Page 1

DCP551 Mark

ΙΙ

DIGITRONIK

Digital Control Programmer

User's Manual

No. CP-SP-1032E

Thank you for purchasing an Azbil

Corporation product.

This manual contains information for

ensuring the correct use of this

product.

It also provides necessary information

for installation, maintenance, and

troubleshooting.

This manual should be read by those

who design and maintain equipment

that uses this product. Be sure to

keep this manual nearby for handy

reference.

(Not for use in Japan)

Page 2

Please, read the ‘Terms and Conditions’ from following URL before

the order and use.

http://www.azbil.com/products/bi/order.html

The DIGITRONIKTMis a trademark of Azbil Corporation in Japan.

NOTICE

© 1998-2016 Azbil Corporation All Rights Reserved.

Be sure that the user receives this manual before the product is used.

Copying or duplicating this user’s manual in part or in whole is forbidden. The information and specifications in this manual are subject to

change without notice.

Considerable effort has been made to ensure that this manual is free

from inaccuracies and omissions. If you should find an error or omission, please contact Azbil Corporation.

In no event is Azbil Corporation liable to anyone for any indirect, special

or consequential damages as a result of using this product.

Page 3

i

To reduce risk of electrical shock which could cause personal injury, follow all safety

notices in this documentation.

This symbol warns the user of a potential shock hazard where hazardous live voltages

may be accessible.

• If the equipment is used in a manner not specified by the manufacturer, the protection

protection provided by the equipment must be impaired.

• Do not replace any component (or part) not explicitly specified as replaceable by your

supplier.

• All wiring must be in accordance with local norms and carried out by authorized experienced

personnel.

• The ground terminal must be connected before any other wiring (and disconnect last).

•A switch in the main supply is required near the equipment.

• Mains power supply wiring requires a (T) 0.5A, 250V fuse(s).

DCP551 models sold in September 2013 or later have a built-in fuse.

Over-voltage:Category II (IEC60364-4-443, IEC60664-1)

Specification of common mode voltage:The common mode voltages of all I/O except for main

supply are less than 33Vrms, 46.7V peak and 70Vdc.

EQUIPMENT RA

TINGS

Supply voltages 85 to 264V AC

Frequency 50/60Hz

Power or current ratings 40VA maximum

EQUIPMENT CONDITIONS

Do not operate the instrument in the presence of flammable liquids or vapors. Operation of any

electrical instrument in such an environment constitutes a safety hazard.

Temperature: 0 to 50˚C

Humidity: 10 to 90%RH

Vibration: 2m/s

2

Over-voltage category: Category II (IEC60364-4-443, IEC60664-1)

Pollution degree: Pollution degree 2

Installation location: Indoors

Altitude: 2000m or less

EQUIPMENT INST

ALLATION

The controller must be mounted into a panel to limit operator access to the rear terminals.

STANDARDS COMPLIANCE

EN61010-1, EN61326-1 (For use in industrial locations)

During EMC testing, the reading or output may fluctuate by ±10 %FS.

However, PV reading is within ±30 %FS.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

SAFETY REQUIREMENTS

Page 4

■ About Icons

The safety precautions described in this manual are indicated by various icons.

Please be sure you read and understand the icons and their meanings described

below before reading the rest of the manual.

Safety precautions are intended to ensure the safe and correct use of this product, to prevent injury to the operator and others, and to prevent damage to property. Be sure to observe these safety precautions.

■ Examples

ii

SAFETY PRECAUTIONS

WARNING

Warnings are indicated when mishandling this

product might result in death or serious injury.

CAUTION

Cautions are indicated when mishandling this

product might result in minor injury to the user, or

only physical damage to the product.

Use caution when handling the product.

The indicated action is prohibited.

Be sure to follow the indicated instructions.

Page 5

iii

WARNING

CAUTION

Be sure to follow the operating requirements (regarding temperature,

humidity, voltage, vibration, shock, mounting direction, atmosphere, etc.) as

stated in the specifications of the controller.

Failure to heed this caution may lead to fire or malfunction.

Do not block ventilation openings.

Failure to heed this caution may lead to fire or malfunction.

Make sure that wire scraps, chips or water do not enter inside the case of the

controller.

Failure to heed this caution may lead to fire or malfunction.

Do not use pointed objects such as mechanical pencils or pins to press the

keys on the controller.

This may result in malfunction.

Connect the controller as specified using designated cables and connection

procedures.

Failure to heed this caution may lead to electric shock, fire or malfunction.

Current applied to current input terminals (55), (56) and (58), (59) must meet

the specified range.

Failure to heed this caution may lead to fire or equipment breakdown.

All terminal screws shall be tightened to specified torque.

Improperly tightened screws may lead to electric shock or fire.

Do not use unused terminals on the instrument as relay terminals for other

equipment. Failure to heed this caution may lead to electric shock, fire or

equipment breakdown.

Before removing, mounting, or wiring this module, be sure to turn off the

power to the module and all connected devices.

Doing so may result in an electric shock.

Do not disassemble the controller as this could lead to electric shock

or malfunction.

Connect the FG terminal to ground with a ground resistance of maximum

100Ω before connecting other equipment and external control circuits.

Failure to do so may cause electric shock or fire.

Be sure to turn off the power supply when you connect the controller.

Failure to do so may lead to electric shock or fire.

Do not touch a live part such as a power terminal.

This may result in electric shock.

Page 6

iv

CAUTION

Attaching the terminal covers after completing the controller connections is

highly recommended.

Failure to heed this caution may lead to fire or malfunction. (Terminal covers

are supplied with the controller.)

If there is a risk of a power surge caused by lightning, use a surge protector

to prevent fire or device failure.

Be sure to turn off the power supply when you are replacing the batteries.

Failure to heed this warning may lead to electric shock.

Be sure not to touch internal components during battery replacement or just

after the power has been turned.

This may result in burn injuries.

•

Make sure that the batteries are inserted with the plus (+) and minus (–)

poles correctly oriented.

•

Do not use damaged batteries or batteries that leak.

•

Do not throw batteries into a fire, recharge, disassemble or expose them to

heat.

•

Store batteries in a cool, dry place.

Failure to heed these cautions may result in burns or battery leakage.

Batteries should be kept out of reach of children, since they may swallow

them. Should a child swallow a battery, contact a doctor immediately.

When disposing of used batteries at the user site, observe local bylaws.

Before you touch internal components, be sure to discharge any static

electricity on your body by touching a metal ground connector.

Failure to heed this caution may lead to equipment damage.

Handling Precautions

After turning on the DCP551 mark ΙΙ, leave it for at least 10 seconds to let it

stabilize before you start using it.

Page 7

Organization of This User's Manual

v

This manual is organized as follows.

Chapter 1. PRODUCT OUTLINE

This chapter explains the use and features of the DCP551 and provides the basic

function block and product model numbers.

Chapter 2. NAMES AND FUNCTIONS OF PARTS

This chapter gives the names and functions of parts of the DCP551, and input

type and range number.

Chapter 3. INSTALLATION AND MOUNTINGS

This chapter describes the procedure for mounting the DCP551 onto an operation

console.

We strongly urge persons responsible for device design on the DCP551 read this

chapter.

Chapter 4. WIRING

This chapter describes the wiring procedure and precautions required for installing

the DCP551.

We strongly urge persons responsible for device design and wiring of the

DCP551 read this chapter.

Chapter 5. FUNCTIONS

This chapter explains detailed functions of the DCP551.

We strongly urge persons responsible for control design on the DCP551 read this

chapter.

Chapter 6. OPERATION

This chapter gives the selections of the basic display, program selection, operation,

and other information.

We strongly urge persons responsible for device design and operation on the

DCP551 read this chapter.

Chapter 7. PARAMETER SETUP

This chapter describes the parameter setting method of the DCP551 and the

meaning of settings.

Chapter 8. PROGRAM SETUP

This chapter describes the program setting method of the DCP551 and the

meaning of settings.

Chapter 9. MEMORY CARD OPERATION

This chapter describes how to use memory cards.

NOTE

This chapter is not applicable to the DCP551B***** model.

Chapter 10. MAINTENANCE AND TROUBLESHOOTING

This chapter describes checkpoints and countermeasures when the DCP551 is not

operating normally.

Chapter 11. DISPOSAL

This chapter describes the disposal of the DCP551.

Chapter 12. SPECIFICATIONS

This chapter gives the general specifications, performance specifications and the

external dimensions of the DCP551.

Page 8

vi

SAFETY REQUIREMENTS

SAFETY PRECAUTIONS

Organization of This User's Manual

Conventions Used in This Manual

Chapter 1. PRODUCT OUTLINE

1-1 Features •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••1-1

1-2 Basic Function Block Diagram•••••••••••••••••••••••••••••••••••••••••••••1-2

1-3 Data Configuration Overview ••••••••••••••••••••••••••••••••••••••••••••••1-3

1-4 System Configuration •••••••••••••••••••••••••••••••••••••••••••••••••••••1-4

■ CPL communications network-based configuration •••••••••••••••••••1-4

1-5 Model Number •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••1-5

Chapter 2. NAMES AND FUNCTIONS OF PARTS

2-1 Structure•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••2-1

2-2 Console••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••2-2

■ Basic display status •••••••••••••••••••••••••••••••••••••••••••••••••••2-2

■ Display •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••2-2

■ Key pad ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••2-4

■ Key chord functions •••••••••••••••••••••••••••••••••••••••••••••••••••2-6

■ Loader jack ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••2-7

2-3 Input Type and Range Number ••••••••••••••••••••••••••••••••••••••••••••2-8

■ Input •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••2-8

Chapter 3. INSTALLATION AND MOUNTING

3-1 Before Installation •••••••••••••••••••••••••••••••••••••••••••••••••••••••••3-1

■ Mounting position••••••••••••••••••••••••••••••••••••••••••••••••••••••3-1

■ Sources of electrical interference and countermeasures

••••••••••••••3-2

3-2 Installation

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••3-3

■ Panel cutout dimension ••••••••••••••••••••••••••••••••••••••••••••••••3-3

■ Installation procedures

••••••••••••••••••••••••••••••••••••••••••••••••3-4

Chapter 4. WIRING

4-1 Precautions on Wiring •••••••••••••••••••••••••••••••••••••••••••••••••••••4-1

4-2 Recommended Cables•••••••••••••••••••••••••••••••••••••••••••••••••••••4-3

4-3 Making Terminal Connections •••••••••••••••••••••••••••••••••••••••••••••4-4

4-4 Terminal Array

•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••4-5

4-5 Power Supply and Grounding

•••••••••••••••••••••••••••••••••••••••••••••4-6

Contents

Page 9

vii

■ Power supply ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••4-6

■ Grounding •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••4-6

4-6 PV Input (Analog Input) Connection •••••••••••••••••••••••••••••••••••••••4-7

■ PV input CH1 connection ••••••••••••••••••••••••••••••••••••••••••••••4-7

■ PV input CH2 connection ••••••••••••••••••••••••••••••••••••••••••••••4-7

4-7 Control Output Connection ••••••••••••••••••••••••••••••••••••••••••••••••4-9

■ Current output (5G, 5S) ••••••••••••••••••••••••••••••••••••••••••••••••4-9

■ Voltage output (6D) ••••••••••••••••••••••••••••••••••••••••••••••••••••4-9

■ Open collector output (8D) •••••••••••••••••••••••••••••••••••••••••••••4-9

4-8 Auxiliary Output (Output CH1, CH2) Connection •••••••••••••••••••••••••4-10

■ Auxiliary output CH1 connection •••••••••••••••••••••••••••••••••••••4-10

■ Auxiliary output CH2 connection •••••••••••••••••••••••••••••••••••••4-10

4-9 Event Output (Open Collector Output) Connection•••••••••••••••••••••••4-11

4-10 External Switch Input Connection ••••••••••••••••••••••••••••••••••••••••4-12

4-11 Communication Connection••••••••••••••••••••••••••••••••••••••••••••••4-13

■ RS-485 connection••••••••••••••••••••••••••••••••••••••••••••••••••••4-13

■ RS-232C connection ••••••••••••••••••••••••••••••••••••••••••••••••••4-16

■ Connection to ST221 •••••••••••••••••••••••••••••••••••••••••••••••••4-17

4-12 Isolation During Input/Output•••••••••••••••••••••••••••••••••••••••••••••4-18

