Page 1

Smart Valve Positioner 700 Series

with HART Communication Protocol

Model AVP701/702

User's Manual

CM2-AVP702-2001

Page 2

Notice

• Make sure that this manual is delivered to the user of this product.

• It is prohibited to copy or reprint this manual in whole or in part without

permission.

• The contents of this manual are subject to change without notice.

• Although Azbil took all possible measures to ensure the accuracy of

this manual, contact us if you find any errors or missing information.

• Note that we cannot be held responsible for the results of customer

operation.

• HART® is a registered trademark of the FieldComm Group.

2014-2019 Azbil Corporation. All Rights Reserved.

©

Page 3

Introduction

Thank you for purchasing our AVP702 Smart Valve Positioner. The AVP702 (called “the

device” below) is a smart valve positioner that can be connected to the 4 to 20 mA loop.

The auto setup function makes it easy to set up the valve.

All adjustments and setup can be performed from the HART communication. The Local

User Interface (LUI), which consists of the LCD (liquid crystal display) and operation

buttons, facilitates monitoring of input signals, valve opening, pressure display, and other

items as well as basic adjustments.

In addition, the built-in pressure sensor can be used to measure the supply air pressure

and output air pressure. As a result, the device can not only perform self-diagnostics but

can also be combined with the control valve maintenance support system called “Valstaff”

in order to monitor the characteristics, operating status, and other data of the control

valve, helping to improve the maintenance efficiency of control valves. This instruction

manual describes how to handle the device. Read this manual to make full use of the

features of this product.

Scope of this manual and related documents

This document describes the functions and method of installation and adjustment of this

device. For details on HART communication, refer to

with HART Communication Protocol Model AVP701/702 HART Communication Manual

(No. CM2-AVP702-2002*).

For details on the control valve diagnostic items, refer to the “Smart Valve Positioner 700

Series Control Valve Diagnostic Function Manual” (No. CM2-AVP700-2003*).

* If you need the above documents, please contact one of our sales representatives.

Smart Valve Positioner 700 Series

i

Page 4

Safety precautions

■ Symbols

The purpose of the safety precautions listed here is to ensure the user uses the product safely

and correctly, to prevent harm to the user and other people and damage to property.

Make sure to obey the safety precautions.

Many different symbols are used in this manual.

Their appearances and meanings are as described below. Thoroughly understand the

explanation before starting to read the main text.

Warning

Cautions

■ Samplesymbols

This symbol indicates “warnings” and “cautions” that you must pay attention to when

handling the device.

This symbol indicates “prohibited” actions that must not be taken.

This symbol indicates “instructions” for the action that must be taken.

Wrong handling may cause the death or severe injury of the user.

Wrong handling may cause a minor injury to the user or damage to

equipment.

ii

Page 5

Precautions for safe work

Do not perform wiring with wet hands or while the device is energized. This may lead to

electric shock. Turn the power off before starting the work and work with dry hands or use

gloves.

Follow the work procedure defined in the explosion protection guidelines when performing the

power distribution work in an explosion-proof area.

For devices equipped with the pressure-resistant, explosion-proof specifications, do not open

the cover during operation (while the power is on).

Do not get on the installed device or use it as a step stool. This is dangerous because the

device may tip over.

Do not touch the device during operation without reason. This is dangerous because the

surface may be hot or cold depending on the usage environment.

Be careful not to touch the edge of the cover or the screw threads of the main unit when

opening the cover of the terminal box. You may be injured by these parts.

Warning

Cautions

Use a DC power supply with overload protection. Overload may cause smoke or fire.

If a tool or other item touches the glass part of the display, it may break, leading to an injury.

Be careful. Wear safety glasses during work.

This product is heavy. Be careful where you step and wear safety shoes during work.

Do not touch the feedback lever or other moving part while the device is operating. You may

be injured by getting your hand or other body part caught in them.

Properly use the power supply based on the specifications. Inputting a different power supply

may damage the device.

Use gloves and other protective equipment during work in a hot, cold, or other severe

environment.

Do not move the device close to a magnet or magnetic driver. The control valve may operate.

Apply the correct supply air pressure in acoordance with the specification of the device. The

overpressure may cause abnormal actions of the control valve or damage to the pressure

gauge.

iii

Page 6

Unpacking, Verification, and Storage of Product

Unpacking

This device is precision measuring equipment. Carefully handle it to prevent

accidents or damage.

After unpacking, check that the items below are included.

• The device

• Feedback lever and hexagon socket bolts x 2

•

(4-mm) hexagon wrench x 1 (for feedback lever) (Included only when the device is shipped alone.)

• Regulator (KZ03) (optional)

• Mounting plate set (optional)

• Pressure-resistant packing cable adapter and pressure-resistant elbow (option for

explosion-proof specifications)

• Instruction manual (this document) (Included if specified at the time of purchase.)

• Extension lever and hexagon socket bolts x 2 (optional)

Specifications check

The specifications are shown on the nameplate of the main unit. Check that the

specifications are the same as what you specified. In particular, confirm the following points.

• Tag No. (TAG No.)

• Model (MODEL)

• Work No. (PROD.)

• Input current range (INPUT)

• Supply air pressure (SUPPLY)

• Explosion protection certification seal (for explosion-proof specifications)

Contact

Storage

WARNING

When using the device in an explosion-proof area, be sure to select the model

that satisfies the necessary explosion-proof requirements. Non-explosion-proof

products cannot be used in an explosion-proof area.

For inquiries about this device, please contact us.

When contacting us, let us know the model number and production number.

When storing the device after purchase, obey the following precautions.

• When storing the device before it has been used

1. Store the device as packed at shipment.

2. Store the device at an indoor location with little vibration or shocks and at

normal temperature and humidity (about 25°C, 65%).

• When storing the device after it has been used

1. Tightly secure the terminal box cover and block the conduit connection

port with tape to prevent humidity intrusion.

2. Block the three pneumatic piping connection ports (SUP , OUT1 and

OUT2) with tape to prevent humidity and dust intrusion.

3. Pack the device in the same way as at shipment.

Store the device at an indoor location with little vibration or shocks where it will not be

4.

exposed to rain or water and at normal temperature and humidity (about 25°C, 65%).

iv

Page 7

Table of Contents

Chapter 1 Structure of the 700 Series Control System ..............1-1

1-1 System Configuration ...............................................1-1

1-2 System Configuration without Motion Transmission ........................1-2

1-3 System Configuration with Motion Transmission ..........................1-2

1-4 Structure of the Device and Description of Each Part .......................1-3

1-4-1 Structure of the Device .........................................1-3

1-4-2 Structure of Terminal Box .......................................1-5

1-4-3 Display on the Local User Interface (LUI) ...........................1-7

Chapter 2 Installation of the 700 Series ..........................2-1

2-1 Usage Conditions ..................................................2-2

2-2 Selection Criteria for Installation Location ................................2-3

2-2-1 Selection Criteria for Installation Location ..........................2-3

2-2-2 Criteria for instrumentation air ...................................2-3

2-3 Installation Procedure ...............................................2-5

2-3-1 Mounting the 700 Series onto the Actuator ..........................2-5

2-3-2 Pneumatic Piping Connection ...................................2-12

2-3-3 Electrical Wiring Connection ....................................2-15

2-3-4 Input Signals and Travel Transmission Power ......................2-17

2-3-5 Cables .....................................................2-18

2-4 Cable gland and flameproof universal elbow for TIIS Flameproof apparatus ....2-20

Chapter 3 Operation of the 700 Series ...........................3-1

3-1 Local User Interface (LUI) ............................................3-2

3-2 Adjustment before Operation .........................................3-5

3-2-1 Auto Setup ..................................................3-5

3-2-2 Zero Span Adjustment .........................................3-9

3-2-3 Supply Bypass ..............................................3-12

3-2-4 Control Parameters ...........................................3-13

3-2-5 Password ..................................................3-15

3-3 Starting Operation .................................................3-16

3-3-1 Preoperation Check ..........................................3-16

Chapter 4 Operation with HART Communication ..................4-1

4-1 Operation with HART Communication ..................................4-1

4-2 Setup and Adjustment of Device .......................................4-2

4-2-1 Process Variables .............................................4-2

4-2-2 Auto Setup ..................................................4-3

4-2-3 Input Range .................................................4-5

4-2-4 Valve System ................................................4-5

4-2-5 Control Configuration ..........................................4-6

4-2-6 Input Characterization ..........................................4-8

4-2-7 Travel Cutoff .................................................4-8

4-2-8 Units .......................................................4-9

4-2-9 Travel Calibration ............................................4-10

4-2-10 Input Calibration .............................................4-12

4-2-11 Pressure Sensor Adjustment ...................................4-12

4-2-12 Simulation .................................................4-12

4-2-13 Adjustment of EPM Drive Signal (Pneumatic Modules) ...............4-13

4-2-14 Restore factory settings .......................................4-13

4-2-15 Operator Action Records ......................................4-13

v

Page 8

4-2-16 Real Time Clock .............................................4-13

4-2-17 Password ..................................................4-13

4-2-18 Device Information ...........................................4-14

4-2-19 Option ....................................................4-16

4-2-20 Diagnostic Messages .........................................4-17

4-2-21 Control Valve Diagnostic Messages ..............................4-19

Chapter 5 Troubleshooting ....................................5-1

5-1 Troubleshooting ...................................................5-2

5-1-1 The Device Does Not Operate. (There Is No Output Air Pressure.) .......5-2

5-1-2 The Control Valve Operates Abnormally (There Is Output Air Pressure.) ...5-2

5-1-3 Failure to communicate with the communicator ......................5-2

5-1-4 Adjustment Procedure When Hunting Occurs .......................5-3

5-1-5 Auto Setup Failure ............................................5-4

5-2 Description of Messages .............................................5-5

Chapter 6 Maintenance .......................................6-1

6-1 A/M Switch .......................................................6-2

6-2 Replacement of Filter and Maintenance of Flow Restriction ..................6-4

6-3 Cleaning the Flapper ................................................6-5

6-4 Adjusting the Pilot Relay .............................................6-6

6-5 Insulation Resistance Test ...........................................6-7

6-6 Adjustment Procedure When Using the Device with the Booster Relay Attached . 6-8

6-7 List of Default Values for Internal Data ..................................6-9

6-8 Internal Block Diagram of the 700 Series ...............................6-10

6-9 Resale Parts .....................................................6-11

6-9-1 Procedure to Change Switch Block ..............................6-15

6-9-2 Procedure to Change Pilot Relay ................................6-16

Chapter 7 Notes on the Explosion-Proof 700 Series ...............7-1

7-1 TIIS Flameproof Model ..............................................7-2

7-2 ATEX Flameproof and Dust Ignition Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

7-3 IECEx Flameproof and Dust Ignition Protection ...........................7-5

7-4 FM Explosionproof / Dust Ignition Protection .............................7-7

7-5 FM Intrinsically safe (ic) and Nonincendive ..............................7-8

7-6 FMC Explosionproof / Dust Ignition Protection ...........................7-13

7-7 NEPSI Flameproof / Dust Ignition Protection ............................7-14

7-8 KOSHA Flameproof ...............................................7-16

7-9 INMETRO Flameproof / Dust Ignition Protection .........................7-17

7-10 EAC Flameproof ..................................................7-19

7-11 ATEX Intrinsic Safety and Dust Ignition Protection ........................7-20

7-12 IECEx Intrinsic Safety and Dust Ignition Protection .......................7-21

Appendix A LUI Display Example ................................A-1

Appendix B Menu List ..........................................B-1

Appendix C Specification .......................................C-1

Appendix D Model Selection ....................................D-1

Appendix E Outline Dimensional Drawing .........................E-1

vi

Page 9

Chapter 1 Structure of the 700 Series Control System

This chapter describes the device configuration of the control system that uses the

device.

• Description of the configuration of the input/output system in the device

• Description of the structure of the main unit of the device and the name and function of

each part

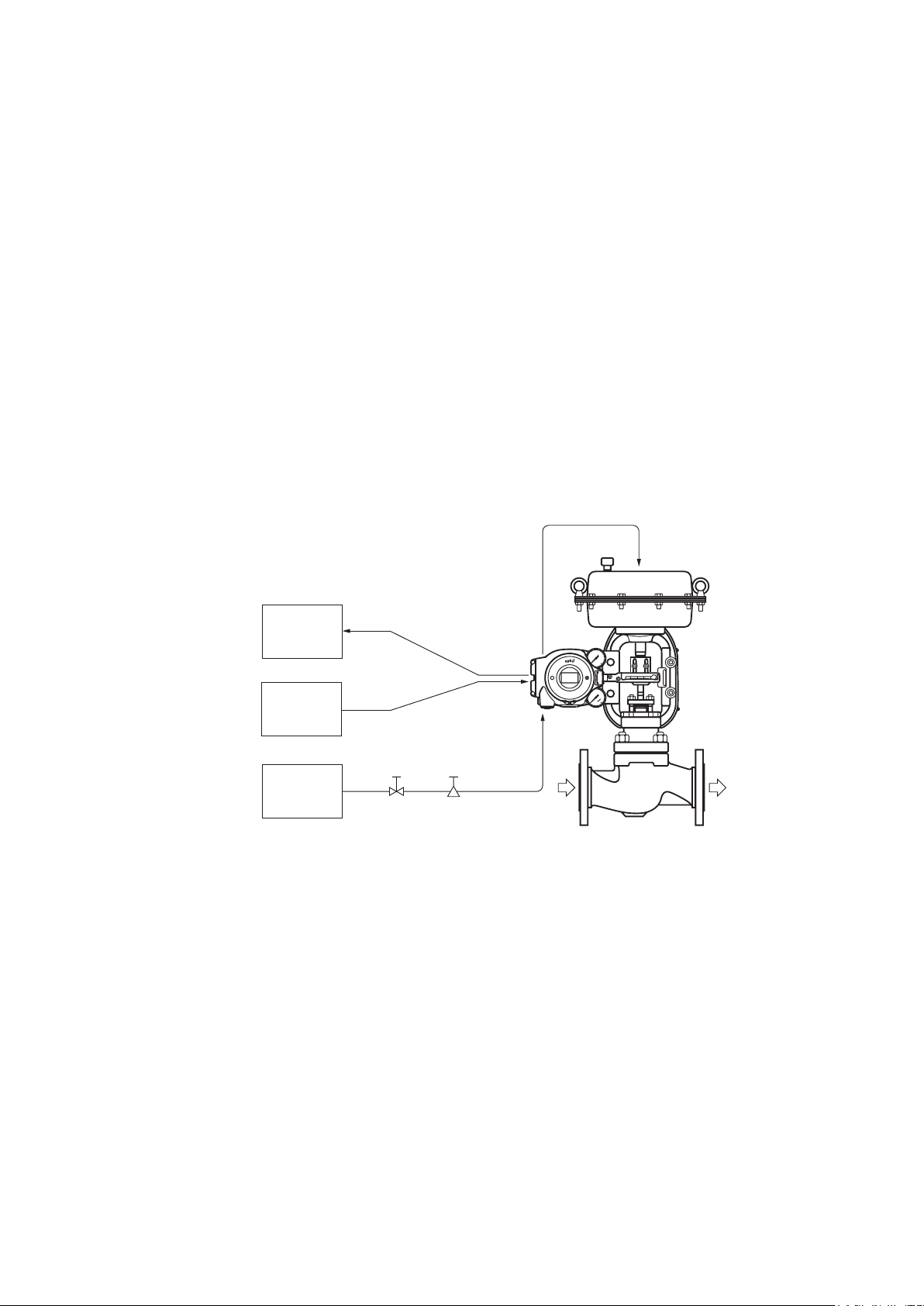

1-1 System Configuration

This device is a smart valve positioner that can be connected to the 4–20 mA DC signal

