Page 1

CP-SP-1213E

Quick Reference Guide for Model C15

This guide offers a summary of key operations, parameter flowcharts, and settings, for convenient reference at

the operation site. This guide is made for repeated use. Dirt wipes off easily and even notes written with an oilbased felt-tip pen can be removed with an eraser. If more detailed information on model C15 is needed, refer

to the user's manuals: CP-SP-1147E for basic operation and CP-SP-1148E for installation and configuration.

The most convenient way to configure the C15 is with the Smart Loader Package (model No. SLP-C35J50).

Please contact the azbil Group or a distributor for more information.

Upper display

Indicators during AT

Lower display

[mode] key

Various indicators

Mode indicators

[para] key

[ ], [ ], and [ ] keys

Loader connector (bottom panel)

Upper display This display shows either the PV value or the display value and set value for each displayed item. If an alarm is triggered, the

normal display and alarm code are displayed alternately. During auto tuning (AT), the rightmost decimal point flashes twice

repeatedly.

Lower display This display shows either the SP/MV/CT or the display value and set value for each displayed item. The rightmost decimal

point lights up or flashes to show RUN/READY mode or communications status, depending on the setting.

Mode indicators rdy: Lights when READY (RUN mode if not lit)

man: Lights when MANUAL (AUTO mode if not lit)

ev1, ev2, ev3: Lights when event relays are ON

ot1, ot2: Lights when the control output is ON (always lit when the current output is used)

[mode] key

• When this key is pressed and held for more than 1 second in the operation display mode, any of the following operations

from 0 to 7 which have been set previously can be executed:

0 : Mode key does not operate (Initial value)

1 : AUTO/MANUAL mode selection

2 : RUN/READY mode selection

3 : AT (Auto Tuning) start/stop selection

4 : LSP (Local SP) group selection

5 : Release all DO (Digital Output) latches

6 : Mode key does not operate

7 : ON/OFF selection of communication DI1

• When pressing the [mode] key in the setup display mode, the display is changed to the operation display

[para] key

[<], [

] , [ ] keys

Loader connector The Smart Loader connector is on the bottom of the C15. Use the dedicated cable that is included with the Smart Loader

: Initial value

(Not for use in Japan)

• This key is used to change the display item.

• When this key is kept pressed for 2 s. or longer in the operation display mode, the display is then changed to the setup

display

Theses keys are used to increase or decrease the numeric value, or to shift the digit.

Package to connect the controller to a PC.

1

Page 2

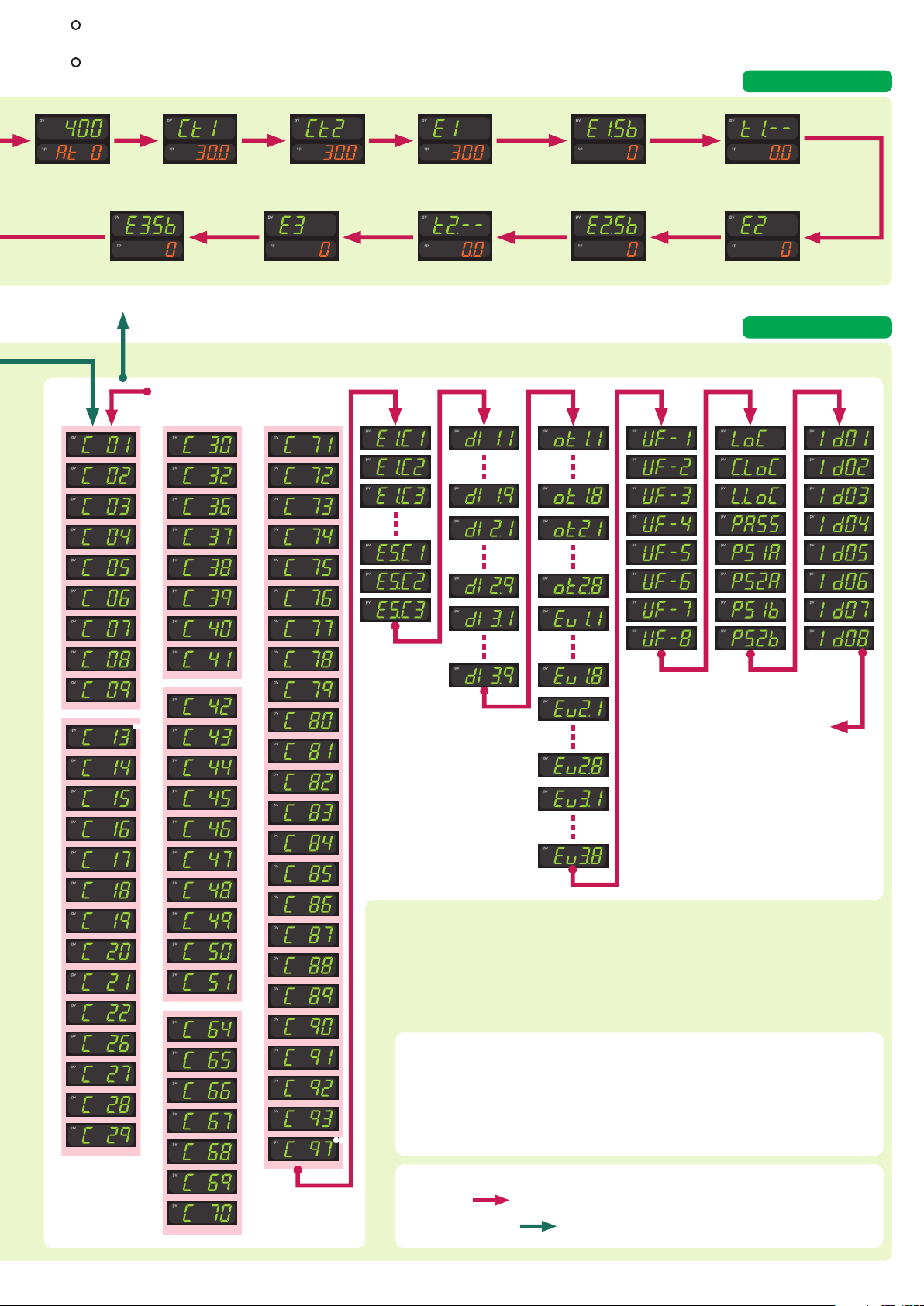

Flowchart of key operations and displays

When the power

is turned ON

PV value

LSP group

number

Manipulated

variable

Heat manipulated

variable

Cool manipulated

variable

Upper and lower displays

remain off for 6s after power

ON. Each mode indicator

lights sequentially, and

then the operation display

appears.