Chapter 5. FUNCTIONS

5-1 Data••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-1

■ Data types••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-1

5-2 Program Pattern •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-2

■ Pattern •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-2

■ Events •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-5

■ PID group selection •••••••••••••••••••••••••••••••••••••••••••••••••••5-16

■ Selection of output limiter group •••••••••••••••••••••••••••••••••••••5-16

■ G.SOAK (Guarantee soak) ••••••••••••••••••••••••••••••••••••••••••• 5-17

■ PV shift •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-18

■ Repeat ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-19

■ PV start •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-20

■ Cycle••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-21

■ Pattern link •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-22

■ Tag••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-23

5-3 Mode •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-24

■ Mode types •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-24

■ Mode transitions ••••••••••••••••••••••••••••••••••••••••••••••••••••••5-26

■ Mode transition operations •••••••••••••••••••••••••••••••••••••••••••5-27

■ Mode transition restrictions ••••••••••••••••••••••••••••••••••••••••••5-28

5-4 Controllers and Programmers••••••••••••••••••••••••••••••••••••••••••••5-29

5-5 Input Process Functions •••••••••••••••••••••••••••••••••••••••••••••••••5-30

■ PV input 1 channel model•••••••••••••••••••••••••••••••••••••••••••••5-30

■ PV input 2 channel model•••••••••••••••••••••••••••••••••••••••••••••5-31

■ Channel switching (PV input 2 channel model) •••••••••••••••••••••• 5-32

5-6 Output Processing Functions ••••••••••••••••••••••••••••••••••••••••••••5-37

Page 10

viii

■ Control output ••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-37

■ SP output •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••5-39

■ Auxiliary output•••••••••••••••••••••••••••••••••••••••••••••••••••••••5-39

Chapter 6. OPERATION

6-1 Power Supply On ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••6-1

6-2 Basic Display Selection••••••••••••••••••••••••••••••••••••••••••••••••••••6-2

■ Program run mode displays •••••••••••••••••••••••••••••••••••••••••••6-3

■ Constant value control mode ••••••••••••••••••••••••••••••••••••••••••6-6

6-3 Selecting Programs••••••••••••••••••••••••••••••••••••••••••••••••••••••••6-7

■ Selecting program numbers •••••••••••••••••••••••••••••••••••••••••••6-7

6-4 External Switch Operation •••••••••••••••••••••••••••••••••••••••••••••••••6-8

■ External switch input ••••••••••••••••••••••••••••••••••••••••••••••••••6-8

■ Selecting programs ••••••••••••••••••••••••••••••••••••••••••••••••••••6-9

■ Read timing •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••6-11

6-5 Manual Operation and Auto-Tuning ••••••••••••••••••••••••••••••••••••••6-12

■ Manual operation •••••••••••••••••••••••••••••••••••••••••••••••••••••6-12

■ Auto-tuning (AT) ••••••••••••••••••••••••••••••••••••••••••••••••••••• 6-12

Chapter 7. PARAMETER SETUP

7-1 Parameter Setup•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••7-1

■ Selecting parameter settings groups ••••••••••••••••••••••••••••••••••7-1

■ Progression of individual items in parameter settings •••••••••••••••••7-1

■ Modifying individual items and exiting the setting mode ••••••••••••••7-2

7-2 Parameter Setting List •••••••••••••••••••••••••••••••••••••••••••••••••••••7-4

■ Variable parameter setting •••••••••••••••••••••••••••••••••••••••••••••7-5

■ Detailed information on variable parameters•••••••••••••••••••••••••••7-9

■ Event configuration data settings ••••••••••••••••••••••••••••••••••••7-12

■ Settings by event type ••••••••••••••••••••••••••••••••••••••••••••••••7-13

■ PID parameter setting•••••••••••••••••••••••••••••••••••••••••••••••••7-18

■ Setup data setting ••••••••••••••••••••••••••••••••••••••••••••••••••••7-21

■ Detailed descriptions of setup data settings ••••••••••••••••••••••••••7-28

■ Constant value control data setting•••••••••••••••••••••••••••••••••••7-34

Chapter 8. PROGRAM SETUP

8-1 Program Setup•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••8-1

■ Selecting number of program to operate•••••••••••••••••••••••••••••••8-1

■ Starting programming •••••••••••••••••••••••••••••••••••••••••••••••••8-2

■ State transition•••••••••••••••••••••••••••••••••••••••••••••••••••••••••8-2

■ Programming map •••••••••••••••••••••••••••••••••••••••••••••••••••••8-4

■ Display items ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••8-5

■ Setting pattern items •••••••••••••••••••••••••••••••••••••••••••••••••••8-5

Page 11

ix

■ Setting event items

••••••••••••••••••••••••••••••••••••••••••••••••••••8-7

■ Setting PID groups and output limiter group number items ••••••••••8-12

■ Setting G.SOAK (Guarantee soak) items••••••••••••••••••••••••••••••8-13

■ Setting PV shift items •••••••••••••••••••••••••••••••••••••••••••••••••8-14

■ Setting repeat items ••••••••••••••••••••••••••••••••••••••••••••••••••8-15

■ Setting PV start items•••••••••••••••••••••••••••••••••••••••••••••••••8-16

■ Setting cycle items •••••••••••••••••••••••••••••••••••••••••••••••••••8-17

■ Setting pattern link items •••••••••••••••••••••••••••••••••••••••••••••8-18

■ Setting tag items••••••••••••••••••••••••••••••••••••••••••••••••••••••8-19

■ Deleting programs ••••••••••••••••••••••••••••••••••••••••••••••••••••8-20

■ Inserting and deleting segments••••••••••••••••••••••••••••••••••••••8-21

8-2 Copying Programs •••••••••••••••••••••••••••••••••••••••••••••••••••••••8-23

■ Program copy procedures ••••••••••••••••••••••••••••••••••••••••••••8-23

8-3 General Reset ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••8-24

■ General reset procedures •••••••••••••••••••••••••••••••••••••••••••••8-24

Chapter 9. MEMORY CARD OPERATIONS

9-1 Memory Card Type and Functions•••••••••••••••••••••••••••••••••••••••••9-1

9-2 Save Procedures•••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9-2

■ Save menu •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9-2

■ Procedures for formatting cards •••••••••••••••••••••••••••••••••••••••9-3

■ Procedures for saving single programs••••••••••••••••••••••••••••••••9-3

■ Procedures for saving all programs •••••••••••••••••••••••••••••••••••9-4

■ Procedures for saving setup data ••••••••••••••••••••••••••••••••••••••9-4

■ Procedures for saving variable parameters ••••••••••••••••••••••••••••9-4

■ Procedures for saving PID parameters•••••••••••••••••••••••••••••••••9-5

■ Procedures for saving event configuration data •••••••••••••••••••••••9-5

■ Procedures for saving all parameters ••••••••••••••••••••••••••••••••••9-5

9-3 Load Procedures ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9-6

■ Load menu •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9-6

■ Card battery alarm panel •••••••••••••••••••••••••••••••••••••••••••••••9-7

■ Procedures for loading individual programs •••••••••••••••••••••••••••9-7

■ Procedures for loading all programs•••••••••••••••••••••••••••••••••••9-8

■ Procedures for loading setup data •••••••••••••••••••••••••••••••••••••9-8

■ Procedures for loading variable parameters •••••••••••••••••••••••••••9-8

■ Procedures for loading PID parameters ••••••••••••••••••••••••••••••••9-8

■ Procedures for loading event configuration data ••••••••••••••••••••••9-9

■ Procedures for loading all parameters •••••••••••••••••••••••••••••••••9-9

9-4 Autoload••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••9-10

■ Key operated autoload procedure ••••••••••••••••••••••••••••••••••••9-10

■ Auto load using external switch inputs •••••••••••••••••••••••••••••••9-11

9-5 Error Message List •••••••••••••••••••••••••••••••••••••••••••••••••••••••9-12

Page 12

x

Chapter 10. MAINTENANCE AND TROUBLESHOOTING

10-1 Self-Diagnostic Functions and Alarm Code Displays•••••••••••••••••••••10-1

■ Maintenance ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••10-1

■ Power ON self-diagnostic routines •••••••••••••••••••••••••••••••••••10-1

■ Self-diagnostic routines performed each sampling cycle •••••••••••••10-1

■ Self-diagnostic routines performed continuously during operation ••10-1

■ Alarm code display •••••••••••••••••••••••••••••••••••••••••••••••••••10-2

■ Alarm classification•••••••••••••••••••••••••••••••••••••••••••••••••••10-2

■ Display behavior and alarm code upon input burnout ••••••••••••••••10-2

10-2 Key Input Related Problemst •••••••••••••••••••••••••••••••••••••••••••••10-3

■ Normal display mode problems•••••••••••••••••••••••••••••••••••••••10-3

■ Parameter setting related problems ••••••••••••••••••••••••••••••••••10-6

■ Program setting related problems ••••••••••••••••••••••••••••••••••••10-6

10-3 When the BAT LED Flashes ••••••••••••••••••••••••••••••••••••••••••••••10-8

■ BAT LED flashes••••••••••••••••••••••••••••••••••••••••••••••••••••••10-8

■ Replacing the battery •••••••••••••••••••••••••••••••••••••••••••••••••10-8

Chapter 11. DISPOSAL

Chapter 12. SPECIFICATIONS

12-1 Specifications ••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••12-1

■ Attachment/auxiliary devices list •••••••••••••••••••••••••••••••••••••12-7

12-2 External Dimensions •••••••••••••••••••••••••••••••••••••••••••••••••••••12-8

■ DCP551 •••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••12-8

Program Work Sheet

Parameter Work Sheet

Index

Page 13

Conventions Used in This Manual

xi

The following conventions are used in this manual.

Handling Precautions

: Handling Precautions indicate items that the user should pay attention

to when handling the DCP551.

NOTE : Notes indicate useful information that the user might benefit by

knowing.

(1), (2), (3) : The numbers with the parenthesis indicate steps in a sequence or

indicate corresponding parts in an explanation.

>> : Indicates the result of an operation, details displayed on the personal

computer or other devices, or the state of the device after operation.

DISP key, key : Indicate this product’s keys. These icons represent keys on the

DCP551’s console.

FUNC+PROG key : Combinations of icons like this indicatate that PROG key must be

pressed while holding FUNC key down.

PA01, C21 : Indicate the 7 segments display of display panel 1 and display panel 2

on this product.

PV SHIFT : Indicates the display of the message display on this product.

Page 14

Page 15

Chapter 1. PRODUCT OUTLINE

1 - 1 Features

The DCP551 is a general purpose single-loop control programmer for controlling temperature, pressure, flow rate

and other parameters. The program provides a total of 99 patterns and up to 99 segments can be set for each

pattern. Note, however, that the maximum number of segments is 2000 or less and that the maximum number of

subfunctions for setting events is 4000 or less.

● High accuracy in multi-range inputs

Featuring a multi-range format, the user can select thermocouple, resistance

temperature detector, DC voltage or DC current. Accuracy is ±0.1% FS ±1 digit,

the sampling cycles is 0.1 sec and some model numbers allow PV2 channel

switching.

● Multi-control output types

Selection at setup allows the user to choose from among current proportional

setting output, current proportional output, voltage time proportional output and

open collector time proportional output.

● Multi-communications

Selection at setup enables the user to switch between RS-485 and RS-232C on the

rear panel terminal base.

At setup it is also possible to switch the communications port from the rear panel

terminal base to the front panel loader jack. A special cable is required to use to

terminal base on the front panel.

● Improved PLC support

The programmer is equipped with 16 external switch inputs and 16 event outputs

for flexible support of PLC based automatic systems.

● Simple operation

The optional plug-in memory card makes it easy to achieve program and

parameter settings for later reuse. Also, the optional smart loader package allows

you to make program and parameter settings from a PC.

