Page 1

Smart Valve Positioner 700Series

CM2-AVP703-2001

with F

OUNDATION

Model AVP703

Fieldbus

User's Manual

Page 2

Important

• Please be sure to hand this manual to the staff who will be using this product.

• No part of this publication may be reproduced or reused in any form or by

any means without the prior written permission of the publisher.

• The information and specifications in this document may be subject to

change without prior notice.

• While the contents of this document have been thoroughly checked, please

contact us if you find any incorrect or incomplete descriptions.

• We can not take responsibility for any unexpected results that are the result of

your handling of the product.

• F

OUNDATION

Fieldbus is a trademark of the FieldComm Group.

™

© 2014–2019 Azbil Corporation. All Rights Reserved.

Page 3

Introduction

Thank you for purchasing our AVP703 Smart Valve Positioner. The AVP703 (called

“the device” below) is a smart valve positioner that can be connected to the Foundation

Fieldbus.

The auto setup function makes it easy to set up the valve.

All adjustments and setup can be performed from the Foundation Fieldbus host. The Local

User Interface (LUI), which consists of the LCD (liquid crystal display) and operation

buttons, facilitates monitoring of input signals, valve opening, pressure display, and other

items as well as basic adjustments.

In addition, the built-in pressure sensor can be used to measure the supply air pressure and

output air pressure. As a result, the device can not only perform self-diagnostics but can

also be combined with the control valve maintenance support system called “Valstaff ” in

order to monitor the characteristics, operating status, and other data of the control valve,

helping to improve the maintenance efficiency of control valves. This instruction manual

describes how to handle the device. Read this manual to make full use of the features of

this product.

Scope of this manual and related documents

This document describes the functions and method of installation and adjustment of this

device. For details on the F

Manual (No. CM2-FBS100-2001*).

OUNDATION

Fieldbus network, refer to Fieldbus Integration

For details on the control valve diagnostic items, refer to the Smart Valve Positioner 700

Series Control Valve Diagnostic Function Manual (No. CM2-AVP700-2003*).

* If you need the above documents, please contact one of our sales representatives.

i

Page 4

Safety precautions

Symbols

The purpose of the safety precautions listed here is to ensure the user uses the product

safely and correctly, to prevent harm to the user and other people and damage to property.

Make sure to observe the safety precautions.

Many different symbols are used in this manual.

Their appearance and meaning are described below. Thoroughly understand the

explanation before starting to read the main text.

WARNING

CAUTION

Sample symbols

This symbol indicates warnings and cautions for handling the device.

This symbol indicates prohibited actions that must not be taken.

This symbol indicates instructions for an action that must be taken.

Handling Precautions:

This symbol indicates a point to be noted when handling the device.

Wrong handling may cause the death or severe injury of the user.

Wrong handling may cause a minor injury to the user or damage to equipment.

ii

Page 5

Precautions for safe work

Do not perform wiring with wet hands or while the device is energized. This may lead to electric

shock. Turn the power off before starting the work and work with dry hands or use gloves.

Follow the work procedure defined in the explosion protection guidelines when performing the

power distribution work in an explosion-proof area.

For devices equipped with the pressure-resistant, explosion-proof specifications, do not open the

cover during operation (while the power is on).

Do not get on the installed device or use it as a step stool. This is dangerous because the device may

tip over.

Do not touch the device during operation without reason. This is dangerous because the surface may

be hot or cold depending on the usage environment.

Be careful not to touch the edge of the cover or the screw threads of the main unit when opening the

cover of the terminal box. You may be injured by these parts.

WARNING

CAUTION

Use a DC power supply with overload protection. Overload may cause smoke or fire.

If a tool or other item touches the glass part of the display, it may break, leading to an injury. Be

careful. Wear safety glasses during work.

This product is heavy. Be careful where you step and wear safety shoes during work.

Do not touch the feedback lever or other moving part while the device is operating. You may be

injured by getting your hand or other body part caught in them.

Properly use the power supply based on the specifications. Inputting a different power supply may

damage the device.

Use gloves and other protective equipment during work in a hot, cold, or other severe environment.

Do not move the device close to a magnet or magnetic driver. The control valve may operate.

Apply the correct supply air pressure in accordance with the specification of the device. The

overpressure may cause abnormal actions of the control valve or damage to the pressure gauge.

iii

Page 6

Unpacking, Verification, and Storage of Product

Unpacking

This device is precision measuring equipment. Carefully handle it to prevent accidents or

damage.

After unpacking, check that the items below are included.

• The device

• Feedback lever and hexagon socket bolts×2

• (4-mm) hexagon wrench×1 (for feedback lever) (Included only when the device is

shipped alone.)

• Solenoid valve (KZ03) (optional)

• Mounting plate set (optional)

• Pressure-resistant packing cable adapter and pressure-resistant elbow (option for

explosion-proof specifications)

• Instruction manual (this document) (Included if specified at the time of purchase.)

• Extension lever and hexagon socket bolts×2 (optional)

Specifications check

The specifications are shown on the nameplate of the main unit. Check that the specifications

are the same as what you specified. In particular, confirm the following points.

When using the device in an explosion-proof area, be sure to select the model that satisfies the

necessary explosion-proof requirements. Non-explosion-proof products cannot be used in an

explosion-proof area.

Contact

Storage

• Tag No. (TAG No.)

• Model (MODEL)

• Work No. (PROD.)

• Supply air pressure (SUPPLY)

• Explosion protection certification seal (for explosion-proof specifications)

WARNING

For inquiries about this device, please contact us.

When contacting us, let us know the model number and production number.

When storing the device after purchase, obey the following precautions.

• When storing the device before it has been used

1. Store the device as packed at shipment.

2. Store the device at an indoor location with little vibration or shocks and at normal

temperature and humidity (about 25°C, 65%).

• When storing the device after it has been used

1. Tightly secure the terminal box cover and block the conduit connection port with

tape to prevent humidity intrusion.

2. Block the three pneumatic piping connection ports (SUP, OUT1 and OUT2) with

tape to prevent humidity and dust intrusion.

3. Pack the device in the same way as at shipment.

4.

Store the device at an indoor location with little vibration or shocks where it will not be

exposed to rain or water and at normal temperature and humidity (about 25°C, 65%).

iv

Page 7

Table of Contents

Chapter 1. Structure of the 700 Series Control System 1-1

1-1. System Configuration

1-2. Structure of the Device and Description of Each Part 1-3

1-2-1. Structure of the Device 1-3

1-2-2. Structure of Terminal Box 1-5

1-2-3. Display on the Local User Interface (LUI) 1-7

1-1

Chapter 2. Installation of the 700 Series 2-1

2-1. Usage Conditions

2-2. Selection Criteria for Installation Location 2-3

2-2-1. Selection Criteria for Installation Location 2-3

2-3. Installation Procedure 2-5

2-3-1. Mounting the 700 Series onto the Actuator 2-5

2-3-2. Pneumatic Piping Connection 2-11

2-3-3. Electrical Wiring Connection 2-14

2-3-4. Cables 2-16

2-4. Cable gland and flameproof universal elbow for TIIS Flameproof apparatus 2-18

2-2

Chapter 3. Operation of the 700 Series 3-1

3-1. Local User Interface (LUI)

3-1-1. Displays 3-4

3-1-2. Disp_TB Display 3-5

3-2. Adjustment before Operation 3-14

3-2-1. Auto Setup 3-14

3-2-2. Zero Span Adjustment 3-17

3-2-3. Supply Bypass 3-20

3-2-4. Control Parameters 3-21

3-3. Starting Operation 3-23

3-3-1. Checking Fieldbus Operation 3-23

3-3-2. Preoperation Check 3-24

3-2

Chapter 4. Operations Using Fieldbus Communication 4-1

4-1. Fieldbus Communication Menus

4-2. Setup and Adjustment of Device 4-1

4-2-1. Process Variables 4-2

4-2-2. Auto Setup 4-2

4-2-3. Valve System 4-4

4-2-4. Control Configuration 4-5

4-2-5. Characterization 4-6

4-2-6. Final Value Cutoff 4-7

4-2-7. Units 4-7

4-2-8. Travel Calibration 4-8

4-2-9. Pressure Sensor Adjustment 4-9

4-2-10. Simulation 4-9

4-2-11. Test 4-10

4-2-12. Restore factory settings 4-11

4-2-13. Operator Action Records 4-11

4-2-14. Device Information 4-12

4-2-15. FF Option 4-12

4-3. Diagnostic Messages 4-13

4-3-1. Self-Diagnostic Messages 4-13

v

4-1

Page 8

4-3-2. Control Valve Diagnostic Messages

4-15

Chapter 5. Troubleshooting 5-1

5-1. Troubleshooting

5-1-1. The Device Does Not Operate. (There Is No Output Air Pressure.) 5-2

5-1-2. The Control Valve Operates Abnormally (There Is Output Air Pressure.) 5-3

5-1-3. Display Transducer Block Does Not Switch To Auto (LUI display says “DISP_OOS.”)

5-3

5-1-4. Adjustment Procedure When Hunting Occurs 5-4

5-1-5. Auto Setup Failure 5-5

5-2. Description of Messages 5-6

5-2

Chapter 6. Maintenance 6-1

6-1. A/M Switch

6-2. Replacement of Filter and Maintenance of Flow Restrictor 6-3

6-3. Cleaning the Flapper 6-4

6-4. Adjusting the Pilot Relay 6-5

6-5. Insulation Resistance Test 6-6

6-6. Adjustment Procedure When Using the Device with the Booster Relay Attached 6-7

6-7. Internal Block Diagram of the 700 Series 6-8

6-8. Resale Parts 6-8

6-8-1. Procedure to Change Switch Block 6-12

6-8-2. Procedure to Change Pilot Relay 6-13

6-2

Chapter 7. Notes on the Explosion-Proof 700 Series 7-1

7-1. TIIS Flameproof Model

7-2. ATEX Flameproof and Dust Ignition Protection 7-3

7-3. IECEx Flameproof and Dust Ignition Protection 7-5

7-4. FM Explosionproof/Dust Ignition Protection 7-7

7-5. FM Intrinsically safe (ic) and Nonincendive 7-8

7-6. FMC Explosionproof/Dust Ignition Protection 7-11

7-7. NEPSI Flameproof/Dust Ignition Protection 7-12

7-8. KOSHA Flameproof 7-14

7-9. INMETRO Flameproof/Dust Ignition Protection 7-15

7-10. EAC Flameproof 7-17

7-11. ATEX Intrinsic Safety and Dust Ignition Protection 7-18

7-12. IECEx Intrinsic Safety and Dust Ignition Protection (FISCO) 7-19

7-2

Appendix A. LUI Display Example A-1

Appendix B. Menu List B-1

Appendix C. Parameter List C-1

Appendix D. Specifications D-1

Appendix E. Model Configuration Table E-1

Appendix F. Outline Dimensional Drawing F-1

Terms and Conditions S2

vi

Page 9

Chapter 1 Structure of the 700 Series Control System

Air to the actuator

Control valve

Process fluid

Chapter 1. Structure of the 700 Series Control System

This chapter describes the device configuration of the control system that uses the device.

•

Description of the configuration of the input/output system in the device

•

Description of the structure of the main unit of the device and the name and function of

each part

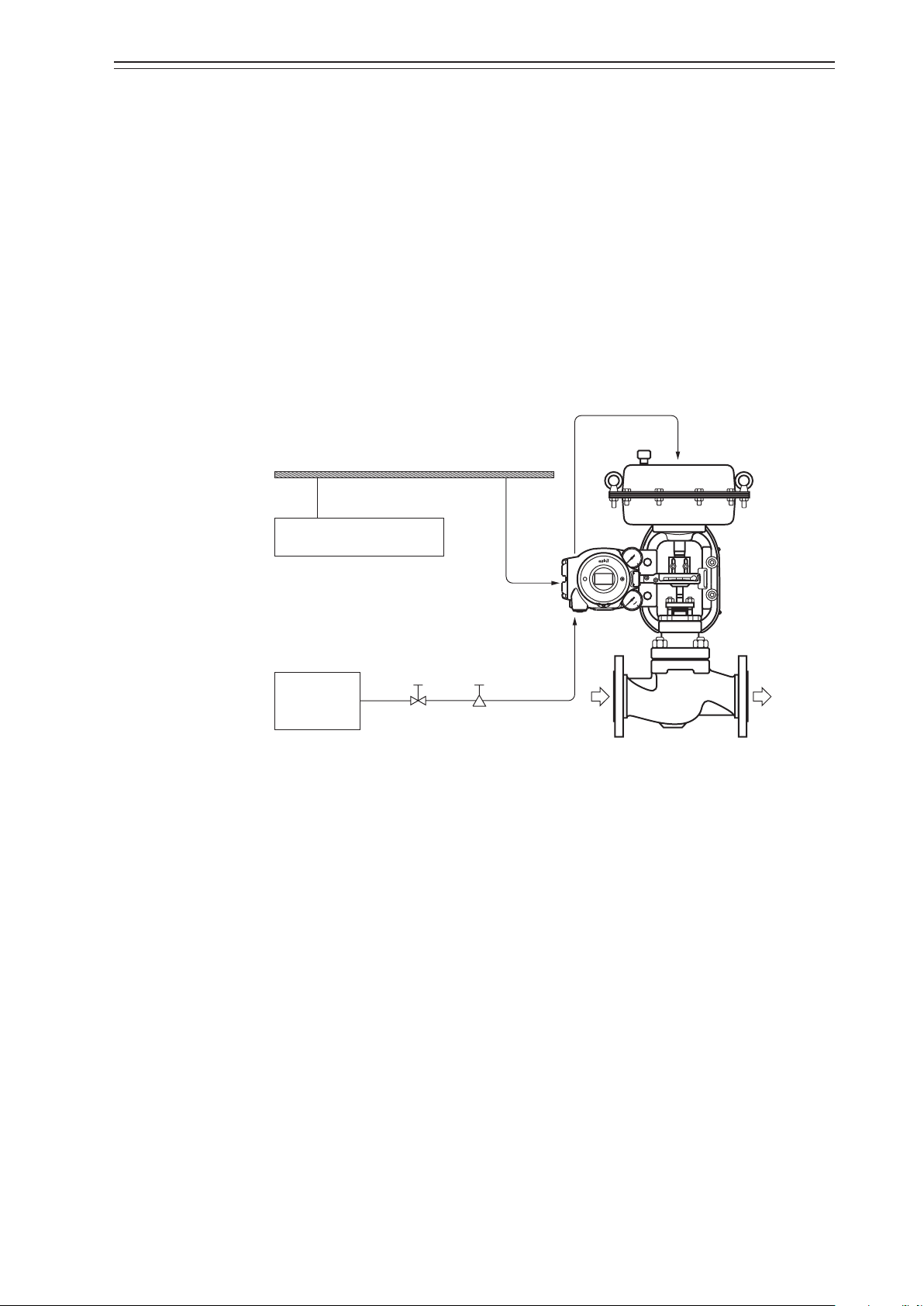

1-1. System Configuration

This device is a Fieldbus-enabled smart valve positioner and registered Foundation Fieldbus product.

The concept and the operation block diagram of the control valve control system that uses

the device are shown below.

Fieldbus

Other Fieldbus device

Air supply

system

Figure 1-1. Concept Diagram of the 700 Series Control System

Shutoff

valve

Device

Supply air

Solenoid valve

with filter

1-1

Page 10

Chapter 1 Structure of the 700 Series Control System

Fieldbus

CV

1) Operation block diagram

The block configuration of a typical function block and positioner is shown in the figure

below.

Resource

Block

PV

SP

PID

IN OUT

AO

Function

Block

Figure 1-2. Operation Block Diagram (AVP703)

Positioner

Transducer

Block

Position

sensor

−

Positioner

control section

Electropneumatic

transduction

section

Pilot

1-2

Page 11

Chapter 1 Structure of the 700 Series Control System

interface (LUI)

Output air pressure gauge

Output air connection port (OUT1)

Electrical conduit connection port

Terminal box cover

Output air connection port (OUT2)

