Page 1

(Not for use in Japan)

No. CP-SP-1402E

Multi-loop Controller with

Multifunction Display

Model C7G

Installation and

Configuration Manual

Thank you for purchasing an Azbil

Corporation product.

This manual contains information for

ensuring the correct use of this product.

It also provides necessary information

for installation, maintenance, and

troubleshooting.

This manual should be read by those who

design and maintain equipment that uses

this product. Be sure to keep this manual

nearby for handy reference.

Page 2

NOTICE

Be sure that the user receives this manual before the product is used.

Copying or duplicating this user’s manual in part or in whole is forbidden.

The information and specifications in this manual are subject to change

without notice.

Considerable effort has been made to ensure that this manual is free from

inaccuracies and omissions. If you should find an error or omission, please

contact the azbil Group.

In no event is Azbil Corporation liable to anyone for any indirect, special or

consequential damages as a result of using this product.

© 2017-2018 Azbil Corporation. All Rights Reserved.

Page 3

Safety Requirements

To reduce the risk of an electric shock that could cause personal injury,

follow all safety notices in this document.

This symbol warns the user of a potential shock hazard where hazardous

live voltages may be accessible.

Use of this product in a manner not specified by the manufacturer will impair its built-in safety features.

Do not replace any component except as specified by the manufacturer.

All wiring work must comply with local regulations and be carried out by authorized and experienced

personnel.

Make sure to provide a cutoff switch for the power to this device within reach of the operator.

Do not remove blocks except to replace them.

Replacing the MOTOR block (p.11-1) (for information on replacement blocks)

For DC models, connect a Class II power supply unit.

Equipment Ratings

Ingress protection: IP67 (display unit)

AC power

Supply voltage: 100–240 V AC (operating voltage: 85–264 V AC)

Power supply frequency: 50/60 Hz

Power consumption: 25 VA max. 10 W max.

Replacement of the CLOCK block (p.11-1) and

DC power

Supply voltage: 24 V DC (operating voltage: 20.4 to 28.8 V DC)

Power consumption: 12 W max.

Environmental conditions

Do not use this device where there are corrosive gases, or flammable fluids or gases.

Operating temperature: 0 to 50 °C

Operating humidity: 10 to 90 % RH (without condensation)

Vibration: 5 m/s

Overvoltage: Category II (IEC 60364-4-443, IEC 60664-1)

Pollution degree: 2

Installation location: Indoors

Elevation: 2000 m max.

Ventilation space: At least 50 mm above and below the main unit. No space is needed

Equipment Installation

Excluding the supplied power, the I/O common mode voltage with respect to the ground should be

30 Vrms max., 42.4 V peak max., and 60 V DC max.

Standards Compliance

EN 61010-1, EN 61326-1 (for use in industrial locations)

During EMC testing, the reading or output may fluctuate by ±10 % FS.

cULus: UL 61010-1, CSA C22.2 No. 61010-1 (UL-compliant models only)

2

(10 to 60 Hz)

around the display unit.

i

Page 4

Conventions Used in This Manual

The safety precautions explained below aim to prevent injury to you and others, and to prevent property damage.

Warnings are indicated when mishandling this

WARNING

product may result in death or serious injury.

CAUTION

product may result in minor injury or property

damage only.

In describing the product, this manual uses the icons and wording listed below.

Indicates that caution is required in handling.

The indicated action is prohibited.

Be sure to follow the indicated instructions.

Handling Precautions:

Precaution is required in handling.

Cautions are indicated when mishandling this

Note:

:

Indicates information that may be useful.

Indicates an item or page to which the user may refer.

(1) (2) (3):

[XXX] button: Square brackets indicate buttons at the bottom of the display unit or buttons and

[XXX] window,

[XXX]

>> :

Numbers inside parentheses indicate steps in a sequence or parts of an explanation.

messages shown on the display unit screen.

Square brackets indicate a window name, message, or menu, shown on the PC screen.

Indicates the result of an operation, or the status after the operation.

ii

Page 5

Safety Precautions

Do not use this device in an environment with conductive pollution, or with dry nonconductive pollution which can become conductive due to condensation, etc. Otherwise,

problems such as tracking phenomena may damage parts, resulting in fire.

Make sure that the frame ground terminal is properly grounded (100 Ω max.) before

connecting the controller to the measurement target or to external control circuits.

Be sure to check that the device has been correctly wired before turning on the power.

Incorrect wiring of this device may cause device failure and also lead to a dangerous accident.

Before removing, mounting, or wiring the device, be sure to turn off the power to this device

and any connected devices. Otherwise, there is a danger of electric shock.

Do not touch electrically charged parts such as the power terminals. There is a danger of

electric shock.

Do not disassemble this device. There is a danger of electric shock or device failure.

To prevent electrical shock, the main unit of this product must be installed in a location that is

only accessible to people with appropriate knowledge about electrical safety. Install the main

unit inside a control panel that cannot be opened without the use of a key or tool.

WARNING

Also, before touching electrically charged components such as the input terminal block for

AC power, be sure to turn off the power. After checking that the voltage has dropped, work

carefully to prevent electrical shock. Always keep the cover on the power input terminal

block. Otherwise, there is a danger of fire or electric shock.

CAUTION

Use this device within the operating ranges given in the specifications (for temperature,

humidity, voltage, vibration, shock, mounting direction, atmosphere, etc.). Otherwise, there

is a danger of fire or device failure.

Wire this device correctly by using the wiring method, power, and installation method

specified in this user’s manual. Otherwise, there is a danger of fire, electric shock, or device

failure.

Do not allow wire clippings, metal shavings, water, etc., to enter the case of this device. There

is a danger of fire or device failure.

Firmly tighten the terminal screws to the torque listed in the specifications. Insufficient

tightening may cause fire or electric shock.

Do not use unused terminals as relay terminals. There is a danger of fire, electric shock, or

device failure.

If the lithium battery used in this device is packaged together with it (installed) and

transported by air or ship, be sure that it is transported in accordance with the IATA DGR/

IMDG Code.

Do not block the ventilation holes. There is a danger of fire or device failure.

iii

Page 6

CAUTION

Do not operate the buttons or the touch panel with a sharp object (such as a mechanical

pencil tip, etc.). Doing so can cause device failure.

The frame ground terminal of this device is a functional ground. Ground the frame ground

terminal to suppress adverse effects from external noise. Otherwise, malfunction may result.

Be sure that the settings are correct for the sensor type. If the settings are incorrect, the

normal PV will not be measured correctly. In that case a dangerous situation such as constant

100 % control output could occur.

iv

Page 7

Copyright, licenses, and registered trademarks

• Notice on use of licensed software of ARM.

This product uses the software according to the license of ARM in a part of the software. The following contents are based on the license

agreement, which does not prescribe customers’ usage restrictions.

Copyright © 2009 - 2015 ARM LIMITED All rights reserved.

Redistribution and use in source and binary forms, with or without modification, are permitted provided that the following conditions are

met:

- Redistributions of source code must retain the above copyright notice, this list of conditions and the following disclaimer.

- Redistributions in binary form must reproduce the above copyright notice, this list of conditions and the following disclaimer in the

documentation and/or other materials provided with the distribution.

- Neither the name of ARM nor the names of its contributors may be used to endorse or promote products derived from this software

without specific prior written permission.

THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS “AS IS” AND ANY EXPRESS OR IMPLIED WARRANTIES,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

DISCLAIMED. IN NO EVENT SHALL COPYRIGHT HOLDERS AND CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL,

EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES;

LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER

IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS

SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

• Notice regarding use of licensed software of STMicroelectronics.

This product uses the software according to the license of STMicroelectronics in a part of the software. The following contents are based

on the license agreement, which does not prescribe customers’ usage restrictions.

COPYRIGHT© 2014 STMicroelectronics

Redistribution and use in source and binary forms, with or without modification,are permitted provided that the following conditions are

met:

1. Redistributions of source code must retain the above copyright notice,this list of conditions and the following disclaimer.

2. Redistributions in binary form must reproduce the above copyright notice,this list of conditions and the following disclaimer in the

documentation and/or other materials provided with the distribution.

3. Neither the name of STMicroelectronics nor the names of its contributors may be used to endorse or promote products derived from

this software without specific prior written permission.

THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND CONTRIBUTORS “AS IS”AND ANY EXPRESS OR IMPLIED WARRANTIES,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

DISCLAIMED. IN NO EVENT SHALL THE COPYRIGHT HOLDER OR CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL,

SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS

OR SERVICES; LOSS OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY,

WHETHER IN CONTRACT, STRICT LIABILITY,OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF

THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

• microSD is trademark or registered trademark of SD-3C, LLC in the United States, other countries or both.

• Ethernet is a trademark of Xerox Corporation in the United States.

• ModbusTM is a trademark and the property of Schneider Electric SE, its subsidiaries and affiliated companies.