1-1

Page 16

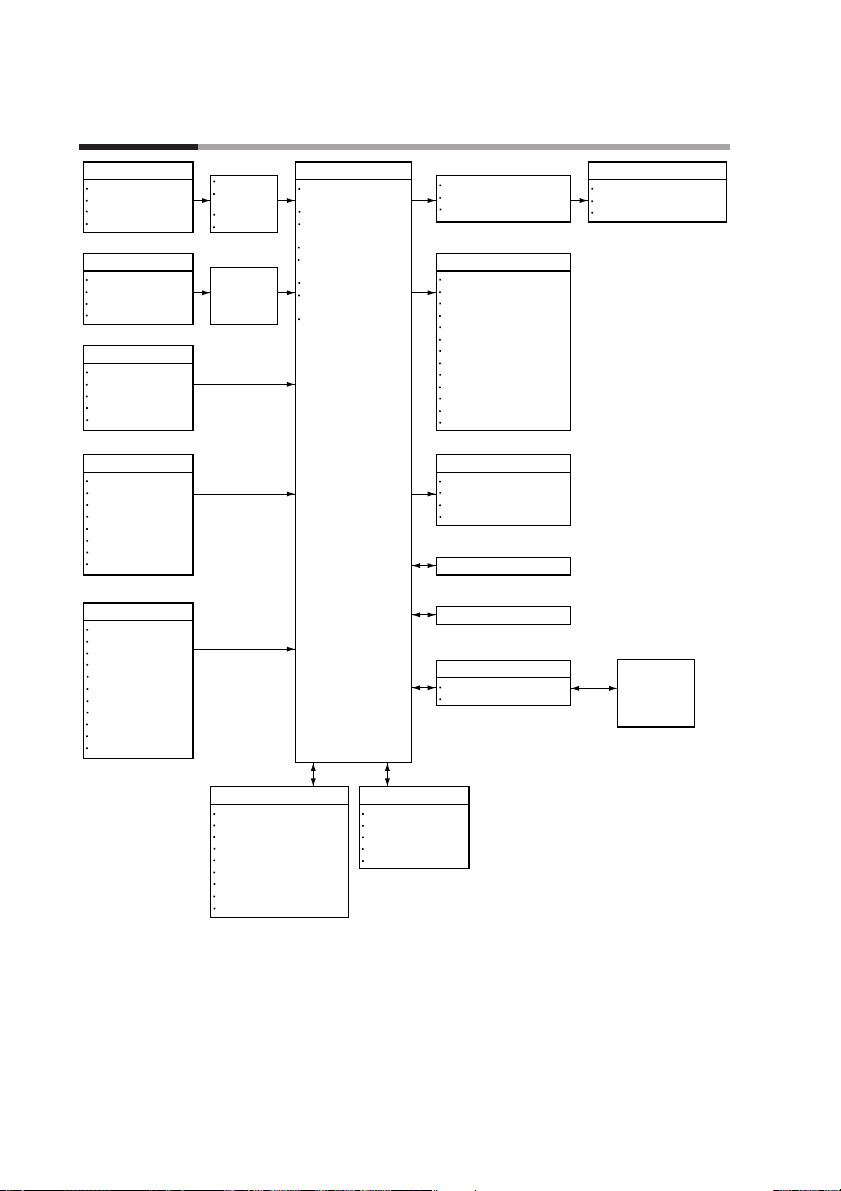

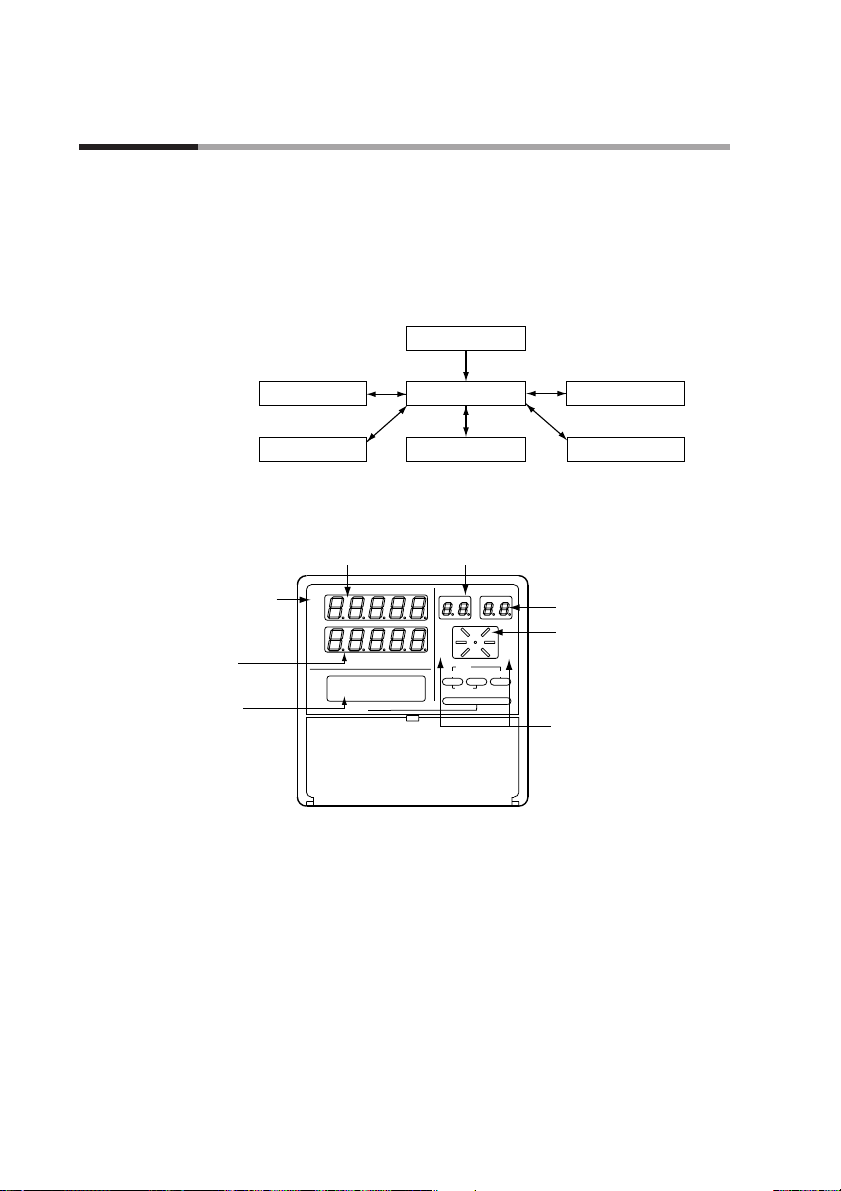

1 - 2 Basic Function Block Diagram

1-2

Chapter 1. PRODUCT OUTLINE

Input 1

Thermocouple

Resistance temperature detector

DC current

DC voltage

Input 2

Thermocouple

Resistance temperature detector

DC current

DC voltage

External switch input: 12 points

RUN

HOLD

RESET

ADV

Program No.

External switch input: 4 points

FAST

RAMP-E

AUTO/MANUAL

AT

G.SOAK reset

Forward-reverse operation

Auto load

PV1/PV2 selection

Key operation

Display selection

Program No.

RUN/HOLD

RESET

ADV

FAST

AUTO/MANUAL

AT

Program setting

Parameter setting

Memory card operation

Root extraction

Approximation by

linearization table

Bias

Filter

•

Root extraction

•

Approximation by

linearization table

•Bias

•Filter

Control operation unit

Mode transition

PID control

Auto tuning

Forward-reverse operation

ON-OFF control

SP limit

SP bias

PV2 channel selection

Output change limit

Upper and lower limit

SP output

Event output : 16 points

Time event

PV

SP

Deviation

MV

Code

Code with a timer

Each mode

Alarm

Segment No. code

Specific segment

Program No. code

PV change rate

Auxiliary output : 1 point/2 points

PV

SP

Deviation

MV

RS-485/RS-232C communication input/output

Loader communication input/output

Memory card

Program

Parameter

Output

Current proportionality

Volt-time proportionality

Open collector time proportionality

*

1

*

1

*

2

Memory Card

Reader Writer

+

Smart Loader

Package

*2*

3

Program Parameter

99 pattern X 99 segment

Event

PID group/output limiter group

G.SOAK

PV shift

Repeat

PV start

Cycle

Pattern link

Variable parameter

Event configuration

PID parameter

Setup

Constant value control

*

1 : Option for some models

*

2 : Option

*

This function is available on the

3 :

model only.

DCP551A

*****

Page 17

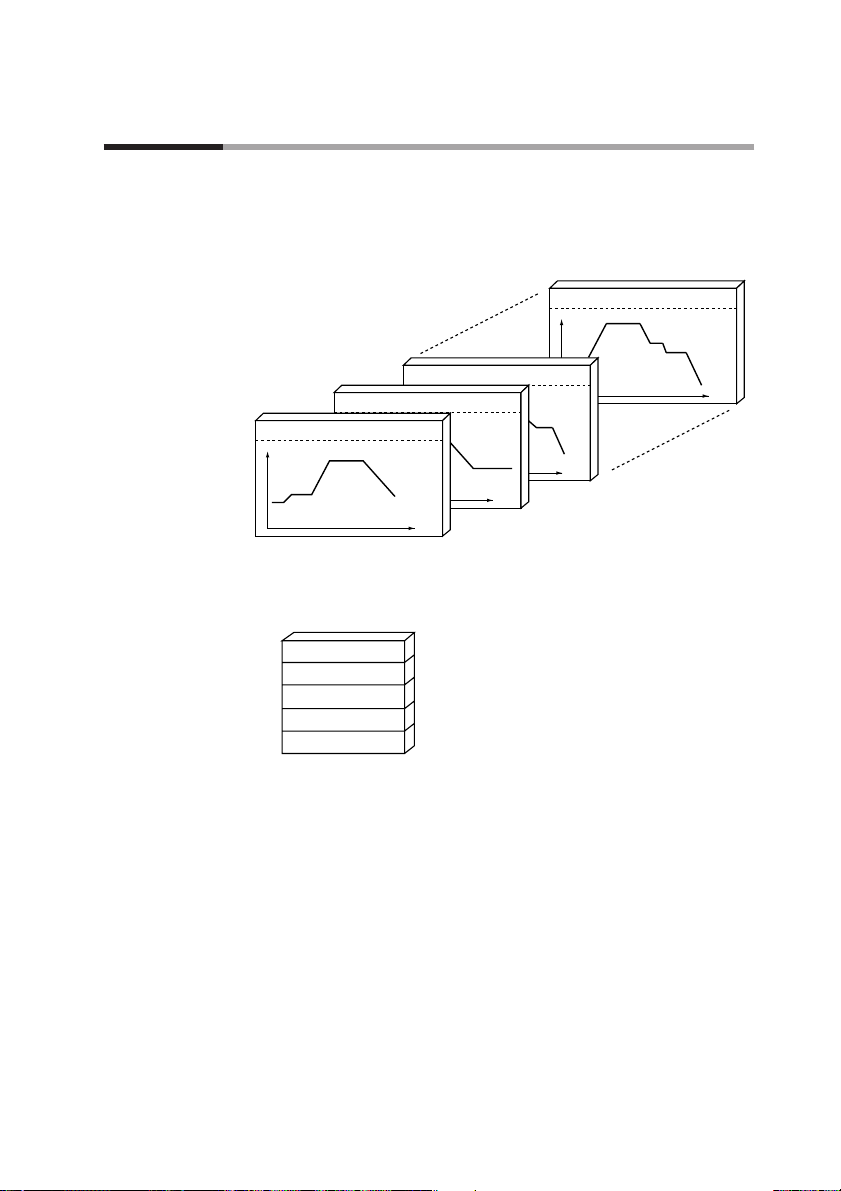

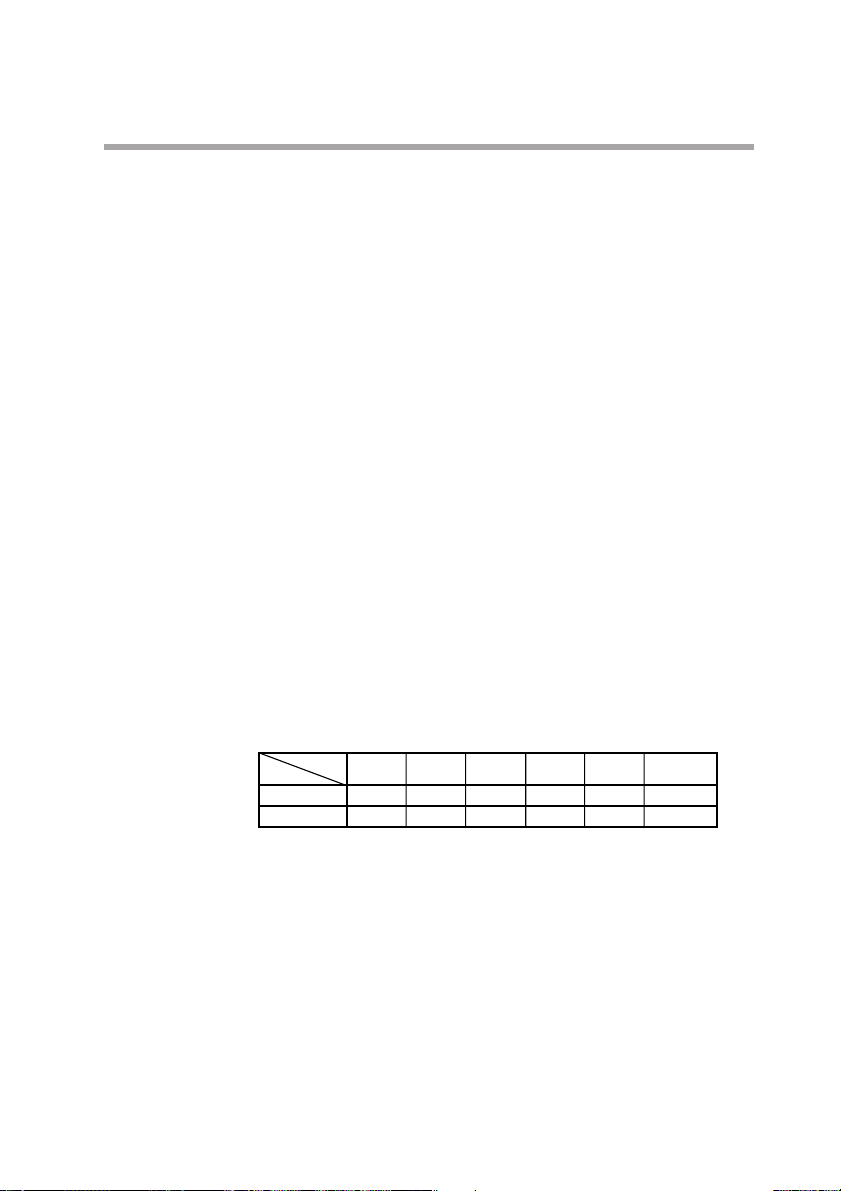

1 - 3 Data Configuration Overview

Data is comprised of parameters and the program.