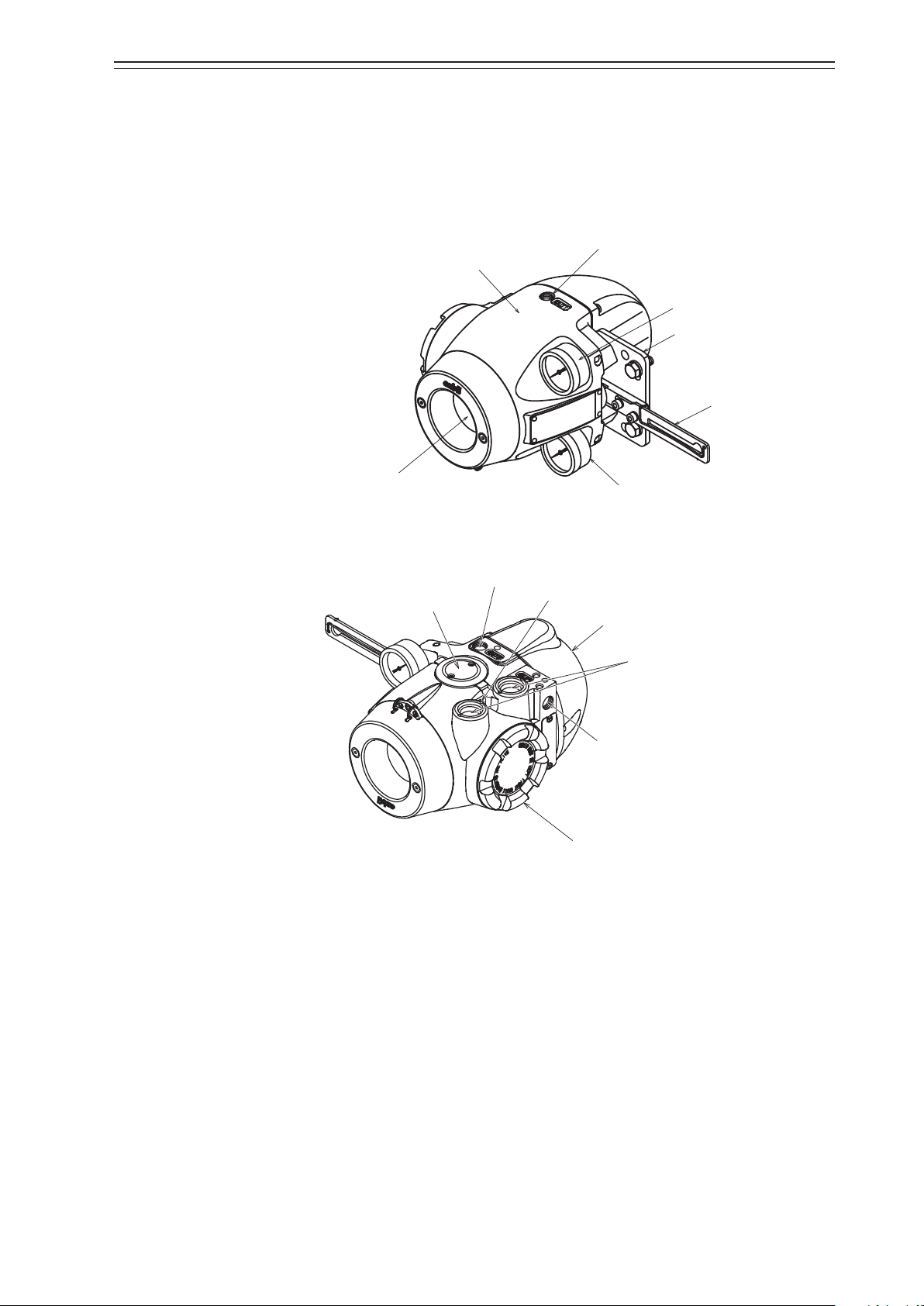

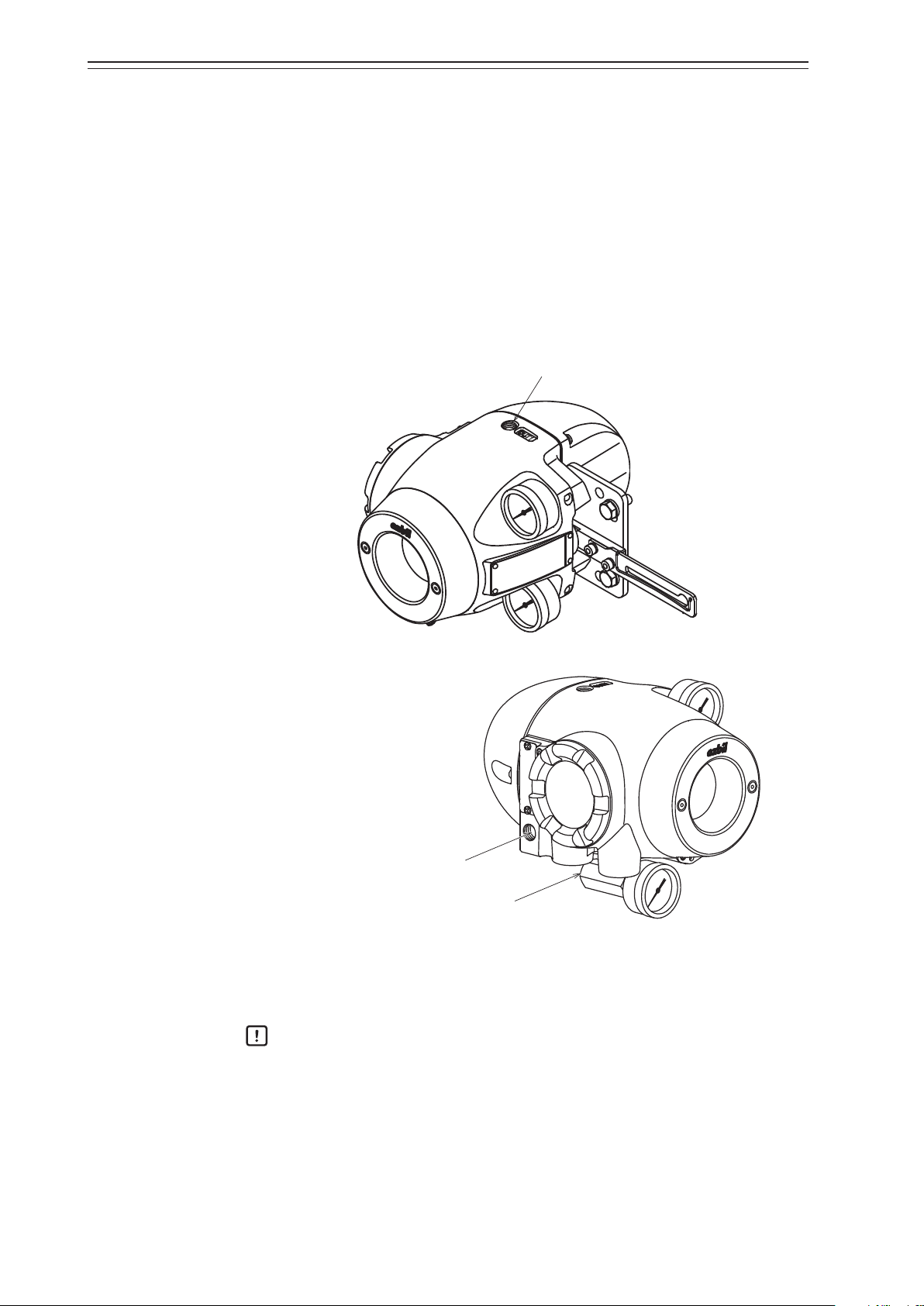

1-2. Structure of the Device and Description of Each Part

1-2-1. Structure of the Device

1) Major components

The structure of the main unit of the device is shown in the figure below.

Main unit

Mounting plate (optional)

Feedback lever

Local user

Exhaust cap

Supply air pressure gauge

Figure 1-3. Structure of the Device (Upper)

External grounding terminal

Pilot relay cover

Supply air connection port (SUP)

Figure 1-4. Structure of the Device (Lower)

1-3

Page 12

Chapter 1 Structure of the 700 Series Control System

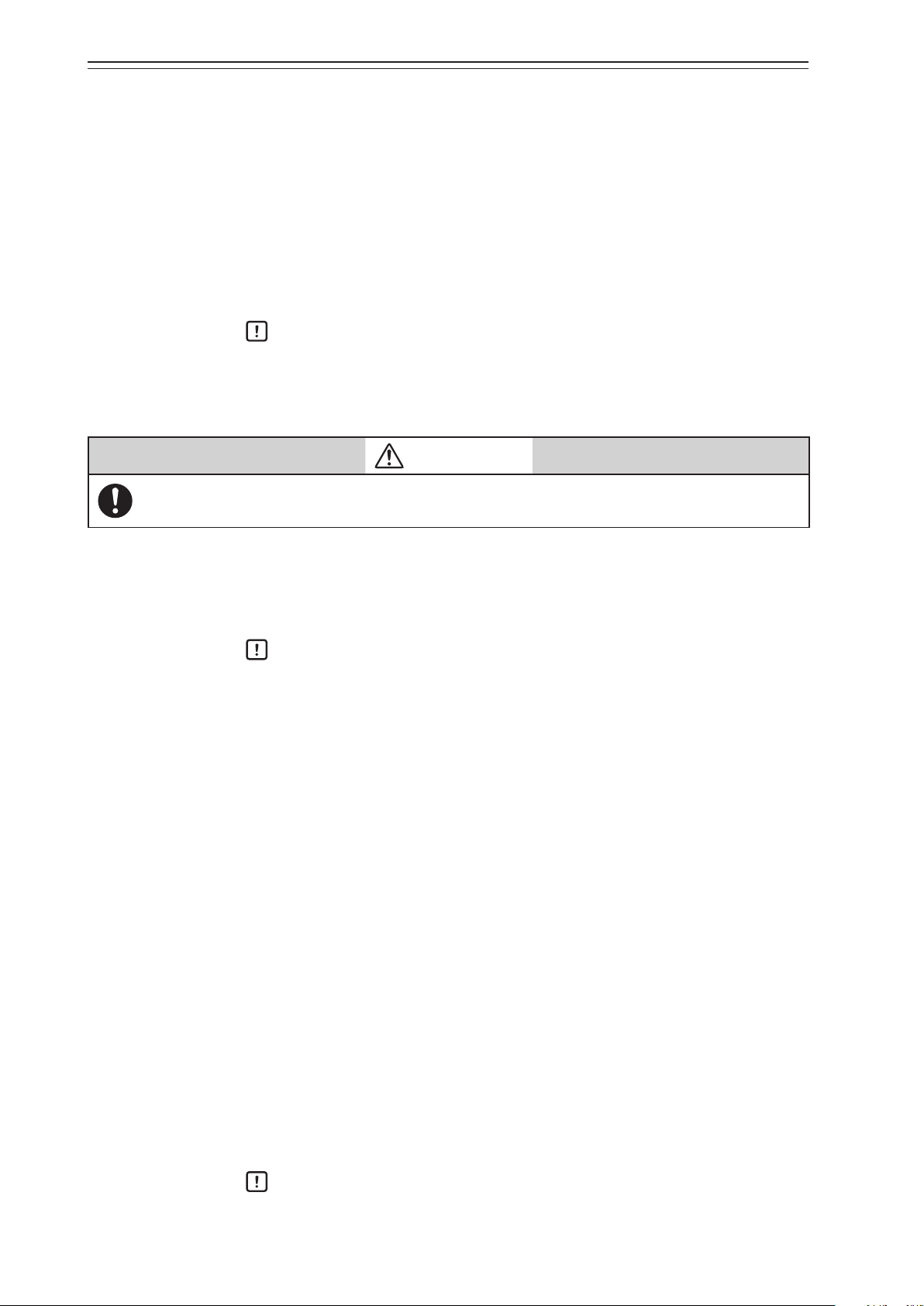

2) Name and description of each part

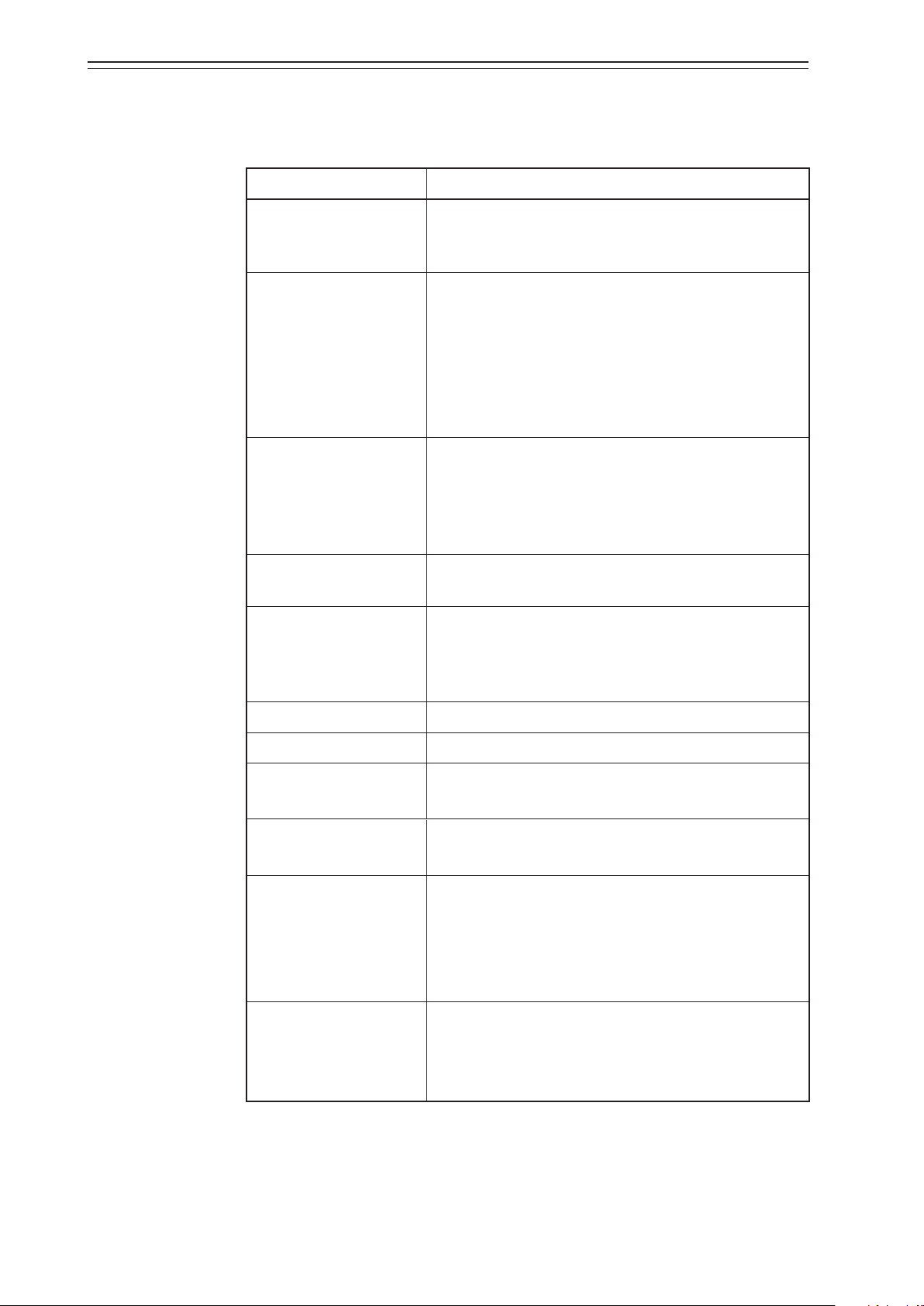

The table below describes each part.

Name Description

Main unit

Pilot relay cover

Auto/Manual (A/M)

switch

Table 1-1. Description of Each Part

•

Houses electronic circuits, an electro-pneumatic transducer (EPM), a position sensor (VTD), and a pressure

sensor.

•

Cover of the pilot relay that amplifies the air signal from

the EPM (electro-pneumatic transducer) and transduces

it into the air signal sent to the actuator.

•

When you must adjust the balance pressure to switch

between the pilot relay for the single-acting actuator and

the pilot relay for the double-acting actuator, remove

this cover.

•

This switch is used to switch how the output air between

the auto operation status and the manual operation

status is controlled. This switch is built into the pilot

relay. This switch can be seen by removing the pilot relay

cover.

Feedback lever

Local user interface (LUI)

Supply air pressure gauge

Output air pressure gauge

Supply air connection

port (SUP)

Output air connection

port (OUT1)

Output air connection

port (OUT2)

Mounting plate (optional)

•

Extracts and transmits the movement of the control

valve lift to the VTD (position sensor).

•

The LUI allows you to adjust the zero span, perform

auto setup, and manually operate the device with the

LCD (liquid crystal display) and operation buttons without using the communicator.

•

Indicates the pressure of supply air.

•

Indicates the pressure of output air.

•

Supply air is input to this port.

•

“SUP” is displayed at this port.

•

Output air is sent out of this port to the actuator.

•

“OUT1” is displayed at this port.

•

Output air is sent out of this port to the actuator.

•

This port is blocked with a blind plug in the singleacting actuator.

•

OUT2 is displayed at the output port for the doubleacting actuator.

•

The mounting plate is used to mount the device onto the

actuator.

•

The shape of the mounting plate differs depending on

the specifications (actuator model).

1-4

Page 13

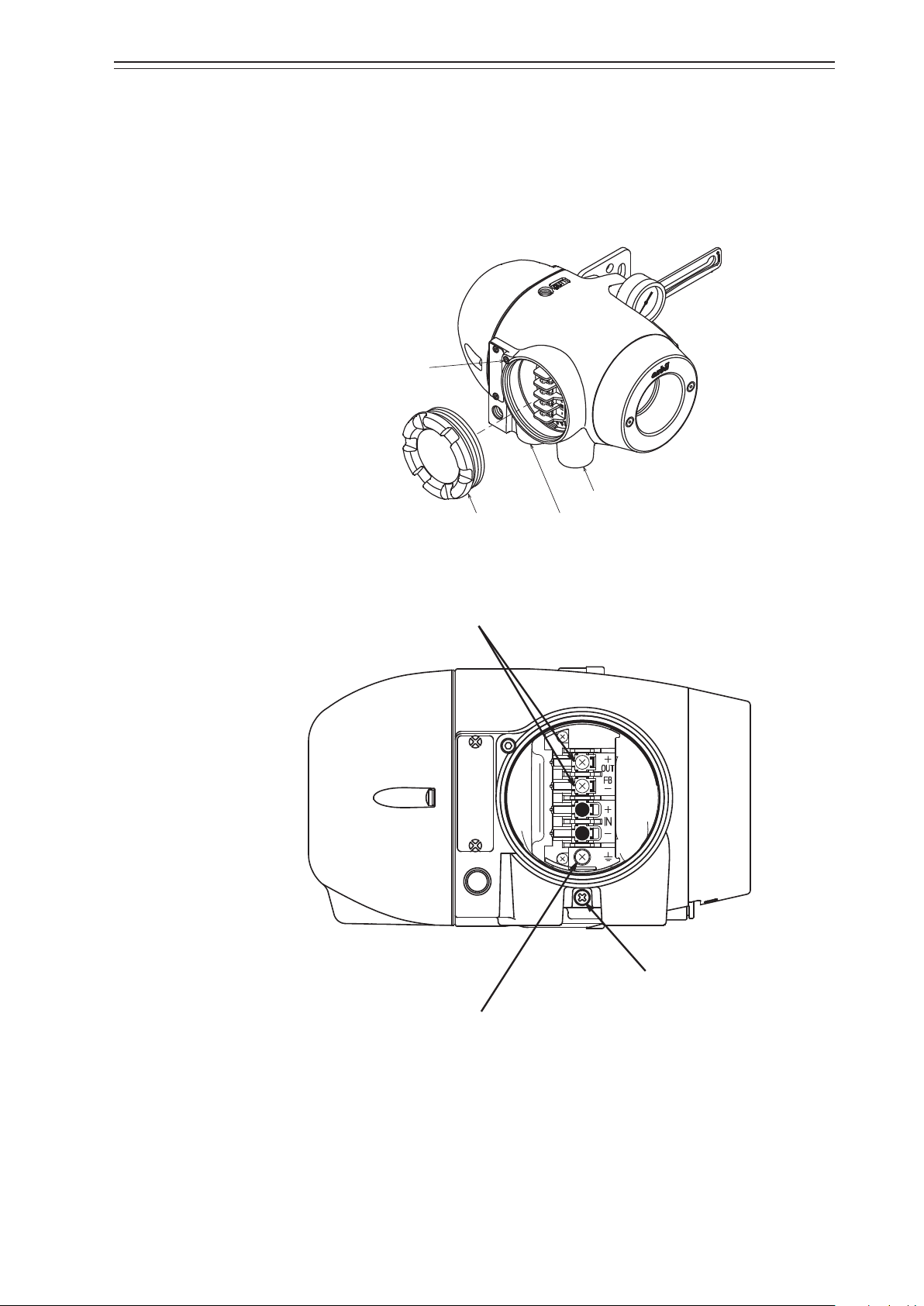

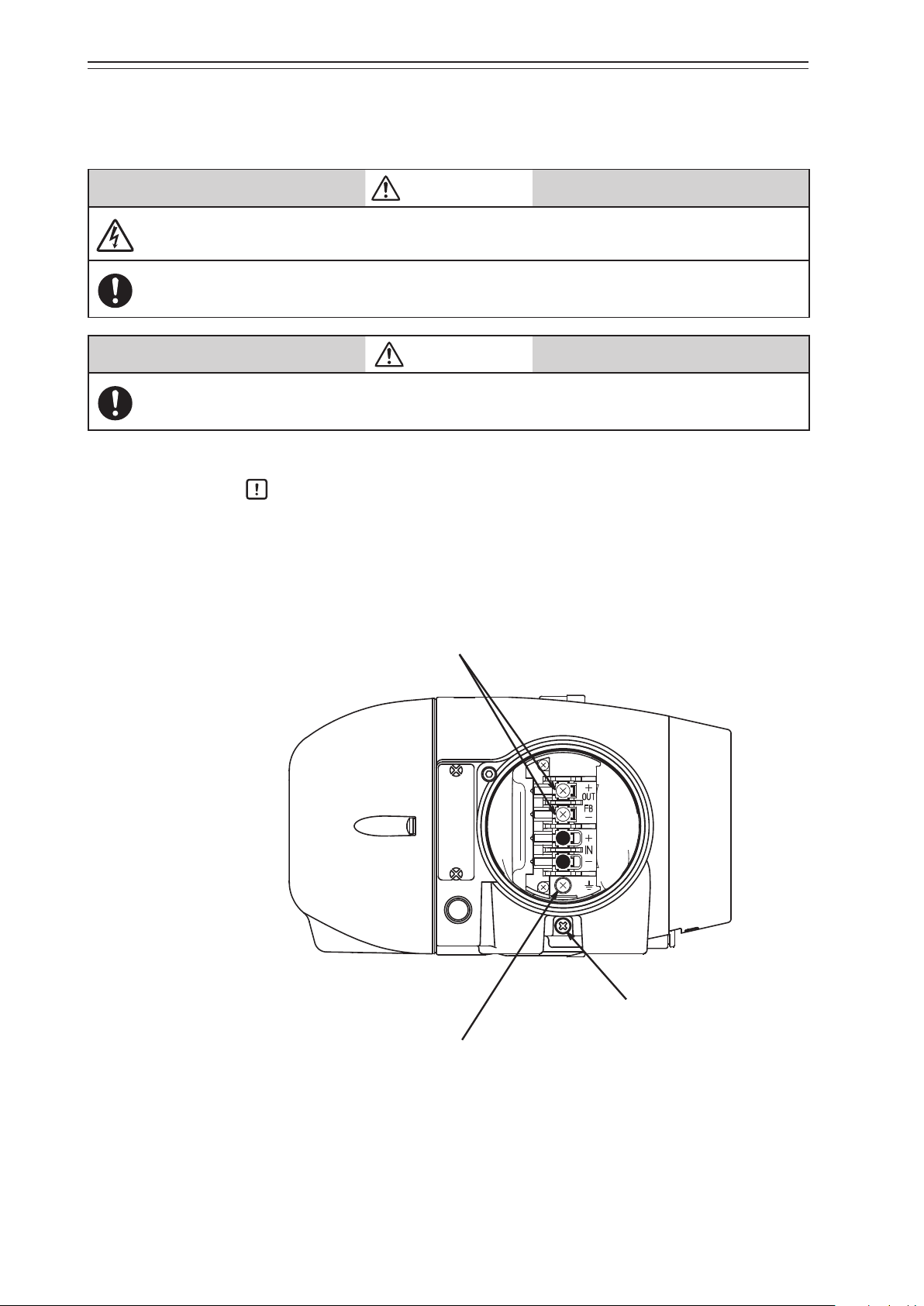

1-2-2. Structure of Terminal Box

Lock screw

Conduit connection port (2)

Conduit connection port (1)

box cover

1) Major components

The terminal box houses the Fieldbus terminal and the internal grounding terminal.