[mode]

(AUTO)

For change from

MANUAL to AUTO

to

(2)

(2) (1)

3

[para] key

*

2-second press + hold of [para] key

(A)

(MANUAL)

For change from

AUTO to MANUAL

to

(1)

SP value

SP value

1

*

MV value

MV value

[SP] [Event] [PID] [Parameter] [Extended tuning]

MV value

Timer remaining

time 3

Internal event 3

delay time

[para] key

3

*

[para] key

to

(A)

2-second

press + hold

of [para] key

2

Page 3

Some items are not displayed depending on the availability of optional functions, model number, display setup (

) and display level (

C78

Pressing [para] key while changing settings has the effect of canceling and moving to the next item.

C79

).

Operation displays

C73

to

Analog inputControl actions

PV value

AT progress

value

Internal event 3

sub setting

Setting value

to

(2)

2-second press + hold of [para] key

2

*

[Setup] [

(B)

SPContinuous outputsCommunications

CT1

Current

value

CT2

Current

value

Internal event 3

main setting

Setting value

Event configuration

] [

DI assignment

Internal event 1

main setting

Setting value

Timer remaining

time 2

Internal event 2

delay time

] [

DO assignment

] [

User function

Internal event 1

sub setting

Setting value

Internal event 2

sub setting

Setting value

] [

Timer remaining

time 1

Internal event 1

delay time

Internal event 2

main setting

Setting value

Setting displays

Instrument information

][Lock]

Key operations and displays

[para] key

4

*

to

(B)

*1 The parameters and numerical values registered as user functions UF are displayed.

*2 If no k ey is pressed for 3 minutes, the display automatically returns to (2) , PV display.

*3 If the [<] key is pressed while holding down the [para] key, various displys/settings can be

navigated in re verse order.

*4 Cannot be selected if ROM version 1 (

4

*

ear lier.

Explanation of arrows

[para] key :

2-second press +

hold of [para] key

:

) of the instrument information bank is 2.26 or

id02

Movement through each setup menu

[para] key Forward movement

•

[para] key + [<] key Backward movement

•

3

Page 4

Operation examples

Red letters : Items before operation

Blue letters : Items during operation

Setup of PV input range type

1

3

Start from the operation display (if necessary press [mode]

once to get the operation display).

If the sensor has not

been wired or is disconnected, an alarm for

abnormal PV input (any

one from

may appear on the

upper display.

Press and hold [para]

for more than 2s

again to get the

setup setting display.

The current set

value for C0 1 (PV

input range type) is

displayed.

AL0 1

to AL11)

2

4

Press and hold [para]

for more than 2s to

get the parameter

setup display.

is shown on the

upper display.

In case of ON/OFF control,

r--r

the upper display.

When the [<], [ ] or

[ ] key is pressed,

the rightmost digit

on the lower display

flashes. If no key is

pressed for more

than 2s after changing to the desired

value in the PV input

range list, the display

changes from flashing to continuously

lit, and the displayed

value is now set.

a--M

appears on

Setup of event operation type

In this example, the event 1 operation type is set to deviation high

limit.

1

3

5

Similarly, use

for event 3.

e3.C1

Start from the operation display (if necessary press [mode]

once to get the operation display).

Press and hold [para]

for more than 2s

again to get the

setup setting display.

The current set

value for C0 1 (PV

input range type) is

displayed.

When the [ ] or [ ] key is pressed, the rightmost digit on

the lower display flashes. Change the flashing digit to 4 by

pressing [ ] or [ ].

If no key is pressed for more than 2s, the displayed value is

set and the display changes from flashing to continuously

lit.

on the lower display indicates that the event operation type is set for

4

deviation high limit.

to set the event 2 operation type, and use

e2.C 1

2

4

Press and hold [para]

for more than 2s to

get the parameter

setup display.

is shown on the

upper display.

Press [para] repeatedly to get e

the upper display. 0

is displayed on the

lower display.

on the lower display

0

indicates that the event

operation type is set to

"none."

a--M

1.c 1

on

Execution of auto tuning (AT )

AT forces ON/OFF of the MV a number of times (a limit cycle) to calculate PID values.

Check that this operation does not create any problems for the associated equipment before executing AT.

1

3

5

Start from the operation display (if necessary press [mode]

once to get the operation display).

Press [para] twice.

The upper display

says at and the lower

display says

If the control method

is ON/OFF control and

if Bit 3 (AT stop/start

display) of the mode

display setup (

to "disabled: 0," nothing

is displayed.

[Press [ ] once.

The lower display

starts to flash

at.Of

) is set

C73

at.On

.

2

4

6

.

Press and hold [para]

for more than 2s to

get the parameter

setup display.

is shown on the

upper display.

When [ ] or [ ] is

pressed,

flashes.

Flashing occurs only in

RUN and AUTO modes,

if there is no PV input

abnormality.

Also, if "AT stop/start" is

selected for DI assignment, the display does

not blink and no change

can be made.

If no key is pressed

for more than 2s,

at.ON

steadily lit and AT

begins.

During AT, the

rightmost decimal

point flashes twice

repeatedly. (When

AT is done, the light

goes off and the new

PID values go into

effect.)

During the AT process, if the mode is changed to READY or

MANUAL, if PV input is faulty, or if a power failure occurs, AT stops

automatically without changing the PID values.

AT can also be stopped by changing the setting from

(return to step 3 above).

At.OF

At.ON

Setup of SP value

1

3

Start from the operation display (if necessary press [mode]

once to get the operation display).

When the [<], [ ] or

[

] key is pressed,

the rightmost digit

on the lower display

flashes and the SP

can be changed to

the desired value.