Parameters are used to set the functions of the DCP551 while the program is the software that operates the

controller at run time.

● A total of 99 patterns

The program can record up to 99 patterns.

● Parameters

Five types of patterns are provided: variable parameters, event configuration data,

PID parameters, setup data and constant value control data.

1-3

Chapter 1. PRODUCT OUTLINE

Program number = 99 Segment count = 8

SP

Time

Program number = 3 Segment count = 15

Time

Program number = 2 Segment count = 19

SP

Time

Program number = 1 Segment count = 6

SP

Time

(1)

(2)

(3)

(4)

(5)

(6)

(18)

(19)

13)

(14)

(15)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Variable parameter

Event configuration data

PID parameter

Setup data

Constant valule control data

Page 18

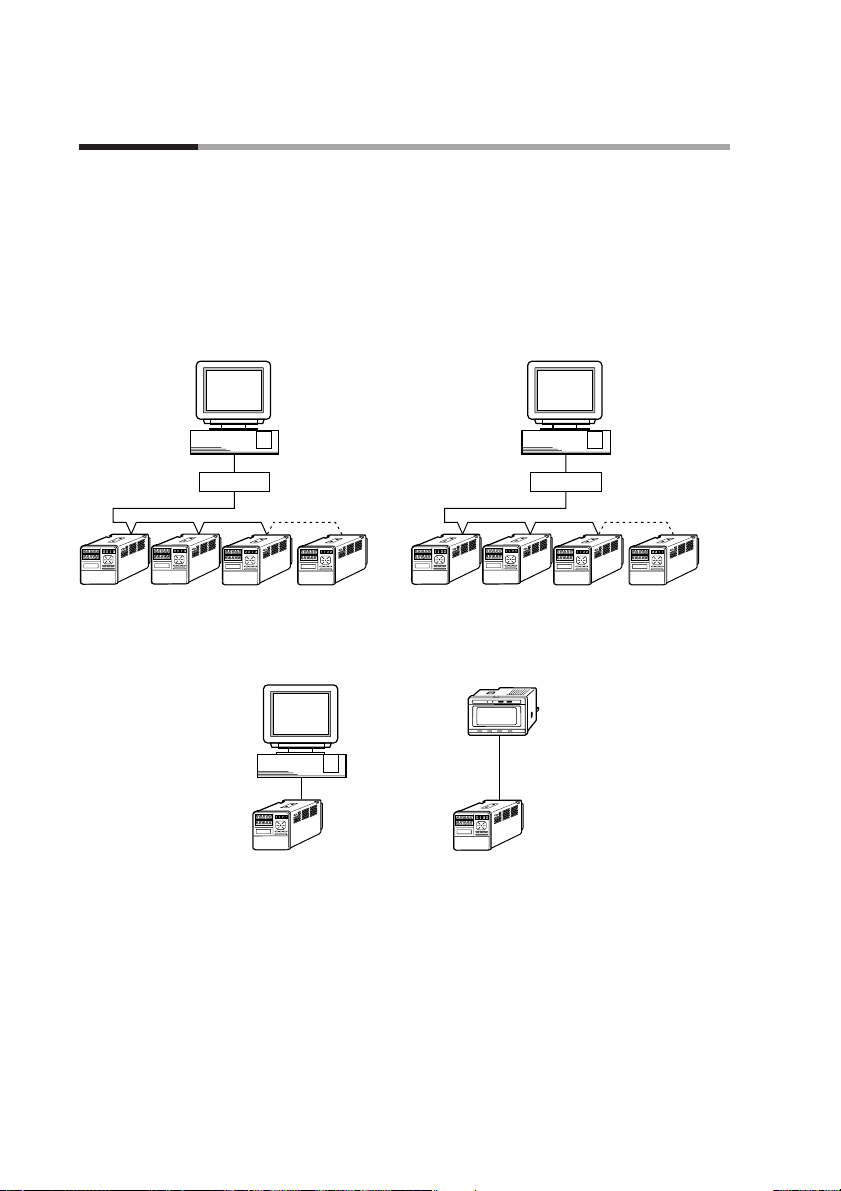

1 - 4 System Configuration

1-4

■ CPL communications network-based configuration

Models equipped with the optional communications interface can be connected as

a slaved DigitroniK’s controller to a CPL communications* network. In this case,

the user can employ as the master station a personal computer.

*: CPL(Controller Peripheral Link) Communications network is the host-

communications.

Chapter 1. PRODUCT OUTLINE

PC

PC PC

RS-232C

DCP551

(slave station)

DCP551

(slave station)

ST221DE05DCP (Smart Terminal dedicated display)

(slave station)

RS-485

DCP551 (master station)

RS-232C/RS-485 converter CMC10L001A000

RS-485 (5-wire system)

RS-485 Connection example

RS-485 (3-wire system)

*

* "Communication controller CMC10L001A000" is

RS-232C/RS-485(3-wire system) converter in Azbil corporation.

Page 19

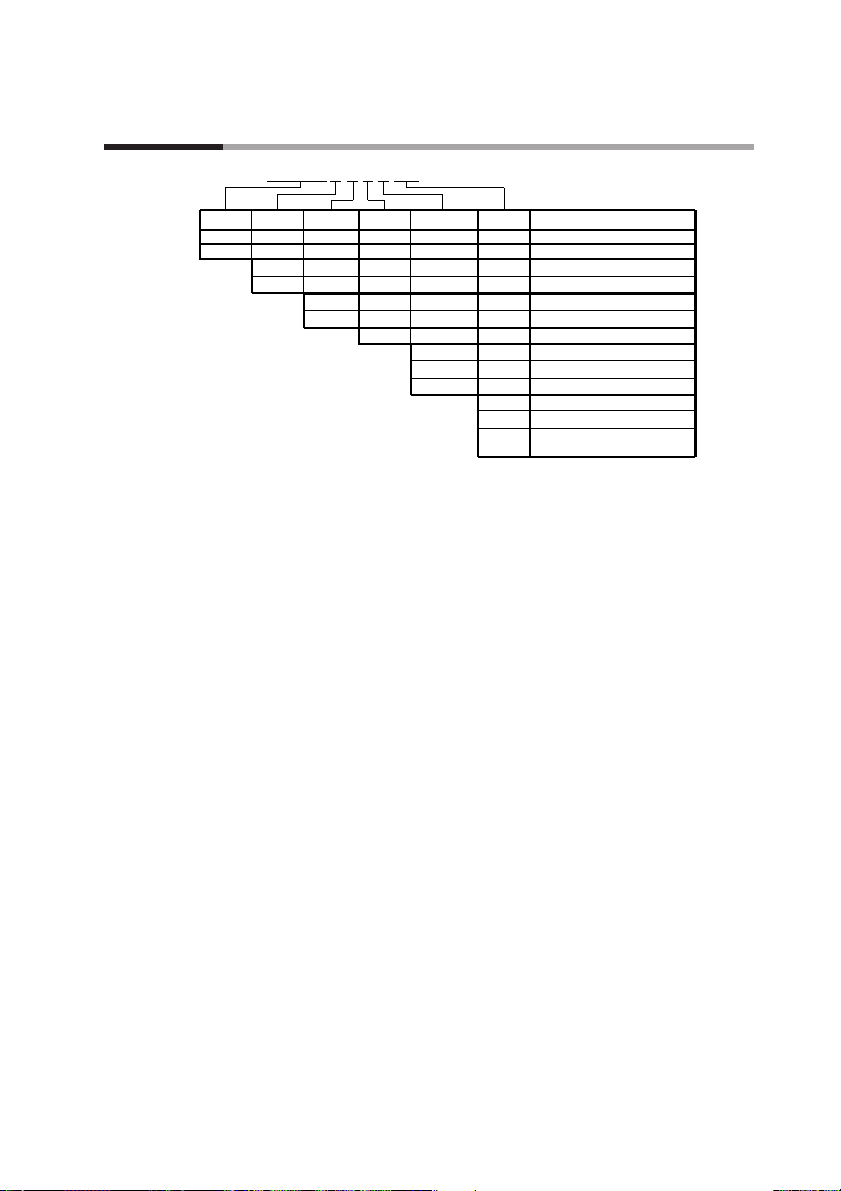

1 - 5 Model Number

1-5

Chapter 1. PRODUCT OUTLINE

Basic mode

l

number

PV input

count

Additional

number

Memory

card

Additional

processing

Option

A

B

1

2

0

0

1

2

00

D0

Y0

DCP551

Contents

Digital programmable controlle

r

With memory card reader/writer

Without memory card reader/write

r

PV input 1 channel

PV input 2 channel

Fixed 0

Not provided

Auxiliary output 1 channel

Auxiliary output 2 channel, communication

Not provided

Inspection certificate provided

Model number :

DCP551✽ ✽ 0 ✽ ✽ ✽

Complying with the traceability

certification

✽✽ ✽✽✽✽

Page 20

Page 21

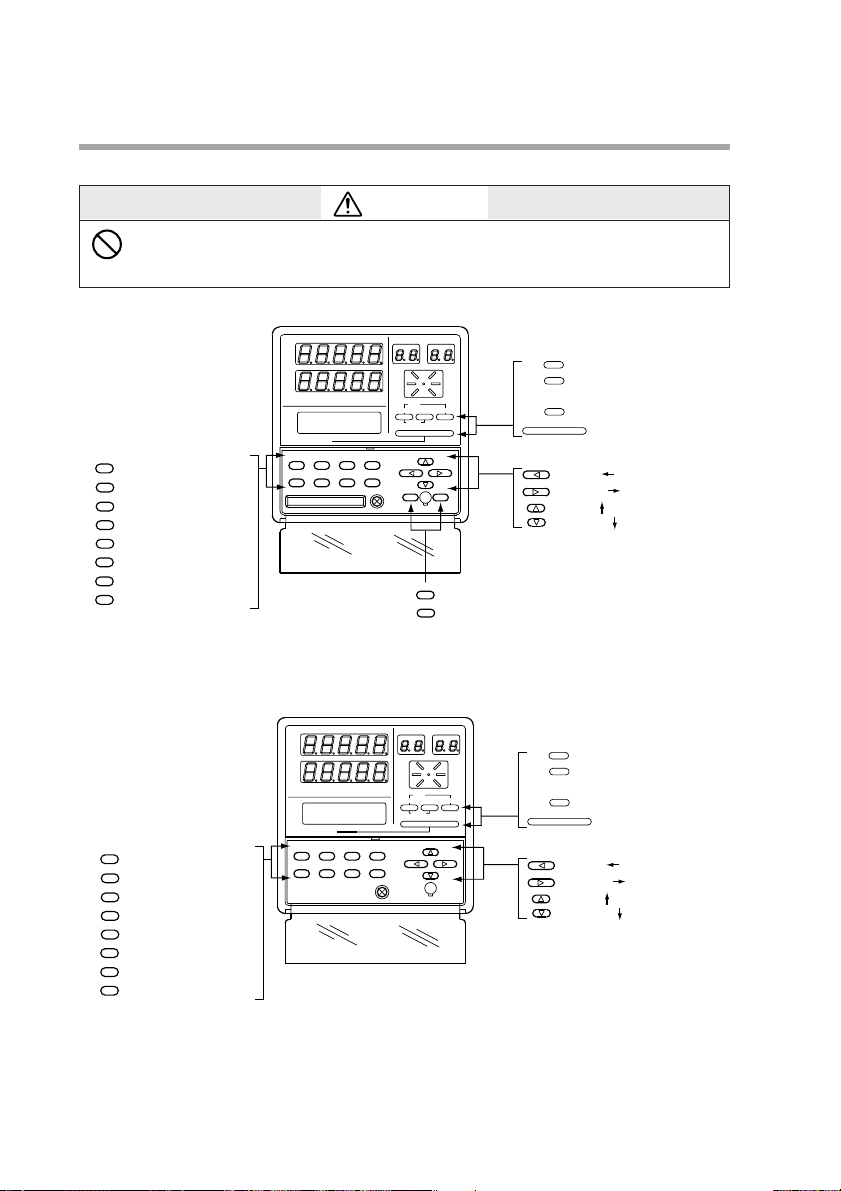

Chapter 2.