v

Page 8

Contents

Safety Requirements

Conventions Used in This Manual

Safety Precautions

Copyright, licenses, and registered trademarks

Chapter 1. Overview

1 - 1 Overview

1 - 2 Model No. 1-2

Model Selection Guide 1-2

Optional Parts (Sold Separately) 1-7

1 - 3 Names of Parts and Their Functions 1-8

Display unit 1-8

Main unit 1-8

Integrating bracket (supplied with integrated mounting models) 1-8

1 - 4 Input/output Configuration 1-9

1 - 5 Button Operation 1-11

Screen transitions 1-11

Parameter bank 1-12

Japanese language display 1-16

Monitor and graph screen transitions 1-17

Screen transitions of the user HOME screen 1-21

1 - 6 Operation M odes 1-23

1-1

1-1

Chapter 2. Mounting 2-1

2 - 1 External View and Mounting Dimensions

Standard mounting 2-1

Integrated mounting 2-1

Mounting locations 2-1

2 - 2 Mounting Method 2-2

Standard mounting 2-2

Integrated mounting 2-5

2-1

Chapter 3. Wiring 3-1

3 - 1 Wiring Precautions

Wiring precautions 3-2

3 - 2 Recommended Cables 3-3

3 - 3 Crimp Terminals 3-4

Crimp terminals 3-4

Recommended Ferrules 3-4

3 - 4 Wiring 3-6

Noise suppression measures 3-6

Power input 3-7

Grounding 3-7

3-1

vi

Page 9

DI/DO block (7 digital inputs or outputs, selectable) 3-8

RS-485 (RS-485 communication port) 3-9

Analog input block (analog input) 3-10

Analog input block layout 3-11

Analog output block (current outputs, CT inputs, and VT inputs) 3-12

Voltage pulse output block (voltage pulse outputs and 2 CT inputs) 3-13

DI block (4 digital inputs) 3-14

DO block (4 digital outputs, sink output) 3-14

MOTOR block (motor drive outputs and motor feedback inputs) 3-15

I/O isolation 3-16

USB connection 3-16

Inserting or removing a microSD memory card 3-17

Connecting the LAN cable for Ethernet 3-17

Connecting the cable between the main unit and display unit 3-18

Chapter 4. Functions 4-1

4 - 1 Loop Types

Model numbers and loop types 4-1

Setting the loop type 4-4

4 - 2 AI (Analog Input) 4-6

Range types 4-7

Linear scaling low and high limits 4-7

Setting the linear input unit character 4-7

Filter 4-8

Ratio and bias 4-9

Linearization table group definition 4-9

Number of decimal places for PV 4-9

Sampling cycle 4-10

PV Hold 4-10

Power supply frequency 4-10

4 - 3 Mode 4-12

AUTO/MANUAL mode 4-12

Constant value operation / Pattern operation 4-13

RUN/READY mode 4-14

LSP/RSP mode 4-14

Pattern start number 4-15

READY/RUN/HOLD/END mode 4-15

ADVANCE 4-17

G.SOAK clear 4-18

AT (auto-tuning) stop/start 4-18

4 - 4 Control 4-19

Functional block diagram of PID control 4-19

Functional block diagram of ON/OFF control 4-19

Functional block diagram of heating/cooling control 4-20

Control action 4-20

Heating/cooling control dead zone 4-21

4-1

vii

Page 10

Fixed value output 4-22

Special control output 4-23

When switching to MANUAL mode 4-23

PID control initialization 4-24

PID initial MV 4-24

MV change limit 4-25

PID control 4-25

AT (Auto-tuning) 4-26

SP lag 4-26

ON/OFF control 4-27

4 - 5 AT (Auto-tuning) 4-28

How to start 4-28

How to stop AT 4-28

4 - 6 SP 4-31

Setting the LSP from the 1-loop monitor screen 4-32

Selecting LSP group and RSP from the 1-loop monitor screen 4-32

Number of LSP system groups 4-32

RSP setting 4-32

LSP1 to 8 and RSP 4-33

PID group number 4-33

LSP group No. 4-34

DI assignment for LSP group selection 4-34

SP ramp unit 4-35

SP ramp up and down slopes 4-36

SP low and high limits 4-37

RSP tracking 4-37

4 - 7 Pattern Operation 4-38

Number of patterns 4-39

Time unit for patterns 4-39

Number of segments 4-39

SP/Time 4-39

PID group number 4-41

G.SOAK (guaranteed soak) 4-41

Segment event 4-43

PV start 4-43

Cycle 4-44

Pattern link 4-44

End of operation 4-45

Pattern start number 4-46

Pattern SP increase/decrease change limit 4-47

4 - 8 DI (Digital Input) 4-49

DI/DO configuration 4-49

DI assignment 4-50

4 - 9 Events 4-55

Operation 4-56

Operation type and Loop definition 4-61

Direct/reverse, Standby, and READY mode operation 4-62

Event main setting, event subsetting, hysteresis, delay 4-64

viii

Page 11

4 - 10 DO (Digital Output) 4-65

DI/DO configuration 4-65

DO assignment 4-66

4 - 11 TP (Time Proportioning) Output 4-68

DI/DO configuration 4-69

TP output type 4-69

TP cycle 4-70

TP operation type 4-70

Linearization table group definition 4-71

4 - 12 Analog Output (AO) 4-72

Output range 4-72

Output type 4-72

Loop definition 4-73

Output scaling low and high limits 4-73

Linearization table group definition 4-74

4 - 13 Motor Drive Output (Position Proportional Control) 4-75

Output type 4-75

Control method 4-76

MFB AT (MFB auto-tuning) 4-77

MFB adjustment value 4-78

Dead zone 4-79

Linearization table group definition 4-80

4 - 14 CT (Current Transformer) Input 4-81

Number of turns and number of power wire loops 4-81

CT input display range and current measurement range 4-82

Current measurement and error detection 4-83

Condition for restoring status before measurement 4-88

Timing for updating CT current measurement 4-88

4 - 15 VT (Voltage Transformer) Input 4-89

Primary voltage and secondary voltage 4-89

4 - 16 Linear Approximation 4-90

Linearization by specifying breakpoints 4-90

Linearization by specifying bias 4-91

Example using linear approximation by analog input 4-91

Example using linear approximation for analog output 4-92

When the increase in magnitude of the breakpoints on the A-axis is not in

numerical order 4-94

When two adjacent breakpoints have the same value on the A-axis 4-94

4 - 17 Internal Cascade 4-95

Master/Slave 4-95

Loop Types 4-95

Example: Internal cascade settings 4-96

4 - 18 Logical Operations 4-98

Processing order for logical operations 4-98

Calculation type 4-99

Input assignments A, B, C, and D 4-99

Input bit polarities A, B, C, and D 4-99

Reverse 4-100

ix

Page 12

ON/OFF delay 4-100

4 - 19 CDS (Compact Data Storage) 4-102

Recording cycle/operation type 4-102

Data selection 4-103

Number of data / Data1 to Data40 4-104

Screen during CDS operation 4-106

Files 4-107

Customizing the number of data items and data types 4-111

Setting the date and time by the SLP-C7 4-113

microSD card operations from SLP-C7 4-114

Specifications of older versions 4-115

4 - 20 Health Index 4-116

R value 4-116

Settings 4-116

Operation 4-117

Graph display 4-118

4 - 21 Display Unit Adjustment 4-119

Brightness adjustment 4-119

Position adjustment 4-119

4 - 22 Advanced Loop Type Setting 4-121

Loop types 4-121

Input assignment 4-121

Virtual AI (analog Input) 4-123

Chapter 5. Screens 5-1

5 - 1 Monitor Screen and Graph Screen

Home screen 5-1

1-loop monitor screen 5-10

Pattern operation monitor screen 5-12

Multi-loop graph screen 5-15

1-loop graph screen 5-17

1-loop monitor screen in MANUAL mode 5-18

1-loop monitor screen during AT execution 5-19

1-loop monitor screen when MFB AT is stopped 5-20

1-loop monitor screen during MFB AT 5-21

Screen at key lock 5-22

1-loop monitor screen if there is an alarm 5-23

Block alarm screen 5-24

Function alarm screen 5-25

SP menu screen 5-26

LSP/RSP select screen 5-27

LSP setting change screen 5-28

Mode menu screen 5-30

Mode menu screen (pattern) 5-31

AUTO/MANUAL change screen 5-32

RUN/READY change screen 5-33

5-1

x

Page 13

AT start/stop screen 5-34

HOLD mode change screen 5-35

ADVANCE operation screen 5-36

G.SOAK clear screen 5-37

DI/DO monitor screen 5-38

DI monitor screen 5-39

DO monitor screen 5-40

EV monitor screen 5-41

SEG-EV monitor screen 5-42

5 - 2 Parameter screen 5-43

Parameter bank menu screen 5-43

Parameter item menu screen 5-44

Parameter item setting change screen 5-45

Pattern settings/segment settings 5-46

IP address 5-48

Date and Time 5-50

Firmware Versions 5-52

Chapter 6. Display and Setting Data 6-1

6 - 1 Operation D isplay Data

Home screen 6-1

1-loop monitor screen 6-2

Graph screen 6-5

6 - 2 Parameter Setting Display Data 6-6

SP bank 6-6

EVENT bank 6-7

PID bank 6-7

ANALOG INPUT bank 6-8

Basic action bank 6-9

CONTROL bank 6-12

SP CONFIG bank 6-15

ANALOG OUTPUT bank 6-16

EVENT CONFIG bank 6-17

DI/DO CONFIG bank 6-19

DO configuration bank 6-20

DI bank 6-22

TP (time proportioning) bank 6-24

Logical operation bank 6-27

User-defined bit bank 6-28

User-defined number bank 6-29

User-defined alarm bank 6-30

CT INPUT bank 6-31

VT INPUT bank 6-32

PP (position proportional) bank 6-33

Linearization table bank 6-35

Cascade bank 6-35

6-1

xi

Page 14

Graph bank 6-36

ETHERNET bank 6-36

IP ADDRESS bank 6-37

RS-485 bank 6-37

CDS bank 6-38

HEALTH INDEX bank 6-40

HEALTH INDEX graph 6-41

Date and time bank 6-41

Input assignment bank 6-42

Virtual analog input bank 6-44

6 - 3 Pattern Setting Display Data 6-46

Pattern configuration bank 6-46

Pattern bank 6-47

Segment bank 6-48

6 - 4 Parameter Data for Communication 6-49

Monitor (RAM)/Loop1 to 4 6-49

Monitor/Mode 6-49

Monitor/Operation display (Loop1 to 4) 6-50

Monitor/Operation display (AO-C block) 6-50

Monitor/operation display (V-P block) 6-51

Monitor/Status (DI/DO block) 6-51

Monitor/Status (Events 1 to 16) 6-52

Monitor/Status (other) 6-52

Alarm condition 6-53

Monitor/Position proportional 6-53

Monitor/Pattern mode 6-54

Monitor/Pattern monitor 6-54

Monitor/Segment event 6-55

SP Configuration (LSP group selection) 6-55

User-defined bits (RAM) 6-55

Device info. 6-56

Standard bits 6-56

Standard numerical code 6-56

Chapter 7. Modbus RTU Communication Functions 7-1

7 - 1 Overview of Communications

Features 7-1

Settings 7-2

Communication procedure 7-2

7 - 2 Message Structure 7-3

Message structure 7-3

Command type 7-4

Exception codes 7-4

Amount of data 7-5

7 - 3 Description of Commands 7-6

Multiple data read command (03H) 7-6

xii

7-1

Page 15

Multiple data write command (10H) 7-7

1 data write command (06H) 7-7

7 - 4 Numeric Value Expression 7-9

Hexadecimal 7-9

7 - 5 Send/Receive Timing 7-10

Time specifications for instruction and response messages 7-10

Specifications of RS-485 driver control timing 7-10

Chapter 8. Modbus TCP Communication Functions 8-1

8 - 1 Overview of Communications

Features 8-1

Settings 8-1

Communication procedure 8-2

General TCP/IP socket communication procedure 8-2

8 - 2 Message structure 8-3

Message structure 8-3

Exception code 8-4

Amount of data 8-5

8 - 3 Description of Commands 8-6

Application section 8-6

Multiple data read command (03H) 8-6

Multiple data write command (10H) 8-7

1 data write command (06H) 8-8

8-1

Chapter 9. User-defined Addresses 9-1

9 - 1 Overview of User-defined Addresses

User-defined addresses 9-1

9 - 2 Address Definition Method 9-2

Setting a user-defined address 9-2

Changing the data address display system 9-4

Normal memory area and RAM area 9-4

Precautions when using both the normal memory area and the RAM area for

the same parameter 9-6

Bit fields 9-8

9 - 3 Initial Values of User-Defined Addresses 9-11

9 - 4 Reception M onitoring 9-13

Reception monitoring settings 9-13

9 - 5 Pattern Communication Data 9-15

Data address overview 9-15

Decimal point 9-16

PATTERN COMMUNICATION SETUP 9-16

Pattern communication access procedure 9-17

Data address details 9-18

9-1

xiii

Page 16

Chapter 10. PLC Link Communication 10-1

10 - 1 Data Transfer

Connectible PLCs 10-4

Usable devices 10-5

10 - 2 PLC Link Setting Method 10-6

Common settings 10-6

Transfer settings 10-7

Transfer setting examples 10-8

10 - 3 List of PLC Link Settings 10-12

PLC connection settings 10-12

Transfer settings 10-12

Data settings 10-13

10 - 4 Mitsubishi PLC 10-14

iQ-R series CPU direct connection 10-14

Q series CPU direct connection 10-16

Q series Ethernet interface module 10-19

iQ-F series CPU direct connection 10-22

10-1

Chapter 11. Maintenance and Troubleshooting 11-1

11 - 1 Maintenance and Troubleshooting

Cleaning 11-1

Parts replacement 11-1

Replacement of the CLOCK block 11-1

Replacing the MOTOR block 11-1

11 - 2 Alarm 11-2

Block alarm screen 11-2

Block alarm 11-3

Function alarm screen 11-5

Function alarm 11-6

11 - 3 Display Error 11-7

Display unit does not work. 11-7

Nothing is shown on display unit. 11-7

An error is indicated on the display unit 11-7

The firmware version of the display unit does not match. 11-8

11-1

Chapter 12. DISPOSAL 12-1

Removing the battery for product disposal 12-1

Chapter 13. Specifications 13-1

Specifications 13-1

Input types and ranges 13-12

Input sensor standards 13-13

xiv

Page 17

Chapter 14. Appendix 14-1

14 - 1 Function Block Diagrams

AI (analog input) process block diagram 14-1

SP process / PID process block diagram 14-2

AO (analog output) process block diagram 14-3

TP (time proportioning) output process block diagram 14-4

PP (position proportional) output process block diagram 14-5

14 - 2 Standard Bit Codes and Standard Numerical Codes 14-6

Standard bit codes 14-6

Standard numerical codes 14-8

14 - 3 Precautions for Communication Function 14-10

Examples of operations when using both the normal memory area and RAM

area for the same parameter 14-10

Support start date: September 2016 14-13

14 - 4 Firmware Version History 14-13

Support start date: December 2016 14-15

Support start date: June 2017 14-18

Support start date: August 2017 14-22

Support start date: August 2018 14-26

14 - 5 Abbreviations and Terms 14-32

14-1

xv

Page 18

Page 19

Chapter 1. Overview

1 - 1 Overview

The C7G multi-loop controller with multifunction display (hereafter also called simply "this device") can calculate

diagnostic parameters, known collectively as the health index, that help to predict failure of other equipment,

in addition to calculations for PID (proportional, integral and derivative) control of process variables such as

temperature, pressure, flow rate, pH, and liquid level.

This product consists of a display unit with a 3.5-inch QVGA LCD touch panel, as well as a main unit capable of

controlling up to four loops with an input sampling cycle of 10 ms and an indication accuracy of ± 0.1 % FS.

The display unit and main unit can be installed separately for installation flexibility.

A wide variety of interfaces, including Ethernet, RS-485 serial communication, microSD memory card, micro USB

port, and 7 digital input/outputs are provided as standard features.

Setup, operation, and monitoring can be easily accomplished using the display unit and Smart Loader Package.

This controller is compliant with IEC directives and is CE marked.