In this case, the flashing of the numerical

value implies that it

is not yet set. A numerical setting that

is being changed

flashes the same way.

If an SP limit is in effect,

the numerical value

cannot be changed to

a value above the limit.

The SP limit must be

changed first.

2

4

Check that the operation display is

displaying the SP.

(If not, press [para]

repeatedly until the

SP is displayed.)

If no key is pressed

for more than 2s, the

displayed value is

set and the display

changes from flashing to continuously

lit.

If the [mode] key is

pressed when the

display is flashing, the

status returns to that of

step 1.

at.Of

remains

to

a--M

4

Page 5

For step numbers indicated in red like 4 , the following precaution applies:

• If the key lock is set, the numerical value does not flash, and the value cannot be changed.

To change a numerical value, cancel the key lock first.

1

3

5

RUN/READY mode selection

Start from the operation display (if necessary press [mode]

once to get the operation display).

Press the [para] key

once. The upper display says

the lower display

says

rdy

The current mode is indicated by

mode or

mode.

When [ ] or [ ] is

pressed,

) on the lower

rdy

display flashes.

rdy

(or

run

run

r--r

and

run

for RUN

for READY

(or

).

2

4

6

Press and hold [para]

for more than 2s to

get the parameter

setup display.

is shown on the

upper display.

In case of ON/OFF control,

the upper display.

When [ ] or [ ] is

pressed, the lower

display flashes.

If the DI assignment is

set to "RUN/READY selection," the display does

not flash and no change

can be made.

If no key is pressed

for more than 2s, the

displayed value is

set and the display

changes from flashing to continuously

lit.

r appears on

r--

a--M

Setup of event value

1

3

5

Start from the operation display (if necessary press [mode]

once to get the operation display).

Press [para] repeatedly to get e 1 on the

upper display. The

lower display says 0.

on the lower display

0

indicates that the event

main set value is "zero."

If no key is pressed for more than 2s, the displayed value is

set and the display changes from flashing to continuously

lit.

If the [mode] key is pressed when the display is flashing, the status returns

to that of step 1.

2

4

Press and hold [para]

for more than 2s to

get the parameter

setup display.

is shown on the

upper display.

When [<], [ ] or [ ]

is pressed, the rightmost digit on the

lower display flashes,

and can be changed

to the desired value

for the event.

In this case, the flashing of the numerical

value implies that it

is not yet set.

A numerical setting that is being

changed flashes the

same way.

a--M

1

3

Setup of PID value

Start from the operation display (if necessary press [mode]

once to get the operation display).

Press [para] repeatedly to get

proportional band)

on the upper display.

The value set for

is displayed on the

lower display.

If the control method is

"ON/OFF control," nothing is displayed.

p-1

(for

p-1

Similarly, use e2 to set a value for event 2, and e3 to set a value

for event 3.

2

4

Press and hold [para]

for more than 2s to

get the parameter

setup display.

is shown on the

upper display.

When [<], [ ] or [ ]

is pressed, the rightmost digit on the

lower display flashes,

and can be changed

to the desired value

for the proportional

band.

In this case, the flashing of the numerical

value implies that it

is not yet set. A numerical setting that

is being changed

flashes the same

way.

The proportional band

can be set in a range

from 0.1 to 999.9%.

a--M

6

Similarly, use

to set a hysteresis value for event 3.

Memo

To set hysteresis as

well, press [para]

once (or twice,

depending on the

settings) to display

on the upper

e 1.hy

display.

The lower display

says 5.

on the lower display

5

indicates that the current set value for event

hysteresis is 5.

to set a hysteresis value for event 2, and

e2.hy

7

When [<], [ ] or [ ]

is pressed, the rightmost digit on the

lower display flashes,

and can be changed

to the desired value

for hysteresis.

If no key is pressed

for more than 2s, the

displayed value is

set and the display

changes from flashing to continuously

lit.

e3.hy

5

Similarly, use

If no key is pressed for more than 2s, the displayed value is

set and the display changes from flashing to continuously

lit.

If the [mode] key is pressed when the display is flashing, the status returns to that of step 1.

to set the integral time (0 to 9999s), and

i-1

the derivative time (0 to 9999s).

d-1

to set

5

Page 6

List of parameters

List of operation displays

Display

Upper display: PV

Lower display: SP

PV

SP

(

LSP 1

LSP

Out

MV

HEAt

Numeric value

COOL

Numeric value

PV

(

Display example

At 1

Ct 1

Numeric value

Ct2

Numeric value

E 1

Numeric value

E 1.Sb

Numeric value

t 1.--

Numeric value

E2

Numeric value

E2.Sb

Numeric value

t2.--

Numeric value

E3

Numeric value

E3.Sb

Numeric value

t3.--

Numeric value

MOdE

Display Item Contents

A--M

r--r

At

dO.Lt

C.dI 1

[SP bank]

SP

Display Item Contents

to

SP- 1

[Event bank]

Ev

Display Item Contents

to

E 1

E5

E 1.Sb

E 1.Hy

E 1.On

E 1.OF

* The decimal point position varies by meeting the internal event operation type.

PI D

Display Item Contents

P- 1

I - 1

d- 1

rE- 1

OL- 1

OH- 1

P- 1C

I - 1C

d- 1C

OL. 1C

OH. 1C

PARA

CtrL

At. OL

At. OH

Control

dI FF

OFFS

FL

rA

PV

bI

CyU

Cy

CyU2

Cy2

tP. ty

Time proportional output

SPU

SP

SPd

*1 0: Unit of "1s" 1: Fixed at 0.5s 2: Fixed at 0.2s 3: Fixed at 0.1s

*2 5 to 120s when output includes the relay output

SP (Target value) SP low limit to SP high limit 0

LSP No.

Display example

)

(

MV (Manipulated Variable) -10.0 to +110.0%

Heat MV (Manipulated Variable) Setting is disabled.

Cool MV (Manipulated Variable)

AT progress display

)

(

CT current value 1 Setting is disabled.

CT current value 2 Setting is disabled.

