Page 1

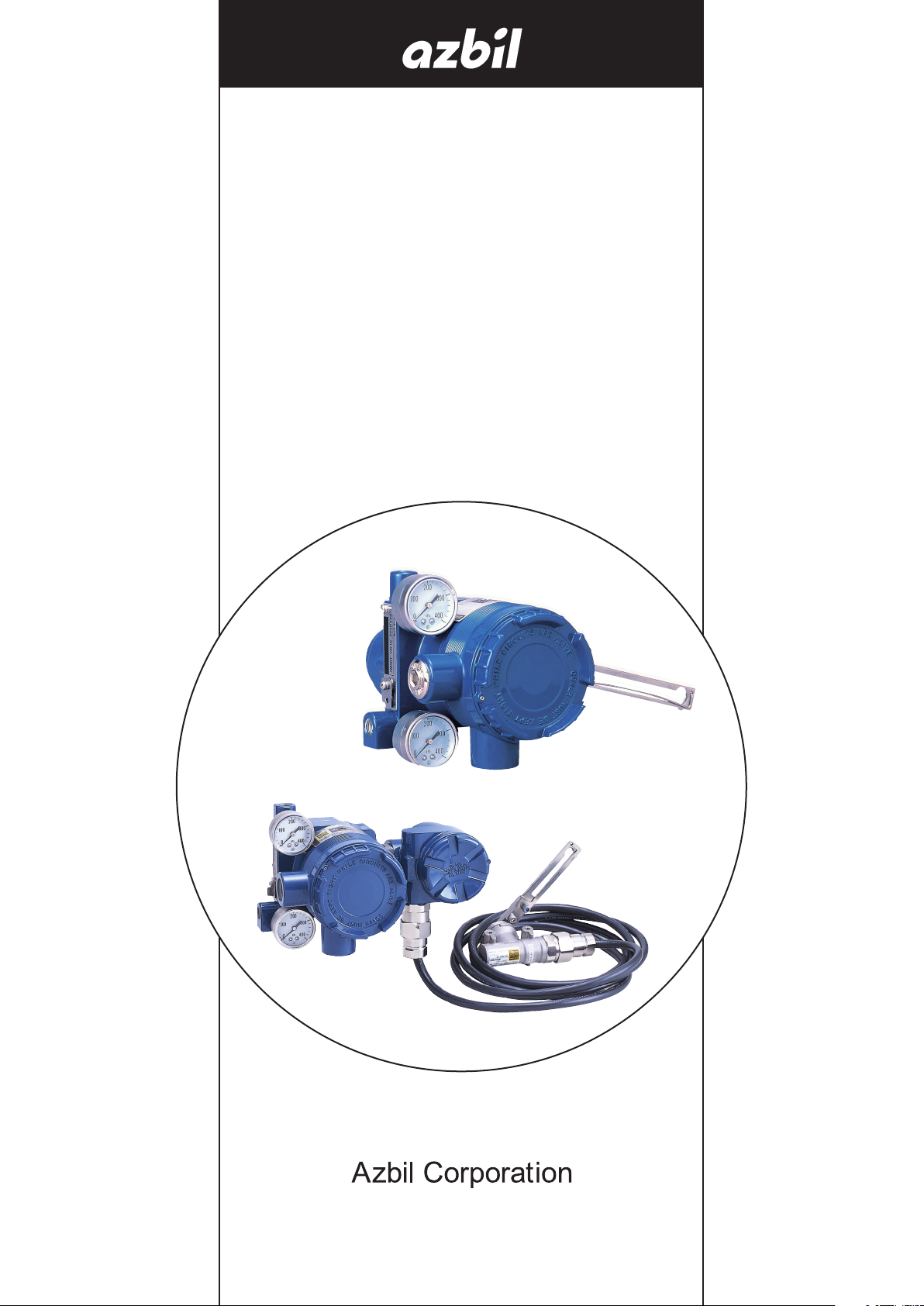

Smart Valve Positioner

CM2-AVP300-2001

300

Series

Model AVP300/301/302 (Integral Type)

200 Series

Model AVP200/201/202 (Remote Type)

User's Manual

Page 2

NOTICE

• Make sure that this manual is available to the user.

• Reproduction or transmission of this manual, in whole or in part, is

prohibited.

• e descriptions in this manual are subject to change without notice.

• It is our hope that this manual is complete and accurate, but in the event

that there is content which is incomplete or whose accuracy is in question,

please contact us.

• Please understand that we cannot in some cases accept responsibility for

the results of use of this equipment by the customer.

• HART® is a trademark of FieldComm Group.

©1998–2017 Azbil Corporation All Rights Reserved.

Page 3

Introduction

Introduction

■ Introduction

Thank you for purchasing an Azbil Corporation Smart Valve Positioner 200/300 Series.

Smart Valve Positioner 200/300 Series (the devices) can be connected to a 4 to 20 mA

signal line. Since all adjustments can be performed electrically using CommStaff, any

desired relationship can be set between the input signal and the position of the control

valve. Split range and other special settings are also easy to specify. This manual describes the use of the Smart Valve Positioner. Use this manual to get the most from the

features of the device.

i

Page 4

Safety precautions

■ Symbols

These safety precautions are intended to help you to use the product safely and correctly, and to prevent injury to yourself or others as well as damage to property. Be sure

to follow all safety precautions.

This manual makes use of a variety of symbols. The symbols and their meanings are as

follows. Gain a good understanding of this information before reading the main text of

this manual.

Cases in which it is conceivable that dangerous situations might arise

Warning

Caution

in which the user of the product could be seriously or fatally injured

if the product is misused.

Cases in which it is conceivable that a dangerous situation might

arise in which the user of the product could sustain minor injuries, or

physical damage could occur, if the product is misused.

■ Examples of visual indicators

This indicates a warning or caution that the user should be aware of during use.

This indicates a prohibited action.

This indicates an instruction that the user should be sure to carry out.

ii

Page 5

Cautions to ensure safe operation

Do not perform wiring work, turn on the electricity, etc., when your hands are wet. There is a risk of

electric shock. Perform this work with the power supply turned off, and with dry or gloved hands.

When wiring in a hazardous area, work according to the methods prescribed by the guidelines for the

hazardous area.

For flameproof explosion-proof specifications, do not under any circumstances open the cover during

operation (when powered up).

After installing the device, do not place your body weight on it, use it as a scaffold, etc. There is a risk that

it could fall over.

Introduction

Warning

Caution

Do not touch the device unnecessarily while it is in operation. Depending on the environment in which

the device is used, there is a danger that the surface of the device may be very hot or very cold.

When opening the cover of the terminal box, be careful of the edges of the cover, the threads of the

screws on the main unit, etc. There is a possibility of injury.

Use a DC power supply that has overload protection. An overload can cause the emission of smoke and

fire.

Bringing tools and the like into contact with the glass portion of the display can cause damage or injury.

Exercise sufficient caution. In addition, be sure to wear safety glasses.

As this product is extremely heavy, watch your footing, and be sure to wear safety shoes.

When the device is in operation, do not touch moving parts such as the feedback lever. Your hand may

become caught, resulting in injury.

Supply power correctly based on the specifications. An incorrect power input can damage the instrument.

When working in a high-temperature or low-temperature environment, wear gloves and other protective

equipment.

Do not bring magnets or magnetic screwdrivers near the device. There is a possibility that the control

valve will move in response.

iii

Page 6

Basic use

■ Basic model number structure

Model AVP 0

0: No transmission

1: With travel transmission (4 to 20mA DC or DE transmission)

2: HART

0: Fixed

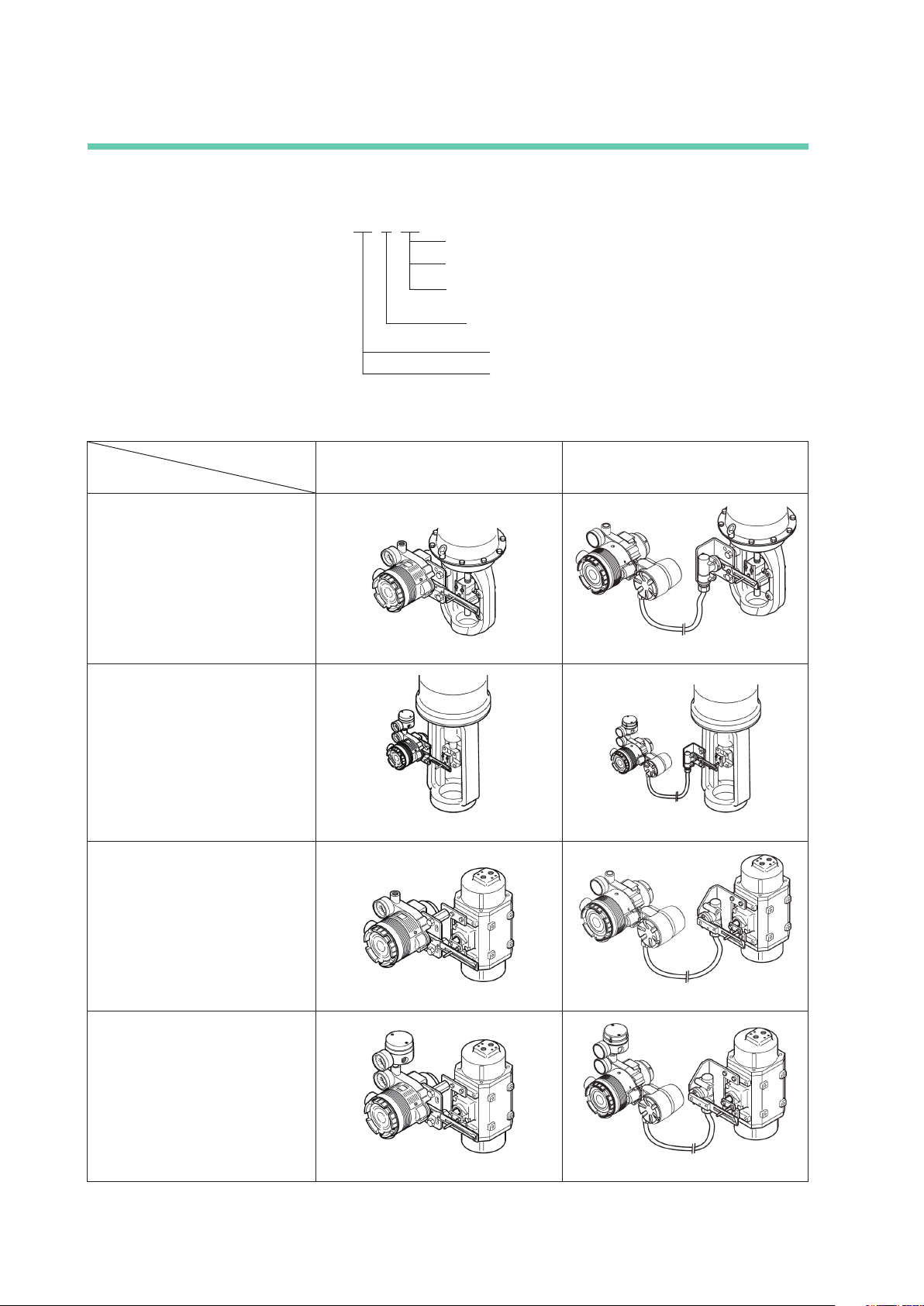

■ Positioner and Actuator Types

® protocol communication

2: Remote type

3: Integral type

Positioner Type

Actuator Type

Single-acting linear diaphragm (Azbil

Corporation actuator model numbers:

PSA, HA, HK, VA, VR, RSA, GOM)

Double-acting linear cylinder (Azbil

Corporation actuator model numbers:

VP, SLOP, DAP)

Single-acting rotary cylinder

(actuator for ball valves and butterfly

valves)

Model AVP300/301/302

(Integral Type)

Model AVP200/201/202

(See p. v.) (See p. xiii.)

(See p. vii.) (See p. xvi.)

(Remote Type)

Double-acting rotary cylinder

(actuator for ball valves and butterfly

valves)

(See p. ix.) (See p. xix.)

(See p. xi.) (See p. xxi.)