1-1

Page 20

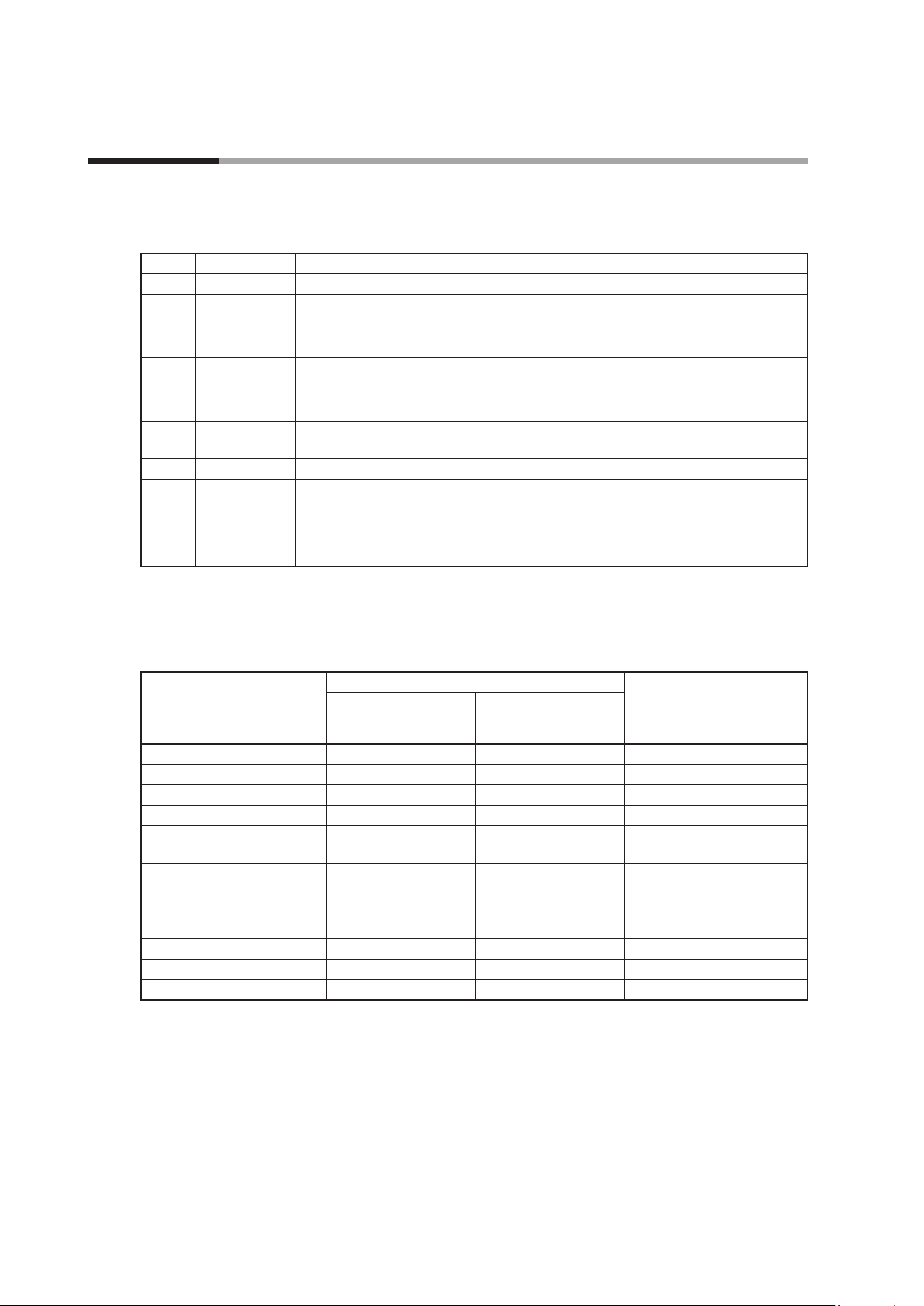

Chapter 1. Overview

1 - 2 Model No.

Model Selection Guide

Block name

Symbol Block Name Description

AI Analog input Full multi-range input (thermocouple, RTD, DC current, DC voltage)

V-P Voltage pulse

output

AO-C Analog current

output

HMI2 Additional

display unit

CLOCK Clock function Clock (available for CDS and health index) with a battery

MOTOR Motor drive

output

DI Digital input 4 digital inputs (external power source required)

DO Digital output 4 digital outputs (sink output)

Voltage pulse output (12 V DC)

2 input terminals for the current transformer (CT) for detecting heater burnout,

overcurrent, and short circuits*

Current output (4–20 mA DC / 0–20 mA DC)

Input terminals for the current transformer (CT) for measuring current and the voltage

transformer (VT) for measuring voltage (1 each)*

Connector for the second display unit*

Motor drive outputs (100/200 V AC) (direct (OPEN), reverse (CLOSE))

with motor feedback (MFB) inputs

1

1

2

*1. Current transformer (CT) and voltage transformer (VT) are sold separately.

*2. Additional display unit is sold separately.

Accessories

Qty.

Part name

Main unit 1 1

Display unit 1 1

Standard gasket 1 0 Mounted on the display unit

Gasket with 92 × 92 mm hole 0 1

Display unit mounting screws

(6 mm)

Display unit mounting screw

(10 mm)

Setscrew for temporary

mounting

Integrating bracket 0 1

Integrating cable 0 1

Installation Manual 1 1 Document No. CP-UM-5487JE

Standard (separate)

mounting model

(C7G_4)

5 5 4 screws plus 1 spare

5 0 4 screws plus 1 spare

2 0

Integrated mounting

model

(C7G_3)

Notes

1-2

Page 21

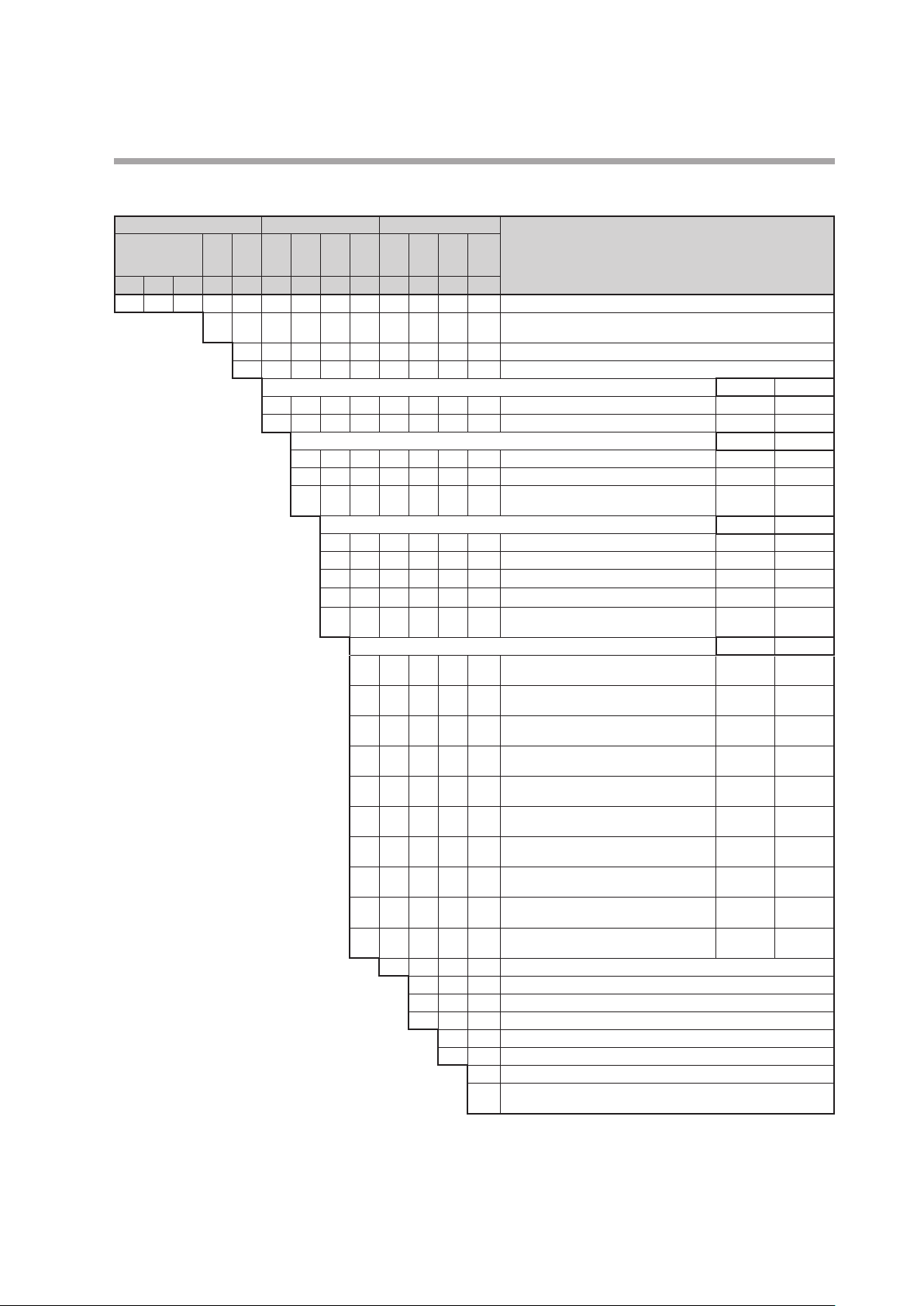

Chapter 1. Overview

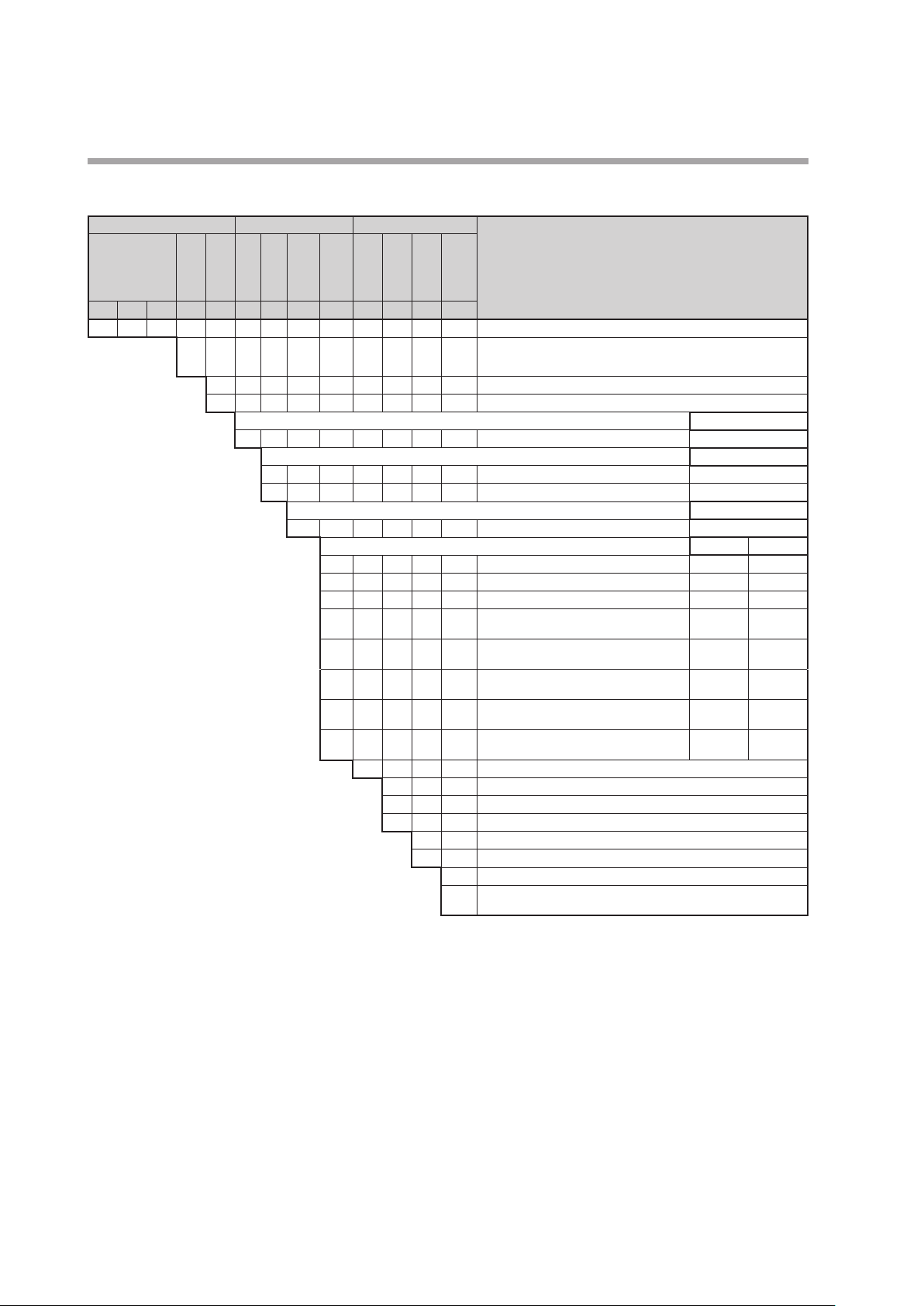

Model C7G (UL-compliant) Example: C7GA411CC0DA0

Main unit I/O Other

Slots

Slots

Slots

Comm.

