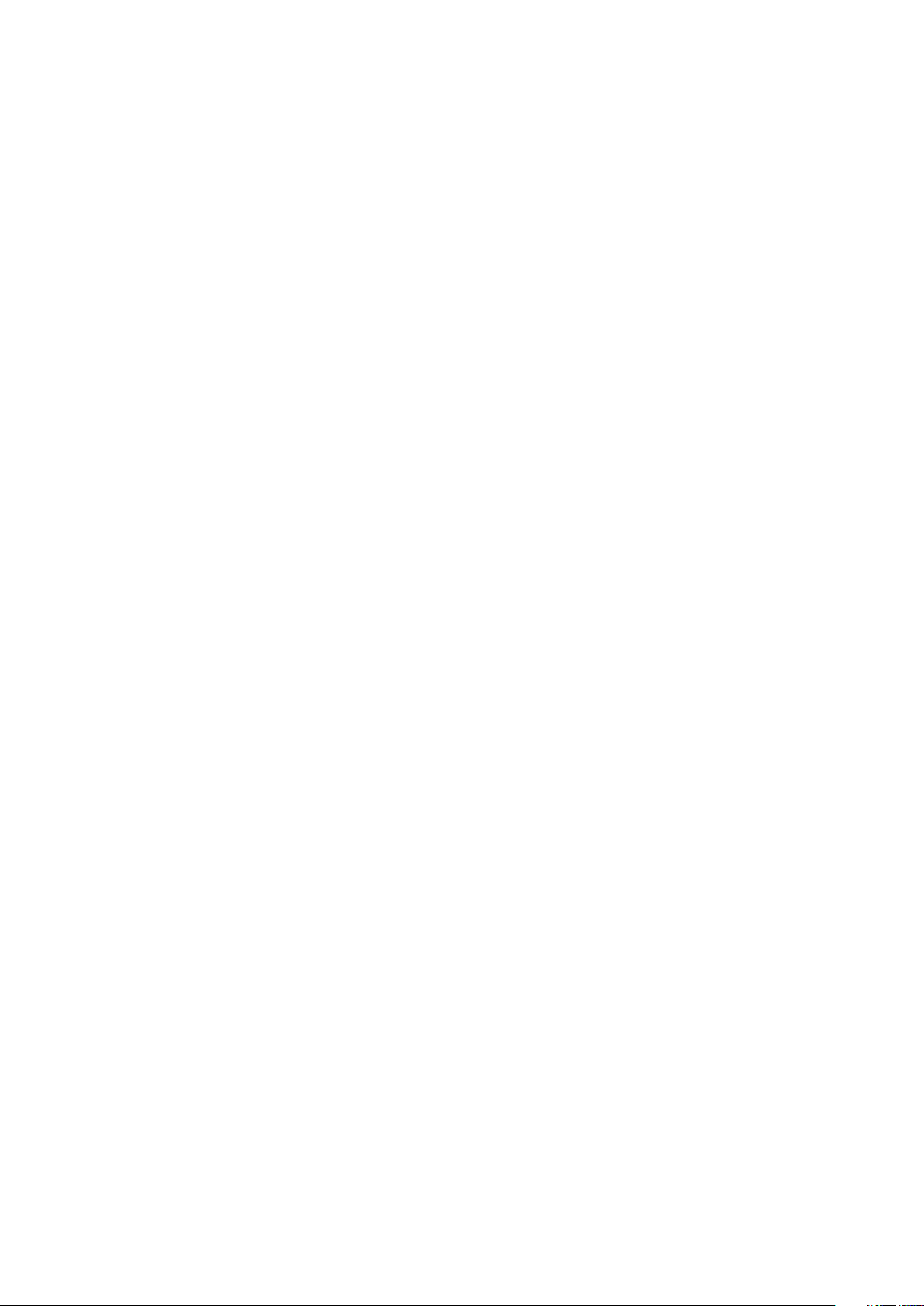

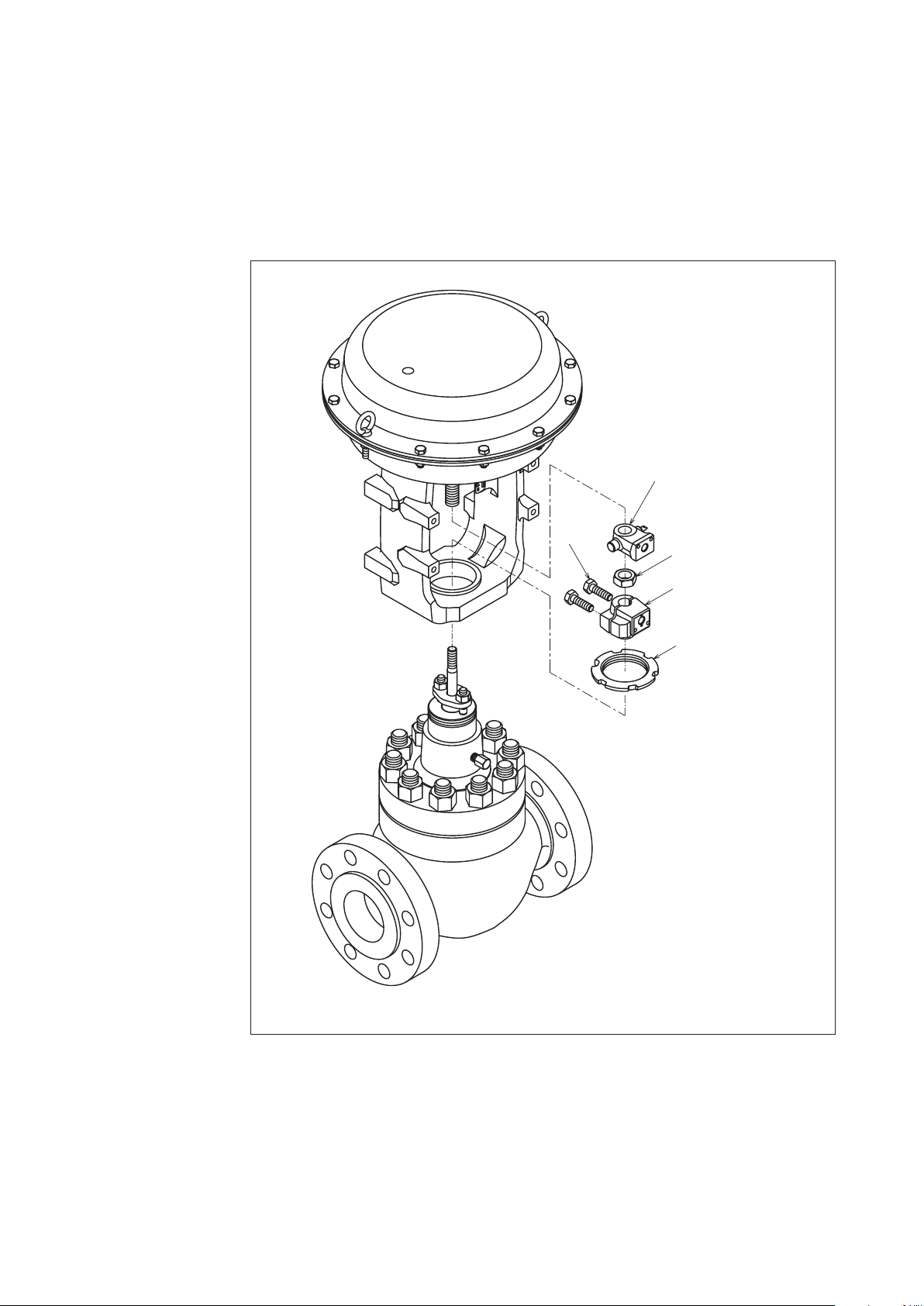

1-3. Structures

The structures of typical control valves are shown is Figure 1-1 through Figure 1-3.

The valve body is connected to the bonnet with stud bolts and nuts. A gasket is (two gaskets

are) provided at the connection Chapter to seal against the internal fluid or to let the valve

body make up a pressure vessel. The valve plug is supported by the guide ring and cage, and

driven by the actuator. The actuator has multiple springs and a diaphragm, and converts the

pneumatic control signal into a mechanical (positional) control signal with which to position

the valve plug.