The structure of the terminal box is as shown below.

Chapter 1 Structure of the 700 Series Control System

Terminal

Figure 1-5. Structure of Terminal Box

M4 screw

for Fieldbus terminal

M4 screw

for external grounding terminal

M4 screw

for internal grounding terminal

Figure 1-6. Terminal Block in the Terminal Box

1-5

Page 14

Chapter 1 Structure of the 700 Series Control System

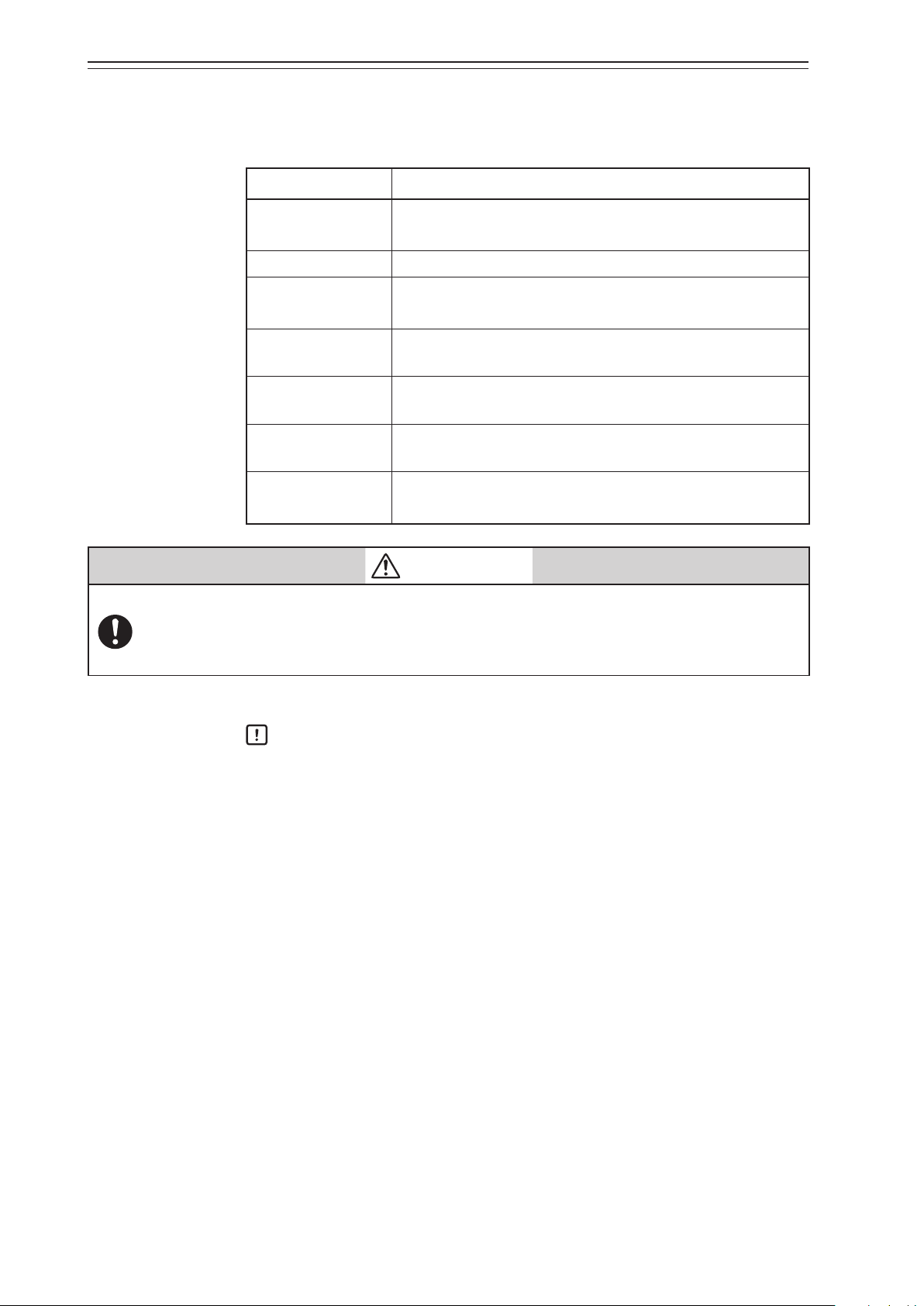

2) Name and description of each part

The table below describes each part of the terminal box.

Name Description

•

Terminal box cover

Lock screw

•

•

•

Fieldbus terminal

External grounding

terminal

Internal grounding

terminal

Conduit connection

port (1)

Conduit connection

port (2)

•

•

•

•

•

•

Table 1-2. Description of Each Part

Lid of terminal box.

This cover has a pressure-resistant explosion-proof structure.

Used to secure the terminal box cover.

“FB” is displayed at this terminal.

The Fieldbus signal cable is connected to this terminal.

External terminal for grounding. The cable for grounding is

connected to this terminal.

Internal terminal for grounding. The cable for grounding is

connected to this terminal.

Service entrance for a cable.

Service entrance for a cable.

This entrance is normally blocked with a blind plug.

WARNING

When using a pressure-resistant explosion-proof model in a dangerous place, be sure to use the

specified cable adapter for pressure-resistant packing for the conduit connection port. Securely

close the terminal box cover all the way. Then, rotate the lock screw counterclockwise to secure the

terminal box cover.

Handling Precautions:

Ground either the external or internal grounding terminal according to the

specifications. Be careful not to ground the device at two points.

1-6

Page 15

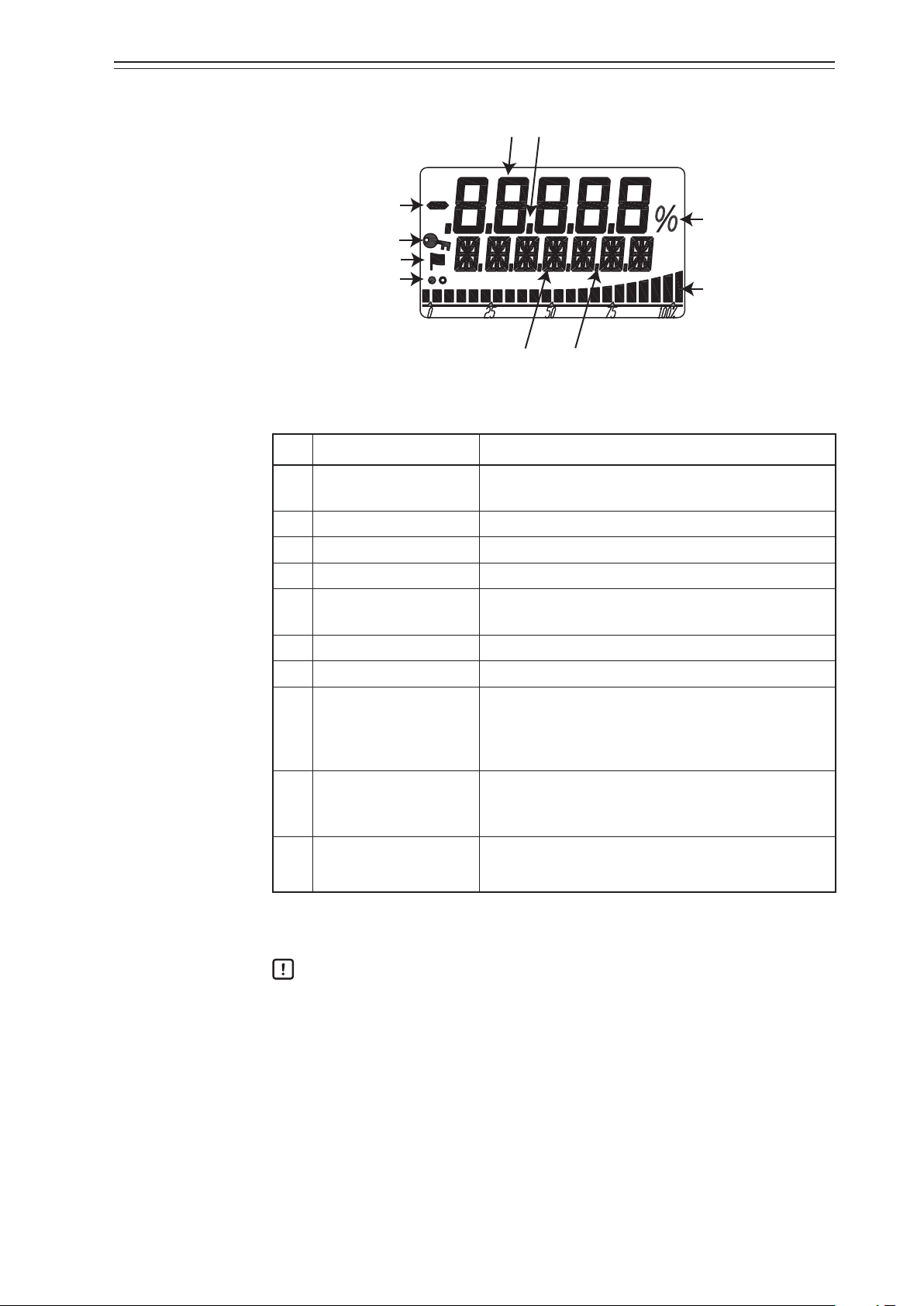

1-2-3. Display on the Local User Interface (LUI)

Chapter 1 Structure of the 700 Series Control System

(1)

(3)

(2)

(8)

(9)

(10)

(4)

(5)

(6)

(7)

Figure 1-7. Segments on the LUI

Table 1-3. Description of Each Part

No. Displayed element Main display

(1) 7 segments (5 digits)

Displays the main numerical values such as the specified opening.

(2) Minus sign Displays the sign for the 7-segment number.

(3) Decimal point (5 places) Displays the decimal point for the 7-segment number.

(4) 16 segments (7 digits) Displays the unit, status, or other data.

(5) Dot (6 places)

Displays the 16-segment auxiliary display, separator, or

other data.

(6) Percentage Displays %.

(7) Bar graph (22 bars) Displays the bar graph in percentage at a set point, etc.

On: LUI operation is unavailable.

(8) Key mark

Off: LUI operation is available.

Blinking: LUI is in operation.

When the self-diagnostic alarm is activated, the key

(9) Flag mark

mark is displayed. For detailed information of the

alarms, please refer to the status monitor of page 3-4 .

Display during operation

(10) Display refresh mark

White and black circles alternately blink.

For a display example, refer to “Appendix A. LUI Display Example.”

Handling Precautions:

The LUI buttons may not respond well near an electromagnetic inductor (such as

a large transformer or high-frequency furnace).

Remove sand, dust, and other foreign objects from the rubber parts of the

operation buttons before operating the LUI. Operating the LUI with foreign

objects on it may damage the rubber parts.

Do not pull the rubber parts of the operation buttons. This may deteriorate the

sealability, possibly causing malfunction.

1-7

Page 16

Chapter 1 Structure of the 700 Series Control System

1-8

Page 17

Chapter 2 Installation of the 700 Series

Chapter 2. Installation of the 700 Series

This chapter describes the usage conditions, installation, piping, and wiring of the device.

Precautions for safe work

WARNING

Do not perform wiring with wet hands or while the device is energized. This may lead to electric

shock. Turn the power off before starting the work and work with dry hands or use gloves.

Follow the work procedure defined in the explosion protection guidelines when performing the

power distribution work in an explosion-proof area.

For devices equipped with the pressure-resistant, explosion-proof specifications, do not open the

cover during operation (while the power is on).

CAUTION

Do not get on the installed device or use it as a step stool. This is dangerous because the device may

tip over.

Do not touch the device during operation without reason. This is dangerous because the surface may

be hot or cold depending on the usage environment.

Be careful not to touch the edge of the cover or the screw threads of the main unit when opening the

cover of the terminal box. You may be injured by these parts.

Use a DC power supply with overload protection. Overload may cause smoke or fire.

If a tool or other item touches the glass part of the display, it may break, leading to an injury. Be

careful. Wear safety glasses during work.

This product is heavy. Be careful where you step and wear safety shoes during work.

Do not touch the feedback lever or other moving part while the device is operating. You may be

injured by getting your hand or other body part caught in them.

Properly use the power supply based on the specifications. Inputting a different power supply may

damage the device.

Use gloves and other protective equipment during work in a hot, cold, or other severe environment.

Do not move the device close to a magnet or magnetic driver. The control valve may operate.

Apply the correct supply air pressure in accordance with the specification of the device. The

overpressure may cause abnormal actions of the control valve or damage to the pressure gauge.

2-1

Page 18

Chapter 2 Installation of the 700 Series

2-1. Usage Conditions

The device must be installed in the location, which satisfies the following conditions.

Also, the divice must be used in accordance with its specification.