iv

Page 7

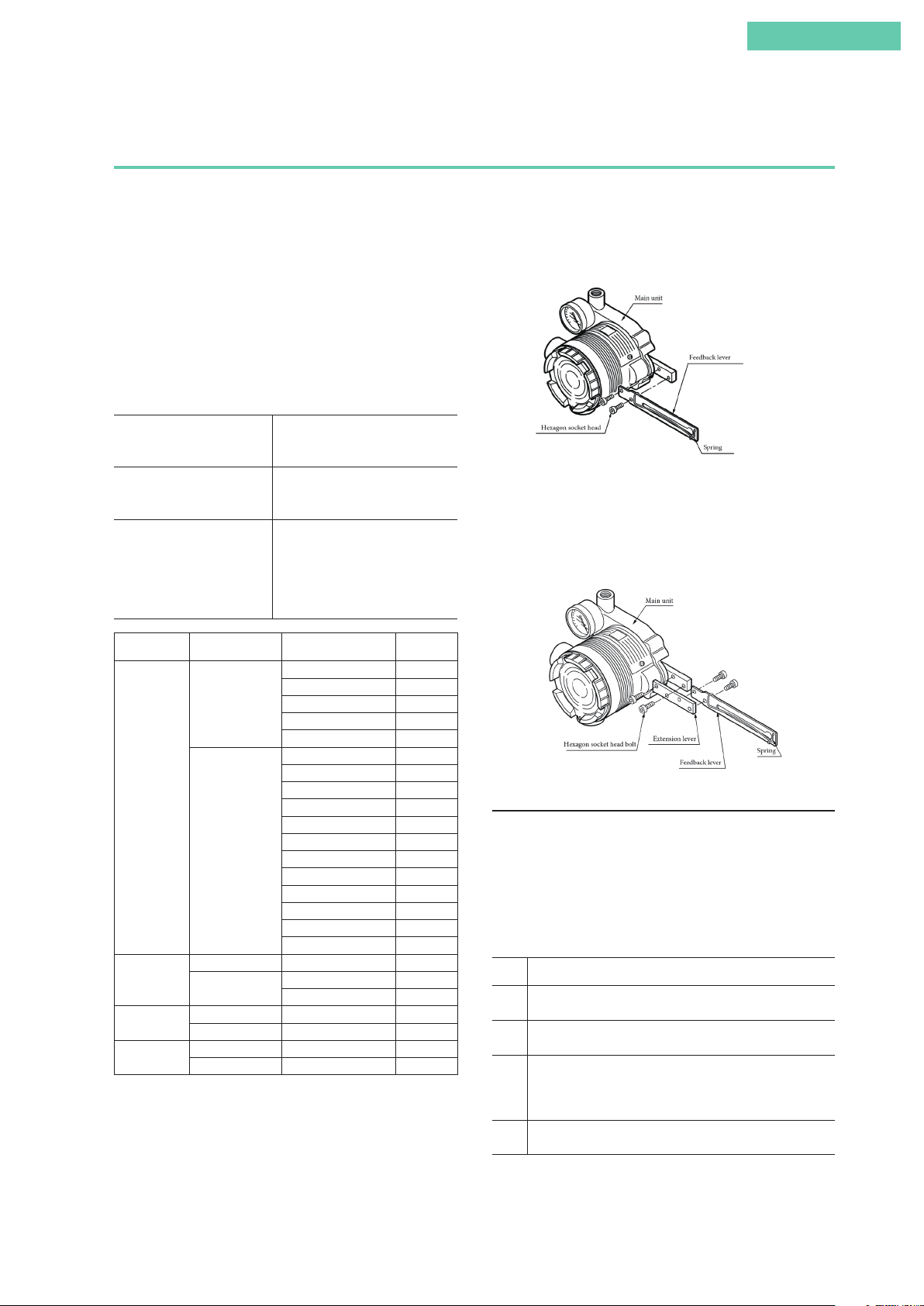

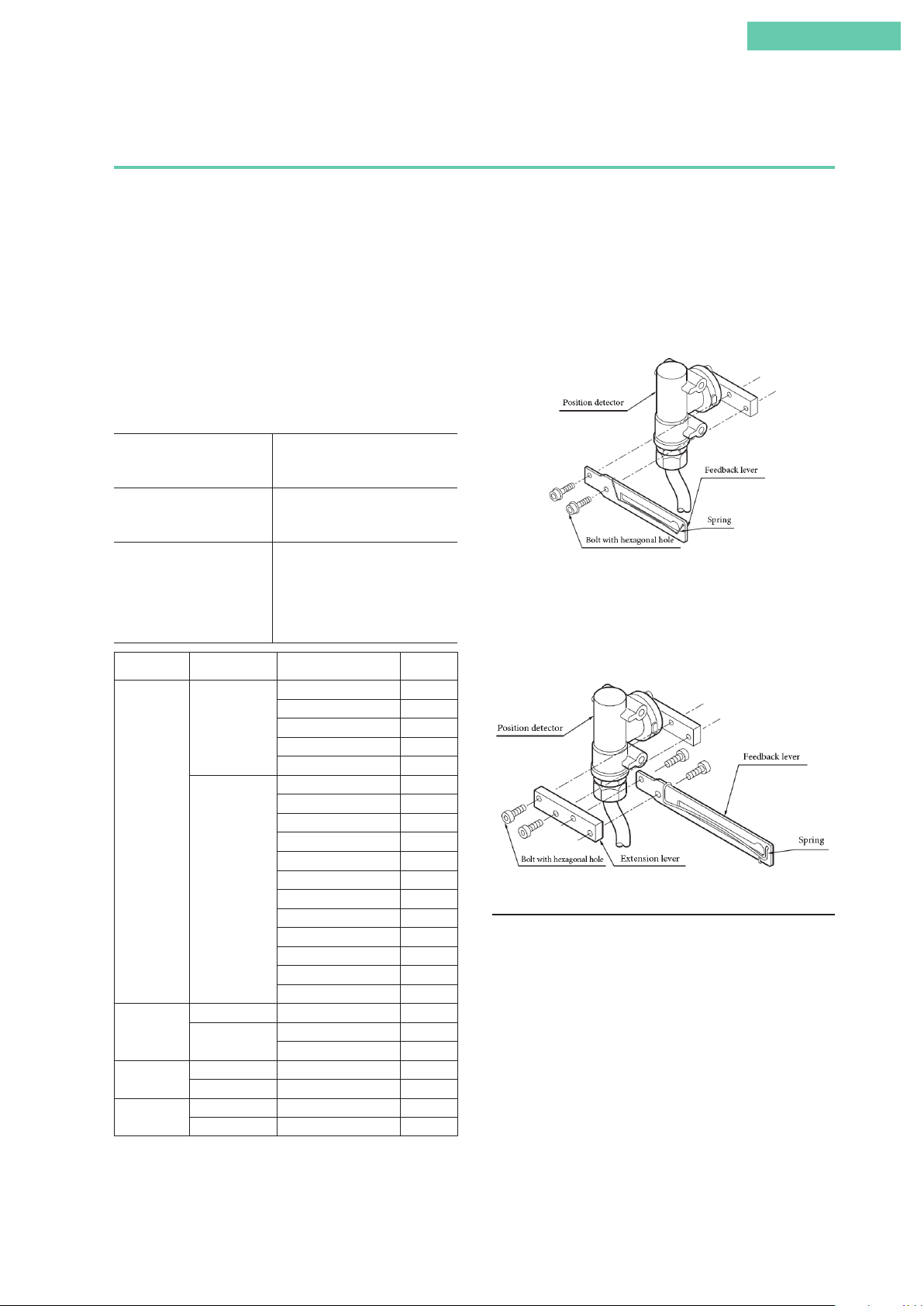

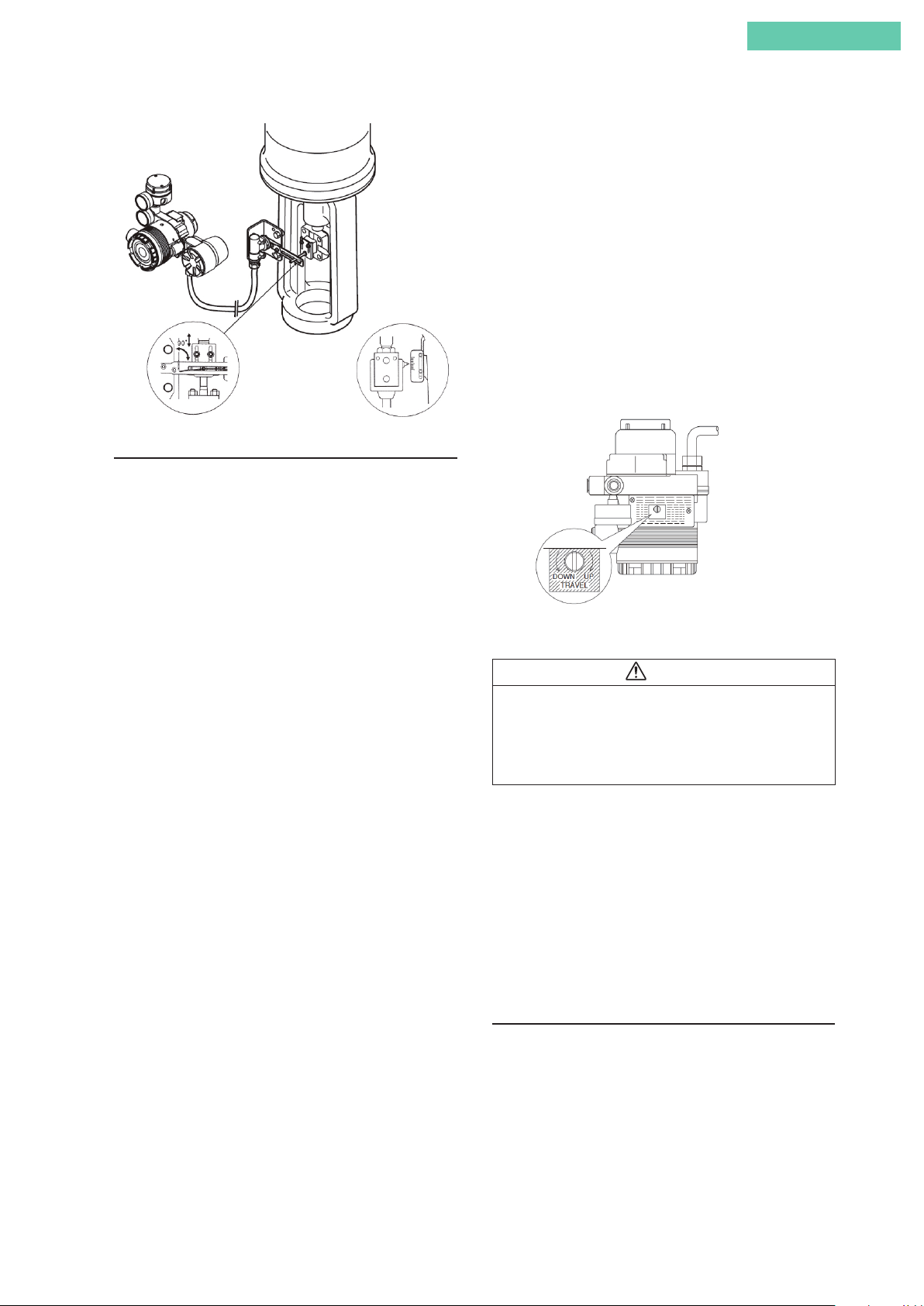

Combination of model AVP300/301/302 (integral type) and single-acting linear

diaphragm actuator

Introduction

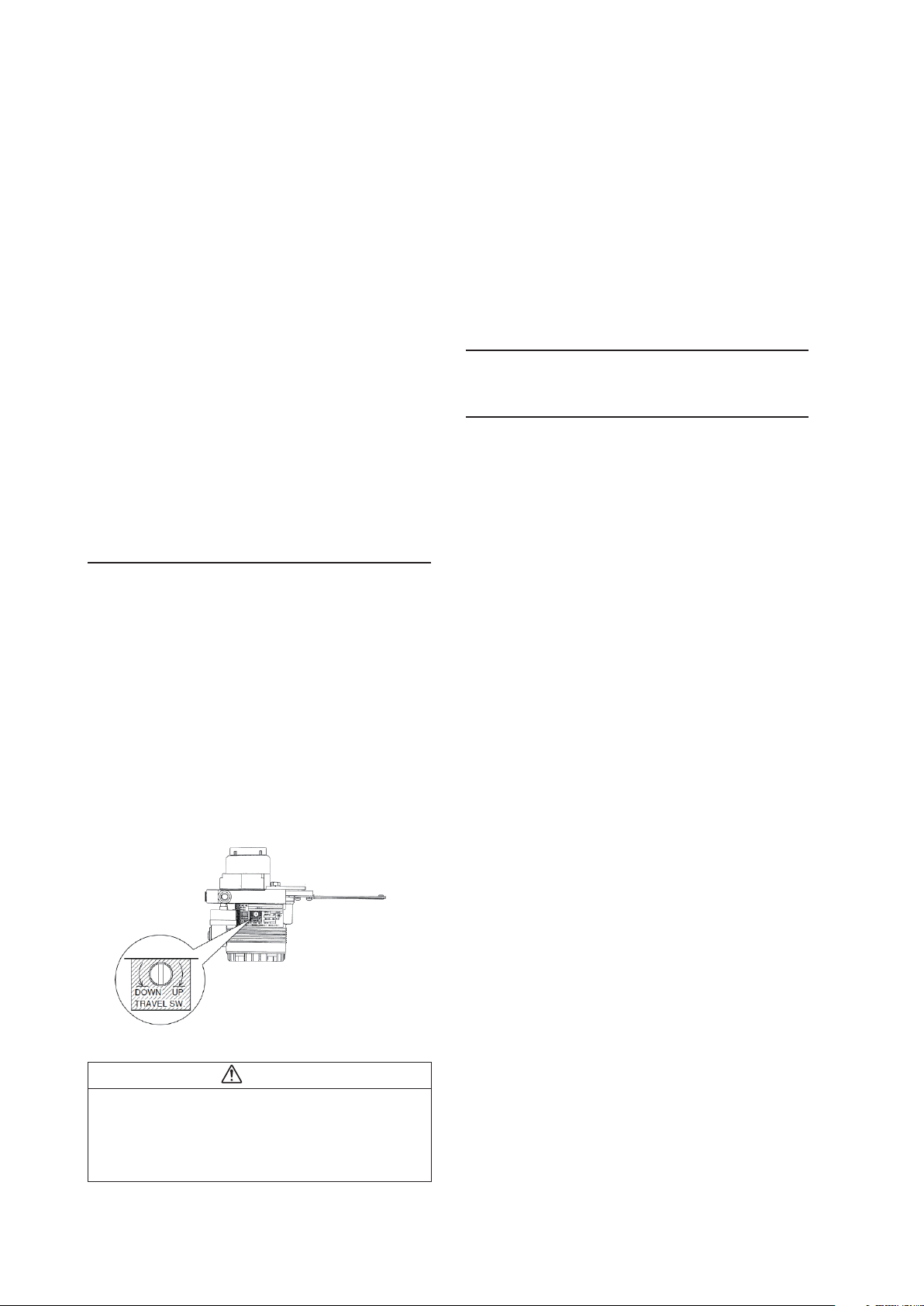

1. Attachment of feedback lever

In order to minimize the risk of damage to the feedback lever

while it is carried or transported, and to minimize the packaging as well, the feedback lever is detached from the body of

the device when it is packed. As a result, the feedback lever

must be attached to the body of the device prior to installation of the device.

The length of the feedback lever can if necessary be adjusted

by attaching the extension lever between the feedback lever

and the body of the device. Adjustment of the feedback lever

length is determined based on the form of the actuator.

If the actuator type is specified

when ordering, and the

extension lever is included:

If the actuator type is specified

when ordering, and the

extension lever is not included:

If the actuator type is not

specified when ordering:

Manufacturer Extension Lever Actuator Type Code

No

Azbil

Corporation

Ye s

No #240, #280, #330 TA, TD

Motoyama

Masoneilan

Nihon Koso

Ye s

No #11, #13 MA, MB

Ye s #15, #18 MC, MF

No #270, #320 TA, TD

Ye s #400, #500 TB, TE

When connecting an actuator other than those in the table,

connect the device and the actuator, and then switch to

manual mode and move the actuator slowly and ensure that

the feedback lever does not interfere with the full stroke of

the actuator.

Attach the extension lever to the

body of the device, and then attach

the feedback lever.

The extension lever is not necessary.

Attach the feedback lever directly to

the body of the device.

The extension lever will be

included. Refer to the table below

to determine, based on the actuator

with which the device is equipped,

whether or not the extension lever

is necessary.

PSA1, 2, PSK1 YS

HA1 YA

HA2, 3 YT

HK1 YK

VA1 to 3 YQ

PSA3, 4 YQ

PSA6 YL

HA4 YN

PSA7 Y8

VA4 to 6 YL

RSA1 YF

RSA2 YU

VR1 YV

VR2, 3 YR

VR3H Y6

GOM83S, 84S, 103S YG

GOM124S YM

#400, #500S, #500L TB, TE

#650S, #650L TC, TF

If the feedback lever alone cannot cover a full stroke, attach

the extension lever to it.

Attach the feedback lever securely, working from the front of

the device, using the two included hexagon socket head bolts.

Attachment of Feedback Lever

Attach the extension lever securely, working from the front of

the device, using the two included hexagon socket head bolts.

Then, in the same way, attach the feedback lever securely,

working from the back of the device. (The feedback lever can

be attached from the front as well.)

Attachment of Extension Lever and Feedback Lever

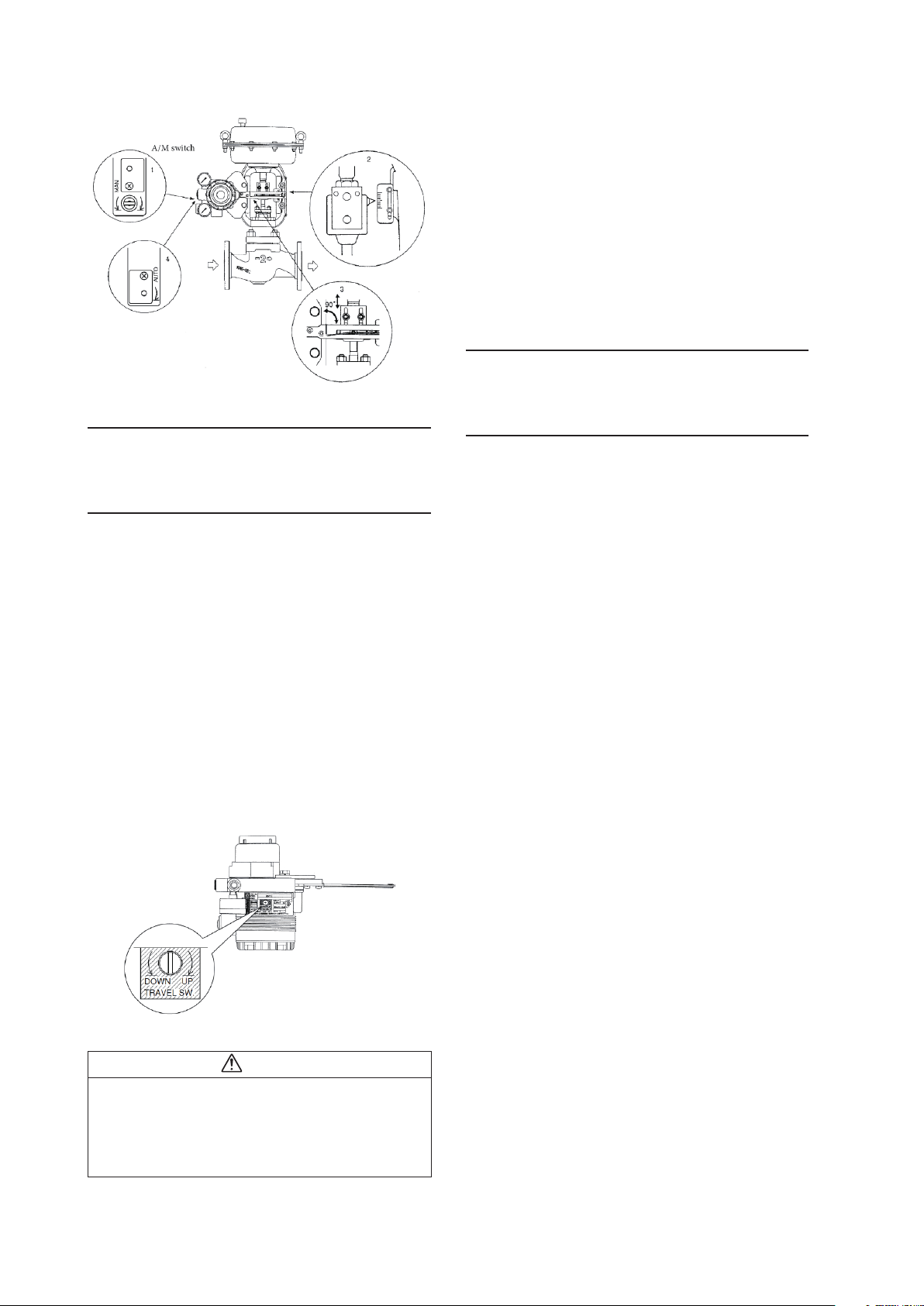

2. Attachment and installation

[1] Attachment to the actuator

Attach to the actuator with a mounting plate that is appropriate for the actuator.