NAMES AND FUNCTIONS OF PARTS

2 - 1 Structure

The DCP551 consists of a main unit, console, case, and terminal base.

DCP551A model DCP551B model

2-1

Console

Provides 7-segment displays, LEDs, operation keys,

and a loader interface unit.

Terminal base

Provides terminals to connect a power supply,

input, output, event output, external switch input,

and auxiliary output (optional) , etc.

Case

Main unit

Console and electric circuit board, etc.

Terminal cover

Covers power supply and

prevents electric shock.

FUNC AT SETUP ENTER

A/M PID PARA CLR

CARD

LOAD SAVE

LOADER

CYC

OUT

DEV

PV

SP

TM

SYN

RUN

HLD

MAN

PRG

AT

BAT

EG1

EG2

PROG RUN/HOLD DISP

RESET

PROG SEG

PROFILE

MESSAGE

MESSAGE

ADV

Lock screw

Secures case

to main unit.

Key cover

Prevents operation errors.

Memory card slot

A memory card is inserted into this slot.

PV

DEV

OUT

CYC

SP

TM

SYN

A/M PID PARA CLR

FUNC AT SETUP ENTER

MESSAGE

PROG SEG

PROFILE

RUN

HLD

MAN

PRG

ADV

PROG RUN/HOLD DISP

RESET

MESSAGE

LOADER

AT

BAT

EG1

EG2

Page 22

2 - 2 Console

2-2

The console consists of the operation keys, displays and LEDs (light emitting diodes).

■ Basic display status

Basic display status shows the running condition of the DCP551 on the console.

The basic display status is invoked when the DCP551 is powered up (power on).

Key operations make it possible to change from the basic display status to

parameter setting status, program setting status, program copy status, memory card

operation status* and general reset status.

Key operations can also be used to return to the basic display status.

* : This function is available on the DCP551A***** model only.

■ Display

● Basic display contents LED

PV : Lights during PV display, otherwise off.

DEV : Lights during deviation display, otherwise off.

OUT : Lights during output display, otherwise off.

CYC : Lights during cycle display, otherwise off.

SP : Lights during SP display, otherwise off.

TM : Lights during time display, otherwise off.

SYN : Off

Chapter 2. NAMES AND FUNCTIONS OF PARTS

Power on

Parameter setting status

Program setting status

Program copy status

Memory card operation status

General reset status

Basic display status

*

CYC

OUT

DEV

PV

SP

TM

SYN

RUN

HLD

MAN

PRG

AT

BAT

EG1

EG2

PROG RUN/HOLD DISP

RESET

PROG SEG

PROFILE

MESSAGE

MESSAGE

ADV

Display panel 1

(Upper display)

Program number display

(PROG display)

Segment number display

(SEG display)

Profile display

Mode display LED

Message display

LCD

(16 characters X 2 lines)

Display panel 2

(Lower display)

Basic display contents

LED

Page 23

2-3

● Display panel 1

Indicates PV and other data in basic display status.

Indicates item codes in parameter setting status.

Indicates set values and item codes in program setting status.

● Display panel 2

Indicates SP, time, output and other data in basic display status.

Indicates set values in parameter setting status.

Indicates set values in program setting status.

● Message display

Indicates output graph, deviation graph, running progress graph, event status,

program tag and other data in basic display status.

Displays reference messages in parameter setting status.

Displays tag settings and reference messages in program setting status.

Indicates selected operation and operation results during memory card

operation.

● Program number display

Indicates a selected program number in basic display status.

Indicates a set program number in program setting status.

Off during constant value control.

Indicates the alarm code “AL” when an alarm occurs in basic display status.

● Segment number display

Indicates a selected segment number in basic display status.

Indicates a set segment number in program setting status.

Off during constant value control.

Indicates an alarm code number when an alarm occurs in basic display status.

● Mode display LED

RUN, HLD : Indicates the RUN, HOLD, FAST, END, and READY FAST

modes (see the table below).

MAN : Lights in MANUAL mode. Off in AUTO mode.

PRG : Lights in program setting status, otherwise off.

AT : Flickers during auto tuning execution, otherwise off.

BAT : Flickers when battery voltage is too low, otherwise off.

EG1, EG2 : Lights when an event number output set by PA41 or PA42 is

set to ON setting. Off when set to OFF.

● Profile display

Indicates the rising, soaking, and falling trends of a program pattern.

Flickers during G.SOAK wait and lights continuously after power on.

Chapter 2. NAMES AND FUNCTIONS OF PARTS

Mode

LED

RUN

HLD

OFF

OFF

READY

Lights

OFF

RUN

OFF

Lights

HOLD

Flicker

OFF

FAST

OFF

Flickers

END

Lights

Lights

READY FAST

Page 24

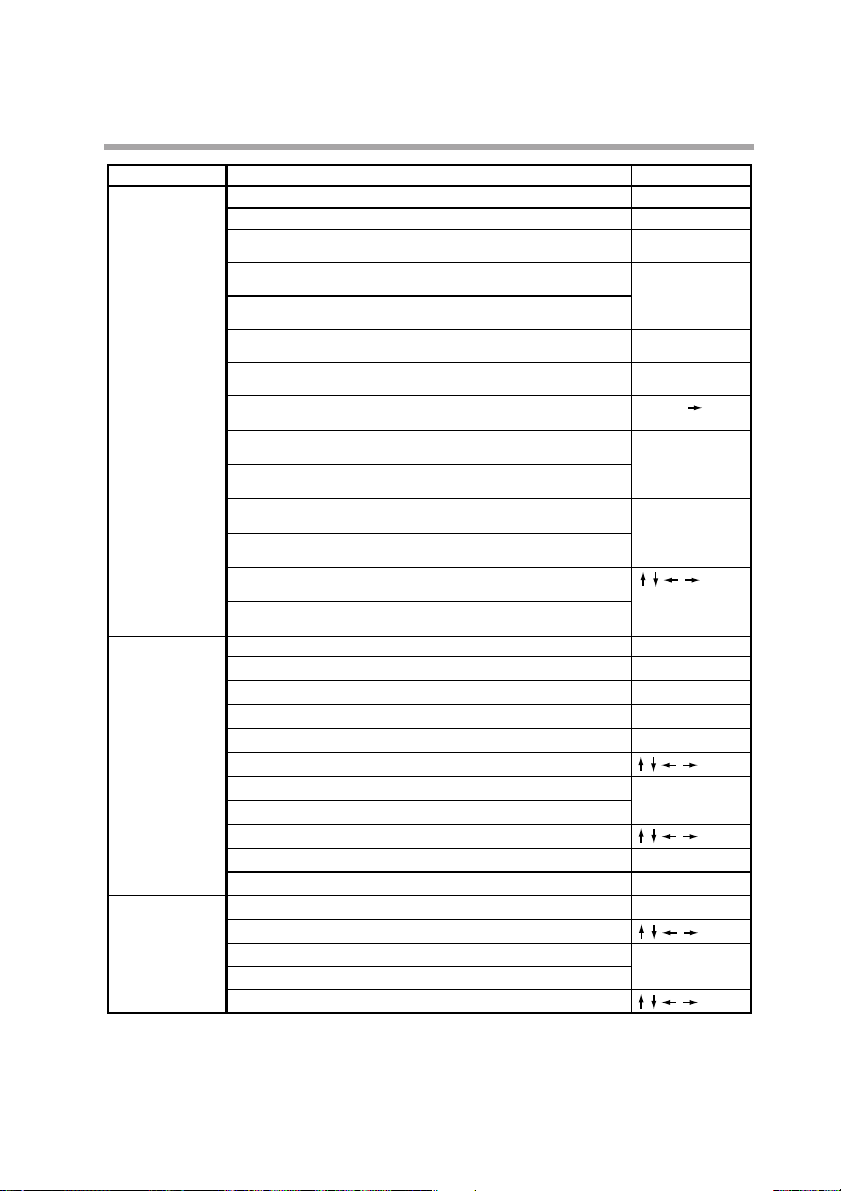

2-4

■ Key pad

DCP551A model

DCP551B model

Chapter 2. NAMES AND FUNCTIONS OF PARTS

FUNC AT SETUP ENTER

A/M PID PARA CLR

CARD

LOAD SAVE

LOADER

CYC

OUT

DEV

PV

SP

TM

SYN

RUN

HLD

MAN

PRG

AT

BAT

EG1

EG2

PROG RUN/HOLD DISP

RESET

PROG SEG

PROFILE

MESSAGE

MESSAGE

ADV

: Program key (PROG key)

: Run/hold key

(RUN/HOLD key)

: Display key (DISP key)

: Message key

(MESSAGE key)

PROG

RUN/HOLD

DISP

MESSAGE

: Left key ( key)

: Right key ( key)

: Up key ( key)

: Down key ( key)

: Load key (LOAD key)

: Save key (SAVE key)

LOAD

SAVE

: Auto/manual key (A/M key)

: PID key (PID key)

: Parameter key (PARA key)

: CLR key (CLR key)

: Function key (FUNC key)

: Auto tuning key (AT key)

: Setup key (SETUP key)

: Enter key (ENTER key)

A/M

PID

PARA

CLR

FUNC

AT

SETUP

ENTER

( ) : Denotes key term used in this manual.

CAUTION

Do not use pointed objects such as mechanical pencils or pins to press the

keys on the controller.

This may result in malfunction.

A/M

PID

PARA

CLR

FUNC

SETUP

ENTER

: Auto/manual key (A/M key)

: PID key (PID key)

: Parameter key (PARA key)

: CLR key (CLR key)

: Function key (FUNC key)

AT

: Auto tuning key (AT key)

: Setup key (SETUP key)

: Enter key (ENTER key)

PV

DEV

OUT

CYC

SP

TM

SYN

MESSAGE

A/M PID PARA CLR

FUNC AT SETUP ENTER

( ) : Denotes key term used in this manual.

PROG SEG

PROFILE

RUN

HLD

MAN

PRG

ADV

PROG RUN/HOLD DISP

RESET

MESSAGE

LOADER

AT

BAT

EG1

EG2

PROG

: Program key (PROG key)

RUN/HOLD

: Run/hold key

(RUN/HOLD key)

DISP

: Display key (DISP key)

MESSAGE

: Message key

(MESSAGE key)

: Left key ( key)

: Right key ( key)

: Up key ( key)

: Down key ( key)

Page 25

2-5

Chapter 2. NAMES AND FUNCTIONS OF PARTS

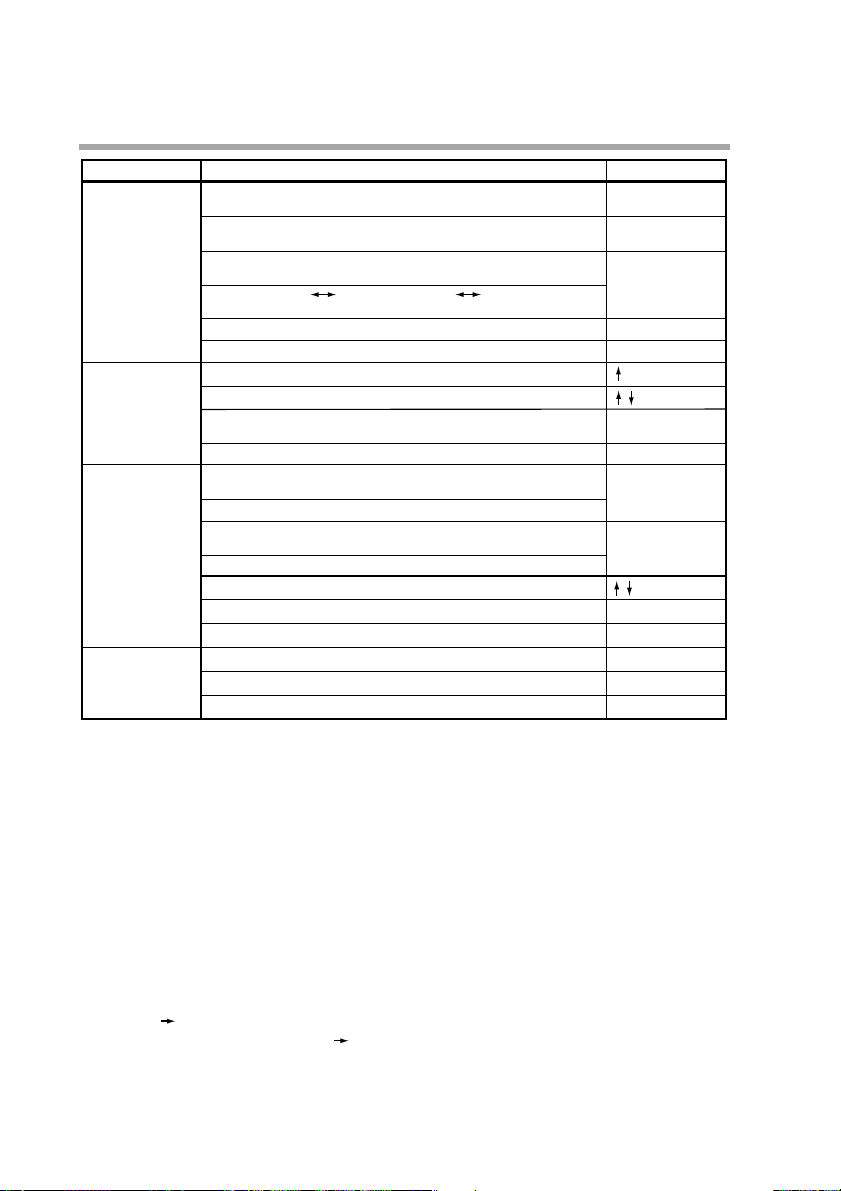

Classification

Basic display

status

Parameter setting

Program setting

Changes the display contents.