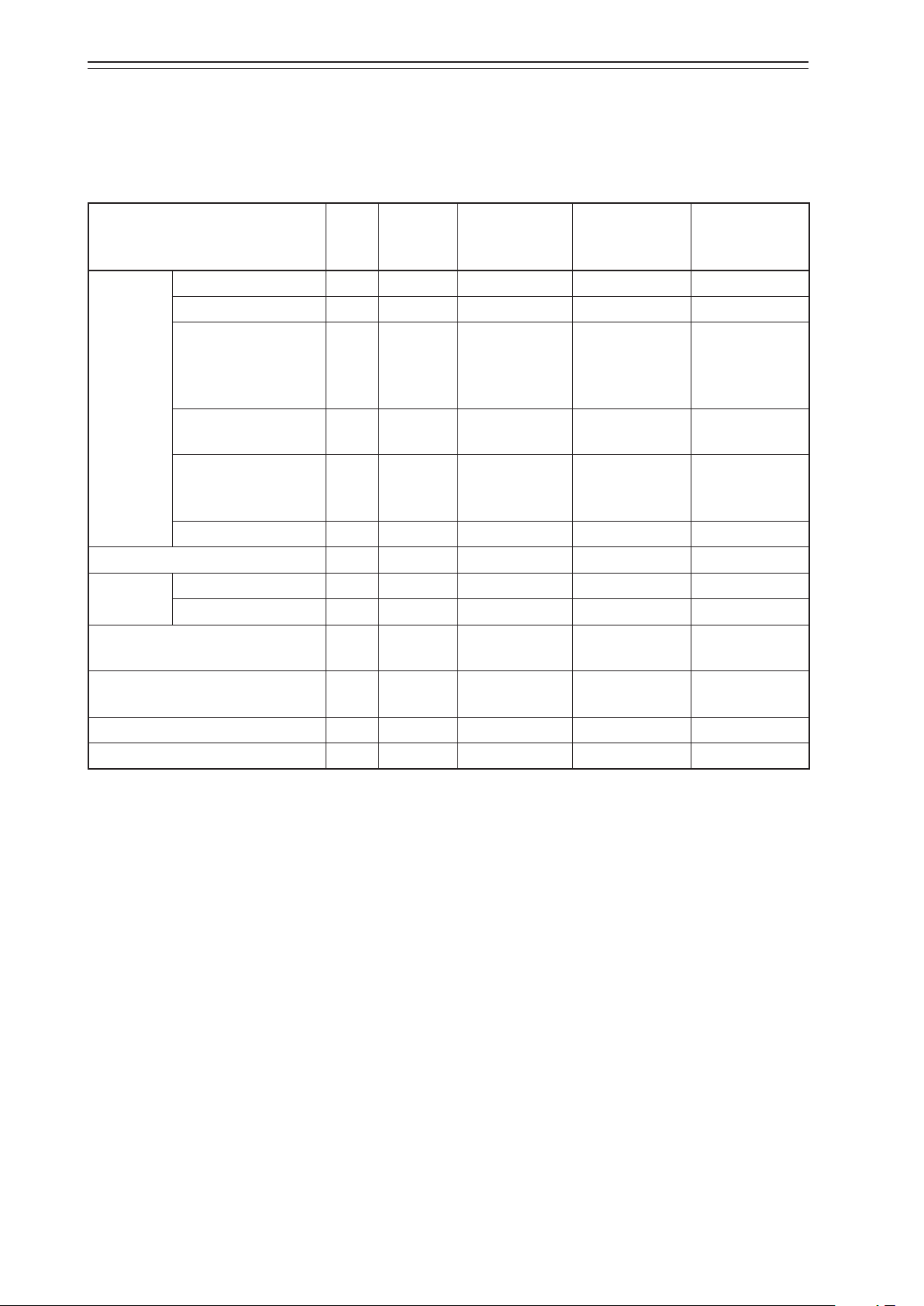

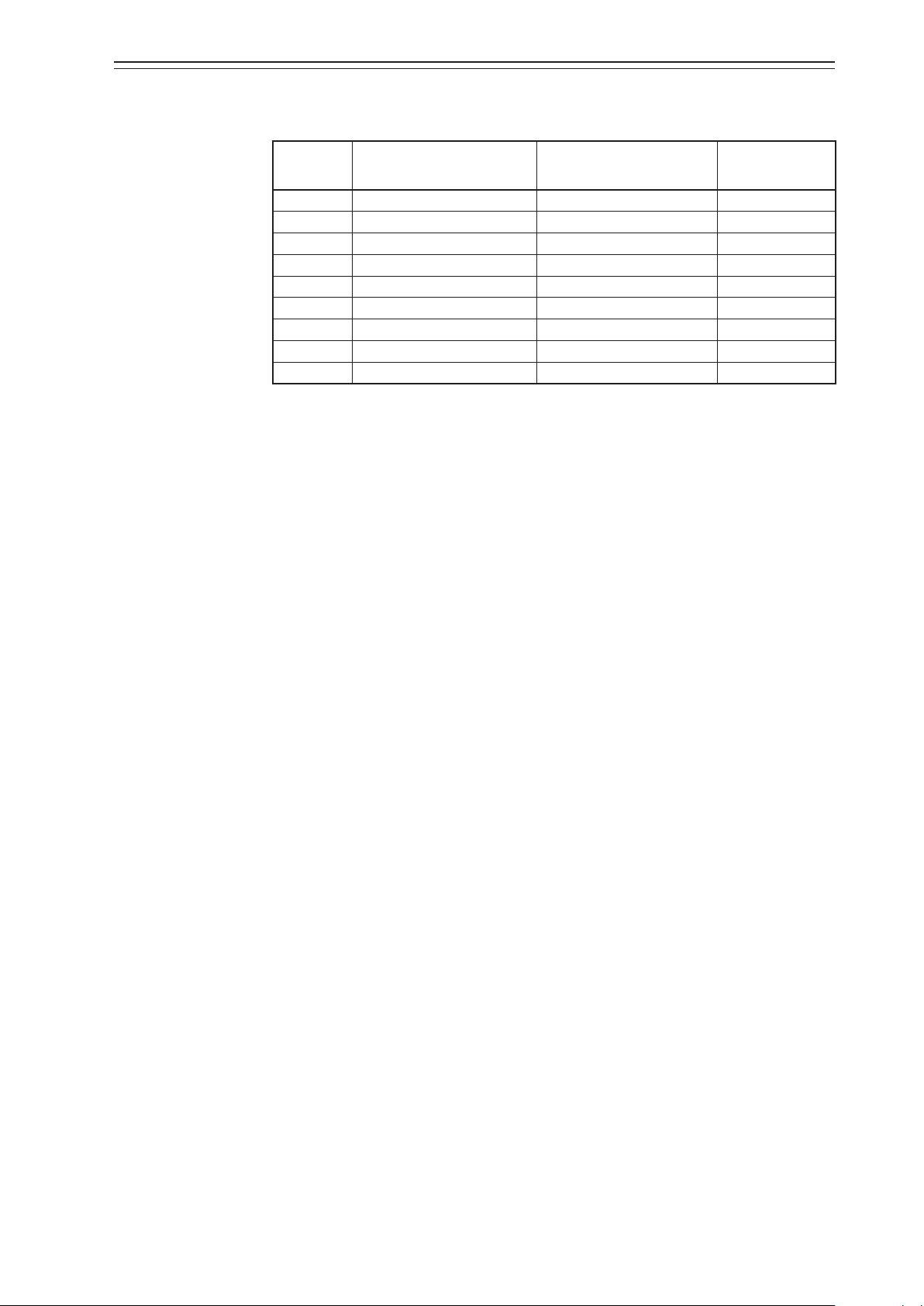

Table 2-1. Range of Usage Conditions

Units

Basic

operating

conditions

Normal

operating

conditions

Marginal

operating

conditions

Transportation

conditions

General model °C +23 ±2 −40 to +80 −40 to +80 −40 to +70

TIIS flameproof model °C +23 ±2 −20 to +55 −20 to +55 −40 to +70

ATEX/IECEx/FM/

Operating

FMC/NEPSI/KOSHA/

EAC/INMETRO

flameproof model

°C +23 ±2 −30 to +75 −30 to +75 −40 to +70

temperature

range

FM Intrinsically Safe (ic)

and Nonincendive

°C +23 ±2 −24 to +75 −24 to +75 −40 to +70

ATEX/IECEx intrinsically safe model

°C 23±2 −40 to +60 −40 to +60 −40 to +70

(FISCO)

LUI °C +23 ±2 0 to +50 −40 to +80 −40 to +70

Power supply voltage V 9 to 32 9 to 32 32 —

Vibration

Amplitude *

Acceleration *

Friction of applied valve % 3 to 20 3 to 20

Supply air pressure Ps

(140kPa≤Ps≤700kPa)

Installation orientation *

1

1 *2

mm

m/s

p-p

0 15/(5 to 8 Hz) 15/(5 to 10 Hz) 15/(5 to 10 Hz)

2

0 20/(8 to 400 Hz) 40/(10 to 400 Hz) 40/(10 to 400 Hz)

0 to 3

20 to 100

—

kPa Ps ±1% 140 to 700 0 to 710 —

3

° ±1*

4

±180 ±180 ±180

Humidity range %RH 50 ±10 5 to 100 5 to 100 5 to 100

Each operating condition is defined as follows.

•

Basic operating condition: Range in which the accuracy is guaranteed

•

Normal operating condition: Range in which the positioner normally operates

•

Marginal operating condition: Range in which performance is not guaranteed but the device can be used with-

out being permanently damaged

•

Transportation condition: Environment condition range in which the non-operating device is not permanently

damaged during transportation

*1. Vibration conditions when the positioner cover is positioned at the center front.

*2. The pressure gauge is not applied.

*3. The slope characteristics are not included.

*4. The status where the drive shaft of the direct-acting actuator is perpendicular to the ground and that is used as the reference.

2-2

Page 19

2-2. Selection Criteria for Installation Location

The device is designed to withstand severe conditions, but the installation location should

be selected according to the criteria described below to maximize performance.

2-2-1. Selection Criteria for Installation Location

Install the device in a location that satisfies all of the following conditions.

•

Operating temperature range that conforms to the explosion protection rules

•

Relative humidity: 5 to 100%RH

•

Ambient temperature change rate: ±20°C/hr or slower

•

Electromagnetic induction: 400 A/m or less (Avoid places near a large transducer, highfrequency furnace, or other such equipment.)

•

Do not use a transceiver near the device.

•

Vibration: 20 m/s2 (5 to 400 Hz) or less (The vibration conditions defined for the device

are the vibrations at the positioner part.)

Chapter 2 Installation of the 700 Series

2-2-1-1. Criteria for instrumentation air

The device employs a nozzle flapper structure in the electropneumatic transduction section. If instrumentation air is contaminated (includes oil, water, or other substance), the

positioner function of the device may not function properly or an irrecoverable failure may

occur. Therefore, the quality of instrumentation air supplied to the device is defined as follows.

•

Solid material: No particles with a diameter larger than 3 μm.

•

Oil: Less than 1 ppm.

•

Supply air humidity: The dew point temperature is at least 10°C lower than that of the

(This criterion is based on Japanese Industrial Standards JIS C 1805-1(2001).)

Select a compressor and main line or terminal-installation type compressed air purifier by

referring to the above specifications.

(1) Compressed air purifier for the main line

Select a compressed air purifier for the main line, such as a main line filter or microalescer, to satisfy the above specifications.

Domestic compressed air purifier manufacturers of Japan: SMC Corporation and CKD

Corporation

device.

(2) Compressed air purifier to be installed on the terminal

If an air purifier cannot be installed on the main line due to installation of a control

valve or for other reasons, use an compressed air purifier that can be installed on the

terminal in order to satisfy the above specifications.

2-3

Page 20

Chapter 2 Installation of the 700 Series

<Example devices>

Products from SMC Corporation

•

Mist Separator AM150 or AM250 Series (Filtering level: 0.3 μm, Secondary oil mist

concentration: 1.0 mg/m3)

CKD Corporation

•

Oil mist filter

•

M1000 or M3000 Series

•

Mantle S Type (Filtering level: 0.3 μm, Remaining oil: 1.0 mg/m3)

Handling Precautions:

Select a compressed air purifier with specifications suited to the usage conditions.

Even when you install the above oil removal equipment, it is necessary to properly

inspect and maintain the air circuit section for long-term stable operation. Install

the oil removal equipment before use and perform periodic inspection and

maintenance.

The warranty is void if the device fails because the quality of the above

instrumentation air was not sufficient.

2-4

Page 21

2-3. Installation Procedure

2-3-1. Mounting the 700 Series onto the Actuator

The device is a smart valve positioner for use with a control valve that uses a direct-acting

or rotary actuator. The main unit of the device weighs approximately 4.2 kg. The basic

mounting procedure is the same as that for conventional electropneumatic positioners.

CAUTION

Be careful not to get injured by sharp parts such as the edge of the main unit or actuator or screw

threads during mounting.

The type of mounting plate, mounting method, and mounting procedure differ depending on the

actuator model to be mounted in the device.

If the device is not properly mounted, not only will the device not be able to operate at its true

performance but it may be damaged or fail. Pay attention to the following points.

•

The mounting plate and its accessories differ depending on the specifications (actuator model).

Be sure to use the appropriate mounting plate and accessories for the actuator to be mounted.

•

When installing the control valve, ensure as much surrounding space as possible and put the

device in the correct orientation taking maintainability (such as piping, wiring, and adjustment)

into consideration.

•

Deliver the device to the installation location in the packaged state if possible.

•

Do not apply excessive force to the feedback lever during mounting.

•

Do not bend the feedback pin.

•

Do not block the exhaust port located underneath.

•

Install the device so that the electrical conduit connection port does not face upward.

•

Securely tighten bolts.

•

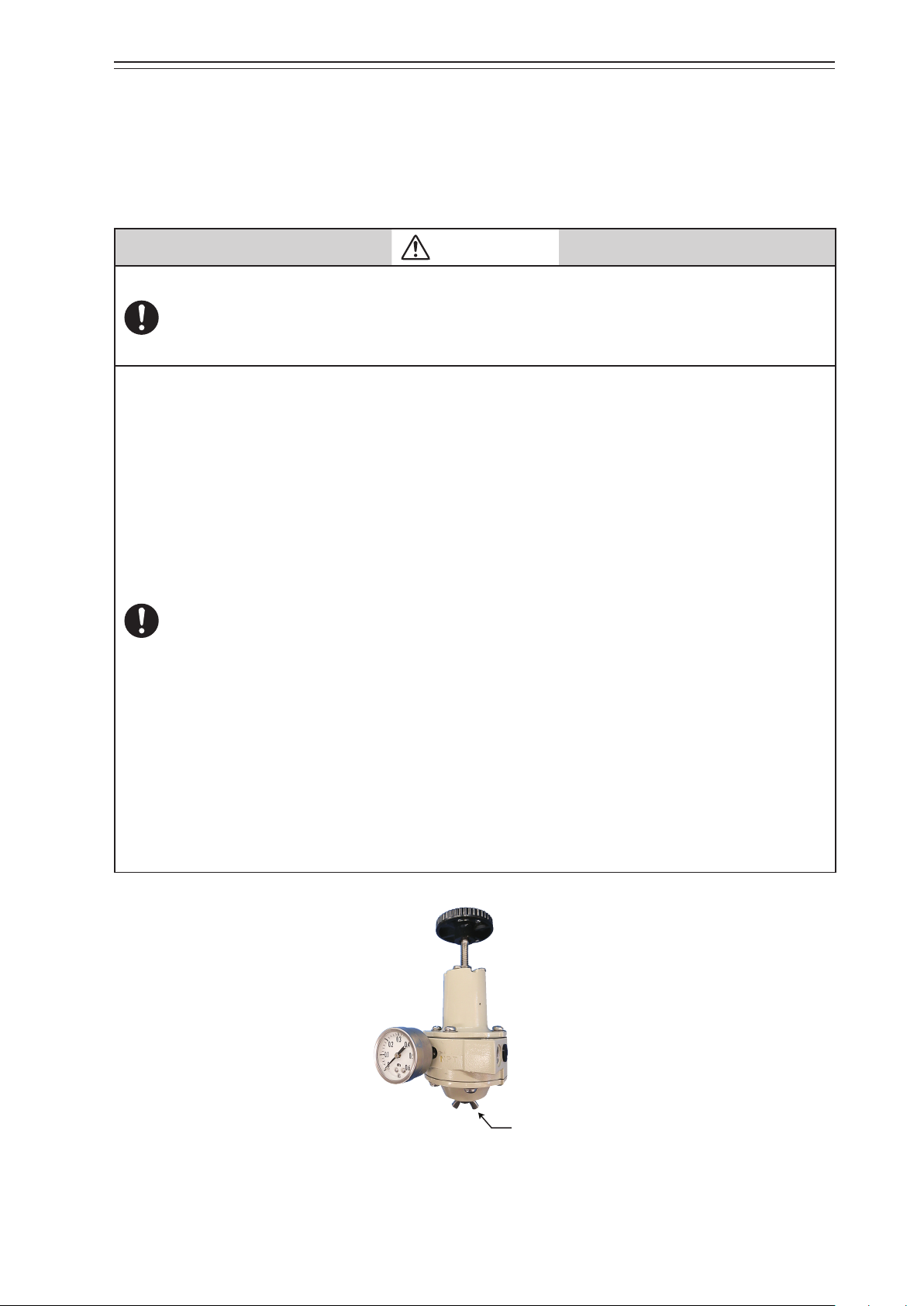

If the model KZ03 pressure regulator with filter is installed with the device, install with the drain

of the KZ03 facing downward. If the KZ03 cannot be attached vertically (with the drain facing

downward), install it separated from the AVP with the proper orientation.

•

In order to avoid the possibility of rainwater entering the pressure gauge, install the gauge

such that it does not face upward or downward. In addition, the pressure gauge has a rainwater

drain on its underside, so install the gauge with this hole facing downward.

•

If you install this device with the LCD facing upwards, use the LCD cover and pressure gauge

elbows as necessary, depending on the circumstances. For details, refer to 6) below, “Installing

the device with the LCD facing upwards.”

Chapter 2 Installation of the 700 Series

2-5

Drain plug

Page 22

Chapter 2 Installation of the 700 Series

Hexagon socket ange bolts (×2)

Yoke

AVP

Hexagonal bolt

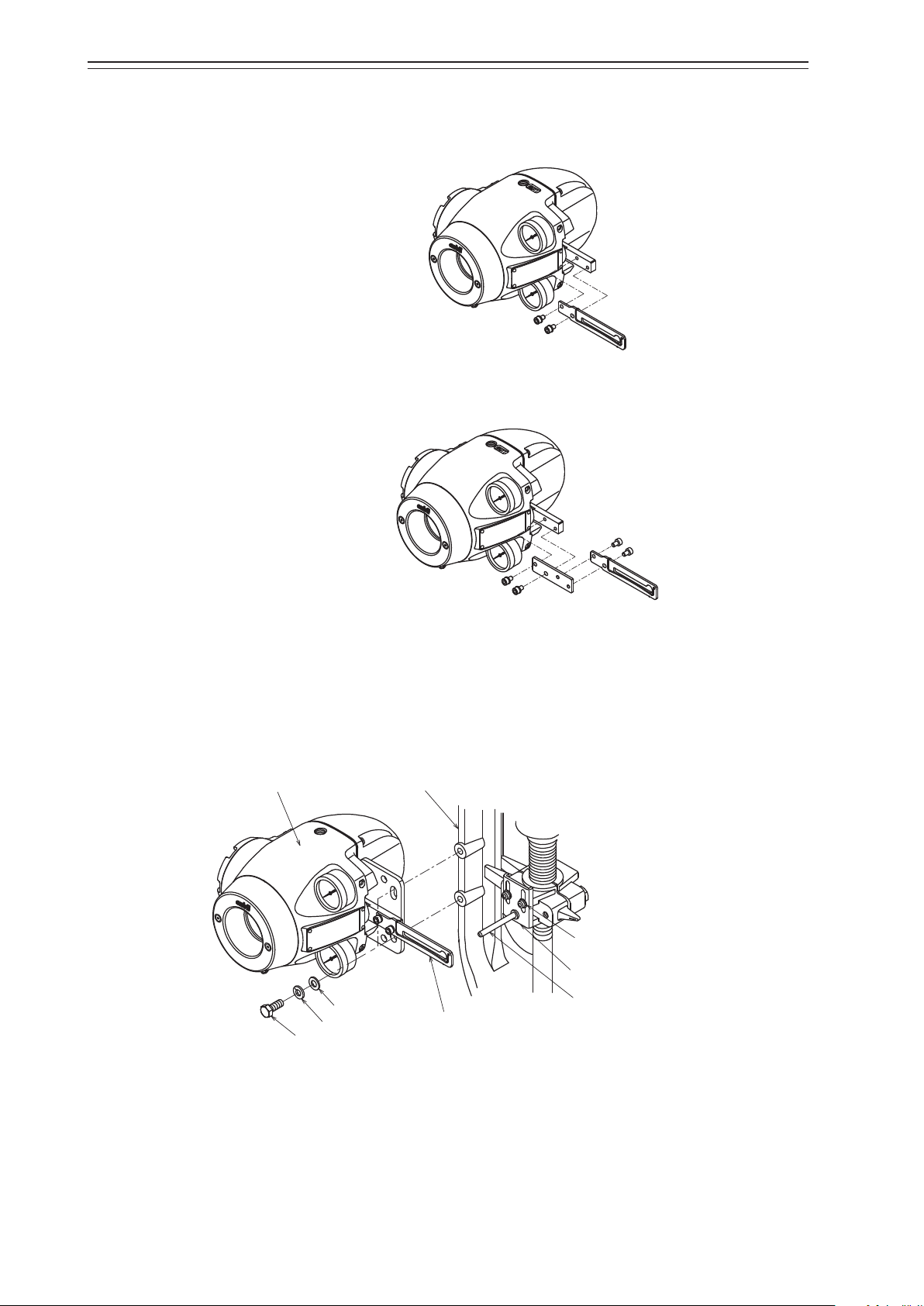

1) Mounting the feedback lever

Assemble the feedback lever from the front of the main unit of the device using the two

included hexagon socket bolts.

Assemble the extension lever as shown in the figure below if necessary.

Figure 2-1. Mounting Procedure for Feedback Lever

Figure 2-2. Mounting Procedure for Extension Lever

2) Mounting example

A typical mounting method is shown in the figure below. If your actuator is not shown in

the figure below, refer to the assembly diagram included with the device.