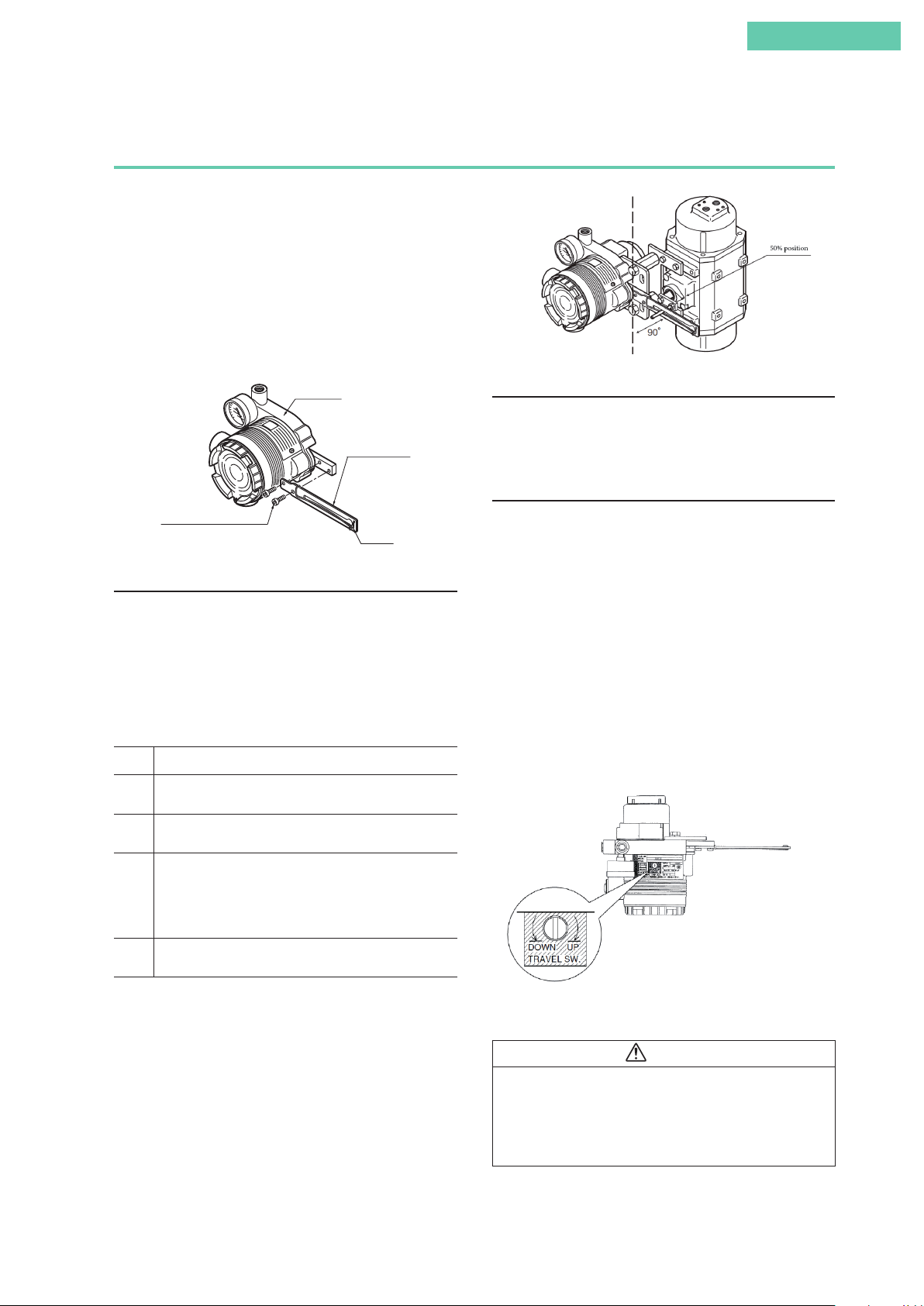

[2] Adjustment of attachment positions

Procedure for adjustment of attachment positions

Step Procedure

1 Set the A/M switch to manual operation.

(See 5.2, “A/M Switch.”)

2 Supply air, and adjust the actuator air pressure such that the

actuator stem reaches the travel midpoint.

3 Adjust the actuator such that the feedback lever reaches a

90° angle to the device's central vertical axis. Depending on

the actuator being used, adjustment may be performed by

moving the device, or it may be performed by moving a pin.

4 Set the A/M switch to automatic operation.

(See 5.2, “A/M Switch.”)

Note: The accuracy specifications can be satisfied by making

the attachment angle 90° ±2°.

v

Page 8

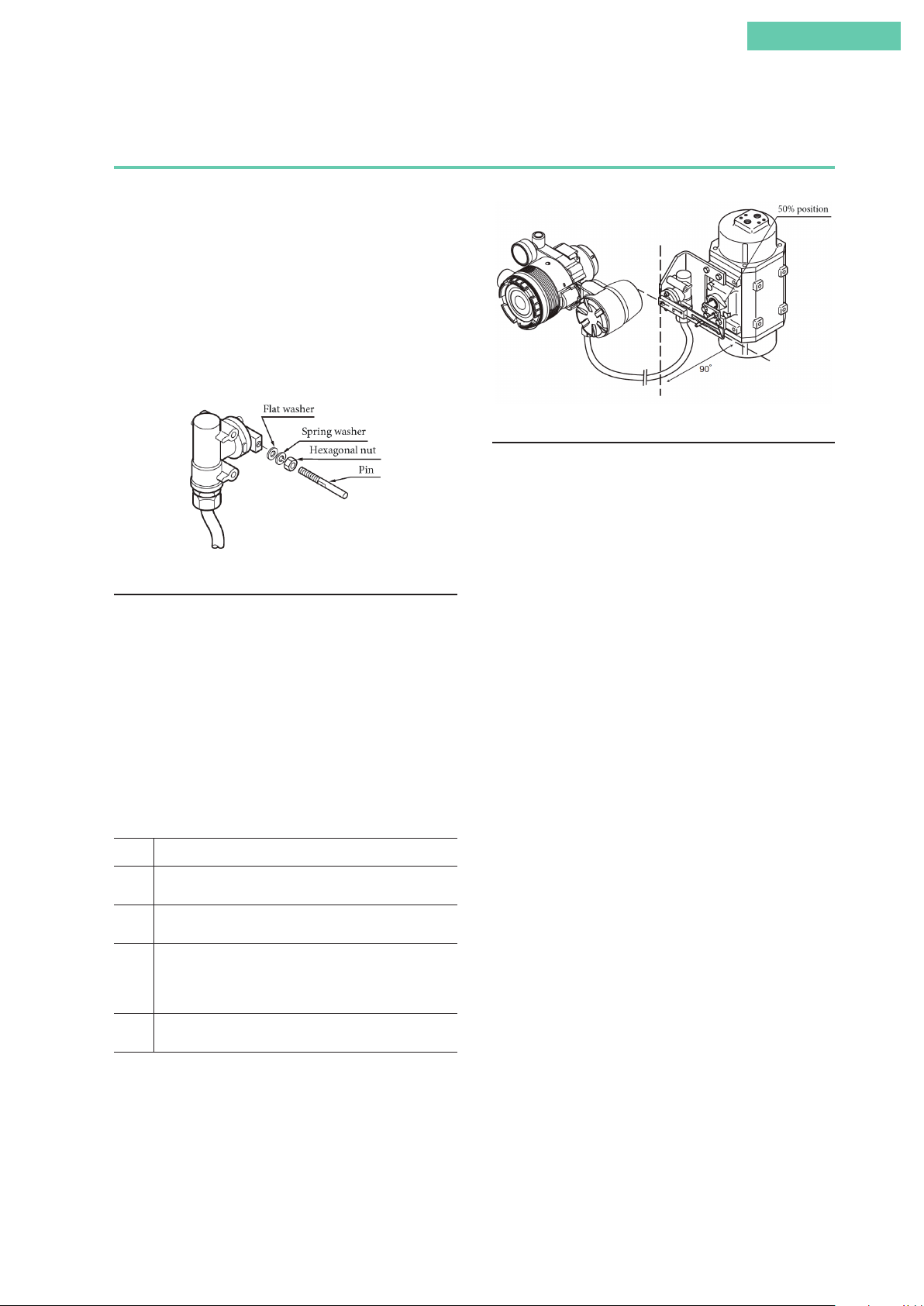

Adjustment of Attachment Positions

Check the span point and perform span adjustment.

(1) Set the input signal to the span point (URV). (Zero ad-

justment can be performed if the input signal is adjusted

to the zero point, and span adjustment can be performed

if the input signal is adjusted to the span point.)

(2) Using a flat-blade screwdriver, turn the external zero

span adjustment switch on the upper part of the case UP

(clockwise) to cause the valve to move such that the feedback lever rises upward, or turn it DOWN (counterclockwise) to cause the valve to move such that the feedback

lever drops downward.

5. Operation confirmation

Vary the input signal, and check the zero point and span

point.

3. Air piping and electric wiring connection

Connect the air piping and electrical wiring.

For details, see 2.2, “Installation Method,” in this document.

4. Auto-setup

(1) Set the input signal to 18 ±1mA.

(2) Using a flat-blade screwdriver, turn the external zero/

span adjustment switch in the upper part of the case 90°

in the UP direction (the DOWN direction for Azbil Corporation's VR and RSA actuators for VFR type control

valves), and hold that position for three seconds.

Note: For reverse close (when the valve's fully closed position is on top), set the valve action to reverse close beforehand. See 4.4.3, “Valve system”

(3) The valve will automatically start to move, and will stop

in about 3 to 4 minutes.

(4) When it stops, adjust it to a position that fits the input

signal.

(5) After that, check whether it has been adjusted correctly.