1-1

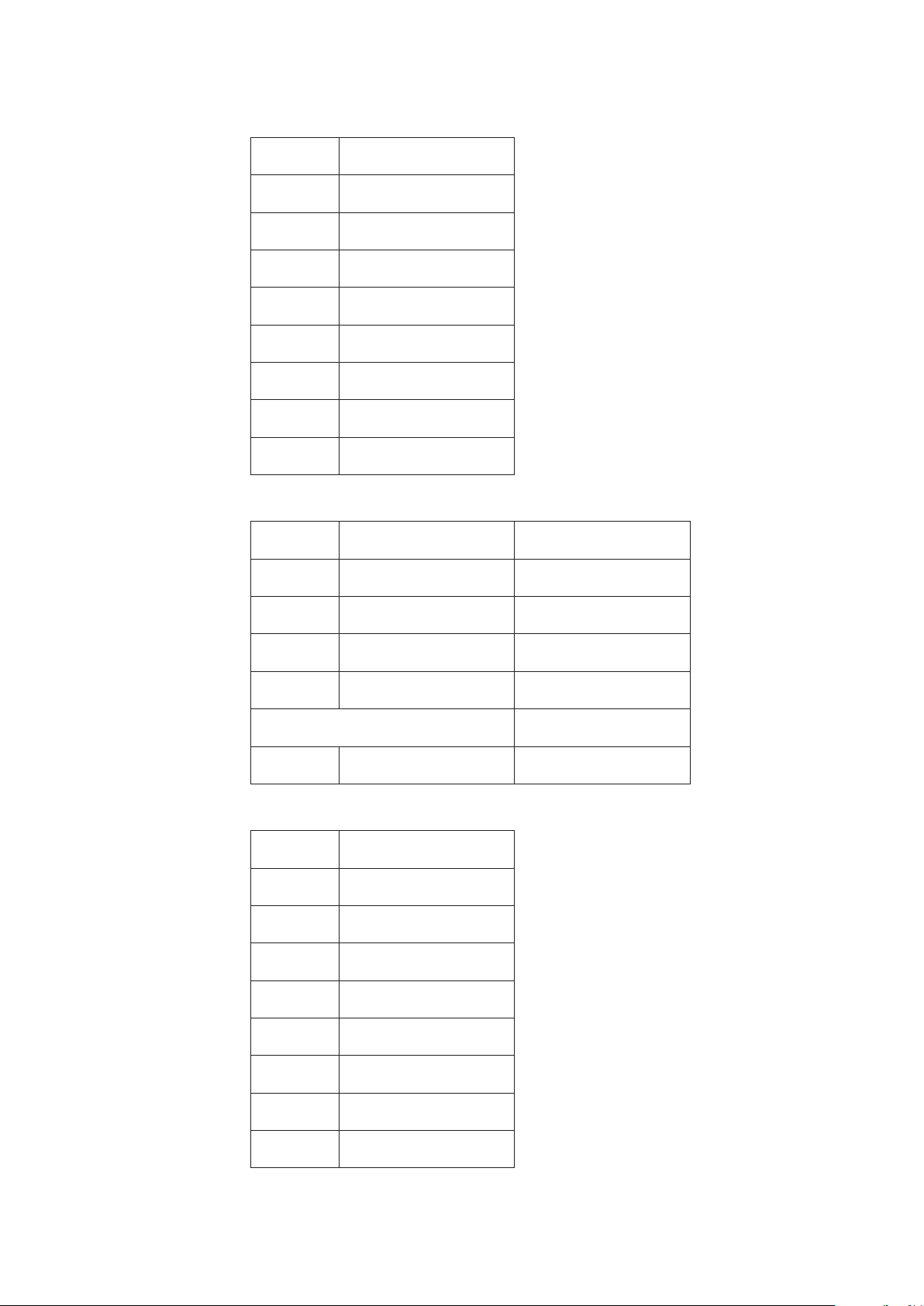

Page 6

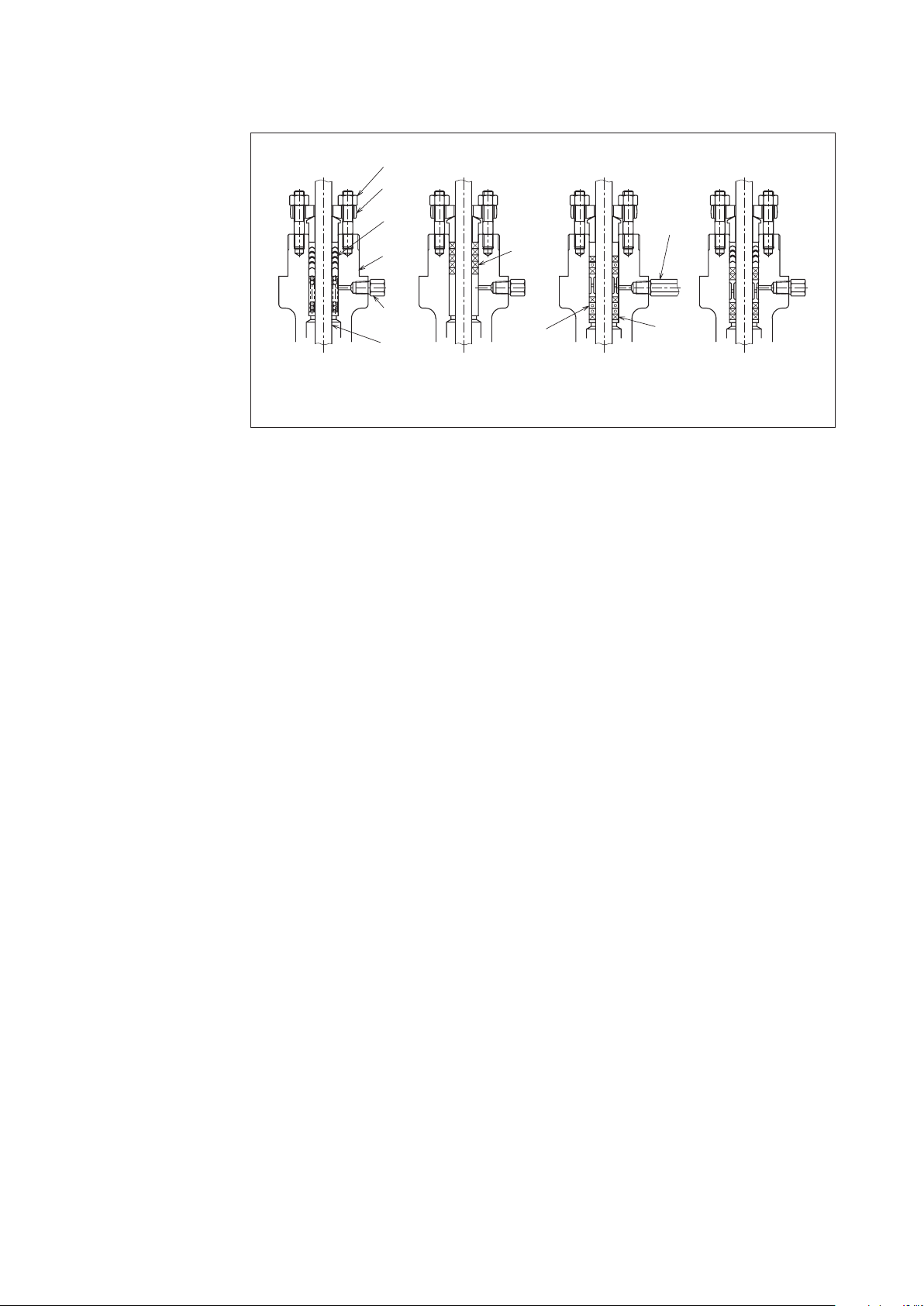

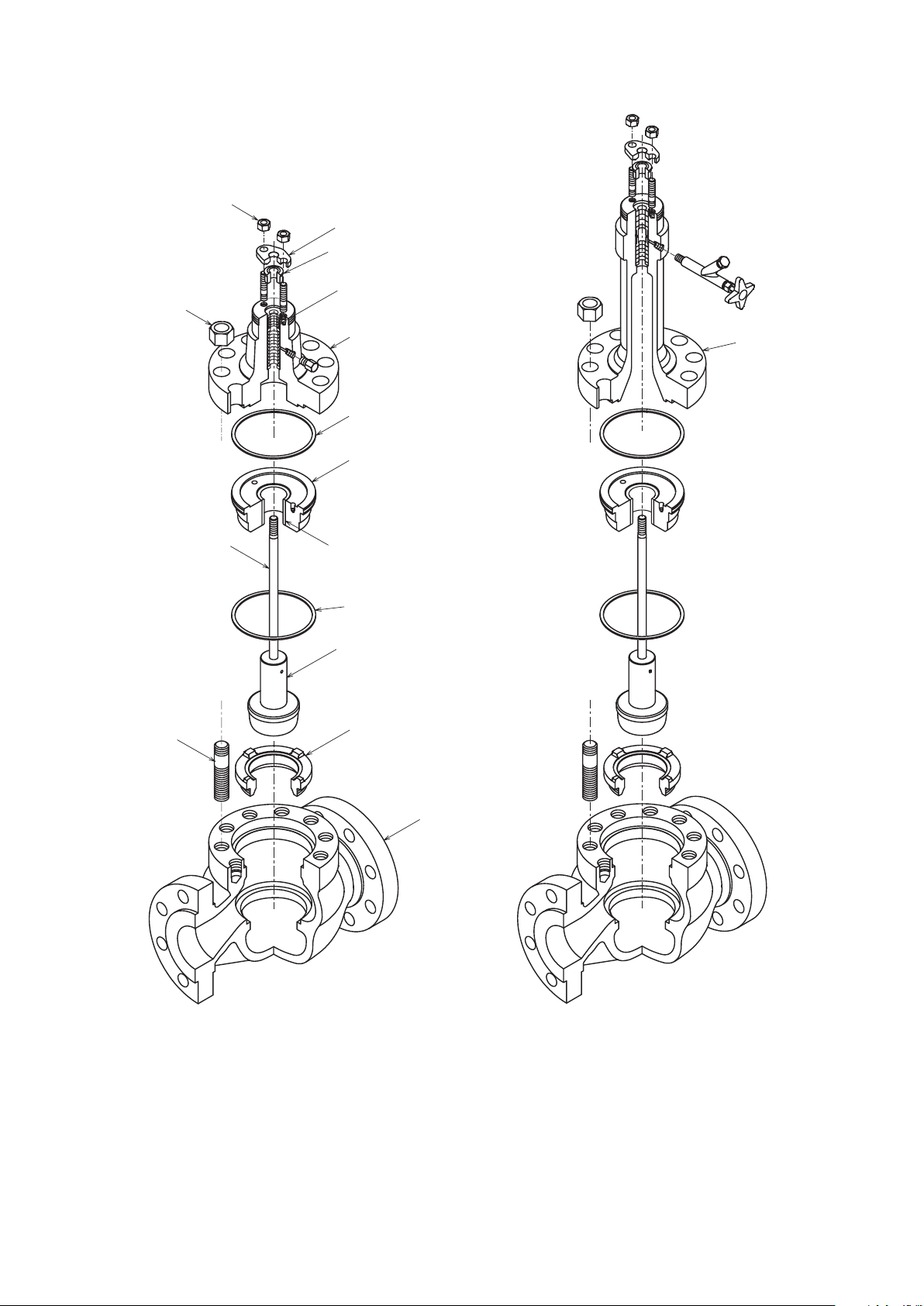

Figure 1-1A Small-Port Single Seated

Control Valve, Model HLS

(Direct Action Type)

Figure 1-1B Model HLC

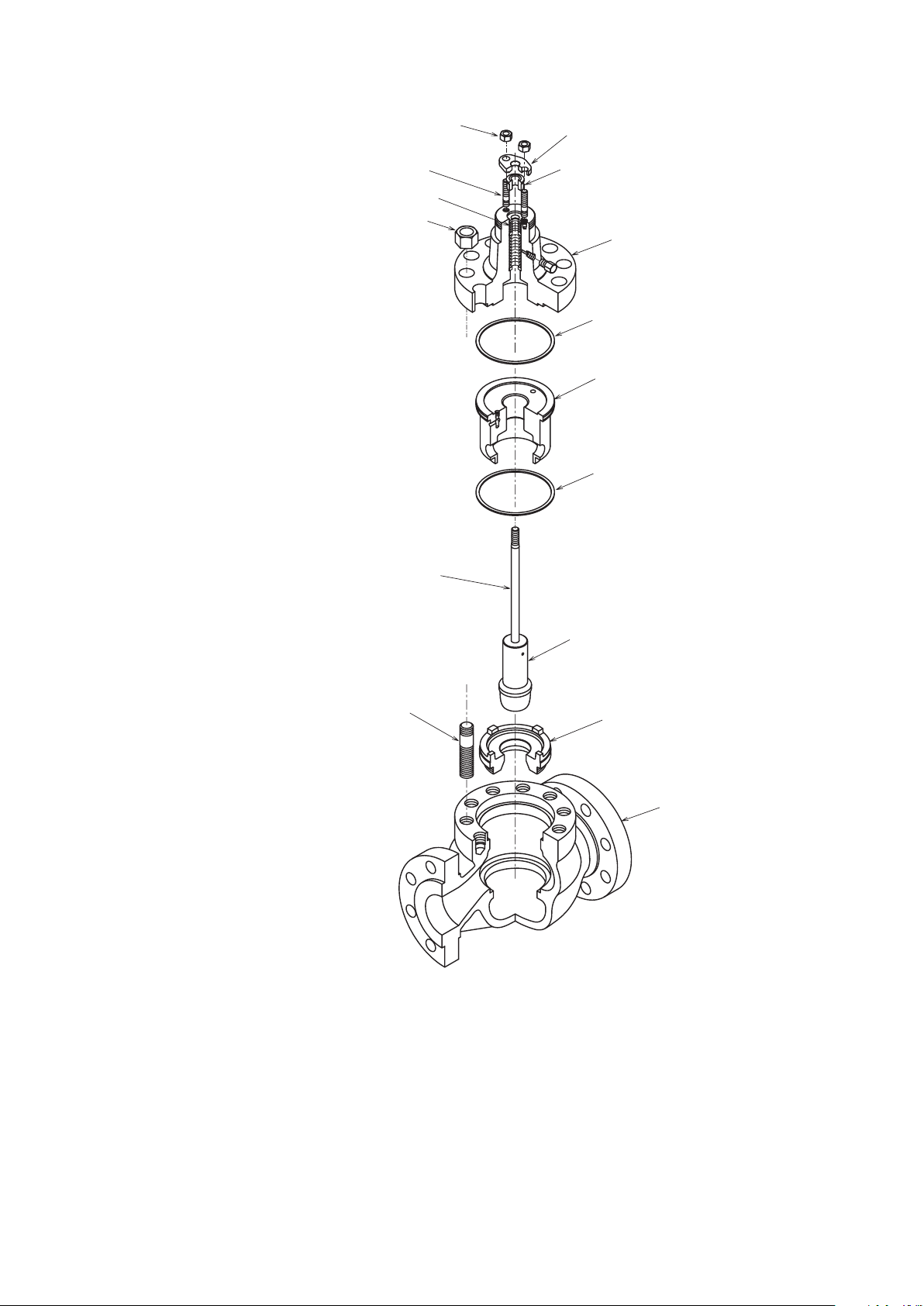

Figure 1-2A Top-Guided Single Seated

Control Valve, Model HTS

Figure 1-3A Top-Guided High-Pressure

Single Seated Control Valve, Model HPS

Figure 1-2B Model HSC

Figure 1-3B Venturi-Throat-Type Angle

Control Valve, Model HAV

1-2

Page 7

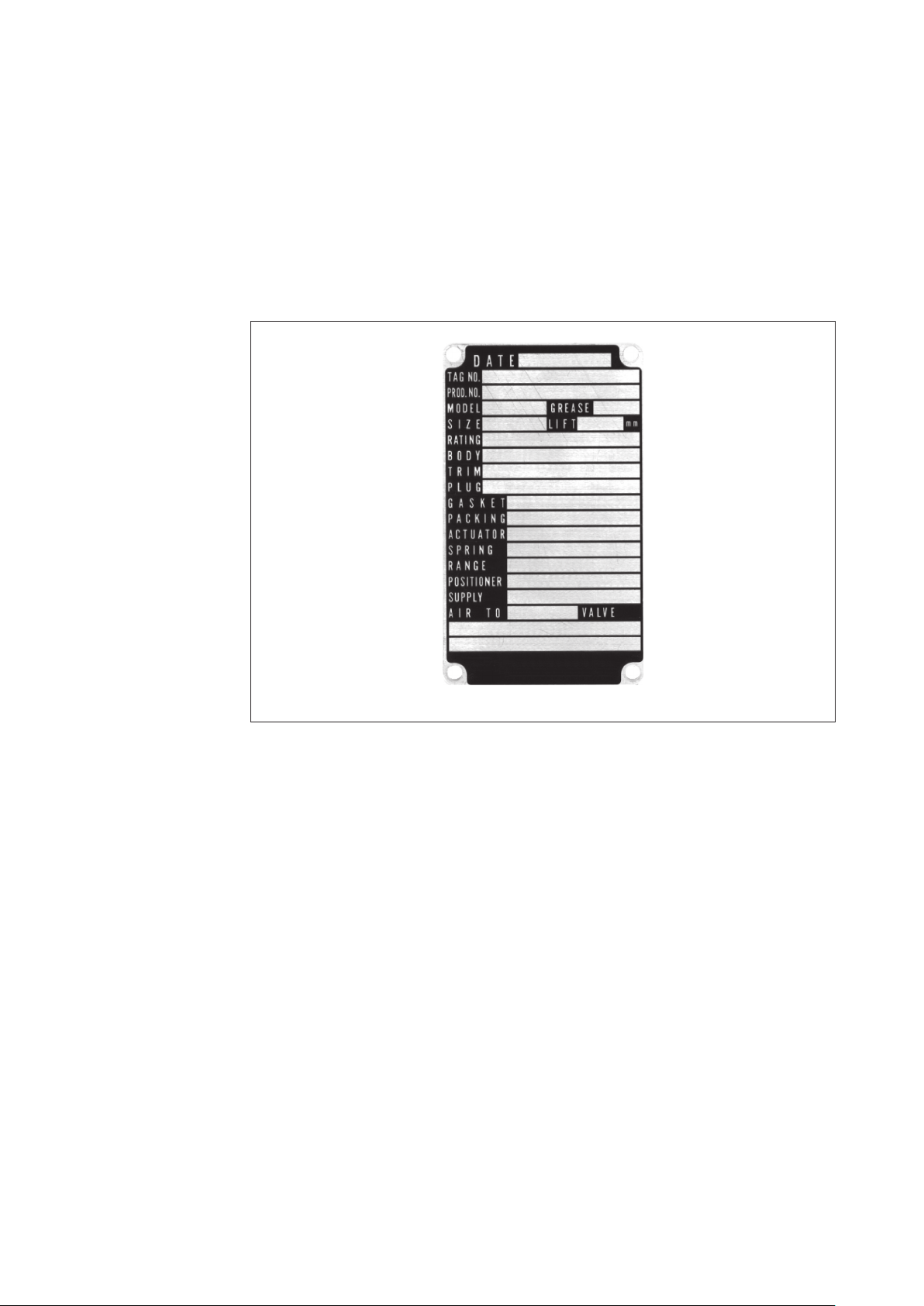

1-4. Nameplate

A nameplate as shown in Figure 1-4 is posted on each control valve. The nameplate indicates

the model number, valve size, pressure rating, trim material, date of manu.facture and other

major specifications of the control valve. Before installing the con.trol valve, make sure

that the specifications indicated on the nameplate conform with the conditions of use. The

nameplate indicate also the product number (PROD.NO.) of the control valve. Please mention

this number also when consulting an Azbil Corp. agent for replacement of parts or other

modification of the control valve.

Figure 1-4 Nameplate

1-3

Page 8

1-4

Page 9

Chapter 2. Installation

2-1. Maximum lifting loads of eyebolts

The diaphragm case has a pair of lifting eyebolts. These eyebolts primarily are for lifting the

actuator alone. When using the eyebolts for other purposes (such as lifting an actuator bed

to its valve body or other components), note that the allowable maxi.mum lifting loads of the

eyebolts are as shown in the following table.

Table 2-1. Maximum lifting loads of eyebolts

Actuator Model No. Allowable Maximum Lifting

PSA1

HA2

HA3

HA4

Note: The eyebolts may be used to lift the actuator together with its valve buy (cast globe

valve) of up to pressure rating “Class 600”. When doing this, be extremely careful so that

no shock or other abnormal force is applied to the actuator or the valve body.

2-1. Installing valve in process pipe

(1) Before installing the valve in the process pipe, remove foreign matter (such as scales and

welding chips) from both upstream and downstream sides of the pro.cess pipe.

(2) Confirm that the direction of process fluid flow conforms with that of the arrow.head

mark provided on the valve body.

(3) Pay attention so that the pipe connection gaskets do not extrude into the process pipe

inside. Be sure to use gaskets made of material which is suitable for the pro.cess fluid. The

welding type of valve employ no gaskets.

(4) Pay attention so that no excessively large stress is conveyed from the process pipe to

the valve body. Uniformly tighten the bolts of the process pipe connection flange. The

high pressure type of valves have no flanges, since they are connected to the process by

welding.

(5) Before connecting the air pipes to the actuator and positioner, blow the pipes to clean

them.

(6) Do not install any heating or cooling provisions on the bonnet.

Load of Eyebolts

160 kg

160 kg

160 kg

220 kg

Weight of Actuator Alone

8 kg

16 kg

32 kg

68 kg

2-1

Page 10

2-1. Item to be checked after installation and before starting operation

(1) Check that there is no leak from air piping.

(2) Check that the bolts and nuts of the diaphragm case are not loose. Standard tight.ening

torques are as follows:

(3) Tighten the packing flange nuts to prevent leak from the gland packing chapter. Standard

tightening torques are as shown in Table 2-2.

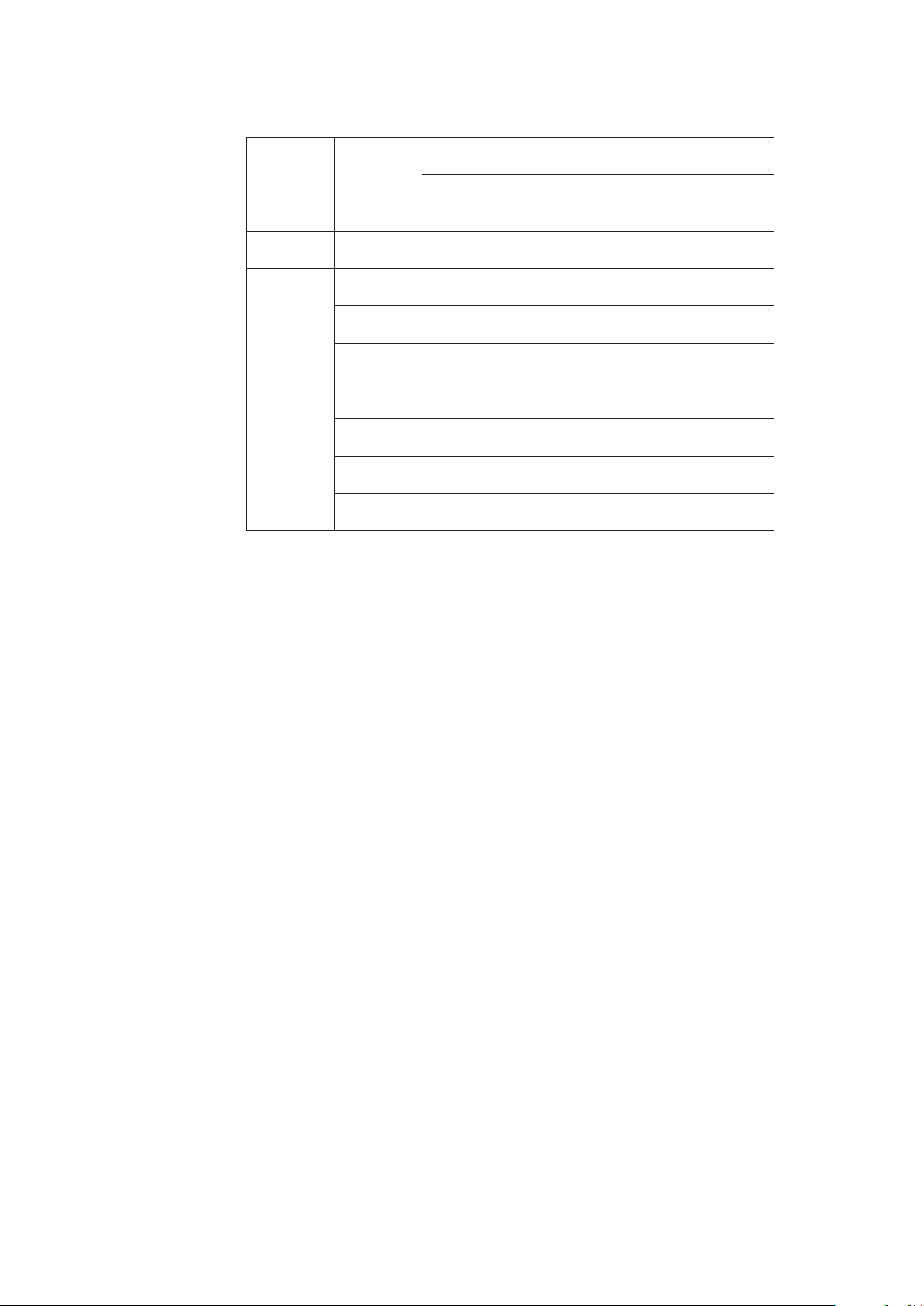

Table 2-2. Tightening Torques of Packing Flange Nuts

Unit: N•m{kgf/cm

2

}

Valve Stem

Diameter

(mm)

10

V PTFE

packing

PTFE Yarn

Packing

(P4519)

Expanded graphite Packing V PTFE + PTFE

P6610CH + P6528

P6610CH + M8590

T2200 + P6710CH (Type2)

Yarn Packing

PTFE + V7233

PTFE + TK2006

9 {90} 5 {50} 3 {30}

13 15 {150} 8 {80} 5 {50}

16 24 {240} 13 {130} 8 {80}

1 {8}

20 32 {320} 18 {180} 10 {100}

25 - - 28 {280} 15 {150}

30 66 {660} 36 {360} 20 {200}

Note: The tightening torques mentioned in the above are only to give you reference values.