Size

A3,

B3,

A4

B4

1 2 3 4 5 6 7 8 9 10 11 12 13

C 7 G Multi-loop controller with multifunction display

A Communication (Ethernet, RS-485, USB)

3 Integrated mounting*

4 Standard (separate) mounting

1 PV1 (full-multi) × 1 (No block) AI

2 PV1 (full-multi) + RSP1 (full-multi)*

0 None (No block) (No block)

1 PV2 (full-multi) × 1 (No block) AI

Selectable if the 6th digit of the model

number (slots A3, A4) = 2 ........................→

Selectable if the 8th digit of the model number

(slots A1, A2) = C, V, or F ..........................→

Selectable if the 8th digit of the model number

(slots A1, A2) = C, F, or N .........................→

Selectable if the 8th digit of the model number

(slots A1, A2) = C, V, W, or N ......................→

Selectable if the 8th digit of the model number

(slots A1, A2) = F .................................→

Selectable if the 8th digit of the model number

(slots A1, A2) = W or N ...........................→

Selectable if the 8th digit of the model number

(slots A1, A2) = F or N ............................→

Selectable if the 8th digit of the model number

(slots A1, A2) = C, F, or N .........................→

Selectable if the 8th digit of the model number

(slots A1, A2) = C, V, W, or N ......................→

Selectable if the 8th digit of the model number

(slots A1, A2) = C, F, or N .........................→

Selectable if the 8th digit of the model number

(slots A1, A2) = C, V, W, or N ......................→

2 PV2 (full-multi) + RSP2 (full-multi)*

Slots

A1,

B1, B2Option

A2

C Current output (CT and VT inputs, 1 each) × 1 (No block) AO-C

V Voltage pulse output (2 CT inputs) × 1 (No block) V-P

F Current output (CT and VT inputs, 1 each) × 2 AO-C AO-C

W Voltage pulse output (2 CT inputs) × 2 V-P V-P

N Current output (CT and VT inputs, 1 each) +

0 None (No block) (No block)

C Current output (CT and VT inputs, 1 each) × 1 (No block) AO-C

V Voltage pulse output (2 CT inputs) × 1 (No block) V-P

F Current output (CT and VT inputs, 1 each) × 2 AO-C AO-C

W Voltage pulse output (2 CT inputs) × 2 V-P V-P

N Current output (CT and VT inputs, 1 each) +

G Current output (CT and VT inputs, 1 each) +

H Voltage pulse output (2 CT inputs) + additional

L Current output (CT and VT inputs, 1 each) +

P Voltage pulse output (2 CT inputs) + clock

Add'l

Add'l

proc.

0 None

0 None

D With inspection report

Y With traceability certificate

Special

spec.

support

7 digital input/outputs (sink output, source input)

voltage pulse output (2 CT inputs)

voltage pulse output (2 CT inputs)

additional display unit

display unit

clock (with battery)

(with battery)

A AC power plus CE, KC, GB, and UL compliance

B DC power plus CE, KC, GB, and UL compliance

0 No special support

F Overseas models: switchable between Celsius/Fahrenheit

Do not use these models in Japan.

DescriptionBase model No.

1

Slot A3 Slot A4

2

Slot B3 Slot B4

3

Slot A1 Slot A2

V-P AO-C

Slot B1 Slot B2

V-P AO-C

HMI2 AO-C

HMI2 V-P

CLOCK AO-C

CLOCK V-P

AI AI

AI AI

*1. A rear mounting bracket and a dedicated cable for connecting the display unit are included with the product.

*2. RSP1 can be switched for use as PV3.

*3. RSP2 can be switched for use as PV4.

1-3

Page 22

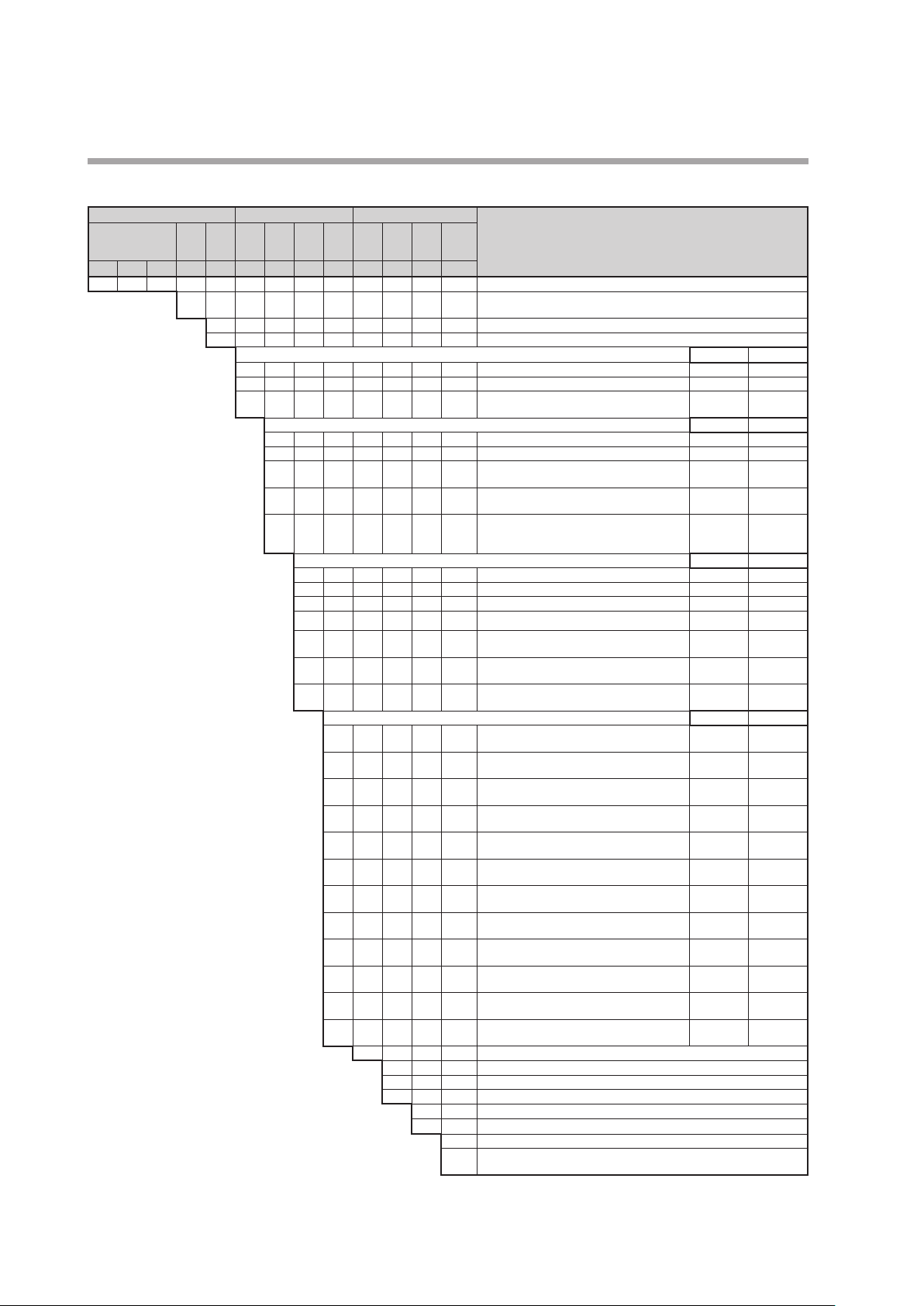

Chapter 1. Overview

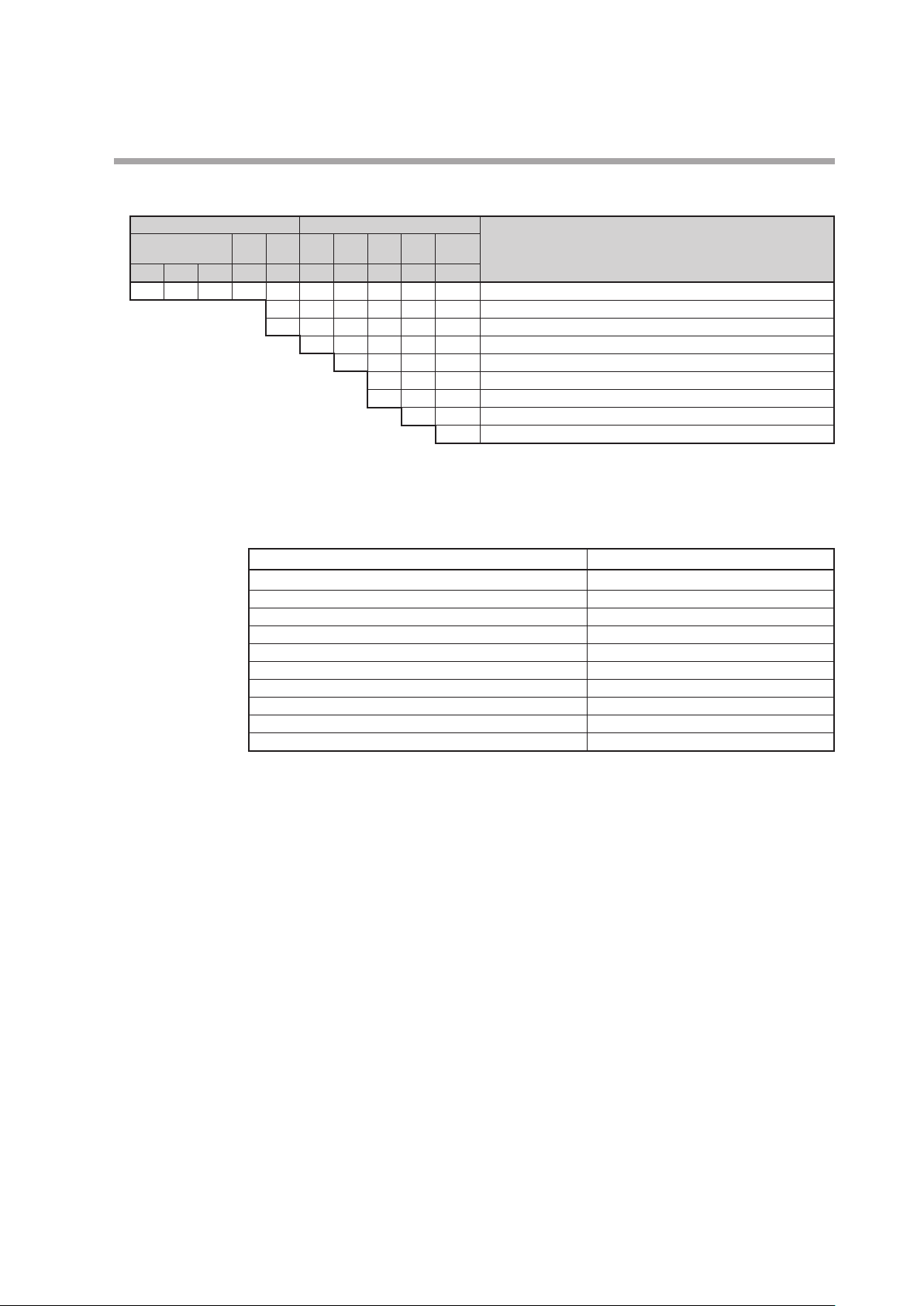

Model C7G (Not UL-compliant) Example: C7GA411CC0D00

Main unit I/O Other

Comm.

1 2 3 4 5 6 7 8 9 10 11 12 13

C 7 G Multi-loop controller with multifunction display

A Communication (Ethernet, RS-485, USB)

Selectable if the 6th digit of the

model number (slots A3, A4) = 2 ..→

Selectable if the 6th digit of the model

number (slots A3, A4) = 2 or A .......→

Selectable if the 9th digit of the

model number (slots B1, B2) = 0, C, V,

F, W, N, G, H, 1, or 2 .................→

Selectable if the 8th digit of the model number

(slots A1, A2) = C, V, F, 1, or 2 .....................→

Selectable if the 8th digit of the model number

(slots A1, A2) = C, F, N, or 1 .......................→

Selectable if the 8th digit of the model number

(slots A1, A2) = C, V, W, N, 1, or 2 .................→

Selectable if the 8th digit of the model number

(slots A1, A2) = F .................................→

Selectable if the 8th digit of the model number

(slots A1, A2) = W or N ...........................→

Selectable if the 8th digit of the model number

(slots A1, A2) = F or N ............................→

Selectable if the 8th digit of the model number

(slots A1, A2) = C, F, N, or 1 .......................→

Selectable if the 8th digit of the model number

(slots A1, A2) = C, V, W, N, 1, or 2 .................→

Selectable if the 8th digit of the model number

(slots A1, A2) = C, F, N, or 1 .......................→

Selectable if the 8th digit of the model number

(slots A1, A2) = C, V, W, N, 1, or 2 .................→

Selectable if the 8th digit of the model number

(slots A1, A2) = F, N, or 1. . . . . . . . . . . . . . . . . . . . . . . . . . →

Selectable if the 8th digit of the model number

(slots A1, A2) = W, N, 1, or 2 ......................→

Slots

Slots

Slots

Size

A3,

B3,

A4

B4

3 Integrated mounting*

4 Standard (separate) mounting

1 PV1 (full-multi) × 1 (No block) AI

2 PV1 (full-multi) + RSP1 (full-multi)*

A PV1 (full-multi) + 4 digital inputs (external

0 None (No block) (No block)

1 PV2 (full-multi) × 1 (No block) AI

2 PV2 (full-multi) + RSP2 (full-multi)*

A PV1 (full-multi) + 4 digital inputs (external

B PV1 (full-multi) + clock (with battery) CLOCK AI

Slots

A1,

B1, B2Option

A2

C Current output (CT and VT inputs, 1 each) × 1 (No block) AO-C

V Voltage pulse output (2 CT inputs) × 1 (No block) V-P

F Current output (CT and VT inputs, 1 each) × 2 AO-C AO-C

W Voltage pulse output (2 CT inputs) × 2 V-P V-P

N Current output (CT and VT inputs, 1 each) +

1 Current output (CT and VT inputs, 1 each) + 4

2 Voltage pulse output (2 CT inputs) × 4 digital

0 None (No block) (No block)

C Current output (CT and VT inputs, 1 each) × 1 (No block) AO-C

V Voltage pulse output (2 CT inputs) × 1 (No block) V-P

F Current output (CT and VT inputs, 1 each) × 2 AO-C AO-C

W Voltage pulse output (2 CT inputs) × 2 V-P V-P

N Current output (CT and VT inputs, 1 each) +

G Current output (CT and VT inputs, 1 each) +

H Voltage pulse output (2 CT inputs) +

L Current output (CT and VT inputs, 1 each) +

P Voltage pulse output (2 CT inputs) + clock

1 Current output (CT and VT inputs, 1 each) × 4

2 Voltage pulse output (2 CT inputs) × 4 digital

Add'l

Add'l

proc.