lines of the controller output. It makes various adjustments using electricity, so the

relationship between input signals and control valve travel can be set to any desired

value. In addition, by connecting the device using four lines, the control valve travel is

transmitted to the host monitoring system as a 4–20 mA DC analog signal. (Only the

AVP701 model supports valve travel transmission.)

Air to the actuator

Host

monitoring

system

Host controller

Air supply

system

DC4–20mA analog signal

(AVP701)

DC4–20mA analog signal

Shutoff Solenoid valve

with filter

valve

Device

Supply air

Control valve

Figure1-1 Concept Diagram of the 700 Series Control System

Process fluid

1-1

Page 10

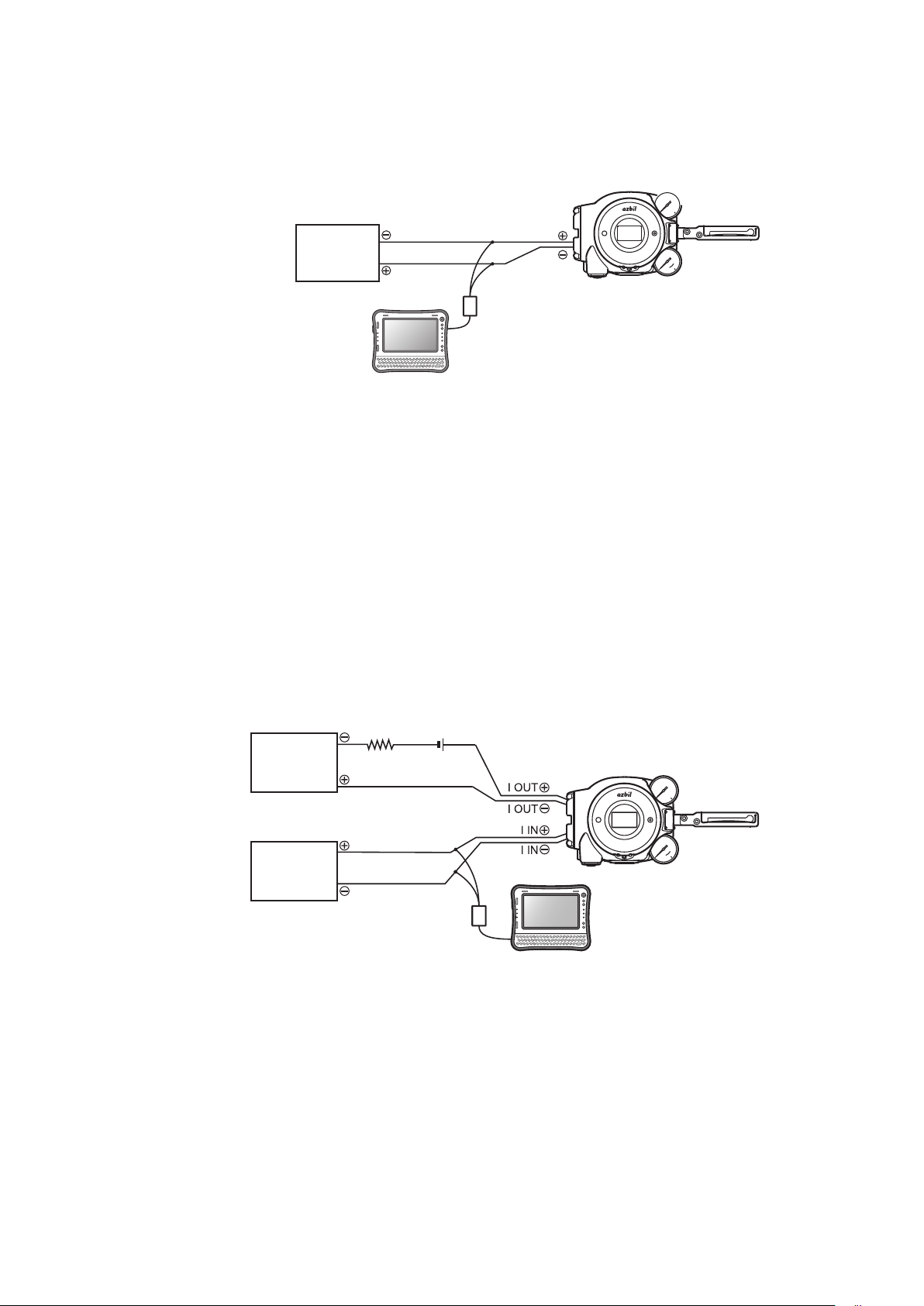

1-2 System Configuration without Motion Transmission

This shows the configuration for a system that does not use the motion transmission

function of this device (model AVP702).

Host

controller

HART configuration

tool

DC4–20mA

HART Modem

I IN

I IN

Device

Figure1-2 System Configuration without Motion Transmission (Model AVP702)

1-3 System Configuration with Motion Transmission

This device (model AVP701) has a function for motion transmission of the control valve.

To output the travel signal to the host monitoring device using analog values, configure

the system with motion transmission. Normally, the travel from fully closed to fully open

are output as 4–20 mA DC.

This shows an example of a system configuration for outputting valve travels detected

with this device as 4–20 mA DC analog signals.

With this system configuration, analog signals are output directly to the higher-order host

monitoring system from this device.

250Ω

Host

monitoring

system

(current input)

Host

controller

*1: For the detailed information of the power supply and resistor, please

refer to the figure 2-18 of 2-3-4 Input Signals and Travel Transmission

Resistor

*1 *1

Analog signal

DC4–20mA

DC4–20mA

DC24V

Power supply

HART Modem

Device

HART configuration tool

Figure1-3 System Configuration with Motion Transmission (Model AVP701)