[Direct-Acting Actuator HA2 to 4, PSA1 to 4, 6, VA1 to 6 from Azbil Corporation]

Connector pin assembly

Plain washer

Spring washer

Feedback lever

Feedback pin

Figure 2-3. Mounting Procedure for Direct-Acting Actuator HA2 to 4, PSA1 to 4, 6, VA1 to 6 from Azbil Corporation

2-6

Page 23

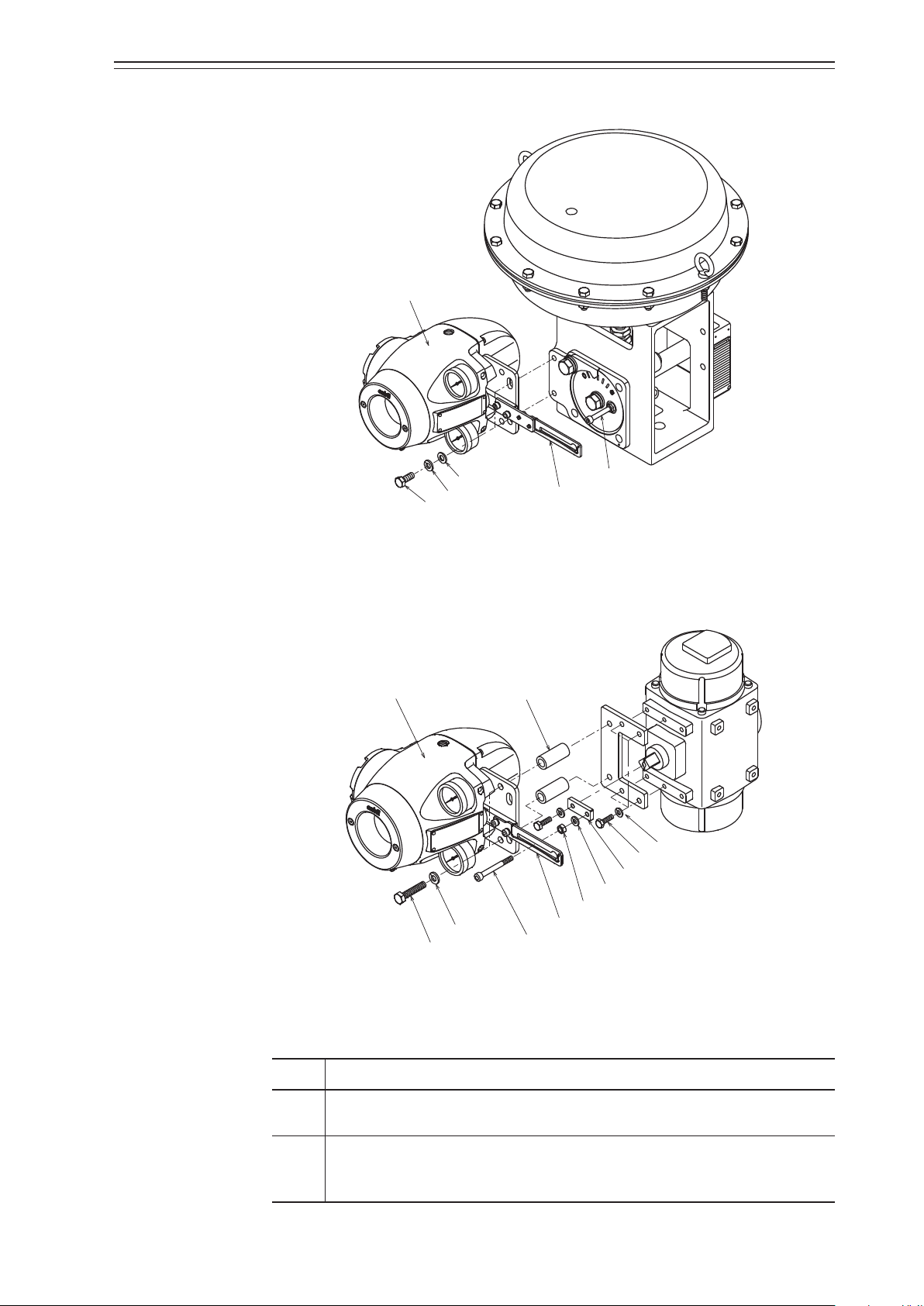

[RSA1, 2, VR3 actuator from Azbil Corporation]

Hexagonal bolt

Hexagonal bolt

AVP

Chapter 2 Installation of the 700 Series

Plain washer

Spring washer

Feedback pin

Feedback lever

Figure 2-4. Mounting Procedure for RSA1, 2, VR3 Actuator from Azbil Corporation

[Example of double-acting rotary cylinder actuator]

SpacerAVP

Spring washer

Hexagonal bolt

Arm

Spring washer

Spring

washer

Feedback pin

Hexagonal nut

Feedback lever

Figure 2-5. Mounting Procedure for Double-Acting Rotary Cylinder Actuator

3) Mounting procedure

The procedure for mounting the feedback lever onto the actuator is shown below.

Step Description

Tightly secure the mounting plate by inserting hexagonal bolts (M8×20) with

1

spring washers into the (two) screw holes at the rear of the device.

Tightly secure the device (mounting plate) onto the mounting seat of the actua-

2

tor by using bolts and washers. At this time, insert the actuator feedback pin into

the slotted hole of the feedback lever in the device.

2-7

Page 24

Chapter 2 Installation of the 700 Series

Spring (cross section)

30°

30°

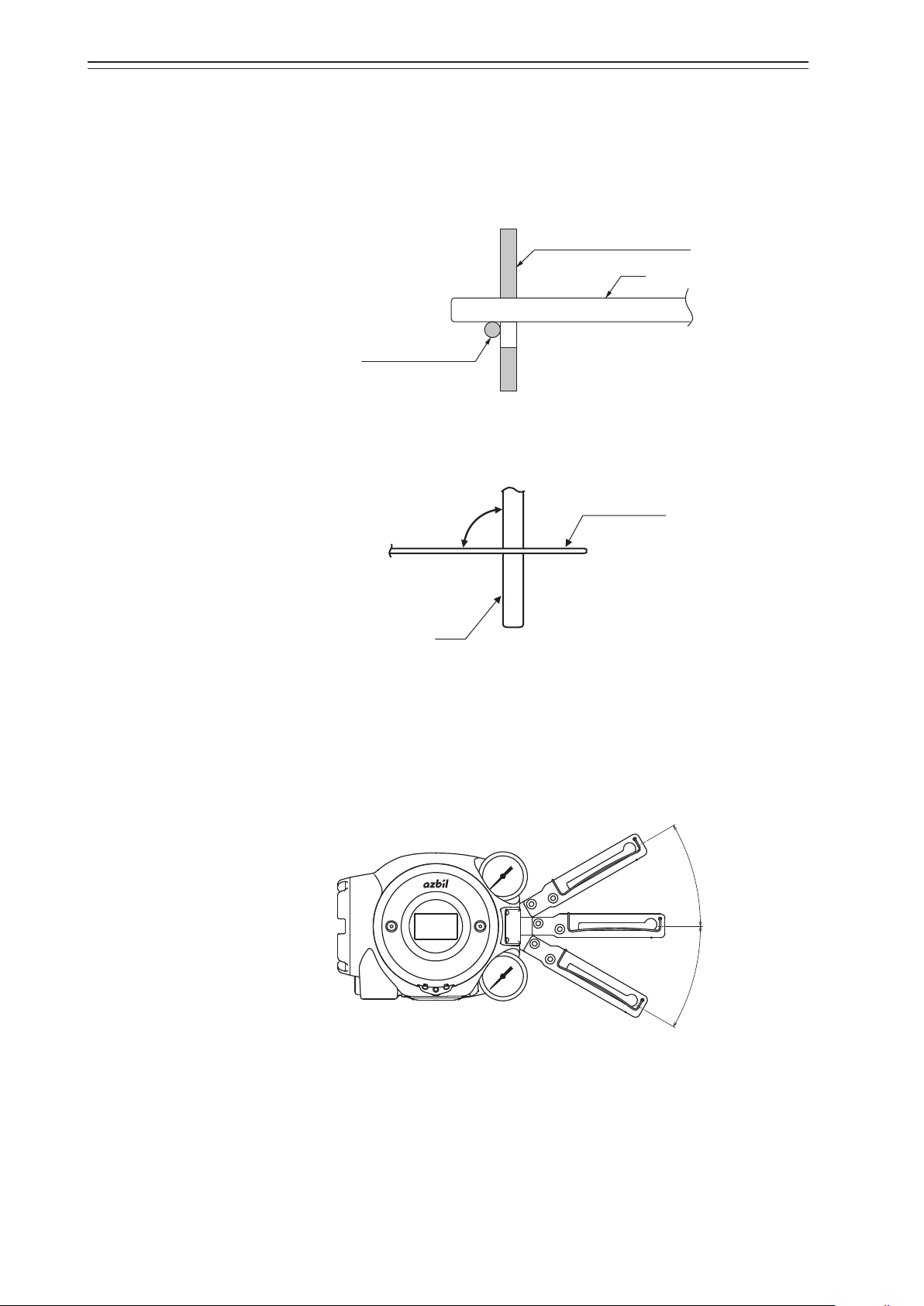

4) Connection of feedback pin and feedback lever (1)

There are several points to be careful of when connecting the feedback lever to the device

and the actuator feedback pin. Connect correctly.

•

Only a pin with a diameter of 6 mm can be used.

•

Insert the pin between the guide and the spring.

•

Make the feedback lever perpendicular to the pin when viewed from the above.

Feedback lever (cross section)

Pin

Figure 2-6. Connection of Feedback Lever and Feedback Pin

90°

Pin

Feedback lever

Figure 2-7. Angle between Feedback Lever and Pin

•

Mount the lever so that it is horizontal when opened by 50%.

•

The allowable rotation angle of the feedback lever is horizontal ± 30°. If the angle exceeds ±30°, the self-diagnostic function detects Valve Travel Detector Out of Range and

the device will not operate normally. (The accuracy is guaranteed when the rotation

angle is between ±4° and ±20°.)

Figure 2-8. Operation Angle of Feedback Lever

2-8

Page 25

Chapter 2 Installation of the 700 Series

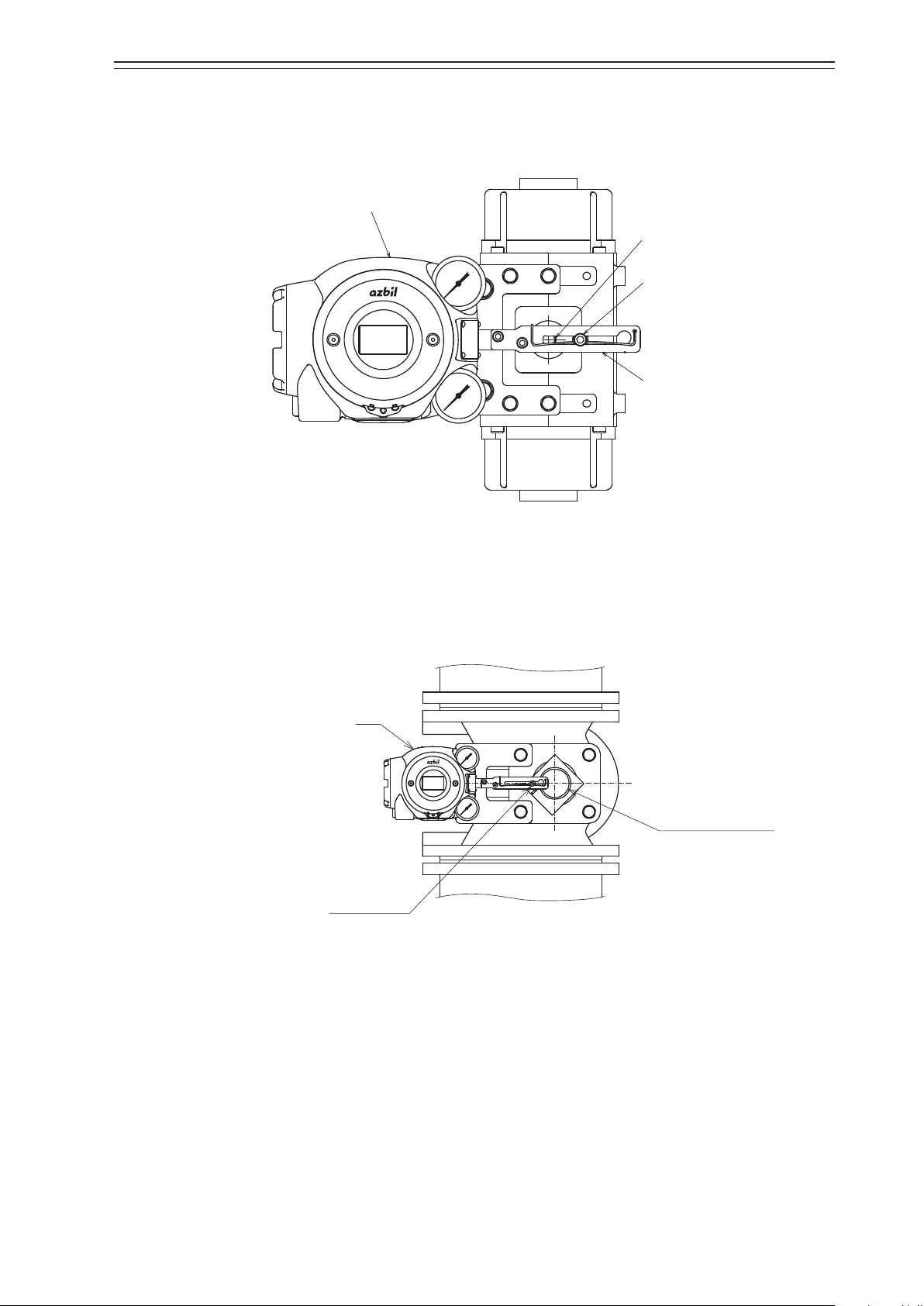

Shaft of rotary cylinder

Feedback pin

Shaft of rotary cylinder

•

When assembling the lever onto a rotary cylinder so that the shaft of the rotary cylinder

is positioned between the feedback pin and the 700 Series as shown in the figure below,

select Rotary/90° (for 90°) or Rotary/other (for angles other than 90°) as the Actuator

Type according to the rotation angle.

AVP

Feedback pin

Feedback lever

Figure 2-9. Connection of the Rotary Cylinder to the Feedback Pin and Feedback Lever

•

When the rotary cylinder is large and the lever is assembled so that the feedback pin is

positioned between the 700 Series and the shaft of the rotary cylinder as shown in the

figure below, select Rotary (sub)/90° (for 90°) or Rotary (sub)/other (for angles other

than 90°) as the Actuator Type according to the rotation angle.

AVP

Figure 2-10. Connection of the Rotary Cylinder to the Feedback Pin and Feedback

Lever(Large cylinder)

5) Maintenance space behind the device

The device has a nozzle flapper mechanism in the back of the main unit. When cleaning

the flapper, you must remove the pilot relay cover secured to the back with three screws.

Design the clamp and feedback mechanism to ensure maintenance space for cleaning.

2-9

Page 26

Chapter 2 Installation of the 700 Series

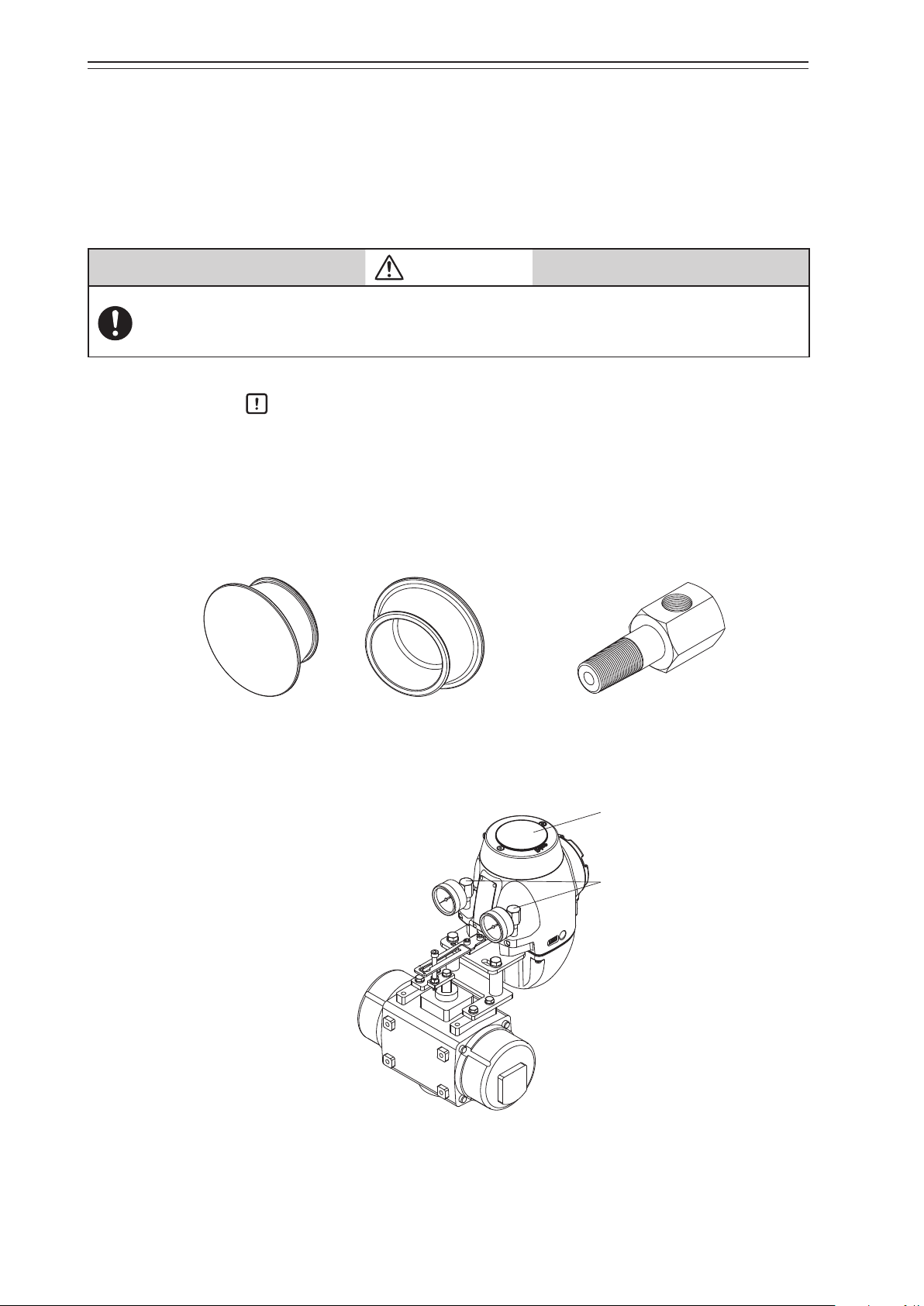

6) Installing the device with the LCD facing upwards

If you install the device with the LCD facing upwards, use the accessories below as required depending on the circumstances. (Refer to 6-9, “Resale Parts.”)

•

LCD cover (material: silicone rubber)

This cover reduces deterioration of the LCD due to sunlight (ultraviolet radiation). Use

the cover if the device is used in a place with strong sunlight (outdoors, etc.).

Before mounting or removing the LCD cover, it is necessary to remove the face cover from the main

unit. Take care as you work not to touch sharp parts of the face cover, such as the rim. You might be

injured.

Handling Precautions:

Remove the face cover when checking the LCD.

•

Pressure gauge elbows (Connection: Rc1/8)

The elbows are for mounting the pressure gauges if the device is installed in a place with

direct exposure to rainwater (outdoors, etc.). (If the pressure gauges are installed facing

upward, they will be damaged by rainwater.