Note that tightening torques may vary depending on the type of packing.

Table 2-3. Tightening Torques of packing Flange Nuts for PTFE yarn (Certified ISO

15848-1-compliant low-emission gland packing)

Model Actuator model Stem size Tightening torque

HLS,HLC

HTS,HSC

HA2

HA3

HA3

HA4

PSA6,DAP560

DAP1000(X)

10 mm 12 N·m

φ

13 mm 20 N·m

φ

16 mm 33 N·m

φ

20 mm 44 N·m

φ

30 mm 54 N·m

φ

40 mm 65 N·m

φ

Table 2-4. Tightening Torques of packing Flange Nuts for expanded graphite (Certified ISO

15848-1-compliant low-emission gland packing)

Model Actuator model Stem size Tightening torque

HLS,HLC

HTS,HSC

HA2

HA3

HA3

HA4

PSA6,DAP560

DAP1000(X)

10 mm 12 → 0 (loosening) → 8 N·m

φ

13 mm 20 → 0 (loosening) → 13 N·m

φ

16 mm 33 → 0 (loosening) → 22 N·m

φ

20 mm 44 → 0 (loosening) → 30 N·m

φ

30 mm 54 → 0 (loosening) → 36 N·m

φ

40 mm 85 → 0 (loosening) → 43 N·m

φ

2-2

Page 11

Nut

Packing

Packing

Packing

Flange

V PTFE Packing

V PTFE

Packing

Bonnet

Blind

Plug

Stem

PTFE Yarn Packing Graphite + Expanded graphite

PTFE Yarn

Packing

Graphite

Packing

Lubricator

Graphite

Yarn

Packing

V PTFE + PTFE Yarn

Figure 2-1 Gland Section

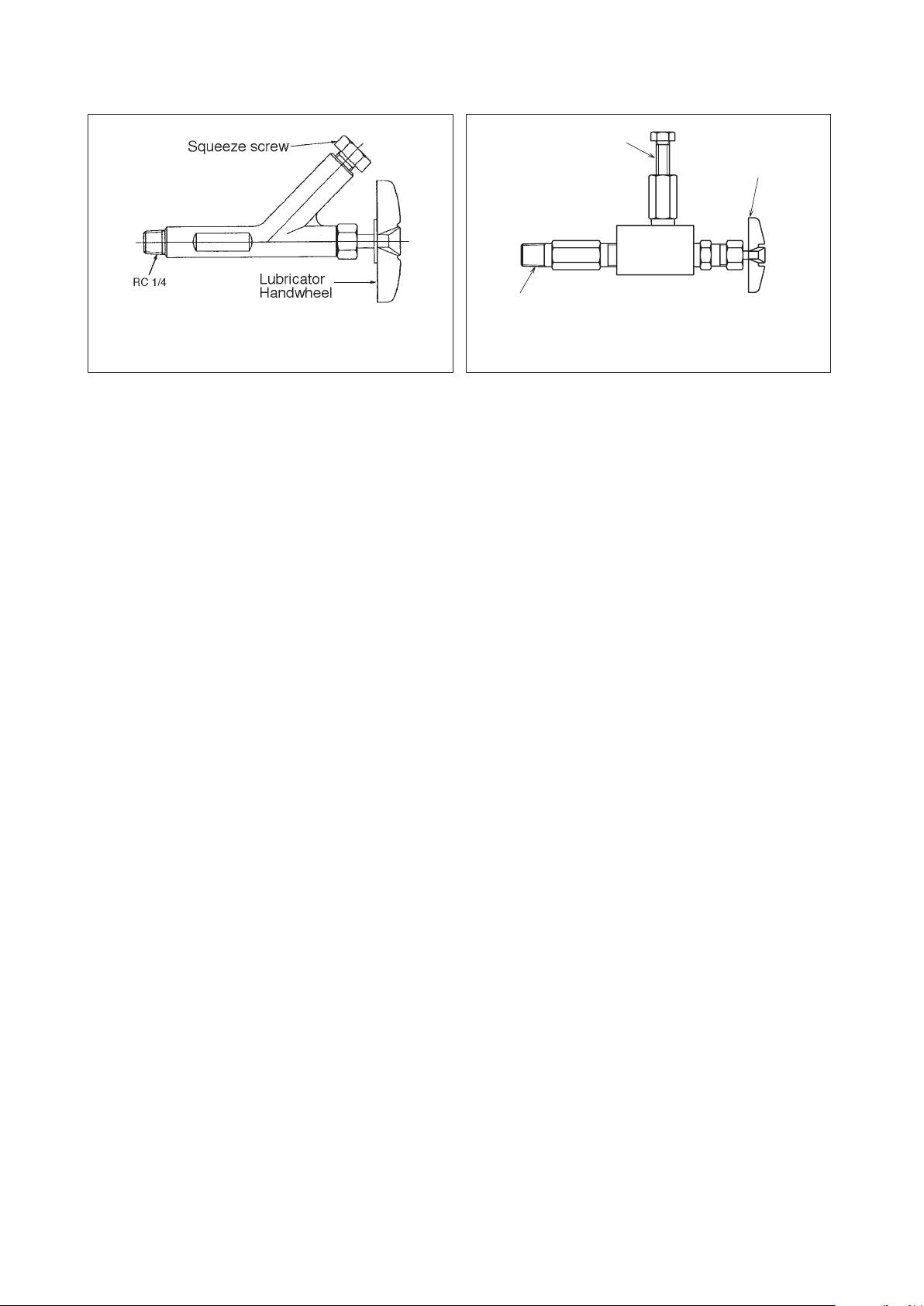

(4) If the valve is provided with a lubricator as shown in Figure 2-2, check whether the

bonnet section has been lubricated or not. To do this, loosen the lubricator handwheel

and turn the squeeze screw. If the squeeze screw turn lightly, and grease in the lubricating

procedure mentioned below. (If the squeeze screw turns heavily, this means that grease

has been applied.)

2-3

Page 12

Squeeze

Handwheel

G1/2

Screw

Lubricator

Figure 2-2 Lubricator (Class 600 or under)

Lubricating procedure

(a) prepare grease of the type indicated on the nameplate.

(b) Tightly close the lubricator handwheel.

(c) Remove the squeeze screw, apply grease, and set the squeeze screw.

(d) Loosen the lubricator handwheel and drive grease by turning the squeeze screw.

(e) Repeat the procedure of 0), (c) and (d) until turning of the squeeze screw becomes

heavier. Tightly close lubricator handwheel.

(5) Pressurizing valve, check that there is no leak from the gasket sections for connection

to the valve body and process pipe. If leak is found, tighten the nuts. (Especially when

the process f luid temperature is 400 or higher, tighten the nuts again after raising

temperature of the valve in order that it may serve for a longer period without requiring

immediate maintenance service.) Standard tightening torques are shown in Table 4-4,

Table 4-5 of Chapter 4.

(6) When raising temperature of a valve which is used for high temperature service, raise

temperature gradually (standard rate is 100 per hour) and do not operate the valve when

its temperature is being raised.

Figure 2-3 Lubricator for High Pressure Valve

(Class 600 or higher)

2-4

Page 13

Chapter 3. Inspection and Maintenance

Inspect and service the actuator as follows:

(1) Tightening the gland:

Tighten the gland once in every 6 months or thereabout. The tightening procedure is as

given in Section 2-3-(3).

(2) Lubricating the gland:

Lubricating the gland once in every 6 months or thereabout. The lubricating procedure is

as given in Section 2-3-(4).

(3) Check for hunting of valve Position:

Refer to ''Troubleshooting.''

(4) Check for abnormal noise and vibration:

Refer to ''Troubleshooting.''

3-1

Page 14

3-2

Page 15

Chapter 4. Disassembly and Assembly

This Chapter covers the disassembly and assembly procedures of the actuator for its overhaul

or modification.

4-1. Detaching actuator from valve body

See Figure 4-7.

(1) Apply to the actuator an air pressure so that the valve position pointer is at a point of 10%

- 20% above the fully closed point.

(2) Loosen the clamping-bolts of the stem connector, remove the stem connector, and detach

the actuator stem from the valve stem.

(3) Remove the clamping-nut of the yoke.

(4) Raise the actuator to detach it from the valve body.

Precautions: For detaching the actuator from the valve body which is kept installed in the

process pipe, be sure to shut down the process for and release the process

pressure before detaching the actuator.

4-2. Disassembly and assembly of valve body

To disassemble or assemble the valve body, refer to Figure 4-1 through Figure 4-6 and proceed

as described below.

(For handling of the bellows sealed type (optional type) of valves, see .)

Disassembly procedure

(1) Loosen the hex nuts of the packing flange.

(2) Remove the hex nuts (1) of the bonnet (extension bonnet).

(3) Raise and detach the bonnet from the valve body.

Precautions: If the valve plug comes out together with the bonnet, remove the plug from the

bonnet by rotating the plug. When doing this, exercise care not to damage the

valve stem.

(4) Model HTS, HPS and HAV Valve

For Model HTS and HPS valve, remove the guide ring. The seat ring is fixed to the valve

body by threading. To remove the seat ring, special tools (optional) are nec.essary.

(Model HLS, HLC valves have no guide ring and in its stead the valve has a guide hushing

pressed in the bonnet.)

Inspection

Inspect the disassembled parts for damage. If any damage is found, replace the parts.

(When ordering parts, mention also the Prod. No. of the valve which is indicated on the

nameplate.)

(1) Do not re-use the removed gland packing. Use fresh packing when assembling the valve.

(2) Check that the seating surfaces of plug and seat ring are not damaged.

4-1

Page 16

(3) Check that the gasket-contacting surfaces of valve body, bonnet and guide ring are not

damaged. Do not re-use the removed gasket. Use fresh gasket when assem.bling the valve.

(4) Check that the plug guide section, the stem, and the internal guiding sections of guide

bushing are not damaged..

Assembly procedure

• Model HLS, HLC

(1) Securely fix the seat ring onto the valve body with threads, using the special tools

(optional). For the tightening torque, see Table 4-1

(2) Set the plug on the seat ring. (Apply lubricant ''Neverseize" to the threaded sec.tions,

except those of the oil-inhibited valves.)

(3) Put the bonnet on the valve body and check that the bonnet is correctly mated with the

indented section of the valve body: Tighten the nuts uniformly, paying atten.tion so that

they are not tightened unevenly (tighten- alternately the ones located at symmetrical

positions). For the tightening torque, see Table 4-3.

(4) Insert the gland packing as shown in Figure 2-1.

Note: When yarn packing sheets are used, overlap sheets in such manner that their cut

ends are positioned alternately.

(5) Place the packing follower and packing Range, and tighten the nuts. For the tight.ening

torques, see Table 2-2

• Models HTS, HSC, HPS and HAV

(1) Securely fix the seat ring onto the valve body with threads, using the special tools

(optional). For the tightening torque, see Table 4-1 or Table 4-2.

(2) Set the plug on the seat ring. (Refer to the Disassembly Procedures.)

(3) Put a sheet of gasket on the valve body side and place the guide ring in a manner of

covering the plug. (Apply lubricant "Neverseize" to the gaskets, except those of the oilinhibited valves.)

(4) Put the gasket on the guide ring. (Apply lubricant "Neverseize" to the gaskets, except those

of the oil-inhibited valves.)

(5) Put the bonnet on the valve body and check that the bonnet is correctly mated with the

indented section of the valve body. Tighten the nuts uniformly, paying atten.tion so that

they are not tightened unevenly (tighten alternately the ones located at symmetrically

positions). For the tightening torque, see Table 4-3.

(6) Insert the gland packing as shown in Figure 2-1.

Note: When yarn packing sheets are used, overlap sheets in such manner that their cut

ends are positioned alternately.

(7) Place the packing follower and packing flange, and tighten the nuts. For the tight.ening

torques, see Table 2-2.

4-2

Page 17

Table 4-1. Model HLS, HTS, HSC, HAV seated ring tightening torques

Size (in.) Torque (N·m{kgf-cm})

1-1/2 260 {2,600}

2 390 {3,900}

2-1/2 520 {5,200}

3 650 {6,500}

4 800 {8,000}

6 1200 {12,000}

8 1500 {15,000}

1, 3/4 180 {18,000}

Table 4-2. Model HPS seated ring tightening torques

Size (in.) ANSI Class Torque (N·m{kgf-cm})

1 900-2,500 250 {2,500}

1-1/2 900-2,500 310 {3,100}

2 900-2,500 570 {5,700}

3 900-1,500 1,100 {11,000}

3 2, 500 700 {7,000}

Table 4-3. Tightening torques of bonnet stud bolts

Bolt Torque (N·m{kgf-cm})

M12 60 {600}

M16 100 {1,000}

M20 150 {1,500}

M22 200 {2,000}

M24 250 {2,500}

M27 350 {3,500}

M30 500 {5,000}

M33 660 {6,600}

4-3

Page 18

Table 4-4. Bonnet-body bolt size

Models Size (in.) Rating

ANSI, JPI 150# JIS 10K ANSI, JPI 300#,600#

JIS16K, 20K, 30K, 40K

HLS 1/2 to 3 M12*4 M12*4

1-1/2 M16*6 M16*8

2 M16*6 M16*10

2-1/2 M16*6 M20*8

HTS, HCB

3 M20*8 M22*10

4 M20*8 M22*12

6 M22*12 M30*3*12

8 M24*12 M33*3*12

4-4

Page 19

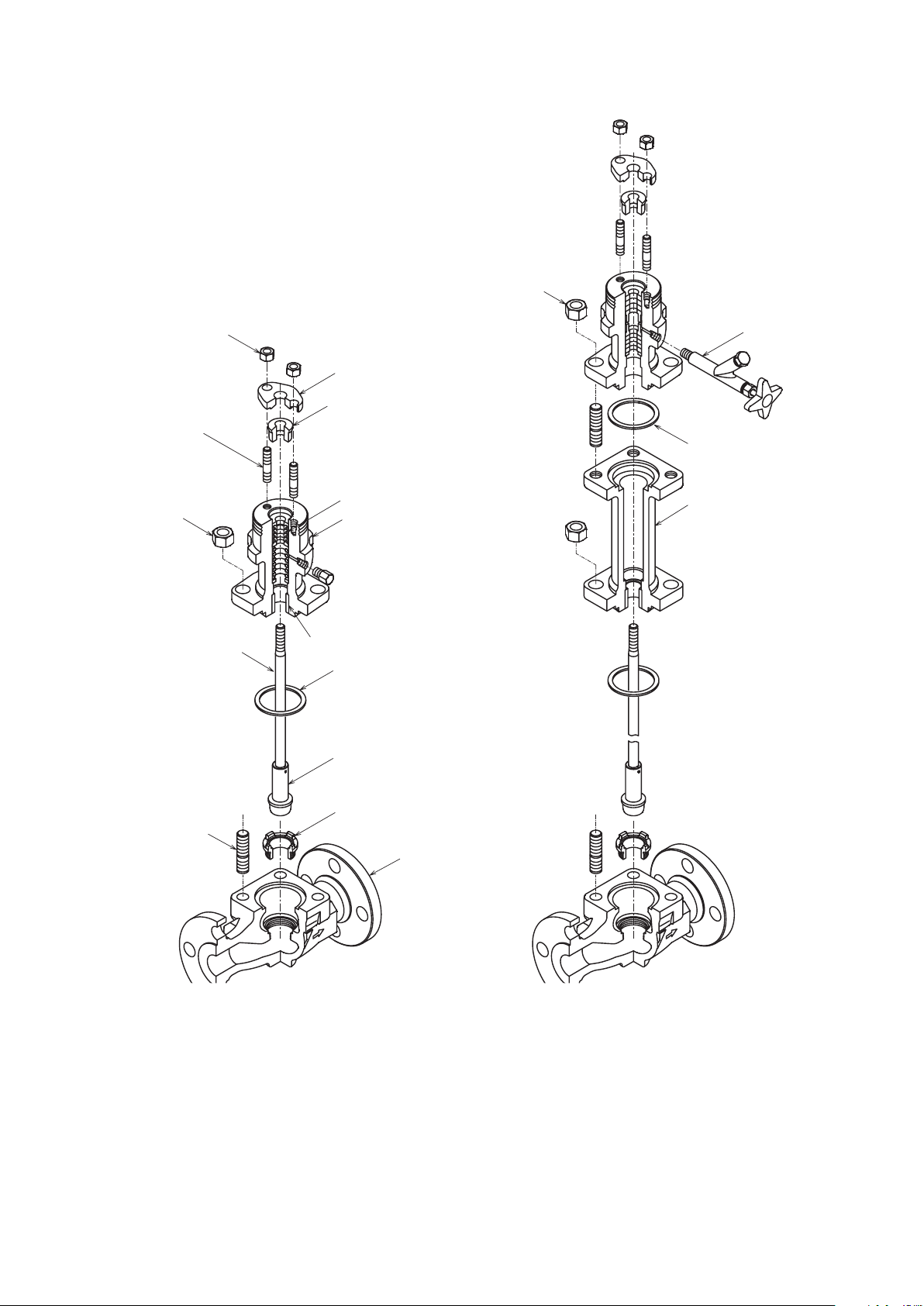

H

Hex Nut (2)