Key operation

DISP

Changes the display contents on the message display.

MESSAGE

PROGChanges set program numbers in ascending order.

(In READY mode)

RUN/HOLD

Performs RUN operation.

(In READY, HOLD, FAST, or READY FAST mode)

Performs HOLD operation.

(In RUN mode)

PROG + RUN/HOLD

Performs RESET operation.

(In RUN, HOLD, FAST, END, or READY FAST mode)

PROG + DISP

Performs ADV operation.

(In RUN, HOLD, FAST, or READY FAST mode)

FUNC +

Performs FAST operation.

(In RUN, HOLD, or READY mode)

A/M

Performs MANUAL operation.

(In AUTO mode)

Performs AUTO operation.

(In MANUAL mode)

AT

Starts auto tuning.

(When auto tuning is not in operation.)

Interrupts auto tuning

(When auto tuning is in operation.)

Changes numerics during MANUAL operation.

(When the MV or SV display flickers.)

Changes program numbers or segment numbers.

(When the program number or segment number flickers.)

PARAStarts the variable parameter setting. (In basic display status)

FUNC + PARA

Starts the event configuration setting. (In basic display status)

PID

Starts the PID parameter setting. (In basic display status)

SETUP

Starts the setup setting. (In basic display status)

FUNC + PID

Starts the fixed command control setting. (In basic display status)

Shifts each item.

ENTER

Enters set values.

Completes a change in a set value. (When a set value flickers.)

Changes each item s set point. (When a set value flickers.)

PARA

Stops each item s set point. (When a set value flickers.)

DISP

Ends parameter setting.

FUNC + PROG

Starts the program setting (programming). (In basic display status)

Shifts to program item or segment number.

ENTER

Enters set values.

Completes a change in a set values. (When a set value flickers.)

Changes each item s set point. (When a set value flickers.)

Function

Page 26

2-6

■ Key chord functions

PROG + RUN/HOLD : Reset key

Press the RUN/HOLD key while holding down the PROG key in basic status

display to perform a RESET.

The READY mode is invoked when a reset is performed in the RUN, HOLD,

FAST, END, or READY FAST modes. This RESET operation does not work

in the READY mode.

PROG + DISP : Advance key

Press the DISP key while holding down the PROG key in the program run mode

in basic status display to perform an ADV (advance) operation. The next segment

is displayed when this action is performed in the RUN, HOLD, FAST, END, or

READY FAST modes. This ADV operation does not work in the READY mode.

FUNC + : Fast key

Press the key while holding down the FUNC key in the program run mode

in basic status display to perform a FAST operation.

The system changes from the RUN or HOLD mode to the FAST mode. If the

system is in the READY mode, it goes to the READY FAST mode.

Chapter 2. NAMES AND FUNCTIONS OF PARTS

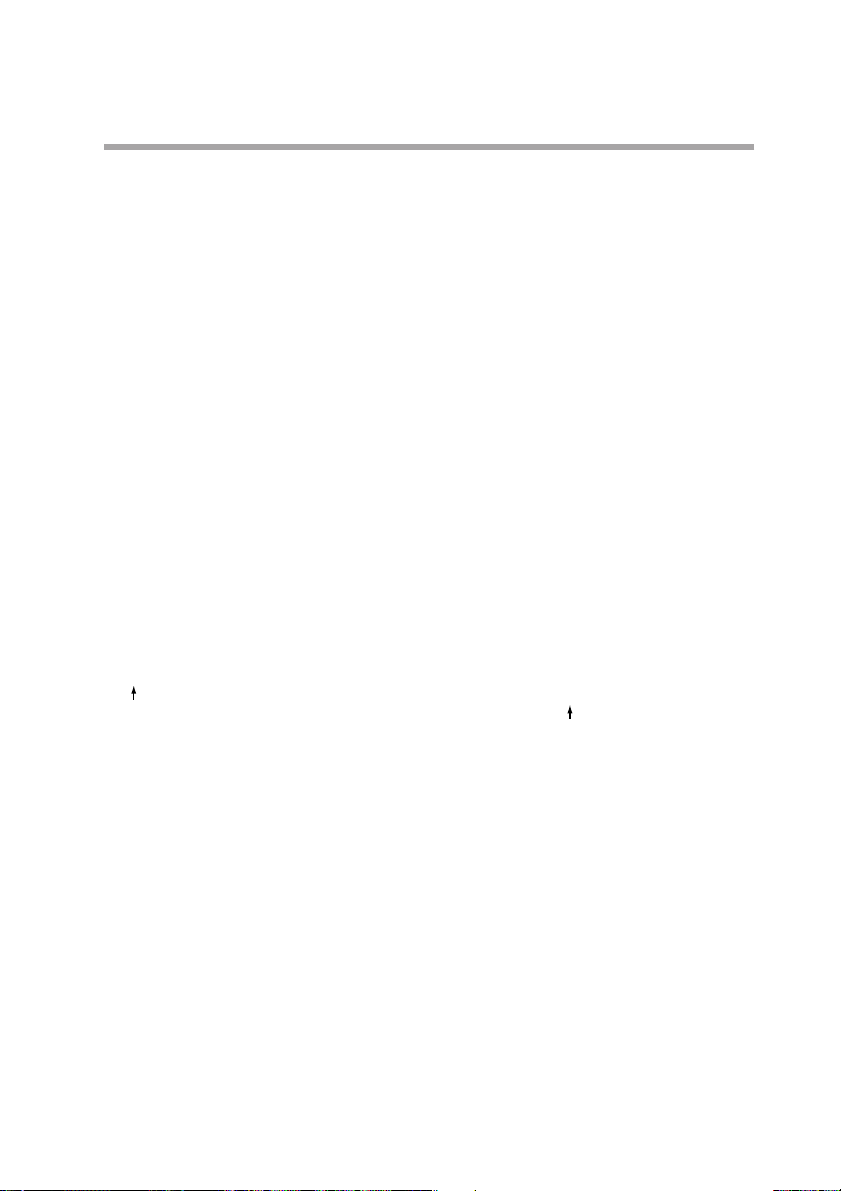

Classification

Program setting

Program copy

General reset

Memory card

operation

(available on the

DCP551A*****

model only)

Erases or resets a set value.

(When a set value flickers.)

Key operation

FUNC + CLR

Cancels change in set value.

(When a set value flickers.)

DISP

FUNC + ENTERInserts or delete a segment when a pattern SP setting is started.

FUNC + PROG

Changes RAMP-X RAMP-T or RAMP-X RAMP-E when a

pattern SP setting is completed.

Starts a program number change.

DISPEnds program setting.

+ PROG

Starts program copy. (In basic display status)

Changes program number at copy destination.

ENTERExecutes the copy.

(When a set value flickers.)

DISPEnds program copy.

SAVEStarts a data write operation to the memory card.

(In basic display status)

Writes data to the memory card.

LOADStarts a data read operation from the memory card.

(In basic display status)

Reads data from the memory card.

Changes selected memory card operation.

ENTER

Enters memory card operation.

DISP

Interrupts memory card operation.

FUNC + CLR + MESSAGE

Returns a check status of the general reset. (In basic display status)

ENTER

Executes a general reset.

DISP

Interrupts a general reset.

Function

Page 27

2-7

FUNC + PARA : Event configuration setting key

Press the PARA key while holding down the FUNC key in basic status

display to switch to the event configuration setting status.

FUNC + PID : Constant value control setting key

Press the PID key while holding down the FUNC key in basic status display

to switch to the constant value control setting status.

FUNC + PROG : Program setting (programming) key

Press the PROG key while holding down the FUNC key in the program run

mode in basic status display to go to the program setting (programming) status.

When the PROG key is pressed while holding down the FUNC key in the

program setting status, allows you to change the number of the program to be

set.

FUNC + CLR : Program delete key

Press the CLR key while holding down the FUNC key during registration in

the program setting status to delete a setting or return to a default value.

FUNC + ENTER : Segment insert/remove/RAMP/selection key

Press the ENTER key while holding down the FUNC key to go to the

segment insert/delete panel during SP and time setting in the program setting

status.

Pressing the ENTER key while the FUNC key is held down during SP

registration in the program setting status allows you to switch between RAMP-

X and RAMP-T as well as RAMP-X and RAMP-E.

+ PROG : Program copy key

Press the PROG key while holding down the key in program run READY

mode in basic display status to go to the program copy panel.

FUNC + CLR + MESSAGE : General reset key

Press the CLR and MESSAGE keys simultaneously while holding down the

FUNC key in the READY AUTO mode in the basic display status to go to the

general reset verification panel.

■ Loader jack

This jack allows the connection of a loader.

Do not insert plugs other than loader plugs.

The terminal base is not isolated from internal digital circuits.

When not in use, always replace the cap.

Chapter 2. NAMES AND FUNCTIONS OF PARTS

Page 28

2 - 3 Input Type and Range Number

2-8

■ Input

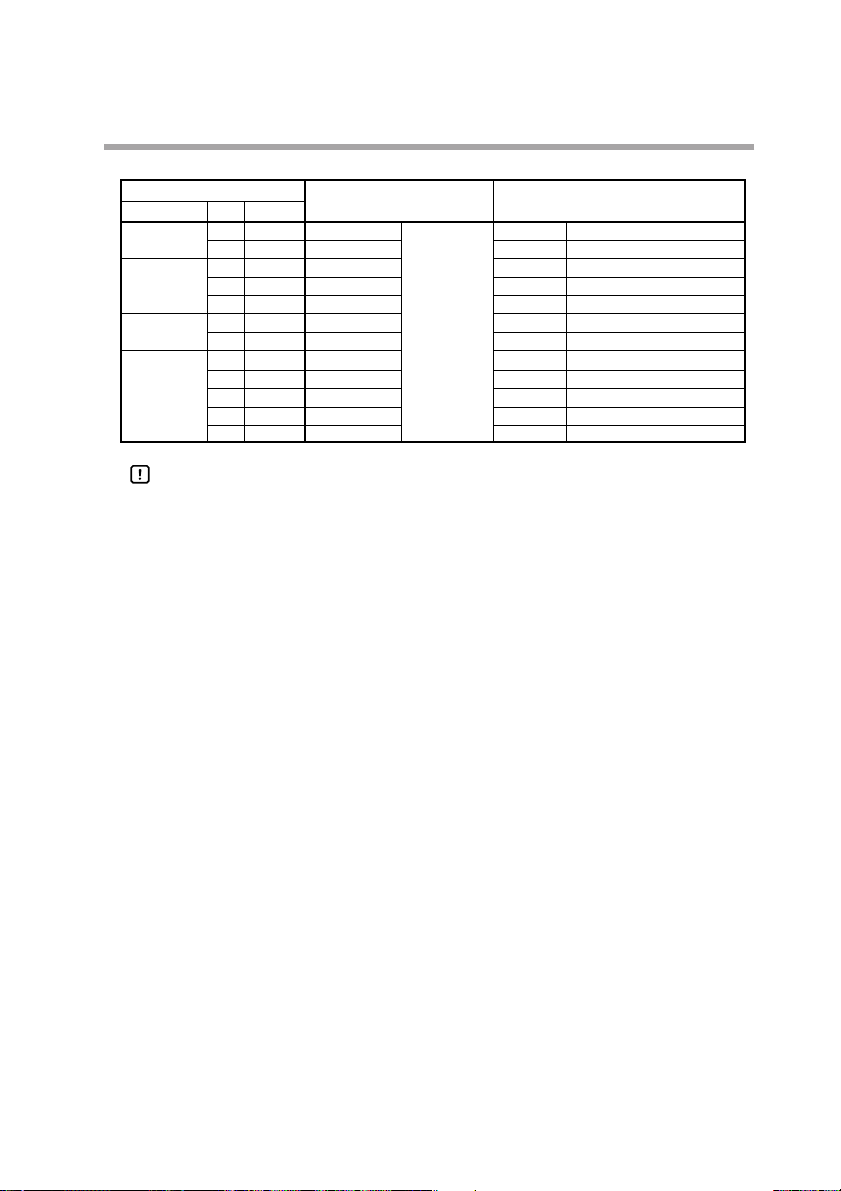

● Thermocouple

● Resistance temperature detector (RTD)

Chapter 2. NAMES AND FUNCTIONS OF PARTS

Input type

Symbol

Code

Accuracy (under standard conditions)

±0.1%FS

Input range (FS)

Range No.