CAUTION

Front Back

Figure 2-11. LCD cover Figure 2-12. Pressure gauge elbow

LCD cover

Pressure gauge elbow

Figure 2-13. Example of LCD cover and pressure gauge elbow mounting

2-10

Page 27

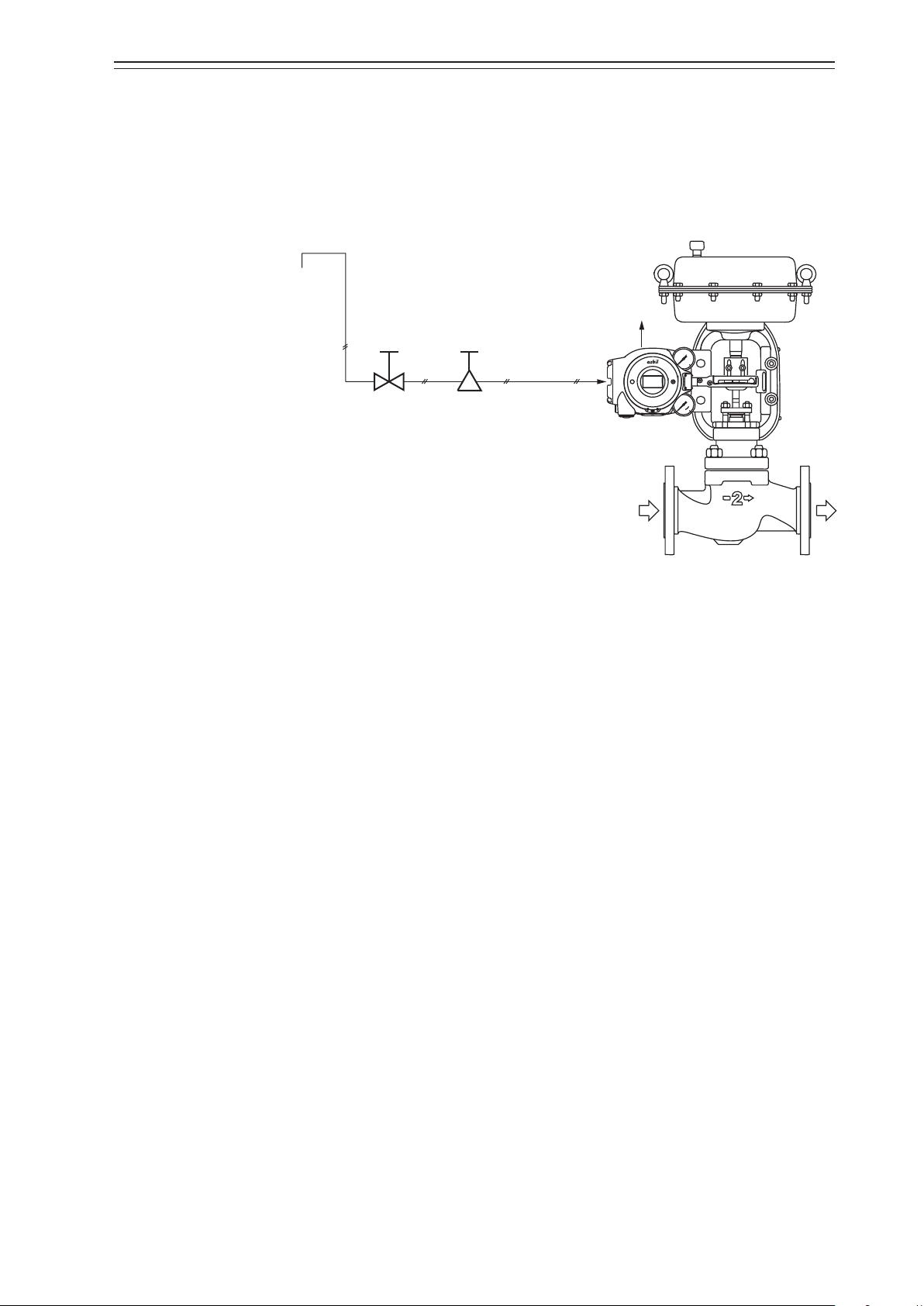

2-3-2. Pneumatic Piping Connection

Supply air

This section describes how to supply the air for the device to drive the actuator.

1) Air supply system

Supply air must be clean and dry to stably use the device for a long time. A typical example

of an air supply system is shown in the figure below.

Chapter 2 Installation of the 700 Series

Shuto

valve

Solenoid valve

with lter

Supply air piping

Figure 2-14. Air Supply System

Output air

piping

2) Supply air

Use supply air that conforms to the instrumentation air standards (on page 2-2).

3) Solenoid valve with filter

•

The solenoid valve with filter is used to adjust the pressure of the supply air to the device.

•

Install this valve as close to the main unit of the device as possible.

•

The control valve can be manually operated by using the A/M switching function. (The

double-acting actuator does not support manual operation.)

•

Use a 3-μm or finer filter.

•

The filter removes solid materials from supply air.

•

If the filter is not equipped, separately insert a (3-μm or finer) filter immediately before

the solenoid valve.

•

Install the solenoid valve so that the drain faces downward.

•

If you select the built-in Azbil solenoid valve KZ03, the filter is built into the device before shipment.

4) Shutoff valve

•

The shutoff valve is used to temporarily stop supplying air to the device.

•

With this valve, the device or control valve can be removed without having to stop the

whole air supply system during maintenance or other operations.

2-11

Page 28

Chapter 2 Installation of the 700 Series

Output air connection port (OUT1)

Rc1/4 or 1/4NPT

5) Piping

•

Use piping with an inside diameter of 6 mm.

•

When using the device in a corrosive atmosphere, select piping appropriate to the environment of the installation location. For example, you may use the vinyl-coated copper pipe.

•

To prevent air leaks, be sure to use a fitting that is appropriate for the pipe.

6) Connection positions

The positions of the supply air connection port and output air connection port are shown

in the figure below. Select the dimensions of the connection port screws according to the

specifications.

Rc1/4 or 1/4NPT

Handling Precautions:

Output air connection port (OUT2)

(For double-acting actuator)

Figure 2-15. Pneumatic Piping Connection

When connecting the electromagnetic valve for emergency shutoff, air valve, or

other part, install it between the output air connection and the actuator rather

than the supply air connection side of the device.

2-12

Page 29

Chapter 2 Installation of the 700 Series

7) Mounting procedure

The procedure for connecting pneumatic piping to operate the device is shown below.

Step Description

Connect the joint for piping to the connection port using seal tape.

Handling Precautions:

•

1

Use seal tape as the seal material. Avoid using solid or liquid seal material

if possible.

•

Do not let the seal tape get in the piping.

•

If you do use a liquid seal, make sure that no drops of the seal material get

in the piping.

Connect the supply and output pipes to each joint in consideration of the arrangement of the piping.

Handling Precautions:

•

2

3 After all piping is complete, make sure that air does not leak.

For the double-acting actuator, the connection between output air connection ports OUT1 and OUT2 and the actuator is determined by the

valve operation. Check the valve operation before connecting pipes.

•

Sufficiently flush piping before connection to prevent burrs on the piping

or other foreign objects from getting in the piping.

•

Keep the output air piping as short as possible.

2-13

Page 30

Chapter 2 Installation of the 700 Series

M4 screw

for external grounding terminal

2-3-3. Electrical Wiring Connection

This section describes how to connect electrical wiring for signal inputs from the controller.

Turn the power off before starting wiring work. Otherwise, electric shock may occur.

When using the explosion-proof 700 Series in a dangerous place, be sure to connect the wiring while

following “Chapter 7. Notes on the Explosion-Proof 700 Series.”

Be sure to perform grounding work following the electrical work guidelines in each region.

Handling Precautions:

Be sure to attach a blind plug to the unused conduit connection port so that it is

completely covered.

WARNING

CAUTION

1) Connection positions

The figure below shows the terminal block in the terminal box.

for Fieldbus terminal

M4 screw

M4 screw

for internal grounding terminal

Figure 2-16. Terminal Block in the Terminal Box

2-14

Page 31

Chapter 2 Installation of the 700 Series

2) Terminal for external grounding

Connect the external grounding terminal to the case with two washers as follows.

Cable lug

Washer

Washer

Figure 2-17. Connection of External Grounding Terminal

3) How to install a Fieldbus network

There are two ways to install a fieldbus network.

(1) Bus type: Connect each field device from the trunk cable within 1 m.

(2) Tree type: Install the trunk cable to the field and connect feeder cables from a junc-

tion box to each field device.

Bus type

Host

Terminator

Power

supply

Host

Power

supply

Trunk cable

Split terminator

(Branch wire: less than 1 m)

Tree type

Trunk cable

Spur

(feeder cable)

Junction box

(terminator built-in)

Figure 2-18. How to Install Fieldbus Networks

2-15

Page 32

Chapter 2 Installation of the 700 Series

4) Precautions for installing cables

Note the following points when installing a cable.

•

Route the cable so as to avoid high-capacity transducers, motors, power supplies for

engines, or other devices that generate noise. Do not put a cable in the same tray or

duct as a cable for an engine.

•

We recommend using conduits and ducts to route cables for waterproofing and protection from damage. Be sure to use a waterproof adapter at the conduit connection

port.

•

When routing cables in a place subject to electromagnetic noise, use conduits and

ducts.

2-3-4. Cables

1) Selection and conditions of cables

The criteria for selection and the conditions of cables for wiring are described below.

•

We recommend using 600-V plastic insulated sheath electric wire CVV (JIS C 3401 by

Japanese Industrial Standards) for control with a conductive cross-section of 1.25mm2

or a stranded cable with equivalent or higher performance.

•

When routing cable in a place subject to electromagnetic noise, use shielded wire CVVS

(JCS 4258 by the Japanese Electric Wire & Cable Makers’ Association) and metal conduits.

•

Select a sheath material that withstands the cable installation environment (including the

ambient temperature, corrosive gas, and corrosive liquid).

Use cable with an outside diameter of 7 to 12mm. When using a pressure-resistant packing cable adapter, be sure to use packing appropriate for the outside diameter of the cable.

A crimping terminal with insulated sleeve (for M4 screw) is recommended for terminals.

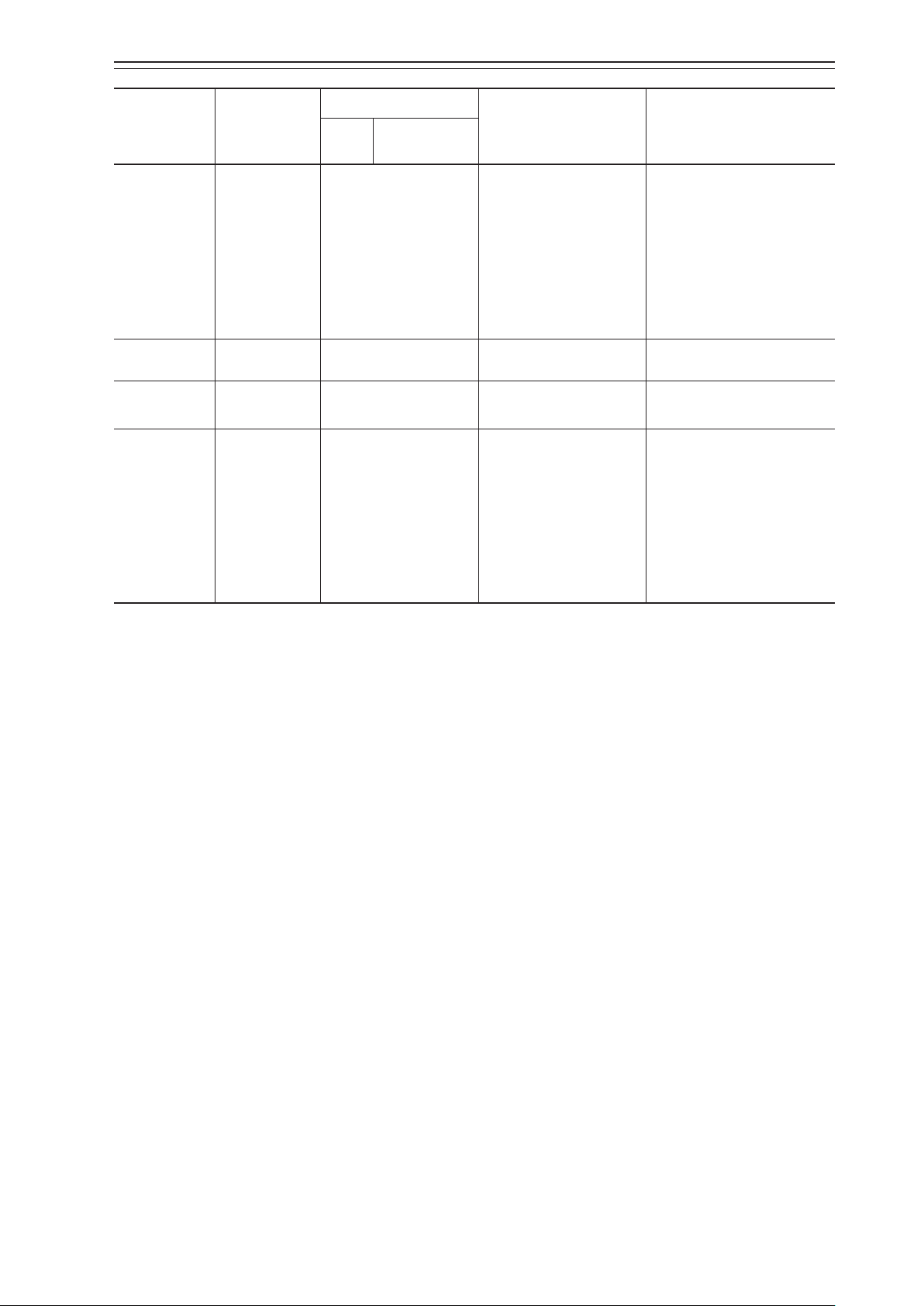

2) Types of Fieldbus cables

The maximum length of Fieldbus cable depends on the cable type. Refer to the table below.

Type Description of cable Size (mm2)

Type A Twisted pair wire with individual shields 0.8 (18AWG) 1900

Type B Common shielded multiple twisted pair wire 0.32 (22AWG) 1200

Type C Unshielded multiple twisted pair wire 0.13 (26AWG) 400

Type D Single unshielded wire 1.25 (16AWG) 200

Maximum

length (m)

Handling Precautions:

Model AVP703 is intended for use in industrial locations defined in CE marking

directive (EN 61326-1).

2-16

Page 33

Chapter 2 Installation of the 700 Series

3) Wiring procedure

The procedure for electrical wiring to operate the device is shown below.

Step Description

1 Turn off the Fieldbus power supply.

Rotate the lock screw (M4) on the terminal box cover with a (3-mm) hexagonal

2

wrench clockwise to loosen it.

Rotate the terminal box cover counterclockwise to remove it.

3

4 Remove the dust-proof plug from the conduit connection port.

5

Handling Precautions:

•

Be careful not to damage the paintwork with a tool or other object.

Insert the cable into the conduit connection port.

Handling Precautions:

•

Be careful not to damage the sheath of the cable.

Wire the cable to the relevant terminal in the terminal box.

Handling Precautions:

6

7

•

Be careful of the polarity.

•

Sufficiently tighten the terminal screw. The recommend tightening torque

is 1.5N·m.

Apply sufficient waterproof treatment to the conduit to prevent rainwater or

other liquid from entering inside.

Handling Precautions:

•

We recommend using silicon non-hardening seal material.

Mount the terminal box cover, sufficiently tighten it with an appropriate tool,

and then secure the cover by rotating the lock screw counterclockwise.

CAUTION

•

Be careful not to get your finger caught in the clamp.

8

•

Be careful not to hurt your finger with the edge of cover or the screw

threads of the main unit.

Handling Precautions:

•

Be careful not to damage the paintwork of the device with a tool or other

object.

2-17

Page 34

Chapter 2 Installation of the 700 Series

O-ring

Cable diameter

2-4. Cable gland and flameproof universal elbow for TIIS Flameproof

apparatus

TIIS Flameproof SVP model is provided with a certified cable gland.

The cable gland seals the cable entering the SVP enclosure to withstand an internal explosion and protects the cable from being damaged mechanically and electrically.

Use the dedicated elbow if it is necessary to change the direction of the cable with these

models.

Handling Precautions:

If the device is to be used under the authorization other than that for the TIIS

Flameproof standards, the wiring of cables must be performed according to local

regulations for electrical installations in explosive atmospheres.

1) Structure of the flameproof cable gland

The Flameproof cable gland is shown below in assembled and exploded views.

Cable diameter ≤ 8mm

Clamp

(Upper)

≥ 8mm

Clamp

(Lower)

Figure 2-19. Flameproof cable gland

Hexa-recess stopper screw

Body

O-ring

Gland

Coupling

O-ring

Clamp

(Upper)

Cross recessed

head screws

Washer

Sealing ring

Washer

Hexa-recess stopper screw (Two)

Union nut

Cross recessed

head screws

Hexa-recess stopper screw (Two)

Gland

Coupling

O-ring

Union nut

Figure 2-20. Constituent elements of flameproof cable gland

2-18

Page 35

Chapter 2 Installation of the 700 Series

Lock nut

2) Structure of the flameproof universal elbow

The figure below shows the universal elbow.

O-ring

Elbow

Figure 2-21. Flameproof elbow

3) Mounting example

The flameproof cable gland and the universal elbow are used to connect the field wiring

cable to the device enclosure, as shown below.

a) Use of flameproof cable gland

b) Use of flameproof cable gland and elbow

Figure 2-22. Mounting example of flameproof cable gland and elbow

2-19

Page 36

Chapter 2 Installation of the 700 Series

4) Mounting procedure for flameproof cable gland

The procedure for mounting the flameproof cable gland is shown below.

Step Description

Securely screw the main unit of the adapter into the conduit connection port of

the terminal box or into the flameproof universal elbow, and fasten the hexagon

socket bolt.

1

Refer to the illustrations and insert the cable carefully.

2

Handling Precautions:

•

Apply adequate waterproofing to these parts. We recommend the use of

silicone resin based non-hardening seal materials.

WARNING

If the diameters of the cable and the packing do not match each

other, the propagation of flame cannot be prevented. Refer to the

table below and select a packing adaptor whose internal diameter matches the outer diameter of the cable.

Cable outer diameter (mm) Packing inner diameter (mm) Notes

7.0 to 8.0 8 Provided

8.0 to 10.0 10 Built in

10.0 to 12.0 12 Provided

The cable outer diameter is 8mm max., fix the cable gland with

the clamps.

Handling Precautions:

•

Pay attention to the surface of the device. Tools may cause damage the

surface.

Screw the gland into the main unit of the adapter to secure it in place.

WARNING

3

4 Pass the cable through the body and insert it into the terminal box.

Screw the union nut onto the body and tighten it down securely to hold it in

5

place. Then, tighten the union nut's recess screw.

To prevent injuries due to a spark travel, be sure to tighten down

the packing adequately.

2-20

Page 37

Chapter 2 Installation of the 700 Series

Elbow

Lock nut

O-ring

O-ring groove end surface

5) Mounting procedure for flameproof universal elbow

The procedure for mounting the flameproof universal elbow is shown below.

Step Description

Align the end surface of the lock nut with the end surface of the O-ring groove

as shown below.

Lock nut end face

1

Figure 2-23. Arrangement of lock nut and O-ring

Screw the flameproof universal elbow into the terminal box conduit connection

port until the lock nut end surface hits the connection port end surface.