Internal Event 1 main setting -1999 to +9999U or 0 to 9999U 0

Internal Event 1 sub setting 0

Timer remaining time 1 Setting is disabled.

(

Display example

)

Internal Event 2 main setting Same as Internal Event 1 main setting 0

Internal Event 2 sub setting Same as Internal Event 1 sub setting 0

Timer remaining time 2 Same as Timer remaining time 1

(

Display example

)

Internal Event 3 main setting Same as Internal Event 1 main setting 0

Internal Event 3 sub setting Same as Internal Event 1 sub setting 0

Timer remaining time 3 Same as Timer remaining time 1

(

Display example

)

[Mode bank]

AUTO/MANUAL

RUN/READY

AT stop/start

Release all DO latches

Communication DI1

SP (for LSP1 to 4) SP low limit to SP high limit 0

SP-4

to

E5.Sb

to

E5.Hy

to

E5.On

to

E5.OF

[PID bank]

[Parameter bank]

Display Item Contents

Item Contents Initial

1st digit: Value at the right end digit

1st digit=Numeric value at right end digit

1 to LSP system group (Max. 4) 1

)

Setting is enabled in MANUAL mode

(Numeric value flashed)

-10.0 to +110.0%

Setting is disabled.

)

Upper display: The distinction by ON delay or

OFF delay is displayed at the side location of “t1.”.

List of parameter setting displays

: AUTO mode

AUTO

: RUN mode

RUN

: AT stop

At.OF

: Latch continue

Lt.ON

: OFF dI

dI .OF

Internal Event 1 to 5 main setting

Internal Event 1 to 5 sub setting

Internal Event 1 to 5 hysteresis

Internal Event 1 to 5 ON delay time

Internal Event 1 to 5 OFF delay time

Proportional band (PID1) 0.1 to 999.9% 5.0

Integration time (PID1) 0 to 9999s (

Derivative time (PID1) 0 to 9999s (

Manual reset (PID1) -10.0 to +110.0% 50.0

MV low limit (PID1) -10.0 to +110.0% 0.0

MV high limit (PID1) -10.0 to +110.0% 100.0

Cool-side proportional band

Cool-side integration time

Cool-side derivative time

Cool-side MV low limit (PID1) -10.0 to +110.0% 0.0

Cool-side MV high limit (PID1) -10.0 to +110.0% 100.0

Control method 0: ON/OFF control 1: Fixed PID 2: ST(Self-tuning) 0 or 1

MV low limit at AT -10.0 to +110.0% 0.0

MV high limit at AT -10.0 to +110.0% 100.0

ON/OFF control differential 0 to 9999U 5

ON/OFF control operating point offset

PV filter 0.0 to 120.0s 0.0

PV ratio 0.001 to 9.999 1.000

PV bias -1999 to +9999U 0

Time proportional cycle unit 1 0 to 3 *

Time proportional cycle 1 5 to 120s or 1 to 120s *

Time proportional cycle unit 2 0 to 3 *

Time proportional cycle 2 5 to 120s or 1 to 120s *

Time proportional cycle mode

SP up ramp (U/min) 0.0 to 999.9U(No ramp when set at "0.0U") 0.0

SP down ramp (U/min) 0.0

-1999 to +9999 or 0 to 9999 * 0

0 to 9999 * 5

0.0 to 999.9 or 0 to 9999 0

(PID1) 0.1 to 999.9% 5.0

(PID1) 0 to 9999s (

(PID1) 0 to 9999s (

-1999 to +9999U 0

1

1

0: Controllability aiming type

1:

Operation end service life aiming type (Only ON/

OFF operation within Time proportional cycle)

: MANUAL mode

MAN

: READY mode

RDY

: AT start

At.ON

: Latch release

Lt.OF

: ON

.On

No integration control action when set at "0"

No derivative control action when set at "0"

No integration control action when set at "0"

No derivative control action when set at "0"

2

2

U: Unit Maximum unit of Industrial volume in

PV range (°C, Pa,L/min, etc.)

Initial value

AUTO

RUN

AT stop

Latch continue

OFF

Initial value

Initial value

Initial value

) 120

) 30

) 120

) 30

Initial value

10 or 2

10 or 2

0 or 1

value

0

0

0

0

: Essential parameters for PV measurement and control

: Basic parameters

: Required parameters when using optional functions

[Extended tuning bank]

Et

Setting

value

Display Item Contents

At.ty

JF.bd

SP.LG

At-P

At-I

At-d

Ctr.A

JF.Ov

St.SA

St.Sb

St.Hb

St.ud

*1 Normal = Standard control characteristics, Immediate response = Control characteristics that respond immediately to

external disturbance, Stable = Control characteristics having less up/down fluctuation of PV

AT type 0: Normal 1: Immediate response 2: Stable *11

Just-FiTTER setting band 0.00 to 10.00 0.30

SP lag constant 0.0 to 999.9 0.0

AT Proportional Band adjust 0.00 to 99.99 1.00

AT Integral time adjust 0.00 to 99.99 1.00

AT Derivative time adjust 0.00 to 99.99 1.00

Control algorithm 0: PID(Conventional PID)

Just-FiTTER assistance coefficient

ST step execution resolution band

ST step setting band 0.0 to 10.00 0.50

ST hunting setting band 0.0 to 10.00 1.00

ST step ramp change 0: ST is executed when the PV moves up or down.

1: Ra-PID(High-performance PID)

0 to 100 0

0.0 to 99.99 10.0

1: ST is executed only when the PV moves up.

List of setup setting displays

[Setup bank]

StUP

Setting value

Setting value

Setting value

Setting value

Setting value

Display Item Contents

C0 1

C02

C03

C04

C05

C06

Analog input

C07

C08

C09

C 13

C 14

C 15

C 16

C 17

C 18

C 19

C20

Control action

C2 1

C22

C26

C27

C28

C29

C30

C32

C36

C37

SP

C38

C39

C40

C4 1

C42

C43

C44

C45

C46

C47

Continuous output

C48

C49

C50

C5 1

C64

C65

C66

C67

C68

Communication

C69

C70

C7 1

C72

C73

C74

C75

Key operation • display

C76

C77

C78

PV input range type For details, refer to the PV Input Range Table

Temperature unit 0: Celsius (°C) 1: Fahrenheit (°F) 0

Cold junction compensation

Decimal point position 0: No decimal point

PV range low limit

PV range high limit 1000

SP low limit PV input range low limit to PV input range high

SP high limit

PV square root extraction dropout

PID calculation adjustment function *20: Enabled 1: Disabled 0

Control action (Direct/Reverse)

Output operation at PV alarm 0: Control calculation is continued.