1-2

Page 11

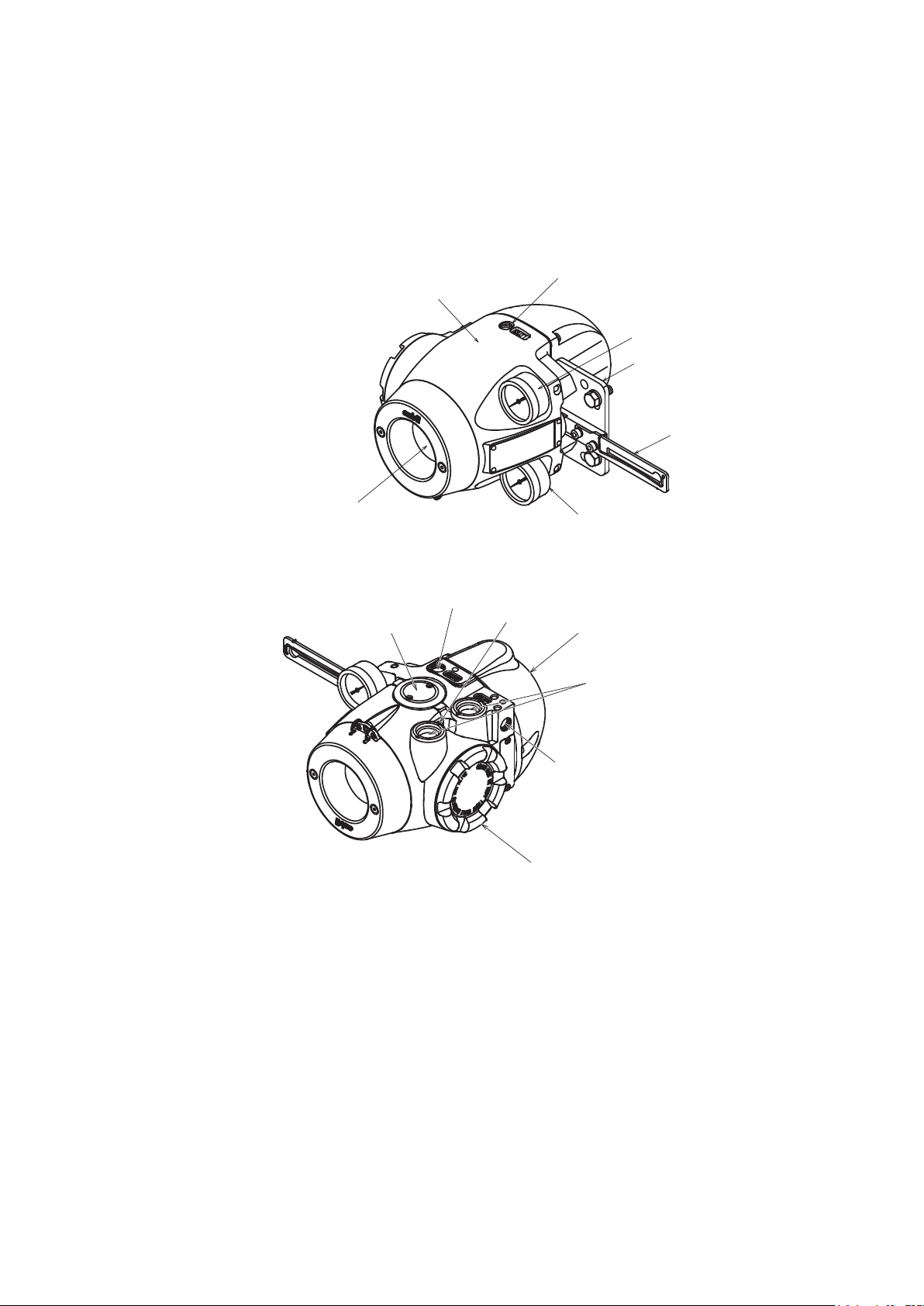

1-4 Structure of the Device and Description of Each Part

1-4-1 Structure of the Device

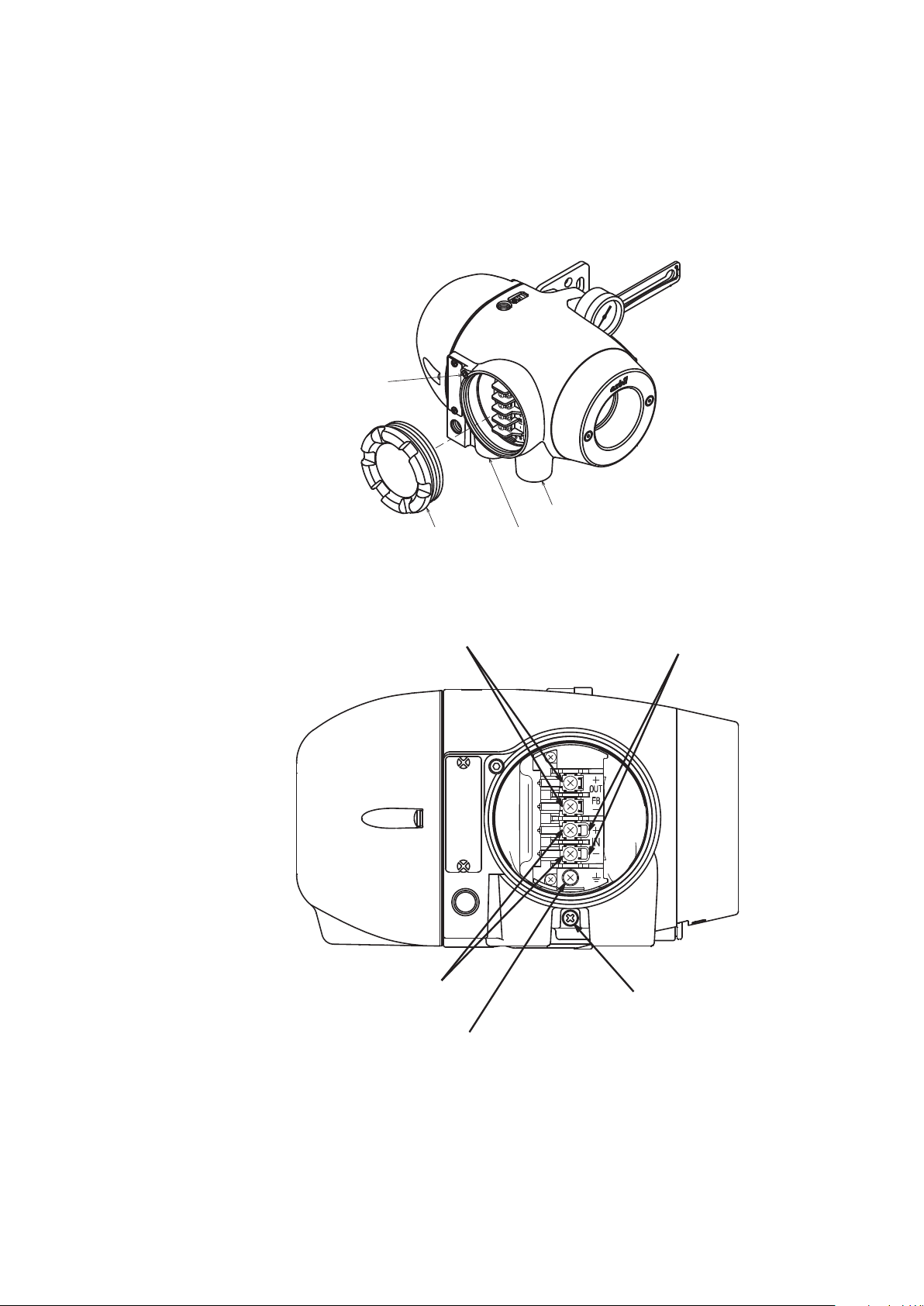

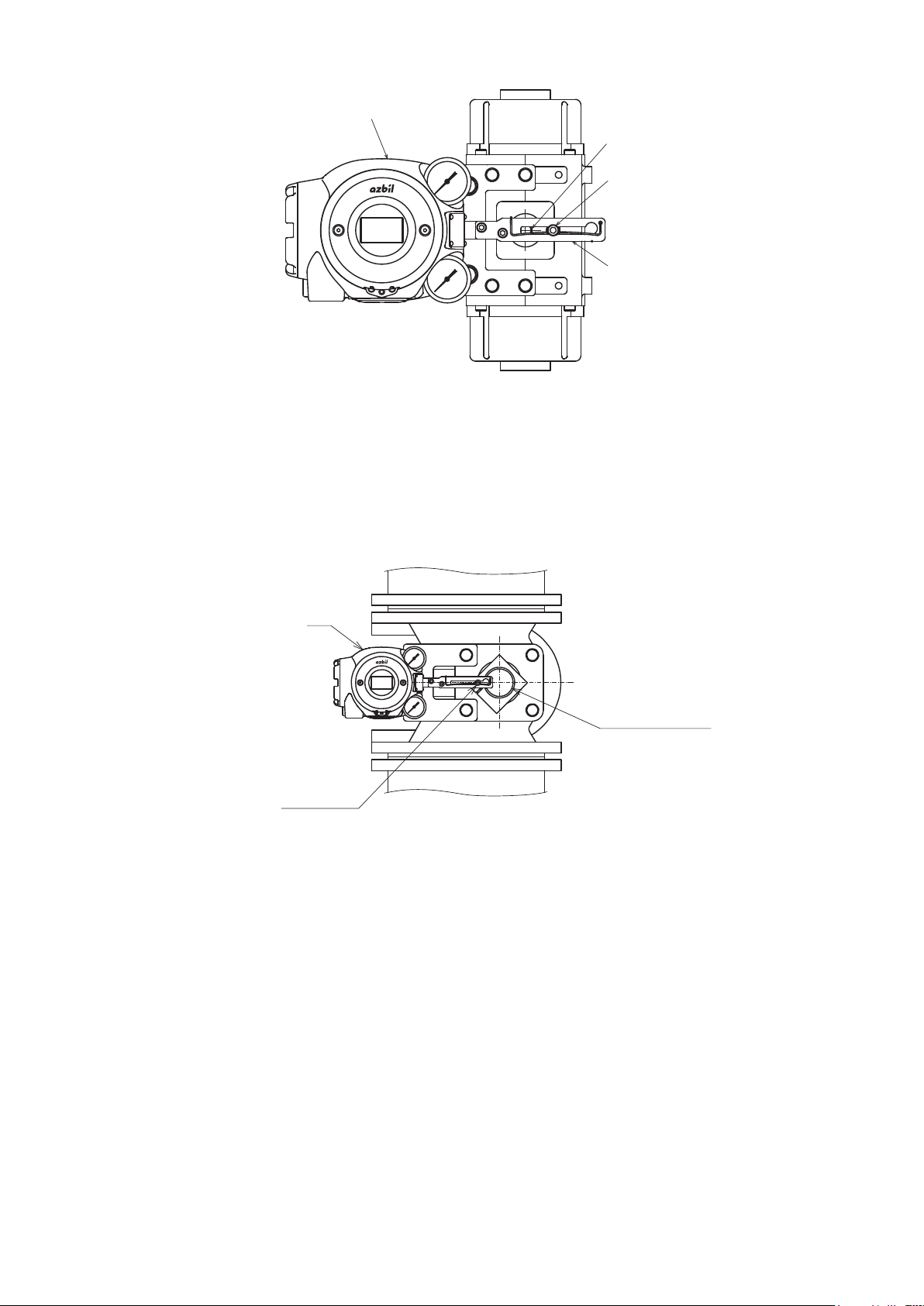

1) Major components

The structure of the main unit of the device is shown in the figure below.

Output air connection port (OUT1)

Main unit

Output air pressure gauge

Mounting plate (optional)

Feedback lever

Local user

interface (LUI)

Exhaust cap

Supply air pressure gauge

Figure1-4 Structure of the Device (Upper)

Output air connection port (OUT2)

External grounding terminal

Pilot relay cover

Electrical conduit connection port

Supply air connection port (SUP)

Terminal box cover

Figure1-5 Structure of the Device (Lower)

1-3

Page 12

2) Name and description of each part

The table below describes each part.

Table 1-1 Description of Each Part

Name Description

Main unit

Pilot relay cover

Auto/Manual (A/M) switch

Feedback lever

Local user interface (LUI)

Supply air pressure gauge - Indicates the pressure of supply air.

Output air pressure gauge - Indicates the pressure of output air.

Supply air connection port (SUP)

Output air connection port (OUT1)

Output air connection port (OUT2)

Mounting plate (optional)

- Houses electronic circuits, an electro-pneumatic transducer (EPM), a

position sensor (VTD), and a pressure sensor.

- Cover of the pilot relay that amplifies the air signal from the EPM

(electro-pneumatic transducer) and transduces it into the air signal

sent to the actuator.

- When you must adjust the balance pressure to switch between the

pilot relay for the single-acting actuator and the pilot relay for the

double-acting actuator, remove this cover.

- This switch is used to switch how the output air between the auto

operation status and the manual operation status is controlled.

This switch is built into the pilot relay. This switch can be seen by

removing the pilot relay cover.

- Extracts and transmits the movement of the control valve lift to the

VTD (position sensor).

- The LUI allows you to adjust the zero span, perform auto setup, and

manually operate the device with the LCD (liquid crystal display) and

operation buttons without using the communicator.

- Supply air is input to this port.

- “SUP” is displayed at this port.

- Output air is sent out of this port to the actuator.

- “OUT1” is displayed at this port.

- Output air is sent out of this port to the actuator.

- This port is blocked with a blind plug in the single-acting actuator.

- OUT2 is displayed at the output port for the double-acting actuator.

- The mounting plate is used to mount the device onto the actuator.

- The shape of the mounting plate differs depending on the

specifications (actuator model).

1-4

Page 13

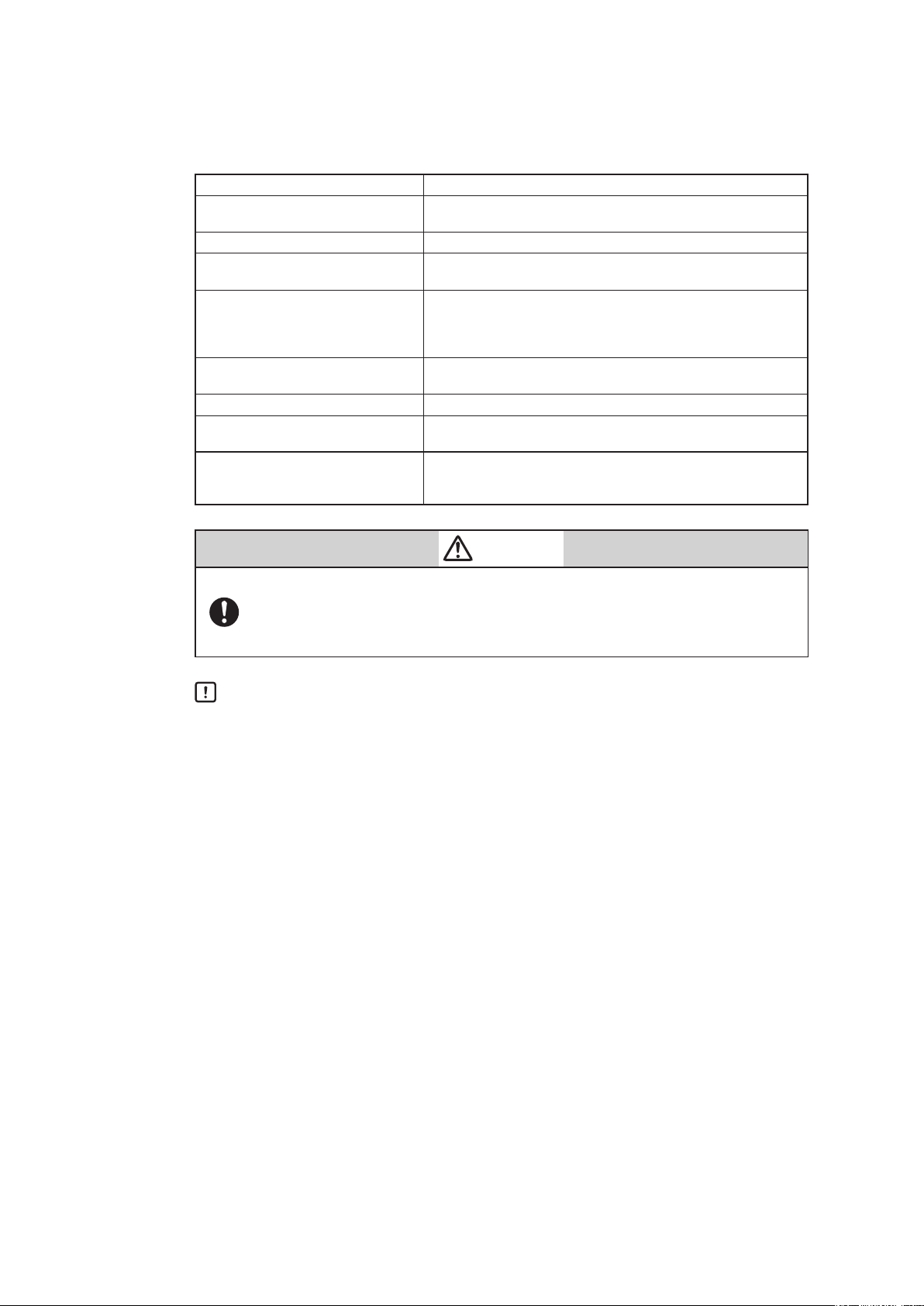

1-4-2 Structure of Terminal Box

1) Major components

This contains the input signal (controller output) terminal, output signal (motion

transmission) terminal, and internal ground terminal.

The structure of the terminal box is as shown below.

Lock screw

Terminal

box cover

Conduit connection port (1)

Conduit connection port (2)

Figure1-6 Structure of Terminal Box

Terminal for output signals

M4 screw

HART check pin

Terminal for input signals

M4 screw

Terminal for internal grounding

M4 screw

Figure1-7 Terminal Block in the Terminal Box

1-5

Terminal for external grounding

M4 screw

Page 14

2) Name and description of each part

The table below describes each part of the terminal box.

Table 1-2 Description of Each Part

Name Description

Terminal box cover

Lock screw - Used to secure the terminal box cover.

Terminal for input signals

Terminal for output signalsl

Internal grounding terminal

Conduit connection port (1) - Service entrance for a cable.

Conduit connection port (2)

Check pin for HART communication

- Lid of terminal box.

- This cover has a pressure-resistant explosion-proof structure.

- Shown as IN.

- Connects the signal cable from the host controller.

- Shown as OUT.

- Connects the signal cable for motion transmission.

- The AVP702 model (without motion transmission) does not have

the terminal screws.

- Internal terminal for grounding. The cable for grounding is

connected to this terminal.

- Service entrance for a cable.

- This entrance is normally blocked with a blind plug.

- By connecting the connection hook for the setting device

communication cable to this pin, it is possible to communicate

with this device.

Warning

When using a pressure-resistant explosion-proof model in a dangerous place,

be sure to use the specified cable adapter for pressure-resistant packing for

the conduit connection port. Securely close the terminal box cover all the way.

Then, rotate the lock screw counterclockwise to secure the terminal box cover.

Handling Precautions:

Ground either the external or internal grounding terminal according to the

specifications. Be careful not to ground the device at two points.