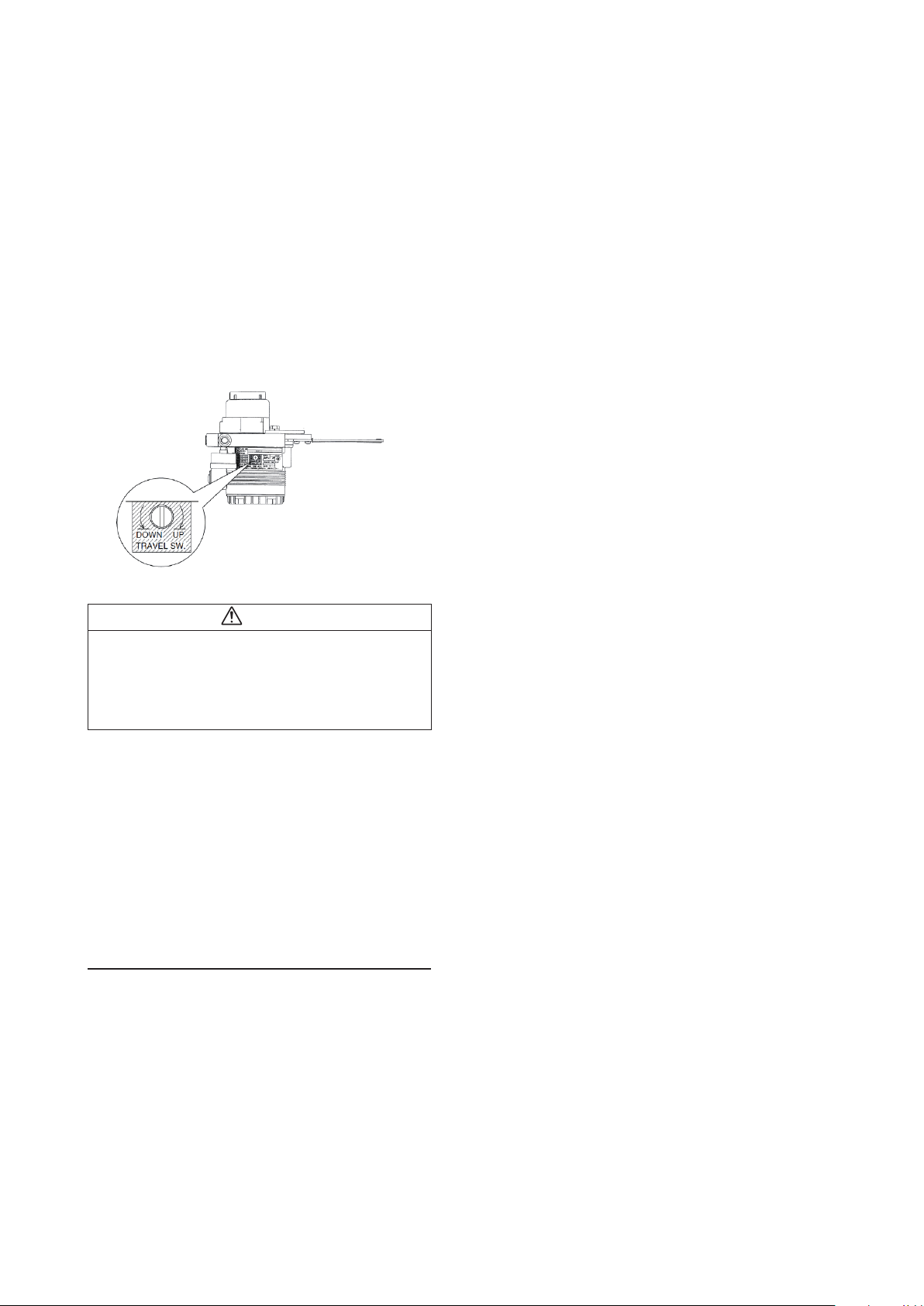

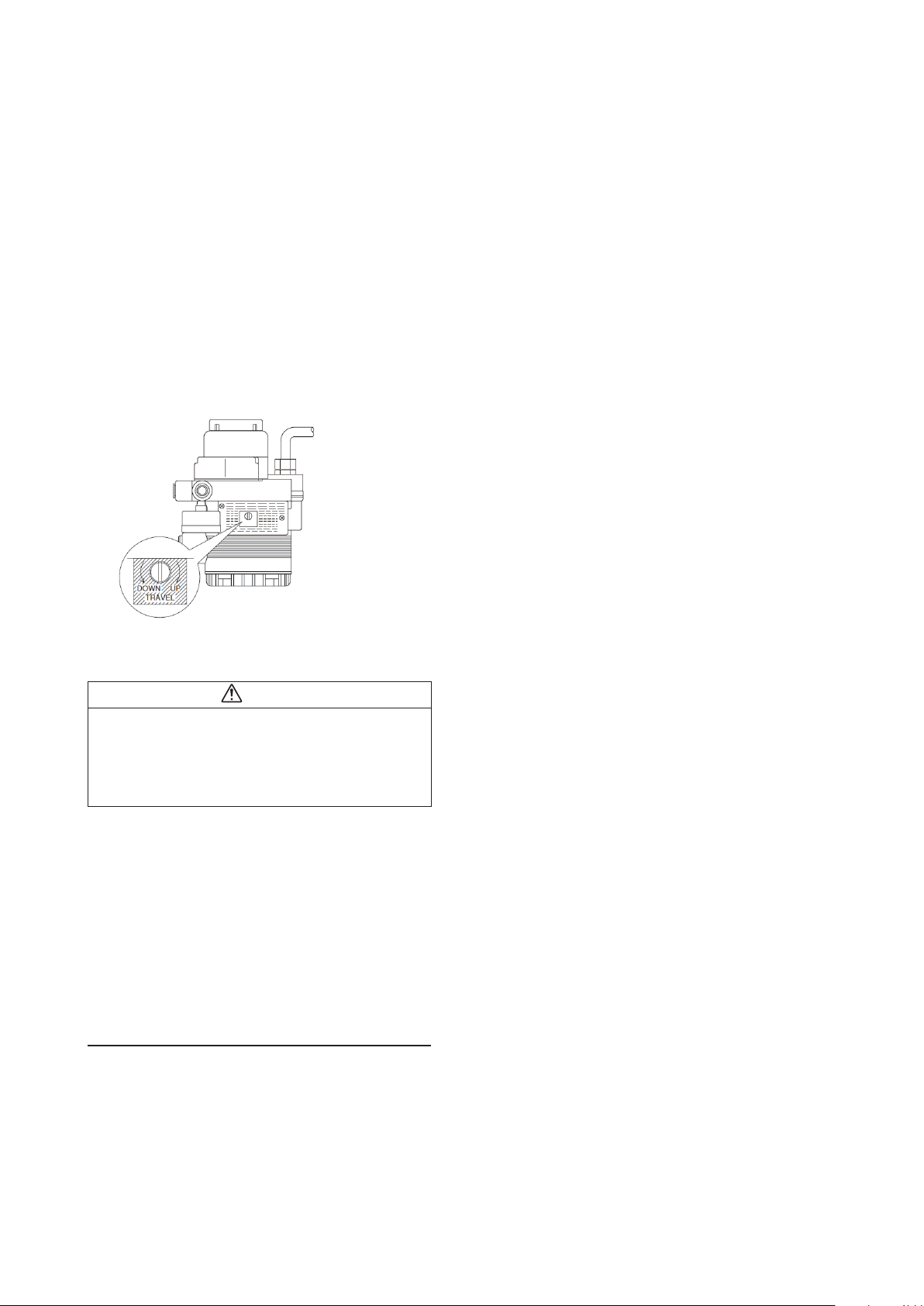

If performing auto-setup

DOWN direction:

VFR type

UP direction: direct type

External zero/span adjustment switch

Note: When closing the

valve of the single-acting

type device with the lever

in the upward direction,

first set it to reverse close.

• Auto-setup can be performed with CommStaff as well.

Warning

When auto-setup is performed, the valve moves from fully

closed to fully open, so there is a danger of, for example,

getting your hand caught or affecting the process.

Before performing auto-setup, move away from the valve,

and confirm that the process is safe.

6. If suitable adjustment was not accomplished

[1] If auto-setup does not operate

• Check whether the input signal is 18 mA ± 1 mA.

• Check whether the A/M switch is set to automatic. If it is

set to manual, switch it to auto. See 5.2, “A/M Switch,” in

this document for information on operating procedures.

• Check the duty value of the electro-pneumatic module.

Regarding the confirmation method, see “EPM (electropneumatic module) operation confirmation procedure” on

page 3-9 in this document.

• Check whether the electronics module (terminal block) is

installed correctly in the case on the body of the device.

[2] If hunting occurs

• Using the setup device, either change the actuator size

(Param) or individually set the valve position control PID.

Regarding the configuration method, see 4.4.4, “Control

configuration,” below.

[3] If the zero point floats or span adjustment cannot be

performed

Referring to Table 3-1, “Integral type setting,” in 3.1, “Autosetup,” in this document, check whether valve action is

configured correctly. If not, it will be necessary to change the

valve action (the direct/reverse setting). Referring to 4.4.3,

“Valve system,” in this document, configure the valve action

correctly.

[4] If linearity characteristic is poor

• Check whether, when the attachment position of the feed-

back lever is the 50% opening position, it is attached horizontally. If not, refer to 2.2, “Installation Method,” in this

document and correctly attach the feedback lever.

• Check the flow rate characteristics data. If equal%, quick

open, or the like has been specified, and these are fundamentally unnecessary, refer to 4.4.6, “Flow Type,” in this

document and change this setting to linear.

vi

Page 9

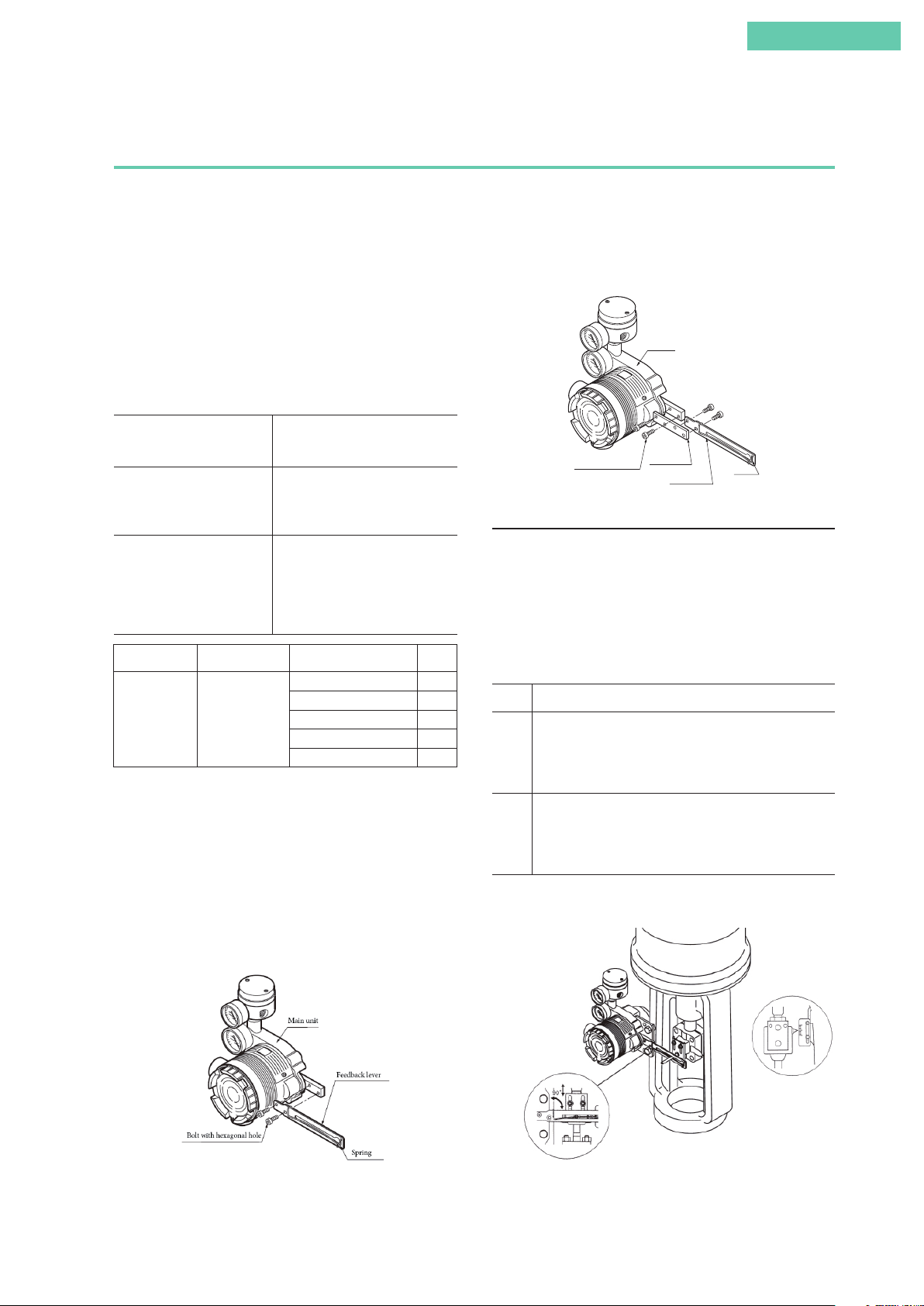

Introduction

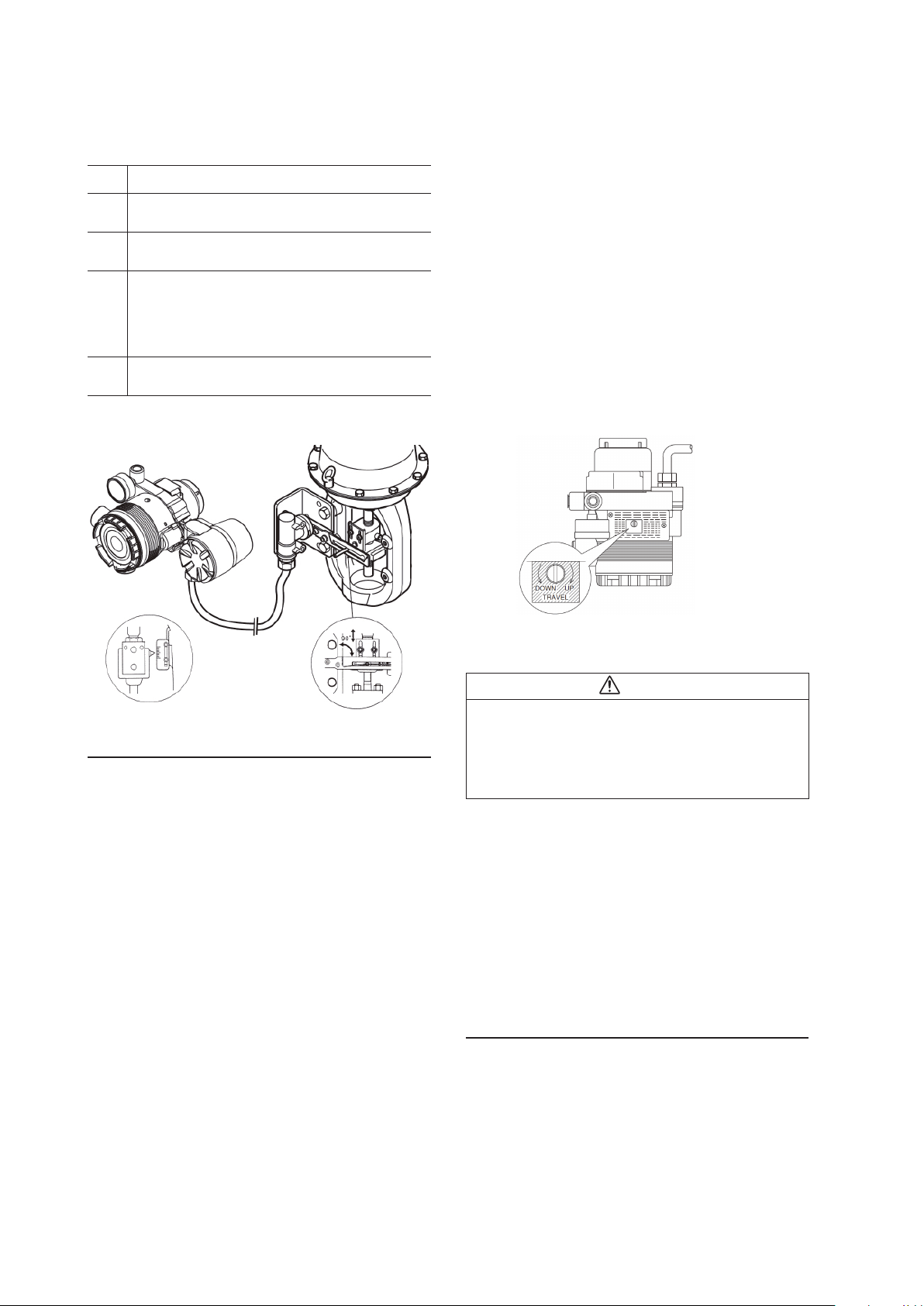

Combination of model AVP300/301/302 (integral type) and double-acting linear cylinder

actuator

1. Attachment of feedback lever

In order to minimize the risk of damage to the feedback lever

while it is carried or transported, and to minimize the packaging as well, the feedback lever is detached from the body of

the device when it is packed. As a result, the feedback lever

must be attached to the body of the device prior to installation of the device.

The length of the feedback lever can if necessary be adjusted

by attaching the extension lever between the feedback lever

and the body of the device. Adjustment of the feedback lever

length is determined based on the form of the actuator.

If the actuator type is specified when ordering, and the

extension lever is included:

If the actuator type is specified when ordering, and the

extension lever is not included:

If the actuator type is not

specified when ordering:

Manufacturer Extension Lever Actuator Type Code

Azbil

Corporation

(SLOP type and DAP type are limited to products with stroke of

100 mm or less)

When connecting an actuator other than those in the table,

connect the device and the actuator, and then, via manual

operation, move the actuator slowly and ensure that the feedback lever does not interfere with a full stroke of the actuator.

If the feedback lever alone cannot cover a full stroke, attach

the extension lever to it.

Attach the feedback lever securely, working from the front of

the device, using the two included hexagon socket head bolts.

Attach the extension lever to the

body of the device, and then attach

the feedback lever.

The extension lever is not necessary. Attach the feedback lever

directly to the body of the device.

The extension lever will be included. Refer to the table below to

determine, based on the actuator

with which the device is equipped,

whether or not the extension lever

is necessary.