Output at PV alarm -10.0 to +110.0% 0.0

Output at READY (Heat) -10.0 to +110.0% 0.0

Output at READY (Cool) -10.0 to +110.0% 0.0

Output operation at changing AUTO/MANUAL

Preset MANUAL value -10.0 to +110.0%

Initial output type (mode) of PID control

Initial output of PID control -10.0 to +110.0%

Heat/Cool control 0: Not used 1: Used 0

Heat/Cool 0: Normal 1: Energy saving 0

Heat/Cool control dead zone -100.0 to +100.0% 0.0

Heat/Cool change point -10.0 to +110.0% 50.0

LSP system group 1 to 4 1

SP ramp unit 0: 0.1U/s 1: 0.1U/min 2: 0.1U/h 1

CT1 operation type

CT1 output

CT1 measurement wait time 30 to 300ms 30

CT2 operation type Same as CT1 0

CT2 output Same as CT1 0

CT2 measurement wait time Same as C T1 30

Control output 1 range 1: 4 to 20mA 2: 0 to 20mA 1

Control output 1 type 0: MV 1: Heat MV 2: Cool MV 3: PV

Control output 1 scaling low limit

Control output 1 scaling high limit

Control output 1 MV scaling bandwidth

Control output 2 range Same as control output 1 1

Control output 2 type Same as control output 1 3

Control output 2 scaling low limit

Control output 2 scaling high limit

Control output 2 MV scaling bandwidth

Communication type 0: CPL 1: Modbus (ASCII format)

Station address

Transmission speed (bps) 0: 4800 1: 9600 2: 19200 3: 38400 2

Data format (Data length) 0: 7 bits 1: 8 bits 1

Data format (Parity) 0: Even parity 1: Odd parity 2: No parity 0

Data format (Stop bit) 0: 1 bit 1: 2 bits 0

Communication minimum response time

Key operation type 0: Standard type 1: Special type 0

[mode] key function 0: Invalid 1: AUTO/MANUAL selection

MODE display setup

(Sum of the weighting)

PV/SP display setup

(Sum of the weighting)

MV display setup

(Sum of the weighting)

EV display setup

(Operation display)

Event remaining time display setup

(Operation display)

CT input current value display setup

(Operation display)

0: Performed (internal) 1: Not performed (external)

1 to 3: 1 to 3 digits below decimal point *

When the PV input type is DC voltage/DC current,

-1999 to +9999U

limit

0.0 to 100.0% (PV square root extraction is not

performed when set at "0.0".)

0: Heat control (Reverse action)

1: Cool control (Direct action)

1: Output at PV alarm is output.

0: Bumpless transfer 1: Preset 0

0: Auto 1: Not initialized 2: Initialized 0

0: Heater burnout detection 1: Current value measurement

0 to 1: Control output 1 to 2, 2 to 4: Event output 1 to 3

4: PV before ratio, bias, and filter 5: SP

6: Deviation 7: CT1 current value

8: CT2 current value 10: SP+MV 11: PV+MV

-1999 to +9999U 0.0

0 to 9999 (Valid when control output 1 type is 10 or 11)

Same as control output 1 0

Same as control output 1 1000

Same as control output 1 200

2: Modbus (RTU format)

0 to 127 (Communication is disabled when set at "0".)

1 to 250ms 3

2: RUN/READY selection 3: AT Stop/Start

4: LSP group selection 5: Release all DO latches

6: Invalid 7:

Communication DI1 selection

Bit 0: AUTO/MANUAL display (Enabled: +1)

Bit 1: RUN/READY display (Enabled: +2)

Bit 3: AT Stop/Start display (Enabled: +8)

Bit 4:

Release all DO latches display (Enabled: +16)

Bit 5:

Communication DI1 ON/OFF display (Enabled: +32)

Other invalid setting, 0, +4, +64, +128

Bit 0: PV display (Enabled: +1)

Bit 1: SP display (Enabled: +2)

Bit 2: LSP group number display (Enabled: +4)

Other invalid setting, 0, +8

Bit 0: MV display (Enabled: +1)

Bit 1: Heat MV/cool MV display (Enabled: +2)

Bit 3: AT progress display (Enabled: +8)

Other invalid setting: 0, +4

0: Not displayed

1: Set value of Internal event 1 is displayed

2: Set values of Internal event 1 to 2 are displayed

3: Set values of Internal event 1 to 3 are displayed

0: Not displayed

1: Internal event 1 is displayed

2: Internal event 1 to 2 is displayed

3: Internal event 1 to 3 is displayed

0: Not displayed 1: CT1 current value is displayed

2: CT1 to 2 current values are displayed

Initial value

Setting value

0

0

Initial value

Setting value

Depending on Model No.

0

0

1

0

0.0

0

0

0.0 or 50.0

0.0 or 50.0

0

0

0

100.0

200

0

0

0

8:

Invalid

255

15

15

0

0

0

6

Page 7

• Items marked in the tables are displayed in standard and/or high function configuration.