When two elbow are used, at first, screw the first elbow into the terminal box.

Next, screw the second elbow into the terminal box in the reverse direction to

2

the first elbow.

Handling Precautions:

•

Apply adequate waterproofing to these parts.

Turn the flameproof universal elbow to loose in the desired direction.

3

4

Handling Precautions:

•

Do not loosen it more than 1 turn.

Lock the flameproof universal elbow in place by tightening down the lock nut

using the special tool.

2-21

Page 38

Chapter 2 Installation of the 700 Series

2-22

Page 39

Chapter 3 Operation of the 700 Series

Chapter 3. Operation of the 700 Series

This chapter describes how to start operating the device and adjust the device using the

local user interface (LUI). When you purchase the device alone, be sure to read “Installation of the 700 Series” before reading this chapter.

Precautions for safe work

WARNING

Do not perform wiring with wet hands or while the device is energized. This may lead to electric

shock. Turn the power off before starting the work and work with dry hands or use gloves.

Follow the work procedure defined in the explosion protection guidelines when performing the

power distribution work in an explosion-proof area.

For devices equipped with the pressure-resistant, explosion-proof specifications, do not open the

cover during operation (while the power is on).

CAUTION

Do not get on the installed device or use it as a step stool. This is dangerous because the device may

tip over.

Do not touch the device during operation without reason. This is dangerous because the surface may

be hot or cold depending on the usage environment.

Be careful not to touch the edge of the cover or the screw threads of the main unit when opening the

cover of the terminal box. You may be injured by these parts.

Use a DC power supply with overload protection. Overload may cause smoke or fire.

If a tool or other item touches the glass part of the display, it may break, leading to an injury. Be careful. Wear safety glasses during work.

This product is heavy. Be careful where you step and wear safety shoes during work.

Do not touch the feedback lever or other moving part while the device is operating. You may be injured by getting your hand or other body part caught in them.

Properly use the power supply based on the specifications. Inputting a different power supply may

damage the device.

Use gloves and other protective equipment during work in a hot, cold, or other severe environment.

Do not move the device close to a magnet or magnetic driver. The control valve may operate.

Apply the correct supply air pressure in accordance with the specification of the device. The overpressure may cause abnormal actions of the control valve or damage to the pressure gauge.

3-1

Page 40

Chapter 3 Operation of the 700 Series

socket bolts

3-1. Local User Interface (LUI)

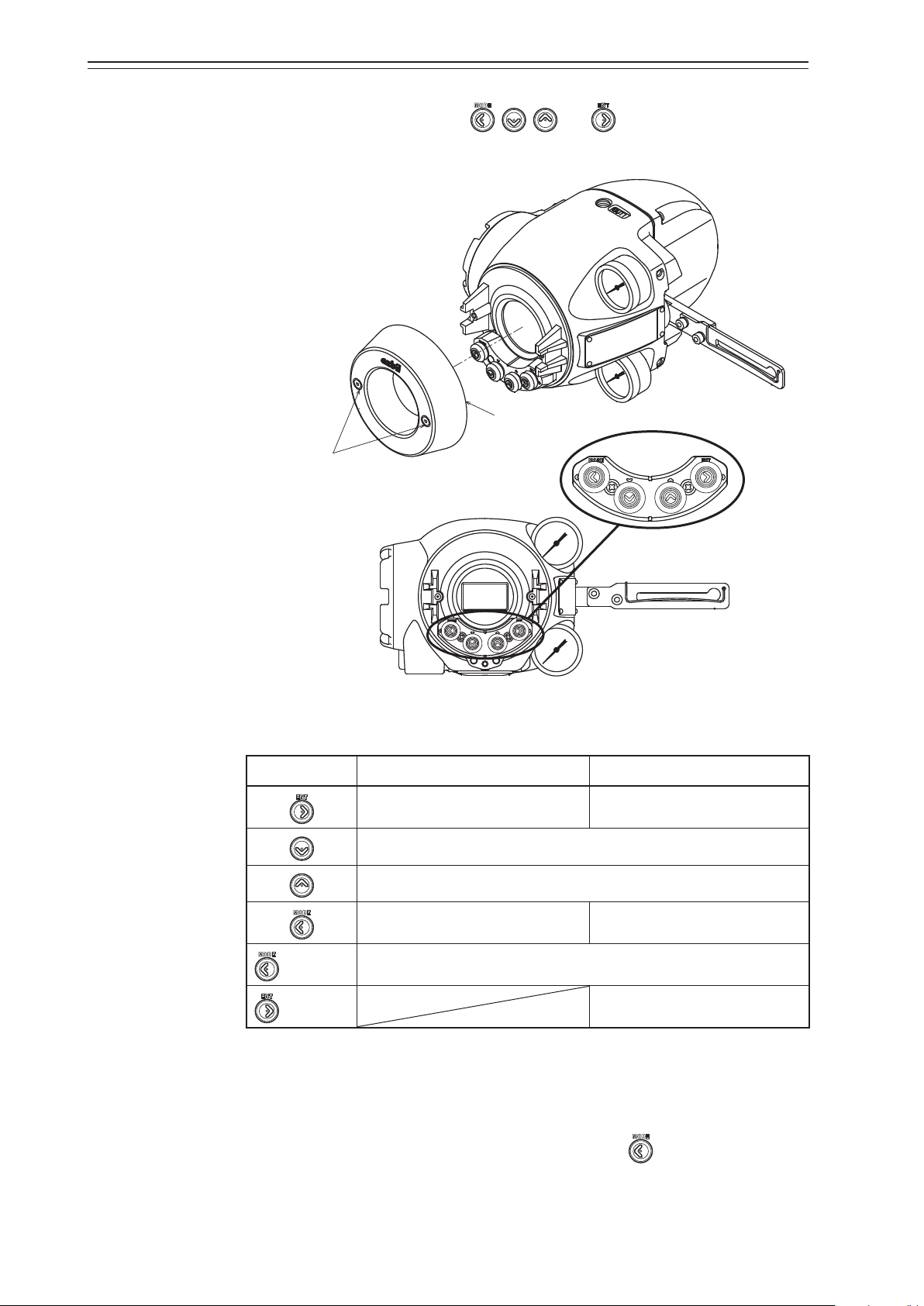

Four push buttons on the LUI (with , , , and symbols) can be operated by

removing two screws ((2.5-mm) hexagonal socket bolts) from the front cover of the device.

Front cover

Hexagonal

Operation

buttons

Figure 3-1. LUI Structure with the Front Cover Removed

Table 3-1.

Key input Monitor mode Setup mode

Switches between display categories. Goes to the next display.

Selects the next item.

Selects the previous item.

Switches between display categories. Goes back to the previous display.

Hold down

Hold down

Switches between setup mode and monitor mode.

Executes the function.

The LUI supports the monitor and setup modes.

In monitor mode, the normal, detailed, status, and FF monitors are available. The normal

monitor can be used to monitor data such as opening and input signals and it displays

alarm information if a self-diagnostic alarm is issued.

To change from monitor mode to setup mode, hold down the

button. In setup mode,

operations such as auto setup and zero span adjustment can be performed. Figure 3-2

shows a diagram of the LUI screen transition.

3-2

Page 41

Chapter 3 Operation of the 700 Series

The LUI displays the dynamic values in the device and can be used to adjust and set up the

following six functions.

•

Auto setup function

•

Zero span adjustment

•

Supply pressure bypass function

•

Starting the PST (Partial Stroke Test)

•

Specification of control parameters

•

Setup of the control valve system

Handling Precautions:

•

To perform adjustments and change settings with the LUI, set Target for MODE_

BLK in the Positioner Transducer Block to OOS (Out of service) from the host.

•

You cannot perform operations from the host while performing adjustments and

changing settings with the LUI.

•

If there is a foreign object near the operation buttons, remove it before starting

operation.

3-3

Page 42

Chapter 3 Operation of the 700 Series

If you use another host or communicator

As for the display variation, refer to Appendix A.

3-1-1. Displays

for communication during setup, this

screen is displayed and the setup mode

cannot be started.

Hold down

Normal

Normal

monitor

monitor

Disp_TB Display

Auto

switching

Details

Details

monitor

monitor

Monitor modeMonitor mode

monitor

monitor

The codes are the same

as those of 5-1-4 and

5-1-5.

Status

Status

FF

FF

monitor

monitor

Setup modeSetup mode

When the alarm is issued

on the normal monitor,

an alarm message is

displayed.

There is no loop that

goes back to ASv.

Figure 3-2.

3-4

Page 43

3-1-2. Disp_TB Display

1) Display at startup

The display changes as follows at startup:

(1) All segments are lit (approx. 0.8s) → (2) All segments are turned off (approx. 0.8s) →

(3) Normal monitor Disp_TB display (“FF_DISCON”) (approx. 10s) → (4) Normal monitor Disp_TB display (“DSP_OOS”) (approx. 30s) → (5) Normal monitor Disp_TB display:

normal display

If “FF_DISCON” continues to be displayed, contact your dealer.

2) Normal Display

With the factory default settings, the values of WORKING_SP and WORKING_POS for

the Positioner Transducer Block are indicated cyclically in the following sequence.

Chapter 3 Operation of the 700 Series

Sequence

No.

Numerical value section Character string section Display duration

(s)

1 WORKING_SP value W_SP (Tag) 5

2 WORKING_SP value % (Unit) 5

3 WORKING_SP value (Status) 5

4 WORKING_POS value W_POS (Tag) 5

5 WORKING_POS value % (Unit) 5

6 WORKING_POS value (Status) 5

To change display duration, change the settings of the following parameter.

•

DISPLAY_CYCLE: 1 to 10s can be specified.

Contents of the character string section can be configured by changing the settings of the

following parameter.

•

DISPLAY_INFO_SELECTION: Factory default settings: 0x07 (Tag, Unit, and Status

are displayed)

To display only Unit, for example, set the parameter to 0x02.

[When displaying other parameters]

To display parameters other than WORKING_SP for the Positioner Transducer Block (the

factory default setting), configure the following parameters.

•

BLOCK_TAG_SELECTION_1: specify the BLOCK_TAG of the block that the pa-

rameter to display belongs to

•

PARAM_SELECTION_1: specify the parameter to display

•

DISPLAY_TAG_1: specify the tag to display

For example, to display the OUT parameter of the AO Function Block, do the following:

(1) Set BLOCK_TAG_SELECTION_1 to “AO_FB” (AO_FB is the default block tag name.

If the name was changed after shipment, specify the new name.)

(2) Check that BLOCK_TYPE_SELECTION_1 is set to “0x0102: Analog Output (AO).”

(3) Set PARAM_SELECTION_1 to “9: OUT.”

(4) Enter “OUT,” for example, for the DISPLAY_TAG_1 parameter, which specifies the tag

name.

For other parameters that can be displayed, see Table 3-3, “Parameters that can be displayed,” on the next page.

3-5

Page 44

Chapter 3 Operation of the 700 Series

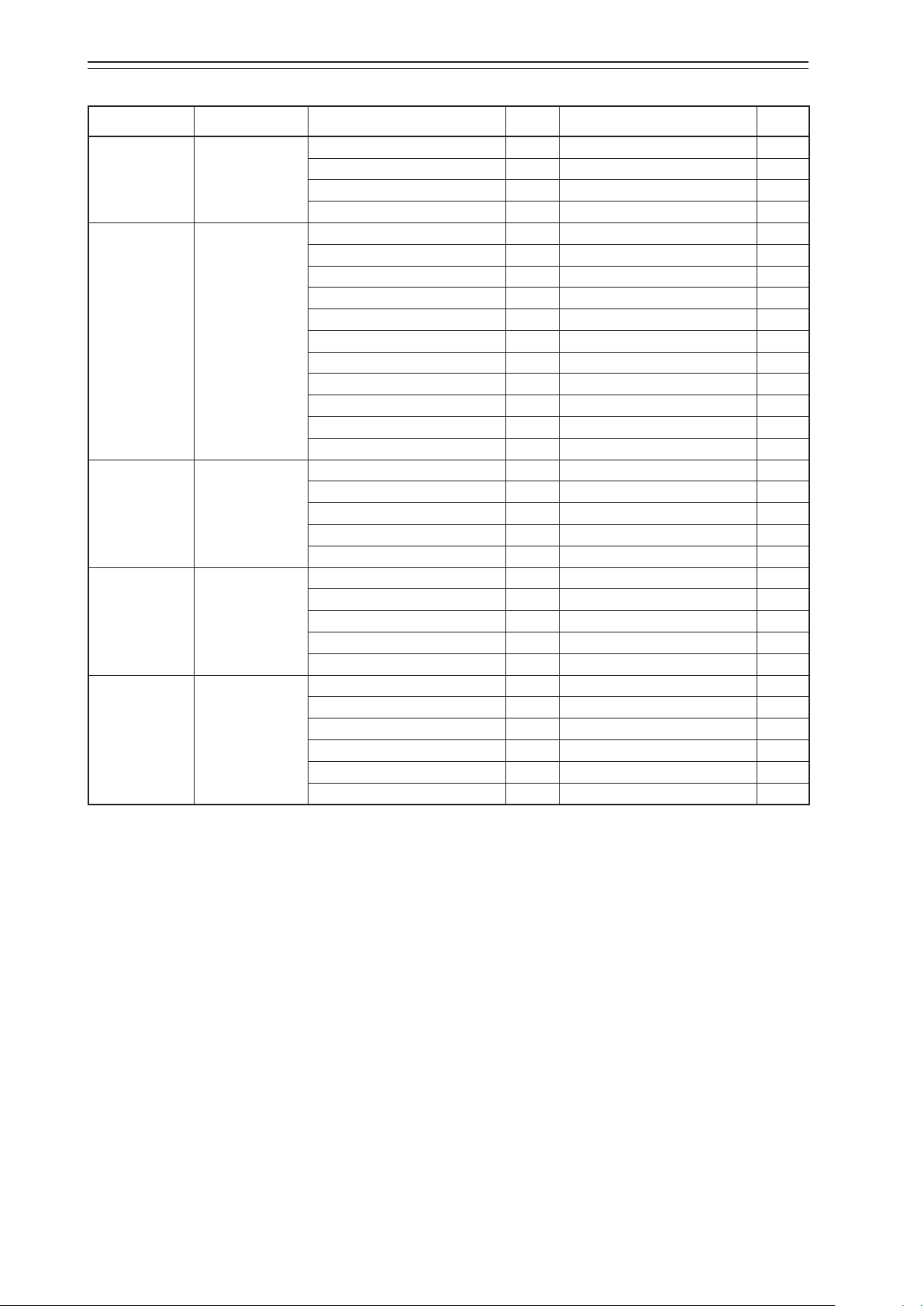

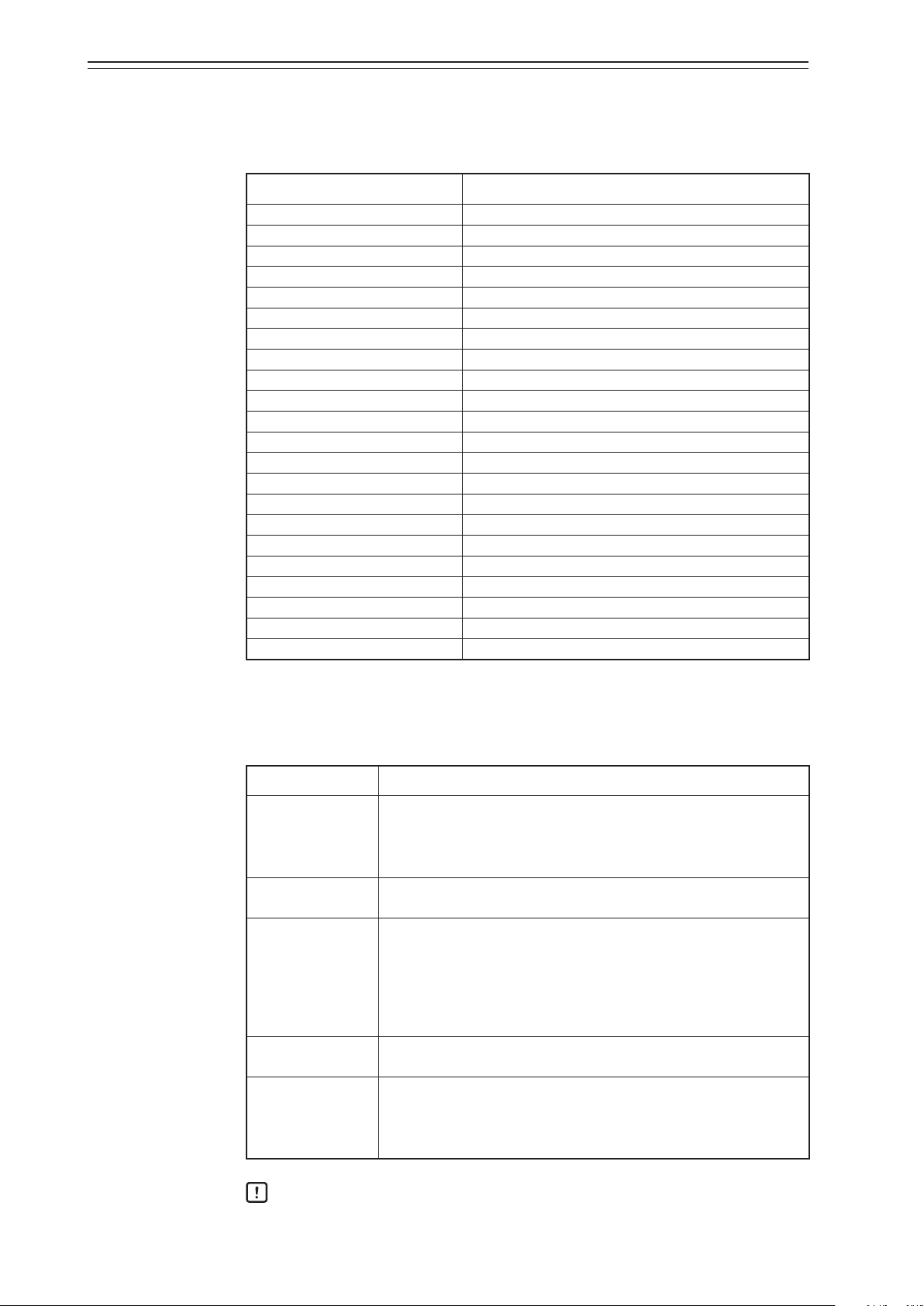

Table 3-2. Parameters that can be displayed

Block Profile Number Parameter Index Range Index

Positioner TB 0x0145 FINAL_VALUE 14 FINAL_VALUE_RANGE 15

FINAL_POSITION_VALUE 18 FINAL_VALUE_RANGE 15

WORKING_POS 19 FINAL_VALUE_RANGE 15

WORKING_SP 20 FINAL_VALUE_RANGE 15

PID FB 0x0108 OUT 9 OUT_SCALE 11

IN 15 PV_SCALE 10

CAS_IN 18 PV_SCALE 10

BKCAL_IN 27 OUT_SCALE 11

BKCAL_OUT 31 PV_SCALE 10

RCAS_IN 32 PV_SCALE 10

ROUT_IN 33 OUT_SCALE 11

RCAS_OUT 35 PV_SCALE 10

ROUT_OUT 36 OUT_SCALE 11

TRK_VAL 39 TRK_SCALE 37

FF_VAL 40 FF_SCALE 41

AO FB 0x0102 OUT 9 XD_SCALE 12

CAS_IN 17 PV_SCALE 11

RCAS_IN 26 PV_SCALE 11

BKCAL_OUT 25 PV_SCALE 11

RCAS_OUT 28 PV_SCALE 11

IS FB 0x0126 OUT 7 OUT_RANGE 8

IN_1 11 OUT_RANGE 8

IN_2 12 OUT_RANGE 8

IN_3 13 OUT_RANGE 8

IN_4 14 OUT_RANGE 8

OS FB 0x011C OUT_1 8 OUT_1_RANGE 10

OUT_2 9 OUT_2_RANGE 11

CAS_IN 14 No unit ×

BKCAL_IN_1 19 OUT_1_RANGE 10

BKCAL_IN_2 20 OUT_2_RANGE 11

BKCAL_OUT 15 No unit ×

3) Adding parameters to be displayed

For the Disp_TB, up to 4 parameters can be cyclically displayed.