Packing Flange Nut

Stud Bolt

ex Nut (1)

Packing

Valve Stem

Packing Flange

Packing Follower

Gland Packing

Bonnet

Guide Bushing

Gasket (1)

Valve Plug

Lubricator

Gasket (2)

Extension

Bonnet

Stud Bolt

Seat Ring

Valve Body

Figure 4-1-1 Normal Temperature Type Figure 4-1-2 High Temperature Type

(Extended Bonnet Type)

Figure 4-1 Model HLS Control Valves

4-5

Page 20

Packing Flange Nut

H

V

e Body

Stud Bolt

ex Nut (1)

a lve Stem

Packing Flange

Packing Follower

Gland Packing

Bonnet

Gasket (1)

Valve Plug

Guide Bushing

Seat Ring

Stud Bolt

Valv

Figure 4-2 Model HLC Control Valves

4-6

Page 21

Packing Flange Nut

Stud Bolt

Extension

Packing Flange

Packing Follower

Hex Nut (1)

Valve Stem

Gland Packing

Bonnet

Gasket (1)

Guide Ring

Guide Bushing

Gasket (2)

Valve Plug

Seat Ring

Bonnet

Valve Body

Figure 4-3-1 Normal temperature type Figure 4-3-2 High temperature type

(Extended bonnet type)

Figure 4-3 Model HTS Control Valves

4-7

Page 22

Packing Flange

Packing Flange Nut

e Body

Stud Bolt

Gland Packing

Hex Nut (1)

Valve Stem

Packing Follower

Bonnet

Gasket (1)

Guide Ring

Gasket (2)

Stud Bolt

Valve Plug

Seat Ring

Valv

Figure 4-4 Model HSC Control Valves

4-8

Page 23

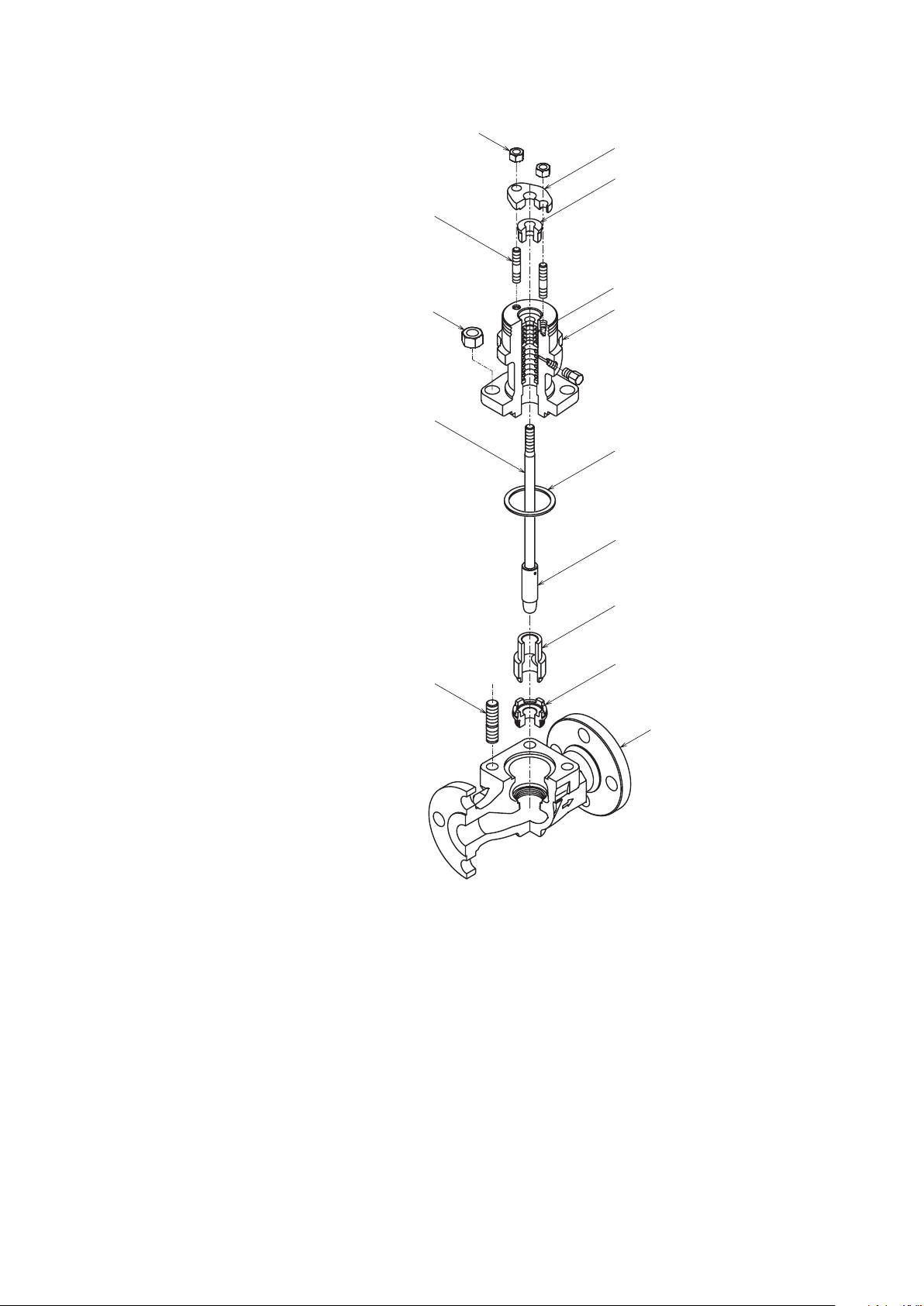

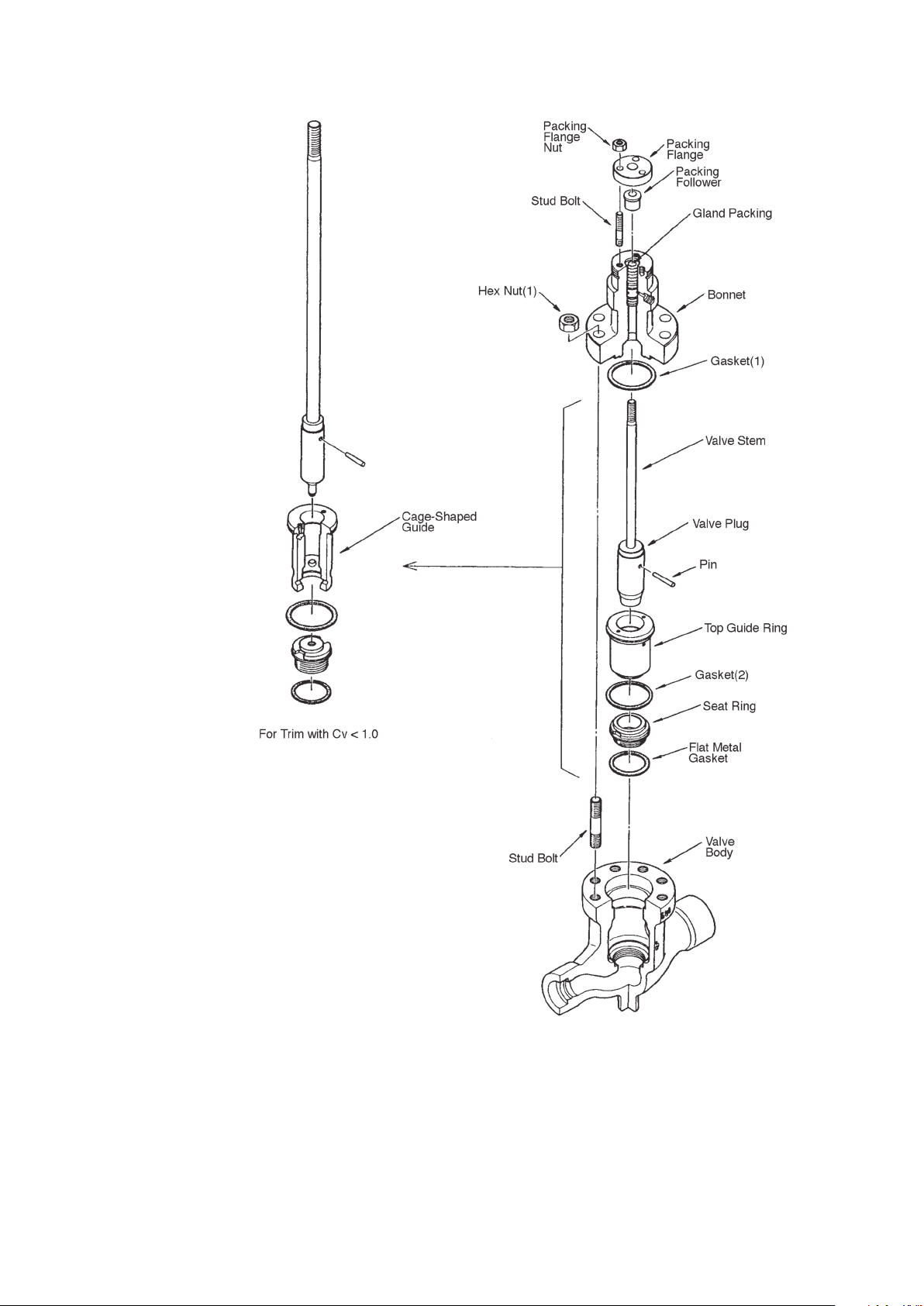

Figure 4-5 Model HPS Control Valves

4-9

Page 24

Paking Flange Nut

Packing Flange

H

e Body

Stud Bolt

ex Nut (1)

Valve Stem

Packing Follower

Gland Packing

Bonnet

Gasket (1)

Guide Ring

Gasket (2)

Valve Plug

Seat Ring

Stud Bolt

Valv

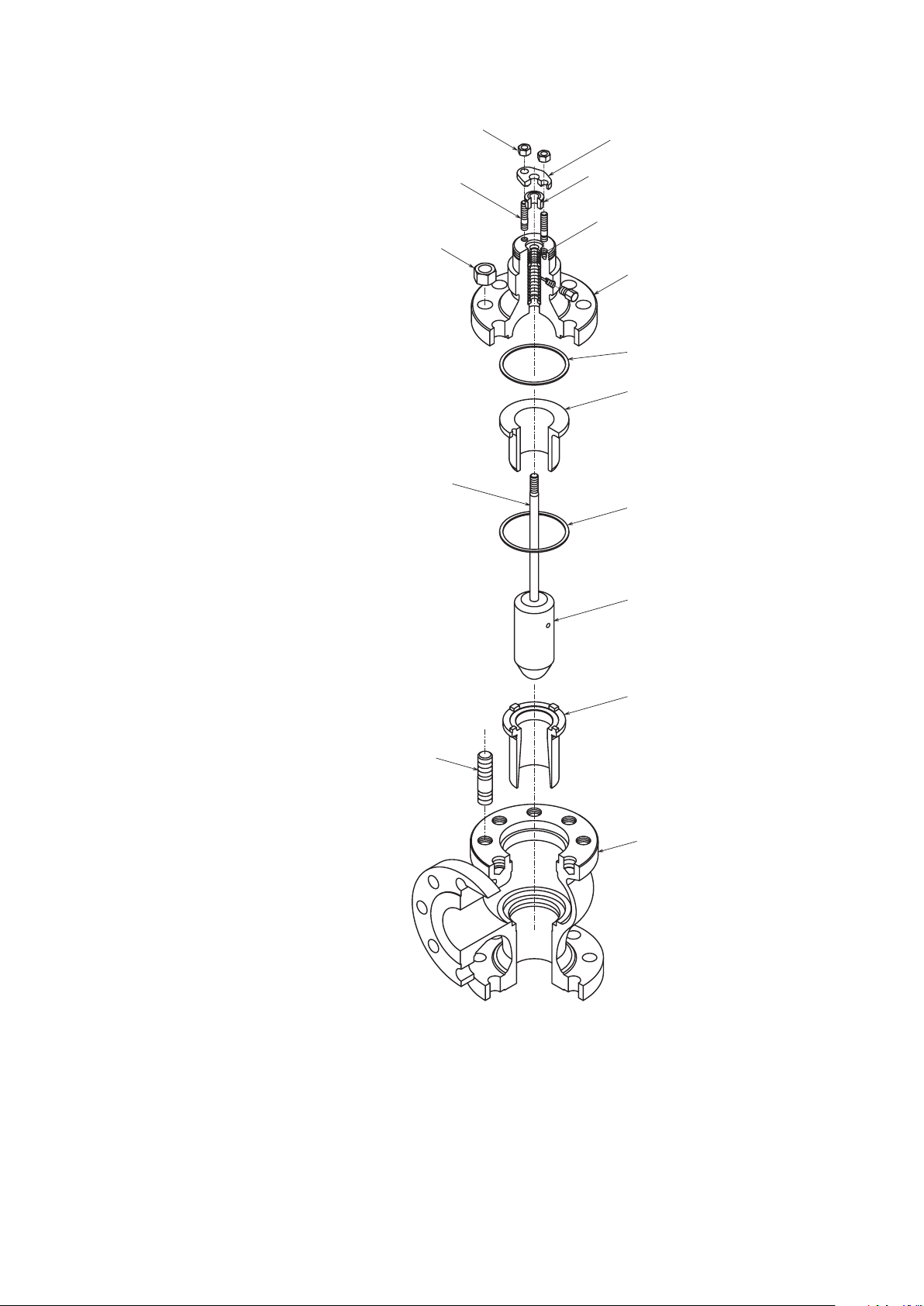

Figure 4-6 Model HAV Control Valves

4-10

Page 25

4-3. Disassembly and assembly of actuator

e Clamping Nut

Normally the actuator requires no adjustment. However, it should be disassembled and

assembled when installing it on a valve body, when modifying its specifications, or when

replacing damaged parts. The disassembly and assembly procedure of the actuator for such

purposes are covered in Sections 4-4 and 4-5. To disassemble the actuator, refer to Figure 4-7

to Figure 4-21.

Pointer

Hex Bolt

Lock Nut

Stem Connector

Yok

Figure 4-7

When disassembling or assembling the actuator, keep it in the vertical attitude. For the

tightening torques of bolts and nuts, see Table 4-4, Table 4-5.

For the names of the parts, see Figure 4-13 and Figure 4-21.

4-11

Page 26

Notes for Disassembly

(1) The nuts for the eyebolts are made of stainless steel. Discriminate these nuts from other

nuts when assembling the diaphragm case.

(2) It is recommendable to make locating marks on the top and bottom diaphragm cases

before disassembly. This will help you to find easily the air piping connector location.

(3) Store the removed parts in a clean place.

CAUTION

Never loosen or remove carelessly the bolts and nuts of the actuator. The actuator

employs powerful compressed springs and if you remove the bolts and nuts carelessly,

the springs may leap out causing hazards. When removing the bolts and nuts, be sure

to observe the instructions given for disassembly and assembly procedures of the

actuator and top handwheel.