• To change a user level, refer to

Display Item Contents

C79

C80

C90

C9 1

C92

C93

Key operation • display

C97

*1 Cannot be set for a thermocouple if ROM version 1 (

*2 Cannot be selected if ROM version 1 (

EvCF

Display Item Contents

to

E 1.C 1

to

E 1.C2

to

E 1.C3

User level 0: Simple configuration 1: Standard configuration

LED monitor 0: Not used

Number of CT1 turns 0: 800 turns 1 to 40: CT turns divided by 100 8

Number of CT1 power wire loops

Number of CT2 turns 0: 800 turns 1 to 40: CT turns divided by 100 8

Number of CT2 power wire loops

PV input failure (under range)

2

type *

) of the instrument information bank is 2.26 or earlier.

id02

[Event configuration bank]

Internal event 1 to 5 Configuration 1

E5.C 1

Internal event 1 to 5 Configuration 2

E5.C2

1st digit: Direct/Reverse 0: Direct 1: Reverse 0

2nd digit: Standby 0: None 1: Standby 2:

EVENT state at READY

3rd digit:

4th digit: Undefined 0 0

Internal event 1 to 5 Configuration 3

E5.C3

1st digit: Alarm OR 0: None 1: Alarm direct + OR operation

2nd digit: Special OFF 0: As usual

3rd digit: Delay time unit 0: 0.1s 1: 1s 2: 1min 0

4th digit: Undefined 0 0

Changing the user level

2: High function configuration

1:

Flashing while data is sending through RS-485 communication.

2:

Flashing while data is receiving through RS-485 communication

3: Logical OR of all DI statuses

4: Flashing in READY mode

0: 1 time 1 to 6: Number of times 1

0: 1 time 1 to 6: Number of times 1

0: 10 %FS

1: 5 mV (This setting is applicable if C01 (PV input

range type) is set for sensor type B (No.17) or

PR40-20 (No. 23))

) of the instrument information bank is 2.26 or earlier.

id02

Refer to event type (see page 8) 0

The digits are determined to 1st, 2nd, 3rd, and

4th digit from the right end.

0: Continue 1: Forced OFF 0

The digits are determined to 1st, 2nd, 3rd, and

4th digit from the right end.

2: Alarm direct + AND operation

3: Alarm reverse + OR operation

4: Alarm reverse + AND operation

1: When the event set value (main setting) is 0,

the event is "OFF".

Standby + Standby at SP change

in the lower right part of this page.

[Lock bank]

Initial value

0

0

0

Initial value

0

0

0

Setting value

Setting value

LOC

Display Item Contents

LOC

C.LOC

L.LOC

PASS

PS 1A

PS2A

PS 1b

PS2b

[Instrument information bank]

I d

Display Item Contents

I d0 1

I d02

I d03

I d04

I d05

I d06

I d07

I d08

Key lock 0: All settings are possible

Communication lock 0: read/write enabled 1: read/write disabled 0

Loader lock 0: read/write enabled 1: read/write disabled 0

Password display 0 to 15 (5: Password 1A to 2B display) 0

Password 1A 0000 to FFFF (Hexadecimal value) 0000

Password 2A 0000 to FFFF (Hexadecimal value) 0000

Password 1B 0000 to FFFF (Hexadecimal value) 0000

Password 2B 0000 to FFFF (Hexadecimal value) 0000

ROM ID 0: Fixed 0

ROM Version 1 XX. XX (2 digits after decimal point)

ROM Version 2 XX. XX (2 digits after decimal point)

Loader information

EST information

Manufacturing date code

(year)

Manufacturing date code

(month, day)

Serial No.

Precaution for setup

• The type of auto tuning can be changed by changing the value of

(AT type) in the extended tuning bank. Set it to match the

At.ty

control characteristics.

1: Mode, event, operation display, SP, UF, lock,

manual MV, [mode] key can be set

2: Operation display, SP, UF, lock, manual MV,

[mode] key can be set

3: UF, lock, manual MV, [mode] key can be set

Subtract 2000 from the year.

Example: "3" means the year 2003.

Month + day divided by 100.

Example: "12.01" means the 1st day of December.

Initial value

0

Initial value

Setting value

Setting value

[DI assignment bank]

di

Display Item Contents

to dI 3.

dI 1. 1

to dI

dI 1.2

to dI

dI 1.3

to dI

dI 1.4

to dI

dI 1.5

to dI

dI 1.6

to dI

dI 1.7

to dI

dI 1.8

to dI

dI 1.9

[DO assignment bank]

dO

Display Item Contents

to

Ot 1. 1

1. 1 to

Ev

to

Ot 1.2

to

Ev

1.2

to

Ot 1.3

to

Ev

1.3

to

Ot 1.4

to

Ev

1.4

to

Ot 1.5

to

Ev

1.5

to

Ot 1.6

to

Ev

1.6

to

Ot 1.7

to

Ev

1.7

to

Ot 1.8

to

Ev

1.8

[User function bank]

UF

Display Item Contents

to

UF- 1

Internal contact 1 to 3

1

Operation type

Internal contact 1 to 3

3.2

Input bit operation

Internal contact 1 to 3

3.3

Input assignment A

Internal contact 1 to 3

3.4

Input assignment B

Internal contact 1 to 3

3.5

Input assignment C

Internal contact 1 to 3

3.6

Input assignment D

Internal contact 1 to 3

3.7

Polarity A to D

1st digit: Polarity A 0: Direct 1: Reverse 0

2nd digit: Polarity B 0

3rd digit: Polarity C 0

4th digit: Polarity D 0

Internal contact 1 to 3 Polarity 0: Direct 1: Reverse 0

3.8

Internal contact 1 to 3

3.9

Internal event No. assignment

Control output 1 to 2, event

Ot2. 1�

output 1 to 3 Operation type

Ev3. 1

Control output 1 to 2, event

Ot2.2�

output 1 to 3 Output assign-

Ev3.2

ment A

Control output 1 to 2, event

Ot2.3�

output 1 to 3 Output assign-

Ev3.3

ment B

Control output 1 to 2, event

Ot2.4�

output 1 to 3 Output assign-

Ev3.4

ment C

Control output 1 to 2, event

Ot2.5�

output 1 to 3 Output assign-

Ev3.5

ment D

Control output 1 to 2, event

Ot2.6�

output 1 to 3 Polarity A to D

Ev3.6

1st digit: Polarity A 0: Direct

2nd digit: Polarity B 0

3rd digit: Polarity C 0

4the digit: Polarity D 0

Control output 1 to 2, event

Ot2.7�

output 1 to 3 Polarity

Ev3.7

Control output 1 to 2, event

Ot2.8�

output 1 to 3 Latch

Ev3.8

User function 1 to 8

UF-8

0: No function 1: LSP group selection (0/+1)