VP5, 6, 7 Y1

SLOP560, 1000, 1000X Y2

Yes

SLOP1500, 1500X Y3

DAP560, 1000, 1000X Y4

DAP1500, 1500X Y5

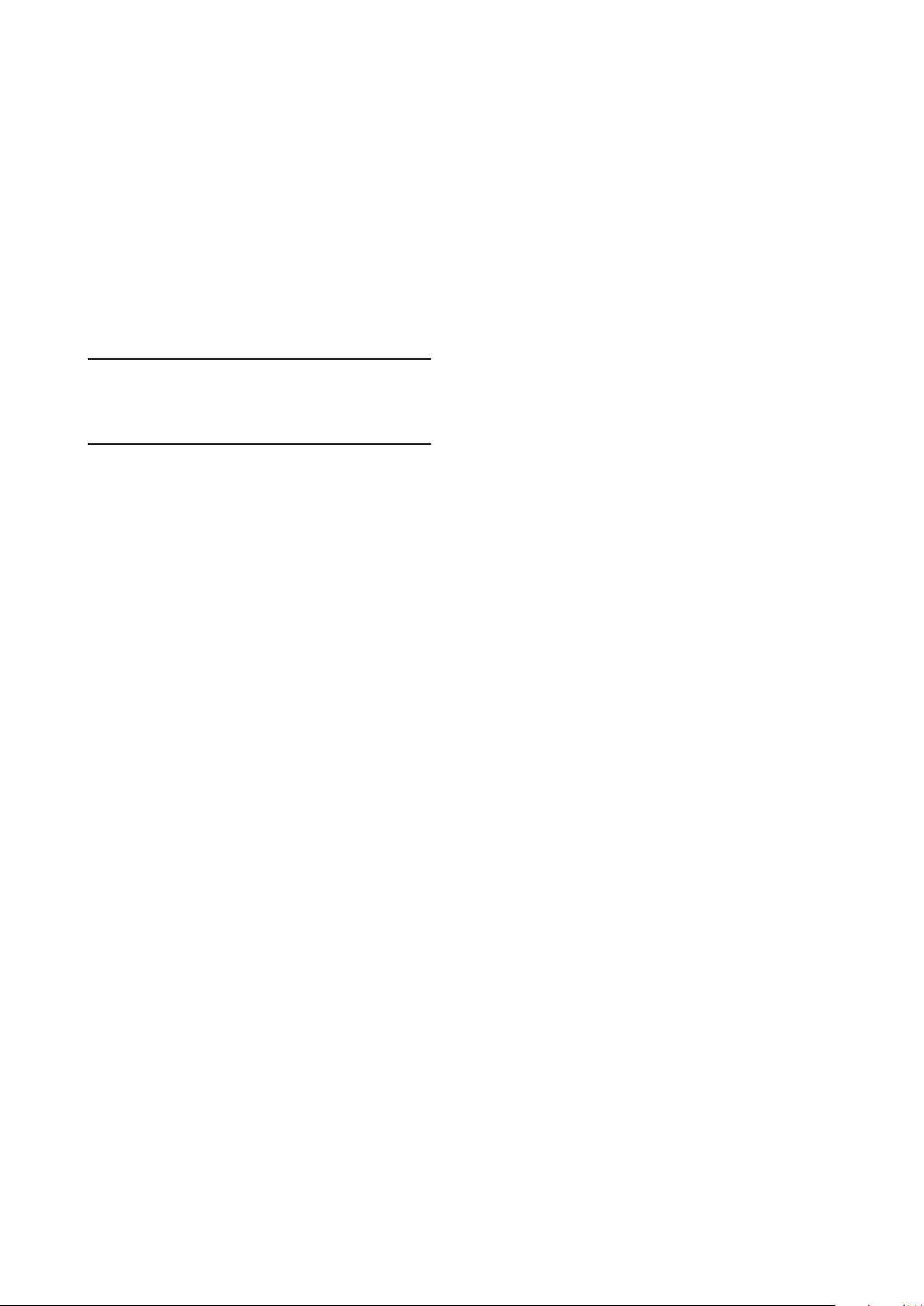

Attach the extension lever securely, working from the front of

the device, using the two included hexagon socket head bolts.

Then, in the same way, attach the feedback lever securely,

working from the back of the device. (The feedback lever can

be attached from the front as well.)

Main unit

Bolt with hexagonal hole

Attachment of Extension Lever and Feedback Lever

Extension lever

Feedback lever

Spring

2. Attachment and installation

[1] Attachment to the actuator

Attach to the actuator with a mounting plate that is appropriate for the actuator.

[2] Adjustment of attachment positions

Procedure for adjustment of attachment positions

Step Procedure

1 Using for example the manual handle of the actuator

or manual operation via the external pressure regulator

with filter, set the position to 50%. (With a double-acting

actuator, manual operation cannot be performed using the

A/M switch.)

2 Adjust the actuator such that the feedback lever reaches a

90° angle to the device's central vertical axis. Depending on

the actuator being used, adjustment may be performed by

moving the device, or it may be performed by moving the

pin.

Note: The accuracy specifications can be satisfied by making

the attachment angle 90° ±2°.

Attachment of Feedback Lever

Adjustment of Attachment Positions

vii

Page 10

3. Air piping and electric wiring connection

• Air piping connection

(1) If control operation of control valve is direct operation

This refers to the state in which the valve moves in the

closing direction as the input signal increases. Connect

the reversing relay output OUT1 to the cylinder chamber

that performs output in order to close the valve in response to increased pressure.

Next, connect the reversing relay output OUT2 to the

cylinder chamber that performs output in order to open

the valve in response to increased pressure.

(2) If control operation of control valve is reverse operation

This refers to the state in which the valve moves in the

opening direction as the input signal increases. Connect

the reversing relay output OUT2 to the cylinder chamber

that performs output in order to close the valve in response to increased pressure.

Next, connect the reversing relay output OUT1 to the

cylinder chamber that performs output in order to open

the valve in response to increased pressure.

For details, see air piping connection and electric wiring

connection in 1.3, “Description of Device Structure and

Functions,” and 2.2, “Installation Method,” in this document.

Check the span point and perform span adjustment.

(1) Set the input signal to the span point (URV). (Zero ad-

justment can be performed if the input signal is adjusted

to the zero point, and span adjustment can be performed

if the input signal is adjusted to the span point.)

(2) Using a flat-blade screwdriver, turn the external zero

span adjustment switch on the upper part of the case UP

(clockwise) to cause the valve to move such that the feedback lever rises upward, or turn it DOWN (counterclockwise) to cause the valve to move such that the feedback

lever drops downward.

5. Operation confirmation

Vary the input signal, and check the zero point and span point.

6. If suitable adjustment was not accomplished

[1] If auto-setup does not operate

• Check whether the input signal is 18 mA ±1 mA.

• Check whether the A/M switch is set to automatic. If it is

set to manual, switch it to auto. See 5.2, “A/M Switch,” in

this document for information on operating procedures.

4. Auto-setup

(1) Set the input signal to 18 ±1 mA.

(2) Using a flat-blade screwdriver, turn the external zero/

span adjustment switch in the upper part of the case 90°

in the UP direction (clockwise), and hold that position

for three seconds.

Note: For reverse close (when the valve's fully closed position is on top), set the valve action to reverse close beforehand. See 4.4.3, “Valve system”)

(3) The valve will automatically start to move, and will stop

in about 3 to 4 minutes.

(4) When it stops, move it to a position that fits the input

signal.

(5) After that, check whether it has been adjusted correctly.

If performing auto-setup

Rotate in UP direction

External zero/span adjustment switch

Note: When closing the

valve of the single-acting

type device with the lever

in the upward direction,

first set it to reverse close.

• Auto-setup can be performed with CommStaff as well.

Warning

When auto-setup is performed, the valve moves from fully

closed to fully open, so there is a danger of, for example,

getting your hand caught or affecting the process.

Before performing auto-setup, move away from the valve,

and confirm that the process is safe.

• Check the duty value of the electro-pneumatic module.

Regarding the confirmation method, see “EPM (electropneumatic module) operation confirmation procedure” on

page 3-9 in this document.

• Check whether the electronics module (terminal block) is

installed correctly in the case on the body of the device.

[2] If hunting occurs

•

Using the setup device, either change the actuator size

(Param) or change the individual PID settings that control

the AVP’s degree of opening. Regarding the configuration

method, see 4.4.4, “Control configuration,” in this document.

[3] If the zero point floats or span adjustment cannot be

performed

Referring to Table 3-1, “Integral type setting,” in 3.1, “Autosetup,” in this document, check whether valve action is

configured correctly. If not, it will be necessary to change the

valve action (the direct/reverse setting). Referring to 4.4.3,

“Valve system” in this document, configure the valve action

correctly.

[4] If linearity characteristic is poor

• Check whether, when the attachment position of the feed-

back lever is the 50% opening position, it is attached horizontally. If not, refer to 2.2, “Installation Method,” in this

document and correctly attach the feedback lever.

• Check the flow rate characteristics data. If equal%, quick

open, or the like has been specified, and these are fundamentally unnecessary, refer to 4.4.6, “Flow Type,” in this

document and change this setting to linear.

viii

Page 11

Introduction

Combination of model AVP300/301/302 (integral type) and single-acting rotary cylinder

actuator

1. Attachment of feedback lever

In order to minimize the risk of damage to the feedback lever

while it is carried or transported, and to minimize the packaging as well, the feedback lever is detached from the body of

the device when it is packed. As a result, the feedback lever

must be attached to the body of the device prior to installation of the device.

Attach the feedback lever securely, working from the front of

the device, using the two included hexagon socket head bolts.

Main unit

Feedback lever

3. Air piping and electric wiring connection

Connect the air piping and electrical wiring.

For details, see section 2.2, “Installation Method,” in this

document.

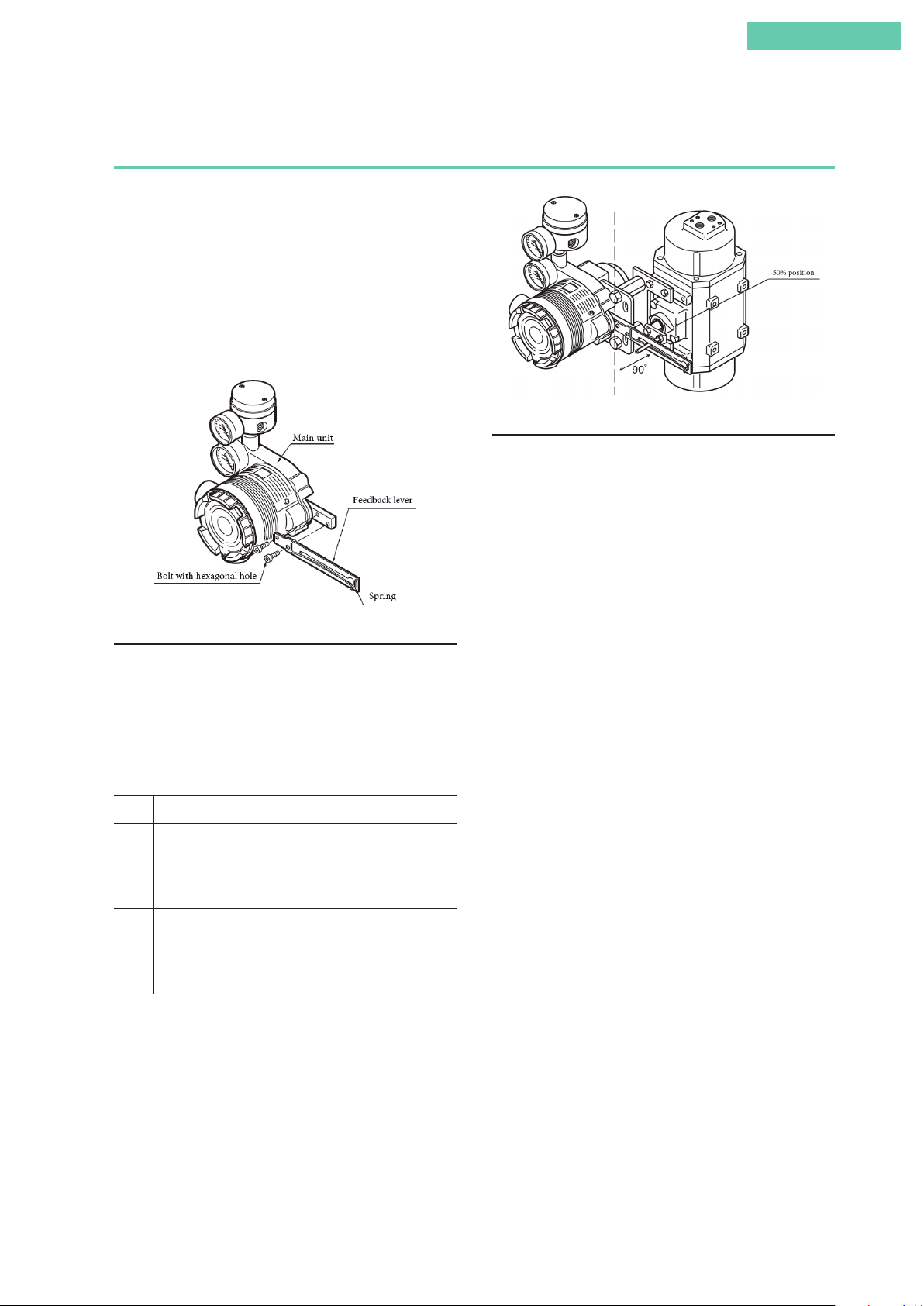

Adjustment of Attachment Positions

Bolt with hexagonal hole

Spring

Attachment of Feedback Lever

2. Attachment and installation

[1] Attachment to the actuator

Attach to the actuator with a mounting plate that is appropriate for the actuator.

[2] Adjustment of attachment positions

Procedure for adjustment of attachment positions

Step Procedure

1 Set the A/M switch to manual operation.

(See 5.2, “A/M Switch.”)

2 Supply air, and adjust the actuator air pressure such that the

actuator stem reaches the travel midpoint.

3 Adjust the actuator such that the feedback lever reaches a

90° angle to the device's central vertical axis. Depending

on the actuator being used, adjustment may be performed

by moving the device, or it may be performed by moving

the pin.

4 Set the A/M switch to automatic operation.

(See 5.2, “A/M Switch.”)

Note: The accuracy specifications can be satisfied by making

the attachment angle 90° ± 2°.

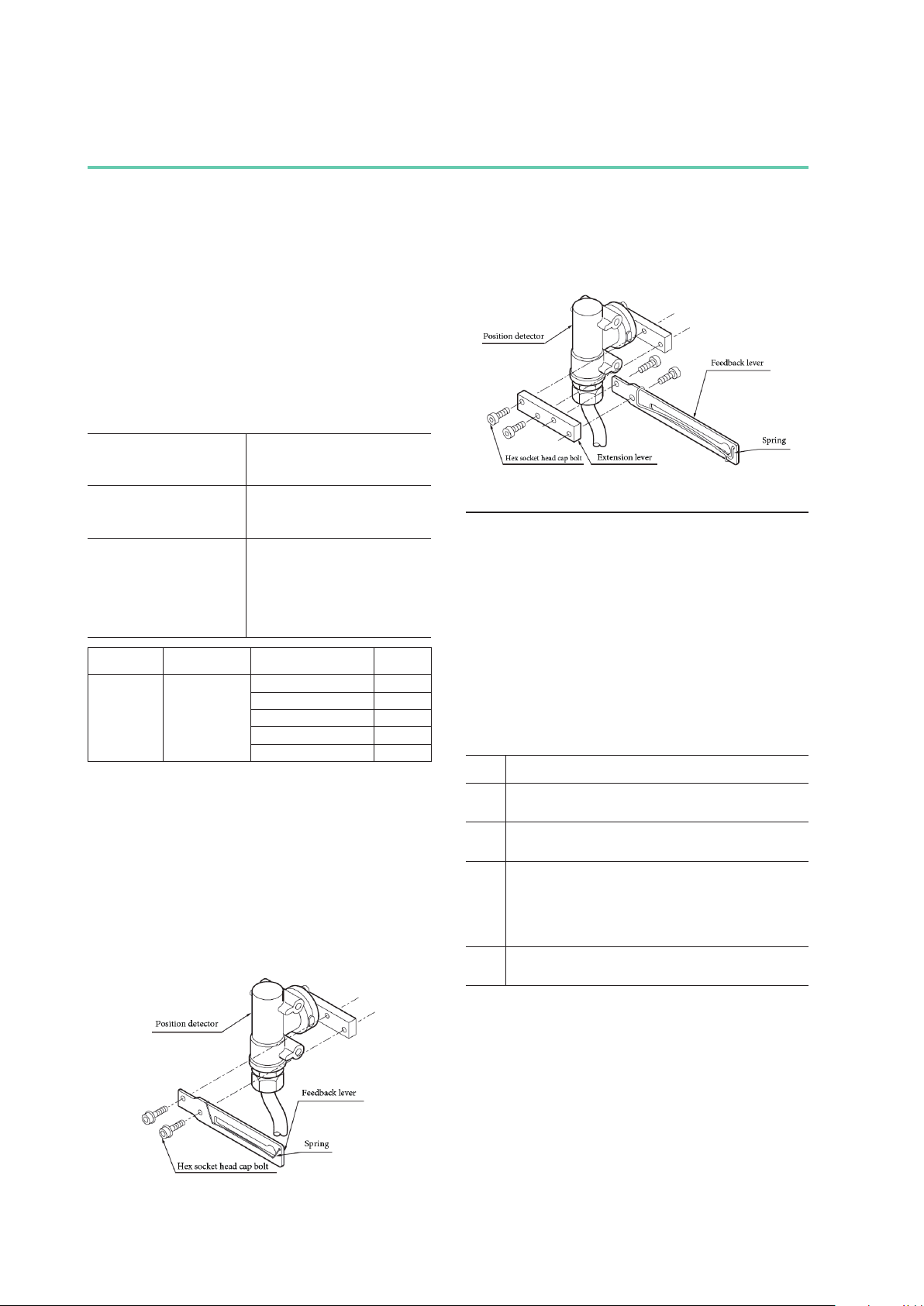

4. Auto-setup

(1) Set the input signal to 18 ± 1 mA.