4-12

Page 27

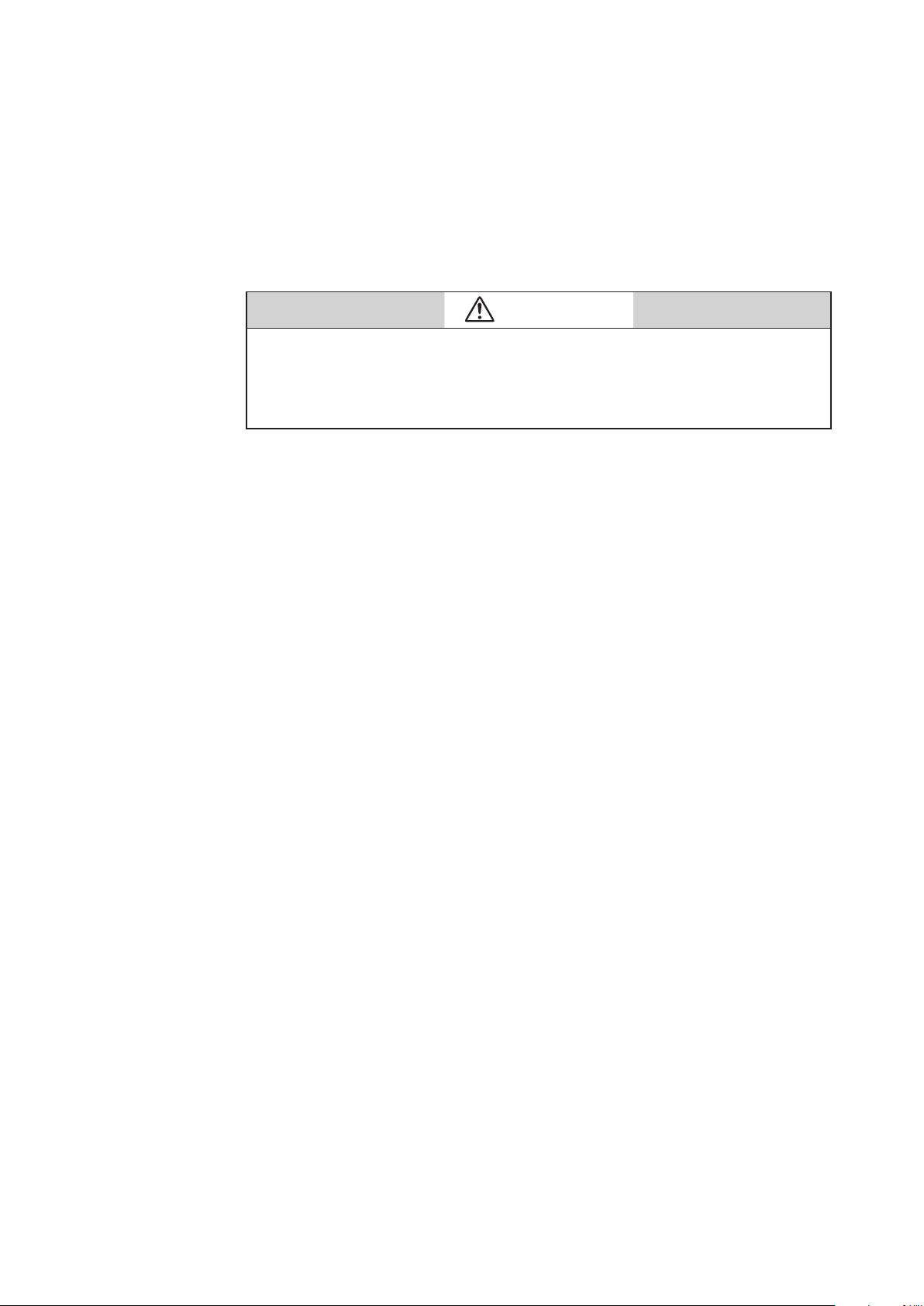

4-4. Disassembly and assembly of model PSA 1

Disassembly procedure

A. Direct action model (see Figure 4-8)

(1) Disconnect the air piping and detach the accessories from the actuator.

(2) Remove the stem connector.

(3) Remove the clamping bolts (except the pair of eyebolts) from the diaphragm case.

(4) Alternatively and evenly loosen the pair of eyebolts. The initial setting of the springs is

achieved using these eyebolts.

(5) Removing the diaphragm case. Pull the actuator rod upward and out together with the

diaphragm.

(6) Take out the springs.

B. Reverse action model (see Figure 4-9)

(1) Disconnect the air piping and detach the accessories from the actuator

(2) Remove the stem connector.

(3) Remove the clamping bolts (except the pair of eyebolts) from the diaphragm case.

(4) Alternately and evenly loosen the pair of eyebolts. The initial setting of the springs is

achieved using the eyebolts.

(5) Remove the diaphragm case. Take on the springs.

(6) Pull the actuator rod upward and out together with the diaphragm.

4-13

Page 28

Diaphragm Case (Top)

Bushing

Rain Cap

Connector

Diaphragm

Case (Top)

Eye Bolt

Hex Bolt

Stopper

Part

Eye Bolt

Hex Bolt

Hex Nut

Was her

Diaphragm

Retainer

Diaphragm

Diaphragm

Plate

Spring Plate

Hex Bolt

Rod

Spring

Diaphragm

Case (Bottom)

Hex Nut

Was her

Spring Plate

Spring

Diaphragm

Plate

Diaphragm

Diaphragm

Retainer

Rod

Hex Bolt

Diaphragm

Case (Bottom)

Seal Washer

Hex Nut

Dust Seal

Yoke

Hex Nut

Drive Screw

Name Plate

Scale Plate

Truss Screw

Stem

Connector

Hex Bolt

O-ring

Rod Packing

Bushing

Dust Seal

Yoke

Hex Bolt

Figure 4-8 Direct Action model PSA1D Figure 4-9 Reverse Action model PSA1R

Drive Screw

Name Plate

Scale Cap Plate

Tr uss Screw

Stem

4-14

Page 29

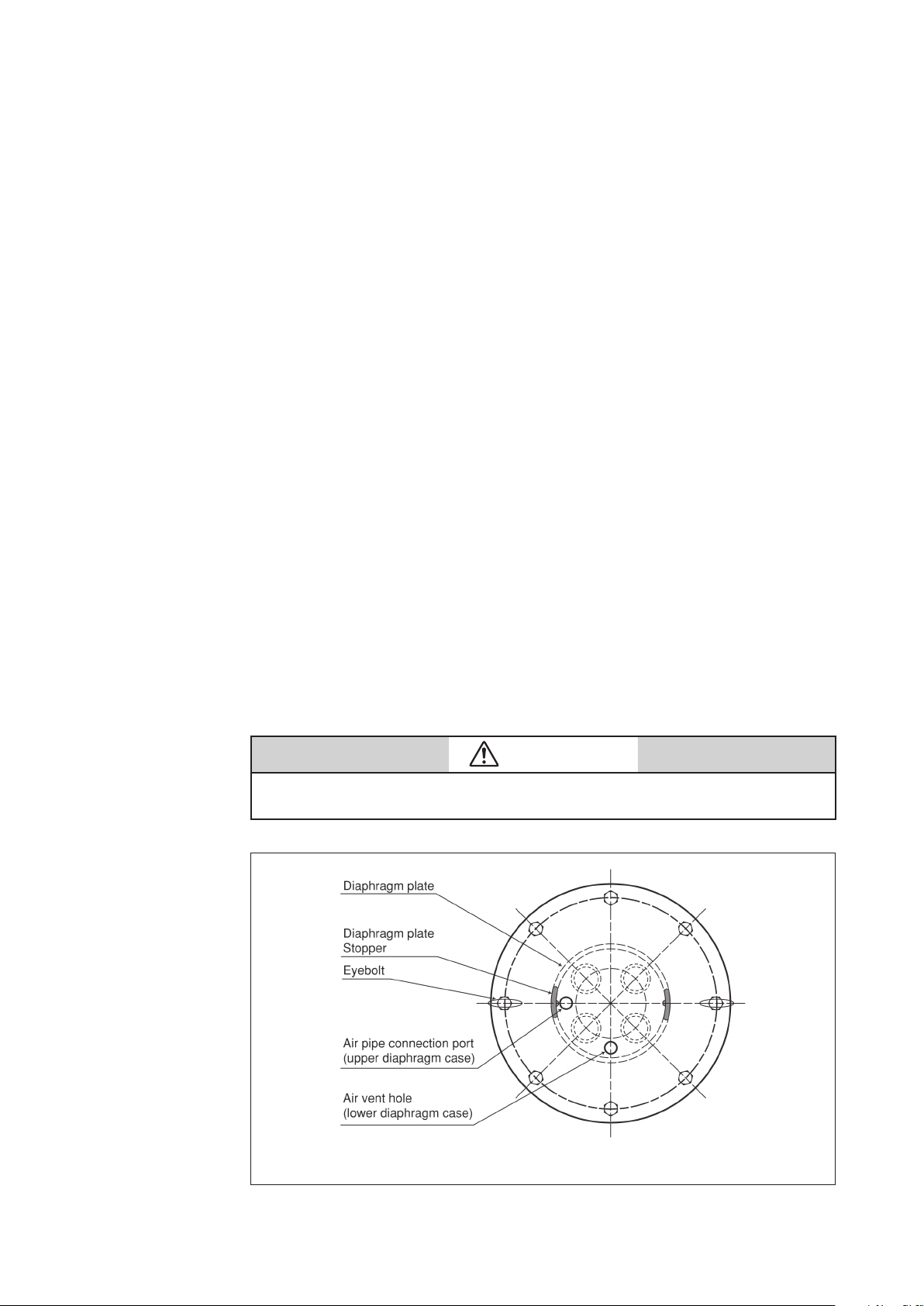

Assembly

Before assembly, check the parts for scratches, damage, deformation, peeling paint or any

other abnormalities. To assemble the actuator, proceed as follows:

A. Direct action models

• See Figure 4-8.

(1) Secure the diaphragm case (bottom) with the four bolts to the yoke. At the same time, set

the air vent hole as in Figure 4-10. For model PSA1D actuator, secure the spring plate to

the diaphragm case and yoke.

(2) Fasten the spring place and install the springs onto the spring plate (see Figure 4-10).

(3) Insert the actuator rod (with diaphragm connected) into the bushing. Be careful to

prevent the bushing's inside surface or dust seal form being damaged by the threaded

section of the rod. If possible, cover the threaded section with adhesive tape.

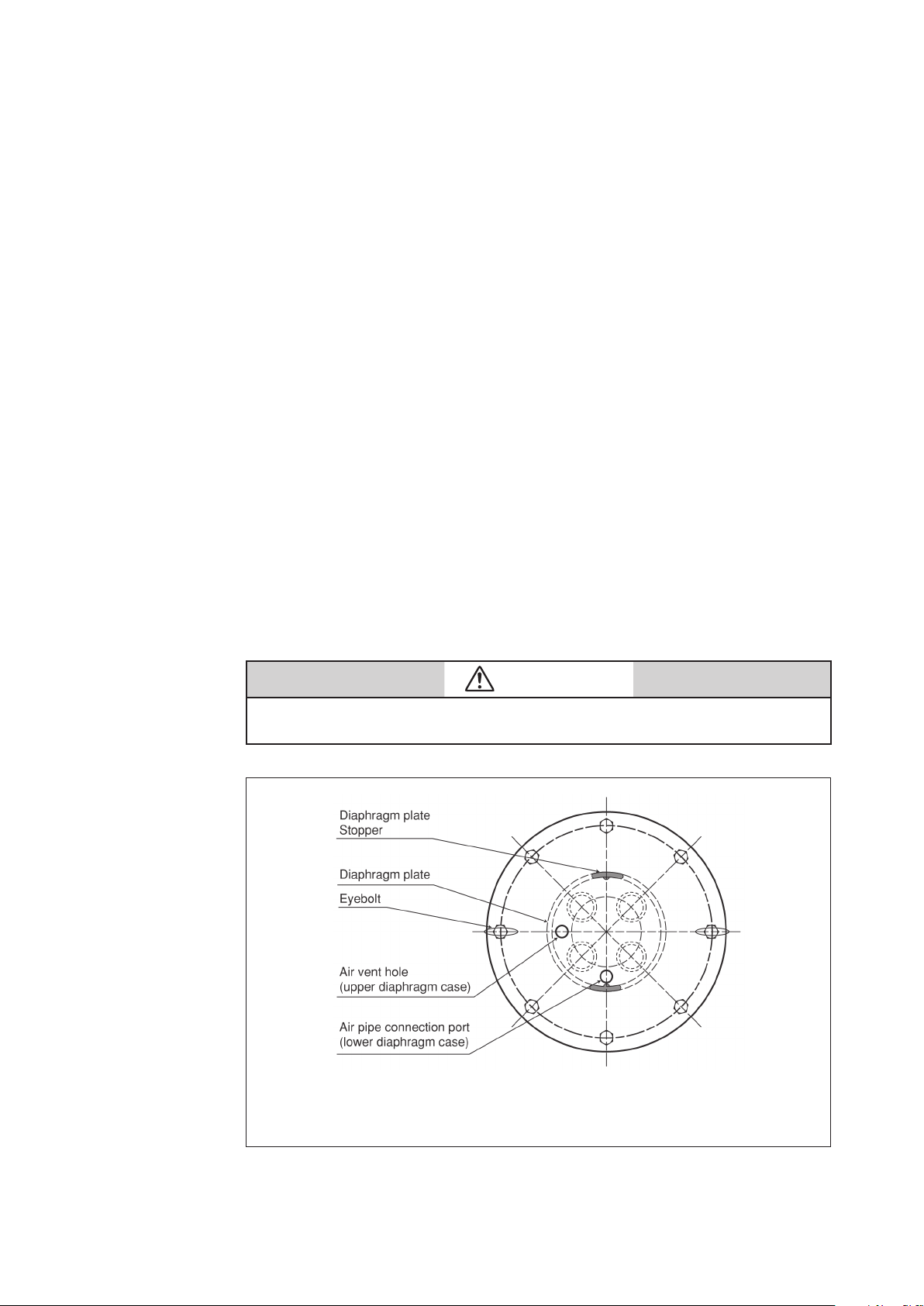

(4) Rotate the actuator rod, locating the diaphragm plate stopper as shown in Figure 4-10.

(5) Place the top diaphragm case and secure it with the pair of eyebolts.

Note: Set the air pipe connection port to the location shown in Figure 4-10. Tighten

the pair of eyebolts uniformly and alternately. The initial setting of the springs is

completed by tightening these eyebolts.

(6) Clamp the diaphragm case with clamping bolts.

(7) Install the stem connector. Connect the air pipe to its connection port at the top

diaphragm case.

(8) After completing assembly, check the following:

• Apply air pressure of 500 kPa {5 kgf/cm

top diaphragm case, and check the diaphragm periphery for air leakage with soapy

water.

• Check that the actuator operates smoothly through to its full stroke by operating it as an

independent unit.

2

} through the air pipe connection port at the

CAUTION

Install packing for the rod and dustseal in the correct direction. Refer to Figure 4-8.

Figure 4-10 Direct Action Models Model PSA1D Actuator

4-15

Page 30

B. Revers action models

(1) Secure the bottom diaphragm case with the four bolts to the yoke. At the same time, set

the air pipe connection port in the location shown in the Figure 4-11.

(2) Insert the actuator rod (with diaphragm connected) into the bushing. Be careful to

prevent the bushing 's inside surface or dust seal from being damaged by the threaded

section of the rod. If possible, cover the threaded section with adhesive tape.

(3) Rotate the actuator rod, locating its diaphragm plate stopper as shown in Figure 4-11.

(4) Fasten the spring plate and install the springs onto the spring plate. (see Figure 4-11).

(5) Place the top diaphragm case and secure it with the pair of eyebolts.

Note: Set the air vent hole to the location shown in Figure 4-11. Uniformly and alternately

tighten the eyebolts. The initial setting of the springs is completed by tightening

these eyebolts.

(6) Clamp the diaphragm case with clamping bolts.

(7) Install the stem connector.

(8) Install the stem cap onto the air vent port.

(9) Connect the air pipe to its connection port at the bottom diaphragm case.

(10) After completing of assembly, check the following.

• Apply air pressure of 500 kPa {5 kgf/cm

diaphragm case, and check the diaphragm periphery for air leakage with soapy water.

• Check that the actuator operates smoothly through to its full stroke by operating the

actuator as an independent unit.

2

}through the air pie connection port at the

CAUTION

Install packing for the rod and dustseal in the correct direction. Refer to Figure 4-9.