1-6

Page 15

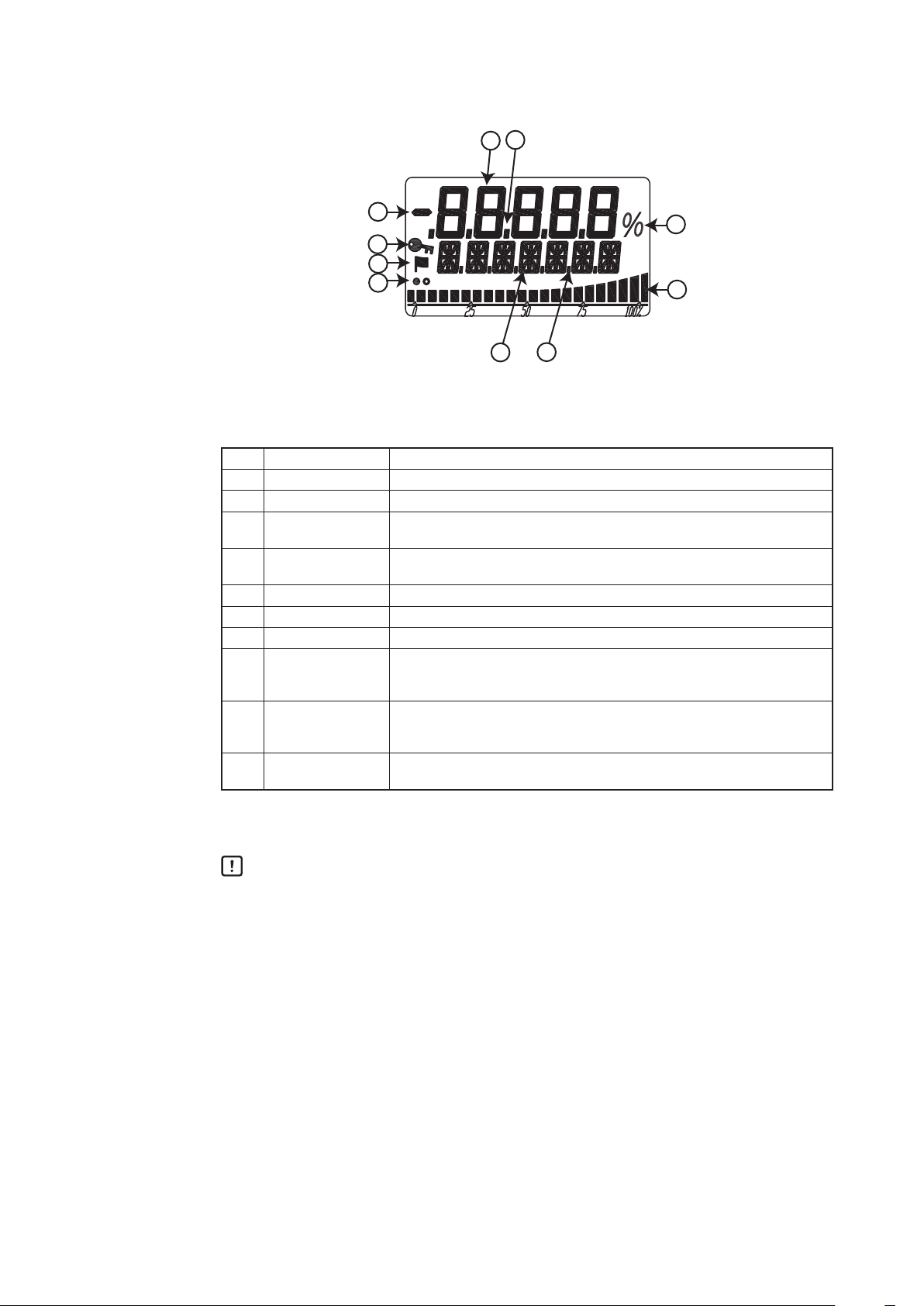

1-4-3 Display on the Local User Interface (LUI)

3

1

2

8

9

10

5

4

6

7

Figure1-8 Segments on the LCD

Table 1-3 Description of Each Part

No. Displayed element Main display

(1) 7 segments (5 digits) Displays the main numerical values such as the specified opening.

(2) Minus sign Displays the sign for the 7-segment number.

Decimal point

(3)

(five places)

16 segments

(4)

(7 digits)

(5) Dot (6 places) Displays the 16-segment auxiliary display, separator, or other data.

(6) Percentage Displays %.

(7) Bar graph (22 bars) Displays the bar graph in percentage at a set point, etc.

(8) Key mark

(9) Flag mark

(10) Display refresh mark

Displays the decimal point for the 7-segment number.

Displays the unit, status, or other data.

On: LUI operation is unavailable.

Off: LUI operation is available.

Blinking: LUI is in operation.

When the self-diagnostic alarm is activated, the key mark is displayed.

For detailed information of the alarms,please refer to the status monitor of

page 3-4.

Display during operation

White and black circles alternately blink.

For a display example, refer to "LUI Display List" in Appendix A.

Handling Precautions:

The LUI buttons may not respond well near an electromagnetic inductor (such as

a large transformer or high-frequency furnace).

Remove sand, dust, and other foreign objects from the rubber parts of the

operation buttons before operating the LUI. Operating the LUI with foreign

objects on it may damage the rubber parts.

Do not pull the rubber parts of the operation buttons. This may deteriorate the

sealability, possibly causing malfunction.

1-7

Page 16

1-8

Page 17

Chapter 2 Installation of the 700 Series

This chapter describes the usage conditions, installation, piping, and wiring of the device.

Precautions for safe work

Warning

Do not perform wiring with wet hands or while the device is energized. This may lead to

electric shock. Turn the power off before starting the work and work with dry hands or use

gloves.

Follow the work procedure defined in the explosion protection guidelines when performing the

power distribution work in an explosion-proof area.

For devices equipped with the pressure-resistant, explosion-proof specifications, do not open

the cover during operation (while the power is on).

Cautions

Do not get on the installed device or use it as a step stool. This is dangerous because the

device may tip over.

Do not touch the device during operation without reason. This is dangerous because the

surface may be hot or cold depending on the usage environment.

Be careful not to touch the edge of the cover or the screw threads of the main unit when

opening the cover of the terminal box. You may be injured by these parts.

Use a DC power supply with overload protection. Overload may cause smoke or fire.

If a tool or other item touches the glass part of the display, it may break, leading to an injury.

Be careful. Wear safety glasses during work.

This product is heavy. Be careful where you step and wear safety shoes during work.

Do not touch the feedback lever or other moving part while the device is operating. You may

be injured by getting your hand or other body part caught in them.

Properly use the power supply based on the specifications. Inputting a different power supply

may damage the device.

Use gloves and other protective equipment during work in a hot, cold, or other severe

environment.

Do not move the device close to a magnet or magnetic driver. The control valve may operate.

Apply the correct supply air pressure in acoordance with the specification of the device. The

overpressure may cause abnormal actions of the control valve or damage to the pressure

gauge.

2-1

Page 18

2-1 Usage Conditions

The device must be installed in the location, which satisfies the following conditions.

Also, the divice must be used in accordance with its specification.

General model °C 23 ± 2 -40 to +80 -40 to +80 -40 to +70

TIIS flameproof

model

ATEX/IECEx/

FM/FMC/NEPSI/

KOSHA/EAC/

Operating

temperature

range

Vibration

Friction of applied valve % 3 to 20 3 to 20

Supply air pressure Ps

(140 kPa ≤ Ps ≤ 700 kPa)

Installation orientation

Each operating condition is defined as follows.

- Basic operating condition: Range in which the accuracy is guaranteed

- Normal operating condition: Range in which the positioner normally operates

Marginal operating condition

-

- Transportation condition: Environment condition range in which the non-operating device is not

INMETRO

flameproof

model

FM Intrinsically

Safe (ic) and

Nonincendive

ATEX/IECEx

intrinsically safe

model

LUI °C 23 ± 2 0 to +50 -40 to +80 -40 to +70

Input current mA 4 to 20 3.84 to 21.6

Amplitude

Acceleration

Humidity range %RH 50 ± 10 5 to 100 5 to 100 5 to 100

Table 2-1 Range of Usage Conditions

Units

Basic

operating

conditions

Normal

operating

conditions

Marginal

operating

conditions

°C 23 ± 2 -20 to +55 -20 to +55 -40 to +70

°C 23 ± 2 -30 to +75 -30 to +75 -40 to +70

°C 23 ± 2 -24 to +75 -24 to +75 -40 to +70

°C 23 ± 2 -40 to +60 -40 to +60 -40 to +70

0 to 3.84

Note 5

21.6 to 24

Note 1

Note 1 Note 2

mm

m/s

p-p

2

0

0

15/(5 to 8 Hz) 15/(5 to 10 Hz) 15/(5 to 10 Hz)

20/(8 to 400 Hz)

40/(10 to 400 Hz) 40/(10 to 400 Hz)

0 to 3

20 to 100 ―

kPa Ps ± 1% 140 to 700 0 to 710 ―

Note 3

° ±1

Note 4

±180 ±180 ±180

: Range in which performance is not guaranteed but the device can be without

being permanently damaged

permanently damaged during transportation

Transportation

conditions

―

Note 1: Vibration conditions when the positioner cover is positioned at the center front.

Note 2: The pressure gauge is not applied.

Note 3: The slope characteristics are not included.

Note 4: The status where the drive shaft of the direct-acting actuator is perpendicular to the ground and that is

used as the reference.

Note 5: In the range of 3.5 mA to 3.84 mA, HART communication is possible though the operation of the

positioner is not guaranteed. (The output air pressure assumes that the power is cut. The pressure

sensor value is not guaranteed.)

2-2

Page 19

2-2 Selection Criteria for Installation Location

The device is designed to withstand severe conditions, but the installation location should

be selected according to the criteria described below to maximize performance.

2-2-1 Selection Criteria for Installation Location

Install the device in a location that satisfies all of the following conditions.

• Operating temperature range that conforms to the explosion protection rules

• Relative humidity: 5 to 100%RH

• Ambient temperature change rate: ±20°C/hr or slower

• Electromagnetic induction: 400 A/m or less (Avoid places near a large transducer,

high-frequency furnace, or other such equipment.)

• Do not use a transceiver near the device.

2

• Vibration: 20 m/s

(The vibration conditions defined for the device are the vibrations at the positioner

part.)

(5 to 400 Hz) or less

2-2-2 Criteria for instrumentation air

The device employs a nozzle flapper structure in the electropneumatic transduction

section. If instrumentation air is contaminated (includes oil, water, or other substance),

the positioner function of the device may not function properly or an irrecoverable failure

may occur. Therefore, the quality of instrumentation air supplied to the device is defined

as follows.

• Solid material : No particles with a diameter larger than 3 μm.

• Oil : Less than 1 ppm.

• Supply air humidity : The dew point temperature is at least 10°C lower than that of the device.

(This criterion is based on Japanese Industrial Standards JIS C 1805-1(2001).)

Select a compressor and main line or terminal-installation type compressed air purifier by

referring to the above specifications.

(1) Compressed air purifier for the main line

Select a compressed air purifier for the main line, such as a main line filter or microalescer, to satisfy the above specifications.

Domestic compressed air purifier manufacturers of Japan: SMC Corporation and CKD

Corporation

(2) Compressed air purifier to be installed on the terminal

If an air purifier cannot be installed on the main line due to installation of a control

valve or for other reasons, use an compressed air purifier that can be installed on the

terminal in order to satisfy the above specifications.

2-3

Page 20

<Example devices>

- Products from SMC Corporation

Mist Separator AM150 or AM250 Series

(Filtering level: 0.3 μm, Secondary oil mist concentration: 1.0 mg/m

- CKD Corporation

Oil mist filter

M1000 or M3000 Series

3

Mantle S Type (Filtering level: 0.3 μm, Remaining oil: 1.0 mg/m

)

Handling Precautions:

Select a compressed air purifier with specifications suited to the usage

conditions. Even when you install the above oil removal equipment, it is

necessary to properly inspect and maintain the air circuit section for long-term

stable operation. Install the oil removal equipment before use and perform

periodic inspection and maintenance.

The warranty is void if the device fails because the quality of the above

instrumentation air was not sufficient.

3

)

2-4

Page 21

2-3 Installation Procedure

2-3-1 Mounting the 700 Series onto the Actuator

The device is a smart valve positioner for use with a control valve that uses a directacting or rotary actuator. The main unit of the device weighs approximately 4.2 kg.

The basic mounting procedure is the same as that for conventional electropneumatic

positioners.

Cautions

Be careful not to get injured by sharp parts such as the edge of the main unit or actuator

or screw threads during mounting.

The type of mounting plate, mounting method, and mounting procedure differ depending

on the actuator model to be mounted in the device.

If the device is not properly mounted, not only will the device not be able to operate at its

true performance but it may be damaged or fail. Pay attention to the following points.

- The mounting plate and its accessories differ depending on the specifications

(actuator model). Be sure to use the appropriate mounting plate and accessories for

the actuator to be mounted.

- When installing the control valve, ensure as much surrounding space as possible

and put the device in the correct orientation taking maintainability (such as piping,

wiring, and adjustment) into consideration.

- Deliver the device to the installation location in the packaged state if possible.

- Do not apply excessive force to the feedback lever during mounting.

- Do not bend the feedback pin.

- Do not block the exhaust port located underneath.

-

Install the device so that the electrical conduit connection port does not face upward.

- Securely tighten bolts.