K (CA) K46

-200.0 to +200.016

-300.0 to +400.0

±0.1%FSK (CA) K09

0.0 to 1200.000 to 2400

±0.1%FSK (CA) K08

0.0 to 800.010 to 1600

±0.1%FSK (CA) K04

0.0 to 400.020 to 750

±0.1%FSE (CRC) E08

0.0 to 800.030 to 1800

±0.1%FSJ (IC) J08

0.0 to 800.040 to 1600

±0.1%FST (CC) T44

-200.0 to +300.0

5 -300 to +700

±0.1%FSB (PR30-6) B18

0.0 to 1800.060 to 3300

±0.1%FSR (RR13) R16

0.0 to 1600.070 to 3100

±0.1%FSS (PR10) S16

0.0 to 1600.080 to 3100

±0.1%FSW (WRe5-26) W23

0.0 to 2300.090 to 4200

±0.1%FSW (WRe5-26) W14

0.0 to 1400.010 0 to 2552

±0.2%FSPR40-20 D19

0.0 to 1900.011 0 to 3400

±0.1%FSN U13

0.0 to 1300.012 32 to 2372

±0.1%FSPL II Y13

0.0 to 1300.013 32 to 2372

±0.1%FSZ13

0.0 to 1300.014 32 to 2372

±0.4%FS

Gold, iron, chromel

Z06

0.0 to 300.0K (K : Kelvin)15

Input type

Symbol

Code

Accuracy (under standard conditions)

±0.1%FS

Input range (FS)

Range No.

JIS’89Pt100 F50

-200.0 to +500.064 -

300.0 to +900.0

±0.1%FSF46

-200.0 to +200.065 -

300.0 to +400.0

±0.1%FSF32

-100.0 to +150.0

66 -

150.0 to +300.0

±0.1%FSF36

-50.0 to +200.067 -50.0 to +400.0

±0.15%FSF33

-40.0 to +60.068 -40.0 to +140.0

±0.15%FSF01

0.0 to 100.069 0.0 to 200.0

±0.1%FSF03

0.0 to 300.070 0.0 to 500.0

±0.1%FSF05

0.0 to 500.071 0.0 to 900.0

±0.1%FSJIS’89Pt100 P50

-200.0 to +500.096 -

300.0 to +900.0

±0.1%FSP46

-200.0 to +200.097

-300.0 to +400.0

±0.1%FSP32

-100.0 to +150.098

-150.0 to +300.0

±0.1%FSP36

-50.0 to +200.099 -50.0 to +400.0

±0.15%FSP33

-40.0 to +60.0100 -40.0 to +140.0

±0.15%FSP01

0.0 to 100.0101 0.0 to 200.0

±0.1%FSP03

0.0 to 300.0102 0.0 to 500.0

±0.1%FSP05

0.0 to 500.0103 0.0 to 900.0

Page 29

2-9

● DC current, DC voltage

Handling Precautions

• The unit for code Z06 is “K” (kelvin).

• Code F50 and P50 do not generate the PV lower bound alarm.

• The number of decimal digits for DC current and DC voltage is

programmable from 0 to 4.

• The lower limit readout of code B18 is 20ºC (68ºF).

Chapter 2. NAMES AND FUNCTIONS OF PARTS

Input type

Symbol

Code

Accuracy (under standard conditions)

±0.1%FS

Input range (FS)

Range No.

mA

C01

4 to 20mA48

Programmable range

—19999 to +20000

(Decimal point

position is variable.)

±0.1%FS

(Linear)

Z51

2.4 to 20mA52

±0.1%FS

mV

M01

0 to 10mV49

±0.1%FSL02

-10 to +10mV50

±0.1%FS

0 to 100mV51

±0.1%FS

mA

C01

4 to 20mA128

±0.1%FS

(Linear)

Z51

2.4 to 20mA134

±0.1%FSV

0 to 1V129

±0.1%FS

(Linear)

-1 to +1V130

±0.1%FSV01

1 to 5V131

±0.1%FS

0 to 5V132

±0.1%FS

0 to 10V133

Page 30

Page 31

Chapter 3.

INSTALLATION AND MOUNTING

3- 1 Before Installation

■ Mounting position

Do not install the DCP551 in locations:

• exposed to high or low temperature or humidity.

• exposed to direct sunlight or to the elements such as outside.

• exposed to water, oil or chemicals.

• exposed to corrosive or inflammable gas.

• exposed to dust or smoke.

• exposed to vibrations or shocks.

• exposed to strong electric or magnetic fields.

• exposed to electric noise such as ignition devices or welding machines.

• Outdoors.

3-1

WARNING

Before removing, mounting, or wiring this module, be sure to turn off the

power to the module and all connected devices.

Doing so may result in an electric shock.

Do not disassemble the controller as this could lead to electric shock or

malfunction.

CAUTION

Be sure to follow the operating requirements (regarding temperature,

humidity, voltage, vibration, shock, mounting direction, atmosphere, etc.) as

stated in the specifications of the controller.

Failure to heed this caution may lead to fire or malfunction.

Do not block ventilation openings.

Failure to heed this caution may lead to fire or malfunction.

Make sure that wire scraps, chips, or water do not enter inside the case of the

controller.

Failure to heed this caution may lead to fire or malfunction.

Page 32

3-2

■ Sources of electrical interference and countermeasures

• The following noise generation sources are generally presumable.

(1) Relays and contacts

(2) Solenoid coils and valves

(3) Power lines (especially those carrying more than 90Vac)

(4) Inductive loads

(5) Inverters

(6) Motor rectifiers

(7) Phase angle control SCR

(8) Wireless communications equipment

(9) Welding machines

(10) High voltage ignition devices

• If the source of noise cannot be removed, take the following measures.

• Use a CR filter to suppress fast-rising noise.

Recommended CR filter : Model No. 81446365-001

• Use a varistor to suppress high-amplitude interference.

Recommended varistors : Model No. 81446366-001 (for 100V)

81446367-001 (for 200V)

Handling Precautions

Varistors must be handled carefully as they become defective if they are

short-circuited.

Chapter 3. INSTALLATION AND MOUNTING

Page 33

3 - 2 Installation

This section describes installation procedures.

■ Panel cutout dimension

Use 2mm thick steel panels in setting up the DCP551.

Handling Precautions

Install the DCP551 in a location where the lower panel is not exposed to

temperatures that exceed the operating temperature range (0 to 50°C).

Make sure that the temperatures above and below the controller meet

specified requirements.

3-3

Chapter 3. INSTALLATION AND MOUNTING

200 or more

450 or more

138

+1

0

138

+1

0

Unit : mm

Page 34

3-4

■ Installation procedures

• Use the provided mounting bracket to firmly secure the upper and lower panels.

• Assemble the instrument before carrying out mounting (1).

Handling Precautions

When the provided mounting brackets are firmly secured and there is

no looseness, turn the screws only one full turn. Over-tightening the

screws of the brackets can deform or damage the case.

• The rear of the instrument must not be more than 10° above or below the

horizontal plane.

Chapter 3. INSTALLATION AND MOUNTING

Mounting (2)

Mounting (1)

Mounting bracket

Mounting bracket

Page 35

Chapter 4. WIRING

4 - 1 Precautions on Wiring

4-1

CAUTION

Connect the controller as specified using designated cables and connection

procedures.

Failure to heed this caution may lead to electric shock, fire or malfunction.

Make sure that wire scraps, chips or water do not enter inside the case of the controller.

Failure to heed this caution may lead to fire or malfunction.

Current applied to current input terminals

(55), (56) and (58), (59)

must meet

the specified range.

Failure to heed this caution may lead to fire or equipment breakdown.

All terminal screws shall be tightened to specified torque.

Improperly tightened screws may lead to electric shock or fire.

Do not use unused terminals on the instrument as relay terminals for other

equipment. Failure to heed this caution may lead to electric shock, fire or

equipment breakdown.

Attaching the terminal covers after completing the controller connections is

highly recommended.

Failure to heed this caution may lead to fire or malfunction. (Terminal covers

are supplied with the controller.)

If there is a risk of a power surge caused by lightning, use a surge protector

to prevent fire or device failure.

Be careful not to allow crimp terminal lugs to touch adjacent terminals.

WARNING

Connect the FG terminal to ground with a ground resistance of maximum

100Ω before connecting other equipment and external control circuits.

Failure to do so may cause electric shock or fire.

Before removing, mounting, or wiring this module, be sure to turn off the

power to the module and all connected devices.

Doing so may result in an electric shock.

Do not touch a live part such as a power terminal.

This may result in electric shock.

Page 36

4-2

Handling Precautions

• Before connecting the lines, verify the model number and terminal

numbers on the label affixed to the side panel of the DCP551. After

completing, always double check to ensure all wiring has been

performed correctly before turning on the power.

• The I/O signal lines and the communications lines shall maintain at least

50cm between them and the power supply line and power supply cables.

Do not route these cables through the same conduit or duct.

• Make sure that no crimp-style solderless wire connectors are touching an

adjacent terminal or connector.

• When connecting a thermocouple input of the DCP551 to another

instrument, make sure the instrument’s input impedance totals at least

1MΩ. If less than 1MΩ, the DCP551 may not be able to detect sensor

disconnection.

• Cautions when using data input devices in combination

Input of the DCP551 input or output (connected in parallel for input) to an

A/D converter, analog scanner, etc., may cause dispersion of the read

data. To prevent such occurrence, take one of the following corrective

measures.

(1) Use a low-speed integral A/D converter.

(2) Insert an isolator with no switching power supply between the

DCP551 and the A/D converter.

(3) Perform averaging with a personal computer when the data is read.

(4) If the device permits, insert an input filter.

• Devices and systems to be connected to this must have the basic

insullation sufficient to with stand the maximam operating voltage levels

of the power supply and input/output parts.

Chapter 4. WIRING

Page 37

4 - 2 Recommended Cables

To perform thermocouple input, connect a thermocouple element to the terminals. When the wiring distance is long

or when connecting the thermocouple without the element to the terminals, connect via shielded compensating lead

wires.

NOTE

• For I/O other than thermocouple, use JCS4364 instrument cable or equivalent

(is commonly called twisted shielded cable for instrument use).

The following cable are recommended.

• A shielded multicore microphone cord (MVVS) may be used, if electromagnetic

induction is comparatively low.

´

´

!

"

´

"

´

4-3

Chapter 4. WIRING

Page 38

4 - 3 Making Terminal Connections

4-4

To connect a line to the terminals, use crimp-style solderless wire connectors that fit an M3.5 screw.

Handling Precautions

• If the DCP551 is mounted in a location subject to noticeable vibration or

impact, be sure to use round crimp-style solderless wire connectors to

prevent lines from becoming disconnected from the terminals.

• Be careful not to allow any of the crimp-style solderless wire connectors

to touch adjacent terminals or connectors.

• The terminal screws shall be tightened to 0.78 to 0.98 N

•

m torque.

Chapter 4. WIRING

Unit : mm

7.4

7.3 or less

6.6 or less

3.7

Page 39

4 - 4 Terminal Array

Wires are connected to the terminal base according to the layout shown below.

4-5

Chapter 4. WIRING

DI

123451627384

12

5678

COM1

13 1412

10

9

DI

COM2

11

41

2625

12

3029

141513

3433

16

3837

ABC

RTD

3

15

OUT *AUX

43 44 45 46 48 49 50 51 52 53

+–

mA

T/C

mV. V

PV CH1 *PV CH2

45

16 17

ABC

RTD

LOAD LOAD

DO DO

DO

COM1

18 19

+++–

T/C

mV. V

SDA SDBSDRDA RDBRDSGSG(RS-485)

O2

mA

*COMM * : OPTION

MADE IN JAPAN 40733000100

10 118967

11912

–+–+–+–+

10

23 2420 22

13

27 28

31 32

39 40

FGAUX2AUX1OUT2OUT1

6463626160595857565554

DO

COM2

161415

(RS-232C)

Page 40

4 - 5 Power Supply and Grounding

4-6

■ Power supply

To supply power to the DCP551, use an instrument-dedicated single-phase power

supply subject to minimal electrical interference.

Handling Precautions

• If electrical interference proves excessive, we recommend adding an

insulating transformer and/or using a line filter.