2: LSP group selection (0/+2)

3: LSP group selection (0/+4) 4: Invalid

5: Invalid 6: Invalid 7: RUN/READY selection

8: AUTO/MANUAL selection

9: LSP/RSP selection 10: AT Stop/Start

11: ST disabled/enabled

12: Control action direct/reverse

13: SP Ramp enabled/disabled

14: PV Hold 15: PV Maximum value hold

16: PV Minimum value hold 17: Timer Stop/Start

18: Release all DO latches (Continue/Release)

19: Invalid 20: Invalid

0: Not used (Default input)

1: Function 1 ((A and B) or (C and D))

2: Function 2 ((A or B) and (C or D))

3: Function 3 (A or B or C or D)

4: Function 4 (A and B and C and D)

0: Normally opened 1: Normally closed

2: DI1 3: DI2 4 to 9: Undefined

10 to 14: Internal Event 1to 5

15 to 17: Undefined

18 to 21: Communication DI1 to 4

22: MANUAL 23: READY 24: Undefined

25:

AT running

26:

28: Alarm occurs 29: PV alarm occurs

30: Undefined 31: mode key pressing status

32:

Event output 1 status

The digits are determined to 1st, 2nd, 3rd and

4th digit from the right end.

0: Every Internal Event

1 to 5: Internal Event No.

0: Default output 1 to 2: MV1 to 2

3 to 6: Function 1 to 4

0: Normally opened 1: Normally closed

2 to 6: Internal Event 1 to 5

7 to 13: Undefined 14 to 15: MV1 to 2

16 to 17: Undefined 18 to 19: DI1 to 2

20 to 25: Undefined

26 to 28: Internal Contact 1 to 3

29 to 33: Undefined 34 to 37: DI1 to 4

38: MANUAL 39: READY 40: Undefined

41: AT running 42: During SP ramp

43: Undefined 44: Alarm occurs

45: PV alarm occurs 46: Undefined

47: Mode key pressing status

48: Event output 1 status

49: Control output 1 status

The digits are determined to 1st, 2nd, 3rd, and

4 th digit from the right end.

1: Reverse

0: Direct

1: Reverse

0: None 1: Latch (Latch at ON)

2: Latch (Latch at OFF except for initialization

at power ON)

During SP ramp

33:

Control output 1 status

27:

Undefined

Initial value

0

0

2: Contact 1

3: Contact 2

4: Contact 3

0

0

0

0

Initial value

0

14:

Output 1

15:

Output 2

2: Event 1

3: Event 2

4: Event 3

0

0

0

0

0

0

Initial value

Setting value

Memo

Changing the user level

This controller's user level can be set to 1 of 3 types in setup

The number of possible displays and settings decreases according

to the user level: high function > standard > simple. All items are

displayed when high function is selected.

1

Setting value

3

Setting value

If necessary press

[mode] once to

change to the operation display.

Next, press and hold

[para] for more than

2s to get the parameter setup display.

a--M

or

r--r

appears on the upper

display.

Press [para] repeatedly to change the

upper display to

c79

(user level).

2

4

.

C79

Press and hold

[para] for more than

2s again to display

on the upper

c0 1

display.

When [<], [ ] or [ ]

is pressed, the lower

display flashes and

can be changed to

the desired numerical

value. Then, if no key

is pressed for more

than 2s, the displayed

value is set and the

display changes from

flashing to continuously lit.

0: Simple configuration

(initial value)

1: Standard configuration

2:

High function configuration

7

Page 8

: https://www.azbil.com

(11)

PV input range table

PV

PV

PV

Main setting

PV

Main setting

PV

PV

PV

PV

PV

SP + Main set ting

PV

PV

PV

PV

PV

PV

SP + Main set ting

PV

PV

PV

CT1 at out put ON

Main setting

CT1 at out put ON

CT1 at out put OFF

CT1 at out put OFF

CT2 at ou tput ON

CT2 at ou tput ON

CT2 at ou tput OFF

CT2 at ou tput OFF

[Thermocouple] [RTD]

Sensor

C0 1

set value

1 K -200 to +1200 -300 to +2200 41 Pt100 -200 to +500 -300 to +900

2 K 0 to 1200 0 to 2200 42 JPt100 -200 to +500 -300 to +900

3 K 0.0 to 800.0 0 to 1500 43 P t100 -200 to +200 -300 to +400

4 K 0.0 to 600.0 0 to 1100 44 JPt100 -200 to +200 -300 to +400

5 K 0.0 to 400.0 0 to 700 45 Pt100 -100 to +300 -150 to +500

6 K -200.0 to +400.0 -300 to +700 46 JPt100 -100 to +300 -150 to +500

9 J 0.0 to 800.0 0 to 1500 51 Pt100 -50.0 to +200.0 -50 to +400

10 J 0.0 to 600.0 0 to 1100 52 JPt100 -50.0 to +200.0 -50 to +400

11 J -200.0 to +400.0 -300 to +700 53 Pt100 -50.0 to +100.0 -50 to +200

13 E 0.0 to 600.0 0 to 1100 54 JPt100 -50.0 to +100.0 -50 to +200

14 T -200.0 to +400.0 -300 to +700 63 Pt100 0.0 to 200.0 0 to 400

15 R 0 to 1600 0 to 3000 64 JPt100 0.0 to 200.0 0 to 400

16 S 0 to 1600 0 to 3000 67 Pt100 0 to 500 0 to 900

17 B 0 to 1800 0 to 3300 68 JPt100 0 to 500 0 to 900

18 N 0 to 1300 0 to 2300

19 PL II 0 to 1300 0 to 2300

WRe5-26

20

WRe5-26

21

PR40-20

23

24 DIN U -200.0 to +400.0 -300 to +700 86 1 to 5 V

25 DIN L -100.0 to +800.0 -150 to +1500 87 0 to 5 V

Initial value 90 4 to 20 mA

• Accuracy for No. 17 (B thermocouple) is as follows. 260 °C or less: ±5 %FS. 260–800 °C: ±1 %FS.

*1

The PV values under 20 °C are not shown. However, if ROM version 1 (

information bank is 2.04 or earlier, the indicated low limi value is -180 °C.