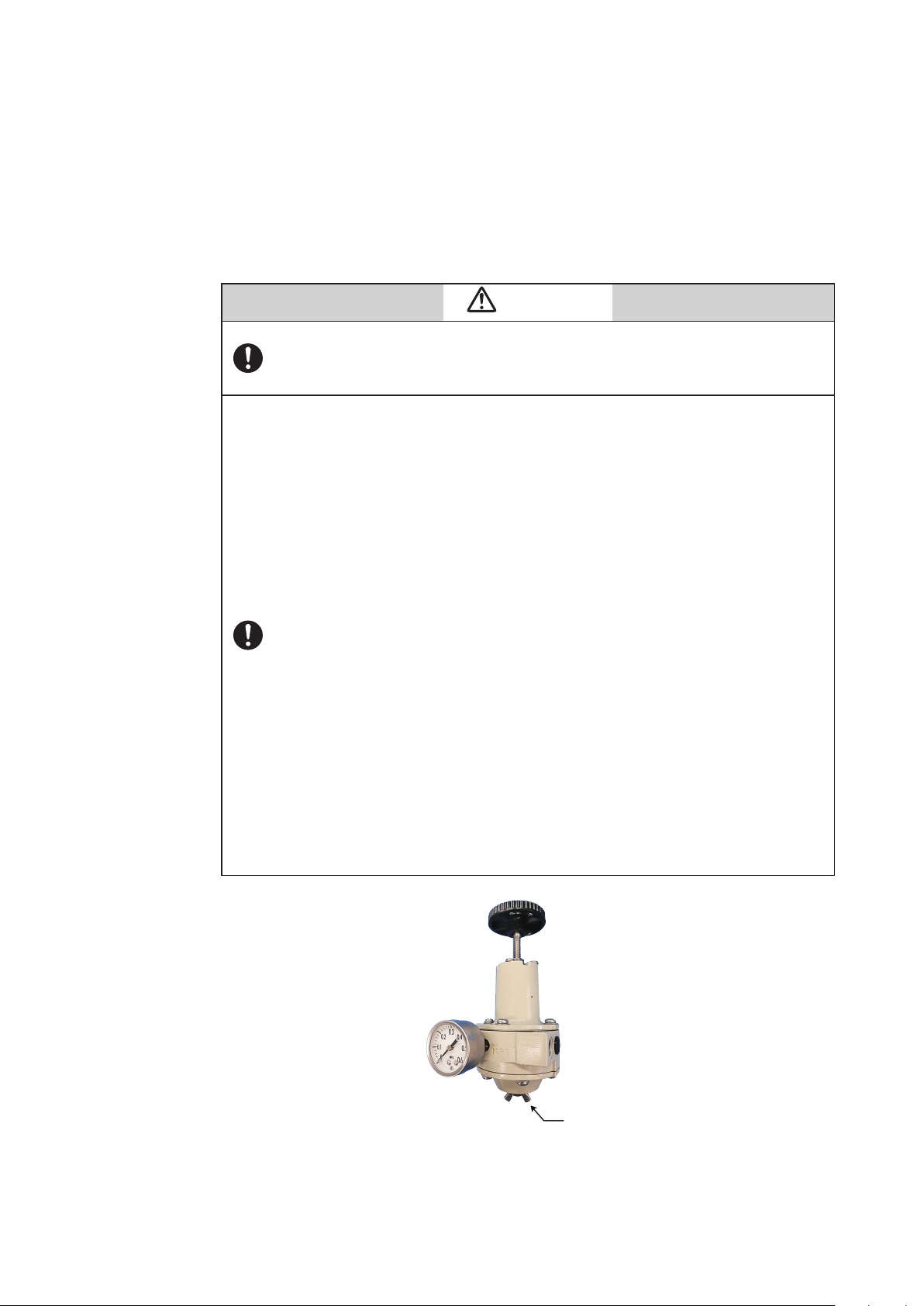

- If the model KZ03 pressure regulator with filter is installed with the device, install

with the drain of the KZ03 facing downward. If the KZ03 cannot be attached

vertically (with the drain facing downward), install it separated from the AVP with the

proper orientation.

- In order to avoid the possibility of rainwater entering the pressure gauge, install the

gauge such that it does not face upward or downward. In addition, the pressure

gauge has a rainwater drain on its underside, so install the gauge with this hole

facing downward.

- If you install this device with the LCD facing upwards, use the LCD cover and

pressure gauge elbows as necessary, depending on the circumstances. For details,

refer to 6) below, “Installing the device with the LCD facing upwards.”

2-5

Drain plug

Page 22

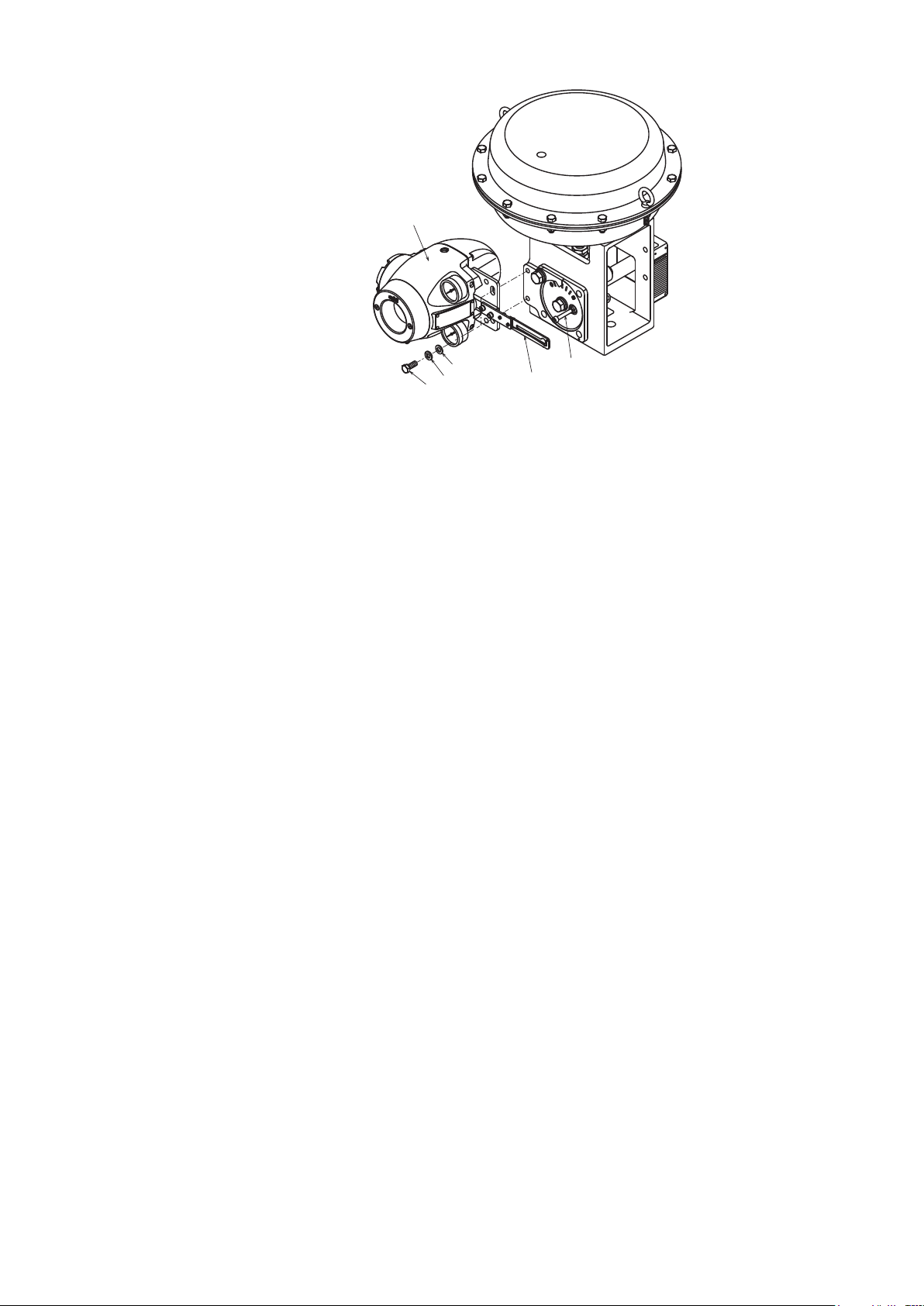

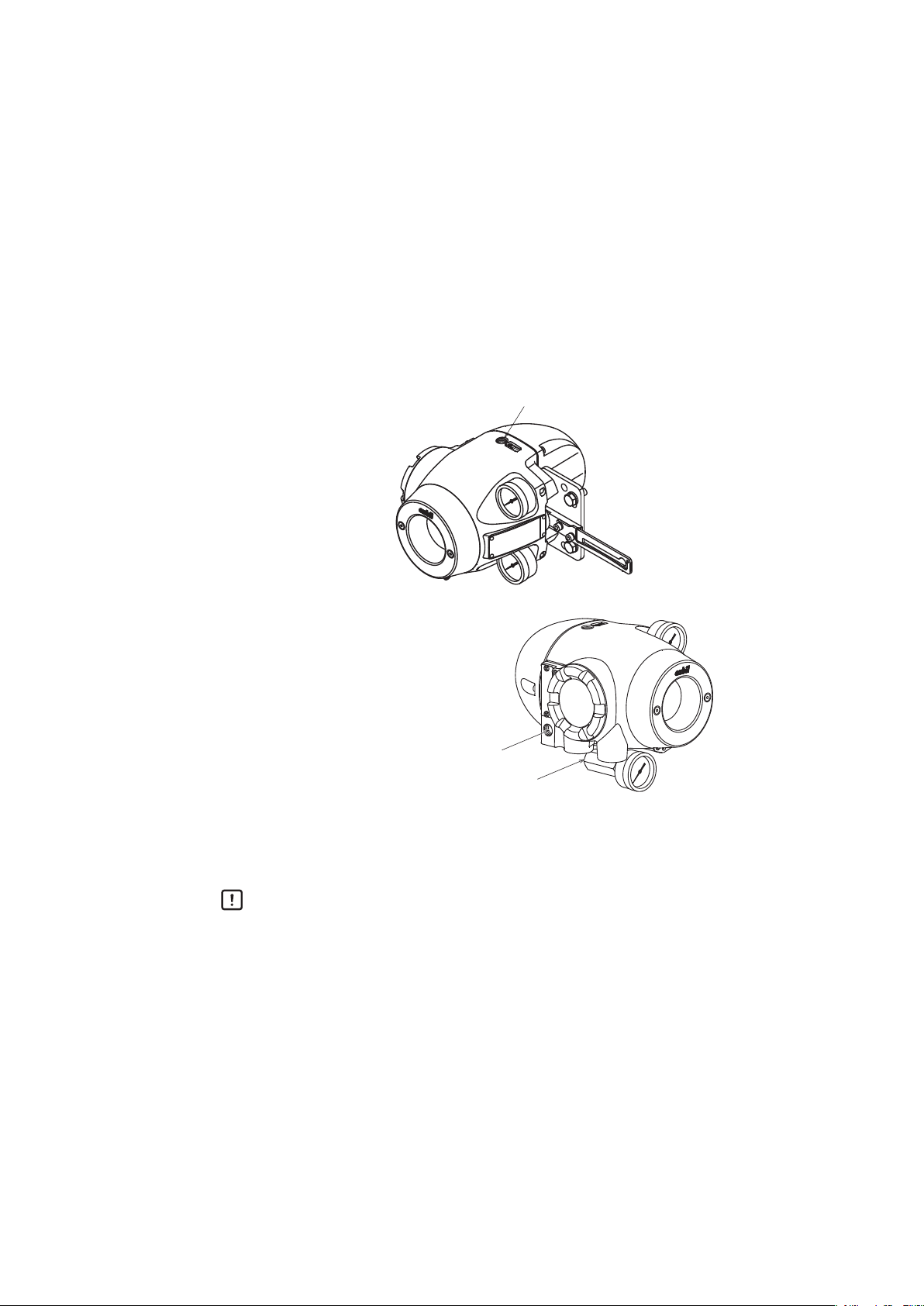

1) Mounting the feedback lever

Hexagon socket flange bolts (x 2)

Yoke

AVP

Hexagonal bolt

Assemble the feedback lever from the front of the main unit of the device using the two

included hexagon socket bolts.

Figure 2-1 Mounting Procedure for Feedback Lever

Assemble the extension lever as shown in the figure below if necessary.

Figure 2-2 Mounting Procedure for Extension Lever

2) Mounting example

A typical mounting method is shown in the figure below. If your actuator is not shown in

the figure below, refer to the assembly diagram included with the device.

[Direct-Acting Actuator HA2 to 4, PSA1 to 4, 6, VA1 to 6 from Azbil Corporation]

Connector pin assembly

Plain washer

Spring washer

Feedback lever

Figure 2-3 Mounting Procedure for Direct-Acting Actuator HA2 to 4, PSA1 to 4, 6, VA1

to 6 from Azbil Corporation

Feedback pin

[RSA1, 2, VR3 actuator from Azbil Corporation]

2-6

Page 23

AVP

Hexagonal bolt

Plain washer

Spring washer

Feedback pin

Feedback lever

Figure 2-4 Mounting Procedure for RSA1, 2, VR3 Actuator from Azbil Corporation

2-7

Page 24

[Example of double-acting rotary cylinder actuator]

Hexagonal bolt

SpacerAVP

Spring washer

Hexagonal bolt

Arm

Spring washer

Spring

washer

Hexagonal nut

Feedback lever

Feedback pin

Figure 2-5 Mounting Procedure for Double-Acting Rotary Cylinder Actuator

3) Mounting procedure

The procedure for mounting the feedback lever onto the actuator is shown below.

Step Work

Tightly secure the mounting plate by inserting hexagonal bolts

1

2

(M8×20) with spring washers into the (two) screw holes at the

rear of the device.

Tightly secure the device (mounting plate) onto the mounting

seat of the actuator by using bolts and washers. At this time,

insert the actuator feedback pin into the slotted hole of the

feedback lever in the device.