The following example is the procedure for configuring the cyclic display of three parameters.

Displayed parameters: WORKING_SP and WORKING_POS from the Positioner Transducer Block, and OUT from the AO Function Block.

•

With the factory default settings, WORKING_SP and WORKING_POS for the Positioner Transducer Block are displayed. In order to add OUT from the AO Function

Block as the third parameter, set DISPLAY_PARAM_SELECTION to 0x07 (bit2: Selection 3 Enable). The default value of DISPLAY_PARAM_SELECTION is 0x03.

•

Set BLOCK_TAG_SELECTION_3 to “AO_FB.” Check that BLOCK_TYPE_SELECTION_3 is set to “0x0102: Analog Output (AO)”.

•

Set PARAM_SELECTION_3 to “9: OUT.”

•

Enter “OUT,” for example, for the DISPLAY_TAG_3 parameter, which specifies the tag

name.

3-6

Page 45

Chapter 3 Operation of the 700 Series

With the above configuration, the parameters are displayed cyclically in the following sequence.

Sequence

No.

1 WORKING_SP value W_SP (Tag) 5

2 WORKING_SP value % (Unit) 5

3 WORKING_SP value (Status) 5

4 WORKING_POS value W_POS (Tag) 5

5 WORKING_POS value % (Unit) 5

6 WORKING_POS value (Status) 5

7 AO: OUT value OUT (Tag) 5

8 AO: OUT value % (Unit) 5

9 AO: OUT value (Status) 5

To change the display duration, change the settings of DISPLAY_CYCLE. 1 to 10 s can be

specified.

To add a fourth parameter, specify the following:

•

DISPLAY_PARAM_SELECTION: 0x0f (bit3: Selection 4 Enable)

•

BLOCK_TAG_SELECTION_4: specify the BLOCK_TAG of the block that the param-

•

PARAM_SELECTION_4: specify the parameter to display

Numerical value section Character string section Display duration

(s)

eter to display belongs to

•

DISPLAY_TAG_4: specify the tag to display

For details on Disp_TB parameters, refer to the “Parameters in the Display Transducer

Block” section in Appendix C, “Parameter List.”

3-7

Page 46

Chapter 3 Operation of the 700 Series

4) Status indication

For the status indicated in the character string section, see Table 3-3, “Indicated status,”

below.

Quality Substatus Units displayed Description

0: Bad 0 Bad_0 Non-specific

1: Uncertain 0 Unctn_0 Non-specific

2: GOOD (NC) 0 GD-NC_0 Non-specific

3: GOOD (C) 0 GD-C_0 Non-specific

Table 3-3. Indicated status

1 Bad_1 Configuration Error

2 Bad_2 Not Connected

3 Bad_3 Device Failure

4 Bad_4 Sensor Failure

5 Bad_5 No Comm, with LUV

6 Bad_6 No Comm, no LUV

7 Bad_7 Out of Service

8 Bad_8 Transducer in MAN

1 Unctn_1 Last Usable Value

2 Unctn_2 Substitute/Manual Entry

3 Unctn_3 Initial Value

4 Unctn_4 Sensor Conversion not Accurate

5 Unctn_5 Engineering Unit Range Violation

6 Unctn_6 Sub-normal

7 Unctn_7 Transducer in MAN

1 GD-NC_1 Active Block Alarm

2 GD-NC_2 Active Advisory Alarm

3 GD-NC_3 Active Critical Alarm

4 GD-NC_4 Unack Block Alarm

5 GD-NC_5 Unack Advisory Alarm

6 GD-NC_6 Unack Critical Alarm

8 GD-NC_8 Initial Fault State (IFS)

1 GD-C_1 Initialization Acknowledge

2 GD-C_2 Initialization Request

3 GD-C_3 Not Invited

4 GD-C_4 Not Selected

6 GD-C_6 Local Override

7 GD-C_7 Fault State Active

8 GD-C_8 Initial Fault State (IFS)

5) Unit to be displayed

The method of displaying the unit can be specified by UNIT_SELECTION_n. The available options are “0: Auto” and “1: Custom.”

If “0: Auto” is selected, parameter values will be displayed in the predefined unit. For details, see Appendix C, “Parameter List,” and Table 3-4,

“Units displayed on the LCD.” If “1: Custom” is selected, the first seven characters of the

unit specified by CUSTOM_UNIT_n (32 characters max.)

will be displayed.

3-8

Page 47

Chapter 3 Operation of the 700 Series

Table 3-4. Units displayed on the LCD

Unit Unit code Display Description

UNIT_K 1000 K Kelvin

UNIT_degC 1001 degC degree Celsius

UNIT_degF 1002 degF degree Fahrenheit

UNIT_degR 1003 degR degree Rankine

UNIT_m3 1034 m3 cubic meter

UNIT_cm3 1036 cm3 cubic centimeter

UNIT_L 1038 L liter

UNIT_gal 1048 gal US gallon

UNIT_ImpGal 1049 ImpGal Imperial gallon

UNIT_bbl 1051 bbl barrel

UNIT_kg 1088 kg kilogram

UNIT_g 1089 g gram

UNIT_t 1092 t metric ton

UNIT_lb 1094 lb pound (mass)

UNIT_Pa 1130 Pa pascal

UNIT_GPa 1131 GPa gigapascal

UNIT_MPa 1132 MPa megapascal

UNIT_KPa 1133 kPa kilopascal

UNIT_mPa 1134 mPa millipascal

UNIT_uPa 1135 uPa micropascal

UNIT_hPa 1136 hPa hectopascal

UNIT_bar 1137 bar bar

UNIT_mbar 1138 mbar millibar

UNIT_torr 1139 torr torr

UNIT_atm 1140 atm atmospheres

UNIT_psi 1141 psi pounds per square inch

UNIT_psia 1142 psia pounds per square inch absolute

UNIT_psig 1143 psig pounds per square inch gauge

UNIT_gcm2 1144 gcm2 gram per square centimeter

UNIT_kgcm2 1145 kgcm2 kilogram per square centimeter

UNIT_inH2O 1146 inH2O inches of water

UNIT_inH2O_4C 1147 inH2O4C inches of water at 4°C

UNIT_inH2O_68F 1148 inH2O68 inches of water at 68°F

UNIT_mmH2O 1149 mmH2O millimeters of water

UNIT_mmH2O_4C 1150 mmH2O4C millimeters of water at 4°C

UNIT_mmH2O_68F 1151 mmH2O68 millimeters of water at 68°F

UNIT_ftH2O 1152 ftH2O feet of water

UNIT_ftH2O_4C 1153 ftH2O4C feet of water at 4°C

UNIT_ftH2O_68F 1154 ftH2O68 feet of water at 68°F

UNIT_inHg 1155 inHg inches of mercury

UNIT_inHg_0C 1156 inHg_0C inches of mercury at 0°C

UNIT_mmHg 1157 mmHg millimeters of mercury

UNIT_mmHg_0C 1158 mmHg_0C millimeters of mercury at 0°C

UNIT_g_s 1318 g/s gram per second

UNIT_g_m 1319 g/m gram per minute

UNIT_g_h 1320 g/h gram per hour

UNIT_g_d 1321 g/d gram per day

UNIT_kg_s 1322 kg/s kilogram per second

UNIT_kg_m 1323 kg/m kilogram per minute

UNIT_kg_h 1324 kg/h kilogram per hour

3-9

Page 48

Chapter 3 Operation of the 700 Series

Unit Unit code Display Description

UNIT_kg_d 1325 kg/d kilogram per day

UNIT_t_s 1326 t/s metric ton per second

UNIT_t_m 1327 t/m metric ton per minute

UNIT_t_h 1328 t/h metric ton per hour

UNIT_t_d 1329 t/d metric ton per day

UNIT_lb_s 1330 lb/s pound per second

UNIT_lb_m 1331 lb/m pound per minute

UNIT_lb_h 1332 lb/h pound per hour

UNIT_lb_d 1333 lb/d pound per day

UNIT_ST_s 1334 STon/s short ton per second

UNIT_ST_m 1335 STon/m short ton per minute

UNIT_ST_h 1336 STon/h short ton per hour

UNIT_ST_d 1337 STon/d short ton per day

UNIT_LT_s 1338 LTon/s long ton per second

UNIT_LT_m 1339 LTon/m long ton per minute

UNIT_LT_h 1340 LTon/h long ton per hour

UNIT_LT_d 1341 LTon/d long ton per day

UNIT_PERCENT 1342 % percent

UNIT_m3_s 1347 m3/s cubic meter per second

UNIT_m3_m 1348 m3/m cubic meter per minute

UNIT_m3_h 1349 m3/h cubic meter per hour

UNIT_m3_d 1350 m3/d cubic meter per day

UNIT_L_s 1351 L/s liter per second

UNIT_L_m 1352 L/m liter per minute

UNIT_L_h 1353 L/h liter per hour

UNIT_L_d 1354 L/d liter per day

UNIT_ML_d 1355 ML/d megaliter per day

UNIT_CFS 1356 CFS cubic feet per second

UNIT_CFM 1357 CFM cubic feet per minute

UNIT_CFH 1358 CFH cubic feet per hour

UNIT_ft3_d 1359 ft3/d cubic feet per day

UNIT_SCFM 1360 SCFM standard cubic feet per minute

UNIT_SCFH 1361 SCFH standard cubic feet per hour

UNIT_gal_s 1362 gal/s US gallon per second

UNIT_GPM 1363 GPM US gallon per minute

UNIT_gal_h 1364 gal/h US gallon per hour

UNIT_gal_d 1365 gal/d US gallon per day

UNIT_Mgal_d 1366 Mgal/d mega US gallon per day

UNIT_ImpGal_s 1367 IpGal/s Imperial gallon per second

UNIT_ImpGal_m 1368 IpGal/m Imperial gallon per minute

UNIT_ImpGal_h 1369 IpGal/h Imperial gallon per hour

UNIT_ImpGal_d 1370 IpGal/d Imperial gallon per day

UNIT_bbl_s 1371 bbl/s barrel per second

UNIT_bbl_m 1372 bbl/m barrel per minute

UNIT_bbl_h 1373 bbl/h barrel per hour

UNIT_bbl_d 1374 bbl/d barrel per day

UNIT_mgal_s 1449 mgal/s milli US gallon per second

UNIT_kgal_s 1450 kgal/s kilo US gallon per second

UNIT_Mgal_s 1451 Mgal/s mega US gallon per second

UNIT_mgal_m 1453 mgal/m milli US gallon per minute

UNIT_kgal_m 1454 kgal/m kilo US gallon per minute

3-10

Page 49

Chapter 3 Operation of the 700 Series

Unit Unit code Display Description

UNIT_Mgal_m 1455 Mgal/m mega US gallon per minute

UNIT_mgal_h 1457 mgal/h milli US gallon per hour

UNIT_kgal_h 1458 kgal/h kilo US gallon per hour

UNIT_Mgal_h 1459 Mgal/h mega US gallon per hour

UNIT_mgal_d 1461 mgal/d milli US gallon per day

UNIT_kgal_d 1462 kgal/d kilo US gallon per day

UNIT_Mgal_d 1463 Mgal/d mega US gallon per day

UNIT_mImpGal_s 1464 mIpGa/s milli imperial gallon per second

UNIT_kImpGal_s 1465 kIpGa/s kilo imperial gallon per second

UNIT_MImpGal_s 1466 MIpGa/s mega imperial gallon per second

UNIT_mImpGal_m 1468 mIpGa/m milli imperial gallon per day

UNIT_kImpGal_m 1469 kIpGa/m kilo imperial gallon per day

UNIT_MImpGal_m 1470 MIpGa/m mega imperial gallon per day

UNIT_mImpGal_h 1472 mIpGa/h milli imperial gallon per hour

UNIT_kImpGal_h 1473 kIpGa/h kilo imperial gallon per hour

UNIT_MImpGal_h 1474 MIpGa/h mega imperial gallon per hour

UNIT_mImpGal_d 1476 mIpGa/d milli imperial gallon per day

UNIT_kImpGal_d 1477 kIpGa/d kilo imperial gallon per day

UNIT_MImpGal_d 1478 MIpGa/d mega imperial gallon per day

UNIT_Mbbl_s 1482 Mbbl/s megabarrel per second

UNIT_Mbbl_m 1486 Mbbl/m megabarrel per minute

UNIT_Mbbl_h 1490 Mbbl/h megabarrel per hour

UNIT_Mbbl_d 1494 Mbbl/d megabarrel per day

UNIT_mm3_s 1496 mm3/s cubic millimeter per second

UNIT_km3_s 1497 km3/s cubic kilometer per second

UNIT_Mm3_s 1498 Mm3/s cubic megameter per second

UNIT_mm3_m 1500 mm3/m cubic millimeter per minute

UNIT_km3_m 1501 km3/m cubic kilometer per minute

UNIT_Mm3_m 1502 Mm3/m cubic megameter per minute

UNIT_mm3_h 1504 mm3/h cubic millimeter per hour

UNIT_km3_h 1505 km3/h cubic kilometer per hour

UNIT_Mm3_h 1506 Mm3/h cubic megameter per hour

UNIT_mm3_d 1508 mm3/d cubic millimeter per day

UNIT_km3_d 1509 km3/d cubic kilometer per day

UNIT_Mm3_d0 1510 Mm3/d cubic megameter per day

UNIT_cm3_s 1511 cm3/s cubic centimeter per second

UNIT_cm3_m 1512 cm3/m cubic centimeter per minute

UNIT_cm3_h 1513 cm3/h cubic centimeter per hour

UNIT_cm3_d 1514 cm3/d cubic centimeter per day

UNIT_kL_m 1518 kL/m kiloliter per minute

UNIT_kL_h 1519 kL/h kiloliter per hour

UNIT_kL_d 1520 kL/d kiloliter per day

UNIT_Nm3_s 1522 Nm3/s Normal cubic meter per second

UNIT_Nm3_m 1523 Nm3/m Normal cubic meter per minute

UNIT_Nm3_h 1524 Nm3/h Normal cubic meter per hour

UNIT_Nm3_d 1525 Nm3/d Normal cubic meter per day

UNIT_Sm3_s 1527 Sm3/s Standard cubic meter per second

UNIT_Sm3_m 1528 Sm3/m Standard cubic meter per minute

UNIT_Sm3_h 1529 Sm3/h Standard cubic meter per hour

UNIT_Sm3_d 1530 Sm3/d Standard cubic meter per day

UNIT_NL_s 1532 NL/s Normal liter per second

3-11

Page 50

Chapter 3 Operation of the 700 Series

Unit Unit code Display Description

UNIT_NL_m 1533 NL/m Normal liter per minute

UNIT_NL_h 1534 NL/h Normal liter per hour

UNIT_NL_d 1535 NL/d Normal liter per day

UNIT_SL_s 1537 SL/s Standard liter per second

UNIT_SL_m 1538 SL/m Standard liter per minute

UNIT_SL_h 1539 SL/h Standard liter per hour

UNIT_SL_d 1540 SL/d Standard liter per day

UNIT_mL_m 1589 mL/m milliliters per minute

UNIT_ML_h 1617 ML/h megaliter per hour

UNIT_ML_m 1618 ML/m megaliter per minute

UNIT_kL_s 1619 kL/s kiloliter per second

UNIT_kft3_d 1620 kft3/d cubic kilofeet per day

UNIT_kCFH 1621 kCFH cubic kilofeet per hour

UNIT_kCFM 1622 kCFM cubic kilofeet per minute

UNIT_kCFS 1623 kCFS cubic kilofeet per second

UNIT_mft3_d 1624 mft3/d cubic millifeet per day

UNIT_mCFH 1625 mCFH cubic millifeet per hour

UNIT_mCFM 1626 mCFM cubic millifeet per minute

UNIT_mCFS 1627 mCFS cubic millifeet per second

UNIT_kgal 1648 kgal kilogallon

UNIT_kImpGal 1649 kImpGal kilo-imperial gallon

UNIT_Mft3_d 1653 Mft3/d cubic Megafeet per day

UNIT_Mm3_d1 1654 Mm3/d cubic Megameters per day

6) Abnormality indication

If the Disp_TB went out of service (OOS) or a communication error occurred between the

two CPUs of the positioner, these abnormalities will be indicated instead of the normal

displ ay.

•

DSP_OOS

If the Disp_TB went out of service, the following will be indicated.

Numerical value section (Turned off)

Character string section DSP_OOS

Change the mode of Disp_TB to Auto to show the normal display.

•

FF_DISCON (communication error between the two CPUs)

If a communication error occurred between the two CPUs of the positioner, the following will be indicated.

Numerical value section FF

Character string section DISCON

If FF_DISCON was displayed, contact your dealer.

3-12

Page 51

Chapter 3 Operation of the 700 Series

7) Alarms

If an error or failure occurred, the following alarms will be indicated cyclically.

Table 3-5. Indicated alarms

FD_xxx_ACTIVE Bit Units displayed Description

0 Check

1 FST Exe Full Stroke Test is Executing

2 PST Exe Partial Stroke Test is Executing

3 VsigExe Valve Signature is Executing

4 SRT Exe Step Response Test is Executing

5 AutoExe Auto Calibration is Executing

6 SIM Exe Simulation is Executing

7 LUT Act Local User I/F Active

8 Not used —

9 Not used —

10 Not used —

11 FST Alm Full Stroke Test Alarm

12 PST Alm Partial Stroke Test Alarm

13 VSD Alm Valve Self-Diagnostics Alarm

14 VTD Alm Valve Trend Diagnostics Alarm

15 Air Alm Positioner Air Circuit Alarm

16

17 OP Alm Operation Condition Alarm

18 DiagAlm FF Standard Diagnostics Alarm

19 FV Alm Final Value Alarm

20 WP Alm Working Position Alarm

21 PspOutR Pressure Supply Out of Range

22 TmpOutR Temperature Out of Range

23 VTDOutR VTD Angle Span Out of Range

24 PST Err Failure of Scheduled PST

25 Exe Err Internal Program Execution Error

26 Tmp Err Temperature Sensor Failure

27 PsenErr Pressure Sensor Failure

28 MBdFail Main Board Failure

29 VTDFail VTD Failure

30 CommErr Main Board Communications Error

31 FBdFail Fieldbus Board CPU Failure

T.B.D.

Failure Response is Executing

T.B.D.

3-13