• Accuracy for No. 23 (sensor type PR40-20) is as follows. 300 °C or less: undefined. 300–800 °C:

±5 % FS. 800–1900 °C: ±2 % FS. However, if ROM version 1 (

bank is 2.26 or earlier, No. 23 cannot be selected.

*2 PL II thermocouple is a range, which has been added to the units manufactured from July, 2003.

*3 The decimal point for thermocouples can be displayed if the ROM version is 2.26 or later.

type

Range

(°C)

Range

(°F)

C0 1

set value

Sensor

type

Range

(°C)

[DC voltage/DC current]

0 to 1400 0 to 2400

0 to 2300 0 to 4200

0 to 1900 0 to 3400 84 0 to 1 V The scaling and decimal

Input type Range

C0 1

set value

88 0 to 10 V

89 0 to 20 mA

i d02

point position can be

changed variably in a

range of –1999 to +9999

) of the instrument information

i d02

List of alarm codes

Alarm

AL0 1

AL02

AL03

Input failure

AL 1 1

AL70

AL95

AL96

Unit failure

AL97

AL98

AL99

Handling Precautions

Failure name Cause Corrective action

code

PV input failure

(Over-range)

Sensor burnout, incorrect

wiring, incorrect PV input

type setting

PV input failure

(Under-range)

Sensor burnout, incorrect

wiring, incorrect PV input

type setting

CJ failure Terminal temperature is

faulty (thermocouple).

PV input failure

(RTD)

CT input failure

(Over-range)

(CT input 1 or 2,

or both)

Sensor burnout, incorrect

wiring

A current exceeding the

upper limit of the display

range was measured. The

number of CT turns or the

number of CT power wire

loops is incorrectly set, or

wiring is incorrect.

A/D conversion

A/D converter is faulty. Replace the unit.

failure

Parameter failure Power is shut-down while

the data is being set, or

data is corrupted by noise.

Adjustment data

failure

Power is shut-down while

the data is being set, or

data is corrupted by noise.

Parameter failure

Data is corrupted by noise.

(RAM area)

Adjustment data

Data is corrupted by noise.

failure (RAM area)

ROM failure ROM (memory) is faulty. • Reset the unit.

• If ROM version 1 (i

2.04 or earlier, CT input failure (

) of the instrument information bank is

d02

) is not displayed.

AL 1 1

Check the wiring.

Set the PV input type

again.

Check the ambient

temperature.

Check the wiring.

• Use a CT with the cor-

rect number of turns

for the display range.

• Reset the number of

CT turns.

• Reset the number of CT

power wire loops.

• Check the wiring.

• Restart the unit.

• Set the data again (set

data for

adjustment data for

AL96/98

• Replace the unit.

• Replace the unit.

Range

(°F)

) of the instrument

and

AL95/97

.

Event type

Operation

No event 0 Always OFF Always OFF

PV high

limit

PV low limit 2

PV high/low

limit

Deviation

high limit

Deviation

low limit

Deviation

high/low

limit

Deviation

high limit

(Final SP

reference)

Deviation

low limit

(Final SP

reference)

Deviation

high/

low limit

(Final SP

reference)

Heater 1

burnout/

Over-current

Heater 1

short-circuit

Heater 2

burnout/

Over-current

Heater 2

short-circuit

Alarm

(status)

*: If the main setting is greater than the sub-setting, operations are performed with the

main setting and sub-setting automatically swapped.

Event types other than the above:

Operation type Set

SP high limit 10 Loop diagnosis 1 20 During AT (status) 27

SP low limit 11 Loop diagnosis 2 21 During SP ramp 28

SP high/low limit 12 Loop diagnosis 3 22 Control action (status) 29

MV high limit 13 READY (status) 24 ST setting standby (status) 30

MV low limit 14 MANUAL (status) 25 Timer (status) 32

MV high/low limit 15

1-12-2 Kawana, Fujisawa

Kanagawa 251-8522 Japan

URL

8

Set

:

shows that the ON/OFF is changed at this value.

type

value

:

shows that the ON/OFF is changed at a point

that "1U" is added to this value.

1

ON

Main setting

3

ON HYS ONHYS

4

SP + Main set ting

5

6

7

8

9

16

17

18

19

23 ON if alarm occurs (alarm code AL01

ON HYS

ON HYS

Main setting Sub-setting

SP + Main set ting

ON HYS

ON HYS

Main setting Sub-setting

ON HYS

OFF before measuring the CT1 current value

HYS

Main setting

OFF before measuring CT1 current value OFF before measuring CT1 current value

ON H YS

Main setitng

OFF before measuring CT2 current value OFF before measuirng CT2 current value

HYS

Main setting

OFF before measuring CT2 current value OFF before measuring C T2 current value

to 99).

OFF in other cases.

: initial value

value

Direct action

ONHYS

Main setting

HYS

*

Sub-setting

*

ONHYS

ONHYS

SP

ONHYS

ONHYS

SP

ON

*

ON

ONHYS

Sub-setting

ONHYS

Sub-setting

*

*

*

Operation type Set

Specifi cations are subjec t to change without n otice.

Reverse action

:

shows that the ON/OFF is changed at this value.

:

shows that the ON/OFF is changed at a point

that "1U" is added to this value.

ON

HYS

Main setting

HYS

ONHYS

Main setting *Sub-setting

ON

HYS

SP + Main set ting

ONHYS HYS

Main setting

ON

Main setting

Main setting

OFF before measuring CT1 current value

ON

Main setting

ON

OFF if alarm occurs (alarm code AL01

to 99).

ON in other cases.

value

Sub-setting

SP

HYS

SP + Main set ting

ONHYS HYS

Sub-setting

SP

ONHYS HYS

*

HYS

Main setting

ONHYS HYS

*

Sub-setting

HYS

Main setting

Operation type Set

1st edition: Mar. 2007 (W)

3rd edition: Apr. 2019 (B) © 2007–2019 Azbil Corporation. All Rights Reserved.

ON

HYS

ONHYS

ONHYS

Sub-setting

*

*

*

value

Loading...

Loading...