2-8

Page 25

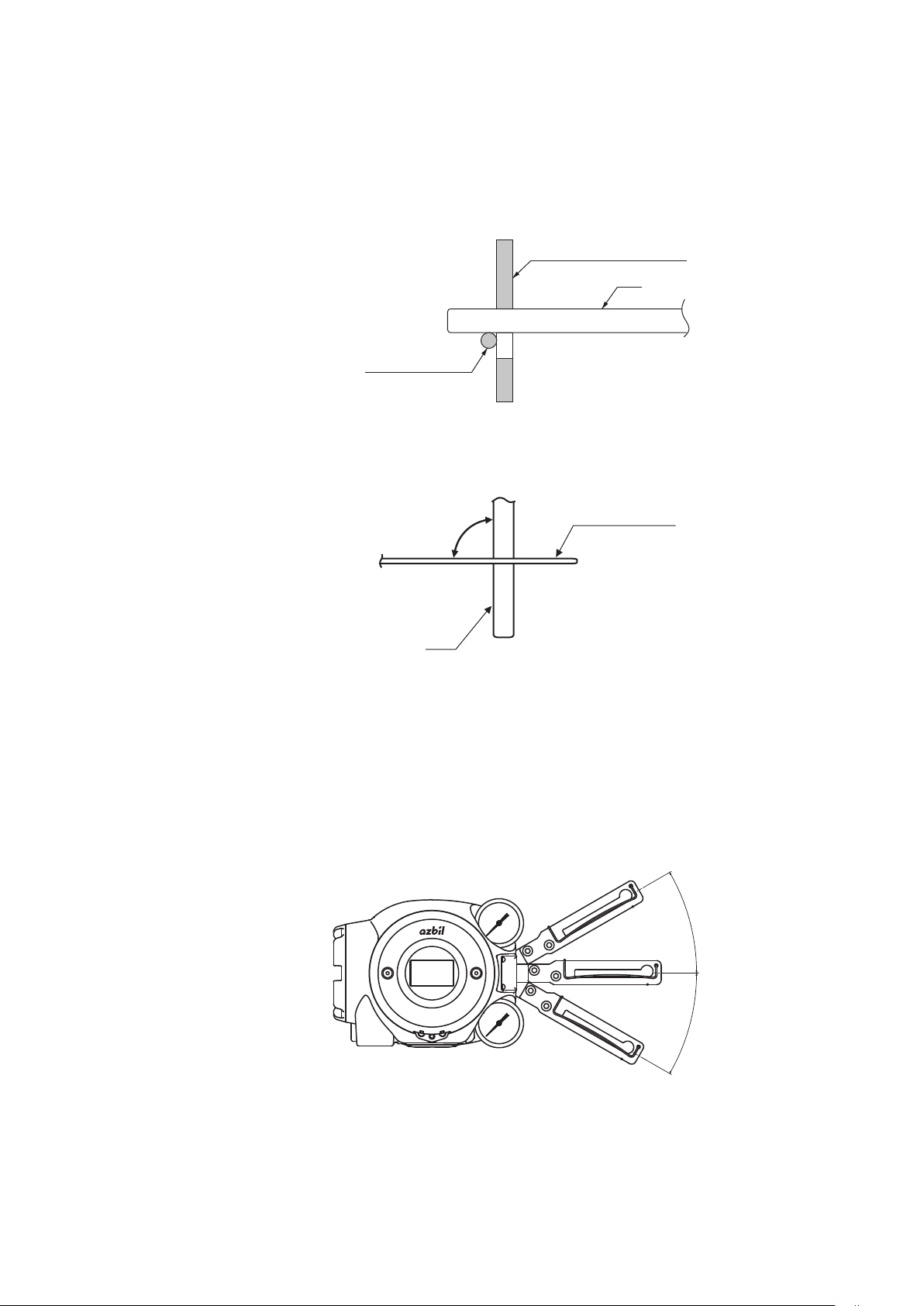

4) Connection of feedback pin and feedback lever (1)

Spring (cross section)

Pin

30°

30°

There are several points to be careful of when connecting the feedback lever to the

device and the actuator feedback pin. Connect correctly.

- Only a pin with a diameter of 6 mm can be used.

- Insert the pin between the guide and the spring.

Feedback lever (cross section)

Pin

Figure 2-6 Connection of Feedback Lever and Feedback Pin

- Make the feedback lever perpendicular to the pin when viewed from the above.

90°

Feedback lever

Figure 2-7 Angle between Feedback Lever and Pin

- Mount the lever so that it is horizontal when opened by 50%.

- The allowable rotation angle of the feedback lever is horizontal ± 30°. If the angle

exceeds ±30°, the self-diagnostic function detects Valve Travel Detector Out of Range

and the device will not operate normally. (The accuracy is guaranteed when the

rotation angle is between ±4° and ±20°.)

Figure 2-8 Operation Angle of Feedback Lever

- When assembling the lever onto a rotary cylinder so that the shaft of the rotary

cylinder is positioned between the feedback pin and the 700 Series as shown in the

figure below, select Rotary/90° (for 90°) or Rotary/other (for angles other than 90°) as

the Actuator Type according to the rotation angle.

2-9

Page 26

Shaft of rotary cylinder

AVP

Feedback pin

Feedback lever

Figure 2-9 Connection of the Rotary Cylinder to the Feedback Pin and Feedback

Lever

- When the rotary cylinder is large and the lever is assembled so that the feedback pin

is positioned between the 700 Series and the shaft of the rotary cylinder as shown

in the figure below, select Rotary (sub)/90° (for 90°) or Rotary (sub)/other (for angles

other than 90°) as the Actuator Type according to the rotation angle.

AVP

Shaft of rotary cylinder

Feedback pin

Figure 2-10 Feedback Pin and Feedback Lever Connection for Rotary Cylinder (Large

Cylinder)

5) Maintenance space behind the device

The device has a nozzle flapper mechanism in the back of the main unit. When cleaning

the flapper, you must remove the pilot relay cover secured to the back with three screws.

Design the clamp and feedback mechanism to ensure maintenance space for cleaning.

2-10

Page 27

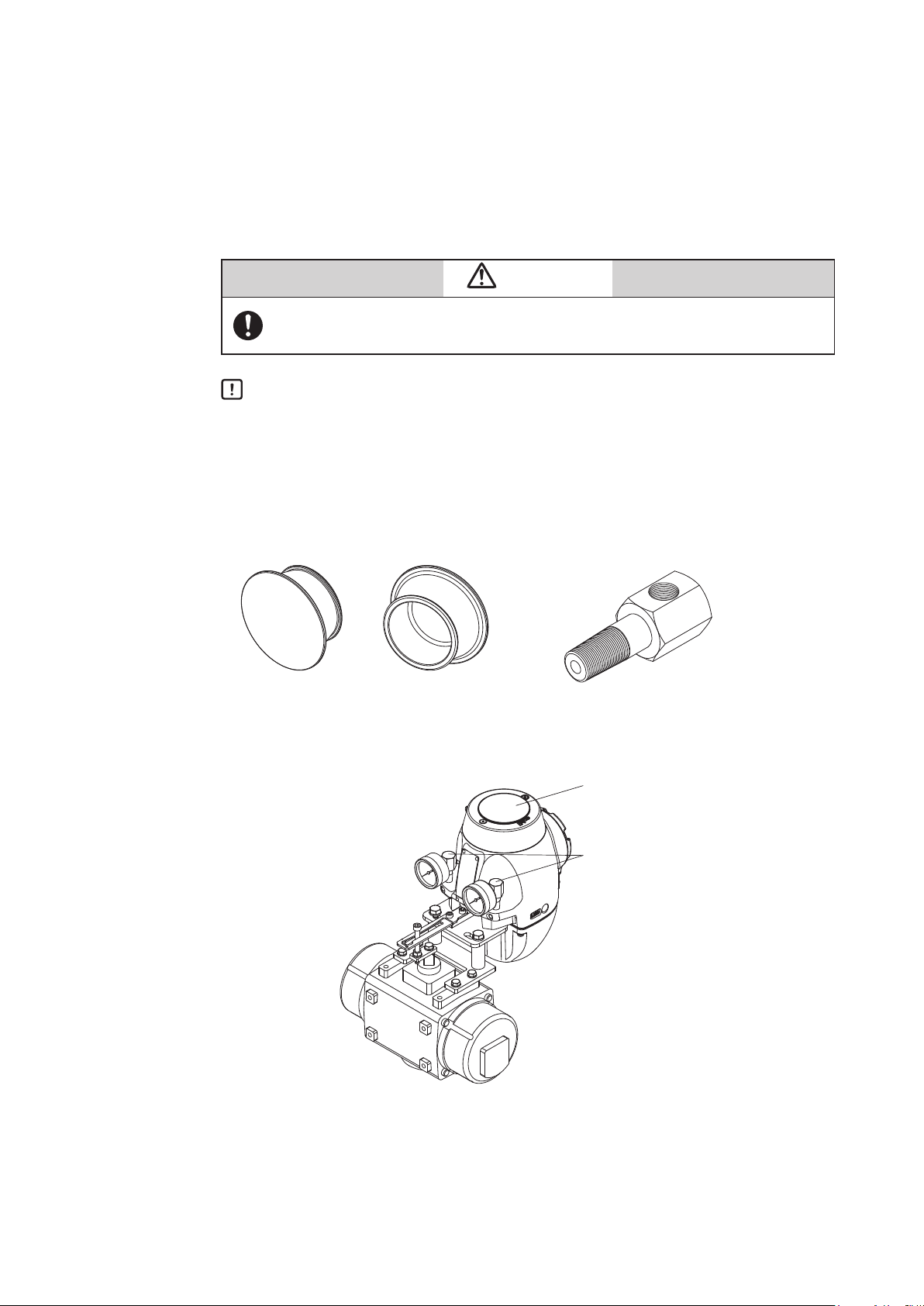

6) Installing the device with the LCD facing upwards

If you install the device with the LCD facing upwards, use the accessories below as

required depending on the circumstances. (Refer to 6-9, “Resale Parts.”)

• LCD cover (material: silicone rubber)

This cover reduces deterioration of the LCD due to sunlight (ultraviolet radiation). Use the

cover if the device is used in a place with strong sunlight (outdoors, etc.).

Cautions

Before mounting or removing the LCD cover, it is necessary to remove the face cover

from the main unit. Take care as you work not to touch sharp parts of the face cover,

such as the rim. You might be injured.

Handling Precautions:

Remove the face cover when checking the LCD.

• Pressure gauge elbows

The elbows are for mounting the pressure gauges if the device is installed in a place

with direct exposure to rainwater (outdoors, etc.). (If the pressure gauges are installed

facing upward, they will be damaged by rainwater.

Front Back

Figure 2-11 LCD cover Figure 2-12 Pressure gauge elbow

LCD cover

Pressure gauge elbow

Figure 2-13 Example of LCD cover and pressure gauge elbow mounting

2-11

Page 28

2-3-2 Pneumatic Piping Connection

Supply air

This section describes how to supply the air for the device to drive the actuator.

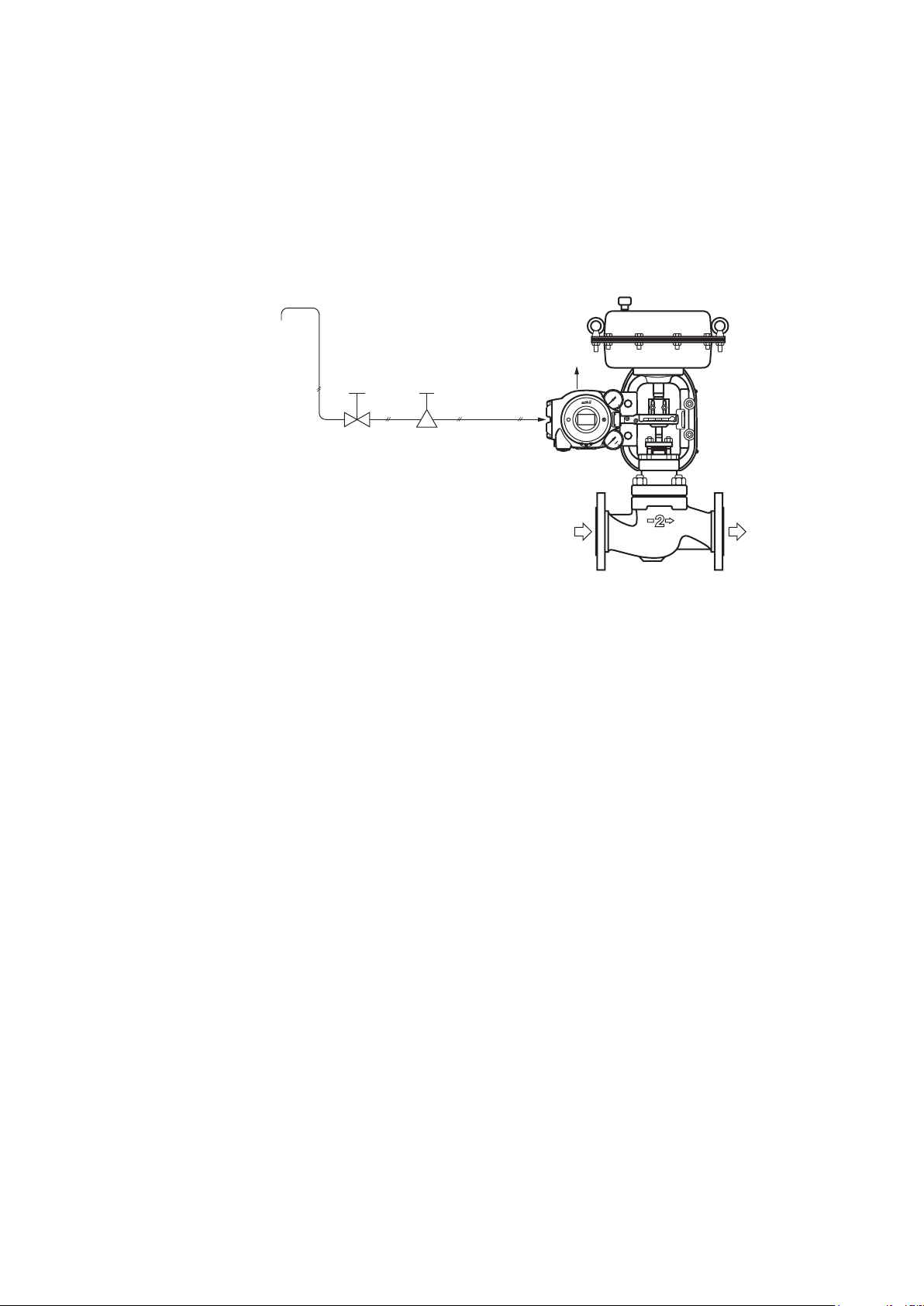

1) Air supply system

Supply air must be clean and dry to stably use the device for a long time. A typical

example of an air supply system is shown in the figure below.