Figure 4-11 Reverse Action Model

Model PSA1R Actuator

4-16

Page 31

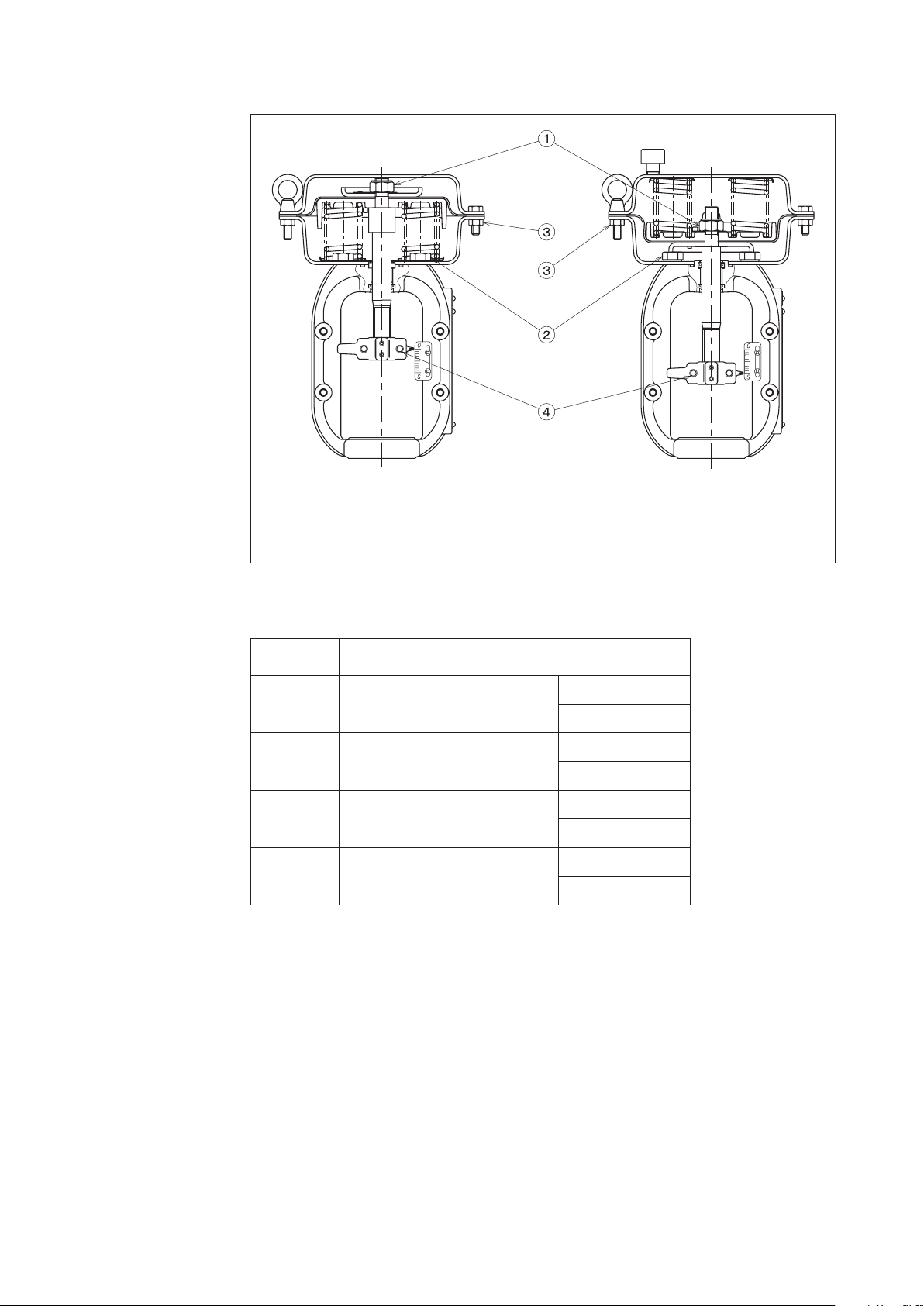

Direct Action Type (Model PSA1D) Reverse Action Type (Model PSA1R)

Figure 4-12 Bolts and Nuts of Actuator

Table 4-5. Tihtening Torques of Bolts and Nuts of Actuator

Unit: (N.m{kgf-cm})

No. Materials

1 SK5 S45C M14

2 S30C M12

3 SUS304 M8

4 SUS304 M8

Note: Install the rain cap on the reverse actuator as follows. Drive the cap into the diaphragm

case until the shoulder (brim) of the cap is brought into contact with the diaphragm

case, then drive the cap further into the diaphragm case by half a turn.

Model

PSA1

45-70

{460-710}

35-50

{360-510}

15-20

{150-200}

10-15

{100-150}

4-17

Page 32

Direct Action Type (Model PSA1D) Reverse Action type (Model PSA1R)

Figure 4-13 Model PSA Actuator

No. Parts Name Material No. Parts Name Material

1 Nut S45C, SUS301 15 Hex Bolt SUS304

2 Diaphragm Case (Top) SAPH400 16 Hex Nut SUS304

3 Diaphragm EPDM, Polyimide 17 Spring Plate SUS304CP

4 Eye Bolt SUS304 18 Hex Bolt S30C

5 Hex Nut SUS304 19 Seal Washer NBR, SPCC

Diaphragm Case (Bottom)

6

7 Bushing SPCC, Bronze, PTFE 21 O-Ring NBR

8 Dust Seal NBR 22 Rod SUS304

9 Yok e A216WBC 23 Truss Screw SUS304, SK5

10 Stem Connector SCS13A 24 Scale Plate SUS304CP

11 Hex Bolt SUS304 25 Drive Screw SUS304

12 Diaphragm Retainer SS400 26 Name Plate SUS304CP

13 Diaphragm Plate AC4A-F 27 Rain Cap SUS304

14 Spring SWOSM-B 28 Washer SUS304CP

SAPH370 20 Rod Packing NBR

4-18

Page 33

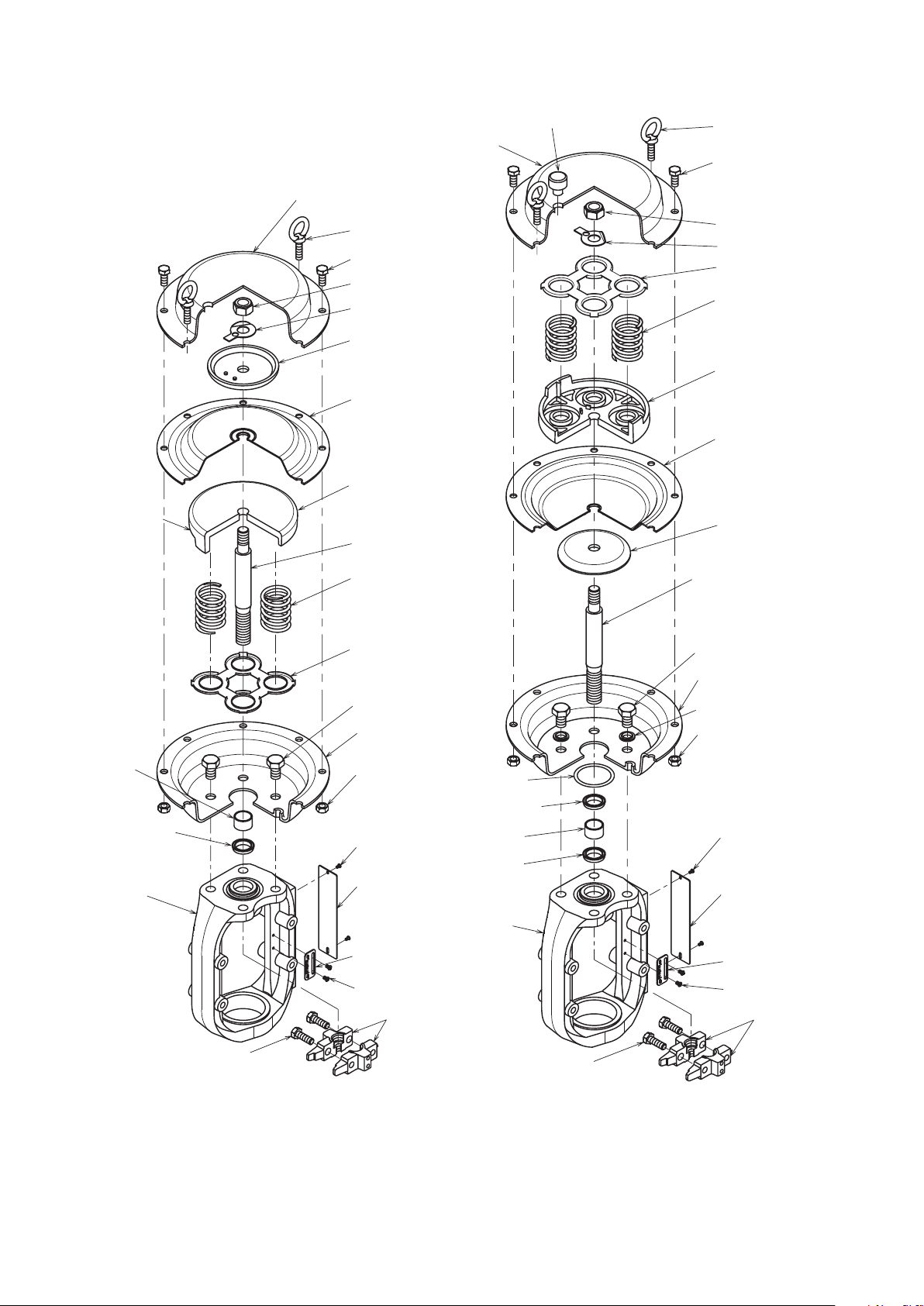

4-5. Disassembly and assembly of model HA2, HA3, or HA4 actuator

Disassembly procedure

(a) Direct action type

(1) Disconnect the air piping and detach the accessories from the actuator.

(2) Remove the stem connector, pointer and lock nut. (See Figure 4-21.)

(3) Remove the clamping-bolts (except the pair of eyebolts) of the diaphragm case.

(4) Loosen evenly and alternately the pair of eyebolts. (The initial setting of the springs is

done by these eyebolts.)

(5) Remove the diaphragm case. Pull out upward the actuator rod together with the

diaphragm.

(6) Take out the springs.

Figure 4-14 Actuator model HA2D or

HA3D

4-19

Figure 4-15 Actuator model HA4D

Page 34

(b) Reverse action type

(1) Disconnect the air piping and detach other external items from the actuator.

(2) Remove the stem connector, pointer and lock nut. (See Figure 4-21.)

(3) Remove the clamping-bolts (except the pair of eyebolts) of the diaphragm case.

(4) Loosen evenly and alternately the pair of eyebolts. (The initial setting of the springs is

done by these eyebolts.)

(5) Remove the diaphragm case. Take out the springs.

(6) Pull out upward the actuator rod together with the diaphragm.

Figure 4-16 Actuator model HA2R or

HA3R

4-20

Figure 4-17 Actuator model HA4R

Page 35

Assembly procedure

Before assembly, check the parts for scrapes, damage, deformation, peeling off of paint, and

other abnormality. To assemble the actuator, proceed as followes:

(a) Direct action type

(1) Fix the bottom diaphragm case and yoke with the bolts. (For models HA2D and HA3D,

install the diaphragm case and spring plate together.)

(2) Install the springs on the spring plate. The quantities of springs are as follwes;

Model HA2.....................4 springs

Model HA3, HA4........... 8 springs

Except particular models as follows:

Model HA2, 38 mm stroke,

80 - 240 kPa (0.8 - 2.4 kgf/cm

2

).......Total 8 springs (with double springs)

Model HA3, 50 mm stroke,

80 - 240 kpa (0.8 - 2.4 kgf/cm

2

)....... Total 16 springs (with double springs)

Model HA4, 75 mm stroke,

80 - 240 kPa (0.8 - 2.4 kgf/cm

2

)...... Total l6 springs (with double springs)

(3) Insert the actuator rod (to which the diaphragm is connected) into the bushing, exercising

are not to damage the bushing inside surface or dust seal with the threaded section of the

rod. (For example, cover the threaded section with adhesive tape to prevent damaging the

hushing.) Set the stopper in parallel with the yoke.

(4) Place the top diaphragm case and fix it with the pair of eyebolts.

Notes: • Set the air piping connection port in the location shown in the illustration.

(Figure 4-18)

• Tighten the pair of eyebolts uniformly by tightening them alternately. The

initial setting of the springs is complete by tightening of these eyebolts.

Figure 4-18 Direct Action Type

(5) Clamp the diaphragm case with other clamping-bolts than the pair of eyebolts.

(6) Install the pointer, secure the lock nut, and install the stem connector. (Connect the air

pipe to the air piping connection port of the top diaphragm case.)

(7) After the assembly is complete as above, check the following.

2

1. Applying an air pressure of 490 kPa (5kgf/cm

) via the air piping connection port of

the top diaphragm case, check the diaphragm periphery for air leak by using soapsuds.

2. Check that the actuator smoothly operates for its full stroke.

Note: Check this operation by operating the actuator as an independent unit.

4-21

Page 36

(b) Reverse action type

(1) Fix the bottom diaphragm case and yoke with the bolts.

(2) Insert the actuator rod (to which the diaphragm is connected) into the hushing, exercising

care not to damage the bushing inside surface or dust seal with the thread section of the

rod. (For example, cover the threaded section with adhesive tape to prevent damaging the

bushing.)

(3) Make the stopper (in the diaphragm plate) in parallel with the yoke by turning the rod.

(4) Install the springs on the spring plate. The quantities of springs are as follows:

Model HA2 ..................... 4 springs

Model HA3, HA4 ........... 8 springs

Except particular models as follows:

Model HA2, 38 mm stroke,

80 - 240 kPa (0.8 - 2.4 kgf/cm

2

).......Total 8 springs (with double springs)

Model HA3, 50 mm stroke,

80 - 240 kpa (0.8 - 2.4 kgf/cm

2

)....... Total 16 springs (with double springs)

Model HA4, 75 mm stroke,

80 - 240 kPa (0.8 - 2.4 kgf/cm

2

)...... Total 16 springs (with double springs)

(5) Place the top diaphragm case and fix it with the pair of eyebolts. Set the air vent hole in

the location shown in the illustration (Figure 4-19). Uniformly and alternately tighten the

eyebolts. The initial setting of the springs is complete by tightening of these eyebolts.

Figure 4-19 Reverse Action Type

(6) Clamp the diaphragm case with other clamping-bolts than the pair of eyebolts.

(7) Install the pointer, secure the lock nut, and install the stem connector.

(8) Install the rain cap on the air vent port.

(9) Connect the air pipe to the air piping connection port of the bottom diaphragm case.

(10) After the assembly is complete as above, check the following.

2

1. Applying an air pressure of 490kPa (5kgf/cm

) via the air Piping connection port

of the bottom diaphragm case, check the diaphragm periphery for air leak by using

soapsuds.

2. Check that the actuator smoothly operates for its full stroke.

Note: Check this operation by operating the actuator as an independent unit.

4-22

Page 37

Reverse Action Type

1

5

5

Direct Action Type

4

2

3

6

Figure 4-20 Bolts and Nuts of Actuator

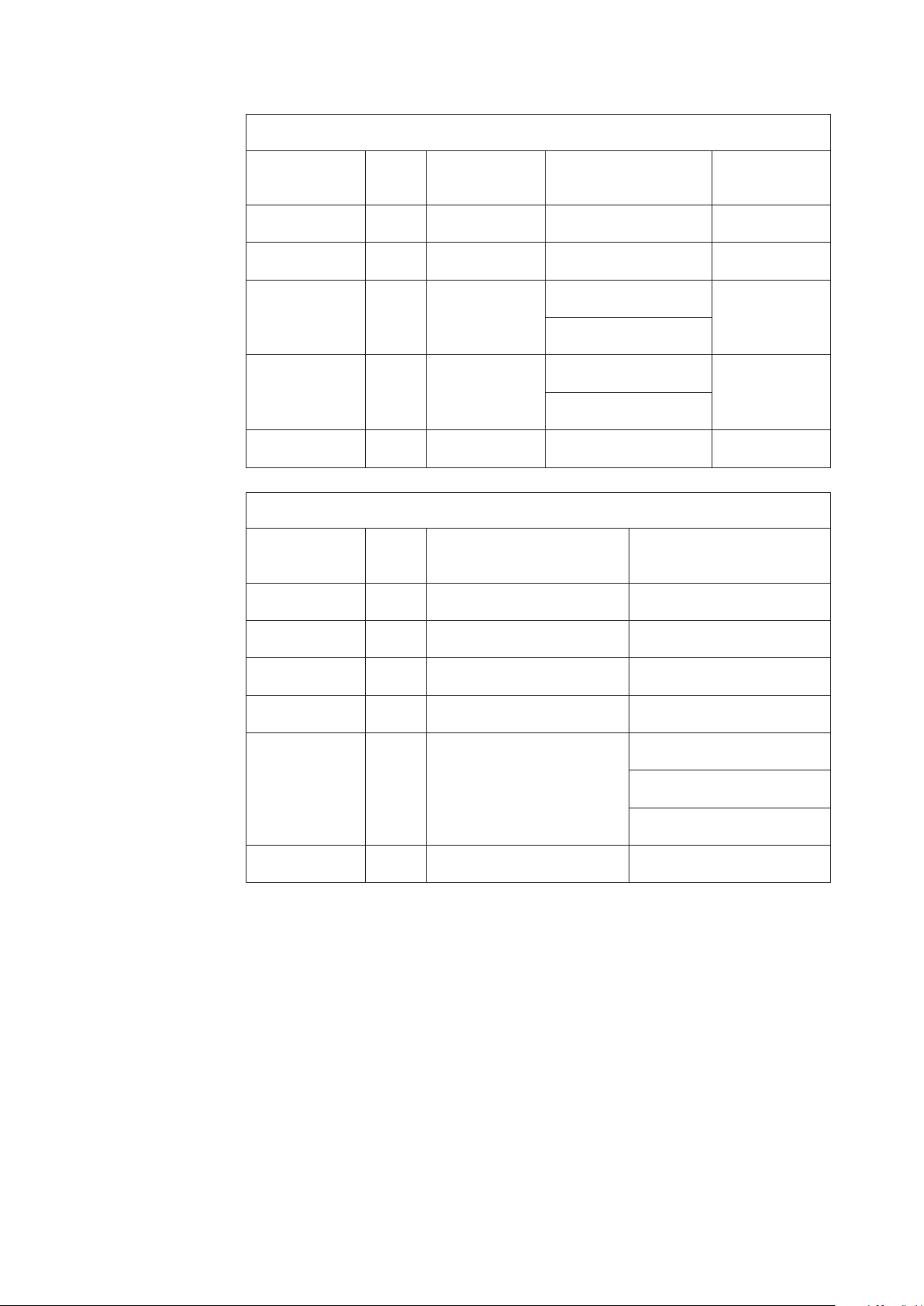

Table 4-6. Tightening Torques of Bolts and Nuts of Actuator

Unit:(N.m{kgf-cm})