Azbil Corporation model no.: 81442557-001

• After carrying out interference reducing measures, do not bundle the

primary and secondary power supply coils together or insert them in the

same conduit or duct.

■ Grounding

If grounding the shield wire or other lines proves difficult, ground them separately

to a grounding terminal block.

Ground resistance : Less than 100Ω

Conductor : Annealed copper wire, min. 2mm2(AWG14)

Max. Length : 20m

Handling Precautions

To ground the DCP551, connect the FG terminal (terminal

(52) or (53)

)

to a single ground point without jumpering.

Chapter 4. WIRING

Instrument power supply

100 to 240Vac

50/60Hz

Other circuits

Less than 100

200/200V

100/100V

Insulating transformer

Recommended product

81442557-001

Line filter

E

2

Grounding

GND

DCP551

31

4

Grounding

39

40

53

52

or

DCP551

53

or

52

FG terminals

Grounding terminal block

Shield

Page 41

4 - 6 PV Input (Analog Input) Connection

■ PV input CH1 connection

PV input CH1 is a multi-input type input for sensors. Connect as shown below,

according to the type of sensor being used.

■ PV input CH2 connection

PV input CH2 is a multi-input type input for sensors. Connect as shown below,

according to the type of sensor being used.

4-7

Chapter 4. WIRING

CAUTION

Current applied to current input terminals

(55), (56) and (58), (59)

must meet

the specified range.

Failure to heed this caution may lead to fire or equipment breakdown.

Thermocouple input Resistance temperature detector input

+ -

54 55 56

DC voltage input

+

54 55 56

+ -

Thermocouple input

+ -

57 58 59

T/C

-

ABC

54 55 56

RTD

DC current input

- +

54 55 56

- +

Current (mA)

transmitter

Resistance temperature detector input

ABC

57 58 59

T/C

RTD

Page 42

4-8

Handling Precautions

• Be careful to connect the input polarities correctly.

• Use shielded cable to connect the input.

Chapter 4. WIRING

DC voltage input

+ -

57 58 59

+ -

DC current input

- +

57 58 59

- +

Current (mA)

transmitter

Page 43

4 - 7 Control Output Connection

■ Current output (5G, 5S)

■ Vo ltage output (6D)

Handling Precautions

The voltage output is a constant current circuit inside. The SSR used is set

to an optimum voltage to meet the requirements of hte load. Enter the

value in the setup data. A normal SSR voltage has been set at the factory

before shipment.

■ Open collector output (8D)

Handling Precautions

• Do not short-circuit the positive (+) terminal of the external power supply

to terminal (43) on the DCP551. Doing so causes the open collector

outputs to malfunction. (There is no short circuit preventing circuit inside.)

• When connecting a semiconductor load such as a programmable

controller (sequencer), select a module in which the current directions

match.

Use one made inoperative by the leakage current produced when the

digital outputs are shut off.

4-9

Chapter 4. WIRING

WARNING

Be sure to turn off the power supply when you are installing or removing the

controller. Failure to do so may cause electric shock or fire.

+ -

43

+ -

Load

44

4 to 20mAdc

Load resistance less than 600

Ω

43 44

43

+ -

Load

+-

+-

SSR

44

12 to 24Vdc

2to22mAdc

With current value adjustment function

(Setup data

Max. load current : 100mA

Leakage current when off : less than 0.1mA

C95

)

Page 44

4 - 8

Auxiliary Output (Output CH1, CH2) Connection

4-10

■ Auxiliary output CH1 connection

■ Auxiliary output CH2 connection

Chapter 4. WIRING

WARNING

Before removing, mounting, or wiring this module, be sure to turn off the

power to the module and all connected devices.

Doing so may result in an electric shock.

+ -

48

49

+ -

Receiver

+ -

50

51

+ -

Receiver

4 to 20mAdc

Load resistance less than 600

4 to 20mAdc

Load resistance less than 600Ω

Ω

Page 45

4 - 9

Event Output (Open Collector Output) Connection

Handling Precautions

• Do not short-circuit the positive (+) terminal of the external power supply

to terminals (5) to (8), (17) to (20), (10), (11), (22), (23), (27), (28), (31),

and (32) on the DCP551. Doing so causes the open collector outputs to

malfunction. (There is no short circuit preventing circuit inside.)

• When connecting a semiconductor load such as a programmable

controller (sequencer), select a module in which the current directions

match.

Use one made inoperative by the leakage current produced when the

digital outputs are shut off.

4-11

Chapter 4. WIRING

EV9 EV10 EV11 EV12 EV13 EV14 EV15 EV16

EV1 EV2 EV3 EV4 EV5 EV6 EV7 EV8

Load

5

Load

10

Load

Load

Load

Load

Load

Load

Load

Load

+

—

+

—

External power supply

12 to 24Vdc

External power supply

12 to 24Vdc

Max. load current

Max. common current

Leakage current when OFF

Max. load current

Max. common current

Leakage current when OFF

: 70mA/point

: 500mA

: less than 0.1mA

: 70mA/point

: 500mA

: less than 0.1mA

11

Load

6

Load

7

8 17 18 19 20 9

Load

Load

Load

Load

22

23 27 28 31 32 24

Page 46

4 - 10 External Switch Input Connection

4-12

● Internal circuit diagram of the DCP551 connecting external switch input

Handling Precautions

• The inputs of the DCP551 unit are provided with a built-in power supply

(open voltage type, 8.5Vdc). Always use no-voltage contacts externally.

• For the no-voltage contacts, use gold contacts or other relays that switch

on small currents. Other types of relay contacts may not switch. Use

contacts that have ample margin over the minimum switching capacity

with respect to the current and open voltage ratings of contacts provided

on the DCP551.

• If using semiconductors (open collectors, etc.) as no-voltage contacts,

use one that maintains a potential of no more than 2V across the

contacts when actuated, and a leakage current of no more than 0.1mA

when shut off.

• The digital inputs (remote switch inputs) of all SDC40 and SDC10 series

units can be connected in parallel. If connecting them in parallel to

another instrument, carefully check the requirements of the other

instrument before proceeding.

• Do not connect SDC20/21, SDC30/31 series in parallel. Doing so may

cause the external switch input to malfunction.

• Common terminals (12) and (41) of the external switch input are

connected internally.

Chapter 4. WIRING

SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

ADV

RESET

HOLD

RUN

3

1 2

SW9 SW10 SW11 SW12 SW13 SW14 SW15 SW16

1 2 4 8 10 20 40 80

25 26

4 13 14 15 16 12

29

30 33 34 37 38

: With BCD

41

8.5Vdc

8.5Vdc

Internal

circuit

Page 47

4 - 11 Communication Connection

■ RS-485 connection

Handling Precautions

• The slave station can be connected in a multi-drop configuration.

• Always set a unique address to each slave station.

• Attach terminating resistances (a total of four when connecting a 5-wire

system) to the ends of the communications lines. Use 1/2W or greater

terminating resistances of 150Ω ±5%.

• If connecting three lines, short-circuit terminals (60), (62) and (61), (63).

• Do not short-circuit the RDA to RDB and SDA to SDB terminals.

Doing so may cause the DCP551 to malfunction.

4-13

Chapter 4. WIRING

SDB

RDA RDB SGSDA

60

61 62 63 64

Page 48

4-14

● 5-wire system RS-485 connection diagram

Attach 1/2W or greater terminating resistances of 150Ω ±5% at each end of the

communications lines. Ground the shield FGs at one end in one location, not at

both ends.

Handling Precautions

Be sure to connect SG terminals each other.

Failure to do so might cause unstable communications.

Chapter 4. WIRING

Terminating resistor

Terminating resistor

Shield

Master station

RDA

RDB

SDA

SDB

SG

FG

Terminating resistor

Terminating resistor

Shield

Shield

Slave station side DCP551

SDA

60

SDB

61

RDA

62

RDB

63

SG

64

FG

Slave station side DCP551

SDA

60

SDB

61

RDA

62

RDB

63

SG

64

FG

Slave station side DCP551

SDA

60

SDB

61

RDA

62

RDB

63

SG

64

FG

Page 49

4-15

● 3-wire system RS-485 connection diagram

Handling Precautions

In the 3-wire system, the CMC10L001A000 can be used as a converter in

the master station.

Attach 1/2W or greater terminating resistances of 150Ω ±5% at each end of the

communications lines. Ground the shield FGs at one end in one location, not at

both ends.

When only three RS-485 terminals are provided, the areas designated with an

asterisk (*) are connected internally.

Handling Precautions

Be sure to connect SG terminals each other.

Failure to do so might cause unstable communications.

Chapter 4. WIRING

Terminating resistor

Master station

RDA

RDB

SDA

*

SDB

*

SG

FG

Terminating resistor

Shield

Shield

Shield

Slave station side DCP551

SDA

60

SDB

61

RDA

62

RDB

63

SG

64

FG

Slave station side DCP551

SDA

60

SDB

61

RDA

62

RDB

63

SG

64

FG

Slave station side DCP551

SDA

60

SDB

61

RDA

62

RDB

63

SG

64

FG

Page 50

4-16

■ RS-232C connection

Handling Precautions

• Connect the slave station to the master station in a single-drop (point-topoint) configuration.

• There are three (RD, SD and SG) communications terminals on the

RS-232C interface on the master station which may not output data if not

short-circuited as shown above.

Chapter 4. WIRING

Example of connection

SD

RD SG

61 63 64

1234567

CDRDSDERSGDRRS

8

Host computer (master station)

CS

Page 51

4-17

NOTE

RS-232C connector signals (9 pins)

Example : IBM and compatibles

■ Connection to ST221

Handling Precautions

• Attach 1/2W or greater terminating resistances of 150Ω ±5% at each end

of the communications lines.

• The DCP551 operates as a master station when connected to an ST221

during communications.

Chapter 4. WIRING

RxD

Signal direction

Host Instrument

Pin No.

1

2

3

4

5

6

7

8

JIS code

CD

RD

SD TxD

ER DTR

SG GND

DR DSR

RS RTS

CS CTS

SG

Name

DCD

60 61 62 63 64

3 4 1 2 5

ST221DE05DCP

Page 52

4 - 12 Isolation During Input/Output

4-18

Isolation between inputs and outputs are shown below. In this figure, the solid lines enclose mutually-isolated

sections. Those sections bounded by dashed lines are not isolated.

Handling Precautions

The terminal base is not isolated from internal digital circuits.

When not in use, always replace the cap.

Chapter 4. WIRING

PV input CH1

PV input CH2

Loader communication

External switch input

Communication

Memory card input*

* : available on the DCP551A***** model only

Digital

circuit

Control output

Auxiliary output CH1

Auxiliary output CH2

Event output

Page 53

Chapter 5. FUNCTIONS

5 - 1 Data

5-1

■ Data types

The data types are listed below.

For further information on data types, see “Chapter 7. PARAMETER SETUP”

and “Chapter 8. PROGRAM SETUP”.

Data Parameter Variable parameter

Constant value control data

Setup data

PID parameter

Event configuration data

Program Pattern

PV shift

G.SOAK

PID group and output

limiter

group number

Event

Repeat

Tag

Pattern link

Cycle

PV start

Data changeable in RUN mode

Event type data

PID group and output limiter group control parameters

Basic data only changeable in the READY mode

Constant value control SP, PID and other data

SP and time, SP and θ or SP and

∆

SP data

Data for event 1 to 16

Data for PID group number used for control

and output limiter group number

Data indicating whether G.SOAK is provided or not

PV shift data

Data indicating whether repeat is used or not

Data indicating whether PV start is used or not

Cycle count data

Pattern link destination program number data

Tag (8 characters) data

Page 54

5 - 2 Program Pattern

5-2

■ Pattern

Three systems for selecting programs are provided: RAMP-X, RAMP-T and

RAMP-E. The first segment of each program is always RAMP-X, but the other

segments can be any system and all three types can be used in one program.

● RAMP-X system

This system, sets a segment of a pattern using SP and time, is called RAMP-X.

SP setting : within the upper and lower SP limiter range

Time setting : 0 hours 00 minutes to 500 hours 00 minutes

0 minutes 00 seconds to 500 minutes 00 seconds or

0.0 seconds to 3000.0 seconds

(Time units are selected using the C62 setup data setting.)

SP is a point on the elapsed time axis in the current segment, which is a straight

line connecting the start point, the SP set value in the previous segment, and the

end point, the SP set value in the current segment. Segments are classified as

follows.

•Rising RAMP (or rising slope)

Previous segment SP setting < current segment SP setting

•Falling RAMP (or descending slope)

Previous segment SP setting > current segment SP setting

•SOAK (soaking)

Previous segment SP setting = current segment SP setting

The start and end points of the first segment are also the SOAK segment of the SP

set value for the first segment.

SP calculation (other than first segment)

SP = (current segment SP set value – previous segment SP set value)

× (current segment elapsed time ÷ current segment time setting)