(2) Using a flat-blade screwdriver, turn the external zero/

span adjustment switch in the upper part of the case 90°

in the UP direction (clockwise), and hold that position

for three seconds.

Note: For reverse close (when the valve's fully closed position is on top), set the valve action to reverse close beforehand. See 4.4.4, “Control configuration,” in this document.

(3) The valve will automatically start to move, and will stop

in about 3 to 4 minutes.

(4) When it stops, adjust it to a position that fits the input

signal.

(5) After that, check whether it has been adjusted correctly.

If performing auto-setup

Rotate in UP direction

External zero/span adjustment switch

• Auto-setup can be performed with CommStaff as well.

Note: When closing the valve

of the single-acting type device

with the lever in the upward

direction, first set it to reverse

close.

Warning

When auto-setup is performed, the valve moves from fully

closed to fully open, so there is a danger of, for example,

getting your hand caught or affecting the process.

Before performing auto-setup, move away from the valve,

and confirm that the process is safe.

ix

Page 12

Check the span point and perform span adjustment.

(1) Set the input signal to the span point (URV). (Zero ad-

justment can be performed if the input signal is adjusted

to the zero point, and span adjustment can be performed

if the input signal is adjusted to the span point.)

(2) Using a flat-blade screwdriver, turn the external zero

span adjustment switch on the upper part of the case in

the UP direction (clockwise) to cause the valve to move

such that the feedback lever rises upward, or turn it

DOWN (counterclockwise) to cause the valve to move

such that the feedback lever drops downward.

5. Operation confirmation

Vary the input signal, and check the zero point and span

point.

6. If suitable adjustment was not accomplished

[1] If auto-setup does not operate

• Check whether the input signal is 18 mA ±1 mA.

• Check whether the A/M switch is set to automatic. If it is

set to manual, switch it to auto. See 5.2, “A/M Switch,” in

this document for information on operating procedures.

• Check the duty value of the electro-pneumatic module.

Regarding the confirmation method, see “EPM (electropneumatic module) operation confirmation procedure” on

page 3-9 in this document.

• Check whether the electronics module (terminal block) is

installed correctly in the case on the body of the device.

[2] If hunting occurs

Using the setup device, either change the actuator size

(Param) or change the individual PID settings that control

the AVP’s degree of opening. Regarding the configuration

method, see 4.4.4, “Control configuration,” in this document.

[3] If the zero point floats or span adjustment cannot be

performed

Referring to Table 3-1, “Integral type setting,” in 3.1, “Autosetup,” in this document, check whether valve action is

configured correctly. If not, it will be necessary to change the

valve action (the direct/reverse setting). Referring to 4.4.3,

“Valve system,” in this document, configure the valve action

correctly.

[4] If linearity characteristic is poor

• Check whether, when the attachment position of the feed-

back lever is the 50% opening position, it is attached horizontally. If not, refer to 2.2, “Installation Method,” in this

document and correctly attach the feedback lever.

• Check the flow rate characteristics data. If equal%, quick

open, or the like has been specified, and these are fundamentally unnecessary, refer to 4.4.6, “Flow Type,” in this

document and change this setting to linear.

x

Page 13

Introduction

Combination of model AVP300/301/302 (integral type) and double-acting rotary cylinder

actuator

1. Attachment of feedback lever

In order to minimize the risk of damage to the feedback lever

while it is carried or transported, and to minimize the packaging as well, the feedback lever is detached from the body of

the device when it is packed. As a result, the feedback lever

must be attached to the body of the device prior to installation of the device.

Attach the feedback lever securely, working from the front of

the device using the two included hexagon socket head bolts.

Adjustment of Attachment Positions

3. Air piping and electric wiring connection

• Air piping connection

(1) If control operation of control valve is direct operation

This refers to the state in which the valve moves in the

closing direction as the input signal increases. Connect

the reversing relay output OUT1 to the cylinder chamber

that performs output in order to close the valve in response to increased pressure.

Attachment of Feedback Lever

2. Attachment and installation

[1] Attachment to the actuator

Attach to the actuator with a mounting plate that is appropriate for the actuator.

[2] Adjustment of attachment positions

Procedure for adjustment of attachment positions

Step Procedure

1 Using for example the manual handle of the actuator

or manual operation via the external pressure regulator

with filter, set the position to 50%. (With a double-acting

actuator, manual operation cannot be performed using the

A/M switch.)

2 Adjust the actuator such that the feedback lever reaches a

90° angle to the device's central vertical axis. Depending on

the actuator being used, adjustment may be performed by

moving the device, or it may be performed by moving the

pin.

Next, connect the reversing relay output OUT2 to the

cylinder chamber that performs output in order to open

the valve in response to increased pressure.

(2) If control operation of control valve is reverse operation

This refers to the state in which the valve moves in the

opening direction as the input signal increases. Connect

the reversing relay output OUT2 to the cylinder chamber

that performs output in order to close the valve in response to increased pressure.

Next, connect the reversing relay output OUT1 to the

cylinder chamber that performs output in order to open

the valve in response to increased pressure.

For details, see air piping connection and electric wiring

connection in 1.3, “Description of Device Structure and

Functions,” and 2.2, “Installation Method,” in this document.

Note: The accuracy specifications can be satisfied by making

the attachment angle 90° ± 2°.

xi

Page 14

4. Auto-setup

(1) Set the input signal to 18 ± 1 mA.

Using a flat-blade screwdriver, turn the external zero/span

(2)

adjustment switch in the upper part of the case 90° in the

UP direction, and hold that position for three seconds.

Note: For reverse close (when the valve's fully closed position is on top), set the valve action to reverse close beforehand. See 4.4.3, “Valve system”

(3) The valve will automatically start to move, and will stop

in about 3 to 4 minutes.

(4) When it stops, adjust it to a position that fits the input

signal.

(5) After that, check whether it has been adjusted correctly.

If performing auto-setup

Rotate in UP direction

External zero/span adjustment switch

Note: When closing the valve

of the single-acting type device

with the lever in the upward

direction, first set it to reverse

close.

• Auto-setup can be performed with CommStaff as well.

Warning

When auto-setup is performed, the valve moves from fully

closed to fully open, so there is a danger of, for example,

getting your hand caught or affecting the process.

Before performing auto-setup, move away from the valve,

and confirm that the process is safe.

Check the span point and perform span adjustment.

(1) Set the input signal to the span point (URV). (Zero ad-

justment can be performed if the input signal is adjusted

to the zero point, and span adjustment can be performed

if the input signal is adjusted to the span point.)

(2) Using a flat-blade screwdriver, turn the external zero

span adjustment switch on the upper part of the case UP

(clockwise) to cause the valve to move such that the feedback lever rises upward, or turn it DOWN (counterclockwise) to cause the valve to move such that the feedback

lever drops downward.

6. If suitable adjustment was not accomplished

[1] If auto-setup does not operate

• Check whether the input signal is 18 mA ± 1 mA.

• Check whether the A/M switch is set to automatic. If it is

set to manual, switch it to auto. See 5.2, “A/M Switch,” in

this document for information on operating procedures.

• Check the duty value of the electro-pneumatic module.

Regarding the confirmation method, see “EPM (electropneumatic module) operation confirmation procedure” on

page 3-9 in this document.

• Check whether the electronics module (terminal block) is

installed correctly in the case on the body of the device.

[2] If hunting occurs

• Using the setup device, either change the actuator size

(Param) or change the individual PID settings that control

the AVP’s degree of opening. Regarding the configuration

method, see 4.4.4, “Control configuration,” in this document.

[3] If the zero point floats or span adjustment cannot be

performed

Referring to Table 3-1, “Integral type setting,” in 3.1, “Autosetup,” in this document, check whether valve action is configured correctly. If not, it will be necessary to change valve

action (the direct/reverse setting). Referring to 4.4.3, “Valve

system,” in this document, configure valve action correctly.

[4] If linearity characteristic is poor

• Check whether, when the attachment position of the feed-

back lever is the 50% opening position, it is attached horizontally. If not, refer to 2.2, “Installation Method,” in this

document and correctly attach the feedback lever.

• Check the flow rate characteristics data. If equal%, quick

open, or the like has been specified, and these are fundamentally unnecessary, refer to 4.4.6, “Flow Type,” in this

document and change this setting to linear.

5. Operation confirmation

Vary the input signal, and check the zero point and span

point.

xii

Page 15

Introduction

Combination of model AVP200/201/202 (remote type) and single-acting linear diaphragm

actuator

1. Attachment of feedback lever

In order to minimize the risk of damage to the feedback lever

while it is carried or transported, and to minimize the packaging as well, the feedback lever is detached from the valve

travel detector when it is packed. As a result, the feedback

lever must be attached to the valve travel detector prior to

installation of the device.

The length of the feedback lever can if necessary be adjusted

by attaching the extension lever between the feedback lever

and the valve travel detector.

Adjustment of the feedback lever length is determined based

on the form of the actuator.

If the actuator type is specified

when ordering, and the

extension lever is included:

If the actuator type is specified

when ordering, and the

extension lever is not included:

If the actuator type is not

specified when ordering:

Manufacturer Extension Lever Actuator Type Code

No

Azbil

Corporation

Ye s

No #240, #280, #330 TA, TD

Motoyama

Masoneilan

Nihon Koso

Ye s

No #11, #13 MA, MB

Ye s #15, #18 MC, MF

No #270, #320 TA, TD

Ye s #400, #500 TB, TE

Attach the extension lever to the

body of the device, and then attach

the feedback lever.

The extension lever is not necessary.

Attach the feedback lever directly to

the body of the device.

The extension lever will be

included. Refer to the table below

to determine, based on the actuator

with which the device is equipped,

whether or not the extension lever

is necessary.

PSA1, 2, PSK1 YS

HA1 YA

HA2, 3 YT

HK1 YK

VA1 to 3 YQ

PSA3, 4 YQ

PSA6 YL

HA4 YN

PSA7 Y8

VA4 to 6 YL

RSA1 YF

RSA2 YU

VR1 YV

VR2, 3 YR

VR3H Y6

GOM83S, 84S, 103S YG

GOM124S YM

#400, #500S, #500L TB, TE

#650S, #650L TC, TF

When connecting an actuator other than those in the table,

connect the device and the actuator, and then, via manual

operation, move the actuator slowly and ensure that the feedback lever does not interfere with a full stroke of the actuator.

If the feedback lever alone cannot cover a full stroke, attach

the extension lever to it.

Attach the feedback lever securely, working from the front of

the device, using the two included hexagon socket head bolts.

Attachment of Feedback Lever

Attach the extension lever securely, working from the front of

the device, using the two included hexagon socket head bolts.

Then, in the same way, attach the feedback lever securely,

working from the back of the device. (The feedback lever can

be attached from the front as well.)

Attachment of Extension Lever and Feedback Lever

2. Attachment and installation

[1] Attachment to the actuator of the valve travel detector

When attaching the valve travel detector to the actuator,

install the cable outlet such that it does not face upward. If it

faces upward, change the direction of the feedback lever. For

details, see 2.3, “Remote Type Handling.”

[2] Positioner body configuration

Install the body of the positioner onto the 2B stanchion.

xiii

Page 16

[3] Adjustment of attachment positions

Procedure for adjustment of attachment positions

Step Procedure

1 Set the A/M switch to manual operation.

(See 5.2, “A/M Switch.”)

2 Supply air, and adjust the actuator air pressure such that the

actuator stem reaches the travel midpoint.

3 Adjust the actuator such that the feedback lever reaches a

90° angle to the valve travel detector's central vertical axis.

Depending on the actuator being used, adjustment may be

performed by moving the valve travel detector, or it may be

performed by moving the pin.

4 Set the A/M switch to automatic operation.

(See 5.2, “A/M Switch.”)

Note: The accuracy specifications can be satisfied by making

the attachment angle 90° ± 2°.

4. Auto-setup

(1) Set the input signal to 18 ±1 mA.

(2) Using a flat-blade screwdriver, turn the external zero/

span adjustment switch in the upper part of the case 90°

in the UP (clockwise) direction (the DOWN direction for

Azbil Corporation's VR and RSA actuators for VFR type

control valves), and hold that position for three seconds.

Note: For reverse close (when the valve's fully closed position is on top), set the valve action to reverse close beforehand. See 4.4.3, “Valve system”

(3) The valve will automatically start to move, and will stop

in about 3 to 4 minutes.

(4) When it stops, adjust it to a position that fits the input

signal.

(5) After that, check whether it has been adjusted correctly.

If performing auto-setup

DOWN direction:

VFR type

UP direction:

direct type

External zero/span adjustment switch

Note: When closing the

valve of the single-acting

type device with the lever

in the upward direction,

first set it to reverse close.

Adjustment of Attachment Positions

3. Air piping and electric wiring connection

[1] Air piping connection

For details, see air piping connection in 2.2, “Installation

Method,” in this document.

[2] Electrical wiring connection (cables between valve

travel detector and positioner)

When shipped from the factory, the valve travel detector and

the positioner body are normally shipped separated at the

connector unit on the positioner body.

Referring to 2.3, “Remote Type Handling,” in this document,

connect the valve travel detector cable to the body of the

device using the remote cable. When laying cable, follow appropriate electrical work guidelines.

• Auto-setup can be performed with CommStaff as well.

Warning

When auto-setup is performed, the valve moves from fully

closed to fully open, so there is a danger of, for example,

getting your hand caught or affecting the process.

Before performing auto-setup, move away from the valve,

and confirm that the process is safe.

Check the span point and perform span adjustment.

(1) Set the input signal to the span point (URV). (Zero ad-

justment can be performed if the input signal is adjusted

to the zero point, and span adjustment can be performed

if the input signal is adjusted to the span point.)

(2) Using a flat-blade screwdriver, turn the external zero

span adjustment switch on the upper part of the case in

the UP direction (clockwise) to cause the valve to move

such that the feedback lever rises upward, or turn it

DOWN (counterclockwise) to cause the valve to move

such that the feedback lever drops downward.

5. Operation confirmation

Vary the input signal, and check the zero point and span

point.

xiv

Page 17

6. If suitable adjustment was not accomplished

[1] If auto-setup does not operate

• Check whether the input signal is 18 mA ± 1 mA.

• Check whether the A/M switch is set to automatic. If it is

set to manual, switch it to auto. See 5.2, “A/M Switch,” in

this document for information on operating procedures.

• Check the duty value of the electro-pneumatic module.

Regarding the confirmation method, see “EPM (electropneumatic module) operation confirmation procedure” on

page 3-9 in this document.

• Check whether the electronics module (terminal block) is

installed correctly in the case on the body of the device.

[2] If hunting occurs

• Using the setup device, either change the actuator size

(Param) or change the individual PID settings that control

the AVP’s degree of opening. Regarding the configuration

method, see 4.4.3, “Valve system,” in this document.

Introduction

[3] If the zero point floats or span adjustment cannot be

performed

Referring to Table 3-1, “Integral type setting,” in 3.1, “Autosetup,” in this document, check whether valve action is

configured correctly. If not, it will be necessary to change the

valve action (the direct/reverse setting). Referring to 4.4.3,

“Valve system,” in this document, configure the valve action

correctly.

[4] If linearity characteristic is poor

• Check whether, when the attachment position of the feed-

back lever is the 50% opening position, it is attached horizontally. If not, refer to 2.2, “Installation Method,” in this

document and correctly attach the feedback lever.

• Check the flow rate characteristics data. If equal%, quick

open, or the like has been specified, and these are fundamentally unnecessary, refer to 4.4.6, “Flow Type,” in this

document and change this setting to linear.