No. Materials For Model HA2 For Model HA3 For Model HA4

1 S45C/SUS301 M10 37 {370} M14 100 {1,000} M20 310 {3,170}

2 S30C M12 42 {420} M16 100 {1,000} M24 360 {3,360}

3 S20C M14 69 {690} M18 140 {1,400} M30 710 {7,160}

4

4 S20C M8 16 {160} M8 16 {160} M12 55 {550}

5 SUS304 M8 18 {180} M8 18 {180} M12 63 {630}

6 SUS304 M10 56 {560} M10 56 {560} M12 63 {630}

4-23

Page 38

No. Parts Name Material No. Parts Name Material

Reverse Action Type (Model HA3R)Direct Action Type (Model HA3D)

1 Nut S45C, SUS301 17 Spring SWOSM-B

2 Diaphragm Case (Top) SAPH370 18 Hex Bolt SUS304

3 Diaphragm EPDM+Nylon66 19 Hex Nut SUS304

4 Eye Bolt SUS304 20 Spring Plate SPCC

5 Hex Nut SUS304 21 Hex Bolt S30C

Diaphragm Case (Bottom)

6

SAPH370 22 Seal Washer NBR, SPCC

7 Bushing SPCC, Bronze, PTFE 23 Rod Packing NBR

8 Bearing S25C 24 Rod SUS304

9 Dust Seal NBR 25 Lock Nut SUS304

10 Pointer S25C 26 Truss Screw, Spring

SUS304, SK5

Washer Nut, or Speed

Nut

11 Yo ke SCPH2, A216WBC 27 Scale Plate SUS304CP

12 Stem Connector S25C, S20C 28 Screw SUS304

13 Hex Bolt SUS304, S30C 29 Name Plate SUS304CP

14 Diaphragm Retainer SS400 30 Rain Cap SUS304

15 Stopper SS400 31 Washer SPCC

16 Diaphragm Plate SS400 32 Tapping Screw S20C

Figure 4-21 Cut View of Actuator

4-24

Page 39

4-6. Disassembly and assembly of model PSA6 actuator

Structure

This actuator is comprised of a cylinder, spring unit, lift stopper, spring retainer, hex stay,

yoke, manual handwheel and a single action positioner. For an external view of the a actuator,

refer to "Figure 4-22 Exterior of Model PSA6R".

Figure 4-22 Exterior of Model PSA6R

Assembly on valve body

The Assembling nuts are integral to the valve body connect the yoke and valve body. The stem

connector connects the actuator's rod and valve stem.

Air piping connection

The tubing is connected to the single action positioner when used as a control valve. Refer to

the following instruction manuals for details on the single action positioners.

• Pneumatic positioner (Model HTP) No. OM2-8310-0200

• Electro-pneumatic positioner (Model HEP) No. OM2-8310-0100

• Electro-pneumatic positioner (Model AVP 300/301/302/200/201/202)

No. CM2-AVP300-2001

• Electro-pneumatic positioner (Model AVP 303/203) No. CM2-AVP303-2001

• Smart valve positioner 700 series with HART type (Model AVP701/702)

No. CM2-AVP702-2001

• Smart valve positioner 700 series with F

No. CM2-AVP703-2001

Calibration

OUNDATION

Fieldbus type (Model AVP703)

This actuator does not require any calibration.

When connecting the valve stem of the valve body with the actuator's rod using a stem

connector, adjustment should be made to sit the valve plug onto the seat ring. Then screws on

actuator's scale plate are loosened, and the stroke and index matched to properly position the

scale plate.

4-25

Page 40

In operation and handling

AUTO/MANUAL

switchover pin

in AUTO position

Indicator

MANUAL position

• When automatically operating an actuator with the manual handwheel, verify

that the AUTO/MANUAL switchover pin is inserted into the pin holder, the chain

is engaged with the handwheel and the indicator is in AUTO position starting

operation.

• When disassembling and assembling, always hold the actuator in an upright

position (spring unit on top and yoke on the bottom)

• While eyebolts are used to suspend the actuator, an assembled valve should not be

suspended with the eyebolts only.

AUTO/MANUAL switchover of manual handwheel

With an actuator with the AUTO/MANUAL switchover function, switchover between

automatic operation and manual operation using the handwheel is possible. See Figure 4-23.

AUTO/MANUAL switchover can be made at any time during operation.

CAUTION

Chain

Figure 4-23

AUTO/MANUAL switchover scheme

AUTO/MANUAL

switchover pin in

Figure 4-24

Operator’s instruction label

4-26

Page 41

Procedure

Step Procedure

1 Pull AUTO/MANUAL switchover pin out of its holder and disengage the chain,

that connects the handwheel with the wheel.

2 Check the label on the handwheel and turn the handle in the shut direction and

lower the slide screw.

3 Align the round holes of the slide screw and the actuator rod, and then insert

pin. Push it all the way in and fix it there.

4 Verify OPEN and SHUT arrows on the label, and turn the handwheel either

direction to open or close the valve. The turning torque should be under

127N(13kgf).

5 When the handwheel does not turn any further, check valve opening and then

finish.

CAUTION

Do not apply undue force onto the valve when it comes to full stop.

Otherwise the valve stem may be damaged. Refer to “Chapter 12.

Troubleshooting” for remedial action.

6 To resume automatic operation, remove the switchover pin, turn handwheel

until the slide screw stop reaches AUTO position (see Figure 4-25 below).

Run the chain on the pin through in order to restrict handwheel move ment

and fix the pin on the holder. Resume automatic operation after verifying this

condition.

Figure 4-25

4-27

Page 42

4-7. Disassembly and assembly actuator

Disassembly and assembly procedures are described herein. Refer to them for periodic

maintenace or if a malfunction occurs which may call for the disassembly or assembly of the

actuator.

Before disassembly

(1) Only the nuts for the eyebolts are made of stainless steel. Keep these nuts separate from

other nuts when disassembling the diaphragm case.

(2) Make locating marks on the top and bottom diaphragm cases before disassembling the

valve. This will help you to find the air piping connector location easily.

(3) Store the removed parts in a clean place.

Use extreme care when removing the bolts and nuts from the actuator. The actuator

contains powerful compressed springs that may cause physical injury or damage

to equipment. When removing the bolts and nuts, be sure to closely follow the

instructions given for the disassembly and assembly of the actuator and top hand

wheel.

Detaching actuator from valve body

CAUTION

Refer to 4-1 : “Detaching actuator from valve body” on page 4-1.

4-28

Page 43

Disassembly of actuator

<Disassembly procedure>

Disassembly procedure of actuator is described herein. Refer to Figure 4-26 and Figure 4-27 or

Table 4-4 for the information.

1. Marking and protection

Step Procedure

1 Match the mark of the spring retainer No.10 at the top of actuator, lift stopper

2 Wrap PVC tape around thread part of rod to protect sealing parts, and the guide

2. Removing slide screw rotation stopper (In case of with handwheel)

Step Procedure

1 Loosen hex head bolt No.37 and hex nuts Mo.38 which fasten the slide screw

No.13, cylinder No.14 and cylinder assembling yoke boss.

bushing.

rotation stopper No.36.

2 Remove slide screw rotation stopper No.36.

3. Removing spring retainer

Step Procedure

1 Loosen hex nuts No.2 and eye nut No.1 at the top of actuator and remove.

2 Lift spring retainer No.10 straight up and remove.

4. Removing lift stopper and spring unit

Step Procedure

1 Loosen hex stays No.4 (four syays) which fasten lift stopper No.13 and cylinder

No.14 and remove.

2 Raise lift stopper 13 straight up and remove.

3 Install eyebolts in the threaded holes on the spring receiver No.9 which is located

on the top of spring unit (M12*2) and lift spring unit (approximately 120 kg) up

with a crane.

4 While suspended by crane, remove the piston’s No.3 sealing parts (tape liner

No.14, O-ring No.15)

4-29

Page 44

5. Removing slide screw and cylinder

Step Procedure

1 Turn slide screw No.32 by hand and extract from the bottom.

2 Loosen hex head bolts No.6 (four bolts) which fasten the cylinder and manual

handwheel and remove.

3 Lift cylinder straight up and remove.

6. Removing worm unit (In case of with handwheel)

Step Procedure

1 Remove in sequential order the bearing holder No.29, single column angular

bearing, (upper) No.30, worm wheel No.31, and single column angular bearing

(lower) No.30.

2 Loosen hex head bolts No.9 (four), which fasten the gear case No.28 and yoke

and remove.

4-30

Page 45

Sp

ring Unit

Figure 4-26 Model PSA6R

4-31

Page 46

Sp

ring Unit

Figure 4-27 Model PSA6R with Handwheel

4-32

Page 47

Table 4-7. Parts reference list

No. Parts description No. Parts description No. Parts description

1 Eye Nut 32 Slide Screw 1 Rod

2 Hex Nut 33 Bushing 2 O-Ring

3 Spring Washer 34 Dust Seal 3 Piston

4 Hex Stay(Long) 35 Tape Liner 4 Spring Washer

5 O-Ring 36 Slide Screw Rotation Stopper 5 Locking Nut

6 Hex Bolt 37 Hex Bolt 6 Stopper

7 Seal Washer 38 Seal Washer 7 Spring (Small)

8 Spring Washer 39 Truss Screw 8 Spring (Large)

9 Hex Bolt 40 Indicator 9 Spring Receiver

10 Spring Retainer 41 Pin Holder 10 Hex Nut

11 Rain Cap 42 Pin 11 Stopper Retainer

12 Lift Stopper Seal 43 Handwheel 12 Hex Bolt

13 Lift Stopper 44 Operating Instruction Label 13 Hex Nut

14 Cylinder 45 Spring Washer 14 Wear Ring

15 Rod Packing 46 Hex Nut 15 O-Ring

16 Bushing 47 Chain 16 Washer

17 Dust Seal 48

18 Scale Plate 49 Worm Shaft

19 Truss Screw 50 Key

20 Drive Screw 51 Gear Case Cap

21 Pointer 52 Dust Seal

22 Stem Connector 53 Hex Bolt

23 Yo ke 54 Hex Nut

24 Name Plate 55 Washer

25 Filter Screen 56 Spring Unit

26 Hex Bolt 57 Caution Plate

27 Washer 58 Hex Bolt

28 Gear Case 59 Bushing Joint

29 Bearing Holder 60 Washer

30

Single Column Angular Bearing

31 Worm Wheel

Single Column Angular Bearing

Spring Unit

61 Hex Nut

4-33

Figure 4-28 Spring Unit

Page 48

Disassembling spring unit

<disassembly procedure>

The disassembly procedure of spring unit is described herein.

See Figure 4-28 for reference on part names.

Disassembly is not required if only the piston's sealing parts (tape liner, O-ring) are to

be replaced.

1. Removing spring unit

Step Procedure

1 Loosen hex nuts No.10 (four at the top) and remove.

2 Remove stopper retainer No.11.

3 Evenly loosen hex nuts No.10 (four at the bottom) until there is no tension on

springs No.7 and No.8.

CAUTION

Follow the disassembly procedure of spring unit when removing bolts

and nuts. Otherwise, the release of the springs may result in physical

injury.

4 Remove spring receiver No.9.

5 Remove springs (large No.8, small No.7).

2. Removing piston unit

Step Procedure

1 Loosen stopper No.6 and remove.

2 Loosen locking nut No.5 and remove, using the flat faces of rod No.1.

3 Remove spring washer No.4, O-ring No.2.

Exercise care so as not to damage the O-ring with the rod sc.

4 Separate rod No.1 from piston No.3.

4-34

Page 49

Assembling actuator

<Cautions during assembly>

Refer to the chapter of inspection items during disassembly and verify that no abnormality

is found on the parts. If any are found, replace or repair as required.

The O-ring of sliding parts should always be replaced at the time of periodic disassembly.

Whenever the O-ring on the fixed part is deformed, damaged, or scarred during

disassembly, replace it.

Clean the O-ring, oil seal, wearing, and tape liner O-ring recess and apply sufficient of

lubricant.

Ensure that no dust or dirt from maintenance work prior to reassembly remains on sliding

part of cylinder and guide bushing.

Assembly of actuator with manual handwheel

See Figure 4-23 and Figure 4-24 for assembly on part names.

1. Assembly of manual handwheel and cylinder assembly

Step Procedure

1 While yoke No.23 is in upright position, place gear case No.28 and temporaily

fasten it with hex head bolts No.9 (four).

2 Apply lubricant on the single column angular bearing (top and bottom) and

assemble in sequential order the bearing (lower) No.30, worm wheel No.31,

Bearing (upper) No.30 and bearing holder No.29. See Figure 4-29 below.

Figure 4-29

3 Insert and screw in from the bottom slide screw No.32 assembled with wear ring

No.14. Apply Inbricant on the threaded parts of slide screw No.32.

4 Assemble slide screw No.32 with slide screw rotation stpper No.36, hex head bolt

No.50 and nut No.51.

5 Apply lubricant on rod packing No.15 and dust seal No.17 and assemble them

into cylinder No.14.

6 Place cylinder No.14 on gear case No.28 and temporarily fasten it with hex head

bolts No.6 (four) and seal washer No.7.

7 Use rod No.1 to set the position of the cylinder by ensuring that the rod moves

smoothly and the tighten with the torque given on Table 4-5. If the rod does not

move smootyly, tap the cylinder or gear case gently with plastic hammer and set

the position.

4-35

Page 50

2. Assembly of piston unit, lift stopper and spring retainer

Step Procedure

1 Install eyebolts into threaded holes (M12*2) at the top of spring retainer No.9 on

the piston unit, suspend with crane and lift upward.

2 While suspended, assemble lubricated O-ring No.15 and wear ring No.14 on

piston No.3.

3 Assemble piston unit in cylinder No.14 from the top. See to it that the round hole

of rod 1 is on the front.

4 Assemble lift stopper seal No.12 in the slot on the top of cylinder no.14.

5 Insert lift stopper No.13 from the top and fix by hex stay No.4 (four).

Screw in on the ones of the same length diagonally.

6 Assemble so that the hex stays No.4 fit into bolt holes of spring retainer No.10.

7 Fix spring retainer No.10 with hex head nuts No.2 (four).

8 Install eye nuts No.1 (two) on hex stay No.4.

Assembly of actuator without manual handwheel

When assembling an actuator without a manual handwheel, follow the procedure given in

“Assembly of actuator with manual handwheel” on page 4-40 except the applicable parts to

actuator.

Parts to be replaced

The actuator's parts have been designed to withstand prolonged usage. However, it is

recommended that the following parts be replaced at these intervals:

Tape liner.................. Every five years

Bushing..................... Every five years

Seal washer............... Every five years

Dust seal................... Every five years (to be replaced when disassembled)

Rod packing............. Every five years (to be replaced when disassembled)

O ring........... ............ Every five years (to be replaced when disassembled)

4-36

Page 51

Tightening torques of actuator assembly

The table below lists the tightening torques for actuator assembly.

Refer to Figure 4-30.

Table 4-8. Tightening torque of bolt and nuts of actuator

Key No. Size Tightening torque (N.m{kgf-cm})

1 M14 45-70 {450-700}

2 M20 160-215 {1600-2200}

3 M24 215-275 {2200-2800}

4 M14 45-70 {450-700}

5 M12 35-50 {350-500}

Figure 4-30 Tightening torque of actuator thread

4-37

Page 52

4-38

Page 53

Chapter 5. Adjustment

As a general rule the diaphragm type control Valves require no adjustment. However, when

coupling an actuator to a valve body after removing the actuator for overhaul or other

purposes, adjustment of travel (stroke) is necessary. For this adjustment, refer to Figure 4-7,

Figure 5-1 and proceed as follows:

(1) Fix the actuator to the valve body by securely tightening the yoke clamping-nut (use a

chisel and a hammer).

(2) Connect an adjustable air pressure (with a pressure regulator) to the actuator - to the top

diaphragm case for the direct action type or to the bottom diaphragm case for the reverse

action type.

(3) Lower the valve seat and check that it is contacted with the valve seat.

For the Direct Action Type

(4) Apply to the actuator the maximum air pressure corresponding to the spring range

indicated on the nameplate.

(5) Increase the air pressure to the supply pressure and check that the actuator stem moves by

1 - 2 mm in response. (This movement represents the allowance of stroke.)