0 None

0 None

D With inspection report

Y With traceability certificate

Special

spec.

support

7 digital input/outputs (sink output, source input)

power source required)

power source required)

voltage pulse output (2 CT inputs)

digital outputs (sink output)

outputs (sink output)

voltage pulse output (2 CT inputs)

additional display unit

additional display unit

clock (with battery)

(with battery)

digital outputs (sink output)

outputs (sink output)

0 AC power plus CE, KC, and GB compliance

D DC power plus CE, KC, and GB compliance

0 No special support

F Overseas models: switchable between Celsius/Fahrenheit

Do not use these models in Japan.

DescriptionBase model No.

1

2

3

Slot A3 Slot A4

AI AI

DI AI

Slot B3 Slot B4

AI AI

DI AI

Slot A1 Slot A2

V-P AO-C

DO AO-C

DO V-P

Slot B1 Slot B2

V-P AO-C

HMI2 AO-C

HMI2 V-P

CLOCK AO-C

CLOCK V-P

DO AO-C

DO V-P

*1. A rear mounting bracket and a dedicated cable for connecting the display unit are included with the product.

*2. RSP1 can be switched for use as PV3.

*3. RSP2 can be switched for use as PV4.

1-4

Page 23

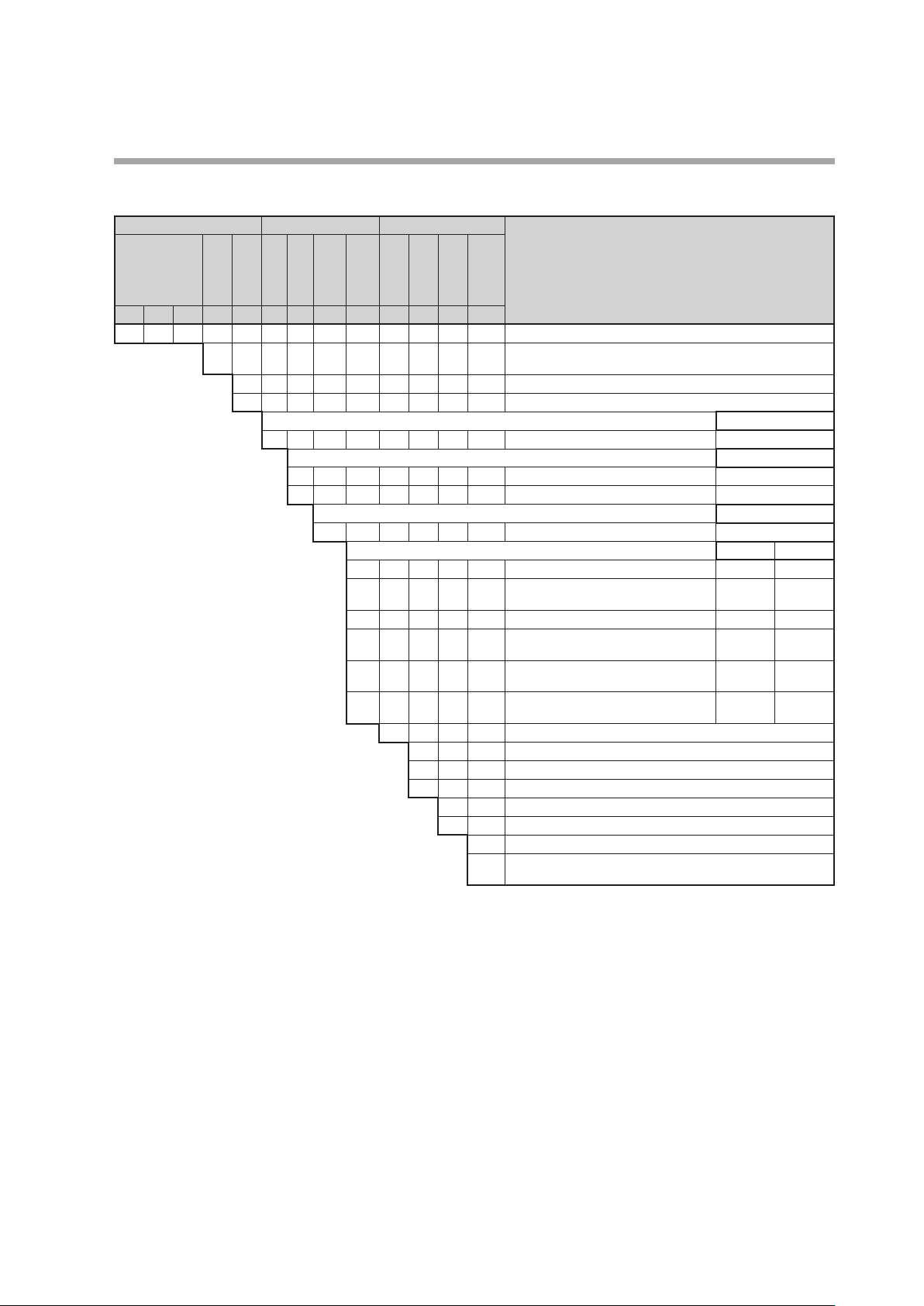

Chapter 1. Overview

Model C7G with MOTOR Block (UL-compliant) Example: C7GA411MC0DA0

Main unit I/O Other

Slots

Slots

Comm.

1 2 3 4 5 6 7 8 9 10 11 12 13

C 7 G Multi-loop controller with multifunction display

A Communication (Ethernet, RS-485, USB)

Slot A4Slot

Size

3 Integrating kit included*

4 Standard mounting

1 PV1 (full-multi) × 1 AI

A2,

A1,

A3,

B4

0 None

1 PV2 (full-multi) × 1*

B1

B2,

B3

M Motor drive output (with MFB input) MOTOR

0 None

C Current output (CT and VT inputs, 1 each)

V Voltage pulse output (2 CT inputs) × 1 V-P

N Current output (CT and VT inputs, 1 each)

G Current output (CT and VT inputs, 1 each)

L Current output (CT and VT inputs, 1 each)

Add'l

Add'l

Option

proc.

0 None

0 None

D With inspection report

Y With traceability certificate

Special

spec.

support

7 digital input/outputs (sink output, source input)

× 1

+ voltage pulse output (2 CT inputs)

+ additional display unit

+ clock (with battery)

A AC power plus CE, KC, GB, and UL compliance

B DC power plus CE, KC, GB, and UL compliance

0 No special support

F Overseas models: switchable between Celsius/Fahrenheit

Do not use these models in Japan.

DescriptionBase model No.

1

2

Slot A4

Slot B4

(No block)

Slots A2, A3, B2, B3

Slot A1 Slot B1

(No block) (No block)

AO-C

AO-C V-P

AO-C HMI2

AO-C CLOCK

AI

(No block)

(No block)

*1. A rear mounting bracket and a dedicated cable for connecting the display unit are included with the product.

*2. PV2 can be switched for use as RSP1.

1-5

Page 24

Chapter 1. Overview

Model C7G with MOTOR Block (Not UL-compliant) Example: C7GA411MC0D00

Main unit I/O Other

Slots

A2,

Comm.

1 2 3 4 5 6 7 8 9 10 11 12 13

C 7 G Multi-loop controller with multifunction display

A Communication (Ethernet, RS-485, USB)

Slot A4Slot

Size

3 Integrating kit included*

4 Standard mounting

B4

1 PV1 (full-multi) × 1 AI

0 None (No block)

1 PV2 (full-multi) × 1*

Slots

A3,

A1,

B2,

B1

B3

M Motor drive output (with MFB input) MOTOR

0 None (No block) (No block)

C Current output (CT and VT inputs, 1 each) × 1 AO-C (No block)

V Voltage pulse output (2 CT inputs) × 1 V-P (No block)

N Current output (CT and VT inputs, 1 each) +

G Current output (CT and VT inputs, 1 each) +

L Current output (CT and VT inputs, 1 each) +

1 Current output (CT and VT inputs, 1 each) × 4

4 4 digital outputs (sink output) + clock (with

Add'l

Add'l

Option

proc.

0 None

0 None

D With inspection report

Y With traceability certificate

Special

spec.

support

7 digital input/outputs (sink output, source input)

voltage pulse output (2 CT inputs)

additional display unit

clock (with battery)

digital outputs (sink output)

battery)

0 AC power plus CE, KC, and GB compliance

D DC power plus CE, KC, and GB compliance

0 No special support

F Overseas models: switchable between Celsius/Fahrenheit

Do not use these models in Japan.

DescriptionBase model No.

1

2

Slots A2, A3, B2, B3

Slot A1 Slot B1

AO-C V-P

AO-C HMI2

AO-C CLOCK

AO-C DO

Slot A4

Slot B4

AI

DO CLOCK

*1. A rear mounting bracket and a dedicated cable for connecting the display unit are included with the product.

*2. PV2 can be switched for use as RSP1.

1-6

Page 25

Chapter 1. Overview

C7D Additional Display Unit Example: C7D-400D00

Main unit Other

Option 1Option 2Add'l

1 2 3 4 5 6 7 8 9 10

C 7 D - Additional display unit for multi-loop controller with multifunction display

3 Integrated mounting*

4 Standard mounting

0 English, Japanese

0 None

Add'l

proc.

0 None

D With inspection report

Special

spec.

support

0 CE marking, KC, GB

0 No special support

DescriptionBase model No. - Size

* Rear mounting bracket included.

Optional Parts (Sold Separately)

SLP-C7 Smart Loader Package (free version)*

SLP-C7 Smart Loader Package (paid version) SLP-C7-J91

Power terminal covers (10) 81447704-001 (available soon)

Integrating kit 84503167-001 (available soon)

MicroSD card (replacement) 84502552-001 (available soon)

Clock block (replacement) 84501420-001 (available soon)

MOTOR Block (replacement) 84501421-001 (available soon)

Current transformer (5.8 mm in diameter) QN206A

Current transformer (12 mm in diameter) QN212A

Voltage transformer (for 200 V AC) 81406725-003

Part name Model No.