Shutoff

valve

Regulator

with filter

Supply air piping

Output air

piping

Figure 2-14 Air Supply System

2) Supply air

Use supply air that conforms to the instrumentation air standards (on page 2-2).

3) Regulator with filter

• The regulator with filter is used to adjust the pressure of the supply air to the device.

• Install this valve as close to the main unit of the device as possible.

• The control valve can be manually operated by using the A/M switching function. (The

double-acting actuator does not support manual operation.)

• Use a 3-μm or finer filter.

• The filter removes solid materials from supply air.

• If the filter is not equipped, separately insert a (3-μm or finer) filter immediately before

the regulator.

• Install the regulator so that the drain faces downward.

• If you select the built-in Azbil regulator KZ03, the filter is built into the device before

shipment.

4) Shutoff valve

• The shutoff valve is used to temporarily stop supplying air to the device.

• With this valve, the device or control valve can be removed without having to stop the

whole air supply system during maintenance or other operations.

2-12

Page 29

5) Piping

Output air connection port (OUT1)

Supply air connection port (SUP)

Rc1/4 or 1/4NPT

• Use piping with an inside diameter of 6 mm.

• When using the device in a corrosive atmosphere, select piping appropriate to the

environment of the installation location. For example, you may use the vinyl-coated

copper pipe.

• To prevent air leaks, be sure to use a fitting that is appropriate for the pipe.

6) Connection positions

The positions of the supply air connection port and output air connection port are shown

in the figure below. Select the dimensions of the connection port screws according to the

specifications.

Rc1/4 or 1/4NPT

Handling Precautions:

Output air connection port (OUT2)

(For double-acting actuator)

Figure 2-15 Pneumatic Piping Connection

When connecting the electromagnetic valve for emergency shutoff, air

valve, or other part, install it between the output air connection and the

actuator rather than the supply air connection side of the device.

2-13

Page 30

7) Mounting procedure

The procedure for connecting pneumatic piping to operate the device is shown below.

Step Work

Connect the joint for piping to the connection port using seal

tape.

Handling Precautions:

1

- Use seal tape as the seal material. Avoid using solid

or liquid seal material if possible.

- Do not let the seal tape get in the piping.

- If you do use a liquid seal, make sure that no drops

of the seal material get in the piping.

Connect the supply and output pipes to each joint in

consideration of the arrangement of the piping.

Handling Precautions:

- For the double-acting actuator, the connection

between output air connection ports OUT1 and

2

3 After all piping is complete, make sure that air does not leak.

OUT2 and the actuator is determined by the

valve operation. Check the valve operation before

connecting pipes.

- Sufficiently flush piping before connection to prevent

burrs on the piping or other foreign objects from

getting in the piping.

- Keep the output air piping as short as possible.

2-14

Page 31

2-3-3 Electrical Wiring Connection

This section describes the methods for electrical wiring for signal input from the controller

and signal output to the monitoring system.

Turn the power off before starting wiring work. Otherwise, electric shock may occur.

When using the explosion-proof 700 Series in a dangerous place, be sure to connect the

wiring while following “Chapter 7 Precautions for the Explosion-Proof 700 Series.”

Be sure to perform grounding work following the electrical work guidelines in each region.

Handling Precautions:

Be sure to attach a blind plug to the unused conduit connection port so that it is

completely covered.

Warning

Cautions

1) Connection positions

The figure below shows the terminal block in the terminal box.

Terminal for output signals

M4 screw

Terminal for input signals

M4 screw

HART check pin

Terminal for external grounding

M4 screw

Terminal for internal grounding

M4 screw

Figure 2-16 Terminal Block in the Terminal Box

2-15

Page 32

2) Terminalforexternalgrounding

Connect the external grounding terminal to the case with two washers as follows.

Cable lug

Washer

Washer

Figure 2-17 Connection of External Grounding Terminal

3) Without motion transmission (model AVP702)

Remove the terminal box cover and connect the wires as shown in the figure below.

Controller

Ground

Figure 2-18 Electrical Wiring without Motion Transmission (2-conductor cable)

Use only one of the two ground terminals (internal or external) and perform the ground

work according to all local laws and ordinances governing electrical work.

4) With motion transmission (model AVP701)

Remove the terminal box cover and connect the wires as shown in the figure below.

Monitoring system

At least 250Ω

(current input)

Analog signal

DC4 - 20mA

Controller

*1

Ground

*1 : For the detailed information of the power supply and resistor,

please refer to the gure 2-18 of 2-3-4 Input Signals and Travel

Figure 2-19 Electrical Wiring with Motion Transmission (4-conductor cable)

• Use the following wiring method if the monitoring system is a voltage input (1 to 5 V)

device.

2-16

Page 33

Monitoring

1,484

(Ω)

Supply voltage E (V DC)

External load resistance

Operable range

system

(Voltage

250Ω min.

input)

Refer to the gure 2-18

*1:

Figure 2-20 Wiring when the Monitoring System Is a Voltage Input Device

• Use only one of the two ground terminals (internal or external) and perform the ground

work according to all local laws and ordinances governing electrical work.

2-3-4 InputSignalsandTravelTransmissionPower

1) Inputsignal

The input signals to this device are 4–20 mA DC. These input signals are also used as

the power source to drive the internal circuit.

Handling Precautions:

• Do not use any more than 24 mA DC.

• It will not operate properly with less than 3.85 mA DC.

1

*

Cautions

Do not apply the overvoltage to the terminals for the input signal. The overvoltage may

cause the failure of the device due to fire damage of the printed wiring boards.

2) TravelTransmissionPower

The travel transmission power is 17.9–45 V DC.

The load resistance of connections to the travel transmission loop should fall within the

operating range shown below for the power voltage to be used.

Handling Precautions:

Do not apply the travel transmission power than 45 V DC.

1,347

E - 12.5

R=

0.0219

525

R

247

*2

Operating

range

17.9 24 450

42

Figure 2-21 Supply Power Voltage/Load Resistance Features

2-17

Page 34

2-3-5 Cables

1) Selection and conditions of cables

The criteria for selection and the conditions of cables for wiring are described below.

• We recommend using 600-V plastic insulated sheath electric wire CVV (JIS C 3401 by

Japanese Industrial Standards) for control with a conductive cross-section of 1.25 mm

or a stranded cable with equivalent or higher performance.

• When routing cable in a place subject to electromagnetic noise, use shielded wire

CVVS (JCS 4258 by the Japanese Electric Wire & Cable Makers’ Association) and

metal conduits.

• Select a sheath material that withstands the cable installation environment (including

the ambient temperature, corrosive gas, and corrosive liquid).

• Use cable with an outside diameter of 7 to 12 mm. When using a pressure-resistant

packing cable adapter, be sure to use packing appropriate for the outside diameter of

the cable.

• A crimping terminal with insulated sleeve (for M4 screw) is recommended for terminals.

• The maximum permissible cable length is 1500 m.

2) Cable installation

Comply with the following when installing cables between this device and the actuator.

• Avoid installing cables near devices that generate noise such as large capacity

transformers, motors, or driving power sources.

2

• Do not install cables in the same tray or duct with other driving power cables.

• We recommend the use of electrical metal conduits and ducts to prevent water and

mechanical damage to electrical lines. Also, always use water-tight glands at conduit

connection ports.

• Use electrical metal conduits and ducts for locations exposed to electromagnetic noise.

• When using shielded cable, the cable must be connected to a single point ground on

the DCS side.

Handling Precautions:

ModelAVP701/702areintendedforuseinindustriallocationsdefinedinCE

markingdirective(EN61326-1).

2-18

Page 35

3) Wiring procedure

Cautions

The procedure for electrical wiring to operate the device is shown below.

Step Work

1

Loosen the locking bolts (M4) on the terminal box cover with a

hex wrench (3). (Rotate the screw clockwise.)

Rotate the terminal box cover counterclockwise to remove it.

2

3 Remove the dust-proof plug from the conduit connection port.

4

Handling Precautions:

Be careful not to damage the paintwork with a tool or other

object.

Insert the cable into the conduit connection port.

Handling Precautions:

Be careful not to damage the sheath of the cable.

Wire the cable to the relevant terminal in the terminal box.

Handling Precautions:

5

6

- Be careful of the polarity.

- Sufficiently tighten the terminal screw. The recommend

tightening torque is 1.5 N·m.

Apply sufficient waterproof treatment to the conduit to prevent

rainwater or other liquid from entering inside.

Handling Precautions:

We recommend using silicon non-hardening seal material.

Mount the terminal box cover, tighten it securely, and then

secure the cover by rotating the lock screw counterclockwise.

7

- Be careful not to get your finger caught in the clamp.

- Be careful not to hurt your finger with the edge of cover or

the screw threads of the main unit.

Handling Precautions:

Be careful not to damage the paintwork of the device with a

tool or other object.

Handling Precautions:

The input resistance for the AVP701/702 models must be the equivalent of 475 Ω

(600 Ω if equipped with overvoltage protection)/20 mA DC and the inter-terminal

voltage must be at least 9.5 V (12 V if equipped with overvoltage protection).

Check the controller's allowable load resistance and the output voltage. Note

that when the controller's allowable load resistance is less than 475 Ω (600 Ω

if equipped with overvoltage protection), an isolator or similar device should be

used.

2-19

Page 36

2-4 CableglandandflameproofuniversalelbowforTIISFlameproof

O-ring

Cable diameter

Cable diameter

apparatus

TIIS Flameproof SVP model is provided with a certified cable gland.

The cable gland seals the cable entering the SVP enclosure to withstand an internal

explosion and protects the cable from being damaged mechanically and electrically.

Use the dedicated elbow if it is necessary to change the direction of the cable with these

models.

Handling Precautions:

If the device is to be used under the authorization other than that for the TIIS

Flameproof standards, the wiring of cables must be performed according to local

regulations for electrical installations in explosive atmospheres.

1) Structure of the flameproof cable gland

The Flameproof cable gland is shown below in assembled and exploded views.

≥ 8mm

≤ 8mm

Clamp

(Lower)

Clamp

(Upper)

Cross recessed

head screws

Figure 2-22 Flameproof cable gland

Hexa-recess stopper screw

Body

O-ring

Washer

Gland

Coupling

O-ring

Hexa-recess stopper screw (Two)

Clamp

(Upper)

Cross recessed

head screws

Hexa-recess stopper screw (Two)

Gland

Coupling

O-ring

Union nut

Sealing ring

Washer

Union nut

Figure 2-23 Constituent elements of flameproof cable gland

2-20

Page 37

2) Structure of the flameproof universal elbow

Lock nut

The figure below shows the universal elbow.

O-ring

Elbow

Figure 2-24 Flameproof elbow

3) Mounting example

The flameproof cable gland and the universal elbow are used to connect the field wiring

cable to the device enclosure, as shown below.

a) Use of flameproof cable gland

b) Use of flameproof cable gland and elbow

Figure 2-25 Mounting example of flameproof cable gland and elbow

2-21

Page 38

4) Mounting procedure for flameproof cable gland

The procedure for mounting the flameproof cable gland is shown below.

Step Procedure

Securely screw the main unit of the adapter into the

conduit connection port of the terminal box or into the

flameproof universal elbow, and fasten the hexagon

socket bolt.

1

Handling Precautions:

Apply adequate waterproofing to these parts. We

recommend the use of silicone resin based nonhardening seal materials.

Refer to the illustrations and insert the cable carefully.

Warning

If the diameters of the cable and the packing do

not match each other, the propagation of flame

cannot be prevented. Refer to the table below

and select a packing adaptor whose internal

diameter matches the outer diameter of the cable.

Cable outer

2

Handling Precautions:

Pay attention to the surface of the device. Tools may

cause damage the surface.

Screw the gland into the main unit of the adapter to

secure it in place.

3

4

5

Pass the cable through the body and insert it into the

terminal box.

Screw the union nut onto the body and tighten it down

securely to hold it in place. Then, tighten the union nut's

recess screw.

diameter

(mm)

7.0〜8.0 8 Provided

8.0〜10.0 10 Built in

10.0〜12.0 12 Provided

The cable outer diameter is 8mm max., fix the cable

gland with the clamps.

To prevent injuries due to a spark travel, be sure

to tighten down the packing adequately.

Packing inner

diameter

(mm)

Warning

Notes

2-22

Page 39

5) Mounting procedure for flameproof universal elbow

Elbow

Lock nut

O-ring

Lock nut end face

The procedure for mounting the flameproof universal elbow is shown below.

Step Procedure

Align the end surface of the lock nut with the end surface of the

O-ring groove as shown below.

1

Figure 2-26 Arrangement of lock nut and O-ring

Screw the flameproof universal elbow into the terminal box

conduit connection port until the lock nut end surface hits the

connection port end surface.

When two elbow are used, at first, screw the first elbow into the

2

terminal box. Next, screw the second elbow into the terminal box

in the reverse direction to the first elbow.

O-ring groove

end surface

Handling Precautions:

Apply adequate waterproofing to these parts.

Turn the flameproof universal elbow to loose in the desired

direction.

3

Handling Precautions:

Do not loosen it more than 1 turn.

4

Lock the flameproof universal elbow in place by tightening down

the lock nut using the special tool.

2-23

Page 40

2-24

Page 41

Chapter 3 Operation of the 700 Series

This chapter describes how to start operating the device and adjust the device

using the local user interface (LUI). When you purchase the device alone, be

sure to read “Installation of the 700 Series” before reading this chapter.

Precautions for safe work

Warning

Do not perform wiring with wet hands or while the device is energized. This may lead to

electric shock. Turn the power off before starting the work and work with dry hands or use

gloves.

Follow the work procedure defined in the explosion protection guidelines when performing the

power distribution work in an explosion-proof area.