Note: When performing valve maintenance, first detach the

valve travel detector of the remote type from the mounting

plate.

xv

Page 18

Combination of model AVP200/201/202 (remote type) and double-acting linear cylinder

actuator

1. Attachment of feedback lever

In order to minimize the risk of damage to the feedback lever

while it is carried or transported, and to minimize the packaging as well, the feedback lever is detached from the valve

travel detector when it is packed. As a result, the feedback

lever must be attached to the valve travel detector prior to

installation of the device.

The length of the feedback lever can if necessary be adjusted

by attaching the extension lever between the feedback lever

and the valve travel detector.

Adjustment of the feedback lever length is determined based

on the form of the actuator.

If the actuator type is specified

when ordering, and the

extension lever is included:

If the actuator type is specified

when ordering, and the

extension lever is not included:

If the actuator type is not

specified when ordering:

Attach the extension lever to the

body of the device, and then attach

the feedback lever.

The extension lever is not necessary.

Attach the feedback lever directly to

the body of the device.

The extension lever will be

included. Refer to the table below

to determine, based on the actuator

with which the device is equipped,

whether or not the extension lever

is necessary.

Attach the extension lever securely, working from the front of

the device, using the two included hexagon socket head bolts.

Then, in the same way, attach the feedback lever securely,

working from the back of the device. (The feedback lever can

be attached from the front as well.)

Attachment of Extension Lever and Feedback Lever

2. Attachment and installation

[1] Attachment to the actuator of the valve travel detector

When attaching the valve travel detector to the actuator,

install the cable outlet such that it does not face upward. If it

faces upward, change the direction of the feedback lever. For

details, see 2.3, “Remote Type Handling.”

Manufacturer Extension Lever Actuator Type Code

VP5, 6, 7 Y1

Azbil

Corporation

(SLOP type and DAP type are limited to products with stroke of

100mm or less)

Ye s

SLOP560, 1000, 1000X Y2

SLOP1500, 1500X Y3

DAP560, 1000, 1000X Y4

DAP1500, 1500X Y5

When connecting an actuator other than those in the table,

connect the device and the actuator, and then, via manual

operation, move the actuator slowly and ensure that the feedback lever does not interfere with a full stroke of the actuator.

If the feedback lever alone cannot cover a full stroke, attach

the extension lever to it.

Attach the feedback lever securely, working from the front of

the device, using the two included hexagon socket head bolts.

[2] Positioner body configuration

Install the body of the positioner onto the 2B stanchion.

[3] Adjustment of attachment positions

Procedure for adjustment of attachment positions

Step Procedure

1 Set the A/M switch to manual operation.

(See 5.2, “A/M Switch.”)

2 Supply air, and adjust the actuator air pressure such that the

actuator stem reaches the travel midpoint.

3 Adjust the actuator such that the feedback lever reaches a

90° angle to the valve travel detector's central vertical axis.

Depending on the actuator being used, adjustment may be

performed by moving the valve travel detector, or it may be

performed by moving the pin.

4 Set the A/M switch to automatic operation.

(See 5.2, “A/M Switch.”)

Note: The accuracy specifications can be satisfied by making

the attachment angle 90° ± 2°.

Attachment of Feedback Lever

xvi

Page 19

Introduction

4. Auto-setup

(1) Set the input signal to 18 ± 1 mA.

(2) Using a flat-blade screwdriver, turn the external zero/

span adjustment switch in the upper part of the case 90°

in the UP direction, and hold that position for three sec-

onds.

Note: For reverse close (when the valve's fully closed position is on top), set the valve action to reverse close beforehand. See 4.4.3, “Valve system.”

(3) The valve will automatically start to move, and will stop

in about 3 to 4 minutes.

(4) When it stops, move it to a position that fits the input

signal.

(5) After that, check whether it has been adjusted correctly.

Adjustment of Attachment Positions

3. Air piping and electric wiring connection

[1] Air piping connection

(1) If control operation of control valve is direct operation

This refers to the state in which the valve moves in the

closing direction as the input signal increases. Connect

the reversing relay output OUT1 to the cylinder chamber

that performs output in order to close the valve in response to increased pressure.

Next, connect the reversing relay output OUT2 to the

cylinder chamber that performs output in order to open

the valve in response to increased pressure.

(2) If control operation of control valve is reverse operation

This refers to the state in which the valve moves in the

opening direction as the input signal increases. Connect

the reversing relay output OUT2 to the cylinder chamber

that performs output in order to close the valve in response to increased pressure.

Next, connect the reversing relay output OUT1 to the

cylinder chamber that performs output in order to open

the valve in response to increased pressure.

For details, see on air piping connection and electric wiring connection in 1.3, “Description of Device Structure

and Functions,” and 2.2, “Installation Method,” in this

document.

[2] Electrical wiring connection (cables between valve

travel detector and positioner)

When shipped from the factory, the valve travel detector and

the positioner body are normally shipped separated at the

connector unit on the positioner body.

Referring to 2.3, “Remote Type Handling,” in this document,

connect the valve travel detector cable to the body of the

device using the remote cable. When laying cable, follow appropriate electrical work guidelines.

If performing auto-setup

Note: When closing the

valve of the single-acting

type device with the lever

in the upward direction,

Rotate in UP direction

External zero/span adjustment switch

first set it to reverse close.

• Auto-setup can be performed with CommStaff as well.

Warning

When auto-setup is performed, the valve moves from fully

closed to fully open, so there is a danger of, for example,

getting your hand caught or affecting the process.

Before performing auto-setup, move away from the valve,

and confirm that the process is safe.

Check the span point and perform span adjustment.

(1) Set the input signal to the span point (URV). (Zero ad-

justment can be performed if the input signal is adjusted

to the zero point, and span adjustment can be performed

if the input signal is adjusted to the span point.)

(2) Using a flat-blade screwdriver, turn the external zero

span adjustment switch on the upper part of the case in

the UP direction (clockwise) to cause the valve to move

such that the feedback lever rises upward, or turn it

DOWN (counterclockwise) to cause the valve to move

such that the feedback lever drops downward.

5. Operation confirmation

Vary the input signal, and check the zero point and span

point.

xvii

Page 20

6. If suitable adjustment was not accomplished

[1] If auto-setup does not operate

• Check whether the input signal is 18 mA ± 1 mA.

• Check whether the A/M switch is set to automatic. If it is

set to manual, switch it to auto. See 5.2, “A/M Switch,” in

this document for information on operating procedures.

• Check the duty value of the electro-pneumatic module.

Regarding the confirmation method, see “EPM (electropneumatic module) operation confirmation procedure” on

page 3-9 in this document.

Check whether the electronics module (terminal block) is

installed correctly in the case on the body of the device.

[2] If hunting occurs

• Using the setup device, either change the actuator size

(Param) or change the individual PID settings that control

the AVP’s degree of opening. Regarding the configuration

method, see 4.4.4, “Control configuration,” in this document.

[3] If the zero point floats or span adjustment cannot be

performed

Referring to Table 3-1, “Integral type setting,” in 3.1, “Autosetup,” in this document, check whether valve action is

configured correctly. If not, it will be necessary to change the

valve action (the direct/reverse setting). Referring to 4.4.3,

“Valve system,” in this document, configure the valve action

correctly.

[4] If linearity characteristic is poor

• Check whether, when the attachment position of the feed-

back lever is the 50% opening position, it is attached horizontally. If not, refer to 2.2, “Installation Method,” in this

document and correctly attach the feedback lever.

• Check the flow rate characteristics data. If equal%, quick

open, or the like has been specified, and these are fundamentally unnecessary, refer to 4.4.6, “Flow Type,” in this

document and change this setting to linear.

Note: When performing valve maintenance, first detach the

valve travel detector of the remote type from the mounting

plate.

xviii

Page 21

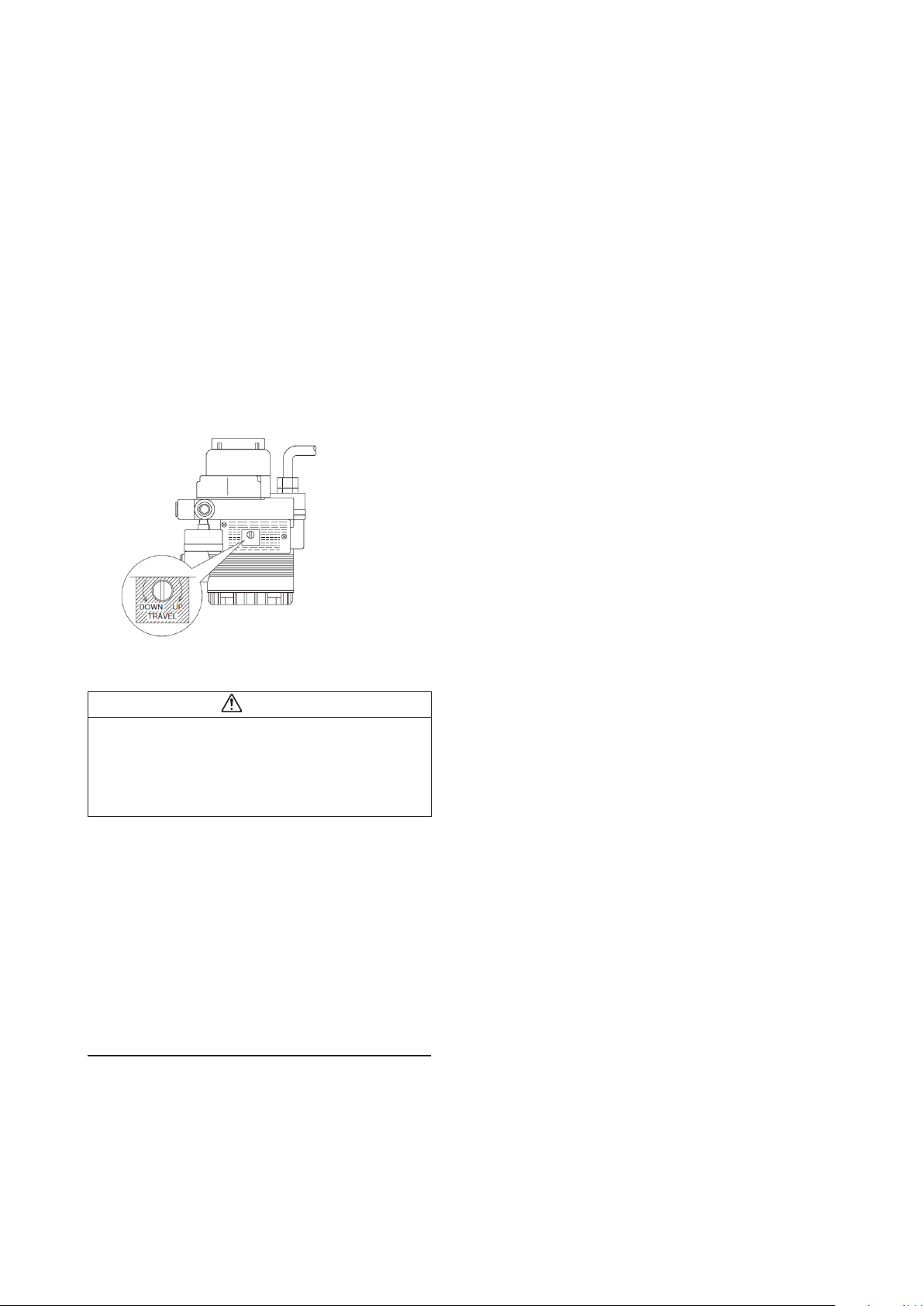

Introduction

Combination of model AVP200/201/202 (remote type) and single-acting rotary cylinder

actuator

1. Attachment of feedback lever (pin)

In order to minimize the risk of damage to the feedback lever

while it is carried or transported, and to minimize the packaging as well, the feedback lever is detached from the valve

travel detector when it is packed. As a result, the feedback

lever (pin) must be attached to the valve travel detector prior

to installation of the device.

Using the two accompanying hexagonal nuts, attach the feedback lever (pin) firmly to the valve travel detector as shown

in the diagram.

Adjustment of Attachment Positions

3. Air piping and electric wiring connection

[1] Air piping connection

For details, see air piping connection in 2.2, “Installation

Method,” in this document.

Attachment of feedback lever (pin)

2. Attachment and installation

[1] Attachment to the actuator of the valve travel detector

When attaching the valve travel detector to the actuator,

install the cable outlet such that it does not face upward. If it

faces upward, change the direction of the feedback lever. For

details, see 2.3, “Remote Type Handling.”

[2] Positioner body configuration

Install the body of the positioner onto the 2B stanchion.

[3] Adjustment of attachment positions

Procedure for adjustment of attachment positions

Step Procedure

1 Set the A/M switch to manual operation.

(See 5.2, “A/M Switch.”)

2 Supply air, and adjust the actuator air pressure such that the

position reaches the travel midpoint.

3 By adjusting the attachment position of the arm that

holds up the feedback pin, adjust the actuator such that

the feedback lever reaches a 90° angle to the valve travel

detector's central vertical axis.

4 Set the A/M switch to automatic operation.

(See 5.2, “A/M Switch.”)

Note: The accuracy specifications can be satisfied by making

the attachment angle 90° ± 2°.

[2] Electrical wiring connection (cables between valve

travel detector and positioner)

When shipped from the factory, the valve travel detector and

the positioner body are normally shipped separated at the

connector unit on the positioner body.

Referring to 2.3, “Remote Type Handling,” in this document,

connect the valve travel detector cable to the body of the

device using the remote cable. When laying cable, follow appropriate electrical work guidelines.

xix

Page 22

4. Auto-setup

(1) Set the input signal to 18 ±1 mA.

(2) Using a flat-blade screwdriver, turn the external zero/

span adjustment switch in the upper part of the case 90°

in the UP direction (the DOWN direction for Azbil Corporation's VR and RSA actuators for VFR type control

valves), and hold that position for three seconds.

Note: For reverse close (when the valve's fully closed position is on top), set the valve action to reverse close beforehand. See 4.4.3, “Valve system.”

(3) The valve will automatically start to move, and will stop

in about 3 to 4 minutes.

(4) When it stops, move it to a position that fits the input

signal.

(5) After that, check whether it has been adjusted correctly.

If performing auto-setup

6. If suitable adjustment was not accomplished

[1] If auto-setup does not operate

• Check whether the input signal is 18 mA ± 1 mA.

• Check whether the A/M switch is set to automatic. If it is

set to manual, switch it to auto. See 5.2, “A/M Switch,” in

this document for information on operating procedures.

• Check the duty value of the electro-pneumatic module.

Regarding the confirmation method, see “EPM (electropneumatic module) operation confirmation procedure” on

page 3-9 in this document.

• Check whether the electronics module (terminal block) is

installed correctly in the case on the body of the device.

[2] If hunting occurs

• Using the setup device, either change the actuator size

(Param) or change the individual PID settings that control

the AVP’s degree of opening. Regarding the configuration

method, see 4.4.4, “Control configuration,” in this document.

Note: When closing the

valve of the single-acting

type device with the lever

in the upward direction,

first set it to reverse close.

Rotate in UP direction

External zero/span adjustment switch

• Auto-setup can be performed with CommStaff as well.

Warning

When auto-setup is performed, the valve moves from fully

closed to fully open, so there is a danger of, for example,

getting your hand caught or affecting the process.

Before performing auto-setup, move away from the valve,

and confirm that the process is safe.

Check the span point and perform span adjustment.

(1) Set the input signal to the span point (URV). (Zero ad-

justment can be performed if the input signal is adjusted

to the zero point, and span adjustment can be performed

if the input signal is adjusted to the span point.)

(2) Using a flat-blade screwdriver, turn the external zero

span adjustment switch on the upper part of the case UP

(clockwise) to cause the valve to move such that the feedback lever rises upward, or turn it DOWN (counterclockwise) to cause the valve to move such that the feedback

lever drops downward.