SLP-C7FJ91

1-7

Page 26

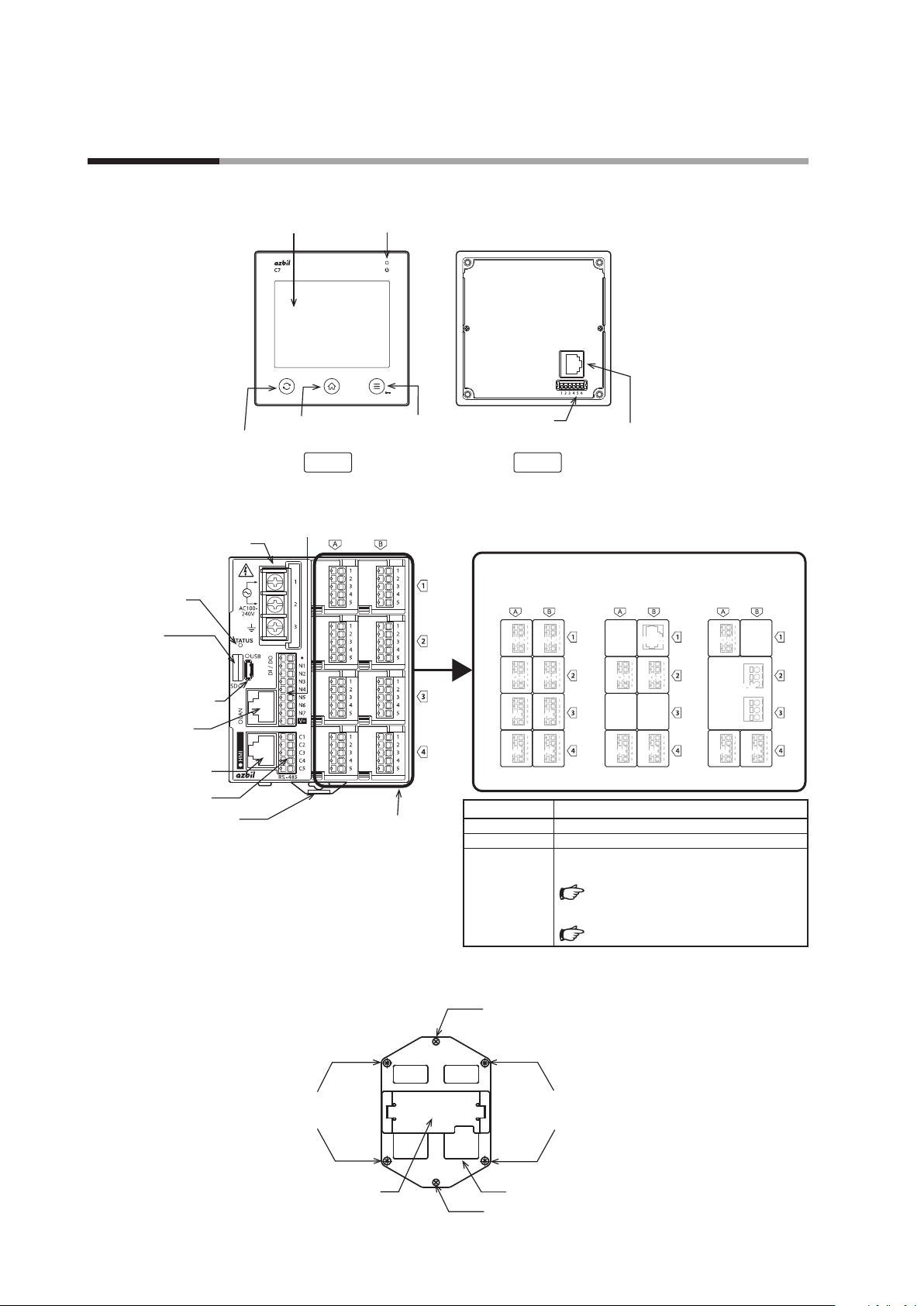

Chapter 1. Overview

1 - 3 Names of Parts and Their Functions

Display unit

Main unit

Power supply terminal block

(with cover)

Status indicator

Connector for

microSD* memory card

LCD touch panel

Change button

Power indicator (green for normal status)

Home button

Front

DI/DO terminal block

Menu button

Top

Terminal block

Back

AO-C AO-CAO-CAO-CAO-C

AO-C

Main unit connector

Block diagram examples

C7G_ _ 11CG_ _ _ _ C7G_ _ 11MC_ _ _ _ C7G_ _ 22FF_ _ _ _

HMI2

HMI2

AO-CAO-C

AO-CAO-C

MicroUSB

(TYPE-A/B)

LAN connector

Display connector

RS-485 terminal block

DIN rail holding tab

*

microSD is trademark or registered

trademark of SD-3C, LLC in the

United States, other countries or both.

IO slot

AI

AI

AI

AI

AI

AI

AI

AI

Status indicator Status

Off Not energized

Lit green Normal operation

Lit red

Malfunction

To check an alarm shown on the display,

11 - 2 Alarm (p.11-2)

If a display unit error occurs,

11 - 3 Display Error (p.11-7)

Integrating bracket (supplied with integrated mounting models)

Control panel mounting screw

(2 locations)

Display unit mounting hole

(4 locations)

Display unit mounting hole

(4 locations)

AO-CAO-C

AO-CAO-C

AI

AI AIAI AIAI

AI

AI

MOTORMOTOR

1-8

Main unit mounting rail

Wiring hole

Control panel mounting screw

(2 locations)

Page 27

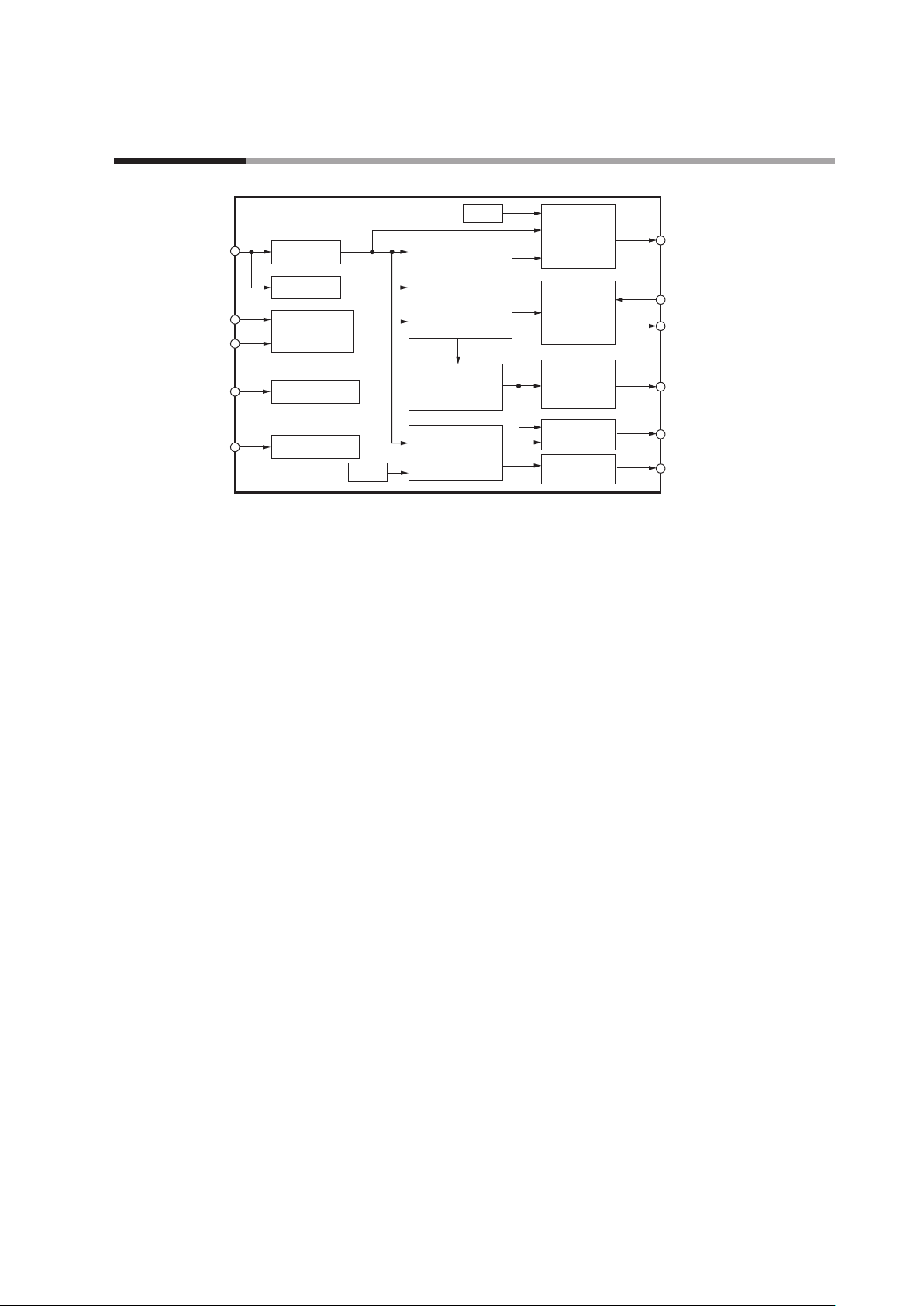

1 - 4 Input/output Configuration

Chapter 1. Overview

Analog input 1 to 4 *

Digital input 1 to 7 *

Digital input 1 to 8 *

CT input 1 to 8 *

VT input 1 to 4 *

*1. There are 7 digital inputs (DI) or outputs (DO) in total. Depending on the setting, they can be switched between DI and DO.

*2. There are from 1 to 4 analog inputs, depending on the model number.

*3. There are from 0 to 4 analog output and VT input points, a total of 4, depending on the model number.

*4. There are from 0 to 8 CT input points, depending on the model number.

*5. There are from 0 to 4 voltage pulse output points, depending on the model number.

*6. There is 0 or 1 set of motor drive outputs (OPEN, CLOSE) and MFB input, depending on the model number.

*7. There are from 1 to 4 control loops, depending on the number of analog inputs and the loop type settings.

*8. There are from 0 to 8 digital inputs, selectable by model number, in addition to the digital inputs described in *1.

*9. There are from 0 to 8 digital outputs, selectable by model number, in addition to the digital outputs described in *1.

Other

2

1

8

4

3

PV process

RSP process

Digital

input process

CT input process

VT input process

Other

Control process*

(PID control,

ON/OFF control)

Internal cascade

control,

Pattern operation)

TP

(time proportioning)

output process

Event process

7

Analog

output

process

Motor drive

output

process

Voltage pulse

output

process

Digital output

process

Digital output

process

Analog output 1 to 4

(Output by scaling the MV,

PV, and other using the

current output.)*

MFB

(motor feedback) input *

Motor drive output

(OPEN, CLOSE) *

Voltage pulse outputs

1 to 4

(TP output) *

Digital output 1 to 7 *

Digital output 1 to 8 *

3

6

5

1

9

6

Analog input (block positions: A4, B4, A3, B3)

The PV can be measured by selecting the sensor type or range. For DC voltage

and DC current, PV and RSP scaling can be set. The input from a thermocouple

or resistance temperature detector can be used as the RSP. Linear approximation is

available.

Analog output (AO-C) (block positions: A2, B2, A1, B1)

The scaled MV can be output as current. Additionally, when PV, SP, or deviation is

selected for the output type, these values can also be scaled and output as current.

Linear approximation is available.

Voltage pulse output (V-P) (block positions: A2, B2, A1, B1)

The time proportioning output function set using the TP (time proportioning)

bank can be used. Linear approximation is available.

Motor drive output (MOTOR) (block position: B2)

The motor drive output function set using the PP (position proportioning) bank

can be used. Linear approximation is available.

Digital input (DI)

Change functions set using the DI bank, such as mode change, or SP group change,

can be used.

1-9

Page 28

Chapter 1. Overview

Digital output (DO)

Output functions such as event output that are set using the DO bank, or the time

proportioning output function set using the TP (time proportioning) bank, can be

used. Linear approximation is available for time proportioning output.

CT (current transformer) input (block positions: A2, B2, A1, B1)

The current can be measured by the input from the CT. The control loop that

displays CT input can be set in the basic action bank.

VT (voltage transformer) input (block positions: A2, B2, A1, B1)

The voltage can be measured by the input from the VT. The control loop that

displays VT input can be set in the basic action bank. The resistance of the actuators

(heaters) calculated from the CT input and VT input can also be displayed in the

same control loop as VT input.

1-10

Page 29

Chapter 1. Overview

1 - 5 Button Operation

Various kinds of data can be displayed or set using the buttons on the display unit screen and the buttons on the

lower section of the display unit screen.