For devices equipped with the pressure-resistant, explosion-proof specifications, do not open

the cover during operation (while the power is on).

Cautions

Do not get on the installed device or use it as a step stool. This is dangerous because the

device may tip over.

Do not touch the device during operation without reason. This is dangerous because the

surface may be hot or cold depending on the usage environment.

Be careful not to touch the edge of the cover or the screw threads of the main unit when

opening the cover of the terminal box. You may be injured by these parts.

Use a DC power supply with overload protection. Overload may cause smoke or fire.

If a tool or other item touches the glass part of the display, it may break, leading to an injury.

Be careful. Wear safety glasses during work.

This product is heavy. Be careful where you step and wear safety shoes during work.

Do not touch the feedback lever or other moving part while the device is operating. You may

be injured by getting your hand or other body part caught in them.

Properly use the power supply based on the specifications. Inputting a different power supply

may damage the device.

Use gloves and other protective equipment during work in a hot, cold, or other severe

environment.

Do not move the device close to a magnet or magnetic driver. The control valve may operate.

Apply the correct supply air pressure in acoordance with the specification of the device. The

overpressure may cause abnormal actions of the control valve or damage to the pressure

gauge.

3-1

Page 42

3-1 Local User Interface (LUI)

socket bolts

Four push buttons on the LUI (with , , , and symbols) can be

operated by removing two screws ((2.5-mm) hexagonal socket bolts) from the

front cover of the device.

Front cover

Hexagonal

Operation

buttons

Figure 3-1 LUI Structure with the Front Cover Removed

Table3-1

Key input Monitor mode Setup mode

Switches between display categories. Goes to the next display.

Selects the next item.

Selects the previous item.

Switches between display categories. Goes back to the previous display.

Hold down Switches between setup mode and monitor mode.

Hold down Executes the function.

The LUI supports the monitor and setup modes.

In monitor mode, the normal, detailed and status are available. The normal

monitor can be used to monitor data such as opening and input signals and it

displays alarm information if a self-diagnostic alarm is issued.

To change from monitor mode to setup mode, hold down the

button. In

setup mode, operations such as auto setup and zero span adjustment can be

performed. Figure 3-2 shows a diagram of the LUI screen transition.

3-2

Page 43

The LUI displays the dynamic values in the device and can be used to adjust and

set up the following five functions.

• Auto setup function

• Zero span adjustment

• Supply pressure bypass function

• Specification of control parameters

• Setup of the control valve system

This section explains adjustment and setup using the LUI.

Handling Precautions:

- Operations cannot be performed from the host when you are using the LUI to

make adjustments or change settings.

- If there is an object near the operation button, remove it before operation.

- Please return display to the nomal monitor when you want to let you display

alarm.

Because you can not display alarm when let you display the monitor except

the normal monitor.

- Alarm and the present value are displayed at that time of the alarm outbreak in

turn.

- If you have made adjustments, make sure to verify them by checking device

operation. If you have also modified settings, make sure that they were

modified correctly.

3-3

Page 44

Normal monitor

Normal monitor

Monitor modeMonitor mode

Details monitorDetails monitor

Enter the password if a

password has been set.

Hold down

Status monitorStatus monitor

If you use another host or

communicator for communication

during setup, this screen is displayed

and the setup mode cannot be started.

Setup modeSetup mode

When the alarm is

activated in the nomal

monitor, the alarm

messages are displayed.

The codes are the same

as those of 5-2.

There is no loop that

goes back to AS

U.

As for the display variation, refer to Appendix A.

Figure 3-2

3-4

Page 45

3-2 Adjustment before Operation

Perform auto setup before using the device. Then, adjust the zero span if necessary.

The zero span adjustment function in the device electrically sets the fully closed and fully

open positions of the valve independently of each other. Therefore, you can adjust each

of these positions without interfering with the other one.

3-2-1 Auto Setup

There are two auto setup methods.

• Method using the LUI

• Method through HART communication

This section describes the method using the LUI. For the method through HART

communication and the details of auto setup, refer to Chapter 4.

Handling Precautions:

• The input signal should be 5 mA or more. If it is less than 5 mA, auto setup may

not operate normally.

• If any of the self-diagnostic messages shown in Table 4-5 in 4-2-20, “Diagnostic

Messages” appears, auto setup cannot be executed.

• Once auto setup and zero span adjustment are completed, always remember

to change the input signal and to check the opening, valve travel, and other

valve operations.

• Correctly set the actuator type and feedback lever position when fully closed

before starting auto setup.

• In some cases, the dynamic characteristic is not set correctly with the actuator

capacity, operation stroke, inner diameter of pneumatic piping and piping

length. If this occurs, refer to '4-2-5 Control Configuration' and adjust the

dynamic characteristic manually.

• When the actuator size is Custom, the size is not changed with the Auto setup.

When selecting the actuator size with the Auto setup, set the size as below.

Param 1 to 6 or

Param A to C.

• In some cases, the initial setting is not same even though the actuator and

valve size is same. Please perform the operation check and configuration of the

device if necessary.

• There is a possibility that the forced open value described on page '4-2-7

Travel Cutoff' may change after performing the Auto-setup operation. Please

reconfigure the forced open value if necessary.

• If the booster relay is on, and is operating the Auto-setup function, there might

be a possibility of hunting. In this case, adjust the booster's sensitivity, or refer

to '4-2-5 Control Configuration and adjust the dynamic characteristic manually.

• If a speed controller is incorporated, set it to full open and execute auto-setup.

Afterwards, adjust the speed with the speed controller.

• When the device is purchased separately, its initial settings are set to those

in the list of default values in '6-7 List of Default Values for Internal Data' of

this manual. Because the default actuator direction is reverse, if you mount

the device on the direct actuator the device will not work. Please be sure to

execute the auto setup program before operation and be sure that appropriate

settings are created in the device.

3-5

Page 46

Cautions

It is dangerous during auto setup because the fully closed valve moves to fully open. Be

prepared in advance to prevent injury and effects on the process when the valve moves.

The Actuator Type is set to Linear and the Valve Closed Position is set to Down when

the valve is fully closed at the time of shipment unless there are other shipment setup

instructions. If factory setting (initial setup) is requested, check the settings at the time

of shipment. Configure settings as needed.

If auto setup fails, refer to 5-1-5, “Auto Setup Failure.”

The reverse action actuator fully closes, fully opens, and fully closes the valve when

auto setup starts. The direct action actuator fully opens, fully closes, and fully opens the

valve.Then, it is opened to between 20% and 25% and between 80% and 85%.

After auto setup, the valve moves to the opening appropriate to the input signal.

Check the following points before starting auto setup.

• Actuator Type

Linear (standard): Direct-acting actuator

Rotary/90°: When the distance between the feedback lever of the

rotary actuator (90°) and the pin is longer than the

distance from the valve shaft

Rotary/Other: When the distance between the feedback lever of the

rotary actuator (around 60°) and the pin is longer than

the distance from the valve shaft

Rotary(sub)/90°: When the distance between the feedback lever of the

rotary actuator (90°) and the pin is shorter than the

distance from the valve shaft

Rotary(sub)/Other: When the distance between the feedback lever of the

rotary actuator (around 60°) and the pin is shorter

than the distance from the valve shaft

• Valve Closed Position

DOWN (standard)

UP

3-6

Page 47

(1) Procedure for performing auto setup

Step Work LUI display

Loosen two (2.5-mm) hexagonal socket bolts and remove

1

the front cover. (A sample initial setup status of the LUI

screen is shown.)

Press and hold the button to enter Settings mode.

2

3

4

5

The ‘FAIL’ signs in the auto setup operation are as follows.

FAIL00: The auto seuup is failed. (The valve does not move, etc.)

FAIL01: The input signal is low level.

FAIL02: A function except for the auto setup is in operation.

FAIL90: The auto setup is forcibly shut down. (Auto setup was stopped from the LUI.)

For countermeasures for these problems, refer to 5-1-5, “Auto Setup Failure.”

Enter the password if prompted to do so. For how to set the

password, refer to "3-2-5 Password". To change Actuator

Type or Valve Closed Position, refer to step (3).

Wait until the input signal becomes at least 5 mA and press

the

is displayed and press and hold the

perform auto setup.

The valve, which is initially fully closed, is fully opened and

fully closed again. Then, it is opened to between 20% and

25% and between 80% and 85%. After the valve operation

ends, the LUI screen changes and the opening appropriate

to the input signal is set.

When you press the button, the initial screen of the

auto setup is displayed again.

button once. Check that the screen on the right

button again to

(2) Procedure for aborting auto setup

Step Work LUI display

1 To abort auto setup during execution, press the

2

3

Holding down the button aborts the execution.

If auto setup is aborted, data is not saved.

When you press the

again.

button, the screen on the right is displayed

button.

3-7

Page 48

(3) Procedure for specifying Actuator Type and Valve Closed Position

Step Work LUI display

Display the screen on the right by repeatedly pressing the

1

2 Press the button.

and button.

Select an appropriate actuator type with the

3

buttons and press the

Select an appropriate feedback lever position when the

4

5

6 Go back to the desired menu with the and buttons.

valve is fully closed with the

down the

The specified actuator type and feedback lever position when

the valve is fully closed are displayed. Check the settings.

button to set that position.

button.

and buttons and hold

and

3-8

Page 49

3-2-2 Zero Span Adjustment

After auto setup, check the 0% and 100% positions. If adjustment is required, adjust the

zero span.

The following two zero span adjustment methods are available.

• Method using the LUI

• Method using HART communication (This method is further broken down into the

following four methods.)

- Auto Travel Calibration

- Angle Correction

- Manual Setting

- Change Travel Angle

This section describes the method using the LUI. For the method using HART

communication, refer to Chapter 4.

Handling Precautions:

If you adjust the span after auto setup, the forced fully opening value is

automatically changed to the value calculated by subtracting 1% from the

overstroke percentage.

Cautions

Then zero span adjustment is dangerous because of valve action. Take measures in

advance to prevent injury to personnel and effects on the process in case the valve

operates.

(1) Procedure for adjusting the zero span

Step Work LUI display

1

2

3

Loosen two hex socket bolts (2.5 mm) to remove

the front cover.

Press and hold the

mode. Enter the password if prompted to do so.

For how to enter the password, refer to "3-2-5

Password".

Press the button to display the screen on the

right (ADJ).

button to enter Settings

3-9

Page 50

Step Work LUI display

Press the

angle for 100% or 0% opening with the

buttons, and press the button. (Refer to

“(2) Procedure for adjusting the angle.”)

4

(2) Procedure for adjusting the angle

Step Work LUI display

1

To manually adjust each opening rather than

using the opening adjustment function, select

manual adjustment for 100% opening (0%

opening) with the

the

manual adjustment.”)

Select the angle (COARSE, MID, FINE) for 100%

opening adjustment (0% opening adjustment)

with the

button.

button, select whether to adjust the

and buttons and press

button. (Refer to “(3) Procedure for

and buttons and press the

and

(100% opening angle adjustment)

(0% opening angle adjustment)

(100% opening manual adjustment)

(0% opening manual adjustment)

COARSE: Angle 1°

MID: Angle 0.1°

FINE: Angle 0.01°

Adjust the angle by pressing the

2

increase the opening and pressing the

to decrease the opening.

button to

button

( )

( )

Pressing the

opening and output air pressure (Pout1). Check

3

that the angle is properly adjusted.

If further adjustment is required, go back to the

adjustment screen with the

button displays the current

button.

( )

3-10

Page 51

(3) Procedure for manual adjustment

Step Work LUI display

1

2 Press the button.

3

Manually specify the desired position for 100%

opening (0% opening).

Check that the desired position is selected and

then hold down the → button. This adjusts the

100% opening (0% opening).

( )

( )

(

)

3-11

Page 52

3-2-3 Supply Bypass

Supply bypass allows the valve to be fully closed and opened and enables operation with

the regulator.

(For double-acting actuators, the valve can only be fully opened or closed.)

When the supply bypass operates, it is dangerous because the valve moves. Be

prepared in advance to prevent injury and effects on the process when the valve moves.

(1) Procedure for supply bypass

Step Work LUI display

Cautions

1

2

3

4

Loosen two (2.5-mm) hexagonal socket bolts and

remove the front cover.

Hold down to enter setting mode. If a

password is required, enter the password.

For details on password entry refer to 3-2-5,

“Password.”

Press the

on the right.

Press the

on the right. To set the output air pressure to 0,

hold down the

(If the output air pressure is already 0 or it is set

to the supply air pressure at the supply bypass,

go to the screen of step 7 where the supply

bypass can be operated.)

To change the output air pressure to the supply

button to display the screen shown

button to go to the screen shown

button.

5

6

7

8

9

air pressure, press the

screen on the right and hold down the

If supply bypass conditions (e.g. the input signal

is less than 5 mA) are not satisfied, the screen on

the right is displayed.

If supply bypass conditions are satisfied, the

screen shows that each bypass operates.

To clear supply bypass operations, press the

button to display the screen shown on the right.

Holding down the button clears the supply

bypass.

button to display the

button.

3-12

Page 53

The ‘FAIL’ signs in the supply bypass operation are as follows.

FAIL01: The input signal is low level.

FAIL02: A function except for the supply bypass is in operation.

FAIL90: The auto setup is forcibly shut down.

3-2-4 Control Parameters

Control parameters are determined by Actuator Size (Param 1 to 6, A, B, C) and

Friction Level (Light(L), Medium(M), Heavy(H)).

Actuator Size Stroke Speed[s] Actuator Model

PARAM C to 0.25 - 200

PARAM B to 0.35 - 300

PARAM A to 0.45 - 400

PARAM 1 to 0.85 PSA1, PSK1 600

PARAM 2 to 2.0 PSA2, HA2 1400

PARAM 3 to 6.5 PSA3, HA3 2700

PARAM 4 to 8.15 PSA4, HA4 6600

PARAM 5 to 12 PSA6 8100