(6) Decrease the air pressure once. Then increase it again to the maximum value

corresponding to the spring range, in the increasing direction.

(7) In the above state, align the actuator stem and valve stem on a straight line, adjust so that

the thread of the stem connector mates with those of actuator stem and valve stem and

securely tighten the clamping-bolts of the stem connector. (See Figure 5-1.)

For the reverse action type

(4) Apply to the actuator the minimum air pressure corresponding to the spring range

indicated on the nameplate, and check that the actuator stem moves by 1-2mm

inresponse.

(5) Increase the air pressure once. Then decrease it again to the minimum value corre.

sponding to the spring range, in the decreasing direction.

(6) Perform a procedure identical with that of Item (7) of ''For the Direct Action Type.'' (See

Figure 5-1.)

5-1

Page 54

Actuator Stem

Yoke-Clamping-Nut

range (for direct or reverse action) by moving

Set at maximum or minimum value of spring

actuator stem in this direction.

Valve

Stem

Yoke

Figure 5-1

5-2

Page 55

Chapter 6. Direct/Reverse Action Type Conversion and

Spring Range Change of Actuator

6-1. Direct/Reverse action change

As a general rule it is most recommendable to prepare separately the direct type and reverse

type of actuators and not to convert actuators into different types. However, when it has

become unavoidable to convert actuators into other types, conversions may be done by using

the parts mentioned below (Table 6-1 and Table 6-2). The parts marked “+” are the ones

which are newly needed and those marked “-” are ones which are not used.

Table 6-1. To Convert the Direct-Action Type into the Reverse Action Type

Model PSA1D -> Model PSA1R

Parts neme Q'ty

82559228-102 14.3mm

Rod unite +1

82559228-101 25mm

82559229-102 14.3mm

Rod -1

82559229-101 25mm

Seal washer +4 82521069-101

Rod packing +1 82521067-102

Rain cap +1 82553334-101

"O" ring +1 82592235-596

Washer +1 82553318-101

Model HA2D -> Model HA2R

Part name Q'ty For stroke 14.3mm, 25mm For stroke 38mm

Seal washers +2 82521069-101 82521069-101

Rod packing +1 82521067-101 82521067-101

82521431-101 (14.3mm)

Rod unit +1

82521431-102 (25mm)

Rain cap +1 82553334-101 82553334-101

82521431-103

Rod (-1)

82521427-101 (14.3mm)

82521427-103

82521427-102 (25mm)

6-1

Page 56

Model HA3D -> Model HA3R

Part name Q'ty

Seal washers +2 82521069-102 82521069-102 82521069-102

Rod packing +1 82521067-102 82521067-102 82521067-102

Rod unit +1 82521431-201

Rain cap +1 82553334-101 82553334-101 82553334-101

Rod (-1) 82521428-101

Part name Q'ty For stroke 25mm

Seal washers +2 82521069-103 82521069-103

For stroke

14.3mm

Model HA4D -> Model HA4R

For stroke

25mm, 38mm

82521431-202 (25mm)

82521431-203 (38mm)

82521428-102 (25mm)

82521428-103 (38mm)

38mm, 50mm, 75mm

For stroke

38mm

82521431-204

82521428-104

For stroke

Rod packing +1 82521067-103 82521067-103

Rod unit +1 82521431-302 82521431-303

82521429-103 (38mm)

Rain unit (-1) 82521429-102

Rain cap +1 82553334-101 82553334-101

Flat washers (-2) 82592131-201 82592131-201

82521429-104 (50mm)

82521429-105 (75mm)

6-2

Page 57

Table 6-2. To Convert the Reverse Action Type into the Direct Action Type

Model PSA1R -> Model PSA1D

Parts neme Q'ty

82559229-102 14.3mm

Rod unite +1

82559229-101 25mm

82559228-102 14.3mm

Rod -1

82559228-101 25mm

Seal washer -4 82521069-101

Rod packing -1 82521067-102

Rain cap -1 82553334-101

"O" ring -1 82592235-596

Washer +1 82553318-101

Model HA2R -> Model HA2D

Part name Q'ty For stroke 14.3mm, 25mm For stroke 38mm

Seal washers (-2) 82521069-101 82521069-101

Rod packing (-1) 82521067-101 82521067-101

82521427-101 (14.3mm)

Rod unit +1

82521427-103

82521427-102 (25mm)

82521431-101 (14.3mm)

Rod (-1)

82521431-103

82521431-102 (25mm)

Rain cap (-1) 82553334-101 82553334-101

6-3

Page 58

Model HA3R -> Model HA3D

Part name Q'ty

For stroke

14.3mm

For stroke 25mm, 38mm For stroke 50mm

Seal washers (-2) 82521069-102 82521069-102 82521069-102

Rod packing (-1) 82521067-102 82521067-102 82521067-102

82521428-102 (25mm)

Rod unit +1 82521428-101

82521428-104

82521428-103 (38mm)

82521431-202 (25mm)

Rod (-1) 82521431-201

82521431-204

82521202-203 (38mm)

Rain cap (-1) 82553334-104 82553334-104 82553334-104

Model HA4R -> Model HA4D

Part name Q' ty For stroke 25mm

For stroke

38mm, 50mm, 75mm

Seal washers (-2) 82521069-103 82521069-103

Flat washaers +2 82592131-201 82592131-201

Rod packing (-1) 82521067-103 82521067-103

Rod unit (-1) 82521431-302 82521431-303

82521429-103 (38mm)

Rod +1 82521429-102

82521429-104 (50mm)

82521429-105 (75mm)

Rain cap (-1) 82553334-104 82553334-104

For the conversion procedure, refer to “Disassembly and Assembly”

6-4

Page 59

6-2. Stroke and range spring change

As a general rule it is most recommendable to prepare separate actuators for different strokes

and spring ranges to avoid modifications. However, modifications can be done by using the

parts mentioned below.

Of Models HA2 and HA3, there are two different diameters of bonnet connection sections.

For these models, note the following:

Of Model HA2, modification for change between read stroke of 14.3 or 25mm and that of

38mm cannot be done.

Of Model HA2, modification for change between rated stroke of 25 or 38mm and that of

50mm cannot be done.

Table 6-3. Parts Required for Respective Stroke Ranges

Actuator model PSA1

Part name Q'ty For Stroke 14.3mm For Stroke 25mm

Scale plate 1 82559230-102 82559230-101

20-98{0.2-1.0} 4 82521340-101 82521340-104

Spring

80-240{0.8-2.4} 4 82521340-102 82521340-103

Note: spring force is equivalent to air pressure(kPa{kgf/cm

2

})

Rod

unit

Spring

Rod

unit

R (Reverse action) 1 82559228-102 82559228-101

D (Direct action) 1 82559229-102 82559229-101

Washer 1 82553318-101 82553318-101

Actuator model HA2

Part name Q'ty For Stroke 14.3mm For Stroke 25mm For Stroke 38mm

Scale plate 1 80225032-164 80225032-464 82554022-103

20-98{0.2-1.0} 4 82521205-101 82521205-103 82521208-102

80-240{0.8-2.4} 4 82521205-102 82521208-101

R (Reverse action) 1 82521431-101 82521431-102 82521431-103

D (Direct action) 1 82521427-101 82521427-102 82521427-103

82521208-103

82521208-104

6-5

Page 60

Actuator model HA3

Part name Q'ty For Stroke 25mm For Stroke 38mm

Scale plate 1 80225032-464 82554022-103

20-98{0.2-0.1} 8 82521206-101 82521206-103

Spring

80-240{0.8-2.4} 8 82521206-102 82521209-101

Rod

unit

Spring

Rod

unit

R (Reverse action) 1 82521431-202 82521431-203

D (Direct action) 1 82521428-102 82521428-103

Actuator model HA4

Part name Q'ty

Scale plate 1 80225032-464 82554022-103 82521424-102 80224425-103

20-98{0.2-0.1} 8 82521244-104 82521207-101 82521207-102 82521210-103

80-240{0.8-2.4} 8 82521244-106 82521210-101 82521210-102

R (Reverse action) 1 82521429-102 82521429-103 82521429-104 82521431-303

D (Direct action) 1 82521431-302 82521431-303 82521431-303 82521429-105

For Stroke

25mm

* : The quantity of springs is 8 set, with 2 springs for each set, or total 16 springs.

For Stroke

38mm

For Stroke

50mm

For Stroke

75mm

82827929-101*

82827930-101*

6-6

Page 61

Color Codes and Dimensions of the Springs of Model HA Actuators

The color codes and dimensions of the springs of Model HA Actuators are as shown in the

following table. The color codes may help you confirm springs when disassem.bling and

assembling actuators for modification or other purpose.

Table 6-4. Color Codes and Dimensions of Springs

Actuator

model

PSA1 HA2 HA3 HA4

Rated stroke Range

14.3

25

38

50

20-98

{0.2-1.0}

80-240

{0.8-2.4}

20-98

{0.2-1.0}

80-240

{0.8-2.4}

20-98

{0.2-1.0}

80-240

{0.8-2.4}

20-98

{0.2-1.0}

80-240

{0.8-2.4}

Red

64.6

Blue

69.8

Green

68.7

Purple

78.8

Red

86

Blue

90

Yellow

91.4

Brown

99

Green

95

Purple

107

Yellow and

Green

99.2

Red and Green

103.6

Red

99.3

Blue

107

Yellow

102.9

Brown

114.9

Green

106.5

Purple

122.2

Yellow and Green

148.1

Red and Green

155.3

Red

152.8

Blue

163.7

Yellow

156.3

Brown

170.6

20-98

{0.2-1.0}

75

80-240

{0.8-2.4}

Green

163.4

White NOTE 1

182, 186.7 *

Note: 1. Each set is comprised of two springs.

2. “0.2-1.0” and “0.8-2.4” are spring forces corresponding to air pressures in the unit

of kPa{kgf/cm

2

}.

3. The dimensions indicated are free lengths of springs.

6-7

Page 62

6-8

Page 63

Chapter 7. Instructions for Top Handwheel of Actuator

7-1. Model PSA1 actuator

7-1-1. Operating instructions

To manually operate the actuator, refer to Figure 7-1 and Figure 7-2 and proceed as follows:

(1) Loosen the lock nut of the handwheel and turn the handwheel in the direction indicated

by the corresponding arrowhead mark.

As you turn the handwheel clockwise, the actuator stem moves downward regardless of

whether the actuator is of the direct action type or reverse action type.

The handwheel bears the ''SHUT' mark to indicate that the valve is closed as the

handwheel is turned clockwise and the ''OPEN” mark to indicate that the valve is made

open as the handwheel is turned counterclockwise.

(2) For automatic operation of the actuator, fully raise the handwheel if the actuator is of the

direct action type or fully lower the handwheel if the actuator is of reverse action type, and

then tighten the lock nut to secure the handwheel in such position.

Precautions: If you forcefully turn the handwheel after it has reached the mechanical

stop position, the valve stem may be damaged. Do not turn the handwheel

with forces larger than 16 kgf at the outermost periphery of the handwheel.

7-1

Page 64

Reverse Action TypeDirect Action Type

No. Parts Name No. Parts Name No. Parts Name

1 Hex Nut 17 Hex Bolt 32 Rod

2 Spring Washer 18 Bushing 33 Truss Screw

3 Washer 19 Dust Seal 34 Scale Plate

4 Handwheel 20 Stem Connector 35 Name Plate

5 Lock Nut 21 Screw Shaft 36 Drive Screw

6 Washer 22 Housing 37 Yo ke

7 O-Ring 23 Spring Pin 38 Rain Cap

8 Bearing 24 Seal Washer 39 O-Ring

9 O-Ring 25 Hex Bolt 40 Rod Packing

10 Nut 26 Diaphragm Case(Top) 41 Bearing Washer

11 Washer 27 Spring 42 Nut

12 Diaphragm Retainer 28 Hex Bolt 43 Bearing Case

13 Eye Bolt 29 Hex Nut 44 Setscrew

14 Diaphragm 30 Diaphragm Plate 45 Connection

15 Hex Nut 31 Diaphragm Case (Bottom) 46 Seal Washer

16 Spring Plate

Figure 7-1 Model PSA1 Actuator with Top Handwheel

7-2

Page 65

7-1-2. Disassembly and Assembly of Top Handwheel

To disassemble or assemble the top handwheel, refer to Figure 7-1 through Figure 7-3 and

proceed as described in this section. For disassembly work, keep the actuator in the vertical

attitude.

(a) Direct action type

(1) Disconnect the air piping.

(2) Set the handwheel shaft in the automatic operation position (fully raise the handwheel

shaft).

(3) Remove the top diaphragm case. When doing this, loosen the pair of eyebolts uniformly

and alternately, after removing all other clamping-bolts of the diaphragm case.

(4) Sufficiently insert the handwheel shaft by turning it and then remove the handwheel and

the lock nut. Insert the shaft further and then remove the screw shaft from the housing.

(5) Remove the O-ring.

To assemble the top handwheel, follow the disassembly procedure in the reverse order.

(b) Reverse action type

(1) Disconnect the air piping.

(2) Set the handwheel shaft in the automatic operation position (fully lower the handwheel

shaft).

(3) Remove the handwheel and the lock nut. Insert the shaft into the housing by means of the

threading until the threaded sections are disengaged.

(4) Remove the top diaphragm case. When doing this, loosen the pair of eyebolts uniformly

and alternately, after removing all other clamping-bolts of the diaphragm case.

(5) Remove the housing by loosening its clamping-screw.

(6) Remove the setscrew and then remove the bearing case.

(7) Remove the spring pin and then remove the castle nut.

(8) Remove the bearing retainer and then remove the bearing.

To assemble the top handwheel, follow the disassembly procedure in the reverse order.

(c) Inspection after assembly

(1) Check that the handwheel turns smoothly for the fun stroke.

(2) For the direct action type of actuator, check by means of soapsuds that there is no air leak

from the connecting section of the top diaphragm case.

7-3

Page 66

Figure 7-2

Model PSA1D (Direct Action Type)

7-4

Figure 7-3

Model PSA1R (Reverse Action Type)

Page 67

7-2. Model HA2, HA3, or HA4 actuator

7-2-1. Operating instructions

To manually operate the actuator, refer to Figure 7-5 through Figure 7-8 and proceed as

follows:

(1) First, loosen the lock nut (which has a bar-shape handle and which locks the handwheel,

and turn the handwheel in the direction indicated by the corresponding arrowhead mark.

As you turn the handwheel clockwise, the actuator stem moves downward regard.less of

whether the actuator is of the direct action type or reverse action type. The handwheel

bears the "SHUT' mark to indicate that the valve is closed as the handwheel is tuned

clockwise and the ''OPEN' mark to indicate that the valve is made open as the handwheel

is tuned counterclockwise.

(2) For automatic operation of the actuator, fully raise the handwheel if the actuator is of the

direct action type or fully lower the handwheel if the actuator is of the reverse action type,

and then tighten the lock nut to secure the handwheel in such position.

Precautions: If you forcefully turn the handwheel after it has reached the mechanical stop

position, the valve stem may be damaged. Do not turn the handwheel with forces

larger than the below-mentioned limits.

Model HA2: 190N {19kgf}

Model HA3: 260N {26 kgf}

Model HA4: 410N {41 kgf}

(at the outermost periphery of the handwheel)

7-2-2. Disassembly and assembly of top handwheel

To disassemble or assemble the top handwheel, refer to Figure 7-5 through Figure 7-9 and

proceed as described in this section. For disassembly and assembly work, keep the actuator in

the vertical attitude.

(a) Direct action type

(1) Disconnect the air piping.

(2) Set the handwheel shaft in the automatic operation position (fully raise the handwheel

shaft).

(3) Remove the top diaphragm case. When doing this, loosen the pair of eyebolts uniformly

and alternately, after removing all other clamping-bolts of the diaphragm case.

(4) Sufficiently insert the handle shaft by turning it and then remove the handwheel and the

lock nut. Insert the shaft further and then remove the screw shaft from the housing.

(5) Remove the O-ring.

To assemble the top handwheel, follow the disassembly procedure in the reverse order.

Azbil Corporation Safety

7-5

Page 68

No. Parts Name

1 Hex Nut

2 Washer

3 Handwheel

4 Screw Shaft

5 Lock Nut

6 O-Ring

7 C type Retaining Ring

8 Nut

9 Diaphragm Case (Top)

10 Eye Bolt

11 Hex Nut

12 Diaphragm

13 Diaphragm Case (Bottom)

14 Bushing

15 Bearing

16 Dust Seal

17 Pointer

18 Yo ke

19 Stem Connector

20 Hex Bolt

21 Housing

22 Bearing

23 Spring Retainer

24 O-Ring

25 Seal Washer

26 Hex Bolt

27 Diaphragm Retainer

28 Stopper

29 Diaphragm Plate

30 Hex Bolt

31 Hex Nut

32 Spring

33 Spring Plate

34 Hex Bolt

35 Spring Washer