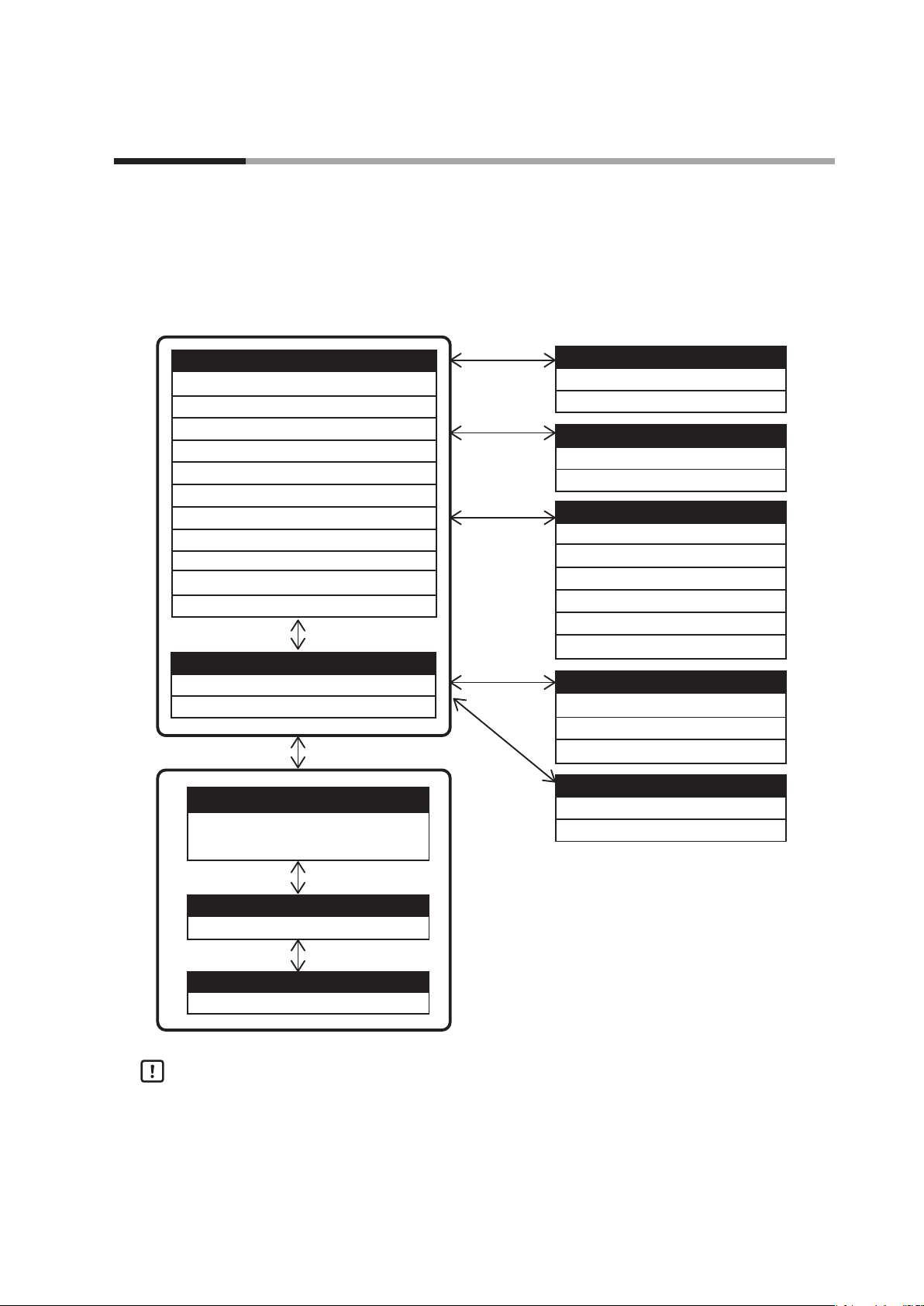

Screen transitions

When the power is turned on, the monitor screen is displayed. Use the buttons on

the monitor screen or graph screen to switch between screens.

Monitor screen

PV, SP, MV, MV bar graph

PV, MV (when in MANUAL mode)

PV, SP, MV, Cool MV, Heat MV (when in heating and cooling control)

PV, SP, MV, pattern time (in pattern operation)

PV, SP, MV, segment time (in pattern operation)

PV, SP, MV, number of cycles, remaining cycles (in pattern operation)

PV、SP、MV、CT、VT(AO-C block

PV、SP、MV

PV、SP、MV、CT1、CT2(V-P block

PV、SP、MV、MFB(MOTOR block

PV、SP、MV、AT progress graph (during AT)

Graph screen

PV, SP, MV graph

PV graph for 2 to 4 loops

、resistance(

Parameter bank menu

Displays the SP, event, PID, and other

parameter banks.

AO-C block

)

)

)

)

Alarm

Block alarm

Function alarm

SP change

LSP group, RSP select

LSP value change

Mode menu

AUTO/MANUAL

RUN/READY

AT start

HOLD ON/OFF (in pattern operation)

ADVANCE (in pattern operation)

G.SOAK clear (in pattern operation)

DI/DO monitor

ON/OFF status of DI, DO

ON/OFF status of events

ON/OFF status of segment events (in pattern operation)

Touch panel position adjust

Touch panel adjust

Touch panel test

Parameter item menu

Displays the items in the parameter bank.

Parameter item setting

Set value can be input using the numeric keypad.

Handling Precautions

• The figure above shows only the major screen transitions. Many screen

transitions are not shown.

• Do not press two or more locations on the touch panel at the same time.

Doing so may cause an error.

• If the firmware version of the MAIN block is earlier than 6.x.x (where x stands

for any number), the screen for pattern operation and the screen showing the

ON/OFF status of events and segment events cannot be displayed.

1-11

Page 30

Chapter 1. Overview

Parameter bank

SP

EVENT

PID

ANALOG INPUT

BASIC ACTION

The order of the parameter banks and parameter items is shown by the tree

structure below.

Parameter bank Parameter item

SP values of LSP1 to LSP8, RSP for loops 1 to 4

PID group number of LSP1 to LSP8, RSP for loops 1 to 4

Main setting for event groups 1 to 16

Sub-setting for event groups 1 to 16

Hysteresis for event groups 1 to 16

ON-delay time for event groups 1 to 16

OFF-delay time for event groups 1 to 16

P (Proportional band) of PID groups 1 to 8 for loops 1 to 4

I (Integral time) of PID groups 1 to 8 for loops 1 to 4

D (Derivative time) of PID groups 1 to 8 for loops 1 to 4

RE (Manual reset) of PID groups 1 to 8 for loops 1 to 4

OL (MV low limit) of PID groups 1 to 8 for loops 1 to 4

OH (MV high limit) of PID groups 1 to 8 for loops 1 to 4

Cooling-use proportional band of PID groups 1 to 8 for

loops 1 to 4

Cooling-use cumulative time of PID groups 1 to 8 for loops

1 to 4

Cooling-use derivative time of PID groups 1 to 8 for loops 1 to 4

Cooling-use MV low limit of PID groups 1 to 8 for loops 1 to 4

Cooling-use MV high limit of PID groups 1 to 8 for loops 1 to 4

Range type of blocks A4, B4, A3, and B3

Linear scaling low limit of blocks A4, B4, A3, and B3

Linear scaling high limit of blocks A4, B4, A3, and B3

Filter of blocks A4, B4, A3, and B3

Ratio of blocks A4, B4, A3, and B3

Bias of blocks A4, B4, A3, and B3

Linearization table group definition of blocks A4, B4, A3, and

B3

Sampling cycle

Power supply frequency

Time unit of patterns

HOME screen layout

Run/Ready at startup for loops 1 to 4

No. of decimal places for PV 1 to 4

Display loop for A2/B2/A1/B1 block input

HOME screen setting for loops 1 to 4

Display intensity

Display language

Engineering mode

1-12

Page 31

Parameter bank Parameter item

CONTROL

SP CONFIG

ANALOG OUTPUT

EVENT CONFIG

DI/DO CONFIG

DO CONFIG

DI

Chapter 1. Overview

Control action for loops 1 to 4

Differential for ON/OFF control for loops 1 to 4

Heating/cooling control dead zone for loops 1 to 4

PID initial MV for loops 1 to 4

PID initialization for loops 1 to 4

Type of change to MANUAL for loops 1 to 4

Preset MANUAL value for loops 1 to 4

MV increase change limit for loops 1 to 4

MV decrease change limit for loops 1 to 4

MV low limit during AT for loops 1 to 4

MV high limit during AT for loops 1 to 4

SP lag factor for loops 1 to 4

READY MV for loops 1 to 4

Output at READY (heat) for loops 1 to 4

Output at READY (cool) for loops 1 to 4

MV select as PV error for loops 1 to 4

MV value as PV error for loops 1 to 4

Fixed-value output 1 to 8 for loops 1 to 4

SP low limit for loops 1 to 4

SP high limit for loops 1 to 4

SP ramp unit for loops 1 to 4

LSP ramp up slope for loops 1 to 4

LSP ramp down slope for loops 1 to 4

RSP tracking for loops 1 to 4

Number of LSP groups for loops 1 to 4

Output range of blocks A2, B2, A1, and B1

Output type of blocks A2, B2, A1, and B1

Loop definition of blocks A2, B2, A1, and B1

Output scaling low limit of blocks A2, B2, A1, and B1

Output scaling high limit of blocks A2, B2, A1, and B1

Linearization table group definition of blocks A2, B2, A1, and

B1

Operation type for event groups 1 to 16

Loop definition for event groups 1 to 16

Direct/reverse for event groups 1 to 16

Standby for event groups 1 to 16

READY mode operation for event group 1 to 16

Operation type of DI/DO 1 to 7

Operation type of DO groups 1 to 7 of DI/DO

Operation type of DO groups 1 to 4 of blocks A1 and B1

Operation type of DI groups 1 to 32

Input type of DI groups 1 to 32

Loop definition of DI groups 1 to 32

1-13

Page 32

Chapter 1. Overview

TP

LOGICAL OPERATION

USER-DEFINED BIT

USER-DEFINED VALUE

USER-DEFINED ALARM

CT

VT

PP (POSITION PROPORTIONAL)

Parameter bank Parameter item

TP output type of DO groups 4 to 7 and blocks A2, B2, A1,

and B1

TP output cycle of DO groups 4 to 7 and blocks A2, B2, A1,

and B1

TP operation type of DO groups 4 to 7 and blocks A2, B2, A1,

and B1

Linearization table group definition of DO groups 4 to 7 and

blocks A2, B2, A1, and B1

Calculation type of logical operations 1 to 32

Input assignments A to D of logical operations 1 to 32

Input bit attributes A to D of logical operations 1 to 32

ON-delay time of logical operations 1 to 32

OFF-delay time of logical operations 1 to 32

Reversal of logical operations 1 to 32

User-defined bits 1 to 16

User-defined values 1 to 16

Assignments 1 to 4 of user-defined alarms 1 to 4

Loop specification for user-defined alarms 1 to 4

Number of turns of blocks A2, B2, A1, and B1

Number of power wire loops of blocks A2, B2, A1, and B1

CT operation of blocks A2, B2, A1, and B1

CT measurement waiting time of blocks A2, B2, A1, and B1

Heater burnout detection current value of blocks A2, B2, A1,

and B1

Minimum current defined as overcurrent of blocks A2, B2,

A1, and B1

Minimum current defined as short circuit of blocks A2, B2,

A1, and B1

Hysteresis of blocks A2, B2, A1, and B1

Delay time of blocks A2, B2, A1, and B1

Condition for restoring status before measurement of blocks

A2, B2, A1, and B1

Primary voltage of blocks A2, B2, A1, and B1

Secondary voltage of blocks A2, B2, A1, and B1

Output type

Control method selection

Dead zone

Auto-tuning

Fully closed MFB count

Fully open MFB count

Full opening time

Linearization table group definition

1-14

Page 33

Parameter bank Parameter item

LINEARIZATION TABLE

CASCADE

PATTERN CONFIG

PATTERN

SEGMENT

GRAPH

ETHERNET

IP ADDRESS

RS-485

CDS

HEALTH INDEX

HEALTH INDEX GRAPH

Chapter 1. Overview

Operation type of linearization table groups 1 to 8

10 break points of linearization table groups 1 to 8

Scaling method

Scaling low limit

Scaling high limit

Filter

Pattern start number for loops 1 to 4

Pattern start number low limit for loops 1 to 4

Pattern start number high limit for loops 1 to 4

PTN SP increase change limit for loops 1 to 4

PTN SP decrease change limit for loops 1 to 4

Number of segments of patterns 1 to 16

G.SOAK time of patterns 1 to 16

PV start of patterns 1 to 16

Cycle of patterns 1 to 16

Pattern link of patterns 1 to 16

End of operation of patterns 1 to 16

SP of segments 1 to 16 of patterns 1 to 16

Time of segments 1 to 16 of patterns 1 to 16

PID Group of segments 1 to 16 of patterns 1 to 16

G.SOAK type of segments 1 to 16 of patterns 1 to 16

G.SOAK width of segments 1 to 16 of patterns 1 to 16

Segment event in segments 1 to 16 of patterns 1 to 16

Multi-loop recording cycle for loops 1 to 4

Graph scaling low limit for loops 1 to 4

Graph scaling high limit for loops 1 to 4

Modbus/TCP port number

IP address

Subnet mask

Default gateway

Station address

Transmission speed

Data type (parity)

Data type (stop bits)

Minimum response time

Recording cycle

Operation type

Operation type for loops 1 to 4

R value scale for loops 1 to 4

Ideal data for loops 1 to 4

Deviation low limit for loops 1 to 4

Deviation high limit for loops 1 to 4

The 10 latest specific R value graph for loops 1 to 4

1-15

Page 34

Chapter 1. Overview

DATE TIME

INPUT ASSIGNMENT

VIRTUAL ANALOG INPUT

FIRMWARE VERSION

Parameter bank Parameter item

Year, month, day, hour, minutes, and seconds

PV assignments for loops 1 to 4

RSP assignment for loops 1 to 4

Assignment range low limit for loops 1 to 4

Assignment range high limit for loops 1 to 4

Virtual AI assignment of virtual AI 1 to 4

Filter of virtual AI 1 to 4

Ratio of virtual AI 1 to 4

Bias of virtual AI 1 to 4

Linearization table group definition of virtual AI 1 to 4

Version of MAIN block

Version of HMI block (display unit)

Version of DI/DO block

Version of RS-485 block

Version of blocks A1 to A4

Version of blocks B1 to A4

(Including additional display unit and CLOCK block)

Japanese language display

If the "Language indication" setting of the basic action bank is set to "1: Japanese,"

the banks, items, and descriptions displayed on the parameter setting screen and

some of the content on the mode change screen will appear in Japanese. The default

setting for "Language indication" is "0: English."