[3] If the zero point floats or span adjustment cannot be

performed

Referring to Table 3-1, “Integral type setting,” in 3.1, “Autosetup,” in this document, check whether valve action is configured correctly. If not, it will be necessary to change valve

action (the direct/reverse setting). Referring to 4.4.3, “Valve

system,” in this document, configure valve action correctly.

[4] If linearity characteristic is poor

• Check whether, when the attachment position of the feed-

back lever is the 50 % opening position, it is attached horizontally. If not, refer to 2.2, “Installation Method,” in this

document and correctly attach the feedback lever.

• Check the flow rate characteristics data. If equal %, quick

open, or the like has been specified, and these are fundamentally unnecessary, refer to 4.4.6, “Flow Type,” in this

document and change this setting to linear.

Note: When performing valve maintenance, first detach the

valve travel detector of the remote type from the mounting

plate.

5. Operation confirmation

Vary the input signal, and check the zero point and span

point.

xx

Page 23

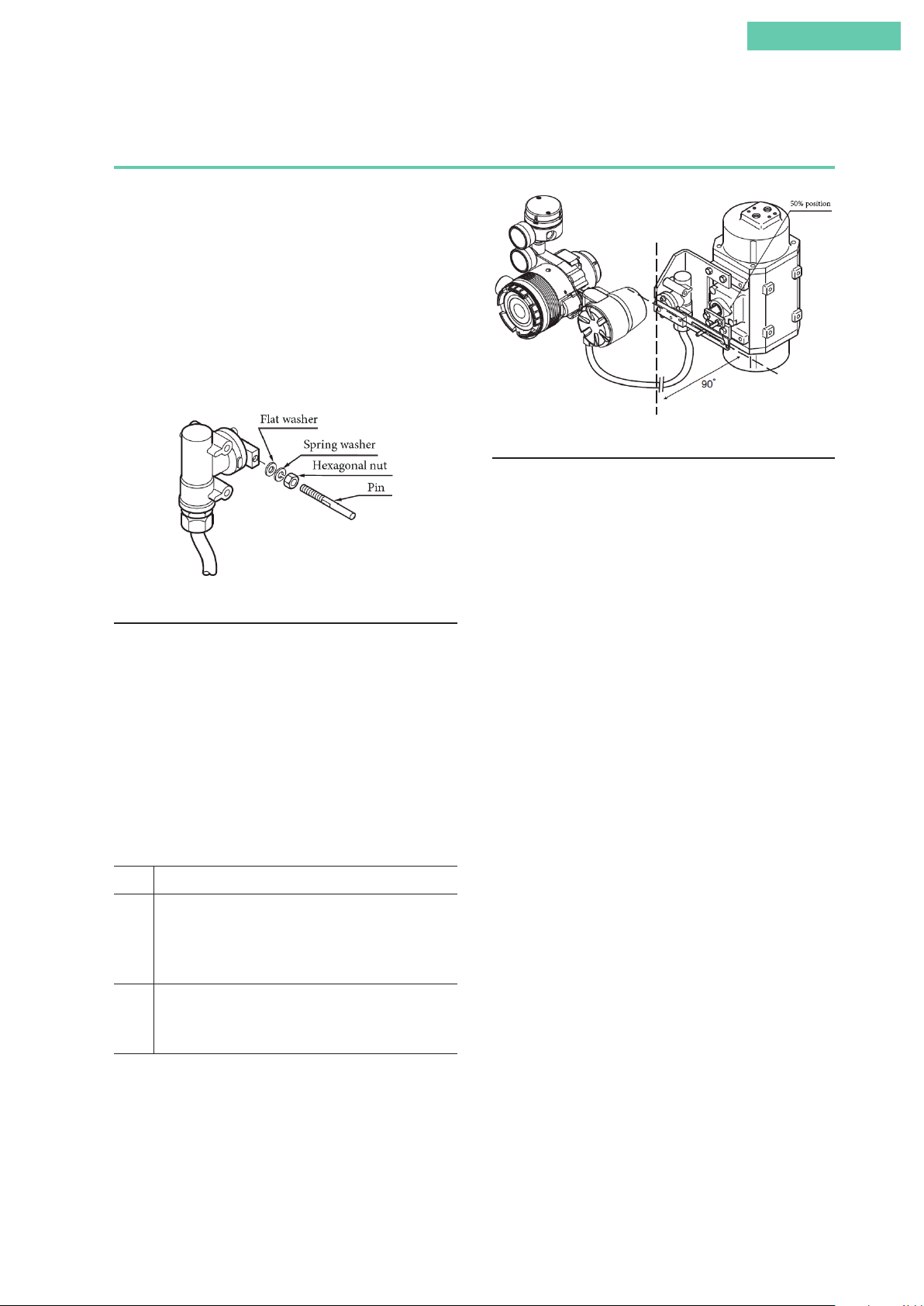

Introduction

Combination of model AVP200/201/202 (remote type) and double-acting rotary cylinder

actuator

1. Attachment of feedback lever (pin)

In order to minimize the risk of damage to the feedback lever

while it is carried or transported, and to minimize the packaging as well, the feedback lever is detached from the valve

travel detector when it is packed. As a result, the feedback

lever (pin) must be attached to the valve travel detector prior

to installation of the device.

Using the two accompanying hexagonal nuts, attach the feedback lever (pin) firmly to the valve travel detector as shown

in the diagram.

Adjustment of Attachment Positions

3. Air piping and electric wiring connection

[1] Air piping connection

(1) If control operation of control valve is direct operation

This refers to the state in which the valve moves in the

closing direction as the input signal increases. Connect

Attachment of Feedback Lever (Pin)

2. Attachment and installation

[1] Attachment to the actuator of the valve travel detector

When attaching the valve travel detector to the actuator,

install the cable outlet such that it does not face upward. If it

faces upward, change the direction of the feedback lever. For

details, see 2.3, “Remote Type Handling.”

[2] Positioner body configuration

Install the body of the positioner onto the 2B stanchion.

[3] Adjustment of attachment positions

Procedure for adjustment of attachment positions

Step Procedure

1 Using for example the manual handle of the actuator or

manual operation via the external pressure regulator with

filter, set the position to 50 %.

(With a double-acting actuator, manual operation cannot be

performed using the A/M switch.)

2 By adjusting the attachment position of the arm that

holds up the feedback pin, adjust the actuator such that

the feedback lever reaches a 90° angle to the valve travel

detector's central vertical axis.

Note: The accuracy specifications can be satisfied by making

the attachment angle 90° ±2°.

the reversing relay output OUT1 to the cylinder chamber

that performs output in order to close the valve in response to increased pressure.

Next, connect the reversing relay output OUT2 to the

cylinder chamber that performs output in order to open

the valve in response to increased pressure.

(2) If control operation of control valve is reverse operation

This refers to the state in which the valve moves in the

opening direction as the input signal increases. Connect

the reversing relay output OUT2 to the cylinder chamber

that performs output in order to close the valve in response to increased pressure.

Next, connect the reversing relay output OUT1 to the

cylinder chamber that performs output in order to open

the valve in response to increased pressure.

For details, see air piping connection and electric wiring

connection in 1.3, “Description of Device Structure and

Functions,” and 2.2, “Installation Method,” in this document.

[2] Electrical wiring connection (cables between valve

travel detector and positioner)

When shipped from the factory, the valve travel detector and

the positioner body are normally shipped separated at the

connector unit on the positioner body.

Referring to 2.3, “Remote Type Handling,” in this document,

connect the valve travel detector cable to the body of the device using a special-purpose connector. When laying cable,

follow appropriate electrical work guidelines.

xxi

Page 24

4. Auto-setup

(1) Set the input signal to 18 ±1 mA.

(2) Using a flat-blade screwdriver, turn the external zero/

span adjustment switch in the upper part of the case 90°

in the UP direction, and hold that position for three sec-

onds.

Note: For reverse close (when the valve's fully closed position is on top), set the valve action to reverse close beforehand. See 4.4.3, “Valve system.”

(3) The valve will automatically start to move, and will stop

in about 3 to 4 minutes.

(4) When it stops, move it to a position that fits the input

signal.

(5) After that, check whether it has been adjusted correctly.

6. If suitable adjustment was not accomplished

[1] If auto-setup does not operate

• Check whether the input signal is 18 mA ± 1 mA.

• Check whether the A/M switch is set to automatic. If it is

set to manual, switch it to auto. See 5.2, “A/M Switch,” in

this document for information on operating procedures.

• Check the duty value of the electro-pneumatic module.

Regarding the confirmation method, see “EPM (electropneumatic module) operation confirmation procedure” on

page 3-9 in this document.

• Check whether the electronics module (terminal block) is

installed correctly in the case on the body of the device.

[2] If hunting occurs

If performing auto-setup

Note: When closing the

valve of the single-acting

type device with the lever

in the upward direction,

first set it to reverse close.

Rotate in UP direction

External zero/span adjustment switch

• Auto-setup can be performed with CommStaff as well.

Warning

When auto-setup is performed, the valve moves from fully

closed to fully open, so there is a danger of, for example,

getting your hand caught or affecting the process.

Before performing auto-setup, move away from the valve,

and confirm that the process is safe.

Check the span point and perform span adjustment.

(1) Set the input signal to the span point (URV). (Zero ad-

justment can be performed if the input signal is adjusted

to the zero point, and span adjustment can be performed

if the input signal is adjusted to the span point.)

(2) Using a flat-blade screwdriver, turn the external zero

span adjustment switch on the upper part of the case UP

(clockwise) to cause the valve to move such that the feedback lever rises upward, or turn it DOWN (counterclockwise) to cause the valve to move such that the feedback

lever drops downward.

• Using the setup device, either change the actuator size

(Param) or change the individual PID settings that control

the AVP’s degree of opening. Regarding the configuration

method, see 4.4.4, “Control configuration,” in this document.

[3] If the zero point floats or span adjustment cannot be

performed

Referring to Table 3-1, “Integral type setting,” in 3.1, “Autosetup,” in this document, check whether valve action is

configured correctly. If not, it will be necessary to change the

valve action (the direct/reverse setting). Referring to 4.4.3,

“Valve system,” in this document, configure the valve action

correctly.

[4] If linearity characteristic is poor

• Check whether, when the attachment position of the feed-

back lever is the 50% opening position, it is attached horizontally. If not, refer to 2.2, “Installation Method,” in this

document and correctly attach the feedback lever.

• Check the flow rate characteristics data. If equal %, quick

open, or the like has been specified, and these are fundamentally unnecessary, refer to 4.4.6, “Flow Type,” in this

document and change this setting to linear.

Note: When performing valve maintenance, first detach the

valve travel detector of the remote type from the mounting

plate.

5. Operation confirmation

Vary the input signal, and check the zero point and span

point.

xxii

Page 25

Product unpacking, verification, and storage

■ Unpacking

This device is a precision instrument. Handle it carefully in order to prevent accidents,

injuries, etc.

Upon unpacking the product, verify that the following items are included. (When the

device is shipped individually)

• Main unit

• Feedback lever and hex socket head cap bolts (2)

• Hexagonal bar wrench (1) (for feedback lever)

• Regulator (model KZ03) (optional)

• Mounting bracket (optional)

Introduction

• Flameproof packing cable gland and flame-proof elbow (explosion-proof option)

• User's Manual (this document) (included when specified during purchase)

• Extension lever and two hex socket head cap bolts (optional)

■ Checking specifications

The specifications are written on the nameplate on the body of this device. Referring to

the Appendix, confirm that these are as designated. In particular, be sure to check the

following points.

• Tag number (TAG NO.)

• Model number (MODEL)

• Production number (PROD)

• Input current range (INPUT) (since the input range can be changed using Com-

mStaff, the inscription on the nameplate is fixed to 4 to 20 mA as per explosionproofing regulations.

• Supply air pressure (SUPPLY)

• Explosion-proofing test conformity label (if explosion-proofing specification applies)

■ Contact point for inquiries

If anything in the specifications is unclear, please contact the office that appears at the

end of this manual. When making an inquiry, be sure to include the model number

(MODEL) and production number (PROD).

xxiii

Page 26

■ Storage

If the device that you have purchased is to be stored, please observe the following precautions.

• If storing the device unused

1. Store the device in the packed state in which it was shipped.

2. Store the device indoors in a low-vibration, low-shock area, and maintain

normal indoor temperature and humidity (about 25°C and 65%).

• If storing the device after being used

1. Prevent humidity from entering the device by attaching the terminal box

cover firmly and cover the conduit connection port with tape.

2. Prevent humidity and contaminants from entering the device by covering

the two air piping connections (SUP and OUT) and the pilot cover bleed

holes with tape.

3. Return the product to the packed state in which it was shipped.

4. Store the device indoors in a low-vibration, low-shock area, and maintain

normal indoor temperature and humidity (about 25°C and 65 %).

xxiv

Page 27

Contents

Chapter 1: Control System Structure ���������������������������������������������������������������������������� 1-1

1.1 System Configuration ......................................................................................................... 1-2

1.2 Travel Transmission Output (Models AVP301 and AVP201) ....................................... 1-3

1.2.1 Structure of system without travel transmission output ............................................. 1-3

1.2.2 Structure of system with travel transmission (analog output) ................................... 1-4

1.2.3 Structure of system with travel transmission (digital output) .................................... 1-4

1.3 Description of Device Structure and Functions .............................................................. 1-5

1.4 Terminal Box ........................................................................................................................ 1-7

Chapter 2: Installation ����������������������������������������������������������������������������������������������������� 2-1

2.1 Installation Location Selection Criteria ............................................................................ 2-2

2.1.1 Installation location selection criteria ........................................................................... 2-2

2.1.2 Instrumentation air .......................................................................................................... 2-2

2.2 Installation Method ............................................................................................................. 2-4

2.2.1 Attachment to actuator .................................................................................................... 2-4

2.2.2 Air piping connection ...................................................................................................... 2-7

2.2.3 Handling of double-acting reversing relay .................................................................. 2-10

2.2.4 Electrical Wiring Connection ....................................................................................... 2-12

2.2.5 Power supply for input signal and travel transmission .............................................. 2-15

2.2.6 Cables (for input signal or travel transmission) ......................................................... 2-16

2.3 Remote Type Handling ..................................................................................................... 2-18

2.3.1 Remote type cable handling .......................................................................................... 2-18

2.3.2 Attachment to the actuator of the valve travel detector ............................................ 2-20

2.3.3 Positioner body installation .......................................................................................... 2-21

2.3.4 Cabling between valve travel detector and positioner body ..................................... 2-21

2.4 Flameproof Cable Gland and Explosion-proof Universal Elbow ................................ 2-22

Chapter 3: Operation ������������������������������������������������������������������������������������������������������� 3-1

3.1 Auto-setup ............................................................................................................................ 3-2

3.1.1 Overview of auto-setup ................................................................................................... 3-3

3.1.2 Auto-setup operation ....................................................................................................... 3-5

3.2 Zero/Span Adjustment ........................................................................................................ 3-6

3.2.1 Procedure to adjust valve to fully closed position (zero point) .................................. 3-7

3.2.2 Procedure to adjust valve to fully open position (span point) ................................... 3-7

3.3 Starting Operation ............................................................................................................... 3-8

3.3.1 Pre-operation confirmation ............................................................................................ 3-8

3.3.2 Starting operation ........................................................................................................... 3-10

3.3.3 Stopping operation ......................................................................................................... 3-10

xxv

Page 28

Chapter 4: Communication-Based Operation ���������������������������������������������������������� 4-1

4.1 Starting Communication .................................................................................................... 4-2

Wiring method ............................................................................................................................... 4-2

4.2 Communication-Based Operation .................................................................................... 4-3

Menu Tree ....................................................................................................................................... 4-4

4.3 Operation Data Confirmation ........................................................................................... 4-7

4.3.1 Measured value confirmation ......................................................................................... 4-7

4.3.2 Adjustment data confirmation ....................................................................................... 4-7

4.4 Device Configuration and Adjustment ............................................................................ 4-8

4.4.1 Auto-setup ......................................................................................................................... 4-8

4.4.2 Zero/span adjustment ...................................................................................................... 4-9