1-16

Page 35

Monitor and graph screen transitions

For 1 loop

Graph icon Numeric icon

Power-on

1-loop monitor

screen

(LOOP1)

1-loop graph

screen

(LOOP1)

Chapter 1. Overview

Home button

The home screen is the

1-loop monitor screen.

1-17

Page 36

Chapter 1. Overview

For 2 loops

Power-on

Home button

The home screen is the multi-loop monitor screen.

Touch the display of each loop.

Multi-loop

monitor screen

(LOOP1 to 2)

Graph icon Numeric icon

Touch the PV No. of each loop.

Multi-loop graph

screen

(LOOP1 to 2)

1-loop monitor

screen

(LOOP1)

Change button

1-loop graph

screen

(LOOP1)

Change button

1-loop monitor

1-loop graph

screen

(LOOP2)

screen

(LOOP2)

1-18

Handling Precautions

• The screen transitions when the loop type is internal cascade are identical to

those for 2 loops.

• The screen set by the user can be displayed when the power is turned ON or

the home button is pressed. Screen transitions of the user HOME screen

(p.1-21)

Page 37

For 3 loops

Chapter 1. Overview

Power-on

Home button

The home screen is the multi-loop monitor screen.

Touch the display of each loop.

Multi-loop

monitor screen

(LOOP1 to 3)

Graph icon Numeric icon

Touch the PV No. of each loop.

Multi-loop graph

screen

(LOOP1 to 3)

1-loop monitor

screen

(LOOP1)

1-loop graph

screen

(LOOP1)

1-loop monitor

screen

(LOOP2)

Change button

1-loop graph

screen

(LOOP2)

Change button

1-loop monitor

screen

(LOOP3)

1-loop graph

screen

(LOOP3)

Handling Precautions

• The screen transitions when the loop type is "Internal cascade + 1 loop" are

identical to those for 3 loops.

• The screen set by the user can be displayed when the power is turned ON or

the home button is pressed. Screen transitions of the user HOME screen

(p.1-21)

1-19

Page 38

Chapter 1. Overview

For 4 loops

Power-on

Touch the display of each loop.

Home button

The home screen is the multi-loop monitor screen.

Multi-loop

monitor screen

(LOOP1 to 4)

Touch the PV No. of each loop.

Multi-loop graph

screen

(LOOP1 to 4)

1-loop monitor

screen

(LOOP1)

Graph icon Numeric icon

1-loop graph

screen

(LOOP1)

1-loop monitor

screen

(LOOP2)

Change button

1-loop graph

screen

(LOOP2)

Change button

1-loop monitor

1-loop graph

screen

(LOOP3)

screen

(LOOP3)

1-loop monitor

screen

(LOOP4)

1-loop graph

screen

(LOOP4)

1-20

Handling Precautions

• The screen transitions when the loop type is "Internal cascade +2 loops" are

identical to those for 3 loops.

• The screen set by the user can be displayed when the power is turned ON or

the home button is pressed. Screen transitions of the user HOME screen

(p.1-21)

Page 39

Screen transitions of the user HOME screen

From the loops set to be used in the loop type setting, enable the loop to be

displayed on the user HOME screen with the following settings.

Item (bank) Display Description Initial value

Loop1 HOME screen setting

(Basic action bank)

MENU>BasicAction

Loop1 HOME screen setting

0: Disabled

1: Enabled

Chapter 1. Overview

0

Power-on

User home

screen

(LOOP1 to 2)

Loop2 HOME screen setting

(Basic action bank)

Loop3 HOME screen setting

(Basic action bank)

Loop4 HOME screen setting

(Basic action bank)

The user HOME screen is displayed only when the power is turned ON or the

home button is pressed.

For example, if the loop type is set to 4 loops and Loop 1 and Loop 2 are selected for

display on the user HOME screen, the transitions on the Numeric Monitor screen

are as shown in the figure below.

Home button

Change button

MENU>BasicAction

Loop2 HOME screen setting

MENU>BasicAction

Loop3 HOME screen setting

MENU>BasicAction

Loop4 HOME screen setting

0: Disabled

1: Enabled

0: Disabled

1: Enabled

0: Disabled

1: Enabled

0

0

0

Touch the display of each loop.

1-loop monitor

Home screen

(LOOP1 to 4)

Separate user HOME screens can be set for the standard display unit and additional

display unit.

Therefore, settings such as the following are also possible.

• Show Loop 1 and Loop 2 on the user HOME screen of the standard display unit.

• Show Loop 3 and Loop 4 on the user HOME screen of the additional display unit.

screen

(LOOP1)

1-loop monitor

screen

(LOOP2)

Change button

1-loop monitor

screen

(LOOP3)

1-loop monitor

screen

(LOOP4)

1-21

Page 40

Chapter 1. Overview

The "HOME screen layout" setting (left/right split, left/right swap, vertically

arranged) also applies to the 2-loop screen.

The 3-loop screen is vertically arranged regardless of the "HOME screen layout"

setting.

If the graph icon on the user HOME screen is touched, the display changes to the

graph screen.

• If the user HOME screen is a multi-loop screen, the destination graph screen will

also be a multi-loop screen.

• If the user HOME screen is a 1-loop screen, the destination graph screen will also

be a 1-loop screen.

• If the numeric icon is touched after going from the user HOME screen to the

graph screen by touching the graph icon, the screen will return to the HOME

screen or the 1-loop monitor screen, but not to the user HOME screen.

Handling Precautions

• If the version of the MAIN block firmware is earlier than 6.x.x (where x stands

for any number), there is no user HOME screen.

1-22

Page 41

Chapter 1. Overview

1 - 6 Operation Modes

Up to four loops can be controlled individually. The operation modes can also be changed individually or all

together.

The following shows the transition of the operation modes.

RUN + AUTO mode

Constant value operation

LSP mode RSP mode

ends

*2

Pattern operation

ends

RUN-HOLD

RUN-END

Operation mode

changes

Pattern operation

RUN mode

Pattern operation

AT stop AT stop

AUTO/MANUAL mode selection AUTO/MANUAL mode selection

RUN +

MANUAL mode

Constant value operation

LSP mode RSP mode

Operation mode

changes

Pattern operation

ends

*3

mode

mode

*3

RUN/READY

mode selection

Pattern operation

ends

*1

RUN/READY

mode selection

READY + AUTO mode

Constant value operation

LSP mode RSP mode

Operation mode

changes

Pattern operation

READY mode

AT stop

READY +MANUAL mode

Constant value operation

LSP mode RSP mode

Operation mode

changes

Pattern operation

RUN mode

Pattern operation

ends

RUN-HOLD

*2

RUN-END

mode

mode

Pattern operation

ends

*1

AT stop

*1. Transition if "End of operation" is set to READY

2

*

. Transition if "End of operation" is set to END

3

*

. Transition if "End of operation" is set to constant value operation

Pattern operation

READY mode

AT stop

1-23

Page 42

Chapter 1. Overview

Constant value operation: Process control uses the LSP or RSP.

Pattern operation: Process control uses the pattern SP (the SP is generated from the segment setting stored

in the measuring instrument).

RUN: Control execution status (the three statuses of RUN, RUN-HOLD, and RUN-END in

the case of pattern operation)

READY: Control stop status

AUTO: Automatic operation (This controller automatically determines the MV value.)

MANUAL: Manual operation (The MV value can be operated manually.)

LSP: Local SP (The control is performed based on the SP stored into the controller.)

RSP: Remote SP (The analog input from an external device is used as the SP.)

RUN-HOLD: Control status in which pattern progression is stopped

RUN-END: Control status in which pattern progression is stopped at the final point

AT: Auto tuning (The PID constants are set automatically using the limit cycle.)

Handling Precautions

• In the case of internal cascade control, it is not possible to switch into pattern

operation.

• With internal cascade control, the master side (Loop 1) in constant value

operation is fixed in LSP mode for RUN + AUTO modes. It cannot be switched

to the READY, MANUAL, or RSP mode.

• For the function to select RUN or READY at startup, a value stored in EEPROM,

RUN, or READY can be selected by setting "Loop1 Run/Ready at startup" to

"Loop4 Run/Ready at startup" in the basic action bank.

• If the version of the MAIN block firmware is earlier than 6.x.x (where x stands

for any number), there is no pattern operation function or Run/Ready at

startup selection function.

1-24

Page 43

Chapter 2. Mounting

2 - 1 External View and Mounting Dimensions

Standard mounting

Unit: mm

Display unit

96 10

96

Standard gasket

Integrated mounting

(3.6)

9.2

32.3

Main unit

115

100.5

Other device

Other device

Panel cutout (front)

+1.5

Hole

80

50 or more

(13)

50 or more

DIN rail holder *

* Dimensions when pulled out

Φ30

−0

±0.3

100

14.6

5

±0.3

17.3

82 ±0.2

Wiring hole

Panel processing method

4×Φ3.6

±0.2 Hole

±0.2

82

Unit: mm

Display unit Main unit

4.7

96

96

2

134

Other devices

50 min.

Control panel mounting

screw (2 locations)

91.4

15

126

Panel cutout (front)

Independent mounting

+0.5

Hole

92

−0

+0.5

Hole

−0

92

Gasket with 92 × 92 mm hole

4.7

Mounting locations

Main unit mounting rail

50 min.

Other devices

26.5

Display unit mounting screw

(4 locations)

91.4

15

Integrating bracket

Panel processing method

126

Gang mounting

+0.5

96 × N − 4

Panel processing method

Hole

−0

Do not install this product in a place with any of the following characteristics:

• Temperature or humidity outside the specified high and low limits

• Corrosive gases such as sulfide gas or silicone gas

• Dust or soot

• Direct sunlight, wind, or rain

• Mechanical vibration or shock outside the range of the specifications

•

Proximity to high-voltage lines, welding machines, or other sources of electrical noise

• Within 15 m of a high-voltage ignition device for a boiler, etc.

• Strong electromagnetic fields

• Flammable liquid or gas

• Outdoor location

Hole

+0.5

92

2-1

−0

Page 44

Chapter 2. Mounting

2 - 2 Mounting Method

Standard mounting

Main unit

Mount the main unit on a DIN rail with a width of 35 mm. Check that the DIN rail

holding tab on the main unit is pushed in. Hook the catches on the upper back of

the main unit onto the DIN rail and press the main unit until it clicks into place.

Display unit and additional display unit

To mount the display unit, follow the steps below.

After mounting the main unit and display unit, connect them using a Cat5E or

higher straight LAN cable* of an appropriate length.

*Cable is not included with the product.

Note

• Connecting the cable between the main unit and display unit (p.3-18)

(for details about the cable to be used)

(1) Screw the setscrews for temporary mounting into the two screw holes in the

upper part of the back of the display unit, turning them approximately three

full turns by hand.

Handling Precautions

• Excessive tightening may cause damage to the protective sheet.

Setscrew

(2) Mount the display unit temporarily on the front of the panel. Align the the

Standard gasket

wiring hole with the connector and insert the setscrews into the mounting

screw holes.

Turn three full turns

2-2

Mounting screw hole

Wiring hole

Page 45

Chapter 2. Mounting

(3) Hold the setscrews firmly from the back of the panel and screw the display

unit mounting screws into the remaining mounting screw holes.

Two types of display unit mounting screws (M3 machine screws) are supplied

with the product.

Select appropriate screws according to the thickness of the control panel.

• 6 mm screws: 1.0–4.5 mm thick control panel

• 10 mm screws: 4.5–8.5 mm thick control panel

Handling Precautions

• Hold the setscrews firmly. Otherwise the display unit may fall.

• Use the mounting screws that are suitable for the thickness of the control

panel to mount the display unit firmly.

(4) Remove the setscrews and insert the display unit mounting screws.

2-3

Page 46

Chapter 2. Mounting

(5) Further tighten the four display unit mounting screws.

(Tightening torque: 0.6 N·m)

(6) Connect the display unit and the display unit connector on the main unit

using the LAN cable.

LAN cable

2-4

Page 47

Integrated mounting

Main unit

Display unit

Chapter 2. Mounting

After mounting the display unit on the control panel, mount the main unit on the

main unit mounting rail of the integrating bracket.

To mount the display unit on the control panel, follow the steps below.

Be sure to mount the display unit securely on the integrating bracket using the

display unit mounting screws (M3 machine screws) included with the product.

(Tightening torque: 0.6 N·m)

(1) Attach the gasket with 92 × 92 mm hole on the display unit and connect the

integrating cable.

Insert the ferrules (part of the cable for integrated mounting supplied with the

product) with the specified colors into the terminal block of the display unit.

Terminal No. 1 2 3 4 5 6

Cable color White/orange Blue White/blue White/green Green Brown

(2) Pass the integrating cable through the wiring hole and attach the display unit

temporarily to the bottom part of the integrating bracket. Tighten the screws

lightly so that the integrating bracket leans forward as shown in the figure

below.

Note

• Connecting the cable between the main unit and display unit (p.3-18)

• (for instructions on wiring with the integrating cable)

Handling Precautions